Page 1

Trademarks

Autel®,MaxiSys®,MaxiDAS®, MaxiScan®, MaxiCheck®, MaxiRecorder®,

and MaxiCheck

registered in China, the United States and other countries. All other marks

are trademarks or registered trademarks of their respective holders.

®

are trademarks of Autel Intelligent Technology Corp., Ltd.,

Copyright Information

No part of this manual may be reproduced, stored in a retrieval system or

transmitted, in any form or by any means, electronic, mechanical,

photocopying, recording, or otherwise without the prior written permission

of Autel.

Disclaimer of Warranties and Limitation of Liabilities

All information, specifications and illustrations in this manual are based on

the latest information available at the time of printing.

Autel reserves the right to make changes at any time without notice. While

information of this manual has been carefully checked for accuracy, no

guarantee is given for the completeness and correctness of the contents,

including but not limited to the product specifications, functions, and

illustrations.

Autel will not be liable for any direct, special, incidental, indirect damages

or any economic consequential damages (including the loss of profits).

IMPORTANT

Before operating or maintaining this unit, please read this manual carefully,

paying extra attention to the safety warningsandprecautions.

For Services and Support

pro.autel.com

www.autel.com

1-855-288-3587/1-855-AUTELUS (North America)

0086-755-86147779 (China)

support@autel.com

For technical assistance in all other markets, please refer to Service and

Support section in this manual.

i

Page 2

Safety Information

For your own safety and the safety of others, and to prevent damage to the

device and vehicles upon which it is used, it is important that the safety

instructions presented throughout this manual be read and understood by

all persons operating or coming into contact with the device.

There are various procedures, techniques, tools, and parts for servicing

vehicles, as well as in the skilloftheperson doing the work. Because of the

vast number of test applications and variations in the products that can be

tested with this equipment, we cannot possibly anticipate or provide advice

or safety messages to cover every circumstance. It is the automotive

technician’s responsibility to be knowledgeable of the system being tested.

It is crucial to use proper service methods and test procedures. It is

essential to perform tests in an appropriate and acceptable manner that

does not endanger your safety, the safety of others in the work area, the

device being used, or the vehicle being tested.

Before using the device, always refer to and follow the safety messages

and applicable test procedures provided by the manufacturer of the vehicle

or equipment being tested. Use the device only as described in this manual.

Read, understand, and follow all safety messages and instructions in this

manual.

Safety Messages

Safety messages are provided to help prevent personal injury and

equipment damage. All safety messages are introduced by a signal word

indicating the hazard level.

DANGER

Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury to the operator or to bystanders.

WARNING

Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury to the operator or to bystanders.

ii

Page 3

Safety Instructions

The safety messages herein cover situations Autel is aware of. Autel

cannot know, evaluate or advise you as to all of the possible hazards. You

must be certain that any condition or service procedure encountered does

not jeopardize your personal safety.

DANGER

When an engine is operating, keep the service area WELL VENTILATED

or attach a building exhaust removal system to the engine exhaust system.

Engines produce carbon monoxide, an odorless, poisonous gas that

causes slower reaction time and can lead to serious personal injury or loss

of life.

SAFETY WARNINGS

Always perform automotive testing in a safe environment.

Wear safety eye protection that meets ANSI standards.

Keep clothing, hair, hands, tools, test equipment, etc. away from all

moving or hot engine parts.

Operate the vehicle in a well-ventilated work area, for exhaust gases

are poisonous.

Put the transmission in PARK (for automatic transmission) or

NEUTRAL (for manual transmission) and make sure the parking brake

is engaged.

Put blocks in front of the drive wheels and never leave the vehicle

unattended while testing.

Be extra cautious when working around the ignition coil, distributor cap,

ignition wires and spark plugs. These components create hazardous

voltages when the engine is running.

Keep a fire extinguisher suitable for gasoline, chemical, and electrical

fires nearby.

Do not connect or disconnect any test equipment while the ignition is

on or the engine is running.

Keep the test equipment dry, clean, free from oil, water or grease. Use

a mild detergent on a clean cloth to clean the outside of the equipment

as necessary.

iii

Page 4

Do not drive the vehicle and operate the test equipment at the same

time. Any distraction may cause an accident.

Refer to the service manual for the vehicle being serviced and adhere

to all diagnostic procedures and precautions. Failure to do so may

result in personal injury or damage to the test equipment.

To avoid damaging the test equipment or generating false data, make

sure the vehicle battery is fully charged and the connection to the

vehicle DLC is clean and secure.

Do not place the test equipment on the distributor of the vehicle.

Strong electro-magnetic interference can damage the equipment.

iv

Page 5

CONTENTS

SAFETY MESSAGES....................................... .................................... .........................II

SAFETY INSTRUCTIONS

1 USING THIS MANUAL

C

ONVENTIONS............................................................................................................1

Bold Text

...................................................................................................... .........

Notes and Important Messages

Hyperlink.......................................................................... .....................................2

Illustrations

...................................................................................................... .....

2 GENERAL INTRODUCTION

F

UNCTIONAL DESCRIPTION......................................................... ..............................3

TECHNICAL SPECIFICATIONS

IRELESS COMMUNICATION

W

POWER SOURCE..................................................................... ...................................5

3 GETTING STARTED

POWERING UP

...................................................................................................... ......

NAVIGATION BUTTONS..............................................................................................8

4EOBD

5 SERVICE

...................................................................................................... ....................

...................................................................................................... .............

O

IL RESET SERVICE................................. .................................... ...........................11

ELECTRONIC PARKING BRAKE (EPB) SERVICE

EPB Safety

...................................................................................................... ...

BMS.........................................................................................................................13

Register Battery Replacement

STEERING ANGLE SENSOR (SAS) SERVICE

DPF SERVICE.................................... .................................... ..................................15

TIRE PRESSURE MONITOR SYSTEM (TPMS) SERVICE

IMMO S

ERVICE

6HISTORY................................... ..................................................................... ...........18

...................................................................................................... .........................

7ME

.............................................................................................

..............................................................................................

.......................................................................

....................................................................................

.....................................................................................

.....................................................................................

.................................................................................................

...................................................

.......................................................................

.........................................................

.......................................

...................................................................................................... .

10

11

12

12

13

14

16

16

19

III

1

1

1

2

3

4

5

6

6

v

Page 6

EGISTER.................................................................................................................19

R

...................................................................................................... ................

LOG IN

EPAIR REPORTS

R

....................................................................................................

19

20

VCI CONNECTION.................................................. .................................... ..............21

APPS UNINSTALL

RDER MANAGEMENT

O

.....................................................................................................

.............................................................................................

21

22

VCI MANAGEMENT....................................... .................................... .......................22

DATA LOGGING

ETTINGS

S

..................................................................................................... ...

..................................................................................................... ............

22

23

Unit................................................... ...................................................................23

User Guide

About

U

SER MANUAL.........................................................................................................24

8 PRODUCT TROUBLESHOOTING

VEHICLE LINKING ERROR

...................................................................................................... ...

...................................................................................................... .............

.......................................................................

........................................................................................

23

24

25

25

9 COMPLIANCE INFORMATION............................................................... ............. 26

10 WARRANTY AND SERVICE

LIMITED ONE YEAR WARRANTY

...............................................................................

.............................................................................

28

28

This warranty does not apply to:....................................................................28

SERVICE AND SUPPORT

..........................................................................................

29

vi

Page 7

1

Using This Manual

This manual contains device usage instructions.

Some illustrations shown in this manual may contain modules and optional

equipment that are not included in your system. Contact your sales

representative for availability of other modules and optional tools or

accessories.

Conventions

The following conventions are used.

Bold Text

Bold text is used to highlight selectable items such as buttons and menu

options.

Example:

Tap OK.

Notes and Important Messages

Notes

A NOTE provides helpful information such as additional explanations, tips,

and comments.

Example:

NOTE

New batteries reach full capacity after approximately 3 to 5 charging and

discharging cycles.

1

Page 8

Important

IMPORTANT indicates a situation which, if not avoided, may result in

damage to the test equipment or vehicle.

Example:

IMPORTANT

Keep the cable away from heat, oil, sharp edges and moving parts.

Replace damaged cables immediately.

Hyperlink

Hyperlinks, or links, that take you to other related articles, procedures, and

illustrations are available in electronic documents. Blue italic text indicates

a selectable hyperlink and blue underlined text indicates a website link or

an email address link.

Illustrations

Illustrations used in this manual are samples, the actual testing screen may

vary for each vehicle being tested. Observe the menu titles and on-screen

instructions to make correct option selection.

2

Page 9

2

General Introduction

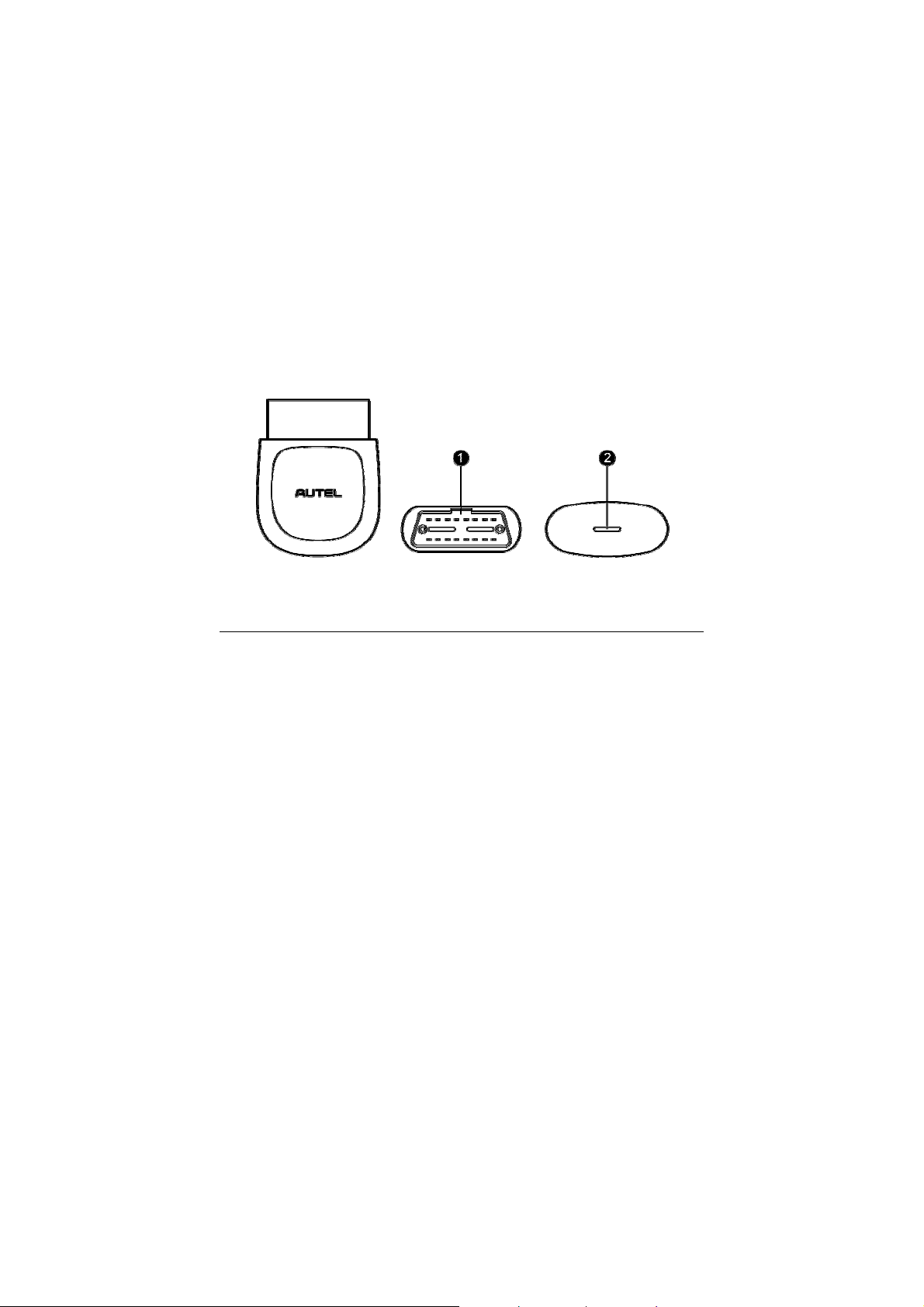

The wireless diagnostic interface MaxiAP AP200 is a small interface

adapter used to connect to a vehicle’s diagnostic connector (DLC) and

connect wirelessly with the iOS or Android devices for vehicle data

transmission, making your iOS or Android devices (hereinafter referred to

as device or devices) into a powerful diagnostic tool.

The MaxiAP AP200 package includes a Bluetooth (BT) OBDII connector

and a MaxiAP200 app. It is the perfect Do-It-Yourself tool for customers

looking for quick and easy OBDII as well as vehicle-specific diagnostic

functions. It is almost compatible with all European, Asian, and U.S.

international vehicle models.

Figure 2- 1 Product View

Functional Description

1. Vehicle Data Connector (16-pin) – connects the MaxiAPAP200 to the

vehicle’s 16-pin DLC directly.

2. Power LED – indicates system status.

The power LED displays green, blue, red depending on power level and

operating state.

3

Page 10

A. Green

Lights solid green when the MaxiAP AP200 is plugged in and not

connected with the device.

B. Blue

Lights solid blue when the device is connected with the MaxiAP

AP200 via Bluetooth.

Flashes blue when the device is communicating with the MaxiAP

AP200, for example, when the device is reading Engine DTCs.

C. Red

Lights solid red when the MaxiAP AP200 is updating the firmware

or when the update failed.

NOTE

When the MaxiAP AP200 has lost connection from the device for more

than 10 minutes, the LED goes off and the AP200 enters power saving

standby mode. The power LED will light when reconnected.

Technical Specifications

Table 2- 1 Specifications

Item Description

Communications BT3.0 + BT4.0

Wireless Frequency 2.4 GHz

Input Voltage Range 9VDCto26VDC

Supply Current 100 mA@12 V

Sleep Mode Current 3mA@12V

Operating Temp. 0°C to 50°C

Storage Temp. -20°C to 70°C

4

Page 11

Dimensions (L * W *H)59.2 mm (2.33’’) * 48.5 mm (1.91’’) * 24.6 mm

(0.97’’)

Weight 35g (0.07 lb.)

Wireless Communication

The MaxiAP AP200 uses BT communication. It can transmit vehicle data to

your iOS or Android devices without a physical connection. The working

range for BT communication is about 33 feet (about 10 m). Signal lost due

to moving out of range will automatically be restored once the device is

brought within transmission range to the MaxiAP AP200 connector.

Power Source

The MaxiAP AP200 operates on 12-volt vehicle power that it receives

through the vehicle data connection port. The unit powers on whenever it is

connected to an OBDII/ EOBD compliant data link connector (DLC).

5

Page 12

3

Getting Started

NOTE

The images and illustrations depicted in this manual may differ from the

actual ones. The user interface for iOS and Android devices might be

slightly different.

Powering Up

1. Download & installation

Search for MaxiAP200 in APP Store or Google Play to download

and install the app to your device.

Or scan the QR code to download the MaxiAP200 app.

2. Register & login

Open the MaxiAP200 app and click Register near the top right.

Follow the on-screen instructions to complete the registration.

Log in with the registered email address and password.

NOTE

You can log i n with your registered Autel user ID if you already have one.

3. Plug the connector of the MaxiAP200 tool into the vehicle’s Data Link

Connector (DLC).

The vehicle’s DLC is generally located under the vehicle dash.

6

Page 13

4. Turn the ignition to Key On, Engine Off position.

The LED on AP200 illuminates solid green.

5. VCI Connection

Tap Me > VCI Connection or the VCI button near the top right of the

Home screen. Tap the Bluetooth name of the MaxiAP AP200 tool to

pair it with the device. The Bluetooth name starts with AP, followed by

the serial number of the tool.

Ensure the device’s Bluetooth is turned on.

When the device is successfully paired with the tool, you will hear

a beep sound and the LED on the tool illuminates solid blue.

Check if the communication status turns to VCI connected. Tap

Done near the top left to return to the Home screen.

NOTE

For IOS devices, pair the MaxiAP AP200 tool with the device via Settings >

Bluetooth and then go back to the app.

6. Bind VCI

Tap Me > VCI Management. Scan the QR code on the MaxiAP AP200

tool to put in the serial number. Check if the email information is

correct. Tap Bind to bind VCI.

7. Your MaxiAP200 app is now ready for use.

Tap Mall to purchase vehicle-specific software.

7

Page 14

Figure 3-1 Sample MaxiAP200 Job Menu

8. The table below briefly describes each of the applications in theAP200

system.

Table 3- 1 Applications

Button Name Description

Eobd Accesses EOBD/OBDII diagnostic functions.

Service Accesses 19 service functions.

History

Accesses diagnosis and service records with

vehicle information and DTCs included.

Navigation Buttons

Operations of the Navigation buttons at the bottom of the screen are

described in the table below:

8

Page 15

Table 3- 2 Navigation Buttons

Button Name Description

Home Returnsto the Home screen.

Mall Displays software programs available

Displays list of functions, including Repair

Me

Reports, VCI Connection, Uninstall Vehicle

Software, Order Management, VCI

Management, Settings and User Manual

9

Page 16

4

n

Eobd

This option provides EOBD/OBDII diagnostic functions for vehicles. read

and clear pending, stored and permanent codes for European, Asian, and

U.S. OBDII/EOBD compatible vehicles, 1996 and newer.

It can also read and clear enhanced codes for engine and transmission

systems of GM, Chrysler, and Ford vehicles. Autel provides regular

updates for this app that will expand vehicle coverage and access to

available modules.

Tap > to view the details of a specific DTC (Diagnostic Trouble Codes). At

the bottom of the DTC Details screen, you can also tap the Previous or

Next button to view the details of the previous or next DTC. Or tap the

snowflake button at the bottom middle of the screen to view the freeze

Figure 4- 1 Sample Eobd Funcion Scree

frame of the specific DTC, if available.

10

Page 17

5

Service

The Service section is specially designed to provide you with quick access

to the vehicle systems for various scheduled service and maintenance

performances. The typical service operation screen is a series of menu

driven executive commands. By following the on-screen instructions to

select appropriate execution options, enter correct values or data, and

perform necessary actions, the system will guide you through the complete

performance for various service operations.

The most commonly performed service functions include:

Oil Reset Service

EPB Service

BMS Service

SAS Service

DPF Service

TPMS Service

IMMO Service

After entering each special function, the displayed screen consists of two

applications: Diagnosis and Hot Functions.TheDiagnosis is for you to

read/clear data since this is necessary after some special functions. Hot

Functions consists of sub functions of the selected special function.

Oil Reset Service

This function allows you to perform reset for the Engine Oil Life system,

which calculates an optimal oil life change interval depending on the

vehicle driving conditions and climate. The Oil Life Reminder must be reset

every time the oil is changed, so the system can calculate when the next oil

change is required.

11

Page 18

IMPORTANT

Always reset the engine oil life to 100% after every oil change.

NOTE

All required work must be carried out before the service indicators are reset.

Failure to do so may result in incorrect service values and cause DTCs to

be stored by the relevant control module.

Electronic Parking Brake (EPB) Service

This function has a multitude of usages to maintain the electronic braking

system safely and effectively. The applications include deactivating and

activating the brake control system, assisting with brake fluid control,

opening and closing brake pads, and setting brakes after disc or pad

replacement, etc.

EPB Safety

It may be dangerous to perform Electronic Parking Brake (EPB) system

maintenance, so before you begin the service work, please keep these

rules i n mind.

Ensure that you are fully familiar with the braking system and its

operation before commencing any work.

The EPB control system may be required to be deactivated before

carrying out any maintenance/diagnostic work on the brake system.

This can be done from the tool menu.

Only carry out maintenance work when the vehicle is stationary and on

level ground.

Ensure that the EPB control system is reactivated after the

maintenance work has been completed.

NOTE

Autel accepts no responsibility for any accident or injury arising from the

maintenance of the Electronic Parking Brake system.

12

Page 19

BMS

The BMS (Battery Management System) allows the scan tool to evaluate

the battery charge state, monitor the close-circuit current, register the

battery replacement, and activate the rest state of the vehicle.

NOTE

1. This function is not supported by all vehicles. The screens shown in

this section are examples.

2. The sub functions and actual test screens of the BMS may vary for

different test vehicles, please follow the on-screen instructions to make

correct option selection.

The vehicle may use either a sealed lead-acid battery or an AGM

(Absorbed Glass Mat) battery. Lead acid battery contains liquid sulphuric

acid and can spill when overturned. AGM battery (known as VRLA battery,

valve regulated lead acid) also contains sulphuric acid, but the acid is

contained in glass mats between terminal plates.

It is recommended that the replacement aftermarket battery has the same

specifications, such as capacity and type, with the battery used in the

vehicle. If the original battery is replaced with a different type of battery (e.g.

a lead-acid battery is replaced with an AGM battery) or a battery with a

different capacity (mAh), the vehicle may require reprogramming the new

battery type in addition to performing the battery reset. Consult the vehicle

manual for additional vehicle-specific information.

Register Battery Replacement

This option allows displaying the mileage reading of last battery

replacement, registering the battery replacement after replacing a new

battery and informing the power management system that a new battery

has been fitted to the vehicle.

If the battery change is not registered, the power management system will

not function properly, which may not provide the battery with enough

charging power to operate the car and limit the functions of individual

electrical equipment.

13

Page 20

Steering Angle Sensor (SAS) Service

Steering Angle Sensor Calibration permanently stores the current steering

wheel position as the straight-ahead position in the steering angle sensor

EEPROM. Therefore, the front wheels and the steering wheel must be set

exactly to the straight-ahead position before calibration. In addition, the

vehicle identification number is also read from the instrument cluster and

stored permanently in the steering angle sensor EEPROM. On successful

completion of calibration, the steering angle sensor fault memory is

automatically cleared.

Calibration must always be carried out after the following operations:

Steering wheel replacement

Steering angle sensor replacement

Any maintenance that involves opening the connector hub from the

steering angle sensor to the column

Any maintenance or repair work on the steering linkage, steering gear

or other related mechanism

Wheel alignment or wheel track adjustment

Accident repairs where damage to the steering angle sensor or

assembly, or any part of the steering system may have occurred

NOTE

1. AUTEL accepts no responsibility for any accident or injury arising from

servicing the SAS system. When interpreting DTCs retrieved from the

vehicle, always follow the manufacturer’s recommendation for repair.

2. All software screens shown in this manual are examples, actual test

screens may vary for each vehicle being tested. Observe the menu

titles and on-screen instructions to make correct option selections.

3. Before starting the procedure, make sure the vehicle has ESC. Look

for the button on dash.

14

Page 21

DPF Service

The DPF function allows you to carry out numerous functions to the Diesel

Particulate Filter system without having to send your car to a main dealer.

The tool will manage DPF regeneration, DPF component replacement

teach-in and DPF teach-in after replacing the engine control unit.

ECM monitors driving style and selects a suitable time to employ

regeneration. Cars driven a lot at idling speed and low load will attempt to

regenerate earlier than cars driven more with high load and high speed. In

order for regeneration to take place, a prolonged high exhaust temperature

must be obtained.

In the event of the car being driven in such a way that regeneration is not

possible, i.e. frequent short journeys, a diagnostic trouble code will

eventually be registered, DPF light and “Check Engine” indicator comes on.

A service regeneration can be requested in the workshop, using the

diagnostic tool.

Before carrying out a forced DPF regeneration using the tool, check the

following items:

The fuel light is not on.

No DPF-relevant faults stored in system.

The vehicle has the correct spec engine oil.

The oil for diesel is not contaminated.

IMPORTANT

Before diagnosing a problem vehicle and attempting to perform an

emergency regeneration, it is important to obtain a full diagnostic log and

read out relevant measured value blocks.

NOTE

1. The DPF will not regenerate if the engine management light is on, or

there is a faulty EGR valve.

2. The ECU must be re-adapted when replacing the DPF and when

topping up the fuel additive Eolys.

15

Page 22

3. If the vehicle needs to be driven in order to perform a DPF service,

ALWAYS have a second person help you. One person should drive

the vehicle while the other person observes the screen on the Tool.

Trying to drive and observe the Scan Tool at the same time is

dangerous, and could cause a serious traffic accident.

Tire Pressure Monitor System (TPMS) Service

This function allows you to quickly look up the tire sensor IDs from the

vehicle’s ECU, as well as to perform TPMS replacement and sensor test.

Take Tire pressure sensor replacement (Front left wheel sensor) as an

example.

NOTE

During this application the wheel unit 8 digit identifications will need to be

entered using the screen displayed.

The sensor identifications can be accessed by reading directly from the

wheel unit or by using the identification reading tool.

On completion, a specific road test will be required followed by the tire

pressure monitor system application.

IMMO Service

An immobilizer is an anti-theft mechanism that prevents an automobile’s

engine from starting unless the correct ignition key or other device is

present. This device prevents thieves from starting the car by a method

known as hot wiring. Most new vehicles have an immobilizer as standard

equipment. An important advantage of this system is that it doesn’t require

the car owner to activate it; it operates automatically. An immobilizer is

considered as providing much more effective anti-theft protection than an

audible alarm alone; many auto insurance companies offer lower rates for

vehicles that are equipped with them.

16

Page 23

As an anti-theft device, an immobilizer disables one of the systems needed

to start a car's engine, usually the fuel supply or the ignition. This is

accomplished by radio frequency identification between a transponder in

the ignition key and a device called a radio frequency reader in the steering

column. When the key is placed in the ignition, the transponder sends a

signal with a unique identification code to the reader, which relays it to a

receiver in the vehicle's computer control module. If the code is correct, the

computer allows the fuel supply and ignition systems to operate and start

the car. If the code is incorrect or absent, the computer disables the system,

and the car will be unable to start until the correct key is placed in the

ignition.

The IMMO service of MX808 enables you to disable the lost vehicle keys

and program the replacement key fob. It could be one replacement key fob

or more, depending on your needs.

To program the replacement key fob(s)

1. Tap IMMO KEYS after entering the Service function from the

MaxiCheck Job Menu.

2. Tap Automatic Selection or Manual Selection to acquire vehicle

VIN information and tap Yes to confirm.

3. Tap Erase/Program all key fobs in the IMMO function list after it

is displayed, the list may vary for different vehicles being tested.

NOTE

1) To complete key fob programming, you need to acquire the Security

Code, which can be acquired through the Security Code Read function

in hot functions.

2) Before programming, please check and erase the fault codes.

17

Page 24

6

History

This function stores records of test vehicle history, including vehicle

information and the retrieved DTCs from previous diagnostic sessions, and

displays all information in an easy-to-check table list, on which you can view

summarized details and manually input other information about the test vehicle

and diagnostic loggings, etc. The Vehicle History also provides direct access

to the previously tested vehicle and allows you to restart a diagnostic session

without the need to do vehicle identification again.

18

Page 25

7

Me

Register

1. Tapthe Register button on the Me screen.

2. Enter the email address, verification code and password on the

register screen. Tap the Verification code button and an email will be

sent to your address.

3. TapRegister to complete the registration.

Figure 14- 1 Sample Register Screen

Log in

After registering the tool, log in with your registered email and password. If

you forget the password, you can tap the Forget password? button to

19

Page 26

Figure 14-2 Sample Log in Screen

retrieve it.

Repair Reports

The MaxiAP AP200 app automatically saves a repair report for each

diagnostic session. Based on the trouble codes found in the specific

vehicle, a repair report contains the definition of the DTCs (stored, pending,

permanent codes and manufacture-specific codes) and possible causes. A

PDF can also be generated for easy viewing, sharing, and printing.

20

Page 27

To create a repair report, tap Read DTCs,tap“I” next to a trouble code on

iOS devices or “>” on Android devices. The repair report is saved under

Figure 12- 1 Sample Repair Reports Screen

Saved Reports on the Me screen.

VCI Connection

Through this option you can do VCI Connection. Tap the Bluetooth name of

the MaxiAP AP200 to pair with the device. When the device is successfully

paired and communicating with the MaxiAP AP200, the LED on the

MaxiAP AP200 lights solid blue. Tap Done on the VCI Management screen

to return to the Me Screen. Your MaxiAP AP200 is now ready.

Apps Uninstall

Tap the Apps Uninstall option, a list of installed Apps will display.There is

an uninstall button on the right side of each App. Tap the corresponding

button to uninstall unwanted Apps.

21

Page 28

Order Management

This function can help you manage orders efficiently.

VCI Management

Tap the VCI Management, the status of VCI connection will display. Below

the status picture, there is a list of connectable BT devices and the word

“paired” and “unpaired” show connection status of each BT devices.

Figure 14- 3 Sample VCI Management Screen

Data Logging

Coming soon.

22

Page 29

Settings

Select the Settings application to open a setup screen to adjust the default

setting and view information about the MaxiAP AP200 system. There are

three system settings.

Unit

User Guide

About

Figure 14-4 Sample Settings Screen

Unit

This option allows you to adjust the measurement unit for the diagnostic

system. You can tap Imperial or Metric to switch between these two

measurement units.

User Guide

Instructions of how to use this app.

23

Page 30

About

About displays the following information, current version of the app, Eobd

version, Privacy Policy & Terms of Use. Tap Privacy Policy & Terms of

Use to view detailed information.

Figure 14-5 Sample About Screen

User Manual

This option allows you to view the User Manual of MaxiAP AP200. The

user manual contains safety instructions, operation instructions, product

troubleshooting, and service and support information.

24

Page 31

8

Product Troubleshooting

This chapter describes problems that you may encounter while using the

MaxiAP AP200.

Vehicle Linking Error

A communication error occurs if the MaxiAP AP200 fails to communicate

with the vehicle’s control module when performing diagnostic procedures.

Please do the following check-ups:

Verify that the ignition is ON.

Check that the MaxiAP AP200 connector is securely connected to the

vehicle’s DLC.

Turn the ignition off and wait for about 10 seconds.Then turn the

ignition back on and continue the operation.

Verify the control module is not defective.

25

Page 32

9

Compliance Information

FCC COMPLIANCE FCC ID:

This device complies with Part 15 of the FCC Rules and with RSS-210 of

Industry Canada. Operation is subject to the following two conditions:

1 This device may not cause harmful interference.

2 This device must accept any interference received, including

interference that may cause undesired operation.

WARNING

Changes or modifications not expressly approved by the party responsible

for compliance would void the user’s authority to operate the equipment.

NOTE

This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

in a residential installation.

This equipment generates uses and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following

measures: ⅰ. Reorient or relocate the receiving antenna. ⅱ. Increase the

separation between the equipment and receiver. ⅲ . Connect the

equipment into an outlet on a circuit different from that to which the receiver

is connected. ⅳ. Consult the dealer or an experienced radio/TV technician

for help.

26

Page 33

FCC Radiation Exposure Statement:

This equipment complies with FCC radiation exposure limits set forth for an

uncontrolled environment. This equipment should be installed and

operated with minimum distance 20cm between the radiator & your body.

RoHS COMPLIANCE

This device is declared to be in compliance with the European RoHS

Directive 2011/65/EU.

CE COMPLIANCE

This product is declared to conform to the essential requirements of the

following Directives and carries the CE mark accordingly:

EMC Directive 2014/30/EU

R&TTE Directive 1999/5/EC

Low Voltage Directive 2014/35/EU

27

Page 34

10

Warranty and Service

Limited One Year Warranty

Autel Intelligent Technology Corp., Ltd. (the Company) warrants to the

original retail purchaser of this Autel device that should this product or any

part thereof during normal usage and under normal conditions be proven

defective in material or workmanship that results in product failure within

one year from the date of purchase, such defect(s) will be repaired, or

replaced (with new or rebuilt parts) with Proof of Purchase, at the

Company’s option, without charge for parts or labor directly related to the

defect(s).

The Company shall not be liable for any incidental or consequential

damages arising from the use, misuse, or mounting of the device. Some

states do not allow limitation on how long an implied warranty lasts, so the

above limitations may not apply to you.

This warranty does not apply to:

1) Products subjected to abnormal use or conditions, accident,

mishandling, neglect, unauthorized alteration, misuse, improper

installation or repair or improper storage;

2) Products whose mechanical serial number or electronic serial number

has been removed, altered or defaced;

3) Damage from exposure to excessive temperatures or extreme

environmental conditions;

4) Damage resulting from connection to, or use of any accessory or other

product not approved or authorized by the Company;

5) Defects in appearance, cosmetic, decorative or structural items such

as framing and non-operative parts.

6) Products damaged from external causes such as fire, dirt, sand,

battery leakage, blown fuse, theft or improper usage of any electrical

source.

28

Page 35

IMPORTANT

All data on the product may be deleted during the repair process. You

should create a back-up copy of all your data on your product before

shipping it for warranty service.

Service and Support

If you have any questions regarding the product, please contact one of our

offices in your region.

AUTEL NORTH AMERICA

Phone: 855-AUTEL-US (855-288-3587) Monday-Friday 9am-6pm

EST

Website: www.autel.com

Email: ussupport@autel.com

Address: 175 Central Avenue, Suite 200, Farmingdale, New York,

USA. 11735

AUTEL EUROPE

Phone: 0049 (0) 61032000522

Website: www.autel.eu

Email: sales.eu@autel.com, support.eu@autel.com

Address: Robert-Bosch-Strasse 25, 63225, Langen, Germany

AUTEL CHINA HQ

Phone: 0086-755-8614 7779

Website: www.autel.com

Email: support@autel.com

Address: 6th-10th floor, Building B1, Zhiyuan, Xueyuan Road, Xili,

Nanshan, Shenzhen, 518055, China.

AUTEL SOUTH AMERICA

Phone: (+507) 308-7566

29

Page 36

Website: www.autel.com/es

Email: sales.latin@autel.com, latsupport@autel.com

Address: Office 103, Building 3845, International Business Park,

Veracruz, Panamá Pacífico, Panamá

AUTEL AUSTRALIA

Phone: 03 9480 2978 / +61 476293327

Website: www.autel.com.au

Email: sales@autel.com.au

Address: 155 Islington Street, Melbourne, Collingwood, VIC

For technical assistance in other markets, please contact your local

distributor.

30

Loading...

Loading...