Autodesk Inventor Simulation 2009

Getting Started

January 2008Part No. 462A1-050000-PM02A

©

2008 Autodesk, Inc. All Rights Reserved. Except as otherwise permitted by Autodesk, Inc., this publication, or parts thereof, may not be

reproduced in any form, by any method, for any purpose.

Certain materials included in this publication are reprinted with the permission of the copyright holder.

Trademarks

The following are registered trademarks or trademarks of Autodesk, Inc., in the USA and other countries: 3DEC (design/logo), 3December,

3December.com, 3ds Max, ActiveShapes, Actrix, ADI, Alias, Alias (swirl design/logo), AliasStudio, Alias|Wavefront (design/logo), ATC, AUGI,

AutoCAD, AutoCAD Learning Assistance, AutoCAD LT, AutoCAD Simulator, AutoCAD SQL Extension, AutoCAD SQL Interface, Autodesk, Autodesk

Envision, Autodesk Insight, Autodesk Intent, Autodesk Inventor, Autodesk Map, Autodesk MapGuide, Autodesk Streamline, AutoLISP, AutoSnap,

AutoSketch, AutoTrack, Backdraft, Built with ObjectARX (logo), Burn, Buzzsaw, CAiCE, Can You Imagine, Character Studio, Cinestream, Civil

3D, Cleaner, Cleaner Central, ClearScale, Colour Warper, Combustion, Communication Specification, Constructware, Content Explorer,

Create>what's>Next> (design/logo), Dancing Baby (image), DesignCenter, Design Doctor, Designer's Toolkit, DesignKids, DesignProf, DesignServer,

DesignStudio, Design|Studio (design/logo), Design Your World, Design Your World (design/logo), DWF, DWG, DWG (logo), DWG TrueConvert,

DWG TrueView, DXF, EditDV, Education by Design, Exposure, Extending the Design Team, FBX, Filmbox, FMDesktop, Freewheel, GDX Driver,

Gmax, Heads-up Design, Heidi, HOOPS, HumanIK, i-drop, iMOUT, Incinerator, IntroDV, Inventor, Inventor LT, Kaydara, Kaydara (design/logo),

LocationLogic, Lustre, Maya, Mechanical Desktop, MotionBuilder, Mudbox, NavisWorks, ObjectARX, ObjectDBX, Open Reality, Opticore,

Opticore Opus, PolarSnap, PortfolioWall, Powered with Autodesk Technology, Productstream, ProjectPoint, ProMaterials, Reactor, RealDWG,

Real-time Roto, Recognize, Render Queue, Reveal, Revit, Showcase, ShowMotion, SketchBook, SteeringWheels, StudioTools, Topobase, Toxik,

ViewCube, Visual, Visual Bridge, Visual Construction, Visual Drainage, Visual Hydro, Visual Landscape, Visual Roads, Visual Survey, Visual Syllabus,

Visual Toolbox, Visual Tugboat, Visual LISP, Voice Reality, Volo, Wiretap, and WiretapCentral

The following are registered trademarks or trademarks of Autodesk Canada Co. in the USA and/or Canada and other countries: Backburner,

Discreet, Fire, Flame, Flint, Frost, Inferno, Multi-Master Editing, River, Smoke, Sparks, Stone, and Wire

All other brand names, product names or trademarks belong to their respective holders.

Disclaimer

THIS PUBLICATION AND THE INFORMATION CONTAINED HEREIN IS MADE AVAILABLE BY AUTODESK, INC. "AS IS." AUTODESK, INC. DISCLAIMS

ALL WARRANTIES, EITHER EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE REGARDING THESE MATERIALS.

Published by:

Autodesk, Inc.

111 Mclnnis Parkway

San Rafael, CA 94903, USA

Contents

Stress Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Chapter 1 Get Started With Stress Analysis . . . . . . . . . . . . . . . . . . 3

About Autodesk Inventor Simulation . . . . . . . . . . . . . . . . . . . 3

Learning Autodesk Inventor Simulation . . . . . . . . . . . . . . . . . . 3

Using Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Using Stress Analysis Tools . . . . . . . . . . . . . . . . . . . . . . . . . 5

Understanding the Value of Stress Analysis . . . . . . . . . . . . . . . . 6

Understanding How Stress Analysis Works . . . . . . . . . . . . . . . . 7

Analysis Assumptions . . . . . . . . . . . . . . . . . . . . . . . . 7

Interpreting Results of Stress Analysis . . . . . . . . . . . . . . . . . . . 9

Equivalent Stress . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Maximum and Minimum Principal Stresses . . . . . . . . . . . . 10

Deformation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Safety Factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Frequency Modes . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Chapter 2 Analyze Models . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Working in the Stress Analysis Environment . . . . . . . . . . . . . . . 13

Running Stress Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Verifying Material . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Applying Loads . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Applying Constraints . . . . . . . . . . . . . . . . . . . . . . . . 19

iii

Setting Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Feature Suppression Tracking . . . . . . . . . . . . . . . . . . . . 21

Setting Solution Options . . . . . . . . . . . . . . . . . . . . . . 21

Obtaining Solutions . . . . . . . . . . . . . . . . . . . . . . . . . 23

Running Modal Analysis . . . . . . . . . . . . . . . . . . . . . . . . . 23

Chapter 3 View Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Using Results Visualization . . . . . . . . . . . . . . . . . . . . . . . . 25

Editing the Color Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Reading Stress Analysis Results . . . . . . . . . . . . . . . . . . . . . . 28

Interpreting Results Contours . . . . . . . . . . . . . . . . . . . . 28

Animate Results . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Setting Results Display Options . . . . . . . . . . . . . . . . . . . 30

Chapter 4 Revise Models and Stress Analyses . . . . . . . . . . . . . . . . 31

Changing Model Geometry . . . . . . . . . . . . . . . . . . . . . . . . 31

Changing Solution Conditions . . . . . . . . . . . . . . . . . . . . . . 32

Updating Results of Stress Analysis . . . . . . . . . . . . . . . . . . . . 34

Chapter 5 Generate Reports . . . . . . . . . . . . . . . . . . . . . . . . . 35

Running Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Interpreting Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Scenario . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Appendices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Saving and Distributing Reports . . . . . . . . . . . . . . . . . . . . . 37

Saving Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Printing Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Distributing Reports . . . . . . . . . . . . . . . . . . . . . . . . . 38

Chapter 6 Manage Stress Analysis Files . . . . . . . . . . . . . . . . . . . 39

Creating and Using Analysis Files . . . . . . . . . . . . . . . . . . . . . 39

Understanding File Relationships . . . . . . . . . . . . . . . . . . 40

Repairing Disassociated Files . . . . . . . . . . . . . . . . . . . . . . . 40

Copying Geometry Files . . . . . . . . . . . . . . . . . . . . . . 41

Resolving File Link Failures . . . . . . . . . . . . . . . . . . . . . 41

Creating New Analysis Files . . . . . . . . . . . . . . . . . . . . . 42

Exporting Analysis Files . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Simulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

iv | Contents

Chapter 7 Get Started with Simulation . . . . . . . . . . . . . . . . . . . 45

About Autodesk Inventor Simulation . . . . . . . . . . . . . . . . . . . 45

Learning Autodesk Inventor Simulation . . . . . . . . . . . . . . . . . 46

Using Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Understanding Simulation Tools . . . . . . . . . . . . . . . . . . . . . 47

Simulation Assumptions . . . . . . . . . . . . . . . . . . . . . . . . . 47

Interpreting Simulation Results . . . . . . . . . . . . . . . . . . . . . 47

Relative Parameters . . . . . . . . . . . . . . . . . . . . . . . . . 47

Coherent Masses and Inertia . . . . . . . . . . . . . . . . . . . . 48

Continuity of Laws . . . . . . . . . . . . . . . . . . . . . . . . . 48

Chapter 8 Simulate Motion . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Understanding Degrees of Freedom . . . . . . . . . . . . . . . . . . . . 49

Understanding Constraints . . . . . . . . . . . . . . . . . . . . . . . . 49

Converting Assembly Constraints . . . . . . . . . . . . . . . . . . . . 50

Defining Forces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Creating Simulations . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Chapter 9 Construct Moving Assemblies . . . . . . . . . . . . . . . . . . 59

Creating Rigid Bodies . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Adding Joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Working with Z Axes . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Working with Joint Triad . . . . . . . . . . . . . . . . . . . . . . . . . 62

Chapter 10 Simulation Tools . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Input Grapher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Output Grapher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Contents | v

vi

Stress Analysis

Part 1 of this manual presents the getting started information for Stress Analysis in the

Autodesk® Inventor™ Simulation software. This add-on to the Autodesk Inventor part and

sheet metal environments provides the capability to analyze the stress and frequency responses

of mechanical part designs.

1

2

Get Started With Stress Analysis

Autodesk® Inventor™ Simulation software provides a combination of industry-specific tools

that extend the capabilities of Autodesk Inventor for completing complex machinery and

other product designs.

Stress Analysis in Autodesk Inventor Simulation is an add-on to the Autodesk Inventor part

and sheet metal environments. It provides the capability to analyze the stress and frequency

responses of mechanical part designs.

This chapter provides basic information about the stress analysis environment and the

workflow processes necessary to analyze loads and constraints placed on a part.

1

About Autodesk Inventor Simulation

Built on the Autodesk Inventor application, Autodesk Inventor Simulation

includes several different modules. The first module included in this manual is

Stress Analysis. It provides functionality for stressing and analyzing mechanical

product designs.

This manual provides basic conceptual information to help get you started and

specific examples that introduce you to the capabilities of Stress Analysis in

Autodesk Inventor Simulation.

Learning Autodesk Inventor Simulation

We assume that you have a working knowledge of the Autodesk Inventor

Simulation interface and tools. If you do not, use Help for access to online

3

documentation and tutorials, and complete the exercises in the Autodesk

Inventor Simulation Getting Started manual.

At a minimum, we recommend that you understand how to:

■ Use the assembly, part modeling, and sketch environments and browsers.

■ Edit a component in place.

■ Create, constrain, and manipulate work points and work features.

■ Set color styles.

Be more productive with Autodesk® software. Get trained at an Autodesk

Authorized Training Center (ATC®) with hands-on, instructor-led classes to

help you get the most from your Autodesk products. Enhance your productivity

with proven training from over 1,400 ATC sites in more than 75 countries.

For more information about training centers, contact atc.program@autodesk.com

or visit the online ATC locator at www.autodesk.com/atc.

We also recommend that you have a working knowledge of Microsoft

Windows NT® 4.0, Windows® 2000, or Windows® XP, and a working

knowledge of concepts for stressing and analyzing mechanical assembly

designs.

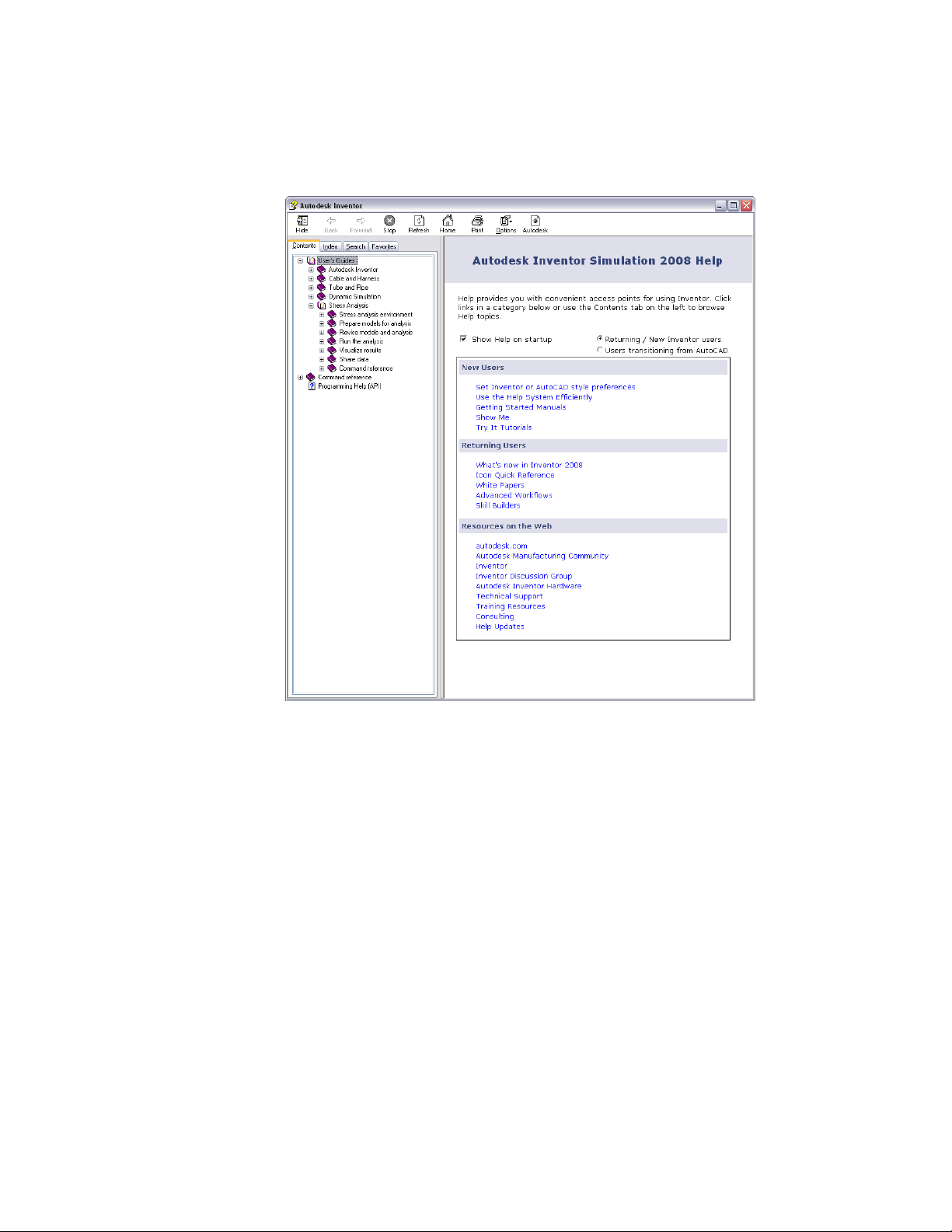

Using Help

®

As you work, you may need additional information about the task you are

performing. The Help system provides detailed concepts, procedures, and

reference information about every feature in the Autodesk Inventor Simulation

Simulation modules as well as the standard Autodesk Inventor Simulation

features.

To access the Help system, use one of the following methods:

■ Click Help ➤ Help Topics, and then use the Table of Contents to navigate

to Stress Analysis topics.

■ Press F1 for Help with the active operation.

■ In any dialog box, click the ? icon.

■ In the graphics window, right-click, and then click How To. The How To

topic for the current tool is displayed.

4 | Chapter 1 Get Started With Stress Analysis

Using Stress Analysis Tools

Autodesk Inventor Simulation Stress Analysis provides tools for determining

structural design performance directly on your Autodesk Inventor Simulation

model. Autodesk Inventor Simulation Stress Analysis includes tools to place

loads and constraints on a part and calculate the resulting stress, deformation,

safety factor, and resonant frequency modes.

Enter the stress analysis environment in Autodesk Inventor Simulation with

an active part.

With the stress analysis tools, you can:

■ Perform a stress or frequency analysis of a part.

Using Stress Analysis Tools | 5

■ Apply a force, pressure, bearing, moment, or body load to vertices, faces,

or edges of the part, or apply a motion load directly to a part.

■ Apply fixed or non-zero displacement constraints to the model.

■ Evaluate the impact of multiple parametric design changes.

■ View the analysis results in terms of equivalent stress, minimum and

maximum principal stresses, deformation, safety factor, or resonant

frequency modes.

■ Add or suppress features such as gussets, fillets or ribs, re-evaluate the

design, and update the solution.

■ Animate part through various stages of deformation, stress, safety factor,

and frequencies.

■ Generate a complete and automatic engineering design report that can be

saved in HTML format.

Understanding the Value of Stress Analysis

Performing an analysis of a mechanical part in the design phase can help you

bring a better product to market in less time. Autodesk Inventor Simulation

Stress Analysis helps you:

■ Determine if the part is strong enough to withstand expected loads or

vibrations without breaking or deforming inappropriately.

■ Gain valuable insight at an early stage when the cost of redesign is small.

■ Determine if the part can be redesigned in a more cost-effective manner

and still perform satisfactorily under expected use.

Stress analysis, for this discussion, is a tool to understand how a design will

perform under certain conditions. It might take a highly trained specialist a

great deal of time performing what is often called a detailed analysis to obtain

an exact answer with regard to reality. What is often as useful to help predict

and improve a design is the trending and behavioral information obtained

from a basic or fundamental analysis. Performing this basic analysis early in

the design phase can substantially improve the overall engineering process.

Here is an example of stress analysis use: When designing bracketry or single

piece weldments, the deformation of your part may greatly affect the alignment

of critical components causing forces that induce accelerated wear. When

6 | Chapter 1 Get Started With Stress Analysis

evaluating vibration effects, geometry plays a critical role in the resonant

frequency of a part. Avoiding or, in some cases, targeting critical resonant

frequencies literally is the difference between part failure and expected part

performance.

For any analysis, detailed or fundamental, it is vital to keep in mind the nature

of approximations, study the results, and test the final design. Proper use of

stress analysis greatly reduces the number of physical tests required. You can

experiment on a wider variety of design options and improve the end product.

To learn more about the capabilities of Autodesk Inventor Simulation Stress

Analysis, view online demonstrations and tutorials, or see how to run analysis

on Autodesk Inventor Simulation assemblies, visit

http://www.ansys.com/autodesk.

Understanding How Stress Analysis Works

Stress analysis is done using a mathematical representation of a physical system

composed of:

■ A part (model).

■ Material properties.

■ Applicable boundary conditions and loads, referred to as preprocessing.

■ The solution of that mathematical representation (solving).

To find a solution, the part is divided into smaller elements. The solver

adds up the individual behaviors of each element to predict the behavior

of the entire physical system.

■ The study of results of that solution, referred to as post-processing.

Analysis Assumptions

The stress analysis provided by Autodesk Inventor Simulation is appropriate

only for linear material properties where the stress is directly proportional to

the strain in the material (meaning no permanent yielding of the material).

Linear behavior results when the slope of the material stress-strain curve in

the elastic region (measured as the Modulus of Elasticity) is constant.

Understanding How Stress Analysis Works | 7

The total deformation is assumed to be small in comparison to the part

thickness. For example, if studying the deflection of a beam, the calculated

displacement must be less than the minimum cross-section of the beam.

The results are temperature-independent. The temperature is assumed not to

affect the material properties.

The CAD representation of the physical model is broken down into small

pieces (think of a 3D puzzle). This process is called meshing. The higher the

quality of the mesh (collection of elements), the better the mathematical

representation of the physical model. By combining the behaviors of each

element using simultaneous equations, you can predict the behavior of shapes

that would otherwise not be understood using basic closed form calculations

found in typical engineering handbooks.

The following is a block (element) with well-defined mechanical and modal

behaviors.

In this example of a simple part, the structural behavior would be difficult to

predict solving equations by hand.

8 | Chapter 1 Get Started With Stress Analysis

Here, the same part is broken into small blocks (meshed into elements), each

with well-defined behaviors capable of being summed (solved) and easily

interpreted (post-processed). For sheet metal, a special element type is used.

It is assumed that the model is thin in one direction relative to the size of the

other dimensions. The model has identical topologies on the top and bottom

and has only one topology through the thickness of the model.

Interpreting Results of Stress Analysis

The output of a mathematical solver is generally a substantial quantity of raw

data. This quantity of raw data would normally be difficult and tedious to

interpret without the data sorting and graphical representation traditionally

referred to as post-processing. Post-processing is used to create graphical

displays that show the distribution of stresses, deformations, and other aspects

of the model. Interpretation of these post-processed results is the key to

identifying:

■ Areas of potential concern as in weak areas in a model.

■ Areas of material waste as in areas of the model bearing little or no load.

■ Valuable information about other model performance characteristics, such

as vibration, that otherwise would not be known until a physical model

is built and tested (prototyped).

The results interpretation phase is where the most critical thinking must take

place. You compare the results (such as the numbers versus color contours,

movements) with what is expected. You determine if the results make sense,

and explain the results based on engineering principles. If the results are other

Interpreting Results of Stress Analysis | 9

than expected, evaluate the analysis conditions and determine what is causing

the discrepancy.

Equivalent Stress

Three-dimensional stresses and strains build up in many directions. A common

way to express these multidirectional stresses is to summarize them into an

Equivalent stress, also known as the von-Mises stress. A three-dimensional

solid has six stress components. If material properties are found experimentally

by an uniaxial stress test, then the real stress system is related by combining

the six stress components to a single equivalent stress.

Maximum and Minimum Principal Stresses

According to elasticity theory, an infinitesimal volume of material at an

arbitrary point on or inside the solid body can be rotated such that only normal

stresses remain and all shear stresses are zero. When the normal vector of a

surface and the stress vector acting on that surface are collinear, the direction

of the normal vector is called principal stress direction. The magnitude of the

stress vector on the surface is called the principal stress value.

Deformation

Deformation is the amount of stretching that an object undergoes due to the

loading. Use the deformation results to determine where and how much a

part will bend, and how much force is required to make it bend a particular

distance.

Safety Factor

All objects have a stress limit depending on the material used, which is referred

to as material yield. If steel has a yield limit of 40,000 psi, any stresses above

this limit result in some form of permanent deformation. If a design is not

supposed to deform permanently by going beyond yield (most cases), then

the maximum allowable stress in this case is 40,000 psi.

10 | Chapter 1 Get Started With Stress Analysis

A factor of safety can be calculated as the ratio of the maximum allowable

stress to the equivalent stress (von-Mises) and must be over 1 for the design

to be acceptable. (Less than 1 means there is some permanent deformation.)

Factor of safety results immediately points out areas of potential yield, where

equivalent stress results always show red in the highest area of stress, regardless

of how high or low the value. Since a factor of safety of 1 means the material

is essentially at yield, most designers strive for a safety factor of between 2 to

4 based on the highest expected load scenario. Unless the maximum expected

load is frequently repeated, the fact that some areas of the design go into yield

does not always mean the part will fail. Repeated high load may result in a

fatigue failure, which is not simulated by Autodesk Inventor Simulation Stress

Analysis. Always, use engineering principles to evaluate the situation.

Frequency Modes

Use vibration analysis to test a model for:

■ Its natural resonant frequencies (for example, a rattling muffler during idle

conditions, or other failures)

■ Random vibrations

■ Shock

■ Impact

Each of these incidences may act on the natural frequency of the model,

which, in turn, may cause resonance and subsequent failure. The mode shape

is the displacement shape that the model adopts when it is excited at a

resonant frequency.

Frequency Modes | 11

12

Analyze Models

2

Once your model is defined, define the loads and constraints for the condition you want to

test, and then perform an analysis of the model. Use the stress analysis environment to prepare

your model for analysis, and then run the analysis.

This chapter explains how to define loads, constraints, and parameters, and run your analysis.

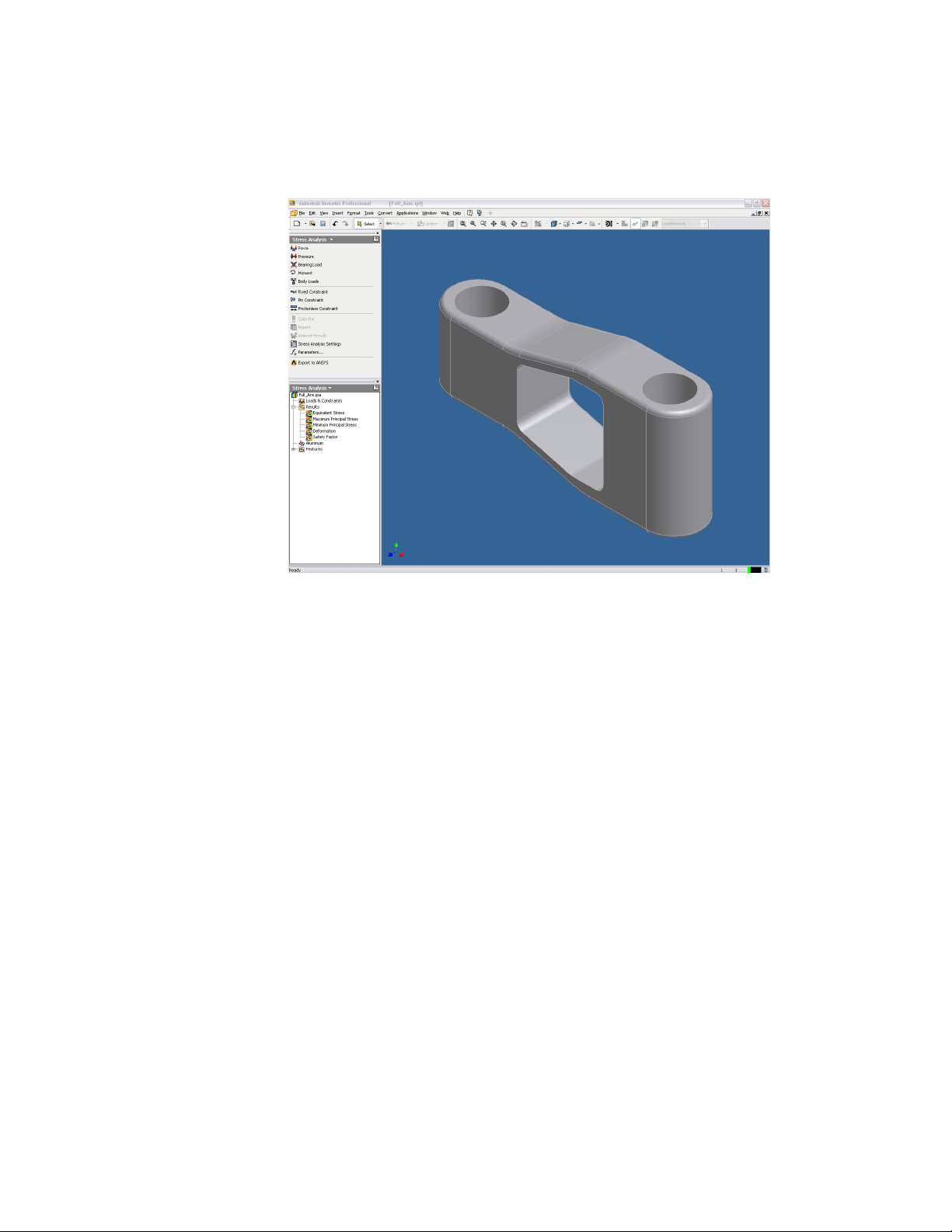

Working in the Stress Analysis Environment

Use the stress analysis environment to analyze your part design and evaluate

different options quickly. You can analyze a part model under different

conditions using various materials, loads, and constraints (or boundary

conditions), and then view the results. You have a choice of performing a stress

analysis, or a resonant frequency analysis with associated mode shapes. After

viewing and evaluating the results, you can change your model and rerun the

analysis to see what effect your changes produced.

You can enter the stress analysis environment from the part and sheet metal

environments.

Enter the stress analysis environment

1 Start with the part or sheet metal environment active.

2 Click Applications ➤ Stress Analysis.

The Stress Analysis panel bar displays.

13

Loads and constraints are listed under Loads & Constraints in the browser. If

you right-click a load or constraint in the browser, you can:

■ Edit the item. The dialog box for that item opens so that you can make

changes.

■ Delete the item.

To rename an item in the browser, click it, enter a new name, and then press

ENTER.

Running Stress Analysis

Once you build or load a part, you can run an analysis to evaluate it for its

intended use. You can perform either a stress analysis or a resonant frequency

analysis of your part under defined conditions. Use the same workflow steps

in either analysis.

The following are the basic steps to perform a stress or resonant frequency

analysis on a part design.

14 | Chapter 2 Analyze Models

Workflow: Perform a typical analysis

1 Enter the stress analysis environment.

2 Verify that the material used for the part is suitable, or select one.

3 On the Stress Analysis panel bar, select the type of load to apply. The

choices are Force, Pressure, Bearing Load, Moment, Body Load, Motion

load (for a part exported from Dynamic Simulation), or Fixed Constraint.

4 On the model, select the faces, edges, or vertices where you want to apply

the load.

5 Enter the load parameters (for example, on the Force dialog box, enter

the magnitude and direction). Numerical parameters can be entered as

numbers or equations that contain user-defined parameters.

6 Repeat steps 3 through 5 for each load on the part.

7 Apply constraints to the model.

8 Change stress analysis environment settings as needed.

9 Modify or add parameters as needed.

10 Start the analysis.

11 View the results.

12 Change the model and reanalyze it until you simulate the appropriate

behavior.

Verifying Material

The first step is to verify that your model material is appropriate for stress

analysis. When you select Stress Analysis, Autodesk® Inventor™ checks the

material defined for your part. If the material is suitable, it is listed in the

Stress Analysis browser. If it is not suitable, a dialog box is displayed so that

you can select a new material.

Verifying Material | 15

You can cancel this dialog box and continue setting up your stress analysis.

However, when you attempt a stress analysis update, this dialog box is

displayed so you can select a valid material before running the analysis.

If the yield strength or density are zero, you cannot perform an analysis.

Once you select a suitable material, click OK.

Applying Loads

The first step in preparing your model for analysis is applying one or more

loads to the model.

Workflow: Apply loads for analysis

1 Select the type of load you want to apply.

2 Select the geometry of the model where the load is applied.

3 Enter the required information for that load.

You can apply as many loads as you need. As you apply them, the loads are

listed in the browser under Loads & Constraints. Once you define a load, you

can edit it by right-clicking it, and then selecting Edit from the menu.

Select and apply a load

1 In the stress analysis environment, Stress Analysis panel bar, click Force.

16 | Chapter 2 Analyze Models

After you select Force, you define the force on the Force dialog box.

2 Click faces, edges, or vertices on the part to select them. Use CTRL-click

to remove a feature from the selection set.

Once you select an initial feature, your selection is limited to features of

the same type (only faces, only edges, only vertices). The location arrow

turns white.

3 Click the direction arrow to set the direction of the force. You can set the

direction normal to a face or work plane, or along an edge or work axis.

Applying Loads | 17

When the force location is a single face, the direction is automatically

set to the normal of the face, with the force pointing to the outside of

the part.

4 To reverse the direction of the force, click the Flip Direction button.

5 Enter the magnitude of the force.

6 To specify the force components, click the More button to expand the

dialog box, and then select the check box for Use Components.

7 Enter either a numerical force value or an equation using defined

parameters. The default value is 100 in the unit system defined for the

part.

8 Click OK.

An arrow is displayed on the model indicating the direction and location

of the force.

You follow a similar procedure for each of the different load types.

18 | Chapter 2 Analyze Models

This table summarizes information about each load type:

Load-Specific InformationLoad

Force

Pressure

Bearing

Load

Moment

Body Loads

Applying Constraints

Apply a force to a set of faces, edges, or vertices. When the

force location is a face, the direction is automatically set to

the normal of the face, with the force pointing to the inside

of the part. Define the direction planar faces, straight edges,

and axes.

Pressure is uniform and acts normal to the surface at all locations on the surface. Apply pressure only to faces.

Apply a bearing load only to cylindrical faces. By default, the

applied load is along the axis of the cylinder and the direction

of the load is radial.

Apply a moment only to faces. Define direction planar faces,

straight edges, two vertices, and axes.

Select a direction from the Earth Standard Gravity list to apply

gravity. Select the Enable check box under Acceleration or

Rotational Velocity. You can only apply one body load per

analysis.

After you define your loads, specify the constraints on the geometry of the

part. You can apply as many constraints as you need. The defined constraints

are listed in the browser under Loads & Constraints. After you define a

constraint, you can edit it by right-clicking it, and then selecting Edit from

the menu.

Select and apply a constraint

1 On the Stress Analysis panel bar, click Fixed Constraint, Pin Constraint,

or Frictionless Constraint.

2 In the graphics window, select a set of faces, edges, or vertices to constrain.

The location arrow turns white.

Applying Constraints | 19

3 Click the More button to specify a fixed displacement for the constraint,

if needed. Check Use Components, and then check the box next to the

global axis label (X, Y, or Z) along which the displacement occurs.

You can use parameters and negative values. Use Components to specify

a non-zero displacement that can be used as a load.

4 Click OK.

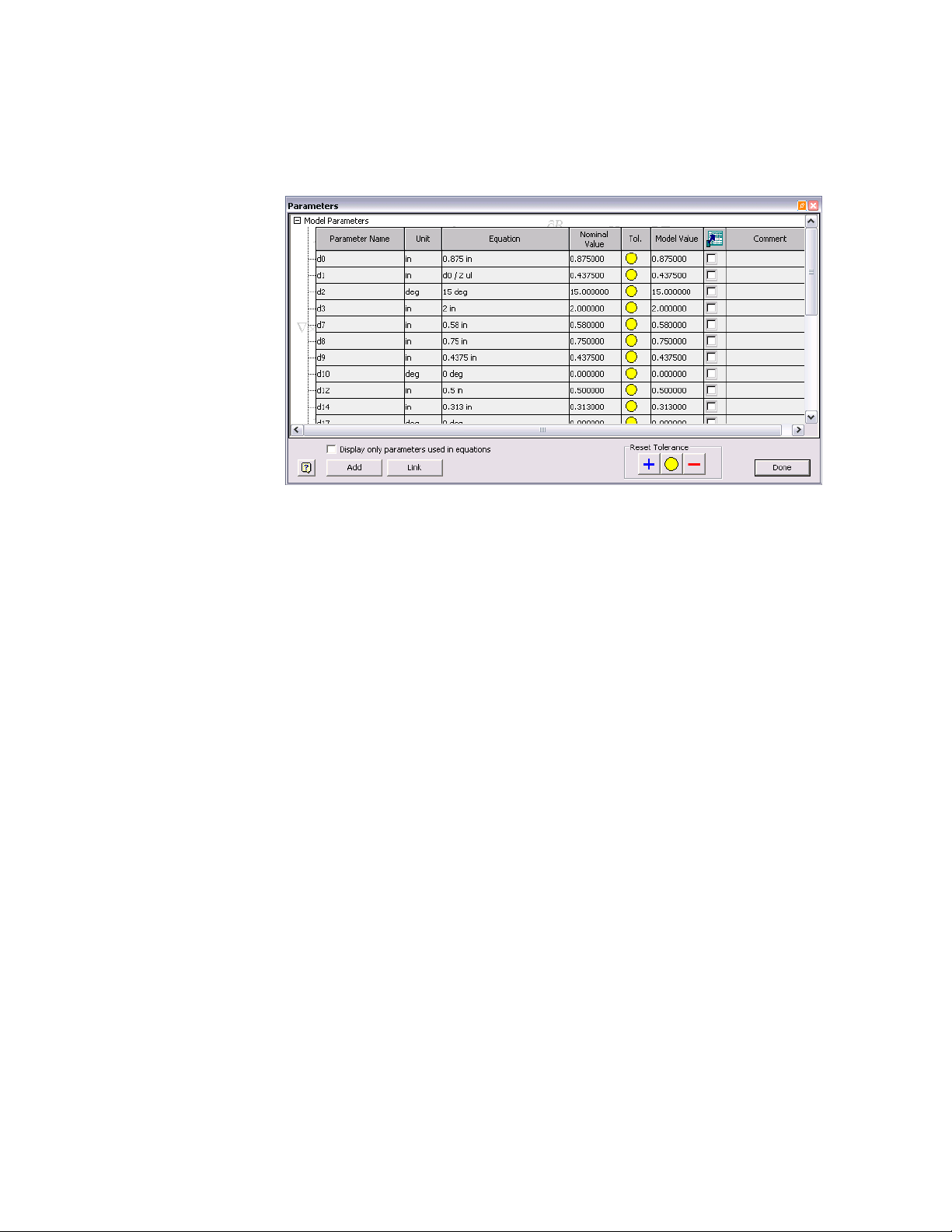

Setting Parameters

When you define loads and constraints for a part, the values you enter

(magnitudes, vector components, and so on) are stored as parameters in

Inventor. It automatically generates the parameter names. For example, load

parameters are labeled dn, where d0 is the first load created, d1 the second

load, and so on.

Load magnitude and constraint displacement values can be entered as

equations when you are defining them. Or, after defining the loads and

constraints, select Parameters from the stress analysis panel bar. On the

Parameters dialog box, enter equations for any of the load or constraint

parameters.

20 | Chapter 2 Analyze Models

You can define and edit parameters at any time, either during part modeling,

analysis setup, or post-processing. If you change the parameters associated

with a load or constraint after a solution is obtained, the Update command

is enabled so you can run a new solution.

You cannot delete the system-generated parameters, although they are deleted

automatically if their associated loads or constraints are deleted. You also

cannot delete parameters that are currently used by a system-generated

parameter.

Feature Suppression Tracking

When conducting analysis studies, you may need to tailor portions of a model

to allow for a more efficient analysis. Generally, this technique involves

removing geometrically small features which only complicated the mesh,

without significant effects to the final result.

Setting Solution Options

Before starting your solution, set the analysis type and mesh relevance for the

analysis, and then specify whether to create new analysis file. Select Stress

Analysis Settings from the stress analysis panel bar to open the dialog box.

When you finish setting the options, click OK to commit them.

Feature Suppression Tracking | 21

Setting Analysis Type

Before starting your solution, on the Settings dialog box, Analysis Type, select

Stress Analysis, Modal Analysis (to perform resonant frequency analysis) or

Both (to run a stress analysis and a prestressed modal analysis of your part).

Setting Mesh Control

There are two meshing model types: standard solid model and optimized thin

model. For a part, the default is standard solid model. It can be meshed in all

X, Y, and Z directions. The default meshing model for sheet metal is optimized

thin model. It is assumed that the model is thin in one direction relative to

the size of the other dimensions, has identical topologies on the top and

bottom, and has only one topology through the thickness of the model. On

the Settings dialog box, move the Mesh Relevance slider to set the size of your

mesh. The default value of zero is an average mesh. Setting the slider to 100

causes a fine mesh to be used. It gives you a highly accurate result, but causes

the solution to take a longer time. Setting the slider to -100 gives you a coarse

mesh, which solves quickly, but may contain significant inaccuracies. The

Mesh Relevance and Result Convergence only work for the standard solid

22 | Chapter 2 Analyze Models

model. You can see the mesh that to use at a particular setting by clicking

Preview Mesh.

Select the Results Convergence check box to allow Autodesk Inventor

Simulation to improve the mesh adaptively.

Multi-Step Motion

Move Active Part

Create OLE Link to

Result Files

Simulates the position for a part applied motion load

from Dynamic Simulation in an assembly.

Moves the active part and fixes other non-active parts

with different time steps.

Fixes the active part and moves other non-active parts.Move Assembly

Keeps the relationship between a part document and

other stress analysis files.

Obtaining Solutions

After you complete all the required steps, the Stress Analysis Update command

on the Standard toolbar is active. Select it to start the solution.

The Solutions Status dialog box is displayed while the solution is in progress.

During the solution, Autodesk Inventor Simulation is unavailable. Once the

solution finishes, the results are displayed graphically.

For information about reviewing the results of your solution, see View Results

on page 25.

Running Modal Analysis

In addition to the stress analysis, you can perform a resonant frequency (modal)

analysis to find the frequencies at which your part vibrates, and the mode

shapes at those frequencies. Like stress analysis, modal analysis is available in

the stress analysis environment.

You can do a resonant frequency analysis independent of a stress analysis.

You can do a frequency analysis on a prestressed structure, in which case you

can define loads on the part before the analysis. You can also find the resonant

frequencies of an unconstrained part.

Your initial steps must be the same as for stress analysis. Refer to the

instructions in Running Stress Analysis on page 14 to set up your loads,

constraints, parameters, and solution options.

Obtaining Solutions | 23

Workflow: Run a modal analysis

1 Enter the stress analysis environment.

2 Verify that the material used for the part is suitable, or select one.

3 Apply any loads (optional).

4 Apply the necessary constraints (optional).

5 Before starting the solution, on the Settings dialog box, Analysis Type

section, select Modal Analysis.

Selecting Both runs a stress analysis and a modal analysis of your part.

Selecting a modal analysis with a load applied produces a prestressed

modal solution.

6 Click OK.

The results for the first six frequency modes are inserted under the Modes

folder in the browser. For an unconstrained part, the first six frequencies

are essentially zero.

7 To change the number of frequencies displayed or limit the range of

frequency results returned, right click the Modes folder, and then select

Options.

The Frequency Options dialog box is displayed. Enter the maximum

number of modes to find, or the range of frequencies to which you want

to limit the results set.

After you complete all the required steps, the Stress Analysis Update

command on the standard toolbar is active.

8 Select Stress Analysis Update to start the solution.

The Solutions Status dialog box is displayed while the solution is in

progress. Once the solution finishes, the results are available for viewing.

24 | Chapter 2 Analyze Models

View Results

3

After analyzing your model under the stress analysis conditions that you defined, you can

visually observe the results of the solution.

This chapter describes the how to interpret the visual results of your stress analyses.

Using Results Visualization

Use results visualization to see how your part responds to the loads and

constraints you apply to it. You can visualize the magnitude of the stresses that

occur throughout the part, the deformation of the part, and the stress safety

factor. For modal analysis, you can visualize the resonant frequency modes.

Enter results visualization

1 Start in the stress analysis environment. Open a part or sheet metal part

that was analyzed previously, or complete the required steps in your current

analysis.

2 On the standard toolbar, click the Stress Analysis Update tool.

The color bar displays in the graphics window.

Post-processing commands are enabled on the standard toolbar, and the display

mode shifts to stepped contours.

25

To view the different results sets, double-click them in the browser. While

viewing the results, you can:

■ Change the color bar to emphasize the stress levels that are of concern.

■ Compare the results to the undeformed geometry.

■ View the mesh used for the solution.

Use the normal view controls to manipulate the model for a 3-dimensional

view of the results.

To change any model parameters, return to part modeling, and then return

to stress analysis and update the solution.

Editing the Color Bar

The color bar shows you how the contour colors correspond to the stress

values or displacements calculated in the solution. You can edit the color bar

to set up the color contours so that the stress/displacement is displayed in a

way that is meaningful to you.

26 | Chapter 3 View Results

Edit the color bar

1 Click Color Bar on the Stress Analysis panel bar.

By default, the maximum and minimum values shown on the color bar

are the maximum and minimum result values from the solution. You

can edit the extreme maximum and minimum values, and the values at

the edges of the bands.

2 To edit the maximum and minimum critical threshold values, click the

Automatic check box to clear the selection, and then edit the values in

the text box. Click Apply to complete the change.

To restore the default maximum and minimum critical threshold values,

select Automatic, and then click Apply.

The levels are initially divided into seven equivalent sections, with default

colors assigned to each section. You can select the number of contour

colors in the range of 1 to 12.

3 To increase or decrease the number of colors, click the Increase

Colors and Decrease Colors buttons. You can also enter the number of

colors you want in the text box.

4 Click the Invert Colors check box to reverse the sequence of colors

displayed in the color bar.

5 You can view the result contours in different colors or in shades

of gray. To view result contours on the grayscale, click Grayscale under

Color.

NOTE It does not work for safety factor.

6 By default, the color bar is positioned in the upper-left corner. Select an

appropriate option under Position to place the color bar at a different

location.

7 Under Size, select an appropriate option to resize the color bar, and then

click Apply.

The color bar preferences such as color, position, and size are applied to

all of the result types.

The Maximum and Minimum threshold values, number of colors and

Invert colors preferences are applied only to the selected result type.

Editing the Color Bar | 27

Reading Stress Analysis Results

When the analysis is complete, you see the results of your solution. If you did

a stress analysis or specified that both types of analyses to do, you initially see

the equivalent stress results set displayed. If your initial analysis is a resonant

frequency analysis (without a stress analysis), you see the results set for the

first mode. To view a different results set, double-click that results set in the

browser pane. The currently viewed results set has a check mark displayed

next to it in the browser. You always see the undeformed wireframe of the

part when you are viewing results.

Interpreting Results Contours

The contour colors displayed in the results correspond to the value ranges

shown in the legend. In most cases, results displayed in red are of most interest,

either because of their representation of high stress or high deformation, or

a low factor of safety. Each results set gives you different information about

the effect of the load on your part.

Equivalent Stress

Equivalent stress results use color contours to show you the stresses calculated

during the solution for your model. The deformed model is displayed. The

color contours correspond to the values defined by the color bar.

Maximum Principal Stress

The maximum principal stress gives you the value of stress that is normal to

the plane in which the shear stress is zero. The maximum principal stress helps

you understand the maximum tensile stress induced in the part due to the

loading conditions.

28 | Chapter 3 View Results

Minimum Principal Stress

The minimum principal stress acts normal to the plane in which shear stress

is zero. It helps you understand the maximum compressive stress induced in

the part due to the loading conditions.

Deformation

The deformation results show you the deformed shape of your model after

the solution. The color contours show you the magnitude of deformation

from the original shape. The color contours correspond to the values defined

by the color bar.

Safety Factor

Safety factor shows you the areas of the model that are likely to fail under

load. The color contours correspond to the values defined by the color bar.

Frequency Modes

You can view the mode plots for the number of resonant frequencies that you

specified in the solution. The modal results appear under the Modes folder in

the browser. When you double-click a frequency mode, the mode shape is

displayed. The color contours show you the magnitude of deformation from

the original shape. The frequency of the mode shows in the legend. It is also

available as a parameter.

Animate Results

Use the Animate Results tool to visualize the part through various stages of

deformation. You can also animate stress, safety factor, and deformation under

frequencies.

Animate Results | 29

Setting Results Display Options

While viewing your results, you can use the following commands located on

the Stress Analysis Standard toolbar to modify the features of the results display

for your model.

Used toCommand

Maximum

Minimum

Condition

Element Visibility

Turns on and off the display of the point of maximum result

in the mode.

Turns on and off the display of the point of minimum result

in the model.

Turns on or off the display of the load symbols on the part.Boundary

Displays the element mesh used in the solution in conjunction

with the result contours.

Use the Deformation Style menu to change the deformed shape exaggeration.

Selecting Actual shows you the deformation to scale. Since the deformations

are often small, the various automatic options exaggerate the scale so that the

shape of the deformation is more pronounced.

Use the Display Settings menu to set the contour style to stepped, smooth, or

no contours. If you turn off the contours, the mesh is displayed for your

deformed part. If you have Element Visibility on, the mesh elements are

displayed. Otherwise, a solid, gray mesh is displayed. The legend shows while

contours are off.

The values of all of the display options for each results set are saved for that

results set.

30 | Chapter 3 View Results

Revise Models and Stress Analyses

After you run a solution for your model, you can evaluate how changes to the model or

analysis conditions will affect the results of the solution.

This chapter explains how to change solution conditions on the part and rerun the solution.

4

Changing Model Geometry

After you run an analysis on your model, you can change the design of your

model. Rerun the analysis to see the effects of the changes.

Edit a design and rerun analysis

1 Return to part modeling by clicking Applications ➤ Part, or Model on the

browser menu.

The part modeling toolbars and browser are displayed, and the graphics

window changes back to the solid undeformed part.

2 Click Last Displayed Stress Result to turn on the display of the last

results set.

Viewing the results of your solution as you edit the initial geometry can

give you an insight as to which dimension to edit to get results closer to

your intent.

3 In the browser, select the feature that you want to edit. It highlights on

the wireframe.

31

4 In the browser, right-click a sketch for the feature that you want to edit.

Click Visibility to make the sketch visible on the model.

5 Double-click the dimension that you want to change, enter the new value

in the text box, and then click the green check mark. The sketch updates.

6 Click Applications ➤ Stress Analysis.

7 On the Standard toolbar, click Stress Analysis Update.

After you update the stress analysis, the load symbols relocate if the feature

that they were associated with moved as a result of the geometry change. The

direction of the load does not change, even if the feature associated with the

load changes orientation.

Changing Solution Conditions

After you run an analysis on your model, you can change the conditions under

which the solution was obtained. Rerun the analysis to see effects of the

changes. You can edit the loads and constraints you defined, add new loads

and constraints, or delete loads and constraints. You can also change the

relevance of your mesh or the analysis type. To change your solution

conditions, enter the stress analysis environment if you are not already in it.

Delete a load or constraint

■ In the browser, right-click a load or constraint, and then select Delete from

the menu.

Add a load or constraint

■ On the panel bar, select the command and follow the same procedure you

used to create your initial loads and constraints.

Edit a load or constraint

1 In the browser, right-click a load or constraint, and then select Edit from

the menu.

The same dialog box you used to create the load or constraint is displayed.

The values on the dialog box are the current values for that load or

constraint.

32 | Chapter 4 Revise Models and Stress Analyses

2 Click the location arrow on the left side of the dialog box to enable feature

picking.

You are initially limited to selecting the same type of feature (face, edge,

or vertex) that is currently used for the load or constraint.

To remove any of the current features, control-click them. If you remove

all of the current features, your new selections can be of any type.

3 Click the white Direction arrow to change the direction of the load.

4 Click the Flip Direction button to reverse the direction, if needed.

5 Change any values associated with the load or constraint.

6 Click OK to apply the load or constraint changes.

Hide a load symbol

■ On the toolbar, click the Boundary Condition display button.

The load symbols are hidden.

Redisplay a load symbol

■ On the toolbar, click the Boundary Condition display button again.

The load symbols redisplay.

Temporarily display load symbols

■ In the browser, pause the cursor over the Loads & Constraints folder

or a particular load.

The load symbols display.

NOTE If you edit a load while the load symbols are hidden, the symbols for

all the loads display. They remain displayed after the editing is complete.

Change the mesh relevance

1 On the Stress Analysis panel bar, click Stress Analysis Settings.

2 On the Settings dialog box, move the slider to set the relevance of your

mesh.

3 Click Preview Mesh to view the mesh at a particular setting.

Changing Solution Conditions | 33

The preview mesh is shown on the undeformed shaded view of your part.

Change the analysis type

1 On the Stress Analysis panel bar, click Stress Analysis Settings.

2 On the Settings dialog box, Analysis Type menu, select the new analysis

type.

If you choose Stress Analysis or Modal Analysis, only the results sets for

the selected analysis type are displayed in the browser. Any previously

obtained results sets are removed.

Change the element type for sheet metal

1 On the Stress Analysis panel bar, click Stress Analysis Settings.

2 On the Setting dialog box, select Standard Solid Model.

Updating Results of Stress Analysis

After you change any of the solution conditions, or if you edit the part

geometry, the current results are invalid. A lightning bolt symbol on the results

icons indicates the invalid status. The Stress Analysis Update item becomes

active on Standard toolbar.

Update stress analysis results

■ On the Standard toolbar, click Stress Analysis Update.

New results generate based on your revised solution conditions.

34 | Chapter 4 Revise Models and Stress Analyses

Generate Reports

5

Once you run an analysis on a part, you can generate a report that provides you with a written

record of the analysis environment and results.

This chapter tells you how to generate a report for an analysis and interpret the report, and

how to save and distribute the report.

Running Reports

After you run a stress analysis on a part, you can save the details of that analysis

for future reference. Use the Report command to save all the analysis conditions

and results in HTML format for easy viewing and storage.

Generate a report

1 Set up and run an analysis for your part.

2 Set the zoom and view orientation to illustrate the analysis results. The

view you choose is the view used in the report.

3 On the panel bar, click Report to create a report for the current analysis.

When it finishes, a browser window containing the report is displayed.

4 Save the report for future reference using the browser Save As command.

Interpreting Reports

The report contains a summary, introduction, scenario, and appendices.

35

Summary

The summary contains an overview of the files used for the analysis and the

analysis conditions and results.

Introduction

The introduction describes the contents of the report and how to use them

in interpreting your analysis.

Scenario

The scenario gives details about the various analysis conditions.

Model

The model section contains:

■ A description of the mesh relevance, and number of nodes and elements

■ A description of the physical characteristics of the model

Environment

The environment section contains:

■ Loading conditions and constraints

Solution

■ Equivalent stress

■ Maximum and minimum principal stresses

■ Deformation

36 | Chapter 5 Generate Reports

■ Safety factor

■ Frequency response results

Appendices

Appendices include labeled scenario figures, which show the contours for the

different results sets. The sets include equivalent stress, maximum and

minimum principal stresses, deformation, safety factor, and mode shapes

Saving and Distributing Reports

The report is generated as a set of files to view in a Web browser. It includes

the main HTML page, style sheets, generated figures, and other files listed at

the end of the report.

Saving Reports

Use your browser Save As command to save all of the report files into a folder

of your choosing. Recent versions of Microsoft Internet Explorer® give you

the option of opening and saving your report in Microsoft® Word.

Be careful when you save a report into a folder where you previously saved a

copy of the same report. It is possible to end up with files in the directory that

were used by the previous version of the report, but are not used by the current

version. To avoid confusion, it is best to use a new folder for each version of

a report, or to delete all of the files in a folder before reusing it.

Printing Reports

Use your Web browser Print command to print the report as you would any

Web page.

Appendices | 37

Distributing Reports

To make the report available from a Web site, move all the files associated

with the report to your Web site. Distribute a URL that points to the main

page of the report, the first file listed in the table.

38 | Chapter 5 Generate Reports

Manage Stress Analysis Files

Running a stress analysis in Autodesk® Inventor™ Simulation creates a separate file that

contains the stress analysis information. In addition, the part file is modified to indicate the

presence of a stress file and the name of the file.

This chapter explains how the files are interdependent, and what to do if the files become

separated.

6

Creating and Using Analysis Files

You can run a stress analysis by creating a part in Autodesk Inventor Simulation,

and then setting up your stress analysis conditions. You can also load a part

that you previously created, on which you have not yet run a stress analysis,

and set up your analysis conditions. Once you set up a stress analysis for a part,

when you save the part you also save the stress analysis information for that

part.

Start a new analysis

1 Load an existing part or create a part in the part or sheet metal

environments.

2 Enter the stress analysis environment by clicking Applications ➤ Stress

Analysis.

3 Set up your analysis conditions.

After you set up any stress analysis information, saving your part also saves the

associated stress analysis information in the part file. Stress analysis input and

results information, including loads, constraints, and all results, is also saved

39

in a separate file. The stress analysis file has the same name as your part file,

but uses the extension .ipa. By default, the .ipa file is stored in the same folder

as the .ipt file.

The _structure.rst (for stress analysis) and the _modal.rst (for modal analysis)

files, used to export to ANSYS, are generated after you save. If you select both,

the _strucure.esave and _structure.db files, used to export to ANSYS, are also

generated and stored in a subfolder like the .ipt file.

Understanding File Relationships

Activating the stress analysis environment, and then saving the .ipt file does

not create the analysis files. Add at least one stress analysis update before

Autodesk Inventor Simulation creates the .ipa file.

The analysis files contain information that indicates which .ipt file is associated

with the .ipa file. Multiple .ipt files cannot reference the same .ipa file, and

multiple .ipa files cannot reference the same .ipt file.

The Save Copy As command does not generate a new .ipa file. This means

that the new .ipt file references the same .ipa file as the old .ipt file.

On the Stress Analysis Setting dialog box, use the Create OLE Link to Result

Files option to keep the relationship between the analysis files except for the

.ipa and .ipt files. If the option is checked, the files are necessary to open the

.ipt file.

For more information about the Save Copy As command, see Copying

Geometry Files on page 41 in this chapter.

NOTE An existing .ipa file is not loaded until you activate the stress analysis

environment.

Repairing Disassociated Files

Under certain circumstances, edit the part file without the presence of the .ipa

file. For example, you sent the .ipt file but not the .ipa file to a consultant.

You can edit the part file through the Skip option on the Resolve Link dialog

box.

If you edit the part while the .ipa file is missing, and then try to reassociate

the part with its analysis file, Inventor makes an attempt to update the stress

40 | Chapter 6 Manage Stress Analysis Files

conditions. There is a possibility that errors can occur when you try to

reassociate the files.

Copying Geometry Files

You can create a copy of an .ipt file using the Save Copy As command or your

operating system file copy command. The copy of the .ipt file still references

the original .ipa file.

Resolving File Link Failures

In some cases, the .ipa file might fail to resolve when you try to perform an

analysis of the part. For example, you rename or move the .ipa file, or a vendor

receives a copy of an .ipt file without the associated .ipa file. The .ipa file fails

to resolve and you are prompted with the Resolve Link dialog box.

You can do two things, other than cancel the file open process:

■ Skip the file.

■ Select an existing .ipa file.

Skipping Missing IPA Files

If you select to edit a part even though the .ipa file is missing, you can enter

the stress analysis environment. Create an .ipa file by rerunning the stress

analysis update and saving. You can edit the part document itself. However,

you cannot perform any stress analysis work.

Selecting Existing IPA Files

If the .ipa file is missing, you can select an existing renamed or moved .ipa

file.

Copying Geometry Files | 41

Creating New Analysis Files

To create an .ipa file, click the Stress Analysis Update button on the standard

toolbar and save it. Inventor attempts to create an .ipa file in the default

location using the default name.

If a file exists using this name and location, Inventor checks the .ipa file to

see if it points to the active .ipt file. If it does, the new .ipa file replaces the old

one.

When you create a file, the new .ipa file has boundary conditions that match

the conditions stored in the .ipt file.

Exporting Analysis Files

To run a more complex analysis on your part than Autodesk Inventor

Simulation Stress Analysis can handle, export your current analysis information

to a file that ANSYS WorkBench can import.

Export your information to ANSYS WorkBench

1 After you set up and run an analysis, on the Stress Analysis panel bar,

click Export to ANSYS.

2 Browse to the location where you store your project files.

3 Click Save.

The file is saved using the same name as your part file, with the extension

.dsdb.

You can now import your part and its analysis file into ANSYS WorkBench to

perform more complex analyses.

42 | Chapter 6 Manage Stress Analysis Files

Simulation

Part 2 of this manual presents the getting started information for Autodesk® Inventor

Simulation. This application environment provides tools to predict dynamic performance

and peak stresses before building prototypes.

™

43

44

Get Started with Simulation

About Autodesk Inventor Simulation

Autodesk®Inventor™ Simulation provides tools to simulate and analyze the

dynamic characteristics of an assembly in motion under various load conditions.

You can also export load conditions at any motion state to Stress Analysis in

Autodesk Inventor Simulation to see how parts respond from a structural point

of view to dynamic loads at any point in the range of motion of the assembly.

The dynamic simulation environment works only with Autodesk® Inventor

assembly (.iam) files.

With the dynamic simulation, you can:

■ Have the software automatically convert all mate and insert constraints into

standard joints.

7

™

■ Access a large library of motion joints.

■ Define external forces and moments.

■ Create motion simulations based on position, velocity, acceleration, and

torque as functions of time in joints, in addition to external loads.

■ Visualize 3D motion using traces.

■ Export full output graphing and charts to Microsoft

■ Transfer dynamic and static joints and inertial forces to Autodesk Inventor

Simulation Stress Analysis or ANSYS Workbench.

®

Excel®.

45

■ Calculate the force required to keep a dynamic simulation in static

equilibrium.

■ Convert assembly constraints to motion joints.

■ Use friction, damping, stiffness, and elasticity as functions of time when

defining joints.

■ Use dynamic part motion interactively to apply dynamic force to the

jointed simulation.

■ Use Inventor Studio to output realistic or illustrative video of your

simulation.

Learning Autodesk Inventor Simulation

We assume that you have a working knowledge of the Autodesk Inventor

Simulation interface and tools. If you do not, use the integrated Help for access

to online documentation and tutorials, and complete the exercises in this

manual.

At a minimum, we recommend that you understand how to:

■ Use the assembly, part modeling, and sketch environments and browsers.

■ Edit a component in place.

We also recommend that you have a working knowledge of Microsoft

Windows® XP or Windows® Vista™, and a working knowledge of concepts

for stressing and analyzing mechanical assembly designs.

Using Help

As you work, you may need additional information about the task you are

performing. The Help system provides detailed concepts, procedures, and

reference information about every feature in the Autodesk Inventor Simulation

Simulation modules as well as the standard Autodesk Inventor Simulation

features.

To access Help, use one of the following methods:

■ Click Help ➤ Help Topics. On the Contents tab, click Dynamic Simulation.

46 | Chapter 7 Get Started with Simulation

®

■ In any dialog box, click the ? icon.

Understanding Simulation Tools

Large and complex moving assemblies coupled with hundreds of articulated

moving parts can be simulated. Autodesk Inventor Simulation Simulation

provides:

■ Interactive, simultaneous, and associative visualization of 3D animations

with trajectories; velocity, acceleration, and force vectors; and deformable

springs.

■ Graphic generation tool for representing and post-processing the simulation

output data.

Simulation Assumptions

The dynamic simulation tools provided in Autodesk Inventor Simulation help

in the steps of conception and development and in reducing the number of

prototypes. However, due to the hypothesis used in the simulation, it only

provides an approximation of the behavior seen in real-life mechanisms.

Interpreting Simulation Results

To avoid computations that can lead to a misinterpretation of the results or

incomplete models that cause unusual behavior, or even make the simulation

impossible to compute, be aware of the rules that apply to:

■ Relative parameters

■ Continuity of laws

■ Coherent masses and inertia

Relative Parameters

Autodesk Inventor Simulation Simulation uses relative parameters. For example,

the position variables, velocity, and acceleration give a direct description of

Understanding Simulation Tools | 47

the motion of a child part according to a parent part through the degree of

freedom (DOF) of the joint that links them. As a result, select the initial velocity

of a degree of freedom carefully.

Coherent Masses and Inertia

Ensure that the mechanism is well-conditioned. For example, the mass and

inertia of the mechanism should be in the same order of magnitude. The most

common error is a bad definition of density or volume of the CAD parts.

Continuity of Laws

Numerical computing is sensitive toward incontinuities in imposed laws. Thus,

while a velocity law defines a series of linear ramps, the acceleration is

necessarily discontinuous. Similarly, when using contact joints, it is better to

avoid profiles or outlines with straight edges.

NOTE Using little fillets eases the computation by breaking the edge.

48 | Chapter 7 Get Started with Simulation

Simulate Motion

8

With the dynamic simulation or the assembly environment, the intent is to build a functional

mechanism. Dynamic simulation adds to that functional mechanism the dynamic, real-world

influences of various kinds of loads to create a true kinematic chain.

Understanding Degrees of Freedom

Though both have to do with creating mechanisms, there are some critical

differences between the dynamic simulation and the assembly environment.

The most basic and important difference has to do with degrees of freedom.

By default, components in Autodesk® Inventor™ Simulation have zero degrees

of freedom. Unconstrained and ungrounded components in the assembly

environment have six degrees of freedom.

In the assembly environment, you add constraints to restrict degrees of freedom.

In the dynamic simulation environment, you build joints to create degrees of

freedom.

Understanding Constraints

By default, any constraints that exist in the assembly have no effect on dynamic

simulation.

Open sample files

1 Set your active project to tutorial_files and then open Gate.iam.

2 Save a copy of this assembly. Name the copy Gate-saved.iam. Close Gate.iam

and then open Gate-saved.iam.

49

3 To see how the assembly moves, drag the door.

As you work through the following exercises, save this assembly

periodically.

Converting Assembly Constraints

Notice that the assembly moves just as it did in the assembly environment.

It seems to contradict preceding explanations, however, the motion you see

is borrowed from the assembly environment. Even though you are in Autodesk

Inventor Simulation Simulation, you are not yet running a simulation. Since

a simulation is not active, the assembly is free to move.

Enter the dynamic simulation environment

1 Click Applications ➤ Dynamic Simulation.

The dynamic simulation environment is active.

NOTE If the open assembly was created in Autodesk Inventor Simulation

2008 or later, Automatically Convert Constraint to Standard Joints is selected

in Dynamic Simulation settings by default. Since this assembly was first created

in a previous version of Inventor and saved in Dynamic Simulation,

Automatically Convert Constraints to Standard Joints is unselected by default.

Although this function is powerful and useful, it is not selected currently for

training purposes.

2 At the bottom of the browser, click the Run button on the

Simulation panel.

50 | Chapter 8 Simulate Motion

The Dynamic Simulation browser turns gray and the status slider on the

simulation panel moves, indicating that a simulation is running.

Since we have not created any joints (and have not specified any driving

forces) the assembly is grounded and does not move.

3 If the status slider is still moving, click the Stop button.

Even though the simulation is not running, the simulation mode is still

active.

4 Attempt to drag the Door component. It does not move.

5 On the Dynamic Simulation panel bar, click Activate Construction

Mode at the bottom of the browser.

It exits the simulation mode and returns to the Dynamic Simulation

construction mode. In construction mode, you perform such tasks as

creating joints and applying loads.

Automatically convert assembly constraints

1 On the Dynamic Simulation panel bar, click Dynamic Simulation Settings.

This dialog box now has the Automatically Convert Constraints to

Standard Joints option, which automatically translates certain assembly

constraints to standard joints.

When you open an assembly created in Autodesk Inventor Simulation

2009, Automatically Convert Constraints to Standard Joints is selected

by default. However, since this assembly was created in an earlier version

of Inventor, the default is not selected.

2 On the Dynamic Simulation Settings dialog box, click Automatically

Convert Constraints to Standard Joints.

3 Click Apply.

One welded group and five standard joints are created.

4 In the Dynamic Simulation browser, navigate to the Mobile Groups folder,

and then open the Welded group folder. Notice the two parts that the

software has welded as one step of translating assembly constraints.

5 In the Standard Joints folder, notice the standard joints that the software

has automatically created for you.

Converting Assembly Constraints | 51

6 On the Dynamic Simulation Settings dialog box, remove the check mark

next to Automatically Convert Constraints to Standard Joints.

NOTE Selecting this option deletes all joints already in the assembly.

7 Click OK.

Convert constraints

1 On the Dynamic Simulation panel bar, click Convert Assembly

Constraints.

NOTE Autodesk Inventor Simulation Simulation converts constraints that

have to do with degrees of freedom, such as Mate or Insert, but does not

convert constraints that have to do with position, such as Angle.

2 Select the Door component (3).

3 Select the Pillar component (4).

Assembly constraints that exist between the two parts are listed on the

dialog box. In this case, there are two mate constraints: an axial constraint

between the hinge axes and a face-to-face constraint between the hinge

top and bottom flat faces.

52 | Chapter 8 Simulate Motion

Axial constraint between the hinge axes

Face-to-face constraint between hinge top and bottom flat faces

4 Select the check box next to Mate1: (door:1, pillar:1). It is the axial

constraint.

Converting Assembly Constraints | 53

Notice that the joint type (Cylindrical) is listed in the Joint field and the

animation switches to the Cylindrical Joint animation. Autodesk Inventor

Simulation Simulation automatically selects the appropriate joint needed

for the constraint conversion.

5 Remove the check mark next to Mate:1 (door:1, pillar:1), and then select

the check box next to Mate2: (door:1, pillar:1) (the face-to-face constraint).

Taken by itself, the face-to-face constraint converts to a planar joint.

6 Select the check box next to Mate1: (door:1, pillar:1).

7 Ensure the check boxes for both constraints are selected.

When taken together, Autodesk Inventor Simulation Simulation infers

that the two constraint types convert to a revolution joint. Taken together,

the two mate constraints function like an insert constraint which

functions like a revolution joint.

8 On the Convert Assembly Constraints dialog box, click OK.

Notice that the new joint was added to the browser under the Standard

Joints node. In addition, the Mobile Groups node appears and the door

component is moved from the Grounded group to the Mobile group.

Defining Forces

To test these joints and see a rudimentary simulation, define the first force.

Define gravity

1 In the browser, right-click Gravity (under External Loads), and then select

Define Gravity.

TIP Alternately, you can double-click the Gravity node.

2 On the Gravity dialog box, deselect Suppress.

3 Ensure Entity is checked.

4 Select the Entity Selection arrow to select the part edge to set a vector for

gravity.

54 | Chapter 8 Simulate Motion

5 Click OK.

6 Drag and position the door approximately, as shown.

Defining Forces | 55

Creating Simulations

The Simulation Panel contains many fields including:

1 Final Time

2 Images

3 Filter

4 Simulation Time

5 Percent of Realized Simulation

6 Real Time of Computation

Simulation Panel

Images field

Filter field

Simulation Time Value

Real Time of Computation value

56 | Chapter 8 Simulate Motion

Controls the total time available for simulation.Final Time field

Controls the number of image frames available for a

simulation.

Controls the frame display step. If the value is set to

1, all frames play. If the value is set to 5, every fifth

frame displays, and so on. This field is editable when

simulation mode is active, but a simulation is not

running.

Shows the duration of the motion of the mechanism

as would be witnessed with the physical model.

Shows the percentage complete of a simulation.Percent value

Shows the actual time it takes to run the simulation.

It is affected by the complexity of the model and the

resources of your computer.

TIP You can click the Screen Refresh button to turn off screen refresh during the

simulation. The simulation runs, but there is no graphic representation.

Before you run the simulation, increase the simulation Final Time value.

Run a simulation

1 On the Simulation Panel, in the Final Time field, enter 10 s.

2 Click Run on the Simulation Panel.

The Door component moves, with acceleration and deceleration in

response to the force of gravity and the inertia of the part.

NOTE The direction of gravity has nothing to do with any external notion