Page 1

Table of Contents

1 SAFETY PRECAUTIONS AND WARNINGS ..................................................... 1

2 GENERAL INFORMATION ................................................................................... 2

2.1 TPMS SYSTEM REVIEW ..................................................................................... 2

2.2 TPMS LEGISLATION .......................................................................................... 2

2.3 TPMS TELL-TALE LIGHT .................................................................................... 3

2.4 BENEFITS OF TPMS .......................................................................................... 3

3 TOOL INFORMATION ........................................................................................... 4

3.1 TOOL DESCRIPTION ........................................................................................... 4

3.2 SPECIFICATIONS ................................................................................................ 5

3.3 ACCESSORIES INCLUDED ................................................................................... 5

3.4 ICONS ................................................................................................................. 6

3.5 KEYBOARD ........................................................................................................ 6

3.6 BATTERY CHARGING ......................................................................................... 6

4 AUTO SCAN ........................................................................................................... 7

4.1 LF SCAN ............................................................................................................ 8

4.2 DEFLATION SCAN ............................................................................................ 11

4.3 MAGNET SCAN ................................................................................................ 12

4.4 HELP ................................................................................................................ 12

5 SCAN BY MMY ..................................................................................................... 14

5.1 IDENTIFY THE VEHICLE ..................................................................................... 14

5.2 TESTING RESULTS............................................................................................ 15

6 MY TOOL ............................................................................................................... 19

i

Page 2

6.1 UPDATE ........................................................................................................... 19

6.2 SETTINGS ......................................................................................................... 22

6.3 ABOUT ................................ ................................ ................................ ............. 29

7 COMPLIANCE INFORMATION .......................................................................... 31

8 WARRANTY AND SERVICE .............................................................................. 33

8.1 LIMITED ONE YEAR WARRANTY ...................................................................... 33

8.2 SERVICE .......................................................................................................... 33

ii

Page 3

1

Safety Precautions and Warnings

To prevent personal injury or damage to vehicles and/or the scan tool,

read this instruction manual first and observe the following safety

precautions at a minimum whenever working on a vehicle:

Always perform diagnosis or service in a safe environment. Wear safety

eye protection that meets ANSI standards.

Wear safety eye protection that meets ANSI standards.

Keep clothing, hair, hands, tools, test equipment, etc. away from all

moving or hot engine parts.

Operate the vehicle in a well-ventilated work area: Exhaust gases are

poisonous.

Put blocks in front of the drive wheels and never leave the vehicle

unattended while running tests.

Use extreme caution when working around the ignition coil, distributor

cap, ignition wires and spark plugs. These components create

hazardous voltages when the engine is running.

Keep a fire extinguisher suitable for gasoline/chemical/electrical fires

nearby.

Put the transmission in PARK (for automatic transmission) or NEUTRAL

(for manual transmission) and make sure the parking brake is engaged.

Refer to the user’s manual for the vehicle being serviced and adhere to

all diagnostic procedures and precautions. Otherwise personal injury or

unneeded repairs may result.

Keep the scan tool dry, clean, free from oil/water or grease. Use a mild

detergent on a clean cloth to clean the outside of the scan tool, when

necessary.

Keep the TPMS tool dry, clean, free from oil, water and grease. Use a

mild detergent on a clean cloth to clean the outside of the TPMS tool

when necessary.

1

Page 4

2 General Information

2.1 TPMS system review

A tire pressure monitoring system (TPMS) is an electronic system designed

to monitor the air pressure inside the pneumatic tires on various types of

vehicles. TPMS report real-time tire-pressure information to the driver of the

vehicle, either via a gauge, a pictogram display, or a simple low-pressure

warning light. TPMS can be divided into two different types - direct (dTPMS)

and indirect (iTPMS). TPMS are provided both at an OEM (factory) level as

well as an aftermarket solution.

2.2 TPMS Legislation

In the United States, the United States Department of Transportation (NHTSA)

released the FMVSS No. 138, which requires an installation of a Tire

Pressure Monitoring System to all new passenger cars, multipurpose

passenger vehicles, trucks, and buses that have a gross vehicle weight rating

(GVWR) of 4,536 kg (10,000 lbs.) or less, except those vehicles with dual

wheels on an axle, as of 2007. In the European Union, starting November 1,

2012, all new models of passenger cars must be equipped with a TPMS, with

even tighter specifications that will be defined by the UNECE Vehicle

Regulations (Regulation No. 64). From November 1, 2014, all new passenger

cars sold in the European Union must be equipped with TPMS. On July 13,

2010, the South Korean Ministry of Land, Transport and Maritime Affairs

announced a pending partial-revision to the Korea Motor Vehicle Safety

Standards (KMVSS), specifying that "TPMS shall be installed to passenger

vehicles and vehicles of GVW 3.5 tons or less, ... [effective] on January 1,

2013 for new models and on June 30, 2014 for existing models". Japan is

expected to adopt European Union legislation approximately one year after

European Union implementation. Further countries to make TPMS

mandatory include Russia, Indonesia, the Philippines, Israel, Malaysia and

Turkey.

2

Page 5

2.3 TPMS tell-tale light

When diagnosing TPMS systems, you should understand what the TPMS

tell-tale light means.

When turning the ignition OFF to ON, the TPMS tell-tale display and then go

off, indicating the system is working fine. If the light stays on, the tire pressure

may be too low or too high. If the TPMS light flashes, an error exist within the

system. Such an error can be caused by a faulty sensors or by the IDs of the

sensors installed on the tires not matching the registered IDs within the

vehicle ECU.

2.4 Benefits of TPMS

The significant advantages of TPMS are summarized as follows:

Fuel saving.

Extended tire life.

Decreased downtime and maintenance.

Improved safety.

Environmental efficiency.

3

Page 6

3 Tool Information

3.1 Tool Description

Figure 3.1

1) PROTECTIVE BOOT -- Protects the TPMS tool from damage caused by

a fall or by abrasions.

2) LCD DISPLAY -- Indicates test results. 1.77 inch LCD display with 128*160

resolution.

4

Page 7

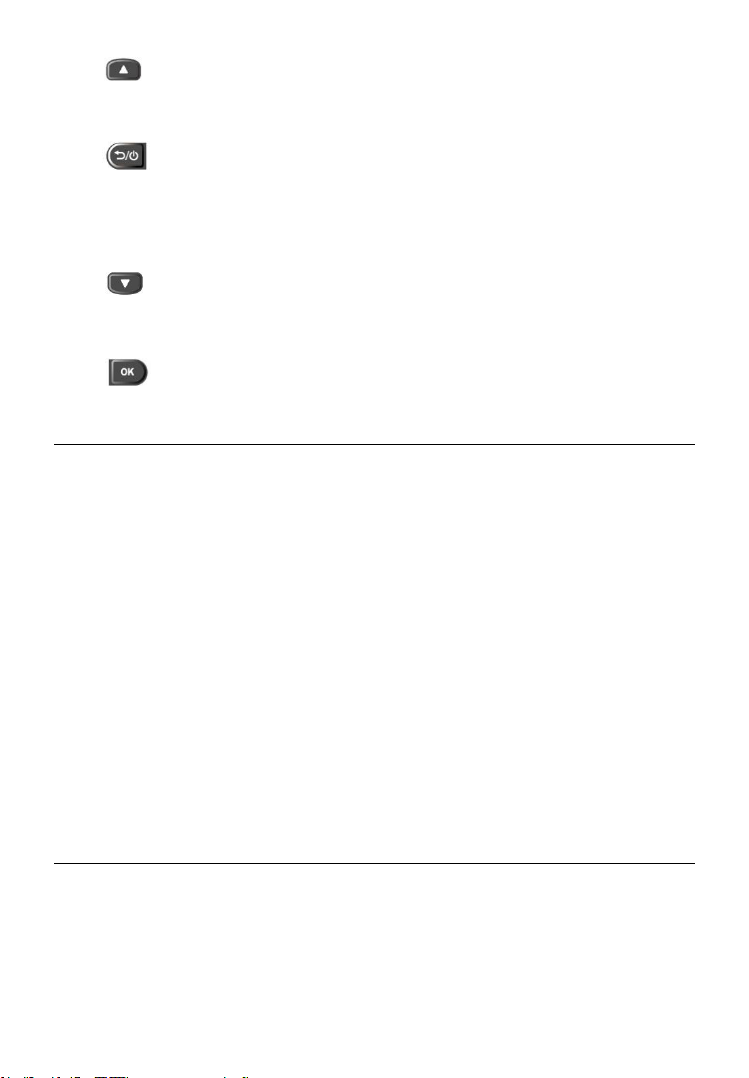

3) UP ARROW BUTTON -- Moves up through menu and submenu

items in menu mode. When more than one set of data are retrieved, use this

button to move down to next screens for additional data.

4) RETURN AND POWER BUTTON -- Cancels a selection (or action)

from a menu or return to previous menu or turns on/off the tool.

5) USB PORT -- Connects the TPMS tool to computer with the supplied USB

cable to update the device or for charging.

6) DOWN ARROW BUTTON -- Moves down through menu and

submenu items in menu mode. When more than one set of data are retrieved,

use this button to move down to next screens for additional data.

7) OK BUTTON -- Confirms a selection (or action) from a menu.

3.2 Specifications

1) Display: 1.77 inch LCD display with 128*160 resolution

2) Power: Rechargeable 3.7V Li-polymer battery

3) Operating Temperature: 0 to 50°C (32 to 122 °F)

4) Storage Temperature: -10 to 60°C (14 to 140 °F)

5) Dimensions:

Length: 155mm (6.10")

Width: 49mm (1.93")

Height: 33mm (1.29")

6) Weight: 134.5g (0.29lb.)

3.3 Accessories Included

1) User’s Manual -- Instructions on tool operations.

2) Quick Guide -- Tool function and software update instructions.

5

Page 8

3) USB Cable -- Allows easy update through PC via internet connection and

charge battery.

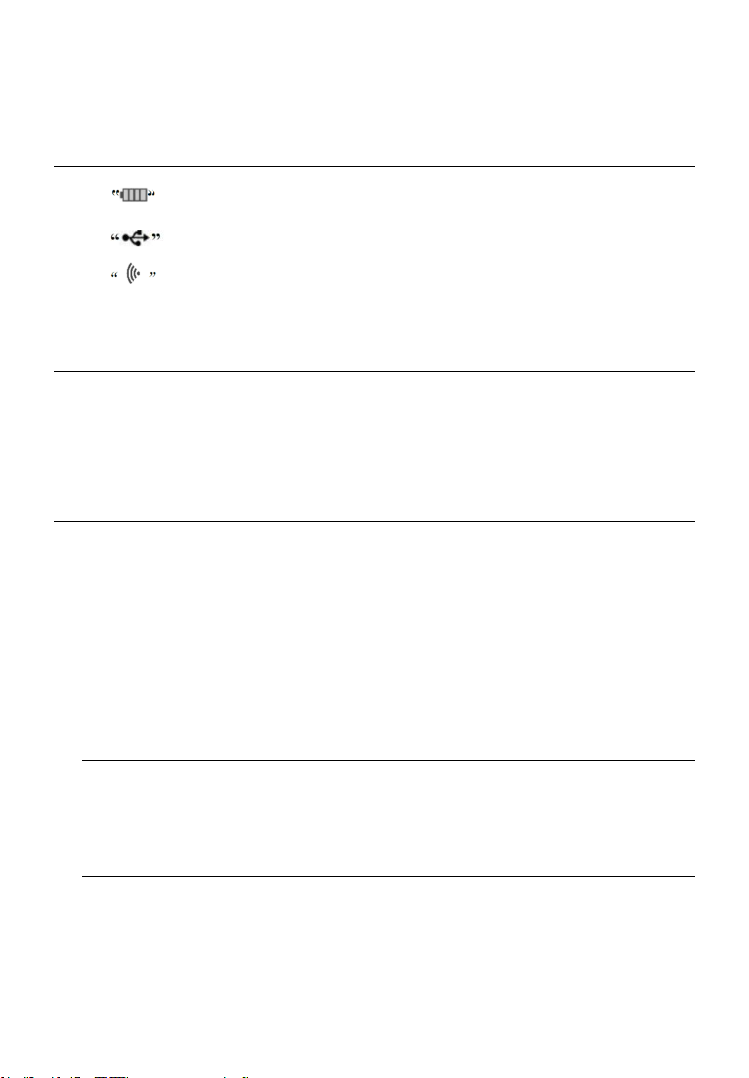

3.4 Icons

1) -- Indicates battery volume.

2) -- Indicates USB communication with the computer is established.

3) -- Indicates the TPMS tool is sending signals to the tire sensor for

activation and test.

3.5 Keyboard

No solvents such as alcohol are allowed to clean the keypad or display. Use

a mild nonabrasive detergent and a soft cotton cloth. Do not soak the keypad

as the keypad is not waterproof.

3.6 Battery Charging

The tool has a 3.7v built-in lithium-ion polymer rechargeable battery.

To charge battery by USB cable

Locate the USB port of the device.

Connect the device and the computer with the USB cable.

For optimum performance, always keep your tool sufficiently charged. It is

recommended that you charge the tool for at least 2 hours before the first use.

NOTE

Only use the USB cable that is included in our pack to charge this tool. The

use of un-approved power supplies may damage your tool and void the tool

warranty.

6

Page 9

4 Auto Scan

The MaxiTPMS® TS201 can automatically trigger the original sensor to

display sensor and tire data by selecting the manufacturer name of the

original sensor. OEM sensors the TS201 can trigger include Schrader, VDO,

TRW, Pacific, Huf/Beru, BAOLONG, etc.

To enter the Auto Scan menu

Turn on the tool. Use the UP or DOWN Arrow button to select Auto Scan

from Main Menu, and press the OK button.

Figure 4.1

There are three options for activating the original sensor: LF (Low

Frequency) Scan, Deflation Scan and Magnet Scan.

7

Page 10

Figure 4.2

4.1 LF Scan

In this function, the tool will send out low frequency (LF) signal to active the

TPMS sensors.

4.1.1 Select sensor’s manufacturer

From the Auto Scan screen, select the manufacturer name or brand of the

original sensor by using the UP and DOWN Arrow buttons. The name of

vehicle manufacturers using these sensors are listed within parenthesis. For

example, GM, Ford, Chrysler and Mercedes often use Schrader (SCH)

sensors.

Figure 4.3

8

Page 11

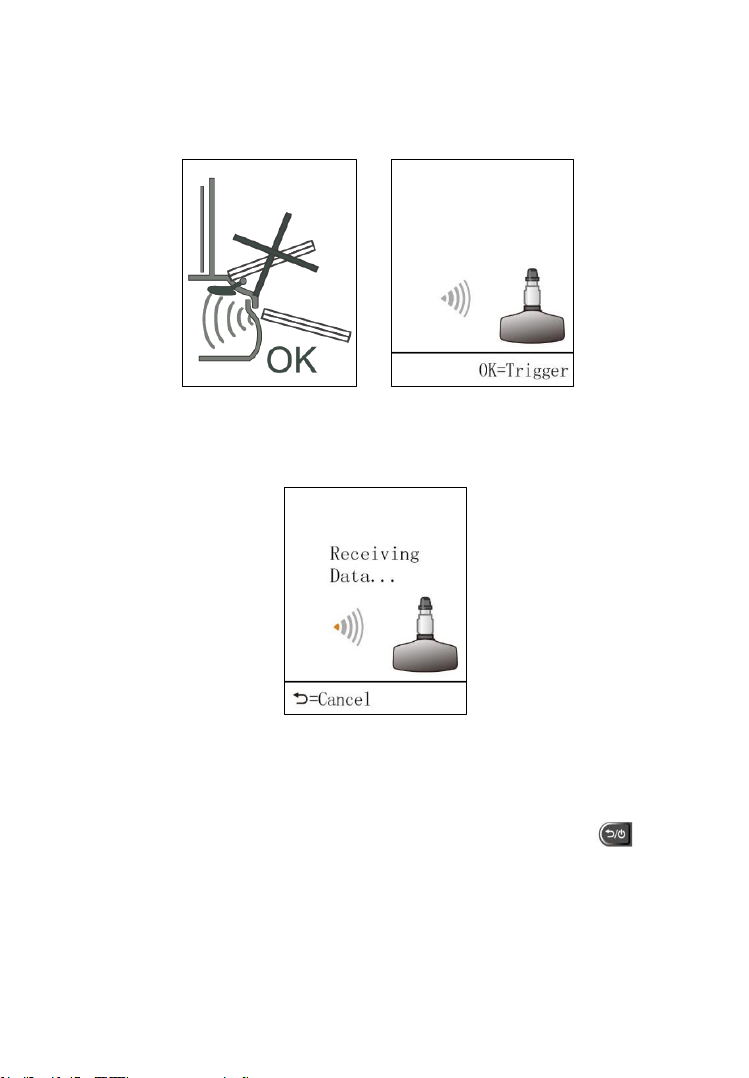

4.1.2 Trigger Process

To trigger or activate the sensor, hold the tool no more than 2 inches from the

sensor or from the tire sidewall (Figure 4.4) and press OK button.

Figure 4.4 Figure 4.5

The tool is receiving data from the sensor.

Figure 4.6

If the sensor is triggered successfully, the screen will display the ID and

battery condition of the original sensor and the associated tire’s pressure and

temperature. Press OK button to re-trigger the sensor or press button

to exit.

9

Page 12

Figure 4.7

“Activation Failed” display when the sensor fails to activate. Press the OK

button to try again. Please contact Autel Support if the tool fails to activate a

sensor you know to be functional.

Figure 4.8

If the activation process is cancelled by the user, the screen displays “User

Aborted”.

10

Page 13

Figure 4.9

TIPS

TS201 may display multiple Make, Mode, Year (MMY) menu options on the

screen after auto scan. The sensor information will be displayed directly

after selecting the specific make, model and year of the vehicle.

4.2 Deflation Scan

For some special vehicles, you may need to use the “Deflation Scan”

method to activate the TPMS sensors. Rapidly deflate (See P↓ on tool

screen) during the entire activation process.

From Auto Scan screen, use the UP or DOWN Arrow button to select

Deflation Scan, and press the OK button. For the detail operation process,

please reference the “Scan By MMY” section on page 14.

Figure 4.10

11

Page 14

4.3 Magnet Scan

Sometimes a magnet is needed when the original sensor is triggered. The

TS201 offers the third method “Magnet Scan” to activate the sensor.

To activate the sensor, put the magnet onto the valve stem and hold the

TS201 no more than 2 inches from the tire sidewall.

Figure 4.11

From Auto Scan screen, use the UP or DOWN Arrow button to select

Magnet Scan, and press the OK button. For the detail operation process,

please reference the “Scan By MMY” section on Page 14.

4.4 Help

This function allows the user to view the explanation about the three methods

for further understanding.

From Auto Scan screen, use the UP or DOWN Arrow button to select

Help, and press the OK button. Wait for the Help screen to display.

12

Page 15

Figure 4.12

13

Page 16

5 Scan By MMY

The MaxiTPMS® TS201 is a handheld tool used to activate TPMS sensors to

view sensor ID, tire pressure, tire temperature and sensor life.

To enter the Scan By MMY menu

Use the UP or DOWN Arrow buttons to select Scan By MMY from Main

Menu (Figure 4.1), and press the OK button.

5.1 Identify the vehicle

Use the UP or DOWN Arrow button to select by make, model and year. Place

the tool alongside the valve stem and press the OK button.

Select by Make

Figure 5.1

14

Page 17

Select by Model

Select by Year

Figure 5.2

Figure 5.3

5.2 Testing results

Activate the sensors in the following order as the tool displays, LF (Left Front),

RF (Right Front), RR (Right Rear), LR (Left Rear) and SPARE (if equipped).

Use the UP or DOWN Arrow button to move to the desired wheel for testing.

15

Page 18

Hold the tool about two inches from the tire sidewall (Figure 4.3) and press

OK button.

Figure 4.3 Figure 5.4

If sensors have been previously activated and there is data saved in the tool,

a Clear Data message displays. Press button to display the sensor

activation menu. Press OK button to clear the previous data.

Figure 5.5

Once the sensor is successfully activated, the tool will display the “√” icon

and tire pressure with an audible beep. If the tire pressure is low, the pressure

16

Page 19

value displays in red. The pressure will display in black if the pressure is at

the recommended level.

Figure 5.6

Use the UP or DOWN Arrow button to select the tested wheel after the sensor

is successfully activated. Press and hold the OK button to display all sensor

data, including the position, sensor ID, tire pressure, temperature and battery

condition. Press the UP or DOWN Arrow button to select sensor on remaining

wheels. Press and hold the OK button to display data or press the

button to return to the previous menu.

Figure 5.7

After a sensor is activated, a test result icon, “√” ,”x”, ”W”, “Dup”, will display

alongside the wheel, indicating the wheel test is completed.

17

Page 20

Icon

Test

Results

Description

√

Successful

Sensor

Read

TPMS sensor is successfully activated and decoded.

The tool displays the sensor information.

X

Failed

Sensor

Read

If the search period expires and no sensor activation

or decode, it may be wrong sensor fitting or nonfunctioning sensor. In this case, repeat test to confirm

the TPMS failure.

W

Wrong

Sensor

Type

A TPMS sensor is activated and decoded, but does

not match the protocol for the Make, Model or Year of

the vehicle. Verify the Make, Model or Year and the

sensor part number.

Dup

Duplicate

ID

A sensor with a duplicate ID has been read. Clear

data and re-read again.

Figure 5.8

TABLE 5-1 POSSIBLE RESULTS FOR TESTING

18

Page 21

6 My Tool

This function allows users to update software, change tool settings and

display tool properties.

To enter the My Tool menu

Use the UP or DOWN Arrow button to select My Tool from Main Menu

(Figure 4.1), and press the OK button to enter the My Tool screen.

Figure 6.1

6.1 Update

This function allows you to update the software on this TPMS tool via your

computer by installing the Maxi PC Suite and attaching the tool to the

computer with the supplied USB cord. Follow the Update the Software

instructions below.

To register the tool

1. Visit the website: http://pro.auteltech.com.

2. On the Sign in page, if you already have an Autel User ID, input the

19

Page 22

account ID and follow the directions displayed.

3. If you do not have an ID, click the Create Autel ID button on the left

side.

4. Enter the required information in the input fields, read through Autel’s

Terms and Conditions and check Agree, click Create Autel ID at the

bottom to continue.

5. The online system will automatically send a confirmation email to the

registered email address. Validate your account by clicking the link

provided through the mail. A product registration screen will display.

6. The TS201’s serial number and password are located on the About

screen of the My Tool menu.

7. Enter the serial number and password on the Product Registration

screen, and click Submit to complete the registration.

To update the software

1. Ensure download the Maxi PC Suite from www.maxitpms.com >

Product > MaxiTPMS TS201 > Downloads, and install it onto your

Windows-based computer. Connect the tool to the computer.

2. Run the Maxi PC Suite on the computer.

3. From the My Tool screen, use the UP or DOWN Arrow button to select

Update. Press the OK button to enter PROGRAM MODE.

Figure 6.2

20

Page 23

4. The Maxi PC Suite will automatically detect the connected tool’s serial

number and display the Update menu.

Figure 6.3

5. On the Updates Available page, click the Update button to continue.

6. When the update is completed, a Program Update End screen will

display on the TPMS tool.

Figure 6.4

21

Page 24

6.2 Settings

The System Setup function allows you to adjust default settings.

To enter the Setting menu

From MY Tool screen, use the UP or DOWN Arrow button to select Setting,

and press the OK button.

Market

TIPS

The default market is dependent on the region in which the tool is sold.

1) From System Setup screen, use the UP or DOWN Arrow button to

select Market, and press the OK button.

Figure 6.5

2) From Market screen, use the UP or DOWN Arrow button to select the

desired market or tool operating region. Press the OK button to save

your selection and return to the previous screen.

22

Page 25

Figure 6.6

TIPS

America market is priority to select for customers who are not in European

and American areas.

Language

TIPS

English is the default language.

1) From System Setup screen, use the UP or DOWN Arrow button to

select Language, and press the OK button.

Figure 6.7

2) From Language screen, use the UP or DOWN Arrow button to select

the desired language and press the OK button to save your selection

23

Page 26

and return to the previous screen. Currently, four language options are

available.

Figure 6.8

ID Format

1) From System Setup screen, use the UP or DOWN Arrow button to

select ID Format, and press the OK button.

Figure 6.9

2) From ID Format screen, use the UP or DOWN Arrow button to select

the desired format of ID.

24

Page 27

Figure 6.10

3) Press the OK button to save your settings and return to previous menu,

or press the button to exit without change.

Pressure Unit

1) From System Setup screen, use the UP or DOWN Arrow button to

select Pressure Unit, and press the OK button.

Figure 6.11

25

Page 28

2) From Pressure Unit screen, use the UP or DOWN Arrow button to select

the desired unit: Kpa, Psi or Bar.

Figure 6.12

3) Press the OK button to save your settings and return to previous menu,

or press the button to exit without change.

Temperature Unit

1) From System Setup screen, use the UP or DOWN Arrow button to

select Temperature Unit, and press the OK button.

Figure 6.13

26

Page 29

2) From Temperature Unit screen, use the UP or DOWN Arrow button to

select the desired temperature unit in degree Celsius or Fahrenheit.

Figure 6.14

3) Press the OK button to save your settings and return to previous menu,

or press the button to exit without change.

Beep Set

This function allows you to turn on/off the build-in speaker for key pressing.

1) From System Setup screen, use the UP or DOWN Arrow button to

select Beep Set, and press the OK button.

Figure 6.15

27

Page 30

2) From Beep Set menu, use the UP or DOWN Arrow button to select OFF

or ON to turn the beep sound off or on.

Figure 6.16

3) Press the OK button to save your settings and return to previous menu,

or press the button to exit without change.

Power Off

1) From System Setup screen, use the UP or DOWN Arrow button to

select Power Off, and press the OK button.

Figure 6.17

28

Page 31

2) From Power Off screen, use the UP or DOWN Arrow button to increase

or decrease the amount of time of inactivity before the tool automatically

powers off. Press the OK button to confirm your change or the button

to cancel and return to the previous menu.

Figure 6.18

NOTE

Before the tool powers off automatically, it will save all the TPMS test data. This

data will be available when the tool is next turned on.

When using external power, the tool stays on until you turn it off. When using

internal battery power, the tool turns off automatically after a set time of inactivity.

6.3 About

This function allows user to view some important information about the tool,

such as its serial number, password, software version and hardware version.

1. From MY Tool screen, use the UP or DOWN Arrow button to select

About, and press the OK button. Wait for the About screen to display.

29

Page 32

Figure 6.19

2. View tool information on screen. Press OK or button to exit

without saving.

Figure 6.20

30

Page 33

7 Compliance Information

FCC STATEMENT:

This device complies with Part 15 of the FCC Rules. Operation is subject to

the following two conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received, including interference

that may cause undesired operation.

WARNING

Changes or modifications not expressly approved by the party responsible

for compliance could void the user’s authority to operate the equipment.

NOTE

This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference in a

residential installation.

This equipment generates uses and can radiate radio frequency energy and,

if not installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following

measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

31

Page 34

8 Warranty and Service

8.1 Limited One Year Warranty

Autel warrants to its customers that this product will be free from all defects

in materials and workmanship for a period of one (1) year from the date of

the original purchase, subject to the following terms and conditions:

1) The sole responsibility of Autel under the Warranty is limited to either the

repair or, at the option of Autel, replacement of the TPMS tool at no

charge with Proof of Purchase. The sales receipt may be used for this

purpose.

2) This warranty does not apply to damage due directly or indirectly, to

misuse, abuse, negligence or accidents, repairs or alterations outside

our Service Center or facilities, criminal activity, improper installation,

normal wear and tear, or to lack of maintenance.

3) Autel shall not be liable for any incidental or consequential damages

arising from the use, misuse, or mounting of the TPMS tool. Some states

do not allow limitations on how long an implied warranty lasts, so the

above limitations may not apply to you.

4) All information in this manual is based on the latest information available

at the time of publication and no warranty can be made for its accuracy

or completeness. Autel reserves the right to make changes at any time

without notice.

8.2 Service

If you have any questions, please contact your local distributor or visit our

website at www.autel.com, www.maxitpms.com, or mail to

supporttpms@auteltech.com ask for some help.

33

Page 35

If it becomes necessary to return the tool for repair, contact your local

distributor for more information.

34

Loading...

Loading...