Page 1

PDU Inspired by Your Data Center

User Manual

IPM-03 PDU management software

Wi Outlet kWh Monitored PDU

WSi Outlet kWh Switched PDU

W kWh Monitored PDU

WS kWh Switched PDU

Designed and manufactured by Austin Hughes

www.austin-hughes.comUM-IPM-03-Q214V3

Page 2

Legal Information

First English printing, October 2002

Information in this document has been carefully checked for accuracy; however, no guarantee is given to the correctness

of the contents. The information in this document is subject to change without notice. We are not liable for any injury or

loss that results from the use of this equipment.

Safety Instructions

Please read all of these instructions carefully before you use the device. Save this manual for

future reference.

■ Unplug equipment before cleaning. Don’t use liquid or spray detergent; use a moist cloth.

■ Keep equipment away from excessive humidity and heat. Preferably, keep it in an air-conditioned environment with

temperatures not exceeding 40º Celsius (104º Fahrenheit).

■ When installing, place the equipment on a sturdy, level surface to prevent it from accidentally falling and causing dam

age to other equipment or injury to persons nearby.

■ When the equipment is in an open position, do not cover, block or in any way obstruct the gap between it and the

power supply. Proper air convection is necessary to keep it from overheating.

■ Arrange the equipment’s power cord in such a way that others won’t trip or fall over it.

■ If you are using a power cord that didn’t ship with the equipment, ensure that it is rated for the voltage and current

labelled on the equipment’s electrical ratings label. The voltage rating on the cord should be higher than the one listed

on the equipment’s ratings label.

■ Observe all precautions and warnings attached to the equipment.

■ If you don’t intend on using the equipment for a long time, disconnect it from the power outlet to prevent being dam

aged by transient over-voltage.

■ Keep all liquids away from the equipment to minimize the risk of accidental spillage. Liquid spilled on to the power

supply or on other hardware may cause damage, fi re or electrical shock.

■ Only qualifi ed service personnel should open the chassis. Opening it yourself could damage the equipment and invali

date its warranty.

■ If any part of the equipment becomes damaged or stops functioning, have it checked by qualifi ed service personnel.

What the warranty does not cover

■ Any product, on which the serial number has been defaced, modifi ed or removed.

■ Damage, deterioration or malfunction resulting from:

□ Accident, misuse, neglect, fi re, water, lightning, or other acts of nature, unauthorized product modifi cation, or

failure to follow instructions supplied with the product.

□ Repair or attempted repair by anyone not authorized by us.

□ Any damage of the product due to shipment.

□ Removal or installation of the product.

□ Causes external to the product, such as electric power fl uctuation or failure.

□ Use of supplies or parts not meeting our specifi cations.

□ Normal wear and tear.

□ Any other causes which does not relate to a product defect.

■ Removal, installation, and set-up service charges.

Regulatory Notices Federal Communications Commission (FCC)

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the

FCC rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation.

Any changes or modifi cations made to this equipment may void the user’s authority to operate this equipment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the following measures:

■ Re-position or relocate the receiving antenna.

■ Increase the separation between the equipment and receiver.

■ Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

www.austin-hughes.comUM-IPM-03-Q214V3

Page 3

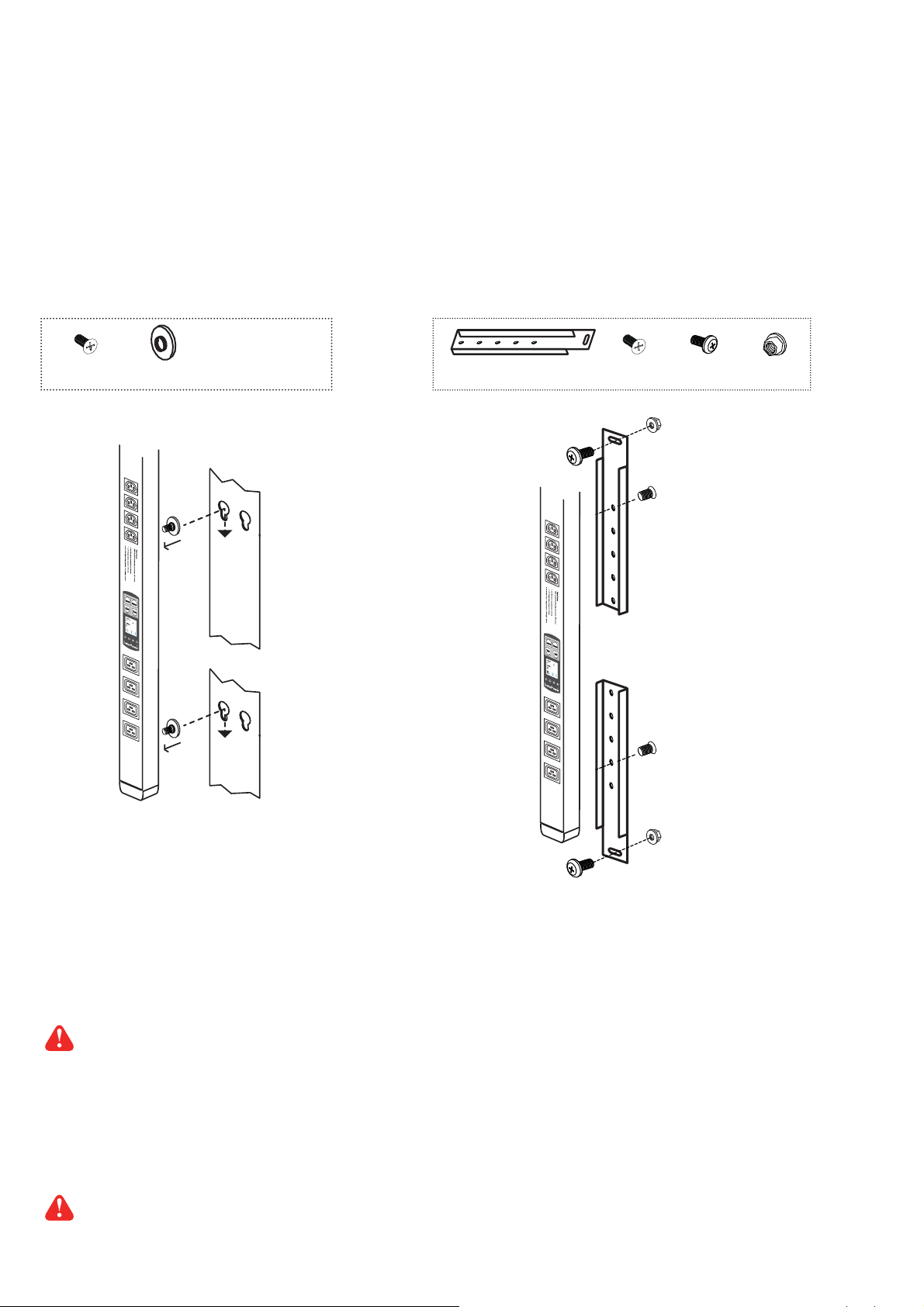

Unpacking

The equipment comes with the standard parts shown on the package contents. Check and make sure they are included and in good

condition. If anything is missing, or damage, contact the supplier immediately.

Package contents

( 1 ) Vertical W / Wi / WS / WSi PDU x 1

- VMS mounting screw, set of 2 or 3 - VMB mounting bracket set

M4

+

PEG

2 - 3 sets

Bracket x 2

M6

M4 x 2

M6 x 2

M6 nut

M6 nut x 2

M4

LINK

OU

T

TH 1 TH 2

31.

15.9

7

15.8

6.97

3.49

3.48

4522.3

6537.5

LINK

OU

T

TH 1 TH 2

31.

15.9

7

15.8

6.97

3.49

3.48

4522.3

6537.5

M4

M6 nut

OR

M6

( 2 ) Rackmount W / Wi / WS / WSi PDU x 1

All electrical power and power control wiring must be installed by a qualifi ed electrician and comply with local

and national regulations.

Power ON

■

Connect the PDU into an appropriately rated receptacle

■ When the PDU is power on, the LED display will light up. That means all outlets are activated

■ Keep the equipments in the power off position until it is plugged into the PDU

Don’t exceed the outlet, branch or phase limitations

www.austin-hughes.comUM-IPM-03-Q214V3

Page 4

Content

Part I. Hardware

< 1.1 > W / Wi / WS / WSi PDU Key Features

< 1.2 > W Meter Display & Setting

< 1.3 > PDU Meter Setting & Cascade

< 1.4 > T

< 1.5 > IP Dongle Installation & Connection

< 1.6 > Easy Change on PDU Power Feed Position

emp. / Humidity Sensor Connection & Specifi cation

Part II. Software

< 2.1 > Key Features

< 2.2 > IP Dongle Confi guration

P. 1

P. 11

< 2.3 > Hardware Requirements of the Management PC

< 2.4 > Supported OS Platform & Language

< 2.5 > Software Download

< 2.6 > First Time Start-up Setting

< 2.7 > Change Port no. of Web Server

Part III. System Setup & Remote Access

< 3.1 > System Setup

< 3.2 > Remote Access

P. 18

Part IV. Software Usage & Operation

P. 25

www.austin-hughes.comUM-IPM-03-Q214V3

Page 5

Content

Part V. Events / Log / Report

Part VI. SNMP Setup / Firmware Upgrade

Part VII. FAQ

Part VIII. Troubleshooting

P.35

P.39

P. 43

P. 47

www.austin-hughes.comUM-IPM-03-Q214V3

Page 6

Part I. Hardware

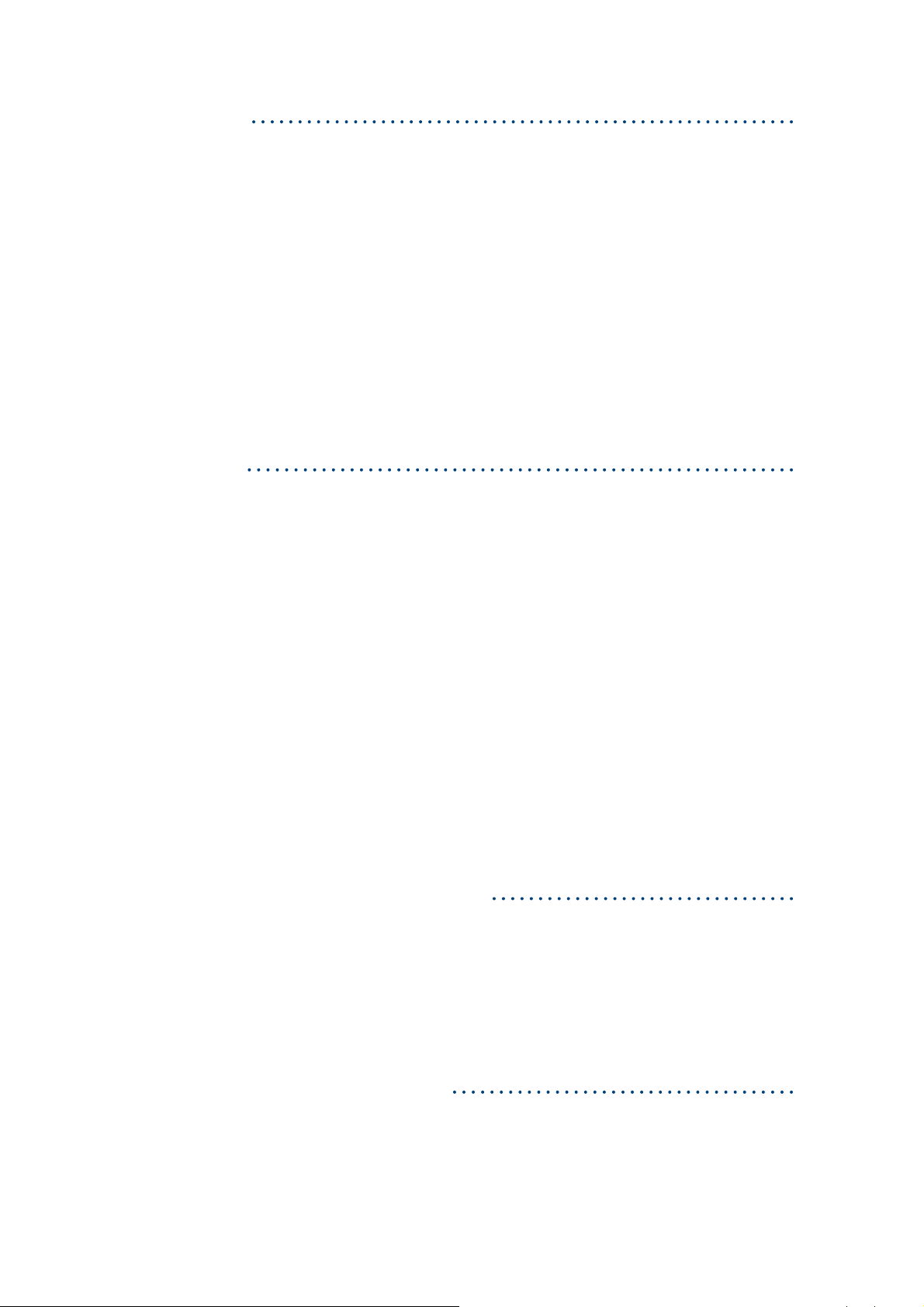

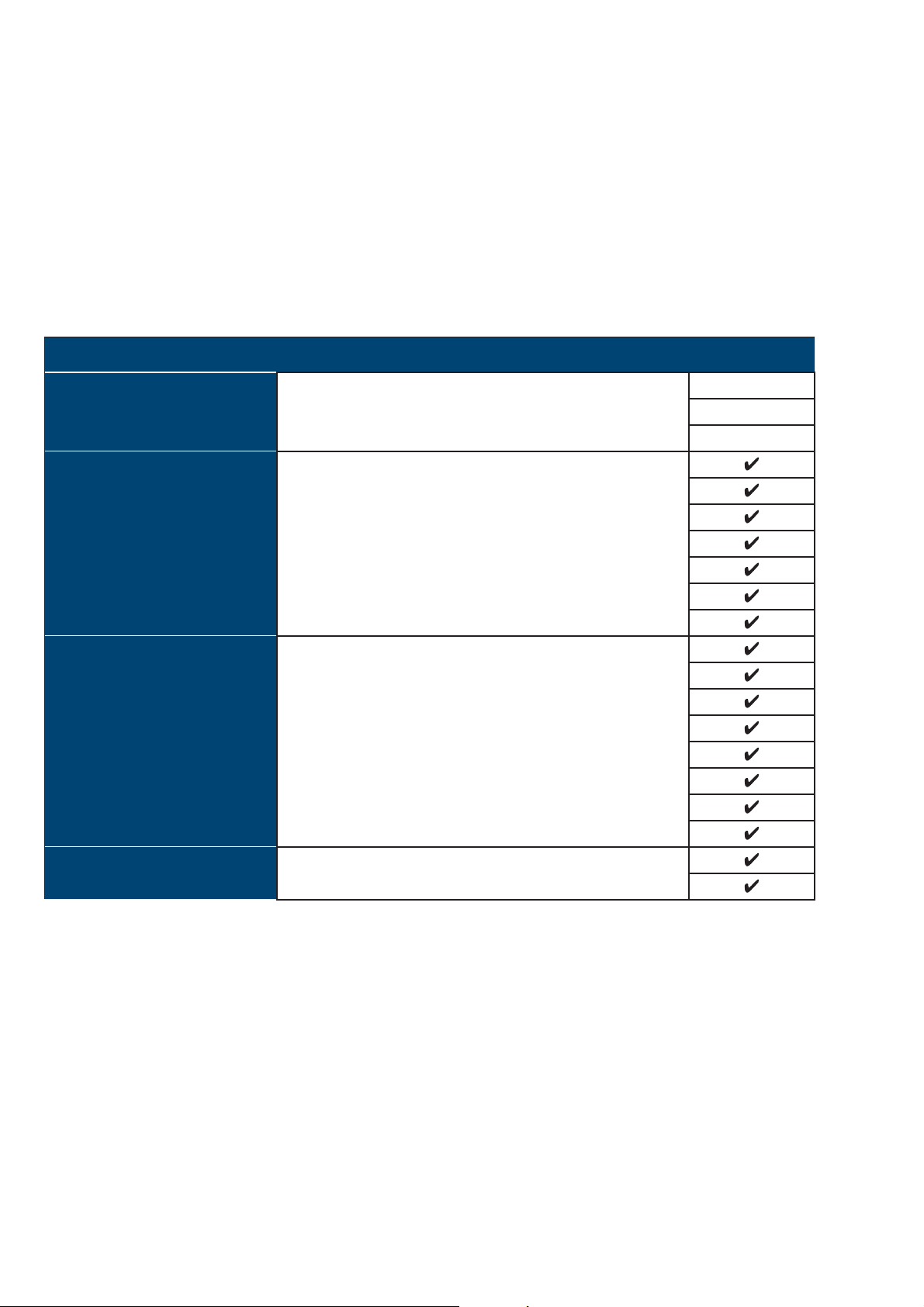

< 1.1 >

Outlet Measurement

Circuit kWh Measurment

Temp-Humid Sensor port x 2

16 Levels in Single Daisy Chain

One IP Access 16 PDU Levels

SNMP Capability via IP Dongle

Hot-pluggable Meter w/ 1.8” Color LCD

Outlet Switch ON / OFF

Local kWh & Amp Meter

W / Wi / WS / WSi PDU Key Features

kWh PDU Outlet kWh PDU

Monitored Switched Monitored Switched

W

WS Wi WSi

Vertical & Horizontal PDUs

Tool-less Mounting for Vertical PDU

Management Software Editions

( Free )

IPM-03

IPM-02

PPS-02-S

(via IPD-02S)

IPM-03

IPM-02

PPS-02-S

(via IPD-02S)

IPM-03

PPS-02-S

(via IPD-02S)

IPM-03

PPS-02-S

(via IPD-02S)

P.1

www.austin-hughes.comUM-IPM-03-Q214V3

Page 7

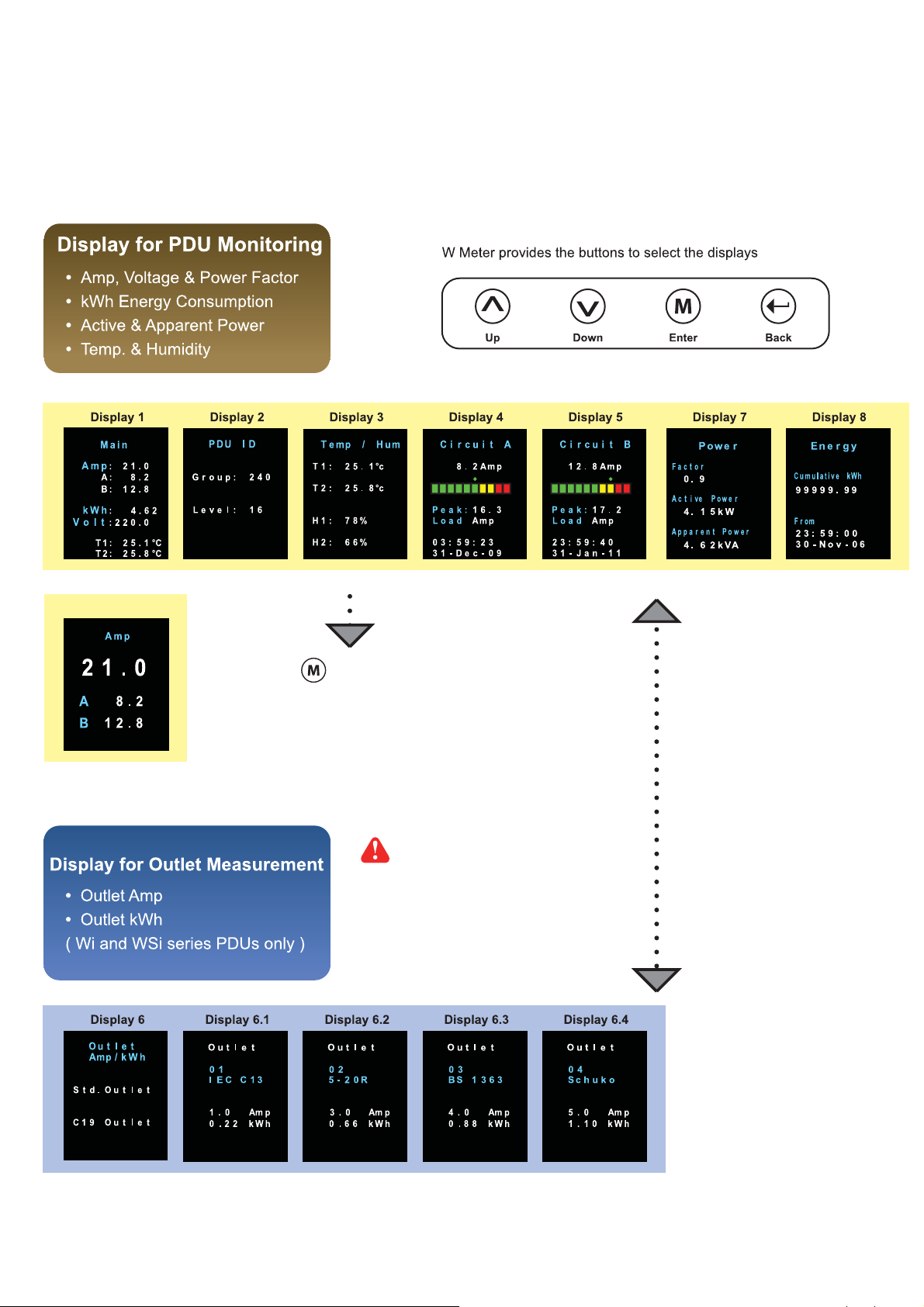

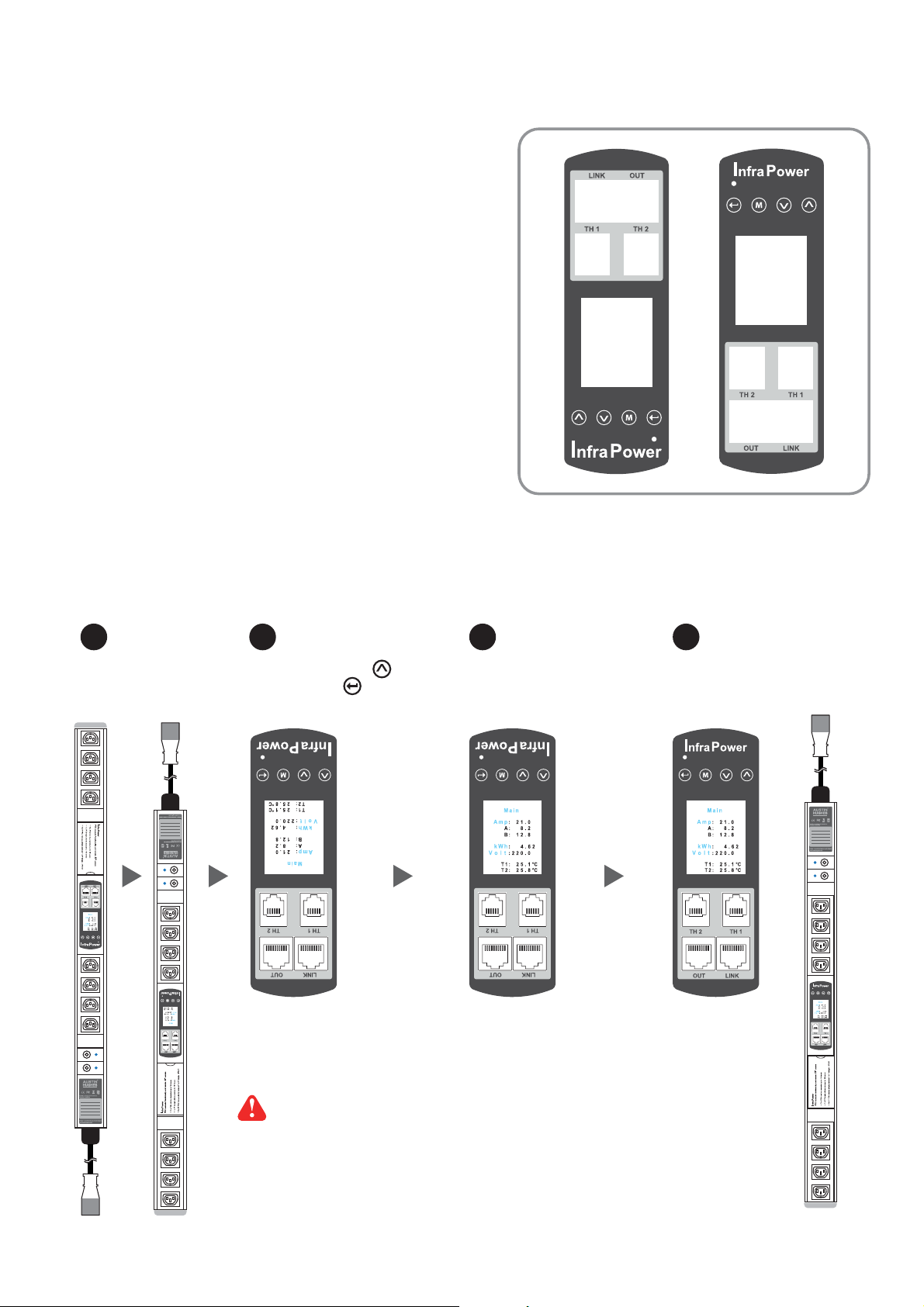

< 1.2 > W Meter Display & Setting

All W series PDUs are equipped with a highly advanced and sophisticated component - W Meter. It

provides the cascade ports for daisy chain up to 16 x PDU. Furthermore, for IP PDU access, simply

connect 1 x IP Dongle for all daisy chain PDUs to save IP network address. Two sensor ports are

integrated for temperature & humidity monitoring. Creatively, 1.8” color LCD display offers a real time

local monitoring and detailed PDU status.

1

PDU cascade port

2

Temp. + Humidity sensor port x 2

Temp. sensor port x 2

3

1.8” color LCD display

4

Menu button

Buzzer

6

Reset button is to re-power the meter. It will not affect any settings and memories.

Reset button

or

5

The buzzer only sounds when the circuit amp. over the alarm amp. setting.

For 1U / 2U rackmount PDU, on the front, on the rear

53 4 1

P.2

2

www.austin-hughes.comUM-IPM-03-Q214V3

Page 8

< 1.2 > W Meter Display & Setting

W meter 1.8” color LCD provides a sharp and highly visible reading for the local reading of Current

( Amp ), Voltage ( Volt ), Power ( kW ), Energy Consumption ( kWh ), Power Factor, Temperature &

Humidity.

Display 1.1

Press to change °C / °F

Display 6 only for Wi / WSi

outlet measurement PDU

P.3

www.austin-hughes.comUM-IPM-03-Q214V3

Page 9

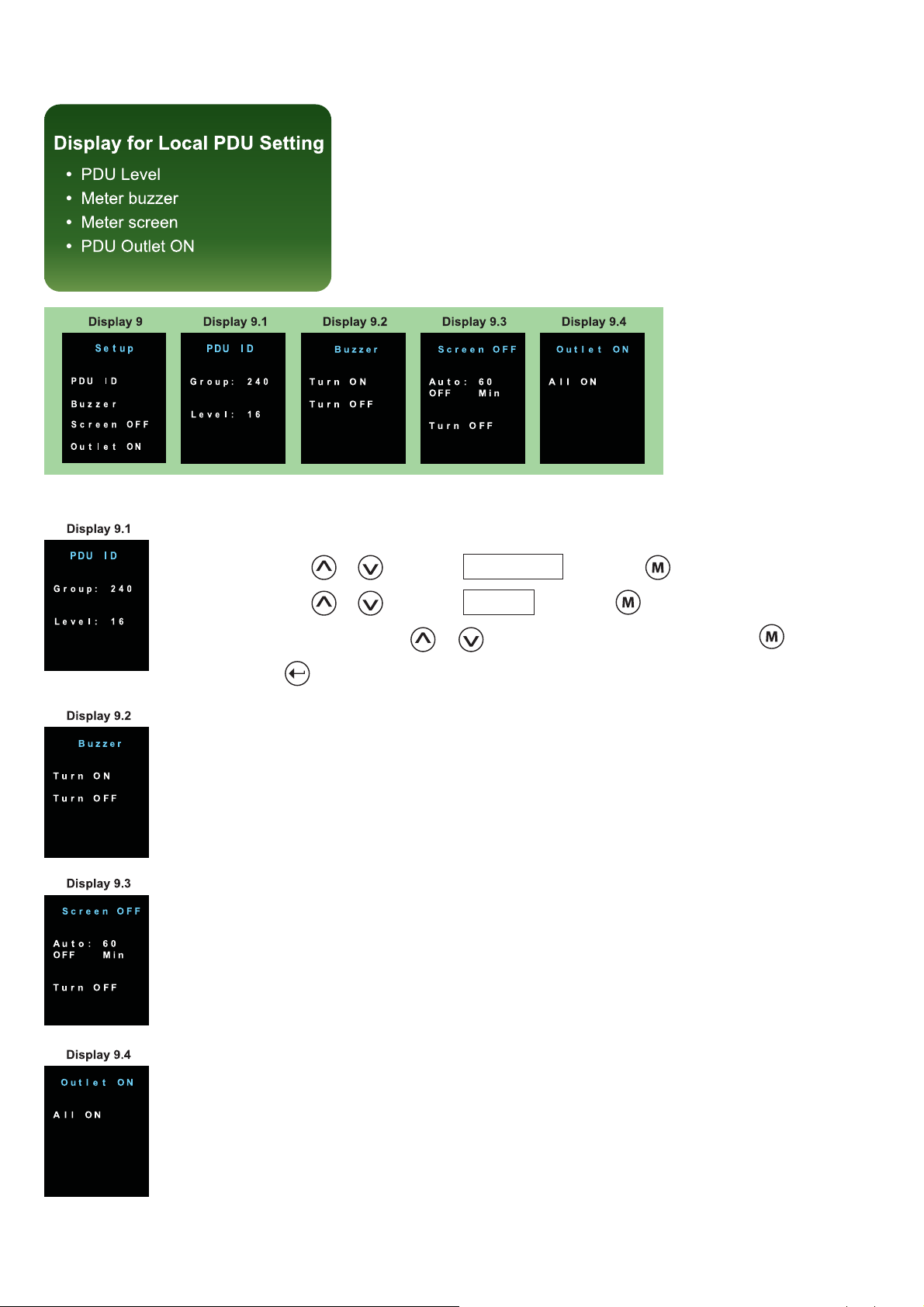

< 1.2 > W Meter Display & Setting

W meter allows the user to do some settings below :

PDU level setting :

Step 1 - Press the & button to display no.9 and press to confi rm

Step 2 - Press the & button to PDU ID and press to confi rm

Step 3 - In display 9.1, Press the & button to select PDU level no. & press to confi rm

Step 4 - Press to exit

Buzzer :

W meter allows the user to set the meter buzzer ON / OFF by meter’s 4 buttons.

All PDUs are shipped with the buzzer in ON status.

When the PDU’s circuit or outlet Amp is over alarm level, the buzzer will sound.

The user can press any button to stop the buzzer sound.

Screen OFF :

All PDUs are shipped with the metter LCD in always ON status.

W meter allows the user to turn off the meter LCD by time setting ( 1 - 60 mins, 0 = always ON )

When the meter is in OFF status, the user can press any button to make it ON.

Outlet ON :

This is for WS kWh Switched / WSi outlet kWh Switched PDU models only. All Switched PDUs

are shipped in outlet ON status.

P.4

www.austin-hughes.comUM-IPM-03-Q214V3

Page 10

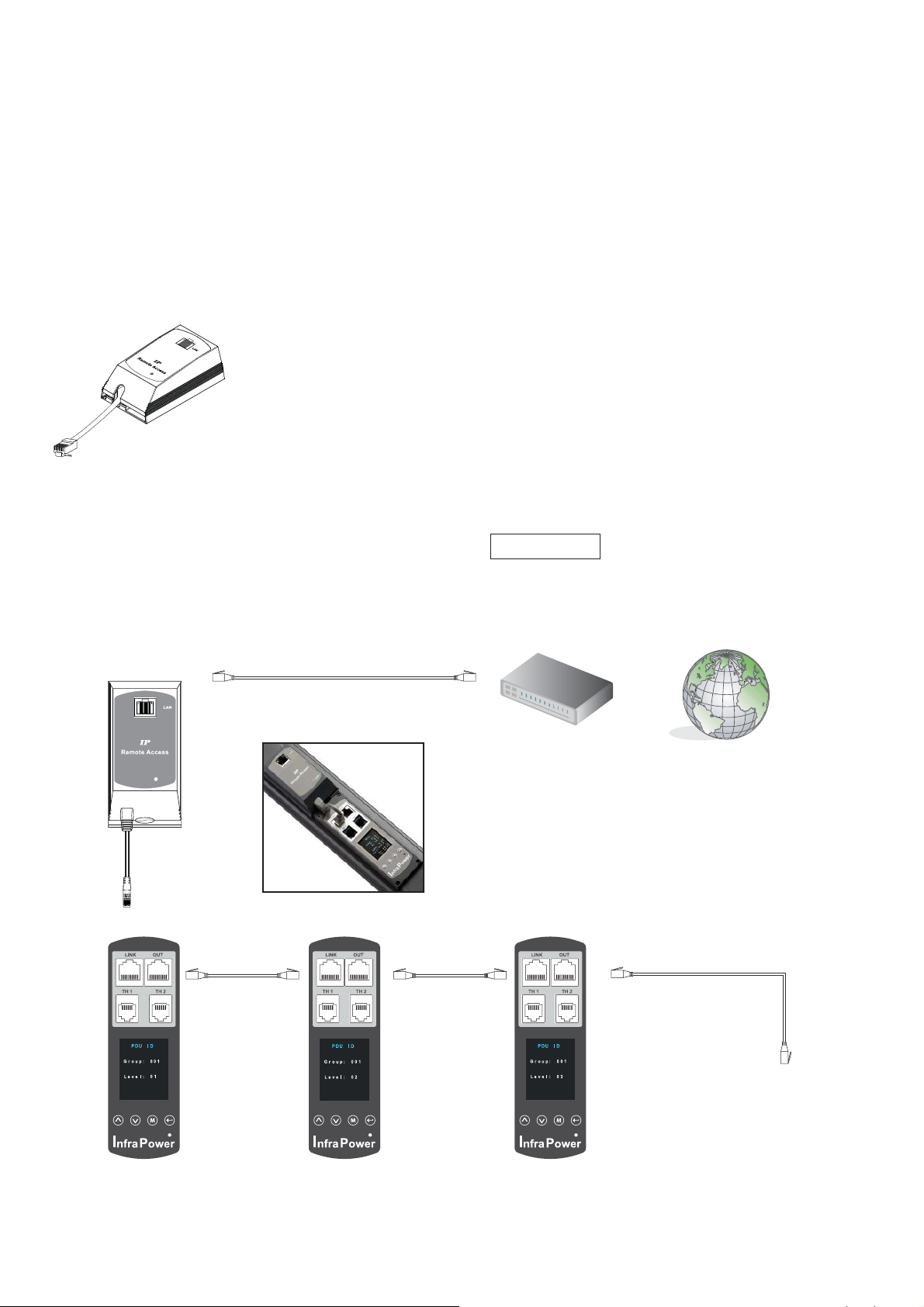

< 1.3 > PDU Meter Setting & Cascade

PDU Daisy Chain up to 16 Levels

The W meter built-in not only provides the local power monitoring, but also the connection ports for

the PDU daisy chain. For daisy chain connection, each PDU just simply to be connected in series to

the next by Cat5/6 cables. Maximum 16 PDUs are supported in one daisy chain group.

■ The PDU can be cascaded up to 16 levels

■ For IP PDU access simply connect 1 x IP dongle - IPD-02-S

■ 1 x IP dongle allows access to 16 levels

Cat 5 / 6 cable

Up to 20M

1st level

PDU meter

For PDU level setting, please refer to previous page.

2nd level

PDU meter

Cat 5 / 6 cable

Up to 20M

3rd level

PDU meter

Final level

PDU meter

P.5

www.austin-hughes.comUM-IPM-03-Q214V3

Page 11

< 1.4 > Temp. / Humidity Sensor Connection & Specifi cation

W meter provides 2 sensor ports for Temp. & Humidity monitoring. The user can see the Temp. /

Humidity reading not only from the local meter display but also from remote management software.

• low profi le design with magnetic base for easy affi xing to the rack cabinet

• Plug n Play

• sensor with 2M or 4M cord

• pair of sensors can be connected to a single W meter

Temp. & Humid. Sensor

Model :

IG - TH01 - 2M ( 2M cord )

IG - TH01 - 4M ( 4M cord )

Temp. Sensor

Model :

IG - T01 - 2M ( 2M cord )

IG - T01 - 4M ( 4M cord )

TH1 TH2

P.6

www.austin-hughes.comUM-IPM-03-Q214V3

Page 12

< 1.4 > Temp. / Humidity Sensor Connection & Specifi cation

Temp. & Humid. Sensor Temp. Sensor

Part no.

IG - TH01 IG - T01

Temperature

Sensitivity

Relative

Humidity

Sensitivity

Power

Requirement

Housing Chassis & Cover

Range

Accuracy

Resolution 0.1°C ( 0.2°F )

Response Time 5 to 30 sec

Range

Accuracy 0 to 100, ±8.0% R.H

Resolution 1% R.H. /

Response Time 8 sec /

Voltage 12VDC, powered by sensor port

Current Consumption

Power consumption 0.24 Watt

Power on indicator Red LED Green LED

Color

Installation Magnetic base for unrestricted installation

0 to 80°C ( 32 to 176°F )

±1.0°C typical ( ±2°F )

0 to 100% R.H

20 to 80, ±4.5% R.H.

±1.5°C ( ±3°F)

/

/

20mA

plastic

Dark gray

Cable

Environmental

Dimensions

Weight

Compatibility

Safety Regulatory

Cable Length

Cable Specifi cation 4-wired 3.5mm to RJ11

Cable Color Black Beige

Operating 0 to 80°C Degree

Storage

Humidity 0~100%, non-condensing

Product 30L x 25Wx 18H mm

Net 10g

InfraPower W / WS / Wi / WSi series PDU

InfraSolution

InfraGuard Cabinet sensor system

TH sensor w/ 2m cable ( standard )

TH sensor w/ 4m cable ( option )

-5 to 80°C Degree

X-2000 series

FCC & CE certifi ed

sensor w/ 2m cable ( standard )

T

T sensor w/ 4m cable ( option )

Environmental

RoHS2 & REACH compliant

P.7

www.austin-hughes.comUM-IPM-03-Q214V3

Page 13

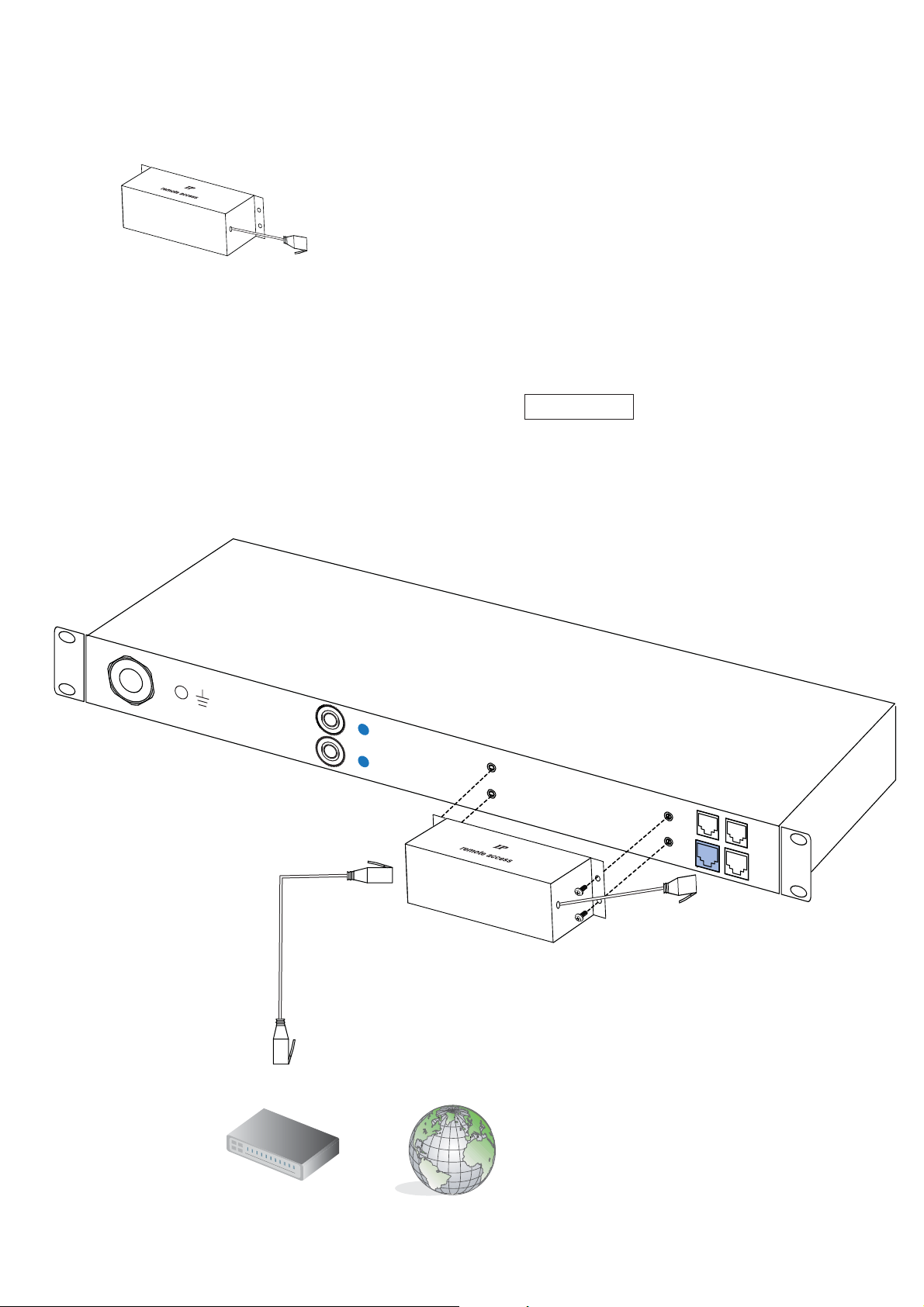

< 1.5 > IP Dongle Installation & Connection

IP Dongle Access to 16 PDU Levels

Patented IP Dongle provides IP remote access to the PDUs by a true network IP address chain.

Only 1 x IP dongle allows access to max. 16 PDUs in daisy chain - which is a highly effi cient ap-

plication for saving not only the IP remote accessories cost, but also the true IP addresses required on the PDU management.

Hot-Pluggable design facilitates the IP dongle installation. Simply integrate the IP Dongle to the

1st PDU, then the entire daisy chain group can be remote over IP. Hence, administrator can remotely access all PDUs in the daisy chain group by one single IP via the IP Dongle.

IP dongle for vertical PDU

Model :

IPD-02-S ( with SNMP feature )

Vertical IP dongle installation steps :

- slide the IP dongle on the plate above the meter

- plug the RJ-45 connector of IP dongle into the LINK port of the 1st level PDU meter

- use the CAT. 5 / 6 cable to connect IP dongle to network device

IP dongle

To LINK port of

the 1st PDU

Cat 5 / 6 cable

Up to 20M

Network Hub

To LAN port

Cat 5 / 6 cable

Up to 20M

1st level

PDU meter

2nd level

PDU meter

P.8

To LINK port

of next PDU

( Up to 16 levels )

3rd level

PDU meter

www.austin-hughes.comUM-IPM-03-Q214V3

Page 14

< 1.5 > IP Dongle Installation & Connection

IP dongle for rackmount PDU

IP dongle

Model :

IPD-H02-S ( with SNMP feature )

Horizontal IP dongle installation steps :

- fi x the IP dongle on the rear side of rackmount PDU with 4 screws

- plug the RJ-45 connector of IP dongle into the LINK port of the 1st level PDU meter

- use the CAT. 5 / 6 cable to connect IP dongle to network device

To LAN port

of IP dongle

Network Hub

A

B

IP dongle

Rear side of rackmount PDU

To LINK port

of the 1st PDU

P.9

www.austin-hughes.comUM-IPM-03-Q214V3

Page 15

< 1.6 > Easy Change on PDU Power Feed Position

Power Feed Entry Flexibility - By Meter Setting

Customization of top feed power entry is available

on request.

The change of the power feed entry position is possible after installation. The W series meter provides

the fl exibility to simply turnover on top feed PDUs

with the use of meter inversion buttons and an alternative membrane.

Meter

Membrane A

1 32 4

Turn the PDU

upside-down

Press fi rst button

& last button to

invert display

B

A

Replace the meter

membrane

Meter

Membrane B

Completed

B

A

Membrane

A

B

A Membrane A Membrane B

Please take the reverse steps to change top-feed to bottom-feed entry.

Outlet no. stickers are provided on request.

P.10

www.austin-hughes.comUM-IPM-03-Q214V3

Page 16

Part II. Software

< 2.1 > Key Features

InfraPower Manger IPM-03 is a free PDU mangement software to remote & monitor up to 30 IP

dongle group ( max. 16 PDU levels in each IP dongle group ), total 480 PDUs

5 concurrent user access are bundled for achieving the demand of multi-user / multi-tasking in

nowadays’ time-sharing date center operation.

InfraPower IPM-03

Features

Capacity

Enhanced

Features

Basic

Features

IP Dongle Group (Just 1 for 16 PDU levels)

PDU number

Concurrent Users

Outlet Level kWh & Amp Measurement

Outlet Scheduling

Energy Consumption (kWh) Monitoring

Apparent Power (kVA) Monitoring

Power Factor Measurement

Circuit Breaker Monitoring

SNMP Capability via IP Dongle

Aggregate Current (Amp) Monitoring

Individual Outlet Switch ON/OFF

Temp-Humid Monitoring

Alarm Threhold Setting

Rising Alert Threshold Setting

Remote Access via Web

Graphic User Interface

Reporting

30

480

5

PDU Series

Support

WSi / Wi (Outlet Measurement)

WS / W

P.11

www.austin-hughes.comUM-IPM-03-Q214V3

Page 17

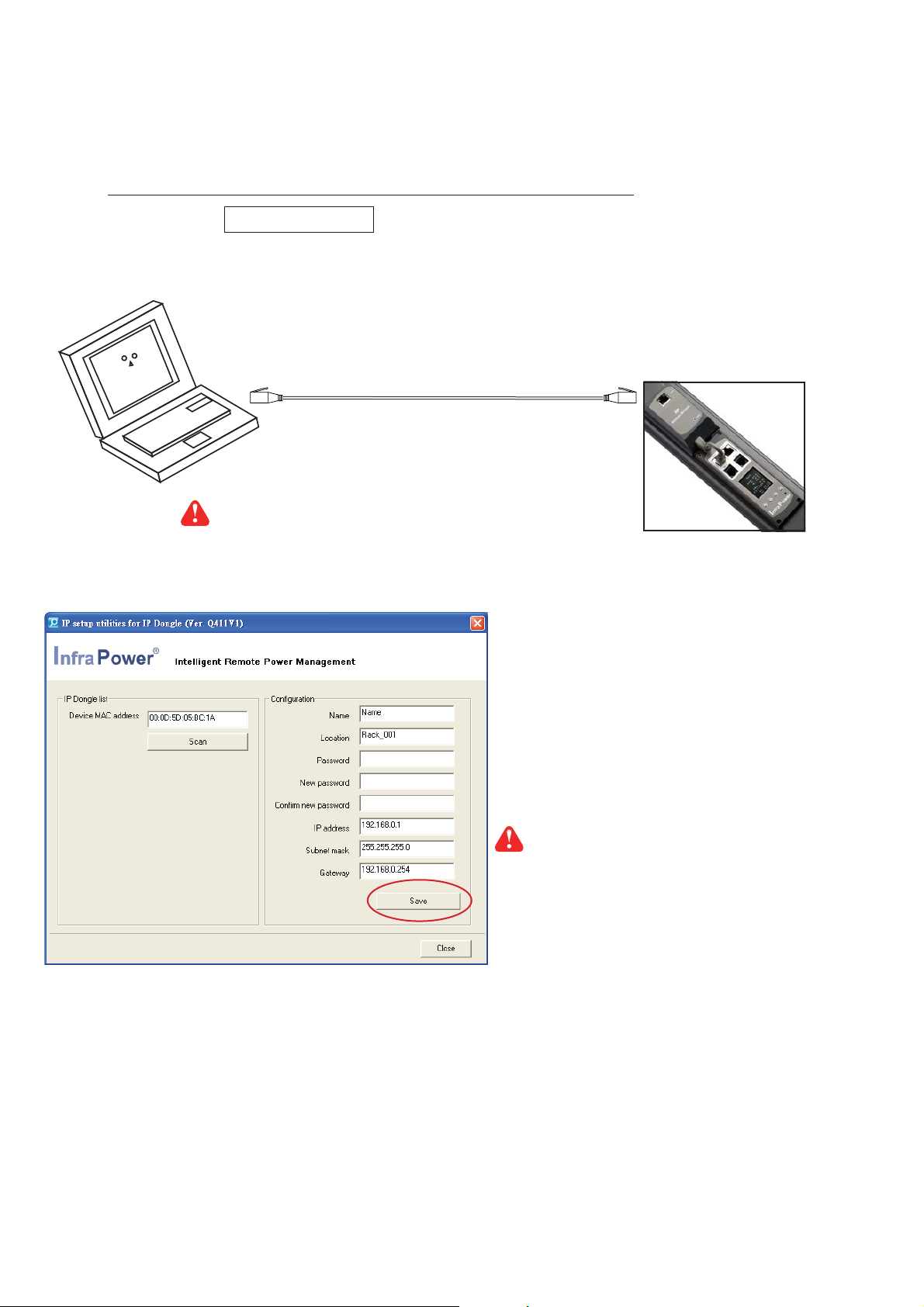

< 2.2 > IP Dongle Confi guration

After the completion of IP dongle connection, please take the following steps to confi gure the IP dongle :

Step 1. Prepare a notebook computer to download the IP setup utilities from the link :

http://www.austin-hughes.com/support/utilities/infrapower/IPdongleSetup.msi

Step 2. Double Click the IPDongleSetup.msi and follow the instruction to complete the installation

Step 3. Go to each fi rst level PDU with the notebook computer & a piece of CAT. 5 / 6 cable to confi gure the

IP dongle by IP setup utilities as below. Please take the procedure for all IP dongles ONE BY ONE

CAT. 5 / 6 cable

To notebook computer

LAN port

To IP dongle

LAN port

Reconnect the IP dongle with the network device

( router or hub ), after fi nish IP dongle confi guration.

IP dongle on 1st level PDU

Ensure the PDU in

power ON status

Write down the new IP address & password

for < Setup > purpose, refer to P.20

Step 4. Click “ Scan ” to search the connected IP dongle

Step 5. Enter device name in “ Name ” ( min. 4 char. / max. 16 char. ). Default is “ Name ”

Step 6. Enter device location in “ Location ” ( min. 4 char. / max. 16 char. ). Default is “ Rack_001 ”

Step 7. Enter password in “ Password ” for authentication ( min. 8 char. / max. 16 char. ) Default is “ 00000000 ”

Step 8. Enter new password in “ New password ” ( min. 8 char. / max. 16 char. )

Step 9. Re-enter new password in “ Confi rm new password ”

Step 10. Change the desired “ IP address ” / “ Subnet mask ” / “ Gateway ”, then Click “ Save ” to confi rm the changes

The default IP setting is as below:

IP address : 192.168.0.1

Subnet mask : 255.255.255.0

Gateway : 192.168.0.254

P.12

www.austin-hughes.comUM-IPM-03-Q214V3

Page 18

< 2.3 > Hardware Requirements of the Management PC

Please prepare a management PC with the hardware requirements as below for

InfraPower Manager - IPM-03

Recommended hardware requirements :

- Processor: Dual Core 2GHz or above

- Memory: 2GB RAM

- Available Disk Space: 500GB

- Drive: DVD ROM drive

- Display: 1440 x 900 or higher resolution monitor

- The default service port of web server is 80.

- A dedicated PC to run InfraPower Manager - IPM-03 is recommended.

- Make sure the management PC is POWER ON & IPM-03 is under operation.

Otherwise, daily data backup will NOT be proceeded.

< 2.4 > Supported OS Platform & Language

InfraPower Manager – IPM-03 supports the OS platforms & languages as below:

- MS Windows XP Professional with SP3 (32bit only)

- MS Windows 7 Professional with SP1

- MS Windows 7 Ultimate with SP1

- MS Windows Server 2003 R2 Standard Edition with SP2

- MS Windows Server 2008 Standard Edition SP2

- MS Windows Server 2008 R2 Standard Edition SP1

Ensure the user logins in the management PC as a member of “Administrators” Group

before IPM-03 Installation and execution.

User can select the following languages under Control Panel > Region and Language in English Edition OS:

1) Arabic (Saudi Arabia)

2) Chinese (Traditional, Hong Kong S.A.R.)

3) Dutch (Netherlands)

4) English (Australia)

5) English (United Kingdom)

6) English (United States)

7) French (France)

8) German (Germany)

9) German (Switzerland)

10) Italian (Italy)

11) Japanese (Japan)

12) Korean (Korea)

13) Norwegian (Norway)

14) Portuguese (Portugal)

15) Russian (Russia)

16) Spanish (Spain)

17) Turkish (Turkey)

P.13

www.austin-hughes.comUM-IPM-03-Q214V3

Page 19

< 2.5 > Software Download

InfraPower Manager, IPM-03, is a PDU management software to enhance the features and benefi ts

of the W kWh Monitored / Wi Outlet kWh Monitored / WS kWh Switched / WSi Outlet kWh Switched

PDUs by providing a centralized and remote management platform, and total reporting with detailed

logs & event occurrences.

InfraPower Manager IPM-03 can support max. 5 concurrent login users and manage multi- IP dongles max. 30, hence the concurrent login users can access & remote PDUs max. 480 ( 30 IP dongles

x 16 level PDUs ).

Software download

Please download the InfraPower Manager - IPM-03 to the management PC

from the link http://www.austin-hughes.com/support/software/infrapower/IPM-03.msi

Double click the IPM-03.msi and follow the instruction to complete the installation.

click “ Next ”

click “ Install ”

click “ Finish ”

IPM-03.msi

P.14

Complete

www.austin-hughes.comUM-IPM-03-Q214V3

Page 20

< 2.6 > First Time Start-up Setting

Step 1. Double Click the InfraPower Manager - IPM-03

and follow the instruction to complete start-up setting.

For MS Windows 7 and MS Windows server 2008,

it requires to run a program with administrator rights before execution:

- Right click InfraPower Manager - IPM-03 , and then select Properties.

- Click the Compatibility tab.

- Tick the box Run this program as an administrator, and then click OK.

IPM-03

InfraPower Manager

3

P.15

www.austin-hughes.comUM-IPM-03-Q214V3

Page 21

< 2.6 > First Time Start-up Setting

Step 2. Click “ Next “ in “ InfraPower Manager start-up setting “ box

Step 3. Input the fi elds of the following window & Click “ Install “

If the port of web server

is not 80, please input the

appropriate no. here and

follow the instruction in “

Change port no. of web

server“ next page to make

the change effective.

PostgreSQL password can be changed by user.

The password MUST contain at least three of the following four character groups:

- English uppercase characters ( A through Z )

- English lowercase characters ( a through z )

- Numerals ( 0 through 9 )

- Non-alphabetic characters ( such as !, $, #, % )

P.16

www.austin-hughes.comUM-IPM-03-Q214V3

Complete

Page 22

< 2.7 > Change Port no. of Web Server

Change port no. of web server.

If users want to use another port no. instead of 80, please take the following steps after

InfraPower Manager IPM-03 “ First time start-up setting “ is completed.

Step 1. Go to the path of web server being installed. ( Default: C:\AppServ\Apache2.2\conf\ )

Step 2. Open “ httpd.conf “ & change “ Listen 80 “ to “ Listen xx “ where xx means the port

users want to use save the change

Step 3. Restart Apache services.

Go to Control Panel > Administrative Tools > Services > Apache2.2 & Click “ Restart “

Complete

P.17

www.austin-hughes.comUM-IPM-03-Q214V3

Page 23

Part III. System Setup & Remote Access

< 3.1 > System setup

Users can follow below step 1 - 3 to access the management PC and InfraPower Manager IPM-03

Step 1. Open Internet Explorer ( I.E. ), version 8.0 or above

Step 2. Enter the URL of management PC into the address bar

( If fail to access, please ask MIS to check if the port for web server is enable.

Default port : 80 )

e.g. http://192.168.0.1/IPM-03/

Step 3. Enter “ User name “ . Default is “ admin “

Enter “ Password “ . Default is “ 00000000 “

12345

Login user

Login user Login user Login user Login user

Router or hub

Management PC

InfraPower Manager IPM-03

Then users should go to < User >, < Setup >, < Alarm >, < General > & < Backup > for initial

system setup

Only Administrator is authorised to access < User >, < Setup >, < Alarm >, < General > &

< Backup >

P.18

www.austin-hughes.comUM-IPM-03-Q214V3

Page 24

< 3.1 > System setup

In < User > page, administrator can create 4 more operators.

Step 1. Tick “ Operator 1: “

Step 2. Input “ User name “ & “ User login password “

Step 3. Input user login password in “ Confi rm password “ again

Step 4. Repeat Step 1 to 3 for other operators if necessary

Step 5. Click “ Apply “ to fi nish the user setup

P.19

www.austin-hughes.comUM-IPM-03-Q214V3

Page 25

< 3.1 > System setup

In < Setup > page, administrator can activate max. 30 IP dongle groups & set the group command

password

Step 1. “ Activate “ IP dongle group 01

Step 2. Input “ IP address “ & “ password “ of the IP dongle

Step 3. “ Enable “ Command password

Step 4. Input “ New command password ”. Default is “ 00000000 “

Step 5. Input new command password in “ Confi rm new password “ again.

Step 6. Click “ Apply “ to fi nish the IP dongle group setup

Step 7. Repeat step 1 to 6 for other IP dongle groups if necessary

P.20

www.austin-hughes.comUM-IPM-03-Q214V3

Page 26

< 3.1 > System setup

In < Alarm > , administrator can confi gure the alarm email server & max. 5 email recipients to receive

alarm notifi cations from the software

Step 1. “ Enable “ alarm email

Step 2. Input “ SMTP server ” and “ SMTP port “

Step 3. Input “ User email “

Step 4. “ Enable “ or “ Disable “ the “ SMTP authentication “

Step 5. Input “ User name “ and “ Password “

Step 6. Select the “ SMTP secure “ ( None / SSL / TLS )

Step 7. Input the “ Alarm interval “

Step 8. Input the alarm recipient email account in “ Alarm mail recipient 01 “

Step 9. Repeat step 8 for other alarm recipients if necessary

Step 10. Click “ Apply “ to fi nish the alarm email server setting

P.21

www.austin-hughes.comUM-IPM-03-Q214V3

Page 27

< 3.1 > System setup

In < General > , administrator can change the “ Refresh rate “ , “ Scan rate “ & “ Temperature unit “

across all IP dongle groups

In < Backup > , administrator can “ Enable “ or “ Disable “ the daily data backup. When “ Enable “,

the backup path can be changed

P.22

www.austin-hughes.comUM-IPM-03-Q214V3

Page 28

< 3.1 > System setup

< Sys log > provides past 2000 event records of < User >, < Setup >, < Alarm >, < General > &

< Backup >

P.23

www.austin-hughes.comUM-IPM-03-Q214V3

Page 29

< 3.2 > Remote Access

After administrator completes < System Setup >, up to 4 additional users can access the

management PC remotely. User can follow the steps below to access management PC &

InfraPower Manager IPM-03

Step 1. Add the port of web server in the fi rewall settings of the management PC.

- Open “ Control Panel ”

- Select “ Windows Firewall “

- Select “ Advanced settings ”

- Right Click “ Inbound Rules ” & select “ New Rule… “

- Select “ Port ” & Click “ Next> ”

- Select ” TCP ” then “ All local ports ” & Click “ Next> ”

- Select “ Allow the connection “ & Click “ Next> “

- Tick all three options & Click “ Next> “

- Input the “ Name “ & “ Description “ of the port & Click “ Finish “

Step 2. Open the web browser of remote client PC

Step 3. Input the URL of InfraPower Manager IPM-03 in the address bar

e.g. http://192.168.0.1/IPM-03/

If the port no. of web server is not 80, please enter the appropriate port no. follow

the IP address e.g. http://192.168.0.1:81/IPM-03/

Step 4. System authentication page pops up automatically.

Input “ User name “, “ Password “ & Click “ Login “

P.24

www.austin-hughes.comUM-IPM-03-Q214V3

Page 30

Part IV. Software Usage & Operation

< Status > provides

- < Search > function to search new installed PDUs in each IP dongle group. The real time

clock of the PDUs will be synchronized from the management PC during searching process

( If search fails, please refer to P.41 for IP dongle fi rmware upgrade )

- Scan function to monitor the PDUs’ status of each IP dongle group ONE by ONE

P.25

www.austin-hughes.comUM-IPM-03-Q214V3

Page 31

Part IV. Software Usage & Operation

In < Details >,

- Change “ Name ” and “ Location ” of PDU & Click “ Apply ”

- Change “ Alarm amp. ” , “ Rising alert amp. “ & “ Low alert amp. ” of PDU’s circuits

& Click “ Apply ”

- Click “ Reset ” to reset peak amp. or kWh of PDU’s circuits

- Click “ ON / OFF ” to swich ON / OFF outlet

( WS kWh Switched and WSi Outlet kWh Switched PDU only )

- View On / Off status of each PDU’s outlet

- View aggregated current on the PDU

- View lastest loading & energy consumption of each PDU’s outlet

( Wi kWh Monitored & WSi Outlet kWh Switched PDU only )

P.26

www.austin-hughes.comUM-IPM-03-Q214V3

Page 32

Part IV. Software Usage & Operation

In < Outlet setting >,

- Change PDU’s outlet name

- Change “ Power up sequence delay ” of PDU’s outlet

( WS kWh switched and WSi Outlet kWh Switched PDU only )

- Change “ Alarm amp. ” , “ Rising alert amp. “ & “ Low alert amp. ” of PDU’s outlet

( Wi kWh Monitored & WSi Outlet kWh Switched PDU only )

Click “ Apply ” to fi nish the above settings

- Click “ Reset ” to reset peak amp. or kWh of PDU’s outlet

( Wi kWh Monitored & WSi Outlet kWh Switched PDU only )

P.27

www.austin-hughes.comUM-IPM-03-Q214V3

Page 33

Part IV. Software Usage & Operation

In < TH status >,

- View status, location, lastest reading & alarm setting of Temp. & Humid sensors connected to

each PDU

The GUI does not show the readings if the TH sensors are not installed & activated.

P.28

www.austin-hughes.comUM-IPM-03-Q214V3

Page 34

Part IV. Software Usage & Operation

In < TH setting >,

- “ Activate ” or “ Deactivate ” Temp. & Humid sensors

- Change “ Location ” , “ Rising alert Setting “ & “Alarm Setting ” of

- Click “ Apply ” to fi nish the above settings

The default TH setting is Deactivate .

- When install

T or TH sensor, please tick Activate . Otherwise, no readings display.

- DON’T activate T or TH sensor if no sensor installed.

Temp. & Humid sensors

P.29

www.austin-hughes.comUM-IPM-03-Q214V3

Page 35

Part IV. Software Usage & Operation

< Outlet Schedule Overview > provides a scan overview on all settings of PDU’s outlet

schedules based on IP dongle group

P.30

www.austin-hughes.comUM-IPM-03-Q214V3

Page 36

Part IV. Software Usage & Operation

In < Outlet Schedule Setting >, user can set max. 6 outlet On / Off schedules in each PDU.

The outlet schedule can be set on one-time, daily or weekly basis.

To set the outlet schedule, please follow the steps in next page

P.31

www.austin-hughes.comUM-IPM-03-Q214V3

Page 37

Part IV. Software Usage & Operation

PDU outlet schedule is a function allowing users to set a specifi c time to switch either ON or OFF

the outlets on daily, weekly or one-time basis.

Each PDU provides 6 schedule tasks. Users can follow the steps below to enable the PDU outlet

schedule

Step 1. Go to < Outlet Schedule Overview > page, Click “ Setting ”

P.32

www.austin-hughes.comUM-IPM-03-Q214V3

Page 38

Part IV. Software Usage & Operation

Step 2. In < Outlet Schedule Setting > page, Select “ Oultet schedule 1 “ & Tick “ Enable “

Step 3. Provide the name of the outlet schedule

Step 4. Select the action ( either ON or OFF )

Step 5. Select the time for outlet schedule.

Daily ON / OFF Schedule

Weekly ON / OFF Schedule

One-time ON / OFF Schedule

P.33

www.austin-hughes.comUM-IPM-03-Q214V3

Page 39

Part IV. Software Usage & Operation

Step 6. Tick the outlets of the connected PDU ( s ) to switch ON / OFF based on the action you

selected

Step 7. Click “ Apply “ to save the settings

Step 8. Repeat step 2 to 7 for Outlet Schedule 2 to 6 if necessary

If the outlet schedule task is “ One-Time “, that specifi c task will be disabled automatically

once the action is completed.

To cancel the outlet schedule, tick “ Disable “ & Click “ Apply “ to fi nish the changes.

P.34

www.austin-hughes.comUM-IPM-03-Q214V3

Page 40

Part V. Events / Log / Report

< Event > provides past 2000 event records of PDUs’ confi guration & connection / outlet confi guration

/ sensors’ confi guration & connection in an IP dongle group

< PDU log > provides past 2000 log records of each PDU. The software will generate a PDU log

record every 10 mins.

i

P.35

www.austin-hughes.comUM-IPM-03-Q214V3

Page 41

Part V. Events / Log / Report

< Outlet log > provides past 2000 log records of each PDU’s outlet. The software will generate an

outlet log record every 10 mins.

< TH log > provides past 2000 TH log records of each PDU. The software will generate a TH log

record every 10 mins.

i

P.36

www.austin-hughes.comUM-IPM-03-Q214V3

Page 42

Part V. Events / Log / Report

< Daily kWh log - PDU > provides past 2000 daily energy consumption log records of each PDU.

The record is logged at 00:00 everyday ( +/- 5 mins. ) for previous day

The daily kWh log will not be recorded at 00:00 if the PDU connected less than 24 hours

i

< Daily kWh log - Outlet > provides past 2000 daily energy consumption log records of each

PDU’s outlet. The record is logged at 00:00 everyday ( +/- 5 mins. ) for previous day. ( Wi kWh

Monitored & WSi Outlet kWh Switched PDU only )

P.37

www.austin-hughes.comUM-IPM-03-Q214V3

Page 43

Part V. Events / Log / Report

< Report > provides monthly report for PDU log , Outlet log , TH Sensor log ,

Daily kWh log & Event log which can be exported in CSV format.

Please follow the steps below to export the log category you want :

Step 1. Select “ Category ” , “ Period “ & “ Target “

Step 2. Click “ Apply ” & Click “ OK “ from the pop up window

Step 3. Right Click the fi le name below & Select “ Save target as “ to download the log fi le

Step 4. Click “ Close “ to complete or “ Open “ to view the content of log fi le

P.38

Complete

www.austin-hughes.comUM-IPM-03-Q214V3

Page 44

Part VI. SNMP Setup / Firmware Upgrade

< SNMP Setup >

The IP dongle can manage the connected W series PDUs in a single daisy-chain up to 16 PDUs via

SNMP v2c ( Simple Network Management Protocol).

Only IP dongle model : IPD-02-S or IPD-H02-S can support SNMP

( I ).

Use the World Wide Web (WWW) to download the SNMP MIB fi le at this URL:

( II ). Enabling SNMP Support

Accessing MIB Files

http://www.austin-hughes.com/support/utilities/infrapower/IPD-MIB.mib

The following procedure summarizes how to enable the IP Dongle for SNMP support.

Step 1. Connect the IP dongle to a computer. ( Please refer to P.12 )

Step 2. Open the Internet Explorer ( I.E. ) version 8.0 or above

Step 3. Enter the confi gured IP dongle address into the I.E. address bar.

Default IP address is “ 192.168.0.1 “

Step 4. Enter “ Login name “ & “ Password “. Default login name & password are “ 00000000 “

P.39

www.austin-hughes.comUM-IPM-03-Q214V3

Page 45

Part VI. SNMP Setup / Firmware Upgrade

Step 5. Select the SNMP from the left navigation

Step 6. The SNMP Settings window appears as below:

Step 7. Click “ Enable “ in “ SNMP Agent “ to start the SNMP agent service

Step 8. Input “ Read Community “. Default is “ public ”

Step 9. Input “ Write Community “. Default is “ private ”

Step 10. Select “ disabled “ or “ V2Trap “ in “ SNMP Traps “

If select “ V2Trap “ , please input IP address of the SNMP management station in “ Station IP: “

Step 11. Click “ Apply “ to fi nish the SNMP settings

P.40

www.austin-hughes.comUM-IPM-03-Q214V3

Page 46

Part VI. SNMP Setup / Firmware Upgrade

< Firmware Upgrade >

If fail to search the PDU, please take the following steps to upgrade the IP dongle fi rmware :

Step 1. Download the IP dongle fi rmware from the link :

http://www.austin-hughes.com/support/software/infrapower/V2395S.img

Step 2. Connect the IP dongle to the computer.

Step 3. Open the Internet Explorer ( I.E. ) version 8.0 or above

Step 4. Enter the confi gured IP dongle address into the I.E. address bar.

Default IP address is “ 192.168.0.1 “

Step 5. Enter “ Login name “ & “ Password “. Default login name & password are “ 00000000 “

Step 6. Select the Firmware from the left navigation

P.41

www.austin-hughes.comUM-IPM-03-Q214V3

Page 47

Part VI. SNMP Setup / Firmware Upgrade

Step 7. The fi rmware upgrade window appears as below :

Step 8. Click “ Browse ” and select the fi rmware fi le ( xxx.img ) from the specifi c path in the

pop up window and Click “ Open ”

Step 9. Click “ Upgrade ” to start the upgrade process. It takes a few minutes to complete.

Step 10. Once complete, UI will return to the login page.

P.42

www.austin-hughes.comUM-IPM-03-Q214V3

Page 48

Part VII. FAQ

InfraPower Manager - IPM-03

1. What is InfraPower Manager?

The InfraPower Manager IPM-03 is a Windows based system to consolidate management of max.

480 PDUs via 30 IP dongles, using a simple web interface which monitors and controls the WSi

Outlet kWh Switched / Wi Outlet kWh Monitored / WS kWh Switched / W kWh Monitored PDUs in the

data center. Authorized users have a secure control over outlets to power ON / OFF at the managed

device level. It also provides the detailed PDU, daily energy consumption and event logged records,

and sends alarm email once ampere & Temp. / Humid. over the predefi ned alarm threshold.

Please fi nd the link below:

http://www.austin-hughes.com/support/software/infrapower/IPM-03.msi

2. Which OS platform does IPM-03 support?

- MS Windows XP Professional with SP3 (32bit only)

- MS Windows 7 Professional with SP1

- MS Windows 7 Ultimate with SP1

- MS Windows Server 2003 R2 Standard Edition with SP2

- MS Windows Server 2008 Standard Edition SP2

- MS Windows Server 2008 R2 Standard Edition SP1

Ensure the user logins in the management PC as a member of “Administrators” Group

before IPM-03 Installation and execution.

3. Why user can’t login to the Management PC remotely ?

Make sure the port for web server is added in the fi rewall setting and the services of web server is

started in the management PC.

4. Which database does the IPM-03 support?

PostgreSQL

5. What is the PostgreSQL default password for IPM-03?

1qaz2WSX

6. How can I receive alarm email and get full log report?

Ensure that IPM-03 is executed and the alarm server is confi gured properly and being enabled.

7. What is the default user name & password of IPM-03?

Default user name “ admin ” & password “ 00000000 ”

8. What is the command password of IPM-03?

Each IP dongle group has its command password. It will be requested for any PDU confi guration and

control. The administrator can set different command password for different IP dongle group or all IP

dongle groups use the same password.

9. The WSi Outlet kWh Switched / Wi Outlet kWh Monitored / WS kWh Switched / W kWh

Monitored PDUs can’t be found by IPM-03?

Please double check the cable connection and the level setting of each PDU. If a cascade chain has

duplicate the level PDUs, it will cause this problem.

P.43

www.austin-hughes.comUM-IPM-03-Q214V3

Page 49

Part VII. FAQ

10. Is it possible to manage the WSi Outlet kWh Switched / Wi Outlet kWh Monitored / WS kWh

Switched / W kWh Monitored PDUs from different workstations?

Yes, the InfraPower manager supports 5 concurrent login users from different workstations.

IP dongle

1. What is the IP dongle?

The IP dongle provides a simple and economical way to consolidate management of max. 16 pcs WSi

Outlet kWh Switched / Wi Outlet kWh Monitored / WS kWh Switched / W kWh Monitored PDUs, by a single

IP connection to the network.

2. What is the IP setup utilities?

This is a windows application used to assign the IP address of IP dongle. You can download the IP setup

utilities from the link below:

http://www.austin-hughes.com/support/utilities/infrapower/IPdongleSetup.msi

3. Does the IP dongle support DHCP (Dynamic Host Confi guration Protocol)?

No, the IP dongle only works with static IP-address.

4. Will the reset of IP dongle affect the power to the outlets?

No, the IP dongle operates on a separate circuit, so the power to the outlets will remain unchanged.

5. How can I replace a failed IP dongle?

As the IP dongle is hot swappable, without power disconnection, you can unplug the RJ45 connector and

slide out the failed IP dongle from the WSi Outlet kWh Switched / Wi Outlet kWh Monitored / WS kWh

Switched / W kWh Monitored PDU. Then replace a new one for the PDU and re-confi gure the IP address

to fi t your network setting. ( Please refer to user manual < 2.2 > for details )

Temp. Humidity sensor

1. How accurate is the Temp. & Humid. sensor?

It is accurate to ± 1°C ( typical ) & ± 4.5% RH ( typical ).

2. How accurate is the Temp. sensor?

It is accurate to ± 1.5°C ( typical ).

3. How to install the Temp. / Temp. & Humid. sensor ?

Plug in the Temp. / Temp. & Humid. sensor ONLY AFTER the PDU is ON.

P.44

www.austin-hughes.comUM-IPM-03-Q214V3

Page 50

Part VII. FAQ

Meter for W series Intelligent kWh PDU

1. What is feature of the Wi Outlet kWh Monitored / W kWh Monitored PDU?

The W kWh Monitored PDU offers simple & highly reliable power distribution to multiple equipments, and built-in

a 1.8” LCD meter indicates the total energy consumption of equipment connected to the PDU. The digital ampere meter has an interface which can connect to an IP dongle to the ethernet network, which allows managers

to real-time remote monitor the PDU load thru the InfraPower manager (IPM-03).

2. What is feature of the WSi Outlet kWh Switched / WS kWh Switched PDU?

The WS kWh Switched PDUs offers the same features as W kWh Monitored PDUs, with an addition remote control power capability to individual PDU outlets. The remote outlet power control allows power on/off functionality

for power recycling to reboot locked-up equipment and to avoid unauthorized use of individual outlets.

3. Can the WSi Outlet kWh Switched / Wi Outlet kWh Monitored / WS kWh Switched / W kWh Moni-

tored PDUs cascade together?

Yes, the WS kWh Switched & W kWh Monitored model PDUs can connect together as a cascade chain.

4. If one of the cascaded WSi Outlet kWh Switched / Wi Outlet kWh Monitored / WS kWh Switched / W

kWh Monitored PDU loses power, will it affect other PDUs in the same chain?

No, the other cascaded WS kWh Switched & W kWh Monitored PDUs in upper & lower level will not be affected.

5. What is the maximum cabling distance between two cascaded PDUs?

Up to 20 meter (66 feet) of CAT. 5 / 6 cable.

6. What is the maximum cascade level of the WSi Outlet kWh Switched / Wi Outlet kWh Monitored /

WS kWh Switched / W kWh Monitored PDU in a chain?

16 levels

Others

1. What is the default outlet status of WSi Outlet kWh Switched / WS Switched PDU ?

The default outlet status is ON.

2. Will the PDU settings remain unchanged after power OFF?

Yes, the settings will remain unchanged such as PDU Name, Location, Alarm amp., Low alert amp., Outlet

Name......

3. Does the InfraPower PDU has the overpower protection?

Yes, the PDU provides the resettable fuse or optional circuit breaker for the overpower protection.

4. What is the standard inlet cable length of InfraPower?

3 meter ( 9.9 feet ).

5. Where can I fi nd the Catalogue / User manual /Model list / Wire diagram of InfraPower

PDUs?

Please visit the www.austin-hughes.com

6. How can we get a further support?

Please send the email to

support@infra-power.com or sales@infra-power.com

P.45

www.austin-hughes.comUM-IPM-03-Q214V3

Page 51

Part VII. FAQ

PDU disconnection

1. GUI shows a certain level PDU disconnected

Step 1 - PDU power off ?

Check the PDU is power ON or not.

Step 2 - PDU level setting duplicated in the same PDU group ?

Check and make sure PDU level is unique and not duplicated in the same PDU group.

(Please refer to to user manual < 1.2 > display 9.1 for details)

2. GUI shows from a certain level PDU to the last one disconnected

Step 1 - Cable disconnected, loose or defective ?

Check the Cat. 5/6 cable connection to PDUs and network devices. Make sure the connectors are

fi rmly attached. And check if any defects on your cable or not. If yes, replace a new one.

Step 2 - The fi rst disconnected PDU failed ?

Unplug the Cat. 5/6 cable on the fi rst disconnected PDU, then plug it to the second disconnected

PDU to check if the problem caused by the fi rst disconnected PDU.

3. GUI shows the whole group of PDU(s) disconnected

Step 1 - Cable disconnected, loose or defective ?

Check the Cat. 5/6 cable connection to PDUs and network devices. Make sure the

connectors are fi rmly attached. And check if any defects on your cable or not. If yes, replace a new

one.

Step 2 - IP dongle failed ?

i. Check if the network setting of the IP dongle is correct or not. If duplicated IP address is in a network, it may cause such problem.

ii. Disconnect the IP dongle from the network and try to direct connect the Cat. 5/6 cable from IP

dongle < LAN > port to a computer network port and use IP Setup utilities to check if the IP dongle

can be found or not. If it cannot be found, the IP dongle may be failed.

Step 3 - 1st level PDU failed ?

Move the IP dongle from 1st level PDU to 2nd level PDU to check if the problem caused by 1st level

PDU’s failure or not. If yes, replace 1st level PDU.

P.46

www.austin-hughes.comUM-IPM-03-Q214V3

Page 52

Part VIII. Troubleshooting

Replacement, Removal or addition for PDU & IP dongle

1. How to replace the failed IP dongle ?

Step 1 - Prepare a new IP dongle.

Step 2 - Disable alarm email in <Alarm> page.

Step 3 - Replace the failed IP dongle with the new one on 1st level PDU.

Step 4 - Confi gure the setting of the new IP dongle same as the old one.

(Please refer to user manual < 2.2 > for details)

Step 5 - Click Start Connection in <Status> page for the relevant IP dongle.

Step 6 - Enable alarm email in <Alarm> page again.

2. How to replace the failed 1st level PDU with a new one ?

Step 1 - Prepare a new PDU and set the PDU to 1st level.

(Please refer to user manual < 1.2 > display 9.1 for details)

Step 2 - Disable alarm email in <Alarm> page.

Step 3 - Power off & unplug the device(s) which connected to the PDU.

Step 4 - Power off & remove the failed 1st level PDU from connection.

Step 5 - Install the IP dongle on the new 1st level PDU.

Step 6 - Install and connect the new PDU.

Step 7 - Power on the new PDU and connect to the device(s).

Step 8 - Click Start Connection in <Status> page for the relevant IP dongle.

Step 9 - Confi gure the new PDU in <Details> and <TH Sensor> page such as Alarm Amp , Name,

Location…

Step 10 - Enable alarm email in <Alarm> page.

3. How to replace a failed certain level PDU with a new one ?

Step 1

(Please refer to user manual < 1.2 > display 9.1 for details)

Step 2 - Prepare an appropriate length Cat. 5/6 cable.

Step 3 - Click Set maintenance in <Details> page for the failed PDU.

Step 4 - Use the Cat. 5/6 cable to bridge over the failed PDU which will be replaced to minimize log / data loss.

Step 5 - Power off & unplug the device(s) which connected to the failed PDU.

- Prepare a new PDU and set the PDU level accordingly

.

Step 6 - Power off & remove the failed PDU from connection.

Step 7 - Install the new PDU, cancel the cable-bridging and reconnect the

PDU to the last and next one.

Step 8 - Power on the new PDU and connect to the device(s).

Step 9 - Click Remove maintenance in <Details> page for the new PDU.

Step 10 - Confi gure the new PDU in <Details> and <TH Sensor> page such as Alarm Amp, Name,

Location…

Ignore step 2 & 4 if the failed PDU is in the last level.

P.47

www.austin-hughes.comUM-IPM-03-Q214V3

Page 53

Part VIII. Troubleshooting

Replacement, Removal or addition for PDU & IP dongle

4. How to move out a PDU (without a replacement) ?

Step 1 - Prepare an appropriate length Cat. 5/6 cable.

Step 2 - Click Disable Monitoring in <Details> page to stop monitoring the removed PDU.

Step 3 - Use the Cat. 5/6 cable to bridge over the removed PDU to minimize log/data loss.

Step 4 - Power off & unplug the device(s) which connected to the PDU.

Step 5 - Power off & remove the PDU from connection.

Step 6 - Enable alarm email in <Alarm> page.

If the removed PDU NOT in the last level, you MUST reconfi gure and reset the level for

the affected PDU(s) which next to the removed PDU.

Ignore step 1 & 3 if the removed PDU is in the last level.

5. How to add an extra PDU to an existing PDU group ?

Step 1 - Prepare a PDU and set the PDU level accordingly.

(Please refer to user manual < 1.2 > display 9.1 for details )

Step 2 - Prepare an appropriate length Cat. 5/6 cable.

Step 3 - Click Set maintenance in <Details> page for the affected PDU(s) which next to the

added PDU.

Step 4 - Install and connect the new PDU.

Step 5 - Power on the new PDU.

Step 6 - Reconfi gure & reset the level for the affected PDU(s) which next to the added PDU.

Step 7 - Click Remove maintenance in <Details> page for the affected PDU(s).

Step 8 - Click Search in <Status> page to search the new installed PDU.

Step 9 - Confi gure the new PDU in <Details>

Location…

Step 10 - Enable alarm email in <Alarm> page.

Ignored step 3, 6 & 7 if the added PDU is in the last level

and <TH Sensor> page such as Alarm Amp , Name,

P.48

www.austin-hughes.comUM-IPM-03-Q214V3

Page 54

Part VIII. Troubleshooting

1.8” meter LCD display

1. LCD meter no display.

Step 1 - Check PDU is power ON or not.

Step 2 - Press any button on the LCD meter. The SCREEN OFF function may be enable.

( Please refer to user manual < 1.2 > display 9.3 for details )

Step 3 - If the LCD meter still no display please call your dealer for support.

2. The whole LCD meter display turn white?

Step 1 - Use a pin to press the reset button to re-power the meter. Don’t worry, it will not

affect any settings & memories.

Step 2 - If the LCD meter still turn white, please call your dealer for support.

InfraPower Manager IPM-03

1. Try to login InfraPower Manager IPM-03 but the web browser only shows “ HTTP 404 Not Found ”

Step 1 - Services for Web server in management PC started ?

Make sure the services is started. Go to Control Panel -> Administrative Tools ->

Services -> Apache2.2 and make sure the status is “ Started ”.

Step 2 - Port for web server in management PC is occupied by other service ?

Check if the port for web server is used by other service. If yes, please release

the port of that particular service and assign another port for it.

Step 3 - Port for web server is added in the fi rewall of management PC ?

Check if the port is added in the fi rewall. If not, please add and enable the connection in

the fi rewall. Please refer to user manual < 3.2 > for details.

The company reserves the right to modify product specifi cations without prior notice and assumes no responsibility

for any error which may appear in this publication.

All brand names, logo and registered trademarks are properties of their respective owners.

Copyright 2014 Austin Hughes Electronics Ltd. All rights reserved.

P.49

www.austin-hughes.comUM-IPM-03-Q214V3

Loading...

Loading...