Page 1

USE AND MAINTENANCE INSTRUCTION MANUAL

CABLE-LAYING MACHINE

Autocable

Drop-in 6

BEFORE USING THE MACHINE, READ THE INSTRUCTION

MANUAL.

www.Autocable.be

TRANSLATION OF THE ORIGINAL INSTRUCTIONS

Page 2

DECLARATION OF CONFORMITY

The Company

CARAVAGGI Srl

REGISTERED OFFICE, FACTORY AND ADMINISTRATION :

20, Via Monte Adamello, 25037 Pontoglio (BS), ITALY

Declares under its own responsibility that the

CABLE-LAYING MACHINE DROP-IN

Model Drop-In 6 petrol

Serial number: see rating plate

Year built: see rating plate

Complies with all the provisions regarding the following European

Directives:

Machinery Directive 2006/42/CE as an amendment to Directive 95/16/CE

And since the machine has been adapted to the following harmonized

standards and specifications, where applicable:

UNI EN ISO 12100-1-2: Machine safety – Basic concepts, general design

principles, basic terminology, methodology, technical principles.

UNI EN ISO 4254-1: Farming machinery - Safety - Part 1: General requirements.

UNI EN 13683: Garden machines - Shredders / Chippers with built-in motor -

Safety.

ISO 11684: Tractors, machinery for agriculture and forestry, powered lawn and

garden equipment - Safety signs and hazard pictorials – General principles.

Person authorised to draw up the declaration of conformity: Valerio Gianpaolo

Caravaggi

The Legal Representative

( Valerio Gianpaolo Caravaggi )

Pontoglio, 01 / 01 / 2015

Page 3

1. HAZARD PICTORIALS

Warning!

Wear a hard hat, hearing protectors and protective

glasses or goggles.

Warning!

Wear protective gloves.

Warning!

Wear safety shoes.

Warning!

Wear clothes that are suitable for work on machines

with moving parts.

Page 4

Warning!

Remove the engine spark plug before carrying out any

maintenance.

Warning!

Switch off the engine before carrying out any

maintenance.

Hazard!

Projection of splinters. Keep to a safety distance from

loading and unloading equipment.

Hazard!

Keep fingers well away from cutting elements.

Page 5

Hazard!

Make sure the blades have stopped completely before

approaching.

STOP

Caution!

Only one person must operate the machine.

Caution!

Do not use petrol engines in closed environments. Risk

of intoxication.

Caution!

Machine lifting point.

Page 6

2. HOW TO USE AND KEEP THE INSTRUCTION MANUAL

This instruction manual is aimed at the user of the machine, the owner, the

maintenance cleaning operator and the repair technician and must always be

available for consultation.

The instruction manual shows the user for which the machine was designed and

the machine’s technical characteristics. It also supplies instructions for transport,

cleaning adjustment, use, personal information maintenance, spare parts

ordering and residual risk, and warnings with regard to operations that must be

carried out with particular care.

The machine is for professional use, so the instruction manual can never be a

substitute for suitable user experience.

The manual should be considered a part of the machine and must by kept for

future reference until the machine is demolished.

The instruction manual must always be available for consultation and must be

kept in a dry, protected place.

In the case of loss or damage the user may request a replacement from the

manufacturer, quoting the series reference, type and year of construction which

are shown on the plate fixed to the Autocable machine (section 5).

The manufacturer reserves the right to update production and manual without the

obligation to update earlier production and manuals.

The manufacturer is relieved from all responsibility in cases of:

• improper use of the Autocable machine;

• uses not conforming with what is expressly specified in this documentation;

• serious deficiencies in prescribed and recommended maintenance;

• unauthorised modifications or interferences;

• use of spare parts that are not original or model specific;

• total or partial failure to follow the instructions;

• force major;

Page 7

3. IDENTIFICATION OF MAIN PARTS

1. Handle

2. Position handle adjustment

3. Regulating working depth

6. Blade

7. Cable housing

8. Graduated rod

4. Set screw

5. Engine

3

8

1

2

4

Fig. 1a

7

5

6

Fig. 2a Fig. 2b

Page 8

4. CORRECT USE OF THE MACHINE

This machine must be used by a single operator, who must remain in his work

position at the control handle during operation.

The operator must be have read and fully understood the instructions in this

manual in order to use the machine correctly.

The operator must be ensure that person or animals do not come within the field

of action while the machine is running.

The Autocable machine was built to bury the wire guide robotic mower

underground gardens.

The machine is not suitable for use in locations other than those listed above.

To work with other products, contact the machine manufactures or authorised

dealers.

The operator must be aware of all the instructions given in the instruction manual.

Fig.3

Page 9

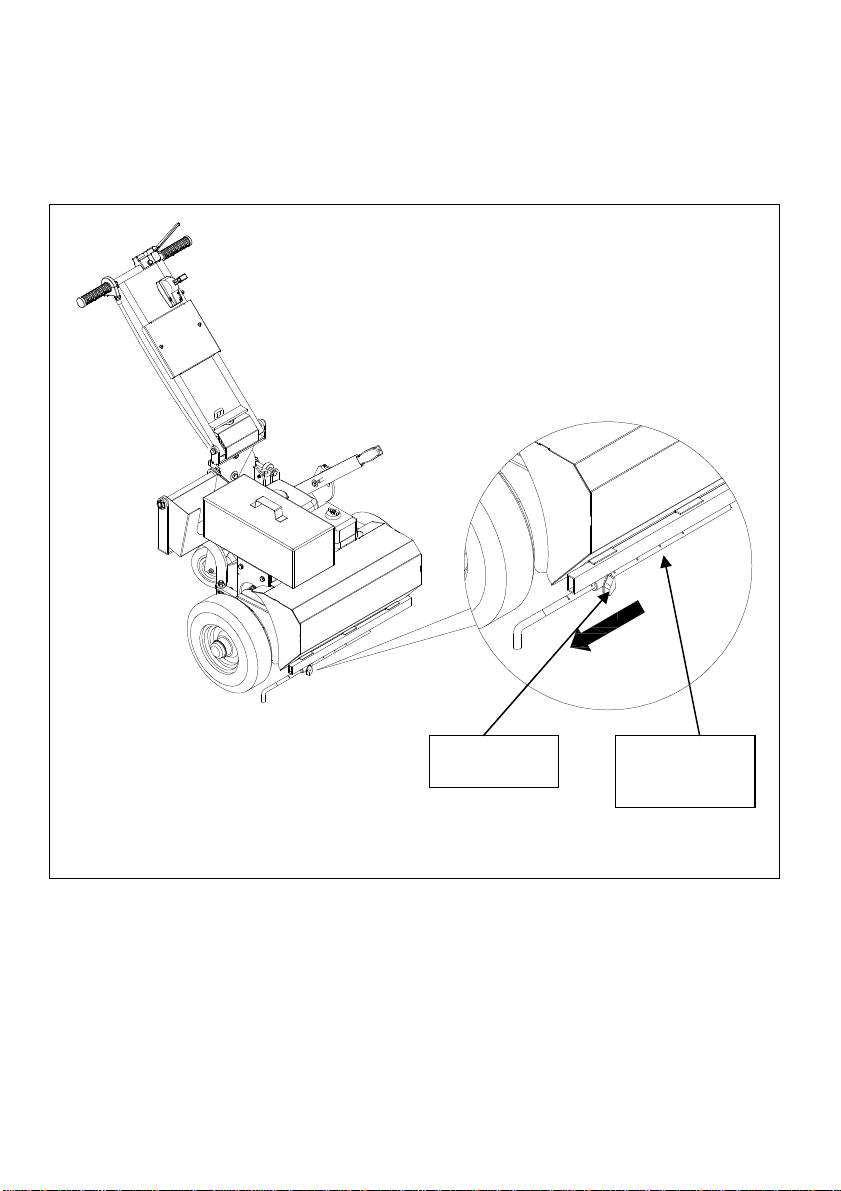

5. UNPACKING AND PREPARATION

The Autocable machine is delivered partially dismantled. Can be supplied assembled or

packaged in cardboard to facilitate the operations of handling and transport before the

operation by the user.

To transport the machine in these conditions it is indispensable to use a transpallet or

similar with a load capacity of around 70 kilos.

Avoid:

• hoisting the autocable machine with ropes or unsuitable hoists;

• drag Autocable machine with the device in contact with the burial ground;

• bumps or shocks;

• exposing the machine to rain, frost or any bad weather.

On taking delivery check that the contents correspond with the delivery note.

Should damage or deformity due to transport be noted, make an immediate compliant to

the carrier and advise the authorised dealer or the manufacturer. In particular, check that:

• there are no dents, signs of bumps or deformations;

• there are no damp areas or signs the may lead to suppose that the pack has been

exposed to foul weather;

• there are no signs of tampering;

After checking that transport has been carried out correctly, proceed to assembling the

machine as shown in figures 5a/b/c.

• Open the box, making sure that the card is oriented in the right direction.

• Remove the machine from packing.

• Place the handle in the transport position and lock it securely.

All the machines can be lifted and transported by means of cranes or winches, using hooks

and cables, which must be approved and of an adequate capacity. Hook up to the lugs, as

shown in the pictogram affixed to the machine.

Only safe hooks, such as snap hooks, must be used for lifting. Take great care and

exercise extreme caution when loading and unloading the machine. These operations must

only be carried out by qualified personnel (slingers, truck operators, etc.). Never pass or

stand underneath the machine when it has been raised off the ground.

To transport the machine, grasp the handle and push in the desired direction with the

engine switched off.

1

Fig.4

Page 10

Fig. 5a Fig. 5b

Closure lock

Fig. 5c

Page 11

6. TECHNICAL CHARACTERISTICS

The EC identification plate is clearly visible on the Autocable Machine Drop-In 5

(fig. 6).

In all communications with the manufacturer state the serial number on the

identification plate.

www.Autocable.be

Type

2006/42

Serial No.

Year

Fig. 6

Version

Power HP (kw)

Autocable DROP-IN 6 5.5 (4.1) Petrol

Supply

Page 12

6.1 Overall dimensions

Model Bre Len Hig

DROP-IN 6 670 1000 950

Weight (kg.): ~ 70

L

WA MAX

(dB): 104

Fig. 7

Page 13

7. SAFETY RULES

This handbook contains rules on how to use the machine properly and details of

the hazards that may be encountered. Besides following the rules, the operator

should use the machine sensibly, based on his experience, and adopt all the

necessary precautions to prevent accident or injury.

The manufacturer cannot be held liable for any alterations to the machine that are

not authorised in advance in writing.

This machine is only designed for laying boundary cable in the ground in stonefree gardens and lawns. It must never be used for any other purposes.

The machine must only be operated by a fully qualified person who is authorised

to do so and is thoroughly acquainted with the operating principles and the

inherent hazards.

Read through the manual before setting to work. The machine must not be

operated by children.

7.1 GENERAL SAFETY AND ACCIDENT PREVENTION RULES

• Basic rules: check the machine carefully each time before starting up.

• Besides following the recommendations contained in this handbook, it is

important to follow the general safety and accident-prevention rules. Before

using the machine, the operator must be fully acquainted with its features,

devices, controls and functions.

• Before starting working, make sure the blades are firmly secured to the vanes.

If they look damaged, they need to be sharpened or replaced. Mount the blades

as instructed and only use original spares supplied by the manufacturer (or an

authorised dealer).

• Before and after each work session, check that the guards, covers and safety

devices are correctly installed and integral, and are properly secured with nuts

and bolts.

• The notices on the machine provide a series of important instructions. They are

there to enable you to work in complete safety. Read all the safety stickers on

the machine and follow the instructions on them. If they become damaged or

unreadable, they need to be cleaned or replaced in the exact position as

described in the relevant section.

• The machine must only be used in an open space, on flat, firm ground that is

free from obstacles.

• Do not use the machine in the rain.

Page 14

• Anyone approaching the machine enters the danger area and hence becomes

an EXPOSED PERSON. It is up to the operator to prevent other people from

entering the danger area and he himself must act with extreme caution. Stop

the machine immediately if anyone enters the danger area.

• Caution: the blades continue to turn for several seconds after the engine has

been switched off.

• Keep the handbook readily available so that you can consult it for details of the

operating cycle and maintenance instructions. If it gets lost or damaged, a

replacement copy can be obtained from the manufacturer.

• This machine must be used by a single operator, who must remain in his work

position at the control handle.

• Do not wear items of clothing that are likely to get caught up in the mechanism,

such as long wide sleeves, belts, and necklaces.

• Hearing protectors and protective goggles must always be worn when operating

the machine.

• Do not leave the machine unattended while it is running.

• Do not place any tools or other objects on the machine as they could damage it

or injure the operator.

• Use only original spares.

Safety rules during operation

• Before setting to work, check there is enough cable in the housing and the

laying device.

• Keep the face and arms well away from the cable-laying device.

• Make sure there are no stones or rocks in the way, as they would blunt the

blades.

• Try to maintain an even balance while operating the machine.

• In the event of a malfunction, excessive vibration or strange noises, switch off

the engine. Disconnect the power supply (remove the sparkplug) and establish

the cause of the problem.

Page 15

7.2 SPECIFIC SAFETY AND ACCIDENT PREVENTION RULES

7.2.1 Petrol version

• If there is a malfunction, and prior to any maintenance, adjustment and cleaning

operations (e.g. removing foreign bodies from the blades), switch off the motor

and remove the spark plug cable.

• Before setting to work, read through and follow the instructions in this handbook

and the accompanying engine handbook.

• Never use the machine in enclosed or poorly ventilated areas (even if the doors

and windows are open), as the exhaust fumes are toxic.

• Avoid smoking and lighting flames when filling with petrol.

• Always fill the fuel tank in an open area with the engine switched off.

Remember that petrol is highly flammable and explosive under certain

conditions. Fuel must be stored in suitable canisters.

• Never place anything on the engine as it could catch fire.

• Never remove the fuel tank cap or top up with petrol with the engine running or

when it is still hot.

• If any petrol gets spilt, do not attempt to start the engine immediately.

• The exhaust pipe gets very hot when the engine is running and remains hot for

some time after it is switched off. Never touch the exhaust pipe. Keep to a

safety distance.

Page 16

8. START-UP

Caution! Before starting up the engine/motor check that the Autocable machine

is on a stable surface and that there are no animals or unauthorised persons in

the work zone.

• Read the engine manufacturer’s instruction book carefully.

• Check that there is oil and fuel in the tank. Fill if necessary.

• Adjust the control handle in the most appropriate, the relevant working the

lever.

• Adjust the height of the wheel from the ground, acting in the relevant handle

clamping.

• Hold the safety lever (Fig. 8c) and grasp the starting knob (fig.8a / 8b) and pull

the cord without force until you feel the resistance caused by compression,

release the knob and then give a sharp tug to start the engine. The release of

safety lever will cause the engine to stop.

• Before beginning work let the engine idle for about 1 minute then take it to

maximum revs (using accelerator lever) and proceed with normal use, after

grip and turn the knob to the start of self-propelled.

Lever in the

home position

Starting Knob

Fig. 8a

Page 17

Accelerator

lever

Self-

propelled

knob

Fig. 8b

Safety lever

Fig. 8c

IMPORTANT!

To stop the engine, even in emergency conditions, release the safety lever.

Page 18

8.1 Use of the machine

• This machine is designed to work at a depth of 3-5 cm. The precise depth can

be regulated via the lever.

• Adjust the depth of the blades, the relevant action lever.

• Regulate the set screw to record the lever position, and hence the working

depth. The purpose of this is to optimise and speed up the cable-laying

operation.

• Regulate the graduated rod to set the distance between cables (see 8.1.1).

Depth adjustment

lever

Set screw

Blades

Fig. 9a

MAX 10° MAX 10°

Fig. 9b

IMPORTANT!

Never exceed an angle of inclination of 10°, otherwise the blades or the

transmission unit could get damaged.

Page 19

8.1.1 Adjusting the graduated rod

• Loosen the wing nut on the graduated rod.

• Pull the rod out the required distance.

• Tighten the wing nut to secure the rod.

Wing nut

Graduated

rod

Fig. 10

Page 20

8.1.2 Operation

• Grasp the handle and regulate the speed control knob as required.

Patch wire

Fig. 11

• When using close to trees, hedges or fences, the handle can be tilted by

raising and then moving to the left. Return the handle to the most comfortable

work position and secure.

1 2 3 4

In order to avoid a rupture of the blades or the transmission, you must use

the machinery on land and gardens free of rocks in the subsurface.

Fig. 12

IMPORTANT!

Page 21

9. MAINTENANCE

Caution! Before proceeding with any maintenance operation switch off the

engine / motor and in any case ensure that there is no possibility of the machine

functioning. Suitable gloves are obligatory for all maintenance operations.

9.1 Replacing the blade

• Unscrew the screw and remove the blade.

• Replacing the blade.

• Fit and tighten the screw.

Securing

screw

Blade

Fig. 13

Page 22

9.2 Tensioning the drive chains

• Remove the front guard.

• Tighten the eccentric hex pin to get the optimal chain tension.

• Remount the guard.

Drive chains

Front

casing

Pin with eccentric

hole

Fig. 14

Fig. 15

Page 23

9.3 Tensioning the drive belts

Drive belts

• Remove the front guard.

• Loosen the screws securing the engine to the base and adjust the engine to

get optimal belt tension.

• Tighten the screws and remount the guard.

Front

casing

Fig. 16

Securing engine

screws

Fig. 17

Page 24

9.4 Routine maintenance

Check engine oil level

Check screws, tightness, casing, etc.

Check belts tension and state of wear

Check chains tension and state of

wear

Check wear on blade

Clean machine

Greasing transmission group with fat

Texaco Metalgrease AC (fig. 18).

Beginning

of season

See

booklet

♦

♦

♦

♦

♦

Before

each job

See

booklet

♦

♦

♦

♦

End of

season

See

booklet

♦

♦

Greaser

Fig. 18

Page 25

10. TROUBLESHOOTING-REMEDIES

Troubleshooting Remedies

Abnormal noise

The machine does not

start

Difficult start-up or loss

of power

The machine loses

revs and functions

irregularly

Excessive vibration

Check cutters and transmission group.

Cleaning and greasing of the machine in the group of

transmission.

Check cutters and transmission group.

Check state of engine/motor (consult the instruction

manual supplied).

Check state of engine/motor (consult the instruction

manual supplied).

Check cutters and transmission group.

Check state of engine/motor (consult the instruction

manual supplied).

Check cutters and transmission group.

Page 26

11. GUARANTEE

1. The Manufacturer hereby guarantees its Autocable machines against

breakage caused by faulty materials or workmanship.

2. This warranty is valid for the first owner only for 12 months as from the date of

purchase and/or delivery.

3. The Manufacturer is entitled to inspect the Autocable machine and any

components for which a claim has been made under the guarantee, in order

to determine the validity of the claim.

4. This warranty covers replacements free of charge only of components found

to be defective due to faulty materials or workmanship under the guarantee

period.

5. This warranty does not cover reimbursement for labour, consumables or

transport charges for repairs under guarantee.

THIS WARRANTY DOES NOT APPLY IN THE FOLLOWING CASES

1. The Manufacturer may in no way held liable for general damage, including

damage or injury, loss due to halts in production, loss of earnings, leasing

costs or any moral or commercial damage.

2. All claims concerning motors or engines mounted on Autocable machines will

be handled by the relevant Manufacturers’ after-sales service.

3. This warranty does not cover damage caused by misuse, abuse, insufficient

maintenance, accident or damage caused during transport.

4. Parts which are subject to war, such as blades, etc. are not covered under

this guarantee.

5. All expenses for setting the machine to work will be charged to the distributor

or dealer.

6. This warranty is not valid if the repairs, maintenance or modifications are

performed by an unauthorised persons or dealers.

7. The owner is responsible for routine maintenance and settings, which are

thus excluded herefrom.

8. The use or fitting or components and accessories that are not original will

immediately invalidate this warranty.

PROCEDURE FOR MAKING CLAIMS UNDER THIS WARRANTY

If the Autocable machine is found to be defective due to faults material or

workmanship, you are required to send the Manufacturer a written claim and

proceed as follows:

1. The machine must be returned to the Seller or the authorised importer.

2. You are required to present the guarantee duly filled in or the bill, if this is not

available.

3. The claim will be completed by the Dealer, who will forward it to the

Manufacturer.

The Manufacturer alone reserves the right to determine whether to accept the

claim or otherwise.

Page 27

NOTES

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

______________________________________________

Page 28

www.autocable.be

Rev.1-2015

Loading...

Loading...