Chair Topper

Autoadapt Hoisting and stowing

EN User manual

2

Chair Topper Hoisting and stowing

Chair Topper

from Autoadapt!

The following manual is an important part of the product, providing you with

information on how to achieve maximum performance and safe operation. Keep the

manual in a safe place so that you can refer to it when necessary.

If you have any questions about your adaptation, please contact your installation

engineer. If you want to share your opinions about the product or the company with

us, you can register them on www.autoadapt.com/register. That way, you will be helping

us to become a better supplier.

Once again, thank you for placing your confidence in our products!

Autoadapt

Thank you for choosing a

Safe vehicle adaptation solutions

For your safety Autoadapt products are

designed and tested according to current

directives and standards.

S

A

F

E

V

E

H

I

C

L

E

A

D

A

P

T

A

T

I

O

N

3

Hoisting and stowing Chair Topper

EN

Index

Manufacturer certificate (declaration of conformity) at the end of the manual.

Safety

4

Operation

6

Emergency operation

8

Maintenance

14

Troubleshooting

17

Technical specification

19

Introduction for users

20

Safety decals located on Chair Topper /

4

Chair Topper Hoisting and stowing

Safety

Please note that changing the wheels,

rims or other modifications to the

vehicle might aect the total height.

Combined height of vehicle and Chair Topper at the time of installation, ______________ cm.

My Chair Topper

5

Hoisting and stowing Chair Topper

EN

Safety

LOAD /

1. Open the vehicle door fully.

2. Transfer from wheelchair to the vehicle. Leave the wheelchair remaining completely

unfolded and facing toward the front of the vehicle. Lock the wheelchair brakes for safety.

3. Press the OUT button and carefully lower the hook. Release the button when the hook

has reached to desired height.

4. Position wheelchair at the predetermined position and insert the hook securely under

the wheelchair seat.

5. Press the IN button and carefully raise the wheelchair. Release the button when the

Chair Topper is fully closed.

UNLOAD /

1. Open the vehicle door fully.

2. Press the OUT button and carefully lower the wheelchair. Release the button when

the wheelchair has reached to ground level.

3. Remove the hook from the wheelchair.

4. Press the IN button and carefully raise the hook. Release the button when the

Chair Topper is fully closed.

BEFORE TRANSPORT /

1. Place the hand held control in its cradle to avoid accidental activation of the Chair Topper.

Operation

6

Chair Topper Hoisting and stowing

Vehicle door

fully open

Wheelchair facing toward

the front of the vehicle

Ensure that the hook is

inserted all the way in.

7

Hoisting and stowing Chair Topper

EN

Operation

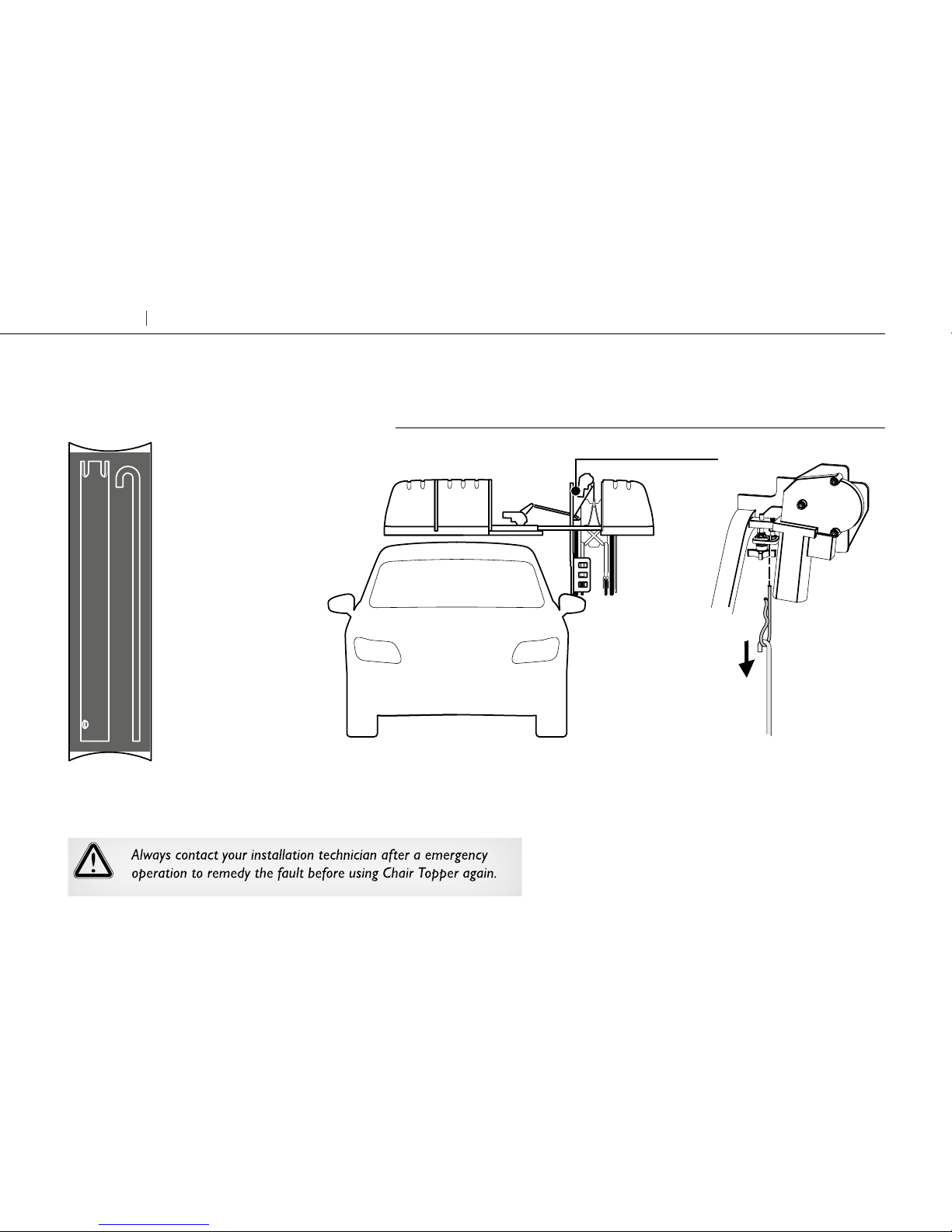

Use the emergency kit, supplied

with the Chair Topper, to easier

the emergency operation.

OUT

1 2

3

Use the supplied hook

to remove the lock pin

through hole in the cover.

Turn the knob 15 full

revolutions counter clock

wise. Use the slotted tube

to reach.

Remove the plug from the cover.

8

Chair Topper Hoisting and stowing

Emergency operation

4

Grab the cover and

pull the slide frame

out.

9

Hoisting and stowing Chair Topper

EN

Emergency operation

Use the supplied hook

to remove the lock pin.

DOWN

5

Use the emergency kit, supplied

with the Chair Topper, to easier

the emergency operation.

10

Chair Topper Hoisting and stowing

6

RISK OF BODILY INJURY AND MATERIAL DAMAGE

DANGER

During this procedure the wheelchair will suddenly

drop and free fall from the Chair Topper. Unless held

by a person of adequate strenght, it may cause injury

to anyone in its path as well as cause damage to the

vehicle.

Turn the knob 15 full revolutions

counter clock wise. If necessary

use the slotted tube again.

11

Hoisting and stowing Chair Topper

EN

Emergency operation

UP and IN

Use the emergency kit, supplied

with the Chair Topper, to easier

the emergency operation.

7

Push in the slide frame until the fold frame is

in a horisontal position. Place the seat hook

and chains on fold frame. Continue to push

in the slide frame until it is fully closed.

12

Chair Topper Hoisting and stowing

8

Turn knob 15 revolutions clock wise.

Use the slotted tube to reach.

13

Hoisting and stowing Chair Topper

EN

Emergency operation

Perform maintenance at the scheduled intervals according to the number of cycles or

elapsed time whichever comes first. Always contact your dealer for disassembly.

Wash and/or wax the ABS plastic in the same manner which you care for your vehicle.

4 weeks

or 100 cycles

Inspect all bearings for wear. Lubricate with light oil.

Fold linkage pivot points. Lubricate with light oil.

Remove and clean any debris or obstructions.

Inspect bearing mounting for proper securement. Correct and replace if needed.

Inspect mounting hardware (frame and topper securement). Make sure there are no loose or missing parts.

Replace, tighten or resecure as needed.

3 months

or 300

cycles

Repeat all checks listed in the 4 weeks or 100 cycles. Repeat maintenance procedures.

Inspect sprockets for securement, slippage, alignment or any damage. Replace, realign or resecure as needed.

Inspect chain channels (plastic for damage, securement or obstructions. Clean, correct or replace.

14

Chair Topper Hoisting and stowing

Maintenance

3 months

or 300 cycles

Inspect chain bolts and all chain connecting points. Inspect master links and chain blocks for positive securement

and/or possible damage. Replace, resecure or correct as needed.

Inspect chains for lubrication, damage, misalignment, binding or twisting. Lubricate with light oil.

Clean before lubricating - realign or correct any other conditions as needed.

Inspect chain boxes (up/down chain enclosure) for obstructions or damage. Clean or correct.

Inspect the side bearing channel on both sides for damage, securement or obstructions. Clean, resecure or correct

as needed.

Inspect all mounting hardware (securing framework, hearings, linkage, motors, etc.) for loos, damaged or missing

parts. Replace, tighten, adjust or realign as needed.

Inspect main wiring harness for possible damage, securement or poor electrical connections.

Correct, resecure or repair as needed.

Inspect control harness for possible damage; securement, or poor electrical connections.

Correct, resecure or repair as needed.

Inspect power cable for damage or poor connections. Correct or replace as needed.

Inspect ground wires damage, securement or poor connections. Correct, resecure or repair as needed.

Inspect the harness/wire socks attachment points on wind screen of vehicle.

Replace worn or missing cable tie/cable tie attachment feet.

Inspect fold springs to see if detached or worn. Correct or replace.

Inspect fold linkage for excessive wear, damage, lubrication and securement.

Lubricate with light oil, resecure or realign as needed.

Inspect pop rivets/washers (securing ABS plastic shell) to see if worn or missing. Replace or resecure as needed.

15

Hoisting and stowing Chair Topper

EN

Maintenance

1 year

or 1250 cycles

Repeat all checks listed in the two previous sections. Repeat maintenance procedures.

Inspect fuse holder and electrical connections. Correct as needed.

Inspect the channel on both sides for damage, securement or obstructions. Clean, resecure or correct as needed.

Lubricate black plastic bearing on three sides with a thin layer of AGS door-ease stick lubricant.

Inspect the two micro switches for possible damage, securement or poor electrical connections.

Replace, resecure or correct wiring connections as needed.

Inspect relays/relay blocks for possible damage, securement or poor electrical connections.

Replace, resecure or correct wiring connections as needed.

Inspect seals and gaskets to see if damaged, worn or missing. Correct as needed.

Inspect decals. Replace if worn, missing or illegible.

Internal moisture (from use during rain or snow). Leave open on dry day to dry interior.

16

Chair Topper Hoisting and stowing

Hand held control does not work ................

Unusual noises heard during operation.....

- Check that the wiring to the hand held control is connected and undamaged.

- Check that the fuse is intact and that the vehicle battery is charged.

- Follow the instructions for “Emergency operation”.

- Do not use the Chair Topper. Contact your installation technician for an

overhaul.

17

Hoisting and stowing Chair Topper

EN

Troubleshooting

Troubleshooting

18

Chair Topper Hoisting and stowing

Model /

Serial number /

Year of manufacture /

Date of purchase /

Notes /

Contact details for the installation engineer /

Please contact your installation technician if you require further assistance or need to ask questions

about warranty. We recommend keeping the following information to hand at all times /

B D

Dimensions

A, length ...................................................... 143 cm

B, width ........................................................ 131 cm

C, height ..............................................46+10* cm

D, extension .................................................91 cm

E, chain lenght (200 cm with ext. kit) ...109 cm

F, max folded height .................................93 cm

G, max folded apex height .................. 83 cm

H, max folded width ................................35 cm

Product data

Lift capacity .................................................... 20 kg

Unit weight ..................................................... 55 kg

Fuse auto reset................................................ 15A

Motors .......................................................... 12VDC

Load cycle time .......................................... 30 sec

All weights and dimensions are for reference only.

*During operation the product extends an additional

10 cm in height.

A

C

E

F

G

H

19

Hoisting and stowing Chair Topper

EN

Technical specification

Technical specification

20

Chair Topper Hoisting and stowing

Date /

Name of dealer /

Signature, installation engineer Signature, user

Introduction for users

Autoadapt would like you, as a user, to feel secure and comfortable with your new

product. For that reason, it is your installer’s duty to go through the following with you /

• Safety

• Operation

• Emergency operation

If any questions about the product should come up later on, you are of course very

welcome to contact your installation technician again.

The above chapters have been gone through /

Conforms to following directives

standards and regulations /

2006/42/EEC

ECE R-10

ISO 11154

Autoadapt AB, Stenkullen 2017-06-15

Håkan Sandberg

CEO

Manufacturer /

Autoadapt AB

Åkerivägen 7, 443 61 Stenkullen

Sweden

Phone: +46 302 254 00

E-mail: info @ autoadapt.com

www.autoadapt.com

Declares that the product /

Chairtopper, model left/right

Declaration of conformity

Accredited by SWEDAC as testing laboratory in accordance with ISO/IEC 17025:2005

Quality system certified in accordance with ISO 9001:2008

Illustrations, descriptions and specifications in the user manual are based on current product information.

Autoadapt reserves the right to make alterations without previous notice.

© 2017 Autoadapt AB

Accred. no. 1976

Testing

ISO/IEC 17025

42 725 6-2 2017/1 2

facebook.com/autoadapt

twitter.com/autoadapt

www.autoadapt.com

AUTOADAPT AB

Åkerivägen 7

S-443 61 Stenkullen

Sweden

Phone: +46 302 254 00

E-mail: info@autoadapt.com

Loading...

Loading...