Autodesk Inventor Routed Systems 2009

Getting Started

January 2008Part No. 462A1-050000-PM01A

©

2008 Autodesk, Inc. All Rights Reserved. Except as otherwise permitted by Autodesk, Inc., this publication, or parts thereof, may not be

reproduced in any form, by any method, for any purpose.

Certain materials included in this publication are reprinted with the permission of the copyright holder.

Trademarks

The following are registered trademarks or trademarks of Autodesk, Inc., in the USA and other countries: 3DEC (design/logo), 3December,

3December.com, 3ds Max, ActiveShapes, Actrix, ADI, Alias, Alias (swirl design/logo), AliasStudio, Alias|Wavefront (design/logo), ATC, AUGI,

AutoCAD, AutoCAD Learning Assistance, AutoCAD LT, AutoCAD Simulator, AutoCAD SQL Extension, AutoCAD SQL Interface, Autodesk, Autodesk

Envision, Autodesk Insight, Autodesk Intent, Autodesk Inventor, Autodesk Map, Autodesk MapGuide, Autodesk Streamline, AutoLISP, AutoSnap,

AutoSketch, AutoTrack, Backdraft, Built with ObjectARX (logo), Burn, Buzzsaw, CAiCE, Can You Imagine, Character Studio, Cinestream, Civil

3D, Cleaner, Cleaner Central, ClearScale, Colour Warper, Combustion, Communication Specification, Constructware, Content Explorer,

Create>what's>Next> (design/logo), Dancing Baby (image), DesignCenter, Design Doctor, Designer's Toolkit, DesignKids, DesignProf, DesignServer,

DesignStudio, Design|Studio (design/logo), Design Your World, Design Your World (design/logo), DWF, DWG, DWG (logo), DWG TrueConvert,

DWG TrueView, DXF, EditDV, Education by Design, Exposure, Extending the Design Team, FBX, Filmbox, FMDesktop, Freewheel, GDX Driver,

Gmax, Heads-up Design, Heidi, HOOPS, HumanIK, i-drop, iMOUT, Incinerator, IntroDV, Inventor, Inventor LT, Kaydara, Kaydara (design/logo),

LocationLogic, Lustre, Maya, Mechanical Desktop, MotionBuilder, Mudbox, NavisWorks, ObjectARX, ObjectDBX, Open Reality, Opticore,

Opticore Opus, PolarSnap, PortfolioWall, Powered with Autodesk Technology, Productstream, ProjectPoint, ProMaterials, Reactor, RealDWG,

Real-time Roto, Recognize, Render Queue, Reveal, Revit, Showcase, ShowMotion, SketchBook, SteeringWheels, StudioTools, Topobase, Toxik,

ViewCube, Visual, Visual Bridge, Visual Construction, Visual Drainage, Visual Hydro, Visual Landscape, Visual Roads, Visual Survey, Visual Syllabus,

Visual Toolbox, Visual Tugboat, Visual LISP, Voice Reality, Volo, Wiretap, and WiretapCentral

The following are registered trademarks or trademarks of Autodesk Canada Co. in the USA and/or Canada and other countries: Backburner,

Discreet, Fire, Flame, Flint, Frost, Inferno, Multi-Master Editing, River, Smoke, Sparks, Stone, and Wire

All other brand names, product names or trademarks belong to their respective holders.

Disclaimer

THIS PUBLICATION AND THE INFORMATION CONTAINED HEREIN IS MADE AVAILABLE BY AUTODESK, INC. "AS IS." AUTODESK, INC. DISCLAIMS

ALL WARRANTIES, EITHER EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE REGARDING THESE MATERIALS.

Published by:

Autodesk, Inc.

111 Mclnnis Parkway

San Rafael, CA 94903, USA

Contents

Tubes and Pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Chapter 1 Getting Started with Tube & Pipe . . . . . . . . . . . . . . . . . 3

About Tube & Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Tube & Pipe Features . . . . . . . . . . . . . . . . . . . . . . . . . 3

Tube & Pipe Environment . . . . . . . . . . . . . . . . . . . . . . 4

Tube & Pipe Browser . . . . . . . . . . . . . . . . . . . . . . . . . 6

Working in Autodesk Inventor Installations . . . . . . . . . . . . . . . . 7

Understanding Prerequisites . . . . . . . . . . . . . . . . . . . . . . . . 8

Backing Up Tutorial Data Files . . . . . . . . . . . . . . . . . . . . . . . 8

Workflow for Tube and Pipe Assemblies . . . . . . . . . . . . . . . . . . 9

Setting Up Projects For Exercises . . . . . . . . . . . . . . . . . . . . . 10

Defining the Master Runs Assembly . . . . . . . . . . . . . . . . . . . 11

Create Master Runs Assemblies . . . . . . . . . . . . . . . . . . . 11

Add Individual Runs . . . . . . . . . . . . . . . . . . . . . . . . 15

Specify Global Settings . . . . . . . . . . . . . . . . . . . . . . . 15

Chapter 2 Route Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

About Rigid Routes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Auto Route Cycling . . . . . . . . . . . . . . . . . . . . . . . . . 20

Parametric Regions . . . . . . . . . . . . . . . . . . . . . . . . . 21

About Flexible Hose Routes . . . . . . . . . . . . . . . . . . . . . . . . 21

Route Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

iii

Rigid Route Points . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Hose Route Points . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3D Orthogonal Route Tool . . . . . . . . . . . . . . . . . . . . . . . . 23

Tool Elements for Pipe Routing . . . . . . . . . . . . . . . . . . . 23

Tool Elements for Tube Routing . . . . . . . . . . . . . . . . . . 24

Change Tool Displays . . . . . . . . . . . . . . . . . . . . . . . . 25

Define Angular Position and Rotation Snap . . . . . . . . . . . . 25

Define 45-degree Angles . . . . . . . . . . . . . . . . . . . . . . . 26

Define Bent Tubes Angles . . . . . . . . . . . . . . . . . . . . . . 27

Using Point Snap to Define Points . . . . . . . . . . . . . . . . . 28

Enter Precise Values . . . . . . . . . . . . . . . . . . . . . . . . . 29

Route Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Basic Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Bend Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Dimension Tools . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Parallel and Perpendicular Tools . . . . . . . . . . . . . . . . . . 34

Other Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Chapter 3 Setting Styles . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

About Tube and Pipe Styles . . . . . . . . . . . . . . . . . . . . . . . . 35

Access Tube and Pipe Styles . . . . . . . . . . . . . . . . . . . . . . . . 36

View and Select Styles . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Setting Style Options . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

General Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Rules Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Working with Styles . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Create Rigid Pipe with Fittings Styles . . . . . . . . . . . . . . . . 43

Tubing with Bends Style . . . . . . . . . . . . . . . . . . . . . . 45

Flexible Hose Styles . . . . . . . . . . . . . . . . . . . . . . . . . 45

Create Flexible Hose Styles . . . . . . . . . . . . . . . . . . . . . 46

Change Styles for Existing Routes . . . . . . . . . . . . . . . . . 47

Change Active Styles for New Routes . . . . . . . . . . . . . . . . 48

Adding Styles to Assembly Templates . . . . . . . . . . . . . . . . . . . 48

Chapter 4 Creating Rigid Routes and Runs . . . . . . . . . . . . . . . . . 51

General Workflow for Rigid Routes . . . . . . . . . . . . . . . . . . . . 51

Creating Auto Route Regions . . . . . . . . . . . . . . . . . . . . . . . 53

Manually Creating Parametric Regions . . . . . . . . . . . . . . . . . . 56

Automatically Dimension Route Sketches . . . . . . . . . . . . . 57

Create Segments With Precise Values . . . . . . . . . . . . . . . . 58

Define Parallel and Perpendicular Segments . . . . . . . . . . . . 59

Snap Route Points to Existing Geometry . . . . . . . . . . . . . . 63

Place Constraints On Route Sketches . . . . . . . . . . . . . . . . 65

Create Bends Between Existing Pipe Segments . . . . . . . . . . . 68

Create Pipe Routes With Custom Bends . . . . . . . . . . . . . . 69

iv | Contents

Create Bent Tube Routes . . . . . . . . . . . . . . . . . . . . . . 76

Realign 3D Orthogonal Route Tool . . . . . . . . . . . . . . . . . 80

Control Dimension Visibility . . . . . . . . . . . . . . . . . . . . 85

Populated Routes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Chapter 5 Creating and Editing Flexible Hose Routes . . . . . . . . . . . . 89

Workflow for Flexible Hose Routes . . . . . . . . . . . . . . . . . . . . 89

Creating Flexible Hose Routes . . . . . . . . . . . . . . . . . . . . . . . 90

Create Hose Routes with Both Fittings . . . . . . . . . . . . . . . 91

Change Nominal Diameters . . . . . . . . . . . . . . . . . . . . 94

Create Hose Routes With One Fitting . . . . . . . . . . . . . . . . 95

Editing Flexible Hose Routes . . . . . . . . . . . . . . . . . . . . . . . 99

Hose Nodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Hose Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Start Fitting and End Fitting . . . . . . . . . . . . . . . . . . . . 103

Bend Radius Check . . . . . . . . . . . . . . . . . . . . . . . . . 104

Delete Flexible Hose Routes . . . . . . . . . . . . . . . . . . . . . . . 105

Practice Your Skills . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Chapter 6 Editing Rigid Routes and Runs . . . . . . . . . . . . . . . . . . 109

About Editing Rigid Routes and Runs . . . . . . . . . . . . . . . . . . 109

Auto Regions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Parametric Regions . . . . . . . . . . . . . . . . . . . . . . . . . 110

Editing Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Route Panel Bar . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Tube & Pipe Panel Bar . . . . . . . . . . . . . . . . . . . . . . . 111

Context Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Controlling Individual Settings . . . . . . . . . . . . . . . . . . . . . 115

Route Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Add to Finished Routes . . . . . . . . . . . . . . . . . . . . . . 116

Insert Intermediate Route Points . . . . . . . . . . . . . . . . . 117

Delete Route Points . . . . . . . . . . . . . . . . . . . . . . . . 118

Auto Regions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Move Auto Route Segments Approximately . . . . . . . . . . . . 119

Move Auto Route Segments Accurately . . . . . . . . . . . . . . 121

Removing Unwanted Segments or Route Points . . . . . . . . . 122

Convert Auto Region to Parametric Sketch . . . . . . . . . . . . 123

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Place Fittings in the Active Project Workspace . . . . . . . . . . 129

Insert Library Parts Using AutoDrop . . . . . . . . . . . . . . . . 130

Adjust Fitting Position and Orientation . . . . . . . . . . . . . . 132

Restore Default Fittings . . . . . . . . . . . . . . . . . . . . . . 133

Replace Existing Fittings . . . . . . . . . . . . . . . . . . . . . . 134

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Contents | v

Delete Fitting Connections . . . . . . . . . . . . . . . . . . . . 136

Connect Fittings and Components . . . . . . . . . . . . . . . . 138

Editing Bent Tube Routes . . . . . . . . . . . . . . . . . . . . . . . . 142

Changing Bend Radius . . . . . . . . . . . . . . . . . . . . . . . 143

Moving Coupling Nodes . . . . . . . . . . . . . . . . . . . . . . 144

Deleting Routes and Runs . . . . . . . . . . . . . . . . . . . . . . . . 144

Chapter 7 Using Content Center Libraries . . . . . . . . . . . . . . . . . 147

About Content Center . . . . . . . . . . . . . . . . . . . . . . . . . . 147

About Content Center Libraries . . . . . . . . . . . . . . . . . . . . . 148

Managing and Libraries . . . . . . . . . . . . . . . . . . . . . . . . . 149

Configuring Libraries . . . . . . . . . . . . . . . . . . . . . . . 150

Placing Tube and Pipe Parts . . . . . . . . . . . . . . . . . . . . . . . 152

Chapter 8 Authoring and Publishing . . . . . . . . . . . . . . . . . . . . 153

About Authoring and Publishing . . . . . . . . . . . . . . . . . . . . 153

Authoring Tube and Pipe Parts . . . . . . . . . . . . . . . . . . . . . 153

Access Tube & Pipe Authoring Tool . . . . . . . . . . . . . . . . 154

Author Parameters . . . . . . . . . . . . . . . . . . . . . . . . . 155

Prepare iParts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Author iParts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Practice Your Skills . . . . . . . . . . . . . . . . . . . . . . . . . 170

Publishing to Content Center . . . . . . . . . . . . . . . . . . . . . . 171

Set Up the Library and Subcategories . . . . . . . . . . . . . . . 172

Publish Authored Parts . . . . . . . . . . . . . . . . . . . . . . 173

Creating Styles Using Published Parts . . . . . . . . . . . . . . . . . . 178

Chapter 9 Documenting Routes and Runs . . . . . . . . . . . . . . . . . 181

About Documenting Routes and Runs . . . . . . . . . . . . . . . . . 181

General Workflow for Documenting Pipe Runs . . . . . . . . . . 182

Using Drawing Templates . . . . . . . . . . . . . . . . . . . . . . . . 183

Preparing Design View Representations . . . . . . . . . . . . . . . . . 183

Creating Drawing Views . . . . . . . . . . . . . . . . . . . . . . . . . 185

Create Base Views . . . . . . . . . . . . . . . . . . . . . . . . . 186

Create Projected Views . . . . . . . . . . . . . . . . . . . . . . . 188

Create Detail Views . . . . . . . . . . . . . . . . . . . . . . . . 189

Practice Your Skills . . . . . . . . . . . . . . . . . . . . . . . . . 193

Recovering Route Centerlines . . . . . . . . . . . . . . . . . . . . . . 193

Dimensioning Drawing Views . . . . . . . . . . . . . . . . . . . . . . 194

Creating and Exporting Bills of Material . . . . . . . . . . . . . . . . 196

Enable the Parts Only View . . . . . . . . . . . . . . . . . . . . 197

Add Base QTY and Stock Number . . . . . . . . . . . . . . . . . 198

Create and Export Bill of Materials . . . . . . . . . . . . . . . . 199

Creating Parts Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

vi | Contents

Annotating Drawings with Piping Styles . . . . . . . . . . . . . . . . 202

Cable and Harness . . . . . . . . . . . . . . . . . . . . . . . . 205

Chapter 10 Getting Started with Cable and Harness . . . . . . . . . . . . 207

About Cable and Harness . . . . . . . . . . . . . . . . . . . . . . . . 207

Understanding Prerequisites . . . . . . . . . . . . . . . . . . . . 207

Backing Up Tutorial Data Files . . . . . . . . . . . . . . . . . . . . . . 208

Setting Up Projects For Exercises . . . . . . . . . . . . . . . . . . . . . 209

Working in Autodesk Inventor Installations . . . . . . . . . . . . . . 209

About Electrical Parts . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Workflow for Electrical Parts . . . . . . . . . . . . . . . . . . . . 210

Creating Electrical Parts . . . . . . . . . . . . . . . . . . . . . . . . . 211

Place Pins and Define Pin-level Properties . . . . . . . . . . . . 211

Set Part Properties . . . . . . . . . . . . . . . . . . . . . . . . . 217

Add RefDes Placeholders . . . . . . . . . . . . . . . . . . . . . . 217

Practice Your Skills . . . . . . . . . . . . . . . . . . . . . . . . . 218

Modifying Pinned Parts . . . . . . . . . . . . . . . . . . . . . . . . . 219

Delete Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Adding Custom Properties to Parts . . . . . . . . . . . . . . . . . . . 220

Placing Electrical Parts . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Chapter 11 Working With Harness Assemblies . . . . . . . . . . . . . . . 223

About Working in Harness Assemblies . . . . . . . . . . . . . . . . . 223

Cable and Harness Environment . . . . . . . . . . . . . . . . . 224

Creating Harness Assemblies . . . . . . . . . . . . . . . . . . . . . . . 225

Workflow for Harness Components . . . . . . . . . . . . . . . . 225

Using the Cable and Harness Browser . . . . . . . . . . . . . . . . . . 228

Setting Properties for Harness Components . . . . . . . . . . . . . . . 229

Customize Properties . . . . . . . . . . . . . . . . . . . . . . . 230

Set Occurrence Properties . . . . . . . . . . . . . . . . . . . . . 230

Assign Occurrence Reference Designators . . . . . . . . . . . . . 230

Chapter 12 Using the Cable and Harness Library . . . . . . . . . . . . . . 233

About the Cable and Harness Library . . . . . . . . . . . . . . . . . . 233

Locating the Cable and Harness Library File . . . . . . . . . . . 234

Displaying the Library Dialog Box . . . . . . . . . . . . . . . . . . . . 236

Adding Library Definitions . . . . . . . . . . . . . . . . . . . . . . . 238

Create New Library Definitions . . . . . . . . . . . . . . . . . . 238

Modifying Library Wire and Cable Definitions . . . . . . . . . . . . . 240

Copy Library Definitions . . . . . . . . . . . . . . . . . . . . . 240

Edit Library Definitions . . . . . . . . . . . . . . . . . . . . . . 240

Delete Library Definitions . . . . . . . . . . . . . . . . . . . . . 241

Add Properties to Library Definitions . . . . . . . . . . . . . . . 242

Contents | vii

Importing and Exporting Library Data . . . . . . . . . . . . . . . . . 243

Import Into the Cable and Harness Library . . . . . . . . . . . . 243

Export Library Data . . . . . . . . . . . . . . . . . . . . . . . . 245

Practicing Your Skills . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

Chapter 13 Working with Wires and Cables . . . . . . . . . . . . . . . . . 249

About Wires and Cables . . . . . . . . . . . . . . . . . . . . . . . . . 249

Setting Modeling and Curvature Behavior . . . . . . . . . . . . . . . 250

Inserting Wires and Cables Manually . . . . . . . . . . . . . . . . . . 251

Insert Wires Manually . . . . . . . . . . . . . . . . . . . . . . . 251

Insert Cables Manually . . . . . . . . . . . . . . . . . . . . . . 254

Moving Wires and Cables . . . . . . . . . . . . . . . . . . . . . . . . 256

Moving Wires . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Moving Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Deleting Wires and Cables . . . . . . . . . . . . . . . . . . . . . . . . 259

Deleting Wires . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Removing Cables and Cable Wires . . . . . . . . . . . . . . . . 259

Replacing Wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Assigning Virtual Parts . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Importing Harness Data . . . . . . . . . . . . . . . . . . . . . . . . . 262

Configuration File Formats . . . . . . . . . . . . . . . . . . . . 263

Comma Separated Value Data File Formats . . . . . . . . . . . . 264

XML File Formats . . . . . . . . . . . . . . . . . . . . . . . . . 265

Review Harness Data . . . . . . . . . . . . . . . . . . . . . . . . 265

Import Harness Data . . . . . . . . . . . . . . . . . . . . . . . . 266

Adding Shape to Wires and Cable Wires . . . . . . . . . . . . . . . . 268

Add Wire Points . . . . . . . . . . . . . . . . . . . . . . . . . . 268

Redefine and Move Wire Points . . . . . . . . . . . . . . . . . . 270

Delete Wire Work Points . . . . . . . . . . . . . . . . . . . . . . 271

Setting Occurrence Properties . . . . . . . . . . . . . . . . . . . . . . 271

Wire Occurrence Properties . . . . . . . . . . . . . . . . . . . . 272

Cable Occurrence Properties . . . . . . . . . . . . . . . . . . . . 273

Override Library-level Properties . . . . . . . . . . . . . . . . . 273

Restore Library-Level Properties . . . . . . . . . . . . . . . . . . 274

Changing Wire and Cable Displays . . . . . . . . . . . . . . . . . . . 274

Chapter 14 Working with Segments . . . . . . . . . . . . . . . . . . . . . 277

About Segments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Define Segments . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Selecting Work Points for Segments . . . . . . . . . . . . . . . . . . . 278

Plan Segment Start Points and Endpoints . . . . . . . . . . . . . 278

Apply Offset Distances . . . . . . . . . . . . . . . . . . . . . . . 279

Creating Segments . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Add Segment Branches . . . . . . . . . . . . . . . . . . . . . . 284

Manipulating Segments . . . . . . . . . . . . . . . . . . . . . . . . . 285

viii | Contents

Redefine or Move Segment Work Points . . . . . . . . . . . . . 285

Insert Segment Work Points . . . . . . . . . . . . . . . . . . . . 287

Delete Harness Segment Work Points . . . . . . . . . . . . . . . 288

Delete Harness Segments . . . . . . . . . . . . . . . . . . . . . 288

Setting Segment Properties . . . . . . . . . . . . . . . . . . . . . . . . 289

Setting Diameter Behavior in Segments . . . . . . . . . . . . . . . . . 290

Changing Displays of Segments . . . . . . . . . . . . . . . . . . . . . 291

Setting Segment Defaults . . . . . . . . . . . . . . . . . . . . . . . . 291

Chapter 15 Routing Wires and Cables . . . . . . . . . . . . . . . . . . . . 293

About Routing and Unrouting . . . . . . . . . . . . . . . . . . . . . . 293

Defining Manual Routes . . . . . . . . . . . . . . . . . . . . . . . . . 294

Defining Semi-automatic Routes . . . . . . . . . . . . . . . . . . . . 295

Route Wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

Defining Automatic Routes . . . . . . . . . . . . . . . . . . . . . . . 297

View Wire and Cable Paths . . . . . . . . . . . . . . . . . . . . 298

Unrouting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

Unroute Wires . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

Unroute Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

Unroute All Wires or Cables from All Segments . . . . . . . . . . 301

Practice Your Skills . . . . . . . . . . . . . . . . . . . . . . . . . 302

Chapter 16 Working with Splices . . . . . . . . . . . . . . . . . . . . . . . 303

About Splices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

Recommended Workflow . . . . . . . . . . . . . . . . . . . . . 303

Creating Splices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

Insert a Splice . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

Modifying Splices . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

Splice Wires or Add Wires to the Splice . . . . . . . . . . . . . . 306

Redefine the Splice . . . . . . . . . . . . . . . . . . . . . . . . 307

Splice Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

Access Properties for Splices and Splice Pins . . . . . . . . . . . 311

Control Length for Splices . . . . . . . . . . . . . . . . . . . . . 311

Delete Splices . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

Practice Your Skills . . . . . . . . . . . . . . . . . . . . . . . . . 312

Chapter 17 Working with Ribbon Cables . . . . . . . . . . . . . . . . . . 313

About Ribbon Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

Defining Raw Ribbon Cables . . . . . . . . . . . . . . . . . . . . . . 314

Placing Connectors from Content Center . . . . . . . . . . . . . . . . 315

Creating Ribbon Cables . . . . . . . . . . . . . . . . . . . . . . . . . 319

Adjust Ribbon Cable Orientation and Shape . . . . . . . . . . . 321

Chapter 18 Generating Reports . . . . . . . . . . . . . . . . . . . . . . . 327

Contents | ix

About Generating Reports . . . . . . . . . . . . . . . . . . . . . . . . 327

Workflow for Harness Reports . . . . . . . . . . . . . . . . . . . 327

Using the Report Generator Dialog Box . . . . . . . . . . . . . . . . . 328

Formatting Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . 329

Use Sample Configuration Files . . . . . . . . . . . . . . . . . . 329

Edit Configuration Files . . . . . . . . . . . . . . . . . . . . . . 331

Generating Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . 335

Create Part and Wire Bills of Material . . . . . . . . . . . . . . . 335

Create Wire Run List Reports . . . . . . . . . . . . . . . . . . . 336

Create Custom Reports . . . . . . . . . . . . . . . . . . . . . . 337

Chapter 19 Working Nailboards and Drawings . . . . . . . . . . . . . . . 341

About Nailboards and Drawings . . . . . . . . . . . . . . . . . . . . . 341

Nailboard Features . . . . . . . . . . . . . . . . . . . . . . . . . 342

Nailboard Environment . . . . . . . . . . . . . . . . . . . . . . . . . 342

The Nailboard Browser . . . . . . . . . . . . . . . . . . . . . . . 344

Creating a Nailboard . . . . . . . . . . . . . . . . . . . . . . . . . . 344

Set Display Behavior . . . . . . . . . . . . . . . . . . . . . . . . 345

Manipulating the Harness . . . . . . . . . . . . . . . . . . . . . . . . 346

Move the Harness . . . . . . . . . . . . . . . . . . . . . . . . . 346

Arrange the Harness Segments . . . . . . . . . . . . . . . . . . . 347

Arrange the Wire Stubs . . . . . . . . . . . . . . . . . . . . . . 348

Arrange the Label . . . . . . . . . . . . . . . . . . . . . . . . . 350

Changing Nailboard Displays . . . . . . . . . . . . . . . . . . . . . . 351

Change Segment and Wire Line Display . . . . . . . . . . . . . 351

Change Fan State and Display . . . . . . . . . . . . . . . . . . 352

Annotating the Nailboard Drawing . . . . . . . . . . . . . . . . . . . 354

Dimension the Nailboard . . . . . . . . . . . . . . . . . . . . . 354

Add Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . 355

Add Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 358

Placing Connector Views . . . . . . . . . . . . . . . . . . . . . . . . 359

Create an Assembly Drawing . . . . . . . . . . . . . . . . . . . . . . 361

Printing Nailboards and Drawings . . . . . . . . . . . . . . . . . . . . 362

Practice your skills . . . . . . . . . . . . . . . . . . . . . . . . . 363

IDF Translator . . . . . . . . . . . . . . . . . . . . . . . . . . 365

Chapter 20 Using the IDF Translator . . . . . . . . . . . . . . . . . . . . . 367

About the IDF Translator . . . . . . . . . . . . . . . . . . . . . . . . . 367

Exchanging Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 368

Understanding Import IDF Options . . . . . . . . . . . . . . . . . . . 370

General Information . . . . . . . . . . . . . . . . . . . . . . . . 370

Select document type to create . . . . . . . . . . . . . . . . . . 370

Select items to import . . . . . . . . . . . . . . . . . . . . . . . 371

x | Contents

Item color . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 371

Importing IDF Board Files . . . . . . . . . . . . . . . . . . . . . . . . 371

Using IDF Board Data . . . . . . . . . . . . . . . . . . . . . . . . . . 376

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 379

Contents | xi

xii

Tubes and Pipes

Part 1 of this manual presents the getting started information for Tube and Pipe in Autodesk

Inventor™ Routed Systems. This add-in to the Autodesk Inventor assembly environment

provides the capability to create complete tube and pipe systems in mechanical assembly

designs.

®

1

2

Getting Started with Tube & Pipe

This chapter provides basic information to help you get started using Tube & Pipe in Autodesk

Inventor™ Routed Systems and the exercises in this manual.

It also provides information about the tube and pipe environment, how to get started with

a tube and pipe assembly, and how to use tube and pipe data.

1

About Tube & Pipe

Tube & Pipe provides features for setting tube and pipe styles, adding runs and

routes to mechanical assemblies or product designs, adding initial fittings to

create route branches, and populating selected routes. When a tube and pipe

assembly is complete, the tube and pipe information can be represented in

drawings and presentations, and output to different data formats.

®

Tube & Pipe Features

With the tube and pipe tools you can:

■ Create tube and pipe assembly files.

■ Define, view, modify, copy, delete, and share tube and pipe styles that

conform to industry standards.

■ Create tube, pipe, or hose routes using automatic solutions the system

calculates based on the style criteria.

■ Create derived routes and edit the underlying base sketch.

3

■ Use sketched tools to create parametric regions in rigid piping and bent

tubing routes.

■ Utilize the existing geometry and drawn construction lines to navigate the

rigid piping and bent tubing routes.

■ Defer updates on automatic routing for the tube and pipe runs assembly,

pipe run, and individual routes.

■ Modify both routes and runs by placing dimensions and geometric

constraints.

■ Access and use the Content Center to place conduit parts and fittings in

tube and pipe assemblies. Fittings can be used to initiate route branches.

■ Author custom tube and pipe iParts and standard parts for publishing to

the Content Center Library.

■ Populate selected routes with library components.

■ Suppress memory-costly tube and pipe components in Level of Detail

representations, especially in large tube and pipe assemblies.

■ Place non-adaptive occurrences of master runs assemblies, runs, hose

assemblies, and routes and make them adaptive for reuse.

■ Swap in the needed master runs assembly member in the tube and pipe

interchangeability set when a tube and pipe iAssembly factory is created.

■ Recover the route centerlines in tube and pipe drawings.

■ Use the bill of materials to document routes and runs.

■ Move pipe runs rigidly and edit hose routes in positional representations.

■ Save tube and pipe data to ISOGEN .pcf files or ASCII bend tables.

■ Use the browser to edit tube and pipe runs and to change visibility for

routes, runs, and components.

Tube & Pipe Environment

Tube & Pipe provides the familiar Autodesk Inventor assembly environment

in addition to design tools for adding routes and runs.

When you open an assembly in Autodesk Inventor Tube & Pipe, a tool appears

on the Assembly panel bar for adding piping runs to your design. Once you

4 | Chapter 1 Getting Started with Tube & Pipe

add your first run, the tools specific to creating tube and pipe runs in an

assembly are displayed.

The following image shows the application window that is displayed once a

piping run is added to a new assembly file. Tube & Pipe-specific tools are added

to the standard toolbar, Model browser, and panel bars are enabled.

The features added by the Tube & Pipe environment include:

Tube & Pipe Runs

panel bar

Tube & Pipe panel

bar

Tube & Pipe Hose

panel bar

Tube & Pipe Route

panel bar

Browser toolbar

Model browser

The tool set for the master runs assembly environment.

Enables you to add new individual runs to the master

runs assembly, define tube and pipe styles, set Gravity,

and output the ISOGEN data.

Use the panel bar title to switch between the Tube &

Pipe Runs and Assembly panel bars.

The tool set for the master runs assembly environment.

Enables you to add new individual runs to the master

runs assembly, define tube and pipe styles, and output

the ISOGEN data.

Use the panel bar title to switch between the Tube &

Pipe, Tube & Pipe Runs, and Assembly panel bars.

The tool set for the hose assembly environment when

the flexible hosing style uses the subassembly structure

to contain the hose route. It does not provide Tube &

Pipe specific tools.

Use the panel bar title to switch between the Tube &

Pipe Hose, Tube & Pipe, Tube & Pipe Runs, and Assembly panel bars.

The tool set when the tube, pipe, or hose route environment is active. There are several ways to enter the

route environment, such as creating new routes in a

pipe run, double-clicking an existing route, and rightclicking a route and selecting Edit.

Enables switching between the Model browser, Content

Center Favorites, and Representations.

Contains the content of the tube and pipe assembly

in a hierarchy, along with the main Tube & Pipe Runs

subassembly. The main run acts as a container for all

routes and runs and the components created or placed

in the routed system.

Tube & Pipe Environment | 5

Standard toolbar

Part Features panel

bar

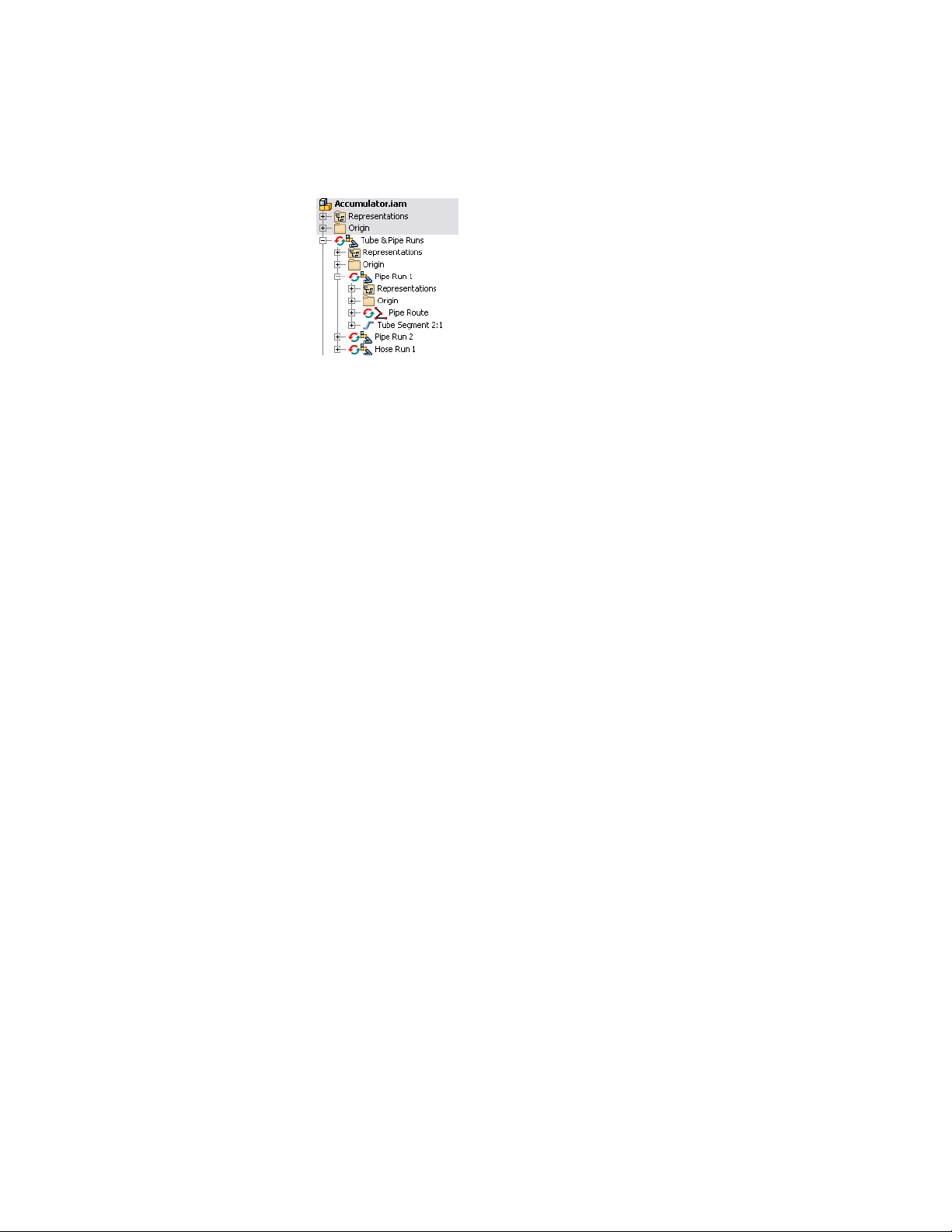

Tube & Pipe Browser

All tube and pipe components added to an assembly are contained in the

main runs subassembly. The components include individual runs and their

associated routes, fittings, segments, and route points.

Each run contains an Origin folder, one or more routes, and any segments or

fittings that are populated or manually inserted.

Routes contain the designated route points. To become familiar with the

various components in the browser, open a sample tube and pipe assembly.

Use the Tube & Pipe Browser

1 Open the sample tube and pipe assembly, Accumulator. By default, it is

located at: Windows®XP C:\Program

Files\Autodesk\Inventor<version>\Samples\Models\Tube & Pipe\Accumulator.

Windows®Vista

C:\Users\Public\Documents\Autodesk\Inventor<version>\Samples\Models\Tube

& Pipe\Cooling Tower

Contains several Tube & Pipe-specific tools in addition

to the standard Autodesk Inventor tools, such as the

Display/Update Settings tool and the Active Style list.

Use Tools ➤ Customize ➤ Toolbars to enable the

additional Tube & Pipe and Tube & Pipe Runs toolbar.

Contains the Tube & Pipe Authoring tool to author

tube and pipe iParts and normal parts for publishing

to the Content Center.

™

2 Activate and expand the master runs assembly Tube & Pipe Runs and

Pipe Run 1.

Pipe Run 1 contains components for a bent tubing style run.

6 | Chapter 1 Getting Started with Tube & Pipe

3 Expand Hose Run 1 to view components for a flexible hose style run.

4 Continue to expand folders in the hierarchy until you are familiar with

the contents, and then close the assembly.

5 To view components for a rigid pipe run, open the sample, Cooling Tower.

By default, it is located at: Windows XP C:\Program

Files\Autodesk\Inventor<version>\Samples\Models\Tube & Pipe\Cooling

Tower.

Windows Vista

C:\Users\Public\Documents\Autodesk\Inventor<version>\Samples\Models\Tube

& Pipe\Cooling Tower

6 Expand the folders in the hierarchy until you are familiar with the

contents, and then close the assembly.

Working in Autodesk Inventor Installations

If Autodesk Inventor Tube & Pipe is not installed on the system viewing the

tube and pipe data, the master runs assembly and all that it contains is

read-only. This means that the outline of the tube and pipe component is

visible through Autodesk Inventor, but the component cannot be edited, and

new tube and pipe components cannot be added.

When the Tube & Pipe add-in is not installed, the tasks you can perform with

the tube and pipe data include:

■ Open a Tube & Pipe Runs subassembly.

■ Determine interferences with tube and pipe components in populated

routes by selecting the entire tube and pipe runs subassembly in the

browser.

Working in Autodesk Inventor Installations | 7

■ View the outline of tube and pipe run data within the context of an open

assembly file.

■ Turn visibility off to completely hide the Tube & Pipe Runs component

in the graphics window.

■ Create detailed drawings of populated routes within any file.

Understanding Prerequisites

It is assumed that you have a working knowledge of the Autodesk Inventor

interface and tools. If you do not, use the integrated Design Support System

(DSS) for access to online documentation and tutorials, and complete the

exercises in the Autodesk Inventor Getting Started manual.

At a minimum, you should understand how to:

■ Use the assembly, part modeling, sketch, and drawing environments, and

browsers.

■ Edit a component in place.

■ Create, constrain, and manipulate work points and work features.

■ Set color styles.

■ Use Content Center.

Be more productive with Autodesk® software. Get trained at an Autodesk

Authorized Training Center (ATC®) with hands-on, instructor-led classes to

help you get the most from your Autodesk products. Enhance your productivity

with proven training from over 1,400 ATC sites in more than 75 countries.

For more information about training centers, contact atc.program@autodesk.com

or visit the online ATC locator at www.autodesk.com/atc.

It is also recommended that you have a working knowledge of Microsoft

Windows® XP, or Windows Vista™, and a working knowledge of concepts for

routing tube and pipe through mechanical assembly designs.

Backing Up Tutorial Data Files

For each exercise in this section, you use files that contain the example

geometry or parts for that task. These files are included in the Tutorial Files

8 | Chapter 1 Getting Started with Tube & Pipe

®

directory for the application. For Tube & Pipe, the files are located in the

installation path of Autodesk Inventor Tube & Pipe, by default, Windows XP

C:\Program Files\Autodesk\Inventor <version>\Tutorial Files\Tube & Pipe.

Windows Vista C:\Users\Public\Documents\ Autodesk\Inventor <version>\Tutorial

Files\Tube & Pipe.

Before you begin the exercises, back up the files so the originals are always

available. You can revert to these files if you make any mistakes during the

exercises, or if you would like to repeat an exercise.

Back up the tutorial files

1 Go to the Tube & Pipe directory and create a new folder called

Exercise_Backup.

2 From within the Tutorial Files directory, copy the exercise data into your

new folder.

Now you can use the files in the Tutorial Files directory as you work through

the exercises in this book. Keep any files you create for an exercise in the

Tutorial Files directory to avoid the possibility of file resolution problems.

Workflow for Tube and Pipe Assemblies

The first step in creating a tube and pipe system is to open an assembly file.

The assembly file can be empty or contain an assembly model. You can then

create the first pipe run and begin adding bent tubing, rigid piping, and flexible

hose routes.

Workflow: Create a tube and pipe runs assembly

1 Set up the project environment such as project type, workspace, and

permissions to the style library. Content Center configuration is also

especially important.

2 Optionally, customize your own master runs assembly template.

3 Within a normal Inventor assembly, create a master runs assembly.

4 Use the Tube & Pipe Styles tool to set style options.

5 Select a tube, pipe, or hose style, and then create a new route using

automatic solutions and parametric regions to guide your selections.

6 Adjust the route to design changes.

Workflow for Tube and Pipe Assemblies | 9

7 Populate the route or insert additional fittings into the tube and pipe

assembly or directly onto a route. Fittings can be used to initiate new

routes.

8 Add additional routes and runs.

9 Make final adjustments to each route and run. Change the active style

or add, remove, reposition, and replace fittings, route points, and

segments.

10 Populate selected route(s).

11 Optionally:

■ To reuse the master runs assembly, runs, routes, or flexible hose

assemblies, place secondary occurrences and use the Make Adaptive

tool to transition them to new primary occurrences.

■ Create Level of Detail representations to save memory if you are

working with a large assembly.

■ Create drawing views based on specific representations and

configurations, create and export bill of material tables for routes and

runs, and annotate drawings using parts lists, piping styles, and so

on.

■ Save the file in a different format such as ISOGEN or bend table to

import to other drawing applications.

Setting Up Projects For Exercises

For the exercises, browse to and select the project file in the Tutorial Files

directory.

Set up the project for Tube & Pipe exercises

1 Click File ➤ Projects.

2 Use the Configure Content Center Libraries tool to configure

libraries. Ensure that you have logged in to your Autodesk data

management server and the needed libraries are ready on the server.

3 Select the AirSystemAssy.ipj as the active project.

10 | Chapter 1 Getting Started with Tube & Pipe

4 Optionally, in the Edit Project pane, right-click Use Styles Library, and

then select Yes or Read Only.

5 Optionally, expand the Folder Options, right-click Content Center Files,

select Edit, and then enter CC.

The CC folder is under the root path of the project work space. You can

specify any other location you need to store the Content Center library

content. You can also use the default Content Center Files location.

6 When you have completed all settings for the project, click Save.

7 Ensure the project is active. If it is not, double-click the project.

8 Click Done.

NOTE For detailed instructions on how to manage and configure Content Center,

start Autodesk Inventor and click Help ➤ Help Topics. On the Inventor home

page, expand the Getting Started Manual link and select Managing Your Data.

Defining the Master Runs Assembly

When an assembly file is first opened, the assembly environment is displayed

and you can begin adding pipe runs. For the first pipe run added, the system

creates the master runs assembly along with an individual run. The master

runs assembly is a container for all pipe runs added to the assembly. The

number of runs you include depends on your design and manufacturing

documentation needs.

Each run can include one or more individual routes. All routes in a run can

use the same or different styles. With the capability to assign unique styles,

it is possible to have all three route types, each with different size diameters

in a single run. Routes can start and end on assembly model geometry or an

initial fitting dropped on the route to create a branch or fork.

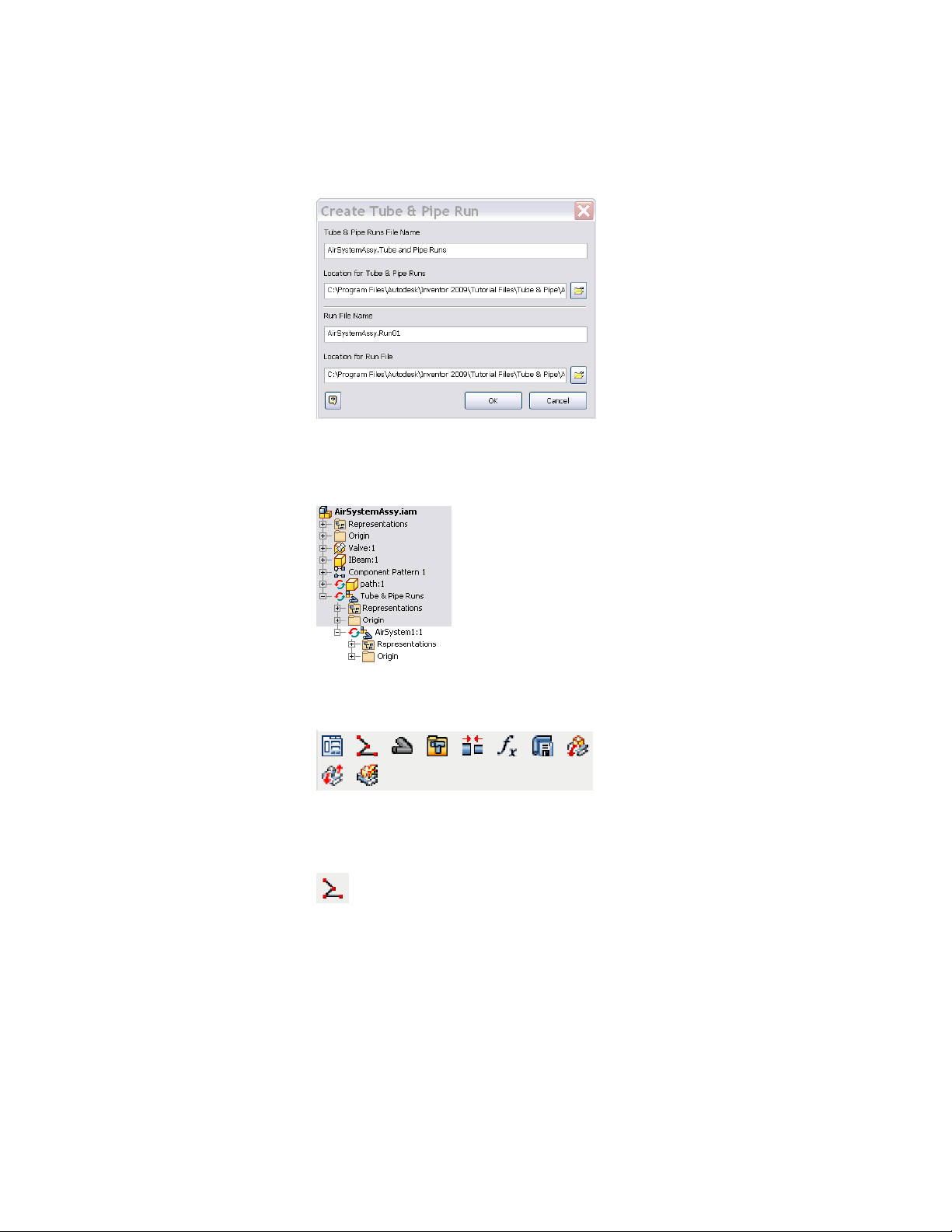

Create Master Runs Assemblies

To create the master runs assembly, you click the Create Pipe Run tool on the

Assembly panel bar. On the Create Tube & Pipe Run dialog box that appears

you provide a unique name and location for the master runs assembly and

individual run respectively. By default, the files are saved to the workspace of

the active project.

Defining the Master Runs Assembly | 11

The Tube & Pipe Runs assembly is added to the browser along with other

placed components and is arranged in the order it was added to the assembly.

In the following exercise, you open an existing assembly and prepare to add

tubing and piping in the context of that assembly. You also become familiar

with the components included in the tube and pipe design environment

including the Tube & Pipe Runs panel bar, Tube & Pipe panel bar, Model

browser, and standard toolbar.

Create a tube and pipe assembly

1 Click File ➤ Open.

2 Open the AirSystemAssy.iam assembly.

3 On the Assembly panel bar, click the Create Pipe Run tool.

4 On the Create Tube & Pipe Run dialog box, enter AirSystem1 as the name

for the first run and accept the other defaults. Verify the default path in

the project workspace.

12 | Chapter 1 Getting Started with Tube & Pipe

5 Click OK.

The individual run is automatically added and activated so you can begin

defining a route and adding components.

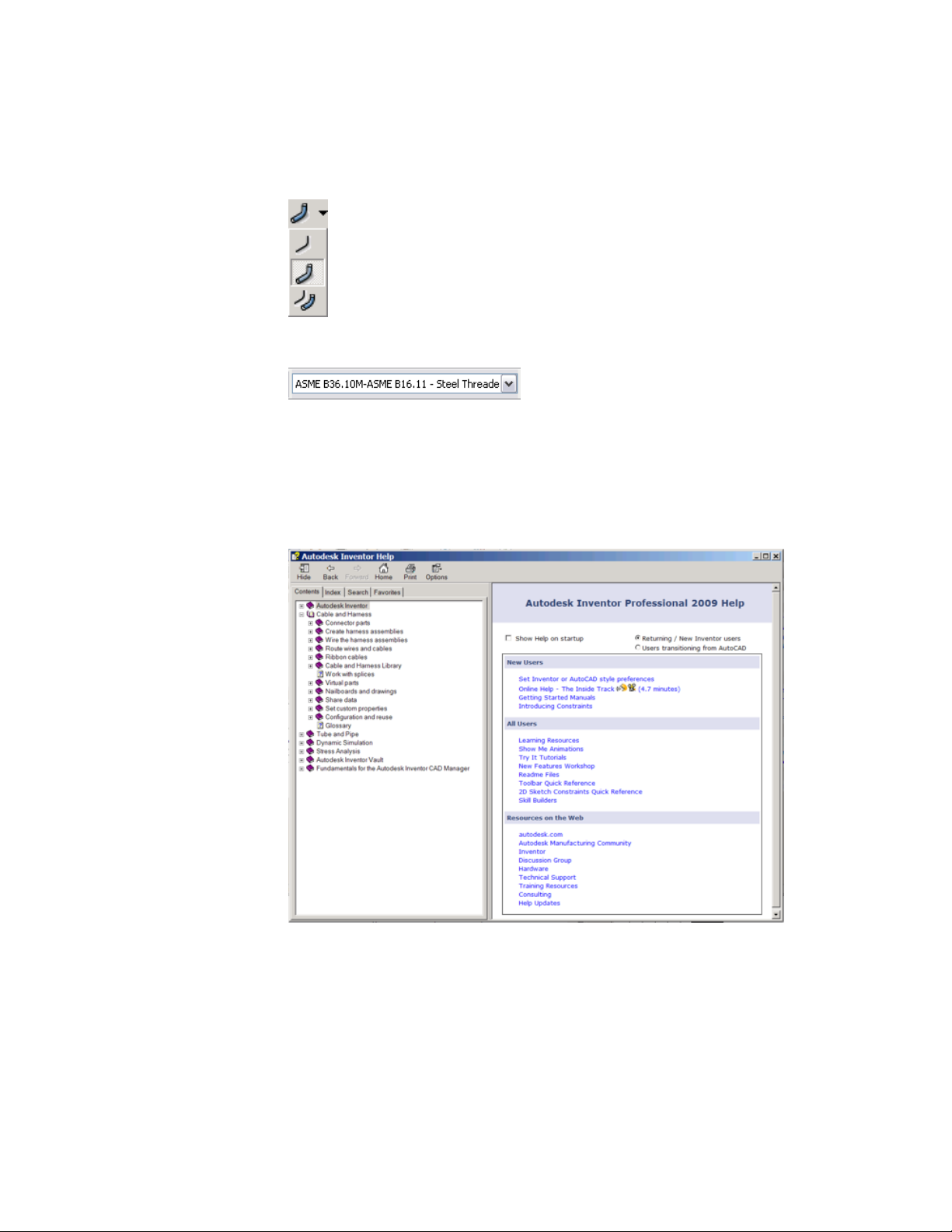

6 Examine the available tools on the Tube & Pipe panel bar, as shown in

the following image. Pause the cursor over the tools to view the tooltip.

7 Examine the standard toolbar to see the New Route tool, the

Display/Update Settings tool for tube and pipe defer updates, and the

Active Style list.

New Route tool

Create Master Runs Assemblies | 13

Display/Update Settings tool

Active Style list

8 Click Help ➤ Help Topics to access Help, and then click the Contents

tab to display the table of contents if it is not already displayed.

9 Click User’s Guides and then Tube and Pipe to display and examine the

Tube and Pipe Help topics.

10 Close the Help window.

14 | Chapter 1 Getting Started with Tube & Pipe

11 Activate the top-level assembly and save the file.

NOTE It is recommended that you save the top assembly regularly. Tube and Pipe

components are not stored in your project workspace until the top assembly is

saved.

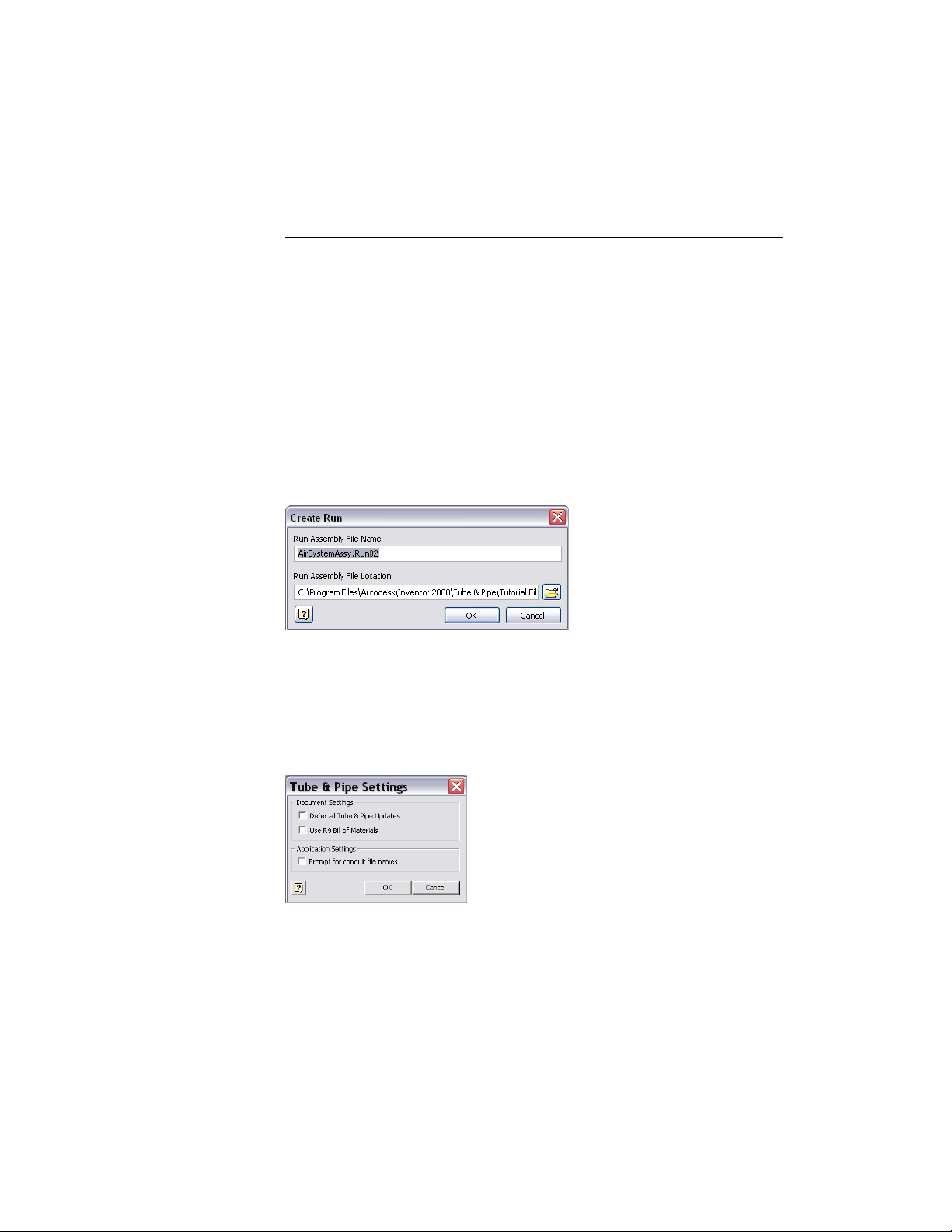

Add Individual Runs

Each time you use the Create Pipe Run tool after the Tube & Pipe Runs

assembly is created, an individual run is added to this container run. Individual

runs are arranged in the order they are added to the tube and pipe assembly.

You can name and locate each run file as it is added.

The following image shows the default settings when you create the second

run:

Specify Global Settings

With the top assembly active, right-click Tube & Pipe Runs in the Model

browser and use the Tube & Pipe Settings dialog box to specify the global

document and application settings for the master runs assembly.

Add Individual Runs | 15

Defer All Tube & Pipe Updates

Defer all tube and pipe updates when you are editing normal parts in a standard

Autodesk Inventor assembly or editing positional representations.

After the Defer All Tube & Pipe Updates check box is selected, most commands

specific to Tube & Pipe are disabled. The tube and pipe runs assembly is not

visible. Neither the tube and pipe runs assembly nor the associated parts in

drawings automatically update. You cannot create new pipe routes and runs

in the tube and pipe runs assembly.

When the Defer All Tube & Pipe Updates check box is cleared, you can defer

updates for individual runs and individual routes. For detailed instructions,

see Controlling Individual Settings on page 115 in Chapter 6.

Specify the setting for defer all tube and pipe updates

1 Activate the top assembly.

2 Right-click Tube & Pipe Runs, and select Tube & Pipe Settings.

3 On the Tube & Pipe Settings dialog box, ensure the Defer All Tube & Pipe

Updates check box is cleared.

You can view automatic responses to edits on the tube and pipe assembly.

4 Click OK.

Use of Bill of Materials

The drawing manager uses the current bill of materials (BOM) to create tube

and pipe drawings. When you migrate R9 or earlier tube and pipe drawings,

you can specify whether to continue using the R9 BOM (default) or to use the

current BOM.

The BOMs mainly differ in how they store the raw material description for

library parts:

■ In the current BOM, the raw material description for conduit parts is stored

in the new stock number property. All BOM items with the same part

number are automatically merged in parts lists. If the part number is blank,

parts do not merge.

■ In the R9 BOM, the raw material description for conduit parts was stored

in the part number property. You had control over the merging of rows

16 | Chapter 1 Getting Started with Tube & Pipe

in the parts list. Even if two pipes had the same part number, you could

choose not to merge them.

In the exercises that follow you use the current version of Autodesk Inventor

Tube and Pipe to create tube and pipe assemblies, so the Use R9 Bill of Materials

check box is cleared by default.

NOTE For more information about how to migrate legacy tube and pipe drawings

to the current version, see the Autodesk Inventor Tube and Pipe Help, Tube and

pipe bill of materials book in the table of contents.

Prompt for Conduit File Names

When conduit parts are saved to your project workspace the first time, the

default file names are used, with a suffix of a 13-digit number that is generated

randomly based on your system time. The conduit file naming convention

can be customized when you enable the Prompt for Conduit File Names option.

Specify the prompt for conduit file names

1 Activate the top assembly or master runs assembly.

2 In the Model browser, right-click the Tube & Pipe Runs and select Tube

& Pipe Settings.

3 On the Tube & Pipe Settings dialog box, Application Settings pane, to

accept the default conduit part file names, clear the Prompt for Conduit

File Names check box. Otherwise, select the check box.

4 In the exercises that follow you do not need to customize the conduit

file names, clear the check box.

5 Click OK.

Specify Global Settings | 17

18

Route Basics

2

A run is a collection of one or more routes with the same or unique styles that work together

to make up a complete flow system. A route is the path that determines the shape of the flow

system within the assembly and the intelligent placement of library components for the run

along that path.

Some routes contained in a run start and end on the assembly model geometry. Other routes

branch off a primary route to create a network of interconnecting rigid pipes, bent tubes, and

flexible hoses required to represent a single flow system.

Once you have a route, you can populate it with the Content Center library content based

on the tube and pipe style and the defined route path through the assembly.

About Rigid Routes

There are two types of rigid routes: rigid piping and bent tubing. The rigid route

styles, Rigid Pipe with Fittings and Tubing with Bends, contain the rules for

conduit parts and elbows. A pipe route can comprise pipe segments, couplings,

45-degree and 90-degree elbows, gaskets, gaps for groove welds, and custom

bends. A tube route comprises tubing segments and tubing bends. Couplings

connect straight segments and elbows or bends connect each directional change

point. If a butt weld style is active and gaps are set to display, straight segments

and directional change points have gaps between them for groove welds instead

of fittings.

A rigid route can be a series of auto regions and parametric regions:

■ An auto region is created by selecting circular openings and work points as

the start and end route points and can have any number of segments that

are automatically created by the system. As you select two circular openings,

vertices, and work points, the system automatically generates the needed

segments and route points. If more than one routing solution exists based

19

on the points selected, you can cycle through the solutions and select the

one that best fits your needs.

■ A parametric region is created using the 3D Orthogonal Route tool along

with the 3D sketch route tools, such as Point Snap, Rotation Snap, Parallel

With Edge, Perpendicular To Face, Bend, and General Dimension.

Auto regions are created where geometric constraints are not important.

Parametric regions are created to constrain the route to existing geometry or

dimensions. An auto region can be converted to a series of continuous sketched

segments at a later time.

Auto Route Cycling

As you select existing valid geometry, the system may calculate more than

one auto region solution based on the points selected and display the Select

Other tool. You can cycle through the solutions upon route creation or later

edits, and select the one that best fits your needs.

Click the arrows to cycle through available solutions. Click the middle green

button to make your selection. If there are multiple auto-route solutions in a

single route, the Select Other tool cycles through the solutions in each section

before advancing to the next section.

20 | Chapter 2 Route Basics

Solutions are evaluated and prioritized based on length and number of

segments. The length and segment information is included in a tooltip as you

consider the available solutions.

If you must switch to a new auto region solution in later edits, activate the

route environment. The Alternate Auto Solution tool is available when

right-clicking the auto region in the Model browser.

Parametric Regions

Along with the 3D Orthogonal Route tool, you can use geometric constraints,

dimensions, custom bends, point snap, and rotation snap to manually define

sketched route points.

If existing geometry such as a vertex, linear geometry, planar faces, and work

features (including work points, work axes, and work planes) can help navigate

through the route system, include them as reference geometry. You can then

apply appropriate geometric constraints and dimension constraints to define

the design.

In addition, you can draw construction lines from sketched route points and

then use the General Dimension tool to position the coplanar segment

accurately.

NOTE It is best to plan for route constraints before starting the design.

About Flexible Hose Routes

Flexible hose routes can contain up to three parts: a start fitting, a hose

segment, and an end fitting. The start fitting and end fitting for a flexible hose

must have two connection points. Flexible hose routes can also consist of only

the hose, with both fittings suppressed, or a hose with one fitting suppressed.

To provide more control over hose shape, you can insert intermediate route

points in the hose route as you create it. As you make your selections, a preview

line appears between the selected points to help you visualize the route.

Flexible hose routes can be created between standard assembly geometry or

initiated from fittings dropped onto existing routes to create a branch.

Parametric Regions | 21

Route Points

Routes are created by selecting at least two route points. Route points can be

manually defined. In rigid routes, the system may also automatically generate

route points in auto regions.

A route typically starts from:

■ Circular geometry such as a face, a hole, and cylindrical cuts

■ Work points that reside in the assembly

■ Vertices on any assembly component

■ Existing free terminal route points in the active route

■ Existing fittings

When you select circular geometry or work points, the route remains associative

to these points. If the model geometry changes, the route automatically

updates.

A variety of edit tools are available for route points on the Route panel bar

and the right-click context menu, depending on the specific route creation

mechanism and route type. For instance, when you are editing a rigid route,

the 3D Move/Rotate tool, Constraints tool, and General Dimension tool are

applicable to sketched route points. However, only the Move Node tool, Move

Segment tool, and Edit Position tool are applicable to auto regions where

appropriate.

Rigid Route Points

Each route point in rigid routes is typically associated to a fitting with an

exception of free terminal route points. Rigid routes with a butt weld style are

also an exception. In this case, gaps can be displayed between route

components. Valid point selections are controlled by styles, connection data,

and the action being performed.

To better control the direction of a route, you can manually define any number

of intermediate route points using the 3D sketch route tools. Appropriate tools

are available to edit route points in both auto regions and parametric regions.

System-generated route points always automatically update to changes made

to the route during editing. Sketched route points in the parametric region

may also dynamically update unless they are fully constrained.

22 | Chapter 2 Route Basics

Hose Route Points

In hose routes, intermediate route points are used to control the shape of the

splines. They are not associated to any fittings. Depending on how the hose

route style defines the start fitting and end fitting, intermediate route points

can be inserted at an appropriate time.

To reposition the hose route points, you can place geometric constraints or

adjust the offset distances from existing geometry using the Redefine tool.

Editing the hose length does not impact the position of the adjacent hose

route points.

3D Orthogonal Route Tool

The 3D Orthogonal Route tool appears as soon as you begin selecting route

points in the graphics window. It contains several elements that guide selection

of valid route points.

When the 3D Orthogonal Route tool first appears, only the line extender is

displayed. With the line extender you can select points that are offset from a

selected edge. Once you select a point along the line, other elements of the

3D Orthogonal Route tool appear at the selected point.

The elements displayed are dependent on what is selected, the connection

geometry, and set styles. For example, the 3D Orthogonal Route tool includes

different elements depending on whether you are creating a pipe route with

fittings or a tube route with bends. Some elements are common to both styles.

Valid points, those that will make a connection of the allowable length, are

highlighted with a green dot as you move the cursor over the lines in the tool.

Points that do not fall within the range set by the style criteria are displayed

as a yellow x. The size of the tool can be increased if the line is not long

enough.

Tool Elements for Pipe Routing

When a rigid piping style is active and all elements are displayed on the 3D

Orthogonal Route tool, you can:

■ Rotate freely around the local axis.

■ Change direction in 90- or 45-degree increments.

Hose Route Points | 23

■ Create points from referenced geometry.

■ Select points offset from selected edges.

The different elements in the 3D Orthogonal Route tool for rigid pipes with

fittings include:

Direction axes

Rotation arrows

45-degree angle control

Shows valid direction for the next route point. Click

the line to add a node in that direction. Together with

the Point Snap tool, you can define a work point on

the axis direction from referenced geometry.

Shows the rotation possibilities for the next route point

and enables the free rotation. Together with the Rotation Snap tool, you can rotate the direction axis to an

orientation from referenced geometry.

Changes direction in 45-degree increments. This is

available only when 45-degree route direction is set for

the active style.

Tool Elements for Tube Routing

When a Tubing with Bends style type is active the line extender, direction

axes, and rotation arrows display along with the elements specific to creating

bent tube runs. In addition to the ability to rotate freely around the local axis,

create points from referenced geometry, and select points offset from selected

edges, you can also:

■ Change direction at any angle between 0 and 180 degrees.

■ Make precise adjustments to the included angle using the rotation arrows.

24 | Chapter 2 Route Basics

■ Change the bend radius using the radius arrows.

Change Tool Displays

Both tool color and size can be changed. Tool size is changed using the plus

(+) or minus (-) keys on the keypad. Use plus (+) to increase the size, and minus

(-) to reduce it. To adjust the colors in which the direction axes, line extender,

or tooltip are displayed, set the colors as you would other color format styles.

Set colors in the display of the 3D Orthogonal Route tool

1 Open a tube and pipe assembly file containing at least one route. You

can use the Tube & Pipe sample files, which are installed in

Autodesk\Inventor <version>\Samples\Models\Tube & Pipe by default.

2 Activate the top-level assembly or Tube & Pipe Runs subassembly.

3 Click Format ➤ Styles Editor.

4 On the Styles and Standards Editor dialog box, expand Color in the left

pane and select a Route_UI_Tool_(toolname) color style.

5 Set the appropriate color attributes.

6 Click Save to apply color changes immediately. Otherwise, colors become

effective when you click Done to close the dialog box.

Define Angular Position and Rotation Snap

The rotation arrows and direction axes can be displayed when defining routes

and placing fittings, and then again when editing and repositioning routes

Change Tool Displays | 25

and fittings. With the Rotation Arrows and Direction Axes displayed, you can

view the rotation possibilities for the current selection.

To rotate freely around the axis, click and drag the Rotation Arrow as needed.

To snap the rotation in 90-degree increments, click on a line of the Direction

Axis.

The tool snaps to all four quadrant border angles as you rotate. The tool also

snaps to edge or face geometry. In this case, a dashed line and preview point

show how the snap is applied.

Click and drag a rotation arrow.

Release the cursor in the new location.

Define 45-degree Angles

When the 45-degree route direction is set in the active style, the Angle Control

can be displayed in the 3D Orthogonal Route tool. When it is displayed, you

can rotate the route position in 45-degree increments.

To use the Angle Control, click the arrow pointing in the angular position

you need. When you are satisfied with the position, select a point on the line

to create a segment at the new angular position.

Click an arrow to direct the path to the angle you want.

26 | Chapter 2 Route Basics

The route path changes to the new angular position. If you select the wrong

direction, click the single arrow displayed on the selected axis to revert to the

previous angular position.

Define Bent Tubes Angles

When a tubing with bends style is active, the Rotation Handles are displayed

on the 3D Orthogonal Route tool. When they are displayed you can create a

bend at any angle.

To use the Rotation Handles click the arrow pointing in the angular position

you need, and drag to the required position. The tool snaps in regular

increments based on the 3D Angle Snap value. This value is set on the Tools

➤ Document Settings, Modeling tab.

Define Bent Tubes Angles | 27

When you are satisfied with the new position, select a point on the line to

create a segment at the new location. The route path changes to the new

angular position. Using the Rotation Handles, you can also create a series of

bends to achieve a compound bend.

Using Point Snap to Define Points

When the 3D Orthogonal Route tool is active and Point Snap is checked in

the context menu, you can define points by snapping to other model geometry.

Pause your cursor over faces, edges, or work points, a dashed line and preview

point are displayed at the intersection of the line and the plane of the

highlighted edge or face.

The dashed line represents the snap point in relation to the highlighted

geometry. When the preview point is displayed at the needed location, click

the selected geometry and the point is created.

28 | Chapter 2 Route Basics

A dashed line shows the point snapped from the face.

Click the face to create the route point at the intersection with the tool.

Enter Precise Values

Although all route points can be selected interactively, sometimes exact values

are needed to create the required route. You can enter precise values for both

angles and distances. The values entered are the distance or angle from the

active position to the current node. If a point was snapped onto a line of the

3D Orthogonal Route tool, the value entered is the distance from the snap

point to the desired node to add. The entered values must comply with set

rules for segment length; otherwise, you are prompted to reenter the value.

For tubing with bends styles, you can also enter a precise bend radius.

To enter an exact distance, start typing the value while your cursor pauses

over the direction axis of the 3D Orthogonal Route tool. You can also

right-click and select Enter Distance to enter a value.

Entering angles is very similar. To enter an angle, start typing the needed value

while your cursor pauses over a rotation arrow or bent tube rotation arrow.

You can also right-click and select Enter Angle to enter an angle.

Enter exact distances while your cursor pauses over the rotation arrows,

rotation arrows, or direction axes of the 3D Orthogonal Route tool.

Enter the value for the distance.

Enter Precise Values | 29

Enter the value for the angle.

To view the current bend radius, pause your cursor over the radius arrow.

Click the tool to enter a different value for the bend radius. You can also start

typing the new value while your cursor pauses over the radius arrow.

30 | Chapter 2 Route Basics

The new radius affects only the next bend. All subsequent bends use the default

radius set on the Tube & Pipe Styles dialog box.

Route Tools

To start creating routes, you must activate an individual pipe run, and then

enter the route environment. Along with the 3D Orthogonal Route tool, a

variety of sketched route tools are available and can assist in the route design.

You can create a route by connecting two or more points and directing the

route through circular openings and around existing geometry in its path.

Basic Tools

To enter the route environment, use the New Route tool on the Tube & Pipe

panel bar or standard toolbar.

New Route tool

In Route mode, the Route panel bar displays and you can begin creating a

path for your route. Use the Route tool to add new routes or continue existing

ones.

Route tool

As you select points for a route, Autodesk® Inventor™ Routed Systems gives

you visual feedback about what is happening in the graphics window and text

messages on the status bar. The messages change based on what is selected

and the action you are performing.

When deciding on the design of your route, you can:

■ Decide whether you must manually define the route direction or allow

the system to automatically calculate solutions.

■ Identify the circular geometry (or work points) that are used as the start

and endpoints.

Route Tools | 31

■ Analyze where directional change points are needed to route through or

■ Create in-line work features, such as a work point at the intersection of

■ Place constraints or dimensions to sketched segments.

■ Convert auto regions to parametric regions so that you can make more

You can define your routes as close to the appropriate results as possible, and

then adjust them later, or you can develop them using precise distances and

dimensions as you go. To speed creation and plan for dynamic editing and

updating, allow the system to automatically create route points whenever

geometric constraints are not important. Define route points manually where

it is critical for a route to navigate through a particular direction and constrain

to existing geometry.

If using in-line work features, consider simplifying the route display by

selecting the Auto-hide in-line features option on the Tools menu, Application

Options, Part tab. In-line work features are hidden as soon as they are

consumed by a feature. The auto-hide option is enabled by default.

Bend Tools

around existing geometry.

work planes, to guide the route path.

edits.

Use bent tubing and flexible hosing styles to create curved routes conforming

to the minimum bend radius. Typically, use the following tools to manually

create bends in the rigid route:

■ Custom Bend tool on the right-click context menu when the 3D

Orthogonal Route tool is active. It is applicable when creating a pipe route.

■ Bend tool on the Route panel bar. It is applicable when editing parametric

regions in a finished route.

Bend tool

In pipe routes, when a bend is required where it has not been manually

defined, the default bend radius of two times the pipe nominal diameter is

used. For instance, applying the Parallel With Edge tool to a certain linear

32 | Chapter 2 Route Basics

geometry may also require a bend if directional fittings in the Content Center

such as 45-degree or 90-degree elbow are not appropriate.

NOTE When an existing bend is deleted by mistake, use the Bend tool to create

a new bend where appropriate.

Dimension Tools

In rigid routes, there are three typical types of dimensions pertaining to the

route sketch:

■ Linear dimension, such as the length of route segments

■ Radial dimension, such as bend radius for custom bends in piping routes

and normal bends in tubing routes

■ Angular dimension, such as angles between directional turns

Dimensions only apply to the route sketch in parametric regions. Auto regions

always dynamically update to assembly changes so the number of segments

typically varies from the new solution. They do not involve dimensions until

the Convert to Sketch command is applied.

The Auto-Dimension tool on the right-click context menu enables you to

switch whether to automatically dimension the subsequent route sketch. To

place and edit dimensions manually, click the General Dimension tool on the

Route panel bar or double-click an existing dimension in place.

General Dimension tool

Similar to Autodesk® Inventor™, dimensions on the route sketch can be

categorized into two types: normal sketched dimension (driving dimension)

and driven dimension. Normal sketched dimensions are used to drive the

route geometry. For instance, sketched route segments are manually created

using a specified dimension. Driven dimensions are enclosed in parentheses

as displayed in the graphics window and allow route geometry to dynamically

respond to associated changes.

NOTE The General Dimension tool cannot create a bend. After you use the Bend

tool to create a bend between two coplanar segments, you can edit the bend

radius using the General Dimension tool.

Dimension Tools | 33

Parallel and Perpendicular Tools

During forward creation of sketched route segments, use the Parallel With

Edge and Perpendicular To Face tools to reorient the axis of the 3D Orthogonal

Route tool against existing geometry. When the next route point is defined

on this axis, a parallel or perpendicular constraint is added to the resultant

route segment. You can also pick up route points in the other two axes.

Applying the two tools may request an irregular angle (neither 45-degree nor

90-degree) at the preceding route point. Consequently, a custom bend is

created. Radius arrow and rotation arrow are available on the 3D Orthogonal

Route tool. Edit the bend radius and rotation angle as needed.

Other Tools

In addition to the 3D Orthogonal Route tool, Point Snap, Rotation Snap,

Custom Bend, Bend, General Dimension, Parallel With Edge, and Perpendicular

To Face tools that are discussed in the preceding sections, Autodesk Inventor

Professional Tube & Pipe provides the following tools to define the route

sketch manually:

Constraints tool

Include Geometry

tool

Draw Construction

Line tool

For detailed instructions on how to use these tools, see the Autodesk Inventor

Professional Tube & Pipe Help.

34 | Chapter 2 Route Basics

Applies the 3D sketch constraints between route points,

segments, and included reference geometry, such as

Perpendicular, Parallel, Tangent, Coincident, Collinear,

and Fix.

Includes the reference geometry from the source geometry to constrain the route sketch, such as vertices,

linear edges, planar faces, and work features (work

points, work axes, and work planes).

Creates any number of construction lines from the

sketched route point and places dimensions, typically

the included angle between the construction line and

the adjacent segment.

Setting Styles

3

Tube and pipe styles describe the characteristics for tube, pipe, and hose routes. These styles

are key to controlling the design of the routed system as it evolves from prototype to

manufacturing.

This chapter provides basic information about the available options, how to set them, how

to modify and change them, and how to add them to a template.

About Tube and Pipe Styles

Tube and pipe styles affect most aspects of route design from route creation and

editing to populating the route. They are used to ensure consistent application

of tube and pipe components. For example, conduit parts and fittings in a pipe

run often have certain requirements for size, route direction, and materials.

With tube and pipe styles, you can set these requirements once, and then apply

them to the design.

When defining a style, you are specifying the conduit part and fittings from

the Content Center libraries that make up the pipe run and establishing rules

to be followed during routing.

There is a list of system-supplied tube and pipe styles in Autodesk® Inventor

Routed Systems. You can use one of these styles, create your own style based

on one of them, or create your own style based on published conduit parts and

fittings.

NOTE It is possible to define a style with which you are unable to create a route,

such as if you select fittings that do not have compatible end treatments. While the

Tube & Pipe Styles tool allows styles to be defined in this way, routes cannot be

created using such a style.

™

35

To correctly define new materials for tube and pipe styles, you must enable

the Use Styles Library setting for your project. For detailed instructions, see

Setting Up Projects For Exercises on page 10 in Chapter 1.

WARNING Do not confuse tube and pipe styles with styles and style libraries in

Autodesk® Inventor™. They are two separate, unrelated entities.

Access Tube and Pipe Styles

Before you begin working with routes and runs, examine the style settings,

and then select the style you need.

To work with styles, activate the tube and pipe environment and start the

Tube & Pipe Styles tool to display the Tube & Pipe Styles dialog box. The Tube

& Pipe Styles tool can be accessed on the panel bars or right-click menu when

you activate:

■ The master runs assembly

■ A run

■ A route

Tube & Pipe Styles tool

Existing styles are also available from the Active Style list on the standard

toolbar.

36 | Chapter 3 Setting Styles

The features on the Tube & Pipe Styles dialog box include:

Toolbar

Active Style

Styles browser

General tab

The tool set for the library that you use to create, edit,

copy, and delete one or more defined styles. Import

and export functions are also provided to bring style

definitions in and out of the local or master runs templates. Pause your cursor over the toolbar to view the

tooltips.

Displays the style used when automatically creating a