Page 1

Trademarks

Autel®, MaxiSysTM, MaxiDAS®, MaxiScan®, MaxiTPMS®, MaxiVideoTM, MaxiRecorderTM,

and MaxiCheck

in China, the United States and other countries. All other marks are trademarks or

registered trademarks of their r es pective holders.

TM

are trademarks of Autel Intelligent Technology Corp., Ltd., registered

Copyright Information

No part of this manual may be reproduc ed, stored in a ret rieval system or transmitted,

in any form or by any means, electronic, mechanical, photocopying, recording, or

otherwise, without the prior written permissi on of Autel.

Disclaimer of Warranties and Limitation of Liabilities

All information, specifications and i llustrations in this manual are based on the latest

information available at the time of printing. Autel reserves the right to make changes at

any time without notice. While information of this manual has been carefully chec ked

for accuracy, no guarantee is given to the completeness and correctness of the

contents, including but not limited to the product specifications, functions, and

illustrations.

Autel will not be liable for an y direct damages or for any special, inc idental, or indir ect

damages or for any economic consequential damages (including lost profits).

IMPORTANT: Before operating or maintaining this unit, please read this manual

carefully, paying extra attention to the safety warnings and precaut ions.

For Services and Support:

http://pro.autel.com

www.autel.com

1-855-288-3587/1-855-AUTELUS (North America)

0086-755-86147779 (China)

Support@autel.com

For technical assistance in all ot her markets, please contact your local s elling agent.

i

Page 2

Safety Information

For your own safety and the safety of others, and to pr event damage to the device and

vehicles upon which it is used, it is important that the safety instructions herein

presented throughout this manual be read a nd understood b y all persons oper ating, or

coming into contact with, the device.

There are various procedures , techniques, tools, and parts for servicing vehi cles, as

well as in the skill of the person do ing the work. Because of the vast number of test

applications and variations in the products that can be test ed with this equipment, we

cannot possibly anticipate or provide advice or safety messages to cover every

circumstance. It is the automotive technician’s responsibility to be knowledgeable of the

system being tested. It is crucial t o use pro per servi ce methods and test procedur es. It

is essential to perform tests in an appropr iate and acceptable manner that does not

endanger your safety, the safety of others in the work area, t he device being used, or

the vehicle being tested.

Before using the device, always refer to and follow the safety messages and applicable

test procedures provided by the manufactur er of the vehicle or equipment being tested.

Use the device only as described in this manual. Read, understand, and follow all

safety messages and instructions in this manual.

Safety Messages

Safety messages are provided t o help pr eve nt perso nal i njur y and equi pment d amage.

All safety messages are introduced by a signal word indicating the hazard l evel.

DANGER: Indi c ates an imminently hazardous situation which, if not av oide d, will

result in death or serious injury to the operator or to bystanders.

WARNING: Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury to the operator or to bystanders.

Safety Instructions

The safety messages herein cover situations Autel is aware of. Autel cannot know,

evaluate or advise you as to all of the possible h azards. You must be certain that any

condition or service procedure encountered do not jeopardize your person al safety.

DANGER: When an engine is operating, keep the service area WELL

VENTILATED or attach a building exhaust removal system to the engine exhaust

system. Engines produce carbon monoxide, an odorless, poisonous gas that

causes slower reaction time and can lead to ser ious personal injury or loss of

life.

ii

Page 3

Safety Information Important Safety Instructions

Do Not Turn the Volume Up Too Loud When Using Headphones

Listening at high volumes that over -stimulate the ear for long periods of time

may result in loss of hearing.

SAFETY WARNINGS:

Always perform automotive testing in a safe environment.

Wear safety eye protection that meets ANSI standards.

Keep clothing, hair, hands, tools, test equipment, etc. away from all

moving or hot engine parts.

Operate the vehicle in a well ventilat ed work area, for exhaust gases ar e

poisonous.

Put the transmission in PARK (for automatic transmission) or NEUTRAL

(for manual transmission) and make sure the parking brake is engaged.

Put blocks in front of the drive wheels and never leave the vehicle

unattended while testing.

Use extreme caution when working around the ignition coil, distributor cap,

ignition wires and spark plugs. These components create hazardous

voltages when the engine is running.

Keep a fire extinguisher suitable for gasoline, chemical, and electrical fires

nearby.

Do not connect or disconnect any test equipment while the ignition is on or

the engine is running.

Keep the test equipment dry, clean, free from oil, water or grease. Use a

mild detergent on a clean cloth to c lean the outside of the equipment as

necessary.

Do not drive the vehicle and operate the tes t equ ipme nt at the sam e ti me .

Any distraction may cause an accid ent.

Refer to the service manual for the vehicle being service d and adhere to

all diagnostic procedures and precautions. Failure to do so may result in

personal injury or damage to the test equipment.

To avoid damaging the test equipment or generating false data, make

sure the vehicle battery is fully ch arged and the con nection to the v ehicle

DLC is clean and secure.

Do not place the test equipm ent on the distributor of the vehicl e. Strong

electro-magnetic interference c an damage the equipment.

iii

Page 4

Contents

SAFETY INFORMATION .......................................................................................... II

CHAPTER 1 USING THIS MANUAL ..................................................................... 1

1.1 CONVENTIONS .................................................................................................... 1

1.1.1 Bold Text .................................................................................................. 1

1.1.2 Terminology ............................................................................................ 1

1.1.3 Notes and Important Messages .............................................................. 1

1.1.4 Hyperlinks ................................................................................................ 1

1.1.5 Procedures ............................................................................................... 2

CHAPTER 2 GENERAL INTRODUCTION .............................................................. 3

2.1 MAXISYS DISP LAY TABLET ..................................................................................... 3

2.1.1 Functional Description ............................................................................. 3

2.1.2 Power Sources ......................................................................................... 5

2.1.3 Technical Specifications ........................................................................... 5

2.2 VCI – J2534 ECU PROGRAMMING DEVICE ............................................................. 7

2.2.1 Functional Description ............................................................................. 7

2.2.2 Power Sources ......................................................................................... 8

2.2.3 Technical Specifications ........................................................................... 9

2.3 DOCKING STATI ON ............................................................................................... 9

2.3.1 Functional Description ............................................................................. 9

2.3.2 Technical Specifications ......................................................................... 10

2.4 ACCESSORY KIT ................................................................................................. 10

2.4.1 Main Cable ............................................................................................ 10

2.4.2 OBD I Adapters ...................................................................................... 11

2.4.3 Other Accessories .................................................................................. 11

CHAPTER 3 GETTING STARTED........................................................................ 13

3.1 POWERING UP .................................................................................................. 13

3.1.1 Application Buttons ............................................................................... 14

3.1.2 Locator and Navigation Buttons ............................................................ 15

3.1.3 System Status Icons ............................................................................... 16

3.2 POWERING DOWN ............................................................................................ 16

3.2.1 Reboot System ....................................................................................... 17

3.3 INSTALLING COMPUTER SOFTWARE ....................................................................... 17

3.3.1 Printing Operation ................................................................................. 17

CHAPTER 4 DIAGNOSTICS OPERATIONS .......................................................... 19

Page 5

4.1 ESTABLISHING VEHICLE COMMUNICATION .............................................................. 19

4.1.1 Vehicle Connection ................................................................................ 19

4.1.2 VCI Connection ...................................................................................... 21

4.1.3 No Communication Message ................................................................ 24

4.2 GETTING START ED ............................................................................................. 25

4.2.1 Vehicle Menu Layout ............................................................................. 25

4.3 VEHICLE IDENTIFICATION ..................................................................................... 27

4.3.1 Auto VIN Scan ........................................................................................ 27

4.3.2 Manual VIN Input .................................................................................. 28

4.3.3 Manual Vehicle Selection ...................................................................... 29

4.3.4 Alternative Vehicle Identification .......................................................... 32

4.4 NAVIGATION ..................................................................................................... 32

4.4.1 Diagnostics Screen Layout ..................................................................... 32

4.4.2 Screen Messages ................................................................................... 35

4.4.3 Making Selections ................................................................................. 36

4.5 MAIN MENU .................................................................................................... 36

4.6 DIAGNOSIS ....................................................................................................... 37

4.6.1 ECU Information .................................................................................... 41

4.6.2 Read Codes ............................................................................................ 42

4.6.3 Erase Codes ........................................................................................... 43

4.6.4 Live Data ................................................................................................ 43

4.6.5 Active Test ............................................................................................. 50

4.6.6 Special Functions ................................................................................... 51

4.7 SERVICE ........................................................................................................... 52

4.7.1 Function Descriptions ............................................................................ 52

4.8 PROGRAMMING AND CODING .............................................................................. 53

4.9 GENERIC OBD II OPERATIONS ............................................................................. 57

4.9.1 General Procedure ................................................................................. 57

4.9.2 Function Descriptions ............................................................................ 59

4.10 EXITING DIAGNOSTICS .................................................................................... 62

CHAPTER 5 DATA MANAGER OPERATIONS ...................................................... 63

5.1 OPERATIONS..................................................................................................... 63

5.1.1 Image Files ............................................................................................ 63

5.1.2 PDF Files ................................................................................................ 65

5.1.3 Review Data .......................................................................................... 66

5.1.4 Apps Manager ....................................................................................... 66

5.1.5 Data Logging ......................................................................................... 67

CHAPTER 6 MAXIFIX OPERATIONS .................................................................. 68

6.1 NAVIGATION ..................................................................................................... 68

Page 6

6.1.1 Terminology ........................................................................................... 70

6.2 OPERATIONS..................................................................................................... 71

6.2.1 Home ..................................................................................................... 71

6.2.2 My MaxiFix ............................................................................................ 73

6.2.3 Search Fix .............................................................................................. 75

6.2.4 All Questions.......................................................................................... 76

6.2.5 My Messages......................................................................................... 76

6.2.6 Support .................................................................................................. 77

CHAPTER 7 SETTINGS OPERATIONS ................................................................ 78

7.1 OPERATIONS..................................................................................................... 78

7.1.1 Unit ........................................................................................................ 78

7.1.2 Language ............................................................................................... 79

7.1.3 Printing Setting ...................................................................................... 79

7.1.4 Wired Network ...................................................................................... 79

7.1.5 Notification Center ................................................................................ 80

7.1.6 Multitask ............................................................................................... 81

7.1.7 About ..................................................................................................... 81

7.1.8 System Settings ..................................................................................... 82

CHAPTER 8 SHOP MANAGER OPERATIONS ..................................................... 83

8.1 VEHICLE HISTORY .............................................................................................. 84

8.1.1 Historical Test Record ............................................................................ 85

8.2 WORKSHOP INFORMATION .................................................................................. 86

8.3 CUSTOMER MANAGER ....................................................................................... 87

8.3.1 History Notes ......................................................................................... 89

CHAPTER 9 UPDATE OPERATIONS ................................................................... 91

CHAPTER 10 VCI MANAGER OPERATIONS ......................................................... 93

10.1 BLUETOOTH PAIRING ...................................................................................... 94

10.2 WIRED NETWORK CONNECTION ....................................................................... 95

10.3 UPD ATE ....................................................................................................... 96

CHAPTER 11 REMOTE DESK OPERATIONS ......................................................... 97

11.1 OPERATIONS ................................................................................................. 97

CHAPTER 12 SUPPORT OPERATIONS ................................................................ 99

12.1 PRODUCT REGISTRATION ................................................................................. 99

12.2 SUPPORT SCREEN LAYOUT ............................................................................. 100

12.3 MY ACCOUNT ............................................................................................. 101

Page 7

12.4 USER COMPLAINT ........................................................................................ 101

12.5 DATA LOGGING ............................................................................................ 104

12.6 COMMUNITIES ............................................................................................ 105

12.7 TRAINING CHANNELS .................................................................................... 107

12.8 FAQ DATABASE ........................................................................................... 108

CHAPTER 13 TRAINING OPERATIONS ............................................................. 109

CHAPTER 14 QUICK LINK OPERATIONS ........................................................... 111

CHAPTER 15 DIGITAL INSPECTION OPERATIONS ............................................. 112

15.1 ADDITIONAL ACCESSORIES ............................................................................. 113

15.2 TECHNICAL SPECIFICATIONS............................................................................ 116

15.3 OPERATIONS ............................................................................................... 116

CHAPTER 16 MAINTENANCE AND SERVICE ..................................................... 119

16.1 MAINTENANCE INSTRUCTIONS........................................................................ 119

16.2 TROUBLESHOOTING CHECKLIST ....................................................................... 120

16.3 ABOUT BATTERY USAGE ................................................................................ 120

16.4 SERVICE PROCEDURES ................................................................................... 121

CHAPTER 17 COMPLIANCE INFORMATION ..................................................... 123

CHAPTER 18 WARRANTY ............................................................................... 124

Page 8

Chapter 1 Using This Manual

This manual contains device us age instructions.

Some illustrations shown in this man ual may contain mod ules and optional equi pment

that are not i ncluded on your system. Contac t your sales repres entative for ava ilabilit y

of other modules and optional tools or accessories.

1.1 Conventions

The following conventions are used.

1.1.1 Bold Text

Bold emphasis is used to highlight selectable items such as buttons and menu

options.

Example:

Tap OK.

1.1.2 Terminology

The term “select” means highlighting a button or menu item and t apping it to

confirm the selection.

1.1.3 Notes and Important Messages

The following messages are used.

Notes

A NOTE provides helpful information such as additional explanations, tips,

and comments.

Important

IMPORTANT indicates a situation which, if not av oided, may result in damage

to the test equipment or vehicle.

1.1.4 Hyperlinks

Hyperlinks, or links, that take you to other r elated articles, procedures, and

illustrations are available in electronic document s. Blue colored text indic ates

a selectable hyperlink.

1

Page 9

Using This Manual Conventions

1.1.5 Procedures

An arrow icon indicates a procedure.

Example:

To use the camera:

1 Tap the Camera button. The camera screen opens.

2 Focus the image to be captured in t he view finder.

3 Tap the blue circle. The view finder now shows the captured picture

and auto-saves the taken photo.

2

Page 10

Chapter 2 General Introduction

The MaxiSysTM Elite Diagno stic Platform is the next generation of smart solution for

specialized automotive diagnosis. Featuring the NVIDIA’s Tegra

1.90GHz processor, a 9.7” Retina display with a super sensitive capacitive screen

supporting air gesture control, combined with an optimized array of powerful

applications, and the best possible coverage of OE-level diagnostics, the MaxiSys Elite

performs every job from comprehensive vehicle diagnostics & analysis to advanced

ECU programming quickly and efficiently.

There are 3 main components to the MaxiSys Elite system:

MaxiSys Display Tablet – the central processor and monitor for the system

Vehicle Communication Interface (VCI) – the J2534 ECU Programming Device

for accessing vehicle data with programming capabilities

Docking Station – provides optimum visibility and convenient charging

This manual describes the construct ion and operation of these devices and h ow they

work together to deliver diagnostic solutions.

®

4-PLUS-1 quad-core

2.1 MaxiSys Display Tablet

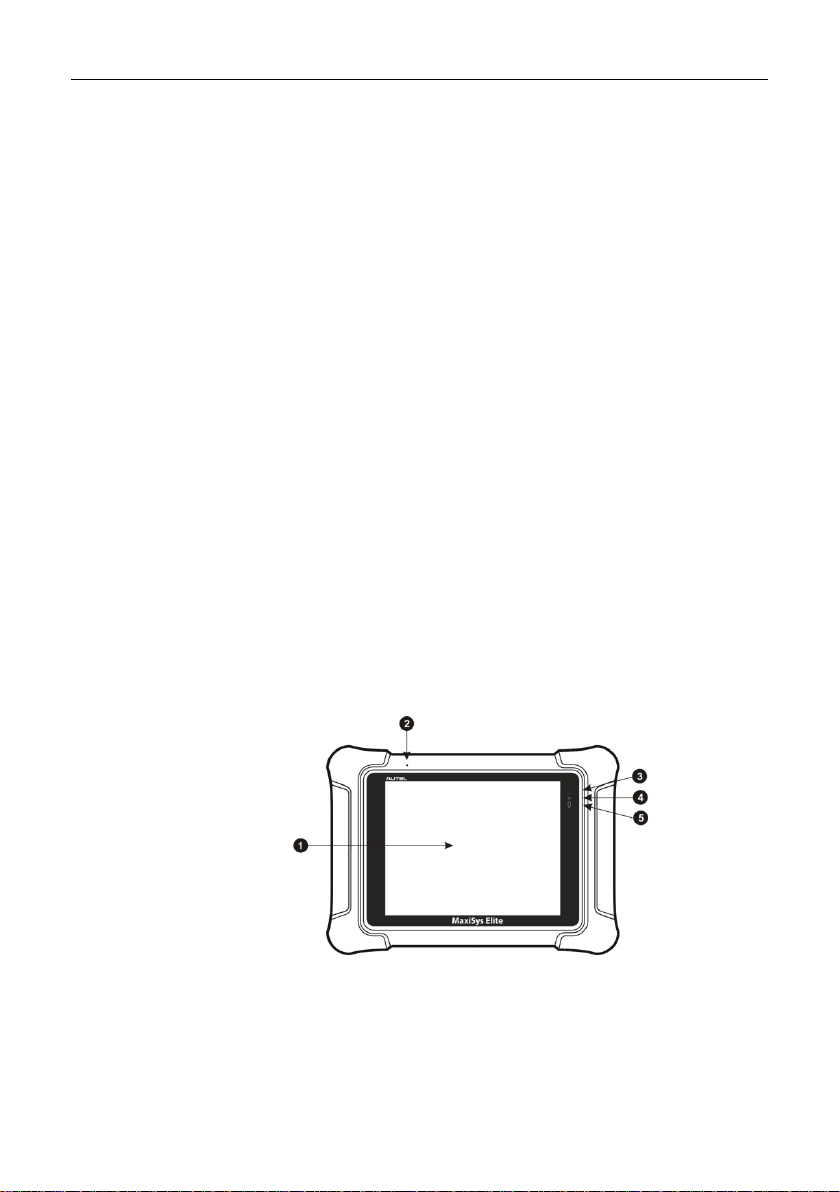

2.1.1 Functional Description

Figure 2-1 MaxiSys Display Tablet Front View

1. 9.7” Retina display with capacitive touch screen

2. Microphone

3

Page 11

General Introduction MaxiSys Display Tablet

3. LED Breath Light – indicates battery level & charging status

4. Front Camera

5. Ambient Light Sensor – detects ambi ent brightness

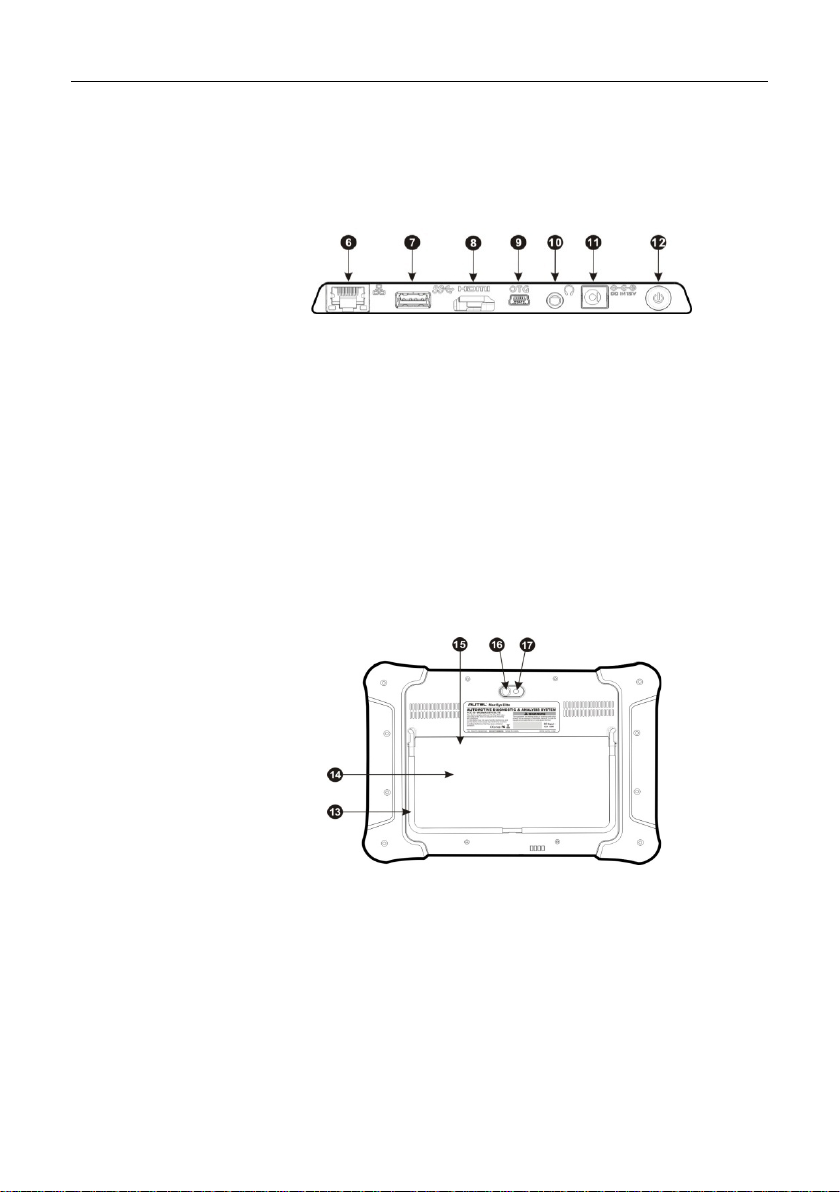

Figure 2-2 MaxiSys Display Tablet Top View

6. Ethernet Port

7. USB Port – for VCI connection

8. HDMI Port

9. Mini USB OTG Port

10. Head Phone Jack

11. DC Power Supply Input Port

12. Lock/Power Button – turns the device on & off with long press, or locks

the screen with short press

Figure 2-3 MaxiSys Display Tablet Back View

13. Collapsible Stand – extends from the back to allow hands-free viewing of

the display tablet at a 30-degree an gle

14. Removable Battery

15. SIM Card Slot – optional module

16. Camera Lens

17. Camera Flash

4

Page 12

General Introduction MaxiSys Display Tablet

Capacitive touch screen

2.1.2 Power Sources

The MaxiSys Elite can receive power from any of the following sources:

Rechargeable Battery Pack

AC/DC Power Supply – using power adapter or docking station

Vehicle Power

Rechargeable Battery Pack

The display tablet can be powered with the r echargea ble b atter y, which if fully

charged can provide sufficient power for about 6.5 hours of continuous

operation.

AC/DC Power Supply

The display tablet can be powered f rom a wall socket using the AC/ DC po wer

adapter or the docking station. The AC/DC power supply also charges the

battery pack.

Vehicle Power

The display tablet can be powered from the ci garette lighter or other suitable

power port on the test vehicle through a direc t cable connection. The vehicle

power cable connects to the DC power supply port on the top side of the

display unit.

2.1.3 Technical Specifications

Item Description

Operating System Android 4.3 Jelly Bean

Processor

Memory 2GB RAM & 32GB Embedded Memory

Display 9.7” Retina display with 2048X1536 resolution &

NVIDIA Tegra® 4 (4-PLUS-1 Quad-core

Processor) 1.8GHz with ARM Cortex – A15 CPU

5

Page 13

General Introduction MaxiSys Display Tablet

Item

Description

4G Mobile Netwo rk (Optional)

Front: 2.0 Megapixel

sensor, Air Gesture

/standard headset

2.0, TP 1.6, SAE J1939, SAE J1708,

Fault-Toler ant C AN

Connectivity 802.11a/b/g/n/ac WIFI

Version 2.1 3Mbs Bluetooth

RJ45 Ethernet Connection

3.0 USB (2.0 Compat ible)

HDMI 1.4a

SD Card (Support up to 32GB)

Camera

Rear: 8.0 Megapixel, Autofocus with Flashlight

Sensors Ambient Light Sensor, G-

Sensing

Audio Input/Output Microphone

Dual Speakers

3-Band 3.5 mm stereo

jack

Power and Battery 3.7V/13600mA H Li thium-polymer battery

DC/12V/3A Power Supply

Input Voltage DC/12V/3A

Power Consumption Max 20W

Operating Temperature -10 to +55°C

Storage Temperature -20 to +70°C

Dimensions (W x H x D) 309 X 225 X 35 (mm)

Weight 1.59 kg

Protocols

ISO 9142-2, ISO 14230-2, ISO 15765-4, K/ L lins,

Flashing Code, SAE-J1850 VPW, SAE-J1850

PWM, CAN ISO 11898, Highspeed, Middlespeed,

Lowspeed and Singlewire CAN, GM UART, UART

Echo Byte Protocol, Honda Diag-H Protocol, TP

6

Page 14

General Introduction VCI – J2534 ECU Programming Device

2.2 VCI – J2534 ECU Progra m ming De vi ce

2.2.1 Functional Description

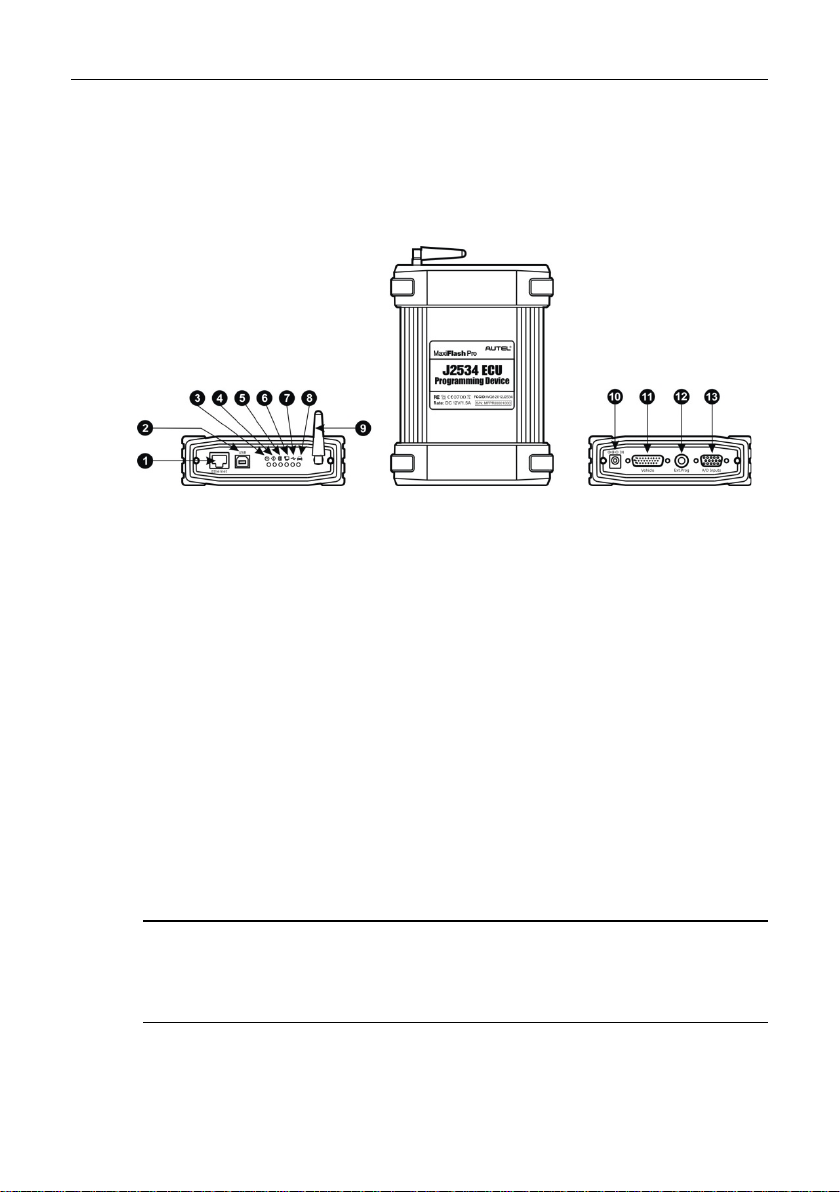

Figure 2-4 J2534 ECU Programming Device

1. Ethernet Port

2. USB Port

3. Power LED - illuminates solid green when po wered on

4. Error LED - illuminates solid red when seri ous hardware failure occurs

5. Bluetooth LED - illuminates solid green when connected with the

MaxiSys display tablet through Bluetooth communication

6. Ethernet LED - illuminates solid green when connected with the MaxiSys

display tablet or an existing LAN v i a the Ethernet serial cable

7. USB Status Light - illuminates solid green when the device is properly

connected and communicating with t he MaxiS ys displ ay tab let or the P C

via the USB cable

8. Vehicle LED - flashes green when communicating with the vehicle’s

network

IMPORTANT: Do not dis connect the reprogramming device while this stat us

light is on! If the flash reprogramming procedure is interrupted while the

vehicle’s ECU is blank or only partially programmed, the module may be

unrecoverable.

9. Bluetooth Antenna

10. DC Power Supply Input Port

7

Page 15

General Introduction VCI – J2534 ECU Programm ing Device

11. Vehicle Data Connector (DB26-Pin MVCI)

12. External Progr am ming Voltage Output Port

13. A/D Input Port

J2534 Reprogramming Capability

The J2534 ECU Programming Device is a SAE J2534-1 & -2 compliant

PassThru reprogramming interface device. Using the updated O EM software,

it is capable of replacing the existing software/firmware in the Electronic

Control Units (ECU), programm ing new ECUs and fixing software-controlled

drivability issues and emission issues.

Communication

The J2534 ECU programming device supp orts Bluetooth, Ethernet and US B

communication. It can transmi t vehicl e data to t he MaxiS ys displ ay tabl et with

or without a physical connection. The working range of the transmitter through

Bluetooth communication is 755 feet (about 230 m). A signal lost due to

moving out of range automatically restores itself when the display tablet unit is

brought closer to the VCI unit.

2.2.2 Power Sources

The J2534 programming device can rec eive power from bot h of the following

sources:

Vehicle Power

AC/DC Power Supply

Vehicle Power

The J2534 programming device op erates on 12-volt vehicle power, which it

receives through the vehicle data connection port. The device powers on

whenever it is connected to an OBD II/EOBD com pliant data link connector

(DLC). For non OBD II/ EOBD compliant vehicles, the device can be powered

from a cigarette lighter or other suitable po wer port on the test vehicle using

the auxiliary power cable.

AC/DC Power Supply

The J2534 programming device can be power ed from a wall socket us ing the

AC/DC power adapter.

8

Page 16

General Introduction Docking Station

Communications

Ethernet: RJ45 Ethernet connec tion

Input Voltage Range

6 VDC to 26 VDC

Supply Current

300 mA @ 6 VDC

Operating Temperature

0°C to +60°C (ambient)

Storage Temperature

-65°C to +100°C (ambient)

Dimensions (L x W x H)

183.8 x 135.5 x 41 (mm)

Weight

0.54 kg (1.20 lb)

2.2.3 Technical Specifications

Item Description

Bluetooth

USB 2.0

200 mA @ 12 VDC

110 mA @ 24 VDC

NOTE: For additi onal please refer to the accompanied us er manual for the

J2534 ECU Programming Device.

2.3 Docking Station

2.3.1 Functional Description

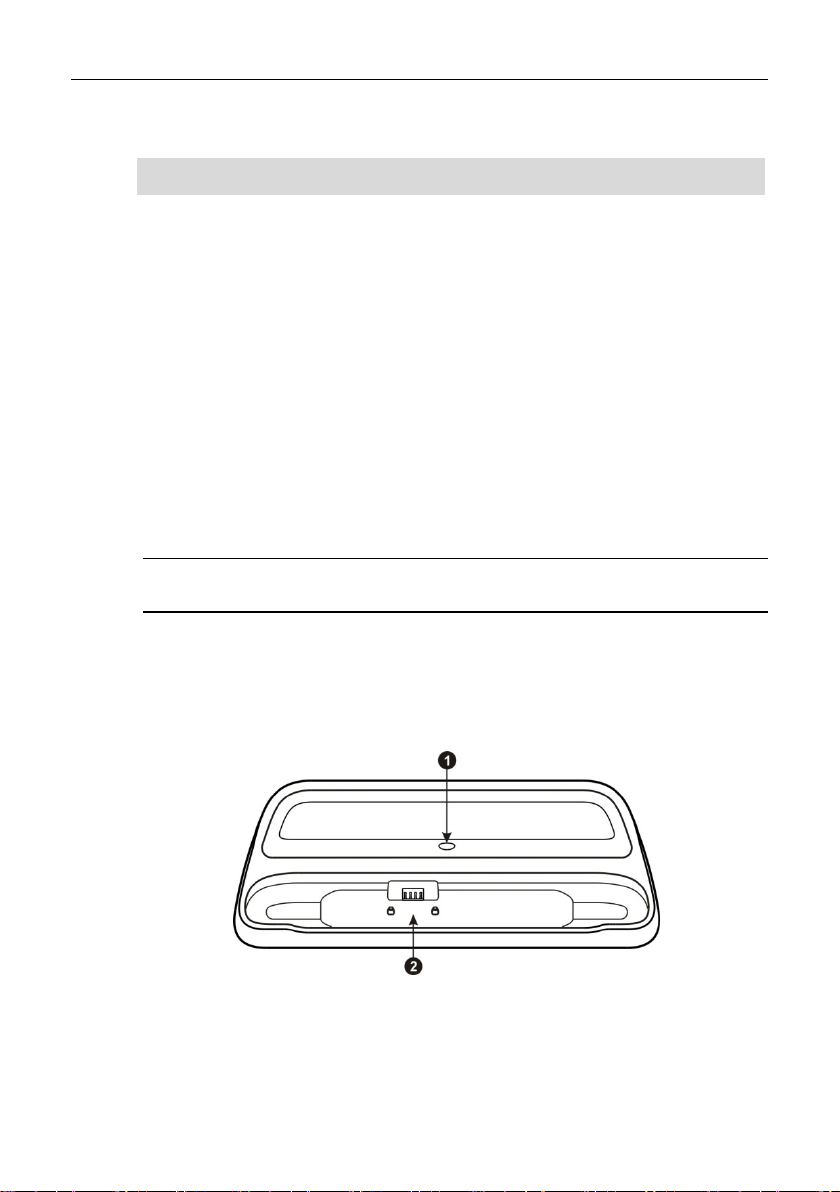

Figure 2-5 Docking Station

9

Page 17

General Introduction Accessory Kit

Operating Temperature

-10°C to +55°C (ambient)

Storage Temperature

-40°C to +85°C (ambient)

Dimensions (L x W x H)

326.5 x 128.5 x 49 (mm)

Weight

0.79 kg (1.74lb)

1. DC Power Supply Input Port – connects to the AC/DC adapter for power

supply

2. Charging Dock – holds the MaxiSys tablet while providing optimum

visibility and convenient charging

NOTE: Please make sure no small metal or other conduct ive parts are around

the Charging Dock to avoid short c i r cuit damage to the device.

2.3.2 Technical Specifications

Item Description

Input Voltage

2.4 Accessory Kit

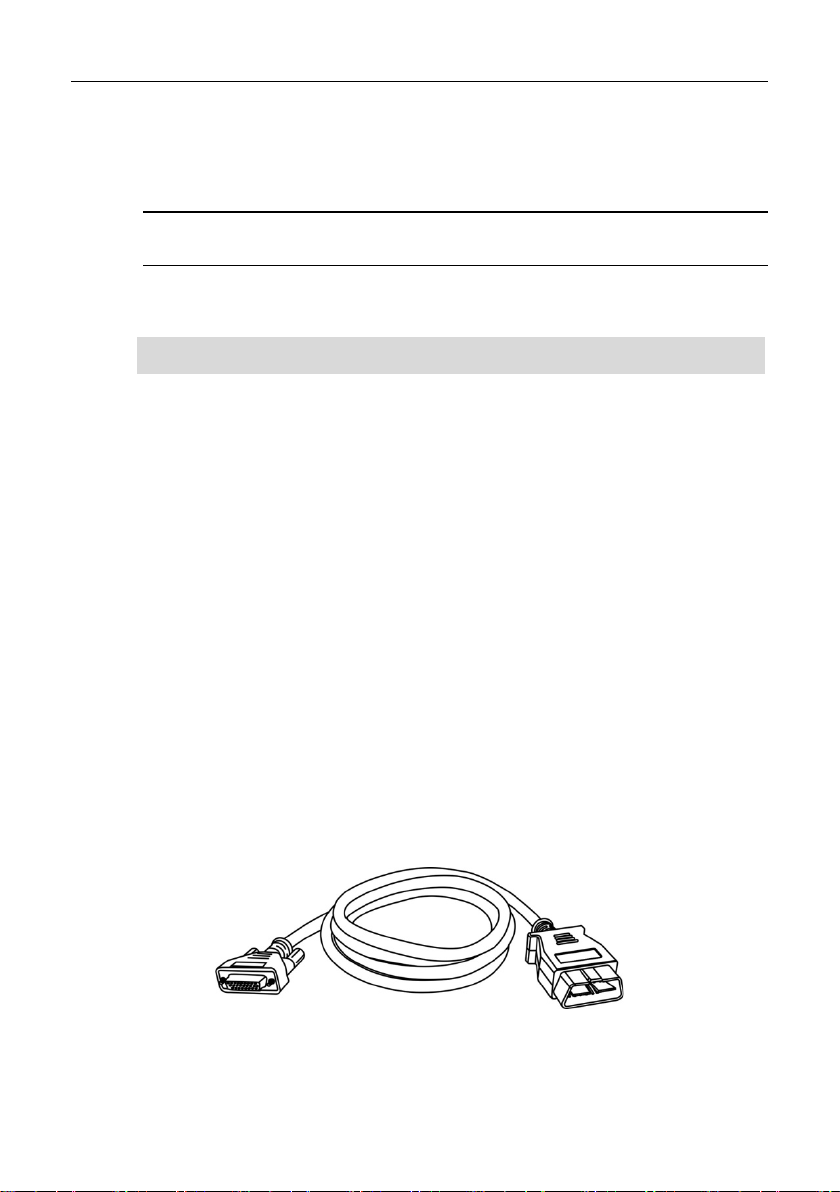

2.4.1 Main Cable

The VCI device can be powered through the Main Cable whe n connected to

an OBD II/EOBD compliant vehicle. The Main Cable c onnects the VCI device

to the vehicle’s data link connector (DLC), throug h which the VCI device can

transmit vehicle data to the MaxiSys display tablet.

DC/12V/3A

Figure 2-6 Main Cable – 1.5 m in length

10

Page 18

General Introduction Accessory Kit

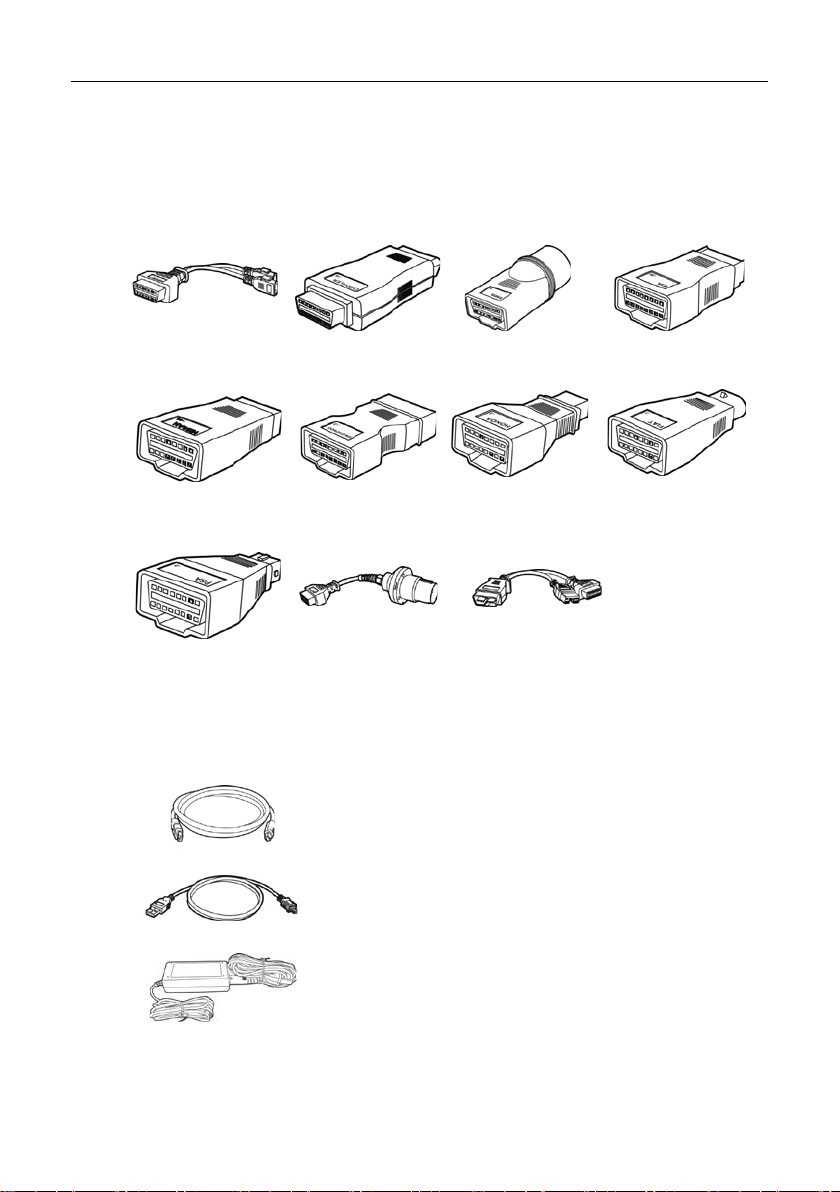

2.4.2 OBD I Adapters

The OBD I adapters are for Non-OBD II vehicles. The adapter used depends

on the type of vehicle make being t ested. The most common adapters are

shown below.

VW/Audi-2+2

Nissan-14

PSA-2

Chrysler-16 BMW-20 Kia-20

GM/Daewoo-12

Benz-38

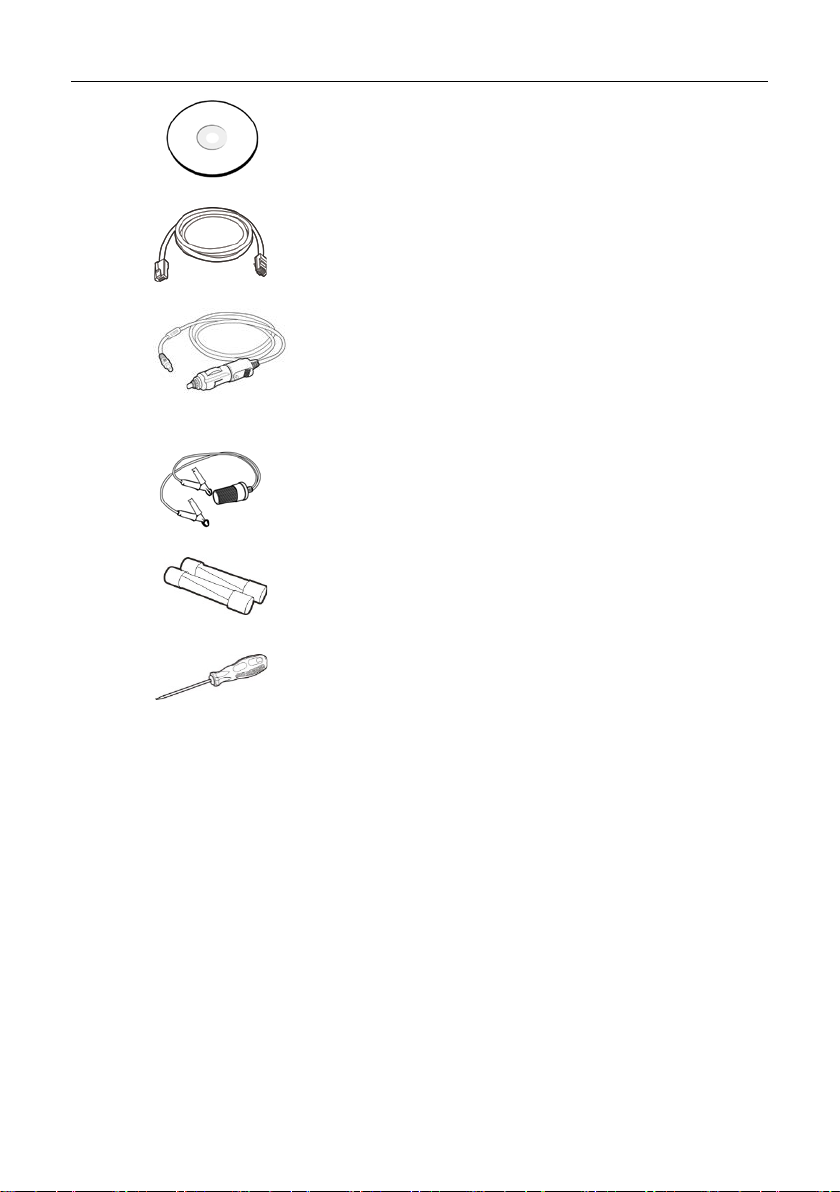

2.4.3 Other Accessories

Standard 2.0 USB Cable

Connects the display tablet to t he V CI unit.

Mini USB Cable

Connects the display tablet to t he P C.

Honda-3

Mitsubishi/Hy

undai-12+16

Fiat-3

AC/DC External Power Adapter

Connects the display tablet t o the external DC power

port for power supply.

11

Page 19

General Introduction Accessory Kit

programming device through connection to the

s cigarette lighter receptacle, as some

to the

Lighter Fuse

Screwdriver

Compact Disc (CD)

Includes the User Manual, Printing Services Program

and Update Application, etc.

Ethernet Serial Cable

Connects the display tablet to t he V C I unit.

Cigarette Lighter

Provides power to the display tablet or the J2534

vehicle’

non-OBD II vehicles cannot provide power via the

DLC connection.

Clipper Cable

Provides power to the display tablet or the J2534

programming device, through connection

vehicle’s battery.

A safety device for the cigarette lighter.

Unscrews the rear cover of the display tablet for easy

replacement of the battery or Mini S D card.

12

Page 20

Chapter 3 Getting Started

Make sure the MaxiSys Display Tablet has a charged battery or is connected to the DC

power supply (see 2.1.2 Power Sour ces on page 5).

3.1 Powering Up

Press the Lock/Power button on the top right side of the display tablet to

switch the unit on. The system boot s up, and shows the lock screen. Press

and drag the inner ring to the edge of the circle to unlock the screen; the

MaxiSys Job Menu is shown.

Figure 3-1 Sample MaxiSys Job Menu

1. Application Buttons

2. Locator and Navigation Buttons

3. Status Icons

NOTE: The screen is locked by default when you first turn on the display tablet.

It is recommended to lock the s creen to pr otect inf ormati on in the s ystem and

reduce battery usage.

Almost all operations on the display tablet are controlled through the touch

screen. The touch screen navigation is menu driven, which allows you to

quickly locate the test procedure, or data that you need, through a seri es of

choices and questions. Detailed descriptions of the menu structures are found

in the chapters for the various applications.

13

Page 21

Getting Started Powering Up

Allows you to set the MaxiSys system settings,

Allows you to edit and save works hop i nformation

Launches the Support platform which

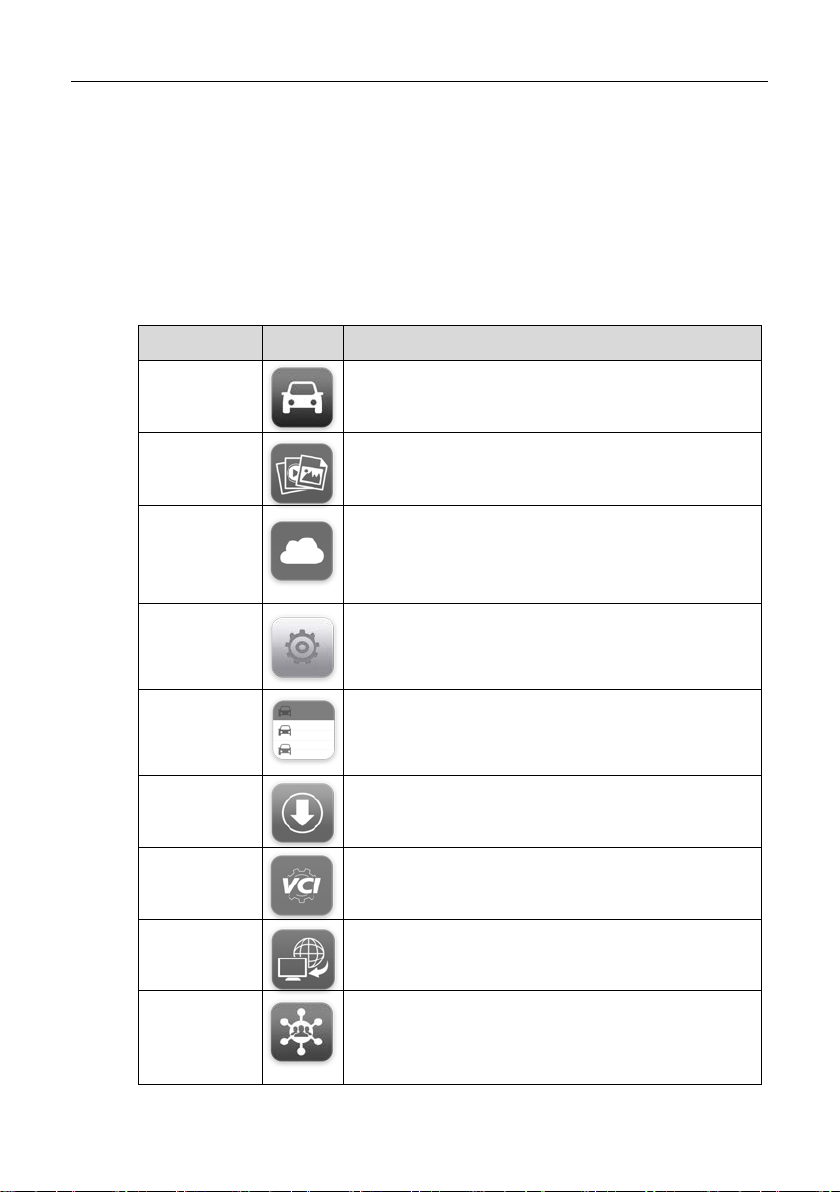

3.1.1 Application Buttons

The Application buttons configure the MaxiSys for the type of operation or

activity to be performed. The table below gives brief descriptions of the

available applications.

Use the stylus pen or your finger tip to select an application from the Job

Menu.

Table 3-1 Applications

Name Button Description

Diagnostics

Data

Manager

MaxiFix

Settings

Shop

Manager

Update

VCI

Manager

Remote

Desk

Configures the unit to operate as a diagnostic

tool. See Diagnostics Operations on page 19.

Opens the organization system for saved data

files. See Data Manager Operations on page 63.

Launches the MaxiFix platform which provides the

most compatible and abundant repair techn iques

and diagnostics database. See MaxiFix

Operations on page 68.

and to view the general information about the

Display Tabl et. See

78.

and customer data, as well as reviewing test

vehicle history records. See

Operations on page 83.

Checks for the latest update available for the

MaxiSys system, and performs updating

procedures. See Update Operati ons on page 91.

Establishes and manages Bluetooth or wired

connections to the VCI device. See VCI Manager

Operations on page 93.

Configures your unit to receive remote support

using the TeamViewer application program. See

Remote Desk Operations on page 97.

Settings Operations on page

Shop Manager

Support

synchronizes Autel’s on-line service base station

with the MaxiSys tablet. See

on page 99.

14

Support Operations

Page 22

Getting Started Powering Up

Opens the camera with short press; takes and

stored in the Data

Allows you to adjust the brightness of the

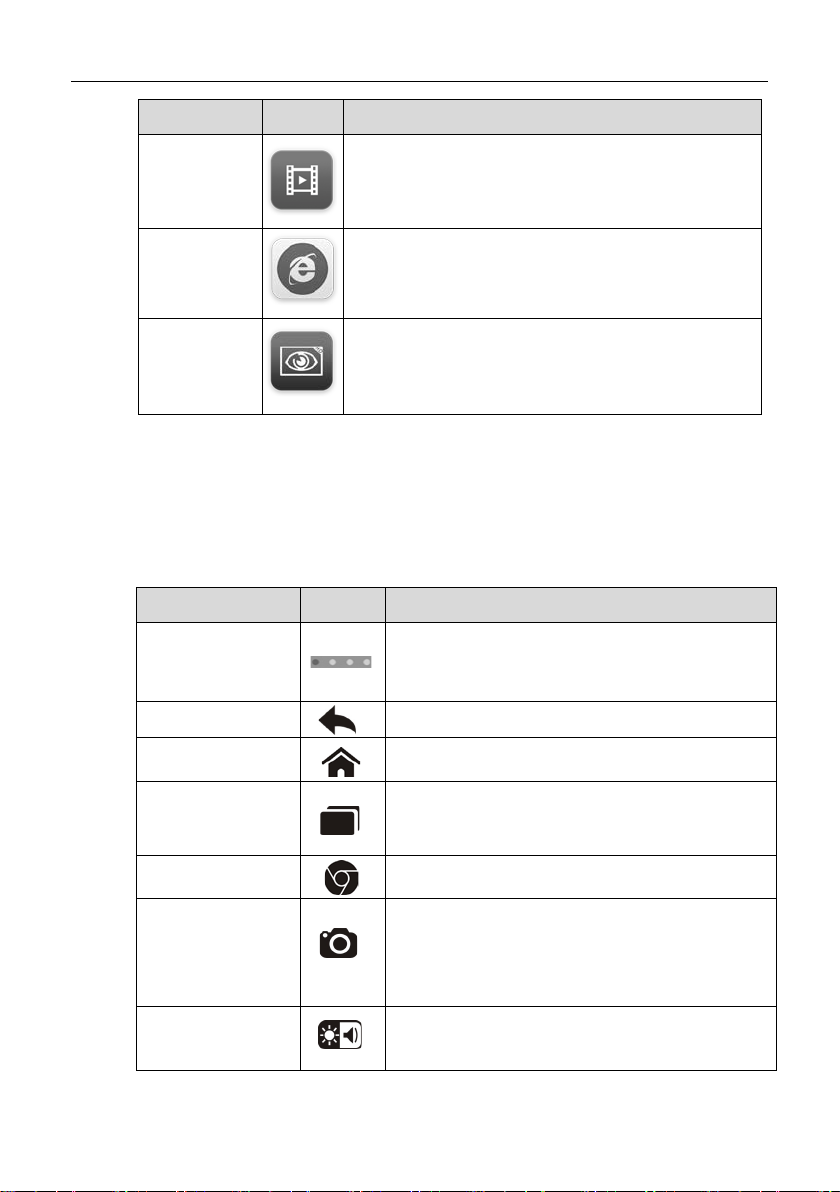

Name Button Description

Allows you to store and play technic al tutorial and

Training

Quick Link

Digital

Inspection

training videos about the device us age or vehicle

diagnostic techniques. See Training Operations

on page 109.

Provides associated website bookmarks to allow

quick access to pro duct update, service, support

and other information. See Q uick Link Operati ons

on page 111.

Configures the unit to operate as a video scope

device by connecting to an Imager hea d cable for

close vehicle inspections. See Digital Inspection

Operations on page 112.

3.1.2 Locator and Navigation Buttons

Operations of the Navigation buttons at the bottom of the screen are described

in the table below:

Table 3-2 Locator and Navigation Buttons

Name Button Description

Indicates the location of the sc reen. S wipe the

Locator

screen left or right to view the previous or ne xt

screen.

Back

Home

Recent Apps

Chrome

Camera

Display & Sound

Returns to the previous screen.

Returns to Android System’s Home screen.

Displays a list of applications that are currently

working. To open an app, touch it. To remove

an app, drag it downwards.

Launches the Chrome browser.

saves screenshot image with lon g press. The

saved files are autoManager application for later reviews. See

Data Manager Operations on page 63.

screen and the volume of the audio output.

15

Page 23

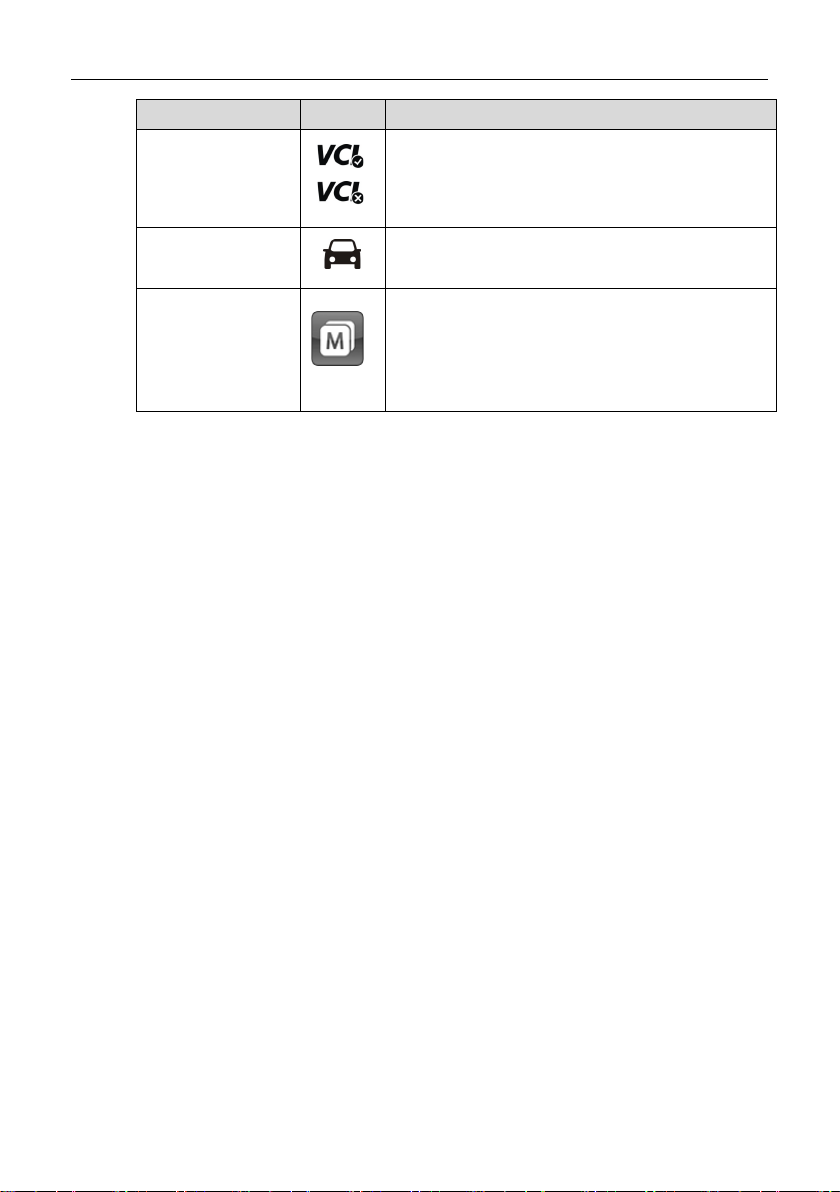

Getting Started Powering Down

Name

Button

Description

up a Multi Task

bookmarks. Tapping a specific

Opens the VCI Manager application. T he tick

VCI

icon at the bottom right corner indicates the

display tablet is communicating with the VCI

device, otherwise a cross icon displays.

MaxiSys

Shortcut

Multi Task

To use the camera:

1. Tap the Camera button. The camera screen opens.

2. Focus the image to be captured in the vi ew finder.

3. Tap the inner blu e circle. The view finder now shows the captured

picture and auto-saves the taken photo.

4. Tap the thum bnail image on the top right corner of the screen to

view the stored image.

5. Tap the Back or Home button to exit the camera application.

Refer to Android documentation f or additional information.

3.1.3 System Status Icons

These are the standard status icons of the Android operating system. Your

MaxiSys display tablet is a fully functional Android Pad. Refer to Android

documentation for additional i nformation.

Returns to the MaxiSys operation interface

from other Android applications.

Tapping this button opens

menu, on which displays the active running

application

bookmark enables you to switch direct l y to the

selected application screen.

3.2 Powering Down

All vehicle communications must be terminated before shutting down the

MaxiSys display tablet. A warning message displays if you attempt to shut

down while the VCI unit is communicating with the vehicle. Forcing a shut

down while communicating may lead to ECM problems on some vehicles. Exit

the Diagnostics application before powering down.

16

Page 24

Getting Started Install Computer Software

To power down the MaxiSys tablet:

1. Press and hold the Lock/Power Button.

2. Tap OK; the tablet will turn off in a few seconds.

3.2.1 Reboot System

In case of system crash, pres s and hold t he Lock/ Power b utton f or 8 seco nds

to reboot the system.

3.3 Installing Computer Software

The MaxiSys Elite Diagnostic Platform allows you to realize some of its

functions on a computer to enhance capabilities and improve user experience.

To realize these functions on a computer, you need to install certain software.

There are two Setup.exe program packages contained in the CD provided

with the MaxiSys Elite tool kit. The package includes the following

applications:

1. PC Link - launches a Printing Services program which receives and

allows editing the files sent from the MaxiSys tablet for printing

2. Driver Program - setup driver program for the VCI dev ice

3. Network Configuration Program and Update Agent - network

configuration program and firmware update agent for the VCI device

To install the Setup.exe program

1. Insert the CD into the CD-ROM of the computer. The driver

installation wizard will load m om entarily.

2. Click on Next on the welcome page.

3. Click the Change button, and select a destination folder to install the

program, and click Next to continue. Or directly click Next to

continue without changing the default installation folder.

4. Click Install and the Setup.e xe program will be installed ont o the

computer.

3.3.1 Printing Operation

This section describes how to receive file from the MaxiSys tablet and perform

17

Page 25

Getting Started Install Computer Software

printing through the computer:

To perform printing through the computer

1. Install the PC Link (Printi ng Services program) to the computer.

2. Make sure the displ ay tablet is connect ed to the computer net work,

either via Wi-Fi or LAN, before printing. See 7.1.3 Printing Setting on

page 79 for more information.

3. Run the Printing Services program on the computer.

4. Tap the Print button on the toolbar displayed in various applicatio ns

of the M axiSys system. A temporary file will be created and s ent to

the computer for printing.

5. Click the Printer Server tab on the top of the program interface on

the computer, and wait for the printing file to load.

6. Click the Print button to s tart printing.

NOTE: Make sure the computer installed with the Printing Services program is

connected to a printer.

Refer to the accompanied user man ual for the corresponding VCI d evice for

detailed information about the operat ion of the net work confi guration pr ogram

and/or the update agent.

18

Page 26

Chapter 4 Diagnostics Operations

By establishing a data link to the electronic control systems of the vehicle being

serviced through the VCI device, the Diagnostics application allows you to retrieve

diagnostic information, view live data parameters, and perform active tests. The

Diagnostics application can access the electronic control module (ECM) for various

vehicle control systems, such as engine, transmission, antilock brake system (ABS),

airbag system (SRS) and more.

4.1 Establishing Vehicle Communication

The Diagnostics operations requ ire connecting the MaxiSys Elite Diagnostic

Platform to the test vehicle through t he VCI device using t he main cable, and

test adapters (for non-OBD II vehicles). To establish proper vehicle

communication to the MaxiSys display tablet, you need to perform the

following steps:

1. Connect the VCI device to the vehicle’s DLC for both communication and

power source.

2. Connect the VCI device to the MaxiSys display tablet via Bluetooth

pairing, USB connection, or Ethernet connection.

3. When these are done, check the VCI navigation button at the bottom bar

on the screen, if the button displays a gr een tick icon at the lower right

corner, the MaxiSys Elite diagnostic platform is ready to start vehicle

diagnosis.

4.1.1 Vehicle Connection

The method used to connect the VCI dev ice to a vehicle’s DLC depends on

the vehicle’s configuration as follows:

A vehicle equipped with an On-board Diagnostics Two (OBD II)

management system supplies both communication and 12-volt power

through a standardized J-1962 DLC.

A vehicle not equipped with an OBD II management system supplies

communication through a DLC connection, and in some c ases supplies

12-volt power through the cigarette light er receptacle or a connection t o

the vehicle battery.

19

Page 27

Diagnostics Operations Establishing Vehicle Communication

OBD II Vehicle Connection

This type of connection only requires the main cable without an y additional

adapter.

To connect to an OBD II vehicle

1. Connect the main cable’s female adapter to the Vehicle Data

Connector on the VCI device, and tighten the captive screws.

2. Connect the cable’s 16-pin male adapter to the vehicle’s DLC, which

is generally located under the vehicle dash.

NOTE: T he vehicle’s DLC is not always located under the dash; refer to

the user manual of the test vehicle for additional connection information.

Non-OBD II Vehicle Connection

This type of connection requires both the main c able and a required OBD I

adapter for the specific vehicle bei ng serviced.

There are three possible conditions for Non-OBD II vehicle connection:

DLC connection supplies both comm uni cation and power.

DLC connection supplies communication and power is to be supplie d v i a

the cigarette lighter connection.

DLC connection supplies communication and power is to be supplie d v i a

connection to the vehicle battery.

To connect to a Non-OBD II Vehicle

1. Connect the main cable’s female adapter to the Vehicle Data

Connector on the VCI device, and tighten the captive screws.

2. Locate the required OBD I adapter and connect its 16-pin jack to the

main cable’s male adapter.

3. Connect the attache d OBD I adapter to the vehicle’s DLC.

NOTE: Some adapters ma y have more than one adapter or may have test

leads instead of an adapter. Whatever the case, make the proper connectio n

to the vehicle’s DLC as required.

20

Page 28

Diagnostics Operations Establishing Vehicle Communication

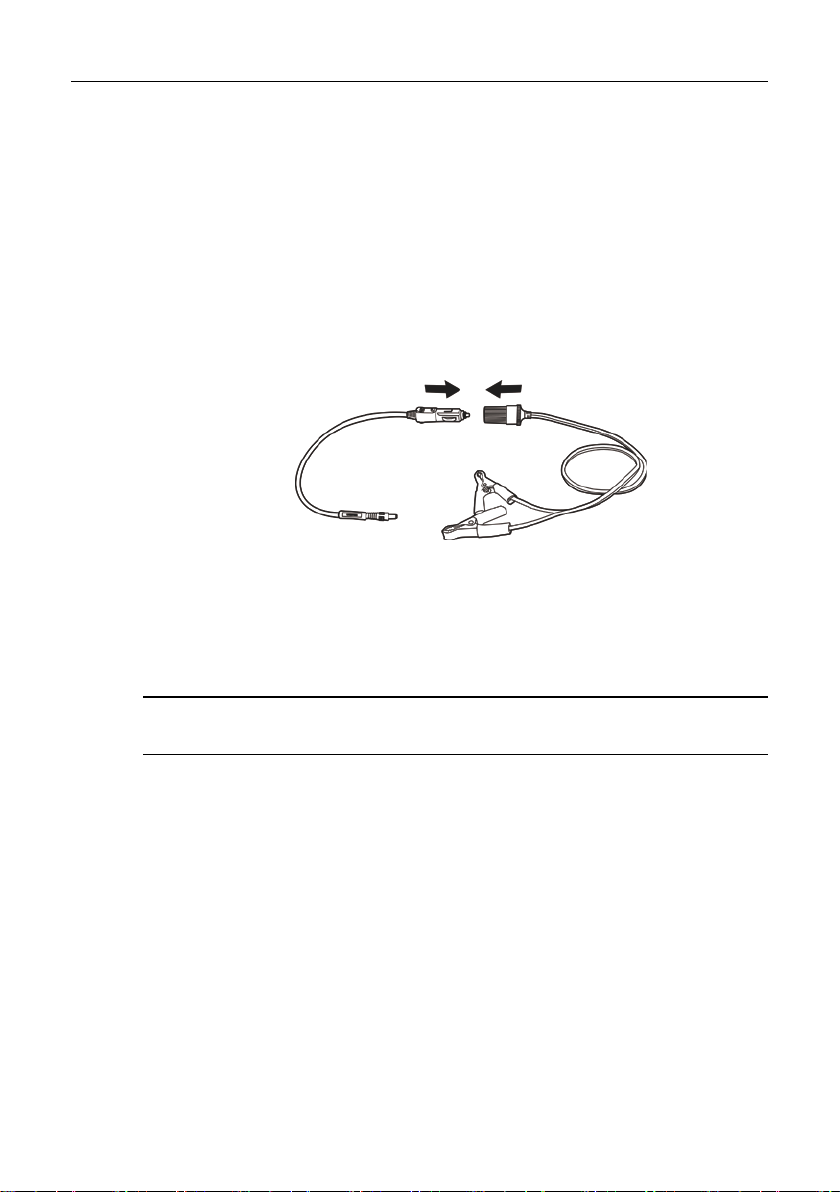

To connect the ci garette lighter

1. Plug the DC power connector of the cigarette lighter into the DC

power supply input port on the device.

2. Connect the male connect or of the ci garett e light er int o the vehic le’s

cigarette lighter receptacle.

To connect the cl ipper cable

1. Connect the tubular plug of the clipper cable t o the male connector

of the cigarette lighter.

Figure 4-1 Connection between Cigarette Lighter and C lipper Cable

2. Plug the DC power connector of the cigarette lighter into the DC

power supply input port of the J2534 programming device.

3. Connect the clipper cable to the vehicle’s battery.

NOTE: After the VCI device is successfully connected to the vehicle, the

Power LED on the device illuminates , and a brief beep sound will be heard.

4.1.2 VCI Connection

After the VCI device is proper ly connected to the vehicle, the Power LED on

the VCI device illuminates solid green light, and is ready to establish

communication with the MaxiSys di splay tablet.

The J2534 ECU Programming Devic e, which comes with the MaxiSys Elite

tool kit, supports 3 commun ication methods with the MaxiSys disp lay tablet:

Bluetooth, USB, and Ethernet connection.

21

Page 29

Diagnostics Operations Establishing Vehicle Communication

Pairing Up via Bluetooth

Among all methods, Bluetooth pairing is recommended as the first choice for

the communication between the Ma xiSys display tablet and the VCI device.

The working range for Bluetooth communication is about 755 feet (230 m); this

means you can perform vehicle diagnosis freely around the workshop with

greater convenience.

If you use more than one VCI device to connect to the test vehicles when

customers are many, you can perform vehicle diagnosis on various veh icles

conveniently, by pairing the MaxiSys display tablet separately to each of t he

VCI devices connected to the different test vehicles, via Bluetooth, without th e

need to repeat the plugging and unplugging proce dure, which is unavoidable

through traditional wired connection, thus s aves you more time and provid es

more efficiency.

To pair up the MaxiSys display tablet with the VCI device via

Bluetooth

1. If not already done, power up the MaxiS ys display tablet.

2. Select the VCI Manager application from the MaxiSys Job Menu.

3. When the VCI Manager application is opened, the device

automatically starts s canning for available VCI devices around for

Bluetooth pairing. The found devices are listed in the Setting

section on the right side of the screen.

NOTE: If no VCI device is found, this may indicate that the signal strength

of the transmitter is too weak to be det ected. In this c ase try to get closer

to the device, or reposition the VCI device, and remove all possible

objects that causes signal interference. When these are done, tap the

Scan button at the top right corner to st ar t searching again.

4. The device name may display as Maxi suffixed with a serial number.

Select the required device for pairing.

5. When paring is successfully done, the conn ection status displayed

to the right of the device name is shown as Paired.

6. Wait for a few seconds, and the VCI button on the system

Navigation bar at the bottom of the screen shall display a green tick

icon, indicating the displa y tablet is connected to the VCI device,

and is ready to perform vehicle diagnosis.

Refer to 10.1 Bluetooth Pairing on page 94 for additional information.

22

Page 30

Diagnostics Operations Establishing Vehicle Communication

USB Cable Connection

The USB cable connection is a simple and quick way to establish

communication between the MaxiSys display tablet an d the VCI device. After

properly conn ecting the USB cable fr om the tablet to the VCI device, the VCI

navigation button at the bottom bar of the screen shows a green tick icon in a

few seconds, and the USB LED on the VCI device illuminates solid green light,

indicating the connection between the devices is successful.

The MaxiSys Elite diagnostic platform is now ready to perform vehicle

diagnosis.

NOTE: Since the USB connection provides the most stable and fastest

communication, it is highly recommended to apply this communication method

when operating ECU programming or coding. When all the three

communication methods are applied at the same time, the MaxiSys system

will use the USB communication as the default priority.

Wired Connection via Ethernet

This section describes the general proc edure to connect the tablet with the

J2534 ECU programming device via Ethernet connection. To establish

successful communication, you need to s et up the network configuration on

the display tablet.

To connect the MaxiSys display tablet with the VCI device via

Ethernet

1. If not already done, power up the MaxiS ys display tablet.

2. Connect the MaxiSys Display Tablet to the J2534 ECU

programming device with the accompanied Ethernet serial cable.

3. Select the VCI Manager application from the MaxiSys Job Menu.

4. Select the Wired Network option o n t he Con nect io n Mod e list. The

Ethernet Setting screen displays on the right section.

5. Select a connection type:

DHCP – obtains the LAN IP address automatically

Manual – allows you to enter IP address manually

23

Page 31

Diagnostics Operations Establishing Vehicle Communication

6. If Manual is selected, you need to set the IP address on your own.

NOTE: If you are not sure about the sp ecific IP address values, please

contact your network administrator.

7. Tap Apply to set up the wired network connection.

When the wired network is successful ly co nnected, the connection status is

displayed as Connected, and the two status lights at the corners alongside the

Ethernet Ports on the display tabl et illuminat e. The solid am ber light in dicates

steady connection, and the flashing green light indicates active

communication, between the unit s. The VCI navigation button at the bottom

bar shall display a green tick icon after a few seconds, indicating the MaxiS ys

Elite diagnostic platform is ready to perform vehicle diagnosis.

Refer to 10.2 Wired Network Connection on page 95 for additional information.

NOTES: After the MaxiSys Elite diagnostic platform has successfully

established communication with the vehicle, the VCI device makes a long

beep sound for confirmation.

4.1.3 No Communication Message

A. If the MaxiSys Display Tablet is not connected to the VCI device, an

“Error” message displays. An “Error” message indicates the display

tablet is not communicating with the VCI device, and so cannot gain

access to the vehicle control module. In this c ase, you need to do the

following check-ups:

Check if the VCI device is powered on.

In cas e of wireless connection, check if the network is configured

correctly, or if the right device has been paired.

If during the diagnosis process, the communication is suddenly

interrupted due to the los s of signal , check if there is an y object that

causes signal interruption.

Check if t he V CI device is properly positioned. It is r ecom m ended t o

put the VCI device with the front side u p.

Try standing closer t o the VCI device to obta in more stable signals,

and faster communication speed.

24

Page 32

Diagnostics Operations Getting Started

In cas e of wired connection, check the cable connection between

the display tablet and the VCI device.

Check if the green LED on the VCI device is illuminated for

Bluetooth, Ethernet, or USB.

Check if the Error LED on the VCI device is on, this may indicate

there is a communication error between the devices, in this case try

re-establishing the connection again; if this does not work, there

may be a hardware problem wit h the devi ce, in this cas e contact for

technical support.

B. If the VCI device is unable to establish a co mmunication link, a prompt

message displays with check inst ructions. The following conditions are

the possible causes for this massag e to display:

T he VCI device is unable to es tablish a co mmunication link with the

vehicle.

You’ve selected a system for testing that t he vehic le is not equ ipped

with.

There is a loose connection.

There is a blown vehicle fuse.

There is a wiring fault on the vehicle, or the data c able or adapter.

There is a circuit fault in the data cable or adapter.

Incorrect vehicle identification was entered.

4.2 Getting Started

Prior to first use of the Diagnostics application, the VCI device must be

synchronized with the MaxiSys Displa y Tablet to establish a comm unication

link. See VCI Manager Operations on page 93.

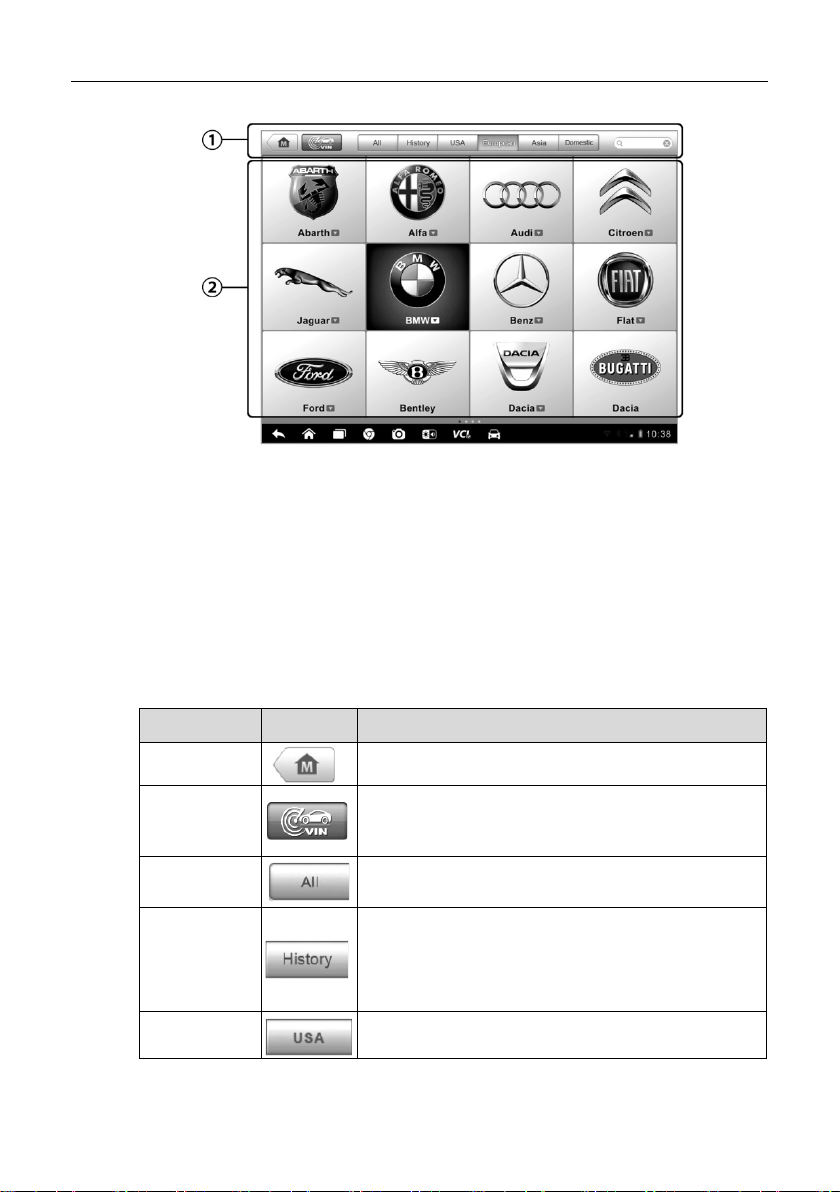

4.2.1 Vehicle Menu Layout

When the VCI device is properly connected to the vehicle, and paired to the

MaxiSys Display Tablet, the platform is ready to start vehicle diagnosis. Tap on

the Diagnostics application but ton on the M axiS ys Job Menu, the scre en then

opens the Vehicle Menu.

25

Page 33

Diagnostics Operations Getting Started

Displays the stored test vehic le history records.

recorded during

on page 84.

Figure 4-2 Sample Vehicle Menu Screen

1. Top Toolbar Buttons

2. Manufacturer Buttons

Top toolbar Buttons

The operations of the Toolbar buttons at the top of the screen are listed and

described in the table below:

Table 4-1 Top Toolbar Buttons

Name Button Description

Home

VIN Scan

All

History

USA

Returns to the MaxiSys Job Menu.

Touching this button opens a dropdown list; tap

Auto Detect for auto VIN detection; tap Manual

Input to enter VIN manually.

Displays all the vehicle makes in the vehicle

menu.

This option provides you direct access to the

previously tested vehicle

previous test sessions. See 8.1 Vehicle History

Displays the USA vehicle menu.

26

Page 34

Diagnostics Operations Vehicle Identification

allowing you to manually enter the specific

Name Button Description

Europe

Asia

Domestic

Search

Cancel

Displays the European vehicle m enu.

Displays the Asian vehicle menu.

Displays the Domestic vehicle menu.

Touching th is button opens the virtual k eyboard,

vehicle make required.

Touching this button exits the search screen, or

cancels an operation.

Manufacturer Buttons

The Manufacturer buttons display the various vehicle logos and the brand

names. Select the required manufacturer button after the VCI device is

properly connected to the test vehicle to start a diagnostic session.

The small envelop icon displa ys beside the vehicle brand name is tappable,

touching which displays an attached PDF file, showing relevant information,

such as vehicle coverage, function list, and so on for the corresponding

vehicle make.

4.3 Vehicle Identification

The Maxisys Elite diagnostic system supports four methods for Vehicle

Identification.

1. Auto VIN Scan

2. Manual VIN Input

3. Manual Vehicle Selection

4. OBD Direct Entry

4.3.1 Auto VIN Scan

The MaxiSys Elite diagnostic system features t he latest VIN-based Auto VI N

Scan function to identify CAN vehicles in just one touch, which allows the

technician to quickly detect vehicles, scan all the di agnosable ECU s on ever y

vehicle and run diagnostics on the selected system.

27

Page 35

Diagnostics Operations Vehicle Identification

To perform Auto VIN Scan

1. Tap the Diagnostics application button from the MaxiSys Job Menu.

The Vehicle Menu displays. (Figure 4-2)

2. Tap the VIN Scan button on the top toolbar.

3. Select Auto Detect. The tester starts VIN s canning on th e vehicle’s

ECU. Once the test vehicle is successfully identified, the system will

guide you to the Vehicle Diagnostics screen directly.

Figure 4-3 Sample Vehicle Diagnostics Screen

4.3.2 Manual VIN Input

For some vehicles that do not support the Auto VIN Scan function, the

MaxiSys Elite diagnostic system all o ws you to ent er t h e ve hicle VI N man u all y,

or simply take a photo of the VIN stick er for quick vehicle identification.

To perform Manual VIN Input

1. Tap the Diagnostics application button from the MaxiSys Job Menu.

The Vehicle Menu displays. (Figure 4-2)

2. Tap the VIN Scan button on the top toolbar.

3. Select Manual Input.

4. Tap the input box and enter the correct VIN.

28

Page 36

Diagnostics Operations Vehicle Identification

Figure 4-4 Manual VIN Input

5. Tap Done. The vehicle will be identified in a f ew seconds, and onc e

the matching is successful, the system will guide you to the Vehicle

Diagnostics screen directly. (Figure 4-3)

6. Tap Cancel to exit Manual Input.

4.3.3 Manual Vehicle Selection

When the vehicle’s VIN is not automatic ally retrievable through the vehic le's

ECU, or the specific VIN is unkno wn, you can choose to select the vehicle

manually.

There are generally three ways to enter t he vehicle information:

A. Step-by-step Vehicle Selection

This mode of vehicle selection is menu driven; you simply follow the scr een

prompts and make a series of cho ices. Each selection you make advances

you to the next screen. A Back button at the lower right corner of the screen

returns you to the previous sc reen. Exact proced ures may var y somewhat by

various vehicles being serviced.

29

Page 37

Diagnostics Operations Vehicle Identification

B. Manual Vehicle Entry

This mode allows you to manually enter and save specific vehicle information,

such as PCM Part Number, Vehicle Calibration Number, or Tear Tag. This

function enables direct access to the vehic le's ECM and saves your time of

doing step-by-step entry selections.

To perform Manual Vehicle Entr y - take Ford for example

1. Tap the Diagnostics application button from the MaxiSys Job Menu.

The Vehicle Menu displays. (Figure 4-2)

2. Tap the USA or the All button on the top toolbar.

3. Select the Ford button from the vehicle menu.

4. Select Manual Vehicle Entry from the Vehicle Selection Menu.

(Figure 4-5) A series of information screen displays, tap Yes to

continue.

Figure 4-5 Sample Vehicle Selection Menu

5. Select one of the three entries in the option screen - PCM Part

Number, Calibration Number or Tear Tag.

6. Take the PCM Part Number entry for example; you need to fill up

the accurate vehicle information in the input boxes.

30

Page 38

Diagnostics Operations Vehicle Identification

Figure 4-6 PCM Part Number Input Screen

7. Tap OK to continue when the input is done. A confirming screen

showing the Vehicle Information displays.

8. Check if the vehicle information is correct, and then from the

confirming screen, select:

a) Yes to continue.

b) No to return to the vehicle selection menu.

9. Select Yes and the vehicle diagnostics screen disp lays.(Figure 4-3)

C. Auto Vehicle Entry

Some vehicles provide an auto scan feature, which allows you to skip the

step-by-step vehicle identification proc edure and retrieve the specific vehicle

information from the vehicle’s ECU directly.

To perform Auto Vehicle Entry - take Ford for example

1. Tap the Diagnostics application button from the MaxiSys Job

Menu. The Vehicle Menu displays. (Figure 4-2)

2. Tap the USA or the All button on the top toolbar.

3. Select the Ford button from the vehicle menu.

4. Select Start New Session from the vehicle selection menu. A

confirming screen showing the Vehicle Information displays.

31

Page 39

Diagnostics Operations Navigation

5. Check if the vehicle information is correct, and then from the

confirming screen, select:

a) Yes to continue.

b) No to return to the vehicle selection menu.

6. Select Yes and the Vehicle Diagnostics screen displays. (Figure

4-3)

4.3.4 Alternative Vehicle Identification

Occasionally, you may identify a test vehicle that the tester does not recognize;

the database does not support, or has some unique characteristics that

prevent it from communicating with the tester through the normal chan nels. In

these instances, you are provided with t he OBD direct entry, thr ough which

you can perform generic OBD II or EOBD tests. See 4.9 Generic OBD II

Operations on page 57 for additional inf ormation.

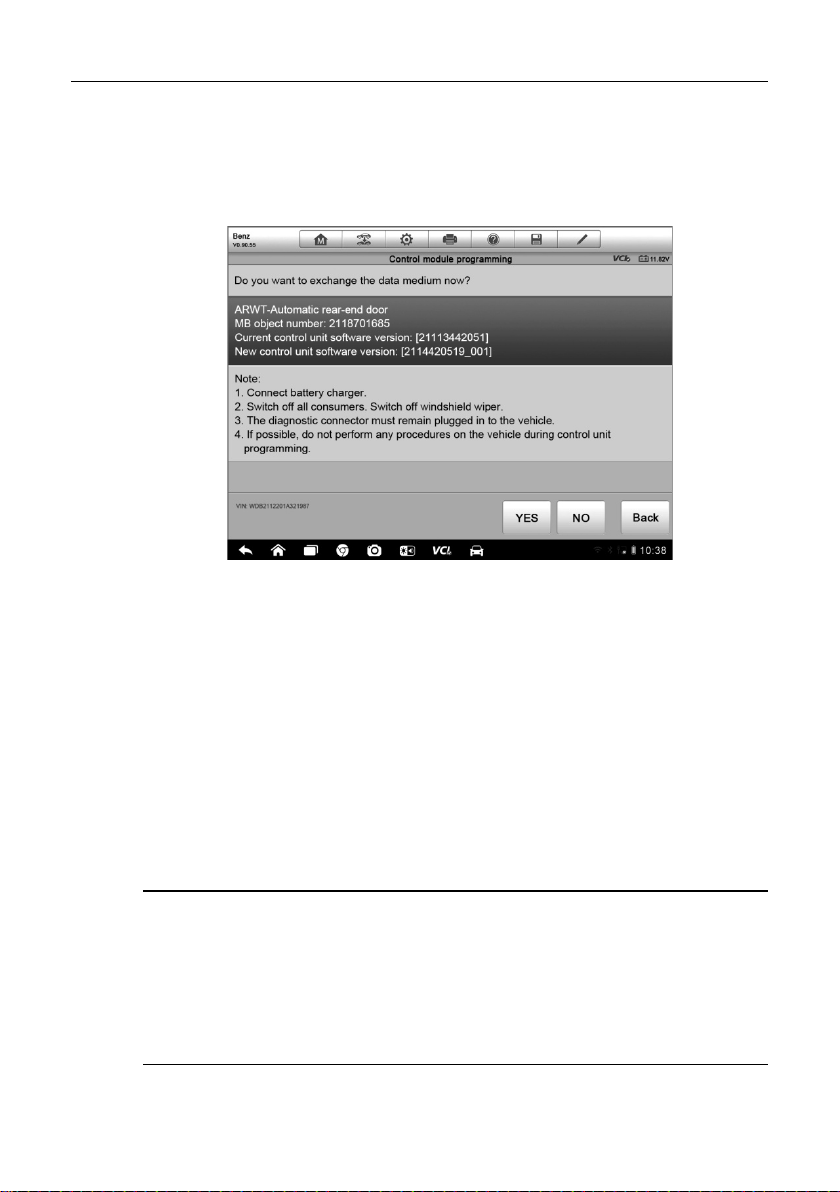

4.4 Navigation

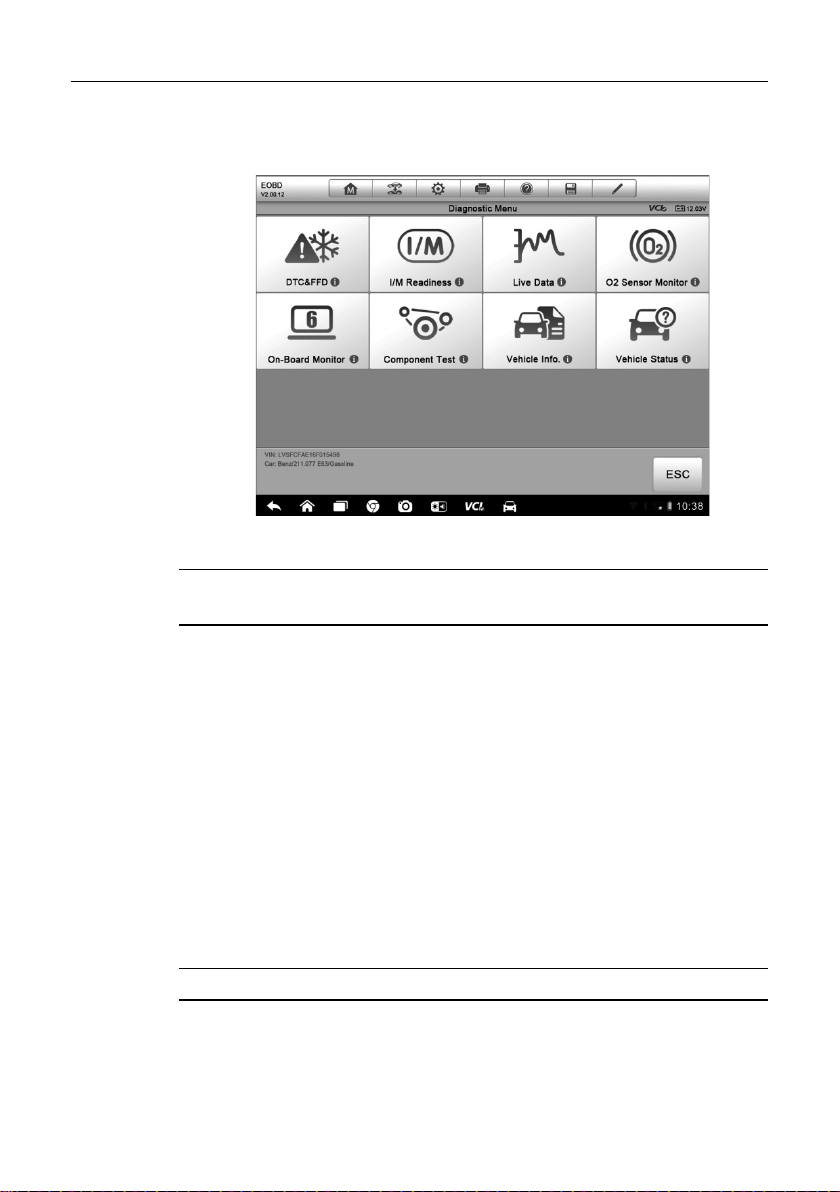

This section describes how to navigate the Diagnostics interface and select

test options.

4.4.1 Diagnostics Screen Layout

The Diagnostics screens typically inc l ude four sections. (Figure 4-7)

Figure 4-7 Sample Diagnostics Screen

32

Page 40

Diagnostics Operations Navigation

Touching this button allows you to exit the

for operations of

1. Diagnostics T oolbar

2. Status Information Bar

3. Main Section

4. Functional Buttons

Diagnostics Toolbar

The Diagnostics toolbar contains a number of buttons that allow you to print or

save the displayed data and make other c ontrols. T he table below provid es a

brief description for the operati ons of the Diagnostics toolbar buttons :

Table 4-2 Diagnostics Toolbar Buttons

Name Button Description

Home

Vehicle

Swap

Returns to the MaxiSys Job Menu.

diagnostic session of the currently identified test

vehicle, and returns you to the vehicle menu s creen

to select another vehicle for test i ng.

Settings

Opens the setting screen. See S ettings Operations

on page 78.

Saves and prints a copy of the displa yed data. See

Print

3.3.1 Printing Operation for additional information

on page 17.

Help

Provides instructions or tips

various diagnostic functions.

Tapping this button opens a submenu, on which

there are 3 options available to save the displayed

data.

Tap Save This Page to take a screenshot

image

Save

Tap Save All Data to save a PDF file (mostly

used to save data that cover more than 1

page)

Tap Start Saving to record a video clip (only

available for recording Live Data or special

graph data)

All saved data are stored in the Data Manager

application for later reviews. See Data Manager

Operations on page 63.

33

Page 41

Diagnostics Operations Navigation

Records the communication data and ECU

104 for detailed information.

Name Button Description

information of the test vehicle. The saved dat a can

Data

Logging

be reported and sent to the technical c enter via the

internet.

You c an go to the Support application to follo w up

the processing progress, see Data Logging on page

Send

To perform data printing in Diagnostics

Tapping this button submits the Data Logging report

to the technical center via the internet.

1. Tap the Diagnostics application button from the MaxiSys Job Menu.

The Print button on the diagnostic toolbar is available throughout

the whole Diagnostics operations.

2. Tap Print whenever you want to make a printing. A drop-down menu

appears.

a) Print This Page – prints a screenshot copy of the current

screen

b) Print All Page – prints a PDF copy of all displayed data

3. A temporary file will be created and sent to the computer for printing.

4. When the file is transferred successfully, a confirmation message

displays.

NOTE: Make sure the disp lay tablet is connected to the computer network,

either via Wi-Fi or LAN, before printing. For more instructions on printing, see

3.3.1 Printing Operation on page 17 for det ailed information.

To submit Data Logging reports in Diagnostics

1. Tap the Diagnostics application button from the MaxiSys Job Menu.

The Data Logging button on the diagnostic toolbar is available

throughout the whole Diagnostic s operations.

34

Page 42

Diagnostics Operations Navigation

2. Tap the Data Logging button whenever you want to commit

recording for the system communicat ion data. The button displays

blue during the active recording proc es s.

3. Tap the button again to finish recording. A submission form will

display to let you fill in the report inf or mation.

4. Tap the Send button to submit the report form via the internet, a

confirmation message displays when sending is successful.

Status Information Bar

The Status Information Bar at the top of the Main Section displays the

following items:

1. Menu Title – indicates the menu subject of the Main Section

2. VCI Icon – indicates the communication status between the tablet and

the VCI device

3. Battery Icon – indicates the batt ery status of the VEHICLE

Main Section

The Main Section of the screen varies depending on the sta ge of operations.

The main section can show vehicle identific ation selections, the main menu,

test data, messages, instructio ns and other diagnostic information.

Functional Buttons

The displayed Functional Buttons at this section of the screen varies

depending on the stage of operations. T hey can be used to navigate, save or

clear the diagnostic data, exit scanning as well as make other functional

controls. The functions of these buttons will be introduced respect ively in the

following sections of the corres ponding test operations.

4.4.2 Screen Messages

Screen messages appear when additi onal in put is ne eded bef ore pr oceed ing.

There are mainly three types of on-screen messages as to their purposes:

Confirmation, Warning, and Error.

35

Page 43

Diagnostics Operations Main Menu

Confirmation Messages

This type of messages usually displays as an “Information” screen, which

informs you when you are about to perform an ac tion that cann ot be rever sed

or when an action has been initiated and your confirmation is needed to

continue.

When a user-response is not required to continue, the message displays

briefly before automatically di sappearing.

Warning Messages

This type of messages informs you when completing the selected act ion may

result in an irreversible change or loss of data. The typical example f or this is

the “Erase Codes” message.

Error Messages

Error message s inform you when a system or procedural error has oc curred.

Examples of possible errors inc lude a disconnected cable or commu nication

interruption due to certain reasons.

4.4.3 Making Selections

The Diagnostics application is a menu driven program that prese nts a series

of choices one at a time. As you se lect from a menu, the next menu in the

series displays. Each selection narrows the focus and leads to the desired test.

Use your fingertip or the stylus pen t o m ake menu selections.

4.5 Main Menu

The Diagnostics application allows you to establish a data link to the electronic

control system of the test vehicle via the VCI device for vehicle diagnosis,

service or programming. You can operate functional tests, retrieve vehicle

diagnostic information such as tr ouble codes, event codes and live d ata, and

perform ECU reprogramming, for various vehicle control systems, such as

engine, transmission, ABS and more.

36

Page 44

Diagnostics Operations Diagnosis

The Vehicle Diagnostics screen (Figure 4-3) has three main options:

1. Diagnosis – a comprehensive section which includes all available

functions: reading, clearing, s aving and printing diagnostic information,

as well as performing active tests and special functions

2. Service – a separate section designed to perform vehicle scheduled

service and maintenance, such as to reset t he service lights and perform

calibration for various systems

3. Programming/Coding – a separat e section designed for quick access

to ECU reprogramming operations

After a section is selected an d the tablet establishes c ommunication with the

vehicle via the VCI device, the corresponding function menu or selection

menu displays.

4.6 Diagnosis

There are two options available when accessing the Diagnosis section:

1. Auto Scan – starts auto scanning for all the available systems on the

vehicle

2. Control Units – displays a selection menu of all available control units of

the test vehicle

Auto Scan

The Auto Scan function performs a comprehensive scanning over all the

systems on the vehicle’s ECU in order to locate fault systems and retrieve

DTCs. The sample operation interface of Auto Scan displays as below:

37

Page 45

Diagnostics Operations Diagnosis

Figure 4-8 Sample Auto Scan Operation Screen

1. Navigation Bar

2. Main Section

3. Functional Buttons

Navigation Bar

1. List Tab – displays the scanned data in list f ormat

2. Tree Tab – display the scanned data in system distribution diagram

format

3. Progress Bar – indicates the test progress

Main Section

A. List Tab

Column 1 - displays the system numbers

Column 2 - displays the scanned s ystems

Column 3 - displays the diagnostic marks indicating different conditions

of the test result:

-!-: Indicates that the scanned system may not support the code

reading function, or there is a communication error between the tester

and the control system.

38

Page 46

Diagnostics Operations Diagnosis

selected.

-?-: Indicates that the vehicle cont rol system has been detected, but

the tester cannot accurately locate it.

Fault | #: Indicates there is/are detected fault code(s) present; “#”

indicates the number of the detected faults.

Pass | No Fault: Indicates the system has passed the scanning

process and no fault has been detected.

B. Tree Tab

The tree tab screen displays a system distribution diagram of the vehicle

control modules. The scanned system which has passed scanni ng with

no fault is shown in blue font; whereas the scanned system that has

been detected with fault present is shown in red font.

Tab the

perform further diagnosis and other test activities. A Function Menu

screen (Figure 4-9) shall then display.

Functional Buttons

The table below provides a brief description of the Functional Buttons’

operations in Auto Scan:

Table 4-3 Functional Buttons in Auto Scan

Name Description

Back Returns to the previous screen or e xit Auto Scan.

Pause

OK

Quick Erase

Report Displays the diagnostic data in the report form.

Save

>E A button to the ri ght of the system item, on which you want to

○

Suspends scanning and changes to show the Continue

button.

Confirms the test result, and continues to the system

diagnosis after selecting the re quir ed system by t apping

the item in the Main Section.

Deletes codes. A warning message screen will display

to inform you of possible data loss when thi s function is

Saves the diagnostic session as a history record, this

allows you to quickly restore access to the test systems.

39

Page 47

Diagnostics Operations Diagnosis

Control Units

This option allows you to manually locat e a r equi red co nt rol s ystem f or t esti ng

through a series of choices. You simply follow the menu driven procedure, and

make proper selection each time; the program will guides you to the diagnostic

function menu after a few choices you’ve made.

Figure 4-9 Sample Function Menu Screen

The Function Menu options vary slightly by different vehicles. The function

menu may include:

ECU Information – provides the retrieved ECU information in detail.

Selecting opens an information sc reen.

Read Codes – displays detailed information of DTC records retrieved

from the vehicle control module.

Erase Codes – erases DTC records and other data from the ECM.

Live Data – retrieves and displays l ive data and parameters from the

vehicle’s ECU.

Active Test – provides specif ic subsystem and component tests. This

selection may appear as Actuators, Actuator Test, or Function Tests,

etc., and the tests options vary depending on the manufacturer and

model.

40

Page 48

Diagnostics Operations Diagnosis

Special Functions – provides component adaptation or variant coding

functions for custom configurations, and also allows you to reprogram

adaptive values for certain components af ter making repair s. Depending

on the test vehicle, this selection may sometimes appear as Control

Unit Adaptations, Variant Coding, Configuration or something similar.

NOTE: With the diag nostic toolbar o n top of the screen t hroughout the whole

diagnostic procedures, you are allowed to make various controls of the

diagnostic information at anyti me, such as printing and saving the displayed

data, get help information, or perfor m data logging, etc.

To perform a diagnostic function

1. Establish communication with the test vehicle via the VCI dev i c e.

2. Identify the test v ehicle by selecting from the menu options.

3. Select the Diagnosis section.

4. Locate the required system for testing by Auto Scan or through

menu driven selections in Control Units.

5. Select the desired test from the Function Menu.

4.6.1 ECU Information

This function retrieves and displays the specific information for the tested

control unit, including unit type, version numbers and other specifications. The

sample ECU Information screen dis pl ays as below:

Figure 4-10 Sample ECU Information Screen

41

Page 49