Page 1

complete smartcard cabinet access management over network

User Manual

X-2000

X-1000

X-800

Smartcard Handle

Designed and manufactured by Austin Hughes

www.austin-hughes.comUM-X-ISM-Q414V3

Page 2

Legal Information

First English printing, October 2002

Information in this document has been carefully checked for accuracy; however, no guarantee is given to the correctness

of the contents. The information in this document is subject to change without notice. We are not liable for any injury or

loss that results from the use of this equipment.

Safety Instructions

Please read all of these instructions carefully before you use the device. Save this manual for

future reference.

■ Unplug equipment before cleaning. Don’t use liquid or spray detergent; use a moist cloth.

■ Keep equipment away from excessive humidity and heat. Preferably, keep it in an air-conditioned environment with

temperatures not exceeding 40º Celsius (104º Fahrenheit).

■ When installing, place the equipment on a sturdy, level surface to prevent it from accidentally falling and causing

damage to other equipment or injury to persons nearby.

■ When the equipment is in an open position, do not cover, block or in any way obstruct the gap between it and the

power supply. Proper air convection is necessary to keep it from overheating.

■ Arrange the equipment’s power cord in such a way that others won’t trip or fall over it.

■ If you are using a power cord that didn’t ship with the equipment, ensure that it is rated for the voltage and current

labeled on the equipment’s electrical ratings label. The voltage rating on the cord should be higher than the one listed

on the equipment’s ratings label.

■ Observe all precautions and warnings attached to the equipment.

■ If you don’t intend on using the equipment for a long time, disconnect it from the power outlet to prevent being

damaged by transient over-voltage.

■ Keep all liquids away from the equipment to minimize the risk of accidental spillage. Liquid spilled on to the power

supply or on other hardware may cause damage, fi re or electrical shock.

■ Only qualifi ed service personnel should open the chassis. Opening it yourself could damage the equipment and

invalidate its warranty.

■ If any part of the equipment becomes damaged or stops functioning, have it checked by qualifi ed service personnel.

What the warranty does not cover

■ Any product, on which the serial number has been defaced, modifi ed or removed.

■ Damage, deterioration or malfunction resulting from:

□ Accident, misuse, neglect, fi re, water, lightning, or other acts of nature, unauthorized product modifi cation, or

failure to follow instructions supplied with the product.

□ Repair or attempted repair by anyone not authorized by us.

□ Any damage of the product due to shipment.

□ Removal or installation of the product.

□ Causes external to the product, such as electric power fl uctuation or failure.

□ Use of supplies or parts not meeting our specifi cations.

□ Normal wear and tear.

□ Any other causes which does not relate to a product defect.

■ Removal, installation, and set-up service charges.

Regulatory Notices Federal Communications Commission (FCC)

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of

the FCC rules. These limits are designed to provide reasonable protection against harmful interference in a residential

installation.

Any changes or modifi cations made to this equipment may void the user’s authority to operate this equipment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the following measures:

■ Re-position or relocate the receiving antenna.

■ Increase the separation between the equipment and receiver.

■ Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

Notice : The changes or modifi cations not expressly approved by the party responsible for compliance could void the

user’s authority to operate the equipment.

IMPORTANT NOTE: To comply with the FCC RF exposure compliance requirements, no change to the antenna or the

device is permitted. Any change to the antenna or the device could result in the device exceeding the RF exposure

requirements and void user’s authority to operate the device.

www.austin-hughes.comUM-X-ISM-Q414V3

Page 3

Before Installation

■ It is very important to locate the equipment in a suitable environment.

■ The surface for placing and fi xing the equipment should be stable and level or mounted into a suitable

cabinet.

■ Make sure the place has good ventilation, is out of direct sunlight, away from sources of excessive dust, dirt, heat,

water, moisture and vibration.

■ Position the equipment with respect to related facilities.

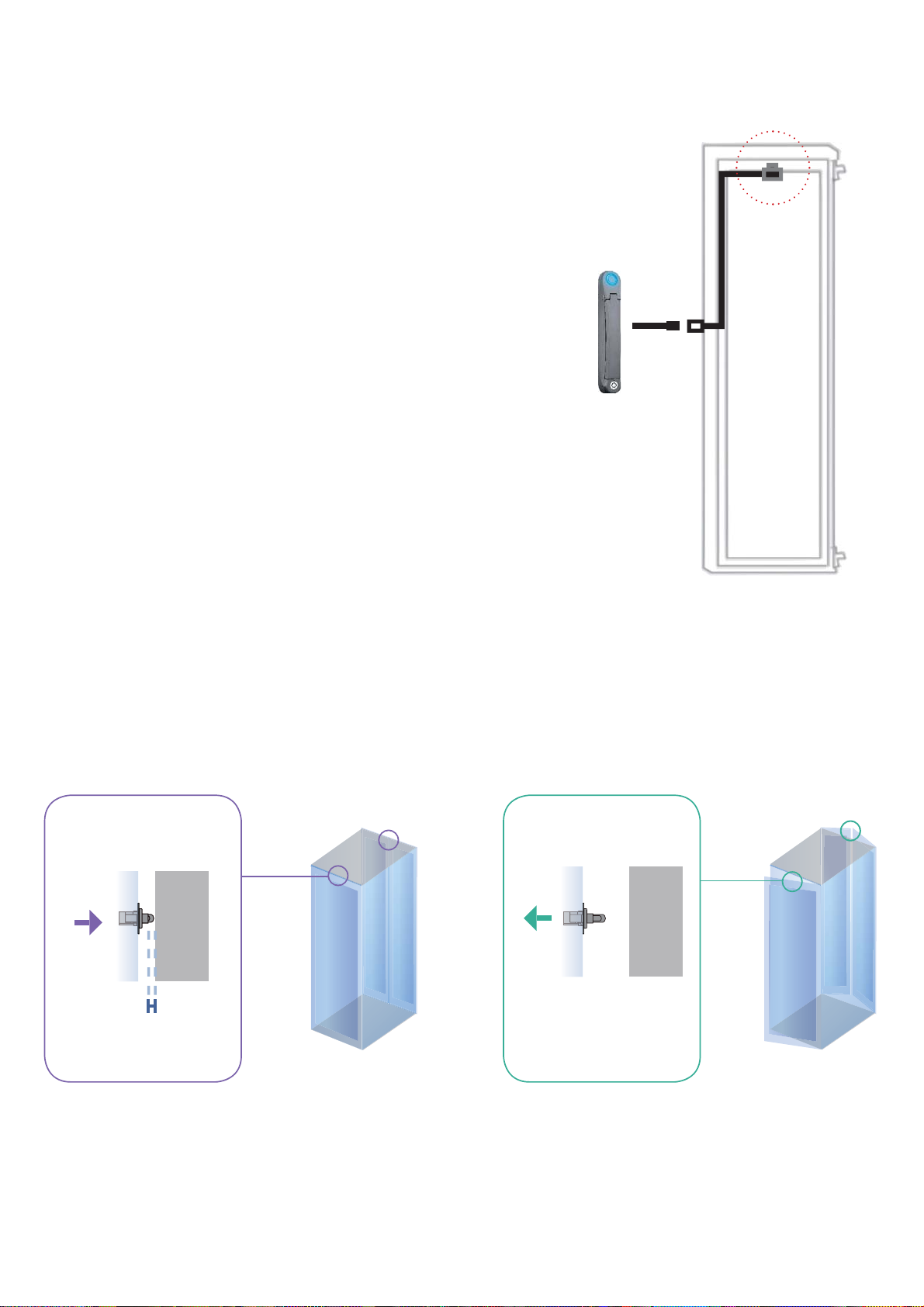

Suggest the installation at the rear top mounting of cabinet

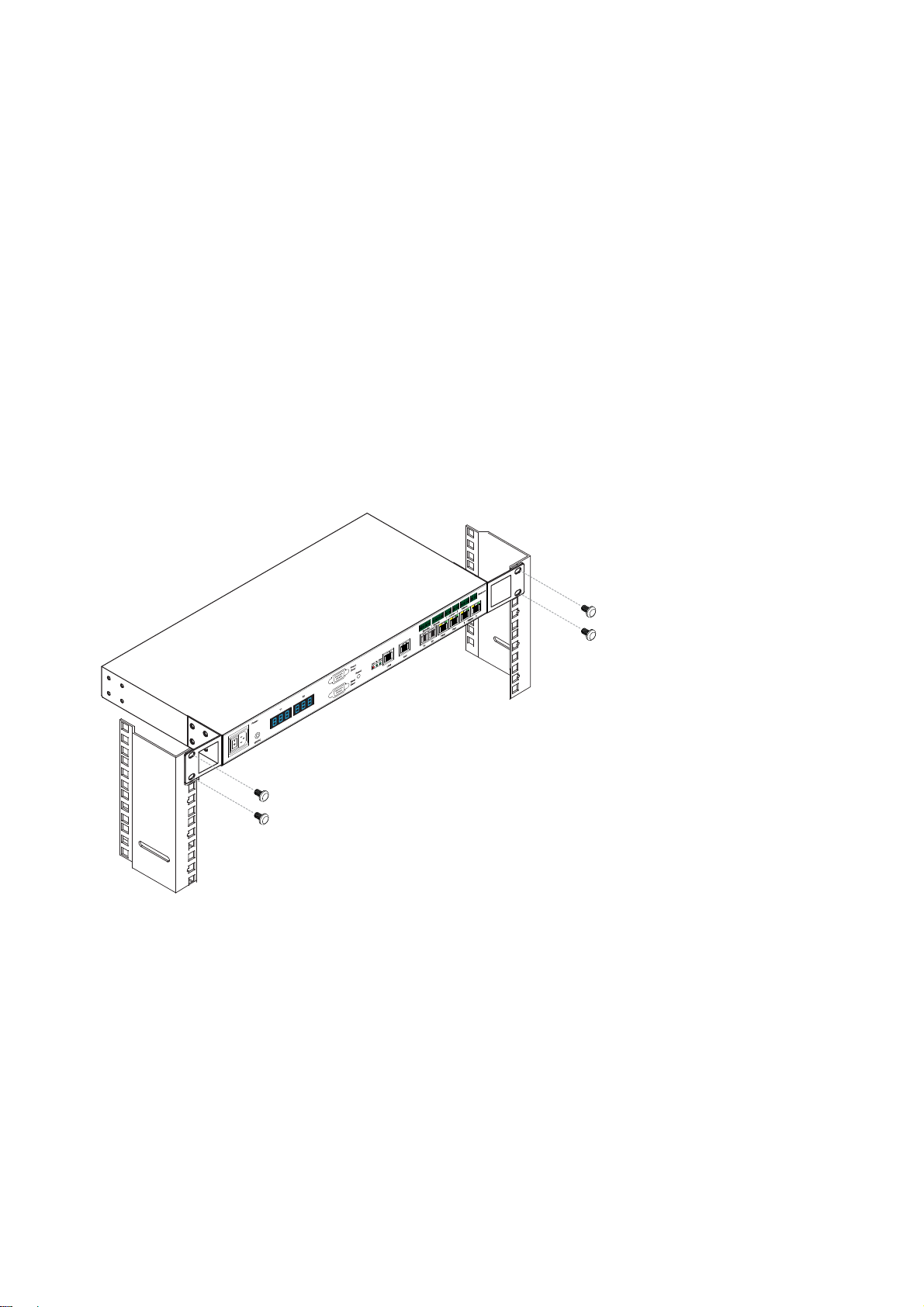

InfraBox Installation

■

■ M6 screws set not provided.

www.austin-hughes.comUM-X-ISM-Q414V3

Page 4

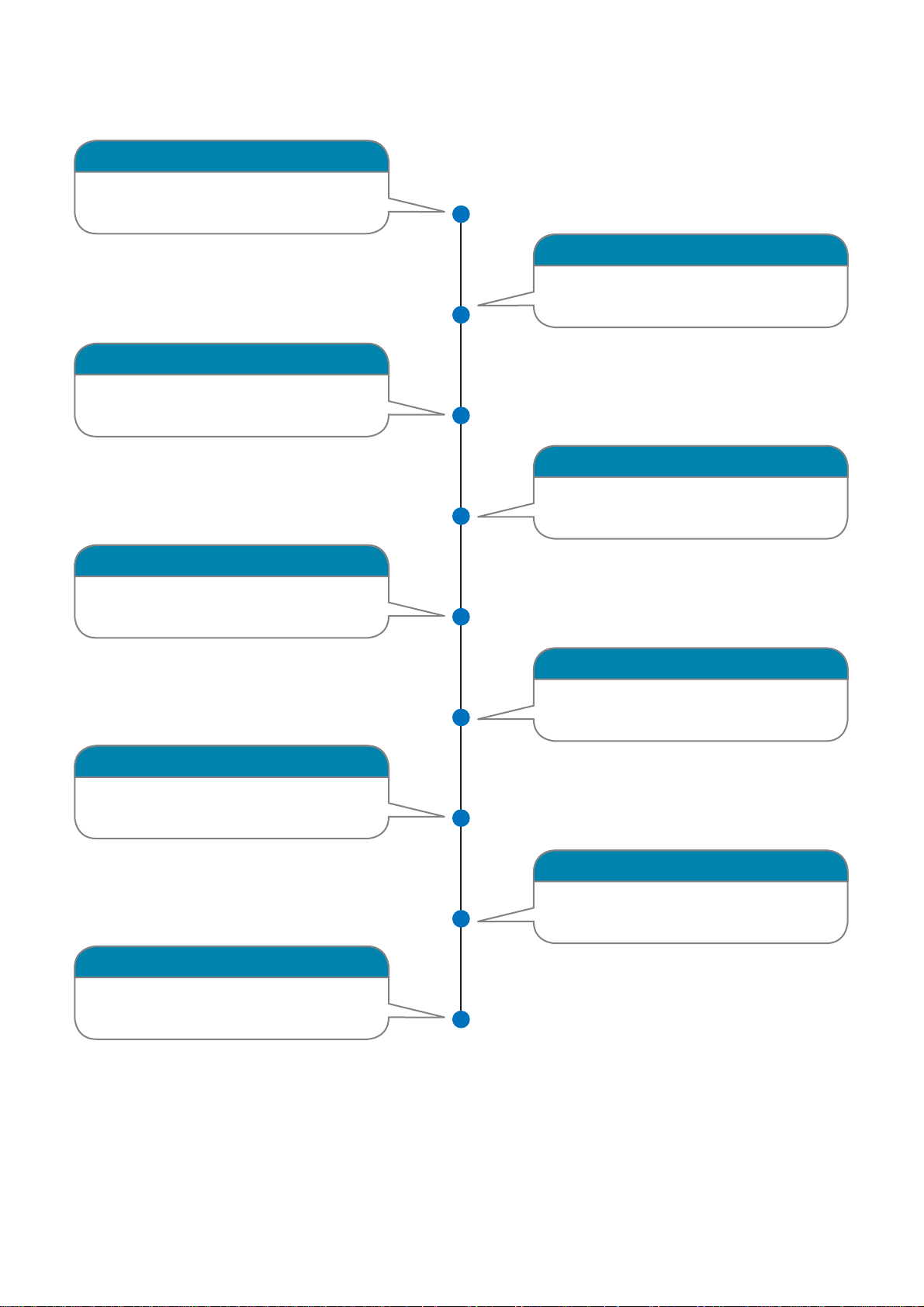

Content

Part I. Hardware & Network Setup

< 1.1 > Tips for Hardware

< 2.1 > Package Contents

< 2.2 > InfraBox X-1000 / X-2000

< 2.3 > Handle X-800P / X-800M

< 2.4 > Door Sensor - Inductive / Mechanical

< 3.1 > PDU

< 3.2 >

< 4.1 > Temp. & Humid Sensor

< 4.2 > Smoke Sensor

< 4.3 > Shock Sensor

< 4.4 > Water Sensor

< 4.5 > LED Light Bar

< 4.6 > LED Beacon

Key Hardware

PDU & Fan Unit

Fan Unit

Environmental Sensor & Peripherals

P. 1

P. 2

P. 3

P. 8

P.15

P.20

P.21

P.23

P.24

P.25

P.26

P.27

P.28

< 5.1 > Daisy Chain

< 5.2 > Star

< 5.3 > Mixed

< 6.1 > Data Centre

< 6.2 > Intelligent Building

< 6.3 > Remote Site

< 6.4 > Branches

Network Connection

Application

P.29

P.29

P.30

P.31

P.32

P.33

P.34

www.austin-hughes.comUM-X-ISM-Q414V3

Page 5

Part II. Software & System Setup

< 7.1 > Tips for System Setup

< 8.1 > Key Word & Cabinet Icon

Software Installation & Activation

< 9.1 > Key features

< 9.2 > CD Key Box

< 9.3 > Management PC & Client PC Requirement

< 9.4 > OS Platform & Web Browser

< 9.5 > Prerequisite before Software Installation

< 9.6 > Software Installation

< 9.7 > Remote Access

< 9.8 > Software Activation

< 10.1 > Cabinet Alignment

< 10.2 > MFP - Master Floor Plan

< 10.3 > CA - Control Area

< 10.4 > User Setup

< 10.5 > Group Setup

< 10.6 > Visitor

Operation Setup

P.35

P.36

P.39

P.40

P.41

P.42

P.42

P.43

P.44

P.45

P.48

P.51

P.53

P.55

P.56

P.58

< 11.1 > Backup & Restore

< 11.2 > Alarm Setting / Mail Server Setting / Audio Visual Alarm

< 11.3 > Temperature Unit

< 11.4 > Door Opening Overdue Setting

< 11.5 > Time Rule

< 12.1 > Individual Cabinet Devices Enable & Disable

< 12.2 > Individual Cabinet Door open by Remote

< 12.3 > Individual Cabinet PDU Confi guration & Control

< 12.4 > Individual Cabinet Fan Unit Confi guration & Control

< 12.5 > Console Message

< 12.6 > PDU Outlet Grouping

< 12.7 > Device & System Event Log

< 13.1 >

System Setup

Operation & Usage

SNMP

P.60

P.62

P.63

P.63

P.64

P.65

P.67

P.68

P.70

P.71

P.72

P.75

P.76

< 14.1 > FAQ & Troubleshooting

P.77

www.austin-hughes.comUM-X-ISM-Q414V3

Page 6

< 1.1 > Tips for hardware

Prepare a notebook computer

To install IP setup utilities

InfraBox installation

Place the rackmount box on the

top rear side of the cabinet

Start

Confi gure IP setting

For each InfraBox ONE by ONE

Smartcard handle installation

For front & rear door

& connect cable to InfraBox

Door sensor installation

Place the sensor to the door

corner & connect to the handle

Sensor & peripheral installation

Connect sensor & peripheral

to InfraBox

Network setup

Daisy Chain / Star / Mixed

connection

PDU & Fan installation

PDU & Fan daisy chain setting

InfraBox Cascade

Connect InfraBox by daisy chain

via Cat5/6 cable

Complete

www.austin-hughes.comUM-X-ISM-Q414V3 P.1

Page 7

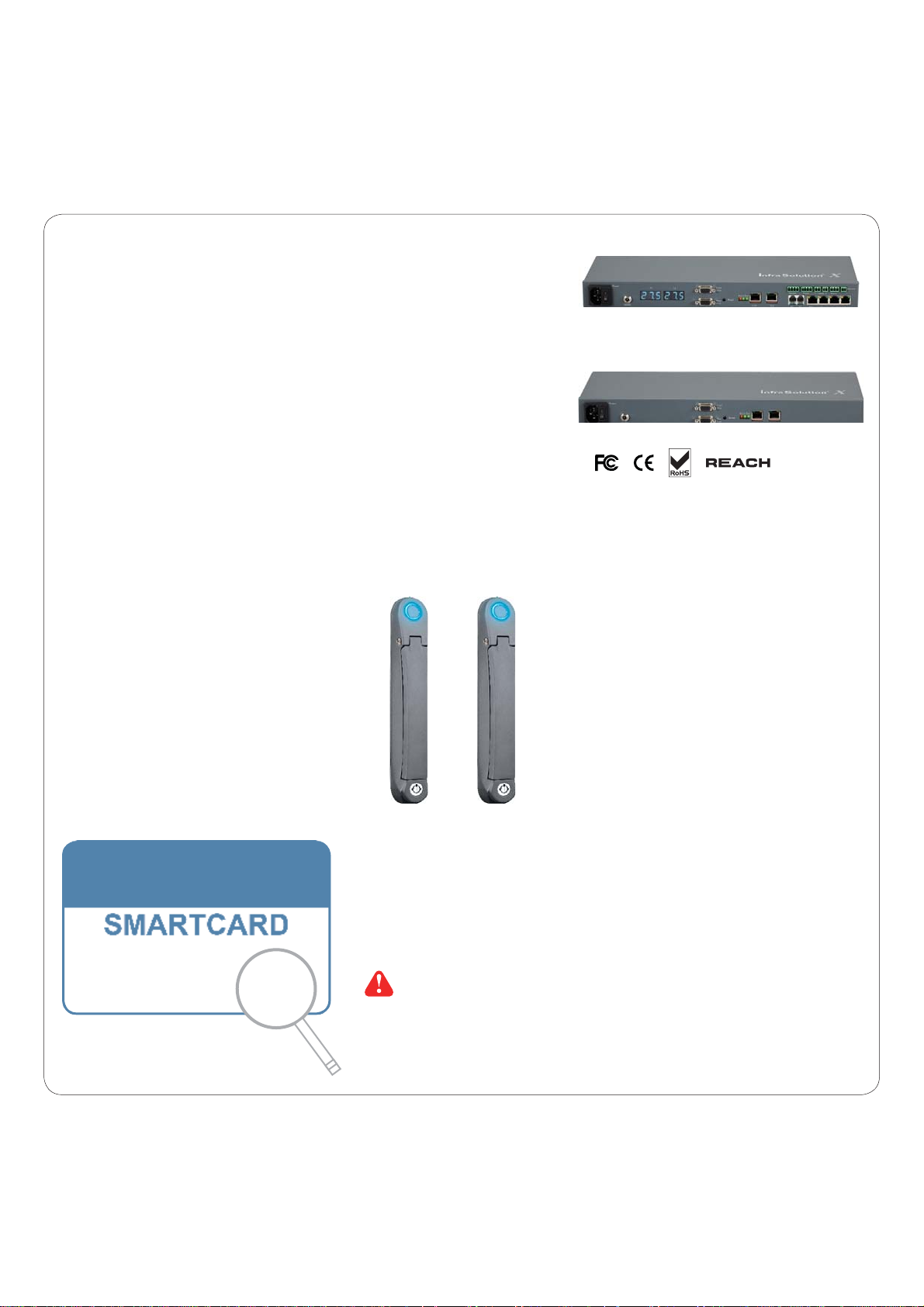

Key Hardware

Card# 12

< 2.1 > Package Contents

Unpacking

The equipment comes with the standard parts shown on the package contents. Check and make sure they are included and in good

condition. If anything is missing, or damage, contact the supplier immediately.

X-2000

- X-2000 OR X-1000 InfraBox, 1 pc

- 800 MiFARE OR Proximity smart card handle, pair

- Inductive OR Mechanical door sensor, pair

- Front door cable, 2-section with joint connector, 1 pc ( 3150mm )

- Rear door cable, 2-section with joint connector, 1 pc ( 2350mm )

- 6’ Power cord, 1 pc

- Activated smartcard, 1 pc

- Key, 1 pc

OR

X-1000

- Cable clip, 8 pcs

X-800P X-800M

OR

Patented and Worldwide

Patents Pending

Handle mounting screw set :

- Handle mounting bracket, 2 pcs

- U bracket x 2

- M3 x 10mm screw, 4 pcs

- M4 x 9mm screw, 4 pcs

- M5 x 10mm screw, 2 pcs

- Circle hole washer, 2 pcs

- Square hole washer, 6 pcs

Card# 12345678

Each package bundled with smartcard x 1. The card

on the bottom right shows card number information :

www.austin-hughes.comUM-X-ISM-Q414V3 P.2

Page 8

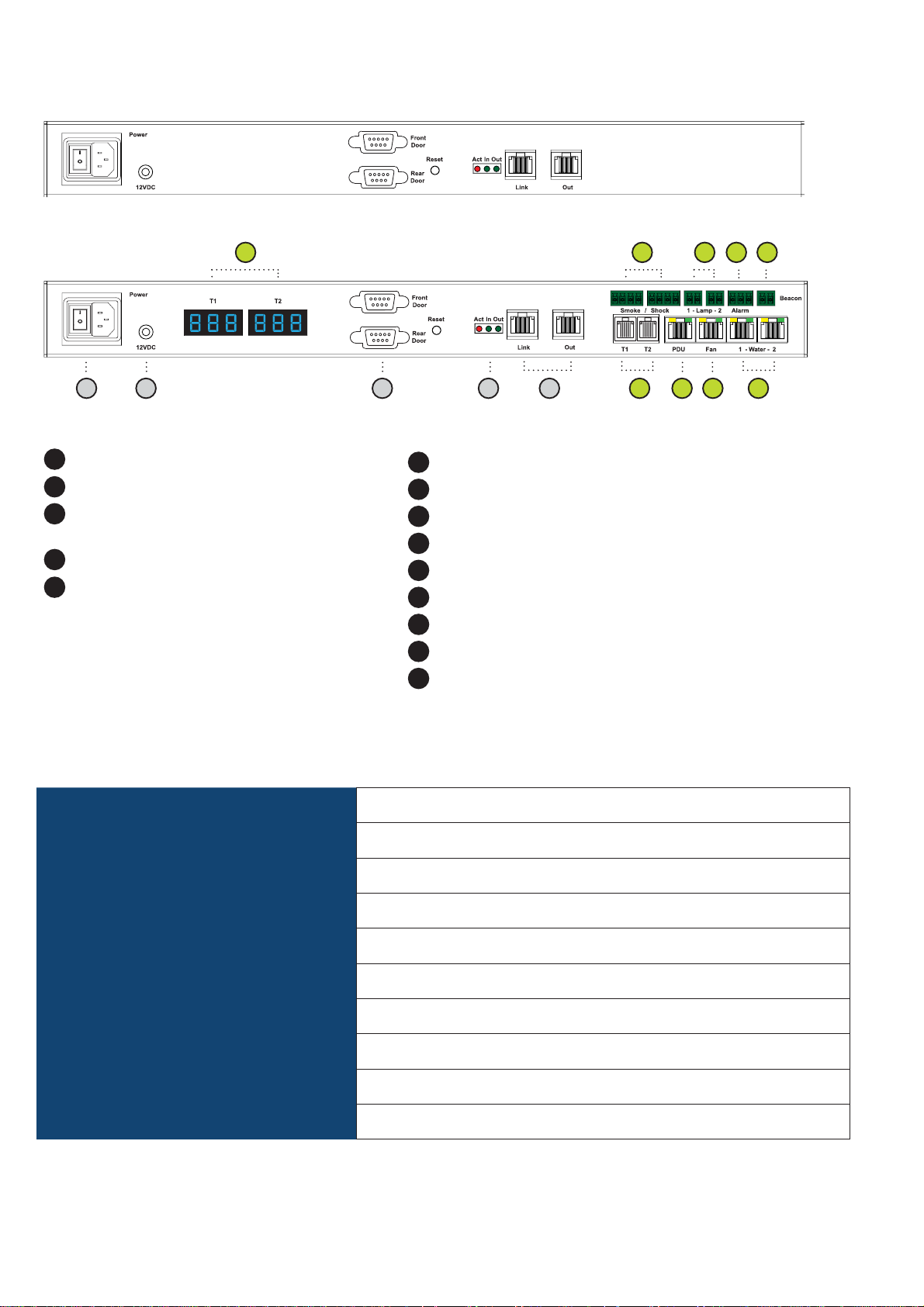

< 2.2 > InfraBox X-1000 / X-2000

X-1000

6 9

X-2000

1 2 3

1

Power input

2

Dual power input ( option )

3

Door cable DB-9 connector x 2

Connect to the front and rear handle

4

“Act in Out” LED

Daisy chain RJ45 port x 2

5

( Link & Out )

7

114

Temp. LED display x 2

6

Smoke / Shock sensor port x 2

7

LED Light Bar port x 2

8

Port for 3rd party alarm board x 1

9

LED beacon port x 1

10

Temp. & Humid. sensor port x 2

11

12

PDU port x 1 ( RJ-45, up to PDU daisy chain level x 4 )

13

Fan unit port x 1 ( RJ-45, up to fan unit daisy chain level x 2 )

14

Water sensor port x 2

8 10

13125 14

X-1000 / X-2000 Specifi cation

Product Dimension ( W x D x H ) 400 x 135 x 39.7 mm / 15.7 x 5.3 x 1.6 inch

Packing Dimension ( W x D x H ) 557 x 367 x 98 mm / 21.9 x 14.4 x 3.9 inch

Net / Gross Weight 1.06 kgs ( 2.3 lbs ) / 2.2 kgs ( 4.8 lbs )

Power Consumption Auto-sensing 100~240VAC, 50 / 60Hz 0.5A, Max. 48 Watt

Operating Temperature 0° to 55°C Degree

Storage Temperature -5° to 60 °C Degree

Relative Humidity 5~90%, non-condensing

Mounting 1U Rackmount

Safety Regulatory FCC & CE certified

Environmental RoHS2 & REACH compliant by SGS

www.austin-hughes.comUM-X-ISM-Q414V3 P.3

Page 9

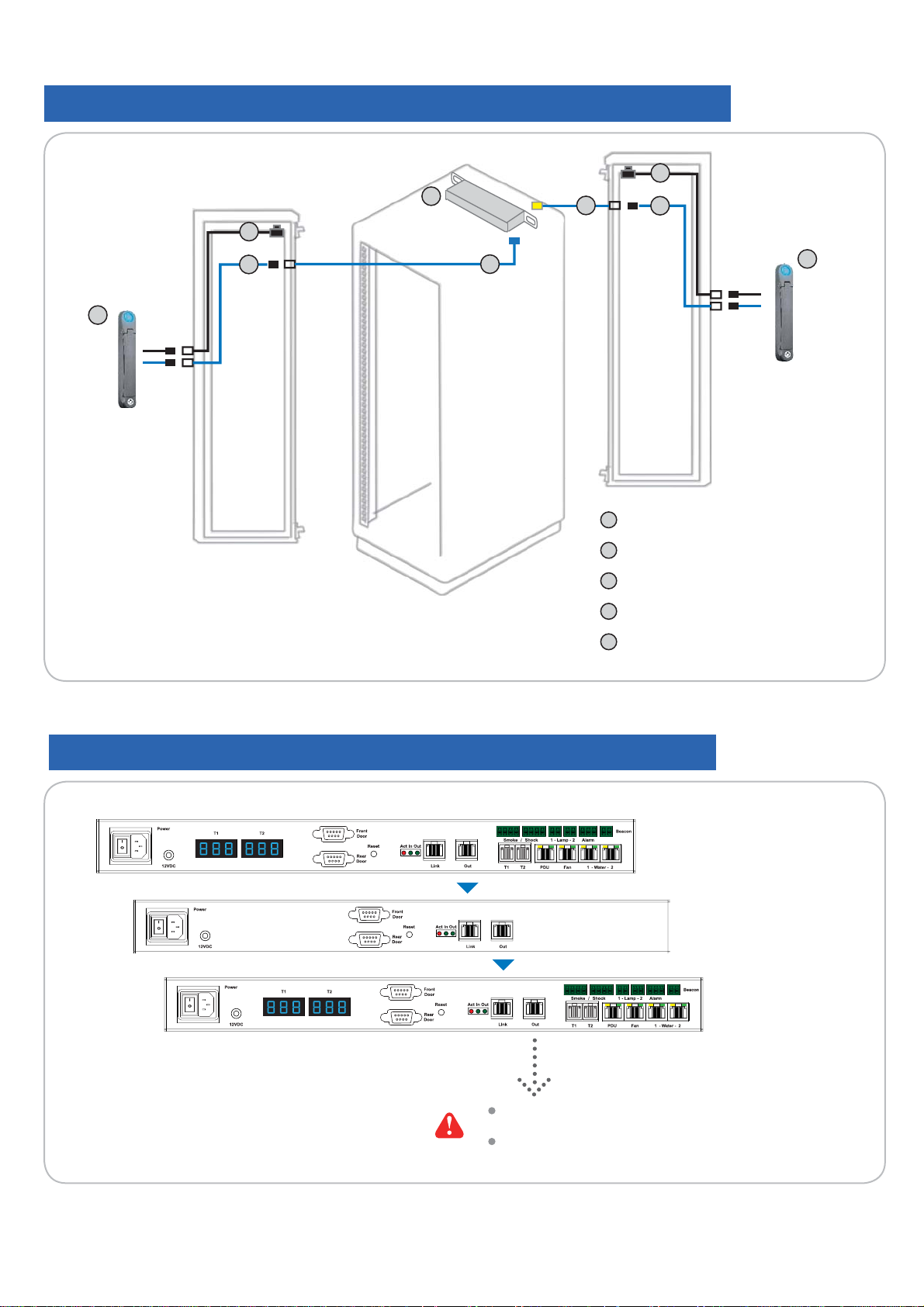

Key hardware Installation Diagram - InfraBox / Handle / Door Sensor

3

1

3

4

22

Front Door

5

5

1

2

4

Rear Door

InfraBox

SmartCard handle

2

2

InfraBox Daisy Chain Connection

3

Door sensor with 6’ cable

4

Door cable ( door section )

5

Door cable ( cabinet section )

InfraBox X-2000

InfraBox X-1000

InfraBox X-2000

Up to 50 Infrabox in a single daisy chain

Up to 100 meters in a single daisy chain

www.austin-hughes.comUM-X-ISM-Q414V3 P.4

Page 10

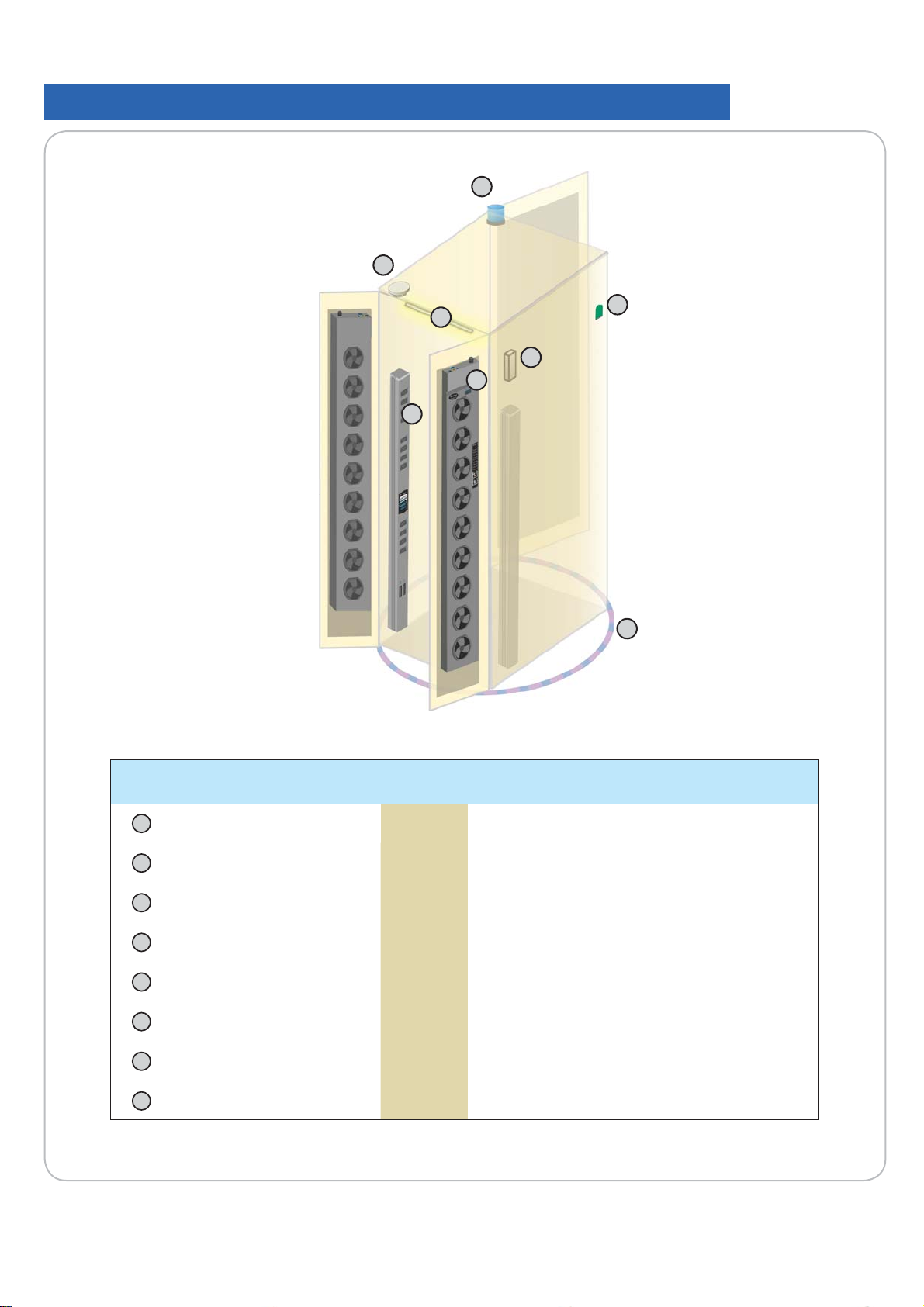

< 2.2 > InfraBox X-1000 / X-2000

Installation Diagram - PDU / Fan / Sensor / Peripheral

3

2

Front Door

Rear Door

1

4

5

6

7

8

Item Qty. Location

1

LED Light Bar 2 front & rear top inside

2

Smoke Sensor 1 rear inside top

3

Flashing LED Beacon 1 front cabinet roof

4

Temp. & Humid. Sensor 2 any inside position

5

Shock Sensor 1 upper inside

6

Fan Unit 2 door mount or rackmount

7

PDU 4 vertical or rackmount

8

Water Sensor 1 surrounding cabinet on fl oor

www.austin-hughes.comUM-X-ISM-Q414V3 P.5

Page 11

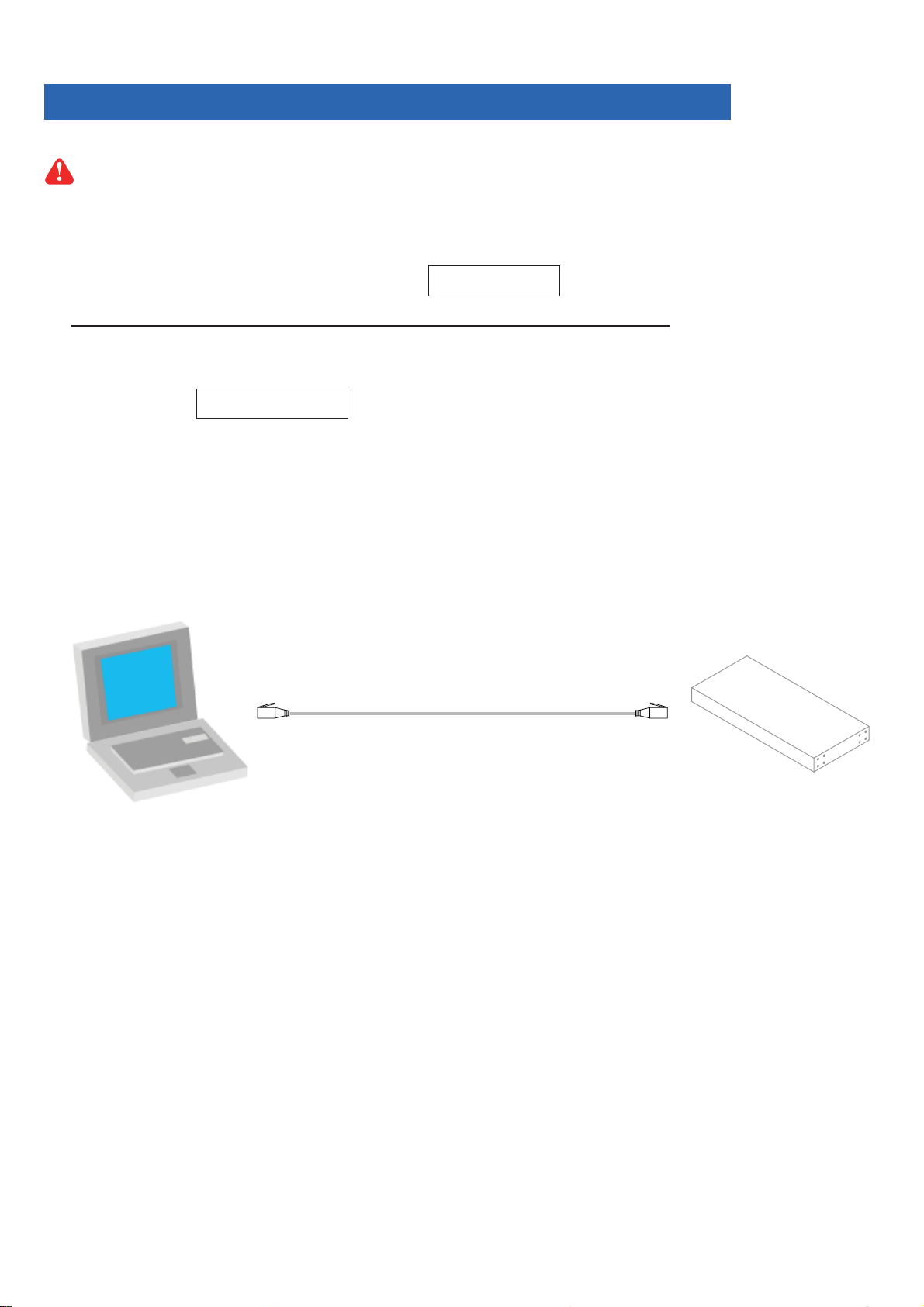

IP Setup for InfraBox

Before place the InfraBox to the cabinet, user MUST confi gure the IP setting for the InfraBox. It takes

around 1-2 minutes to complete :

1. Prepare a notebook computer to download the IP setup utilities from the link below :

http://www.austin-hughes.com/support/utilities/infrasolutionX/InfraBoxSetup.msi

2. Double click the InfraBoxSetup.msi and follow the instruction to complete the utilities installation.

3. Power ON the InfraBox.

4. Go to each InfraBox with the notebook computer & a piece of CAT. 5 / 6 cable to confi gure the InfraBox

as below.

CAT. 5 / 6 cable

To

notebook computer

LAN port

InfraBox LAN port

To

www.austin-hughes.comUM-X-ISM-Q414V3 P.6

Page 12

< 2.2 > InfraBox X-1000 / X-2000

IP Setup for InfraBox

Write down the new IP address for < 10.2 > MFP - Master Floor Plan

5. Click “ Scan “ to search the connected InfraBox.

6. Change the IP address / Subnet mask / Gateway, then Click “ Save “ to confi m the setting of InfraBox.

The default IP address is as below :

IP address: 192.168.0.20

Subnet mask: 255.255.255.0

Gateway: 192.168.0.254

Please take the procedure no. 3 to 6 for all InfraBoxes ONE BY ONE.

www.austin-hughes.comUM-X-ISM-Q414V3 P.7

Page 13

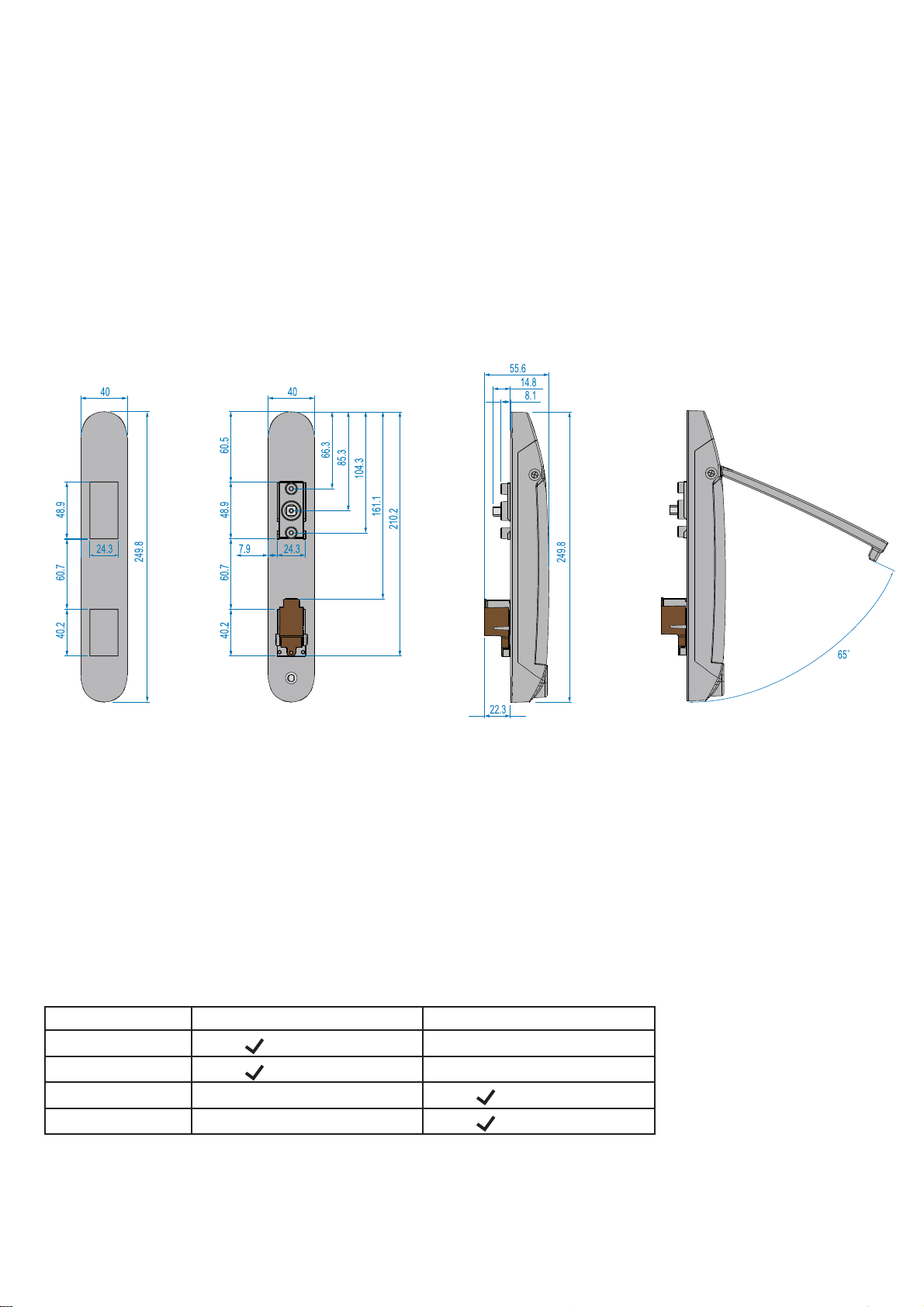

< 2.3 > Handle X-800P / X-800M

Universal Mounting Cut-out

To achieve the highest level of interoperability offered in the cabinet industry, the X-800 handle applies the universal

mounting cut-out. It avoids costly and complicated door customization for the smartcard handle integration.

Unit : mm

Back ViewCut-out Side View

Close

Side View

Open

Models of left / right side opening

X-800P / X-800M support left side open. If user requires right side open,

please order X-800P-R / X-800M-R.

Model Left side open Right side open

X-800P

X-800M

X-800P - R

X-800M - R

Proximity

MiFARE

Proximity

MiFARE

www.austin-hughes.comUM-X-ISM-Q414V3 P.8

Page 14

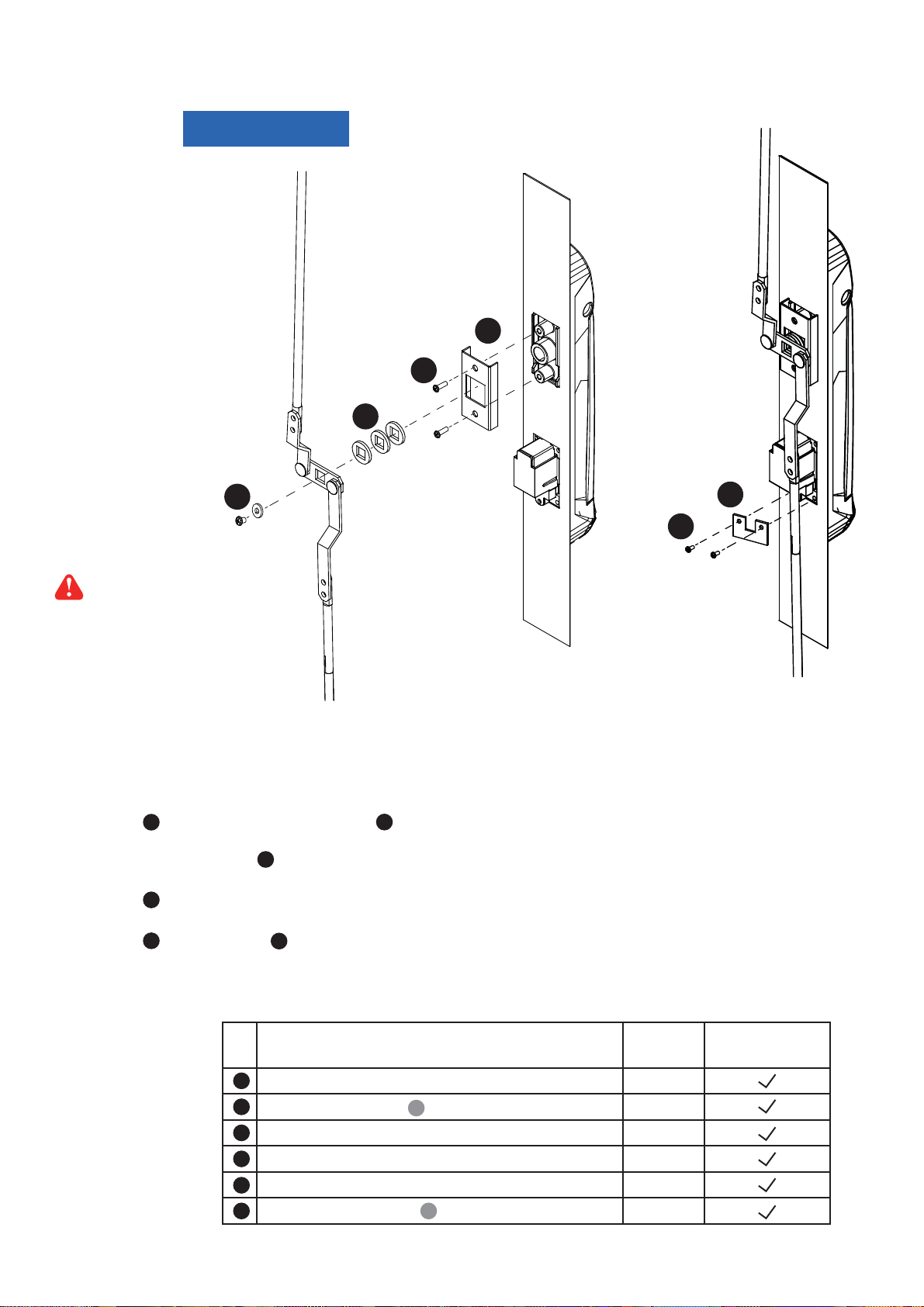

< 2.3 > Handle X-800P / X-800M

Installation for

4

While insert the screws to secure

the handle with electronic screw-

driver, please set the torque NOT

exceed 8 kgf/cm

Single Point Lock

Cam

>>>>>

2

3

1

>>>>>

Cabinet

door

6

5

1. Mount the smartcard handle to the universal mounting position.

2. Place the handle mounting bracket with M4 x 9mm screw x 2 to secure the handle.

3. Attach the Cam with square hole washer(s) to adjust and to fi t the cam locking position.

Note : - If the cam cannot fi t the locking position after adjustment, customization for the cam is required.

- Cam customization service upon your request, please contact your sales representative

4. Insert the M5 x 10mm screw x 1 with circle hole washer to secure the Cam to the handle.

5. Place the U bracket with M3 x 10mm screw x 2 to further secure the handle in place.

1

3

4

5

6

2

Handle mounting screw set for single point lock

Qty. Single Point

Lock

Handle mounting bracket 2

1

M4 x 9mm screw for 4

2

Square hole washer 6

3

Circle hole washer w/ M5 x 10mm screw 2

4

U bracket 2

5

M3 x 10mm screw for 4

6

1

5

www.austin-hughes.comUM-X-ISM-Q414V3 P.9

Page 15

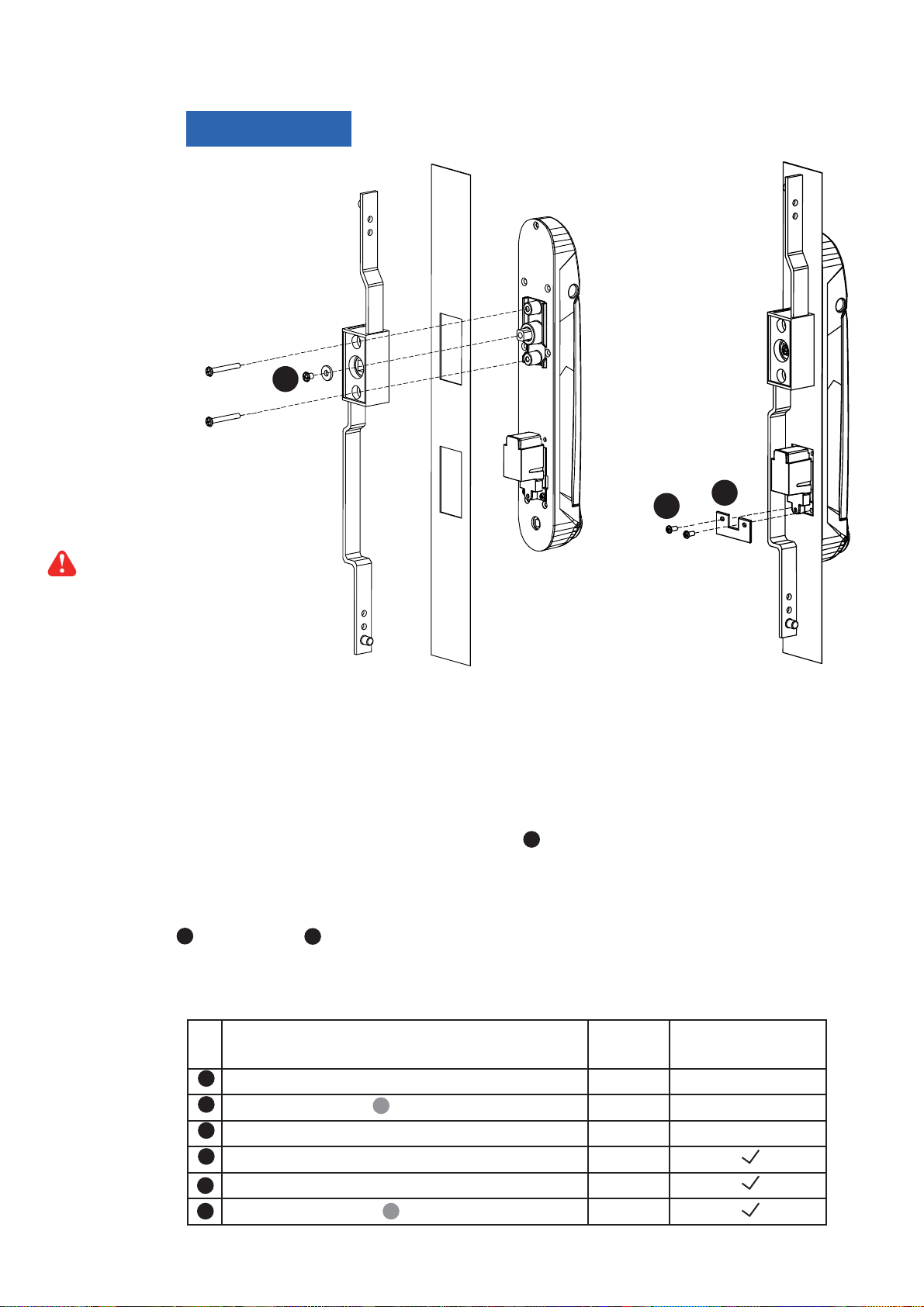

Installation for ( light-duty rod-latch )

2 - point Lock

>>>>>

Rod latch

1

2

3

4

5

6

>>>>>

Cabinet

While insert the screws to secure

the handle with electronic screw-

driver, please set the torque NOT

exceed 8 kgf/cm

1. Mount the smartcard handle to the universal mounting position.

2. Place the handle mounting bracket with M4 x 9mm screw x 2 to secure the handle.

3. Attach the Rod-latch with square hole washer(s) to adjust and to fi t the door top & bottom locking position.

4. Insert the M5 x 10mm screw x 1 with circle hole washer to secure the Rod-latch to the handle.

5. Place the U bracket with M3 x 10mm screw x 2 to further secure the handle in place.

1

3

4

5

6

2

door

Handle mounting screw set for 2-point lock ( light-duty )

Qty. 2-Point Lock

Handle mounting bracket 2

1

M4 x 9mm screw for 4

2

Square hole washer 6

3

Circle hole washer w/ M5 x 10mm screw 2

4

U bracket 2

5

M3 x 10mm screw for 4

6 5

1

www.austin-hughes.comUM-X-ISM-Q414V3 P.10

( light-duty )

Page 16

< 2.3 > Handle X-800P / X-800M

Installation for ( rod control system )

2 - point Lock

Rod control

system

Orignal

handle screws

>>> >>>

>>>>>

4

6

5

While insert the screws to secure

the handle with electronic screw-

driver, please set the torque NOT

exceed 8 kgf/cm

1. Mount the smartcard handle to the universal mounting position.

2. Attach the Rod control system to the handle and insert the M5 x 10mm screw x 1 with circle hole

washer to secure the position.

3. Insert Orignal handle screws x 2 through the Rod control system and door to the handle to fi x it in place.

4. Place the U bracket with M3 x 10mm screw x 2 to further secure the handle in place.

5

6

>>>>>

Cabinet

door

4

Handle mounting screw set for 2-Point Lock ( with rod control )

Qty. 2-Point Lock

( with rod control )

1

Handle mounting bracket 2

2

M4 x 9mm screw for 4

3

Square hole washer 6

4

Circle hole washer w/ M5 x 10mm screw 2

U bracket 2

5

M3 x 10mm screw for 4

6 5

1

www.austin-hughes.comUM-X-ISM-Q414V3 P.11

Page 17

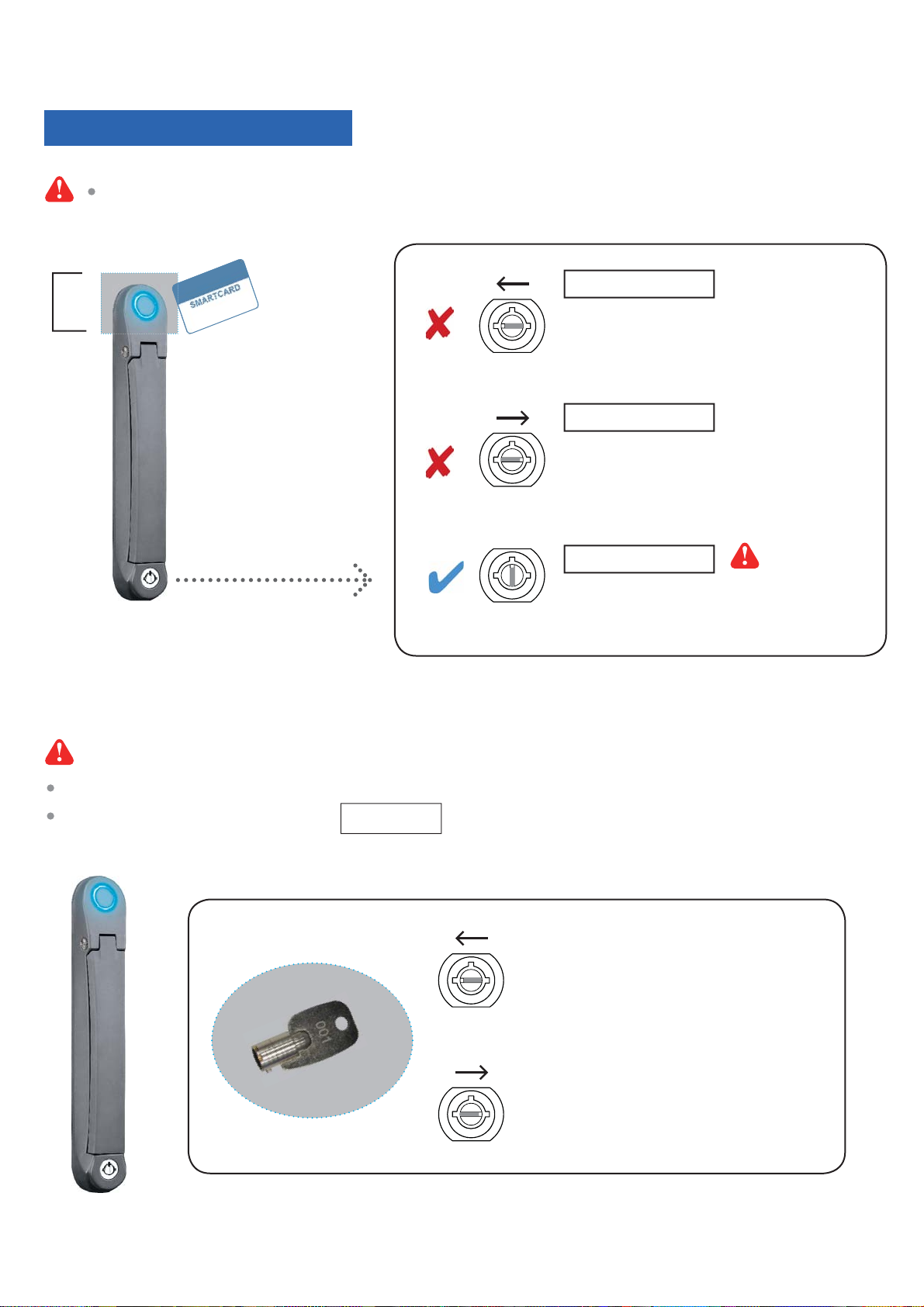

Important Note for Key lock

Under Smartcard mode, always keep key cylinder to 12 o’clock direction.

Sensor

area

Present the smartcard and

touch the handle sensor

area for 1 to 2 seconds

Key lock mode

Key cylinder to 9 o’clock direction

Under key lock mode, even present the

smartcard, the handle still keeps locked.

Key unlock mode

Key cylinder to 3 o’clock direction

Under key unlock mode, the handle

keeps unlocked.

Smartcard mode

For smartcard operation,

keep key cylinder always

to 12 o’clock direction.

Unless the smartcard handle is defective, lock / unlock the handle by key is NOT recommended

Please insert & turn the key with push force

Key lock mode

Key cylinder to 9 o’clock direction.

Key unlock mode

Key cylinder to 3 o’clock direction.

www.austin-hughes.comUM-X-ISM-Q414V3 P.12

Page 18

Maintenance Key ( MK-001 )

Improper key usage may cause the cylinder stuck at abnormal direction 1 to 2 o’ clock.

Under this circumstance, the maintenance key (MK-001) is required to solve the problem.

Please insert the maintenance key to the cylinder with push force for turning it to normal

direction 9 or 12 or 3 o’clock.

Important Note for Handle

For your own safety, please return the handle to park position properly in case reckless collision.

www.austin-hughes.comUM-X-ISM-Q414V3 P.13

Page 19

< 2.3 > Handle X-800P / X-800M

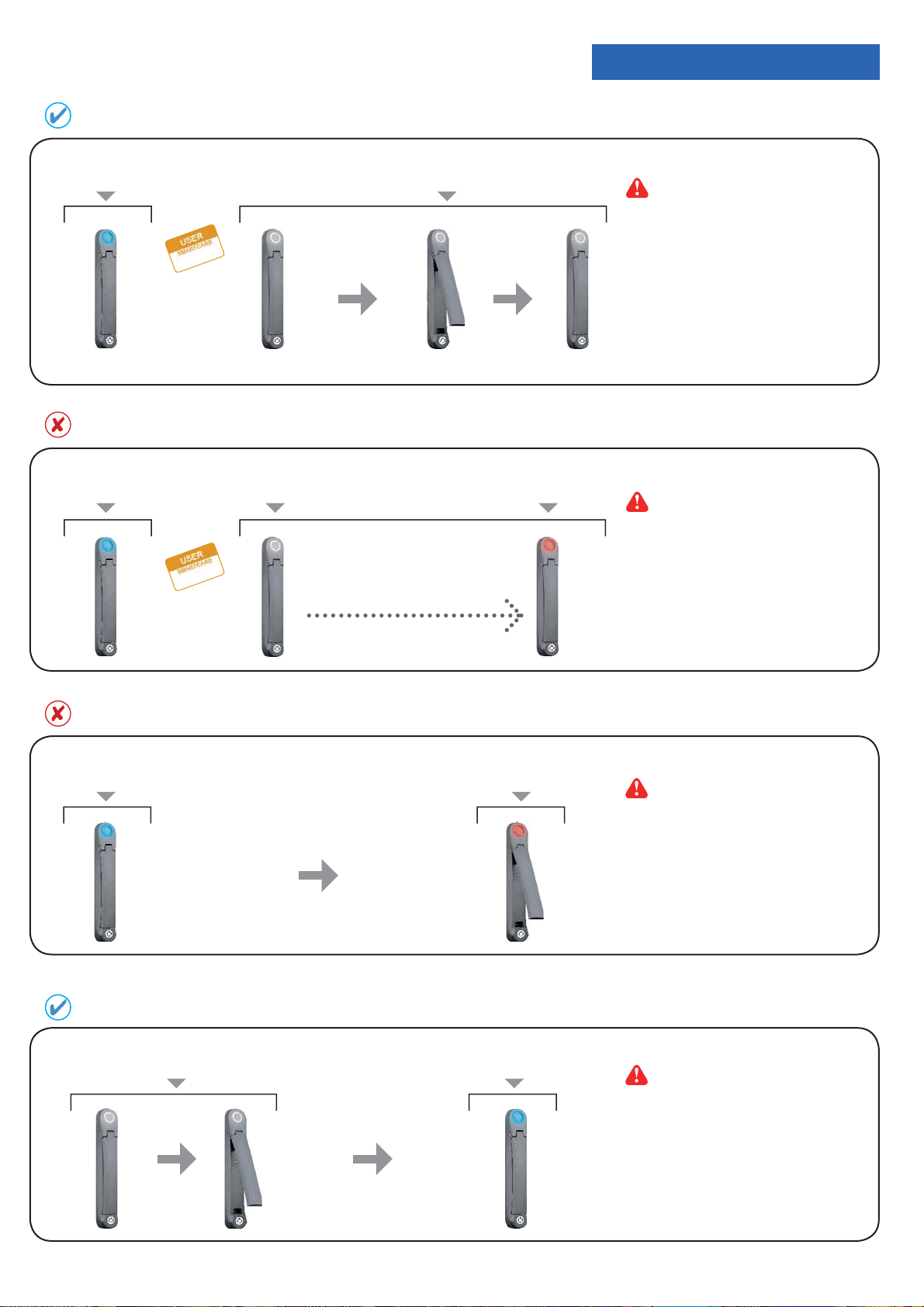

How to unlock the handle & open the door properly

Handle Operation

Locked status in

blue or green

>>>

Flashing Flashing

To open the door

( within 10 seconds )

Unlock the handle but NOT open the door

Locked status in

blue or green

Unlocked status in

silver white

Flashing

>>>

Unlocked status in

silver white

Stop

Unlocked status in

red

Within 10 seconds after smartcard

detection, users should :

- lift up the handle

- open the door

- return the handle to park

position properly in case reckless

collision causes handle damage.

Over 10 seconds, the

handle still

If DO NOT lift up the handle and open

the door within 10 seconds, the LED

will change to RED to draw user’s

attention that the handle in unlock

status and cabinet security at risk now.

keeps unlock.

Unauthorized door-open

Locked status in

blue or green

NO Authenticated

Smartcard Detection

How to close the door properly

Unlocked status in

silver white

10 seconds

Unlocked status in

Door Opening

improperly or by force

Locked status in

fl ashing red

If the door is opened improperly or

by force, handle LED will turn to

red fl ashing with audio alarm ‘beep’

sound.

blue or green

To close the door

Users should :

- lift up the handle

- close the door

- return the handle to park

position properly

- the handle will

auto-lock

www.austin-hughes.comUM-X-ISM-Q414V3 P.14

Page 20

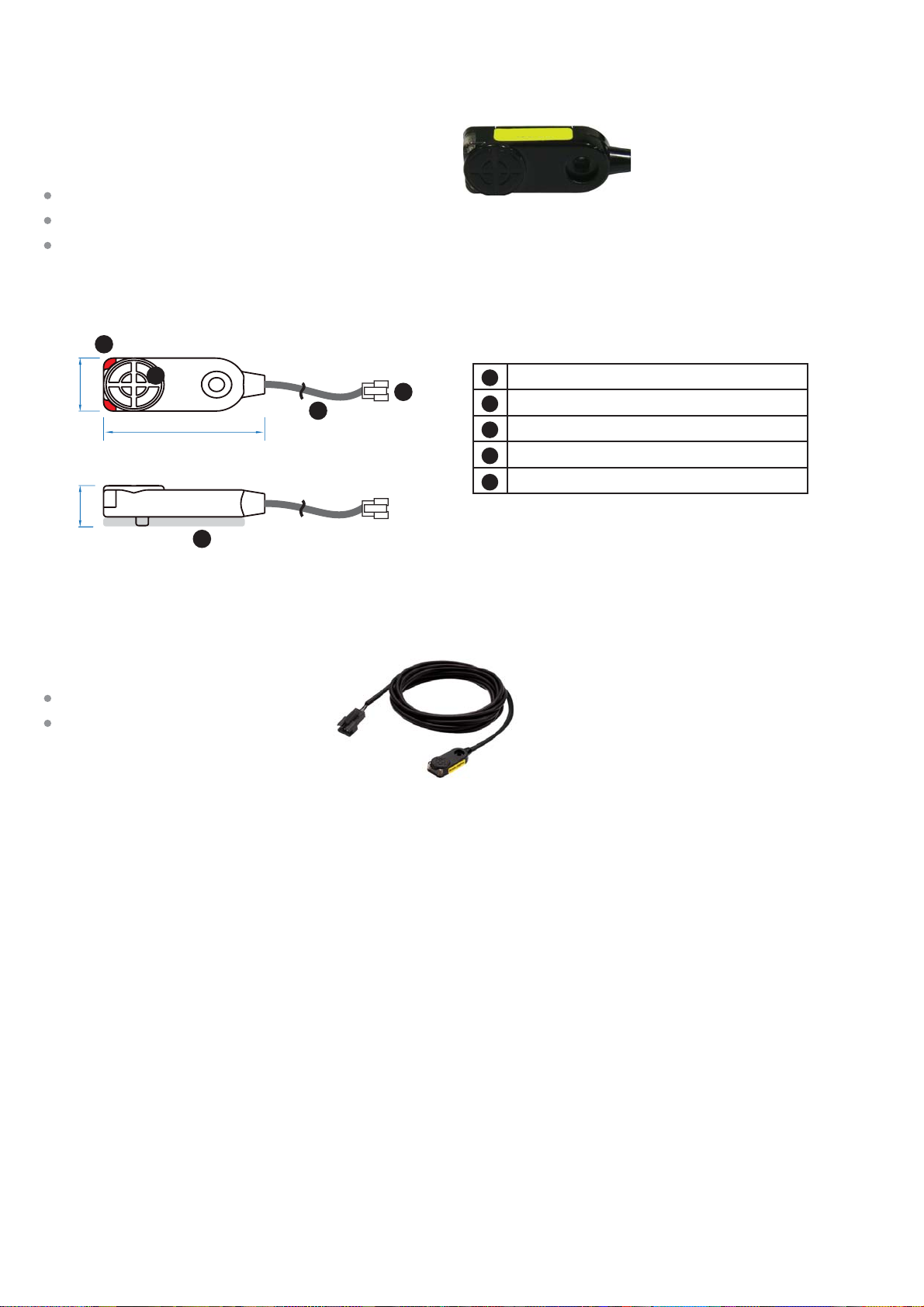

< 2.4 > Door Sensor - Inductive

Inductive Door Sensor, pair ( S-DSI )

Features

light weight / adhesive

mini size ( 32.5 x 12.2 x 9.2 mm )

no custom cutting required on door

32.5 mm

Front View

3

Side View

5

2

1

12.2 mm

9.2 mm

Austin Hughes

Sensor area

4

1

Red LED ( light up while door opening )

2

2m cable

3

Cable jack ( connect to handle )

4

2mm adhesive tape

5

Package content

Inductive sensor w/ 2m cable x 2

2mm adhesive tape x 6

www.austin-hughes.comUM-X-ISM-Q414V3 P.15

Page 21

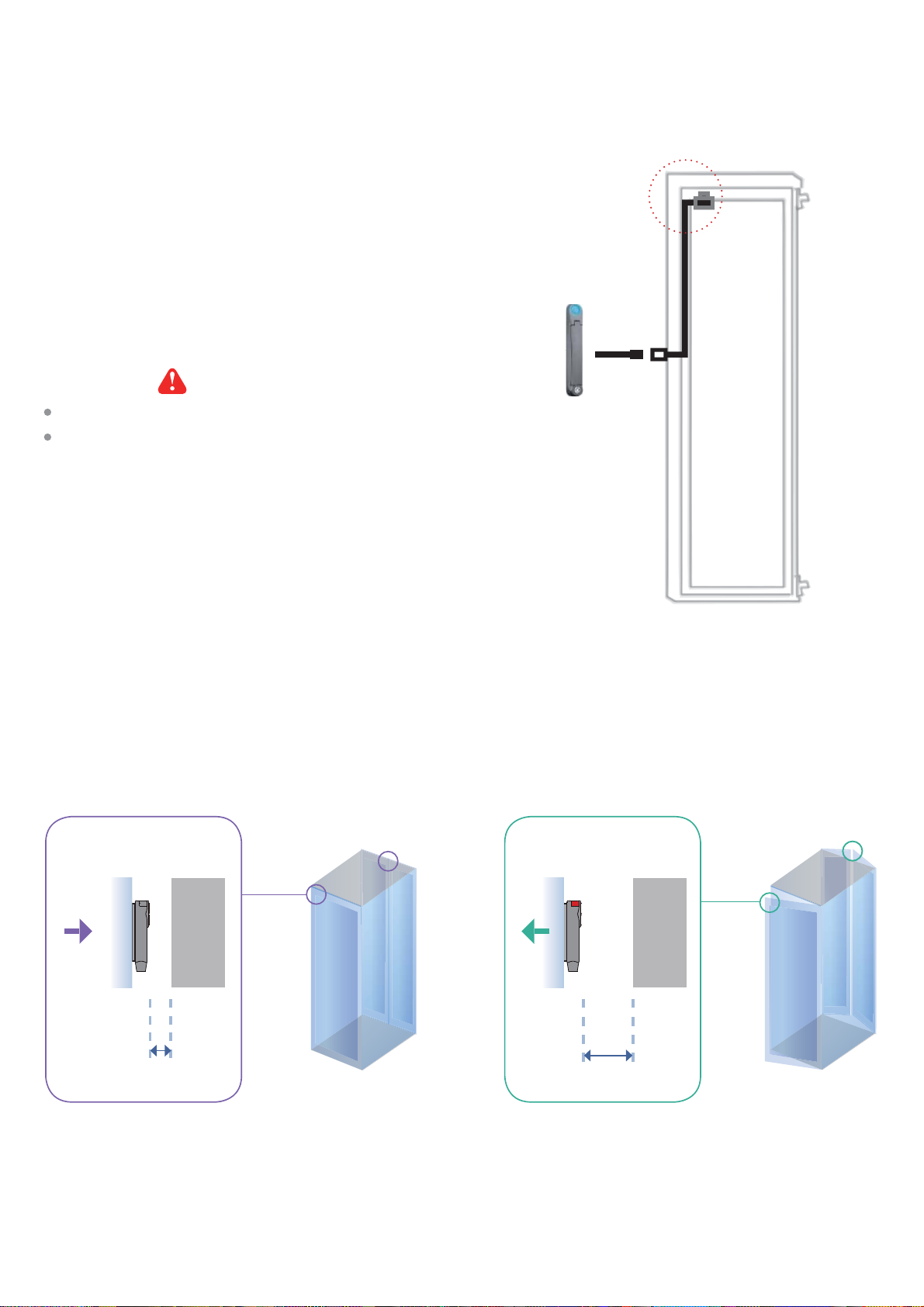

< 2.4 > Door Sensor - Inductive

Installation steps

- connect to the handle

- guide & fi x the cable with cable clips ( bundle with handle package )

- place the sensor at the top of the door, close to the opening side

- adjust the sensor with adhesive tape to ensure the sensing distance

between door to frame within 3mm while door in close status

Requirements

cabinet frame made of ferrous metal ( iron )

sensing distance 3mm

Suggested

sensor position

Sensor Operation

DOOR CLOSE

- close door

- inductive sensor detects the cabinet frame

- DOOR CLOSE SIGNAL sends out

Door

frame

CLOSED

Sensing distance

Cabinet

frame

< 3mm

DOOR OPEN

- open door

- inductive sensor lose detection with cabinet frame

- Red LED of sensor light up

- DOOR OPEN SIGNAL sends out

Door

frame

OPENED

Sensing distance

Cabinet

frame

> 3mm

www.austin-hughes.comUM-X-ISM-Q414V3 P.16

Page 22

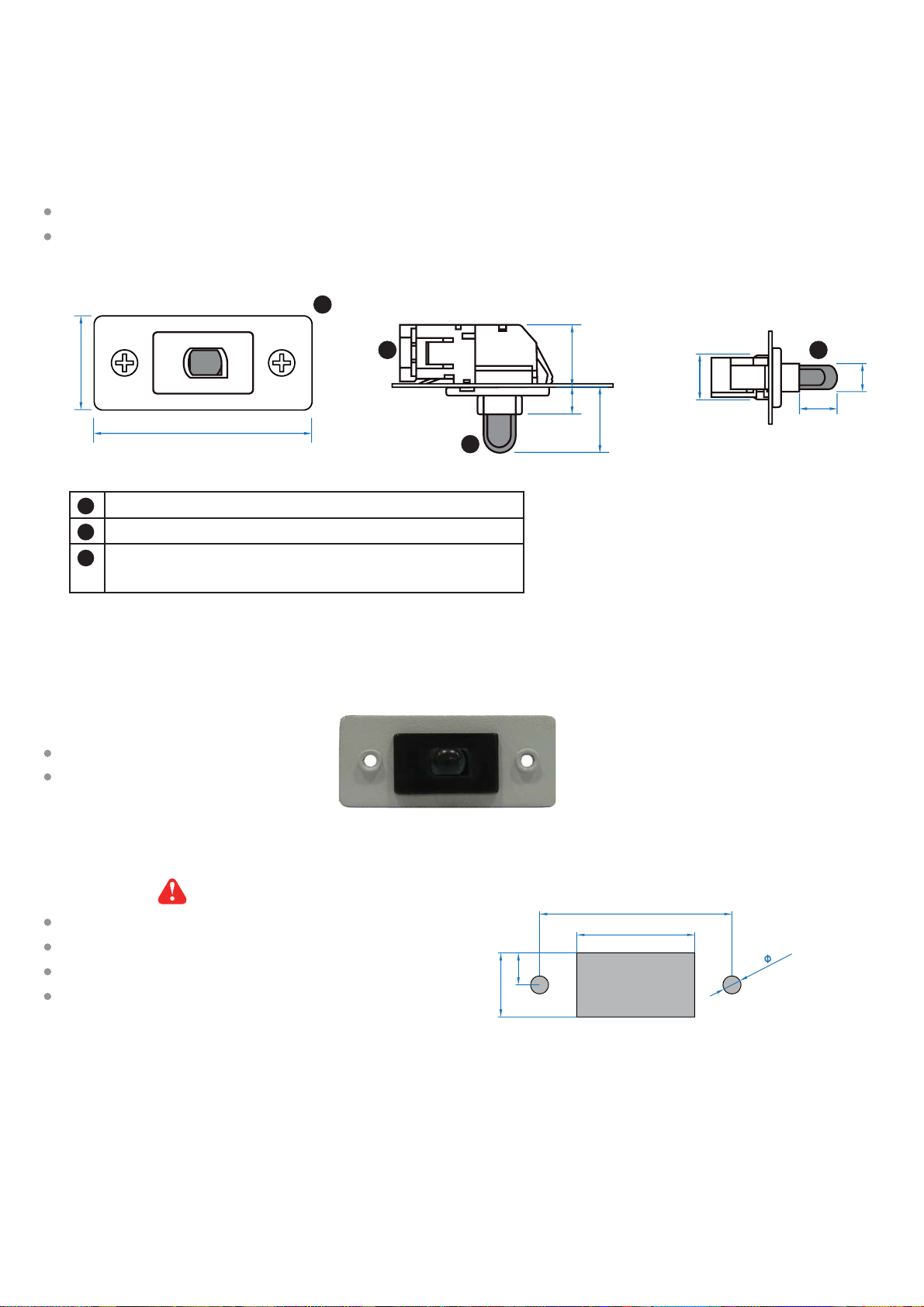

< 2.4 > Door Sensor - Mechanical

Mechanical Door Sensor ( S-DSW )

Features

low cost / precise

cost effi cient integration to new cabinet

unit : mm

22.5

52.0

Steel mounting plate with 2 screw holes

1

Cable connector

2

Press button ( total travel distance : 9.25 mm )

3

( min. actuation distance : 3.00 mm )

Package content

Mechanical sensor w/ 2m cable x 2

Mounting screws 6#32x4.5mm x 2

1

Side ViewFront View Top View

6.515.0

32

11

15.75

9.25

7.3

3

Requirements

custom hole cutting required on doors

ordering a sample for custom cutting is highly suggested

min. actuation distance : 3.00 mm

total travel distance : 9.25 mm

unit : mm

37.5

23

6.3

12.5

2

Dimension of door cutting hole

- circle hole x 2 for screw mounting

- rectangle hole x 1 for sensor installation

www.austin-hughes.comUM-X-ISM-Q414V3 P.17

5

.

3

-

Page 23

< 2.4 > Door Sensor - Mechanical

Installation steps

- connect to the handle

- place the sensor at the top middle of the door

- install the sensor in the custom hole

- secure it with bundled mounting screws 6#32x4.5mm x 2

Suggested

sensor position

Sensor Operation

DOOR CLOSE

- close door

- Sensor button is pressed on

- DOOR CLOSE SIGNAL sends out

Door

frame

CLOSED

Actuation distance > 3mm

Physical touch required

Cabinet

frame

DOOR OPEN

- open door

- Sensor button is released

- DOOR OPEN SIGNAL sends out

Door

frame

OPENED

Button released

Cabinet

frame

www.austin-hughes.comUM-X-ISM-Q414V3 P.18

Page 24

< 2.4 > Door Sensor

Specifi cation

Part no.

Inductive Door Sensor Mechanical Door Sensor

S-DSI S-DSW

Sensitivity Actuation

Travelling Distance

Operating Force

Sensing distance

Sensing object

Power Requirement

Housing Material

Connection Cable Length

Environmental

Voltage 12VDC, powered by sensor port

Current Consumption 100mA

Color

Operating -20 to 60°C Degree

Storage -20 to 60°C Degree -30 to 70°C Degree

Relative Humidity 5~90%, non-condensing

/

/

/

Max. 3mm

Ferrous metal

3.00 mm

9.25 mm

3.5±1 N

/

/

/

/

Plastic

Black

sensor w/ 2m cable

Dimensions

Weight

Supply includes

Compatibility

Safety Regulatory

Environmental

Product 32.5L x 12.2W x 9.2H mm

Packing / /

Net / Gross 6g 14g ( with metal plate )

1

2 2mm Adhesive tape Metal plate

3 / 2m cable

Inductive door sensor

with 2m cable

X-2000 series

FCC & CE certifi ed

RoHS2 & REACH compliant by SGS

52W x 22.5L mm

( with metal plate )

Mechanical door sensor

www.austin-hughes.comUM-X-ISM-Q414V3 P.19

Page 25

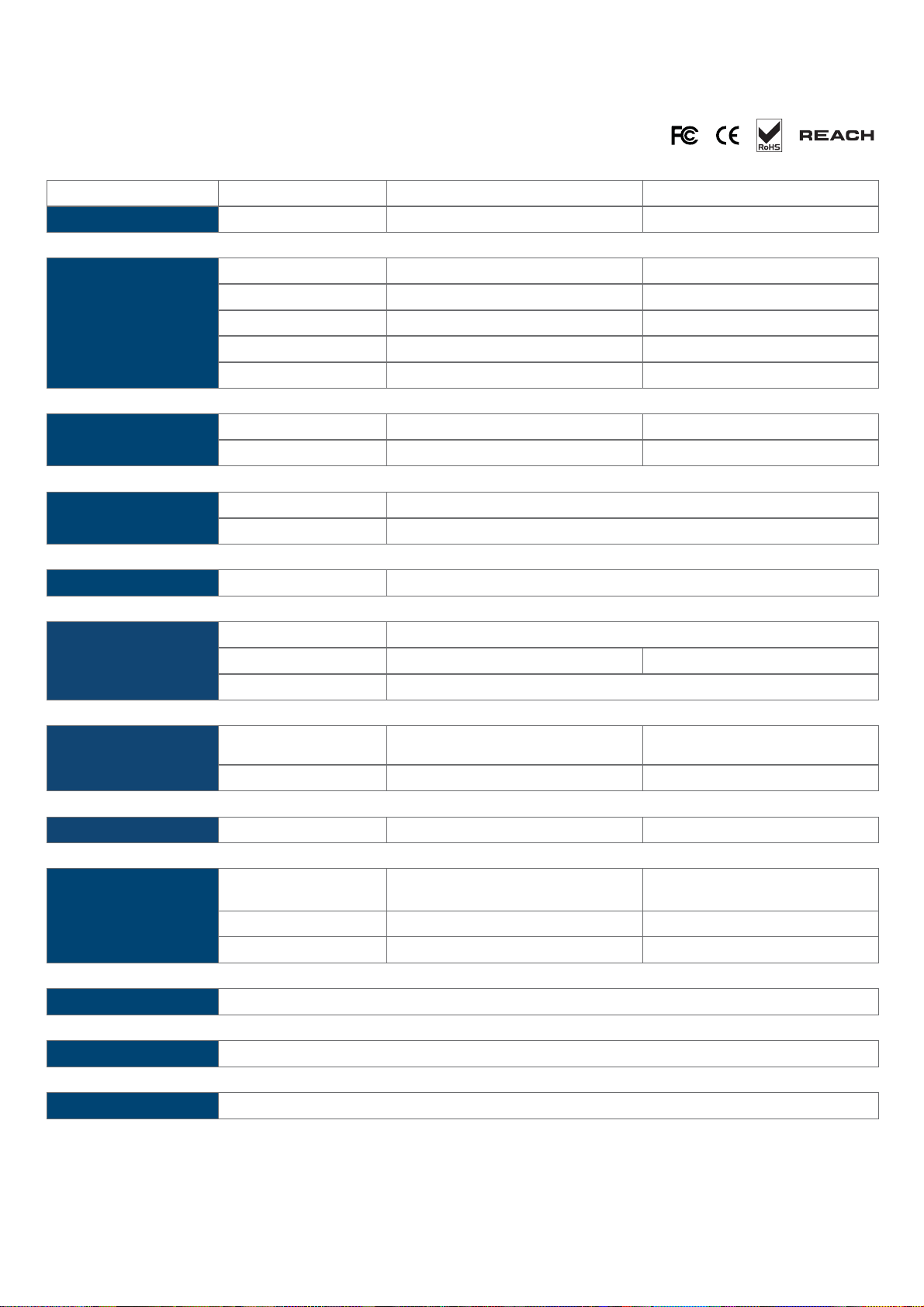

< 3.1 > PDU

Under an InfraSolution X network, each InfraBox supports InfraPower intelligent PDU x 4 in a daisy chain.

Each PDU comes with Temp. & Humid. sensor port x 2

W series : monitored PDU

WS series : switched PDU

WSi series : outlet level measurement switched PDU

Please visit below link to select desired PDU & download the PDU drawing & specifi cations.

http://www.austin-hughes.com/solutions/intelligent-kWh-pdu.html#Single_Phase

InfraBox

Cat 5 / 6 cable Up to 20M

1st level

PDU meter

PDU level setting :

Step 1 - Press the & button to display no.9 and press to confi rm

Step 2 - Press the & button to PDU ID and press to confi rm

Step 3 - In display 9.1, Press the & button to select PDU level no.1 - 4

Cat 5 / 6 cable

Up to 20M

2nd level

PDU meter

Cat 5 / 6 cable

Up to 20M

3rd level

PDU meter

Max. daisy chain distance from InfraBox to the 4th PDU up to 80M

Cat 5 / 6 cable

Up to 20M

4

4th ( last ) level

PDU meter

and press to confi rm

Step 4 - Press to exit

( Neglect Group no. in display 9.1. It’s not appliable to InfraSolution X Software )

For details about PDU level setting, please refer to IPM-03 user manual < 3.1 > :

http://www.austin-hughes.com/support/usermanual/infrapower/UM-IPM-03.pdf

www.austin-hughes.comUM-X-ISM-Q414V3 P.20

Page 26

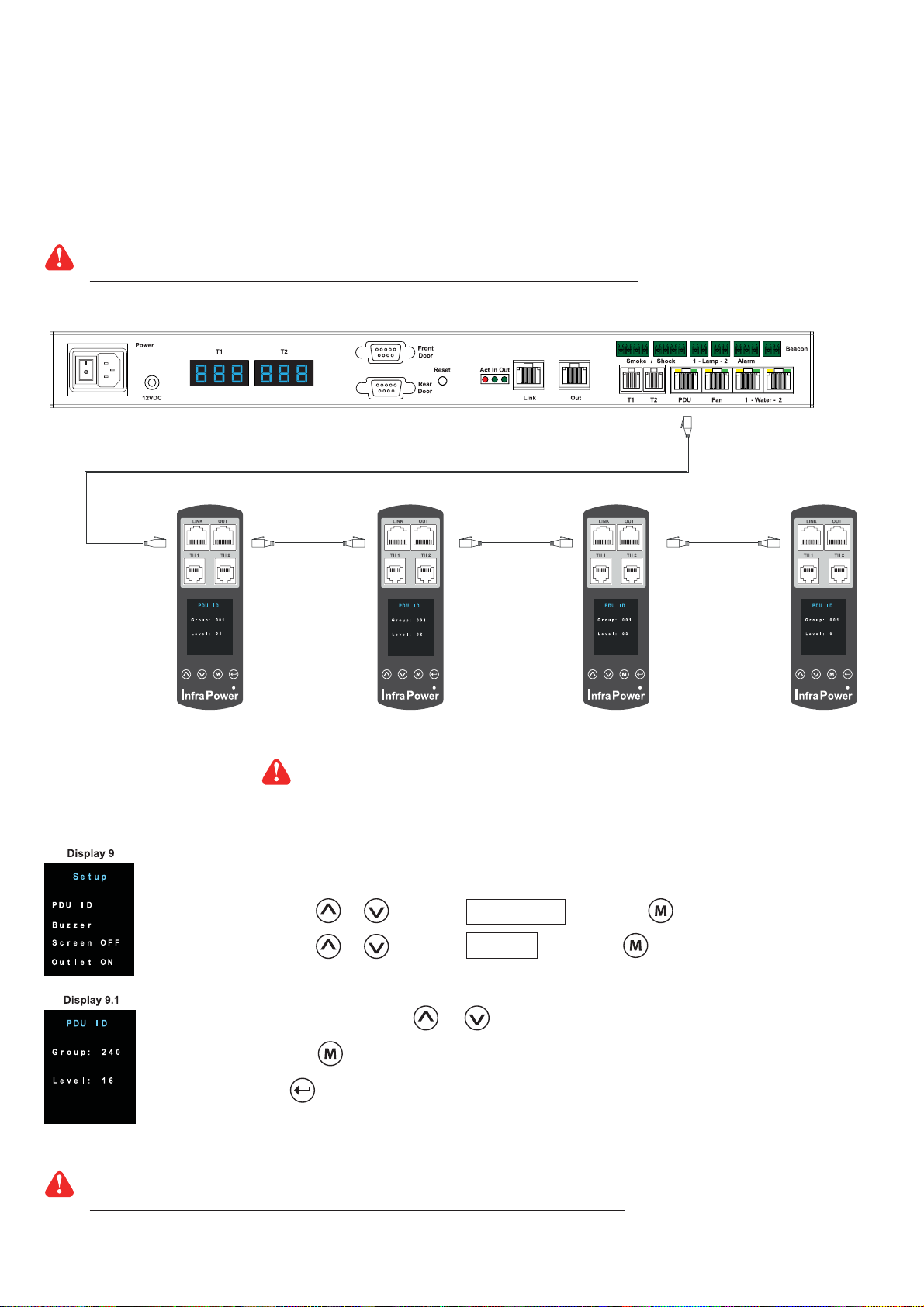

< 3.2 > Fan Unit

Under an InfraSolution X network, each InfraBox supports InfraCool remote fan unit x 2 in a daisy chain.

Each fan unit comes with TEMP. sensor port x 1

InfraBox X-2000

2nd ( last ) level Fan unit

Cat 5 / 6 cable

OUT

LINK

Up to 20M

OUT

LINK

1st level Fan unit

Max. daisy chain distance from InfraBox to the 2nd fan unit up to 40M

Please visit below link to select desired Fan unit models

http://www.austin-hughes.com/solutions/intelligent-fan-units.html#RMounted

Using dip switch no. 1, 2, 3, 4, 5, 6 & 8 to setup each FAN unit level as below :

Cascaded

FAN unit

1st level Fan Unit On On On On On On Off

2nd level Fan Unit Off On On On On On Off

1234568

Dip switch no.

ON

OFF

Using dip switch no. 7 to setup each FAN unit audio alarm as below :

Dip switch 7

Enable On

Disable Off

If enable the audio alarm, the buzzer will

sound when the outside temperature is

over the preset alarm temperature.

www.austin-hughes.comUM-X-ISM-Q414V3 P.21

Page 27

< 3.2 > Fan Unit

Specifi cation

Remote Fan

Temperature

Sensor

Power

Environmental

Conditions

Dimensions

Model

No. of Fan

Mounting 1U Door mount

CFM Level Normal / High / Max.

Individual Fan ON / OFF Yes

Individual Fan CFM 108 CFM

Unit CFM ( Approximately ) 324 / 648 / 972 CFM 648 / 972 CFM

IP Remote Access Not available, must be via Master IP fan on the 1st level

Daisy Chain Level 2nd to 16th level

Temperature Port 1 x temperature sensor port ( sensor bundled )

Measurement Range 0 to 99.9°C

Measurement Accuracy +/- 1.5%

Temperature Alarm Yes

Input 100V or 240V AC at 50 or 60Hz via IEC type cord

Consumption 20W / 40W / 60W 40W / 60W

Operating 0 to 50°C

Storage -5 to 60°C

Relative Humidity 90%, non-condensing

Shock 50G peak acceleration ( 11ms, half-sine wave )

Vibration 58~100Hz / 0.98G ( 11ms / cycle )

Model Product Dimension Packing Dimension

RF-1.3 480 x 298.3 x 43.5 mm

RF-1.6 480 x 458.3 x 43.5 mm

RF-1.9 480 x 623.3 x 43.5 mm

RF-33.6 195 x 42.9 x 1466 mm

RF-33.9 195 x 42.9 x 1466 mm

RF-1.3 / 1.6 / 1.9 RF-33.6 / 33.9

3 / 6 / 9 6 / 9

380 x 535 x 120 mm

18.9 x 11.7 x 1.71 inch

18.9 x 18 x 1.71 inch

18.9 x 24.5 x 1.71 inch

7.7 x 1.7 x 57.7 inch

7.7 x 1.7 x 57.7 inch

15 x 21.1 x 4.7 inch

550 x 550 x 120 mm

21.7 x 21.7 x 4.7 inch

550 x 730 x 120 mm

21.7 x 28.7 x 4.7 inch

263 x 106 x 1650 mm

10.4 x 4.2 x 65.0 inch

263 x 106 x 1650 mm

10.4 x 4.2 x 65.0 inch

Weight

Safety Regulatory FCC & CE certifi ed

Environmental RoHS2 & REACH compliant by SGS

Model Net Weight Gross Weight

RF-1.3

RF-1.6

RF-1.9

RF-33.6 4.3 kgs / 9.5 lbs 6.6 kgs / 14.5 lbs

RF-33.9 5 kgs / 11 lbs 7.4 kgs / 16.3 lbs

4 kgs / 8.8 lbs 5 kgs / 11 lbs

6.8 kgs / 15 lbs 8 kgs / 17.6 lbs

9 kgs / 19.8 lbs 11 kgs / 24.2 lbs

www.austin-hughes.comUM-X-ISM-Q414V3 P.22

Page 28

< 4.1 > Temp. & Humidity Sensor

Each InfraBox provides Temp. & Humid. Sensor port x 2. If more TH sensors required, two temp. & humid. sensor ports

on each integrated PDU can be applied.

Temp. & Humid. Sensor Temp. Sensor

Part no.

IG-TH01-2M IG-T01-2M

Temperature

Sensitivity

Relative

Humidity

Sensitivity

Power

Requirement

Housing Chassis & Cover

Range

Accuracy

Resolution 0.1°C ( 0.2°F )

Response Time 5 to 30 sec

Range

Accuracy

Resolution 1% R.H. /

Response Time 8 sec /

Voltage 12VDC, powered by sensor port

Current Consumption 20mA

Power consumption 0.24 Watt

Power on indicator Red Green

Color

Installation Magnetic base for unrestricted installation

0 to 80°C ( 32 to 176°F )

±0.5°C typical ( ±1°F ) ±1°C ( ±2°F)

0 to 100% R.H /

0 to 100, ±8.0% R.H

20 to 80, ±4.5% R.H.

Plastic

Dark gray

/

Connection

Environmental

Dimensions

Weight

Supply includes

Compatibility

Cable Length

Cable Specifi cation 4-wired 3.5mm to RJ11

Cable Color Black Beige

Operating 0 to 80°C Degree

Storage -5 to 80°C Degree

Humidity 0~100%, non-condensing

Product 30L x 25W x 18H mm

Net 66g

1 TH Sensor Temperature Sensor

2 4-wired 3.5mm to RJ11 cable ( 2m, black color )

InfraPower W / WS / Wi / WSi series PDU

InfraSolution X-2000 series

InfraGuard EC-300M & EC-300

TH sensor w/ 2m cable ( standard )

TH sensor w/ 4m cable ( option )

T sensor w/ 2m cable ( standard )

T sensor w/ 4m cable ( option )

Safety Regulatory

Environmental

FCC & CE certifi ed

RoHS2 & REACH compliant by SGS

www.austin-hughes.comUM-X-ISM-Q414V3 P.23

Page 29

< 4.2 > Smoke Sensor

Smoke sensor comes with a RED LED. When smoke alarm triggers, the RED LED lights on with beep sound continuously.

Smoke Sensor

Part no.

IG-S01-1M

Sensitivity Smoke sensitivity

Alarm Output Solid State Relay

Alarm LED Red

Audio Alarm 80 dB

Audio Alarm Pattern

Power Requirement

Housing Chassis & Cover

Connection

Environmental

Voltage 12VDC, powered by sensor port

Current Consumption 200uA

Power ON LED Red LED fl ashes every 6 seconds

Color

Cable Length 1m / 3m ( option )

Operating -5 to 50°C Degree

Storage -10 to 60°C Degree

Humidity 5~90%, non-condensing

0.15 ~ 0.3 dB/m

24VDC@1A

Continuous beeps

ABS plastic

Ivory White

Dimensions

Weight

Supply includes

Compatibility:

Safety Regulatory

Environmental

Product 103L x 103W x 55H mm

Net 165g

1 Smoke Sensor with 1m cable

InfraSolution X-2000 series

InfraGuard EC-300M & EC-300

FCC & CE certifi ed

RoHS2 & REACH compliant by SGS

www.austin-hughes.comUM-X-ISM-Q414V3 P.24

Page 30

< 4.3 > Shock Sensor

Shock sensor comes with a RED LED. When shock alarm triggers, the RED LED lights on continuously.

Shock Sensor

Part no.

IG-V01-1M

Sensitivity Detection radius

Adjustable sensitivity

Alarm Output Solid State Relay

Alarm hold time Approx. 2.0 sec.

Alarm LED Red

Power Requirement

Housing Chassis & Cover

Connection

Environmental

Voltage 12VDC, powered by sensor port

Current Consumption 15mA

Power consumption 0.18 Watt

Color

Cable Length 1m / 3m ( option )

Operating -5 to 55°C Degree

Storage -10 to 60°C Degree

Humidity 5~90%, non-condensing

3.5 m

Internal micro knob with screwdriver cross slot

12VDC@100mA

ABS plastic

White

Dimensions

Weight

Supply includes

Compatibility

Safety Regulatory

Environmental

Product 26 x 85 x 24 mm

Net 40g

1 Shock Sensor with 1m cable

InfraSolution X-2000 series

InfraGuard EC-300M & EC-300

FCC & CE certifi ed

RoHS2 & REACH compliant by SGS

www.austin-hughes.comUM-X-ISM-Q414V3 P.25

Page 31

< 4.4 > Water Sensor

Part no.

+

Water Sensor

IG-W01-3M

Measurement Range

Rope Sensor Length

Power Requirement

Connection Extension cable length

Environmental

Weight

Supply includes

Compatibility

Voltage 5VDC, powered by sensor port

Power consumption 125 mWatt

Operating -20 to 60°C Degree

Storage -20 to 80°C Degree

Net 450g ( Sensor & extension cable )

1 Rope water sensor

2 Extension cable

InfraSolution X-2000 series

InfraGuard EC-300M & EC-300

Wet or Dry (-20°C to 60°C)

5m

3m ( non-detection )

Safety Regulatory

Environmental

FCC & CE certifi ed

RoHS2 & REACH compliant by SGS

www.austin-hughes.comUM-X-ISM-Q414V3 P.26

Page 32

< 4.5 > LED Light Bar

Under InfraSolution X software, the LED light bar can be enabled / disabled / always ON.

When the LED light bar is enabled & connected, it will be ON within 10 seconds after the handle lock is released.

LED Light Bar

Part no.

CLB-IX-002-2M

Light Color

Output

Color Temperature

Number of LED

Life Expectancy

Power Requirement

Housing

Connection Cable Length 2m / 3m ( option )

Environmental

Voltage 12VDC, powered by sensor port

Current Consumption 0.375A

Power consumption

Chassis

Diffuser

Installation

Operating -20 to 50°C Degree

Storage -20 to 60°C Degree

Relative Humidity 5~90%, non-condensing

18 High Output CREE SMD LED

Extruded aluminum with silver powder coat

Magnetic base for unrestricted installation

Cool White

250 Lumens

5600-7000K

30,000 hrs

4.5 Watt

Acrylic with milky white

Dimensions

Weight

Compatibility

Safety Regulatory

Environmental

Product 300L x 20W x 12H mm

Net 84g

InfraSolution X-2000 series

InfraGuard EC-300M & EC-300

FCC & CE certifi ed

RoHS2 & REACH compliant by SGS

www.austin-hughes.comUM-X-ISM-Q414V3 P.27

Page 33

< 4.6 > LED Beacon

The LED Beacon can be stuck fi rmly by the bundled adhesive tape.

Part no.

LED Beacon

IG-FB03-1M

Notifi cation Len Color

Light Source

Flash Rate

Power Requirement

Housing Cover Len

Connection Cable Length

Environmental

Dimensions

Voltage 12VDC, powered by sensor port

Current Consumption 0.175A

Color

Operating -20 to 50°C Degree

Storage -20 to 60°C Degree

Relative Humidity 5~90%, non-condensing

Product 72L x 72W x 45H mm

Blue

White

120 fl ashes per minute

Polycarbonate

Blue

1m / 3m

Weight

Supply includes

Compatibility

Safety Regulatory

Environmental

Net 50g

1 LED Beacon with 1m cable

InfraSolution X-2000 series

InfraGuard EC-300M & EC-300

FCC & CE certifi ed

RoHS2 & REACH compliant by SGS

www.austin-hughes.comUM-X-ISM-Q414V3 P.28

Page 34

Network Connection

InfraSolution X provides 3 connection ways - Daisy Chain, Star , Mixed.

Which connection applied is subject to the site scale, environment and users’ requirements.

< 5.1 > Daisy Chain

Key Benefi ts

Simple connection

No network switch required

Appropriate for small networks

Connect all InfraBoxes by Cat5/6 cable, and no any network switch required

Client PCs

Management

PC

Quantity of InfraBox / Cabinet : Up to 50

Total distance in a single daisy chain : Up to 100M

< 5.2 > Star

Connect to network switch by a point-to-point connection

Key Benefi ts

Appropriate for large networks

Increased fault tolerance

Easy for troubleshooting

Network

Client PCs

Switch

Management

PC

Network switch required

Total distance for each InfraBox to Network Switch : Up to 100M

www.austin-hughes.comUM-X-ISM-Q414V3 P.29

Page 35

Network Connection

< 5.3 > Mixed

Combining daisy chain with star connection

Key Benefi ts

Most effective and practical for large scale of networks

Take all advantages of Daisy Chain and Star connection

Flexible to meet a variety of network environments and needs

Up to 50 in each row

Client PCs

Up to 50 in each row

Management

Network

Switch

Total InfraBox Qty in Mixed Network : Up to 3000

PC

www.austin-hughes.comUM-X-ISM-Q414V3 P.30

Page 36

Application

< 6.1 > Data Center

By mixed connection, InfraSolution X can be scalable up to 3000 cabinets. X-2000 and X-1000 InfraBoxes can be

coexisted in the same network. Users are enabled to manage and remotely access all cabinets under a centralized

and user friendly GUI.

Connect the 1st InfraBox in each daisy chain to the network switch

Connect the management PC and client PCs via the network switch

Up to 3000 Infraboxes / Cabinets

Client PCs

Network Switch

Management PC

www.austin-hughes.comUM-X-ISM-Q414V3 P.31

Page 37

< 6.2 > Intelligent Building

It is essential for a Multi-Storey Intelligent Building to be applied with a centralized management system for the building’s

mechanical and electrical equipment such as security, power, ventilation, and lighting systems, etc.

InfraSolution X system allows equipment to be distributed throughout a building simply by deploying an Ethernet network.

To keep capital costs down, InfraSolution X can also be cascaded between boxes up to 100m over a Cat5/6 cable. Signal

weakness problem for long distance between InfraBoxes can be solved by applying network hubs with repeater function.

Connect the InfraSolution X network in each fl oor via the network ethernet / fi ber switch

Up to 3000 Infraboxes / Cabinets

Daisy Chain Scenario

(Up to 50)

Daisy Chain Scenario

(Up to 50)

Star Connection

(Up to 50)

Star Connection

(Up to 50)

Mixed Connection

(Up to 50)

Backbone Network /

Fiber Switch

Network Switch for Star / Mixed

Connection

Mixed Connection

(Up to 50)

Control Room

Management

PC

Client PCs

www.austin-hughes.comUM-X-ISM-Q414V3 P.32

Page 38

< 6.3 > Remote Site

InfraSolution X can be also applied to the remote site for access and monitoring over IP anytime and anywhere.

InfraSolution X Software License is required for each remote site / management PC

Headquarter

Workstation

Router

Remote Site A

InfraSolution X network

Remote Site B

InfraSolution X network

VPN

Router

Management

PC

Network

Switch

Internet

VPN

Router

Client PCs

Management

PC

www.austin-hughes.comUM-X-ISM-Q414V3 P.33

Page 39

< 6.4 > Branches

For a global or scalable company, it is vital to remote access and monitor the network of their nationwide and worldwide

branches. InfraSolution X provides an ideal solution to keep an eye on cabinet access security and environmental condition.

InfraSolution X Software License is required for each remote site / management PC

Headquarter

Workstation

Router

Branch A

InfraSolution X network

Up to 50 in each row

VPN

Router

Management

PC

Branch B

InfraSolution X network

Up to 50 in each row

Up to 50 in each row

Switch

Switch

VPN

Router

Management

PC

Management

Internet

VPN

Router

PC

Branch C

InfraSolution X network

www.austin-hughes.comUM-X-ISM-Q414V3 P.34

Page 40

< 7.1 > Tips for System Setup

Prepare a management PC

- Install Java SE 6 / 7

- Install Microsoft Visual C++ 2008

SP1 Redistributable Package

Remote Access Setting

- Enable fi rewall

- Set incoming port

- Set outgoing port

MFP - Master Floor Plan

- Create MFP

- Add cabinet

- Confi gure cabinet IP setting

Start

Software installation

- Disable fi rewall

- Install InfraSolution X manager

- Reboot management PC

Software activation

- Activate InfraSolution X manager

User Setup

- Create user

System Setup

- Alarm / email server / temp. unit

- Door opening overdue setting

- Time rule

- Backup & restore

CA - Control Area

- Create CA

- Load cabinet

Group Setup

- Create user group

Complete

www.austin-hughes.comUM-X-ISM-Q414V3 P.35

Page 41

< 8.1 > Key Word

MFP - Master Floor Plan

- An actual cabinet fl oor plan.

- Only in MFP, you can create cabinet & confi gure the IP setting for the cabinet.

- If you want to monitor & control cabinets & their devices, you need to build the control area.

- MFP can be more than one. No. of MFP is subject to the site scale & plan by fl oor, zone, building, branches

or remote sites.

CA Loading

- There is a button in MFP - CA Loading. It is to provide a quick and effi cient path for the user to move cabinet

to build the control area.

CA - Control Area

- You can build a Control Area for some specifi c cabinets which you want to monitor, confi gure & control.

- All cabinets in the CA should be loaded from the MFP by CA Loading button.

- CA can be more than one. How many CA is subject to your plan.

- CA has 2 modes : Edit mode & View mode.

- Under Edit mode, you can confi gure not only cabinets but also devices such as PDU, fan unit & sensors.

- View mode is designed for users with limited authority so they can ONLY monitor the status of cabinet & device.

User Setup

- To build a user list. Afterward, you can use the list to build the user group.

- Each user has his own login name & password for remote system login.

- Each user also has his own smartcard for cabinet access.

- However, before users join a user group in next step, they can do nothing.

User Group

- You can form a user group from the user list.

- You can defi ne the user group with authority and which control area / areas to monitor & access.

- Each user subordinated to ONLY ONE user group.

- If the user wants to join another user group, a new login name, password & smartcard MUST BE assigned.

- Each user group must select ONE time rule. All group users can access the cabinet and remote system login

according to the time period of the selected time rule.

- Without time rule assignment, all group users can do nothing.

Time Rule

- Time rule is designed for security. It tries to restrict the users with a time period to access the system and cabinet.

- In system setup section < 11.5 >, you can set time rules up to 32.

- Afterward, all time rules will be shown in user group for their selection.

- Only one time rule can be assigned to one user group.

www.austin-hughes.comUM-X-ISM-Q414V3 P.36

Page 42

< 8.1 > Cabinet Icon

Cabinet Icon layer

Cabinet icon has two layers, the layer one by default shows on all control area under view mode

for status monitoring. User can click cabinet icon to switch to layer two.

Layer one

- show PDU status ( P1, P2, P3, P4 )

- if PDU is enabled & connected, P icon in WHITE color

Cabinet

0014

- if PDU is enabled BUT disconnected, P icon in RED color

- if PDU is on alarm status, P icon also in RED color

- if PDU is disabled, P icon in GREY color

P3 P4

P2

P1

F1

Layer two

F2

Cabinet

0014

S1 S2 S3 S4

S5 S6

- show Fan unit status ( F1, F2 )

- if Fan unit is enabled & connected, F icon in WHITE color

- if Fan unit is enabled BUT disconnected, F icon in RED color

- if Fan unit is on alarm status, F icon also in RED color

- if Fan unit is disabled, F icon in GREY color

- show TH sensor status ( S1, S2 )

- if TH sensor is enabled & connected, S1, S2 icon in WHITE color

- if TH sensor is enabled BUT disconnected, S1, S2 icon in RED color

- if TH sensor is on alarm status, S1, S2 icon also in RED color

- if TH sensor is disabled, S1, S2 icon in GREY color

- show smoke & shock sensor status ( S3, S4 )

- if smoke & shock sensor is enabled & connected, S3, S4 icon in WHITE color

- if smoke & shock sensor is on alarm status, S3, S4 icon also in RED color

- if smoke & shock sensor is disabled, S3, S4 icon in

- show water sensor status ( S5, S6 )

- if water sensor is enabled & connected, S5, S6 icon in WHITE color

- if water sensor is on alarm status, S5, S6 icon also in RED color

- if water sensor is disabled, S5, S6 icon in GREY color

GREY color

www.austin-hughes.comUM-X-ISM-Q414V3 P.37

Page 43

< 8.1 > Cabinet Icon

Door direction

Cabinet

0014

P3 P4

P2

P1

P2

Cabinet

0014

F2

F2

P3 P4

F1

F1

P1

Front door

Front door

Door status

Cabinet

0014

P3 P4

P2

P1

F1

10m

Cabinet

0014

P3 P4

P2

P1

F1

Door close status in white

Door open status in green

F2

Door open overdue status in red

( show overdue time )

Door alarm status in red

( unauthorized open )

F2

Connection status Non-confi gure cabinet

In grey color

P1

P1

F1

F1

Cabinet

0014

P2

Cabinet

0014

P2

Normal connection status

( color in blue )

P3 P4

F2

Disconnection status

( color in red )

P3 P4

F2

P1

F1

Cabinet

0014

P2

P3 P4

F2

In MFP master fl oor plan,

the grey cabinet icon

shows that the cabinet has

not been confi gured with IP

setting yet.

In CA control area, the grey

cabinet icon shows that the

cabinet has been deleted in

master fl oor plan.

The user should remove this

non-function cabinet from

control area.

www.austin-hughes.comUM-X-ISM-Q414V3 P.38

Page 44

Software Installation & Activation

< 9.1 > Key Features

InfraSolution X Manager X-ISM is a LICENSED cabinet management software to monitor up to 3000

cabinets remotely.

Each InfraBox connects a pair of smartcard handles to secure the cabinet access control.

Each InfraBox can also connect a variety of sensors to provide an environmental monitoring solution.

To enhance the functionality, up to 12000 x kWh PDU / 6000 x Fan Unit can be monitored through

InfraSolution X Manager as well.

Up to 100 concurrent users can access the management software remotely to achieve the demand of

multi-user / multi-tasking in nowadays’ time sharing data center operation.

InfraSolution X Manager X-ISM

Features

Capacity

System Setup

Cabinet Overview

Door

Sensor

Peripherals

PDU

InfraBox

Concurrent user

Backup / Restore Setting

Time Rule Setting

Alarm Mail Server Setting

Audio and Visual Alarm Output Setting

Status of Door, PDU, Sensor & Fan unit

Door open by remote

Last door open & close record

Status Monitoring

Temp-Humid Alarm Threshold Setting

Energy Consumption kWh / Amp. Monitoring

Outlet Level Measurement

PDU Outlet Grouping / Schedule

Outlet Switch ON / OFF

Amp. Alarm Threshold Setting

Amp. Rising / Low Alert Threshold Setting

3000

100

Fan Unit

Chart / Event / Reporting

Temp-Humid Monitoring

CFM & Temp. Monitoring

Unit CFM ( fan speed ) Setting

Auto CFM Control Setting

Individual Fan Kit ON / OFF

Fan Unit ON / OFF

System & Device Event Reporting

Temp-Humid Line Chart of InfraBox

www.austin-hughes.comUM-X-ISM-Q414V3 P.39

Page 45

< 9.2 > CD Key Box

A licensed software, InfraSolution X Manager X – ISM, is bundled with a CD Key.

The CD Key Box consists of a software CD and a software license certifi cate

www.austin-hughes.comUM-X-ISM-Q414V3 P.40

Page 46

< 9.3 > Management PC & Client PC Requirement

Management PC requirement

Management PC requirement is highly related to the no. of cabinet. Please refer to the table below :

No. of Cabinet Processor Memory Hard Disk LCD Resolution No. of days log fi le

kept in database

2 - 200 Quad Core Xeon x 1 4GB 1TB x 2

201 - 500 Quad Core Xeon x 1 8GB 1TB x 2

501 - 1000 Quad Core Xeon x 1 16GB 2TB x 4

Over 1000 Quad Core Xeon x 2 32GB 4TB x 4

- The default service port of web server is 80.

- A dedicated PC to run InfraSolution X Manager X- ISM is recommended.

1660 x 1200, 1600 x 900,

1920 x 1080

1660 x 1200, 1600 x 900,

1920 x 1080

1660 x 1200, 1600 x 900,

1920 x 1080

1660 x 1200, 1600 x 900,

1920 x 1080

31

31

15

7

- If the PC is a notebook computer, the power adapter MUST be plugged in & power ON.

- Make sure the management PC is POWER ON & X-ISM is under operation.

Otherwise, daily data backup will NOT be proceeded.

To legally access Microsoft server software, a Client Access License ( CAL ) may be required.

For more information, please visit the link below :

http://www.microsoft.com/licensing/about-licensing/client-access-license.aspx

Client PC requirement

Processor Memory Hard Disk LCD Resolution

Dual Core x 1 2GB 500GB 1660 x 1200, 1600 x 900,

1920 x 1080

For better view of cabinet status, an appropriate LCD size is necessary.

Please refer to the table below :

No. of Cabinet in CA Preferred LCD Size

2 - 100 21" ( 1920 x 1080 )

101 to 300 46” ( 1920 x 1080 )

www.austin-hughes.comUM-X-ISM-Q414V3 P.41

Page 47

< 9.4 > OS Platform & Web Browser

OS platform

- MS Windows Server 2008 Standard Edition ( 32 bit & 64 bit, English Edition )

- MS Windows Server 2008 R2 ( English Edition )

Web browser

- I.E. Version 9.0 , 10.0

- Google Chrome Version 23 or above

Make sure users login the management PC as a member of “ Administrator “ Group before X-ISM installation & execution.

< 9.5 > Prerequisite before software installation

Components

OS Platform

Java SE 6 / 7 ( i586 )

Java SE 6 / 7 ( x64 )

Microsoft Visual C++ 2008 SP1

Redistributable Package ( X86 )

Microsoft Visual C++ 2008 SP1

Redistributable Package ( X64 )

The fi rewall setting of the management PC MUST be OFF

Windows 2008 server

standard, 32bit

Windows 2008 server

standard, 64bit

Windows 2008 server

R2

www.austin-hughes.comUM-X-ISM-Q414V3 P.42

Page 48

< 9.6 > Software Installation

After the InfraBox installation, please follow the steps below to install the

InfraSolution X Manager - Matrix Server

1. Double click the X-ISM.exe in software CD come with the CD Key Box and follow the instruction

to complete the installation.

click “ Next ”

click “ Install ”

click “ Finish ”

The management PC must reboot before proceed to Software Activation

Complete

www.austin-hughes.comUM-X-ISM-Q414V3 P.43

Page 49

< 9.7 > Remote Access

After software installation, administrator can turn on fi rewall of the management PC and set the inbound &

outbound rules of fi rewall.

Inbound rules :

1. Open “ Control Panel “

2. Select “ Windows Firewall “

3. Select “ Advanced settings “

4. Right Click “ Inbound Rules “ & select “ New Rules… “

5. Select “ Port “ & Click “ Next> “

6. Select “ TCP “ then input “ 80, 4000, 5432, 18081 “ in “ Specifi c local ports: “

7. Select “ Allow the connection “ & Click “ Next> “

8. Tick all three options & Click “ Next> “

9. Input the “ Name “ & “ Description “ of the port & Click “ Finish “

Outbound rules :

1. Open “ Control Panel “

2. Select “ Windows Firewall “

3. Select “ Advanced settings “

4. Right Click “ Outbound Rules “ & select “ New Rules… “

5. Select “ Port “ & Click “ Next> “

6. Select “ TCP “ then input “ 4001, 4003, 4006, outgoing SMTP port “ in “ Specifi c remote ports: “

7. Select “ Allow the connection “ & Click “ Next> “

Tick all three options & Click “ Next> “

8.

9. Input the “ Name “ & “ Description “ of the port & Click “ Finish “

The port no. of outgoing SMTP port depends on the mail server setting in < 11.2 >

www.austin-hughes.comUM-X-ISM-Q414V3 P.44

Page 50

< 9.8 > Software Activation

After software installation is completed, please follow the steps below to do the software activation

1. Click “ Start “ & Select “ Software Activation or Upgrade “

2. The “ Software Activation / Upgrade “ web page pops up

3. Input “ CD Key “ & Click “ Submit “. The “ Installation Key “ will be generated automatically.

4. Click “ Activate Online “ & go to “ Software Online Activation Centre “ directly

www.austin-hughes.comUM-X-ISM-Q414V3 P.45

Page 51

< 9.8 > Software Activation

5. Fill in all necessary information & Click “ Submit “. Then Click “ OK “ from the pop up window to get the

“ Activation Code “

6. Input the “ Activation Code “ & Click “ Submit “ in the “ Software Activation / Upgrade “ web page

to complete the software activation

7. Once the software activation is completed, the following web page will be displayed.

Complete

www.austin-hughes.comUM-X-ISM-Q414V3 P.46

Page 52

Operation Setup

After the software is activated, user can follow below steps to access the management PC and InfraSolution X

Manager – Matrix Server

1. Open the web browser of remote client PC

2. Enter “ http:// ManagementPC IP address/RMS_2013/RMS_2013.html “

3. Enter the login name & password

Default login name : admin

Default login password : admin

www.austin-hughes.comUM-X-ISM-Q414V3 P.47

Page 53

< 10.1 > Cabinet Alignment

In MFP & CA, the system provides alignment function for user to arrange the cabinet in a neat way

Alignment - Left

1. Press < Shift > to select the 3 highlighted cabinets

2. Release < Shift >

3. Press < Align Left >

Alignment - Center

1. Press < Shift > to select the 2 highlighted cabinets

2. Release < Shift >

3. Press < Align Center >

www.austin-hughes.comUM-X-ISM-Q414V3 P.48

Page 54

Alignment - Right

1. Press < Shift > to select the 2 highlighted cabinets

2. Release < Shift >

3. Press < Align Right >

Alignment - Top

1. Press < Shift > to select the 5 highlighted cabinets

2. Release < Shift >

3. Press < Align Top >

www.austin-hughes.comUM-X-ISM-Q414V3 P.49

Page 55

< 10.1 > Cabinet Alignment

Alignment - Middle

1. Press < Shift > to select the 5 highlighted cabinets

2. Release < Shift >

3. Press < Align Middle >

Alignment - Bottom

1. Press < Shift > to select the 5 highlighted cabinets

2. Release < Shift >

3. Press < Align Bottom >

www.austin-hughes.comUM-X-ISM-Q414V3 P.50

Page 56

< 10.2 > MFP - Master Floor Plan

- An actual cabinet fl oor plan.

- Only in MFP, you can create cabinet & confi gure the IP setting for the cabinet.

- If you want to monitor & control cabinets & their devices, you need to build the control area.

- MFP can be more than one. No. of MFP is subject to the site scale & plan by fl oor, zone, building, branches

or remote sites.

Ensure ONLY one user confi gures the cabinet IP in the same MFP at the same time

Add MFP

1. Click “ MFP “ tab

2. Click “ Add “

3. Input the MFP title & Description

( min. 1 char / max. 32 char )

4. Click “ OK “ to fi nish

Edit MFP

1. Select the MFP you want to edit

2. Click “ Edit “

3. Edit the MFP title / Description

4. Click “ OK “ to fi nish

www.austin-hughes.comUM-X-ISM-Q414V3 P.51

Page 57

< 10.2 > MFP - Master Floor Plan

Add Cabinet

1. Select the MFP you want to add cabinet (s )

2. Click “ “ to add cabinet. ( 1 / 5 / 10 cabinets at one time )

3. Click “ “ & Click “ Yes “ to confi rm cabinet addition

Cabinet IP confi guration

1. Select a cabinet

2. Input : “ Cabinet No. “ (min 4 char / max. 16 char. ),

“ Title 1 “ ( min. 2 char / max. 8 char ),

“ Title 2 “( min. 2 char / max. 8 char ),

“ IP address “, Enable / Disable the email & audio alarm

( If email alarm is “ Disable “ , NO alarm email will be sent to user. )

3. Click “ Save “ to fi nish the cabinet IP confi guration

Repeat step 1 to 3 for all cabinets ONE BY ONE.

Once the cabinet is confi gured, the IP address CANNOT BE edited.

Users need to delete cabinet in the MFP & create a new one.

Delete Cabinet

1. Select the cabinet you want to delete in the MFP

2. Click “ “ & Click “ Yes “ to confi rm the cabinet deletion

Delete MFP

1. Select the MFP you want to delete

2. Select all cabinets in the MFP to clear fi rst

3. Click “ “ & Click “ Yes “ to confi rm to clear all cabinet

4. Then select the MFP & Click “ Delete “

5. Click “ Yes “ in the confi rmation window to confi rm MFP deletion

www.austin-hughes.comUM-X-ISM-Q414V3 P.52

Page 58

< 10.3 > CA - Control Area

- You can build a Control Area for some specifi c cabinets which you want to monitor, confi gure & control.

- All cabinets in the CA should be loaded from the MFP by CA Loading button.

- CA can be more than one. How many CA is subject to your plan.

- CA has 2 modes : Edit mode & View mode.

- Under Edit mode, you can confi gure not only cabinets but also devices such as PDU, fan unit & sensors.

- View mode is designed for users with limited authority so they can ONLY monitor the status of cabinet & device.

Add CA

1. Click “ Control Area “ tab

2. Click “ “ & input the login password

in validation window to enter “ Edit Mode “

3. Click “ Add “

4. Input the CA title & Description

( min. 1 char / max. 32 char )

5. Click “ OK “ to fi nish CA addition

Load Cabinet

1. Go back to “ MFP “ tab

2. Select the MFP where the cabinet( s ) you want to load to CA

3. Click “ CA loading “

4. You can load whole MFP cabinets or part of them by tick

5. In “ Cabinet Orientation “, you can select Normal if the rear

door at bottom side, or select Inverted if the rear door at top side

6. Click “ Load “ button to fi nish CA loading.

5

6

www.austin-hughes.comUM-X-ISM-Q414V3 P.53

Page 59

< 10.3 > CA - Control Area

Edit CA

1. In < CA – Edit Mode >, select the CA you want to edit

2. Click “ Edit “

3. Edit the CA title / Description

4. Click “ OK “ to fi nish

Delete CA

1. In < CA – Edit Mode >, select the CA you want to delete & Click “ Delete “

2. Click “ Yes “ in the confi rmation window

3. Input login password in validation window to confi rm CA deletion

Remove Cabinet from CA

Cabinet removal from CA

1. In < CA – Edit Mode >, select the CA you want the cabinet(s) to be removed

2. Select the cabinet(s)

3. Click “

4. Click “ Yes “ in the confi rmation window to confi rm the cabinet removal

“

www.austin-hughes.comUM-X-ISM-Q414V3 P.54

Page 60

< 10.4 > User Setup

- To build a user list. Afterward, you can use the list to build the user group.

- Each user has his own login name & password for remote system login.

- Each user also has his own smartcard for cabinet access.

- However, before users join a user group in next step, they can do nothing.

Add User

1. Click “ User Setup “ tab

2. Click “ Add “

3. In the user window, please input all the fi elds.

4. If you want to receive device alarm email, tick

“ Email Alert “ ( Default : untick )

5. If you want to suspend the user authority and

access temporarily, tick “ User Suspended “

( Default : untick )

6. Then click “ Save “ to fi nish

4

5

Edit User

1. Select the user you want to edit

2. Click “ Edit “ in “ User Details ” window

3. Edit the fi eld ( s ) you want

4. Click “ Save “ & Click “ Yes “ in the confi rmation window to confi rm user edition.

Delete User

1. Select the user you want to delete

2. Click “ Delete “ in “ User Details ” window & Click “ Yes “ in the warning window to confi rm user deletion

www.austin-hughes.comUM-X-ISM-Q414V3 P.55

Page 61

< 10.5 > Group Setup

- You can form a user group from the user list.

- You can defi ne the user group with authority and which control area / areas to monitor & access.

- Each user subordinated to ONLY ONE user group.

- If the user wants to join another user group, a new login name, password & smartcard MUST BE assigned.

- Each user group must select ONE time rule. All group users can access the cabinet and remote system login

according to the time period of the selected time rule.

- Without time rule assignment, all group users can do nothing.

Add group

1. Select the Group Profi le where a group you want to add

2. Click “ Add “

3. Input the Group Title & Description ( min. 1 char / max. 32 char )

4. Click “ OK “ to fi nish

Edit group

1. Select the group title you want to edit

2. Click “ Edit “

3. Edit the Title / Description

4. Click “ OK “ to fi nish

www.austin-hughes.comUM-X-ISM-Q414V3 P.56

Page 62

Assign group authority

To assign authority to User group, please take the steps below :

1. Select the group

2. Click “ Edit “

3. Tick the user( s ) you want to assign to the group

4. Tick the Control Area( s ) you want the group to control & monitor

5. Assign appropriate “ Setup “ , “ Device Confi guration “ , “ System & Device Log “ authority to the group

6. Select one of the time rule in “ Time Access Setting for User Group: “

7. Tick “ SmartCard Access “, otherwise the group user CANNOT access the cabinets by smartcard

( Default : untick )

8. If you want the group user can NOT access the software out of the time rule,

please tick “ Remote System Login “

( Default : untick )

9. Click “ Save “ & “ Yes “ in the warning window to fi nish Group authority assignment

43

5

6

7

8

Delete group

1. Select the group you want to delete

2. Click “ Delete “ & Click “ Yes “ to fi nish.

The deleted group’s users will be moved to the

unassigned user list simultaneously.

www.austin-hughes.comUM-X-ISM-Q414V3 P.57

Page 63

< 10.6 > Visitor

Add Visitor

1. Go to “ Visitor “ tab

2. Click “ Add “

3. Input all the fi elds in the following window

4. Tick the cabinet( s ) to allow visitor to access by smartcard

5. Tick “ Visitor Card Activate “ to activate the smartcard to access the

cabinets under a specifi c time period

6. Click “ Save “ to fi nish Visitor addition

Edit Visitor

1. Select the visitor you want to edit

2. Click “ Edit “ in “ Visitor Details “ window

3. Edit the fi eld( s ) you want

4. Click “ Save “ & Click “ Yes “ to fi nish

Delete Visitor

1. Select the visitor you want to delete

2. Click “ Delete “ in “ Visitor Details “ window & Click “ Yes “ to fi nish

www.austin-hughes.comUM-X-ISM-Q414V3 P.58

Page 64

System Setup

In System Setup tab, it provides the following settings which apply to the whole system.

( 1 ) Backup & Restore

( 2 ) Alarm Setting, Mail Server Setting, Audio Visual Alarm

( 3 ) Temperature unit

( 4 ) Door opening overdue setting

( 5 ) Time Rule

www.austin-hughes.comUM-X-ISM-Q414V3 P.59

Page 65

< 11.1 > Backup & Restore

Backup

You can set

- the backup path of device confi guration & system setting

- the time period the system & event log kept in the system

- the drive space used in term of percentage before the backup process STOP

Those event log over the defi ned time period will be saved as

CSV format which located at “ Backup File Path ” \logbackdist folder

The system setup backup fi le will be saved in the “ Backup File Path ”

\sysbackdist folder

Restore

1. Click “ Upload “ button

2. Click “ Browse “ to select the fi le you want to restore

Restore MUST BE done at the management PC side NOT client side

www.austin-hughes.comUM-X-ISM-Q414V3 P.60

Page 66

3. Select the fi le & Click “ Open “

4. Click “ Submit “ to start to restore. When restore is completed, “ Restore succeeded “

will be displayed in the web page

Complete

After system restore, users need to activate the software again

if the backup fi le is from a different management PC

www.austin-hughes.comUM-X-ISM-Q414V3 P.61

Page 67

< 11.2 > Alarm Setting / Mail Server Setting / Audio visual Alarm

Alarm Setting

System will send out device alarm email to user if enable “ Email Alert “

Default : Untick

Mail Server Setting

It is used to setup the sender account to send out the device alarm email to the user

Audio Visual Alarm

Enable or disable “ Buzzer “ , “ Beacon “ & “ Alarm out “.

By this setting, all sensors under alarm status WILL or WILL NOT trigger audio visual alarm accordingly.

www.austin-hughes.comUM-X-ISM-Q414V3 P.62

Page 68

< 11.3 > Temperature unit

Select the temperature unit °C / °F displaying in the system

Default : Celsius

< 11.4 > Door Opening Overdue Setting

Set the door opening overdue time after the cabinet door is open.

When time overdue, user can view overdue timing with mins in cabinet icon.

Default : 2 mins

( Min. 1 min / max. 9999 mins ).

www.austin-hughes.comUM-X-ISM-Q414V3 P.63

Page 69

< 11.5 > Time Rule

- Time rule is designed for security. It tries to restrict the users with a time period to access the system and cabinet.

- In this section, you can set time rules up to 32.

- Afterward, all time rules will be shown in user group for their selection.

- Only one time rule can be assigned to one user group.

1. Click “ Setup “ under time rule section

2. Select time rule no. ( 1 - 32 )

3. Edit the “ Time Rule Name “

4. Tick the time slot to set date-time period & weekday for the time rule

5. Click “ Save “ to fi nish

6. Repeat step 2 to 5 for other time rules

www.austin-hughes.comUM-X-ISM-Q414V3 P.64

Page 70

Operation & Usage

< 12.1 > Individual Cabinet Devices Enable & Disable

Enter CA – Edit Mode to enable / disable individual cabinet sensor & device :

- TH Sensors / Sensors / PDU / Fan

1. Double click the cabinet icon & show the window below

2. Click “ Edit “ in T / H pane

3. Disable if no TH sensors connection ( default : disable )

OR

Enable if TH sensor connected and set alarm level

4. Click “ Apply “ to fi nish

www.austin-hughes.comUM-X-ISM-Q414V3 P.65

Page 71

< 12.1 > Individual Cabinet Devices Enable & Disable

5. Click “ Edit “ in Sensors pane

6. Disable if no sensors connection ( default : disable )

OR

Enable if sensor connected

7. Click “ Apply “ to fi nish

8. In PDU pane, disable if no PDU connection ( default : disable )

OR

Enable if PDU connected

9. In Fan pane, disable if no Fan connection ( default : disable )

OR

Enable if Fan connected

10. Click “ Save “ to fi nish the PDU & Fan section

When enable or disable PDU & fan,

the InfraBox will reboot to make the changes effective

www.austin-hughes.comUM-X-ISM-Q414V3 P.66

Page 72

< 12.2 > Individual Cabinet Door Open by Remote

In Door pane, you can proceed

- door open by remote

- view the record of last door open & close record

www.austin-hughes.comUM-X-ISM-Q414V3 P.67

Page 73

< 12.3 > Individual Cabinet PDU Confi guration & Control

In PDU pane, Click “ PDU Details “ to go to PDU Details page

In “ PDU Details “ , you can

- Change “ Name “ & “ Location “ of PDU

- Change “ Alarm amp. ” , “ R. alert amp. “ & “ Low alert amp. “ of PDU’s circuits

- Click “ Save” to fi nish

- Click “ Reset “ to reset peak amp. & kWh of PDU’s circuits

- Click “ On / Off “ to switch on / off PDU’s outlet ( Switched PDU models only )

www.austin-hughes.comUM-X-ISM-Q414V3 P.68

Page 74

In “ PDU Details “ , you can Click outlet icon to

go to Outlet Setting page

In “ Outlet Setting “ , you can

- Change the “ Name “ of PDU outlet

- Change “ Power up sequence delay “ of PDU

outlet ( Switched PDU models only )

- Change “ Alarm amp. “ , “ R. alert amp. “ &

“ Low alert amp. “ of PDU outlet

( Outlet level measurement PDU models only )

- Click “ Save” to fi nish

- Click “ Reset “ to reset peak amp. & kWh

of PDU outlet

( Outlet kWh Switched PDU only )

To confi gure the TH sensors of PDU, you can Click “ View “ button in “ TH Status “ to go the TH Setting page

In “ TH Setting “ , you can

- Activate / Deactivate TH sensors of PDU

- Change “ Location “ , “ Alarm Setting “ of TH sensors

- Click “ Save “ to fi nish

www.austin-hughes.comUM-X-ISM-Q414V3 P.69

Page 75

< 12.4 > Individual Cabinet Fan Unit Confi guration & Control

In Fan pane, Double Click “ Fan Details “ to go to Fan Details page

In “ Fan Details “ , you can

- Change “ Name “ & “ Position “ of Fan unit

- Change “ Unit CFM “

- Click “ Save” to fi nish

- Switch ON / OFF Fan unit

www.austin-hughes.comUM-X-ISM-Q414V3 P.70

Page 76

In Fan pane, Double Click “ Temp Settings “ to go to Temp Settings page.

You can

- Activate / Deactivate Temp. sensor

- Change “ Position “ of Temp. sensor

- Enable / Disable Auto CFM Control

- Change the “ Alarm “ of Temp. sensor

- Click “ Save ” to fi nish

< 12.5 > Console Message

In the bottom side of the web page, you can view the console message pane.

All action related to the cabinet doors will be shown in this area.

To collapse and hide the console message pane, Click

To expand and display the console message pane , Click

www.austin-hughes.comUM-X-ISM-Q414V3 P.71

Page 77

< 12.6 > PDU Outlet Grouping

PDU Outlet Grouping is a feature which you can assign different PDUs for scheduled outlet ON / OFF / Reboot.

Each PDU CAN ONLY BE ASSIGNED to one PDU Outlet Grouping.

In each PDU Outlet Grouping, there are 6 outlet ON / OFF / Reboot schedules on Once, Daily & Weekly basis

To add a PDU outlet grouping, please follow the steps below:

1. Click “ PDU Outlet Grouping “ Tab

2. Click “ Add “

3. Input “ Outlet Group Title “ & “ Outlet Group Description “

4. Click “ OK “ in “ Add New Outlet Group “ window to fi nish

To enable an outlet schedule, please follow the steps below :

1. Select one of the outlet group

2. Click “ Edit “

www.austin-hughes.comUM-X-ISM-Q414V3 P.72

Page 78

3. Select schedule 1

4. Select “ Enable “

5. Select “ Action “ ( ON / OFF / Reboot )

6. Select “ Time “ ( Once / Daily / Weekly )

7. Select “ Issue Date “ & “ Issue Time “

once

Daily

Weekly

www.austin-hughes.comUM-X-ISM-Q414V3 P.73

Page 79

< 12.6 > PDU Outlet Grouping

8. Select the PDU you want to add to this schedule by Clicking “ Unassigned List “ > “ MFP “ > “ Cabinet “ >

“ PDU “ in MFP pane

If the PDU already assigned to another outlet schedule

in the same outlet grouping, you can select the PDU in

the “ Assigned List “

9. Tick the outlet of the selected PDU for the schedule

10. Repeat step 9 for outlet ( s ) of other PDU ( s ) you want to add to the same schedule

11. Click “ Save “ to fi nish

12. Repeat Step 2 to 11 for other schedules if necessary