Page 1

Autodesk Inventor 2010

Getting Started

January 2009Part No. 527B1-050000-PM01A

Page 2

©

2009 Autodesk, Inc. All Rights Reserved. Except as otherwise permitted by Autodesk, Inc., this publication, or parts thereof, may not be

reproduced in any form, by any method, for any purpose.

Certain materials included in this publication are reprinted with the permission of the copyright holder.

Trademarks

The following are registered trademarks or trademarks of Autodesk, Inc., in the USA and other countries: 3DEC (design/logo), 3December,

3December.com, 3ds Max, ADI, Alias, Alias (swirl design/logo), AliasStudio, Alias|Wavefront (design/logo), ATC, AUGI, AutoCAD, AutoCAD

Learning Assistance, AutoCAD LT, AutoCAD Simulator, AutoCAD SQL Extension, AutoCAD SQL Interface, Autodesk, Autodesk Envision, Autodesk

Insight, Autodesk Intent, Autodesk Inventor, Autodesk Map, Autodesk MapGuide, Autodesk Streamline, AutoLISP, AutoSnap, AutoSketch,

AutoTrack, Backdraft, Built with ObjectARX (logo), Burn, Buzzsaw, CAiCE, Can You Imagine, Character Studio, Cinestream, Civil 3D, Cleaner,

Cleaner Central, ClearScale, Colour Warper, Combustion, Communication Specification, Constructware, Content Explorer, Create>what's>Next>

(design/logo), Dancing Baby (image), DesignCenter, Design Doctor, Designer's Toolkit, DesignKids, DesignProf, DesignServer, DesignStudio,

Design|Studio (design/logo), Design Web Format, Discreet, DWF, DWG, DWG (logo), DWG Extreme, DWG TrueConvert, DWG TrueView, DXF,

Ecotect, Exposure, Extending the Design Team, Face Robot, FBX, Filmbox, Fire, Flame, Flint, FMDesktop, Freewheel, Frost, GDX Driver, Gmax,

Green Building Studio, Heads-up Design, Heidi, HumanIK, IDEA Server, i-drop, ImageModeler, iMOUT, Incinerator, Inferno, Inventor, Inventor

LT, Kaydara, Kaydara (design/logo), Kynapse, Kynogon, LandXplorer, LocationLogic, Lustre, Matchmover, Maya, Mechanical Desktop, Moonbox,

MotionBuilder, Movimento, Mudbox, NavisWorks, ObjectARX, ObjectDBX, Open Reality, Opticore, Opticore Opus, PolarSnap, PortfolioWall,

Powered with Autodesk Technology, Productstream, ProjectPoint, ProMaterials, RasterDWG, Reactor, RealDWG, Real-time Roto, REALVIZ,

Recognize, Render Queue, Retimer,Reveal, Revit, Showcase, ShowMotion, SketchBook, Smoke, Softimage, Softimage|XSI (design/logo),

SteeringWheels, Stitcher, Stone, StudioTools, Topobase, Toxik, TrustedDWG, ViewCube, Visual, Visual Construction, Visual Drainage, Visual

Landscape, Visual Survey, Visual Toolbox, Visual LISP, Voice Reality, Volo, Vtour, Wire, Wiretap, WiretapCentral, XSI, and XSI (design/logo).

The following are registered trademarks or trademarks of Autodesk Canada Co. in the USA and/or Canada and other countries:

Backburner,Multi-Master Editing, River, and Sparks.

The following are registered trademarks or trademarks of MoldflowCorp. in the USA and/or other countries: Moldflow, MPA, MPA

(design/logo),Moldflow Plastics Advisers, MPI, MPI (design/logo), Moldflow Plastics Insight,MPX, MPX (design/logo), Moldflow Plastics Xpert.

All other brand names, product names or trademarks belong to their respective holders.

Disclaimer

THIS PUBLICATION AND THE INFORMATION CONTAINED HEREIN IS MADE AVAILABLE BY AUTODESK, INC. "AS IS." AUTODESK, INC. DISCLAIMS

ALL WARRANTIES, EITHER EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE REGARDING THESE MATERIALS.

Published by:

Autodesk, Inc.

111 Mclnnis Parkway

San Rafael, CA 94903, USA

Page 3

Contents

Chapter 1 Digital Prototypes in Autodesk Inventor . . . . . . . . . . . . . . 1

Digital Prototype Workflow . . . . . . . . . . . . . . . . . . . . . . . . 1

Components of Digital Prototypes (file types) . . . . . . . . . . . . . . . 3

Associative Behavior of Parts . . . . . . . . . . . . . . . . . . . . . 7

Associative Behavior of Assemblies . . . . . . . . . . . . . . . . . . 7

Associative Behavior of Drawings . . . . . . . . . . . . . . . . . . 8

Chapter 2 Create Digital Prototypes . . . . . . . . . . . . . . . . . . . . . 9

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Single Body Parts . . . . . . . . . . . . . . . . . . . . . . . . . . 10

iParts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Sheet Metal Parts . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Derived Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Multi-body Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Shrinkwrap Parts . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Assembly Substitute Parts . . . . . . . . . . . . . . . . . . . . . . 15

Content Center Parts . . . . . . . . . . . . . . . . . . . . . . . . 16

Content Center Libraries . . . . . . . . . . . . . . . . . . . 18

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Sketched Features . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Sketch Environment . . . . . . . . . . . . . . . . . . . . . 23

Sketch Blocks . . . . . . . . . . . . . . . . . . . . . . . . . 24

Sketch Constraints . . . . . . . . . . . . . . . . . . . . . . 25

iii

Page 4

2D AutoCAD Data in Sketches . . . . . . . . . . . . . . . . 25

Placed Features . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

iFeatures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Assembly Features . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Work Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Edit Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Place Components . . . . . . . . . . . . . . . . . . . . . . . . . 30

Drag Components into Assemblies . . . . . . . . . . . . . . 31

Assembly Constraints . . . . . . . . . . . . . . . . . . . . . . . . 31

Degrees of Freedom . . . . . . . . . . . . . . . . . . . . . . 32

Top-down Design . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Create Subassemblies In-place . . . . . . . . . . . . . . . . . . . 33

Design Accelerator Components . . . . . . . . . . . . . . . . . . 34

Design Mechanisms . . . . . . . . . . . . . . . . . . . . . . . . . 35

Check for Interference . . . . . . . . . . . . . . . . . . . . . . . 37

iAssemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Chapter 3 Document and Publish Designs . . . . . . . . . . . . . . . . . . 39

Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Start Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Types of Drawing Files . . . . . . . . . . . . . . . . . . . . . . . 40

Create Views of Models . . . . . . . . . . . . . . . . . . . . . . . 41

Types of Drawing Views . . . . . . . . . . . . . . . . . . . . 41

Drawing View Operations . . . . . . . . . . . . . . . . . . . 43

Drawing View Tips . . . . . . . . . . . . . . . . . . . . . . 44

Exploded Views . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Annotate Drawing Views . . . . . . . . . . . . . . . . . . . . . . 45

Types of Drawing Annotations . . . . . . . . . . . . . . . . 46

Styles and Standards . . . . . . . . . . . . . . . . . . . . . . . . 50

Studio in Autodesk Inventor . . . . . . . . . . . . . . . . . . . . . . . 51

Publish Designs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Chapter 4 Manage Data . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Share Files in Work Groups Using Vault . . . . . . . . . . . . . . . . . 55

Autodesk Vault Add-ins for Design Applications . . . . . . . . . . 56

Microsoft Office Add-ins . . . . . . . . . . . . . . . . . . . . . . 57

Copy Designs Using Vault . . . . . . . . . . . . . . . . . . . . . 57

Share Files Externally . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Autodesk Vault Manufacturing . . . . . . . . . . . . . . . . . . . 58

Autodesk Design Review . . . . . . . . . . . . . . . . . . . . . . 58

Import and Export Data . . . . . . . . . . . . . . . . . . . . . . . . . . 59

AutoCAD Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Import Files from Other CAD Systems . . . . . . . . . . . . . . . 61

Export Files to Other CAD System Formats . . . . . . . . . . . . . 62

iv | Contents

Page 5

Chapter 5 Set Your Environment . . . . . . . . . . . . . . . . . . . . . . . 63

Commands and Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Environment Preferences . . . . . . . . . . . . . . . . . . . . . . . . . 65

Application Options . . . . . . . . . . . . . . . . . . . . . . . . . 65

Document Settings . . . . . . . . . . . . . . . . . . . . . . . . . 65

Styles and Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Style Libraries . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Views of Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Templates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Vault Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Default Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

New Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Learning Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

New Features Workshop . . . . . . . . . . . . . . . . . . . . . . . 71

Integrated Help . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Tutorials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Skill Builders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Contents | v

Page 6

vi

Page 7

Digital Prototypes in Autodesk Inventor

Autodesk Inventor® provides a comprehensive set of 3D mechanical CAD tools for producing,

validating, and documenting complete digital prototypes. The Inventor model is a 3D digital

prototype. The prototype helps you visualize, simulate, and analyze how a product or part

works under real-world conditions before it is built. Manufacturers get to market faster with

fewer physical prototypes and more innovative products.

Inventor provides an intuitive 3D design environment for creating parts and assemblies.

Engineers can focus on the function of a design to drive the automatic creation of intelligent

components, such as steel frames, rotating machinery, tube and pipe runs, electrical cables,

and wire harnesses.

Tightly integrated motion simulation and stress analysis in Inventor are easy to use. They

make it possible for engineers to optimize and validate the digital prototype.

Generating manufacturing documentation from a validated 3D digital prototype reduces

errors and associated engineering change orders (ECOs) before manufacturing. Inventor offers

rapid and accurate output of production-ready drawings directly from the 3D model.

Inventor is tightly integrated with Autodesk® data management applications. This integration

enables the efficient and secure exchange of digital design data and promotes earlier

collaboration between design and manufacturing workgroups. Different workgroups can

manage and track all components of a digital prototype with Autodesk® Design Review

software. This software is the all-digital way to review, measure, mark up, and track changes

to designs. You can better reuse crucial design data, manage bills of materials (BOMs), and

collaborate with other teams and partners.

1

Digital Prototype Workflow

Before you start a design, determine the most efficient workflow. A top down

workflow is often the most efficient way to create a design. In a top down

1

Page 8

workflow, you design your components in the context of other components.

This method can greatly reduce errors in form, fit, and function.

Some examples of a top-down workflow are:

■ Create new parts or sub-assemblies in the destination assembly.

■ Create multiple solid bodies in a part file and then save the individual

bodies as unique parts.

■ Create 2D sketch blocks in a part file to simulate a mechanism. You can

use the sketch blocks to create 3D components in an assembly that is

controlled by the layout.

Following are questions to consider before you start:

■ Which view of the part best describes the basic shape?

■ Is the part a sheet metal part?

■ Can this part be used as a part factory (iPart) to generate multiple parts?

■ Can a spreadsheet control one or more parts?

■ Can I create the part automatically by using a Design Accelerator?

■ If the part is a component in a structural steel frame, can I use Frame

Generator to create the entire frame?

■ If the part is a common library part, does it exist in the Content Center or

other library?

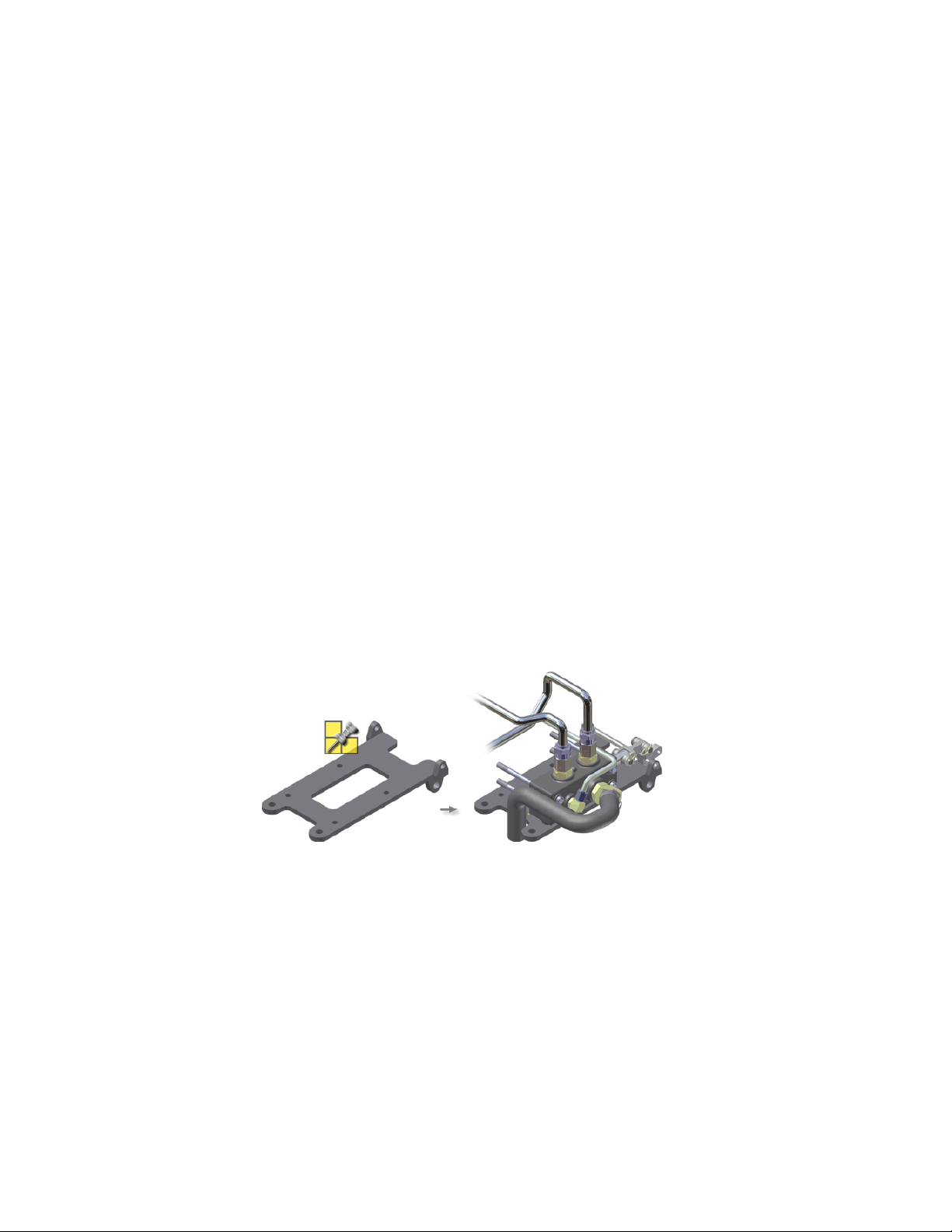

The following image shows a multi-body part file saved as individual parts in

an assembly. Individual bodies in a multi-body part file can share features

with other bodies such as fillets and holes.

2 | Chapter 1 Digital Prototypes in Autodesk Inventor

Page 9

LocationFor more information

Search: “Multi-body parts”Help topic

Parts 1 - Create PartsTutorial

PartsSkill Builders

Components of Digital Prototypes (file types)

Create or activate a project file before you open an existing file or start a new

file to set the file location. Click New to see the New File dialog box with

templates for a new part, assembly, presentation file, sheet metal part,

weldment, or drawing. You can choose from several templates with predefined

units.

A template can contain property information, such as part and project data,

and drawing views. You can see information stored in a file by viewing its

properties.

For more information about templates, see Templates on page 67. For more

information about projects, see Projects on page 68.

For more information about projects, see Projects on page 68.

Components of Digital Prototypes (file types) | 3

Page 10

Part (.ipt) Files

When you open a part file, you are in the part environment. Part tools

manipulate sketches, features, and bodies which combine to make parts. You

can insert a single body part into assemblies and constrain them in positions

they occupy when the assembly is manufactured. You can extract multiple

part files from a multi-body part.

Most parts start with a sketch. A sketch is the profile of a feature and any

geometry (such as a sweep path or axis of rotation) required to create the

feature.

A part model is a collection of features. If necessary, solid bodies in a

multi-body part file can share features. Sketch constraints control geometric

relationships such as parallel and perpendicular. Dimensions control the size.

Collectively this method is called Parametric modeling. You can adjust the

constraints or dimensional parameters that control the size and shape of a

model, and automatically see the effect of your modifications.

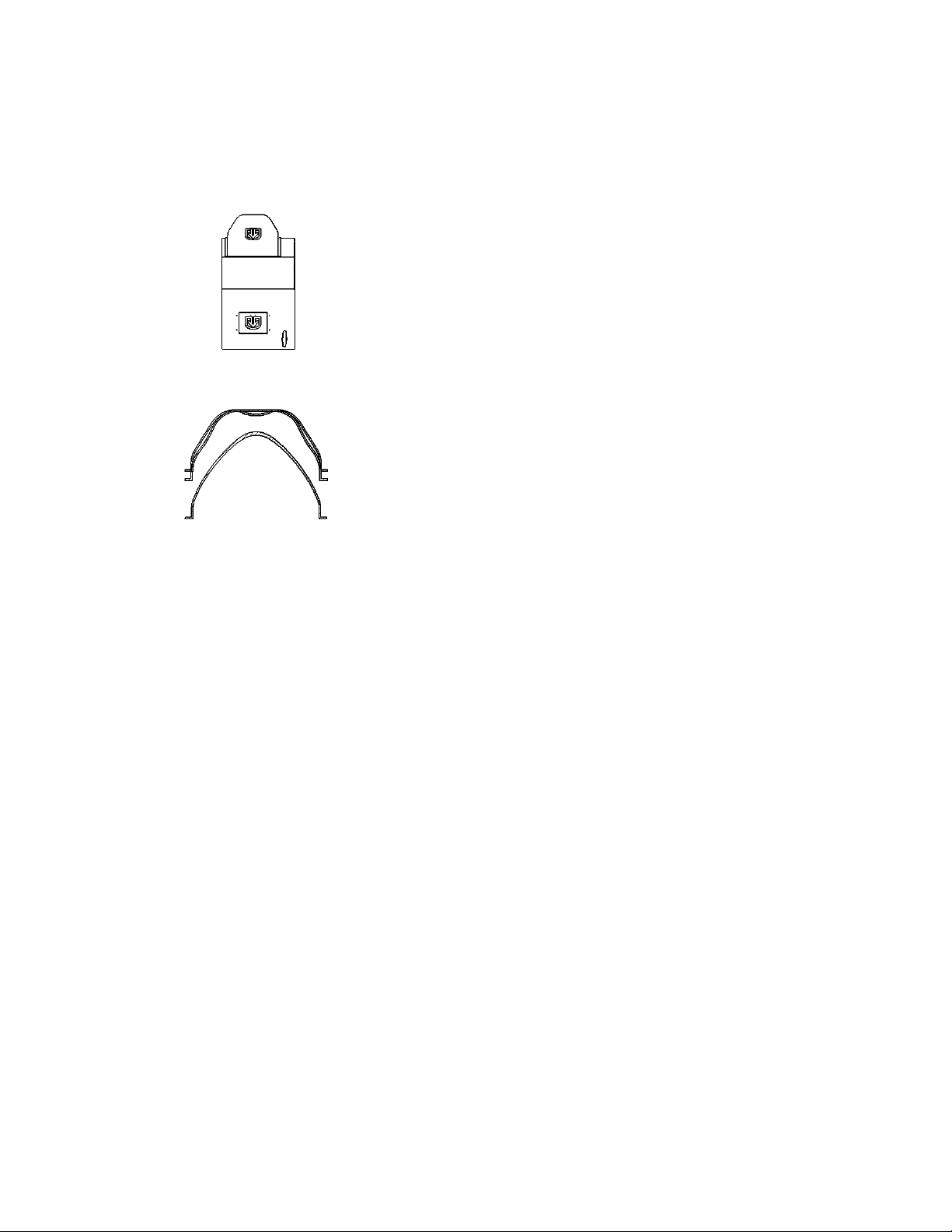

The following image shows a single body part in the upper half of the image,

and a multi-body part in the lower half of the image. Notice the different part

icons in each image.

Assembly (.iam) Files

In Autodesk Inventor, you place components that act as a single functional

unit into an assembly document. Assembly constraints define the relative

position these components occupy with respect to each other. An example is

the axis of a shaft aligning with a hole in a different component.

4 | Chapter 1 Digital Prototypes in Autodesk Inventor

Page 11

When you create or open an assembly file, you are in the assembly

environment. Assembly tools manipulate whole subassemblies and assemblies.

You can group parts that function together as a single unit and then insert

the subassembly into another assembly.

You can insert parts into an assembly or use sketch and part tools to create

parts in the context of an assembly. During these operations, all other

components in the assembly are visible.

To complete a model, you can create assembly features that affect multiple

components, such as holes that pass through multiple parts. Assembly features

often describe specific manufacturing processes such as post-machining.

The assembly browser is a convenient way to activate components you want

to edit. Use the browser to edit sketches, features, and constraints, turn

component visibility on and off, and do other tasks. In the following image

of an assembly, two of the components display an icon indicating they are

part of a contact set. Components that belong to a contact set behave as they

would in the physical world.

Presentation (.ipn) Files

Presentation files are a multi-purpose file type. Use a presentation file to:

■ Create an exploded view of an assembly to use in a drawing file.

■ Create an animation which shows the step by step assembly order. The

animation can contain view changes and the visibility state of components

at each step in the assembly process. You can save the animation to a .wmv

or .avi file format.

Components of Digital Prototypes (file types) | 5

Page 12

Drawing (.idw, .dwg) Files

After you create a model, you can create a drawing to document your design.

In a drawing, you place views of a model on one or more drawing sheets. Then

you add dimensions and other drawing annotations to document the model.

A drawing that documents an assembly can contain an automated parts list

and item balloons in addition to the required views.

The templates to use as the starting point for your drawings have the standard

drawing file extension (.idw, .dwg).

6 | Chapter 1 Digital Prototypes in Autodesk Inventor

Page 13

Autodesk Inventor maintains links between components and drawings, so

you can create a drawing at any time during the creation of a component. By

default, the drawing updates automatically when you edit the component.

However, it is a good idea to wait until a component design is nearly complete

before you create a drawing. Edit the drawing details (to add or delete

dimensions or views, or to change the locations of notes and balloons) to

reflect the revisions.

LocationFor more information

Help topic

Guide

Search:

“Autodesk Inventor file types”

“Set file names”

Manual in PDF format.Autodesk Vault Implementation

Associative Behavior of Parts

Other than the origin work planes, work axes, the center point, and grounded

work points, all work features are associated to the features or geometry used

to create them. If you modify or delete the locating geometry, the work feature

changes accordingly. Conversely, changes to the work feature affect any feature

or geometry that is dependent on a work feature for its definition.

A parent-child relationship is a term frequently used to describe the

relationship between features. A child feature cannot exist without the parent

feature. If you delete a parent feature, you can choose to retain the originating

sketch of a child feature. If you create geometry on an origin plane or a work

plane created from an origin plane you can often avoid creating parent-child

relationships.

A derived part can maintain associative links to the source component so it

can be updated. You can also choose to break the link between the derived

part and the source part or assembly to disable updates.

For more information about derived parts and work features, see Parts on page

9 and Features on page 18.

Associative Behavior of Assemblies

An assembly maintains active links to the source components. Each time you

open an assembly, Inventor detects the latest version of the components

Associative Behavior of Parts | 7

Page 14

contained in the assembly. When you open an assembly file in which one or

more components are modified, a message displays asking if you want to

update the assembly. Answer yes to update the assembly to the last saved state

of the components. Answer no to disregard any modifications to the referenced

components.

Associative Behavior of Drawings

Drawings maintain associativity to the components contained in the file views.

If you change a component, the component view automatically updates the

next time the drawing file is opened. You can choose to disable automatic

updates by enabling Defer Updates in the Drawing tab of Document Settings.

If the drawing contains a parts list and item balloons, the balloon numbers

are associative to the item numbers in the parts list. The parts list is also

associative to the Bill of Materials in the source assembly. If items are deleted

from the assembly, they are no longer contained in the drawing parts list. The

parts list is associative to the iProperties of the components being detailed for

entries such as part number and description.

LocationFor more information

Help topic

Search:

“3D modeling concepts”

“2D to 3D bidirectional associativity”

“Assembly components in patterns”

“Design view representations in drawings”

8 | Chapter 1 Digital Prototypes in Autodesk Inventor

Page 15

Create Digital Prototypes

2

Traditionally, designers and engineers create a layout, design the parts, and then bring

everything together in an assembly. Once the design is created, the next step in the traditional

process is to build and test a physical prototype.

NOTE This chapter describes how to create digital prototypes in Inventor LT

With Autodesk Inventor®, you can create an assembly at any point in the design process. You

can virtually explore, test, and validate a digital prototype as the design evolves. You can

visualize and simulate real-world performance of the design, so there is less reliance on costly

physical prototypes.

The basic component of a digital prototype is the part file. A part model is a collection of

features or solid bodies that define your digital prototype. Parametric modeling provides the

ability to apply driving dimensions and geometric relationships to the model. These dimensions

and relationships are called parameters. Parameters control the size and shape of a model.

When you change a parameter, the model updates to reflect the changes. Using parameters,

you can control multiple parts in an assembly.

Parts

A file with an .ipt extension represents a part file. A part is represented on disk

with only one file type. However, there are many different types of part files.

They can be simple to complex. Some of the common types of parts are

explained in the following section. The workflow you use to create the part is

what determines the part type.

9

Page 16

Single Body Parts

The most basic part type can vary greatly in complexity from just a few features

to a complex design. The distinguishing features are that it is composed of

one material and one solid body, of which the thickness can vary.

A single body part contains one solid body that shares

a collection of one or more features. A single body part

defines a single item in a parts list.

LocationFor more information

iParts

Help topics

Search:

“Create parts in assemblies”

“Work with parts”

Parts 1 - Create PartsTutorial

Most designers have parts that differ by size, material, or other variables, but

the same basic design works in many models.

An iPart is a table driven master part that

configures standard parts to different sizes

and states. The table can be edited within

Inventor or externally in a spreadsheet.

Each row can control feature state (enabled or suppressed), and many other

variables such as feature size, color, material, and part number. Table driven iFeatures can also be included in an iPart

table.

10 | Chapter 2 Create Digital Prototypes

Page 17

An iPart typically generates multiple

unique parts that belong to the same

family.

NOTE You can create an iPart and save

it as a table-driven iFeature.

Use the iPart Author to create the part family members in each table row.

When placing the part in an assembly, select a row (member) to generate a

unique part.

LocationFor more information

Search: “iPart Fundamentals”Help topic

Skill Builder

Sheet Metal Parts

Within the Autodesk Inventor design environment, a sheet metal part can be

displayed as a folded model or a flat pattern. With sheet metal commands,

you can unfold features and work on a model in a flattened state, and then

refold the features.

You create sheet metal parts from a template file. The sheet metal template

file incorporates a set of rules. The rules determine some common attributes

such as material type and thickness, unfolding rules, gap sizes, and so on. By

changing a single rule, you can change the material of a sheet metal part from

Parts:

iParts - The Basics

iParts - Beyond the Basics

Chances are that a design you have been asked to create

contains components that lend themselves to fabrication

from sheet metal.

Autodesk Inventor provides functionality that simplifies the

creation, editing, and documentation of digital prototypes

of sheet metal components.

A sheet metal part is often thought of as a part fabricated

from a sheet of uniformly thick material. If you design small

objects, this material is often thin. However, in Autodesk

Inventor you can utilize the sheet metal commands on any

design where the material is of uniform thickness.

Sheet Metal Parts | 11

Page 18

aluminum to stainless steel. A change of material often requires changes to

the attributes that define bends and corners. Such changes often require

changes to shop floor machinery and set-ups used to fabricate the parts.

Like other parts created within Autodesk Inventor, sheet metal parts begin

with a base feature. The base feature of a sheet metal part is often a single face

of some shape to which other features (often flanges) are added. A complex

design could use a contour flange or contour roll as the initial base feature.

Some parts could utilize a lofted flange as the initial feature.

Unlike regular parts, sheet metal parts are always created from a uniformly

thick sheet that is flat. This sheet is formed into the final part using various

fabrication techniques. In the sheet metal environment, you can create a

folded model and unfold it into a flat pattern. The flat pattern is typically

used to detail the fabrication. The sheet metal commands you use to work

with flat patterns can provide critical fabrication information.

If a regular part created in Autodesk Inventor is of a consistent thickness, you

can convert it to a sheet metal part. The same is true for parts imported from

other systems.

LocationFor more information

Help topics

Skill Builders

Search:

“Sheet Metal Defaults”

“Templates for sheet metal parts”

Build sheet metal partsTutorial

Parts:

Sheet Metal Punch iFeatures - part 1

Sheet Metal Punch iFeatures - part 2

12 | Chapter 2 Create Digital Prototypes

Page 19

Derived Parts

A derived part can contain features independent of the parent component,

and can be:

■ Driven by the original component or the link can be disabled.

■ Used for scaling and mirror operations.

■ Derived from a specific assembly Level of Detail.

■ Used to perform add and subtract operations on assembly components.

A derived part is a new part or body created from an

existing part or assembly.

Use Derived Component to:

■ Create modified or simplified versions of other

components.

■ In an empty part file, create a derived part from

another part or assembly.

■ In a multi-body part, insert components as toolbodies.

■ Mirror or scale a part or assembly

■ Perform Boolean operations.

■ An existing component inserted as a new toolbody in a multi-body part

file.

LocationFor more information

Help topics

Search:

“Derived parts and assemblies”

“Derived parts”

Create Parts from Derived GeometryTutorial

Parts - Derived PartsSkill Builder

Derived Parts | 13

Page 20

Multi-body Parts

Shrinkwrap Parts

A shrinkwrap part uses the derived component mechanism to create a

simplified part file from an assembly. The Shrinkwrap command uses rule

based face and component removal and hole patching to simplify an assembly.

A shrinkwrap surface composite (the default setting) uses less memory and

Multi-body parts are used to control complex curves across

multiple parts in plastic part design or organic models.

A multi-body part is a central design composed of features

contained in bodies that can be exported as individual part

files.

You can insert components into a multi-body part file with

the Derived Component command. Use the Combine

command to perform Boolean operations.

LocationFor more information

Search: “Combine solid bodies”Help topic

Explore Multi-Bodies and Plastic FeaturesTutorial

14 | Chapter 2 Create Digital Prototypes

Page 21

provides the best performance when used as a substitute LOD in consuming

assemblies.

Use Shrinkwrap to:

■ Create an envelope of an assembly to provide

information to an outside group such as AEC.

■ Create a part that uses less memory and provides

better performance in consuming assemblies.

■ Create a part that protects intellectual property

by concealing holes and components.

■ Create a simplified part to use as a substitute LOD

in the owning assembly.

NOTE A shrinkwrap part is created from an assembly

to remove parts and small features from the assembly.

Use a shrinkwrap part to simplify a design or protect

intellectual property.

LocationFor more information

Search: “Shrinkwrap assemblies”Help topic

Assembly Substitute Parts

An assembly substitute part is a simplified representation of an assembly. It

can be created from any part file on disk, or derived in place in the owning

assembly. You can create a shrinkwrap substitute part in an assembly to reduce

file size and complexity.

Assembly Substitute Parts | 15

Page 22

Content Center Parts

Autodesk Inventor Content Center libraries provide standard parts (fasteners,

steel shapes, shaft parts) and features to insert in assemblies.

Two types of parts are included in the Content Center library: standard parts

and custom parts. Standard parts (fasteners, shaft parts) have all part parameters

defined as exact values in the table of parameters. Custom parts (steel shapes,

rivets) have a parameter set arbitrarily within the defined range of values.

LocationFor more information

Search: “Create Substitutes”Help topic

The basic component in a Content Center library is a family (part

family or feature family). A family contains family members that

16 | Chapter 2 Create Digital Prototypes

Page 23

have the same template and family properties, and represent

size variations of a part or feature.

Families are arranged in categories and subcategories. A

category is a logical grouping of part types. For example, studs and hex head

bolts are functionally related

and are nested under the

Bolts category. A category

can contain subcategories

and families.

Use the Content Center environment to work with Content Center library

parts in the design process.

■ Open and view a part family, and choose the family member.

■ Insert a part from Content Center library into an assembly file.

■ Insert a feature from Content Center library in a part.

■ Use AutoDrop to place a part interactively from a Content Center library

into an assembly file.

■ Change the size of a placed Content Center library part.

■ Replace an existing (also non-Content Center) part with a part from the

Content Center library.

LocationFor more information

Search: “Content Center Environment”Help topic

Use Content CenterTutorial

Content CenterSkill Builders

Content Center Parts | 17

Page 24

Content Center Libraries

Content Center libraries contain data required to create part files for Content

Center library parts. The data are:

■ Parametric .ipt files which provide models for Content Center library parts.

■ Family tables which include values of part parameters.

■ Descriptions for parts including family properties such as family name,

description, standard, and standard organization.

■ Preview pictures displayed in the Content Center.

Parametric .ipt files, description texts, and preview pictures are common for

all members of one family. Sets of parameter values specify particular family

members.

A set of standard Content Center libraries can be installed with Autodesk

Inventor. Standard libraries are read-only and cannot be edited directly. You

must copy parts to the read/write library first.

Use the Content Center Editor to build user libraries and to modify or expand

standard content delivered with the Autodesk Inventor installation.

LocationFor more information

Search: “Content Center Editor”Help topic

Features

The building blocks of a part model are called features. There are four basic

types of Features:

■ Sketched Features that require a sketch.

■ Placed Features that modify existing geometry. For example, a hole is a

placed feature.

■ Work Features used for construction purposes.

■ iFeatures that represent common shapes and are saved in a reusable library.

An iFeature driven by a table can represent different shape configurations.

18 | Chapter 2 Create Digital Prototypes

Content Center User LibrariesTutorial

Page 25

You can create surfaces with many of these operations to define shapes or

aspects of the part body. For example, you can use a curved surface as a

termination plane for cuts in a housing.

You can edit the characteristics of a feature by returning to its underlying

sketch or changing the values used in feature creation. For example, you can

change the length of an extruded feature by entering a new value for the

extent of the extrusion. You can also use equations to derive one dimension

from another.

Sketched Features

Most parts start with a sketch. A sketch is the profile of a feature and any

geometry (such as a sweep path or axis of rotation) required to create the

feature. Your first sketch for a part can be a simple shape.

Sketched part features depend on sketch geometry. The first feature of a part,

the base feature, is typically a sketched feature. All sketch geometry is created

and edited in the sketch environment, using Sketch commands on the ribbon.

You can control the sketch grid, and use sketch commands to draw lines,

splines, circles, ellipses, arcs, rectangles, polygons, or points.

LocationFor more information

Search: “Adaptive features, parts, and subassemblies”Help topics

Create and Reuse iFeaturesTutorial

You can select a face on an existing part, and sketch on it. The sketch displays

with the Cartesian grid defined. If you want to construct a feature on a curved

surface, or at an angle to a surface, first construct a work plane. Then sketch

on the work plane.

The browser displays the part icon, with its features nested under it. Surface

features and work features are nested or consumed by default. To control

nesting, or consumption of surface and work features for all features, set the

option on the Part tab of the Applications Options dialog box. To override

consumption on a per-feature basis, right-click the feature in the browser, and

then select Consume Inputs.

Sketched Features | 19

Page 26

The following features are dependent on a sketch you create:

Extrude

Adds depth to a sketch profile along

a straight path.

Can create a body.

Revolve

Projects a sketch profile around an axis.

The axis and the profile must be coplanar.

Can create a body.

Loft

Constructs features with two or more

profiles.

.

Transitions the model from one shape

to the next.

Aligns the profiles to one or more

paths.

Can create a body.

20 | Chapter 2 Create Digital Prototypes

Page 27

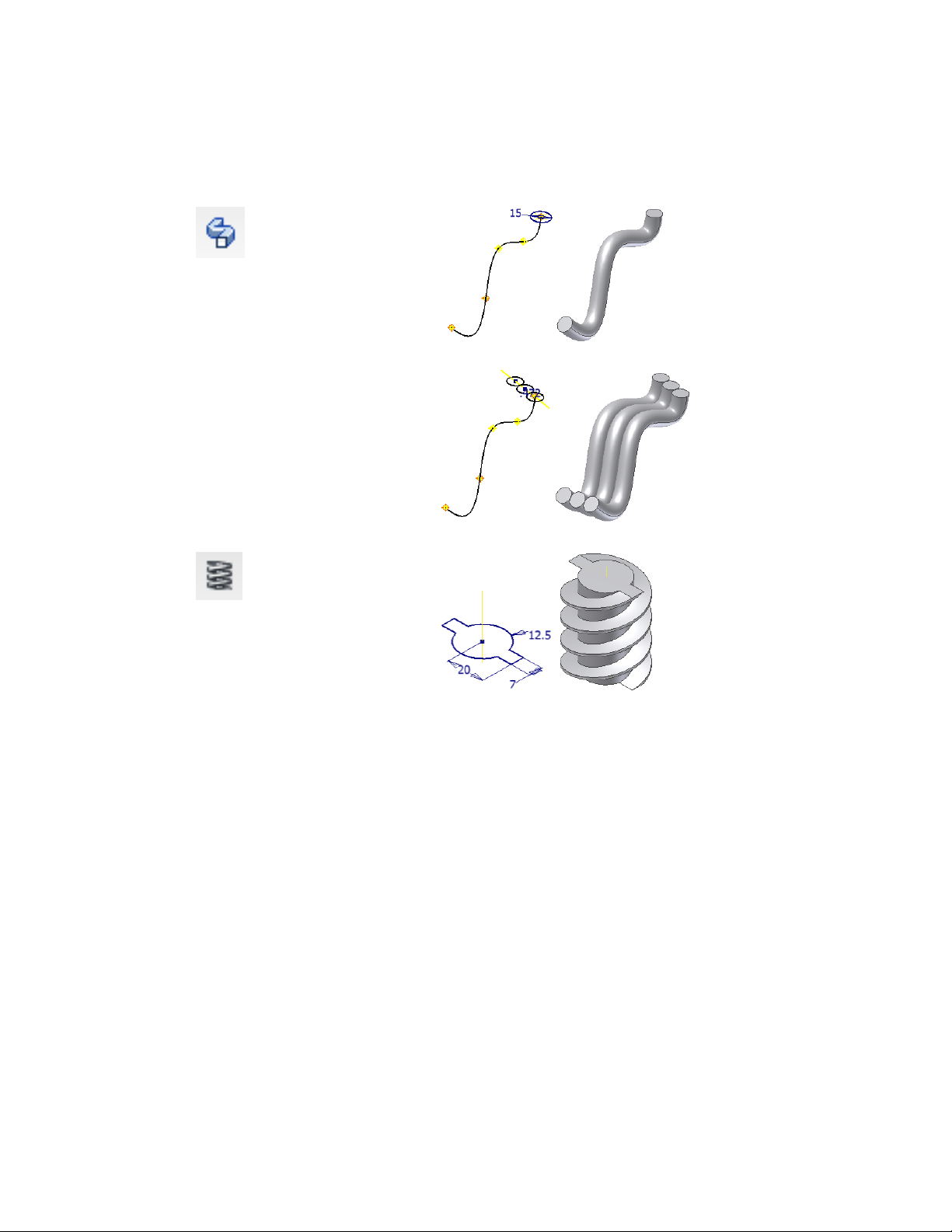

Sweep

Projects a single sketch profile along

a single sketched path.

The path can be open or closed.

A sketch profile can contain multiple

loops that reside in the same sketch.

Can create a body.

Coil

Projects a sketch profile along a helical

path.

Use Coil to create springs or to model

physical threads on a part.

Can create a body.

The models created by these operations are typically solid features or new

bodies that form a closed volume.

Surfaces

You can create surfaces with many of these operations. Surfaces can form an

open or closed volume but contain no mass. Use surfaces to define shapes,

use as a split tool, or sculpt certain aspects of the part body.

Sketched Features | 21

Page 28

The following features require sketches, but do not create a base feature because

they are dependent on existing geometry.

Rib

Creates a rib or web extrusion from a

2D sketch.

Use Rib to create thin-walled closed

support shapes (ribs) and thin-walled

open support shapes webs.

Emboss

Creates a raised (emboss) or recessed

(engrave) feature from a sketch profile.

22 | Chapter 2 Create Digital Prototypes

Page 29

Decal

Applies an image file to a part face.

Use decal to add realism or to apply a

label.

LocationFor more information

Help topic

Search:

“Plan and create sketches”

“Sketch properties”

Parts 1 - Create PartsTutorial

Sketch Environment

When you create or edit a sketch, you work in the sketch environment. The

sketch environment consists of a sketch and sketch commands. The commands

control the sketch grid and draw lines, splines, circles, ellipses, arcs, rectangles,

polygons, or points.

When you open a new part file, the sketch environment is active. The 2D

Sketch button is selected, and the Sketch commands are available, along with

a sketch plane on which to sketch. You can control the initial sketch setup

by using template files, or settings in the Application Options dialog box,

Sketch tab.

When you create a sketch, a sketch icon displays in the browser. When you

create a feature from a sketch, a feature icon displays in the browser with the

sketch icon nested under it. When you click a sketch icon in the browser, the

sketch is highlighted in the graphics window.

After you create a model from a sketch, re-enter the sketch environment to

change or start a new sketch for a new feature. In an existing part file, first

activate the sketch in the browser. This action activates the commands in the

Sketched Features | 23

Page 30

sketch environment. You can create geometry for part features. The changes

you make to a sketch are reflected in the model.

LocationFor more information

Help topic

Search:

“Sketch Environment”

“Application Options settings > Part tab”

“Application Options settings > Sketch tab”

Work with Sketch BlocksTutorial

Sketch Blocks

In many assembly designs, rigid shapes are repeated.

You can use sketch blocks to capture such shapes as a

fixed set, and place instances of the set where needed.

You can define nested sketch blocks and place flexible

instances of these blocks. These flexible instances retain

specified degrees of freedom that allow them to simulate

kinematic subassemblies.

Sketch blocks are created in 2D part sketches and can be comprised only of

sketch objects. Sketch block definitions are contained in the Blocks folder

while sketch block instances reside under the parent sketch. You can control

the appearance and format of block definitions and instances.

Use sketch blocks to represent components in your top-down design layout.

After you create a sketch block, you can add instances of the block to your

layout. This method for adding components in multiple locations in the design

is quick and associative. Any changes to the block definition are propagated

to all block instances.

LocationFor more information

Help topic

Search:

“Sketch blocks”

“Top-down design”

Sketch BlocksTutorial

24 | Chapter 2 Create Digital Prototypes

Page 31

Sketch Constraints

Constraints limit changes and define the shape of a sketch. For example, if a

line is horizontally constrained, dragging an endpoint changes the length of

the line or moves it vertically. However, the drag does not affect its slope. You

can place geometric constraints between:

■ Two objects in the same sketch.

■ A sketch and geometry projected from an existing feature or a different

sketch.

As you sketch, constraints are automatically applied to the various sketch

elements. For example, if the horizontal or vertical symbol displays when you

create a line, then the associated constraint is applied. Depending on how

accurately you sketch, one or more constraints could be required to stabilize

the sketch shape or position. You can also add constraints manually to any

sketch element.

Although you can use unconstrained sketches, fully constrained sketches result

in more predictable updates.

LocationFor more information

Search: “Constrain Sketches”Help topic

Explore Sketch ConstraintsTutorial

2D AutoCAD Data in Sketches

When you open an AutoCAD® file in Autodesk Inventor, you can place 2D

translated data:

■ On a sketch in a new or existing drawing.

■ As a title block in a new drawing.

■ As a sketched symbol in a new drawing.

■ On a sketch in a new or existing part.

You can import AutoCAD (DWG) drawings into a part sketch, drawing, or

drawing sketch overlay. The entities from the XY plane of model space are

placed on the sketch. In a drawing, certain entities, such as splines, cannot

Sketched Features | 25

Page 32

be converted. You can choose to import AutoCAD blocks as Autodesk Inventor

sketch blocks.

When you export Autodesk Inventor drawings to AutoCAD, the converter

creates an editable AutoCAD drawing. All data is placed in paper space or

model space in the DWG file. If the Autodesk Inventor drawing has multiple

sheets, each is saved as a separate DWG file. The exported entities become

AutoCAD entities, including dimensions.

You can open a .dwg file and then copy selected AutoCAD data to the clipboard

and paste into a part, assembly, or drawing sketch. The data is imported at

the cursor position.

LocationFor more information

Help topic

Placed Features

Placed features are common engineering features that do not require a sketch

when you create them with Autodesk Inventor. You usually provide only the

location and a few dimensions.

The standard placed features are shell, fillet, chamfer, face draft, hole, and

thread.

The commands for placed features are located on the Sketch and Model tabs:

Fillet Places a fillet or round on selected edges loops, and features.

Chamfer Breaks sharp edges. Removes material from an outside edge and

adds material to an inside edge.

Hole Places a specified hole in a part, optionally with thread.

Thread Creates regular and tapered external and internal threads on cylindrical

or conical faces.

Shell Produces a hollow part with a wall thickness you define.

Rectangular Pattern Creates a rectangular pattern of features.

Search:

“3D sketch environment”

“AutoCAD, using geometry in Inventor”

Circular Pattern Creates a circular pattern of features.

Mirror Feature Mirrors different type of features across a plane.

26 | Chapter 2 Create Digital Prototypes

Page 33

iFeatures

Dialog boxes define values for placed features, such as the Hole dialog box.

An iFeature is one or more features that you can save and reuse in other

designs. You can create an iFeature from any sketched feature. Features

dependent on the sketched feature are included in the iFeature. After you

create an iFeature and store it in a catalog, you can drag it from Windows

Explorer and drop it in the part file. You can also use the Insert iFeature

command.

LocationFor more information

Help topic

Assembly Features

Assembly features are like part features, except that you create them in the

assembly environment. They can affect multiple components in an assembly

file, but the modifications do not alter the included component files. If

assembly features are used, use LOD reps to exclude unnecessary components.

The more participants, the bigger the file size and the longer it takes to

calculate the feature. You usually suppress assembly features before saving.

Assembly features include chamfers, fillets, sweeps, revolved features,

extrusions, holes, move face, rectangular feature pattern, circular feature

pattern, and mirror. They also include the work features and sketches used to

create them. The workflow and dialog boxes are the same as for part features.

However, some operations are not available, such as creating a surface for

extruded and revolved features.

You can edit, add to, suppress, or delete assembly features. You can also roll

back the state of the assembly features and add or remove components that

participate in the feature.

Search:

“Placed features”

“iFeature fundamentals”

LocationFor more information

Search: “Assembly Features”Help topic

Assemble and Constrain ComponentsTutorial

iFeatures | 27

Page 34

Work Features

Work features are abstract construction geometry that you can use to create

and position new features when other geometry is insufficient. To fix position

and shape, constrain features to work features.

Work features include work planes, work axes, and work points. The proper

orientation and constraint conditions are inferred from the geometry you

select and the order in which you select it.

The work feature commands provide on-screen prompts to help you with

selection and placement. You can:

■ Create and use work features in the part, assembly, sheet metal, and 3D

sketch environments.

■ Use and refer to work features in the drawing environment.

■ Project work features into a 2D sketch.

■ Create in-line work features to help you define a 3D sketch or position a

part or assembly feature.

LocationFor more information

Show me how to create an assembly featureShowme

■ Make work features adaptive.

■ Turn the visibility of work features on or off.

■ Drag to resize work planes and work axes.

LocationFor more information

Help topics

Search:

“Adaptive work features”

“Work axes”

“Work planes”

“Work points”

Explore Sketch ConstraintsTutorial

28 | Chapter 2 Create Digital Prototypes

Page 35

Edit Features

In the browser, right-click a feature, and then use one of several options on

the menu to modify the feature:

Displays the sketch dimensions so you can edit them.Show Dimensions

■ Change the dimensions of a feature sketch.

■ Change, add, or delete constraints.

Activates the sketch so it is available for edit.Edit Sketch

■ Modify or create a new profile for the feature.

After you modify a part sketch, exit the sketch and the

part updates automatically.

Opens the dialog box for that feature.Edit Feature

■ Choose a different method to terminate the feature.

■ Choose whether the feature joins, cuts, or intersects

another feature.

3D Grips

Assemblies

Assembly modeling combines the strategies of placing existing components

in an assembly, and creating other components in place within the context

Uses grip handles to drag a feature or face, or snap to

other geometry to resize a feature. Arrows indicate the

drag direction. The feature preview shows the expected

results before you commit to the change.

LocationFor more information

Search: “Features and feature termination”Help topic

Parts 2 - Create Base PartsTutorial

Edit Features | 29

Page 36

of the assembly. In a typical modeling process, some component designs are

known and some standard components are used. Create the designs to meet

specific objectives.

Place Components

In the assembly environment, you can add existing parts and subassemblies

to create assemblies, or you can create parts and subassemblies in-place.

A component (a part or subassembly) can be an unconsumed sketch, a part,

a surface, or any mixture of both.

When you create a component in-place, you can do one of the following:

■ Sketch on one of the assembly origin planes.

■ Click in empty space to set the sketch plane to the current camera plane.

■ Constrain a sketch to the face of an existing component.

When a component is active, the rest of the assembly is shaded in the browser

and graphics window. Only one component can be active at a time.

Choose a fundamental part or subassembly, such as a frame or base plate, to

be the first component in an assembly. Except for the first placed component,

all placed components are unconstrained and ungrounded. You add the

constraints you need.

The first component you place in an assembly is automatically grounded (all

degrees of freedom are removed). Its origin and coordinate axes are aligned

with the origin and coordinate axes of the assembly. It is a good practice to

place assembly components in the order in which they would be assembled

in manufacturing.

30 | Chapter 2 Create Digital Prototypes

Page 37

When you create a component in the assembly context, the created component

is nested under the active main assembly or subassembly in the browser. A

sketch profile for the in-place component that uses projected loops from other

components within the assembly, is associatively tied to the projecting

components.

Drag Components into Assemblies

You can place multiple components in an assembly file in a single operation

by dragging them into an open assembly window.

Drop the files over the graphics window where the assembly model is displayed.

A single occurrence of each component is placed in the assembly file. The

dropped components appear at the bottom of the browser in the receiving

assembly.

LocationFor more information

Search: “Assembly components”Help topic

Assembly Constraints

Assembly constraints establish the orientation of the components in the

assembly and simulate mechanical relationships between components. For

example, you can:

■ Mate two planes.

■ Specify that cylindrical features on two parts remain concentric.

■ Constrain a spherical face on one component to remain tangent to a planar

face on another component.

Each time you update the assembly, the assembly constraints are enforced.

Assemble and Constrain ComponentsTutorial

Assembly Constraints | 31

Page 38

Degrees of Freedom

Each unconstrained component in an assembly has six degrees of freedom

(DOF). It can move along or rotate about each of the X, Y, and Z axes. The

ability to move along X, Y, and Z axes is called translational freedom. The

ability to rotate around the axes is called rotational freedom.

Whenever you apply a constraint to a component in an assembly, you remove

one or more degrees of freedom. A component is fully constrained when all

degrees of freedom (DOF) are removed. You are not required to constrain

completely any component in an assembly in Autodesk Inventor.

To verify the DOF of components in an assembly:

■ Select Degrees of Freedom from the Visibility panel of the View tab.

■ Drag a component in the graphics window. Other components in the

assembly will move based on existing constraints.

LocationFor more information

Help topic

Search:

“Assembly Constraints Overview”

“Degrees of Freedom in Assemblies”

“Plan Constraints”

Assemble and Constrain ComponentsTutorial

32 | Chapter 2 Create Digital Prototypes

Page 39

Top-down Design

Once you are satisfied with the state of your layout, you make components

from the sketch blocks. This process, also known as push-derive, results in

part and assembly files that are associated to the layout sketch blocks. When

you change the sketch block definitions, your component files automatically

reflect the changes.

Experiment with top-down design to experience the power of truly associative

designs.

The top-down design technique (also known

as skeletal modeling) centralizes control of your

design. The technique enables you to update

your design efficiently and with minimal disruption to your design documents.

Top-down design begins with the layout. The

layout is a 2D part sketch that is the root document of your design. You create a layout that

represents your assembly, subassembly, floor

plan, or equivalent. In the layout, you use 2D

sketch geometry and sketch blocks to represent

the design components. You position these

components, in the layout, to evaluate design

feasibility.

LocationFor more information

Search: “Top-down design”Help topics

Top-down WorkflowTutorial

Create Subassemblies In-place

In the assembly environment, you can add existing parts and subassemblies

to create assemblies or you can create new parts and subassemblies in-place.

A component (a part or subassembly) can be an unconsumed sketch, a part,

a surface, or any mixture of both.

Top-down Design | 33

Page 40

When you create a component in-place, you can do one of the following:

■ Sketch on one of the assembly origin planes.

■ Click in empty space to set the sketch plane to the current camera plane.

■ Constrain a sketch to the face of an existing component.

When you create a subassembly in place, you define an empty group of

components. The new subassembly automatically becomes the active assembly,

and you can start to populate it with placed and in-place components. When

you reactivate the parent assembly, the subassembly is treated as a single unit

in the parent assembly.

Optionally, you can select components at the same assembly level in the

browser, right-click, and then select Component ➤ Demote to place them

into a new subassembly. You are asked to specify a new file name, template,

location, and default bill of materials structure. You can then move

components between assembly levels by dragging components in the browser.

Subassemblies can be nested many layers deep in a large assembly. By planning

and building subassemblies, you can efficiently manage the construction of

large assemblies. You can create subassemblies that match the intended

manufacturing scheme to facilitate the creation of your assembly

documentation.

LocationFor more information

Search: “Top-down, bottom-up, middle-out design”Help

Design Assemblies and ConstraintsTutorial

AssembliesSkill Builders

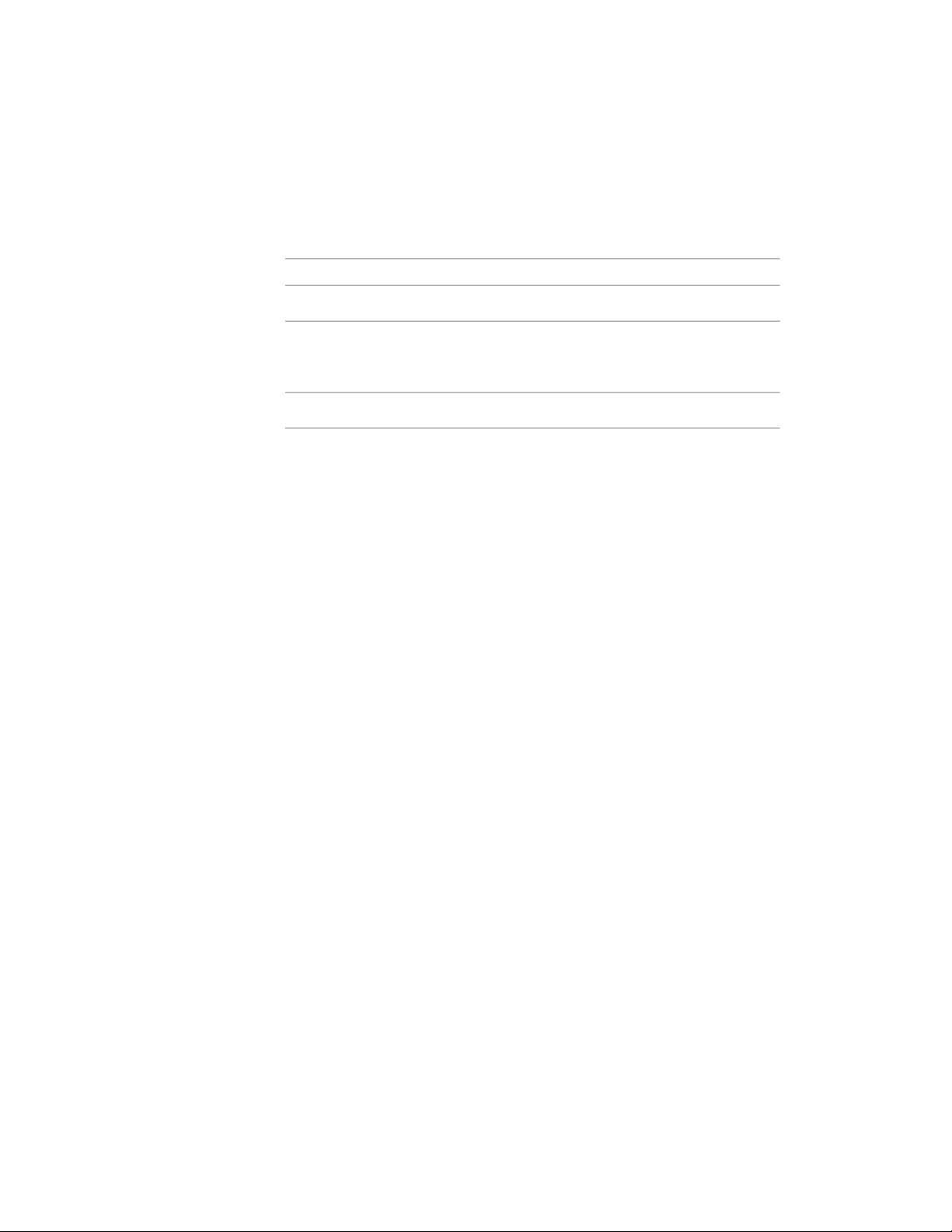

Design Accelerator Components

Design Accelerator provides a set of generators and calculators to create

mechanically correct components automatically from simple or detailed

mechanical attributes you enter.

34 | Chapter 2 Create Digital Prototypes

Page 41

You insert components using Design Accelerator generators and calculators

in the assembly environment. The generators and calculators are grouped

according to functional areas. For example, all welds are together.

For more information

Search: “Design Accelerator”Help topic

Tutorials

Design Mechanisms

A mechanism is defined as a design with one or more moving parts. Inventor

provides numerous tools to assist you in creating and evaluating a mechanical

design.

Use sketch blocks in a 2D part sketch to create a schematic layout of your

mechanism. Create flexible, nested blocks and apply sketch constraints to

define subassembly kinematics. Derive sketch blocks into component files

and create other features to develop your 3D models. The components remain

associated to their corresponding blocks and update to reflect any changes in

block shape.

Use the following tools to evaluate a mechanism in the 3D environment:

■ Animate an assembly constraint and enable collision detection to determine

the exact point of contact. For example, animate an angular constraint to

evaluate the range of motion before contact occurs.

Design Bolted Connections, Shafts, Spur Gears Connections,

Bearings, V-belts Connections, Disc Cams, Compression

Springs

Design AcceleratorSkill Builder

Design Mechanisms | 35

Page 42

■ Create a Contact Set and add members as required to simulate physical

contact between components and to determine the range of motion.

■ Use Positional representations to save a mechanism in various states such

as maximum and minimum extension.

■ Use Inventor Studio to animate simultaneous or sequential movement.

36 | Chapter 2 Create Digital Prototypes

Page 43

■ Use the Dynamic Simulation Environment to calculate displacements,

velocities, accelerations, and reaction forces without the cost of a physical

prototype.

■ Use the Stress Analysis Environment to conduct structural static and modal

stress analysis studies on the digital prototype.

LocationFor more information

Search: “Physical environment”Help topic

Tutorial

Check for Interference

In the physical product built from your design, two or more components

cannot occupy the same space at the same time unless they are specifically

designed to do so. To check for such errors, Autodesk Inventor can analyze

assemblies for interference.

The Analyze Interference command checks for interference between sets of

components or among the components in a single set. If interference exists,

Autodesk Inventor displays it as a solid and displays a dialog box that contains

the volume and centroid of each interference. You can then modify or move

the components to eliminate the interference.

Animate Assemblies

Explore Part Stress Analysis

Explore Assembly Simulation

LocationFor more information

Search: “Check for interference between components”Help topic

Optimize AssembliesTutorial

Check for Interference | 37

Page 44

iAssemblies

An iAssembly is a configuration of a model with a few or many variations

called members. Each member has a set of unique identifiers, such as diameter

or length. A member could have different components, such as a power train

for a vehicle with several different engine sizes.

Create an iAssembly if you want to show different quantities for assembly

components in a parts list. You can define the required parts list quantity for

each iAssembly member.

You can manage iAssemblies from a table. In an iAssembly, you can replace

one member with another member from the same factory by selecting a

different row in the table. The bill of materials and parts list automatically

update when you edit members.

LocationFor more information

Search: “iAssemblies”Help topic

38 | Chapter 2 Create Digital Prototypes

Page 45

Document and Publish Designs

During the process of creating digital prototypes in Inventor, there is often a need to

communicate the design to individuals outside the design team. In Autodesk Inventor®, you

can create the appropriate type of documentation for any consumer, such as customers or

manufacturers. The document types available are:

■ 2D drawings

■ 3D CAD files

■ Read-only files, such as DWF or PDF

■ Photo realistic renderings

You can create the documentation at any stage during the process of creating digital prototypes.

3

Drawings

A drawing consists of one or more sheets that each contain one or more 2D

drawing views and annotations. Drawings are associative to the digital

prototypes. Any change to the model is automatically reflected in the drawing

the next time you open it. You can create a drawing at any point in the design

process, and it always reflects the current state of the digital prototype.

Annotations can include dimensions, symbols, tables, and text.

Start Drawings

Drawings are created from a drawing template file. Autodesk Inventor includes

standard templates (.idw, .dwg) stored in the Autodesk\Inventor (version

39

Page 46

number)\Templates folder. The available templates are presented in the tabs

of the New File dialog box.

Drawing templates can contain sheet formats, borders, title blocks, and

sketched symbols. Templates also control the default styles and standards used

for the appearance of views and annotations.

When you start a drawing, the title block, border, sheet size, and other elements

come from the template.

Inventor Drawing Tips:

■ The template you select to create a drawing file determines the default

sheet size, title block, border, and so on. You can change the sheet size,

title block, and border after you create the drawing. The template controls

the default styles and standards used for the appearance of views and

annotations.

■ You can create customized templates and save them in the Templates folder.

To set up a drawing template, open a template file from Autodesk\Inventor

(version number)\Templates. Make your changes, and save the file with a

new name in the Templates folder. The new template is available the next

time the New File dialog box displays.

■ You can create different templates for the different sheets sizes you use,

or create multiple sheet formats in a single template.

■ To customize a drawing sheet in a template, change the default sheet size

and specify sheet orientation. Then modify the border and title blocks to

fit the sheet. Available borders and title blocks are listed in the Drawing

Resources folder in the browser.

LocationFor more information

Help topics

Search:

“Drawing Environment”

“Templates for drawings”

“Create drawings”

Prepare Final DrawingsTutorial

Types of Drawing Files

Autodesk Inventor supports IDW and DWG file types for drawings. Both file

types produce identical drawings. IDW files are the native Inventor format.

40 | Chapter 3 Document and Publish Designs

Page 47

You can open them only in Inventor or Inventor View. This file type results

in smaller file sizes.

The DWG file type is native to AutoCAD®. You can open DWG files in

AutoCAD, Inventor, or DWG TrueView. If you create data using Inventor in

a DWG file, you can modify the data only with Inventor. If you create data

using AutoCAD in a DWG file, you can modify the data only with AutoCAD.

If a downstream consumer of your Inventor data needs a DWG file, consider

using DWG files as the default in Inventor.

LocationFor more information

Help topics

Create Views of Models

A drawing view is a 2D representation of a 3D digital prototype that is placed

on a drawing sheet. The commands for views in Inventor are like view types

in drafting. The two types of view commands in Inventor are author and

modify. Author commands create new views. They are located in the Author

panel of the ribbon. Modify commands change existing views. They are located

on the Modify panel of the ribbon.

The first view placed on a drawing is a base view. Subsequent views are either

children of the base view or additional base views. As you create views, they

are listed in the browser with the sheet, title block, and border.

Types of Drawing Views

Base View

The first view created in a drawing. The base view is the source for

subsequent views and controls the scale and alignment for them.

You can create one or more base views on a drawing sheet.

You select the orientation of the view when you create it. The default

orientations are based on the origin in the digital prototype.

Search:

“Create drawing templates”

“DWG Translation”

Create Views of Models | 41

Page 48

Projected View

An orthographic or isometric view that is generated from a base view

or other existing view. You can create multiple projected views in a

single operation. The position of the cursor relative to the parent view

determines the orientation of the projected view.

Projected views inherit the scale and display settings from the parent

view. Orthographic projected views keep alignment with the parent

view. The active drafting standard defines the first-angle or third-angle

projection.

Auxiliary View

A view projected perpendicular to a user-selected line or edge. Use

Auxiliary View to document features on inclined faces.

The position of the cursor relative to the parent view determines the

orientation of the auxiliary view. Auxiliary views inherit the scale and

display settings from the parent view.

Section View

A view created by sketching a line that defines a plane used to cut

through a part or assembly. You draw the cutting line when you

create the view, or select it from a sketch associated to the parent

view. The cutting line can be a single straight segment or multiple

segments. The cutting line arrowheads on the base view automatically

orient to reflect the position of the section view relative to the base

view.

The crosshatching, section line, and labels are placed automatically.

Detail View

An enlarged view of a specified portion of another drawing view. By

default, the scale of the detail view is double the scale of the parent

view, but you can specify any scale. A detail view is created without

alignment to its parent view.

Autodesk Inventor labels the detail view and the area it is derived

from on its parent view. You can set either a circular or rectangular

fence for the detail.

42 | Chapter 3 Document and Publish Designs

Page 49

Overlay View

A single view that shows an assembly in multiple positions. Overlays

are available for base, projected, and auxiliary views. The overlay view

is created on top of the parent view.

Draft View

A view created from a 2D sketch in the drawing file. You can place a

draft view and construct a drawing without an associated model. A

draft view can provide detail that is missing in a model.

Drawing View Operations

Break

An operation that reduces the size of a model by removing or

“breaking” irrelevant portions. Create a break in a view if the component view exceeds the length of the drawing, or contains large

areas of nondescript geometry. An example is the center portion of

a shaft.

Dimensions that span the break reflect the true length.

Break Out

An operation that removes a defined area of material to expose obscured parts or features in an existing drawing view. The parent view

must have an associated sketch that contains the profile defining the

break out boundary.

Create Views of Models | 43

Page 50

Crop

An operation that provides control over the view boundary in an existing drawing view. The clipping boundary can be a rectangle or

circle you create during the command, or a closed profile you select

from a sketch.

Slice

An operation that produces a zero-depth section from an existing

drawing view. You perform the Slice operation in a selected target

view. The slice lines are defined in a sketch associated to a different

view.

Drawing View Tips

■ You can edit views placed in drawings to change settings such as scale,

hidden line display, thread display, and so on. If the edited view is a parent

view, changes to the view parameters are reflected in dependent views.

■ You can remove the association between a parent and a dependent view

by editing the dependent view. Then you can set independent scale, style,

and alignment for the dependent view.

■ You can move a view by clicking and dragging the red border. You can

move multiple views with a crossing selection window.

■ Most dependent views are created with an alignment (vertical, horizontal,

in position) to the parent. An aligned view can be moved only within its

constraints. If the parent view is moved, the aligned view moves to

maintain its alignment. You can manually break the alignment between

the child and parent view.

■ You can delete views that are no longer needed. If you delete a base view,

dependent projected and auxiliary views can be deleted or retained. Section

and detail views require a parent view and cannot be retained.

44 | Chapter 3 Document and Publish Designs

Page 51

■ You can suppress views so that they do not display on the drawing sheet.

Suppressed views are useful when one view is created only for creating a

child view. The suppressed view can still be accessed in the browser.

Exploded Views

LocationFor more information

Search: “Drawing views”Help topic

Prepare Final DrawingsTutorial

DrawingsSkill Builders

Exploded views are commonly used to describe assemblies by moving

components out from their assembled position. Exploded views are

often used to balloon an assembly using item numbers found in a

parts list or bill of material. Exploded views are created by using a

combination of assembly (.iam), presentation (.ipn), and drawing

(.idw, .dwg) files. A view of the assembly is created in the presentation

file and the components are repositioned in the view. Drawing views

are then generated from the presentation file.

Annotate Drawing Views

Drawing annotations provide additional information to drawing views to

complete documentation of a digital prototype. The styles that correspond to

the active drawing standard determine the appearance of drawing annotations.

Drawing annotations are linked to model geometry and update accordingly

with model changes. Once annotations are placed on the sheet, they can be

moved using grips.

LocationFor more information

Search: “Exploded views and presentations”Help topic

Create Exploded ViewsTutorial

Exploded Views | 45

Page 52

Types of Drawing Annotations

General Dimensions

You can create general dimensions in orthographic or isometric views.

The geometry you select determines the dimension type and the

options available in the right-click menu.

You can override the dimension text, which does not affect the

model geometry.

You can change the dimension precision and tolerance, edit the

leader and arrowheads, or modify the content of dimension text.

Baseline Dimensions and Baseline Dimension Sets

Creates multiple dimensions that display the orthogonal distance

between the origin (base line) and selected edges or points. The first

edge or point selected is the origin geometry. You can create individual dimensions or a dimension set.

Ordinate Dimensions and Ordinate Dimension Set

Creates multiple ordinate dimensions in a single process. Ordinate

dimensions automatically align as you place them. If dimension text

overlaps, you can modify the dimension position or dimension style.

You can create individual dimensions or a dimension set.

Retrieve Dimensions

Displays all model dimensions, or only dimensions related to selected

parts or features. You select the dimensions to maintain in the drawing

view.

Only model dimensions parallel to the view plane are available.

Model dimensions can be modified to manipulate the part file.

46 | Chapter 3 Document and Publish Designs

Page 53

Center Marks

Center marks are added to the selected arc or circle. Center mark

extension lines are automatically sized to fit the geometry.

Center marks can be added individually or using the automated

centerlines command.

Centerlines

Creates centerlines for selected edges, at the midpoint for lines, or

at the center point of arcs or circles. Creates a circular centerline when

features form a circular pattern.

Autodesk Inventor supports three types of centerlines: bisector,

centered pattern, and axial.

Hole/Thread Notes

Hole or thread notes display the information from hole, thread, and

cylindrical cut extrusion features on a model. The style of the hole

note varies depending on the type of feature selected.

Chamfer Notes

Chamfer notes contain distance and angle measurements for selected

model edges or sketched lines.

You can attach chamfer notes to angled edges in views and sketches.

A chamfer edge and reference edge from different bodies, models,

or sketches, must be part of the same view.

Symbols

Various types of symbols are available: Surface texture, welding, feature control frame, feature identifier, datum target, and datum identifier symbols. Symbols are created with or without a leader.

Annotate Drawing Views | 47

Page 54

User-defined or sketched symbols are defined in the Drawing Resources and are placed like standard symbols. They are used to define

custom symbols that are not available in Autodesk Inventor.

Bend Notes

A bend not adds fabricating information to sheet metal bend, contour

roll, and cosmetic centerlines. Bend notes can be added to flat pattern

views of sheet metal parts.

A bend note is associated with the selected bend centerline. The default placement of the bend note is above the selected bend centerline. It constrains the bend text to the midpoint of the centerline and

offsets by the Origin Offset value from the Dimension Style.

Punch Notes

A punch note includes data related to the punch feature: for example

the punch ID, angle, direction, depth, quantity note, and so on.

Punch notes can be added to flat pattern views of sheet metal parts.

Caterpillars

Weld caterpillars are used to denote weld features in 2D views. You

can add weld caterpillars manually using the Caterpillar command.

Add them automatically from weld features using Get Model Annotations > Get Weld Annotations on the right-click menu.

End Fills

End fills are used to represent the filled region indicating the end of

a weld bead. You can add them manually using the End Fill command

or automatically from weldment models using Get Model Annotations

> Get Weld Annotations.

Change end fill appearance through object properties.