Page 1

Trademarks

Autel®, MaxiSys®, MaxiDAS®, MaxiScan®, MaxiTPMS®, MaxiRecorder®, and

MaxiCheck® are trademarks of Autel Intelligent Technology Corp., Ltd.,

registered in China, the United States and other countries. All other marks

are trademarks or registered trademarks of their respective holders.

Copyright Information

No part of this manual may be reproduced, stored in a retrieval system or

transmitted, in any form or by any means, electronic, mechanical,

photocopying, recording, or otherwise without the prior written permission of

Autel.

Disclaimer of Warranties and Limitation of Liabilities

All information, specifications and illustrations in this manual are based on

the latest information available at the time of printing.

Autel reserves the right to make changes at any time without notice. While

information of this manual has been carefully checked for accuracy, no

guarantee is given to the completeness and correctness of the contents,

including but not limited to the product specifications, functions, and

illustrations.

Autel will not be liable for any direct damages or for any special, incidental,

or indirect damages or for any economic consequential damages (including

the loss of profits).

IMPORTANT

Before operating or maintaining this unit, please read this manual carefully,

paying extra attention to the safety warnings and precautions.

For Services and Support

pro.autel.com

www.autel.com

1-855-288-3587/1-855-AUTELUS (North America)

0086-755-86147779 (China)

Support@autel.com

For technical assistance in all other markets, please contact your local selling

agent.

i

Page 2

Safety Information

For your own safety and the safety of others, and to prevent damage to the

device and vehicles upon which it is used, it is important that the safety

instructions presented throughout this manual be read and understood by all

persons operating or coming into contact with the device.

There are various procedures, techniques, tools, and parts for servicing

vehicles, as well as in the skill of the person doing the work. Because of the

vast number of test applications and variations in the products that can be

tested with this equipment, we cannot possibly anticipate or provide advice

or safety messages to cover every circumstance. It is the automotive

technician’s responsibility to be knowledgeable of the system being tested. It

is crucial to use proper service methods and test procedures. It is essential

to perform tests in an appropriate and acceptable manner that does not

endanger your safety, the safety of others in the work area, the device being

used, or the vehicle being tested.

Before using the device, always refer to and follow the safety messages and

applicable test procedures provided by the manufacturer of the vehicle or

equipment being tested. Use the device only as described in this manual.

Read, understand, and follow all safety messages and instructions in this

manual.

Safety Messages

Safety messages are provided to help prevent personal injury and equipment

damage. All safety messages are introduced by a signal word indicating the

hazard level.

DANGER

Indicates an imminently hazardous situation which, if not avoided, will result

in death or serious injury to the operator or to bystanders.

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result

in death or serious injury to the operator or to bystanders.

ii

Page 3

Safety Instructions

The safety messages herein cover situations Autel is aware of. Autel cannot

know, evaluate or advise you as to all of the possible hazards. You must be

certain that any condition or service procedure encountered does not

jeopardize your personal safety.

DANGER

When an engine is operating, keep the service area WELL VENTILATED or

attach a building exhaust removal system to the engine exhaust system.

Engines produce carbon monoxide, an odorless, poisonous gas that causes

slower reaction time and can lead to serious personal injury or loss of life.

Do Not Turn the Volume Up Too Loud When Using Headphones

Listening at high volumes that over-stimulate the ear for long periods of time

may result in loss of hearing.

SAFETY WARNINGS

Always perform automotive testing in a safe environment.

Wear safety eye protection that meets ANSI standards.

Keep clothing, hair, hands, tools, test equipment, etc. away from all

moving or hot engine parts.

Operate the vehicle in a well ventilated work area, for exhaust gases are

poisonous.

Put the transmission in PARK (for automatic transmission) or NEUTRAL

(for manual transmission) and make sure the parking brake is engaged.

Put blocks in front of the drive wheels and never leave the vehicle

unattended while testing.

Be extra cautious when working around the ignition coil, distributor cap,

ignition wires and spark plugs. These components create hazardous

voltages when the engine is running.

Keep a fire extinguisher suitable for gasoline, chemical, and electrical

fires nearby.

Do not connect or disconnect any test equipment while the ignition is on

or the engine is running.

iii

Page 4

Keep the test equipment dry, clean, free from oil, water or grease. Use a

mild detergent on a clean cloth to clean the outside of the equipment as

necessary.

Do not drive the vehicle and operate the test equipment at the same time.

Any distraction may cause an accident.

Refer to the service manual for the vehicle being serviced and adhere to

all diagnostic procedures and precautions. Failure to do so may result in

personal injury or damage to the test equipment.

To avoid damaging the test equipment or generating false data, make

sure the vehicle battery is fully charged and the connection to the vehicle

DLC is clean and secure.

Do not place the test equipment on the distributor of the vehicle. Strong

electro-magnetic interference can damage the equipment.

iv

Page 5

1 Using this Manual

This manual contains device usage instructions.

Some illustrations shown in this manual may contain modules and optional

equipment that are not included in your system. Contact your sales

representative for availability of other modules and optional tools or

accessories.

Conventions

The following conventions are used.

Bold Text

Bold text is used to highlight selectable items such as buttons and menu

options.

Example:

Tap OK.

Notes and Important Messages

Notes

A NOTE provides helpful information such as additional explanations, tips,

and comments.

Example:

NOTE

New batteries reach full capacity after approximately 3 to 5 charging and

discharging cycles.

1

Page 6

Important

IMPORTANT indicates a situation which, if not avoided, may result in damage

to the test equipment or vehicle.

Example:

IMPORTANT

Keep the cable away from heat, oil, sharp edges and moving parts. Replace

damaged cables immediately.

Hyperlink

Hyperlinks, or links, that take you to other related articles, procedures, and

illustrations are available in electronic documents. Blue italic text indicates a

selectable hyperlink.

Illustrations

Illustrations used in this manual are samples, the actual testing screen may

vary for each vehicle being tested. Observe the menu titles and on-screen

instructions to make correct option selection.

2

Page 7

2 General Introduction

When it comes to ultra-portability, MaxiCheck MX808 is your perfect

companion. Installed with fast quad-core processor, MX808 offer maximum

convenience and swift diagnosis. The intuitive user interface makes using the

device effortless through a 7-inch LCD touchscreen that displays at 1024 x

600 quality. Together with the ability to quickly read and clear O.E.M.

enhanced codes for all available modules of the majority of the makes and

models on the market, MX808 provides you with superior special functions

for 7 systems, including Oil Reset, EPB (Electronic Parking Brake), SAS

(Steering Angle Sensor), BMS (Battery Management System), DPF (Diesel

Particulate Filter), IMMO, and TPMS (Tire Pressure Monitoring System).

This manual describes the construction and operation of the devices and how

it works to deliver diagnostic solutions.

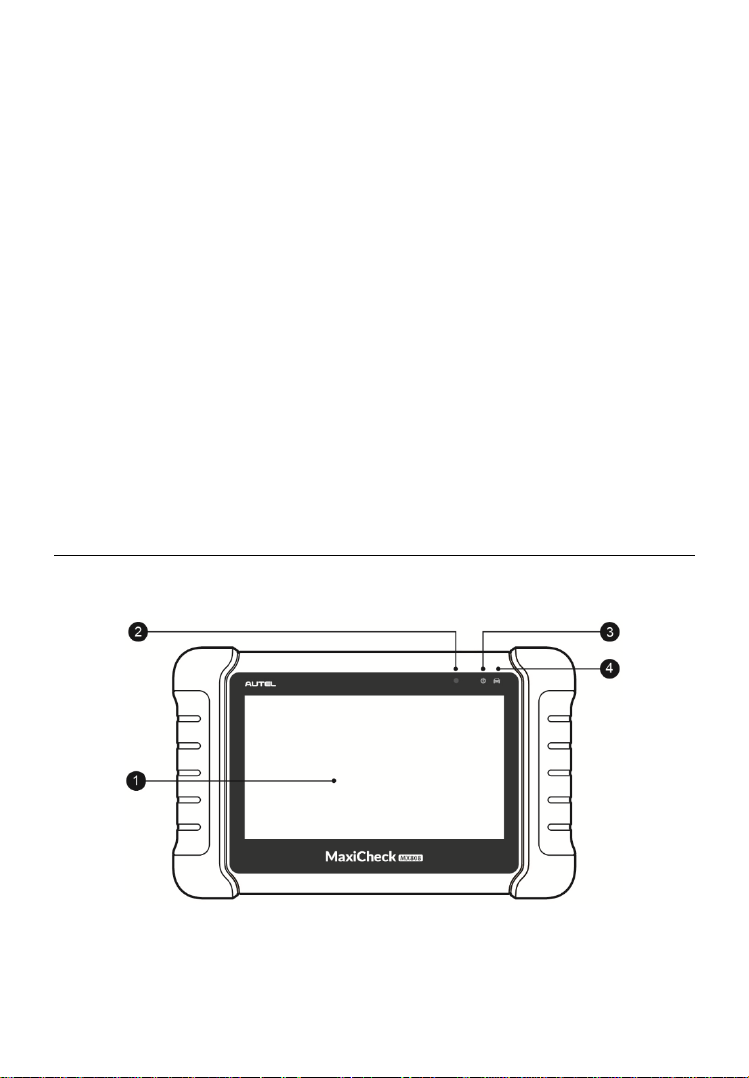

MaxiSys System Display Tablet

Functional Description

Figure 2-0-1 MaxiCheck MX808 Display Tablet Front View

1. 7.0” LCD capacitive touchscreen

3

Page 8

2. Ambient Light Sensor – detects ambient brightness.

3. Power LED – indicates battery level & charging or system status.

4. Vehicle Communication LED – flashes green when the Display Tablet is

communicating/linking with the vehicle’s system.

The power LED displays different colors in response to the following

scenarios:

A. Green

Illuminates green when the Display Tablet is charging and the

battery level is above 90%.

Illuminates green when the Display Tablet is powered on and the

battery level is above 15%.

B. Yellow

Illuminates yellow when the Display Tablet is charging and the

battery level is below 90%.

C. Red

Illuminates red when the Display Tablet is powered on and the

battery level is below 15%.

Figure 2-0-2 MaxiCheck MX808 Display Tablet Back View

5. Collapsible Stand – extends from the back to allow hands-free viewing

of the Display Tablet.

6. Heat Sink

4

Page 9

7. Built-in Battery

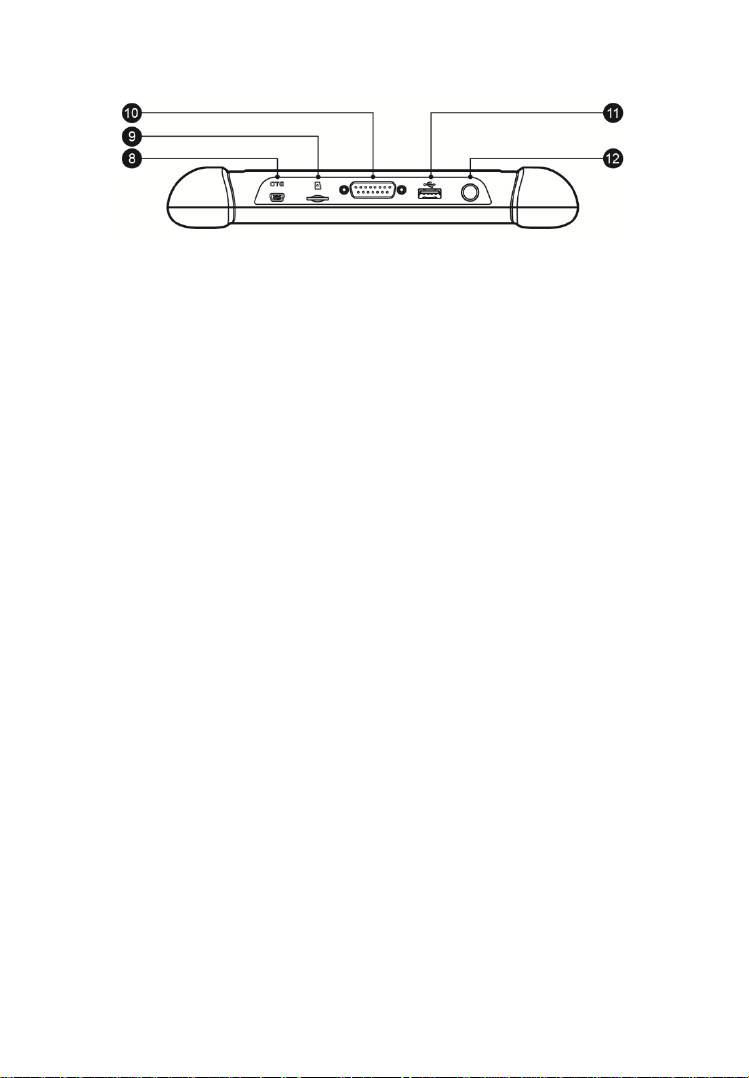

Figure 2-0-3 MaxiCheck MX808 Display Tablet Top View

8. Mini USB OTG Port

9. Micro SD Card Slot - holds the micro SD card.

10. DB15-Pin Port – connects the vehicle DLC cable.

11. USB Port

12. Lock/Power Button – turns the device on & off with long press, or locks

the screen with short press.

Power Sources

The Display Tablet can receive power from any of the following sources:

Internal Battery Pack

Vehicle Power

Mini USB Power Supply

Internal Battery Pack

The Display Tablet can be powered with the internal rechargeable battery,

which if fully charged can provide sufficient power for about 4.5 hours of

continuous operation.

Vehicle Power

The Display Tablet can be powered from the cigarette lighter or other suitable

power port on the test vehicle through a direct cable connection. The vehicle

power cable connects to the DC power supply port on the top side of the

display unit.

5

Page 10

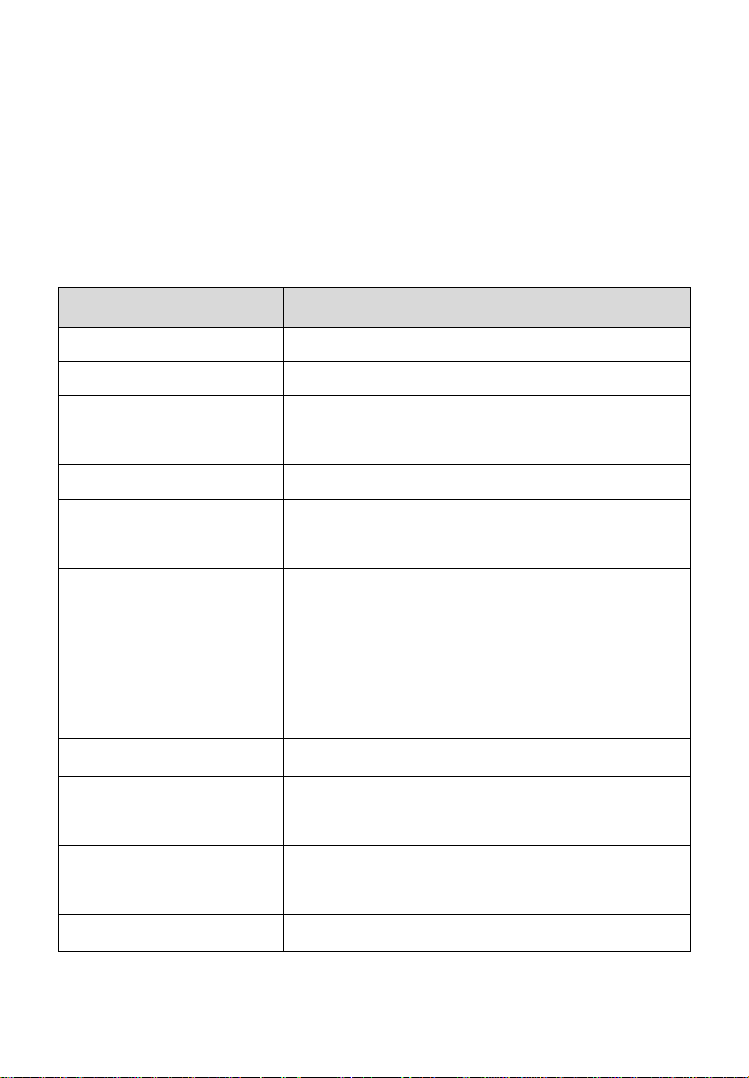

Item

Description

Recommended Use

Indoor

Operating System

AndroidTM 4.4.4

Processor

RockChip RK3188 Cortex-A9 processor (1.5

GHz)

Memory

1GB RAM DDR3 & 16GB ROM

Display

7-inch LCD capacitive touchscreen with

1024x600 resolution

Connectivity

Mini USB 2.0

USB 2.0

Wi-Fi

HDMI Type A

SD card (supports up to 32GB)

Sensors

Light sensor for brightness auto changing

Audio Input/Output

Input: NA

Output: buzzer

Power and Battery

3.7 V/3200 mAh lithium-polymer battery

Charges via 5 VDC power supply

Tested Battery Life

Around 4.5 hours of continuous use

Mini USB Power Supply

The Display Tablet can be powered from a wall socket using the Mini USB

power adapter. The AC/DC power supply also charges the internal battery

pack.

Technical Specifications

Table 2-1 Specifications

6

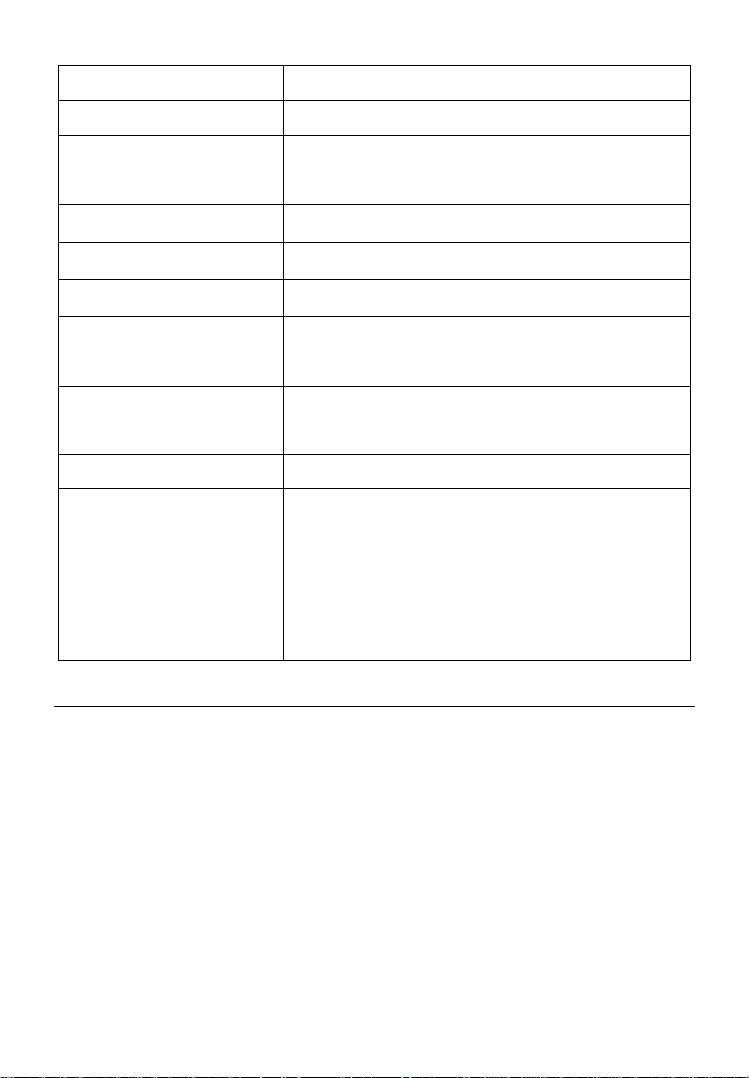

Page 11

Battery Charging Input

5 V/1.5 A

Input Voltage

12 V (9-35 V)

Power Consumption

500 mA (LCD on with default brightness, Wi-Fi

on) @3.7 V

Operating Temp.

-10 to 60°C(14 to 140°F)

Storage Temp.

-20 to 70°C (-4 to 158°F)

Operating Humidity

5% - 95% non-condensing

Housing

Strong plastic housing with protective rubber

boot

Dimensions (W x H x D)

237.8 mm (9.4”) x 148.6 mm (5.9”) x 35.5 mm

(1.4”)

Net Weight

788 g (2.42 lb.)

Supported Automotive

Protocols

ISO9142-2, ISO14230-2,ISO15765, K/L-Line,

Flashing Code, SAE-J1850 VPW, SAE-J1850

PWM, ISO11898(Highspeed, Middlespeed,

Lowspeed and Singlewire CAN,fault-tolerant

CAN), SAE J2610,GM UART,UART Echo Byte

Protocol, Honda Diag-H Protocol, TP2.0, TP1.6

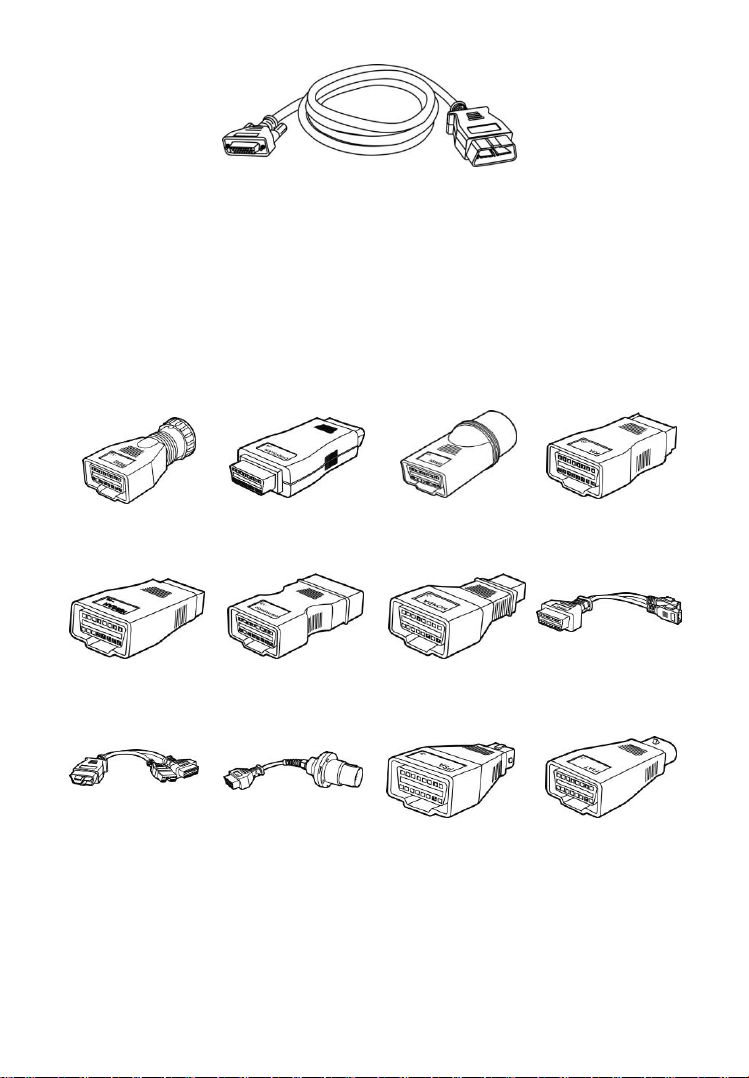

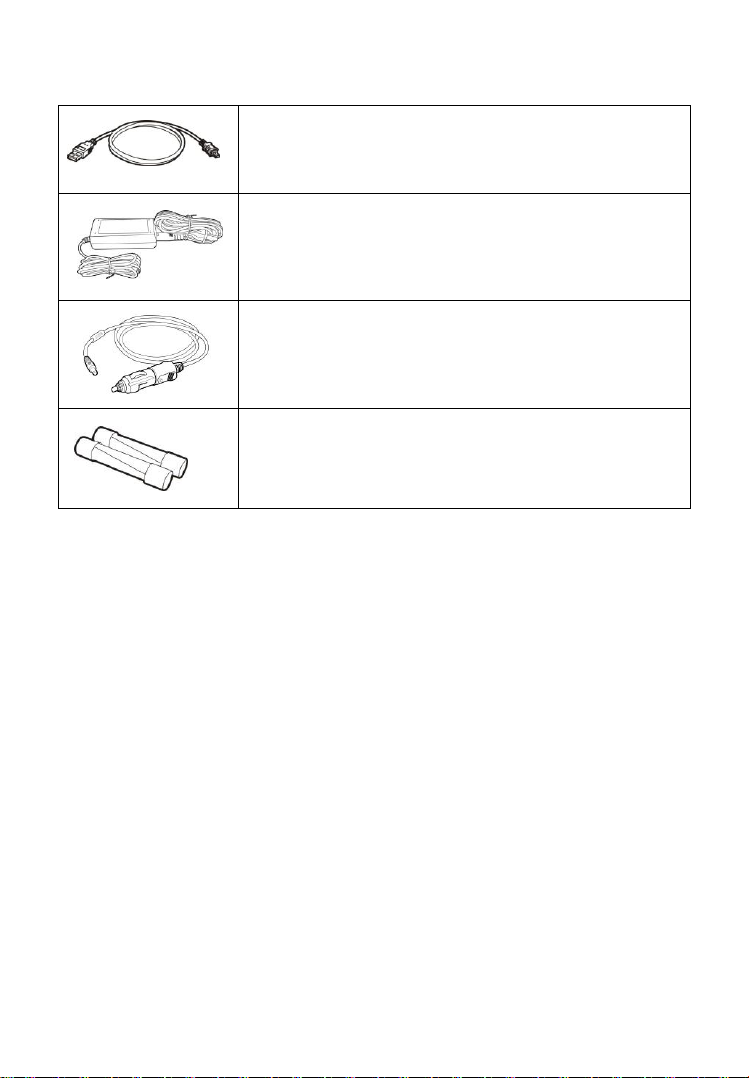

Accessory Kit

Main Cable

The Display Tablet can be powered through the Main Cable when

connected to an OBD II/EOBD compliant vehicle. The Main Cable

connects the Display Tablet to the vehicle’s data link connector (DLC).

7

Page 12

Benz-14

Chrysler-16

BMW-20

Kia-20

Nissan-14

GM/Daewoo-12

Honda-3

VW/Audi-2+2

Mitsubishi/

Hyundai -12+16

Benz-38

PSA-2

Fiat-3

Figure 2-0-4 Main Cable – 1.7 m in length

OBD I Adapters

The OBD I adapters are for Non-OBD II vehicles. The adapter used

depends on the type of vehicle being tested. The most common adapters

are shown below. (Benz-14 is for European unit only and Chrysler-16 is

for American unit only.)

8

Page 13

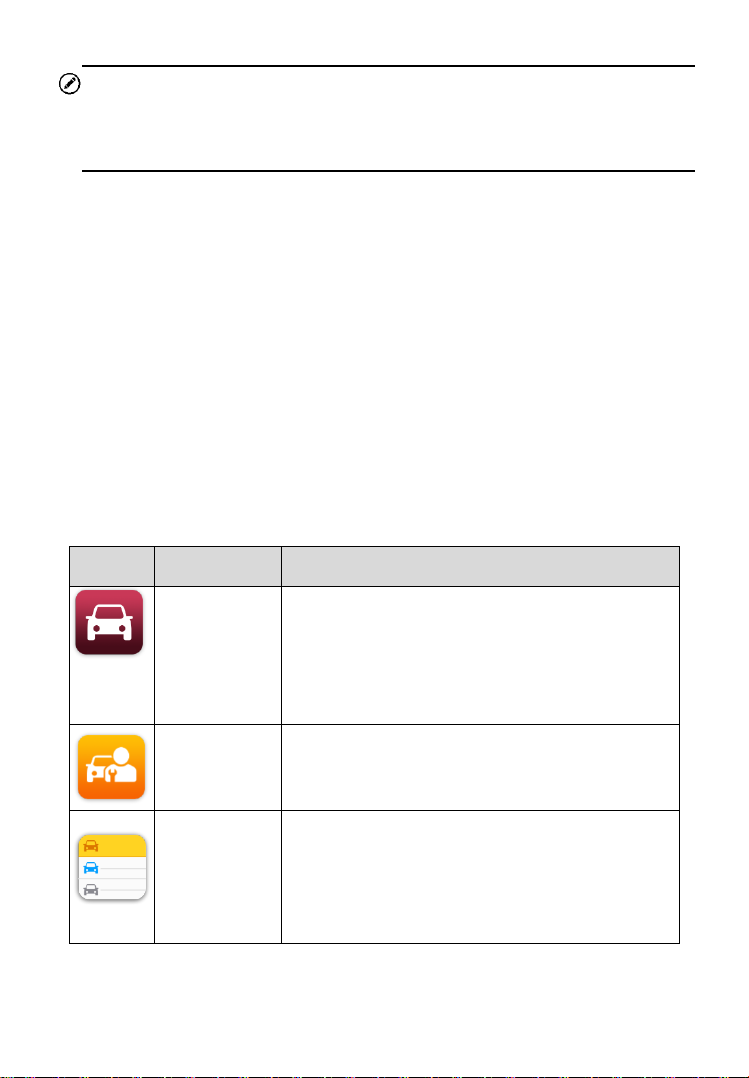

Mini USB Cable

Connects the Display Tablet to the PC or the VCI unit.

AC/DC External Power Adapter

Connects the Display Tablet to the external DC power

port for power supply.

Cigarette Lighter

Provides power to the Display Tablet through

connection to the vehicle’s cigarette lighter receptacle.

Lighter Fuse

A safety device for the cigarette lighter.

Other Accessories

9

Page 14

3 Getting Started

Make sure the Display Tablet has sufficient power or is connected to the

DC power supply (see 0 Power Sources on page 6).

NOTE

The images and illustrations depicted in this manual may differ from the actual

ones.

Powering Up

Long press the Lock/Power button on the top right of the Display Tablet to

switch the unit on. The power LED light will illuminate green. The system

boots up, and shows the lock screen. Sliding the Lock icon to unlock and

enter the MaxiCheck Job Menu (Figure 3-1):

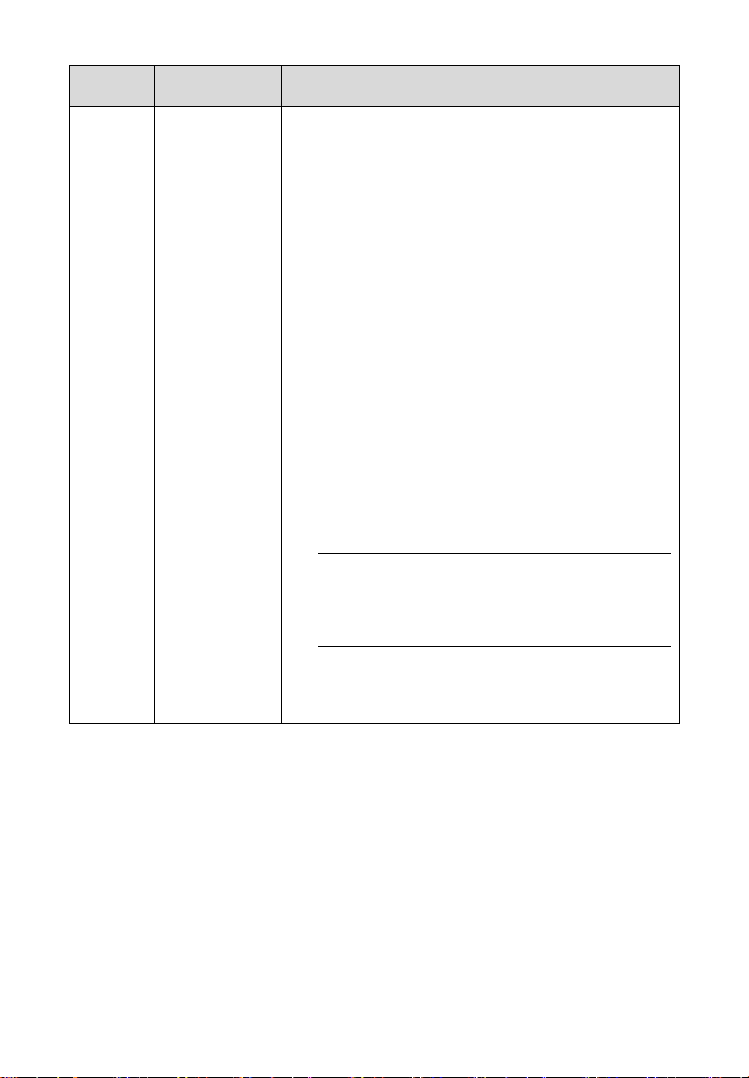

Figure 3-1 Sample MaxiCheck MX808 Job Menu

1. Application Buttons

2. Locator and Navigation Buttons

3. Status Icons

10

Page 15

Button

Name

Description

Diagnostics

Configures the unit to operate as a diagnostic

tool. See

4 Diagnostics

Operations on page 17.

Service

Consists of special functions for six systems: Oil

Reset, EPB, BMS, DPF, SAS, TPMS, and

IMMO.

Shop

Manager

Allows you to edit and save workshop

information and customer data, as well as

reviewing test vehicle history records. See 7

Shop Manager Operations on

page 79.

NOTE

The screen is locked by default when you turn on the display tablet. It is

recommended to lock the screen to protect the information in the system and

reduce the power consumption.

Almost all operations on the Display Tablet are controlled through the

touchscreen. The touchscreen navigation is menu driven, which allows you

to quickly locate the test procedure, or data that you need, through a series

of choices and questions. Detailed descriptions of the menu structures are

found in the chapters for the various applications.

Application Buttons

The Application buttons configure the MaxiSys for the type of operation or

activity to be performed. The table below gives brief descriptions of the

available applications.

Tap on the screen to select an application from the Job Menu.

Table 3-1 Applications

11

Page 16

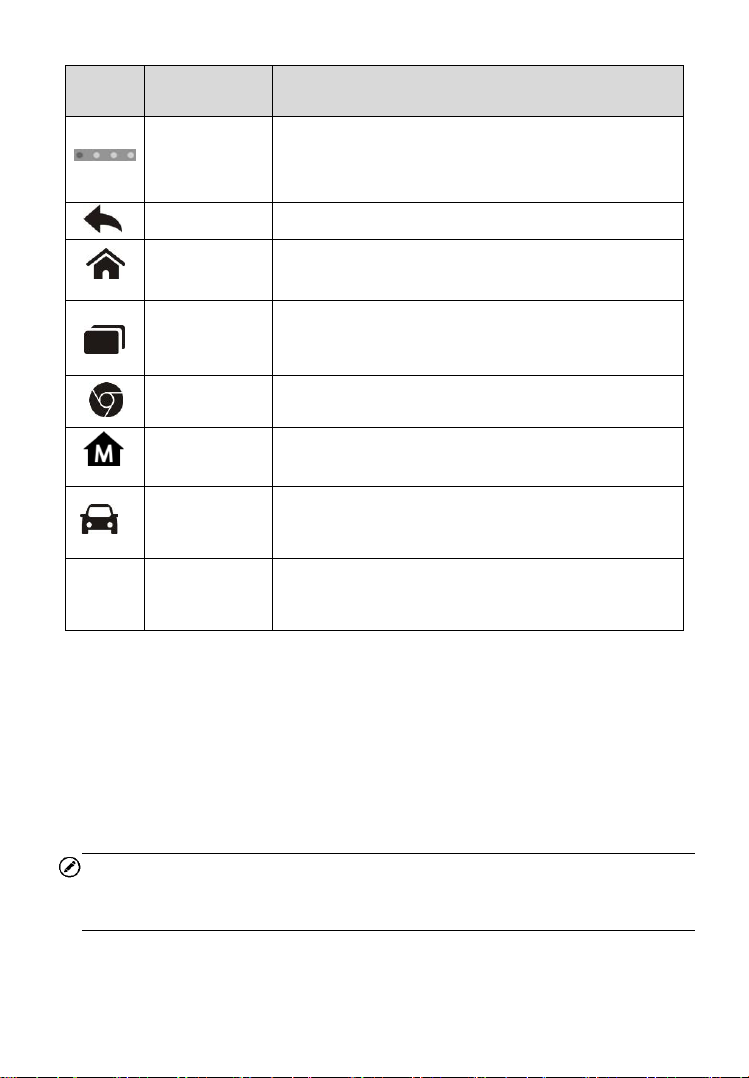

Button

Name

Description

Data

Manager

Opens the organization system for saved data

files. See 错误!表格结果无效。 on page 88.

Settings

Allows you to set the MaxiSys system settings,

and to view the general information about the

Display Tablet. See 9 Settings Operations on

page 93.

Update

Checks for the latest update available for the

MaxiSys system, and performs updating

procedures. See 10 Update Operations on

page 99.

Support

Launches the Support platform which

synchronizes Autel’s on-line service base

station with the MaxiSys tablet. See 11Support

Operations on page 102.

Training

Allows you to store and play technical tutorial

and training videos about the device usage or

vehicle diagnostic techniques. See 12 Training

Operations on page 112.

Remote

Desk

Configures your unit to receive remote support

using the TeamViewer application program.

See 13 Remote Desk Operations on page 114.

MaxiFix

Launches the MaxiFix platform which provides

the most compatible and abundant repair

techniques and diagnostics database. See 错

误!表格结果无效。 on page 69.

Quick Link

Provides associated website bookmarks to

allow quick access to product update, service,

support and other information. See 14 Quick

Link Operations on page 116.

12

Page 17

Button

Name

Description

Function

Viewer

Configures the unit to operate as an automotive

oscilloscope to perform electrical and electronic

circuit tests and monitor signal activitie

s. See

15 Function Viewer

The Function Viewer allows you to search

the functions supported by our tools and the

version information. There are two ways of

searching, either by searching the tool and

the vehicle or searching the functions.

To Search by the vehicle

1. Tap the Function Viewer

application on the MaxiSys Job

Menu. The Function Viewer

application screen displays.

2. Tap the tool name on the top left to

drop down the tool list, tap the one

you want to search.

3. Tap the vehicle brand, model, and

year you want to search.

4. All the functions support by the

selected tool for the selected

vehicle displays with three column,

13

Page 18

Button

Name

Description

function, sub function, and version.

Search by the functions

1. Tap the Function Viewer

application on the MaxiSys Job

Menu. The Function Viewer

application screen displays.

2. Tap the tool name on the top left to

drop down the tool list, tap the one

you want to search.

3. Type in the function you want to

search to the top right search

column. All the vehicles with this

function will be listed with 8

columns, the Brand, Model, Year,

System, Sub system, Function,

Sub function, and Version.

NOTE

Fuzzy search is supported, type in part of

the function you want to search can also find

you all the related.

on page

116.

Locator and Navigation Buttons

Operations of the Navigation buttons at the bottom of the screen are

described in the table below:

Table 3-2 Locator and Navigation Buttons

14

Page 19

Butto

n

Name

Description

Locator

Indicates the location of the screen. Swipe the

screen left or right to view the previous or next

screen.

Back

Returns to the previous screen.

Android

Home

Returns to Android System’s Home screen.

Recent

Apps

Displays a list of applications that are currently

working. To open an app, touch it. To remove an

app, swipe it to the top or bottom.

Chrome

Launches the Android built-in browser.

MaxiSys

Home

Returns to MaxiSys Job Menu.

MaxiSys

Shortcut

Returns to the MaxiSys operation interface from

other Android applications.

Service

Shortcut

Returns to the Service operation interface from

other Android applications.

System Status Icons

As the Display Tablet is working with the Android operating system, you may

refer to Android documents for more information.

By tapping on the bottom right corner, a Shortcuts Panel will be displayed, on

which you are allowed to set various system settings of the tablet. Operations

of each button on the panel are described in the table below:

NOTE

The shortcuts buttons will be highlighted when enabled, and dimmed when

disabled.

Table 3-3 Shortcuts Panel Buttons

15

Page 20

Button

Name

Description

Wi-Fi

Enables/disables Wi-Fi when pressed.

Battery

Indicates battery level and charging

status of the scan tablet.

Powering Down

All vehicle communications must be terminated before shutting down the

Display Tablet. A warning message displays if you attempt to shut down the

Display Tablet when it is communicating with the vehicle. Forcing a shutdown while communicating may lead to ECM problems on some vehicles.

Please exit the Diagnostics application before powering down.

To power down the display tablet

1. Press and hold the Lock/Power Button.

2. Tap Power off option.

3. Tap OK, the tablet will turn off in a few seconds.

Reboot System

In case of system crash, press and hold the Lock/Power button for 8 seconds

to reboot the system.

Installing Computer Software

The MaxiCheck MX808 Diagnostic Platform allows you to print the

information needed for your convenience. To realize the printing function, you

need to install the printer driver program.

To install the printer driver program

1. Insert the included CD into the CD-ROM of the computer and open

the CD folder.

2. Double click on Autel Run.exe item.

3. Click the MaxiSys Printer icon in the MaxiSys PC Suite screen.

4. Select the installation language and the printer driver installation

wizard will load momentarily.

16

Page 21

5. Follow the wizard instructions on the screen and click Next to

continue.

6. Click on Install and the printer driver program will be installed onto

the computer.

7. Click on Finish to complete the whole installation procedure.

NOTE

The MaxiSys Printer runs automatically after the installation.

Printing Operation

This section describes how to receive file from the Display Tablet and

perform printing through the computer:

To perform printing through the computer

1. Install the printer driver to the computer.

2. Before printing make sure the Display Tablet is connected to the

computer network, either via WiFi or LAN. See 0 Printing Setting on

page 94 for more information.

3. Run the MaxiSys Printer program on the computer to open up the

printer interface.

4. Click Test Print to make sure the printer is working successfully.

5. Tap the Print button on the toolbar. A temporary document will be

created and sent to the computer for printing.

6. The MaxiSys Printer will print the received document automatically

when the Auto Print option is selected.

7. If you need to print the document later, click Open PDF file and

select the document, and double click the Print button on the

MaxiSys Printer interface to start the printing.

NOTE

Make sure the computer installed with the Printing Driver program is

connected to a printer.

17

Page 22

4 Diagnostics Operations

By establishing a data link to the electronic control systems of the vehicle

being serviced directly, the Diagnostics application allows you to retrieve

diagnostic information, view live data parameters, and perform active tests.

The Diagnostics application can access the electronic control module (ECM)

for various vehicle control systems, such as engine, transmission, antilock

brake system (ABS), airbag system (SRS) and more.

Establishing Vehicle Communication

The Diagnostics operations require connecting the MaxiCheck MX808

diagnostic platform to the test vehicle using the main cable.

Vehicle Connection

The method used to connect the Display Tablet to a vehicle’s DLC depends

on the vehicle’s configuration as follows:

A vehicle equipped with an On-board Diagnostics Two (OBD II)

management system supplies both communication and 12-volt power

through a standardized J-1962 DLC.

A vehicle not equipped with an OBD II management system supplies

communication through a DLC connection, and in some cases supplies

12-volt power through the cigarette lighter receptacle or a connection to

the vehicle battery.

OBD II Vehicle Connection

This type of connection only requires the main cable without any additional

adapter.

To connect to an OBD II vehicle

1. Connect the main cable’s female adapter to the Vehicle Data

Connector on the Display Tablet, and tighten the captive screws.

18

Page 23

2. Connect the cable’s 16-pin male adapter to the vehicle’s DLC, which

is generally located under the vehicle dash.

NOTE

The vehicle’s DLC is not always located under the dash; refer to the user

manual of the test vehicle for additional connection information.

Non-OBD II Vehicle Connection

This type of connection requires both the main cable and a required OBD I

adapter for the specific vehicle being serviced.

To connect to a Non-OBD II Vehicle

1. Connect the main cable’s female adapter to the Vehicle Data

Connector on the Display Tablet and tighten the captive screws.

2. Locate the required OBD I adapter and connect its 16-pin jack to the

main cable’s male adapter.

3. Connect the attached OBD I adapter to the vehicle’s DLC.

NOTE

Some adapters may have more than one adapter or may have test leads

instead of an adapter. Whatever the case, make the proper connection to the

vehicle’s DLC as required.

Getting Started

Prior to first use of the Diagnostics application, the Display Tablet must be

properly connected to the vehicle’s DLC.

Vehicle Menu Layout

When the Display Tablet device is properly connected to the vehicle, the

platform is ready to start vehicle diagnosis. Tap on the Diagnostics

application button on the MaxiCheck MX808 Job Menu, the screen then

opens the Vehicle Menu.

19

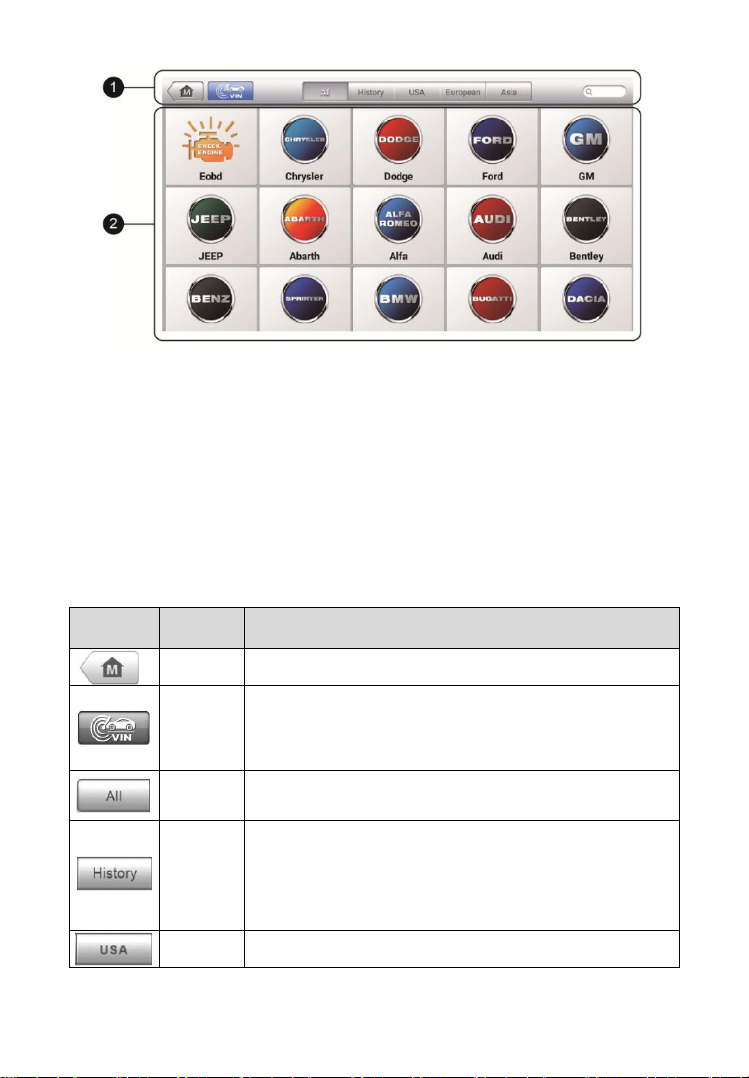

Page 24

Button

Name

Description

Home

Returns to the MaxiSys Job Menu.

VIN

Scan

Touching this button opens a dropdown list; tap

Auto Detect for auto VIN detection; tap Manual

Input to enter VIN manually.

All

Displays all the vehicle makes in the vehicle menu.

History

Displays the stored test vehicle history records. This

option provides you direct access to the previously

tested vehicle recorded during previous test

sessions. See 0 Vehicle History on page 80.

USA

Displays the USA vehicle menu.

Figure 0-1 Sample Vehicle Menu Screen

1. Top Toolbar Buttons

2. Manufacturer Buttons

Top toolbar Buttons

The operations of the Toolbar buttons at the top of the screen are listed and

described in the table below:

Table 0-1 Top Toolbar Buttons

20

Page 25

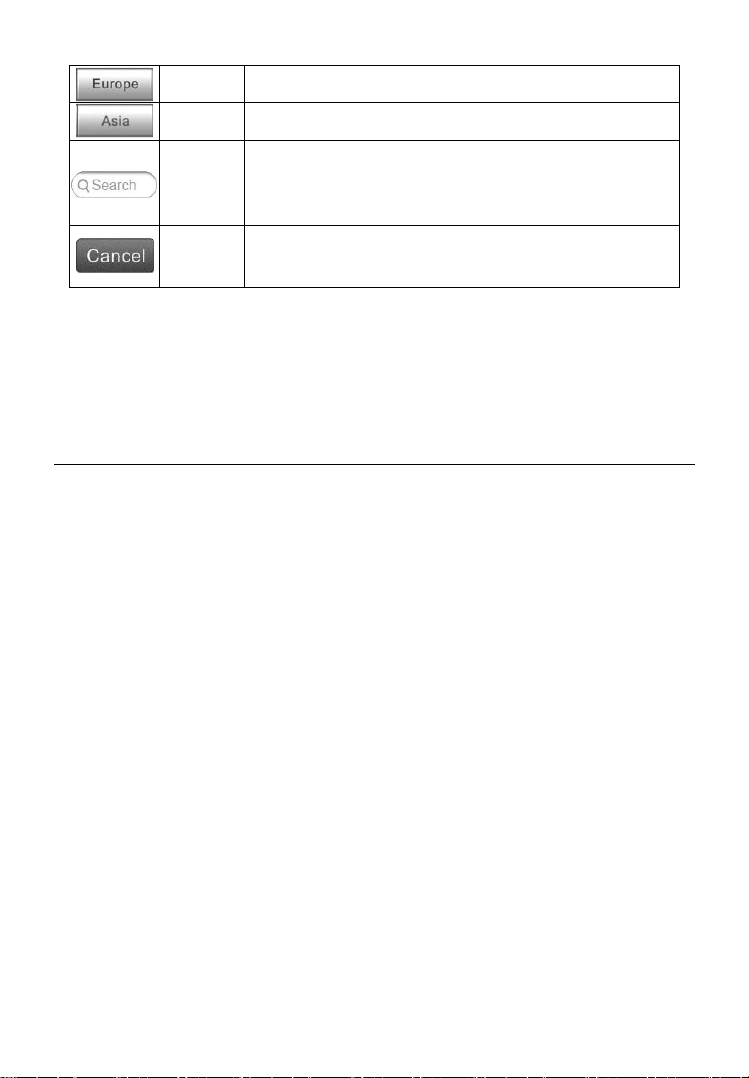

Europe

Displays the European vehicle menu.

Asia

Displays the Asian vehicle menu.

Search

Touching this button opens the virtual keyboard,

allowing you to manually enter the specific vehicle

make required.

Cancel

Touching this button exits the search screen, or

cancels an operation.

Manufacturer Buttons

The Manufacturer buttons display the various vehicle logos and the brand

names. Select the required manufacturer button after establishing the

communication with the test vehicle to start a diagnostic session.

Vehicle Identification

The MaxiSys diagnostic system supports four methods for Vehicle

Identification.

1. Auto VIN Scan

2. Manual VIN Input

3. Automatic Selection

4. Manual Selection

Auto VIN Scan

The MaxiSys diagnostic system features the latest VIN-based Auto VIN Scan

function to identify CAN vehicles in just one touch, which allows the technician

to quickly detect vehicles, scan all the diagnosable ECUs on every vehicle

and run diagnostics on the selected system.

To perform Auto VIN Scan

1. Tap the Diagnostics application button from the MaxiSys Job Menu.

The Vehicle Menu displays (Figure 0-).

2. Tap the VIN Scan button on the top toolbar.

21

Page 26

Figure 4-3 Sample Auto Detect Screen

Figure 4-2 Sample Auto VIN Screen

3. Select Auto Detect. Enter VIN manually or tap “Read” to acquire

VIN, the scan tool starts VIN scanning on the vehicle’s ECU. Once

the test vehicle is successfully identified, the screen will show you

the vehicle VIN, tap OK at the bottom to confirm the vehicle VIN.

4. Then tap OK to confirm the vehicle profile or NO to cancel.

22

Page 27

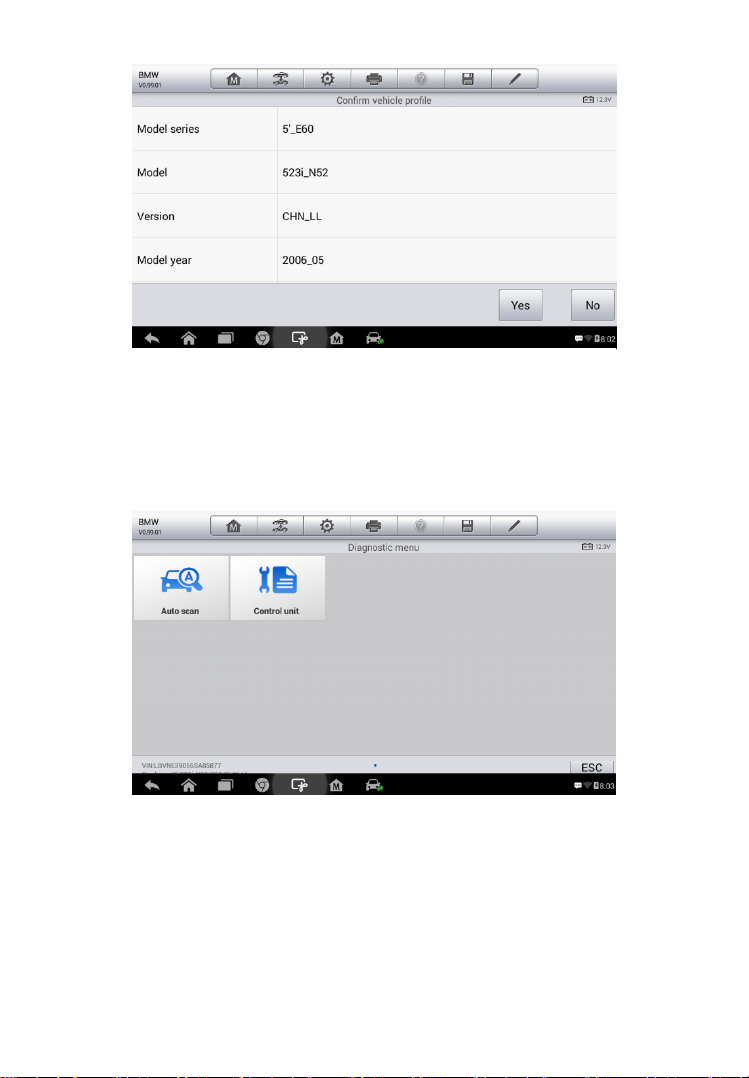

Figure 4-4 Sample Vehicle Profile Screen

Figure 4-0-1 Sample Vehicle Profile Screen

5. The tool would start establishing vehicle communication and reading

control unit information. You can choose Auto Scan to scan all the

available systems of the test vehicle or tap Control Unit to access

the desired system that you want to diagnose.

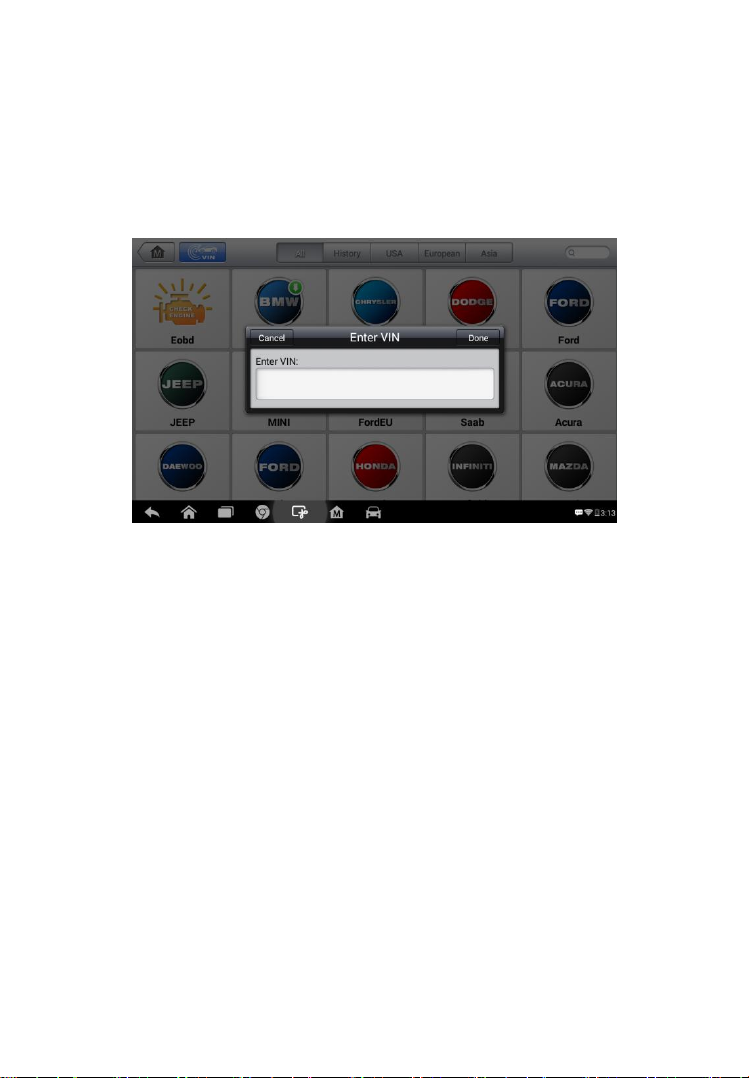

Manual VIN Input

For some vehicles that do not support the Auto VIN Scan function, the

MaxiSys diagnostic system allows you to enter the vehicle VIN manually.

23

Page 28

To perform Manual VIN Input

1. Tap the Diagnostics application button from the MaxiSys Job Menu.

The Vehicle Menu displays.

2. Tap the VIN Scan button on the top toolbar.

3. Select Manual Input.

4. Tap the input box and enter the correct VIN.

Figure 0-6 Sample Manual VIN Input

5. Tap Done. The vehicle will be identified in a few seconds, and once

the matching is successful, the system will guide you to the Vehicle

Diagnostics screen directly (错误!未找到引用源。).

6. Tap Cancel to exit Manual Input.

Automatic Selection

In some cases when users have selected the vehicle brand instead of

performing Auto VIN Scan in the first place, the system still provides an option

for vehicle VIN scan.

To perform Manual VIN Input

1. Tap the Diagnostics application button from the MaxiSys Job Menu.

The Vehicle Menu displays.

2. Tap the vehicle brand of the test vehicle.

24

Page 29

Figure 4-7 Sample Automatic Selection Screen

3. Tap Automatic Selection and the system will proceed to acquire

VIN information automatically. Follow the on-screen instruction to go

into diagnostic screen.

Manual Selection

When the vehicle’s VIN is not automatically retrievable through the vehicle's

ECU, or the specific VIN is unknown, you can choose to select the vehicle

manually.

Step-by-step Vehicle Selection

This mode of vehicle selection is menu driven; you can simply follow the onscreen prompts and make a series of choices. Each selection you make

advances you to the next step. A Back button at the bottom right corner of

the screen will bring you back to the previous step. Exact procedures may

vary for different vehicles being serviced.

Alternative Vehicle Identification

Occasionally, you may identify a test vehicle that the tester does not

recognize; the database does not support, or has some unique

characteristics that prevent it from communicating with the tester through the

normal channels. In these instances, you are provided with the OBD direct

25

Page 30

Figure 4-8 Sample Diagnostics Screen

entry, through which you can perform generic OBD II or EOBD tests. See 0

Generic OBD II Operations on page 44 for details.

Navigation

This section describes how to navigate the Diagnostics interface and select

test options.

Diagnostics Screen Layout

The diagnostic screens typically include four sections (错误!未找到引用源。).

1. Diagnostics Toolbar

2. Status Information Bar

3. Main Section

4. Functional Buttons

Diagnostics Toolbar

The Diagnostics Toolbar contains a number of buttons that allow you to print

or save the displayed data and make other controls. The table below provides

a brief description for the operations of the Diagnostics Toolbar buttons.

26

Page 31

Button

Name

Description

Home

Returns to the MaxiSys Job Menu.

Vehicle

Swap

Touching this button allows you to exit the diagnostic

session of the currently identified test vehicle, and

returns you to the vehicle menu screen to select

another vehicle for testing.

Settings

Opens the setting screen. See 9 Settings

Operations on page 93.

Print

Saves and prints a copy of the displayed data. See

0 Printing Operation for additional information on

page 15.

Help

Provides instructions or tips for operations of various

diagnostic functions.

Save

Tapping this button opens a submenu, on which

there are 3 options available to save the displayed

data.

Tap Save This Page to take a screenshot

image

Tap Save All Data to save a PDF file (mostly

used to save data that cover more than 1 page)

Tap Start Saving to record a video clip (only

available for recording Live Data or special

graph data)

All saved data are stored in the Data Manager

application for later reviews. See

错误!表格结果

无效。

on page 88.

Data

Logging

Records the communication data and ECU

information of the test vehicle. The saved data can

Table 0-2 Diagnostics Toolbar Buttons

27

Page 32

Button

Name

Description

be reported and sent to the technical center via the

internet.

You can go to the Support application to follow up

the processing progress, see 0 Data Logging on

page 107 for detailed information.

Send

Tapping this button submits the Data Logging report

to the technical center via the internet.

To print data in Diagnostics

1. Tap the Diagnostics application button from the MaxiSys Job Menu.

The Print button on the diagnostic toolbar is available throughout

the whole Diagnostics operations.

2. Tap Print whenever you want to make a printing. A drop-down menu

appears.

a) Print This Page – prints a screenshot copy of the current

screen.

b) Print All Page – prints a PDF copy of all displayed data.

3. A temporary file will be created and send to the computer for printing.

4. When the file is transferred successfully, a confirmation message

displays.

NOTE

Make sure the Display Tablet is connected to the computer network, either

via Wi-Fi or LAN, before printing. For more instructions on printing, see 0

Printing Operation on page 15 for details.

To submit Data Logging reports in Diagnostics

1. Tap the Diagnostics application button from the MaxiSys Job Menu.

The Data Logging button on the diagnostic toolbar is available

throughout the whole Diagnostics operations.

2. Tap the Data Logging button. The button displays blue during the

active recording process.

3. Tap the Data Logging button again to finish recording. A submission

28

Page 33

form will display to let you fill in the report information.

4. Tap the Send button to submit the report form via the internet, a

confirmation message displays when sending is successful.

Status Information Bar

The Status Information Bar at the top of the Main Section displays the

following items:

1. Menu Title – indicates the menu subject of the Main Section.

2. Voltage Icon – indicates the voltage status of the VEHICLE.

Main Section

The Main Section of the screen varies depending on the stage of operations.

The Main Section can show vehicle identification selections, the main menu,

test data, messages, instructions and other diagnostic information.

Functional Buttons

The displayed Functional Buttons at this section of the screen varies

depending on the stage of operations. They can be used to navigate, save or

clear the diagnostic data, exit scanning as well as make other functional

controls. The functions of these buttons will be introduced respectively in the

following sections of the corresponding test operations.

Screen Messages

Screen messages appear when additional input is needed before proceeding.

There are mainly three types of on-screen messages as to their purposes:

Confirmation, Warning, and Error.

Confirmation Messages

This type of messages usually displays as an “Information” screen, which

informs you when you are about to perform an action that cannot be reversed

or when an action has been initiated and your confirmation is needed to

continue.

29

Page 34

When a user-response is not required to continue, the message displays

briefly before automatically disappearing.

Warning Messages

This type of messages informs you when completing the selected action may

result in an irreversible change or loss of data. The typical example for this is

the “Erase Codes” message.

Error Messages

Error messages inform you when a system or procedural error has occurred.

Examples of possible errors include a disconnection or communication

interruption due to certain reasons.

Making Selections

The Diagnostics application is a menu driven program that presents a series

of choices one at a time. As you select from a menu, the next menu in the

series displays. Each selection narrows the focus and leads to the desired

test. Use your fingertip to make menu selections.

Diagnosis

The Diagnostics application allows you to establish a data link to the

electronic control system of the test vehicle for vehicle diagnosis or service.

You can operate functional tests, retrieve vehicle diagnostic information such

as trouble codes, event codes and live data for various vehicle control

systems, such as engine, transmission, ABS, and more.

There are two options available when accessing the Diagnosis section:

1. Auto Scan – starts auto scanning for all the available systems on the

vehicle.

2. Control Units – displays a selection menu of all available control units

of the test vehicle.

After a section is selected and the tablet establishes communication with the

vehicle via the VCI device, the corresponding function menu or selection

menu displays.

30

Page 35

Figure 4-9 Sample Auto Scan Operation Screen

Auto Scan

The Auto Scan function performs a comprehensive scanning over all the

systems on the vehicle’s ECU in order to locate fault systems and retrieve

DTCs. The sample operation interface of Auto Scan displays as below:

1. Navigation Bar

2. Main Section

3. Functional Buttons

Navigation Bar

1. List Tab – displays the scanned data in list format.

2. Progress Bar – indicates the test progress.

Main Section

A. List Tab

Column 1 - displays the system numbers.

Column 2 - displays the scanned systems.

Column 3 - displays the diagnostic marks indicating different

conditions of the test result:

-!-: Indicates that the scanned system may not support the

code reading function, or there is a communication error

between the tester and the control system.

31

Page 36

Name

Description

ESC

Returns to the previous screen or exit Auto Scan.

Pause

Suspends scanning and changes to show the Continue

button.

OK

Confirms the test result, and continues to the system

diagnosis after selecting the required system by tapping

the item in the Main Section.

Quick

Erase

Deletes codes. A warning message screen will display to

inform you of possible data loss when this function is

selected.

Report

Displays the diagnostic data in the report form.

-?-: Indicates that the vehicle control system has been detected,

but the tester cannot accurately locate it.

Fault | #: Indicates there is/are detected fault code(s) present;

“#” indicates the number of the detected faults.

Pass | No Fault: Indicates the system has passed the scanning

process and no fault has been detected.

Tap the

want to perform further diagnosis and other test activities. A

Function Menu screen (Figure 0-10) shall then display.

Functional Buttons

The table below provides a brief description of the Functional

Buttons’ operations in Auto Scan:

> button to the right of the system item, on which you

○

Table 0-3 Functional Buttons in Auto Scan

32

Page 37

Control Units

This option allows you to manually locate a required control system for testing

through a series of choices. Please follow the menu driven procedure, and

make proper selection each time; the program will guide you to the diagnostic

function menu after a few choices you’ve made.

Figure 0-10 Sample Function Menu Screen

The Function Menu options vary slightly for different vehicles. The function

menu may include:

ECU Information – provides the retrieved ECU information in detail.

Selecting opens an information screen.

Read Codes – displays detailed information of DTC records retrieved

from the vehicle control module.

Erase Codes – erases DTC records and other data from the ECM.

Live Data – retrieves and displays live data and parameters from the

vehicle’s ECU.

Active Test – provides specific subsystem and component tests. This

selection may appear as Actuators, Actuator Test, or Function Tests,

etc., and the tests options vary depending on the manufacturer and

model.

NOTE

With the diagnostic toolbar on top of the screen throughout the whole

diagnostic procedures, you are allowed to make various controls of the

33

Page 38

Figure 4-11 Sample ECU Information Screen

diagnostic information at any time, such as printing and saving the displayed

data, getting help information, or performing data logging, etc.

To perform a diagnostic function

1. Establish communication with the test vehicle.

2. Identify the test vehicle by selecting from the menu options.

3. Select the Diagnosis section.

4. Locate the required system for testing by Auto Scan or through

menu driven selections in Control Units.

5. Select the desired diagnostic function from the Function Menu.

ECU Information

This function retrieves and displays the specific information for the tested

control unit, including unit type, version numbers and other specifications.

The sample ECU Information screen displays as below:

1. Diagnostics Toolbar Buttons – see

2. Table 0-2 Diagnostics Toolbar Buttons on page 26 for detailed

descriptions of the operations for each button.

3. Main Section – the left column displays the item names; the right column

shows the specifications or descriptions.

34

Page 39

Figure 4-12 Sample Read Codes Screen

4. Functional Button – In this case, only an ESC (or sometimes a Back)

button is available; tap it to exit after viewing.

Read Codes

This function retrieves and displays the DTCs from the vehicle’s control

system. The Read Codes screen varies for each vehicle being tested. On

some vehicles, freeze frame data can also be retrieved for viewing. The

sample Read Codes screen displays as below:

1. Diagnostics Toolbar Buttons – see

2. Table 0-2 Diagnostics Toolbar Buttons on page 26 for detailed

descriptions of the operations for each button.

3. Main Section

Code Column – displays the retrieved codes from the vehicle.

Status Column – indicates the status of the retrieved codes.

Description Column – detailed descriptions for the retrieved codes.

Snowflake Icon – only displays when freeze frame data is available

for viewing; Selecting this icon will display a data screen, which

looks very similar to the Read Codes interface, therefore same

operation method may be applied.

4. Functional Button

Help – tap this to view the information of the fault code, including

35

Page 40

fault description, condition for fault identification, driver information,

etc.

Freeze – tap this to view the freeze frame.

Search – tap this icon to search the fault code related information in

Google.

ESC – tap it to return to the previous screen or exit the function.

Erase Codes

After reading the retrieved codes from the vehicle and certain repairs have

been carried out, you can erase the codes from the vehicle using this function.

Before performing this function, make sure the vehicle’s ignition key is in the

ON (RUN) position with the engine off.

To erase codes

1. Tap Erase Codes from the Function Menu.

2. A warning message displays to inform you of data loss when this

function is applied.

a) Tap Yes to continue. A confirming screen displays when the

operation is successfully done.

b) Tap No to exit.

3. Tap ESC on the confirming screen to exit Erase Codes.

4. Perform the Read Codes function again to check if the code erasing

is successful.

36

Page 41

Figure 0-13 Sample Live Data Screen

Live Data

When this function is selected, the screen displays the data list for the

selected module. The items available for any control module vary from one

vehicle to another. The parameters display in the order that they are

transmitted by the ECM, so expect variation between vehicles.

Gesture scrolling allows you to quickly move through the data list. Simply

swipe the screen up or down to locate the data you want. The figure below

shows a typical Live Data screen:

1. Diagnostics Toolbar Buttons – tap the drop-down button at the

center of the screen and the toolbar buttons will display. See

2. Table 0-2 Diagnostics Toolbar Buttons on page 26 for detailed

descriptions of the operations for each button.

3. Main Section

Name Column – this column displays the parameter names.

a) Check Box - tap the check box at the left side of the parameter

name to make selection of an item. Tap the check box again to

deselect the item.

b) Drop-down Button – tapping the drop-down button at the right

side of the parameter name opens a submenu, which provides

various choices for data display mode.

37

Page 42

Value Column – displays the values of the parameter items.

Unit Column – displays the unit for the parameters.

To change the unit mode, tap the Setting button on the top

toolbar and select a required mode. See 0 Unit on page 93 for

more information.

4. Display Mode

There are 4 types of display modes available for data viewing, allowing

you to view various types of parameters in the most suitable way.

Tapping the drop-down button on the right side of the parameter name

opens a submenu. There are 4 buttons to configure the data display

mode, and one Help button on the right that you can tap for additional

information.

Each parameter item displays the selected mode independently.

Analog Gauge Mode – displays the parameters in form of an analog

meter graph.

Text Mode – this is the default mode which displays the parameters in

texts and shows in list format.

NOTE

Reading of status parameters, such as a switch reading, which are mostly in

word form, like ON, OFF, ACTIVE, and ABORT, etc., can only be displayed

in Text Mode. Whereas reading of value parameters, such as a sensor

reading, can be displayed in text mode and other graph modes.

Waveform Graph Mode – displays the parameters in waveform graphs

When this mode is applied, three control buttons will appear on the right

side of the parameter item, allowing you to manipulate the display status.

Text Button – resumes Text Display Mode.

Scale Button – changes the scale values, which are displayed

below the waveform graph. There are 3 scales available: x1, x2,

x4 and x8.

Zoom-in Button – tap once to display the selected data graph

in full screen.

38

Page 43

Digital Gauge Mode– displays the parameters in form of a digital gauge

graph.

Full Screen Display – this option is only available in the waveform graph

mode, and mostly used in Graph Merge status for data comparison.

There are three control buttons available on the top right side of the

screen under this mode.

Edit Button – tapping this button opens an edit window, on

which you can set the waveform color and the line thickness

displayed for the selected parameter item.

Scale Button - changes the scale values, which are displayed

below the waveform graph. There are 4 scales available: x1, x2,

x4 and x8.

Zoom-out Button – exits full screen display.

To edit the waveform color and line thickness in a data graph

1. Select 1 to 3 parameter items to display in Waveform Graph

mode.

2. Tap the Zoom-in Button on the right to display the data graph

in full screen.

3. Select a parameter item on the left column.

4. Select a desired sample color from the second column.

5. Select a desired sample line thickness from the right column.

6. Repeat step 3-5 to edit the waveform for each parameter item.

7. Tap Done to save the setting and exit, or tap Cancel to exit

without saving.

5. Functional Buttons

The operations of all the available functional buttons on Live Data screen

are described below:

Back – returns you to the previous screen or exit the function.

Record – starts recording the retrieved live data; the recorded data is

then stored as a video clip in the Data Manager application for future

reviews. This function could be triggered automatically at preset

threshold value or manually as you choose, and the triggering mode and

record duration can be configured in the Setting mode of Live Data.

39

Page 44

Freeze – displays the retrieved data in freeze mode.

Previous Frame – Moves to the previous frame in the freeze

data.

Next Frame – Moves to the next frame in the freeze data.

Resume – this button appears when the Record or Freeze function is

applied. Tapping this button stops data recording, or exit freeze data

mode, and resumes normal data display mode.

Flag – this button appears when the Record function is applied. Tapping

this button sets flags for the recorded data at points wherever you choose.

When playing back the recorded video clip later in Data Manager, the

preset flag will enable a popup to allow input of text to take notes.

Clear Data – clears all previously retrieved parameter values at a cutting

point whenever you choose.

To Top – moves a selected data item to the top of the list.

Graph Merge – tap this button to merge selected data graphs (for

Waveform Graph Mode only). This function is very useful when making

comparison between different parameters.

NOTE

This mode supports Graph Merge for 2 to 3 parameter items only, so select

no less than 2 or no more than 3 items each time when making graph merge.

To cancel Graph Merge mode, tap the drop-down button on the right side

of the parameter name, and select a data display mode.

Show Selected/Show All – tap this option to switch between the two

options; one displays the selected parameter items, the other displays

all the available items.

40

Page 45

Setting – tapping this button opens a setting screen, which allows you

to set the trigger mode, recording duration, and various threshold values

for data recording, and make other controls.

Figure 4-14 Sample Setting Mode in Live Data

There are four navigation buttons on top of the Setting mode screen.

Selected Button – displays the configuration screen on which you can

set the threshold values, an upper limit and a lower limit, for triggering

the buzzer alarm. This function is only applied to the Waveform Graph

display mode.

a) MIN – tapping which opens a virtual keyboard, allowing you to enter

the required lower limit value

b) MAX – tapping which opens a virtual keyboard, allowing you to enter

the required upper limit value

c) Buzzer Alarm – switches the alarm on and off. The alarm function

makes a beep sound as a reminder whenever the data reading

reaches the preset minimum or maximum point

To set threshold limits for the parameter values

1. Tap the Setting functional button at the bottom of the Live Data

screen.

2. Tap the Selected navigation button.

41

Page 46

3. Select a parameter item on the left column, or enter the item name

in the Search bar.

4. Tap on the right side of the MIN button, and enter the required

minimum value.

5. Tap on the right side of the MAX button, and enter the required

maximum value.

6. Tap the ON/OFF button on the right side of the Buzzer Alarm button

to turn it on or off.

7. Tap Done to save the setting and return to the Live Data screen; or

tap Cancel to exit without saving.

If the threshold limits are successfully set, two horizontal lines will appear on

each of the data graphs (when Waveform Graph Mode is applied) to indicate

the alarming point. The threshold lines are shown in different colors from the

waveform of the parameters for distinction.

Record Button – displays the configuration screen for Record Setting,

on which you can set the trigger type, duration and trigger point for the

data recording function.

a) Trigger Type – sets the trigger mode for data recording, mainly of

two kinds: Manual and Auto. There are four options available:

1) Manual – allows you to manually start and stop data recording

2) DTC – auto triggers data recording when any DTC is detected

3) DTC Check Mode – auto triggers data recording when certain

pre-selected DTC types are detected

4) Parameter – auto triggers data recording when any parameter

value reaches the preset threshold

b) Duration – sets the recording time (for Auto trigger mode only)

c) Trigger Point – reserves a relative percentage of a record length

before the data recording start point for reference (for Auto trigger

mode only)

To perform setting for live data record

1. Tap the Setting functional button at the bottom of the Live Data

screen.

2. Tap the Record navigation button.

42

Page 47

3. Tap the ○> button on the right of Trigger Type bar and select the

required trigger mode.

4. Tap the ○> button on the right of Duration bar and select a length

of time.

5. Tap the ○> button on the right of Trigger Point bar and select a

relative percentage of a record length to be reserved before the data

recording start point.

6. Tap Done to save the setting and return to the Live Data screen; or

tap Cancel to cancel without saving and exit Setting.

Done Button - confirms and saves the setting, and returns you to the

Live Data screen.

Cancel Button – cancels the setting operation, and returns you to the

Live Data screen.

Active Test

The Active Test function is used to access vehicle-specific subsystem and

component tests. Available tests vary depending on the manufacturer, year,

and model, and only the available tests display in the menu.

During an active test, the tester outputs commands to the ECU in order to

drive the actuators. This test determines the integrity of the system or parts

by reading the engine ECU data, or by monitoring the operation of the

actuators, such as switching a solenoid, relay, or switch, between two

operating states.

Selecting Active Test opens a menu of test options that varies by make and

model. Selecting a menu option activates the test. Follow all screen

instructions while performing tests. The content and pattern of the on-screen

information vary according to the type of test being performed. Some toggle

and variable control tests display Active Test Controls at the top of the screen

with data stream information below, or vice versa.

43

Page 48

Figure 4-15 Sample Active Test Menu

Figure 4-10-2 Sample Active Test Operation Screen

The functional buttons at the lower right corner of the Active Test screen

manipulate the test signals. The operational instructions are displayed on the

main section of the test screen. Simply follow the on-screen instructions and

make appropriate selections to complete the tests. Each time when an

operation is successfully executed, message such as “Command Finished”,

“Activation Successful”, or something similar displays.

Tap the ESC functional button to exit the test when finished.

44

Page 49

Generic OBD II Operations

A fast-access option for OBD II/EOBD vehicle diagnosis is available on the

Vehicle Menu screen (Figure 0-). This option presents a quick way to check

for DTCs, isolate the cause of an illuminated malfunction indicator lamp (MIL),

check monitor status prior to emissions certification testing, verify repairs, and

perform a number of other services that are emissions-related. The OBD

direct access option is also used for testing OBD II/EOBD compliant vehicles

that are not included in the Diagnostics database.

Functions of the diagnostics toolbar buttons at the top of the screen are the

same as those available for specific vehicle diagnostics. See

Table 0-2 Diagnostics Toolbar Buttons on page 26 for details.

General Procedure

To access the OBD II/EOBD diagnostics functions

1. Tap the Diagnostics application button from the MaxiSys Job Menu.

The Vehicle Menu displays.

2. Tap the EOBD button. There are two options to establish

communication with the vehicle.

Auto Scan – When this option is selected the diagnostic tool

attempts to establish communication using each protocol in

order to determine which one the vehicle is broadcasting on.

Protocol – When this option is selected the screen opens a

submenu of various protocols. A communication protocol is a

standardized way of data communication between an ECM and

a diagnostic tool. Global OBD may use several different

communication protocols.

45

Page 50

3. Select a specific protocol under the Protocol option. Wait for the

OBD II Diagnostic Menu to appear.

Figure 5-1 Sample OBD II Diagnostic Menu

NOTE

Tapping the ○i button displayed beside the function name opens a bubble

with additional function information.

4. Select a function option to continue.

DTC & FFD

I/M Readiness

Live Data

O2 Sensor Monitor

On-Board Monitor

Component Test

Vehicle Information

Vehicle Status

NOTE

Some functions are supported only on certain vehicle makes.

46

Page 51

Function Descriptions

This section describes the various functions of each diagnostic option:

DTC & FFD

When this function is selected, the screen displays a list of Stored Codes and

Pending Codes. When the Freeze Frame data of certain DTCs are available

for viewing, a snowflake button will display on the right side of the DTC item.

The Erase Codes function can be applied by tapping the functional button at

the lower bottom of the screen.

Figure 5-2 Sample DTC & FFD Screen

Stored Codes

Stored codes are the current emission related DTCs from the ECM

of the vehicle. OBD II/EOBD Codes have a priority according to their

emission severity, with higher priority codes overwriting lower

priority codes. The priority of the code determines the illumination of

the MIL and the codes erase procedure. Manufacturers rank codes

differently, so expect to see differences between makes.

Pending Codes

These are codes whose setting conditions were met during the last

drive cycle, but need to be met on two or more consecutive drive

cycles before the DTC actually sets. The intended use of this service

47

Page 52

is to assist the service technician after a vehicle repair and after

clearing diagnostic information, by reporting test results after a

driving cycle.

a) If a test failed during the driving cycle, the DTC associated with

b) Test results reported by this service do not necessarily indicate

Freeze Frame

In most cases the stored frame is the last DTC that occurred. Certain

DTCs, which have a greater impact on vehicle emission, have a

higher priority. In these cases, the top prioritized DTC is the one for

which the freeze frame records are retained. Freeze frame data

includes a “snapshot” of critical parameter values at the time the

DTC is set.

Erase Codes

This option is used to clear all emission related diagnostic data such

as, DTCs, freeze frame data and manufacturer specific enhanced

data from the vehicle’s ECM, and reset the I/M Readiness Monitor

Status for all vehicle monitors to Not Ready or Not Complete status.

that test is reported. If the pending fault does not occur again

within 40 to 80 warm-up cycles, the fault is automatically

cleared from memory.

a faulty component or system. If test results indicate another

failure after additional driving, then a DTC is set to indicate a

faulty component or system, and the MIL is illuminated.

A confirmation screen displays when the clear codes option is

selected to prevent accidental loss of data. Select Yes on the

confirmation screen to continue or No to exit.

I/M Readiness

This function is used to check the readiness of the monitoring system. It is an

excellent function to use prior to having a vehicle inspected for compliance to

a state emissions program. Selecting I/M Readiness opens a submenu with

two choices:

Since DTCs Cleared – displays the status of monitors since the last time

48

Page 53

the DTCs are erased.

This Driving Cycle – displays the status of monitors since the beginning

of the current drive cycle.

Live Data

This function displays the real time PID data from ECU. Displayed data

includes analog inputs and outputs, digital inputs and outputs, and system

status information broadcast on the vehicle data stream.

Live data can be displayed in various modes, see 0 Live Data on page 36 for

detailed information.

O2 Sensor Monitor

This option allows retrieval and viewing of O2 sensor monitor test results for

the most recently performed tests from the vehicle’s on-board computer.

The O2 Sensor Monitor test function is not supported by vehicles which

communicate using a controller area network (CAN). For O2 Sensor Monitor

tests results of CAN-equipped vehicles, refer to On-Board Monitor.

On-Board Monitor

This option allows you to view the results of On-Board Monitor tests. The tests

are useful after servicing or after erasing a vehicle’s control module memory.

Component Test

This service enables bi-directional control of the ECM so that the diagnostic

tool is able to transmit control commands to operate the vehicle systems. This

function is useful in determining whether the ECM responds to a command

well.

Vehicle Information

The option displays the vehicle identification number (VIN), the calibration

identification, and the calibration verification number (CVN), and other

information of the test vehicle.

49

Page 54

Vehicle Status

This item is used to check the current condition of the vehicle, including

communication protocols of OBD II modules, retrieved codes amount, status

of the Malfunction Indicator Light (MIL), and other additional information.

Exiting Diagnostics

The Diagnostics application remains open as long as there is an active

communication with the vehicle. You must exit the diagnostics operation

interface to stop all communications with the vehicle before closing the

Diagnostics application.

NOTE

Damage to the vehicle electronic control module (ECM) may occur if

communication is disrupted. Make sure all connections, such as USB cable

and wireless connection, are properly connected at all times during testing.

Exit all tests before disconnecting the test connection or powering down the

tool.

To exit the Diagnostics application

1. From an active diagnostic screen, tap the Back or ESC functional

button to exit a diagnostic session step-by-step; Or

2. Tap the Vehicle Swap button on the diagnostics toolbar to return to

the Vehicle Menu screen.

3. From the Vehicle Menu screen, tap the Home button on the top

toolbar; or tap the Back button on the navigation bar at the bottom

of the screen. Or

4. Tap the Home button on the diagnostics toolbar to exit the

application directly and go back to the MaxiSys Job Menu.

Now, the Diagnostics application is no longer communicating with the vehicle

and it is safe to open other MaxiSys applications, or exit the MaxiSys

Diagnostic System and return to the Android System’s Home screen.

50

Page 55

5 Service

The Service section is specially designed to provide you with quick access to

the vehicle systems for various scheduled service and maintenance

performances. The typical service operation screen is a series of menu driven

executive commands. By following the on-screen instructions to select

appropriate execution options, enter correct values or data, and perform

necessary actions, the system will guide you through the complete

performance for various service operations.

The most commonly performed service functions include:

Oil Reset Service

EPB Service

BMS Service

DPF Service

SAS Calibration Service

TPMS Programming Service

IMMO Keys

After entering each special function, the following screen consists of two

applications: Diagnosis and Hot Functions. The Diagnosis is for you to

read/clear data since this is necessary after some special functions. Hot

Functions consists of sub functions of the selected special function.

Oil Reset Service

This function allows you to perform reset for the Engine Oil Life system, which

calculates an optimal oil life change interval depending on the vehicle driving

conditions and climate. The Oil Life Reminder must be reset every time the

oil is changed, so the system can calculate when the next oil change is

required.

51

Page 56

IMPORTANT

Always reset the engine oil life to 100% after every oil change.

NOTE

All required work must be carried out before the service indicators are reset.

Failure to do so may result in incorrect service values and cause DTCs to be

stored by the relevant control module.

NOTE

For some vehicles, the scan tool can perform added functionality to reset

additional service lights (maintenance cycle, service interval). Taking BMW

as an example, its service reset function includes engine oil, spark plugs,

front/rear brakes, coolant, particle filter, brake fluid, micro filter, vehicle

inspection, exhaust emission inspection and vehicle check.

All software screens shown in this manual are examples, actual test screens

may vary for each vehicle being tested. Observe the menu titles and onscreen instructions to make correct option selections.

To perform oil reset functions

1. Tap the Service application button from the MaxiSys Job Menu.

2. Tap Oil Reset button and wait for the vehicle manufacturer screen.

You can tap Automatic Selection or Manual Selection to acquire

vehicle VIN information and tap Yes to confirm.

3. Tap the function you want in the Oil Reset function list, the list may

vary for different vehicles being tested (Figure 5.1).

52

Page 57

Figure 5-1 Sample Oil Reset Function List

Figure 5-2 Sample Oil Reset Service Screen 1

4. Follow the step-by-step on-screen instruction to complete the

service. Take CBS Reset UDS as an example.

5. Tap CBS Reset UDS on the Oil Reset function list to start the

operation. The screen will guide you to confirm the date and time, if

the displayed date and time are correct, tap Yes to confirm. If no,

tap No and go to the Settings menu to set the correct date and time.

6. On the next screen, the available items would be listed with three

columns displayed: CBS value, availability, and service counter.

53

Page 58

Figure 5-3 Sample Oil Reset Service Screen 2

Figure 5-4 Sample Oil Reset Service Screen 3

7. Tap on the value you want to reset and then tap the Reset button on

the right bottom of the screen.

8. When the reset is done, the availability would display as 100%. Tap

ESC to exit.

Electric Parking Brake (EPB) Service

This function has a multitude of usages to maintain the electronic braking

system safely and effectively. The applications include deactivating and

54

Page 59

activating the brake control system, assisting with brake fluid control, opening

and closing brake pads, and setting brakes after disc or pad replacement, etc.

EPB Safety

It may be dangerous to perform Electric Parking Brake (EPB) system

maintenance, so before you begin the service work, please keep these rules

in mind.

Ensure that you are fully familiar with the braking system and its

operation before commencing any work.

The EPB control system may be required to be deactivated before

carrying out any maintenance/diagnostic work on the brake system. This

can be done from the tool menu.

Only carry out maintenance work when the vehicle is stationary and on

level ground.

Ensure that the EPB control system is reactivated after the maintenance

work has been completed.

NOTE

Autel accepts no responsibility for any accident or injury arising from the

maintenance of the Electric Parking Brake system.

To perform EPB functions

1. Tap the Service application button from the MaxiSys Job Menu.

2. Tap EPB button and wait for the vehicle manufacturer screen. You

can tap Automatic Selection or Manual Selection to acquire

vehicle VIN information and tap Yes to confirm.

3. Tap the service you want in the EPB function list, the list may vary

for different vehicles being tested (Figure 5.5).

55

Page 60

Figure 5-5 Sample EPB Function List

Figure 5-6 Sample EMF Star-up Screen 1

4. Follow the step-by-step on-screen instruction to complete the

service.

5. Press OK button to exit.

EMF Star-up

This service function would start up the parking brake, it must be conducted

after the following repairs:

Replacing an EMF control unit.

Replacing the parking brake button.

56

Page 61

Figure 5-0-3 Sample EMF Star-up Screen 2

Figure 5-0-4 Sample EMF Star-up Screen 3

1) Tap Continue to proceed this service function or the Back button at the

bottom left to exit.

2) Tap on the action that has been carried out to continue.

3) In the following step, the screen will remind you that the fault memory of

the parking brake control unit will be deleted, press Continue to proceed

or the Back button to exit.

4) Follow the on-screen instructions to pull the parking brake button and

wait for around 3 seconds until the parking brake is set. When the

operation is successfully completed, a “Completed successfully”

57

Page 62

message will appear on the screen. Press “OK” to exit.

Parking Brake: Workshop Mode

This service is used to activate and deactivate the so-called installation

position for the Automatic Hold brake. In this mode the parking brake is move

into the opened position and temporarily deactivated (personal protection).

The installation position must be activated for the following repairs:

Replacement of brake pads.

Replacement of a brake caliper.

Replacement of an actuator.

Select Parking Brake: Workshop Mode and follow the on-screen

instructions to perform a series of operations to start the brake pad after

replacement.

When the operation is successfully completed, a “Completed successfully”

message will appear on the screen. Press “OK” to exit.

BMS

The BMS (Battery Management System) allows the scan tool to evaluate the

battery charge state, monitor the close-circuit current, register the battery

replacement, activate the rest state of the vehicle, and charge the battery via

the diagnostic socket.

NOTE

1. This function is not supported by all vehicles. The screens shown in this

section are examples.

2. The sub functions and actual test screens of the BMS may vary for

different test vehicles, please follow the on-screen instructions to make

correct option selection.

The vehicle may use either a sealed lead-acid battery or an AGM (Absorbed

Glass Mat) battery. Lead acid battery contains liquid sulphuric acid and can

spill when overturned. AGM battery (known as VRLA battery, valve regulated

lead acid) also contains sulphuric acid, but the acid is contained in glass mats

between terminal plates.

It is recommended that a replacement aftermarket battery has the same

specifications, such as capacity and type, of the battery used in the vehicle.

58

Page 63

Figure 5-2 Sample BMS Function List

Figure 5-0-5 Sample BMS Screen 1

If the original battery is replaced with a different type of battery (e.g. a leadacid battery is replaced with an AGM battery) or a battery with a different

capacity (mAh), the vehicle may require reprogramming the new battery type

in addition to performing the battery reset. Consult the vehicle manual for

additional vehicle-specific information.

Register Battery Replacement

This option allows displaying the mileage reading of last battery replacement,

registering the battery replacement after replacing a new battery and

informing the power management system that a new battery has been fitted

to the vehicle.

If the battery change is not registered, the power management system will

not function properly, which may not provide the battery with enough charging

power to operate the car and limit the functions of individual electrical

consumers.

Take BMW as an example.

To display the battery history

1. Tap the Service application button from the MaxiSys Job Menu.

2. Tap BMS button and wait for the vehicle manufacturer screen. You

can tap Automatic Selection or Manual Selection to acquire

vehicle VIN information and tap Yes to confirm.

3. Tap Register Battery Replacement in the EPB function list, the list

may vary for different vehicles being tested (Figure 5.1).

59

Page 64

Figure 5-10 Sample BMS Screen 2

Figure 5-11 Sample BMS Screen 3

4. Tap on the corresponding service you want to carry out. In this case,

it is function 1 Display kilometer reading at last battery change

and one before last. A notice screen displays.

5. Read carefully the complete information and press Continue to

continue.

6. Check the battery capacity and the battery replacement information

on the screen.

60

Page 65