Austria Email ECO SWIFT, ECO SWIFT E, ECO SWIFT EZ User Manual

ECO SWIFT

ECO SWIFT E

ECO SWIFT EZ

FRESHWATER STATION

CONTROLLER MANUAL

Contents

A. Saft y instr uctions 3

A.1. EC declaration of conformity 3

A.2. General instructions 3

A.3. Explanation of symbols 3

A.4. Changes to the unit 4

A.5. Warranty and liability 4

B. Description of controller 5

B.1. Specications 5

B.2. Temperature resistance table

for Pt100 0 sensors 5

B.3. About the controller 6

B.4. Scope of supply 6

B.5. Disposal and pollutants 6

B.6. Hydraulic variants 7

C. Installation 8

C.1. Wall installation 8

C.2. Electrical connection 9

C.3. Electrical connection 10

C.4. Installing the temperature sensors 11

D. Terminal connect ion diagrams 12

E. Operation 13

E.1. Display and input 13

E.2. Menu sequence and menu structure 14

F. Parametrisation 15

F.1. Commissioning help 15

F.2. Free commissioning 15

F.3. Calibration 16

1. Measurement values 17

2. Statistics 18

2.1. Operating hours HW 18

2.2. Operating hours circ. 18

2.3. Heat output 18

2.4. Graphic overview 18

2.5. Error messages 18

2.6. Reset / clear 18

3. Operating mode 19

3.1. Automatic 19

3.2. Manual 19

3.3. Of f 19

4. Settings 20

4.1. Tset 20

4.2. Tmax 20

4.3. VFS -Type 20

4.4. Circulation 21

4.4.1. Circulation 21

4.4.2. Circ. Tmin. 21

4.4.3. Circ. hysteresis 21

4.4.4. Circ. maximum Flow rate 21

4.4.5. Circulation period 21

4.4.6. Tap support 22

4.4.7. Min storage temp 22

4.4.8. Tap support calibration 22

4.6. Zone valve 22

4.12. Comfort 22

5. Protections / Protective functions 23

5.1. Antilegionella 23

5.2. Limescale Protection 24

5.3. Discharge Protection 24

5.4. Seizing protection 24

6. Special functions 25

6.1. Pump menu 25

6.1.1. Type of pump 25

6.1.2. Pump 25

6.1.3. Output Signal 25

6.1.4. 0 -10V off / PWM of f 25

6.1.5. 0 -10V on / PWM on 26

6.1.6. 0 -10V Max / PWM Max 26

6.1.7. Show signal 26

6.2. Speed control R1 / R2 26

6.2.1. max. speed 26

6.2.2. min. speed 26

6.5. Relay functions 27

6.5.1. Circulation 27

6.5.2. Storage heating 27

6.5.2.1.Storage heating 27

6.5.2.2.Storage minimum temperature 27

6.5.2.3.SH Setpoint Temperature 27

6.5.2.4.SH hysteresis 27

6.5.2.5.Periods 27

6.5.3. Storage stratication 28

6.5.3.1.Storage stratication 28

6.5.3.2.∆T return storage 28

6.5.4. Parallel operation V1 28

6.5.4.1.Parallel operation V1 28

6.5.4.2.Delay 28

6.5.4.3.Followup time 28

6.5.5. Parallel operation V2 28

6.5.6. Always on 28

6.6. Relay 2 28

6.7. Relay 3 28

6.8. Signal V2 29

6.8.1. Signal V2 29

6.9. Pressure monitor 29

6.9.1. Pressure monitor 29

6.9.2. RPS1 / RPS2 29

6.9.3. Pmin 29

6.9.4. Pma x 29

6.10. Sensor calibration 30

6.11. Commissioning 30

6.12. Factory settings 30

6.13. Time & Date 30

6.14. Daylight saving time 31

6.15. Sleep mode 31

6.16. Temperature unit 31

7. Menu lock 32

7.1. Menu lock 32

7.2. Expert mode 32

8. Ser vice values 33

9. Language 34

Z. Malfunctions 35

Z.1. Malfunctions with error messages 35

Z.2. Replacing the fuse 36

Z.3 . Maintenance 37

Safety instructions

A.1. - EC declaration of conformity

By afxing the CE mark to the unit the manufacturer declares that the ECO SWIFT conforms

to the following relevant safety regulations:

- EC low voltage directive 2006/95/EC

- EC electromagnetic compatibility directive 2004/108/EC

Conformity has been veried and the corresponding documentation and the EC declaration

of conformity are kept on le by the manufacturer.

A.2. - General instructions

It is essential that you read this!

These installation and operating instructions contain basic instructions and important information regarding safety, installation, commissioning, maintenance and the optimal use of the

unit. Therefore these instructions must be read completely and understood by the installation

technician/ specialist and by the system user before installation, commissioning and operation of the unit.The valid accident prevention regulations, VDE regulations, the regulations

of the local power utility, the applicable DIN-EN standards and the installation and operating

instruction of the additional system components must also be observed. The controller does

not under any circumstances replace any safety devices to be provided by the customer!

Installation, electrical connection, commissioning and maintenance of the unit may only be

carried out by specialists who possess the appropriate training.

For the user: Make sure that the specialist gives you detailed information on the function and

operation of the controller. Always keep these instructions in the vicinity of the controller.

A.3. - Explanation of symbols

Failure to observe these instructions can result in danger to life from electric

Danger

voltage.

Failure to observe these instructions can result in serious damage

Danger

to health such as scalding, or even life-threatening injuries.

Failure to observe these instructions can result in destruction of

Caution

the unit or the system, or damage to the environment.

Information which is especially important for the function and optimal use of

Caution

the unit and the system.

3

Safety instructions

A.4. - Changes to the unit

Changes to the unit can compromise the safety and function of the unit or the entire

Danger

- Changes, additions to or conversion of the unit are not permitted without the written permission from the manufacturer

- It is likewise forbidden to install additional components that have not been tested together

with the unit

- If it becomes clear that safe operation of the unit is no longer possible, for example because

of damage to the housing, then turn the controller off immediately

- Any parts of the unit or accessories that are not in perfect condition must be exchanged

immediately

- Use only original spare parts and accessories from the manufacturer.

- Markings made on the unit at the factory must not be altered, removed or made illegible

- Only the settings actually described in these instructions may be made on the controller

A.5. - Warranty and liability

The controller has been manufactured and tested with regard to high quality

and safety requirements. The unit is subject to the statutory guarantee period

of two years from the date of sale.

The warranty and liability shall not include, however, any injury to persons or

material damage that is attributable to one or more of the following causes:

- Failure to observe these installation and operating instructions

- Improper installation, commissioning, maintenance and operation

- Improperly executed repairs

- Unauthorised structural changes to the unit

- Installation of additional components that have not been tested together with the unit

- Any damage resulting from continued use of the unit despite an obvious defect

- Failure to use original spare parts and accessories

- Use of the device for other than its intended purpose

- Operation above or below the limit values listed in the specications

- Force majeure

system.

4

Description of controller

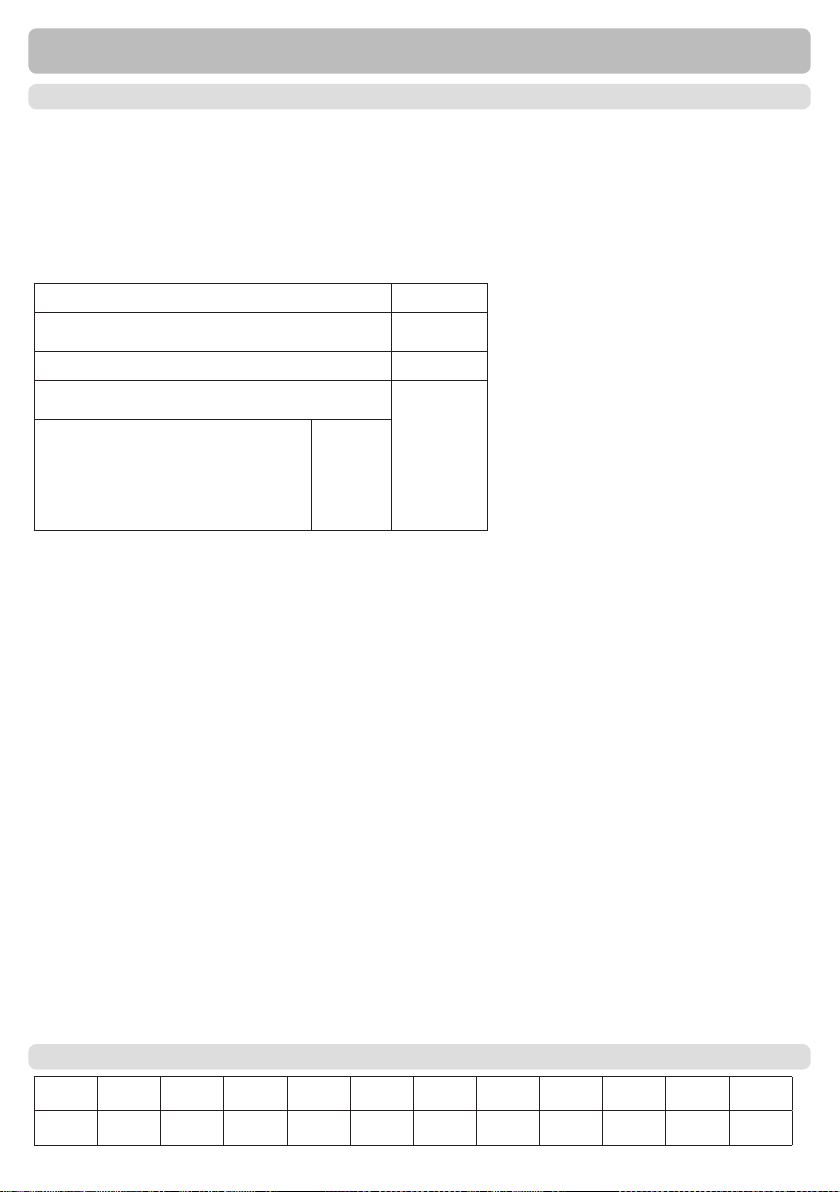

B.1. - Specications

Electrical specications:

Mains voltage 100 - 240VAC

Mains frequency 50 - 60Hz

Power consumption 0,5W - 2,5W

Internal fuse T2 A / 250V slow blow

Protection category IP40

Protection class II

Overvoltage Category II

Degree of Pollution Category II

mechanical relay 460VA for AC1 / 46 0W for AC3 3 (R1- R3)

0-10V outp ut, tolerance 10%, 10 k Ω loa d or

PWM out put freq. 1 kHz, level 10 V

PT1000 se nsor input measurin g range - 40°C to 30 0°C 6

VFS / RPS in puts

0°C -100°C (-25°C /120 °C short t erm)

1 l/m in - 12 l/min (V FS1-12)

1 l/m in - 20 l/min ( VFS1- 20)

2 l/m in - 40 l/min ( VFS2- 40)

5 l/m in - 100 l/min ( VFS5 -100)

10 l/m in - 200 l/min (VFS10- 200)

Permissible cable length of sensors and appliances:

other PT1000 sensors <10m

VFS/RPS Sensoren <3m

CAN <3m

PWM / 0...10V <3m

mechanichal relay <10m

Real Tim e Clock RTC with 24 hour power reserve

Permissible ambient conditions:

Ambient temperature

for controller operation 0°C...40°C

for transport/storage 0°C...60°C

Air humidity

for controller operation max. 85% rel. humidity at 25°C

for transport/storage no moisture condensation permiddled

Other specications and dimensions

Housing design 2-part, ABS plastic

Installation methods Wall installation, optionally panel installation

Overall dimensions 163mm x 110mm x 52mm

Aperture installation

dimensions 157mm x 106mm x 31mm

Display Fully graphical display, 128 x 128 dots

Light diode Multicolor red/green

Operation 4 entry keys

0-0,6 bar

0-1 bar

0-1,6 bar

0-2,5 bar

0- 4 bar

0- 6 bar

0-10 bar

2

2

B.2. - Temperature resistance table for Pt1000 sensors

°C 0 10 20 30 40 50 60 70 80 90 100

Ω 1000 1039 1077 1116 1155 1194 1232 1270 1308 1347 1385

5

Description of controller

B.3. - About the controller

The Fresh water controller ECO SWIFT facilitates efcient use and function control through

of your fresh water system. Tap water temperature is regulated fast and precise. The device

is impressive most of all for its functionality and simple, almost self-explanatory operation.

For each step in the input process the individual entry keys are assigned to appropriate functions and explained. The controller menu contains headwords for the measured values and

settings, as well as help texts or clearly-structured graphics.

Important characteristics of the ECO SWIFT:

- Depiction of graphics and texts in a lighted display

- Simple viewing of the current measurement values

- Analysis and monitoring of the system by means of statistical graphics,etc.

- Extensive setting menus with explanations

- Menu block can be activated to prevent unintentional setting changes

- Resetting to previously selected values or factory settings

B.4. - Scope of supply:

- Fresh water controller ECO SWIFT

- replacement fuse 2A slow-blow

- Installation and operating instructions ECO SWIFT

Optionally contained depending on design/order:

- Pt1000 temperature sensor and Vortex Flow Sensor

B.5. - Disposal and pollutants

The unit conforms to the European RoHS directive 2011/65/EU for the restriction of the use

of certain hazardous substances in electrical and electronic equipment.

The unit must not under any circumstances be disposed of with ordinary

Caution

6

household refuse. Dispose of the unit only at appropriate collection points or ship it

back to the seller or manufacturer.

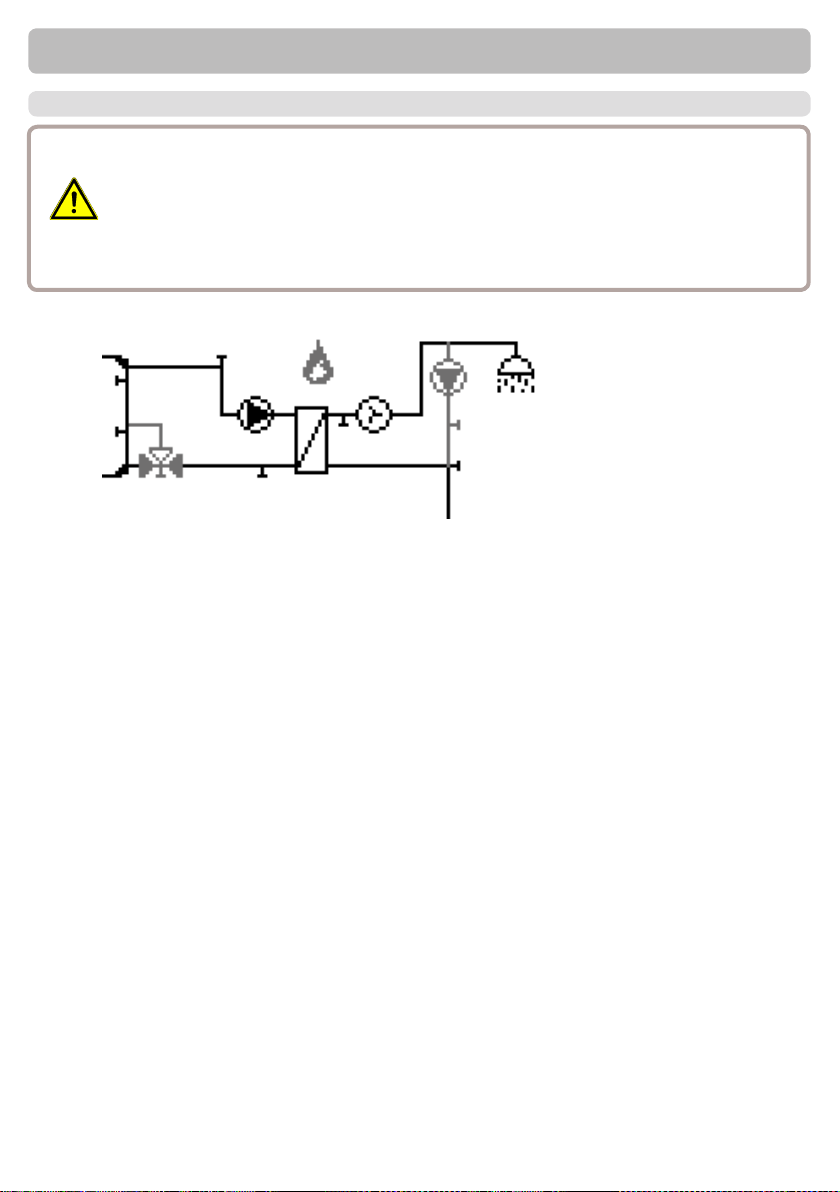

Description of controller

B.6. - Hydraulic variants

The following illustrations should be viewed only as schematic diagrams showing

the respective hydraulic systems, and do not claim to be complete. The controller

does not replace safety devices under any circumstances. Depending on the spe-

Caution

cic application, additional system components and safety components may be

mandatory, such as check valves, non-return valves, safety temperature limiters,

scalding protectors, etc., and must therefore be provided.

S3

S4

S5

VFS

S1

S2

S6

7

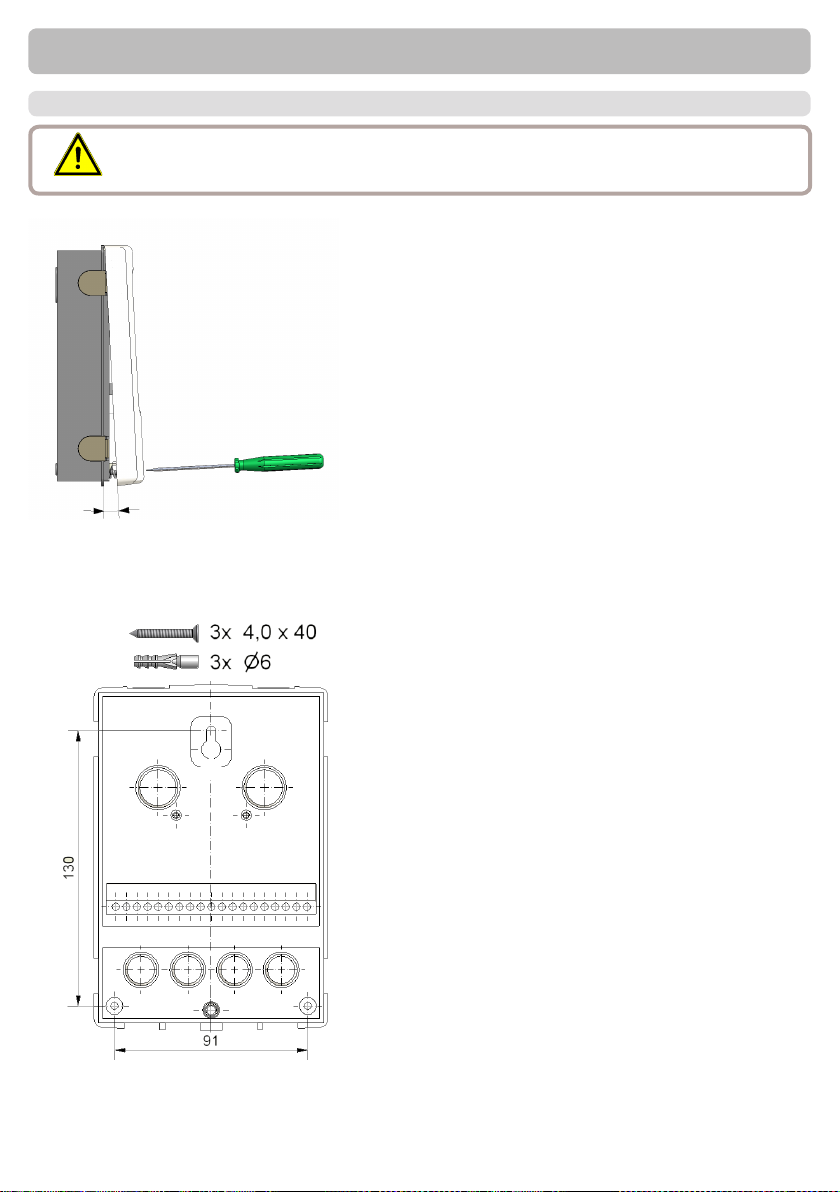

C.1. - Wall installation

Install the controller only in dry areas and under the ambient conditions

Caution

described under 2.1 “Specications”. Carry out the following steps 1-8.

Installation

Fig.C.1.2

A

Fig.C .1.1

1.Unscrew cover screw completely

2.Carefully pull upper part of housing

from lower part.

3.Set upper part of housing aside, being

sure not to touch the electronics when

doing so.

4.Hold the lower part of the housing up

to the selected position and mark the 3

mounting holes. Make sure that the wall

surface is as even as possible so that the

housing does not become distorted when

it is screwed on.

5.Using a drill and size 6 bit, drill 3 holes

at the points marked on the wall and push

in the plugs.

6.Insert the upper screw and screw it in

slightly.

7.Fit the upper part of the housing and

insert the other two screws.

8. Align the housing and tighten the three

screws.

8

C.2. - Electrical connection

Before working on the unit, switch off the power supply and secure it against being

switched on again! Check for the absence of power! Electrical connections may

Danger

only be made by a specialist and in compliance with the applicable regulations. Do

not use the controller if the housing shows visible damage.

Low-voltage cables such as temperature sensor cables must be routed separately

from mains voltage cables. Feed temperature sensor cables only into the left-hand

Caution

side of the unit, and mains voltage cables only into the right-hand side.

The customer must provide an all-pole disconnecting device, e.g. a heating emer-

Caution

gency switch.

The cables being connected to the unit must not be stripped by more than 55mm,

Caution

and the cable jacket must reach into the housing just to the other side of the strain

relief.

Controller and VFS sensor have to have the same ground potential. The VFS

Caution

sensor uses a functional earth connector (PELV). The PE-connector of the

controller has to be connected to the pipe system near the sensor.

Installation

9

C.3. - Electrical connection

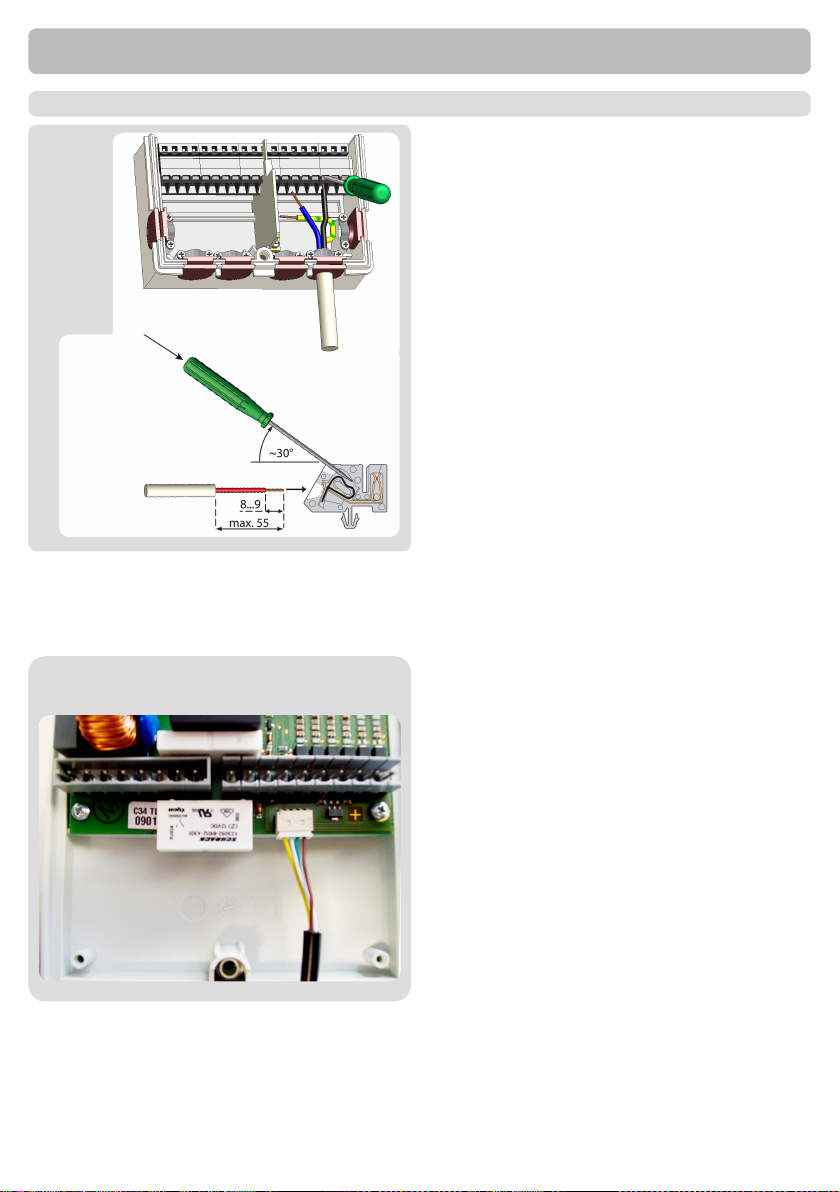

C.3.1.

C.3.2.

Installation

1. Select necessary program/ hydraulics

2. Open controller

3. Strip cables by 55mm max., insert, t the

strain relief devices, strip the last 8-9mm

of the wires. (Fig. C.3.1)

4. Open the terminals using a suitable

screwdriver (Fig. C.3.2) and make electrical

connections on the controller

5. Connect the ow sensor to the socket

on the board (Fig. C.2.3.).

6. Ret upper part of housing and fasten

with screw.

7. Switch on mains voltage and place controller in operation.

C.3.3.

10

Installation

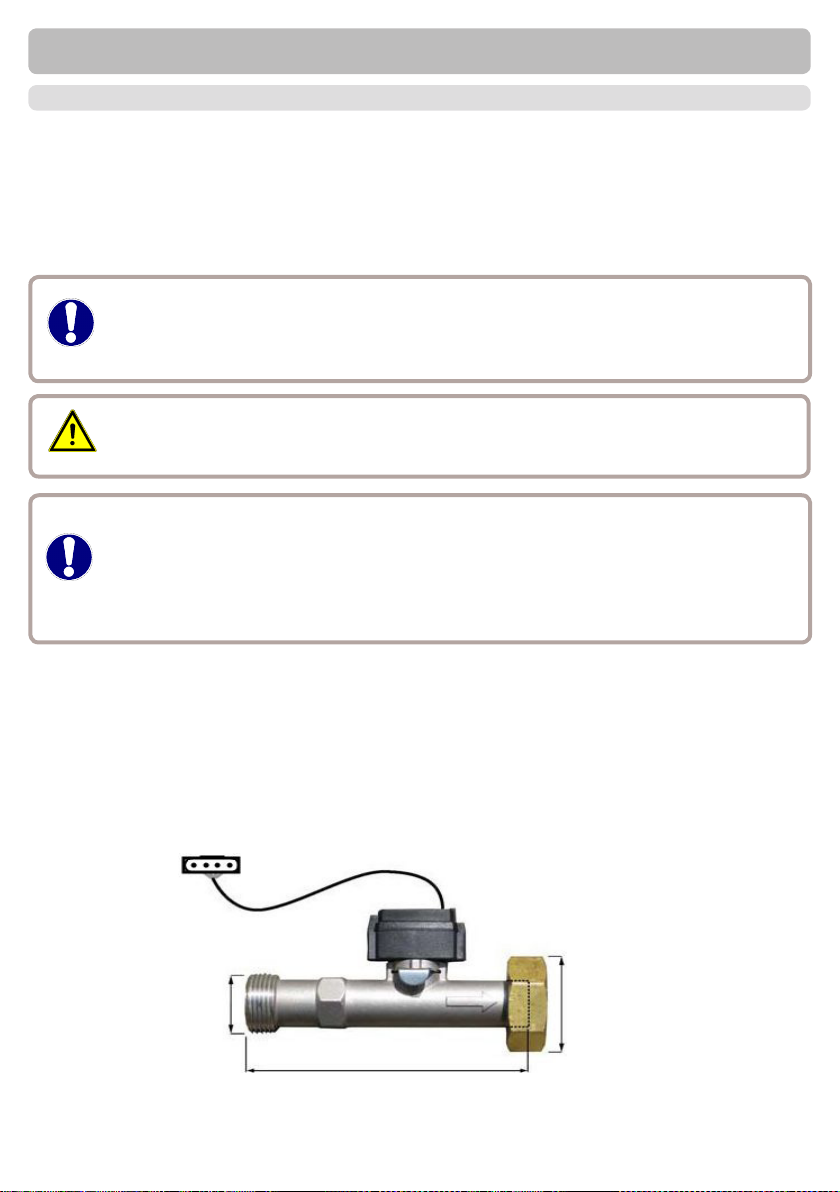

C.4. - Installing the temperature sensors

The controller operates with Pt1000 temperature sensors which are accurate to the

degree, thus ensuring optimal control of system functions.

Position the sensor precisely in the area to be measured!

It is recommended that at least 20 cm of the sensor cable at the sensor are installed inside the

pipe insulation.

Connect the VFS sensors with the matching jacks.

Sensor cables for PT1000 can be extended to a maximum of 10m using a

cable with a cross-section of at least 0.75mm².

Caution

Caution

Caution

Sensor cables for the VFS sensor can be extended to 3m.

Make sure that there is no contact resistance!

The temperature sensor cables must be routed separately from mains voltage

cables, and must not, for example, be routed in the same cable duct!

Controller and VFS sensor have to have the same ground potential. The VFS

sensor uses a functional earth connector (PELV). The PE-connector of the

controller has to be connected to the pipe system near the sensor.

Example:

Connections and dimensions of the Vortex Flow Sensors VFS2-40

3/4 “

10,7 cm

1 “

11

Installation

S6V1V2

+

S5

S4 S3 S2 S1

-

PELV

R3I

R3 R2 R1 L N

VFS2 VFS1CAN CAN

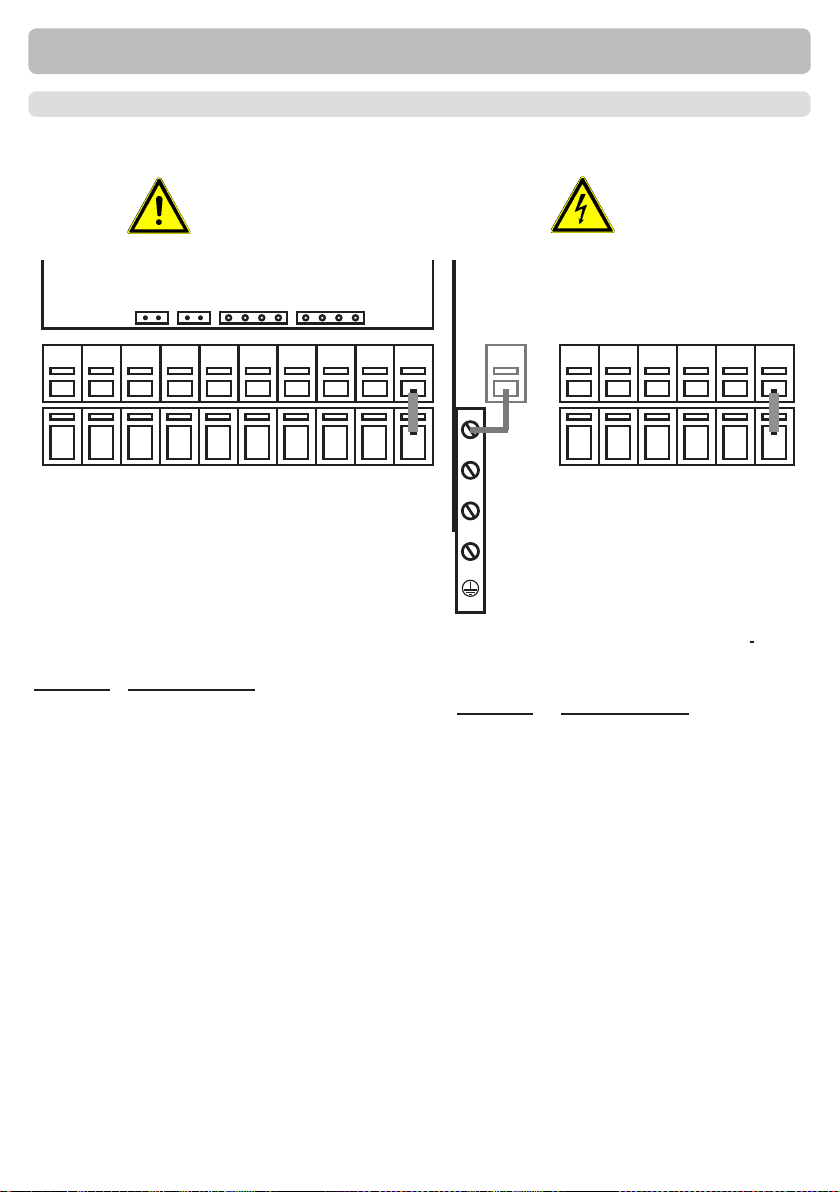

D. - Terminal connection diagrams

D.1. - „With circulation pump“

Sensor side

max. 12V

Caution

Low voltage max. 12VAC/DC connection in

the left-hand terminal compartment!

Terminal: Connection for:

S1 Circulation (opt.)

S2 Cold water (optional, see box below)

S3 Primary ow (opt.)

S4 Storage top (opt.)

S5 storage middle (opt.)

V1 0-10V/PWM signal primary pump

V2 0-10V/PWM signal (opt.)

S6 Primary return ow (opt.)

- Terminal connection sensor VFS1 Warm water tap

Mains voltages 230VAC 50-60Hz

Connection in the right-hand terminal

compartment!

Terminal: Connection for:

L Mains phase conductor L

N Mains neutral conductor N

R1 Primary pump (opt.)

R2 Relay 2

R3 Relay 3 (normally open)

R3I Relay 3 (normally closed)

The PE protective conductor must be

connected to the PE metal terminal block!

Mains side

230VAC

Danger

VFS2 optional

The polarity of the sensors is freely selectable.

Relay connection changes depending on the additional functions selected.

Connection of sensor earths (1-6) via terminal block sensor(-)

VFS sensor has to be connected to the socket on the circuit board.

Sensor 2 / Cold water: If no sensor is connected, a temperature of 10° C is set. See also „6.2

Sensor calibration“

12

Loading...

Loading...