Figure 8-48 Sample DLC Connection Diagram

To open and set the DLC channel

1. Tap the right column of the channel D button at the bottom of the screen to

open the setting dialog box.

2. Select the DLC Channel in the left column of the dialog box.

3. Swipe the Enable DLC channel to ON. Select the appropriate pins.

Figure 8-49 Sample DLC Channel Setting Screen 1

4. Close the dialog box, the selected result is displayed on the screen. Tap the

amplitude setting button on the bottom of the screen to adjust the value for

the DLC channel.

135

Figure 8-50 Sample DLC Channel Setting Screen 2

Figure 8-51 Sample DLC Channel Setting Screen 3

5. Tap the DLC icon in the lower left corner of the screen to close the DLC

channel.

136

Figure 8-52 Sample DLC Channel Setting Screen

Trigger

The trigger feature is used to stabilize repetitive waveforms to obtain a clear signal

characterization.

A trigger is activated when a signal crosses set thresholds. Trigger points can also

be set manually as the user views a waveform.

When the oscilloscope is capturing the signal, tap the left column of the Trigger

button to activate the trigger function. A trigger point displays as a blue point.

137

Figure 8-53 Sample Trigger Point Screen

When the oscilloscope is capturing the signal, tap the right column of the Trigger

button to open the trigger settings dialog box.

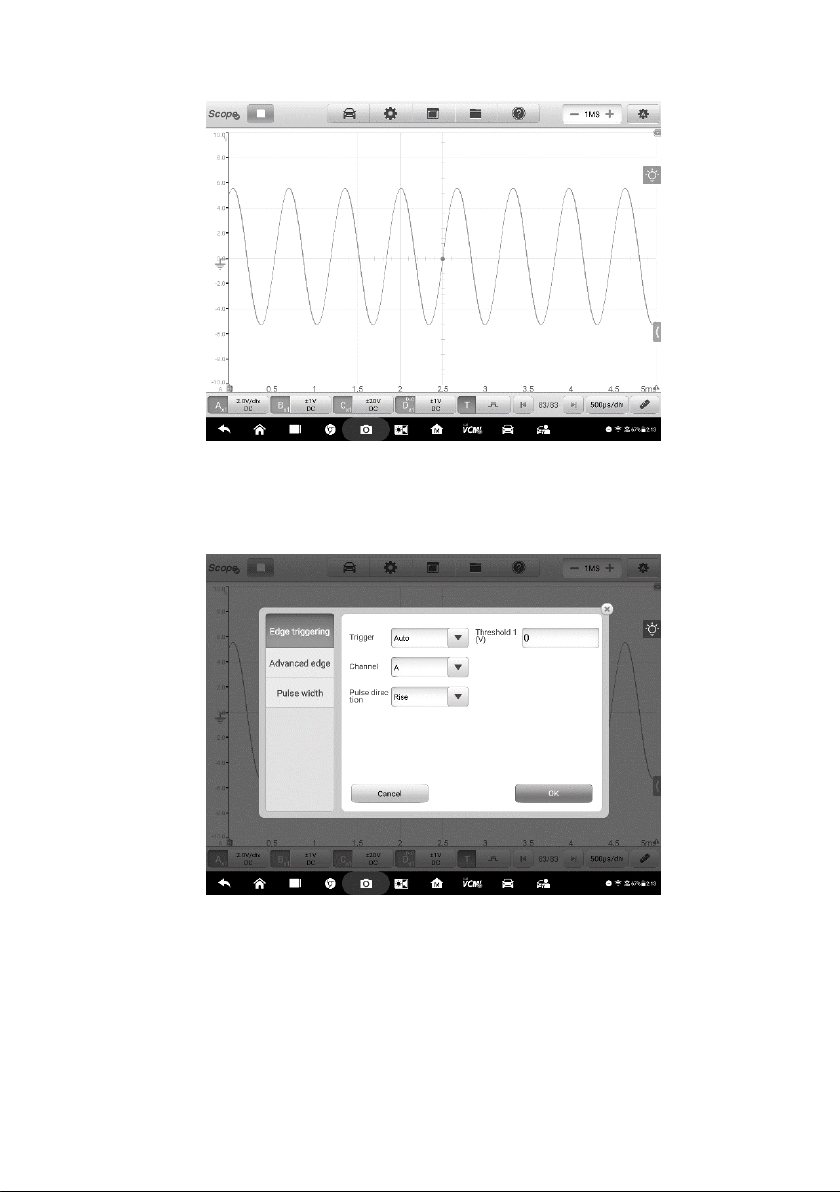

Figure 8-54 Sample Trigger Settings Screen

Edge Triggering

The edge trigger is one of the most common trigger modes and is activated when

voltage rises above or falls below a preset threshold. This trigger type allows you to

138

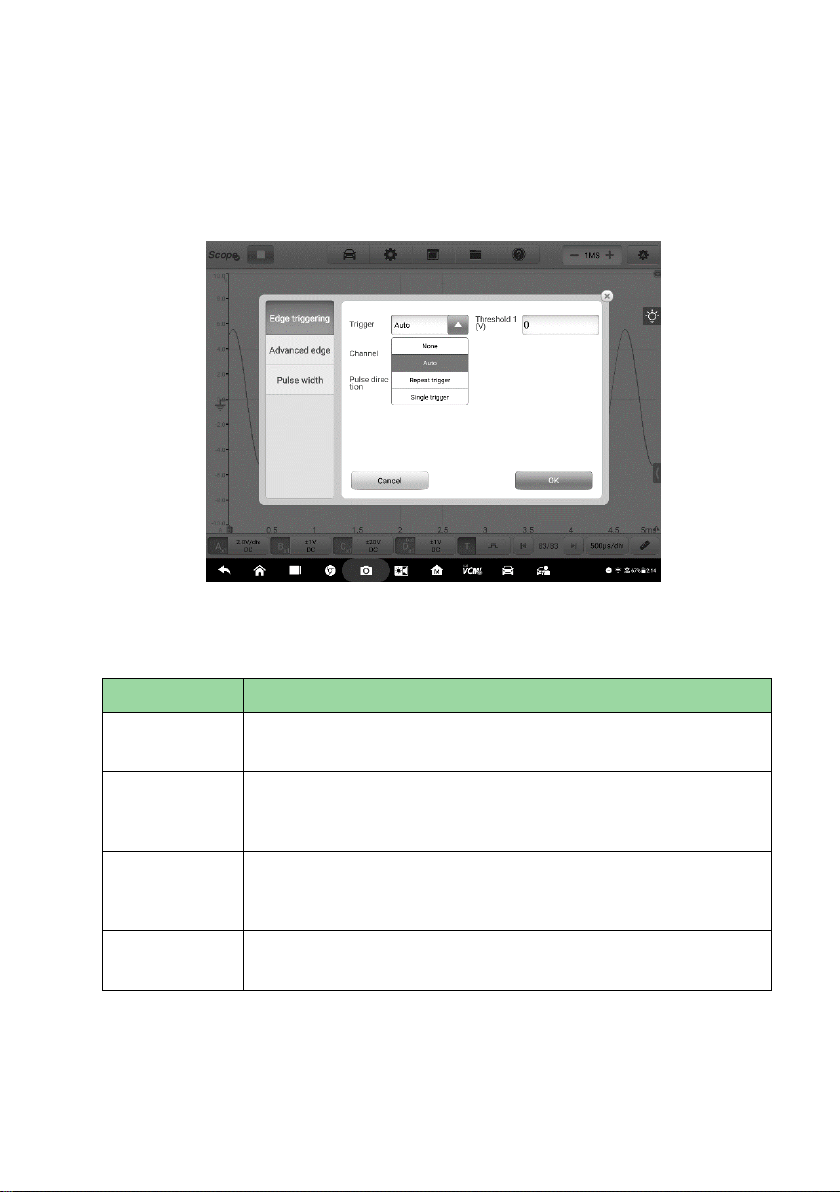

Trigger Mode

Description

None

In this trigger mode, the oscilloscope can continuously capture

data, without waiting for a trigger event.

Auto

In this trigger mode, the oscilloscope will wait for a trigger

before capturing data. It can automatically update after a short

period, even if the signal does not across the trigger point.

Repeat

In this trigger mode, the oscilloscope waits until a trigger event

occurs. If there is no trigger event, nothing will be displayed on

the screen.

Single

In this trigger mode, the oscilloscope stops capturing data once

a trigger event occurs.

configure the trigger mode, threshold, trigger channel and pulse direction settings.

Tap Done to save the settings or tap Cancel to exit without saving.

Trigger Mode

Four trigger modes are available: None, Auto, Repeat and Single.

Figure 8-55 Sample Trigger Mode Screen

The table below offers brief descriptions for each trigger mode.

Table 8-4 Trigger Mode Table

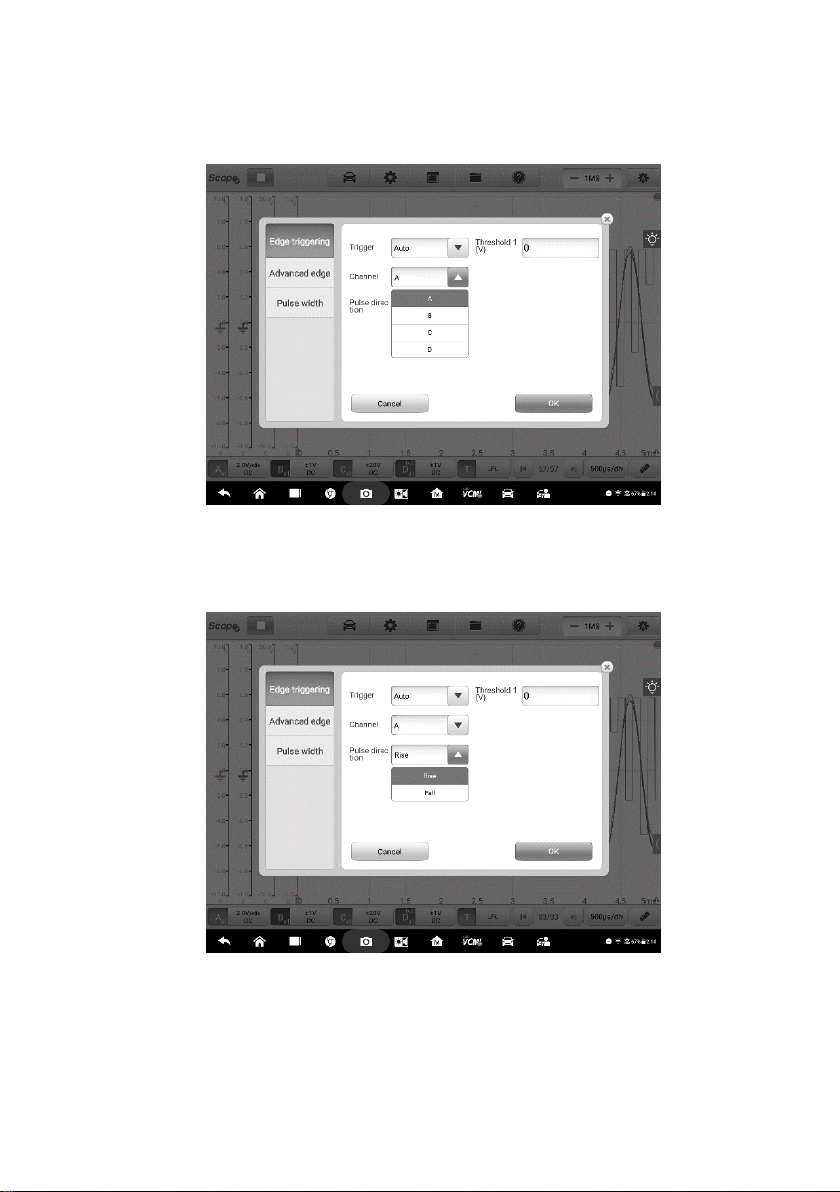

Channel

139

Select the applicable trigger channel from the dropdown menu. The selected

channel is the one that the oscilloscope monitors for the trigger condition.

Figure 8-56 Sample Trigger Channel Screen

Pulse Direction

Two pulse direction settings are available: Rise and Fall.

Figure 8-57 Sample Pulse Direction Screen

Rising Edge Trigger - Indicates trigger is turned on to start the trace on the rising

edge of the waveform.

140

Falling Edge Trigger – Indicates trigger is turned on to start the trace on the

falling edge of the waveform

Threshold

The Threshold allows you to set the voltage threshold for the trigger.

To precisely position the trigger point, input the value in the Threshold field in the

trigger settings dialog box.

To roughly position the trigger point, drag the trigger point to a desired position.

To configure the trigger settings

1. Tap the right column of the Trigger button to open the trigger settings dialog

box.

2. Select the trigger mode, trigger channel and pulse direction in the dropdown

list.

3. Input the value in the Threshold field in the trigger settings dialog box.

4. Tap Done to save settings or tap Cancel to exit without saving.

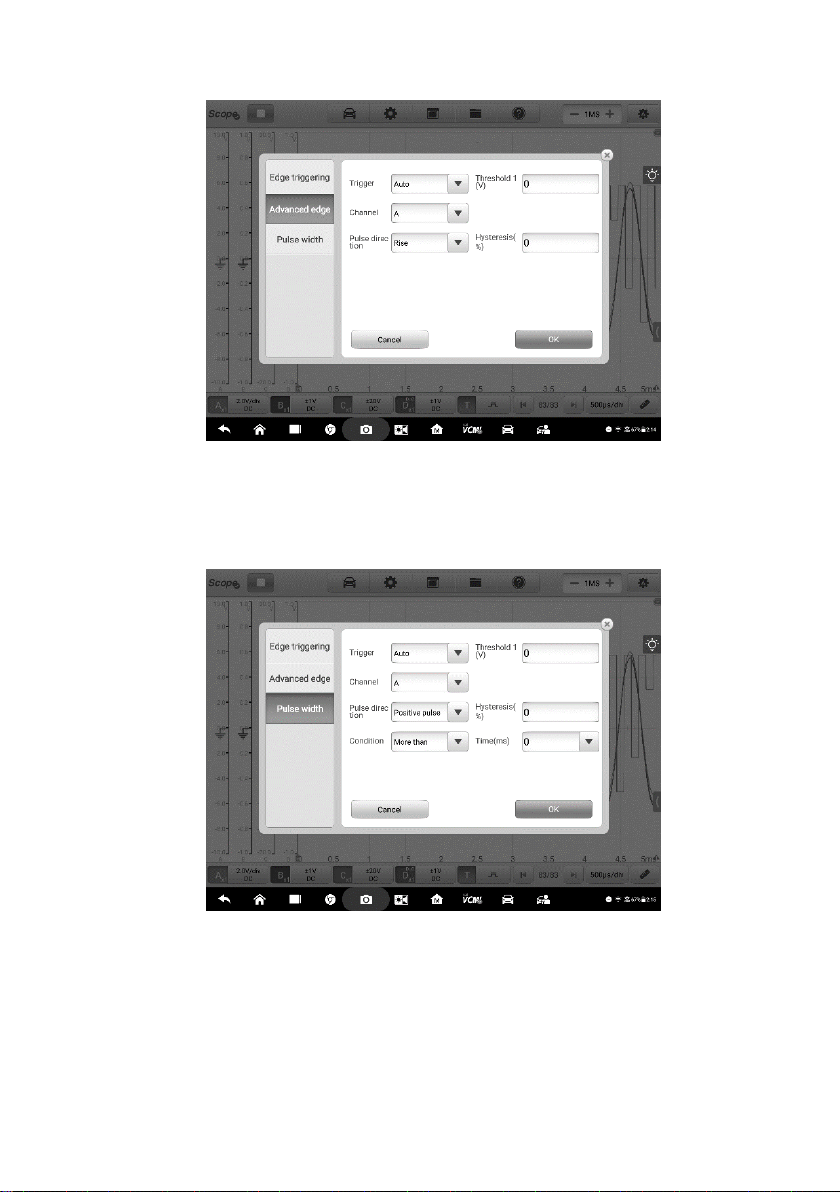

Advanced Edge

This trigger type includes all the functions of the edge trigger type, plus two

additional options: the Rising or Falling option and the hysteresis option.

Rising or Falling option in the dropdown menu of the pulse direction: Dual edges

of a waveform can be triggered. This mode is especially useful for monitoring pulses

of both polarities at once.

Hysteresis option: It is used to reduce false triggering on noisy signals. When

hysteresis is enabled, a second trigger threshold voltage is used in addition to the

main trigger threshold. The trigger fires only when the signal crosses the two

thresholds in the correct order. The first threshold arms the trigger, and the second

causes it to fire.

141

Figure 8-58 Sample Advanced Edge Screen

Pulse Width

This trigger type allows you to monitor pulses of a specified width.

Figure 8-59 Sample Pulse Width Settings Screen

To set the pulse width

1. Tap the Trigger button at the bottom of the screen to open the Trigger

Settings dialog box.

142

2. Select the Pulse Width in the left column of the dialog box.

3. Select the desired trigger mode and channel mode.

4. Set the pulse direction to either Positive pulse or Negative pulse according to

the polarity of the pulse.

5. Select one of the four Conditions:

More than: triggers on pulses wider than the specified time.

Less than: triggers on pulses narrower than the specified time.

In the time range: triggers on pulses wider than Time 1 but narrower

than Time 2.

Out of the time range: triggers on pulses narrower than Time 1 but

wider than Time 2.

6. Set the trigger Threshold and Hysteresis.

7. Set the Time 1 or Time 2 in minutes (if available) to define the pulse width.

8. Tap Done to save settings or tap Cancel to exit without saving.

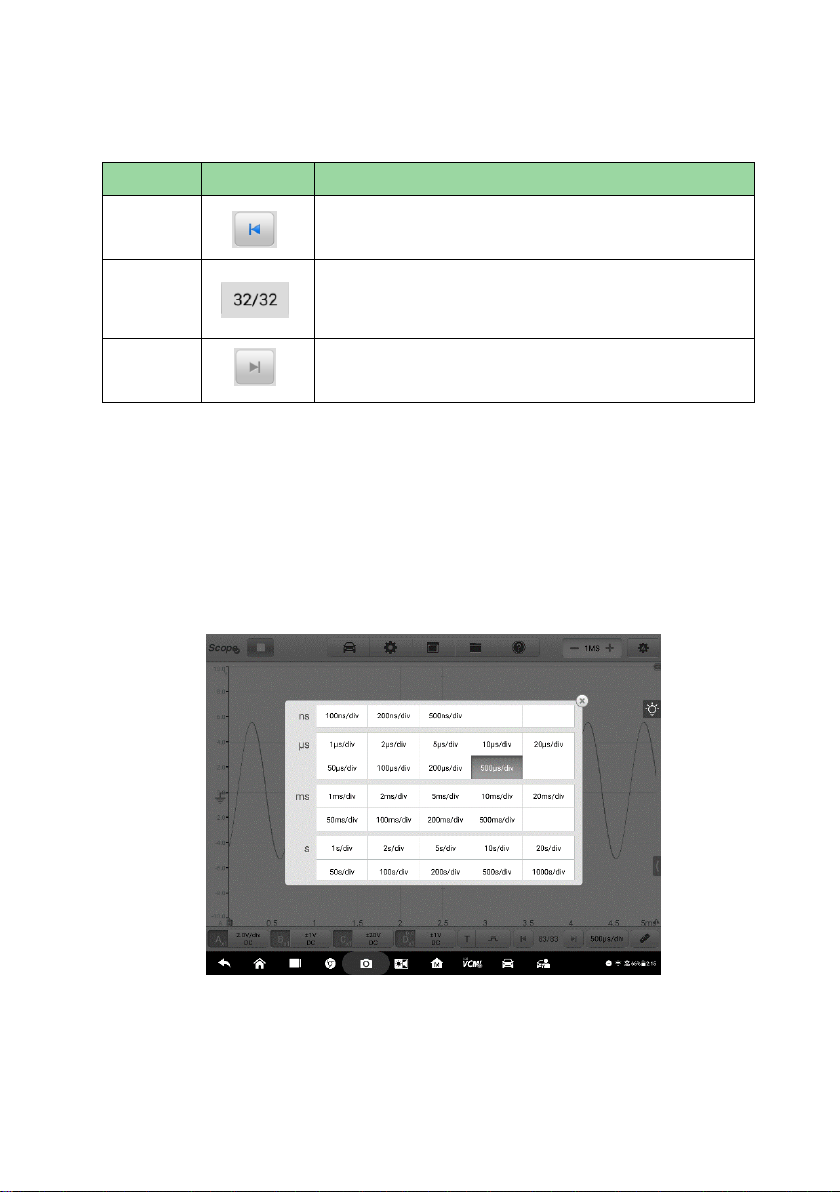

Buffer

The waveform buffer shows which signal waveform is displayed on the current

screen and how many signal waveforms are captured and stored in the buffer

memory.

The oscilloscope can capture and store up to 32 waveforms. Select a waveform

from the waveform buffer by tapping the Previous or Next button.

143

Name

Button

Description

Previous

Tap to display the previous waveform in the buffer.

Buffer

Index

Displays the number of the waveform currently

displayed onscreen out of the total number of

buffered waveforms.

Next

Tap to display the next waveform in the buffer.

Figure 8-60 Sample Buffer Screen

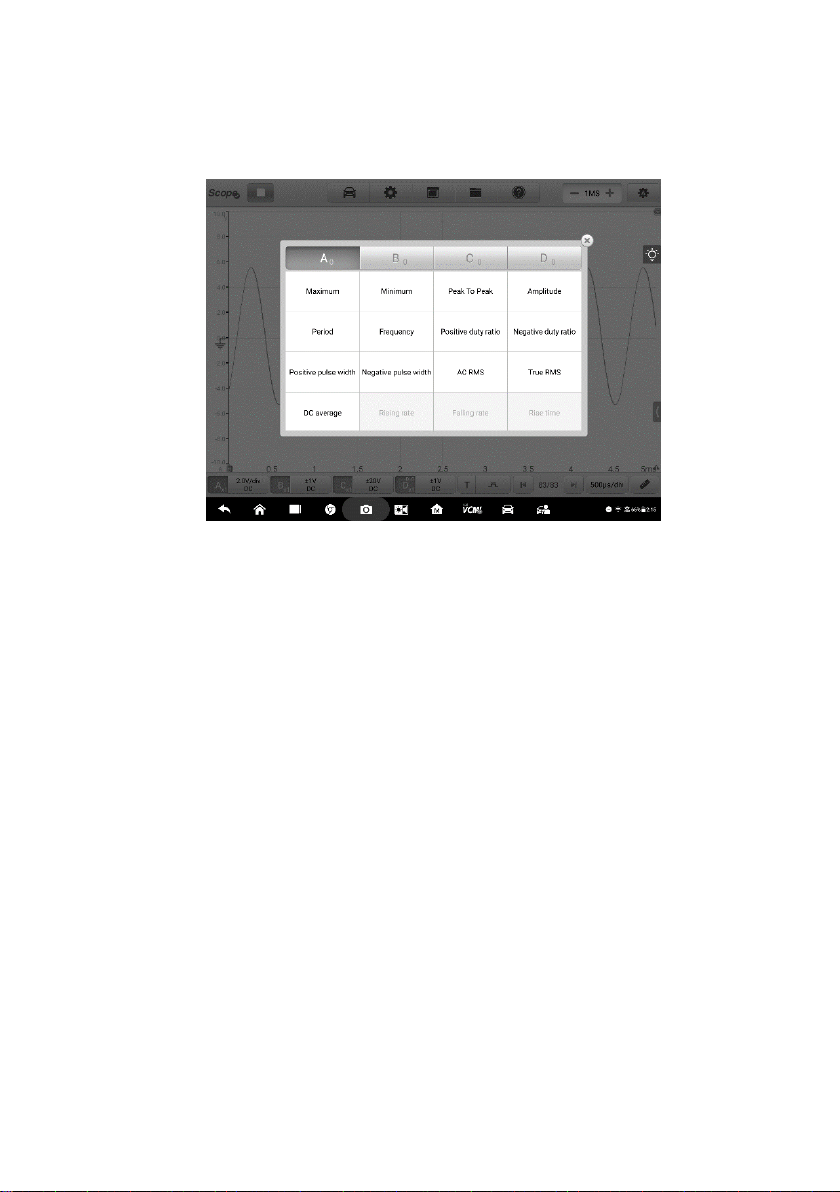

Time Base

The time base controls the time interval across the oscilloscope display. Tap the

Time Base button at the bottom to open the setting dialog box.

Continuous Mode: if the time base is set to more than or equal to 200ms/div, the

oscilloscope switches to the continuous mode. In this mode, the oscilloscope

updates the trace continuously as each capture progresses, rather than waiting for

a complete capture before updating the trace.

Figure 8-61 Sample Time Base Screen

144

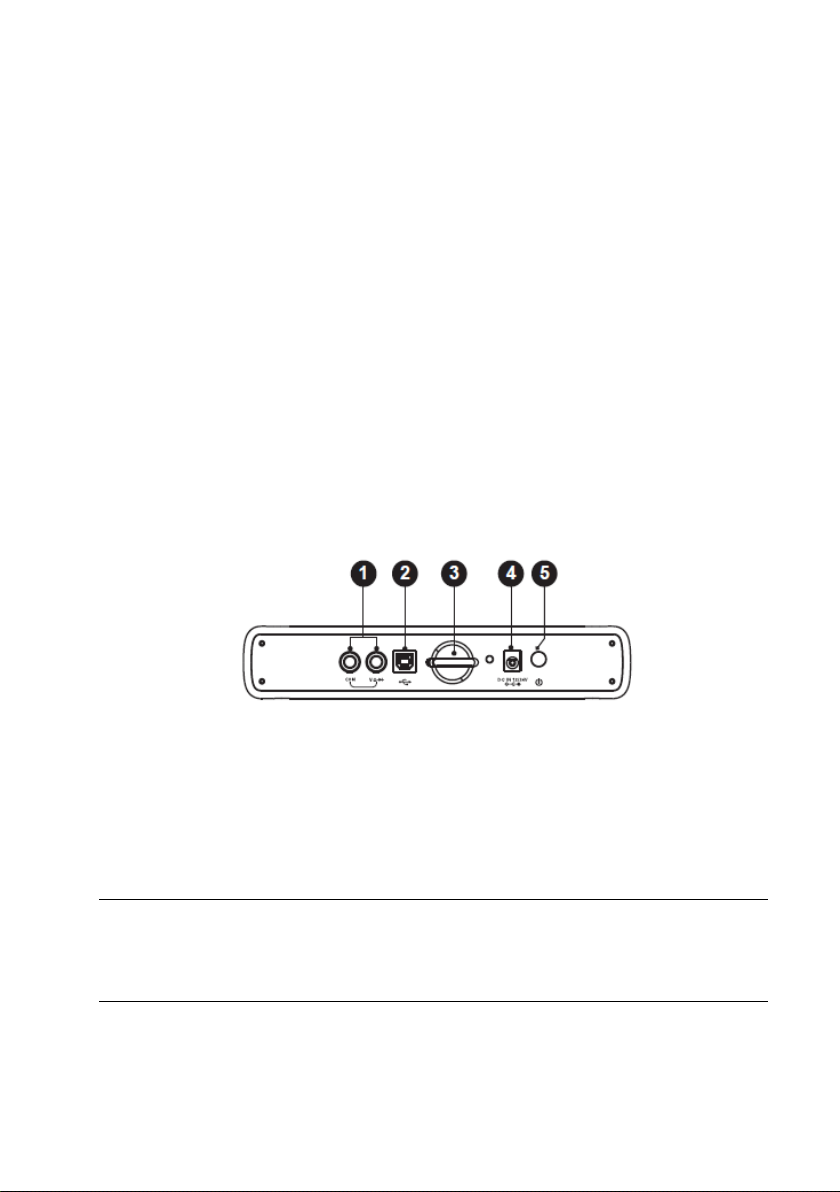

Measurement

The available measurements for each channel are (from left to right):

Figure 8-62 Sample Measurement Screen

Maximum – the highest level that the signal reaches

Minimum – the lowest level that the signal reaches

Peak To Peak – the difference between maximum and minimum

Amplitude – the top value minus the bottom value

Period – the duration of one cycle in a repeated pattern in the waveform

Frequency – the number of signal occurrences per second

Positive Duty Ratio – the ratio of positive pulse width to period width

Negative Duty Ratio –the ratio of negative pulse width to period width

Positive Pulse Width – the amount of time that the signal spends above its

average value

Negative Pulse Width – the amount of time that the signal spends below its

average value

AC RMS – the root mean square (RMS) value of the waveform minus the DC

Average

True RMS – the root mean square (RMS) value of the waveform, including

the DC component

DC Average – the average value of the waveform

145

Rising Rate – the rate at which the signal level rises

Falling Rate – the rate at which the signal level falls

Rise Time – the time the signal takes to rise from the lower threshold to the

upper threshold

Fall Time – the time the signal takes to fall from the upper threshold to the

lower threshold

X@Max – the corresponding value of X axis when the amplitude is the

maximum

X@Min – the corresponding value of X axis when the amplitude is the

minimum

Positive Acreage – the waveform acreage measured above the zero

baseline

Negative Acreage – the waveform acreage measured below the zero

baseline

Full Acreage – the positive acreage plus negative acreage

Top Value – 90% of the waveform maximum value

Bottom Value – 10% of the waveform minimum value

Positive Overshoot – the ratio of the difference between the maximum value

and the top value and the amplitude

Negative Overshoot – the ratio of the difference between the bottom value

and the minimum value and the amplitude

Positive Pre-shoot – the ratio of the difference between the bottom value

and the minimum value and the amplitude

Negative Pre-shoot –the ratio of the difference between the maximum value

and the top value and the amplitude

To set the measurements

1. Tap the Measure button at the bottom of the screen to open the

measurement dialog box.

2. Select the channel to be measured.

3. Select the appropriate measurement options. The Whole Track and Ruler

Track can be toggled through the Edit icon in the upper corner of the option.

146

Figure 8-63 Sample Measurement Setting Screen

4. Close the dialog box, and the corresponding measurement readings are

displayed on the right-hand side of the screen. Adjust the whole track or ruler

track on the displayed screen or delete the measurement directly by tapping

the X button.

Figure 8-64 Sample Measurement Display Screen

147

8.1.6 Troubleshooting

A. If the oscilloscope cannot communicate with the MaxiSys Tablet:

Ensure the VCMI device is properly connected to the MaxiSys Tablet via Wi-Fi or

with the supplied USB cable.

Restart the MaxiSys Tablet and reconnect the VCMI device if communication

between the two continues to fail.

B. If unwanted signals are displayed or signals are distorted:

Use only the supplied test leads or probes to connect with the input channels.

Check the test leads or probes for damage.

Ensure the polarity of the test leads connections are correct.

Ensure the signal and ground connections are clean and secure.

Ensure the ground lead is providing a direct ground from the circuit to the input

channel.

Isolate the test leads from other components, leads, or systems that may induct

unwanted noise into the signal being tested including the electric motors,

secondary ignition components, relays, alternators.

8.1.7 Glossary

AC/DC Control

Each channel can be set to either AC coupling or DC coupling. With DC coupling,

the voltage displayed onscreen is equal to the true voltage of the signal with respect

to ground. With AC coupling, any DC component of the signal is filtered out, leaving

only the variations in the signal for the AC component.

Aliasing

When the signal frequency gets higher than half the scope’s maximum sampling

rate and exceeds the limit, a distorted waveform displays. This distortion is called

aliasing.

Amplitude

The maximum voltage generated from the zero volts line of the oscilloscope.

148

Analog Bandwidth

The frequency at which a displayed sine wave has half the power of the input sine

wave (about 71% of the amplitude).

Buffer Size/Cache Size

The size of the oscilloscope’s buffer memory. The buffer memory is used by the

oscilloscope to temporarily store data. This helps to compensate for the differences

in data transfer rate from one device to another.

Frequency

The number of signal occurrences per second. Frequency is measured in Hz

(hertz).

Peak to peak voltage

The difference in voltage between the minimum and maximum voltages occurring in

the waveform.

Time Base

The time interval across the scope display.

Voltage Range

The range between the maximum and minimum voltages that can be accurately

captured by the oscilloscope.

Sampling Rate

The number of samples per second captured by the oscilloscope. The faster the

sampling rate of the scope, the more frequently it measures the signal voltage, and

so the more detailed will be the trace that appears on the scope screen.

149

8.2 Multimeter Operation

A multimeter is an electronic measuring instrument that is used to measure voltage,

resistance, frequency, diode, duty cycle and pulse width and continuity test. The

VCMI (Vehicle Communication and Measurement Interface) working with MaxiSys

Ultra can function as a multimeter to provide precise measurements.

8.2.1 Safety Information

Follow the instructions below to reduce the risk of injury from electric shock and

prevent equipment damage.

Use the multimeter only as specified in this manual.

Do not apply more than the rated voltage between terminals or between any

terminal and earth ground.

Do not input a value beyond the range when measuring. Remember that the limit

value range of this multimeter is ±200V.

To prevent injury or death, do not use the multimeter if it appears to be damaged

in any way, and stop use immediately if you are concerned with any abnormal

operations.

To prevent injury or death, never ground yourself when taking electrical

measurements. Isolate yourself from ground by using dry rubber insulating mats

to cover all exposed/grounded metal. Ensure all clothing including gloves are dry.

Stand on rubber mats when using tool.

Use the test leads or probes supplied with the product, or proper and applicable

terminals. Inspect the test leads or probes for damage before use.

When using probes, keep fingers behind the finger guards on the probes.

Use the supplied replacement fuses or specified replacement parts.

Always consider electrical and electronic equipment to be energized (live). Never

assume any equipment is de-energized.

When making electrical connections, connect the common test lead before

connecting the live test lead; when disconnecting, disconnect the live test lead

before disconnecting the common test lead.

When measuring current, turn off circuit power before connecting the multimeter

to the circuit. Remember to place the multimeter in series with the circuit.

After current measurement is finished, turn off the power to the circuit before

removing the test leads and before reconnecting any disconnected wires or

devices.

150

Do not add voltage to the input terminal when measuring resistance.

To avoid electric shock, turn off the power to the component before connecting.

To prevent damage, always use and store your multimeter in appropriate

environments.

Do not use in wet or damp conditions, or around explosive gas or vapor.

Do not tamper with or disassemble the multimeter, connectors or accessories.

Internal damage will affect performance.

Before carrying out maintenance and cleaning of the multimeter, make sure the

unit is NOT connected to a power source, vehicle or computer.

When cleaning the multimeter, use a damp, soft cloth with mild detergent. Do not

allow water to enter the multimeter casing.

8.2.2 General Introduction

8.2.2.1 Component Locations

The multimeter jacks are located on the top of the VCMI device while the input

channels are located on the bottom.

VCMI Top View

1. Multimeter Jacks – for ground and signal cables

2. USB Port

3. Hook

4. DC Power Supply Input Port

5. Power Button

IMPORTANT

When using the multimeter function, please insert the supplied multimeter probes to

the multimeter probe jacks. The input channel A is assigned when measuring

current.

151

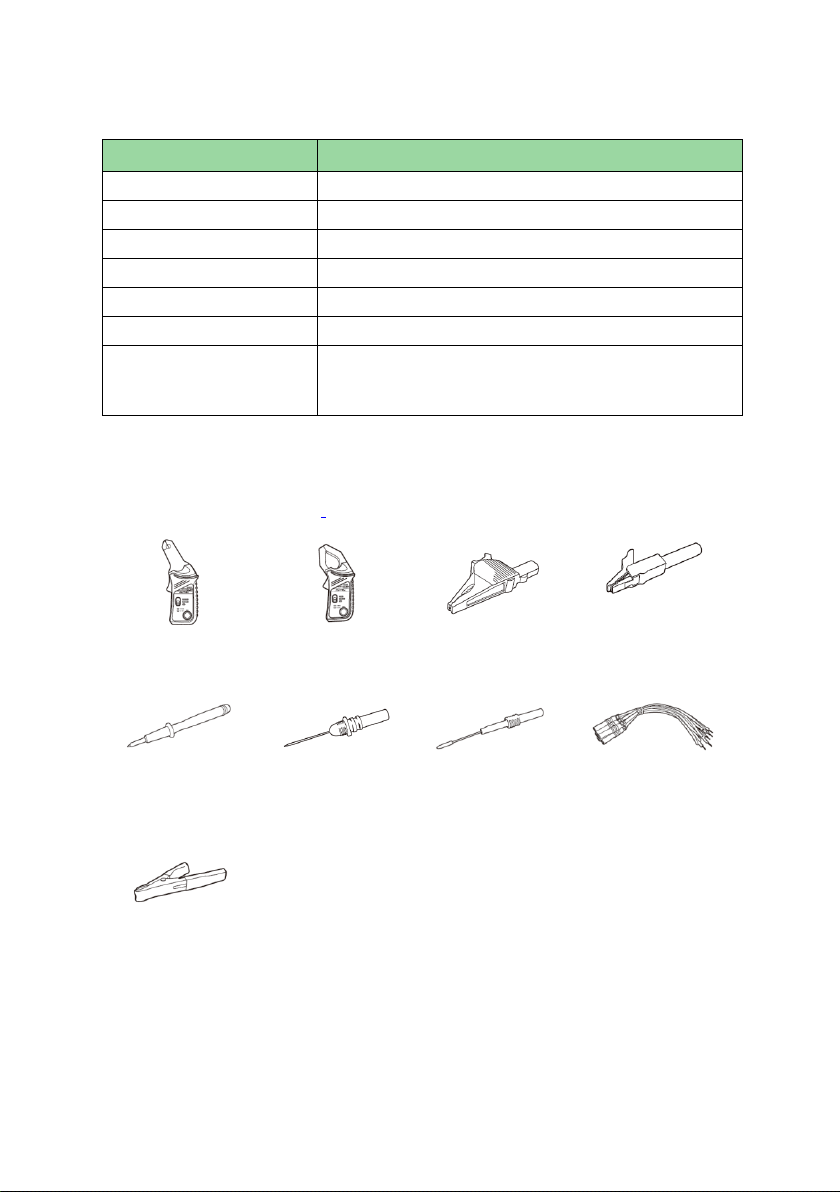

Item

Description

Voltage Range

±200V

Resistance Range

1Ω to 10MΩ

Diode

2V

Frequency Range

1Hz to 1MHz

Duty Cycle Range

%1 to 99%

Pulse Width Range

10us to 1000ms

Current Range

0 to 65A (65A current clamp)

0 to 650A (650A current clamp)

65A current

clamp

650A current

clamp

Large Dolphin

Clip

Small Crocodile

Clip

Multimeter

Probe

Back-pinning

Probe

Flexible

Back-pinning

Probe

Breakout Lead

Battery Clip

8.2.2.2 Technical Specifications

8.2.2.3 Accessories

The following accessories are compatible with the multimeter and oscilloscope.

Please refer to Accessories on page 107 for details.

152

Multimeter Test Lead

Used to connect the multimeter and multimeter probe.

The two multimeter test leads (Red: SA015 / Black: SA016) are standard for the

multimeter and signal generator.

8.2.3 Getting Started

Before opening the Multimeter application, ensure the VCMI device is connected to

the tablet Wi-Fi or with the supplied USB cable. For more information, see Establish

Vehicle Communication on page 20.

Figure 8-1 Sample Connection Diagram

To open the multimeter application

1. Insert the applicable test leads or probe terminal ends into the multimeter

jacks to complete the connection.

2. Tap the Measure icon on the Home screen of the MaxiSys Ultra Tablet. The

Measurement screen opens.

3. Tap the Multimeter icon to open the Multimeter Menu.

4. Select a test to continue.

153

NOTE

Please check the multimeter LED status indicator on the front panel of VCMI device.

The multimeter LED lights green when operating in the multimeter mode.

8.2.4 Multimeter Update

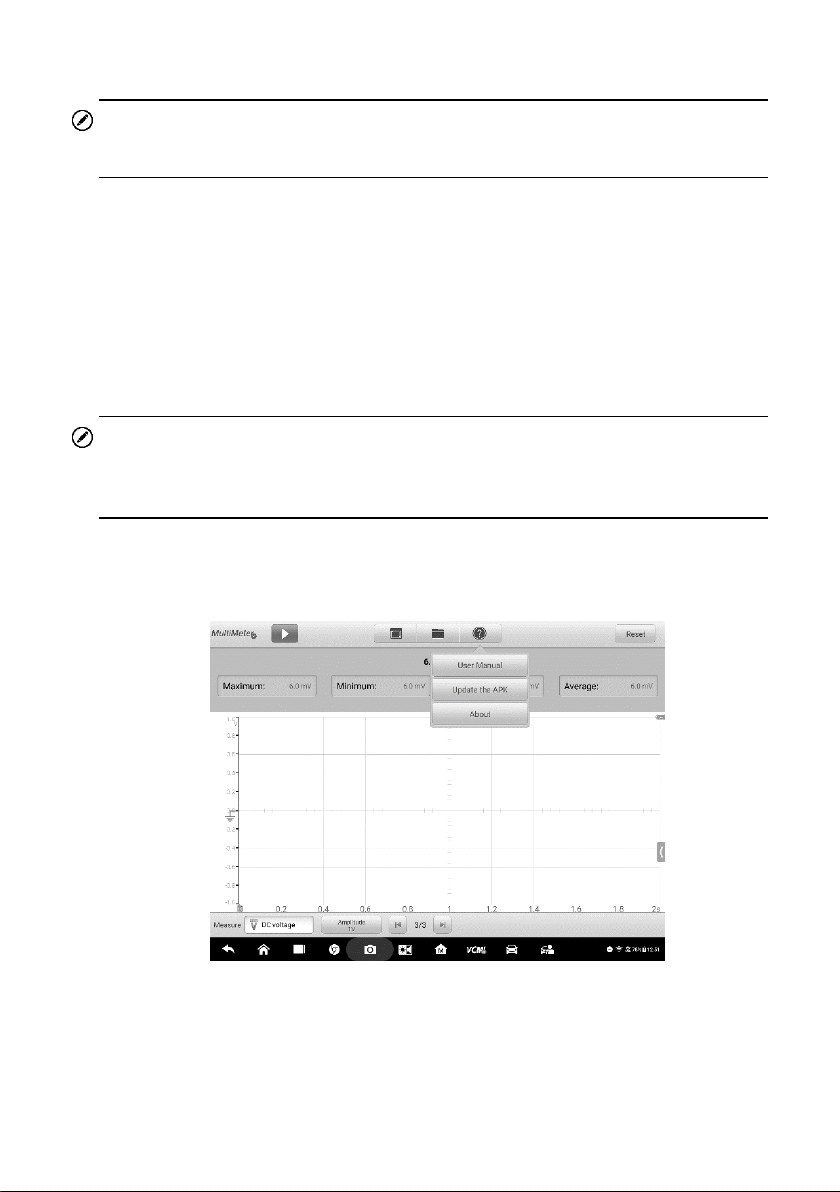

The operating software of the multimeter is continually optimized. Tap the Help

button in the upper half of the screen to update.

Before update the multimeter software, please ensure the tablet has a stable

Internet connection.

8.2.4.1 APK Update

NOTE

The acronym APK (Android Package Kit) is used on the tablet and in this manual.

This file contains all the assets of a particular app. To update the APK, is to install

the latest version of the app on your tablet.

To update the APK

1. Tap the Help button on the upper half of the screen. A dropdown menu

displays.

Figure 8-2 Sample Help Screen

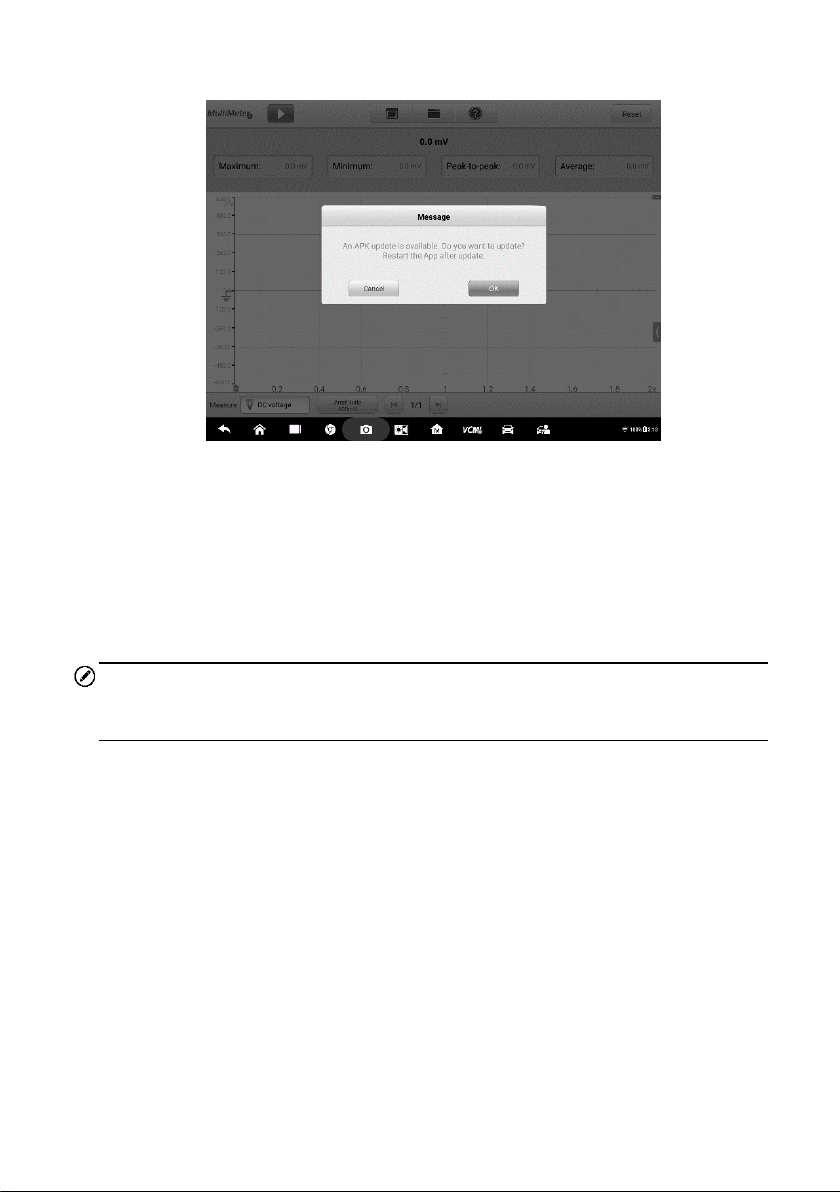

2. Tap the Update the APK in the dropdown menu. A confirmation message

displays.

154

Figure 8-3 Sample Update Confirmation Screen

3. Tap OK to update the software or tap Cancel to exit.

8.2.5 Screen Layout and Operations

Tap the Measurement icon on the home screen then tap the Multimeter icon in the

menu, the multimeter page displays. The screen typically includes the following

button sections.

NOTE

The Multimeter application can also be opened via the Android home screen. Tap

the Measure icon at the top of the Android home screen. Tap Multimeter icon.

155

Name

Button

Description

Multimeter

Icon

Displays the multimeter connection status. See

Multimeter Button on page 173 for more

information.

Start/Stop

Start or stop the multimeter device. See Start/Stop

Button on page 173 for more information.

Display

Mode

Set the display mode. See Display Mode Menu on

page 173 for more information.

Figure 8-4 Sample Multimeter Menu Screen

1. Upper Toolbar Buttons - see 8.2.5.1 Upper Toolbar Buttons on page 172 for

details.

2. Main View Section – see 8.2.5.2 Main View Section on page 177 for details.

3. Lower Toolbar Buttons - see 8.2.5.3 Lower Toolbar Buttons on page 181 for

details.

8.2.5.1 Upper Toolbar Buttons

The upper toolbar buttons are used for configurations of various settings and

operations. The following table provides brief descriptions of each button:

Table 8-1 Upper Toolbar Buttons

156

Name

Button

Description

File

Print, open and save the waveform data. See File

Menu on page 174 for more information.

Help

View the user manual, update the APK and

firmware. See Help Menu on page 176 for more

information.

Reset

Reset the digital readouts displayed in the figure

mode.

Name

Button

Description

Start

Tap to start the multimeter.

Stop

Tap to stop the multimeter.

Multimeter Button

This Multimeter status button displays the multimeter connection status. A green

check mark means the tablet and the Multimeter are connected; a red X means the

device and the tablet are not connected.

Start/Stop Button

Press this Start/Stop Button icon to start and stop the multimeter device.

Display Mode Menu

The position of the digital readouts and waveform in the main view section can be

selected in the Display Mode Menu.

To set the display mode

1. Tap the Display Mode button in the top navigation bar. A submenu opens.

157

Icon

Mode

Description

Digital Mode

Displays the digital readouts only.

Waveform Mode

Displays the waveform only.

Digital +

Waveform Mode

Displays both the digital readouts and waveform.

Figure 8-5 Sample Display Mode Menu Screen

2. Select one of the three display modes.

3. The corresponding display mode will be shown on the screen.

Table 8-2 Display Mode Table

File Menu

The file menu supports the following functions.

158

Figure 8-6 Sample File Menu Screen

Print – Tap to create and print a temporary JPG picture of the current waveforms.

NOTE

Ensure the tablet is configure to print (see Printer setup instructions) and is

connected to the printer. Ensure the tablet and printer share the same network.

Waveform File Operation

Save and open the waveform files in this section. Only Waveform mode and Digital

+ Waveform mode support this operation.

Save Waveform – Tap to capture and save the current waveforms. On the Save

File screen, tap each item to input the corresponding information and then tap Save

or Save Default to finish.

NOTE

The file name is required when saving waveforms.

Open Waveform – Tap to retrieve the saved waveforms. Tap the Edit button in the

upper right corner of the screen to select and/or delete the saved waveform.

Save as text – Tap to save the current waveform data to a text file. Use the ES File

Explorer app on the Android home screen to review file: Home > ES File Explorer >

Local > Internal Storage > Scan > Data > Scope > txt.

159

Configuration Operation

The configurations can be saved and imported.

Save the Configuration – Tap to save the configuration settings (i.e., the

amplitude, the time base, the number of samples) of waveforms on the current

screen.

Import the Configuration – Tap to import the saved configuration settings for

waveforms.

Help Menu

The Help Menu allows you to view the user manual, update the software, and view

versions of the device.

Figure 8-7 Sample Help Menu Screen

User Manual – displays instruction for the prosper use of the multimeter.

Update the APK – connects to the Autel server to check for latest application

software.

About – displays the model number of the multimeter and version numbers of the

installed software and firmware.

8.2.5.2 Main View Section

The main view section displays differently depending on the selected mode.

160

Digital Mode

The main view section in the digital mode displays only the digital readouts such as

values of current measurement, maximum measurement, minimum measurement,

peak to peak measurement and average measurement.

Figure 8-8 Sample Main View Section Screen (Digital Mode)

Current Value: the current value can be the AC voltage, DC voltage, resistance,

frequency, or duty cycle

Maximum: the recorded maximum value of the measurement

Minimum: the recorded minimum value of the measurement

Peak to Peak: the difference between the maximum and minimum values

Average: the average value of the measurements

Waveform Mode

The main view section in the scope mode only displays the waveform.

161

Figure 8-9 Sample Main View Section Screen (Waveform Mode)

The main view section features a coordinate grid with the X-axis representing the

time duration and the Y-axis representing the voltage level.

The voltage level on the Y-axis can be configured in the Amplitude Settings while

the time duration on the X-axis can be set in the Time Base Settings.

Channel Selection

In the main view section, a channel has two conditions: selected and unselected. A

channel must be selected in order for the waveform to be movement, to use the

zoom-in or to add voltage rulers.

To select and unselect the channel

1. Tap the zero baseline marker or the Y-axis (the line thickens when

selected).

2. Tap the zero baseline marker or the Y-axis again to exit the channel

selection.

Waveform Zooming

The zooming function allows you to change the size and position of a signal during

or after capturing a waveform to examine it in greater details. It does not change the

stored data, but the way it displays.

162

The X-axis and Y-axis can be zoomed using your fingertips. The waveform can be

zoomed during or after capturing the signal.

Measurement Rulers

In the coordinate grid, there are two kinds of measurement rulers, which allow the

voltage and time duration of a waveform to be measured precisely. They are useful

when determining signal characteristics such as amplitude at specific points, the

cycle time (duration) and frequency.

The vertical Time Ruler - Tap the Ruler Activator in the bottom left corner of the

grid and drag it across the screen to the desired position. A Time Ruler is

generated.

The horizontal Y-axis Ruler - The Ruler can be generated in the similar way by

tapping the Ruler Activator in the upper right corner and dragging it downwards.

NOTE

The horizontal Y-axis ruler varies according to the settings of the voltage, current,

frequency, duty cycle, etc.

When Measurement Rulers are generated, a Ruler Table showing time and voltage

values for the corresponding channels will be displayed. The Delta icon refers to the

absolute difference between the values of the rulers, which can be locked by

tapping the Lock icon. Tap the X button in the upper right corner of the ruler table to

delete all rulers.

163

Figure 8-10 Sample Measurement Rulers Screen

Zero Baseline

The zero baseline is marked the 0 value in the Y-axis, showing the ground level of

each channel waveform. After the channel is selected, the zero baseline can be

adjusted by dragging the baseline marker up/down along the Y-axis, or dragging the

waveform up/down or moving the screen up/down in the grid.

NOTE

Tap the baseline marker to make the vertical scale line thinner. In this case, the

waveform is unselected and cannot be dragged. Tap the baseline marker again to

select.

Figure 8-11 Sample Zero Baseline Screen

Wiring Diagram and Help

Tap the arrow button in the lower right corner of the screen to open the Wiring

Diagram and Help window.

The Wiring Diagram function provides the connection diagram, operation steps

and operation notes.

The Help function provides the content-sensitive help, displaying information

relevant to the procedure, operation or instructions.

164

Figure 8-12 Sample Wiring Diagram and Help Screen

To open and close the Wiring Diagram and Help window

1. Tap the arrow button on the right-hand side of the screen.

Figure 8-13 Arrow Button Position Screen

2. The Wiring Diagram and Help window displays.

3. Tap the arrow button again or tap any space outside of the window.

165

Name

Button

Description

Measure

Tap to select an appropriate measurement.

See Measure Setting on page 181 for more

information.

Amplitude

Tap to select an appropriate amplitude

value. See Amplitude Setting on page 183

for more information.

Buffer

Tap the Previous or Next button to switch to

the previous or the next waveform. See

Buffer on page 187 for more information.

Digital + Waveform Mode

In this mode, the main view section displays the digital readouts on the top and the

waveform in the grid.

Figure 8-14 Sample Main View Section Screen (Digital + Waveform Mode)

8.2.5.3 Lower Toolbar Buttons

The measurement, buffer and time base can be configured in the lower toolbar.

Table 8-3 Lower Toolbar Buttons

166

Measure Setting

This multimeter can be used to measure or test AC voltage, DC voltage, resistance,

AC electricity, DC electricity, diode, frequency, duty cycle, pulse width, continuity

and period.

The measurement types include:

AC/DC voltage: measures the voltage in the electrical circuit

Resistance: measures the resistance of the electrical circuit or the component

AC/DC electricity: measures current amperage through the input channel A by

using the optional current clamp

Note

The type of current clamp can be selected in the dropdown list.

Diode: conducts the diode test of the electrical circuit

Frequency: measures the frequency of the input signal

Duty Cycle (+)/(-): measures the (+) and (-) duty of the input signal

Continuity: determines whether a low impedance exists two points in the

electrical circuit. If the impedance is less than 10 ohms, the circuit is “closed”,

otherwise, the circuit is “open”.

Period: measures the amount the time that one complete cycle of the input signal

endures

Pulse Width (+)/(-): measures the pulse width of the input signal

To set the measure setting

1. Tap the Measure Setting button in the lower left corner of the screen. A dialog

box appears.

167

Figure 8-15 Sample Measure Setting Position Screen

2. Select the measure type you want to measure or test in the right column of

the dialog box. The blue color indicates the option is selected.

Figure 8-16 Sample Measure Setting Screen

3. Close the dialog box, the measure type you set displays on the screen.

Amplitude Setting

Amplitude value can be configured for the selected measurement type excluding

resistance measurement.

168

The amplitude settings allow you to set up the multimeter to capture signals within

the specified range. If the input signal exceeds the selected range, an over-range

indicator will be displayed. Select Auto to enable the device to adjust the vertical

scale automatically.

There are two modes available to set the amplitude value.

Mode 1: For example, selecting AC 1V sets the amplitude to Voltage 1V (displays

on the amplitude button). The vertical scale range is from -1V to +1V. As the vertical

scale is divided into 10 segments, each segment increases by 0.2V.

Figure 8-17 Channel Setting Dialog Box Screen (AC 1V)

Mode 2: Select the ## /div button to adjust the value increments of each division.

For example, selecting AC 2.0V/div, sets the amplitude to Voltage 2.0V/div

(displays on the amplitude button). Each segment increases by 2V. As the vertical

scale is divided into 10 segments, the entire vertical scale range is from -10V to

+10V.

169

Figure 8-18 Sample Amplitude Setting Screen (AC 2.0V/div)

Testing Procedures

The following section describes how to use the multimeter. The testing procedures

are the same for each measurement type.

The following directions are for measuring AC voltage.

To measure AC voltage

1. Tap the Measure Setting button in the lower left corner of the screen to open

the setting dialog box. Select AC voltage in the dialog box.

2. Set the proper amplitude value in the Amplitude Setting menu in the same

dialog box.

3. Insert the supplied multimeter probes into the VCMI multimeter jacks.

4. Measure the AC voltage by holding the probes to the correct points of the

circuit.

5. The voltage displays onscreen.

Note

Use the optional current clamp connected to the input channel A when measuring

currents. Use the supplied multimeter probes to connect with the multimeter jacks

for other measurement types.

170

Probe Edit

Use the probe edit menu to add the not included robes into the probe menu.

Figure 8-19 Sample Probe Edit Screen 1

To add custom probes

1. Tap the Measure Setting button in the lower left corner of the screen to open

the setting dialog box.

2. Select the Probe Edit option in the left column of the dialog box.

3. Tap each field to open the virtual keyboard and input the required information.

171

Figure 8-20 Sample Probe Edit Screen 2

4. Tap Add to save the settings, or tap Clear to exit without saving.

5. The added probe will be listed in the Measure Settings window.

Figure 8-21 Sample Probe Edit Screen 3

Buffer

The waveform buffer displays the number of the waveform currently displayed

on-screen out of the total number of stored waveforms.

The multimeter can capture and store up to 32 waveforms. Tap the Previous or

Next button to review waveforms.

172

Name

Button

Description

Previous

Tap to display the previous waveform in the buffer.

Buffer Index

Displays the number of the waveform currently

displayed onscreen out of the total number of

buffered waveforms.

Next

Tap to display the next waveform in the buffer.

Figure 8-22 Sample Buffer Screen

8.2.6 Troubleshooting

If the multimeter cannot communicate with the MaxiSys Tablet:

Check if the VCMI device is properly connected to the MaxiSys Tablet via Wi-Fi or

the supplied USB cable.

If the communication between the VCMI device and the MaxiSys still fails, restart

the MaxiSys Tablet and reconnect the VCMI device.

173

8.2.7 Glossary

AC

Alternating Current - electrical current that switches polarity at regular intervals.

DC

Direct Current - electrical current that flows in one direction only.

Amperage

The strength of an electric current, expressed in amperes.

Amplitude

The maximum voltage generated from the zero volts line of the multimeter.

Frequency

The number of signal occurrences per second. Frequency is measured in Hz

(hertz).

Duty Cycle

The length of a signals on time. Specified as a percentage (ratio), of the total cycle

time.

Peak to Peak

The difference between maximum and minimum value.

Cursor

The onscreen markers used to measure time and amplitude.

Diode

A semiconductor device that allows current flow only in one direction.

Grid

A network of horizontal and vertical scales displayed on the scope screen that aids

in the measuring of signal characteristics.

174

8.3 Signal Generator Operation

The VCMI (Vehicle Communication and Measurement Interface) working with

MaxiSys Ultra can function as a signal generator to send out electric signals to the

vehicle’s sensor or actuator for testing or measuring.

8.3.1 Safety Information

Follow the instructions below to reduce the risk of injury from electric shock and

prevent equipment damage.

Use the signal generator only as specified in this manual.

Do not apply more than the rated voltage between terminals or between any

terminal and earth ground.

To minimize shock hazard, please connect the device ground input (chassis) to an

electrical ground.

Do not alter the ground connection. Without the protective ground connection, all

accessible conductive parts can render an electric shock.

To avoid electric shock hazard, disconnect power cable before removing covers.

To prevent injury or death, do not use the signal generator if it appears to be

damaged in any way, and stop use immediately if you are concerned any

abnormal operations.

Inspect the test leads or probes for damage before use.

Use the accessories supplied with the product.

Use the supplied replacement fuses or specified replacement parts.

To prevent damage, always use and store your signal generator in appropriate

environments.

Do not place the signal generator in an area that is directly exposed to sunlight or

under high humidity.

Do not tamper with or disassemble the signal generator, connectors or

accessories. Internal damage will affect performance.

Disconnect multimeter from power source, vehicle and tablet before cleaning.

When cleaning the signal generator, use a damp, soft cloth with mild detergent.

Do not allow water to enter the multimeter casing

175

Item

Description

Voltage Range

0.1 to 12V

Frequency Output

1Hz to 30KHz

Duty Cycle Range

1% to 99% (1Hz to 30KHz)

Accuracy

3%

8.3.2 General Introduction

8.3.2.1 Component Locations

The multimeter jacks are used when operating the signal generator. The two

multimeter jacks are located on the top of the VCMI device.

VCMI Top View

1. Multimeter Jacks – for ground and signal cables

2. USB Port

3. Hook

4. DC Power Supply Input Port

5. Power Button

8.3.2.2 Technical Specifications

8.3.2.3 Accessories

The following accessories are compatible with the signal generator and

oscilloscope. Please refer to Accessories on page 107 for details.

176

Large Dolphin

Clip

Small Crocodile

Clip

Multimeter

Probe

Back-pinning

Probe

Flexible Back-pinning Probe

Breakout Lead

Battery Clip

Multimeter Test Lead

Used to connect the signal generator and the probe.

The multimeter test leads (Red: SA015 / Black: SA016) are standard for the signal

generator and multimeter.

8.3.3 Getting Started

Before opening the Signal Generator application, the VCMI device must be

connected to the Tablet via the provided USB cable or Wi-Fi network. For more

information, see Establish Vehicle Communication on page 20.

177

Figure 8-1 Sample Connection Diagram

To open the signal generator application

1. Insert the multimeter test lead ends into the multimeter jacks on the top of the

VCMI device to compete the connection.

2. Tap the Measure icon on the Home screen of the MaxiSys Ultra Tablet. The

Measurement screen displays.

3. Tap the Signal Generator icon to open the signal generator Menu.

4. Select a test to continue.

NOTE

Please check the signal generator LED status indicator on the front panel of VCMI

device. The signal generator LED lights green when operating in the signal

generator mode.

8.3.4 Signal Generator Update

The operating software of the signal generator is continually optimized. Tap the

Help button in the upper half of the screen to update.

8.3.4.1 APK Update

178

NOTE

The acronym APK (Android Package Kit) is used on the tablet and in this manual.

This file contains all the assets of a particular app. To update the APK, is to install

the latest version of the app on your tablet.

To update the APK

1. Tap the Help button on the upper half of the screen. A dropdown menu

displays.

Figure 8-2 Sample Help Screen

2. Tap the Update the APK in the dropdown menu. A confirmation message

displays.

179

Figure 8-3 Sample Update Confirmation Screen

3. Tap OK to update the software or tap Cancel to exit.

8.3.5 Screen Layout and Operations

Tap the Measurement icon on the home screen and select Signal Generator from

the menu, the signal generator page displays. The screen typically includes the

following button sections.

NOTE

The Signal Generator application can also be opened via the Android home screen.

Tap the Measure icon at the top of the Android home screen. Tap Signal

Generator icon.

180

Name

Button

Description

Signal

Generator

Icon

Displays the signal generator connection status.

See Signal Generator Button on page 197 for

more information.

Start/Stop

Start and stop the signal generator device. See

Start/Stop Button on page 197 for more

information.

File

Print, open and save the waveform data. See File

on page 197 for more information.

Figure 8-4 Sample Signal Generator Menu Screen

1. Upper Toolbar Buttons - see 8.3.5.1 Upper Toolbar Buttons on page 196 for

details.

2. Main View Section – see 8.3.5.2 Main View Section on page 199 for details.

3. Lower Toolbar Buttons - see 8.3.5.3 Lower Toolbar Buttons on page 202 for

details.

8.3.5.1 Upper Toolbar Buttons

The upper toolbar buttons are used to configure settings and operations. The

following table provides brief descriptions of each button.

Table 8-1 Upper Toolbar Buttons

181

Name

Button

Description

Help

View the user manual, update the software and

view version numbers. See Help on page 198 for

more information.

Reset

Reset the configurations and refresh the screen.

Name

Button

Description

Start

Tap to start the signal generator.

Stop

Tap to stop the signal generator.

Signal Generator Button

This Signal Generator Icon displays the signal generator connection status. A

green check mark means the tablet and the signal generator are connected; a red

X means the device and the tablet are not connected.

Start/Stop Button

You can tap the Start/Stop Button icon to start or stop the signal generator device.

File Menu

The file menu supports the following functions.

182

Figure 8-5 Sample File Menu Screen

Print – Tap to create and print a temporary JPG picture of the current waveforms.

NOTE

Ensure the tablet is configure to print (see Printer setup instructions) and is

connected to the printer. Ensure the tablet and printer share the same network.

Save Waveform – Tap to capture and save the current waveform. On the Save

File screen, tap each item to input the corresponding information and then tap

Save or Save Default to finish.

NOTE

You must name the file to save the waveform.

Open Waveform – Tap to retrieve the saved waveforms. Tap the Edit button in

the upper right corner of the screen to select and/or delete the saved waveform.

Save as text – Tap to save the current waveform data to a text file. Use the ES

File Explorer app on the Android home screen to review file: Home > ES File

Explorer > Local > Internal Storage > Scan > Data > Scope > txt.

Help Menu

The Help Menu allows you to view the user manual, update the software, and view

versions of the device.

183

Figure 8-6 Sample Help Menu Screen

User Manual – displays instruction for the prosper use of the signal generator.

Update the APK – connects to the Autel server and check for latest application

software.

About – displays the model numbers of the signal generator and the installed

versions of the software and firmware.

8.3.5.2 Main View Section

The main view section screen displays as a coordinate grid with X-axis and Y-axis,

representing the duration and voltage level respectively.

Channel Selection

In the main view section, a channel has two conditions: selected and unselected. A

channel must be selected in order for the waveform to be movement, to use the

zoom-in or to add voltage rulers.

To select and unselect the channel

1. Tap the zero baseline marker or the Y-axis (the line thickens when selected).

2. Tap the zero baseline marker or the Y-axis again to exit the channel selection.

184

Waveform Zooming

The zooming function allows you to change the size and position of a signal during

or after capturing a waveform to examine it in greater details. It does not change the

stored data, only the way it displays.

The X-axis and Y-axis can be zoomed using your fingertips. The waveform can be

zoomed during or after capturing the signal.

Measurement Ruler

In the coordinate grid, there are two types of measurement rulers, which allow the

voltage and duration of a waveform to be measured precisely. They are useful when

determining signal characteristics such as amplitude at specific points, and the

cycle time (duration).

The vertical Time Ruler - Tap the Ruler Activator in the lower left corner of the grid

and drag it across the screen to the desired position. A Time Ruler is generated.

The horizontal Voltage Ruler - The Voltage Ruler can be generated in the similar

way by clicking the Ruler Activator in the upper right corner and dragging it

downwards.

When Measurement Rulers are generated, a Ruler Table showing time and voltage

values will be displayed. The Delta icon refers to the absolute difference between

the values of the rulers, which can be locked by tapping the Lock icon. Tap the X

button in the upper right corner of the ruler table to delete all rulers.

Figure 8-7 Sample Measurement Rulers Screen

185

Zero Baseline

The zero baseline is marked as the 0 value in the Y-axis, showing the ground level

of each channel waveform. After the channel is selected, the Zero Baseline can be

adjusted by dragging the zero baseline marker up/down along the Y-axis.

Wiring Diagram and Help

Tap the arrow button in the lower right corner of the screen to open the Wiring

Diagram and Help window.

The Wiring Diagram function provides the connection diagram, operation steps

and operation notes.

The Help function provides the content-sensitive help, displaying information

relevant to the procedure, operation or instructions.

Figure 8-8 Sample Wiring Diagram and Help Screen

To open and close the Wiring Diagram and Help window

1. Tap the arrow button on the right-hand side of the screen.

186

Name

Button

Description

Waveform

Mode

Setting

Tap to select an appropriate waveform

mode. See Waveform Mode Setting on page

203 for more information.

Voltage

Setting

Tap to select an appropriate voltage value.

See Voltage Setting on page 208 for more

information.

Frequency

Setting

Tap to select an appropriate frequency

value. See Frequency Setting on page 211

for more information.

Duty Cycle

Setting

Tap to select an appropriate duty cycle

value. See Duty Cycle Setting on page 214

for more information.

Figure 8-9 Arrow Button Position Screen

2. The Wiring Diagram and Help window displays.

3. Tap the arrow button again or tap any space outside of the window.

8.3.5.3 Lower Toolbar Buttons

The waveform mode, voltage, frequency and duty cycle can be configured via the

lower toolbar buttons.

Table 8-2 Lower Toolbar Buttons

187

Waveform Mode Setting

The signal generator supports numerous waveform modes including the DC voltage,

square wave, square wave (X+Y), triangle wave, and actuators drive, and arbitrary

waveform.

Figure 8-10 Waveform Mode Setting Screen

DC Voltage

Figure 8-11 Sample DC Voltage Connection Diagram

188

Set the DC voltage in the signal generator interface. The signal generator can

simulate the signals of numerous sensors including the water temperature sensor,

oil pressure sensor and position sensor and then feed back to the engine ECU.

Actuator Drive

Figure 8-12 Sample Actuator Drive Connection Diagram

This function can drive 2-wire solenoid valve, solenoid coil and low-power motor,

including the canister solenoid valve, injector solenoid valve, transmission hydraulic

valve, hydraulic control valve, ignition coil, idle motor, and throttle motor.

It can change the operation speed and working time of the actuator by setting the

frequency and duty cycle. The higher the frequency, the faster the speed, and the

higher the duty cycle, the longer the working time, and vice versa.

NOTE

To avoid damaging the actuator, do not actuate it for a long time, and do not set too

high a frequency.

This function needs to be tested on the car. If the actuator is removed, it cannot be

driven individually.

189

Square Wave

Figure 8-13 Sample Square Wave Connection Diagram

Once the voltage and frequency are set in the signal generator interface, the square

wave signals simulate the signals of various Hall sensors.

Square Wave (X+Y)

Figure 8-14 Sample Square Wave (X+Y) Connection Diagram

190

This function is mainly used to simulate the missing tooth signals of Hall-type

crankshafts and camshafts. The X value represents the normal tooth signal and the

Y represents the missing tooth signal. The default setting is 58+2, which can be

adjusted as needed.

Triangle Waveform

Figure 8-15 Sample Triangle Waveform Connection Diagram

This is a symmetrical triangular waveform, which is mainly used to simulate the

triangle wave signals. The amplitude and frequency can be configured in this

waveform.

191

Arbitrary Waveform

Figure 8-16 Sample Arbitrary Waveform Connection Diagram

Any type of the mentioned waveforms can be loaded again after the waveform and

parameter settings are saved.

Voltage Setting

After you select the waveform mode, you can also set the amplitude value for that

mode.

There are three methods to adjust the voltage value:

Method 1: Tap the “+” and “-” buttons on the bottom of the screen in the Voltage

Setting.

192

Range

Button

Description

0.1V to 0.9V

Raises the voltage by 0.1V

Lowers the voltage by 0.1V

1V to 12V

Raises the voltage by 1V

Lowers the voltage by 1V

Figure 8-17 Sample Voltage Setting Screen 1

Method 2: Tap the Voltage Setting button at the bottom of the screen to open a

dialog box. Adjust the voltage value by tapping the positive or negative value at

the bottom of the dialog box. Then tap OK to confirm or Cancel to exit without

saving.

193

Value

Description

+0.1V

Raises the voltage by 0.1V

-0.1V

Lowers the voltage by 0.1V

+1.0V

Raises the voltage by 1V

-1.0V

Lowers the voltage by 1V

Figure 8-18 Sample Voltage Setting Screen 2

Method 3: Input the voltage value using the virtual keyboard. Tap the voltage field

to clear the current value and input the new value. Tap OK to confirm or Cancel to

exit without saving.

194

Figure 8-19 Sample Voltage Setting Screen 3

Frequency Setting

When the waveform mode is selected and the signal generator is operating, you

can also set the frequency value for that mode.

There are also three methods to adjust the frequency value:

Method 1: Tap the “+” and “-” buttons on the bottom of the screen in the

Frequency Setting.

195

Range

Button

Description

1Hz to 10Hz

Raises the frequency by 1Hz

Lowers the frequency by 1Hz

10Hz to 100Hz

Raises the frequency by 10Hz

Lowers the frequency by 10Hz

100Hz to 1000Hz

Raises the frequency by 100Hz

Lowers the frequency by 100Hz

1.0KHz to 30.0KHz

Raises the frequency by 1KHz

Lowers the frequency by 1KHz

Figure 8-20 Sample Frequency Setting Screen 1

Method 2: Tap the Frequency Setting button at the bottom of the screen to open a

dialog box. Adjust the frequency value by tapping the positive or negative value at

the bottom of the dialog box. The unit of the frequency can be switched Hz to KHz.

Tap OK to confirm or Cancel to exit without saving.

Figure 8-21 Sample Frequency Setting Screen 2

196

Value

Description

+1.0Hz

Raises the frequency by 1Hz

-1.0Hz

Lowers the frequency by 1Hz

+10.0Hz

Raises the frequency by 10Hz

-10.0Hz

Lowers the frequency by 10Hz

+1.0KHz

Raises the frequency by 1KHz

-1.0KHz

Lowers the frequency by 1KHz

+10.0KHz

Raises the frequency by 10KHz

-10.0KHz

Lowers the frequency by 10KHz

Method 3: Input the frequency value using the virtual keyboard. Tap the frequency

field to clear the current value and input the new value. Tap OK to confirm or

Cancel to exit without saving.

Figure 8-22 Sample Frequency Setting Screen 3

197

Range

Button

Description

1% to 99%

Raises the duty cycle ratio by 1%

Lowers the duty cycle ratio by 1%

Duty Cycle Setting

When the waveform mode is set, you can also set the duty cycle ratio for that mode.

There are three methods to adjust the duty cycle ratio:

Method 1: Tap the “+” and “-” buttons on the bottom of the screen in the Duty

Cycle Setting.

Figure 8-23 Sample Duty Cycle Setting Screen 1

Method 2: Tap the Duty Cycle Setting button at the bottom of the screen to open a

dialog box. Adjust the duty cycle by tapping the positive or negative ratio at the

bottom of the dialog box. Tap OK to confirm or Cancel to exit without saving.

198

Value

Description

+1.0%

Raises the duty cycle ratio by 1.0%

-1.0%

Lowers the duty cycle ratio by 1.0%

+10.0%

Raises the duty cycle ratio by 10%

-10.0%

Lowers the duty cycle ratio by 10%

Figure 8-24 Sample Duty Cycle Setting Screen 2

Method 3: Input the duty cycle ratio using the virtual keyboard. Tap the duty cycle

field to clear the current value and input the new value. Tap OK to confirm or

Cancel to exit without saving.

199

Waveform

Type

Description

Sample Waveform

DC Voltage

A waveform with constant

voltage

Figure 8-25 Sample Duty Cycle Setting Screen 3

8.3.6 Troubleshooting

If the signal generator cannot communicate with the MaxiSys Tablet:

Check if the VCMI device is properly connected to the MaxiSys Tablet through the

supplied USB cable.

IMPORTANT

To avoid damaging the vehicle and/or the equipment, all vehicle communications must

be terminated before resetting the connection. The Internet connection may be aborted

during resetting.

If the communication between the VCMI device and the MaxiSys Tablet still fails,

restart the MaxiSys Tablet and reconnect the VCMI device.

8.3.7 Glossary

200

Waveform

Type

Description

Sample Waveform

Square

Wave

A non-sinusoidal periodic

waveform with the duty cycle

of 50%

Square

Wave (X+Y)

A special square waveform

with normal and missing

teeth signals

Triangle

Wave

A asymmetrical triangular

waveform

201

8.4 OBDII Communication Line Inspection Operation

The VCMI (Vehicle Communication and Measurement Interface) working with MaxiSys

Ultra is designed with the OBDII communication line inspection function by checking

the ON-OFF lamps on the tablet screen.

Generally, the vehicle’s electronic control systems are designed to comply with the

specific communication protocols. The control units in the electronic control systems

communicate with the Tablet through the OBDII (DLC) adapter.

With the OBD communication line inspection function, you can check whether the

control units in vehicle’s electronic control systems work properly or not by illuminating

ON-OFF lamps according to the condition of sending out the communication signals.

8.4.1 Safety Information

Follow the instructions below to ensure proper communication line inspection

performance.

Different preconditions for different functions. Before inspection, please read the

inspection guides carefully.

The pin number for OBDII vary by vehicle modes. Please check and confirm for

correct pin number and then proceed inspection.

Select OBDII connector’s signal pins manually if the test vehicle’s actual

communication signal pins are assigned differently.

Ensure the DLC main cable is connected to the vehicle before inspection.

Ensure the ignition key is in ON position when testing the vehicle’s communication

line.

If the inspection fails due to no signal input, consult vehicle circuit diagram to ensure

correct communications are being tested.

Do not use in wet or damp conditions, or around explosive gas or vapor.

Do not tamper with or disassemble the product, connectors or accessories. Internal

damage will affect performance.

Disconnect the product from power source, vehicle and tablet before cleaning.

When cleaning the product, use a damp, soft cloth with mild detergent. Do not allow

water to enter the product casing, as this will cause damage to the electronics inside.

202

8.4.2 General Introduction

8.4.2.1 Component Locations

The main connectors are located on the bottom of the VCMI device.

1. Ethernet Connector

2. Vehicle Data Connector

3. Input Channel A

4. Input Channel B

5. Input Channel C

6. Input Channel D

8.4.3 Getting Started

Before opening the OBDII Communication Line Inspection application, you have to

complete three steps below:

1) Connect the VCMI device to the Tablet via Wi-Fi or the supplied USB, see Establish

Vehicle Communication on page 20.

2) Connect the VCMI device to the vehicle’s OBDII connector.

3) Place the ignition in the key on position.

203

Figure 8-1 Sample Connection Diagram

To open the OBDII Communication Line Inspection application

1. Please refer to Figure 8-1 Sample Connection Diagram to complete the

connection. Place the ignition in the key on position.

2. Tap the Measure icon on the Home screen of the MaxiSys Ultra Tablet. The

Measurement screen opens.

3. Tap the OBD icon to open the OBDII Communication Line Inspection Menu.

4. Select a communication protocol to test.

8.4.4 Update

The operating software of the device is continually optimized. Tap the Help button in

the upper half of the screen.

8.4.4.1 APK Update

NOTE

The acronym APK (Android Package Kit) is used on the tablet and in this manual. This

file contains all the assets of a particular app. To update the APK, is to install the latest

version of the app on your tablet.

To update the APK

1. Tap the Help button on the upper half of the screen. A dropdown menu displays.

204

Loading...

Loading...