Autodesk Inventor 2009

Getting Started

January 2008Part No. 527A1-050000-PM01A

©

2008 Autodesk, Inc. All Rights Reserved. Except as otherwise permitted by Autodesk, Inc., this publication, or parts thereof, may not be

reproduced in any form, by any method, for any purpose.

Certain materials included in this publication are reprinted with the permission of the copyright holder.

Trademarks

The following are registered trademarks or trademarks of Autodesk, Inc., in the USA and other countries: 3DEC (design/logo), 3December,

3December.com, 3ds Max, ActiveShapes, Actrix, ADI, Alias, Alias (swirl design/logo), AliasStudio, Alias|Wavefront (design/logo), ATC, AUGI,

AutoCAD, AutoCAD Learning Assistance, AutoCAD LT, AutoCAD Simulator, AutoCAD SQL Extension, AutoCAD SQL Interface, Autodesk, Autodesk

Envision, Autodesk Insight, Autodesk Intent, Autodesk Inventor, Autodesk Map, Autodesk MapGuide, Autodesk Streamline, AutoLISP, AutoSnap,

AutoSketch, AutoTrack, Backdraft, Built with ObjectARX (logo), Burn, Buzzsaw, CAiCE, Can You Imagine, Character Studio, Cinestream, Civil

3D, Cleaner, Cleaner Central, ClearScale, Colour Warper, Combustion, Communication Specification, Constructware, Content Explorer,

Create>what's>Next> (design/logo), Dancing Baby (image), DesignCenter, Design Doctor, Designer's Toolkit, DesignKids, DesignProf, DesignServer,

DesignStudio, Design|Studio (design/logo), Design Your World, Design Your World (design/logo), DWF, DWG, DWG (logo), DWG TrueConvert,

DWG TrueView, DXF, EditDV, Education by Design, Exposure, Extending the Design Team, FBX, Filmbox, FMDesktop, Freewheel, GDX Driver,

Gmax, Heads-up Design, Heidi, HOOPS, HumanIK, i-drop, iMOUT, Incinerator, IntroDV, Inventor, Inventor LT, Kaydara, Kaydara (design/logo),

LocationLogic, Lustre, Maya, Mechanical Desktop, MotionBuilder, Mudbox, NavisWorks, ObjectARX, ObjectDBX, Open Reality, Opticore,

Opticore Opus, PolarSnap, PortfolioWall, Powered with Autodesk Technology, Productstream, ProjectPoint, ProMaterials, Reactor, RealDWG,

Real-time Roto, Recognize, Render Queue, Reveal, Revit, Showcase, ShowMotion, SketchBook, SteeringWheels, StudioTools, Topobase, Toxik,

ViewCube, Visual, Visual Bridge, Visual Construction, Visual Drainage, Visual Hydro, Visual Landscape, Visual Roads, Visual Survey, Visual Syllabus,

Visual Toolbox, Visual Tugboat, Visual LISP, Voice Reality, Volo, Wiretap, and WiretapCentral

The following are registered trademarks or trademarks of Autodesk Canada Co. in the USA and/or Canada and other countries: Backburner,

Discreet, Fire, Flame, Flint, Frost, Inferno, Multi-Master Editing, River, Smoke, Sparks, Stone, and Wire

All other brand names, product names or trademarks belong to their respective holders.

Disclaimer

THIS PUBLICATION AND THE INFORMATION CONTAINED HEREIN IS MADE AVAILABLE BY AUTODESK, INC. "AS IS." AUTODESK, INC. DISCLAIMS

ALL WARRANTIES, EITHER EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE REGARDING THESE MATERIALS.

Published by:

Autodesk, Inc.

111 Mclnnis Parkway

San Rafael, CA 94903, USA

Contents

Chapter 1 Introducing Autodesk Inventor . . . . . . . . . . . . . . . . . . 1

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Data Files for Exercises . . . . . . . . . . . . . . . . . . . . . . . . 2

File Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Application Options . . . . . . . . . . . . . . . . . . . . . . . . . 3

Document Settings . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Styles and Standards . . . . . . . . . . . . . . . . . . . . . . . . . 3

Using Shortcut Keys and Command Aliases . . . . . . . . . . . . . . . . 5

Viewing Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Zoom Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Zoom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Zoom All . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Zoom Window . . . . . . . . . . . . . . . . . . . . . . . . . 9

Zoom Selected . . . . . . . . . . . . . . . . . . . . . . . . . 9

Pan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Look At . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Rotate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Shaded, Hidden Edge, and Wireframe Display . . . . . . . . . . . 11

Ground Shadow Display . . . . . . . . . . . . . . . . . . . . . . 11

Orthographic and Perspective Camera Views . . . . . . . . . . . . 11

Importing and Exporting Data . . . . . . . . . . . . . . . . . . . . . . 12

AutoCAD Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Autodesk Mechanical Desktop Files . . . . . . . . . . . . . . . . . 14

iii

Files from Other Applications . . . . . . . . . . . . . . . . . . . . 14

SAT Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

STEP Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

IGES Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

DWF Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Learning Autodesk Inventor . . . . . . . . . . . . . . . . . . . . . . . 16

Using Technical Publications . . . . . . . . . . . . . . . . . . . . 16

Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Help for AutoCAD Users . . . . . . . . . . . . . . . . . . . . . . 18

Tutorials and Show Me Animations . . . . . . . . . . . . . . . . . 19

Feedback Links . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Skill Builders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Chapter 2 Creating Sketches . . . . . . . . . . . . . . . . . . . . . . . . . 21

Understanding Sketches . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Sketch Environment . . . . . . . . . . . . . . . . . . . . . . . . 22

Sketch Coordinate System . . . . . . . . . . . . . . . . . . . . . 23

Using Model Edges as References for Sketches . . . . . . . . . . . 24

Precise Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Creating Sketches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Create Sketches . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Create Profiles with Tangencies . . . . . . . . . . . . . . . . . . . 28

Drag Sketch Geometry . . . . . . . . . . . . . . . . . . . . . . . 30

Tips for Sketching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Constraining Sketches . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Add Constraints . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Open Data Files for Exercises . . . . . . . . . . . . . . . . . . . . 32

Add Constraints to the First Sketch . . . . . . . . . . . . . . . . . 33

Add Constraints to Existing Sketches . . . . . . . . . . . . . . . . 34

Delete and Add Constraints . . . . . . . . . . . . . . . . . . . . . 36

Tips for Constraining Sketches . . . . . . . . . . . . . . . . . . . . . . 37

Dimensioning Sketches . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Place Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Automatic Dimensions . . . . . . . . . . . . . . . . . . . . . . . 39

Dimension Types . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Diametric Dimensions . . . . . . . . . . . . . . . . . . . . 41

Driven Dimensions . . . . . . . . . . . . . . . . . . . . . . 41

Dimension Profiles . . . . . . . . . . . . . . . . . . . . . . . . . 41

Delete and Add Dimensions . . . . . . . . . . . . . . . . . . . . 45

Tips for Creating Dimensions . . . . . . . . . . . . . . . . . . . . . . . 46

Modifying Sketches . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Patterning Sketches . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Tips for editing sketch patterns . . . . . . . . . . . . . . . . . . . 49

Delete Sketches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Learning about 3D Sketches . . . . . . . . . . . . . . . . . . . . . . . . 50

iv | Contents

Chapter 3 Working with Sketched Features . . . . . . . . . . . . . . . . . 53

Parametric Part Modeling . . . . . . . . . . . . . . . . . . . . . . . . . 53

Part Modeling Environment . . . . . . . . . . . . . . . . . . . . 54

Workflows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Base Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Adding Sketched Features . . . . . . . . . . . . . . . . . . . . . . . . . 57

Extrude Features . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Revolve Features . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Sweep Features . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Loft Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Coil Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Rib and Web Features . . . . . . . . . . . . . . . . . . . . . . . . 64

Modifying Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Chapter 4 Creating and Editing Placed Features . . . . . . . . . . . . . . 69

Adding Placed Features . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Hole Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Fillet Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Chamfer Features . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Chamfers and Fillets . . . . . . . . . . . . . . . . . . . . . . . . 75

Tips for Working with Fillets . . . . . . . . . . . . . . . . . 84

Thread Features . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Shell Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Creating Pattern Features . . . . . . . . . . . . . . . . . . . . . . 90

Rectangular Patterns . . . . . . . . . . . . . . . . . . . . . 90

Suppress Pattern Occurrences . . . . . . . . . . . . . . . . . 94

Circular Patterns . . . . . . . . . . . . . . . . . . . . . . . 94

Mirror Features . . . . . . . . . . . . . . . . . . . . . . . . 96

Patterns Along Paths . . . . . . . . . . . . . . . . . . . . . 97

Suppress Pattern Occurrences . . . . . . . . . . . . . . . . . 99

Analyzing Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Create Zebra Analyses . . . . . . . . . . . . . . . . . . . . . . . 101

Create Draft Analyses . . . . . . . . . . . . . . . . . . . . . . . 102

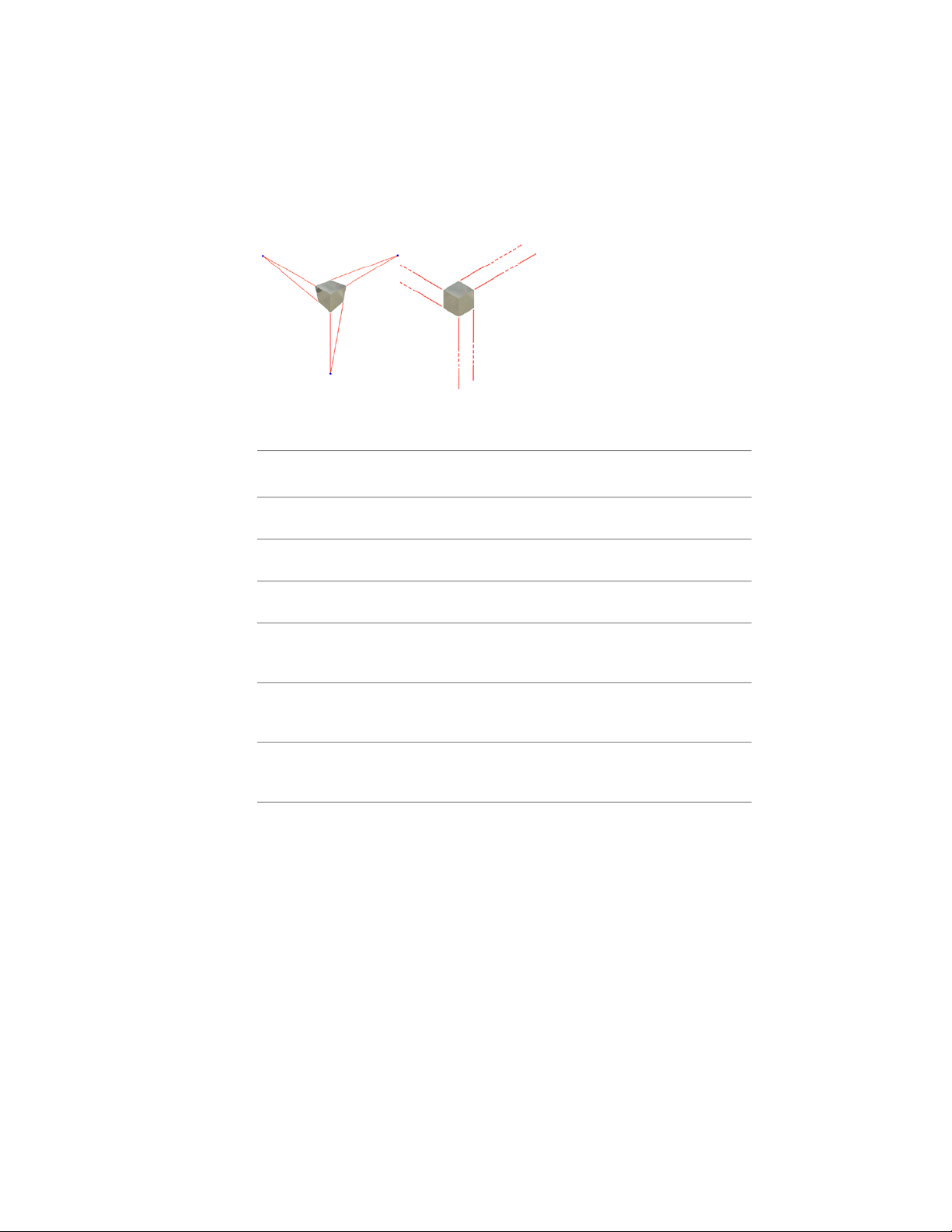

Chapter 5 Creating and Editing Work Features . . . . . . . . . . . . . . 105

Defining Work Features . . . . . . . . . . . . . . . . . . . . . . . . . 105

Work Planes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Work Axes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Work Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Grounded Work Points . . . . . . . . . . . . . . . . . . . . . . 108

Modifying Work Features . . . . . . . . . . . . . . . . . . . . . . . . 109

Chapter 6 Using Projects to Organize Data . . . . . . . . . . . . . . . . 111

Key Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Contents | v

Learn About Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Default Project . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Set an Active Project . . . . . . . . . . . . . . . . . . . . . . . . 114

How Referenced Files are Found . . . . . . . . . . . . . . . . . . 115

Setting Up Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Project Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Single-user Projects . . . . . . . . . . . . . . . . . . . . . 117

Vault Projects . . . . . . . . . . . . . . . . . . . . . . . . 118

Set Up Folder Structures . . . . . . . . . . . . . . . . . . . . . . 119

Creating Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Set Project Options . . . . . . . . . . . . . . . . . . . . . . . . . 123

Workspace . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Library Locations . . . . . . . . . . . . . . . . . . . . . . 124

Library Locations for Mechanical Desktop Parts . . . . . . 125

Library Locations for iParts and iAssemblies . . . . . . . . 126

Content Center Files . . . . . . . . . . . . . . . . . . . . . 127

Other Types of Libraries In Projects . . . . . . . . . . . . . 128

Avoid Duplicate File Names . . . . . . . . . . . . . . . . . 129

Creating and Opening Files In Projects . . . . . . . . . . . . . . . . . 129

Chapter 7 Managing Assemblies . . . . . . . . . . . . . . . . . . . . . . 131

Assembly Environment . . . . . . . . . . . . . . . . . . . . . . . . . 131

Assembly Design Strategies . . . . . . . . . . . . . . . . . . . . 132

Bottom-Up Assembly Design . . . . . . . . . . . . . . . . 132

Top-Down Assembly Design . . . . . . . . . . . . . . . . . 133

Middle-Out Assembly Design . . . . . . . . . . . . . . . . 133

Assembly Coordinate System . . . . . . . . . . . . . . . . . . . 133

Assembly Constraints . . . . . . . . . . . . . . . . . . . . . . . 134

Assembly Analysis . . . . . . . . . . . . . . . . . . . . . . . . . 134

Storing Data Files In Projects . . . . . . . . . . . . . . . . . . . . . . 134

Working with the Assembly Browser . . . . . . . . . . . . . . . . . . 135

In-Place Activation . . . . . . . . . . . . . . . . . . . . . . . . . 135

Visibility of Components . . . . . . . . . . . . . . . . . . . . . 136

Assembly Structures . . . . . . . . . . . . . . . . . . . . . . . . 136

Restructure Assemblies . . . . . . . . . . . . . . . . . . . . . . . 137

Browser Display . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Graphics Window Display . . . . . . . . . . . . . . . . . . . . . 139

Producing Bills of Materials . . . . . . . . . . . . . . . . . . . . . . . 140

Tips for Working with Assemblies . . . . . . . . . . . . . . . . . . . . 140

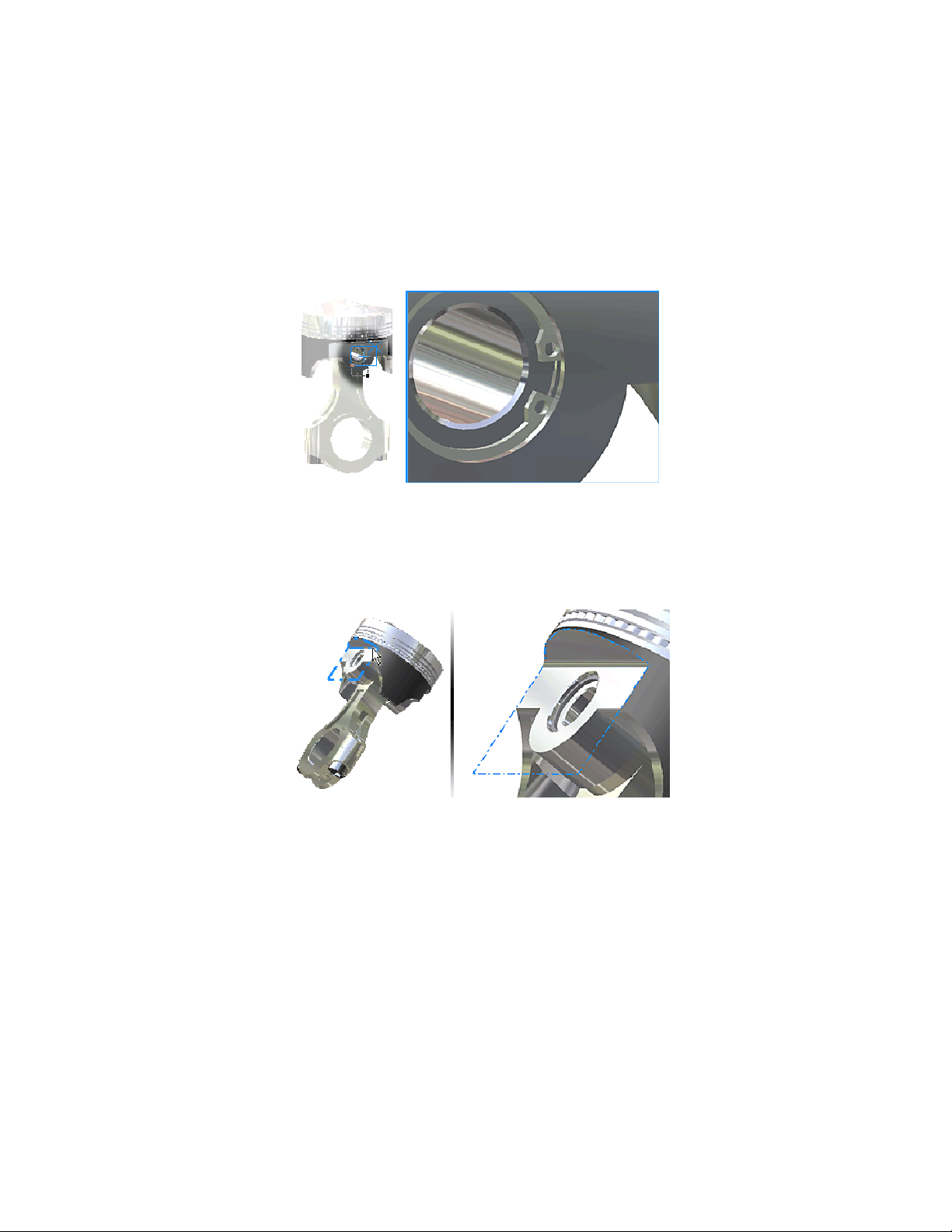

Chapter 8 Placing, Moving, and Constraining Components . . . . . . . . 141

Placing Components In Assemblies . . . . . . . . . . . . . . . . . . . 141

Drag Components into Assemblies . . . . . . . . . . . . . . . . 143

Simplify Assemblies . . . . . . . . . . . . . . . . . . . . . . . . 143

Grounded Components . . . . . . . . . . . . . . . . . . . . . . 144

vi | Contents

Other Sources of Components . . . . . . . . . . . . . . . . . . . . . . 144

Moving and Rotating Components . . . . . . . . . . . . . . . . . . . 145

Constraining Components . . . . . . . . . . . . . . . . . . . . . . . 145

Place Constraints . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Mate Constraint . . . . . . . . . . . . . . . . . . . . . . . 148

Angle Constraint . . . . . . . . . . . . . . . . . . . . . . . 150

Tangent Constraint . . . . . . . . . . . . . . . . . . . . . 151

Insert Constraint . . . . . . . . . . . . . . . . . . . . . . . 152

Motion Constraints . . . . . . . . . . . . . . . . . . . . . 152

iMates . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Viewing Constraints . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Editing Constraints . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Tips for Managing Assembly Constraints . . . . . . . . . . . . . . . . 154

Chapter 9 Creating Assemblies . . . . . . . . . . . . . . . . . . . . . . . 157

Creating Assembly Components . . . . . . . . . . . . . . . . . . . . 157

Parts In Place . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Projected Edges and Features . . . . . . . . . . . . . . . . . . . 159

Subassemblies In Place . . . . . . . . . . . . . . . . . . . . . . . 160

Guidelines for Selecting Subassembly Components . . . . 161

Creating Component Patterns . . . . . . . . . . . . . . . . . . . . . . 161

Independent Instances . . . . . . . . . . . . . . . . . . . . . . . 163

Creating Assembly Features . . . . . . . . . . . . . . . . . . . . . . . 164

Use Assembly Features . . . . . . . . . . . . . . . . . . . . . . . 164

Using Work Features in Assemblies . . . . . . . . . . . . . . . . . . . 165

Replacing Components . . . . . . . . . . . . . . . . . . . . . . . . . 165

Mirroring Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Copying Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

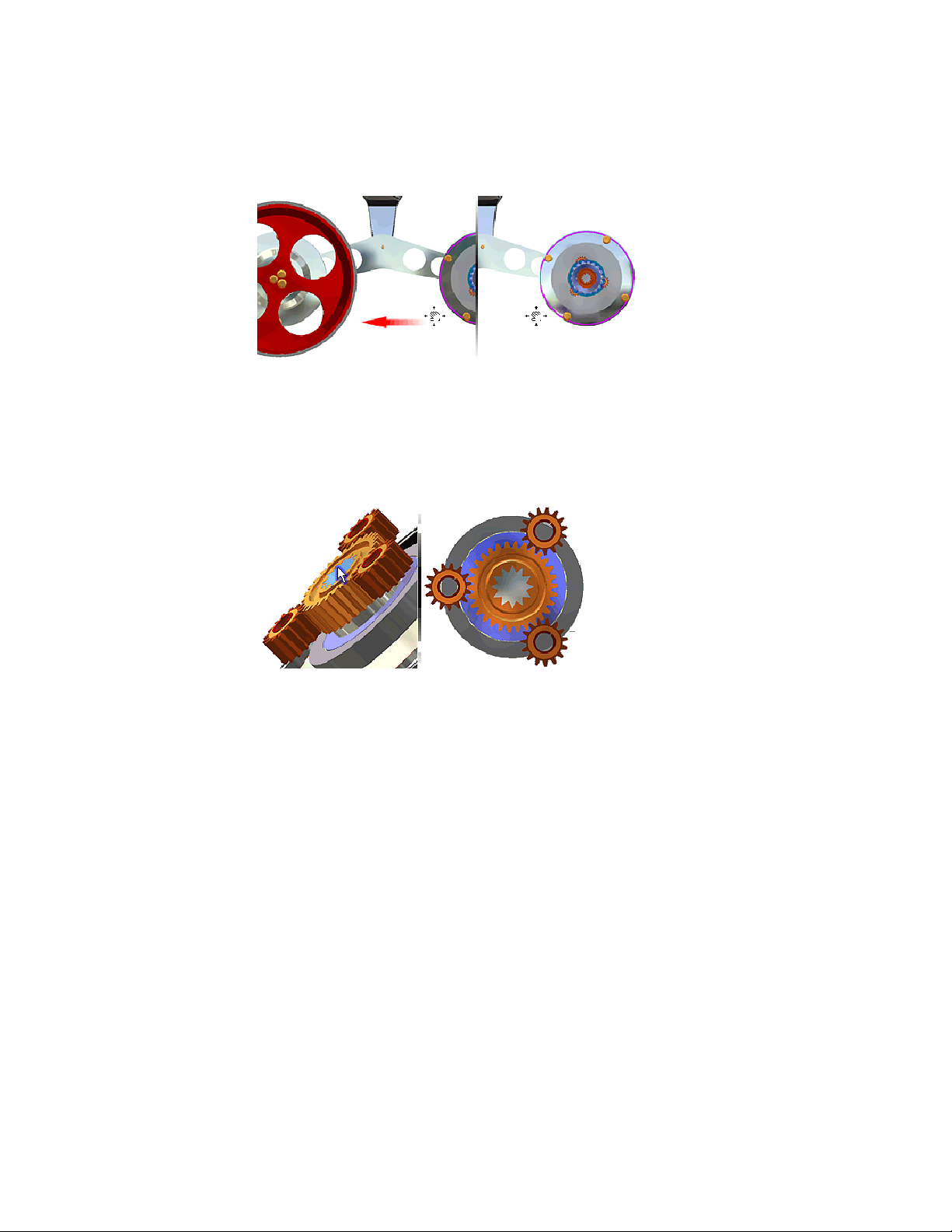

Chapter 10 Analyzing Assemblies . . . . . . . . . . . . . . . . . . . . . . 173

Checking for Interference . . . . . . . . . . . . . . . . . . . . . . . . 173

Checking for Degrees of Freedom . . . . . . . . . . . . . . . . . . . . 174

Unconstrained Drag . . . . . . . . . . . . . . . . . . . . . . . . 175

Constrained Drag . . . . . . . . . . . . . . . . . . . . . . . . . 175

Constraint Drivers . . . . . . . . . . . . . . . . . . . . . . . . . 176

Drive Constraints . . . . . . . . . . . . . . . . . . . . . . . . . 176

Animating Assembly Components . . . . . . . . . . . . . . . . . . . 178

Selecting Components . . . . . . . . . . . . . . . . . . . . . . . . . . 180

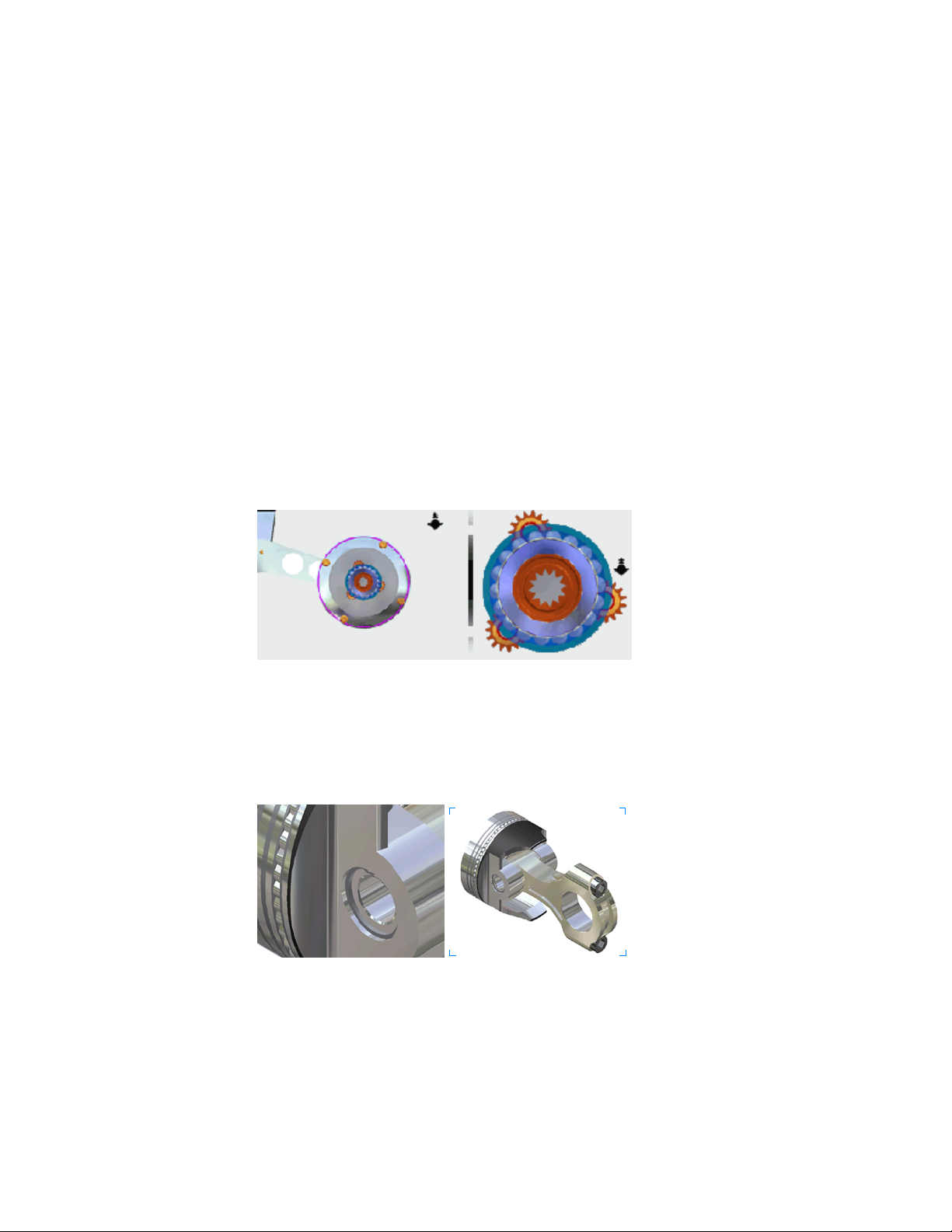

Chapter 11 Using Design Accelerator . . . . . . . . . . . . . . . . . . . . 185

What is Design Accelerator . . . . . . . . . . . . . . . . . . . . . . . 185

What operations can I perform within Design Accelerator? . . . 186

Work with Generators . . . . . . . . . . . . . . . . . . . . . . . 186

Work with Bolted Connections . . . . . . . . . . . . . . . 188

Contents | vii

Insert All Components At Once . . . . . . . . . . . . . . . 194

Work with Calculators . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Author User Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Set File Names . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Chapter 12 Setting Up Drawings . . . . . . . . . . . . . . . . . . . . . . . 203

Creating Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Edit Model Dimensions in Drawings . . . . . . . . . . . . . . . 205

Formatting Drawings with Styles . . . . . . . . . . . . . . . . . . . . 205

Use Styles In Templates . . . . . . . . . . . . . . . . . . . . . . 206

Share Styles Between Documents . . . . . . . . . . . . . . . . . 207

Use Styles Available In Drafting Standards . . . . . . . . . . . . 207

Create Styles . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Object Defaults Styles and Layers . . . . . . . . . . . . . . . . . 209

Using Drawing Resources . . . . . . . . . . . . . . . . . . . . . . . . 210

Sheet Layouts . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

Edit Default Sheets . . . . . . . . . . . . . . . . . . . . . . . . . 211

Format Sheets . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Sketch Overlays . . . . . . . . . . . . . . . . . . . . . . . 212

Drawing Borders . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Title Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Align Title Blocks . . . . . . . . . . . . . . . . . . . . . . 216

Edit Title Blocks . . . . . . . . . . . . . . . . . . . . . . . 216

Tips for Creating Drawings . . . . . . . . . . . . . . . . . . . . . . . 216

Chapter 13 Creating Drawing Views . . . . . . . . . . . . . . . . . . . . . 219

Drawing Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Drawing View Types . . . . . . . . . . . . . . . . . . . . . . . . 219

Base Views . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Projected Views . . . . . . . . . . . . . . . . . . . . . . . 221

Editing Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Creating Multiview Drawings . . . . . . . . . . . . . . . . . . . . . . 222

Base Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Section Views . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Defining Section Views . . . . . . . . . . . . . . . . . . . 225

Auxiliary Views . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Detail Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Break Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Draft Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Modifying Views and Sections . . . . . . . . . . . . . . . . . . . . . . 232

Delete Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Align Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Edit Hatch Patterns . . . . . . . . . . . . . . . . . . . . . . . . 235

Rotate Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Move Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

viii | Contents

Viewing Multiple Positions of Assemblies . . . . . . . . . . . . . . . . 236

Tips for Creating Drawing Views . . . . . . . . . . . . . . . . . . . . 237

Chapter 14 Annotating Drawings . . . . . . . . . . . . . . . . . . . . . . 239

Annotation Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Using Styles to Format Annotations . . . . . . . . . . . . . . . . . . . 241

Working with Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Hole Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

General and Configuration Tables . . . . . . . . . . . . . . . . . 242

Parts Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Creating Dimensions In Drawings . . . . . . . . . . . . . . . . . . . . 243

Place Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . 243

Model Dimensions . . . . . . . . . . . . . . . . . . . . . . 243

Drawing Dimensions . . . . . . . . . . . . . . . . . . . . 244

Change Dimensions . . . . . . . . . . . . . . . . . . . . . . . . 245

Controlling Dimension Styles . . . . . . . . . . . . . . . . . . . . . . 245

Copy Dimension Styles among Drawings . . . . . . . . . . . . . 247

Placing Center Marks and Centerlines . . . . . . . . . . . . . . . . . . 247

Adding Notes and Leader Text . . . . . . . . . . . . . . . . . . . . . . 248

Using Hole and Thread Notes . . . . . . . . . . . . . . . . . . . . . . 249

Thread Representations . . . . . . . . . . . . . . . . . . . . . . 249

Working with Title Blocks . . . . . . . . . . . . . . . . . . . . . . . . 250

Working with Dimensions and Annotations . . . . . . . . . . . . . . 250

Turn Off Tangent Edge Displays . . . . . . . . . . . . . . . . . . 253

Add Model Dimensions . . . . . . . . . . . . . . . . . . . . . . 254

Reposition Model Dimensions . . . . . . . . . . . . . . . . . . . 255

Add Centerlines and Center Marks . . . . . . . . . . . . . . . . 256

Add Drawing Dimensions . . . . . . . . . . . . . . . . . . . . . 257

Format Dimensions . . . . . . . . . . . . . . . . . . . . . . . . 259

Add Notes and Leader Text . . . . . . . . . . . . . . . . . 260

Edit Model Dimensions . . . . . . . . . . . . . . . . . . . 261

Complete Title Blocks . . . . . . . . . . . . . . . . . . . . 262

Printing Drawing Sheets . . . . . . . . . . . . . . . . . . . . . . . . . 263

Plotting Multiple Sheets . . . . . . . . . . . . . . . . . . . . . . . . . 264

Tips for Annotating Drawings . . . . . . . . . . . . . . . . . . . . . . 264

Chapter 15 Using Content Center . . . . . . . . . . . . . . . . . . . . . . 265

About Content Center . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Set and Manage Permissions . . . . . . . . . . . . . . . . . . . . 265

Content Center Library . . . . . . . . . . . . . . . . . . . . . . 266

Content Center Library Data . . . . . . . . . . . . . . . . 266

Working with Content Center . . . . . . . . . . . . . . . . . . . . . . 267

Content Center Environments . . . . . . . . . . . . . . . . . . 267

Consumer Environment . . . . . . . . . . . . . . . . . . . . . . 268

Editor Environment . . . . . . . . . . . . . . . . . . . . . . . . 269

Contents | ix

Tips for Using Content Center . . . . . . . . . . . . . . . . . . . . . . 270

Using the Publish Tool . . . . . . . . . . . . . . . . . . . . . . . . . . 270

Managing Administrative Tasks . . . . . . . . . . . . . . . . . . . . . 271

Chapter 16 Autodesk Inventor Utilities . . . . . . . . . . . . . . . . . . . 273

Editing Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

Legacy Project Types . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Resolving File Links . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Search for Library and Non Library Files . . . . . . . . . . . . . 278

Search for Library References . . . . . . . . . . . . . . . . 278

Search for Non Library Locations . . . . . . . . . . . . . . 279

Use Substitution Rules to Find Missing Files . . . . . . . . . . . 279

Keeping Old File Versions . . . . . . . . . . . . . . . . . . . . . . . . 281

Moving, Copying, and Archiving Design Files . . . . . . . . . . . . . 283

Zip Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

Temporary Root Folders . . . . . . . . . . . . . . . . . . . . . . 285

Pack and Go . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

Design Assistant Manager . . . . . . . . . . . . . . . . . . . . . 287

Move and Copy Files Between Projects . . . . . . . . . . . . . . 288

Deleting Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

Changing File Structure . . . . . . . . . . . . . . . . . . . . . . . . . 290

About Autodesk Vault . . . . . . . . . . . . . . . . . . . . . . . . . . 291

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

x | Contents

Introducing Autodesk Inventor

Welcome to Autodesk® Inventor™. This book explains the fundamental skills to start using

Autodesk Inventor. In these chapters, the basic features are presented through examples and

step-by-step procedures. The data files used in the procedures are installed with the Autodesk

Inventor software.

1

Getting Started

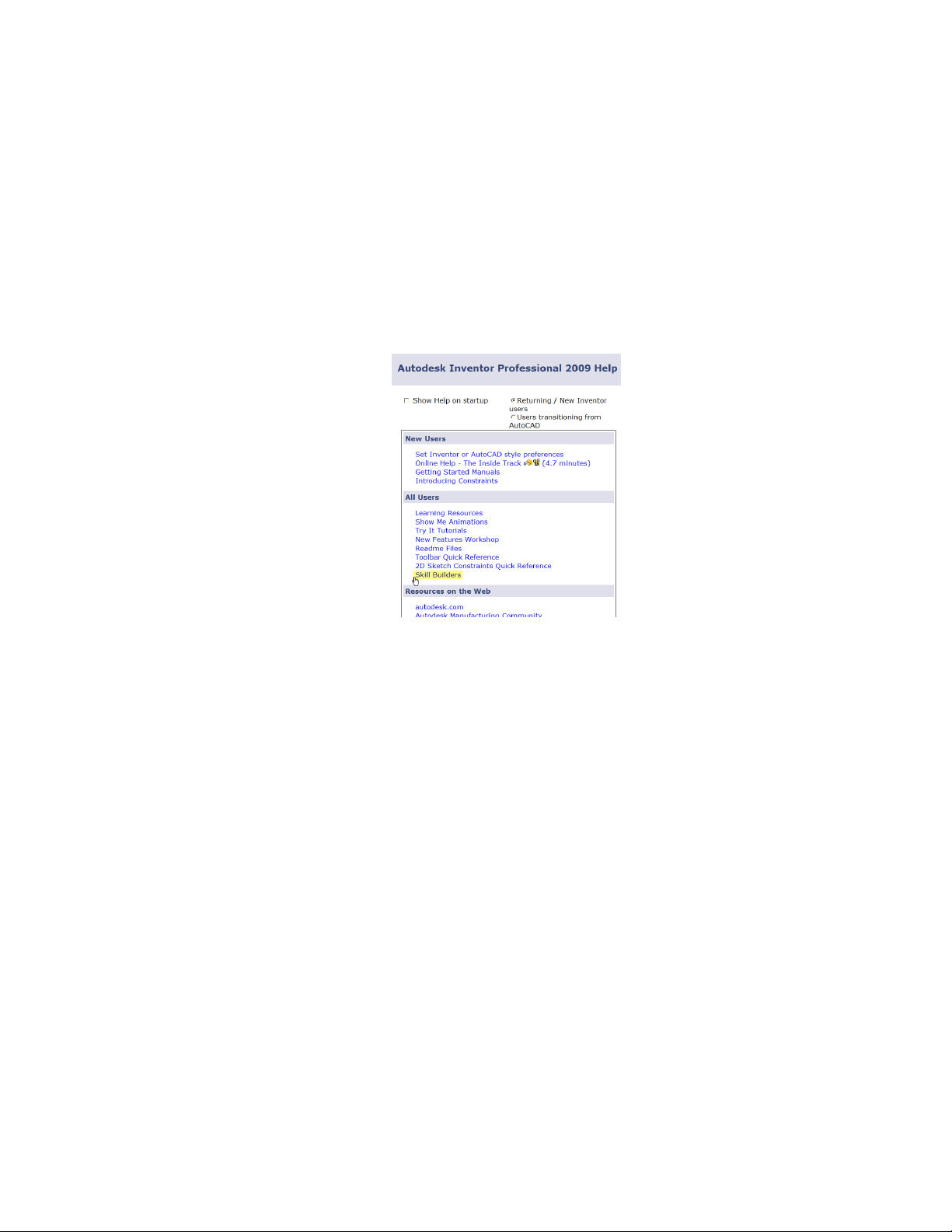

Autodesk Inventor provides options during installation. The options selected

determine what you see the first time you start Autodesk Inventor. If you indicate

during installation that you are a new or returning Autodesk Inventor user, you

are presented with the Open dialog box. If you indicated that you are

transitioning to Autodesk Inventor from AutoCAD®, an empty part file is

displayed (like opening a new DWG file during AutoCAD start-up). The main

Autodesk Inventor Help page is displayed with slightly different selections

depending on the selected install options. No matter how Autodesk Inventor

was installed, you can tailor the start-up experience through settings in the

Application Options dialog box to suit your needs. You can specify that Autodesk

Inventor always starts with the Open dialog box or always starts in a new file.

You can decide if you want to see Help on start-up or not (and which version

of the main Help page to see).

Projects

Autodesk Inventor uses projects to represent a logical grouping of a complete

design project. A project organizes your data by maintaining information about

1

where design data is stored, where you can edit files, and maintains valid links

between them. You use projects when you work in a team, work on multiple

design projects, and share libraries among several design projects. See

ProductName Utilities on page 273, for detailed information about setting up

and using projects.

Data Files for Exercises

When you install Autodesk Inventor, a project called tutorial_files is created.

Make this project active so that you can locate the data files that are used for

some exercises in this book.

TRY IT: Make the tutorial_files project active

1 In Autodesk Inventor, on the Standard toolbar, click Files ➤ Projects.

2 On the Project Editor, Select Project pane, double-click the tutorial_files

project to make it the active project.

In the Edit Project pane, in Location, the path to the folder containing

the tutorial data files is displayed. It is the folder where the files you create

and edit while performing the exercises are saved.

3 Close the Project Editor dialog box.

4 Click File ➤ Open.

The data files contained in the tutorial_files project are listed in the Open

File dialog box.

5 Click a file to see a preview of it, and double-click a file to open it in

Autodesk Inventor.

File Types

Once you activate a project, you can open an existing file or start a new file.

Click New to see the New File dialog box with templates for a new part,

assembly, presentation file, sheet metal part, weldment, or drawing. You can

choose from several templates with predefined units.

Templates are stored in the Autodesk\Inventor(version number)\Templates

directory or in the English or Metric subdirectories. Subdirectories in the

Templates directory are displayed as tabs in the Open New File dialog box. You

can create and save custom templates in the Templates directory.

2 | Chapter 1 Introducing Autodesk Inventor

A template can contain property information, such as part and project data,

and drawing views. You can see information stored in a file by viewing its

properties.

TRY IT: View the Properties dialog box

■ With a file open, right-click a component in the browser or in the graphics

window, and then choose Properties from the menu.

■ Click the tabs to see properties.

Application Options

You can change the look and feel of Autodesk Inventor using settings on the

Application Options dialog box. On the Standard toolbar, select Tools ➤

Application Options. Use the tabs on the Options dialog box to control the

color and display of your Autodesk Inventor work environment, the behavior

and settings of files, the default file locations, and a variety of multiple-user

functions.

Application options remain in effect until you change them.

Document Settings

You can specify settings in individual files. On the Standard toolbar, select

Tools ➤ Document Settings to display the Document Settings dialog box.

Click the tabs to view and specify settings for the active document, such as

indicating the active styles, units of measure, sketch and modeling preferences,

bill of materials, and default tolerance.

Styles and Standards

You select a drafting standard when you install Autodesk Inventor, and it

includes a default set of styles that control most objects used in documents,

such as balloons, dimensions, text, layers, parts lists, symbols and leaders,

materials, and lighting. Usually the default styles are enough to get you started,

but you can use the Styles and Standards Editor to create, modify, and purge

unused styles.

Application Options | 3

By default, actions such as creating or modifying styles affect only the current

document. You can choose to save the style to the style library, a master library

that contains definitions for all available styles associated with a drafting

standard. Usually, the style library is managed by a CAD administrator. This

practice ensures that the style definitions, used by all documents that use the

drafting standard, are not accidentally replaced by a custom style.

Style libraries make it easy to share formatting conventions across projects

because they contain the definitions of formatting objects. Using a style library,

you can update a style for all documents, such as revising the arrow heads of

dimensions, by editing the style and saving the revision to the master style

library. All documents that use that drafting standard have access to the library

and any new or changed styles that are added to it.

TRY IT: View the Styles and Standards Editor dialog box

1 In Autodesk Inventor, click File ➤ New and select the drawing template.

2 On the Standard toolbar, click Format ➤ Styles Editor.

3 On the Styles and Standards Editor dialog box, click Standard in the Style

Type browser, and then double-click a listed standard.

4 Click the General tab to see the values controlled there, and then click

the Available Styles tab to see the list of styles. As you click through the

style type list, you may notice that most names are checked. If the check

box is cleared, that style is not available for use in the current document.

5 In the left pane of the Styles and Standards Editor, click the Dimension

style, and then double-click one of the dimension styles to display it in

the right pane. Click through the tabs to see the settings for units,

alternate units, text, tolerance, options, and notes and leaders. Click a

different dimension style to see if any of the values differ.

6 In the top-right corner of the dialog box, click the Filter list and change

the filter type. Notice how the list of available styles changes if you select

All Styles, Local Styles (for the current document), or Active Standard.

You may notice differences in the lists because the local styles may have

had some unused styles purged to make the file size smaller.

7 Click Done. Any changed values are discarded.

If you click Save to preserve changes, the changes are saved only in the

current document.

4 | Chapter 1 Introducing Autodesk Inventor

Using Shortcut Keys and Command Aliases

Autodesk Inventor provides shortcut keys and command aliases to help you

perform certain tasks more quickly. A command alias is an alphanumeric

character or character sequence used to start a command. Define a shortcut

by using any of the following keys or key combinations:

■ A punctuation key (including ` - = [ ] \ ; ' , . /), or one of the following

virtual keys: Home, End, Page Up, Page Down, Up Arrow, Down Arrow.

■ A combination of the SHIFT key along with a numeric key (0-9),

punctuation key, or one of the following virtual keys: Home, End, Page

Up, Page Down, Up Arrow, Down Arrow.

■ Any combination of SHIFT, CTRL, and ALT keys along with an alphanumeric

character.

Remember that some shortcut keys and command aliases are active in specific

environments only.

TRY IT: View a complete guide to shortcut keys and command aliases

1 Open Autodesk Inventor.

2 On the Standard menu, click Tools ➤ Customize ➤ Keyboard tab. For

each category, there is a list of the command name and its associated

shortcut or alias, if one exists.

3 Click through several categories to see the associated commands.

The following is a list of some of the commonly used shortcut keys and

command aliases.

ResultKey

Displays Help for the active command or dialog box.F1

Pans the graphics window.F2

Zooms in or out in the graphics window.F3

Rotates objects in the graphics window.F4

Using Shortcut Keys and Command Aliases | 5

ResultKey

Returns to the previous view.F5

Returns to isometric view.F6

Adds a balloon to a drawing.B

Adds an assembly constraint.C

Adds a dimension to a sketch or drawing.D

Adds an ordinate dimension to a drawing.DO

Extrudes a profile.E

Adds a feature control frame to a drawing.FC

Adds a hole feature.H

Creates a line or arc.L

Places a component in the current assembly.P

Creates a revolved feature.R

Creates a 2D sketch on a face or plane.S

Tweaks a part in the current presentation file.T

Quits a command.ESC

Deletes selected objects.DELETE

In the active Line tool, removes the last sketched segment.BACKSPACE

In assemblies, applies a mate constraint.ALT + drag mouse

6 | Chapter 1 Introducing Autodesk Inventor

tool

ResultKey

In a sketch, moves spline shape points.

Activates the Select tool menu.SHIFT + right-click

Automatically rotates model in graphics window. Click to quit.SHIFT + Rotate

Return to previous editing state.CTRL + ENTER

Activates Redo (revokes the last Undo).CTRL + Y

Activates Undo (revokes the last action).CTRL + Z

Spacebar

NOTE Click Help ➤ Shortcut Quick Reference to see the list of command names

and associated shortcuts and aliases in the active environment.

Viewing Models

Use viewing tools to view a model:

■ Use the ViewCube to orbit your 3D model and to switch between standard

and isometric views.

■ Use the SteeringWheels to access a variety of navigational tools.

■ Select one of the viewing tools in the Standard toolbar to achieve a specific

view.

■ Right-click in the graphics window, and then select Isometric View from

the menu. The view vector changes to the isometric orientation.

■ Right-click in the graphics window, and then select Previous View from

the menu. The view changes back to the previous view.

■ Press F5 to return the model to the last view.

When the 3D Rotate tool is active, switches between dynamic rotation and standard isometric and single plane views.

Viewing Models | 7

To rotate a view in 3D, use the Free Orbit or Constrained Orbit tool in the

Standard toolbar to rotate a view around one of the coordinate axes.

Zoom Tools

The zoom tools are located in the Standard toolbar and are also available from

the SteeringWheels.

Zoom

Use the Zoom tool on the Standard toolbar to enlarge or reduce the image in

the graphics window. Click the tool. In the graphics window, press the cursor

as you move it up or down to zoom the view dynamically in or out. You can

zoom the view while other tools are active.

Zoom All

Use the Zoom All tool on the Standard toolbar to resize the image of a part or

assembly so that all elements are displayed in the graphics window. You can

zoom a drawing so that the active sheet fits within the graphics window.

8 | Chapter 1 Introducing Autodesk Inventor

Zoom Window

Use the Zoom Window tool on the Standard toolbar to define an area of a

part, assembly, or drawing to fill the graphics window.

Zoom Selected

Use the Zoom Selected tool on the Standard toolbar to zoom a selected edge,

feature, or other element to the size of the graphics window.

Pan

Use the Pan tool on the Standard toolbar to move the view in the graphics

window in any direction planar to the screen. You can pan the view while

other tools are active.

Pan | 9

Look At

Rotate

Use the Look At tool on the Standard toolbar to zoom and rotate the display

in the graphics window. You can position a selected planar element parallel

to the screen or position a selected edge or line horizontal to the screen.

Use the Orbit tools on the Standard toolbar to:

■ Rotate a part or assembly in the graphics window.

■ Display standard, isometric, and single plane projections of a part or

assembly.

■ Redefine the isometric view.

10 | Chapter 1 Introducing Autodesk Inventor

Shaded, Hidden Edge, and Wireframe Display

Use one of the Change Display tools to switch among the three display modes:

Shaded, Hidden Edge, and Wireframe. You can apply display modes to part

and assembly models, and to views in the Engineer's Notebook.

Ground Shadow Display

Use the Ground Shadow tool to cast a shadow on the plane beneath the model.

Orthographic and Perspective Camera Views

The Camera View tool has two settings: Orthographic Camera mode and

Perspective Camera mode.

In Perspective Camera mode, part or assembly models are displayed in

three-point perspective, a visual effect where parallel lines converge on a

Shaded, Hidden Edge, and Wireframe Display | 11

vanishing point. It is the way real objects are perceived by the human eye or

by a camera.

The following chart shows how the other viewing tools behave and how they

can be modified in each camera mode.

Zoom or

Pan Type

era Target Point Zoom

Zoom

tion

Orthographic

Camera mode

Camera mode

Importing and Exporting Data

You can import Pro/ENGINEER®, Parasolid®, SolidWorks™, UGS NX, SAT,

STEP, IGES, and AutoCAD and Autodesk® Mechanical Desktop® (DWG) files

for use in Autodesk Inventor. You can export AAutodesk Inventor parts and

assemblies to many file formats, including Pro/ENGINEER and Parasolid, and

Keys/CommandsPerspective

F2 PanYesYesCamera Translation Pan

SHIFT+F2 PanYesYesCamera Pivot Pan

F3 ZoomYesYesCamera Position Zoom

SHIFT+F3 ZoomYesNoCamera Position/Cam-

CTRL+F3 ZoomYesNoLens Focal Length

SHIFT+CTRL+F3 ZoomSet Perspective Distor-

12 | Chapter 1 Introducing Autodesk Inventor

you can export Autodesk Inventor drawings as DXF™ or AutoCAD drawing

(DWG) files.

The options for importing and saving AutoCAD files in Autodesk Inventor

are:

■ Selection of layers.

■ Window selection of entities.

■ Saving files in DWG format.

■ Support for DXF files back to version 12.

■ Creation of AutoCAD

installed.

NOTE Mechanical Desktop files can be linked to Autodesk Inventor assemblies

without importing.

AutoCAD Files

When you open an AutoCAD file in Autodesk Inventor, you can specify the

AutoCAD data to translate. You can select:

■ Model space, a single layout in paper space, or 3D solids.

®

Mechanical files, if AutoCAD Mechanical is

■ One or more layers.

You can also place 2D translated data:

■ On a sketch in a new or existing drawing.

■ As a title block in a new drawing.

■ As a sketched symbol in a new drawing.

■ On a sketch in a new or existing part.

If you translate 3D solids, each solid becomes a part file containing an ASM

solid body. Blocks are translated as sketched symbols.

When you import AutoCAD (DWG) drawings into a part sketch, a drawing,

or a drawing sketch overlay, the converter takes the entities from the XY plane

of model space and places them on the sketch. In a drawing, certain entities,

such as splines, cannot be converted.

AutoCAD Files | 13

When you export Autodesk Inventor drawings to AutoCAD, the converter

creates an editable AutoCAD drawing and places all data in paper space or

model space in the DWG file. If the Autodesk Inventor drawing has multiple

sheets, each is saved as a separate DWG file. The exported entities become

AutoCAD entities, including dimensions.

You can open a .dwg file and then copy selected AutoCAD data to the clipboard

and paste into a part, assembly, or drawing sketch. The data is imported at

the cursor position.

Autodesk Mechanical Desktop Files

Autodesk Inventor can translate Autodesk Mechanical Desktop parts and

assemblies so the design intent is preserved. You can import a Mechanical

Desktop file as either an ASM body or a full conversion when Mechanical

Desktop is installed and running on your system. Using the DWG/DXF File

Import Wizard, you can import Mechanical Desktop data, including parts,

assemblies, and drawings. The data is associative to Autodesk Inventor drawing

views and annotations.

Features that are supported in Autodesk Inventor are converted. Unsupported

features t are not translated. If Autodesk Inventor cannot translate a feature

it skips that feature, places a note in the browser, and then completes the

translation.

Files from Other Applications

You can open and change models created in Pro/ENGINEER, Parasolid,

SolidWorks, and UGS NX. Autodesk Inventor translates assembly and part

files, solids, multi-solids, surfaces, and more. After the import operation is

complete, you can change the model as if it was originally created in Autodesk

Inventor.

After changing a file, you can continue to use it as an Autodesk Inventor file

or export it to other file formats, including Pro/ENGINEER and Parasolid.

14 | Chapter 1 Introducing Autodesk Inventor

SAT Files

SAT (*.sat) files contain nonparametric solids that can be Boolean solids or

parametric solids with the relationships removed. You can use a SAT file in

an assembly and add parametric features to the base solid.

When you import a SAT file that contains a single body, it produces an

Autodesk Inventor part file with a single part. If it contains multiple bodies,

it produces an assembly with multiple parts. Surface data in a SAT file is also

supported.

STEP Files

STEP files are the international format developed to overcome some of the

limitations of data conversion standards. Past efforts in developing standards

have resulted in localized formats such as IGES (U.S.), VDAFS (Germany), or

IDF (for circuit boards). Those standards do not address many developments

in CAD systems. The STEP converter for Autodesk Inventor is designed for

effective communication and reliable interchange with other CAD systems.

When you import a STEP (*.stp, *.ste, *.step) file, only 3D solid, part, surface,

and assembly data are converted. Drafting, text, and wireframe data are not

processed by the STEP converter. If a STEP file contains one part, it produces

an Autodesk Inventor part file. If it contains assembly data, it produces an

assembly with multiple parts.

IGES Files

IGES (*.igs, *.ige, *.iges) files are a standard in the United States. Many NC/CAM

software packages require files in IGES format. Autodesk Inventor imports and

exports IGES files, including wireframe data.

DWF Files

Design Web Format (DWF™) is a compressed, secure format used to publish

CAD data. DWF files are fast to open and view, and can easily be shared by

e-mail with customers, vendors, marketing, and others who do not have

Autodesk Inventor installed. Use the DWF Publisher to publish an accurate

SAT Files | 15

visual representation of 2D and 3D data in one file. Download and install the

free Autodesk Design Review viewer to view a DWF file.

Learning Autodesk Inventor

You can select a learning tool that suits your preferred learning style. You can

get help for the current task, follow a workflow in a tutorial or Show Me

animation, learn a new skill using a Skill Builder, or click through Help topics.

You can gain 3D knowledge as you transition from 2D and watch animations

of operations.

Be more productive with Autodesk software. Get trained at an Autodesk

Authorized Training Center (ATC®) with hands-on, instructor-led classes to

help you get the most from your Autodesk products. Enhance your productivity

with proven training from over 1,400 ATC sites in more than 75 countries.

For more information about Autodesk Authorized Training Centers, contact

atc.program@autodesk.com or visit the online ATC locator at

www.autodesk.com/atc.

Using Technical Publications

Autodesk Inventor integrates software tools, knowledge, and interactive

learning for assistance in specific work tasks and to increase your productivity.

The complete set of technical publications includes:

®

■ Printed Getting Started manual

■ Help

■ Help for the AutoCAD user

■ Welcome modules

■ Tutorials

■ Show Me animations

■ New Features Workshop to explore what’s new in Autodesk Inventor

■ User comments links

■ Skill Builders

16 | Chapter 1 Introducing Autodesk Inventor

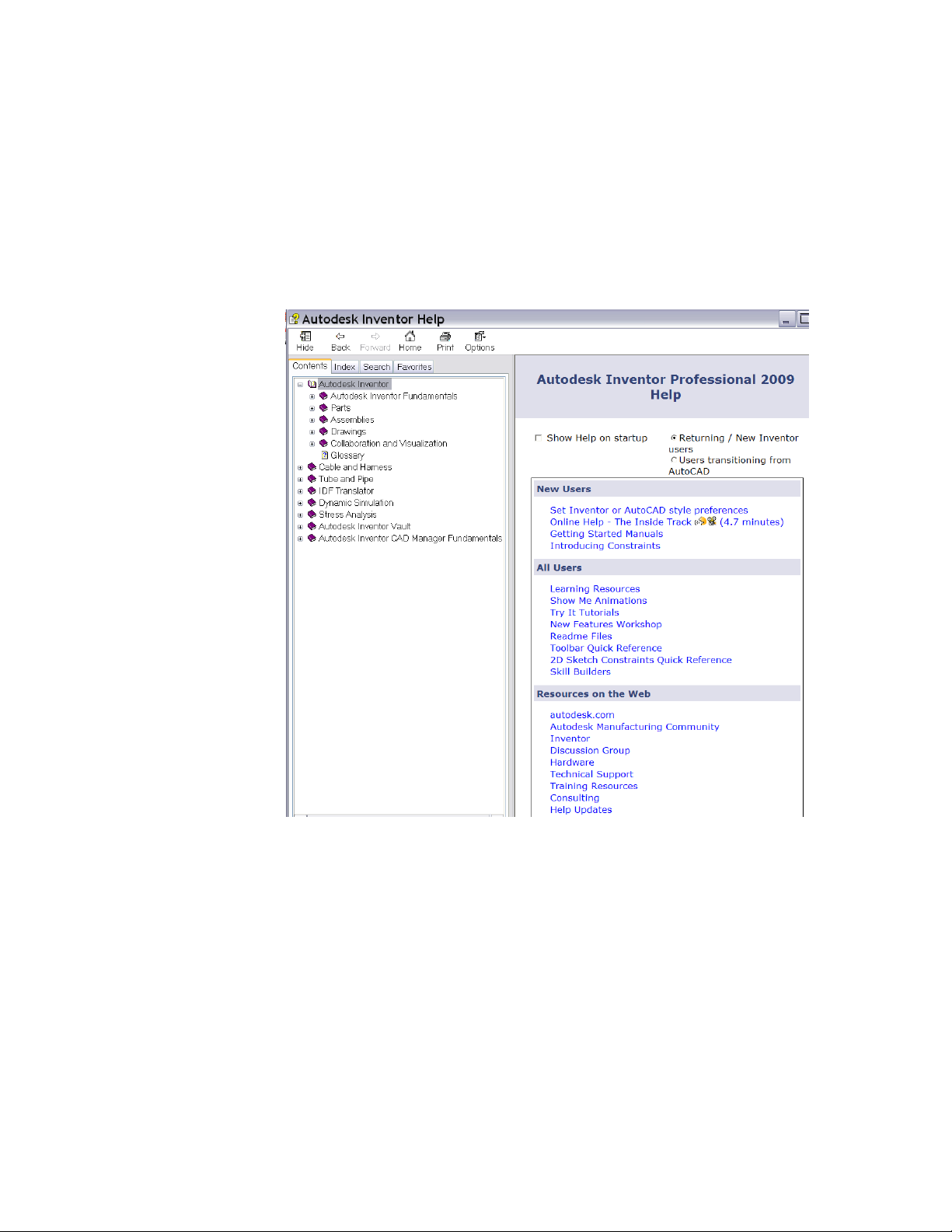

Help

Click Help ➤ Help topics for easy access to the Help topics, Skill Builders,

and Tutorials. You can also navigate through the Table of Contents or use the

Index and Search functions.

When using Autodesk Inventor, click Help buttons on dialog boxes to retrieve

a reference topic automatically that describes options for the dialog box.

Help | 17

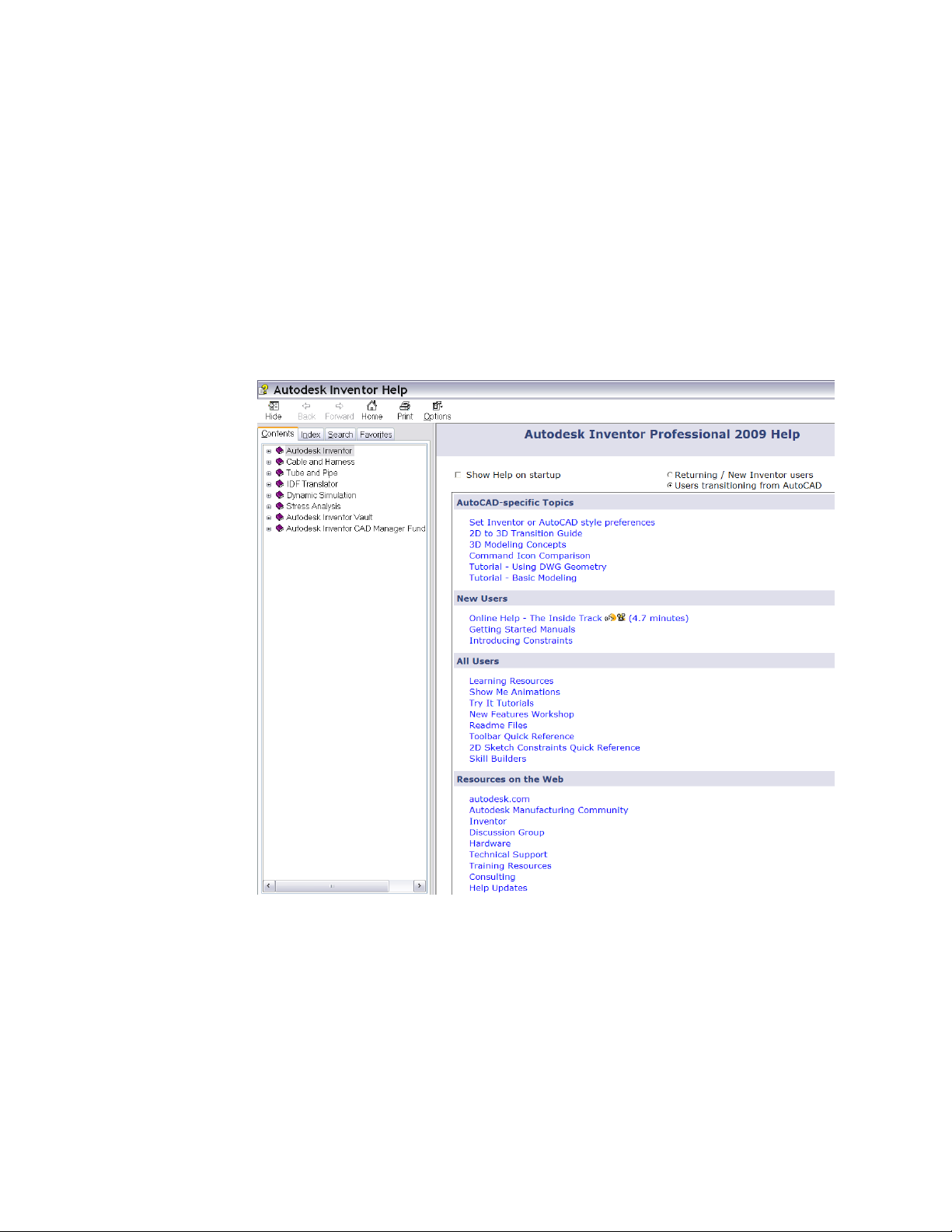

Help for AutoCAD Users

In Autodesk Inventor, click Help. If you selected “Users transitioning from

AutoCAD” as your preference during the installation, your Help home page

opens with topics and tutorials that ease the transition from 2D to 3D. You

can also navigate to them through the AutoCAD Topics section in the Table

of Contents. There are explanations of the differences between designing in

2D and 3D, equivalents to AutoCAD commands, tutorials, and a workflow to

explain everything from sketching to presentations.

18 | Chapter 1 Introducing Autodesk Inventor

Tutorials and Show Me Animations

Online tutorials are step-by-step illustrated lessons that show you how to

create and document your designs. You can access them from the Help home

page or click Help ➤ Tutorials.

Show Me animations are videos that show step-by-step instructions how to

complete an operation. You can access Show Me animations from the Standard

toolbar, the Help home page, and in individual help topics.

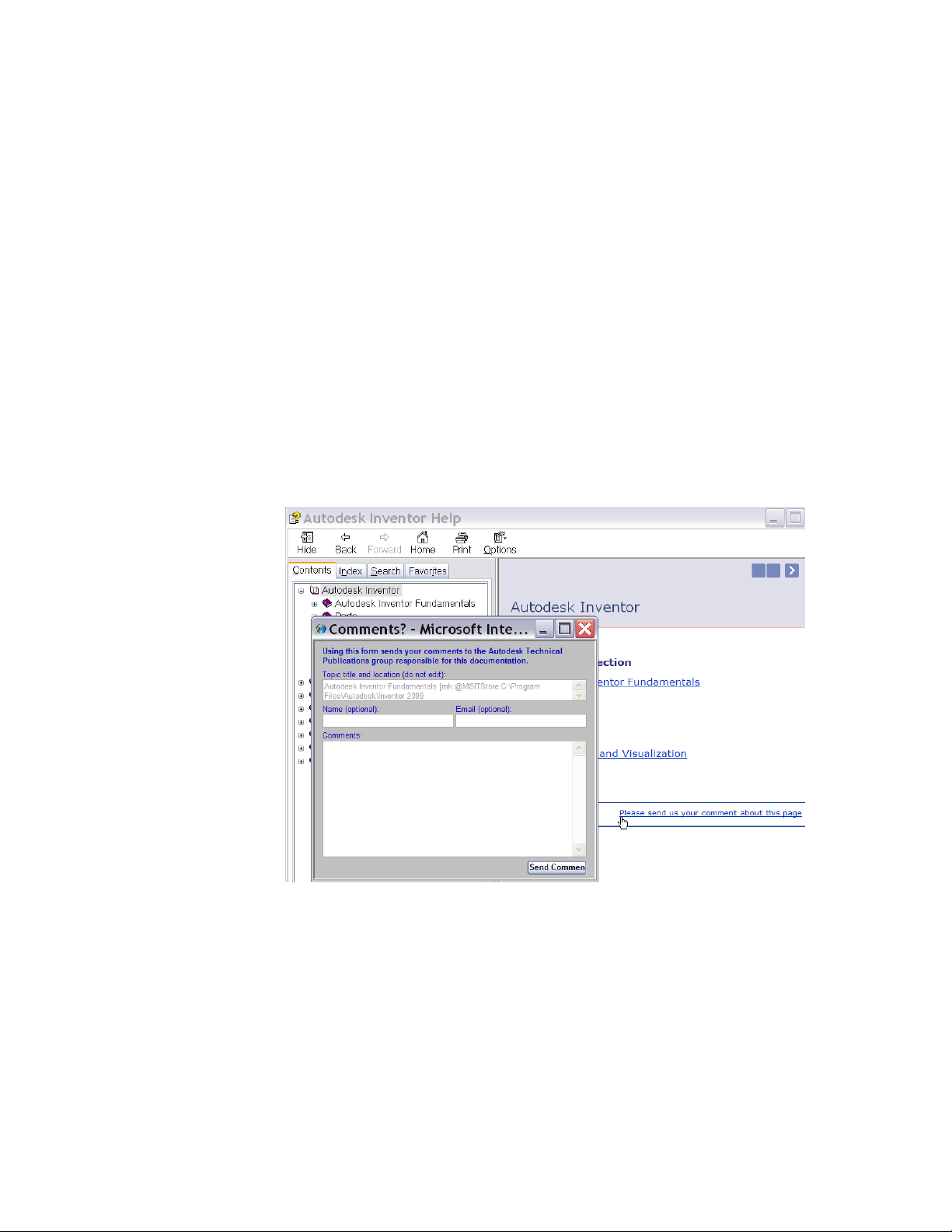

Feedback Links

Click the Comments Link on a Help topic page to address specific topics,

provide general feedback about the topic, and submit input about what you

want and need from the Autodesk Inventor Technical Publications team.

Tutorials and Show Me Animations | 19

Skill Builders

Autodesk Inventor provides extended learning through its Skill Builders

learning modules. Skill Builders are posted throughout a release cycle on the

Web to address customer needs and requests.

You can access them (if you have Internet access) by clicking the link on the

Help home page.

20 | Chapter 1 Introducing Autodesk Inventor

Creating Sketches

2

In Autodesk® Inventor™, sketching is the first step in creating a part. This chapter gives you

an overview of the sketch environment and the workflow for creating sketches.

Understanding Sketches

Most parts start with a sketch. A sketch is the profile of a feature and any

geometry (such as a sweep path or axis of rotation) required to create the feature.

All sketch geometry is created and edited in the sketch environment, using

Sketch tools on the panel bar. You can control the sketch grid, and use sketch

tools to draw lines, splines, circles, ellipses, arcs, rectangles, polygons, or points.

You can fillet corners, extend or trim curves, and offset and project geometry

from other features.

To start a sketch from scratch, open a new part file, select a Sketch tool, and

then start sketching in the graphics window. As you sketch, constraints are

automatically applied to the various sketch elements as you sketch. For example,

if you sketch a line nearly horizontal, a horizontal constraint is implied. You

can modify or delete any implied sketch constraint. You can also add constraints

manually to any sketch element. To exit a given sketch tool right-click, and

then select Done, or press ESC.

You create a 3D model from a sketch by extruding the profile or revolving it

around an axis.

21

The model you create in Autodesk Inventor is linked to its underlying sketches

and sketch information. If you change a sketch, the model is automatically

updated.

Sketch Environment

When you create or edit a sketch, you work in the sketch environment. The

sketch environment consists of a sketch and sketch tools to control the sketch

grid, and to draw lines, splines, circles, ellipses, arcs, rectangles, polygons, or

points.

When you open a new part file, the sketch environment is active. The 2D

Sketch button is selected, and the Sketch tools are available, along with a

sketch plane on which to sketch. You can control the initial sketch setup by

using template files or settings on the Sketch tab of the Application Options

dialog box. Click Tools ➤ Application Options ➤ Sketch tab to customize

the settings.

When you create a sketch, a sketch icon is displayed in the browser. When

you create a feature from a sketch, a feature icon is displayed in the browser

with the sketch icon nested under it. When you click a sketch icon in the

browser, the sketch is highlighted in the graphics window.

After you create a model from a sketch, re-enter the sketch environment to

make changes or start a new sketch for a new feature. In an existing part file,

first activate the sketch in the browser. This action activates the tools in the

sketch environment. You can create geometry for part features. The changes

you make to a sketch are reflected in the model.

22 | Chapter 2 Creating Sketches

Sketch Coordinate System

When you start a new sketch, the sketch coordinate system is displayed as X

and Y axes of the sketch grid. You can turn on the 3D indicator to display it

at the sketch origin. (Click Tools ➤ Application Options ➤ Sketch tab. In

the Display box, select the Coordinate System Indicator check box.) The default

grid lies on the sketch plane.

You can reposition and change orientation of the sketch coordinate system

to:

■ Change the orientation of dimensions you create.

■ Aid in precise input for sketch geometry.

TRY IT: Reposition the sketch origin in the coordinate system

1 Open a part file. In the browser, click the plus sign in front of a feature

to expand the display.

2 In the expanded feature display, right-click the sketch, and then click

Edit Coordinate System on the menu.

In the graphics window, the axis icon is displayed for the highlighted

sketch.

3 On the axis icon, click the red arrow to realign the X axis, the green arrow

to realign the Y axis, or the blue centroid to relocate the origin.

4 Select one of the following methods to relocate the highlighted axis:

■ A feature vertex to move the coordinate system.

■ A feature edge to rotate the coordinate system.

To flip the axis, right-click and select Flip axis from the menu.

5 Right-click, and then click Done to activate the new coordinate system.

The sketch origin in the coordinate system is repositioned.

Sketch Coordinate System | 23

Using Model Edges as References for Sketches

While you sketch, you can:

■ Automatically project edges of the part to the sketch plane as you sketch

a curve.

■ Create dimensions and constraints to edges of the part that do not lie on

the sketch plane.

■ Control the automatic projection of part edges to the sketch plane.

Workflow overview: Project part edges to a sketch plane

■ Click the Project Geometry tool, and then select any part edge.

■ Select an edge of the part while creating a dimension or constraint.

NOTE You can also use model edges as references for continuous loops or points.

Precise Values

In the sketch environment, you can enter relative X and Y distances from the

last point selected. The tools for precise input are located on the Precise Input

toolbar. It is only available when a sketch tool that requires placement of a

point is activated. For example, you can use precise input to define a line, a

sketch point, and a three-point arc, among others.

Enter precise values for geometry as you sketch. The Precise Input toolbar has

X and Y fields. You can enter both values to define a point, or enter only X

or Y to limit the placement of the point to a vertical or horizontal line.

TRY IT: Input precise values

1 In the sketch environment, click a Sketch tool to make it active.

2 On the standard toolbar, click View ➤ Toolbar ➤ Autodesk Inventor

Precise Input.

The toolbar is displayed in the graphics window.

3 Click a start point, or on the Precise Input dialog box, enter a value in

the X field.

24 | Chapter 2 Creating Sketches

4 Press TAB to activate the Y field, and then enter a value.

5 Press ENTER to accept your input.

The sketch is drawn according to the input.

6 Right-click and select Done to end the sketch tool.

Creating Sketches

In this exercise, you create a part file, and then create sketch geometry using

basic sketching techniques. The following illustrates a completed sketch and

sketched feature.

Create Sketches

When you open a new part file, the Sketch environment is active.

The current grid setting provides a visual clue to the size of sketches. Use

Application Options and Document Settings to define the grid display.

TRY IT: Modify the sketch grid display

1 Click Tools ➤ Application Options.

2 On the Sketch tab, define the grid line display. You can also select the

Snap to Grid setting.

TRY IT: Modify the grid spacing

1 Click Tools ➤ Document Settings.

2 Select the Sketch tab and make adjustments, as needed.

Creating Sketches | 25

TRY IT: Start a sketch

1 On the standard toolbar, click File ➤ New. On the Metric tab,

double-click Standard(mm).ipt.

The new part is listed in the browser, and the sketch environment is

active.

2 On the 2D Sketch panel bar, click the Line tool. Click the left side of the

graphics window to specify a first point, move the cursor to the right

approximately 100 units, and then click to specify a second point.

As you sketch, the position of the current point, length, and angle of the

line are dynamically displayed in the lower right border of the graphics

window.

NOTE Use the Zoom tool to zoom out if a line of 100 units does not fit in the

graphics window.

The position of the current line point is relative to the sketch 0,0 coordinates.

The line angle is relative to the sketch X axis. Symbols to indicate implied

constraints are displayed next to the current line point as you sketch.

TRY IT: Complete the sketch

1 Move the cursor up approximately 40 units, and then click to create a

perpendicular line.

2 Move the cursor to the left and create a horizontal line of approximately

30 units. The parallel constraint symbol is displayed.

26 | Chapter 2 Creating Sketches

3 Move the cursor down and create a vertical line of approximately 10

units.

4 Move the cursor to the left to create a horizontal line of approximately

40 units.

5 Move the cursor up until the parallel constraint symbol is displayed and

a dotted line appears. Click to specify a point.

6 Move the cursor left until the parallel constraint symbol is displayed and

a dotted line appears, and then click to specify a point.

Create Sketches | 27

7 Move the cursor down until it touches the first point you specified at the

beginning of the exercise. When the coincident constraint symbol is

displayed, click to close the sketch.

8 In the graphics background, right-click and select Done.

9 Right-click again and select Finish Sketch.

The sketch is completed. Do not save the file.

Create Profiles with Tangencies

In this exercise, you create a part file, and then use basic sketching techniques

to create a simple profile. The profile consists of lines and tangential arcs.

TRY IT: Create a sketch

1 Click the New tool on the standard toolbar, select the Metric tab, and

then double-click Standard(mm).ipt.

A new part and sketch are listed in the browser. The sketch environment

is active.

28 | Chapter 2 Creating Sketches

2 On the standard toolbar, click View ➤ Toolbar ➤ Autodesk Inventor

Precise Input to display the Precise Input toolbar.

3 Click the Line tool on the panel bar or on the 2D Sketch panel toolbar.

Click the center of the graphics window, and then enter 65 in the X field

of the Precise Input toolbar. Move the cursor to the right to display the

horizontal constraint symbol, and then click to create a 65-mm horizontal

line.

4 On the Precise Input dialog box, click the Y field, and then enter 15.

Move the cursor to display the perpendicular constraint symbol, and

then click the second point. A perpendicular line of 15 units is sketched.

NOTE Use the Zoom tool to zoom out and view the entire line if it is not

visible in the graphics window.

5 Move the cursor up and to the left, and then click to create a sloping line.

The exact angle is not important.

TRY IT: Complete the sketch

1 Click the end of the line, hold, and drag the endpoint to create a tangent

arc. Release the mouse button to place the endpoint of the arc.

Create Profiles with Tangencies | 29

2 Move the cursor to the start point of the profile and click when the

coincident constraint symbol is displayed.

3 In the graphics background, right-click, and select Done, and then

right-click and select Finish Sketch.

The sketch is completed. Do not save the file.

Drag Sketch Geometry

After you create sketch geometry, and while it is unconstrained or

underconstrained, you can drag it to resize it.

Tips for Sketching

■ Start a line by dragging off a circle or an arc.

Drag radially for a perpendicular line or drag tangentially for a tangent

line.

■ Start a line by dragging off the interior (not the endpoints) of another line

and drag in a perpendicular direction.

The new line is constrained perpendicular to the existing line.

■ Create an arc by dragging off the end of a line.

Return the pointer to the endpoint of the line to change the direction of

an arc.

■ Start a spline tangent to a line by dragging off the line.

Select the endpoint of a line, and then drag it in the direction of tangency

to end a spline tangent to a line.

■ Create coincident constraints.

30 | Chapter 2 Creating Sketches

When you start a new line, arc, or circle from an existing line, Autodesk

Inventor can infer a coincident constraint to the midpoint, endpoint, or

interior of the line.

■ Use SHIFT to drag.

All drag features, except for a tangent spline, are also available by pressing

and holding SHIFT while moving the cursor.

■ Drag multiple lines, curves, or points at the same time.

Select the geometry, and then drag the last item you selected.

■ Switch between the Trim and Extend tools.

Press SHIFT or select the other tool from the context menu to switch

between Trim and Extend.

Constraining Sketches

Constraints limit changes and define the shape of a sketch. For example, if a

line is horizontally constrained, dragging an endpoint changes the length of

the line or moves it vertically, but does not affect its slope. You can place

geometric constraints between two objects in the same sketch, or between a

sketch and geometry projected from an existing feature or a different sketch.

Constraints are automatically applied when you sketch. For example, if the

horizontal or vertical symbol is displayed when you create a line, then the

associated constraint is applied. Depending on how accurately you sketch,

one or more constraints may be required to stabilize the sketch shape or

position.

Although you can use unconstrained sketches, fully constrained sketches result

in more predictable updates.

NOTE The term constraints is often used in Autodesk Inventor to refer to both

geometric constraints and dimensions. Remember that dimensions and geometric

constraints work together to create a sketch that meets design intent.

Add Constraints

Define your design intent by adding geometric constraints to the sketch. You

can use autodimensioning to confirm whether a sketch is fully constrained

and apply any needed constraints. You can also create constraints by inference

Constraining Sketches | 31

by dragging geometry until the cursor brushes the geometry you want to

constrain.

To view or remove constraints, use the Show Constraints tool on the 2D Sketch

panel toolbar. Alternatively, right-click in the graphics window, and then use

options on the menu to show or hide all constraints at once. To delete a

constraint, select a constraint symbol, right-click, and then select Delete.

Some geometric constraints work only with lines, while others work only with

arcs, circles, or radial features.

Open Data Files for Exercises

The location of data files for the exercises in this manual are specified in the

project called tutorial_files. This project must be activate so you have access

to the required files. Once the project is active, you can open the tutorial files.

TRY IT: Activate the project file and open the tutorial file for an exercise

1 Close any open Autodesk Inventor files.

2 On the standard toolbar, click File ➤ Projects.

3 On the Project Editor, top pane, double-click the tutorial_files project to

make it the active project. Click Done.

4 Click File ➤ Open.

5 On the Open dialog box, click the file consketch.ipt see a preview of it,

and double-click it to open it.

The file opens in Autodesk Inventor. You are ready to start the exercise.

32 | Chapter 2 Creating Sketches

Add Constraints to the First Sketch

In this exercise, you practice adding geometric constraints to an existing sketch

containing three closed loops. In some cases, you can greatly reduce the

number of dimensional constraints required on a sketch.

This exercise contains geometry that does not meet design criteria and requires

additional geometric constraints to comply with the design intent.

TRY IT: Add constraints to the first sketch

1 On the standard toolbar, click the Look At tool, and then select any curve.

The plan view is displayed.

2 Click the Zoom All tool on the standard toolbar to view the three loops.

3 In the browser, double-click Sketch1 to make it active.

4 On the standard toolbar, click the Zoom Window tool, and then draw a

window around the sketch loop on the left.

The sketch loop is centered on your screen.

5 Right-click the graphics window, and select Show All Constraints. The

current sketch constraints are displayed.

6 Move the cursor over the constraint glyphs to highlight the sketch

geometry that is constrained.

In this example, you want the sloping lines in the sketch to be vertical,

so you now add a vertical constraint.

7 Right-click the graphics window, and select Hide All Constraints.

8 Click the down arrow beside the Constraint tool in the 2D Sketch panel

bar, and then click the Vertical constraint tool.

NOTE The cursor displays the constraint type. In this case, the vertical symbol

is displayed.

Add Constraints to the First Sketch | 33

Click the three sloping lines (be sure that you do not select the midpoint

of the lines).

Your sketch should look like the one in the following figure.

9 Right-click the graphics window, and select Done.

10 Right-click the graphics window, and select Show All Constraints.

11 All constraints display as shown in the following figure.

12 Right-click the graphics window, and select Hide All Constraints.

13 Click Return on the standard toolbar to exit the sketch.

Add Constraints to Existing Sketches

Constraints can be added to a sketch after it is created. In this procedure, you

add constraints to the second sketch.

To redisplay all of the sketches, use the Zoom All tool on the standard toolbar.

TRY IT: Add constraints to a sketch

1 Double-click Sketch2 in the browser.

2 On the standard toolbar, click the Zoom Window tool, and then drag a

window around the second sketch loop.

The second sketch loop is centered on your screen.

34 | Chapter 2 Creating Sketches

3 Click the arrow beside the Constraint tool on the panel bar or on the 2D

Sketch panel toolbar to open the pop-up menu. Click the Collinear

constraint tool. Click the horizontal lines at the top of the sketch.

Your sketch should look like the following figure. Note the collinear lines

identified by the red arrows.

4 Press ESC to cancel the Collinear constraint tool. Drag the top-right

horizontal line down and note how the sketch changes. This technique

is known as constrained drag.

5 Click the down arrow beside the Constraint tool again, and then click

the Equal constraint tool. Click the horizontal line at the lower left of

the sketch and then click the horizontal line at the upper left.

Make the two horizontal lines on the right side equal to the line at the

lower left.

Your sketch should look like the following figure.

6 Press ESC to cancel the Constraint tool. Drag the right vertical line and

note how the sketch changes. With the equal constraint applied, the

sketch retains its symmetry as you drag the vertical lines.

Add Constraints to Existing Sketches | 35

7 In the graphics background, right-click and select Done, and then

right-click Finish Sketch to exit the sketch.

Delete and Add Constraints

Constraints can be removed from sketches. Show constraints, and then use

the Delete option on the context menu.

TRY IT: Delete a constraint and add a constraints

1 Activate Sketch3.

2 On the standard toolbar, click the Zoom Window tool, and then drag a

window around the third sketch loop.

The third sketch loop is centered on your screen.

Click the Show Constraints tool on the panel bar or on the 2D Sketch

panel toolbar. Pause the cursor over the vertical line at the left of the

sketch. The constraints are displayed.

3 Move the cursor over the Equal constraint symbol, and then click to select

it. Right-click, and then select Delete to remove the constraint.

4 Click the down arrow beside the Constraint tool on the panel bar or the

2D Sketch panel toolbar to open the pop-up menu. Click the Horizontal

constraint tool.

5 Click the center point of the arc at the left of the sketch, and then click

the center point of the arc in the center of the sketch.

Repeat this process for the third center point.

Your sketch should look like the following figure.

36 | Chapter 2 Creating Sketches

6 Apply a tangent constraint to the arc and line at the left side of the sketch.

7 Apply equal constraints to the radii of the three arcs.

Your sketch should look like the following figure.

8 In the graphics background, right-click and click Finish Sketch to exit

the sketch.

Do not save the file.

Tips for Constraining Sketches

■ Turn off automatic constraints. Press and hold CTRL while sketching.

■ Infer a constraint. Move the cursor over other geometry while sketching

to infer a constraint.

■ Define dimensions with equations. Double-click a dimension to open the

Edit Dimension dialog box. Click the reference geometry, and its dimension

identifier appears on the dialog box. You can use the dimension identifier

in a mathematical expression (for example, D1*2). Dimensions that are

based on equations are marked with the fx: prefix.

■ Override the units on a particular dimension. For example, in a part file

set to metric dimensions, you can enter 1 inch on the Edit Dimension

dialog box.

Tips for Constraining Sketches | 37

Dimensioning Sketches

To retain design intent, sketch geometry generally requires dimensions in

addition to geometric constraints to maintain size and position.

Geometric constraints, such as horizontal, vertical, or parallel can be applied

while you sketch. Dimensions are typically added after your sketch geometry

is in place.

In general, all dimensions within Autodesk Inventor are parametric. You can

modify the dimension to change the size of the item dimensioned. You can

also specify that a dimension be driven. The dimension reflects the size of the

item but cannot be used to modify the size of the item.

When you add parametric dimensions to sketch geometry, you are applying

constraints that control the size and position of objects in the sketch. The

sketch is automatically updated when changes are made to the dimension

values.

Examples of dimensioned sketches are shown in the following illustration.

To create dimensions, use the General Dimension tool on the panel bar or on

the 2D Sketch panel toolbar. You select the sketch geometry you want to

dimension, and then click to place the dimension.

The selection of geometry and the placement of the dimension determine the

kind of dimension that is created. For example, if you select the edge of one

circle, a radial dimension is created. If you select the edges of two circles, a

linear dimension is established between their center points.

Place Dimensions

Parametric dimensions define the size of your sketch. After you add a

dimension, you cannot change the size of a line or curve by dragging it. In

Autodesk Inventor, you cannot apply double dimensions to a sketch.

38 | Chapter 2 Creating Sketches

TRY IT: Create a parametric dimension

1 Create a sketch, or open an existing sketch.

2 In the Sketch environment, on the panel bar or on the 2D Sketch panel

toolbar, click the General Dimension tool.

3 Select the sketch geometry you want to dimension, and then drag to a

point to display the dimension.

4 Double-click the dimension to open the Edit Dimension box.

5 Enter a dimension value. You can enter numeric values or the parameter

names associated with other dimensions or equations. Dimensions based

on equations, as shown in the following image, are preceded by the fx:

prefix.

Automatic Dimensions

You can also use the Auto Dimension tool on the panel bar or from the 2D

Sketch panel toolbar to speed up the dimensioning process. You individually

select sketch geometry such as lines, arcs, circles, and vertices and dimensions

and constraints are automatically applied. If you do not individually select

sketch geometry, all undimensioned sketched objects are automatically

dimensioned. The Auto Dimension tool provides a fast and easy way to

dimension sketches in a single step.

You can:

■ Use Auto Dimension to fully dimension and constrain an entire sketch.

■ Identify specific curves or the entire sketch for constraining.

■ Create only dimensions, only constraints, or both.

Automatic Dimensions | 39

■ Use the Dimension tools to provide critical dimensions, and then use Auto

Dimension to finish constraining the sketch.

■ Use AutoDimension in complicated sketches when you are unsure which

dimensions are missing to constrain the sketch fully.

■ Remove automatic dimensions and constraints.

NOTE To ensure that your sketch is fully dimensioned, use the Project Geometry

tool to project all reference geometry to the sketch before using the Auto

Dimension tool.

You can define dimensions with other dimension values. The names of

dimensions are parameters. When you edit a dimension, you can enter an

equation that uses one or more parameters.

You can display sketch dimensions in one of three forms:

■ Calculated value

■ Parameter name

■ Parameter name and calculated value

You can modify dimensions using the Edit Dimension box. To display the

Edit Dimension box, click the dimension when it is placed, or double-click

the dimension when the General Dimension tool is not active.

There are two ways to display the Edit Dimension box upon placement of a

dimension:

■ Click Tools ➤ Application Options ➤ Sketch tab, and turn on Edit

Dimension when Created

■ With General Dimension active, right-click in the graphics window and

select Edit Dimension.

Dimension Types

In some cases, the dimension preview does not meet the design intent. You

can change the dimension type by repositioning the dimension, or you can

right-click, and then select the type from the menu. You can also control

which type of linear dimension is applied by selecting and edge or a vertex.

40 | Chapter 2 Creating Sketches

For example, when you dimension an edge to a vertex, the dimension