Carony Go

Carony Drive

Safety

General

Service and

maintenance

Mechanics

Service manual

(Discontinued)

3

Carony Go/Drive

Safety

General

Service and

maintenance

Mechanics

Electrics

Service manual

1:! Service check-ups

1:2 Instructions for service and

maintenance

1:3 Updates

2:1 Description

2:2 Exploded views and components

2:3 Trouble shooter

2:4 Repair manual

0:! Technical data

3:1 Description / Programming

3:2 Wiring diagrams

3:3 Trouble shooter

3:4 Repair manual

4

5

This chapter covers general safety rules

when servicing the Carony Go/Drive

Safety

!

Use safety glasses, gloves, protective work shoes and other

protective items as required by the work situation.

Batteries contain sulphuric acid which is very corrosive to

the human body and parts of the Carony Go.

Batteries give off Hydrogen gas when charged. This gas is

together with oxygen very explosive.

Begin by disconnect the ground lead when removing a battery. And also connect the ground lead last when fi tting batteries.

Do not connect a discharged battery in series with a

charged one. It can cause the batteries to explode.

Do not wear metal objects like rings and wristwatches. Even

a small voltage can produce high current and can cause

burn injuries.

Always cover the top of the battery with a rag or other nonconducting material when you work close to the batteries.

Batteries always contain substances dangerous to health

and the environment. Discarded batteries must be disposed

of according to local and/or national regulations.

6

7

0:1 Technical data

General

Seat angle 17º

Depth of seat 493 mm

Seat width 408 mm

Height of seat surface in front 510 mm

Backrest inclination -19º till 23º

Backrest height 653 mm

Backrest width 435 mm

Distance of headrest in front of backrest 34 mm

Height of backrest above seat 775 mm

BEV seat specifi cations

Total width, with air tyres 62 cm

Total width, puncture free wheels 60,9 cm

Length 75 cm

Length with anti-tip and foot rests 108 cm

Height without seat 38 cm

Height with seat 115 cm

Total weight 93 kg

Weight of wheel unit with batteries 75 kg

Clearence beneath wheelchair 65 mm

Adjustable seat height 42-55 cm

Dimension front wheels 200x50 mm

Tyre pressure front wheels 2,6 bar

Dimension rear wheels 315x50 mm

Tyre pressure rear wheels 2,8 bar

Range 25 km

Max speed 6,5 km/h

Max reverse speed 3 km/h

Braking distance 0,8 m

Obstacle clearence 6 cm

Turning space180 degrees 150 cm

Hill-climbing ability 6 grader

Max user weight 120 kg

Battery type AGM; 1245

Batteriy max dimension 198x 165x170

Main fuse 50 A

Carony Go/ Drive

Go: Drive:

110-122 cm

33,5 cm

112-126 cm

110 kg

92 kg

65 mm (35 mm)

37-51 cm

Distance from footplate to seat 404-550 mm in 8 steps

Length of footplate 129 mm

Footplate angle variable

Angle of legrest to seat surface 104º

Armrest height 285 mm

Distance to backrest from front edge

of armrest 335 mm

Armrest length 356 mm

Armrest width 57 mm

Armrest angle -38º to 10º

Distance between armrests 438 mm

Carony Go

Carony Drive

8

Carony Go Measurements for TURNOUT applications

INSIDE THE VEHICLE:

Total height with TURNOUT

Measured from vehicle sill + Carony rails and seat:

Carony rails

Turnout + Carony rails + BEV seat

Turnout + Carony rails + Bev-seat

A

B

C

D

E

F

= 950 mm

Measured from where the sill moulding starts to

bend upwards.

= 830 mm

= 630 mm

= 650 mm

Max 375mm (425mm with raising kit)

Measured from ground to vehicle sill.

= 600 mm

0:1 Technical data

840 mm

vehicle sill

9

Carony rails

Turny + Carony rails + Bev-seat

0:1 Technical data

Carony rails

Turny seat raising

spacer 35 mm

B

C

A

A

B

C

D

E

= 1050 mm

This measure depends on the user. A tall person, who is unable to bend the neck, needs

more space. This can, up to a certain point,

be compensated by inclining the backrest a

little bit.

= 1000 mm

Measured by penulating by the approximate

point of Turnys height including the seat.

= 750 mm

Measured by the ultimate out shooting point

of the dashboard.

= 650 mm

Minimum leg space.

Turny 395: max 587 mm

or Turny 300: max 492 mm

E

Carony Go Measurements for TURNY applications

10

0:1 Technical data

11

Service and Maintenance

1:1 Service check-ups

When servicing the Carony Go /Drive, every 6 months

(12 months if rarely used) following chek-ups should be made:

Check:

1. Motor release, see page 12.

2. Rubber housing for lift pillars, see page 12.

3. Control unit arm lock/unlock in the position chosen, see page 12.

4. Front tyres: 2.6 bar, Rear tyres: 2.8 bar

5. Tighten drive motors, see page 12 or method 2:4:1 step 1- 3

Switch the power on and check:

6. Electrical functions

7. Seat adjustment

8. Speed limit when seat raised

9. Battery indicator when charged

10. Reading fault codes

Remove cover and check:

11. Battery contacts, possible oxidation

12. Check battery voltage

13. Check cables and connector.

Every 12 months:

14. Change spring for docking mechanism, see page 13.

15. Adjust release wire for docking mechanism, see page 13.

12

1:2 Instructions for service and maintenance

Tighten drive motors

It is IMPORTANT to tighten all drive motor nuts at every

service situation. If they are not properly tightened the

fastening might be damaged.

See method 2:4:1, pic. 1- 3 for removing the wheel.

Tighten the three nuts on both sides of the wheelchair

as shown in picture.

WARNING!

Do not use too much force! These are aluminium threads and shall not be over tightened.

Rather use some lock fl uid, such as Loctite.

Instructions for the 6 months service

Motor release

If the motor release is not working as it should, see

method 2:4:4 Change of transversal release shaft.

Check if any of the joints or bars are broken.

Control unit arm lock/unlock in the position chosen

If the joystick arm doesent lock in the position chosen, the cause is

most probably a defect gas spring or release lever.

See method 2:4:12 Joystick arm release, change incl. adjustment

and change of gas spring

Rubber housing for seat lift pillars

It is IMPORTANT to check that the rubber housings are not defect.

Defect rubber housings can expose the Ketter-pillars and the seat

height system to water and rust.

See methods 2:4:6, pic. 1- 4, Carony Go

2:4:7, pic. 1- 3, Carony Drive

13

1:2 Instructions for service and maintenance

Change of spring for docking mechanism (Carony Go)

At the 12 month service the spring shall be changed.

Spare part kit: Art. No: 418097 (leaf spring)

See method 2:4:5 Change of docking mechanism (Carony Go)

The wires on both sides shall be adjusted to make the release levers affect the docking mechanism directly.

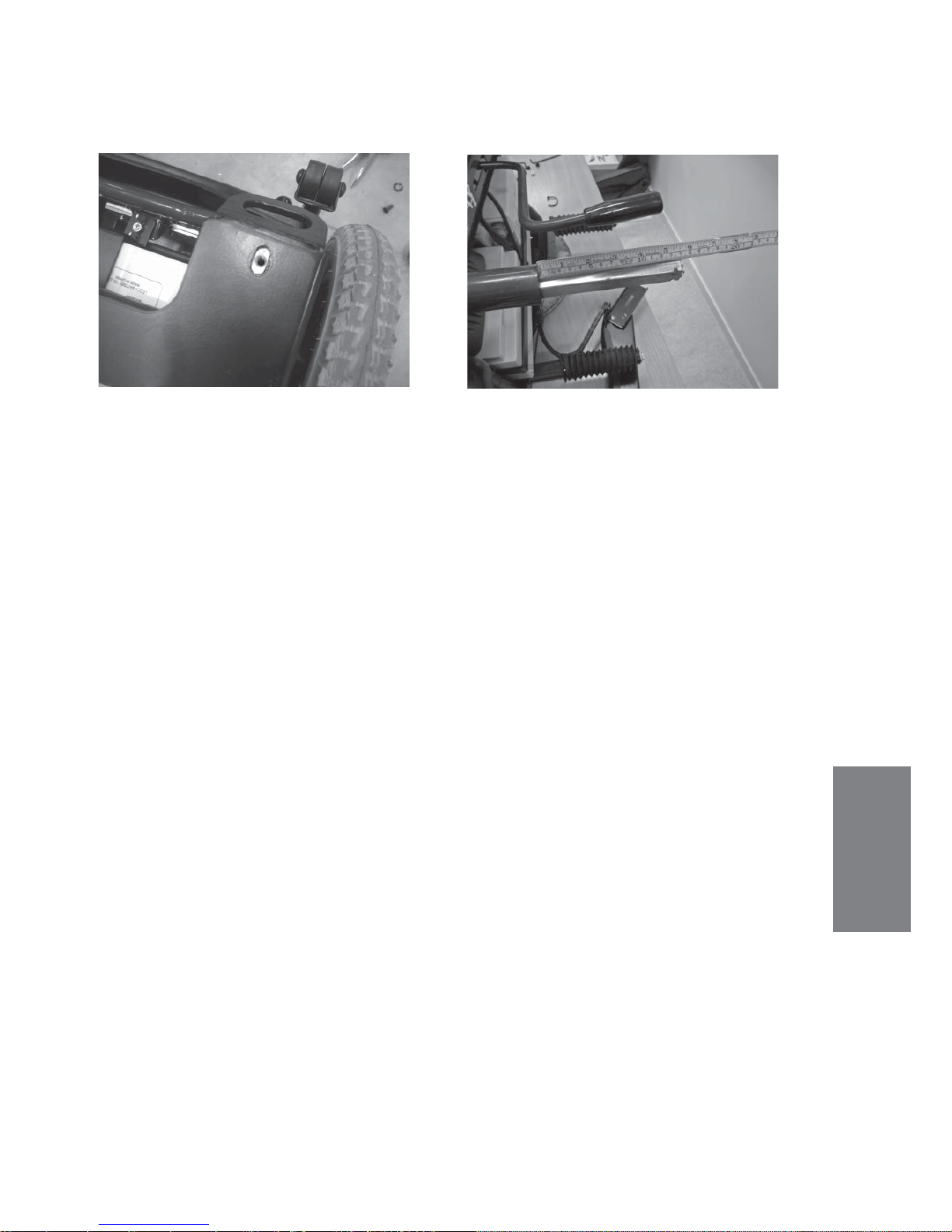

Adjust release wire for docking mechanism (Carony Go)

Adjust at front.... ...or at the back

14

1:2 Instructions for service and maintenance

Batteries

The Batteries of the wheelchair are of gel type and therefore don’t need any liquid check-up.

Regular charging prolongs the lifetime of the batteries.

When Carony Go is not in use - connect to battery charger!

Charging the batteries

Batteries shall be charged in a ventilated area, using a charger

of type IVO 24/6 IP65.

The charge socket is placed in the front edge of the control box.

Charge socket

!

Cleaning

Cleaning should be done regularly.

Wheels

The wheel pressure needs to be checked regularly. The driving wheels (rear wheels)

shall have a pressure of 2.8 Bar. The front wheels shall have 2.6 Bar.

Low air pressure can cause extra wear and tear to the wheels and drains the battery faster.

Replacing the tube

Place pieces of board under all wheels except the one that shall be amended.

Remove the rear wheel by using a 17 mm wrench.

Remove the front wheel by using a 6 mm hexagon key and a 13 mm wrench.

Let the air out of the tube and remove the tyre from the rim.

Replace the old tube with a new one. Restore and mount the wheel.

Don’t forget to tighten the nut. Infl ate the wheel to specifi ed air pressure.

For upholstery use vacuumcleaner and

upholstery cleaner.

The seat cushion is detachable and can be machine washed in 40 degrees C.

N.B! Do not dry in tumble-drier or drying cupboard!

DO NOT use a high-pressure cleaner and

DO NOT fl ush water on the wheelchair!

This might cause damage to the electricity system etc.

Clean the wheelchair with a moist

towel and a gentle cleaning agent.

Too high air pressure

can cause an explosion!

Tube for rear wheel: Art. No: 418914

Tube for front wheel: Art. No: 420797

Instructions from the user manual

15

Replacing the fuse

The fuse is placed under the plastic cover of the wheel unit.

The cover is Velcro fastened and is easy to pull off.

The main fuse of 50 Ampere is placed on the red cable.

A defective fuse might be caused by a major fault of the electric system.

Replacing the bulbs

Bulbs:

Headlight

Indicators front

Indicators back

Rear light

Socket:

BA 15 s

Ba 15

Ba 15 f

BAY 15 d

Specifi cation:

24V/21W

24V/5W

24V/5W

24V/3W

Replacing headlight bulb:

Remove the lamp body from the control box arm, by unscrewing the two

screws with a size 3 hexagon key.

Unscrew the two screws that fi x the lamp body to its holder.

Unscrew the black socket from the lamp body. Remove the bayonet fastened bulb and replace it with a new.

Remount and tighten all screws.

Replacing bulbs of rear light and rear indicator :

Unscrew and remove the glass from the rear light. Change bulb and

remount the glass.

Replacing bulb of front indicators:

Use a blunt knife or other tool to remove the glass.

Replace the bulb and remount the glass.

1:2 Instructions for service and maintenance

Replacing the batteries

Always replace both batteries at the same time!

Remove the plastic cover, fastened by Velcro. Loosen the wing

nut holding the battery bracket and remove this. Raise the rear

battery upright. Disconnect the cables and remove the battery.

Push the remaining battery as far back as possible, raise it up

and remove it.

When new batteries are connected it is

very important that they are correctly placed.

First connect the minus then the plus poles.

Under the plastic cover of the wheel unit.

battery

battery

16

1:3 Updates

From May 2008 the Control Unit Protection will be updated

From Mrch 2008 there is a new release lever without a lock pin

Control unit protection

A hexagon lock screw is used instead.

Method 2:4:1 step 10: Release the lock screw and lift it up.

17

Mechanics

2:1 Description of mechanical system

Seat lift pillars (Ketter-pillars)

There are two types of pillars:

• Front pillars: Art. No: 417423

• Rear pillars: Art. No: 417424

In case of a defective pillar, replace with a new.

The Carony Go/ Drive is a very compact and low electrical wheel chair.

It has a height adjusting possibility which will provide the driver optimal height for all

opportunities. It is made of steel and powder painted for the rust and impact protection.

The wheels are made of aluminium (drive wheel) and plastic (front wheel), both use

infl atable rubber tyres. See specifi cation for the right pressure.

The height adjustment is mechanically driven by one electrical motor and four Ketterpillars, consisting of an angled gearbox and a screw.

The lift system has a micro switch mounted in one of the Ketter-pillars, this will provide the power module with information about the height, in order to slow down the

wheelchair if the seat is not at its lowest position.

The propulsion system uses two strong 24V electrical motors giving the wheelchair

good performance and good handling. The two motors have both brakes and gear

box included. This is one of the reasons for the compactness, but will still be reliable,

strong and rigid.

Remember when the wheel chair isn’t in use always

put it on charging!

Low and compact

Wheels

Height

adjustment

The motors

18

2:2 Exploded views and components

Carony Go wheel unit

1

15

2

27

14

21

13

3

17

26

25

18

24

11

23

16

5

49

47

22

48

7

4

22

6

28

45

42

46

44

43

31

30

32

39

33

40

12

34

36

20

37

50

38

35

41

19

2:2 Exploded views and components

Component list for Carony Go wheel unit

50 4 Self-cutting screw R6B B6x9.5

49 2 Locking nut M6LM - M5 412215

4

81

814

pma

l ra

eR

2

84

47 1 Bracket rear lamp 001070 418098

46 4 Locking nut M6LM M4 416646

45 4 Screw MC6S M4 x 8 417732

44 2 Direction asher 418185

43 1 Bracket right 418100

42 1 Bracket left 418099

41 2 45 Ah battery 418164

40 2 a-lock Ø6 without cap

073214 h

c

tiwS

1

9

3

38 2 Dummy plug IKPT1713S 418179

37 2 Tapping screw 3.5x13 fzb Berner

87777

418178

36 4 Pop rivet 3,2x6,3 Alu/steel 418182

35 2 Velcro tape rm 418156 2QNN020 ADS Svart

34 2 Velcro tape soft 418155 1QNN020 ADS Svart

33 1 Stop screw SK6SS M4x5 FZB 415597

21081

41

31

1

00

tekcarB4

2

3

31 2 Reex side self-adhering yellow 417868

30 2 Washer BRB 17x30x3 fzb 412959

pot pa

C

1

92

46

7

71475

1100

rae

r

paC

1

8

2

27 2 Column rear 417424

26 4 Plug screw Ø6 L=11,0 417832

25 4 Screw MC6S M4 x 35 417809

24 2 Screw MK6S M6 x 16 414079

23 2 Locking nut M6LM - M6 412305

22 10 Screw MK6S M5 x 10 416744

21 6 Screw MK6S M6 x 12 414079

20 2 Tapping screw 4.2x25 418177 Berner 723851

19 1 Wing nut DIN 315 - M6 417806

18 1 Lifting motor 4028 417427

17 2 Hexagon bar L=369 417426

16 1 Hexagon bar L=434 417425

15 4 Guide bushing 001155 417954

14 1 Power module 417417

13 2 Wheel Ø315 417420

12 1 Motors dynamic 418409 (right) 418410 (left)

11 1 Bracket motor 001074 418011

10 1 Fastening eyes right 001072 418009

9 1 Fastening eyes left 001073 418010

8 1 lock lever battery 418157

7 2 Reex rear round red 418086

6 2 Reex front self-adhering white 417867

3677

1

4 r

ednu

p

a

C

1

5

4 1 Carony Go emblem 418183

3 2 Column front 417423

2 1 Chassis weld assy. 001005 417899

1 4 Rubber bellows 412213

Fig. pcs. Description Art.No:

20

2:2 Exploded views and components

Carony Drive footrest system (DISCONTINUED)

1

2

6

8

22

7

20

4

5

9

3

14

16

15

17

13

16

21

17

18

14

11

12

19

17

15

10

21

2:2 Exploded views and components

Component list for Carony Drive footrest system (DISCONTINUED)

Fig. pcs. Description Art.No:

Konstr Ritad

Kop

va ttasrE

r

ettäsrEalak

S

kdoG

r

tnoK

Artikel nr

Dat

Ritn.nr

Autoadapt AB

jno

JNO

M36

2008-03-31

M36-0034

A

Carony Drive_Right

Carony Drive

Projekt

419195

M36-0001419196Bottom11

411791

Sliderail

22

M36-0017419197Slide_right13

M36-0033419203Upper footrest14

M36-0032419214Footrest1

5

M36-0028419229

Chairplate

1

6

M36 0003419234

Slide rod bracket

17

M36-0021419235

Axel

18

GFM-1214-15419218Glide bushing19

ISO 7380416359Screw M8x40110

ISO 7380

412747

Screw M8x12

411

ISO 7380

411345

Screw M8x16

412

DIN 7991 419239

Screw M6x16

213

DIN 125 - A 6,4412300Washer 6,4x12x1,6814

DIN 125 - A 8,4412332Washer 8,4x16x1,6215

DIN 934 - M6413038Nut M6816

DIN 934 - M8411509Nut M8617

DIN 557 - M8414321Weld Nut

418

SF-DF-3452-Lesjofors

419181

Spring

219

M36-0043419236Sliderod120

ISO 7380 - M6 x 16

410759Screw M6x16

621

419240Starlock222

Anmärkning

Ämne Dim.

BenämningAntalDet-nr.

Exploded view

22

2:2 Exploded views and components

Carony Go foot rest

3

4

2

5

6

7

1

3

4

5

2

6

7

1

23

Ritn.nr

Konstr.

Godk.

Ritad

Kop.

Stand. Skala

Ersätter

Ersatt av

Register nr

Dat.

Kontr.

Autoadapt AB

Ant.

Benämning

Material

Mod-nr Ämne

Dimension

Anm.

Art.Nr.

Det.nr

Exploded view foot rest left

JWA

2005-05-31

000996

A

Carony Go, all

Carony Go

1:2

7 1 Included in fig.6

6 1 Foot / heel support 100630

5 1 Included in fig 2

4 1 Wing screw 412186

3 1 Tube ttings Ackurat 22x19

28-32S

418176

2 1 Footrest left 416562

1 1 Holder foot rest weld assy. 001040 417982

7 1 Included in fig.6

6 1 Foot / heel support 100630

5 1 Included in fig.2

4 1 Wing screw 412186

3 1 Tube ttings Ackurat 22x19

28-32S

418176

2 1 Footrest right 416561

1 1 Holder foot rest weld assy. 001040 417982

2:2 Exploded views and components

Component list for Carony Go footrest left

Component list for Carony Go footrest right

Fig. pcs. Description Art.No:

Fig. pcs. Description Art.No:

24

2:2 Exploded views and components

Carony Go / Drive anti-tip

3

10

7

6

4

11

1

9

5

8

2

12

2

10

6

7

3

4

1

8

9

5

11

12

25

2:2 Exploded views and components

Component list for Carony Go / Drive anti-tip left

Ritn.nr

Konstr.

Godk.

Ritad

Kop.

Stand. Skala

Ersätter

Ersatt av

Register nr

Dat.

Kontr.

Autoadapt AB

Ant.

Benämning

Material

Mod-nr Ämne

Dimension

Anm.

Art.Nr.

Det.nr

Exploded view anti-tip left

JWA

2005-05-30

001000

A

Carony Go, all

Carony Go

1:2

12 2 Screw MK6S M6 x 12 414079

11 1 Spring SF-TF SS1774-04 418180

10 2 Washer 6.4x12x1.6 412300

303414 6O kcol-a29

8 1 Shaft wheel 60 240 414465

103414 8Ø kcol-a27

699714221100 tfahS16

503414 leehW25

599714121100 tlob k

coL14

3 1 Bracket left 001120 417994

2.913 NG046114 eldnaH12

1 1 Anti-tip left weld assy. 001116 417984

12 2 Screw MK6S M6 x 12 414079

11 1 Spring SF-TF-1552-SS1774-04 418180

10 2 Washer 6.4x12x1.6 412300

303414

6Ø kcol-a29

8 1 Shaft wheel 60 240 414465

69

9714221100 tfahS17

103414 8Ø kcol-a26

503414

leehW

2

5

2.913

NG04611

4

el

dn

aH

14

3 1 Locking bolt 001121 417995

2 1 Bracket right 001119 417993

1 1 Anti-tip right weld assy 001115 417983

Component list for Carony Go / Drive anti-tip right

Fig. pcs. Description Art.No:

Fig. pcs. Description Art.No:

26

2:2 Exploded views and components

Carony Go / Drive lever system

1

2

4

9

7

5

6

8

10

11

3

27

2:2 Exploded views and components

Component list for Carony Go / Drive lever system

Fig. pcs. Description Art.No:

838014 pac tuN411

10 2 Shims 12x18x0.5 415716

9 1 Screw MK6S M6 x 12 414079

8 1 Washer 7x35x2 SRKB fzb 417804

7 2 Locing nut M6LM - M12 412984

6 2 Locking nut M6LM - M8 413232

5 2 Screw MC6S M8 x 80 416585

4 2 Front wheel Ø175 412193

3 2 Alu front forks 151mm MBL 418084

2 2 Slide bearing COB010F/FS-1F 2515 418163

1 1 Lever arm weld assy. 001032 417985

28

2:2 Exploded views and components

Carony Go / Drive joystick arm system

A-A ( 1 : 2 )

B ( 0,30 : 1 )

A

A

B

6

11

22

8

12

13

3

23

7

24

20

27

21

2

1

9

10

25

28

31

32

33

34

29

30

18

15

16

14

5

17

4

19

26

29

2:2 Exploded views and components

Component list for Carony Go / Drive joystick arm system

Fig. pcs. Description Art.No:

34 1 Conduit entry Berner 6x9.5x1.6 418172

33 1 Cable chain E04.07.015.0 418134

32 1 Washer 8.4x16x1.6 412332

31 1 Screw MK6S M8 x 12 svartkrom 412348

30 2 Screw MC6S - M5 x 20 412311

29 2 Screw MF6S M5 x 16 410761

28 2 Washer Ø8x14x1 Unlico 418170 Det.nr 1006710000VR

27 1 Draw spring Berner 418171 Art.Nr. 30437.9

26 1 Screw MK6S M5x6 412360

25 1 Screw MF6S M5 x 10 416726

24 1 Slide bearing Ø12 Ulinco 418169 Det.nr. 31-36624

23 1 Slide bearing Ø8 Ulinco 418168 Det.nr. 31-1092270000

22 3 Plug screw Ø5 L=9.6 416007

29971

4130100

t

fahS

1

12

16771482010

0

thgi

r

pa

C

102

19 1 Latch right 001030 417970

18 1 Protection device 001200 417990

17 1 Joystick Shark 417416

16 1 Spacer latch 001273 417991

15 2 Screw MC6S M4 x 10 417731

14 1 Hinged bracket right 417972

13 1 Slide bearing COB010/FS-1 1412 418161

12 1 Slide bearing COB010F/FS-1F1417 418160

103

414

8Ø kco

l

-a

411

10 2 Screw MF6S M5 x 8 410142

98

971

4

01

6

000

t

f

ahS

1

9

889714

90600

0

t

fahS

2

8

869714

717000

thgir raB17

6 1 Protective device weld assy. 001024 417966

5 1 Bracket right weld assy. 001021 417962

4 1 Arm right weld assy. 000589 417964

3 1 Bracket arm right weld assy. 000581 417960

2 1 Gas-Spring Eurimex 418154 10-28-30-173-3000N

1 1 Release-Mechanics 418153 LA-SOHE67-KU

* pos. 6 Protective device weld assy. New from 2008-05: Art. No: XXXXXX

(*)

30

2:2 Exploded views and components

Carony Go / Drive motor release handle left

18

12

11

19

5

14

10

4

13

9

7

6

8

21

22

24

25

23

22

3

26

20

15

16

2

17

1

31

2:2 Exploded views and components

Component list for Carony Go / Drive motor release handle left

Fig. pcs. Description Art.No:

26 1 Screw MC6S M6x25 412904

25 2 Screw MC6S M6 x 10 414971

24 6 Nut M6M M5 413084

23 4 Plug screw 416007

22 2 Locking nut M6LM M6 412305

21 6 locking nut M6LM M5 412215

20 2 Tension pin FRP 3x12 412585

19 1 Screw MC6S M5 x 16 417736

095214 ssoB181

17 2 Retaining ring DIN 6799 - 8 418158

16 2 Slide bearing Iglidur clip-2

MYM-10-10

418142

1418

1

49531

00 kco

l25

1

14 1 Tension pin FRP 3 x 20 412585

13 1 Screw MC6S M6x45 414237

12 1 Release knop 001049 417978

2

59

71

4

8

40100

tekca

rB

11

1

10 1 Adjusting lever left 001047 417976

9 1 Bracket left 001046 417974

8 2 Thread rod M5 L=35 M4171

7 1 Thread rod M5 L=110 M4170

6 6 Toggle joint A8 Kontima M5 418175

5 1 Spring SF TFK 3190 418174

4 1 Washer 6,4x18x2 418173

3 1 Screw MK6S M6x16 410759

2 1 Shaft weld assy. 001354 417998

1 2 Bracket weld ass

y

. 001042 417986

32

2:2 Exploded views and components

Carony Go rails

5

7

4

3

9

10

8

11

12

1

2

6

13

9

11

2

8

10

12

4

1

7

3

6

5

13

33

Component list for Carony Go rail left

Fig. pcs. Description Art.No:

Ritn.nr

Konstr.

Godk.

Ritad

Kop.

Stand. Skala

Ersätter

Ersatt av

Register nr

Dat.

Kontr.

Autoadapt AB

Ant.

Benämning

Material

Mod-nr Ämne

Dimension

Anm.

Art.Nr.

Det.nr

Exploded view slide bar left

JWA

2005-06-01

001003

A

Carony Go, all

Carony Go

0,46:1

13 1 Washer BRB 6,4x12x1,6 FZB 412300

12 1 Plate spring 001261 418097

11 2 Screw MF6S M6x20 417042

10 1 Tension pin FRP 3x12 412585

30

0814760100

tfahS19

359714850100 pac kcoL18

718714960100 eriW17

303414 6Ø kcol-a16

525614 bon

K15

491214701 06

gnisuoH14

3 2 Slide bearing COB010F/FS-1F 0608 418162

2 1 Release handle left weld assy. 001297 418001

1 1 Slide bar left weld assy. 001053 417981

Ant.

Benämning

Material

Mod-nr Ämne

Dimension

Anm.

Art.Nr.

Det.nr

13 1 Washer BRB 6,4x12x1,6 FZB 412300

12 1 Spring plate 001261 418097

11 2 Screw MF6S M6 x 20 417042

10 1 Tension pin FRP 3 x 12 412585

30

081476010

0

tfahS

1

9

35

9714

850100

pac

kcoL

18

303414 6O kcol-a17

49121

4701 0

6 gnisuoH1

6

525614

bonK15

718714 eriW

14

3 2 Slide bearing COB010F/FS-1F 0608 418162

2 1 Slide bar right weld assy 000597 417980

1 1 Release handle right weld assy 001296 418002

Fig. pcs. Description Art.No:

Component list for Carony Go rail right

2:2 Exploded views and components

34

2:2 Exploded views and components

Carony Go / Drive seat and armrests

1

8

7

6

3

5

2

10

9

4

35

Component list for Carony Go / Drive seat and armrests

Fig. pcs. Description Art.No:

2:2 Exploded views and components

Ant.

Benämning

Material

Mod-nr Ämne

Dimension

Anm.

Art.Nr.

Det.nr

10 1 Arm rest left. Inkl. screw and

washer

417847

9 1 Arm rest right. Inkl. screw and

washer

417846

8 2 Washer BRB 6.4x16x1.5 FZB 415511

7 2 Screw MK6S M6 x 12 414079

6 4 Screw MK6S M10 x 50 412226

700814451100 recapS

25

4 2 Bracket weld assy. 001294 418006

500814251100 tekcarB

2

3

40

0814351100

r

eca

pS

22

024001

riahC1

1

36

2:3 Trouble shooter

Trouble shooting on Mechanics

Height adjustment does not function, but the lift motor is running.

Height adjustment is lifting unevenly.

Drive motor is running but the the

wheelchair is not moving.

Wheelchair is making turns to the

left or to the right when joystick is

moved forward or backwards.

Carony Drive footrest is not moving forward when the seat is

lowered.

The seat is unstable and wobbly.

The joystick arn can not be folded

up or down.

The joystick arm is loose.

The brake is not functioning

Carony feels slow and unstable.

Motor can not be released.

Check lift motor or all Ketter-pillars.

Check lift motor or Ketter-pillars

Adjustment or change of linkage

for the motor release.

Check transversal release shaft or

motor/transmission.

Linkage for Carony Drive footrest

system is loose or needs adjusting.

Ketter-pillar bushings are worn out.

Adjust lock lever for the gas spring

or replace it.

Change the arm attachment.

Change brakes or motors

Check tyre pressure

Check release linkage.

SYMPTOM MEASURE METHOD

Lift motor: 2:4:10 or11

Pillars: 2:4: 6 to 9

Lift motor: 2:4:10 or11

Pillars: 2:4: 6 to 9

Motor release: 2:4:4

Transversal release shaft:

2:4:4

or

Motor change 2:4:1 or 2

See Exploded view of Carony

Drive footrest system. Adjust

and tighten the linkage.

Bushing: 2:4:16

Joystick arm release:

2:4:12

Spare part “Arm attachment”:

Right side # 417960

Left side # 417961

Change brake plates:

2:4:3

or Change motors:

2:4:1 or 2

Front wheels: 2.6 bar

Rear wheels: 2.8 bar

Transversal release shaft:

2:4:4

37

2:4 Repair manual

2:4:1 Right side drive motor, replace and service

2:4:2 Left side drive motor, replace and service

2:4:3 Brakes, replace

2:4:4 Transversal release shaft, replace

2:4:5 Docking mechanism Carony Go, replace

2:4:6 Rear Ketter-pillar of Carony Go, replace

2:4:7 Rear Ketter-pillar of Carony Drive, replace

2:4:8 Front Ketter-pillar of Carony Go, replace

2:4:9 Front Ketter-pillar of Carony Drive, replace

2:4:10 Lift motor Carony Go, replace

2:4:11 Lift motor Carony Drive, replace

2:4:12 Joystick arm release, replace

incl. adjustment and change of gas spring

2:4:13 Docking mechanism wire, replace

2:4:14 Anti-tip, replace

2:4:15 Footrest rails for Carony Drive, replace

2:4:16 Ketter-pillar bushings, replace

38

2

2:4 Repair manual

2:4:1 Replace and service the right side drive motor

RIGHT MOTOR

1. Place a distance under the chassis. 2. Set the motor release lever in drive position.

Remove the hub cap.

3. Remove the wheel nut by using a 17 mm

socket wrench.

4. Remove the wheel. Fix the wedge to the motor

axle with a tape.

5. Release the pin lock from the ball joint of the

motor release mechanism.

6. Loosen the ball joint.

39

2:4 Repair manual

2

RIGHT MOTOR

7. Remove the power module according to 3:4:2

Remove the batteries: User manual

8. Unscrew the three screws that fi x the motor by

using a 4 mm hexagon key.

9. Lift out the motor. 10. If the motor needs to be replaced push out

the small pin of the release lever and dismount

the spring and the lever.

11. If the brushes need to be replaced you can keep the release lever mounted.

Unscrew the brushes and replace them with new.

40

2:4 Repair manual

LEFT MOTOR

2

2:4:2 Replace and service left side drive motor

Follow the instruction acording to 2:4:1 Replacing

and servicing the motor on the right side

Fig. 1- 7/8.

Remove the batteries according to the User Manual.

7. Remove the screw that fi xes the motor release

lever and remove the lever.

8. Cut the bundle band holding the cable.

9. Unscrew the three hexagon screws for the

motor

41

2

LEFT MOTOR

2:4 Repair manual

10. Lift out the motor and disconnect the contact for the power module. The motor might be diffi cult

to remove, it has to be lifted as high up as possible to allow the support towards the bottom of the

compartment to run free.

11. If the motor needs to be replaced, pusch out

the small pin for the release lever and dismount

lever and spring from the old motor.

12. If the coal cinders need to be replaced the

lever can remain mounted. Dismount the brushes

from te holders and replace them with new.

13. Remount the motor in reversed order.

NOTE! Run the cable through the slit and do

not forget to fi x it to the bottom with a bundle

band.

42

2:4 Repair manual

BRAKE

2

2:4:3 Replace motor brake plate

1. Dismount the motor according to instructions

2:4:1 and 2:4:2.

Unscrew the two screws of the motor cover and

remove the cover.

2. Unscrew the hexagon screws holding the

thrust plate. Remove the thrust plate.

Use a solder pen to heat them before trying to

loosen them, it will save the Loctite.

3. Remove the friction lining, clean it (wipe it off)

or replace it with a new if required.

4. Remount the thrust plate. This can only be

mounted in one way.

Mount the motor cover and the motor according

to instructions 2:4:1 and 2:4:2.

43

2

TRANSVERSAL RELEASE SHAFT

2:4 Repair manual

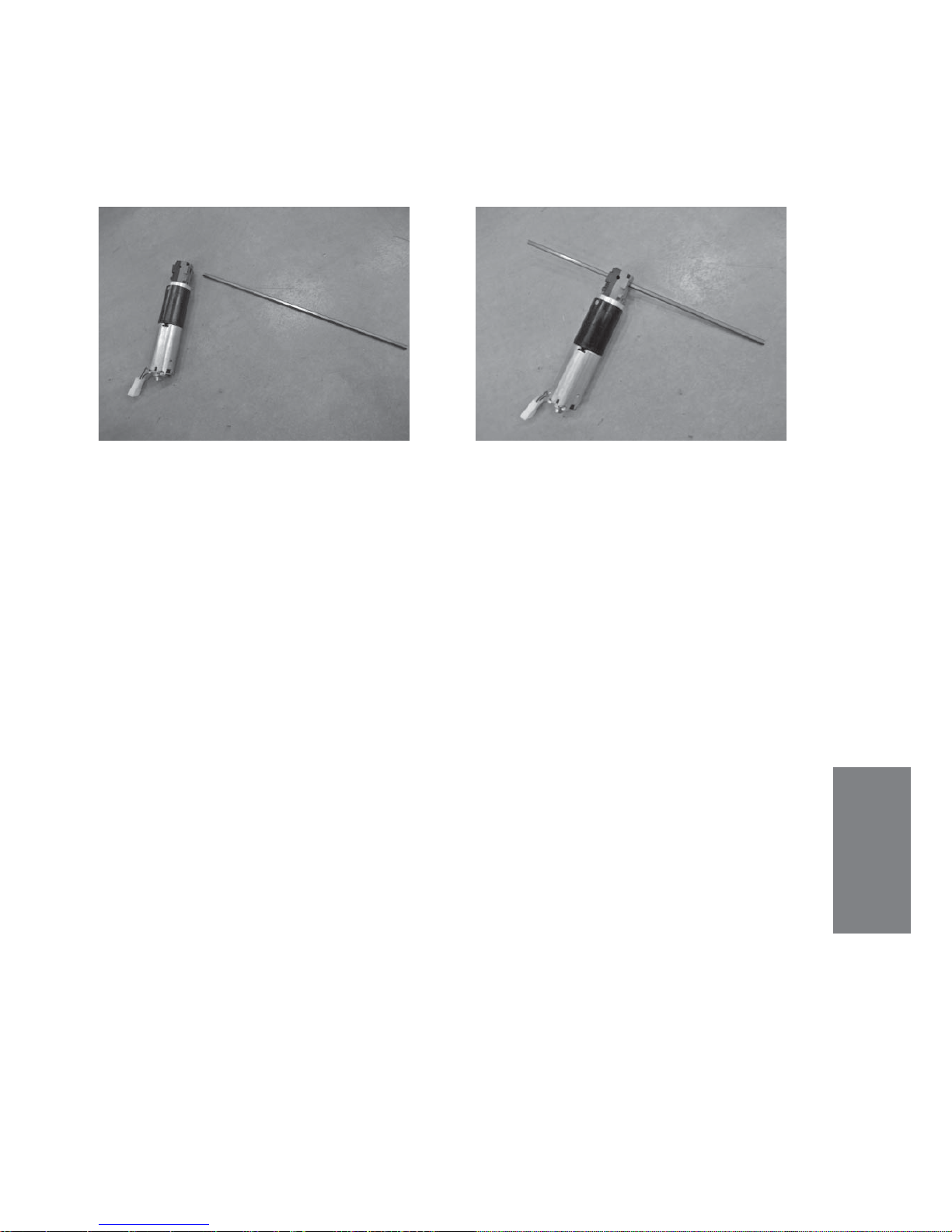

2:4:4 Replace transversal release shaft

1. Dismount the ball joint on both sides. (instruc-

tions 2.4.1 fi g. 5 and 6)

2. Unscrew the two M4 screws that fi x the clip

bearings.

3. Lift out the transversal release shaft. 4. The clip bearings may now ne replaced.

5. Mount the new in reversed order.

Adjust the linkage so that both wheels

are released at the same time.

44

2:4 Repair manual

DOCKING MECHANISM

2

2:4:5 Replace docking mechanism (Carony Go)

1. Remove the seat. Take away the plug from the

wire hole by using a fl at tool.

2. Unhook the wire from the hole.

4. Dismount the plate spring behind the docking

mechanism.

3.

5. Locate the pin that holds the axle for the cup. 6. Knock away the pin by using a 3 mm drift.

45

2

DOCKING MECHANISM

2:4 Repair manual

7. The tension pin.

9. Remount in reversed order and make sure to

use a new pin.

8. Press out the axle for the cup.

The spring shall be changed every 12 months !

46

2:4 Repair manual

REAR KETTER PILLARS CARONY GO

2

2:4:6 Replace REAR Ketter-pillars of Carony Go

3. Place the wheel unit on the side and remove

the bottom cover.

1. Remove the seat and pull away the top cover.

Unscrew the 4 hexagon screws of the Carony

rails.

2. Put the rails aside and loosen the cable chain.

4. Cut away the bundel bands from both of of

the Ketter-pillar rubber housings.

5. Unscrew the two screws holding the Ketter-pillars.

6. Unscrew the two screws of the lift motor attachment.

• Rear pillars: Art. No: 417424

47

2

REAR KETTER PILLARS CARONY GO

2:4 Repair manual

7. Pull the pillars slightly outwards unil the hexa-

gon rod can go free. Cut away the locking clips

from the hexagon rod. Pull away the hexagon

rods, one at a time, to allow removal of the damaged pillar. Replace the damaged pillar with a

new.

8. Make sure to get the upper part of the new

Ketter-pillar facing towards the correct position,

to fi t the Carony rail when remounting.

Do not forget to place an o-ring to lock

the hexagon rod!

9. Be extremely careful to get the same height

of the new Ketter-pillar, - shall not differ more than

1 mm compared to the others.

Uneven pillar heights causes damage.

Make sure to measure from the pipe (not

from the bushing, which might be differently

mounted).

48

2:4 Repair manual

REAR KETTER-PILLAR OF CARONY DRIVE

2

2:4:7 Replace REAR Ketter-pillar of Carony Drive

1. Remove the seat by unscrewing the 4 screws.

Take away the top cover. Unscrew the one screw

holding the joystick arm and put it aside. Loosen

the cable chain.

2. Remove the nut from the balljoint attachment

for the footrest system.

3. Unscrew the entire Carony Drive unit from the

Ketter-pillars (4 screws).

4. Dismount the batteries, according to method

3:4:1. Remove plastic cover by pulling the bottom edge. Disconnect possible rear light cables.

5. Place the Carony on one side and remove the

botton cover.

6. Unscrew the screws holding the DroveLOC

plate.

• Rear pillars: Art. No: 417424

49

2:4 Repair manual

2

7. Unscrew also the two front screws for the

DriveLOC plate.

8. Cut away the bundle band and remove the

rubber housing from the Ketter-pillar that is going

to be changed.

9. Unscrew the two screws of the lift motor at-

tachment.

10. Pull the pillars slightly outwards unil the hexagon rod can go free. Cut away the locking of

the hexagon rod. Pull away the hexagon rods,

one at a time, to allow removal of the damaged

pillar. Replace the damaged pillar with a new.

11. Make sure to get the upper part of the new

Ketter-pillar facing towards the correct position,

to fi t the Carony rail when remounting.

Do not forget to place an o-ring to lock

the hexagon rod!

12. Be extremely careful to get the same height

of the new Ketter-pillar, - shall not differ more than

1 mm compared to the others.

Uneven pillar heights causes damage.

Make sure to measure from the pipe (not from

the bushing, which might be differently mounted).

REAR KETTER PILLAR CARONY DRIVE

50

2:4 Repair manual

FRONT KETTER-PILLAR OF CARONY GO

2

2:4:8 Replace FRONT Ketter-pillar of Carony Go

3. Place the wheel unit on the side and remove

the bottom cover.

1. Remove the seat and pull away the top cover.

Unscrew the 4 hexagon screws of the Carony

rails.

2. Put the rails aside and loosen the cable chain.

5. Unscrew the two screws holding the Ketter-pillars.

10. Pull the pillars slightly outwards unil the hexagon rod can go free. Cut away the locking of

the hexagon rod. Pull away the hexagon rods,

one at a time, to allow removal of the damaged

pillar. Replace the damaged pillar with a new.

4. Cut away bundle band from rubber housing

of the the Ketter-pillar that shall be changed.

• Front pillars: Art. No: 417423

51

2:4 Repair manual

2

FRONT KETTER PILLARS CARONY DRIVE

2:4:9 Change of FRONT Ketter-pillar of Carony Drive

12. Be extremely careful to get the same height

of the new Ketter-pillar, - shall not differ more than

1 mm compared to the others.

Uneven pillar heights causes damage.

Make sure to measure from the pipe (not from

the bushing, which might be differently mounted).

Follow the instructions of method 2:4:7 Change of REAR ketter-pillar of Carony Drive

Use the instructions from 1 - 3

Do NOT remove rear cover or disconnect batteries, pic. 4

Pic. 5: Just remove the plastic cover (NOT the DriveLoc plate)

Proceed from pic. 8 through to pic. 12.

11. Make sure to get the upper part of the new

Ketter-pillar facing towards the correct position,

to fi t the Carony rail when remounting.

Do not forget to place an o-ring to lock

the hexagon rod!

• Front pillars: Art. No: 417423

52

2:4 Repair manual

LIFT MOTOR CARONY GO

2

2:4:10 Replace lift motor on Carony Go

3. Place the wheel unit on the side and remove

the bottom cover.

1. Remove the seat and pull away the top cover.

Unscrew the 4 hexagon screws of the Carony

rails.

2. Put the rails aside and loosen the cable chain.

4. Unscrew the two screws holding the Ketter-pillars.

5. Unscrew the two screws of the lift motor attachment.

6. Pull the pillars slightly outwards unil the

hexagon rod can go free. Cut away the locking

of the hexagon rod. Pull away the hexagon rod,

enough to remove the lift motor.

53

2:4 Repair manual

2

LIFT MOTOR OF CARONY GO

7. Mount the new lift motor.

Do not forget to place an o-ring to lock

the hexagon rod!

2:4:11 Replace lift motor of Carony Drive

Follow the instructions according to 2:4:7 Change of REAR Ketter-pillar of Carony Drive

Use the instructions from 1 - 9

Then follow the instructions from pic. 6 through to 8, according to 2: 4:10 Change of Lift

motor on Carony Go

54

2

2:4 Repair manual

2:4:12 Replace Joystick arm release lever

incl. adjustment and change of gas spring

1. Remove the plastic cover under the joystick

arm, by fi rst unscrewing the Phillips screw and

then the three plastic clips.

2. Disconnect the cable from the joystick.

3. Remove the release head by fi rst removing

the ball of the release lever.

4. Unscrew the locking screw that is placed underneath the joystick. The dismounting will

be easier if you fi rst compress the gas spring 5-10 mm, fold the arm slightly and lock it.

5. Place the arm with the inner side facing up.

To be able to remove the A-lock washer from the pin it is easier if you fi rst use a centre punch

and a hammer. Now you can dismount the gas spring.

JOYSTICK ARM RELEASE LEVER

55

2

JOYSTICK ARM RELEASE LEVER

2:4 Repair manual

6. Remove the counter nut and unscrew the

release head from the gas spring.

Screw the new release head onto the gas spring

until the head of the pin is in contact with the

contact plate. Then screw the gas spring 1 and

3/4 turns further.

Direct the gas spring in line with the release head

and lock it with the counter nut.

Now the gas spring is ready to be remounted.

REMOUNTING:

7. Place the completed gas spring in the right

position and fi x it with a pin.

Place the arm so that the pin holds on to the side

where the A-lock is, then beat in a second pin.

8. Compress the gas spring 5-10 mm. Mount the

arm onto the arm attachment. Fix it with the locking screw.

9. Remount the cover.

56

2

2:4 Repair manual

2:4:13 Replace docking mechanism wire.

1. Use a pair of slim fl at pliers and release the

end of the wire from the lock head.

2. Remove the outer nut of the wire adjustment

from the rail.

3. Remove the outer nut also from the front wire

adjustment.

4. Twist out the z-formed end piece from the arm.

5. Mount a new wire in the reversed order.

Note how the wire runs by the rear pillar.

6. Adjust until there is no play.

DOCKING MECHANISM

57

2

ANTI-TIP

2:4 Repair manual

2:4:14 Anti-tip

1. Knock away the A-lock washer on one side and pull out the pin.

2. Protect the handle with a piece of cloth.

Remove the handle by unscrewing it, using a

pair of universal pliers.

3. Remove the lock head and the spring.

Clean and grease the spring and the lock head.

4. Remount in reversed order.

58

2

2:4 Repair manual

FOOTREST RAILS

2:4:15 Replace footrest rails for Carony Drive

1. Unscrew the 4 screws of seat from underneath. Adjust the height of the unit until the rear

rail screws are reachable.

2. Start by unscrewing the rear screw of the rail

that needs changing.

3.

4. Adjust the height to be able to unscrew also

the front screw.

5. Locate the bolts from underneath and unscrew

them. The bolts have loose welded nuts inside the

rail, so there is no need for a key.

6. Now you can press the rail backwards to

remove it.

59

2

2:4 Repair manual

FOOTREST RAILS

7. This is what has been removed.

8. When remounting, place the weded nuts

inside the rail when the rail is in position.

Screw in reversed order.

Check the function!

60

2

2:4 Repair manual

KETTER PILLAR BUSHINGS

2:4:16 Replace Ketter-pillar bushings

1. Remove the seat:

Carony Go: release the seat and remove it.... ...Carony Drive: unscrew the 4 screws from

underneath and remove the seat.

2. Carony Drive: Remove the fottrest system unit

from the Ketter-pillars by dismounting the link

and unscrewing the 4 srews.

Carony Go: remove the Carony rails.

3. BE CAREFUL with the cable chain from the

joystick arm, it can easily be damaged.

4. Cut away the bundle band that fi xes the rubber housing and remove this.

5. Drill out the pop rivet.

61

2

2:4 Repair manual

KETTER PILLAR BUSHINGS

6. Carefully remove the bushing by using a tool.

7. Tap down the new bushing in level with

the pipe, by using a plastic hammer.

8. Drill a new hole in the bushing and mount a

new pop rivet.

62

2

63

Electrics

3:1 Description and programming

of the electrical system

Control unit Shark dk-remd21 (boost + 2 seats + lights)

1

2

Decrease speed

Speedometer

Hazard lights

Left indicator

Right indicator

Battery gauge

ON/off

1 Seat height adjustement

2 not in use

Headlights/rear lights

Service indicator (fl ash code)

Horn

Increase speed

ON/OFF button When pressed all battery gauge indicators will light briefl y. Holding

it down for four seconds the Carony Go will enter lock mode (to turn the Carony Go

on again press the horn button twice).

DRIVING SPEED. To increase speed press Hare for decrease press Turtle. The speed is

set to 20% intervall but can be changed for more precise speed. Press both hare and

turtle buttons at the same time, than you can adjust the speed in small units by holding

the respectively buttons for 1 s.

BATTERY GAUGE All green LED indicate well charged batterys

Amber and red indicates moderately charged batterys

Red indicates almost empty batteries.

ALWAYS CHARGE THE CARONY GO WHEN YOU ARE NOT USING IT !

64

3:1 Description and programming

Display Description This means... Notes

All LED is off

All LED is on steady

Left RED LED is fl ashing

Right to left “chase”

Left to right “chase”

alterning with steady

display

All LED is fl ashing

2 fl ashing Amber LEDs

Power is off

Power is on

Battery charge is low

SHARK is being brought out

of lock mode

SHARK is in programming,

inhibit and/or charging

mode

SHARK has detected an

Out Of neutral At Power Up

(OONAPU) condition

A comunication fault exists

between the power module

and the remote.

Charge batteries as soon

as possible.

To unlock SHARJK press the

horn button twice within

10 s.

The steady LED indicate

the current state of battery

charge

Release the joystick back to

neutral.

Check the power module

for a fault, the cable for

damage, and that the battery is suffi ciently charged.

SEAT FUNCTION The Carony go uses only seat function number one. Pressing this

button means that you can move the seat up and down. Avoid end positions to prevent overload for the lift motor.

1

2

HEAD LIGHTS (Option) If the Carony Go is equipped with lightnings this is the button

to turn the front and rear lights on. Pressing the button again will turn the lights off.

(Optional) INDICATORS To indicate left or right turns. Pressing the button again will

make it stop. The Carony Go is equipped with a auto cancel for the indicators wich

means that after 10 s the indicators will go off.

(Optional) HAZARD LIGHTS When a malfunction occurs you can press the hazard

wich will turn the both left- and right indicators on.

ATTENDANT CONTROL LED, indicating when the Attendant Remote Control is

switched on. (User mode is off).

SERVICE INDICATOR LIGHT Referring to the Flash Codes. For a list of the Flash Codes

and what faults they indicate, reference

65

3:1 Description and programming

Locking and unlocking the control unit

The lock function of the control unit is disabled (off) as supplied from the factory.

However the programmable feature can be enabled and used to prevent unauthorized people from turning it on.

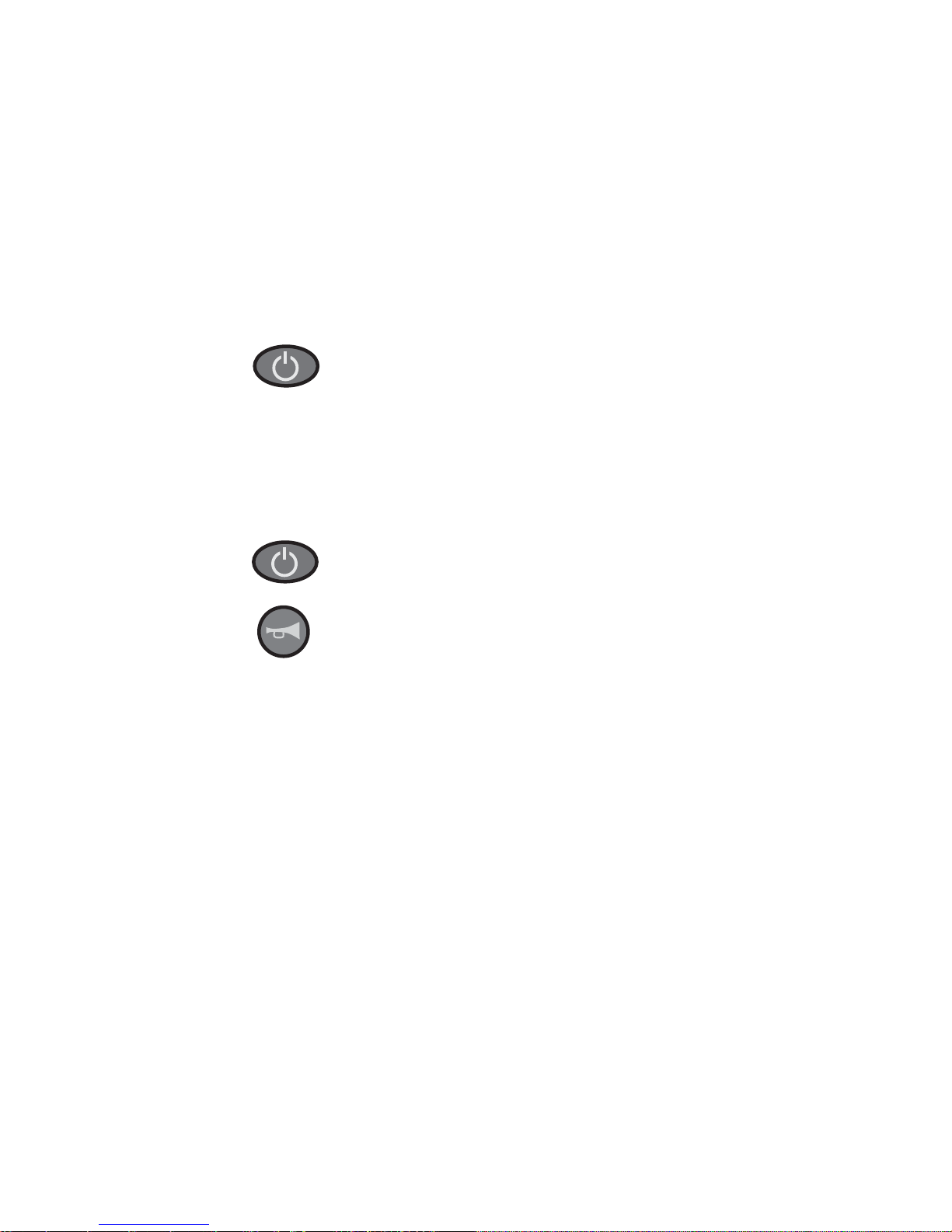

To lock the control unit

While power is ON, press and hold the power button for

4 seconds.

The display will turn off immediately.

After 4 seconds all LED’s will fl ash briefl y and the horn will

sound a sharp beep.

The power will then turn off.

When the control unit is locked, press the power button to

turn it on.

All LED’s will fl ash briefl y. The Battery Gauge LED*s will

then perform a slow right-to-left chase.

Press the Horn button 2 times before the countdown is

completed (approximately 10 seconds).

The current state-of-charge will then be displayed and the

control unit may be operated normally.

To unlock the control unit

66

3:1 Description and programming

3

3

CHARGING The charge socket is underneath the control unit. The Carony Go

will be charged both if the unit is on or off.

ALWAYS CHARGE THE CARONY GO WHEN NOT USING IT!

Power module DK-PMB-21 (boost + 2 seats + lights)

The power module has a capacity of 60 amp.

For the Carony Go only 35 amps is used to save power.

There is a boost function that gives extra 15 amps for maximum 10 s. when needed.

Electrical specifi cations:

Minimal Nominal Max Units

Carony Go operating voltage 18 24 27 V

Carony Go Current 0 0-35 35 A

Boost Current 0 0-15 15 A

Boost Current time 0 0-10 10 s

Idle Current - 120 - mA

Seat Current 0 6 12 A

Light feeding - 24 - V

Drive motor 0 0-230 230 W

Drive motor cont. current - 8 - A

Drive motor resistance - 250mOhm - Ohm

Short Circuit Current Control* 8 - 15 mA

* Because there is only one main fuse (50 A) the Carony Go is equipped

with a short circuit control system that inhibit current fl ow through circuits if

short circuited.

Charging

• When chargeing, charge will continue also if the control is turned OFF

• Use the Battery Charger indication to show if the battery is fully charged or not,

even if the control panel should indicate otherwise.

67

Communication between power module and control unit

SHARK BUS The power module communicates with the Control Unit through the SHARK BUS. There

are four cables, two primarily and two as back up.

Attendance drive

ATTENDANCE DRIVE (Option) The attendance drive makes it possible for the care giver to operate the Carony Go. You can switch between user mode and attendant mode. The speed potentiometer adjust the overall speed/response of the chair. Adjust it depending on the speed you

want to travel in (depending on the walking speed of the care giver).

3:1 Description and programming

68

3:1 Description and programming

Programming the control system

WARNING:

Performance adjustments should only be made by professionals in the health care fi eld or

by persons fully conversant with the adjustment process and the user’s capabilities.

Incorrect settings, or programming in an unsafe location, could cause injury to the operator

or bystanders or damage to property.

After the wheelchair has been confi gurated, check to make sure it performes to the specifi cations entered in the programming procedure. If the wheelchair does nor perform to

specifi cations, reprogram it.

Ensure that deceleration parameters are always higher than acceleration parameters, to

ensure safe response.

It is the health care professionals responsability to ensure that the user is capable both of

cognitively understanding and physically operating the programmed features.

With inappropriate programming settings, certain features and options may not be accessible or perform as expected.

Introduction

All SHARK systems are fully programmable to provide superb performance for a wide variety of

powerchair confi gurations or users.

All programmed values are stored in the Power Module. In the event the remote is replaced, there

is no need to reprogram SHARK. If the Power Module is replaced, SHARK can simply be reprogrammed with an identical powerchair program.

Parameter names displayed on the hand held programmer may be different to those displayed by

Wizard. Not all parameters are available on all power module variants. Wizard will auto-detect

which parameters are appropriate for your unit based on the power module version and your

Wizard access level.

69

3:1 Description and programming

Drive Programs

Settings Description

Maximum Forward

Speed

Forward Acceleration

Forward Deceleration

Maximum Reverse

Speed

Reverse Acceleration

Reverse Deceleration

Maximum Turn Speed

Turn Acceleration

Turn Deceleration

Tremor Damping

The maximum speed Carony Go/Drive will drive with the joystick full

forward and the speed pot fully clockwise.

Sets how quickly Carony Go/Drive will accelerate when the joystick is

moved forward from neutral.

Sets how quickly Carony Go/Drive will decelerate when joystick is moved

towards neutral from a forward position.

The maximum speed Carony Go/Drive will drive with the joystick full

revere and the speed clock fully clockwise.

Sets how quickly Carony Go/Drive will accelerate when the joystick is

moved to reverse from neutral.

Sets how quickly Carony Go/Drive will decelerate when the joystick is

moved towards neutral from a reversed position.

The maximum speed Carony Go/Drive will turn with the joystick full left or

right and the speed pot fully clockwise.

Sets how quickly Carony Go/Drive will accelerate into a turn when the

joystick is moved to the left or right from neutral.

Sets how quickly Carony Go/Drive will decelerate out of a turn when the

joystick is moved towards neutral from left or right position.

Dampens (softens) the introduction of acceleration / deceleration from /

to a steady speed, allowing for a smoother driving experience.

Particularly useful for reducing drive sensitivity to hand tremors.

70

3:1 Description and programming

Settings Description

Load Compensation

Max Load Compensation

Active Stability Profi le

Traction

This matches SHARK to the motors. it indicates to SHARK the resistance

of the motors so that it can compensate apropriately for adverse driving

conditions, for example when going over curbs and ramps.

SHARK will not control the chair correctly unless this is set correctly.

This sets the maximum load compensation value that can be selected by

the HHP.

The basis of “Chair Tamer”, select one of the eight predefi ned stability

profi les to defi ne the application of “Chair Tamer”.

Defi nes the amount of assistance SHARK provides in controlling the chair

when a Stability Profi le with “Chair tamer” is selected, effectively amplifying the effect of the Stability Profi le.

Set to 0% for no modifi cation of the Stability Profi le, with higher values

providing increasing assistance to keep the chair stable and safe.

When resetting, please refer to the Flow Chart !

Service and Confi guration Warnings

• After the chair has been confi gurated, check to make sure the chair performs to the

specifi cations entered in the programming procedure. If the chair does not perform to

specifi cations, reprogram it. Repeat this procedure until it performs to specifi cations.

• The completed installation must be thoroughly checked, and all programmable options

correctly adjusted, for safe operation prior to use.

71

DX HHP V.1.20

Select language

GB D NL S

Dynamic Shark V2.5c5

System OK

Lang prog diag tech

** Program **

View/edit

No chair tamer

exit next yes

Joystick throw

normal

exit next swap

Sleep timer

5 minute

exit next down up

Veer compensation

0%

exit next left right

Fault log –page 1

”Code in digits presented”

exit next more

Fault log –page 2

”Code in digits presented”

exit next more

If there are more codes it will be

more pages

Usage statistics

Time on: xxx:xx

exit next more

Usage statistics

powered: xxxx

exit next more

Usage statistics

driven: xxxx

exit next more

Here you chose a suitable

language.

Lang. Will sometimes in

other menues change the

written language

** Program **

View/edit

Attendant

exit next yes

Go to page 2 for

programming wheelchair

And page 3 for attendant

programming

This menu depends

on if the attendant

drive is activated.

Attention !

Changing in values will

effect certificates of the

wheelchair

Tech = for technicans

only and a code most

be used to enter.

Page 1

Here you can change to

short or very short throw.

Up and down will change

the time in 1 minute step.

From off to 30 minutes

Left and right will

compensate for abnormal

drift when driving straight

forward. 1 % per step up

to 10% each way

Flowhart of the handheld

programmer, based upon

version 1:3

* Technician *

Calibrate joystick

Exit next yes

* Technician *

Actve program is:

No chair tamer

Exit next swap

3:1 Description and programming

Flow Chart, pic. 1

72

Page 2

Programming the wheelchair from page 1

No chair tamer

Max forward speed

100%

exit next down up

No chair tamer

Forward acceleration

30%

exit next down up

No chair tamer

Forward deceleration

55%

exit next down up

No chair tamer

Max reverse speed

40%

exit next down up

No chair tamer

Reverse acceleration

25%

exit next down up

No chair tamer

Reverse deceleration

45%

exit next down up

No chair tamer

Max turn speed

40%

exit next down up

No chair tamer

Turn acceleration

40%

exit next down up

No chair tamer

Turn deceleration

50%

exit next down up

No chair tamer

Tremor damping

40%

exit next down up

No chair tamer

Traction

0%

exit next down up

No chair tamer

Stability profile

No chair tamer

exit next swap

No chair tamer

Load compensation

100 mOhms

exit next down up

All exit buttons will take you back to Dynamic Shark menu on page 1

Possible value is 0-

100% in 5% step

Possible value is 0-

90% in 5% step

Possible value is 30-

100% in 5% step

Possible value is 0-

100% in 5% step

Possible value is 30-

100% in 5% step

Possible value is 0-

90% in 5% step

Possible value is 0-

90% in 5% step

Possible value is 20-

100% in 5% step

Possible value is 20-

100% in 5% step

Possible value is 10-

100% in 5% step

Possible value is 0-

80% in 5% step

Possible value is

0-200 mOhms

Call support

before swapping

ONLY

TECHNICIANS!

ONLY

TECHNICIANS!

3:1 Description and programming

Flow Chart, pic. 2

73

3:1 Description and programming

Flow Chart, pic. 3

Page 3

Programming the attendant drive from page 1

Attendant

Max forward speed

100%

exit next down up

Attendant

Forward acceleration

40%

exit next down up

Attendant

Forward deceleration

60%

exit next down up

Attendant

Max reverse speed

70%

exit next down up

Attendant

Reverse acceleration

35%

exit next down up

Attendant

Reverse deceleration

70%

exit next down up

Attendant

Max turn speed

50%

exit next down up

Attendant

Turn acceleration

40%

exit next down up

Attendant

Turn deceleration

60%

exit next down up

Attendant

Tremor damping

40%

exit next down up

No chair tamer

Traction

0%

exit next down up

All exit buttons will take you back to Dynamic Shark menu on page 1

Possible value is 0-

100% in 5% step

Possible value is 0-

90% in 5% step

Possible value is 30-

100% in 5% step

Possible value is 0-

100% in 5% step

Possible value is 30-

100% in 5% step

Possible value is 0-

90% in 5% step

Possible value is 0-

90% in 5% step

Possible value is 20-

100% in 5% step

Possible value is 20-

100% in 5% step

Possible value is 10-

100% in 5% step

Possible value is 0-

80% in 5% step

74

To charger

or HHD

or Wizard

J6

J8

J9

J7

VO 1.3

Lift Motor

Headlight

Optional Lights

Tail lights

LR

RR

RF

LF

GN 0.75

BL 1.3

LB 0.75

GN 0.5

Y 0.75

R 0.75

GN 0.5

WT 2.0

R 4.0

SB 4.0

WT 2.0

Brake

LEFT

RIGHT

Brake

WT 2.0

R 6.0

SB 6.0

WT 2.0

R 4.0

SB 4.0

Height

switch

50 A

3:2 Wiring diagram

75

BLBNGNORGRRSBVOWYP

S GB D F E I

blå

brun

grön

orange

grå

röd

svart

violett

vit

gul

rosa

blue

brown

green

orange

grey

red

black

violet

white

yellow

pink

blau

braun

grün

orange

grau

rot

schw.

violet

weiss

gelb

rosa

bleu

brun

vert

orange

gris

rouge

noir

violet

blanc

jaune

rose

azul

marrón

verde

naranja

gris

rojo

negro

violeta

blanco

amarillo

rosa

blu

marrone

verde

arranc.

grigio

rosso

nero

viola

bianco

giallo

rosa

76

3:3 Trouble shooting

Diagnistics Tools

Hand Held Programmer

Plugging a Hand Held Programmer into the SHARK Remote when an abnormal condition exists

will cause the fault to be displayed. A 4-digit code will be displayed which indicates the condition.

The fi rst two digits provide the fl ach code number. The second two digits provide more specifi c

diagnostics information that is suitable for repair technicians.

In some cases, viewing a history of any abnormal conditions that occurred previously on the

system may be useful in diagnosting the current condition. This can be done by entering the

Fault Log from the Diagnostics menue. Usage statistics are also available from this menue.

DYNAMIC Wizard

Wizard is the preferred diagnostics tool in the workshop environment, providing a full fault history and verbal descriptions of each fl ash code.

If after analyzing the data, the condition can not be diagnosed, it is possible to print or safe a

Status Report for further analysis or distribution to a cervice centre.

77

Electrical system, work instructions

1. Fully charged batteries must be used when testing the electrical system

2. When fi tting batteries check that the polarity is correct.

3. When charging batteries connected in series, make sure that they are of equal capacity

i.e. same Ah and near exactly the same voltage on one decimal (i.e 12.82 V and 12.88V

may fi t together).

Electrical system, description

The Carony Go has a 24 V electrical system with two 12 V batteries connected in series. Voltage feed is supplied via a 50 A slow burn main fuse to the power module.

The power module distribute current and voltage to each of the three motors (drive motors and

lift motor) depending on the drivers demands. The power module also distribute feeding to the

lights and control unit.

Troubleshooting strategies

When a symptom or malfunction is detected the basis for troubleshooting is basic data collection.

• Customer information

• Dealer information

• Specifi cations (use the hand held programmer)

o Serial nr

o Machine hours

o Model year

• Flash codes

Description of malfunction or symptom

• Describe the problem

• When did the problem occur

• What happened just before the problem

Lead and connector checks

In an electrical system there is very important to check lead and connectors. Damaged electrical leads or loose connectors can cause malfunctions. Fuses are also to be checked before

any further troubleshooting.

Important!

• Testing should NOT be conducted by sticking objects through electrical lead insulation.

Use the proper electrical wiring diagram to fi nd suitable test points!

• Look for cable terminal oxidation

• Check for cable terminal damage, correct placement in the insulator.

• Check for good mechanical contact in the sockets.

3:3 Trouble shooting

78

3:3 Trouble shooting

The Carony Go and Drive is equipped with a self diagnose system which can tell the service

technician what kind of problem there is to fi nd. In the control unit there is a wrench which

fl ashes between 1-11 times.

You can use the hand held programmer or Wizard (not supplied to all dealers) or you can just

count the number of fl ashes.

When using the hand held programmer there is a four digit code in the display. The fi rst two

digits provide the fl ash code number. The second pair of nubers provide a sub-code for a more

specifi c fault message.

Flash

Code Fault Type Suggested actions

01 User fault Possible stall timeout or user error.

Release the joystick to normal and try again

02 Battery fault Check batteries and cables. Try changing the batteries

03 Left Motor fault Check the left motor, cables and connections

04 Right Motor fault Check the right motor, cables and connections

05 Left park brake fault Check the left park brake, cables and connections

06 Right park brake fault Check the right park brake, cables and connections

07 SHARK Control Unit fault Internal control unit fault. Replace control unit

08 SHARK Power Module fault Check SHARK connections and wiring. Replace

the power module.

09 SHARK communications fault Check SHARK connections and wiring. Replace the

SHARK Control Unit

10 Unknown fault Check all connections and wiring. Consult a service agent

11 Incompatible control unit Wrong type of Control Unit connected. Ensure the branding

of the Power Module matches that of the control unit.

DIAGNOSTICS

Flash Codes

Flashing wrench

79

3:3 Trouble shooting

DIAGNOSTICS

Code Fault source Sub code Meaning

M1

M2

When a motor fault occurs:

• Swap the motor connections: If the chair has two parking brakes, you can simply swap the motor connec-

tors on the Shark Power Module, if the connectors are not keyed.

If the chair has only one parkbrake, swap the motor connections at the mo-

tor end. This will swap the parkbrake connections too and rusult in a park-

brake fault with only one parkbrake, because it must be connected to M1.

• When after swapping the fault moves from motor 1 to motor 2 or vice versa, the fault is caused by the

motor or by the cables. Only when the fault does not move after swapping, the controller itself can be faulty.

01

02

03

04

User

Battery

Motor 1

Motor 2

00

00

00

01

02

03

04

06

All other

Out Of Neutral At Power Up (OONAPU) :

• Release the joystick to the centre and try again

Motor overload (too steep) :

• The motor is nort strong enough, try another route

Control unit is locked :

• Unlock the control unit

Voltage too high or too low :

• Check the batteries and the cables

• Batteries may be empty, charge the batteries.

• Batteries may be overcharged, if driving downhill slow down

• Batteries may be damaged, replace the batteries

Short circuit :

• Check the motor cables for damage

• Motor brushes may be too stiff, bouncing against the case.

Replace motor brushes or motor

Open circuit :

• Check if the motor cables are loose

• Motor brushes may be worn

Turn wheels to reconnect

or replace motor brushes or motor

Motor terminal connected to battery negative (-) :

• Check if the motor has been connected correctly

• Check the motor cables for damage

Motor terminal connected to battery positive (+) :

• Check if the motor has been connected correctly

• Check the motor cables for damage

Motor voltage not consitent during drive

• Possible motor short circuit

Check the motor cables for damage

or motor brushes may be too stiff and bouncing

• Otherwise internal controller fault, contact Dynamic

Intermittent short circuit

• Check for damaged cables

• Motor brushes may be too stiff, bouncing against the case

Replace motor brushes or motor

Internal fault

• Contact Dynamic

Continuation on next page

80

3:3 Trouble shooting

DIAGNOSTICS

Code Fault source Sub code Meaning

When a parkbrake fault occurs:

• Swap the motor/parkbrake connectors, if the motor connectors are not keyed.

• When after swapping the fault moves from Parkbrake 1 to the Prkbrake 2 or vice versa, the fault is in the

parkbrake or in the cables. Only when the fault does not move after swapping, the controller itself is faulty.

05

06

07

08

09

10

11

Parkbrake 1

Parkbrake 2

Remote

Power

Module

Communications

Internal fault

Wrong

remote

00

01

02

03

04

04

05

All other

13

14

All other

00

01

02

00

00

Drive-time test failed :

• Check the parkbrake cables.

Parbrake not connected or broken :

• Check if the cables of the parkbrake are loose.

Parkbarek short circuit or broken :

• Check the parkbrake cables for damage :

Fault during power-up testing :

• Check if parbrake cables are loose or damaged.

Parbrake short circuit or broken :

• Check the parkbrake cables for damage.

Attendant remote fault :

• Check attendant remote cables for damage

• Disconnect and reconnect attendant remote

• If fault doesn’t go away, disconnect the attendant remote as

a temporary solutution and contact Dynamic.

Internal fault :

• Contact Dynamic

Actuator fault :

• Check the actuator and the acteuator cables

Lighting fault :

• Check the light bulb and the lighting cables

Internal fault :

• Contact Dynamic

Loss of communication between remote and power module :

• Check for loose connectors or a damaged cable

• Check for worn motor brushes

Limp mode caused by unreliable communication :

• Check for loose connectors or a damaged cable

• Check for worn motor brushes

Loss of communication with attendant remote :

• Disconnect and reconnect attendant remote and try again.

• Check the attendant remote cables

• If the fault doesn’t go away, disconnect the attendant remote

as a temporary solution and contact Dynamic

• Contact Dynamic

Incompatible remote connected :

• Check that the brand on the remote and the power module

are the same.

continuation

81

3:3 Repair manual

3:4:1 Batteries, replace

3:4:2 Power module, replace

3:4:3 Joystick, dismount

3:4:4 Speedlimiter and height switch, replace

82

3:4 Repair manual

BATTERIES

3:4:1 Replace batteries

1. Remove the cover from the wheel unit.

Remove the battery clamp by fi rst unscrewing the

wing nut.

2. Disconnect the cable contacts and turn the

battery 90º (standing up).

3. Lift out the battery.

4. Pull the remaining battery as far back as possible and lift it out.

Disconnect the cables in the two removed batteries.

5. Connect the cables to the new batteries and

mount the new batteries in reversed order.

IMPORTANT: Both batteries must be replaced at the same time.

Always replace batteries of the same type and brand.

83

3:4 Repair manual

POWER MODULE

3:4:2 Replace Power module

4. Replace the power module and connect all the

contacts.

5. Fix the power module with the two screws.

6. Connect the batteries.

7. Check the functions of the new power module.

3. Lift up the power module as high as possible

and disconnect the contacts from the bottom side.

The contacts, counting from the left, are:

joystick, multi contakt, motor right side, battery

contact and motor left.

2. Unscrew the two screws fi xing the power

module.

1. Disconnect the battery contact by the fuse

holder.

84

3:4 Repair manual

3:4:3 Dismounting the joystick

JOYSTICK

1. Fold down the joystick arm and the joystick.

2. Remove the two hexagon screws that hold the

impact protection.

3. Remove the two counter sunk screws. Remove

the joystick and the cable protection.

4. Replace the joystick with a new and mount this

in reversed order.

85

3:4 Repair manual

3:4:4 Replacing the speed limiter/height switch

SPEED LIMITER / HEIGHT SWITCH

1. Remove the seat and the Velcro fastened plas-

tic cover.

Locate the microswitch.

2. Remove both the cables from the switch.

3. Unscrew the lock screw with a 2mm Allen

wrench, don’t remove it, just loosen it.

4. Remove the switch by pulling it out.

Remount in reversed order and verify the function.

Make sure that you don’t push the switch completely to the bottom, because it will then hit the pillar

when it travels. Just push it inwards and release it ½ mm or less, then tighten it.

Measure the switch with an ohm meter:

In raised position it should be infi nite ohms.

In lowered position it should be zero ohms.

86

Notes

87

Notes

Notes

Art. No: Not Available

Autoadapt Customer Support Centre (CSC)

Tel: +46 302 25440

Fax: +46 302 25407

E-mail: support@autoadapt.com

Autoadapt AB

Åkerivägen 7 S-443 61 Stenkullen Sweden

Tel: +46 302 25400

E-mail: contact@autoadapt.com

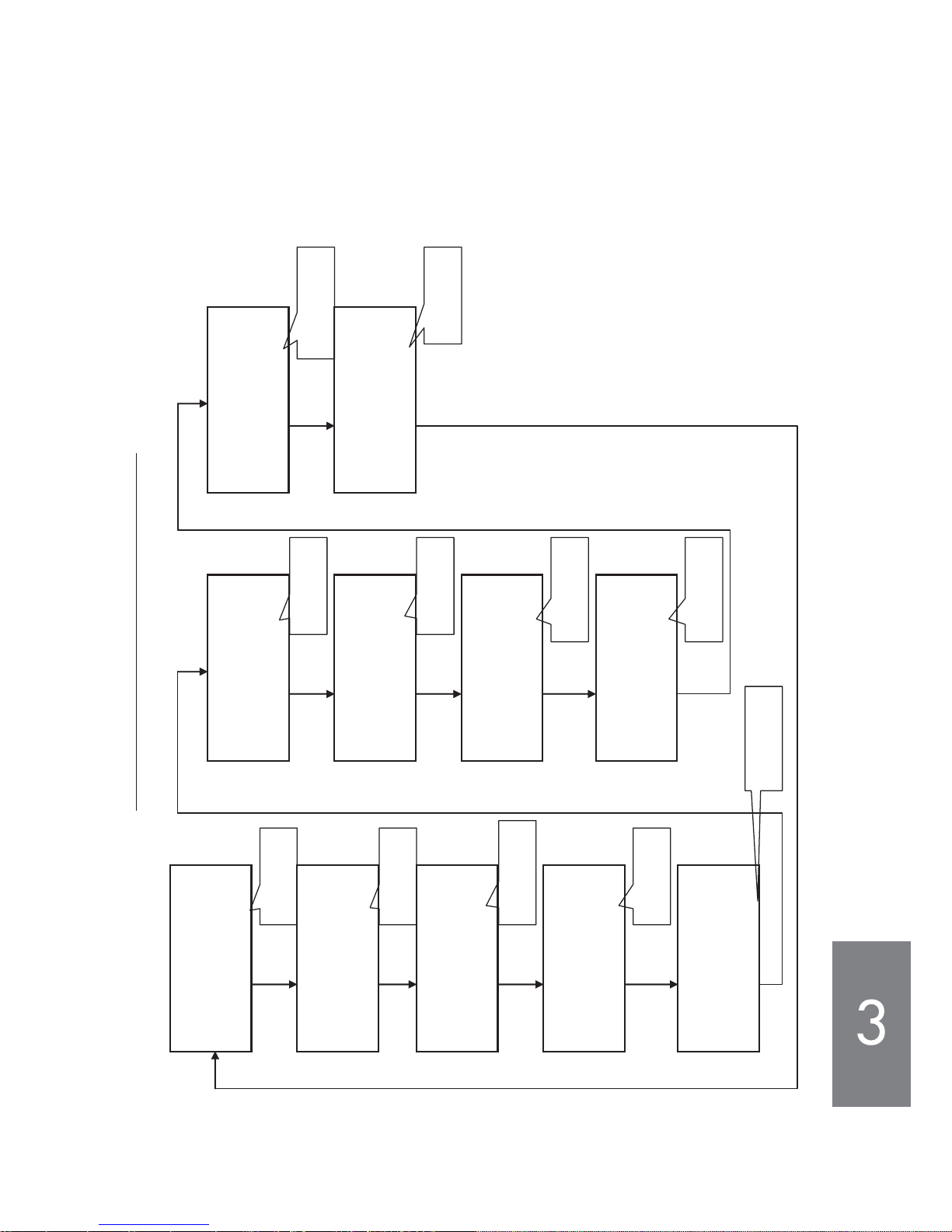

www.autoadapt.com www.autoadapt.de