Mk8 MM

End User Guide

Mk8 MM

End User Guide

Issued by:

AUTOFLAME ENGINEERING LTD

Unit 1-2, Concorde Business Centre

Airport Industrial Estate, Wireless Road

Biggin Hill, Kent TN16 3YN

Tel: +44 (0)845 872 2000

Fax: +44 (0)845 872 2010

Email: salesinfo@autoflame.com

Website: http://www.autoflame.com/

Registered Holder:

Company:

Department:

This manual and all the information contained herein is copyright of

Autoflame Engineering Ltd. It may not be copied in the whole or part without

the consent of the Managing Director.

Autoflame Engineering Ltd’s policy is one of continuous improvement in both

design and manufacture. We therefore reserve the right to amend

specifications and/or data without prior notice. All details contained in this

manual are correct at the time of going to print.

Important Notes

A knowledge of combustion related procedures and commissioning is essential before

embarking work on any of the M.M./E.G.A. systems. This is for safety reasons and

effective use of the M.M./ E.G.A. system. Hands on training is required. For details on

schedules and fees relating to group training courses and individual instruction, please

contact the Autoflame Engineering Ltd. offices at the address listed on the front.

Short Form - General Terms and Conditions

A full statement of our business terms and conditions are printed on the reverse of all

invoices. A copy of these can be issued upon application, if requested in writing.

The System equipment and control concepts referred to in this Manual MUST be installed,

commissioned and applied by personnel skilled in the various technical disciplines that

are inherent to the Autoflame product range, i.e. combustion, electrical and control.

The sale of Autoflame’s systems and equipment referred to in this Manual assume that

the dealer, purchaser and installer has the necessary skills at his disposal. i.e. A high

degree of combustion engineering experience, and a thorough understanding of the

local electrical codes of practice concerning boilers, burners and their ancillary systems

and equipment.

Autoflame’s warranty from point of sale is two years on all electronic systems and

components.

One year on all mechanical systems, components and sensors.

The warranty assumes that all equipment supplied will be used for the purpose that

it was intended and in strict compliance with our technical recommendations. Autoflame’s warranty and guarantee is limited strictly to product build quality, and design.

Excluded absolutely are any claims arising from misapplication, incorrect installation

and/or incorrect commissioning.

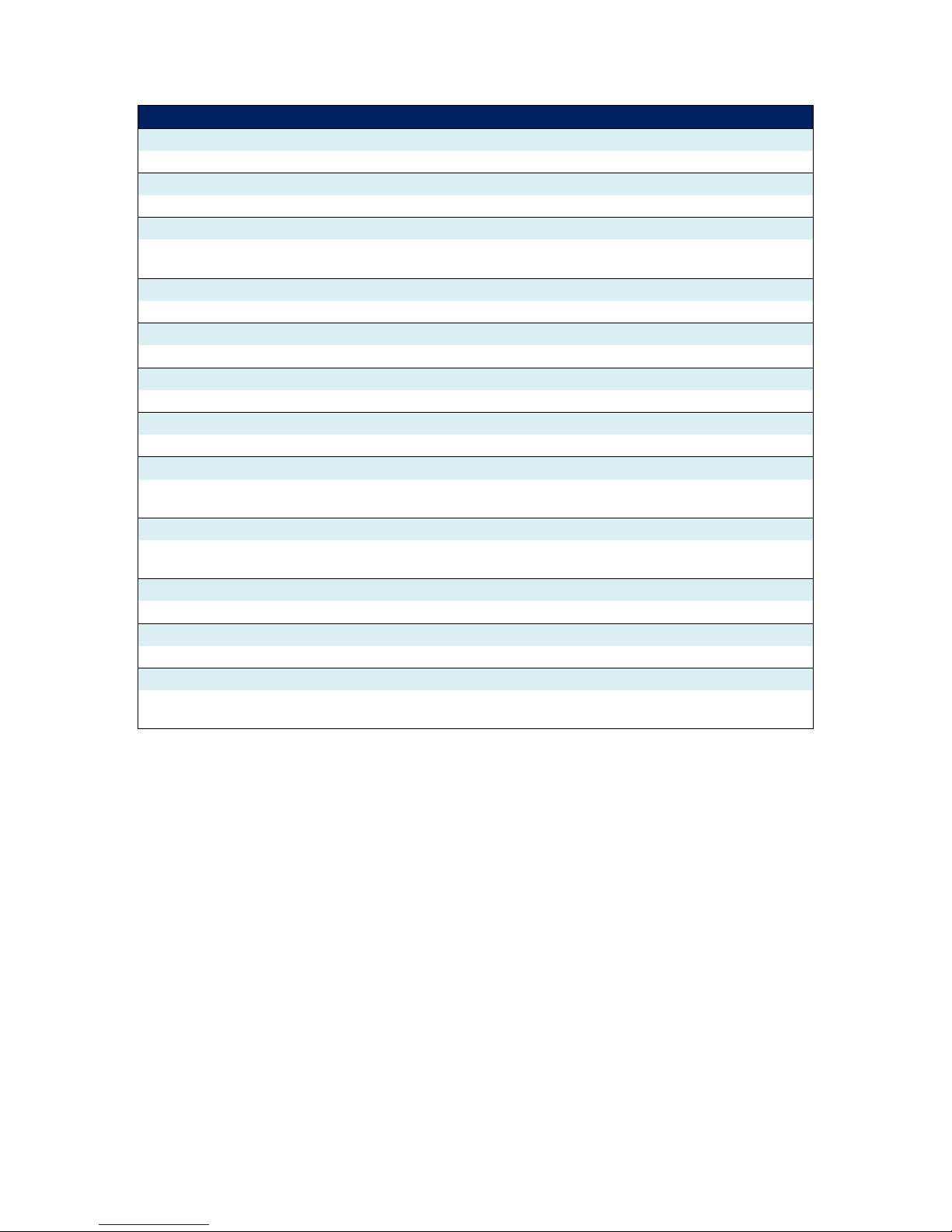

Contents

1 OVERVIEW AND BENEFITS……………………………………………………………………………… 1

1.1 Features and Benefits…………………………………………………………………………………………… 1

1.2 System Example…………………………………………………………………………………………………… 4

1.3 Micro-Modulation (MM)………………………………………………………………………………………. 5

2 ELECTRICAL SPECIFICATIONS………………………………………………………………………….. 6

2.1 Classifications………………………………………………………………………………………………………. 6

2.2 Inputs and Outputs………………………………………………………………………………………………. 6

2.3 Cable Specifications……………………………………………………………………………………………… 8

3 END USER OPERATION…………………………………………………………………………………… 9

3.1 Home Screen…………………………………………………………………………………………………… 9

3.1.1 Home Screen Components……………………………………………………………………… 10

3.1.2 Faults……………………………………………………………………………………………………… 12

3.2 Status Screen…………………………………………………………………………………………………. 13

3.2.1 Status………………………………………………………………………………………………………13

3.2.2 Status – History………………………………………………………………………………………. 14

3.2.3 Status – Burner Enable/Disable……………………………………………………………… 15

3.2.4 Status – Low Flame Hold………………………………………………………………………… 16

3.2.5 Status – Hand Mode………………………………………………………………………………..17

3.3 Fuel-Air Screen……………………………………………………………………………………………… 18

3.3.1 Fuel-Air – Curve……………………………………………………………………………………… 18

3.3.2 Fuel-Air – Map……………………………………………………………………………………….. 19

3.3.3 Fuel-Air – History……………………………………………………………………………………. 20

3.4 Flame Safeguard Screen………………………………………………………………………………….21

3.4.1 Flame Safeguard…………………………………………………………………………………….. 21

3.4.2 Flame Safeguard – History……………………………………………………………………… 22

3.5 Channels Screen…………………………………………………………………………………………….. 23

3.5.1 Servomotor…………………………………………………………………………………………… 23

3.5.2 VSD Channel…………………………………………………………………………………………. 24

3.6 Gas Pressure Sensor Screen 35 3.6.1 Gas Pressure…………………………………………. 25

3.6.2 Gas Sensor – History………………………………………………………………………………. 26

3.7 Air Pressure Sensor Screen……………………………………………………………………………. 27

3.7.1 Air Pressure……………………………………………………………………………………………. 27

3.7.2 Air Sensor – History………………………………………………………………………………… 28

3.8 First Outs………………………………………………………………………………………………………..29

3.9 System Configuration Screen…………………………………………………………………………. 30

3.9.1 Language Selection…………………………………………………………………………………. 31

3.9.2 Options……………………………………………………………………………………………………32

3.9.3 Parameters…………………………………………………………………………………………… 33

3.9.4 Expansion Options…………………………………………………………………………………..34

3.9.5 Set Clock………………………………………………………………………………………………….35

3.9.6 Manual…………………………………………………………………………………………………… 36

3.9.7 Commission Data……………………………………………………………………………………. 37

3.9.8 Diagnostics ……………………………………………………………………………………………. 38

3.9.9 System Log……………………………………………………………………………………………… 39

4 ERRORS AND LOCKOUTS……………………………………………………………………………… 40

4.1 Errors…………………………………………………………………………………………………………………. 40

4.2 Lockouts………………………………………………………………………………………………………………44

4.3 Alarms and Warnings…………………………………………………………………………………………. 49

4.4 Settings Conflicts………………………………………………………………………………………………… 57

4.5 Forced Commission Reasons………………………………………………………………………………. 62

4.6 Troubleshooting and Further Information…………………………………………………………… 64

4.6.1 UV Shutter Faults………………………………………………………………………………………… 64

4.6.2 UV Problems……………………………………………………………………………………………….. 64

4.6.3 Snubbers…………………………………………………………………………………………………….. 64

4.6.4 Channel Positioning Error……………………………………………………………………………. 65

4.6.5 Input Fault…………………………………………………………………………………………………… 65

6 STANDARDS…………………………………………………………………………………………………. 66

1 Overview and Benefits

22.05.2017 Mk8 MM End User Guide Page 1

1 OVERVIEW AND BENEFITS

1.1 Features and Benefits

Micro-Modulation (MM) / Flame Safeguard

Fuel/ air ratio control

Full colour touch screen

120V or 230V standard operation 50/60Hz

Controls up to 5 servomotors and 2 variable speed drives (VSD/ VFD)

4 independent fuel programmes

Fully adjustable PID load control for temperature or pressure

Internal flame safeguard – full flame supervision with self-check UV or IR

Dual flame scanner operation (IR and UV scanners)

Gas valve train leak supervision and high/low gas pressure monitoring

Air pressure proving and monitoring

128 lockouts, errors, alarms and warnings stored with date, time, phase and reset

1000 entry system log stored with date, time and status

Online diagnostics showing system electronics information

Single point change for adding, removing and adjusting fuel/air positions on fuel-air curve

Golden start position for optimum ignition position

Flue gas recirculation start position

Variable servomotor travel speed

Burner control safety times user selectable

External voltage/current load control and setpoint adjustment

Outside temperature compensation of boiler setpoint

Second setpoint and run times scheduling

Hand/auto/low flame hold firing modes

Various boiler load detectors available

Fuel flow metering capability – instantaneous and totalised

Fuel flow feedback

Multi-burner capability with synchronised firing rate up to 10 MMs

4-20mA (0-20mA) / 0-10V (2-10V) input for external modulation

4-20mA (0-20mA) / 0-10V (2-10V) output confirming firing rate

Fully metered combustion control for commissioning based on equivalence ratio and excess air

Draft control to maintain stack pressure

Password protection of all safety related functions

Infra-red port for upload/download of commission data

1 Overview and Benefits

Page 2 Mk8 MM End User Guide 22.05.2017

15 First out annunciation inputs

4 fuel commission curves possible

24 hour history graphical information on MM when powered on

Custom boiler display configuration

Water Level Control

Fully modulating feed water control with servomotor and VSD as well pump on/off

Capacitance probes for patented wave signature level detection

Water level alarms 2

nd

low, 1st low, high water and optional pre 1st low and pre-high water

Conductivity probe for auxiliary 2

nd

low alarm

Automatic bottom blowdown with time reduction for blowdown savings

Continuous modulating top blowdown control to maintain TDS in water

Steam/ hot water flow metering to calculate flow rates based on temperature sensor

Exhaust Gas Analyser (EGA)

3 Parameter trim of O

2, CO2 and CO

Analysis of O

2, CO, CO2, NO, exhaust gas temperature, efficiency and delta temperature

Optional analysis of NO

2 and SO2

Local display for re-calibration, changing cells, user configuration and standalone operation

Upper/lower offset and absolute limits for O

2, CO, CO2, NO and exhaust gas temperature

Six 4-20mA output signal for interface with other controls/chart recorders

Intelligent Boiler Sequencing

System will sequence hot water boilers or steam boilers via lead/lag distribution

Fully adjustable user options within the system to tailor sequencing operation to the application

System control for isolation of valves or pumps (2 port valve operation)

Standby setpoint and warming for lag boilers via a standby pressure and timing sequence

Lead boiler and lag boiler warming modes selection

Remote Control and Data Transfer Interface (DTI)

Direct Modbus communications from MM including remote setpoint and firing rate adjustment,

burner enable/disable (without DTI or intelligent boiler sequencing)

DTI will collect operational data for up to 10 MM modules, 10 EGA modules and 10 universal

I/O modules in one communications loop

Information transmitted via RS422 or Ethernet link to local PC/network for running Autoflame

CEMS Audit software

1 Overview and Benefits

22.05.2017 Mk8 MM End User Guide Page 3

PC Compatible

Download all commissioning data and controller settings from MM module to a PC

Upload commission data and controller settings from PC to MM module

Universal Digital and Analogue Input/ Output Module

Detailed logging inputs and outputs when coupled with Mk7 DTI

16 Line voltage inputs (110V/ 230V)

6 Analogue inputs and 6 analogue outputs

8 Volt free contacts

Configurable alarms through Mk7 DTTI

1 Overview and Benefits

Page 4 Mk8 MM End User Guide 22.05.2017

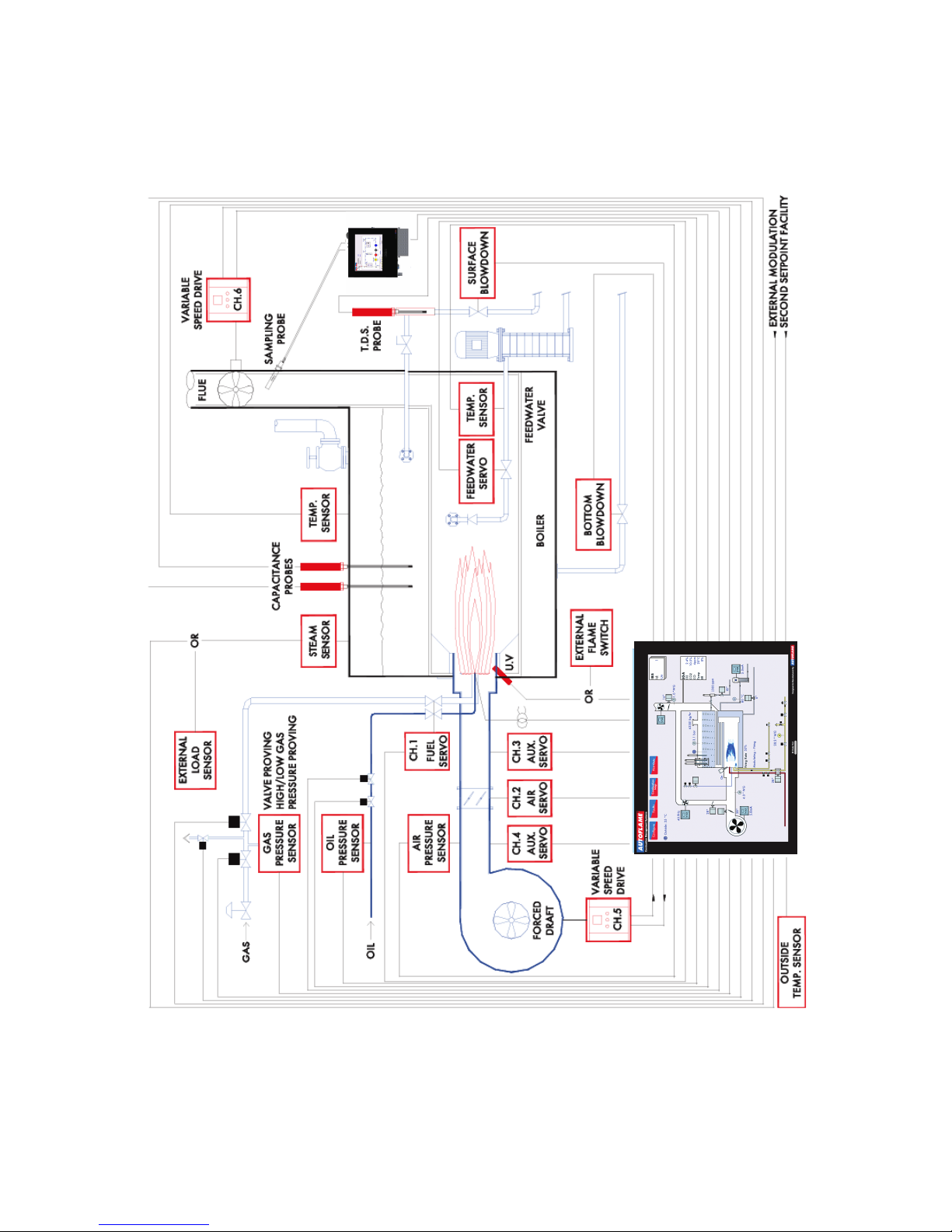

1.2 System Example

1 Overview and Benefits

22.05.2017 Mk8 MM End User Guide Page 5

1.3 Micro-Modulation (MM)

To ensure maximum efficiency and reliability of the boiler plant operation, two requirements are of

paramount importance, the air to fuel ratio and the target temperature or pressure:

The air to fuel ratio must be kept to the minimum to ensure complete combustion within the

limitations of the combustion head design. A very high air to fuel ratio will be an indication of

high excess air, which decreases the overall efficiency of the boiler. The fuel valve and air

damper positions set for this minimum air to fuel ratio along the whole commission curve must

be infinitely repeatable to an incredibly high degree of accuracy.

The target temperature or pressure of the boiler should be monitored by the combustion system

and at all times, with exactly the right amount of fuel and air fired to achieve this target value.

Irrespective of load changes, the burner/boiler system should be able to meet the target

temperature or pressure.

The burner’s fuel to air ratio was traditionally governed by mechanical systems which involved multiple

cams, shafts and linkages controlled by one motor. The inherent hysteresis that occurred from the

system design allowing components to be loose, which made the level of accuracy required impossible.

With this poor accuracy, the response of the fuel input to the monitored temperature/ pressure of the

boiler meant that the set target value at most times would overshoot or fall short.

The Micro-Modulation module is the basic building block of the Autoflame System. The Autoflame MM

module provides an easily programmable and flexible means of optimising combustion quality

throughout the load requirement range of the burner/boiler unit whilst ensuring the temperature is

accurate to within 1°C (°F) and pressure to within 1 PSI (0.1Bar). Using direct drive motors to

individually control the air damper and fuel valve(s), gives the optimum combustion of the burner at

every point along the firing range. The allowed error in angular degrees of rotation between the two

servomotors at any position in the load range is 0.1°.

This automated system of burner control can achieve ‘locked on’ near stoichiometric air to fuel mixing

throughout the fuel input range of the boiler while maintaining exact temperature or pressure target

values. The load control incorporates user-variable Proportional Integral Derivative control. The PID

control is infinitely adjustable to match any boiler room requirements.

2 Electrical Specifications

2 ELECTRICAL SPECIFICATIONS

2.1 Classifications

Classification according to BS EN298:2012

Mains

Supply:

Single phase 230V, +10%/-15%}

47-63 Hz, unit max. consumption 140W

Single phase 120V, +10%/-15%}

Climate: Min. Temperature 0

O

C (32OF)

Recommended Temperature Less than 40

O

C (104OF)

Max. Temperature 60

O

C (140OF)

Humidity 0 to 90% non-condensing

Storage: Temperature -20 to 85

O

C (-4 to 185OF)

Protection

Rating:

The unit is designed to be panel mounted in any orientation and the front facia is IP65,

NEMA4. The back of the unit is IP20, NEMA1.

2.2 Inputs and Outputs

MM Inputs and Outputs

230V Unit:

Outputs Terminal 57 250mA Must be connected through contactor

Max Load 6A

58 250mA Must be connected through contactor

59 1A 0.6 power factor

60 1A 0.6 power factor

61 1A 0.6 power factor

62 1A 0.6 power factor

63 1A 0.6 power factor

78 100mA To drive relay only – switched neutral

79 100mA To drive relay/lamp only – switched neutral

120V Unit:

Outputs Terminal 57 250mA Must be connected through contactor

Max Load 6A

58 250mA Must be connected through contactor

59 2A 0.6 power factor

60 2A 0.6 power factor

61 2A 0.6 power factor

62 2A 0.6 power factor

63 2A 0.6 power factor

78 100mA To drive relay only – switched neutral

79 100mA To drive relay/lamp only – switched neutral

22.05.2017 Mk8 MM End User Guide Page 6

2 Electrical Specifications

Expansion Board Inputs and Outputs

Outputs: 120/230 V All outputs with the exception of PF are switched neutrals

BFW 250mA Must be connected through contactor

BB 250mA Must be connected through contactor

HWV 100mA (alarm indicator)

2LA 100mA (alarm indicator)

2LV 100mA (alarm indicator)

H1A 100mA (alarm indicator)

1LV 100mA (alarm indicator)

79 100mA (alarm indicator on MM board)

TB 250mA Solenoid only, must be connected through contactor

PF Maximum 2A (load currents for above terminals)

Note: Max number of alarm indicators on at any time is 3 (1LV, 2LA, 2LV)

Main Voltage Signal Inputs:

At 120V current loading is approximately maximum 0.7mA per input.

At 230V current loading is approximately maximum 1.5mA per input.

Note:

1. The high and low voltage connections are not safe to touch. Protection against electric shock is

provided by correct installation. CAUTION – ELECTRIC SHOCK HAZARD.

2. Control voltage cabling should be maximum 10m, screened (if not screened then less than 1m,

however servomotors can be unscreened up to 10m)

3. Any cabling over 10m must have additional surge protection.

4. Low voltage cables should be screened cable as specified in section 2.3.

5. The burner ‘High Limit Stat’ must be a manual reset type.

Note: There is a lid (back plate) fitted onto the back of the Mk8 MM with a Warning label to prevent

any unauthorised fuse replacements.

Page 7 Mk8 MM End User Guide 22.05.2017

2 Electrical Specifications

2.3 Cable Specifications

Low Voltage

The screened cable used for low voltage wiring from the MM to the servomotors, detectors and

variable speed drive must conform to the following specification:

U.V. cable length should not exceed 25m, all other screened cable should not exceed 50m.

16/0.2mm PVC insulated overall braid, screened, PVC sheathed.

Sixteen wires per core

Diameter of wires in each core 0.2mm

Rated at 440V AC rms at 1600Hz

DEF 61-12 current rating per core 2.5A

Maximum operating temperature 70

o

C (158oF)

Nominal conductor area 0.5sq mm per core

Nominal insulation radial thickness on core 0.45mm

Nominal conductor diameter per core 0.93mm

Nominal core resistance at 20

o

C. 40.1Ω/1000m

Nominal overall diameter per core 1.83mm

Fill factor of braid screen 0.7

Equivalent imperial conductor sizes 14/0.0076

Use the number of cores suitable for the application. A universal part numbering system appears to

have been adopted for this type of cable as follows:

16-2-2C 2 Core

16-2-3C 3 Core

16-2-4C 4 Core

16-2-6C 6 Core

16-2-8C 8 Core

(5 Core not readily available)

Note: If using 4 Core cable and interference is detected, use 2 sets of 2 Core.

Data Cable

Data cable must be used for communication connections between MMs for sequencing applications as

well as between MMs to EGAs, MMs to a DTI and DTI to BMS systems.

Communication cable should not exceed 1km.

Types of data cable that can be used:

1 Beldon 9501 for 2-core shielded cable (1 twisted pair)

2 Beldon 9502 for 4-core shielded cable (2 twisted pairs)

3 STC OS1P24

Samples are available upon request. Low voltage and data cable can be ordered directly from

Autoflame Engineering, please contact Autoflame Sales.

When using a VSD, please review the manufacturer’s guidelines on installations to prevent EMC

including the recommendations for reactors and filters.

22.05.2017 Mk8 MM End User Guide Page 8

3 End User Operation

3 END USER OPERATION

3.1 Home Screen

Figure 3.1.i Home Screen

The home screen shown in Figure 3.1.i displays the current boiler setup. It provides operation

information for each component of the burner/boiler in real time. Pressing on components will display

further information e.g. pressing on the servomotor image will show the servomotor position history.

This boiler room setup can be configured to display what is actually on site, please see section 3.19.5

Boiler Room Configuration.

22.05.2017 Mk8 MM End User Guide Page 9

3 End User Operation

3.1.1 Home Screen Components

Servomotor Variable

speed drive

Flame

scanner

Oil pressure

sensor

Air pressure

sensor/

boiler steam

pressure

detector

Gas pressure

sensor

Boiler

temperature

detector/

outside

temperature

sensor

Feed water

temperature

sensor

Main fuel

valve open

Main fuel

valve closed

Pilot gas

valve open

Pilot gas

valve closed

Control fuel

valve open

Control fuel

valve closed

Main gas

regulator

Pilot gas

regulator

Gas flowing

No gas

flowing

Oil flowing

No oil

flowing

Combustion

air fan

Induced

draught fan

Gas flame Oil flame

#

Capacitance

probes

2

nd

Low

conductivity

probe

External level

sensor for

water level

Steam

header

TDS probe Feed water

pump

Page 10 Mk8 MM End User Guide 22.05.2017

3 End User Operation

IBS

Information

Three Pass

Fire Tube

22.05.2017 Mk8 MM End User Guide Page 11

3 End User Operation

3.1.2 Faults

Figure 3.1.2.i Lockouts

Press in the Home screen to view the faults, which are categorised into lockouts, errors,

alarms, warning and first out alarms, and are access by pressing on the corresponding tabs.

Fault Type Shuts Down Burner Reset By

Lockout Burner control fault Yes Reset button or input on T56

Error Internal or hardware fault Yes Power cycle

Alarm Critical system fault Yes Reset button or input

Warning Non-critical fault No Reset button

First out Configurable fault Optional Reset button/ auto

Page 12 Mk8 MM End User Guide 22.05.2017

3 End User Operation

3.2 Status Screen

3.2.1 Status

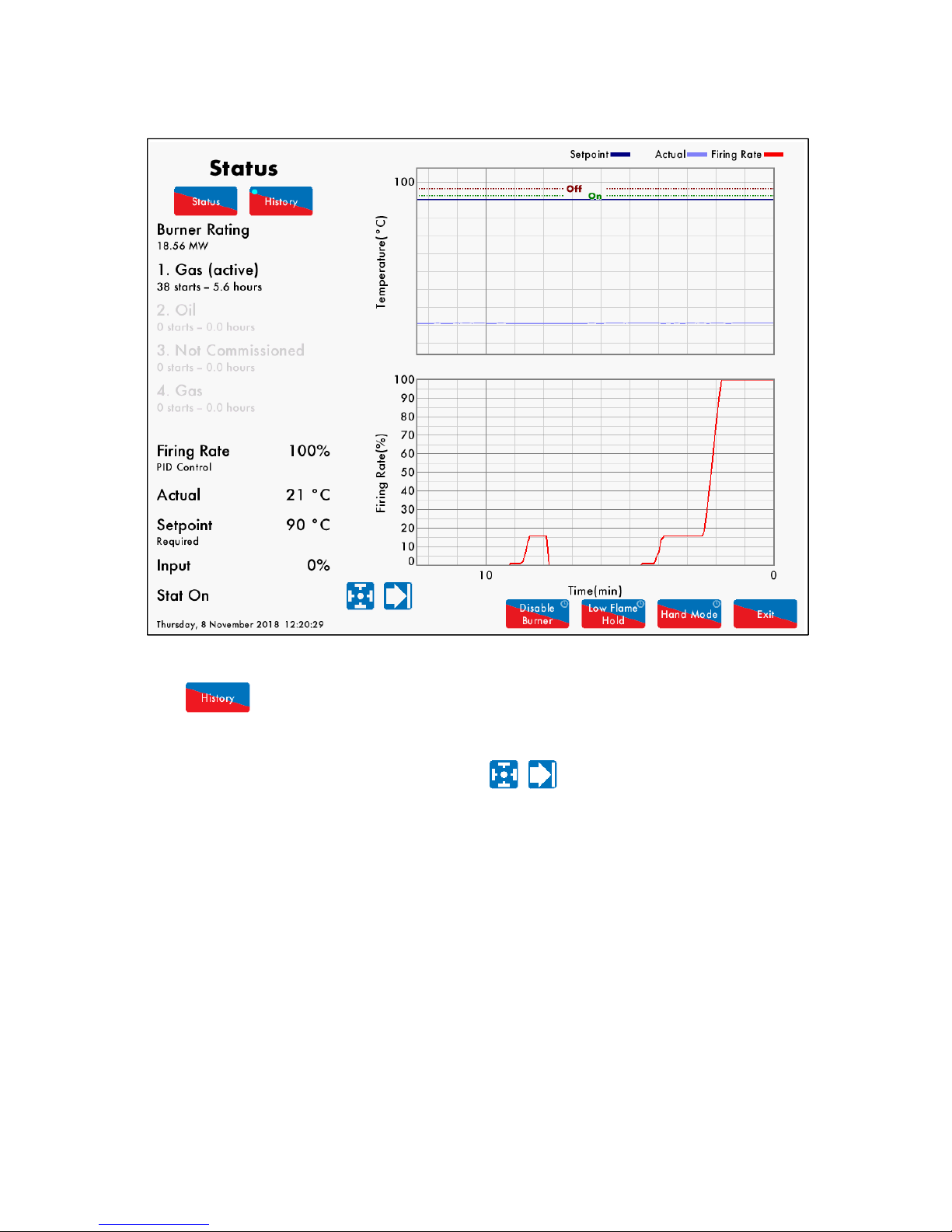

Figure 3.2.1.i Status

Press on the boiler load detector or the boiler image in the Home screen (Figure 3.1.i) to display the

Status screen, which gives the following information:

Burner rating

Current fuel selected and type

Burner starts and run hours

Current firing rate

Control method – internal PID control, external modulation or DTI/remote firing rate

Actual temperature/pressure reading from load detector

Current setpoint – required, reduced, DTI or external

Stat status – running interlock T53/ internal stat

Burner switch on/off offset

Reduced setpoint

Indication if MM is firing to meet required or reduced setpoint (red = active, grey = inactive)

Arrows for adjusting setpoint

Press the arrows to change the required or reduced setpoints. If these arrows are not

displayed, then either the user setpoint change has been disabled (option 15), the DTI is controlling the

setpoint (option 16), external setpoint is enabled (parameter 72), or OTC is enabled (option 80).

Note: Use parameters 29 and 30 to adjust the load detector reading if required.

22.05.2017 Mk8 MM End User Guide Page 13

3 End User Operation

3.2.2 Status – History

Figure 3.2.2.i Status – History

Press in the Status screen in Figure 3.2.1.i to show the Status History. The setpoint, actual

temperature/pressure and firing rate are displayed graphically.

This data is logged for 24 hours on the MM. Use the buttons to change the timescale of the

data displayed, and press and drag on the axis to zoom in/out of the graph.

This information is logged for 2 years on the DTI when connected with the MM.

Note: Power cycling the MM or changing fuel will reset the 24 hour history data log on the MM.

Page 14 Mk8 MM End User Guide 22.05.2017

3 End User Operation

3.2.3 Status – Burner Enable/Disable

Figure 3.2.3.i Status – Burner Enable/Disable

Press and hold for 3 seconds in the Status screen in Figure 3.2.1.i to disable the burner.

Press and hold this same button to enable the burner.

22.05.2017 Mk8 MM End User Guide Page 15

3 End User Operation

3.2.4 Status – Low Flame Hold

Figure 3.2.4.i Status – Low Flame Hold

Press and hold for 3 seconds in the Status screen in Figure 3.2.2.i to put the MM in low

flame hold. Press and hold this button again to return to normal modulation.

Alternatively, the Mk8 MM can also be put in low flame hold via an input on terminal 95.

If low flame hold or hand mode is selected on the MM screen, this will override an input made on

terminal 94 or 95.

Note: If using intelligent boiler sequencing, then putting the MM into low flame hold will remove the

MM from the sequence loop. It will resume sequencing once low flame hold is deselected and after the

next scan time elapses.

Note: If low flame hold and hand mode are both selected, then hand mode takes priority.

Page 16 Mk8 MM End User Guide 22.05.2017

3 End User Operation

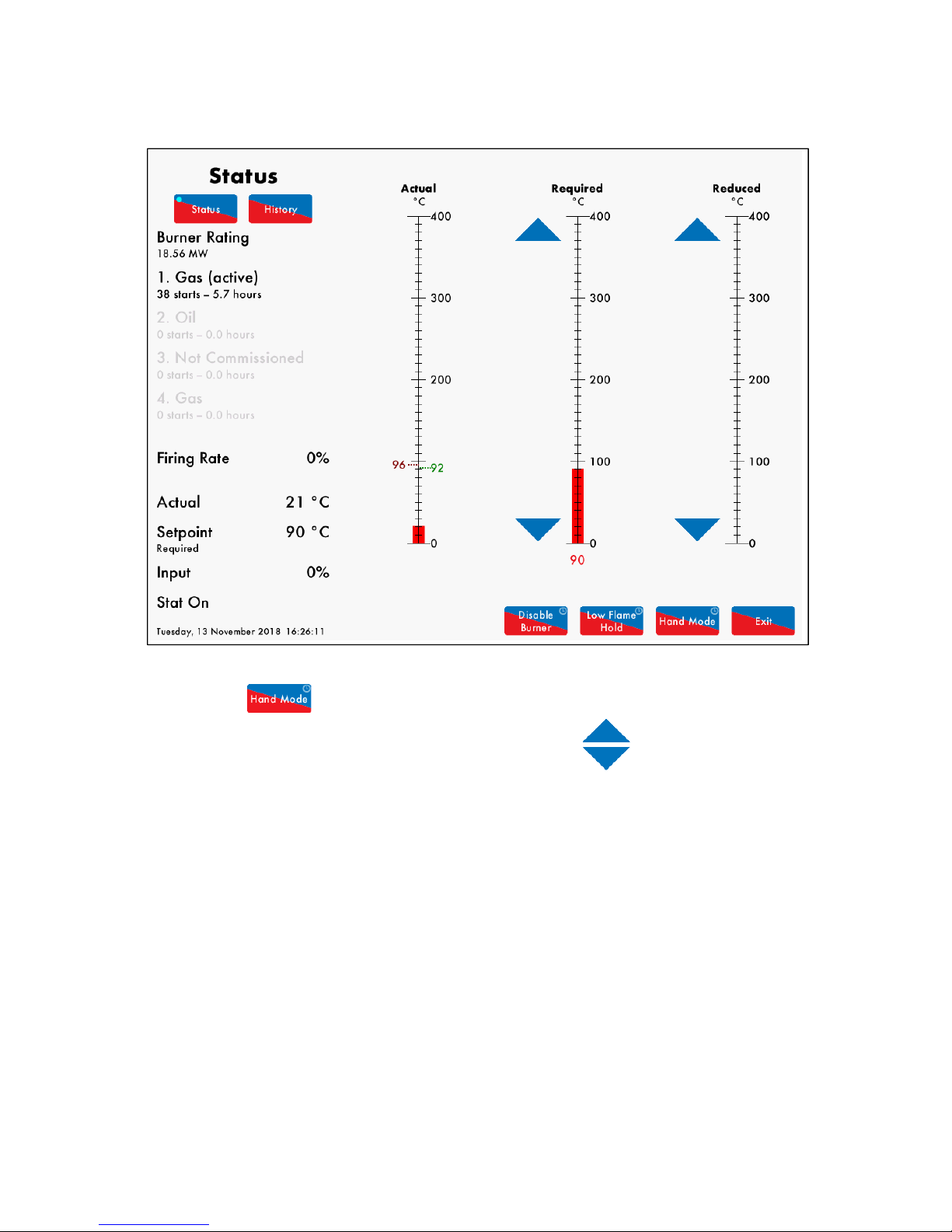

3.2.5 Status – Hand Mode

Figure 3.2.5.i Status – Hand Mode

Press and hold for 3 seconds in the Status screen in Figure 3.2.1.i to put the MM into hand

mode, where the firing rate can be driving up or down by using the arrows.

Alternatively, the MM can be put into hand mode by an input on terminal 94.

If low flame hold or hand mode is selected on the MM screen, this will override an input made on

terminal 94 or 95.

Note: If using intelligent boiler sequencing, then putting the MM into hand mode will remove the MM

from the sequence loop. It will resume sequencing once hand mode is deselected and after the next

scan time elapses.

Note: If low flame hold and hand mode are both selected, then hand mode takes priority.

Note: If a firing rate limit is set (option 66), then the firing cannot be driven past this in hand mode.

22.05.2017 Mk8 MM End User Guide Page 17

3 End User Operation

3.3 Fuel-Air Screen

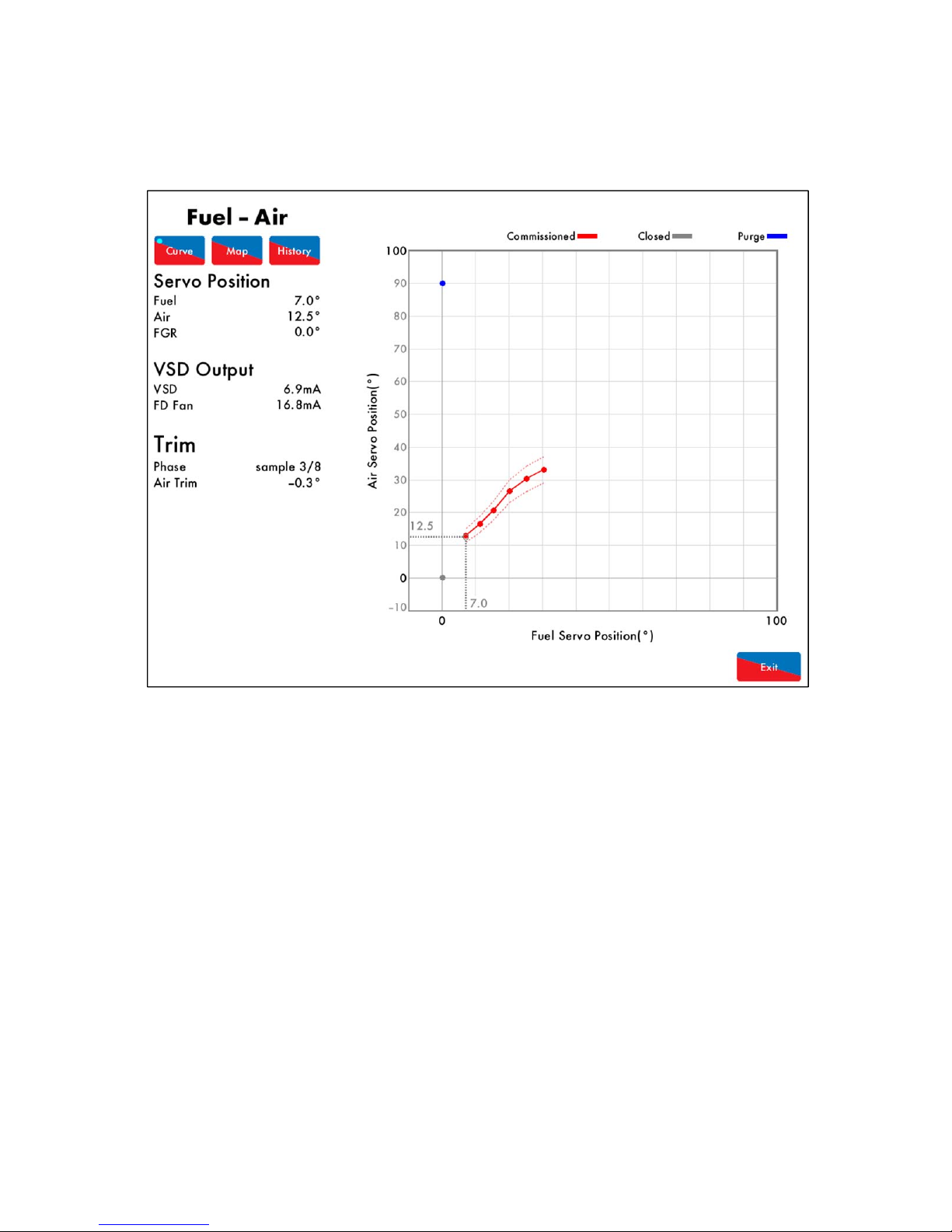

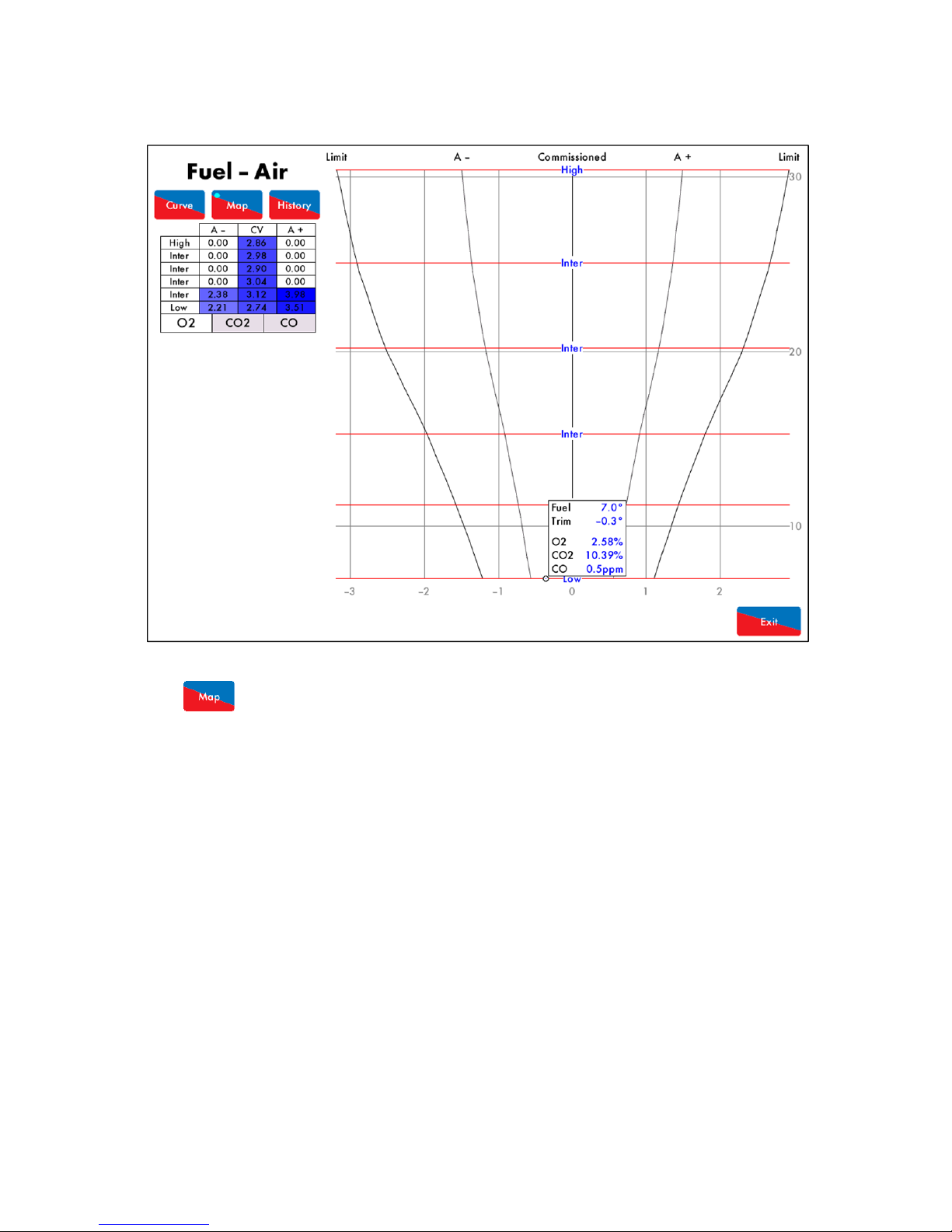

3.3.1 Fuel-Air – Curve

Figure 3.3.1.i Fuel-Air – Curve

Press the flame in the Home screen in Figure 3.1.i to view the Fuel-Air screen, which shows current

servomotor and VSD output positions, the trim status and the commission curve graph.

Page 18 Mk8 MM End User Guide 22.05.2017

3 End User Operation

3.3.2 Fuel-Air – Map

Figure 3.3.2.i Fuel-Air – Map

Press in the Fuel-Air screen in Figure 3.3.1.i to view the commissioned trim values if an EGA

has been enabled with trim. The air rich (A+) and fuel rich (A-) values are shown for each

commissioned point on the fuel-air curve, for the O

2

, CO and CO2. The graph shows the EGA’s current

readings and if there is any trim correction on the air damper. The circle on the fuel-air map indicates

the current position of the trim correction, and how far the current combustion values are from the

commissioned values.

Note: Option 12 must be set to 2 or 3 for the 3-parameter trim function to be activated.

22.05.2017 Mk8 MM End User Guide Page 19

3 End User Operation

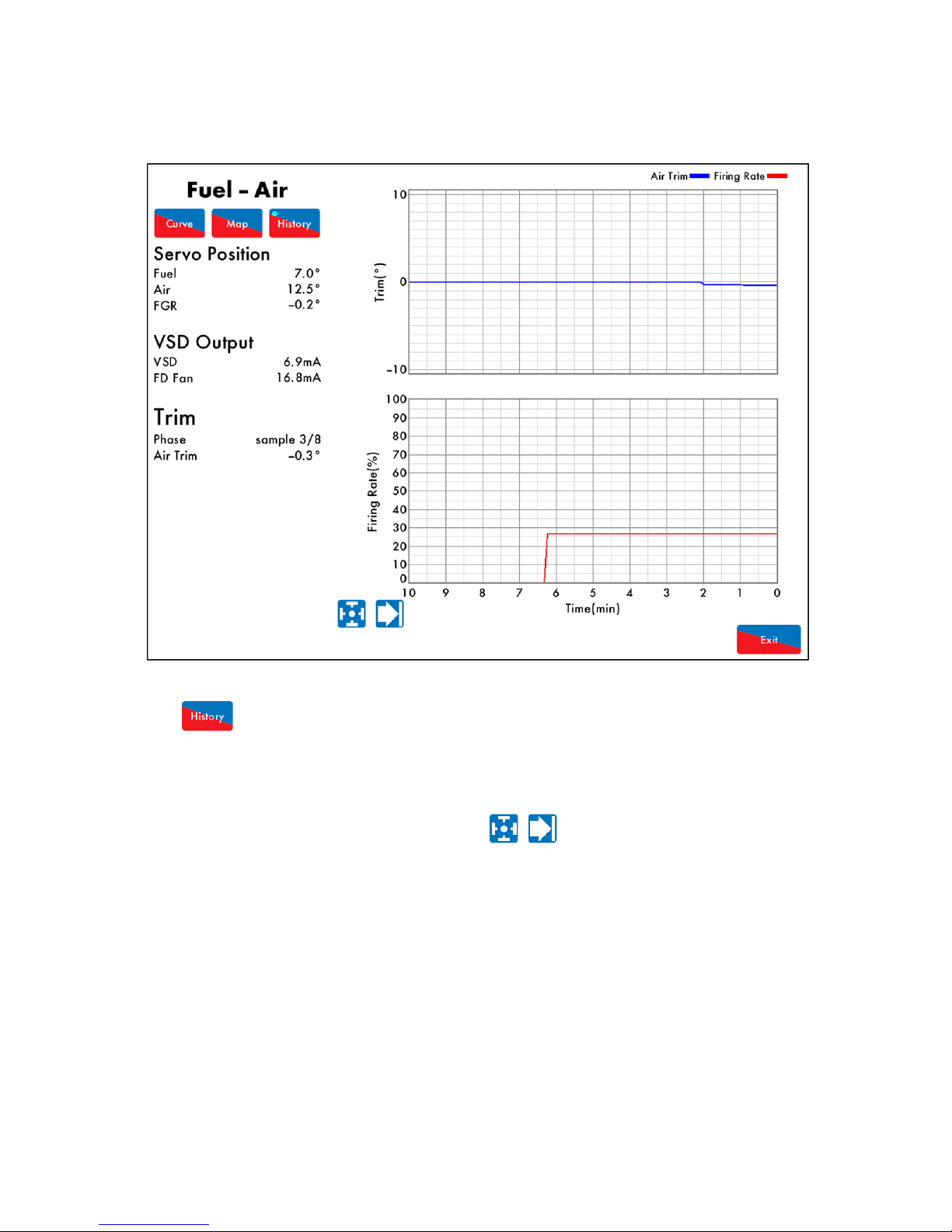

3.3.3 Fuel-Air – History

Figure 3.3.3.i Fuel-Air – History

Press in the Fuel-Air screen in Figure 3.3.1i to view the Fuel-Air History screen, which shows the

firing rate and air trim history.

Note: Option 12 must be set to 2 or 3 for the 3-parameter trim function to be activated.

This data is logged for 24 hours on the MM. Use the buttons to change the timescale of the

data displayed, and press and drag on the axis to zoom in/out of the graph.

This information is logged for 2 years on the DTI when connected with the MM.

Note: Power cycling the MM or changing fuel will reset the 24 hour history data log on the MM.

Page 20 Mk8 MM End User Guide 22.05.2017

3 End User Operation

3.4 Flame Safeguard Screen

3.4.1 Flame Safeguard

Figure 3.4.1.i Flame Safeguard

Press on the flame scanner in the Home scree in Figure 3.1.i to view the Flame Safeguard screen,

which shows the current firing phase of the MM, pilot type and flame scanner signal strength.

Throughout the entire burner start-up and firing sequence, the vertical dotted line will move horizontally

showing which phase the burner is at currently. The rows refer to:

Post purge

Pre purge

Air damper position

Main fuel valve

Pilot fuel valve

Ignition

Blower motor

Note: If a flame switch is used for flame detection, then flame switch show as either on (flame

detected) or off (no flame detected).

Please refer to section XX for the start-up sequence of the burner.

22.05.2017 Mk8 MM End User Guide Page 21

3 End User Operation

3.4.2 Flame Safeguard – History

Figure 3.4.2.i Flame Safeguard - History

Press in the Flame Safeguard screen in Figure 3.4.1.i to view the Flame Safeguard History,

showing the flame scanner signal and firing rate.

This data is logged for 24 hours on the MM. Use the buttons to change the timescale of the

data displayed, and press and drag on the axis to zoom in/out of the graph.

This information is logged for 2 years on the DTI when connected with the MM.

Note: Power cycling the MM or changing fuel will reset the 24 hour history data log on the MM.

Page 22 Mk8 MM End User Guide 22.05.2017

3 End User Operation

3.5 Channels Screen

3.5.1 Servomotor

Figure 3.5.1.i Servomotor

Press on a servomotor in the Home screen in Figure 3.1.i to view the Channels screen, which shows the

current servomotor positions and VSD outputs and inputs.

This data is logged for 24 hours on the MM. Use the buttons to change the timescale of the

data displayed, and press and drag on the axis to zoom in/out of the graph.

This information is logged for 2 years on the DTI when connected with the MM.

Note: Power cycling the MM or changing fuel will reset the 24 hour history data log on the MM.

22.05.2017 Mk8 MM End User Guide Page 23

3 End User Operation

3.5.2 VSD Channel

Figure 3.5.2.i VSD Channel

Press or in the Channels screen in Figure 3.5.1.i to view the VSD Channel 5 or

VSD Channel 6 output and input history, respectively. Alternatively, pressing on the VSD in the Home

screen in Figure 3.1.i will also display the VSD Channel screen.

This data is logged for 24 hours on the MM. Use the buttons to change the timescale of the

data displayed, and press and drag on the axis to zoom in/out of the graph.

This information is logged for 2 years on the DTI when connected with the MM.

Note: Power cycling the MM or changing fuel will reset the 24 hour history data log on the MM.

Page 24 Mk8 MM End User Guide 22.05.2017

3 End User Operation

3.6 Gas Pressure Sensor Screen

3.6.1 Gas Pressure

Figure 3.6.1.i Gas Pressure

Press on the gas pressure sensor (if enabled) in the Home screen in Figure 3.1.i to view the gas

pressure screen, which shows the following information:

Commissioned gas pressure for the corresponding point on fuel-air curve

Actual (current) gas pressure

Valve proving gas pressure

Status of main gas and vent valves

Upper/lower offset gas pressure limits for fuel-air curve

22.05.2017 Mk8 MM End User Guide Page 25

3 End User Operation

3.6.2 Gas Sensor – History

Figure 3.6.2.i Gas Sensor – History

Press in the Gas Pressure screen in Figure 3.6.1.i to view the Gas Pressure History screen,

showing the commissioned and actual gas pressure histories.

This data is logged for 24 hours on the MM. Use the buttons to change the timescale of the

data displayed, and press and drag on the axis to zoom in/out of the graph.

This information is logged for 2 years on the DTI when connected with the MM.

Note: Power cycling the MM or changing fuel will reset the 24 hour history data log on the MM.

Page 26 Mk8 MM End User Guide 22.05.2017

3 End User Operation

3.7 Air Pressure Sensor Screen

3.7.1 Air Pressure

Figure 3.7.1.i Air Pressure

Press on the air pressure sensor in the Home screen in Figure 3.1.i to view the Air Pressure screen,

which shows the expected air pressure, actual (current) air pressure and the difference between these

values, for the corresponding point on the fuel-air curve.

The graph shows the commissioned air pressure for the fuel-air curve and the upper/lower offset limits,

as well as the air pressure values with trim function enabled on the air damper.

If commissioned with an EGA, the air pressure is stored during the commissioning the trim function, and

shown as the red line on the graph.

22.05.2017 Mk8 MM End User Guide Page 27

3 End User Operation

3.7.2 Air Sensor – History

Figure 3.7.2.i Air Sensor – History

Press in the Air Pressure screen in Figure 3.7.1.i to view the Air Pressure History screen,

showing the commissioned and actual air pressure histories.

This data is logged for 24 hours on the MM. Use the buttons to change the timescale of the

data displayed, and press and drag on the axis to zoom in/out of the graph.

This information is logged for 2 years on the DTI when connected with the MM.

Note: Power cycling the MM or changing fuel will reset the 24 hour history data log on the MM.

Page 28 Mk8 MM End User Guide 22.05.2017

3 End User Operation

Outs

Figure 3.17.i First Outs

Press (if enabled) in the Home Screen in Figure 3.1.i to view the First Outs screen. The

functions of a first out when active is summarised below:

Function When Active Description

Disabled Does not function.

Monitor Burner continues firing, but the events will be logged.

Non-recycle Burner stops firing and the first out must be reset for the burner to restart.

Recycle Burner stops firing and restarts automatically when the input state changes.

Stop EGA Sampling Burner continues firing, but the EGA stops sampling.

Stops EGA Trimming Burner continues firing, but the EGA trim stops operating.

22.05.2017 Mk8 MM End User Guide Page 29

3.8 First

3 End User Operation

Figure 3.19.i

Press in the Home screen in Figure 3.1.i to access the System Configuration screen. From

this screen is is possible to:

Change language (password protected)

View all options

View all parameters

View all expansion options

Change boiler configuration display in Home screen (password protected)

Access online changes (password protected)

Acess single point change (password protected)

Set clock (password protected)

Set run times (password protected)

Set bottom blowdown scheduel if enabled (password protected)

View operating manual

View commission data

View real-time diagnostics

View system log

In the top left corner, the serial number and bootloader of the MM are shown, and in the top righ, the

BC, MM and Display software versions are shown.

22.05.2017 Mk8 MM End User Guide Page 30

3.9 System Configuration Screen

3 End User Operation

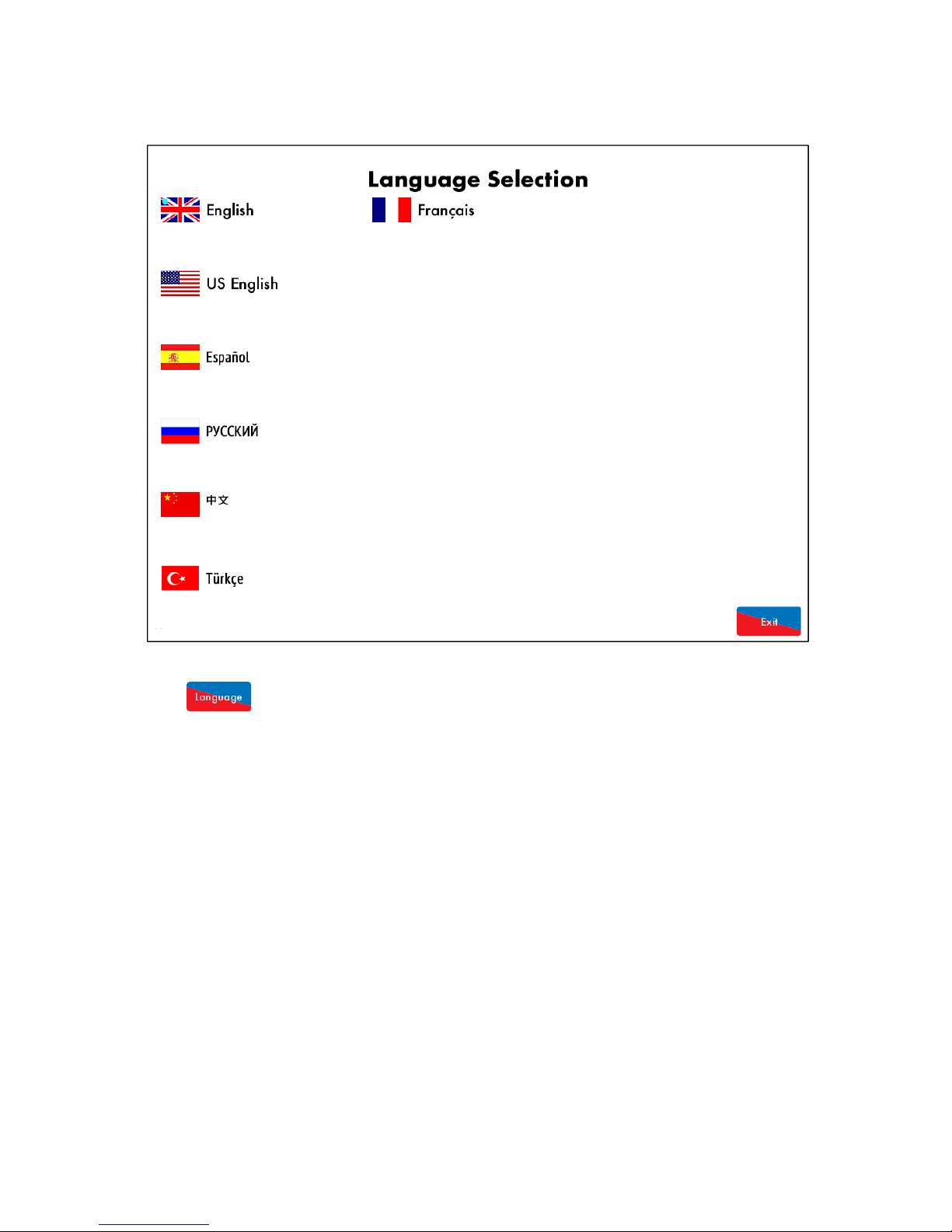

Figure 3.19.1.i Language Selection

Press in the System Configuration screen in Figure 3.19.i to access Language Selection

screen; you be will be prompted to enter the Online Changes password. Please contact your local

approved Autoflame tech centre for this password.

Note: The SD card must contain the language file to be able to select the language. If a language

required is not available, please contact the Autoflame office.

Page 31 Mk8 MM End User Guide 22.05.2017

3.9.1 Language Selection

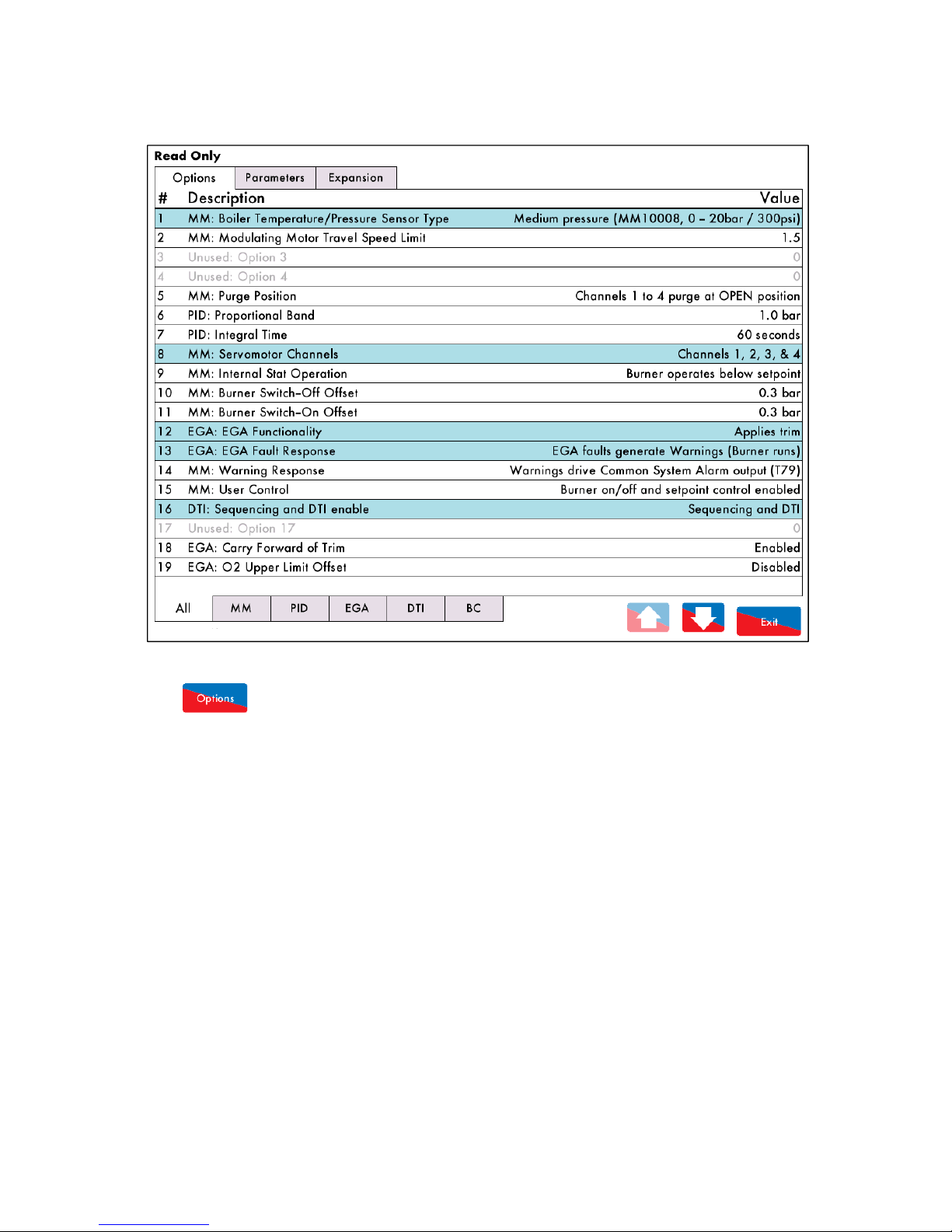

3 End User Operation

Figure 3.19.2.i Options

Press in the System Configuration screen in Figure 3.19.i to view the Options screen, which

displays all of the options and their ranges and settings. This is a read only mode, so no changes can

be made to the options in this screen. Options highlighted in blue are ones which have been changed

from the default values.

Press on the MM, PID, EGA, DTI and BC tabs to group together options in those categories.

22.05.2017 Mk8 MM End User Guide Page 32

3.9.2 Options

3 End User Operation

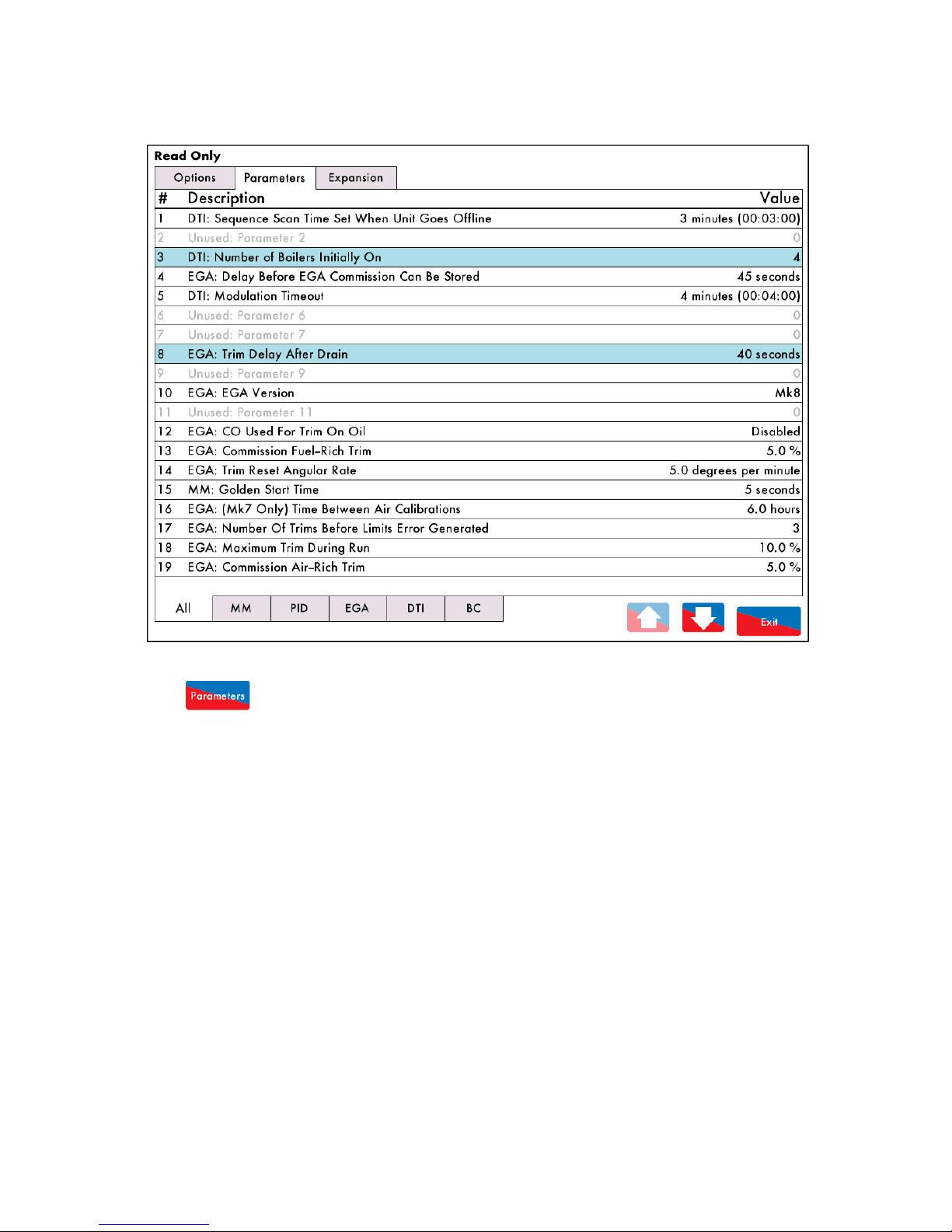

Figure 3.19.3.i Parameters

Press in the System Configuration screen in Figure 3.19.i to view the Parameters screen,

which displays all of the parameters and their ranges and settings. This is a read only mode, so no

changes can be made to the parameters in this screen. Parameters highlighted in blue are ones which

have been changed from the default values.

Press on the MM, PID, EGA, DTI and BC tabs to group together parameters in those categories.

Page 33 Mk8 MM End User Guide 22.05.2017

3.9.3 Parameters

3 End User Operation

Figure 3.19.4.i Expansion Options

Press in the System Configuration screen in Figure 3.19.i to view the Expansion Options

screen, which displays all of the expansion options and their ranges and settings. This is a read only

mode, so no changes can be made to the expansion options in this screen. Expansion options

highlighted in blue are ones which have been changed from the default values.

Press on the MM, PID, EGA, DTI and BC tabs to group together expansion options in those categories.

22.05.2017 Mk8 MM End User Guide Page 34

3.9.4 Expansion Options

3 End User Operation

Figure 3.19.7.i Set Clock

Press in the System Configuration screen in Figure 3.19.i to access the Set Clock screen; you

will be prompted to enter the password (10, 10). Change the time and data using the

arrows and then press and then press .

Note: If the MM is connected to a DTI, then then time and data will be set by the DTI and cannot be

adjusted on the MM.

Page 35 Mk8 MM End User Guide 22.05.2017

3.9.5 Set Clock

3 End User Operation

Figure 3.19.10.i Manual

Press in the System Configuration screen in Figure 3.19.i to view the Manual screen. Press

on the section headings to navigate through the operating manual.

Note: The SD card must contact the manual file to be able to view the operating manual on the MM

screen.

22.05.2017 Mk8 MM End User Guide Page 36

3.9.6 Manual

3 End User Operation

Figure 3.19.11.i Commission Data

Press in the System Configuration screen in Figure 3.19.i to view the Commission Data

screen.

Page 37 Mk8 MM End User Guide 22.05.2017

3.9.7 Commission Data

3 End User Operation

Figure 3.19.12.i Diagnostics

Press in the System Configuration screen in Figure 3.19.i to view the real-time diagnostics.

This data is logged hourly on the SD card for up to 3 months. The minimum and maximum values are

the lowest and highest values the MM as detected for this measurement.

22.05.2017 Mk8 MM End User Guide Page 38

3.9.8 Diagnostics

3 End User Operation

Log

Press in the System Configuration screen in Figure 3.19.i to view the System Log screen,

which stores 1000 entries of the following information:

Stat on/ off

Setting changes

Commission/single point change

Fuel flow commission

MM restart

Setpoint changes

Page 39 Mk8 MM End User Guide 22.05.2017

3.9.9 System

Figure 3.19.13.i System Log

AND LOCKOUTS

Errors occur when the MM detects an internal fault, component out of range, internal check failure or

power supply issue. To clear an error, the MM must be restarted.

Error Message Description

1 Channel 1 Positioning Error Servomotor is outside of the commissioned range

Check wiring on terminals 40 – 47

Check signal cable from the MM to the servomotor is screened at one end

Check potentiometer is zeroed correctly

Go into Commissioning mode, check the servomotor position and ensure that closed is at 0.0

O

2 Channel 2 Positioning Error Servomotor is outside of the commissioned range

Check wiring on terminals 40 – 47

Check signal cable from the MM to the servomotor is screened at one end

Check potentiometer is zeroed correctly

Go into Commissioning mode, check the servomotor position and ensure that closed is at 0.0

O

3 Channel 3 Positioning Error Servomotor is outside of the commissioned range

Check wiring on terminals 40 – 47

Check signal cable from the MM to the servomotor is screened at one end

Check potentiometer is zeroed correctly

Go into Commissioning mode, check the servomotor position and ensure that closed is at 0.0

O

4 Channel 4 Positioning Error Servomotor is outside of the commissioned range

Check wiring on terminals 40 – 47

Check signal cable from the MM to the servomotor is screened at one end

Check potentiometer is zeroed correctly

Go into Commissioning mode, check the servomotor position and ensure that closed is at 0.0

O

5 Channel 7 Positioning Error Servomotor is outside of the commissioned range

Check wiring on terminals DP-, DP+, DPW

Check signal cable from the MM to the servomotor is screened at one end

Check potentiometer is zeroed correctly

Go into Commissioning mode, check the servomotor position and ensure that closed is at 0.0

O

6 Channel 1 Gain Error Servomotor position measurement hardware error

Check wiring and voltages on terminals 40 – 47 and 70 – 77

7 Channel 2 Gain Error Servomotor position measurement hardware error

Check wiring and voltages on terminals 40 – 47 and 70 – 77

8 Channel 3 Gain Error Servomotor position measurement hardware error

Check wiring and voltages on terminals 40 – 47 and 70 – 77

9 Channel 4 Gain Error Servomotor position measurement hardware error

Check wiring and voltages on terminals 40 – 47 and 70 – 77

10 Channel 7 Gain Error Servomotor position measurement hardware error

Check wiring and voltages on terminals DP-, DP+, DPW and DCI, DCD

11 Channel 1 Movement Error Servomotor moves when not expected and vice versa

Check wiring and voltages on terminals 70 – 77

Check servomotors drive in correct direction and valve is not stuck

22.05.2017 Mk8 MM End User Guide Page 40

4 Errors and Lockouts

4 ERRORS

4.1 Errors

Error Message Description

12 Channel 2 Movement Error Servomotor moves when not expected and vice versa

Check wiring and voltages on terminals and 70 – 77

Check servomotors drive in correct direction and damper is not stuck

13 Channel 3 Movement Error Servomotor moves when not expected and vice versa

Check wiring and voltages on terminals and 70 – 77

Check servomotors drive in correct direction and valve is not stack

14 Channel 4 Movement Error Servomotor moves when not expected and vice versa

Check wiring and voltages on terminals and 70 – 77

Check servomotors drive in correct direction and valve is not stuck

15 Channel 7 Movement Error Servomotor moves when not expected and vice versa

Check wiring and voltages on terminals DCI and DCD

Check servomotor drives in correct direction and damper is not stuck

16 Analogue Power Supply Error ADC measured 12V supply out of range

Check wiring for shorts on terminals 41, 47 and 39

17 Digital Power Supply Error ADC measured 3.3V supply out of range

Check for noise on the mains input, wiring and voltages on all terminals

18 EEPROM Error Fault communicating with the on board EEPROM

Contact Autoflame approved local tech centre

19 ADC Error Internal fault

Contact Autoflame approved local tech centre

20 Watchdog Timeout Internal fault

Contact Autoflame approved local tech centre

21 Processor Clock Error Internal fault

Contact Autoflame approved local tech centre

22 System Error Internal fault

Contact Autoflame approved local tech centre

23 Flash Data Error Internal fault

Re-install software SD card

24 Processor Temperature Error Internal fault

Check ambient temperature of unit does not exceed maximum recommended temperature

25 Burner Control Comms Error Internal fault

Contact Autoflame approved local Tech Centre

26 Burner Control Reset Internal fault

Contact Autoflame approved local Tech Centre

27 Software Error Internal fault

Contact Autoflame approved local Tech Centre

28 Zero-Crossing Detection Error Internal fault

Check mains supply going to unit is within acceptable voltage range

29 Mains Input Detection Error Mains input stuck on

Check wiring and voltages on terminals 89 – 92

30 Channel 5 VSD Error Feedback incorrect

Check VSD feedback against commissioned VSD and ensure the feedback is stable

31 Channel 6 VSD Error Feedback incorrect

Check VSD feedback against commissioned VSD and ensure the feedback is stable

Page 41 Mk8 MM End User Guide 22.05.2017

4 Errors and Lockouts

Error Message Description

32 VSD Feedback Change Too

Small

Feedback change detected during commissioning is too

small

Check VSD feedback during commissioning

Check option 99 for VSD on channel 5 and option 109 for VSD on channel 6

Check wiring on terminals 1 – 3, 4 – 6, 10 – 12 and 13 – 15

33 Missing Commissioning Data Internal fault

Check there is commissioning data for all options servomotors/VSD

34 FAR Execution Speed Internal fault

Contact Autoflame approved local Tech Centre

35 Software Error Internal fault

Contact Autoflame approved local Tech Centre

36 Software Error Internal fault

Contact Autoflame approved local Tech Centre

37 Software Error Internal fault

Contact Autoflame approved local Tech Centre

38 Software Error Internal fault

Contact Autoflame approved local Tech Centre

39 VSD Sampling Error VSD feedback current/ voltage too high on channel 5/6

Check wiring on terminals 1 – 3, 4 – 6, 10 – 12 and 13 – 15

40 VSD Feedback Too Low VSD feedback value is too low during commissioning on

channel 5/6

Check VSD feedback while commissioning

41 APS Commission Data Fault No air pressure trim data for a point with EGA trim

Check EGA trim and air pressure trim in fuel-air curve

42 Comm VPS Gas Pressure Low Commissioned gas pressure during VPS below option/

parameter 133 threshold

Check option/ parameter 133 and check gas pressure

Re-commission gas pressure sensor

43 Comm Running Gas Pressure

Low

Commissioned gas pressure during running below option/

parameter 136

Check option/ parameter 136 and check gas pressure

Re-commission gas pressure sensor

44 Comm Air Pressure Low Commissioned air pressure during running below option/

parameter s 147 and 149

Check option/parameters 147 and 149

Re-commission air pressure sensor

45 Software Error Internal fault

Contact Autoflame approved local tech centre

46 Software Error Internal fault

Contact Autoflame approved local tech centre

47 Expansion PF Output (Check F5) Internal fault

Check wiring on terminal PF

Check fuse 5 (2A) on expansion board

48 WL Alarm Output Internal Fault Internal fault

Check expansion option 5

Check wiring and voltages on terminals HAI, 1AI, 2AI

22.05.2017 Mk8 MM End User Guide Page 42

4 Errors and Lockouts

Error Message Description

49 Expansion Servo Hardware Fault Internal fault

Contact Autoflame approved local tech centre

50 Triac Power Supply Error (Check

F2)

Internal fault

Check wiring on terminal 69

Check fuse 2 (2A T)

51 Fused 12V Supply Error (Check

F4)

Internal fault

Check gas/air pressure sensor wiring on terminals 31 – 34, and load detector on 37 – 39

Check fuse 4 (500mA)

52 Fused 13.5V Supply Error

(Check F3)

Internal fault

Check IR scanner wiring on terminals 29, 30, 48, 49 and oil pressure sensor on 48, 49

Check fuse 3 (500mA)

53 Air Pressure Zeroing Fault Commissioned air zero pressure is more than 5mbar from

sensor’s zero value

Check air pressure sensor value during VPS

54 Software error Internal fault

Contact Autoflame approved local Tech Centre

55 Software error Internal fault

Contact Autoflame approved local Tech Centre

56 Software error Internal fault

Contact Autoflame approved local Tech Centre

57 Software error Internal fault

Contact Autoflame approved local Tech Centre

58 Software error Internal fault

Contact Autoflame approved local Tech Centre

59 Software error Internal fault

Contact Autoflame approved local Tech Centre

60 Software error Internal fault

Contact Autoflame approved local Tech Centre

61 Software error Internal fault

Contact Autoflame approved local Tech Centre

62 Software error Internal fault

Contact Autoflame approved local Tech Centre

63 Software error Internal fault

Contact Autoflame approved local Tech Centre

64 ADC Reference Voltage Error Hardware fault

Contac Contact Autoflame approved local Tech Centre

Contact Autoflame approved local Tech Centre

65 Software error Internal fault

Contact Autoflame approved local Tech Centre

66 Software error Internal fault

Contact Autoflame approved local Tech Centre

67 Software error Internal fault

Contact Autoflame approved local Tech Centre

Page 43 Mk8 MM End User Guide 22.05.2017

4 Errors and Lockouts

Lockouts occur when the MM detects a fault with the burner operation such as VPS, gas/air pressure

sensor and flame scanners. The lockout must be cleared and investigated on the MM.

Lockout Message Description

1 CPI Input Wrong State Proof of closure switch opened during ignition sequence

Check wiring on terminal 55

Check proof of closure switches

2 No Air Proving No air pressure during start/ firing

Check wiring on terminal 54

Check air pressure switch

Check air pressure sensor

Check air pressures during running

3 Ignition Output Fault Voltage detected when output is off (and vice versa)

Check wiring and voltage on terminal 63

4 Motor Output Fault Voltage detected when output is off (and vice versa)

Check wiring and voltage on terminal 58

5 Start Gas Output Fault Voltage detected when output is off (and vice versa)

Check wiring and voltage on terminal 59

6 Main Gas 1 Output Fault Voltage detected when output is off (and vice versa)

Check wiring and voltage on terminal 60

7 Main Gas 2 Output Fault Voltage detected when output is off (and vice versa)

Check wiring and voltage on terminal 61

8 Vent Valve Output Fault Voltage detected when output is off (and vice versa)

Check wiring and voltage on terminal 62

9 Failsafe Relay (Check F1) Voltage detected when output is off (and vice versa)

Check wiring and voltage on terminal 57

Check fuse 1 (6.3A T) and wiring on terminals 50 – 64

10 Simulated Flame Flame is present when it not should be

Isolate gas/ oil immediately

Call a certified Commissioning Engineer to investigate

If this lockout occurs during shutdown a post-purge may be required for after burn

11 VPS Air Proving Fail Leak detected during ‘air proving’ part of VPS

Check 1

st

main valve

Call a certified Commissioning Engineer to investigate

12 VPS Gas Proving Fail Leak detected during ‘gas proving’ part of VPS

Check option/parameter 133

Check 2

nd

main gas valve and vent valve

Check pilot valve if using single valve pilot

Isolate gas and call a certified Commissioning Engineer to investigate

13 No Flame Signal No flame detected during ignition/ firing

Visually check flame

Check the flame scanner

Call a certified Commissioning Engineer to investigate

14 Shutter Fault UV signal detected during shutter operation on self-check

Check wiring on terminals 21 and 22

Check UV scanner type and check option/ parameter 110 is set accordingly

22.05.2017 Mk8 MM End User Guide Page 44

4 Errors and Lockouts

4.2 Lockouts

Lockout Message Description

15 NO CPI Reset Proof of closure switch not made after valves closed

Check wiring on terminal 55 and check proof of closure switches

16 Prolonged Lockout Reset Prolonged voltage detected on terminal 56/ lockout reset

button permanently pressed

Check lockout reset button is not pressed

Check wiring on terminal 56

17 Gas Pressure Low Gas pressure low limit exceeded while firing(gas sensor)

Check gas pressure

Check option/ parameter 136

18 Gas Pressure High Gas pressure high limit exceeded while firing (gas sensor)

Check gas pressure

Check option/ parameter 137

19 RAM Test Failed Hardware fault

Contact Autoflame approved local tech centre

20 PROM Test Failed Hardware fault

Contact Autoflame approved local tech centre

21 FSR Test 1A Internal relay test failed

Check wiring and voltages on terminals 50 – 63

22 FSR Test 2A Internal relay test failed

Check wiring and voltages on terminals 50 – 63

23 FSR Test 1B Internal relay test failed

Check wiring and voltages on terminals 50 – 63

24 FSR Test 2B Internal relay test failed

Check wiring and voltages on terminals 50 – 63

25 Watchdog Fail 2A Internal check failed

Contact Autoflame approved local tech centre

26 Watchdog Fail 2B Internal check failed

Contact Autoflame approved local tech centre

27 Watchdog Fail 2C Internal check failed

Contact Autoflame approved local tech centre

28 Watchdog Fail 2D Internal check failed

Contact Autoflame

29 Input Fault Power supply fault

Check mains voltage to the MM

32 Gas Pressure Low Limit Gas pressure lower than commissioned VPS value

Check gas pressure sensor value

Check option/parameter 136

33 VPS Air Zeroing Gas pressure sensor cannot be zeroed at VPS venting

Check gas pressure is within zero range (see MM Application Possibilities)

Check vent valve

36 Oil Pressure Too Low Oil pressure below offset lower limit during running

Check option/parameter 139

Check oil pressure sensor

37 Oil Pressure Too High Oil pressure above offset upper limit during running

Check option/parameter 140

Check oil pressure sensor

Page 45 Mk8 MM End User Guide 22.05.2017

4 Errors and Lockouts

Lockout Message Description

39 Freeze Timeout MM kept in Phase Hold for more than 10minutes

MM kept in Phase Hold during commissioning for more than 10 minutes

40 Purge Air Pressure Low Insufficient air pressure during purge

Check option/parameter 141

Check air pressure sensor/ air pressure switch

42 Terminal 86 Inverse Input detected on both terminals 85,86 where there

should not be, and vice versa

Check option/parameter 122

Check wiring and voltages on terminals 85, 86

43 Terminal 85/86 Fault Hardware fault on terminals 85/86

Check wiring and voltages on terminals 85, 86 and contact Autoflame

44 Proving Circuit Fail T52 Loss of input on terminal 52; MM must see input at all

times from position to purge to post purge

Check wiring on terminal 52

45 No Proving Circuit Set Secondary proving timeout elapsed

Check option/parameter 157

Check wiring on terminal 52

46 Proving Interlock Timeout Purge interlock timeout elapsed

Check option/ parameters 155 and 158

Check wiring on terminal 81

52 High IR Ambient Flame detected when there should not be

Visually check flame and check IR scanner

Call a certified Commissioning Engineer to investigate

53 IR Comms Lost Loss of comms with IR scanner

Check wiring and screen on terminals 29, 30, 48 and 49

Check that the IR scanner is not removed from the magnetic ring socket

54 Watchdog Long X A Internal check failed

Contact Autoflame approved local tech centre

55 Watchdog Long Y A Internal check failed

Contact Autoflame approved local tech centre

56 Watchdog Off A Internal check failed

Contact Autoflame approved local tech centre

57 Watchdog Short X B Internal check failed

Contact Autoflame approved local tech centre

58 Watchdog Short Y B Internal check failed

Contact Autoflame approved local tech centre

59 Watchdog Long X B Internal check failed

Contact Autoflame approved local tech centre

60 Watchdog Long Y B Internal check failed

Contact Autoflame approved local tech centre

61 Watchdog Off B Internal check failed

Contact Autoflame approved local tech centre

62 UV Signal Too High Internal check failed for UV

Check wiring on terminals 21, 22, 50 and 51

22.05.2017 Mk8 MM End User Guide Page 46

4 Errors and Lockouts

Lockout Message Description

63 Purge Limit Switch Interlock not made on terminal 81

Check option/ parameter 155

Check wiring on terminal 81

64 Start Limit Switch Interlock not made on terminal 80

Check option/ parameter 154

Check wiring on terminal 80

65 FSR A Internal check failed

Check wiring and voltages on terminals 50 – 63

66 FSR B Internal check failed

Check wiring and voltages on terminals 50 – 63

67 Gas Sensor Comms Signal lost from gas pressure sensor

Check wiring and screen on terminals 31 – 34

68 Gas Sensor Type Internal fault

Contact Autoflame approved local tech centre

69 Gas Sensor Fault Internal pressure sensor fault

Contact Autoflame approved local tech centre

70 UV Pot Fault Internal UV scanner fault

Contact Autoflame approved local tech centre

71 Air Sensor Comms Signal lost from air pressure sensor

Check wiring and screen on terminals 31 – 34

72 Air Sensor Type Internal fault

Contact Autoflame approved local tech centre

73 Air Sensor Fault Internal pressure sensor fault

Contact Autoflame approved local tech centre

74 Air Sensor Zero Air pressure is more than 5mbar from sensor’s zero value

Check air pressure sensor value during VPS

75 Air Sensor Signal High Air pressure is above 400mbar

Check Autoflame approved local tech centre

76 Air Sensor Error Window Air pressure outside of these limits for 3 seconds

Check air pressure

Check option/parameter 147

77 Wait Air Switch Timeout Voltage has not been reset for 2minutes

Check air pressure sensor value during VPS

Check voltage has been reset on terminal 54 within 2minutes before run to purge

Check wiring and voltage on terminal 54

78 Gas Proving Fail High Gas pressure too high during VPS

Isolate gas

Check 1

st

main valve and vent valve

Check option/ parameters 133 and 134

Call a certified Commissioning Engineer to investigate

79 FSR Test 1C Hardware fault

Contact Autoflame approved local tech centre

80 Timeout on Reaching Purge Time set in option/parameter 124 has elapsed

Check option/parameter 124

81 Oil Pressure Sensor Fault No comms received from oil pressure sensor

Check wiring and screen on terminals 48, 49

Page 47 Mk8 MM End User Guide 22.05.2017

4 Errors and Lockouts

Lockout Message Description

82 Purge Pressure Proving Input Input on T81 read high during relay test phases

Input has been made before the blower starts; it should only be made continuously during purge.

Check wiring on terminal 81.

198 BC Input Short Internal fault

Contact Autoflame approved local tech centre

199 Lockout 199 Internal fault

Contact Autoflame approved local tech centre

200 Lockout Cleared Lockout has been cleared

MM status after lockout has been reset (Modbus)

201 Power up CPU Test Fail Internal check failed

Contact Autoflame approved local tech centre

202 Power up EEPROM Test Fail Internal check failed

Contact Autoflame approved local tech centre

22.05.2017 Mk8 MM End User Guide Page 48

4 Errors and Lockouts

Alarms and warnings are faults detected with the system operation. If an alarm occurs, the burner will

stop running, and if a warning occurs, the burner will continue to run. The following

options/parameters set whether system operation faults are set as alarms or warnings:

Option 13 EGA Fault Response

Option 14 Warning Response

Expansion Option 9 Burner Operation at High Water

Expansion Option 20 Burner Operation on Feed water Control Fault

Expansion Option 88 Action on Pressure Sensor Fault

Fault Message Description

1 EGA Internal Error Fault on EGA

Alarm or warning depending on option 13

Check EGA for fault description

2 No EGA Communications MM has lost communications with EGA

Alarm or warning based on option 13 (warning if option 12 is set to monitoring only)

Check parameter 10 is set to correct EGA version

Check EGA operating mode is selected as ‘EGA with MM’

Check wiring between EGA and MM (terminals 25 and 26 on MM)

3 O2 Upper Limit O2 value is above upper limit offset of commissioned value*

Alarm or warning depending on option 13

Check exhaust gas readings and option 19

4 O2 Absolute Limit O2 value is below absolute limit*

Alarm or warning depending on option 13

Check exhaust gas readings and option 25

5 O2 Lower Limit O2 value is below lower limit offset of commissioned value*

Alarm or warning depending on option 13

Check exhaust gas readings and option 22

6 CO2 Upper Limit CO2 value is above upper limit offset of commissioned value*

Alarm or warning depending on option 13

Check exhaust gas readings and option 20

7 CO2 Absolute Limit CO2 value is above absolute limit*

Alarm or warning depending on option 13

Check exhaust gas readings and option 26

8 CO2 Lower Limit CO2 value is below lower limit offset of commissioned value*

Alarm or warning depending on option 13

Check exhaust gas readings and option 23

9 CO Upper Limit CO value is above upper limit offset of commissioned value*

Alarm or warning depending on option 13

Check exhaust gas readings and option 21

10 CO Absolute Limit CO value is above absolute limit*

Alarm or warning depending on option 13

Check exhaust gas readings and option 27

11 NO Upper Limit NO value is above upper limit offset of commissioned value*

Alarm or warning depending on option 13

Check exhaust gas readings and parameter 94

Page 49 Mk8 MM End User Guide 22.05.2017

4 Errors and Lockouts

4.3 Alarms and Warnings

Fault Message Description

12 Exhaust Temperature Upper

Limit

Exhaust temperature is above upper limit offset of

commissioned value*

Alarm or warning depending on option 13

Check exhaust gas readings and parameter 96

13 Exhaust Temperature

Absolute Limit

Exhaust temperature is above absolute limit*

Alarm or warning depending on option 13

Check exhaust gas readings and parameter 97

50 Load Sensor Fault Incorrect/no load sensor detected

Alarm

Check option 1

Check wiring on terminals 37 – 39

51 Auxiliary Input Low 3mA or lower received from 4-20mA external modulation/

external setpoint

Alarm

Check parameter 69

Check feedback from external modulation/ external setpoint controller

Check wiring on terminals 7 – 9

80 Oil Pressure Sensor Fault No comms received from oil pressure sensor

Warning (lockout 81 if oil pressure limits set in option/parameters 139 and 140)

Check wiring and screen on terminals 48, 49

100 Cap Probe 1 Communications

Fault

No comms with capacitance probe 1

Alarm

Check wiring and screen on terminals 1P+, 1P-, 1T+ and 1T-

101 Cap Probe 2 Communications

Fault

No comms with capacitance probe 2

Alarm

Check wiring and screen on terminals 2P+, 2P-, 2T+ and 2T-

102 Cap Probe 1 Short Circuit Hz reading is below 10kHz

Alarm

Check water level Hz reading

Check wiring on terminals 1P+, 1P-, 1T+ and 1T-

103 Cap Probe 2 Short Circuit Hz reading is below 10kHz

Alarm

Check water level Hz reading

Check wiring on terminals 2P+, 2P-, 2T+ and 2T-

104 Cap Probe 1 Temp

Compensation Error

Temperature corrected probe reference is not as expected

Alarm

Re-commission capacitance probes at temperature

105 Cap Probe 2 Temp

Compensation Error

Temperature corrected probe reference is not as expected

Alarm

Re-commission capacitance probes at temperature

106 Cap Probe 1 Still Water

Detected

Wave signature high to low peak distance is less than still

water threshold

Alarm

Check still water threshold in expansion option 28

Check capacitance probe 1 reading history

22.05.2017 Mk8 MM End User Guide Page 50

4 Errors and Lockouts

Fault Message Description

107 Cap Probe 2 Still Water

Detected

Wave signature high to low peak distance is less than still

water threshold

Alarm

Check still water threshold in expansion option 28

Check capacitance probe 2 reading history

108 Cap Probe 1 Serial Number

Mismatch

Probe serial number detected is not the commissioned probe

serial number

Alarm

If changing capacitance probe 1, re-commission is required

109 Cap Probe 2 Serial Number

Mismatch

Probe serial number detected is not the commissioned probe

serial number

Alarm

If changing capacitance probe 2, re-commission is required

110 Cap Probe 1 Detected But

Not Optioned

Probe connected but not optioned

Alarm

Check expansion options 1 and 3

Check wiring on terminals 1P+, 1P-, 1T+ and 1T-

111 Cap Probe 2 Detected But

Not Optioned

Probe connected but not optioned

Alarm

Check expansion options 1 and 3

Check wiring on terminals 2P+, 2P-, 2T+ and 2T-

112 External Level Sensor Input

Low

3mA or lower received from 4-20mA external level sensor

Alarm

Check feedback from external level sensor

Check wiring on terminals EX- and EX+

113 Probe Reading Mismatch Difference between probes/sensor readings is below

mismatch threshold

Alarm

Check expansion option 27

Check capacitance probes and sensor readings

114 Probe Serial Numbers are the

Same

One capacitance probe detected on both capacitance probe

terminals

Alarm

If using two capacitance probes, then two individual probes must be connected

Check wiring on terminals 1P+, 1P-, 1T+, 1T-, 2P+, 2P-, 2T+ and 2T-

120 Aux WL Inputs Mismatch High water and 1st or 2nd low auxiliary level inputs detected

simultaneously

Alarm

Check wiring on terminals HAI, 1AI and 2AI

121 Water Levels Diverse Probes/ sensor detects 1st or 2nd low and high water

simultaneously

Alarm

Check water level readings for probes and sensor if optioned

Re-commission probes/sensor

122 Permanent Alarm Reset Input Input held on alarm reset terminal for more than 10 seconds

Alarm

Check input on terminal M/R

Page 51 Mk8 MM End User Guide 22.05.2017

4 Errors and Lockouts

Fault Message Description Type

123 Second Low Probe

Communications Fault

No comms with second low probe

Alarm

Check wiring and screen on terminals 5T+, 5T-, 4P- and 4P+

124 Second Low Probe Hardware

Fault

Internal check failed

Alarm

Contact Autoflame approved local tech centre

125 Permanent Test Input Input held on test terminal for more than 60 seconds

Alarm

Check input on terminal TST

126 Second Low Probe Detected

But Not Optioned

Second low probe connected but not optioned

Alarm

Check expansion option 6

Check wiring on terminals 5T+, 5T-, 4P- and 4P+

127 Aux WL Inputs Detect But Not

Optioned

Mains detected on auxiliary WL inputs but not optioned

Alarm

Check expansion option 5

Check wiring on terminals HAI, 1AI and 2AI

130 Feed Water Servo Position

Error

Servomotor is outside of the commissioned range

Alarm or warning or depending on expansion option 20

Check wiring on terminals P-, FW and P+

Check signal cable form the MM to the servomotor is screened at one end

Check that the servomotor is zeroed correctly

131 Feed Water Servo Movement

Error

Servomotor moves when not expected and vice versa

Alarm or warning depending on expansion option 20

Check wiring and voltages on terminals MVI and MVD

Check servomotor drives in correct direction

Check feed water valve is not stuck

150 High Water Probes/sensor detect water level above commissioned high

water

Alarm or warning depending on expansion option 9

Check water level reading

151 Pre-High Water Probes/sensor detect water level above set pre-high water

Warning

Check water level reading

Check expansion option 7

152 Pre-1st Low Probes/sensor detect water level below set pre-1st low

Warning

Check water level reading

Check expansion option 8

153 1st Low Probes/sensor detect water level below commissioned 1st low

Alarm

Check water level reading

1

st

low alarm will automatically clear if water level increases above 1st low

22.05.2017 Mk8 MM End User Guide Page 52

4 Errors and Lockouts

Fault Message Description

154 2nd Low Probes/sensor detect water level below 2nd low

Alarm

Check water level reading

2

nd

low alarm requires manual reset

155 Shunt Switch Time Expired Once shunt switch time expires, system goes to normally

running

Warning

If water drops after shunt switch time expires, system will generate 1

st

or 2nd low as relevant

200 Top Blowdown Sensor

Communications Fault

No comms with the top blowdown sensor

Warning

Check wiring and screen on terminals 3P+, 3P-, 3T+ and 3T-

201 Top Blowdown Servo Position

Error

Servomotor is outside of the commissioned range

Warning

Check wiring on terminals P-, TW, P+ and TBI, TBD

Check signal cable form the MM to the servomotor is screened at one end

Check that the servomotor is zeroed correctly

202 Top Blowdown Servo

Movement Error

Servomotor moves when not expected and vice versa

Warning

Check wiring on terminals TBI and TBD

Check servomotor drives in correct direction

Check top blowdown valve is not stuck

250 Top Blowdown Reading High TDS value detected too high

Warning

Check expansion option 46 and TDS value

300 Bottom Blowdown Controller

Comms

No comms with bottom blowdown controller

Warning

Check bottom blowdown controller is powered on and enabled

Check wiring and screen on terminals 5T+ and 5T-

301 Bottom Blowdown Controller

Software Fault

Internal check failed

Warning

Contact Autoflame approved local tech centre

302 Bottom Blowdown Servo

Closing Fault

No movement detected when bottom blowdown valve goes

to close

Warning

Check wiring on terminals 5T+ and 5T-

Check bottom blowdown valve is not stuck

303 Bottom Blowdown Servo

Opening Fault

No movement detected when bottom blowdown valve goes

to open

Warning

Check wiring on terminals 5T+ and 5T-

Check bottom blowdown valve is not stuck

304 Bottom Blowdown Servo

Battery Drive Fault

Battery has failed on bottom blowdown

controller

Warning

Warning

Contact Autoflame approved local tech centre

Page 53 Mk8 MM End User Guide 22.05.2017

4 Errors and Lockouts

Fault Message Description

305 Bottom Blowdown Controller

Main Power Fault

Main power has failed on bottom blowdown controller

Warning

Contact Autoflame approved local tech centre

350 Bottom Blowdown Servo Not

Commissioned

Bottom blowdown controller has not been requested to drive

servomotor to closed since it was powered on

Warning

Commission bottom blowdown servomotor

400 Draught Pressure Sensor

Timeout

No comms within 2 seconds from draught pressure sensor

Alarm or warning depending on option 88

Check wiring and screen on terminals DT+, DT-, DP- and DP+

410 Draught Pressure Outside

Tolerance

Pressure is outside of set tolerance

Alarm or warning depending on option 88

Check expansion option 87

420 Fuel flow Feedback Input Low 3mA or lower received from 4-20mA external fuel flow input

Warning

Check feedback from external fuel flow input

Check wiring on terminals EX- and EX+

430 Fuel flow Feedback Below

Tolerance

Fuel flow signal below fuel flow feedback fault tolerance

Warning

Check feedback from external fuel flow input

Check option 60

431 Fuel flow Feedback Above

Tolerance

Fuel flow signal above fuel flow feedback fault tolerance

Warning

Check feedback from external fuel flow input

Check option 60

440 Temperature Sensor T1Fault Fault or no comms with T1 sensor

Warning

Check wiring and screen on terminals –and T1

441 Temperature Sensor T2 Fault Fault or no comms with T2 sensor

Warning

Check wiring and screen on terminals – and T2

442 Temperature Sensor T3 Fault Fault or no comms with T3 sensor

Warning

Check wiring and screen on terminals – and T3

443 Make Up Flow Meter Fault Fault or no comms with make up flow meter

Warning

Check wiring and screen on terminals F- and MF

444 Condensate Flow Meter Fault Fault or no comms with condensate flow meter

Warning

Check wiring and screen on terminals F- and CF

445 Deaerator IO Comms Fault Fault or no comms with deaerator IO

Warning

Check wiring and screen on terminals 6T+ and 6T-

22.05.2017 Mk8 MM End User Guide Page 54

4 Errors and Lockouts

Fault Message Description

500 Multi-Burner Communications

Fault

Loss of comms between MMs in multi-burner loop

Alarm

Check wiring on terminals 23 and 24 on all MMs in multi-burner loop

501 Multi-Burner Version

Mismatch

Software versions of MMs in multi-burner loop do not match

Alarm

Check that software versions of MMs in multi-burner loop match

502 Multi-Burner Not Polled MM in multi-burner loop has been detected but not polled

Alarm

Check option 51 on master MM

Check wiring on terminals 23 and 24

503 Multi-Burner Config (Multi-

Burner Mode)

Multi-burner mode is not the same for all MMs in loop

Alarm

Check option 43 on all MMs in multi-burner loop

504 Multi-Burner Config (Fuel

Index)

Same fuel number must be selected on all MMs in multiburner loop

Alarm

Check which fuel is selected on all MMs in multi-burner loop

Check wiring on terminals 89, 90, 91 and 92

505 Multi-Burner Config (Fuel

Type)

Fuel type is not the same for all MMs in multi-burner loop

Alarm

Check option/parameters 150 – 153 on all MMs in multi-burner loop

506 Multi-Burner Config (Pilot

Type)

Pilot type not the same for all MMs multi-burner loop

Alarm

Check option/parameter 111 on all MMs in multi-burner loop

507 Multi-Burner Config (Load

Sensor)

Load sensor not set the same for all MMs in multi-burner loop

Alarm

Check option 1 on all MMs in multi-burner loop

550 Fuel Flow Meter Fault Less than 3mA signal received from fuel flow meter

Alarm or warning depending on expansion option 152 (if set to warning, the MM will use the

commissioned value without any fuel or air servomotor adjustment)

Check wiring and screen on terminal MF and F-

551 Air Flow Meter Fault Less than 3mA signal received from air flow meter

Alarm or warning depending on expansion option 152 (if set to warning, the MM will use the

commissioned value without any fuel or air servomotor adjustment)

Check wiring and screen on terminal EX+ and EX-

552 Fuel Temperature Sensor

Fault (T2)

Fault or no comms with T2 sensor

Warning (MM will use commissioned temperature)

Check wiring and screen on terminals – and T2

553 Air Temp Sensor Fault (T3) Fault or no comms with T3 sensor

Warning (MM will use commissioned temperature)

Check wiring and screen on terminals – and T3

Page 55 Mk8 MM End User Guide 22.05.2017

4 Errors and Lockouts

Fault Message Description

554 Fuel Pressure Sensor Fault Fault or no comms with fuel pressure sensor

Warning or lockout if VPS and/or pressure limits enabled in option/parameters 125 – 128 (if

warning, MM uses commissioned pressure)

Check wiring and screen on terminals 31 – 34

555 Air Pressure Sensor Fault Fault or no comms with air pressure

sensor

Warning/Lockout

– option 148