Page 1

©2017 Autogrow Systems Ltd V5.4

IntelliDose

Installation and User Guide

• Doses up to 9 parts of nutrient, additives and pH

• Measures Conductivity, pH, Temperature

• Displays EC, CF, TDS, oC, oF, pH

• USB – PC/Mac Interface (USB cable supplied)

• Variable ratios for nutrient part (change from vegetative to generative)

• Auto schedule of nutrient ratios and EC’s

• Proportional Dosing (for rapid dosing between irrigations)

• Direct drive dosing pumps (keeps costs down)

• Irrigation with day/night control – precision timer

• Day/Night EC levels

• Water level control – to lower EC

Page 2

IntelliDose Manual

©2017 Autogrow Systems Ltd V5.4 2

Contents

Quick-start page with helpful hints

Important notice:

When using automatic dosing equipment all chemicals must be in dilute

form especially acids and alkalis.

Acids and alkalis should be diluted to a maximum strength of 2% or less. We

recommend diluting your nutrients 1 part nutrients to 4 parts water while

dialling in your dosing settings.

Section A

Introduction to the IntelliDose

TM

Hydroponic doser

Section B

Settings

Section C

Settings for simple 1- or 2-part doser

Section D

Settings for three-part doser

Section E

Proportional dosing (default OFF)

Section F

Sequential dosing (default ON)

Section G

Installation

Section H

Software installation

Section I

Maintenance

Section J

Fault finding

Section K

Specification

Section L

Advanced Irrigation Features

Page 3

IntelliDose Manual

©2017 Autogrow Systems Ltd V5.4 3

Quick-start

This is not a substitute for reading the relevant sections of the manual but is

included to emphasise some important and useful points.

Install the controller to one side of the mixing tank where it will not be exposed to

splashes and vapours (especially acid vapour). Remember that the sensor leads

must be able to reach the sample pot which should be mounted low down just above

the top of the mixing tank. See section H for detailed installation notes.

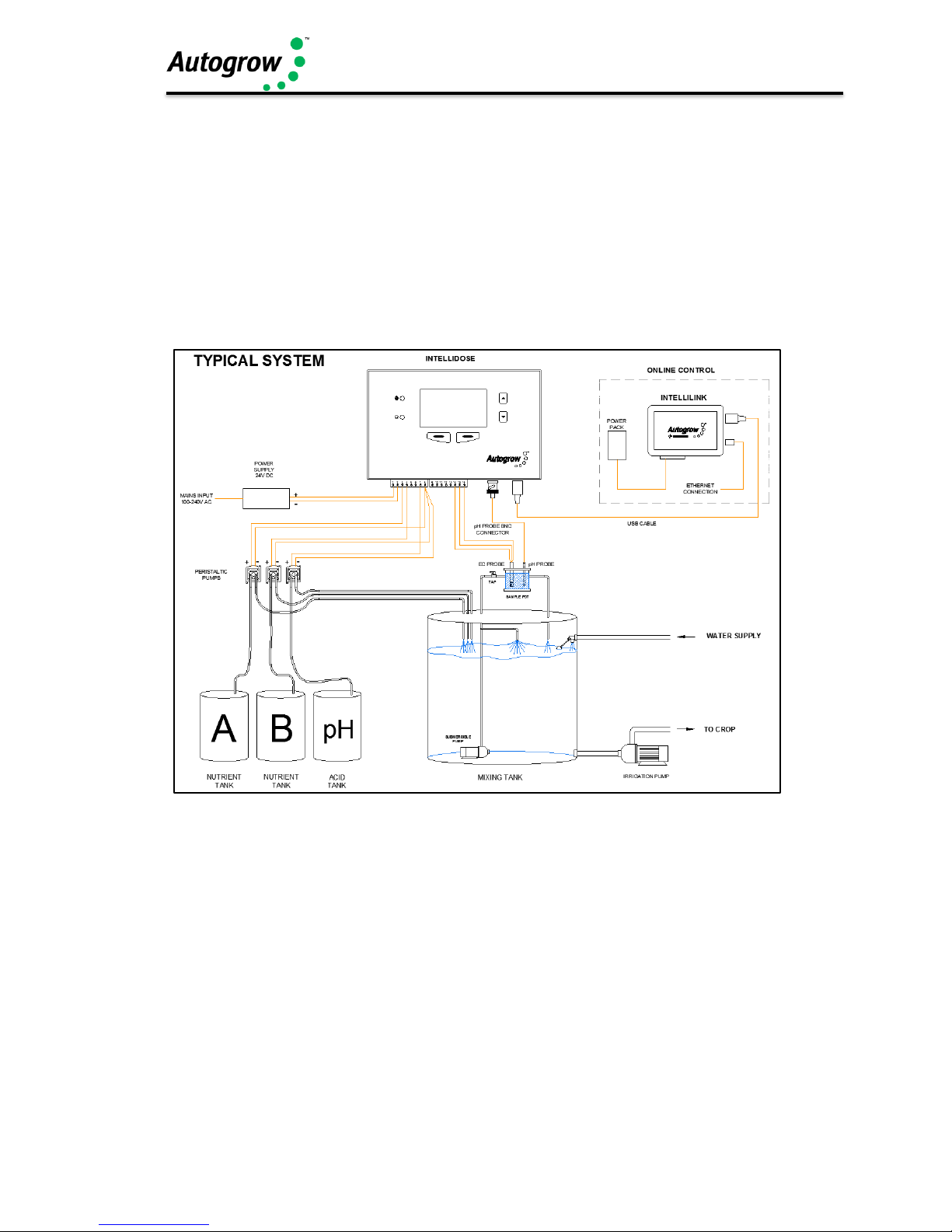

Typical installation using peristaltic pumps

HINTS:

(1) Keep sample pot low down just above top of tank as

many small pumps have quite low head pressure

capability

(2) Mount IntelliDose away from spray and humidity from tank

and stock solution, preferably just outside grow room

(3) Adjust the valve in the pipe to the sample pot to achieve a

steady flow without excessive turbulence or air bubbles in the

sample pot

Clean the EC sensor and calibrate all sensors before use – see section J for details

Fill all stock tanks and mix tank with plain water and run for a day to check for leaks

and observe operation is correct. (This saves the hassle of emptying a stock tank of

nutrient or acid if a leak is found).

Page 4

IntelliDose Manual

©2017 Autogrow Systems Ltd V5.4 4

IMPORTANT:

When using an automatic doser, the stock solutions and acid/alkali must be

very dilute. This is particularly important if a small mixing tank (e.g. under

250gal)

NB: The acid or alkali for pH adjustment must be diluted to no more than 2%

You may need to experiment with the dilution rate of the nutrients so that a 3 to 8

second dose results in a TDS change of 50ppm (0.1EC or 1CF) and for pH a 3 to 8

second dose results in a pH change of about 0.1pH. In any event, the acid should be

diluted to below 2% strength to ensure that it does not react adversely with your

nutrient and this will also increase the life of tubing and solenoid valves etc.

It is also important that the tank is continually stirred while dosing and there is a

continuous gentle flow through the sample pot. If the sample pot is mounted too high

there is a danger of the flow ceasing if the pump loses pressure (head) for any

reason such as wear or partially clogged input filter.

Software installation

When installing software, it may be necessary to temporarily turn off your virus

checker if you get an error message when the installer tries to copy files into the

program files folder.

Windows XP note. It has been found that whenever a new USB controller is

connected to Windows XP it detects the new hardware and requests that the drivers

are reloaded. When this happens click to allow it to reload drivers and allow it to

search for new software and then to install automatically.

Windows 2000 note: Older machines running under windows 2000 may

occasionally experience the USB going off-line. We have found that some older

machines have USB difficulties if the USB lead is over 2m (6ft) in length. If a cable

longer than this is required we suggest using an “active” USB cable. These are

available from most computer/electronics stores.

Page 5

IntelliDose Manual

©2017 Autogrow Systems Ltd V5.4 5

Section A - Introduction to the IntelliDoseTM Hydroponic doser

The IntelliDose hydroponic doser is, without doubt, the most advanced and user

friendly doser on the market. It has a wide range of possible applications which we

will discuss briefly in this section. To keep the user interface as simple as possible,

only the readings and settings relevant to the selected features are displayed on the

controller’s LCD and on the computer. To add extra features, you must select them

by going into the configure menus on either the controller or the computer.

Features

A full specification is attached as appendix 1. Here we will review the features

available to you. Remember, to enable any feature mentioned here you will need

to go into the configuration menus on either the controller or IntelliGrow to select

them. When the controller is supplied it is set up as a simple two-part nutrient plus

pH lower, timed dosing controller.

Please head to our online Help, found here: help.autogrow.com/intelligrow.

Software

Please head to our online Help, found here: help.autogrow.com/intelligrow.

Selection of units

You may select either EC, CF or TDS (ppm) units for the nutrient strength and either

degrees C or degrees F for temperature. The acidity or alkalinity is always measured

in pH. In this manual, we will use EC (electrical conductivity) to denote either EC, CF

or TDS. The date format is selectable between mm/dd/yy and dd/mm/yy formats.

(The TDS standard used for this controller is EC x 500 but it is also possible to

select ECx640 and ECx700)

Mixing nutrients - IMPORTANT - PLEASE READ THIS CAREFULLY!

When using any automatic doser it is important that the nutrients and acid/alkali are

very dilute. The instructions on many dry powdered nutrients tell you to prepare the

stock solutions to quite a concentrated level (100:1 or more). Liquid nutrients are also

very concentrated. For a small mixing tank, this will be too strong and even if very

short doses are given the system will overshoot. If using powdered nutrient mix them

into water so that for each 1Kg of powder you obtain at least 20ltrs of solution. Liquid

nutrients should be diluted with water to make up at least 5 times their original

volume. Acids and alkalis should be diluted to be less than 2% strength. (if using

strong acids, always wear goggles, gloves and add the acid to the water then stir

well).

When you have the dilution right you should get a 0.1 mS/cm change in EC when

you add around 25ml of A and B stock solutions. In a similar way, the pH should

change by about 0.1pH when 25mL of stock solution is added. If it changes by less

than this – that is fine but if it changes by more - then you will need to dilute the stock

solution further.

Page 6

IntelliDose Manual

©2017 Autogrow Systems Ltd V5.4 6

One part or two-part dosing

For one part dosing, only one dosing pump is used to add nutrient to the mixing tank.

When two-part dosing is selected then two dosing pumps will be used to add part A

and part B stock solutions. In this case it is sometimes found the part A and part B do

not dose at exactly the same rates (one tank empties quicker than the other). There

are a number of reasons why this may occur including different pipe arrangements,

filters partly blocked, tanks or dosing valves mounted at different heights and even

the fact that the two solutions may have different specific densities. To compensate

for this, you may adjust the two dose rates electronically by reducing either A or B

dose rates below 100%. For example, if you set A at 100% and B at 95% then B will

dose a little less than A each time that a dose is added to the tank. This is set by trial

-and-error starting with both A and B at 100%. (Always leave one at 100% and

reduce the other)

Multi-part dosing

With 3 to 8-part dosing, the ratios may be varied to suit a feeding schedule as

recommended by the nutrient supplier. In this case the ratios between all the

nutrient parts can be individually varied. A schedule may be added with IntelliGrow

which will automatically vary the nutrient ratios and EC as required. This can be

used to gradually and automatically change the mix from vegetative to generative

whilst at the same time gradually changing the EC. Note, on each date specified,

the settings change to the new values and then stay at these settings until the next

date in the schedule is reached. Once the last entry is reached the settings just stay

at those values permanently. It is important to note, that when using variable ratios

for the various nutrient part, the dose time must be set to be long enough that the

part with smallest ratio still gets a dose of at least one second. When set for more

than 2 nutrient parts the dose interval must be set for greater than 0 seconds.

Sequential dosing (default ON)

This causes the dosing pumps or valves to activate in sequence, one after the

other and allows high current valves or pumps are connected to the unit without

fear of overloading the controller or its power adapter. If in doubt about the

current required to drive the pumps then always select sequential dosing. If 3

or more nutrient parts are selected sequential dosing is enforced to avoid

damage to the controller.

Proportional dosing (default OFF)

This causes the dose size to automatically vary in proportion to the error and is

useful when you want the tank to dose up quickly. If this is selected then the dose

size is specified as both a maximum and minimum dose time. The controller then

looks at the size of the error and if large gives large doses but as the EC or pH

setpoint is approached, the controller will give smaller and smaller doses

approaching the minimum size. This is useful in irrigating (drip) systems that do not

re-circulate as it allows rapid dosing after each irrigation occurs. This feature is not

available with more than 2 part mixes.

Page 7

IntelliDose Manual

©2017 Autogrow Systems Ltd V5.4 7

Different EC for day and night

This feature is useful for crops needing a weaker solution during the heat of the day

and a stronger mix when it cools down at night time. (e.g. to help prevent tip burn in

lettuce) The user can define when “day” starts and ends and this does not have to

align in any way with actual day time i.e. you can set day to start at 11am and end

at 3:30pm if you wish. Note that the controller is able to both strengthen the mixture

(by dosing) and weaken the mixture by adding water.

Automatic addition of water

By installing a mixing tank (reservoir tank) with two water level ball valves, one at a

low level and the other at a high level it is possible for the controller to dilute the

nutrient tank by adding water. This is done by operating a solenoid valve in line with

the high-level valve. See diagram later in this manual. This function is mainly of

interest to lettuce growers.

Irrigation

This allows a pump to be switched on periodically for a set time to irrigate plants in

pots or bags. The irrigation can be specified to operate in the “day only” mode or it

can have a different interval set for day and night. For example, you could set it to

irrigate for 4 minutes every 1 hours 35 minutes during the day and for 4 minutes

every 5 hours at night. (or not at all during the night)

Alternatively, it can be set to come one once every day at the same time. This

could even be used to operate lighting (instead of irrigation) for indoor crops.

If the pump is a mains voltage pump then a relay will be needed to re-power the

24V DC so that it can supply mains power to the pump. Your distributor should

have convenient relay boxes available for this

Fail safe dosing

Dosing may be inhibited if any of the following is detected.

- EC probe failure

- pH sensor module failure

- EC of zero measured

- pH outside limits detected

Alarms

The alarms can be enabled to operate on the controller buzzer or to text/email you

when using IntelliGrow. Each of these can be silenced or enabled. Any enabled

alarm will sound when a relevant reading deviates outside user set limits. For

humour, we have a selection of alarm sounds including regular, fun and adult.

These can be selected on IntelliGrow under setup.

Outputs

The outputs voltages for dosing and irrigation control are all dependent on the

power supply adapter used.

Page 8

IntelliDose Manual

©2017 Autogrow Systems Ltd V5.4 8

Power supply

The controller requires a power supply between 12V and 24V either AC or DC.

Whatever power is applied will appear at the outputs (when they are ON). The

default power adapter included with this controller is compatible with the solenoid

valves or pumps supplied. Note that the outputs are limited to a current of 1.2A

inductive load and 3A resistive load. The power supply should be sized according to

the maximum load that can be applied at any one time. The maximum total draw at

any one time should not exceed 4A. Normally we supply a 24V DC power supply.

How to use this manual

The IntelliDose has a number of advanced modes of operation and so we have

divided this manual into sections, each of which represents a particular feature.

Please start by reading section C which gives basic setting information for the one or

two-part nutrient doser and then refer to the chapters covering features you require.

For installation advice, go to the installation section at the back of this manual.

Getting Started

Follow the installation instructions in the installation section and when everything is

installed and connected do the following.

Switch on the power. Check that the power light on the front panel is on and that the

LCD display has some information on it.

From here, you need to create your IntelliGrow account. Please head to our online

Help, found here: help.autogrow.com/intelligrow

Once you have your IntelliGrow account setup, you can install the IntelliGrow

Installer. You’ll need to select either Windows or Mac setup, depending on what

computer/operating system you are using.

Please head to our online Help, found here: help.autogrow.com/intelligrow.

If you have more than one new controller, connect their USB cables one-at-a-time

and when the software asks, provide the requested information. For new or

replacement controllers, you'll be asked which grow room it's located in and then to

give the controller a name.

Use a short meaningful name like Doser1, Climate2 etc so that understanding which

device is located in which area is simple to understand as you add more devices.

IntelliGrow will automatically detect any connected controllers and will communicate

immediately. You will also see information from the controller(s) on your computer

screen.

Page 9

IntelliDose Manual

©2017 Autogrow Systems Ltd V5.4 9

Section B – Settings

B1 – Setting from the PC/Mac

ORDER OF SETTING UP A NEW CONTROLLER

1) Visit autogrow.com/intelligrow to get online

2) Set the configuration of the controller to match the physical

equipment. Print the wiring diagram and connect the dosing valves

accordingly.

3) If using scheduling set this or load a ready-made file from disk

4) At the controller, clean the EC probe

5) At the controller calibrate both EC (TDS) and pH

6) At the status tab set dose times

7) Enable all functions that you wish to use

8) Check the time/date on the computer and on the controller

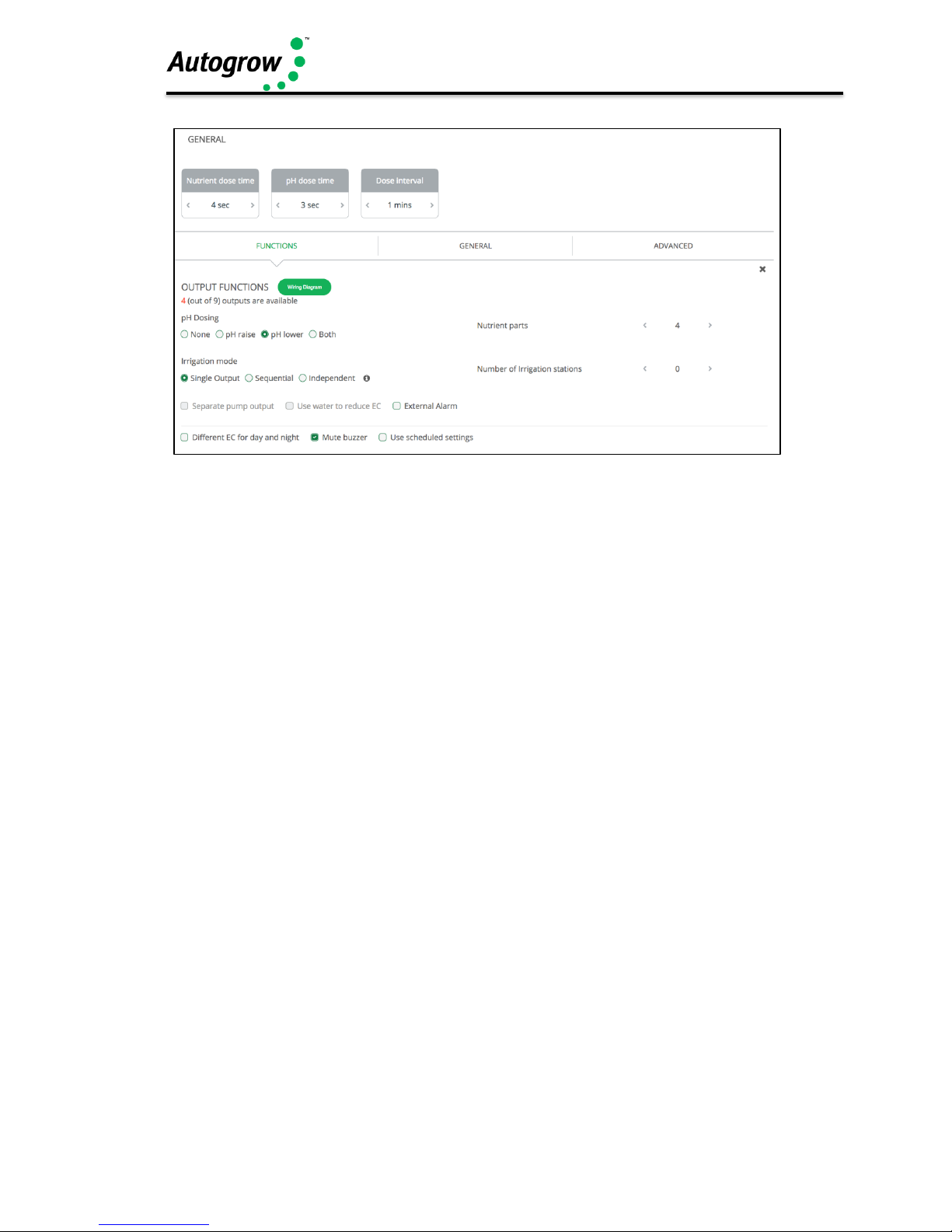

Configuration

Next are the dawn and dusk time settings. These are only needed if you select

“Irrigate during day only” or “different EC for day/ night”. The times entered here do

not have to align with the actual day time and for indoor growing they will be set to

reflect the period that the lights are on. After changing any settings, you must click

the save button at the bottom to send them to the controller.

Next, select the number of nutrient parts that you wish to automatically dose. This

needs some careful consideration. For example, there is no need to include an

additive that is used only once in the initial tank of water.

Similarly, a flushing agent which is added to a fresh tank of water for the last day or

two certainly does not need to be automatically dosed.

Remember also, that you have a total of 8 outputs (9 from version 3.03) and the

more you use for nutrients, the less will be available for pH dosing and irrigation.

Having selected the number of nutrients that are to be dosed continue by selecting

the pH dosing required, then whether irrigation output is required.

If you wish to have a different EC (TDS) for day and night then this can also be

selected and if selected you can also chose to add water automatically to reduce EC.

As soon as you have used all the 8 available outputs (9 from version 3.03) the

options will appear greyed out and will be un-selectable. The only way to select them

is to go back and deselect some previous choices.

Then you can select “scheduling” if desired. This gives you the opportunity to set up

a complete growing schedule by specifying the nutrient ratios and EC for each stage

of growth. This schedule or table is very easy to modify and so if the plant growth is

slower or faster than expected you can easily make alterations at any time.

Note that it is possible to save the schedule to disk so that it can be used for future

grows. We supply a standard schedule based on the recommendations as published

by various manufacturers of three part nutrients.

This should be modified to suit the particular species of crop that you are growing

and to suit your climatic conditions.

Page 10

IntelliDose Manual

©2017 Autogrow Systems Ltd V5.4 10

In the Advanced section, you can select proportional dosing if required. This will only

work satisfactorily on systems that irrigate large quantities of water from the tank and

therefore need very rapid dosing to get the EC and pH back to correct levels. If this is

not the case then deselect this option.

Sequential dosing should always be selected unless there is a good reason not to. In

fact, if you select more than 3 nutrient parts it will be enforced anyway. It should only

be used with 1 or 2 part mixes and where you intend setting the dose interval to zero

to achieve continuous dosing. This is sometimes used on very large irrigated

systems so that continuous dosing occurs while irrigation takes place and fresh

make-up water is entering on a continuous basis.

The fail-safe disables for dosing should always be enabled for safety. These prevent

dosing if the controller suspects that a probe has become faulty or if the EC/pH are

too far out.

The “Save current settings to disk” and “Restore settings from disk” do exactly that.

They fetch all settings from the controller and store them in a file on your computer's

hard drive. This allows you to quickly reset the controller to a previously saved setup

that was known to work well for a particular season, for example.

Dose times

Note that if scheduling has been selected then settings like the nutrient set points and

nutrient dose ratios will appeared “greyed out” on this tab as they are derived from the

entries on the schedule tab and cannot be altered here.

Dosing times and intervals can be set by trial and error.

Scheduling tab

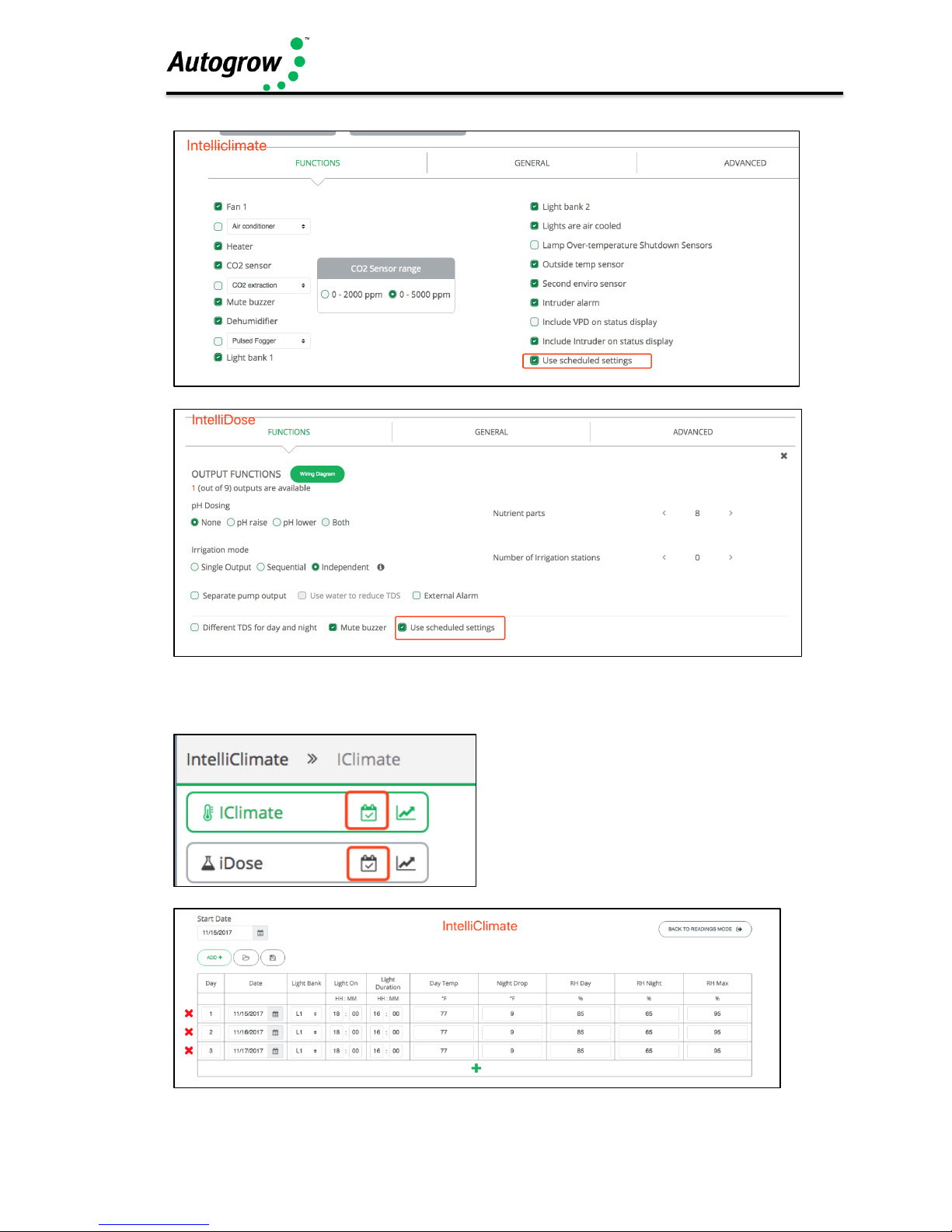

To set up the scheduling function, scroll down the page to Functions and tick the

"Use scheduled settings".

Page 11

IntelliDose Manual

©2017 Autogrow Systems Ltd V5.4 11

After saving, you'll see the scheduling icon showing up by your device name where

you can manage your Schedules.

Page 12

IntelliDose Manual

©2017 Autogrow Systems Ltd V5.4 12

If you need any help with setting Schedules, feel free to send us a message by

clicking on the toggle to the right or emailing us directly -

help.autogrow.com/intelligrow.

Page 13

IntelliDose Manual

©2017 Autogrow Systems Ltd V5.4 13

History tab

This history tab allows you to graphically view all data logged from the controller.

This is very useful for diagnosing problems.

The pop-up calendar allows you to easily view records from previous days, months

or years.

Export the data

You have the option to export the data as a csv file if needed.

Variable Options

If you only wish to look at some key grow variables, you can do so by using the

options and save it as your preference

Page 14

IntelliDose Manual

©2017 Autogrow Systems Ltd V5.4 14

B2 – Setting from the controller key pad

Just about all settings available at IntelliGrow are also available from the keypad.

Exceptions are the scheduling which is not available without IntelliGrow and the

calibrations which are only available at the controller.

Operation of the keypad is similar to a cell phone. The two keys at the bottom of the

display are “soft keys”. This means that their function at any particular time is shown

on the screen above them. After switching on, you will find that the right-hand key

has the label “menu” on the LCD above it and the left-hand key is unused at this

point. To the right of the LCD screen are two arrow keys. These are for moving down

or back up, through the menus and when you are in a screen which allows you to

edit a numeric value they are used for incrementing or decrementing the values.

They are also used to select between different options.

On first pressing the “menu” button, you will find yourself in the main menu. Use

the down arrow to move down through this and you will find the following items

DOSING

CALIBRATION

OVERRIDES

IRRIGATION

ALARMS

CLOCK

CONFIGURE

If you wish to make a change to, say, irrigation timings, you would move down to

irrigation and then press the “enter” key to enter the Irrigation sub-menu. Now

again by pressing the down and/or up arrows move through this sub-menu to find

the item that you wish to change and then press enter to access this item. After

making any changes the soft keys will allow you to either save the new setting or

to cancel and exit out of that screen.

The setting order is the same as when using IntelliGrow and the settings that you

will access are also the same, so we suggest that you use the previous pages on

IntelliGrow settings to guide you through the setting procedure.

Page 15

IntelliDose Manual

©2017 Autogrow Systems Ltd V5.4 15

General section - Dose and dose interval timings.

Dose times and interval are set by trial and error. The smaller the reservoir the

smaller the dose times need to be. The strength or concentration of your stock

solutions will also affect the dose time setting. Obviously, the stronger the stock

solution, the shorter the time the pump runs. If you are using a small reservoir tank

you must ensure that your stock solutions are very dilute.

Ideally, you are trying to achieve a dose time such that the EC(TDS) goes up by

about 0.1EC (50 ppm) for each dose. If you need to set the dose time to a very small

number to achieve this then you need to dilute the stock solution. The minimum time

that any pump should run for is 1 second, so, if at any stage you have a ratio for one

of the nutrient parts set for, say 20%, then the minimum dose time has got to be at

least 100/20 = 5 seconds. This is because 5 seconds corresponds to a 100% dose

and 20% is only 1/5th of this so the pump for this nutrient part will only run for 1

second. The process is similar for pH dosing where you are trying to achieve a

change of, about, 0.1pH for each dose.

The dose interval is set to allow time for a dose to fully mix in before the controller

makes the decision as to whether another dose is required. Normally set to 1

minute for a small tank and up to 10 minutes for very large systems.

If the dose interval is set to zero then the valves will open continuously while the

measured EC and pH are below the set point and close as soon as they exceed the

setpoint. This feature can be used as a simple in-line injection system in which

irrigation water is rapidly taken from a small tank and fresh water is added

simultaneously such that rapid dosing is required to maintain the EC and pH.

Irrigation intervals and durations for day and night are also set here as is the water

ON time for each addition of water. This should be set so that each time it adds water

it dilutes the nutrient by about 0.1EC (1CF or 50ppm).

Page 16

IntelliDose Manual

©2017 Autogrow Systems Ltd V5.4 16

Section C - Settings for simple 1 or 2 part doser

In the advanced menu on the IntelliDose or the advanced tab on IntelliGrow,

select the units that you wish to use and then select one or two-part dosing.

If you wish to use AutoSet then turn to Section A in this manual, alternatively, to set

up manually, continue below. (You cannot use AutoSet for 3 part nutrients).

To set manually

1) Calibrate the EC and pH sensors as described below

2) In “Configure” on the controller or IntelliGrow select one or two-part nutrient

3) In Dosing settings set the desired EC, pH and pH raise or lower

4) In Dosing settings set the EC dose time. This should be set so that each

dose raises the EC by about 0.1mS/cm (1CF or 50ppm)

5) In Dosing set the pH dose time so that each dose alters the pH by about

0.1pH

6) In Dosing settings select either pH raise or pH lower. The most usual

selection is pH lower (acid dosing) and if you are unsure then select this. If

you find that the pH continually drifts down below 5.5pH then change this to

pH raise and ensure that you have a dosing pump connected the pH raise

output and to a stock tank containing pH raise (alkali)

7) In Dosing settings set the dose interval. This is the time taken for each dose

to mix in and for the EC and pH readings to stabilise. For a small system, 2

or 3 minutes is typical. Larger systems may require 10 minutes or more. Note

that dosing will not occur unless the reading has been below the setpoint

continuously for this amount of time

Calibrate EC sensor

1) Clean the face of the probe. Remove the shroud from the end of the probe

and use a little kitchen liquid scouring cleaner such as “Jif" or "SoftScrub” on

a clean “Scotchbrite” nylon scouring pad. Alternatively, use 600 grit wet-and-

dry paper with the cleanser. Use a circular motion to scour the face of the

probe and then rinse well in running water. Do not touch the face of the probe

but shake off any residual water.

2) Replace the shroud and then place in the calibrating solution. The solution

supplied has an EC of 2.77mS/cm (CF=27.7, ppm = 1382). Allow about 5

minutes for the temperature compensation to fully kick-in and then press the

menu button to get down to the Calibrate screen. Then press “Enter” to get to

the Calibrate sub-menu where you will again press menu to step through this

sub menu until you reach the “Calibrate EC” screen. Then press “Enter”

again, to get into the “Calibrate EC screen”.

3) Now press either the UP or Down arrow keys to get the calibrated reading to

correspond with the Standard calibrating solution (normally 2.77mS/cm,

27.7CF or 1382ppm). When this is achieved, press the save button to save

this in permanent memory.

Page 17

IntelliDose Manual

©2017 Autogrow Systems Ltd V5.4 17

Calibrate pH sensor

1) The glass bulb at the end of the pH electrode should be shiny and clear.

If necessary, clean the glass bulb at the tip of the sensor with a very soft

“child’s” toothbrush or a special cleaning tool with a little liquid scouring

agent such as “Jif”or "SoftScrub”. The bulb is very delicate – TAKE

CARE.

2) Rinse thoroughly in water and then place in the pH 7 buffer solution. NOTE

THAT YOU MUST ALWAYS CALIBRATE AT pH 7 BEFORE pH 4.

3) Allow a few minutes for the reading to stabilise and then press the menu

button to reach the Calibration screen. Press Enter to get into the Calibration

sub-menu and then “Enter” the Calibrate pH 7 screen. Now press the up and

down arrows until the reading matches the calibration solution (e.g. pH 7.0).

Press “Save” to store the calibration.

4) Rinse the probe and place in pH 4 buffer solution. Allow to stand for a few

minutes until there is no further change in the pH reading. Now use the Menu

and Enter keys to navigate to the Calibrate pH 4 screen. Press the up and

down arrows to get the calibrated reading to match the calibration solution

and then press “Save” to save the calibration and exit from that screen.

The EC probe should be cleaned regularly and calibrated every other week. The

pH probe should be calibrated weekly. In addition, it is advisable to use a hand-held

meter to check the EC and pH every day. If ever the hand-held instrument and

controller readings differ then all probes should be cleaned, checked and

recalibrated.

Page 18

IntelliDose Manual

©2017 Autogrow Systems Ltd V5.4 18

Section D – Settings for three part doser

General

Best dosing accuracy is achieved with larger dose sizes and if any of the ratios of

a multi-part mix is set to a small value then it important to ensure that its dose time

is still above 1 second.

For example, say a dose time is set to 5 seconds and one part is set to a ratio of

10%. This means that a ratio of 100% = 5 seconds and so a ratio of 10% will equal

only ½ second. This is not sufficient time for a pump to run so the dosing of this part

will be very inaccurate if it manages to dose at all. The solution is to increase the

dose time to 10 or even better 20 seconds. At ten seconds the 10% component will

dose for 1 second (just long enough but still not very accurate) while at 20 seconds

it will dose for 2 seconds which should be much more accurate.

However, you may now find that each of these larger nutrient doses raises the EC

by more than the desired 0.1 EC (50ppm). The only solution to this is either to 1)

dilute the stock solutions, or 2) use a larger reservoir tank or even a combination of

both. If diluting the stock solutions, it is important to dilute them all in exactly the

same ratio. E.g. 1 part nutrient to 3 parts of water (makes a 25% solution). This

would result in each dose casing the EC to rise by ¼ of its previous value.

Another approach is to dilute only the nutrient parts that require the low % ratios. For

example, a recipe recommends 100:50:10. If the dose size was set to 5 seconds the

part A would dose for 5 seconds, part B for 2.5 and part C for only 1/2 second. By

diluting part C in water with one part C to 4 parts water we will reduce its strength to

1/5th of the original. Then we would schedule 100:50:50 which would be much more

accurate.

Using a schedule

Using IntelliGrow, it is possible to schedule automatic changes in a two or threepart dosing regime. To do this please head to our online Help, found here:

help.autogrow.com/intelligrow.

Note that changes can be on a daily basis or less often as necessary. It is usually

required to make frequent changes during the cutting or seedling stage and then

less frequently as the crop matures.

Of course, every crop develops at a different rate and so the table is very easy

to modify. Days can be added, or deleted at will and dates can easily be

changed.

Changes will only happen if IntelliGrow is connected and on line. If the controller is

taken “off-line” then when it is next connected if any change is required it will be

made straight away. Normally, changes will take place at midnight preceding the

date specified.

Page 19

IntelliDose Manual

©2017 Autogrow Systems Ltd V5.4 19

Section E – Proportional Dosing (default OFF)

Proportional dosing allows rapid dosing toward the set point. A maximum dose time must

be entered as well as a minimum dose time. The maximum time should be set so that a

dose of this size would raise the EC from its raw water value to 80% of the setpoint value in

a single dose. The minimum dose time should be set to achieve a rise in EC of 0.1mS/cm

(CF=1, ppm=50). The controller will then select the most appropriate dose size within this

range depending on the measured EC. This means that when starting with a tank of pure

water, the controller will make one very large dose followed by smaller and smaller doses

as the setpoint is approached.

Note that proportional dosing is not available for use with 3 (or more) part mixes.

Section F – Sequential Dosing (default ON)

By selecting sequential dosing, the dosing outputs will operate in sequence, one after the

other. This allows a small power supply to be used with dosing devices that draw a heavy

current. For example, small peristaltic pumps typically draw 1.2 Amps or so at 24V DC. If

three-part dosing was used and three pumps were allowed to come on at the same time the

power supply would need to be rated at about 4 or 5 Amps. By selecting sequential dosing

a 2Amp supply could be used.

Page 20

IntelliDose Manual

©2017 Autogrow Systems Ltd V5.4 20

Section G - Installation

Mount the IntelliDose controller within 1.5 metres of the sample pot but in a position well

away from water splashes or mist/vapour rising from the reservoir tank. It should be

mounted in a cool, dry place out of direct sunlight. Remove the screws holding the back on

and fit the mounting feet, then screw to the wall. If using the dry wall (plaster board) anchors

use the longer screws supplied but if fixing to a ply back board use the shorter screws.

Typical installation using peristaltic pumps

HINT:

(1) Keep sample pot low down just above top of tank as many small

pumps have quite low head pressure capability

(2) Mount IntelliDose away from spray and humidity from tank and

stock solutions

Typical installation using solenoid valves

Page 21

IntelliDose Manual

©2017 Autogrow Systems Ltd V5.4 21

Note that a small jet of water may be directed over the surface of the tank to stir and

aerate the nutrient solution. This can be achieved by heating and squeezing with pliers

an outlet from a Tee fitting. Ensure that your pump has excess capacity before doing

this.

Layout showing use of high and low water levels

NOTES

1) If irrigation is used then a second small pump should be used to

continuously circulate the solution through the sample pot and keep the tank

stirred. The irrigation pump would then need a “pump start relay” with a 24V

DC coil to switch it on only when an irrigation is called for.

2) If the irrigation water is returned to the reservoir tank then allowance must

be made for the level to rise a little above the float valve level.

Page 22

IntelliDose Manual

©2017 Autogrow Systems Ltd V5.4 22

The power supply to the IntelliDose must be between 12V and 24V either AC OR

DC. The outputs to the solenoid valves or pumps will be the same as the

supply going into the controller. This means that if 24V AC solenoid valves are

used then the supply adapter must provide 24V AC. Never connect a power supply

exceeding 24V to the controller. A 24V DC power supply adapter is normally

supplied together with either 24V DC solenoid valves or 24V DC peristaltic pumps

Connection diagram for 1,2 or 3 part nutrient dosing

The low voltage power from the adapter is connected to the two-left connection on

the left-hand connector. With many power supplies the cable is a screened “co-axial”

type. In this case the screen should be connected to the “Common” and the centre

wire to the 24V line connection on the controller.

The connection diagram for more than three part nutrients must be printed by

IntelliGrow software AFTER configuration has been complete.

Please head to our online Help, found here: help.autogrow.com/intelligrow.

If you are not intending to use IntelliGrow, please ask your supplier if they are

able to pre-configure and print out the wiring diagram for you.

Solenoid valves

Secure the solenoid valve panel to the wall. If using the plaster board anchors,

screw the anchors in firmly until they are flush with the wall. The anchors supplied

are self-drilling and so there is no need to predrill the wall. Just position them, give

them a light tap to get started and then turn to drill/screw in with a Phillips or pozi

screw driver. Use the longer metal screws to fix the valve plate to the nylon anchors

or if fixing to a solid wood back board, use the shorter screws supplied.

Next connect the valve using the cable supplied to the outputs as shown above.

Check that the voltage rating of the valves matches the voltage rating of the

power supply e.g. if the valves are 24V DC then the supply should also be 24 V

DC.

The solenoid valves are installed as shown overleaf.

Peristaltic pumps

You can direct drive 24V DC peristaltic pumps if you have the appropriate power

supply. The small pumps available from our distributors draw a current of up to 1.2

Amps and so to run three pumps at the same time, you will need a 4 or 5A, 24V

Page 23

IntelliDose Manual

©2017 Autogrow Systems Ltd V5.4 23

DC power supply. To avoid the necessity of such a powerful supply you may select

the “Sequential dosing” option (in the configure menu). In this case, pumps are run

one after the other and so at any one time there is only one pump running. A 2A,

24V DC supply is sufficient for this. We have available a 2.5A supply that allows 2part (but NOT 3 part) dosing to run simultaneously or 3-part dosing to run

sequentially.

To install stock tanks and solenoid valves

1) If the stock tanks are to be installed on a raised shelf this must be attached to

the wall in a very strong way as full stock tanks can be very heavy and if the

shelf was to give way could result in a serious injury. If in doubt, get a skilled

tradesman to install the shelf.

2) Carefully drill clean holes near the bottom of the stock tanks. Insert the tank

fittings and tighten securely. Thoroughly clean out the drums. Attach the flexible

hose to the tank fittings and lead down to the solenoid valve board. Push the

tubes on to the inlet at the front of the valves

3) Fit the reducers and thin tubes to the bottom outlet pipes. Thin 5mm tube is

used here to restrict the flow through the solenoid valves, which might

otherwise be too great for small systems. If you shorten these pipes ensure that

they are of equal length or the flow rates from the A, B, C tanks will be unequal.

4) After filling the stock tanks leave the lids loose to allow air to enter the tank

as the stock solution is drawn off via the solenoid valves (or drill a small

hole through the lid)

Page 24

IntelliDose Manual

©2017 Autogrow Systems Ltd V5.4 24

1) Thoroughly clean tanks to ensure that no plastic shavings are left in them

2) Test with water first to ensure no water leaks and system operates

correctly then fill tanks with the stock solutions

3) For acids and alkalis, ensure that they are diluted to less than 2% strength

4) Some valves have breather pipes that must reach the top of the stock tanks.

These pipes ensure that the tubes are fully emptied after each dose. Note

that although some valves have tube shapes moulded on the side these

might be closed off in which case no breather is required. If in doubt, check

by blowing through the side tubes to see if they are blanked off.

5) Wire the two solenoid valves to their respective connections on the

controller as shown in the wiring diagram

Page 25

IntelliDose Manual

©2017 Autogrow Systems Ltd V5.4 25

Wiring Diagrams

Note that all the connections marked 24V common are connected together

internally and you may connect the return from any solenoid valve or pump to any

of these commons

The common wire from the power supply is the bare silver wire.

IMPORTANT

The voltage at the outputs will always be the same as the voltage from the

power adapter. We normally supply 24V DC unless a different voltage or AC

has been specifically requested.

Page 26

IntelliDose Manual

©2017 Autogrow Systems Ltd V5.4 26

Wiring Peristaltic pump wiring

Note that all the connections marked 24V common are connected together

internally and you may connect the return from any solenoid valve or pump to any

of these commons.

IMPORTANT

The connection diagram for more than three part nutrients must be printed

by IntelliGrow software AFTER configuration has been complete.

Please head to our online Help, found here: help.autogrow.com/intelligrow.

If you are not intending to use IntelliGrow, please ask your supplier if they

are able to pre-configure and print out the wiring diagram for you.

Page 27

IntelliDose Manual

©2017 Autogrow Systems Ltd V5.4 27

Section H – Software installation

Please head to our online Help, found here: help.autogrow.com/intelligrow.

Section I – Maintenance

Clean EC probe

Remove shroud from end of probe. Clean the face of the probe, use a little kitchen

liquid scouring cleaner such as “Jif" or "SoftScrub” on a clean “Scotchbrite” nylon

scouring pad. Alternatively, use 600 grit wet-and-dry paper with the cleanser. Use a

circular motion to scour the face of the probe and then rinse well in running water.

Do not touch the face of the probe but shake off any residual water..

Replace the shroud and check calibration.

Calibrating the EC probe

After cleaning and rinsing the probe, shake vigorously to remove any surplus water.

Now place the probe in EC standard solution and allow the temperature

compensation to take full effect by leaving for 5 minutes or more. Calibration

solutions are usually 2.76mS/cm referenced to 25oC but any calibration solution may

be used.

The reading should settle to within 0.1 EC (1 CF or 5ppm) of the value stated on the

bottle. If not then navigate to the EC calibration screen on the controller (not

available on IntelliGrow) and press the up/down arrows until the reading exactly

matches the value printed on the bottle. Note that calibration solutions are easily

contaminated or changed by evaporation and should be replaced with fresh solutions

every 3 months or more frequently if high accuracy is required.

Cleaning the pH electrode

The pH electrode is supplied with a protective cap or cover over its active

end. Its purpose is to keep the glass bulb moist during storage and transit.

This cover must be removed before use.

The glass bulb at the end of the pH electrode should be shiny and clear. If not then

it may be cleaned by brushing with a soft toothbrush or special cleaning tool

together with a little liquid scourer such as Jif or Soft Scrub. Do this very carefully as

the glass bulb is extremely delicate. Rinse thoroughly with clean water.

Calibrating the pH electrode

Every week you should check the pH calibration. To do this place the probe in the

pH7 buffer solution and allow to stand for 10 minutes. The reading should be 7.0 +/-

0.1 pH. If not then navigate to the pH 7 calibration screen and use the up/down

arrows to correct the displayed reading. When correct, press save.

Next rinse the probe in fresh water and shake off excess water. Now place in the

pH 4 buffer solution and allow to stand for 10 minutes. The reading should be 4.0

+/-0.1. If not navigate to the pH 4 calibration screen and use the up/down arrows to

correct. Now press save to store the calibration.

IMPORTANT: The pH 7 calibration MUST be carried out before the pH 4

calibration.

Page 28

IntelliDose Manual

©2017 Autogrow Systems Ltd V5.4 28

pH electrodes last for between 6 months and two years. As soon as the

electrode shows signs of drifting or slow response it should be renewed. For

storage, the tip of the pH probe must always be kept wet, if they dry out, they

will not work.

Page 29

IntelliDose Manual

©2017 Autogrow Systems Ltd V5.4 29

Peristaltic pump maintenance

These require very little maintenance other than occasional greasing of the

rubber tubes (using special rubber grease from the manufacturer). The grease

may be applied via the two greasing access points in the clear plastic pump

covers. When the tubes become flattened they should be replaced.

Hint: it is sometimes possible to extend the life of the tube by sliding the tube

around a little so that a new section of tube is exposed to the rollers. To do this,

loosen the two screws in the front cover, slide tube and then retighten. Finally, add

extra grease via the two greasing points in the front cover.

Solenoid valves

These need very little maintenance but if the flow rates of the A and B solutions

becomes unequal the valves can easily be opened up for inspection and cleaning. If

a valve stops working completely there is a possibility that the solenoid coil has

become defective. The coils can be replaced.

General maintenance

Frequently inspect your system for leaks and repair these as soon as possible.

Water dripping onto solenoids or pumps will soon cause them to fail. Ensure the

controller, pump unit and solenoids are kept clean and shielded from all water

splashes and vapours.

Section J - Fault finding

1) Unit is completely dead – i.e. no display, no power light and no outputs

Check that the power pack is functioning (by measuring with a voltmeter if

possible) and that it is plugged in, switched on and properly connected to

the controller. If the unit still fails to function then the probability is that the

internal 4A fuse (20mm x 5mm miniature glass fuse) may have been blown.

The most likely cause of this happening is that wires connecting to the

solenoid valves or pumps have touched together and shorted out. To fix this

it is important to clear the fault first. Inspect all wiring and ensure that all

wires are well insulated right to the point where they enter the connector.

Also check the connections at the solenoid valves. Then replace the fuse

with a genuine 4A fuse. DO NOT ATTACH WIRE OR ALUMINIUM FOIL

ACROSS IT.

2) Cannot calibrate pH. Replace the pH electrode with a standard BNC gel

filled electrode.

3) EC calibration out or EC reading varies. Ensure that there is a small non-

turbulent flow of solution past the face of the EC probe. Ensure probe has

been properly cleaned and is free from grease or oil. (water should easily

wet the face and should not bead).

4) pH fails to dose. Ensure that the controller is set for raise or lower to match

the solution used. i.e. if you are using acid (pH down) then set the controller

to pH lower and ensure that that pump/solenoid is connected to the pH

lower output.

Page 30

IntelliDose Manual

©2017 Autogrow Systems Ltd V5.4 30

5) pH overdoses. Check that the controller is set for pH raise or lower as

described in 4 above. Also, check that the dose time is not excessive.

Each dose should change the pH by about 0.1pH

6) EC overdoses. Check that there is adequate flow through the sample pot

and that the EC dose time is not excessive. Each dose should change the

EC by 0.1 (CF1 or 50ppm)

Section K – Specification

8 outputs (9 from version 3.03) which can be flexibly configure to operate 1 to 8-part

variable ratio nutrient dosing, pH raise, pH lower, Irrigation, add water and alarm

Output voltage same as supplied voltage 12V to 24V AC or DC. Normally 24V DC

supplied Nutrient measurement units EC, CF or ppm (EC x 500)

Measured range 0.00 to 9.99EC, 0.1 to 99.9CF, 0 to 4999 ppm Nutrient resolution

0.01 mS/cm, 0.1 CF, 5ppm

Nutrient measurement accuracy +/- 0.1 EC, 1.0 CF or 50ppm - temperature

compensated Nutrient dosing range 0.10EC to 5.99EC, 0.1 to 59.9CF, 50ppm to

2999 ppm

pH resolution and accuracy – 0.1 pH pH measurement range 2pH to 12pH pH

dosing range 4.5pH to 8pH

Temperature resolution and accuracy 1oC, 2oF

Temperature measuring range 0-50oC,

32-125 oF

Operating temperature range 0-45oC,

32-110oF

(and not in direct sunlight)

Power source – mains transformer pack supplied; specify mains voltage and pin

type (power to controller can be between 12V and 24V either AC or DC to suit the

output devices) Outputs will have the same voltage as the supplied voltage from the

power pack.

Large graphics display using simple four key interface

Nutrient sensor uses DiPulseTM technique to resist fouling

Dosing fail safe shut-off (can be disabled)

- if nutrient is below 0.1EC, 1CF, 50ppm

- if pH below 4.5pH or above 8.0pH

- if sensor fault detected (some pH faults cannot be

detected) USB connection and software supports multiple

controllers Sample pot supplied.

Valves available separately with cables and flow restricting

pipes Valves chemically resistant to 5% Phosphoric acid,

2% Nitric acid

Compatible triple peristaltic pumps available separately as an alternative to solenoid

valves.

Page 31

IntelliDose Manual

©2017 Autogrow Systems Ltd V4.0 31

Section L – Advanced Irrigation Features

IntelliDose firmware version 3.01 released March 2015 expands on the original irrigation

functionality by providing the ability to control up to 4 irrigation stations with an optional

master pump.

Each station is assigned its own duration and control is either:

➢ Sequential - where each station is run in turn, all being triggered by a single trigger

(day/night interval or time of day) or

➢ Independent – where each station is completely independent, each having its own

trigger (day/night interval or time of day).

If a master pump is selected then this output will run each time any of the station outputs is

run, to accommodate having a single irrigation pump with each station being watered by

opening a solenoid valve.

Irrigation outputs are configured on the IntelliDose by navigating through the following

menus:

Menu > Configure > Advanced > Output

➢ Irrigation – to enable all irrigation functionality

➢ Station Outputs Use Station Outputs – select No to provide backwards

compatibility with pre-version 3.01 wiring configurations; Yes enables up to 4 outputs

to be assigned to irrigation stations

➢ Station Outputs No. Station Outputs – select from 1 to 4 stations

➢ Pump Output – Select Yes/No for a separate pump output which is activated each

time any of the stations is activated

➢ Station Mode – chose between Independent and Sequential

Irrigation settings for each station in Independent Mode are accessed by navigating through

the following menus:

Menu > Irrigation >

Irrig Stn 1 – access irrigation settings for station 1

➢ Irrig Run Time – specify how many hours/minutes/seconds the station will run

➢ Irrigate every – specify the daytime irrigation interval days/hours/minutes (if Irrigate

at same time each day is No)

➢ Irrigate every – specify the night-time irrigation interval days/hours/minutes (if

Irrigate at same time each day is No)

➢ Irrigate at: - specify the time of day to start irrigation (if Irrigate at same time each

day is Yes)

➢ Irrigation Enabled/Disabled – temporarily enable or disable the station (note the

output remains assigned to this station even if disabled)

➢ Irrigate during – specify if irrigation will occur during both Day & Night or Day Only

➢ Irrigate at same time each day – specify if the irrigation for this station is triggered

at a single time of day only (or triggered using daytime/nightie interval)

Each station’s settings can be accessed in a similar manner.

Page 32

IntelliDose Manual

©2017 Autogrow Systems Ltd V4.0 32

Irrigation Overrides are accessed by navigating through the following menus:

Menu > Overrides > Force Irrig. 1 – immediately start irrigating station 1

Menu > Overrides > Force Irrig. 2 – immediately start irrigating station 2

Menu > Overrides > Force Irrig. 3 – immediately start irrigating station 3

Menu > Overrides > Force Irrig. 4 – immediately start irrigating station 4

Irrigation settings in Sequential Mode are accessed by navigating through the following

menus:

Menu > Irrigation >

➢ Irrig 1 Run Time – specify how many hours/minutes/seconds the station will run

➢ Irrig 2 Run Time – specify how many hours/minutes/seconds the station will run

➢ Irrig 3 Run Time – specify how many hours/minutes/seconds the station will run

➢ Irrig 4 Run Time – specify how many hours/minutes/seconds the station will run

➢ Irrigate every – specify the daytime irrigation interval days/hours/minutes (if Irrigate

at same time each day is No)

➢ Irrigate every – specify the night-time irrigation interval days/hours/minutes (if

Irrigate at same time each day is No)

➢ Irrigate at: - specify the time of day to start irrigation (if Irrigate at same time each

day is Yes)

➢ Irrigation Enabled/Disabled – temporarily enable or disable irrigation (note the

outputs remains assigned to stations/pump even if disabled)

➢ Irrigate during – specify if irrigation will occur during both Day & Night or Day Only

➢ Irrigate at same time each day – specify if irrigation is triggered at a single time of

day only (or triggered using daytime/nightie interval)

In Sequential mode the whole irrigation cycle can be forced on by navigating to the menu:

Menu > Overrides > Force Irrig. 1 – immediately start irrigating all stations, one at a time

IMPORTANT

If Station Outputs is set to Use Station Outputs then a different wiring strategy is used

compared to previous firmware versions. It is therefore critical when wiring up an IntelliDose

using firmware version 3.01 or later to verify the wiring diagram using IntelliGrow software.

Please head to our online Help, found here: help.autogrow.com/intelligrow.

This is especially important if upgrading an existing IntelliDose to the new firmware or if

replacing an older IntelliDose with a newer one.

Please also note that with this revision the irrigation cycle is now taken from the start of the

cycle (previously it was taken as the interval from the end of one irrigation to the start of the

next).

This means that if you set an irrigation interval of 1 hour then the irrigation will start exactly

one hour apart.

So for example, if the interval is 1 hour and the duration is 20 minutes and irrigation begins

at the start of the day at 6am then irrigation will be as follows:

0600-0620

0700-0720

Page 33

IntelliDose Manual

©2017 Autogrow Systems Ltd V4.0 33

Using the advanced Irrigation Features in IntelliGrow PC software

Configure Tab

Irrigation Mode - chose between:

➢ Single Output (for backwards compatibility – only one output is used for irrigation)

➢ Sequential (for single trigger and each irrigation station runs in turn)

➢ Independent irrigation (up to 4 irrigation stations with own triggers and durations)

Number of irrigation stations - 0 to 4, where 0 means no irrigation is configured

Separate pump output – indicate if a main pump output should be activated along with

each station

For Single output or Sequential irrigation, you can specify whether the trigger is 'Irrigate at

same time each day' OR 'Irrigate during day only'

For Independent irrigation, these settings can be set for each station

The wiring diagram has been updated to accommodate the new irrigation scheme:

IMPORTANT

When using sequential or independent irrigation stations and a Separate pump output

there will be one additional output allocated to the irrigation pump. This is to accommodate

the scenario where a single pump drives the irrigation while individual solenoid valves are

operated for watering each station. This additional output is labelled as 'Irrig pump' on the

wiring diagram and only needs to be used if using a single irrigation pump.

If individual irrigation pumps are used for watering each station then it is not necessary to

use the Separate pump output.

Page 34

IntelliDose Manual

©2017 Autogrow Systems Ltd V4.0 34

Status Tab

Each independent irrigation station can be disabled or forced on:

Each independent irrigation station can be set to use a different duration and trigger:

When using single output or sequential irrigation then only one irrigation trigger can be

specified:

Upgrade

If the firmware version of your IntellIDose is prior to 3.01 and you would like to take

advantage of this new functionality please contact your local Autogrow distributor to find out

how you can upgrade your controller.

Latest Manual

To access the latest version of your instruction manual, please head to

help.autogrow.com/intelligrow.

Loading...

Loading...