Page 1

THE

CASSELL.BOOK

AUSTIN

A 35

OF

(1957-9)

THE

Page 2

CA

SSELL

B Y

ELLISONHAWKS

1. The Cassell Book

2. The Cassell Bookofthe A ustin T en (1939-47)

3.

Th

e Cassell Bookofthe Fo

4. Th e Cassell Bookofthe

5. The Cassell Book

6. Th e Cassell B ook

7. Th e Cassell Bookofthe F

8. T he Cassell Book of the

9. The Cassell BookoftheAustin

10. Th e Cassell Book

11. The Cassell Book

12. Th e Cassell Bookofthe M orris M inor (Series

13. Th e Cassell Bookofthe A ustin A 35 (1957

14. Th e Cassell Bookofthe

Th

e Cassell Bookofthe Vauxhall Wyve rn (19

16.

BYIAN NICK

15. The Cassell Book of the Hillman M inx

OLS

MOTORING

of

the

Austin

rd'Prefect'

Ford'

of

the

Ford'Popular'

of

theAustin A 40 Somerset (1952

ord'

Ford'

of

the

Ford'

of

the Standard E ight (1953

Ford'

SERIES

A 40 Devon (1947

A nglia ' (to 1953)

Consul ' (1951

Zephyr' and ' Zodiac'(1951

A30

•Seven ' (1951-6)

New A ng

New Pref

(1938

-53)

(from 1953)

-6)

lia'

(1953-7)

-5)

MM)

-9)

ect'

(after 1953)

51-

-52)

7)

-4)

-6)

The Cassell .Book

of

the

AUSTIN

(1957

by

ELLISON HAWKS

A35

-9)

CASSELL LONDON

Page 3

CASSELL & COMPANY LTD

35

Red

Lion

Square.London

and

at

MELBOURNE•SYDNEY

JOHANNESBURG•AUCKLAND

© Ellison

First

published 1960

..'

TORONTO•CAPE

Hawks

13

1960

wei

TOWN

II

III

IV

V

VI

VII

INTRODUC

FOR

THE

GENERAL

AND

TYRES

STEERING

SUSPENSION

BRAKING

ENGINE

CONTENTS

ING

THE

BEGINNER

MAI

NTEN

GEAR

SYSTEM

AUSTIN

ANCE;

\

PAGE

A35

I

9

BODY,

WHEELS

29

5

I

59

66

80

Butler

Set

and

Printed

& Tann er

in 10

pt.

in Great

Ltd.,

F.1259

Old

Britainby

Frome

Style

and

London

CARBURETTOR

VIII

FUEL

IX

COOLING

X

TRANS

XI

ELECTR

X

II

LUBRICATION

XIII

RECOMMENDED

FAULT

WIRING

INDEX

PUMP

SYSTEM

MISSION

ICAL

FINDING

DIAGRAM

SYSTEM

LUBRICANTS

CHART.

I06

n6

I25

I39

I 55

I93

2

I7

2I8

220

223

v

Page 4

PREFACE

HE

PURPOSE

simple language howthe owner-driver may

T

thebest

The

tempt

saryifthe

reduces efficiency

to deteriorate,

probable. The effici

life of any car are determined by the

Thi

appe

tively small

first-class

scribe to

Minor running

to time.

is

very

h

ave

small routine

Detailed instructions are given so

hecarried

devoted to overhauling to

mechanically-minded owner.

necessary, however,itis generally advisable to allow

local Au

facilities to

familiar

failure

give a course of

possible satisfaction from his Au

inherent

owners to neglect

best performance is to be

thusrend

s book is

arance of his car,

been avoided

and

writt

amount

ord

er.

the

' DoitYourself ' vogue .

The

old

true, for neglect

attention.

out

regularly

stin

dealer to do

handl

with

all

suggest remedies.

OF

THISBOOK

reliability of mod

the

and

causes

ering a breakdown onthe

ent

running, reliability

en for

the

and

of time necess

The

jobs involved are for those who sub-

adjustments

prov

erb

that'astitchintime

may

had

the

and

the

the

e such jobs. His staff is thoroughly

Austin

models,

training

ern

routinemaint

both

appe

owner who

who is able to devote

may

lead to expense

owner been familiar

thoroughly. A section has been

extent

When

heavy

can

The

and

vn

is to describe in

stin

cars

obt

arance

attent

arytomaintain

be required from

that

possiblebythe

extensive

work. He has

diagnose

Austin Motor Co.

instru

ction to selected

A35.

may

sometimes

enance so neces-

ain

ed. Neglect

and

mechanism

road

and

ion given to it.

takes

pride in

saves

that

with

lubrication

attention

symptoms

length of

the

average

obt

ain

mor

the

relait in

time

nine'

might

some

may

your

better

Ltd.

e

is

of

Page 5

Vlll

mechanics from dealers' staffs,

th

make use of

Ano

ther

gained conside

Naturally, it

part

s are used when necessary.

A few readers

is elemen

e expert knowledge

point to bear in mind isthatthe Comp

rab

str

esses

may

tary.

Ex

PREFACE

and

owners are advis ed to

thu

s gained.

any

has

le experience from years of research.

that

only genuine Austin replacement

feelthat

perience shows, however, that often

some ofthe information given

the

minor point isthe one that is overlooked, due to lack of

kn

owledge of its imp

atur

ticular fe

delay on

e. This can give rise to inconvenience due to

the

road, as well as expense in

This book is

who have no responsibility for it. At

would tender my

ha

ve given, and for supplying illu

data

.

Victoria H ouse.

Southport

"

ort

ance or

unf

amiliarity with a

upk

not

publishedbythe

th

anks tothem forthe assistance they

Austin Motor Co. Ltd.,

th

e same time I

str

ations

and

ELLISON

par

eep.

technical

H AW KS

CHAPTER I

INTRODUCING THE AUSTIN A35

HE AUSTIN A35 is another

a popular li

-

T

port

at low-

dat

e developments,italso has thecommodious luggagespace

so necess

elli

pti

c leaf-springs at rear,

ght

run

ary

car designed to give comfortabletrans-

ning cost. Equipped withthe most up-to-

for

tour

ing. Suspension incorporates semi-

out

and

independentfr

standing example of

ont

wheel

coils and wishbones at front. The driver has a clear view

th

e road ah ead,

of

Th

ere are two touring models

door saloons, and

and

Coun

trym

Mechanical design follows typical Austin

th

e car is simple to

can

be relied ontogive many years of care-free motoring.

Dri

ver's bucket seatis adjus

passenger's se

m

ents

of individual drivers and passengers and ensuring

thatlong-distance

and

threeoth

an.

maint

attothr

trav

controls fall readily to hand.

-th

e two-door and four-

er types

-th

e A35 Van , Pick-up

pr

actice in th

ain. Construction is suchthat

tab

le to five positions and

ee positions,

thu

s meeting require-

elling imposes a minimum of

at

it

fatigue.

Once

the

car is in use it isthe responsibility ofthe owner

tte

to keep it in good condition by careful a

tion and m

bri

efly in

aint

enance.

the

general specification given below.

Th

e main compon

ntion to lubrica-

ents

are described

Engine

Engine, identical in all models, is of

our-str

cylinder f

stroke 3-00in. ('76 mm.).

giving 34 b.h.p.

oke type. Bore, 2'48 in. (62'9 mm.) and

Capacity:

at

4,750 r.p.m. with a maximum torque of

50 lb. zft. at 2,000 r.p.m. Compression r

Cylinders are cast en bloc and, with

crankcase, provide a rigid mounting for the

beatings 'carrying

construction ensures

th

e counterbalanced crankshalf. This

the

least possible vibration.

the

usual four-

57'82 cu. in. (948c.c.)

atio:

upp

8'3 to

er half of the

thr

ee main

I.

A detachable cover gives ready access to overhead-type

I

Page 6

z

THE

BOOK OF

THE

AUSTIN A35

push-rod operated valves. Oil seals are fitted to prev

reaching

is driven

rubber ins

correct chain tension. The overhead valves

screwed rocker adj

mechanism is lubri

adjustment to a minimum.

lubric

th

e combustion heads by wayof

the

The camshaft , which is on the near side of

by

a duplex roller chain.

ertinth

atedund

The overhead

e sprocket to ens

ust

ment. The totally enclosed valve

cat

ed fromthe engine,thus r

er pressure fromthe oil

-va

lve rockers have a passage along which

It

incorpo

ure

silent running and

Th

e rocker shaft bearings are

pum

valve guides.

th

e engine,

rat

es a special

hav

e a simple

edu

p.

oil is fed to an outlet at the spherical ball-end, this l

fi

tting

rod. Oil at

as it is delivered

cleara nce' purposely provided between

and

intothe correspondingly shaped end of the push

thi

th

e rocker

s point n

tip

atur

ally obviates wear

und

er pres

sure,it

th

thu

s minimizing valve noise.

but

takes up the

e end ofthe valve

The four I-section connecting rods carry gudgeon pins

locked in

pin

eyes,

c

are

permit oil to reach

adequate supply of

th

s are

e little-end eyes by clamp bolts. Asthegudgeon

not

itisunn

free to

ecessary to provide circlips or

turn

in the connecting-rod

of endwise pin movement.

Th

e big-end bearings areprovided with small h

th

e cylinder walls,

lubricant

und

er all operating conditions

thu

littl

pad

s to take

<;>l

s assunng an

and particularly when th e engine is cool.

The dish-he

aded

pistons are of a special aluminium alloy

with alumite sur face to ensure efficient lubrication,

skirts being of

upp

ermost is a

are taper

oil-con

tro

Lubri

cati

type oil

pump

meshing gears driven from

passed

of

r

choked,

int

lost.

the

throu

the

engine

eturn

s to

the

erru

pted

Inst

filter would be by-passed.

the

split type. There are four rings :

plaiD;

compression rings, and

compression ring, the second .and .thlrd

th

e bottom n ngISan

lled slotted scraper ring.

on by pressure is developed by a submerged-

situated in a housingthatcont

the

camshaft.

gh an external filter

and

cleaned by a filter element before It

the

sump. Should this filter become completely

mountedonth

:=ti?-

s two

OllI

Sconstantly

e

oil flow tothe various bearings would

althoughthe

eadofth

e oil passing

purp

ose ofthe filter would be

throu

gh it to be cleaned,

ent

oil

cing

att

er

also,

sma

ll

e-end

es to

th

e

~h

e

int

er-

offsi~

e

not

be

INTRODUCING T

Oil is also supplied

main

bearings, big-end bearings, camshaft, and overheadvalve gear. A special a

camshaft bearing to provide oil to

pump

itself

has

a filterthat

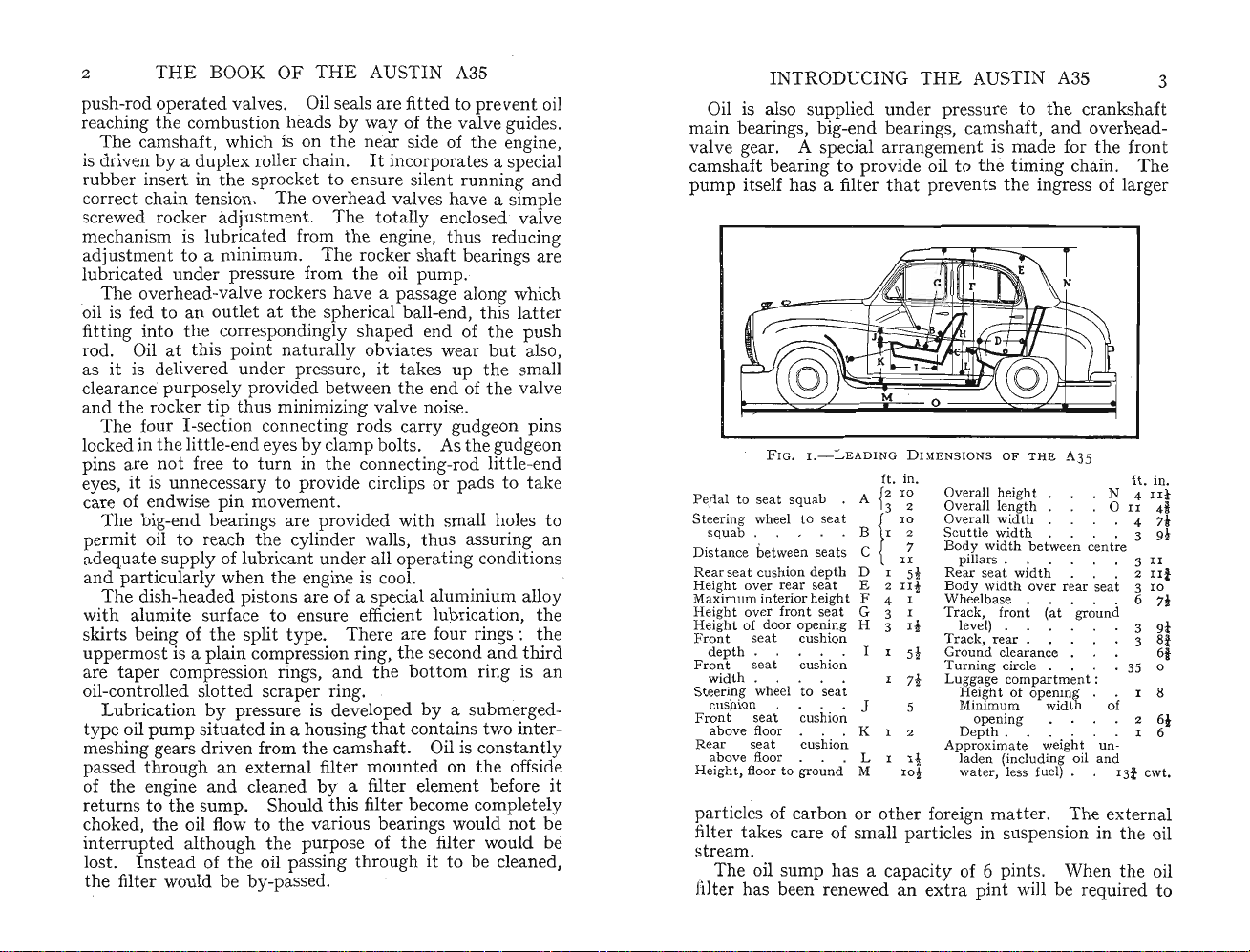

FIG.I.-LE ADING

Pe,rial to sea t

St

eering wheel to seat t

sq

uab

Distance be tween sea ts C I

Rear

sea t cushion

Height over r

Maximum int erior height F 4 I

Height

Heightof door

F

ron

t seat cu

depth . .

Front s

width . . . . .

Steerin g wheel to

cushion . . . . J

Front

abo ve floor . , . K

Rear

above

Height

squa

b .

A

. B I 2

dep

th D I

ear

seat E 2

over fron t

eat

seat cushion

seat cushion

floor . . . L I I!

, floor to

sea

opening

shion

cushion

seat

ground

t G 3 I

H 3 I!

I I

M

particles of carbon or

fi

ltertake

s care of small particles in suspension inthe oil

HE

AUSTIN A35

und

er pressure to

rra

ngement is made forthe front

th

prev

entsthe ingress of larger

DIM

ENSIO NS

ft . in .

2

10

{

3

other

Overall heig

Overall length 0

Overa ll wi

1

~

Scuttle wid th . . . . 3

Body

~

5!

II!

5!

I 7!

5

I 2

ro;

widt

illars.

p

Rear sea t wi

Body

wid th over rear sea t 3 ro

Wheelbase • . 6

Track, fro nt (at

level) . . 3

Tr

ack,

Ground clearance 61

urningcircle.

T

Luggage

Height of op ening

inimum

M

opening

Depth

Approximate

laden (including oil

wate

r, less fuel) . 13i cwt,

foreign m

the

e timing cham .

OF

T HE A35

ht

dth

h between cen tre

. . 3

dth

rear.

. 3 8i

compartmen

width of

. . . . . . I 6

weight un-

att

er. The external

tream.

The oil sump has a capacity of 6 pints . When

ilter has been renewed an

extra

pint

will be required to

crank

shaft

Th

ft. in.

N 4

II

. 4

. . . 2

ground

" 35 0

t:

I 8

2 61

and

the

II

II

IIi

oil

3

e

t

4i

7t

9~

7;

9t

Page 7

THE

BOOK

compens

and

ate

for

circulating

theamount

pip

be readily determined, a dip-stick is fitt ed on.

of

the

engine near

Th

e engine

unit

, are moun

not

only insulates sound

the

power unit . The front engine m

and

tedonrubb

porate rubber pads to control undue movem

tend

to occur

Thewat

centrifugal

and driven

It

is controlled by athermostat fitt ed inthe water outlet

und

er inthe cooling system is circulated by a

pump

by

a V-type belt fromthe cranksh

atthe front endof the cylinder h

entirely auto

of

1640F.

The radi

to

pr

event loss of

on the

assist cooling.

8!

pints.

is

ma

tic with a

ator

incorporates a chamber in

pump

shaft, draws air throughthe radi

The

Two drain taps are provided to allow

dr

ainedin frosty weatherifan a

Carburettor

Th

e Zenith carburettor (Model 26 VME) of down-

drau

ght

typ

starting.Fu

is drawn from

Th

e fuel capacity ofthe t

The

e on near side of engine,has a choke for easy

el fedbya

th

A.C. oil-we

OF

THE

AU

STI

normally retainedinthe

es. To enable

the

distributor.

gearbox, bolted t og

the

engine-oil level to

eth

er to form a single

er pads. This type of moun

but

also absorbs vibration from

ount

er certain conditions.

built

into

the

front of

the

ead.Its

nor

mal operating temper

wat

er due to expansion. A fan, m

wat

er capacityofthe cooling system

the

nti

-freeze solutionis

,

pump

operated bythe camshaft

e t

ank

mount

ed atthe rear of the car,

ank

tted

air cleaner fitted tothe car

is 5£ gallons.

N A3S

filter

th

e offside

tin

ings also incor-

ent

tha

t may

cylinder block

aft

pulley.

working is

atur

the

header tank

ounted

ator

core to

system to be

not

used.

bur

ettor

is efficient in reducing noise due to the rush of air entering

th

e carburettor particularly when accelerating.

ant

has the adv

into the engine where it can cause

pipe leads from

fumes from

th

ey are drawn intothe engine

age ofpreventing grit from being drawn

pr

emature wear. A

the

valve cover to

th

e engine do

the

not

air cleaner sothat

reachthe body. Instead,

by

thenatur

It

also

oil

al suction

at this point.

ount

An electric-type petrol contents gauge is m

the

dashbo

ardsothat

the driver can seeata glance

ed on

the

INTRODUCING

level of the fuel in

when

th

e ignition is ' on '.

Clutch

Th

g

e Borg

loaded friction disc giving smooth engagement.

clu

tch

lubr

ication,

provided

adju

sted.

and

-release bearing is of

and

thatthe clutch pedal free movem

Thi

required to free

ad

justme

nt ofthe free-pedaltravel is a simple m

Gearbox

Th

e

e gearbox, of u

lted

direc

bo

wa

rd

tlytoth

speeds and reverse with remote cen

the

Beck single dry-plate clutch has a spring-

will operate indefinitely without

s linkage is so designed

the

'There is synchromesh engagem

THE

AUS

TIN

tank

. This gauge will only read

the

carbon type, requires no

that

clutch. When necess

nit

construction with

e flywheel housing.

ent

on second,third and

A3S

ent

is correctly

littl

ary,th

the

It

has

tral

lever control.

Th

att

ention

e effort. is

e i

in

att

er.

engine, is

four for-

5

e

,

top gears, making gear-changing easy and effortless.

The

gears are of

the

helical type, ensuring a considerable

degree of silence as well as great strength. A pair of helical

to

gears transmit drive

Th

is a

rra

cable.

ngementensures automatic lubrication for

drive gears as well as obviating

Oil capaci

Transmission "

Th

e drive fromthe gearbox to the rear axle is by an

open-type

ty

of gearbox ,: 2! pints.

pr

opeller shaft at each end of which is a

speedometer

th

e need for anyadjustment.

Spicer universal joint with needle roller

haft

front end of the s

,in a correspondingly splined

With the rise

and

is free to move sligh

the cha nge in len

Rear Axle ',. l r

is a splined member that engages

par

fall of

the

tly

gththat

rear axle,

at the splined end, so taking up

occurs due to this movement.

A'banjo '-type housing cons

th

at is rigid yet light. The axle shafts are

. le

hr e-quarter floating

" , iJy detachable. On

type

, splined attheir inner ends and

the

axle-housing nd the hubs

thr

ough a flexible

'I,

Har

bea

rings. At the

t ofthe universal joint.

the

propeller shaft

tru

ction result s in a rear

o

~

dy-

the

Page 8

6

are

shaft

THE

BOOK

mount

ed on ball races. A flange formed on each axle-

out

er end is bolted to the

OF

THE

AU

hub

STIN

to imp

A3S

artthe final

drive. '

Th

e crown wheel and pinion are of spiral bevel design,

the

pinion being mounted on

tap

er roller bearings.

Th

differential is of t he two-pinion type and mounted on a

single centre spindle. The cage is

journal and

thrustball bearings, provision being made for

mount

ed on combined

mesh adjustment.

Th

e oil capacityofthe rear axle is I t

pint

s.

Braking System

Th

e Lockheed braking system employs hydraulicallyoperated leading brake shoes onthe front wheels and

mechanically operated brake shoes on the rear.

mechanical linkage is

actuat

ed by means of a h

ydra

Th

ulic

cylinder and stirrup mount ed under the body. A pullup

type of handbrake operates dir ectly onthe mechanical

linkage tothe rear wheels.

Th

e fr

ont

Tho

se of the rear have one shoe ofthe trailing type and

th

e other leading.

the

front and single leadin g atthe rear-results in extremely

wheel brakes consist of two leading shoes.

Th

is combination- two leading shoes at

efficient braking.

Brak

e-shoe lining wear is taken up by a simple means.

The

brake shoes can readily be examinedbydrawing off

the

brake

drum

s, these being so m

nothave to be dismantled for

ount

thispur

ed thatthe

pose.

hub

s do

Steering

Th

e steering, of the cam-gear type, is a self-contained

unitofextr

st

eering

eme simplicitywith a ratio of

boxismounted

forward ofthe toeboard

12:

1.

The

and

provides a short steering column of greatrigidity.

Body

Th

e body ofthe A35 is essentially a single unit and

does

not

require a

and

front

andrear

reinforced body shell.

tions welded

of

great

rigi

dit

and

y.

cha

ssis frame.

suspen sion

Thi

riveted

The

engine, gearbox,

unit

s are anchored to

s is made up of six

tog

eth

er to form a

major

box

the

sec-

section

I

NTROD

The

body

fully stressed skin.Its

left ofthe scuttle inthe engine compartment

Suspension at the

e

Thi

s is achieved by.

members of unequal len

int

erposed. A double-acting Arm

type shock abso

UCING

TH

E AUST IN A35

itself is of all-steel uni tary con

numb

er will be f

fro~t

is

i!1d

COl

I spnngs and WIsh-bone WIth

gth

epend er:t

, a compression spring being

stron

rber

is incorporated on each side inthe

oun

g h

structi

on with

d on the top

.

f.or

each

ydr

aulic piston-

7

;vh~el.

upper wish-bone member. . . . .

Th

e rear road springs, of the

type, are

low

bu

shed shackles, do not require any lubric

lubric

e

periodically be given

und

body

er-slung be

mountin

nea

th.

g. The spring-eyes,WIth their

atorsatthe centre ofthe upper rear s

att~ntion.

the

.

mult

i-leaf semi-elliptic

axle

h

~lUsin

hac

.

g

.to give a

rubb

ati

on. The

kles should

er-

An anti-rollbar-adevice to limit body roll when cornering- is fitt ed tothe

s

tee

l bar m

ount

rear

axle.

It

consists of a U-shaped

ed so that its two arms point tothe rear.

E ach arm is bolted tothe shock-absorber lever arm and

thence connect ed,

axle housing. A fuller descr

is given on page 60. .

The four hydraulic shock absorbers assist

throu

gh rubber-bushed links, tothe

ipti

on of this ingenious device

.,

in

damping

out road shocks and in conjunction with the independent

front suspension help t o give a comf

The pressed-steel road wheels

pierced intheir discs adjacent to the

coolthe

E

brakedrum

xtr

a low-pressure 52'0

s.

-13

ort

able ride.

hav~ventilati~n~lo

nm

to p

ermit

tub

eless

tyres

are fitted.

ts

arr to

Electrical Equipment

Lighting and starting equipment is of

Th

e 43-amp.

engine side ofthe

hr.

batt

bulkh

ery

(at

ead

zo-hr..

where ItISre

The generator is ventilated to prev

11

t. Output is automatically controlled by a regulator

0.

orc1

ing tothe requirem

Th starter motor is m

L ting it as required by a small pinion

I I )\1 rht into and

'I

II

· ignition system is of

out

entsofthe

ount

ed onthe off side ofthe engine,

of mesh withthe flywheel ring gear.

the

the

I2-v

olt

type.

r

~te)

is .fitted on. the

adily

accessible.

entitbecoming too

system.

automa

tically

high-t ension type, with

Page 9

8 T

distributor

breaker

Ignit ion switch,

when

Automatic

fugally

enables

according to

The li

lamp

lamps

lights,

column,

andrear

lights. The

full-ah

A warning light on

the

serves as a warning that on-coming

and

Th

on when

Underth

car

The

only

. Switching on of

HE

BOOK

and

rotor readily accessible b

gap setting

the

key is remo

advance

by

the

an

engine speed. A vacuum-assisted device

appropriate degree of advance to be made

the

ghtin

ounted

mount

l~

cat

IS

lights,

g equipm

in each fron t wing, and two 6-

ed on

ed

onthe

turned

andtoth

s m

third

ead

position. .

OF

and

for timing. .

mount

ed on

ved

.

andretard

load.

ent

consists of two 4zl36-watt head-

topofth

~i

ght-hand

clockwise to

e second

notch

bringsth

th

e facia

THE

the

e wings.

the

e headli

pan

AUSTIN

oth

A3S

for

contact

dash, is locked ' off '

are

controlled centri-

watt

The

switch for

side ofthe steering

first

notch

for

notch

to dip

ght

el is illumin

s to

the

the

ated

the

normal

headlamp beams are inthe full-ah ead position . This

tr

affic may be dazzled

that

the

headl

amp

e twin stop and tail lamps are

thebra

e facia

floor when

in.

~vaI~able

the

strument

whenthe side lights or headlights are in use.

s should be dipped.

automat

ically switched

ke ped al is depressed. '

pan

el is a courtesy light to illuminatethe

doors are opened. ., . '

pan

el is lit .byconcealed interior lamps

th

ese

pan

el li

ght

s indicatesthat,the

sidelamps have also been switched on. .

Th

ere is.a warning l

has been left on with

if the generator is not c

Thetr

~roll

in

late

a se

of a .s

.i

ste

afficators, ofthe solenoid-operated type, are con..

ed

from a switch tothe ri

early models,

r '

mod

els. .

The

windscreen wipers are ele

pa

rate control. .. . '

The he

at

er, when fitted, circulates h

ma

ll electric fan controlled from

'I

he electric

.ering wheel

amp

to showthe driver ifthe-.ignition

th

e engine statio

ha

rging. . .

ghtofth

andatthe c

horn

is controlled from

and

operates independently of

entr

ctr

ically ope

nary

.

e steering wheel

e of

the

eatedair

the

thecentre

It

also shows

dashbo

rated

and

by means

facia panel.

the

ignition

switch, ,. .

side-

the

side

head-

when

ard

have

of th e

iii

-

CH

APTER

II

FOR THE BEGINNER

E

FOLLOWING

that

the

T

y may be helpful to a new driver who

it is a sumed is al

road curtesy.

Th

that are to be learned from expe

dctrirn

perf

nta

l practices

rrnance and

durationofthenorma

This chapter describes some of

pro dure.

habits~oavoid,

at

will

th

If

atthe

youmay

not

only enable you to

A35 but will also avoid undue mechanical wear

Although an

cons i nti

f

llOWlI

By

<;>usly loo.ked

~g

inanimat

th

e in

amply repaid fo.r care and a

thousands of miles of pleasurable motoringthat

Fir

st let us refer tothe in

tr

at 1 in

rel~van

Fig-

s. z and 3, by si

t illu

stra

tions

HINT

S are given inthe hope

ready

familiar withthe

rudiment

s of

ere are not only.the niceties of driving

ne

nce,

but

also various

th~t

may re

sult

in reducing potential

l life of

th

out

set you are not clear

train

yours

e

object

aft

~r

str

as

uctions youWIll findthat you

tte

e correct methods of

el~

to

arn

adopt

the

obt

a car requires to be

much .as a horse or a dog.

ntionbyenjoying

the

about

a technique

best from yo

and

tear.

the

many

car.

the

ur

are

lie ahead.

strum

ava

ilable.

entsand

tti

ng inthe car withthe

It

is

imp

ort

controls illus-

ant

to be able

to find, and use, any appropriate control without hesitation .

The id al to

foot .on

movmg

th

may seem, it is surprising how

sary to look for a

congested state ofthe roads at

bearing in m

m"lst. have

In

also

and

yo,?r

your abilityto op

autom

car

switched on so

gear or

brake

the controlshould be ope

B 9

att

th

ain is to be able to

e control desired

withoutthe necessity of re-

pla

ce the h

and

e eyes fromthe road. Obvious as this advice

many

nyparti

indthe n

sup~~

me

cular co

ormalroad

confidence notonly in your

erate

ati

~all

y

. . At ni

ght

efficiently If you must

you

drivers finditneces-

ntrolthey want.

the

present

In

timeand

speed of traffic: you

car

t.he various controls swiftly

cannot

havethe interior

expect to control

top

thatyou can determinethe position of

levers.

It

is also

rated

import

ant

in order to give th necessary

to know how

or

the

but

light

the

Page 10

I O

THE

BOOK

OF

THE

AUSTIN

A3S

FORTHE

BEGINNER

II

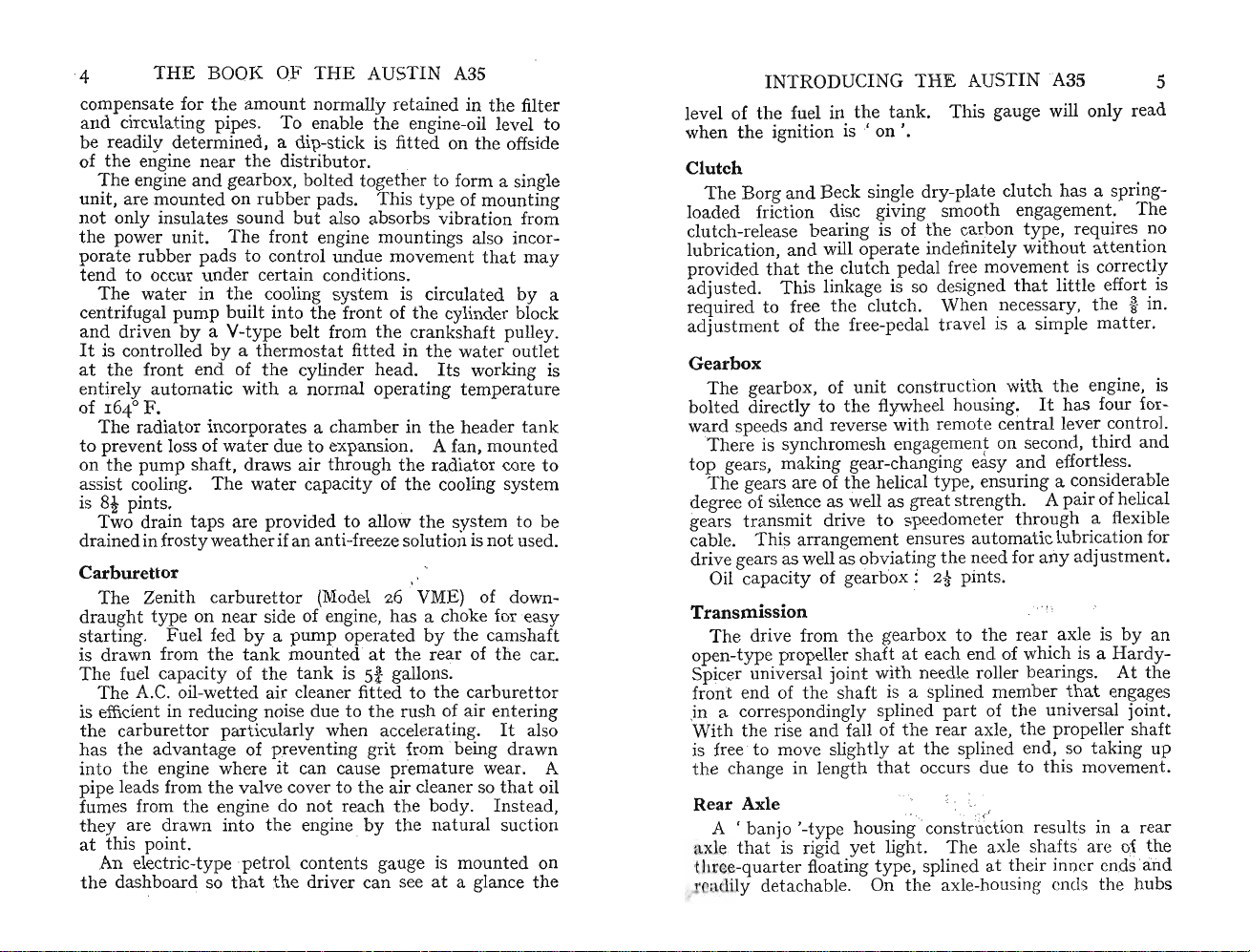

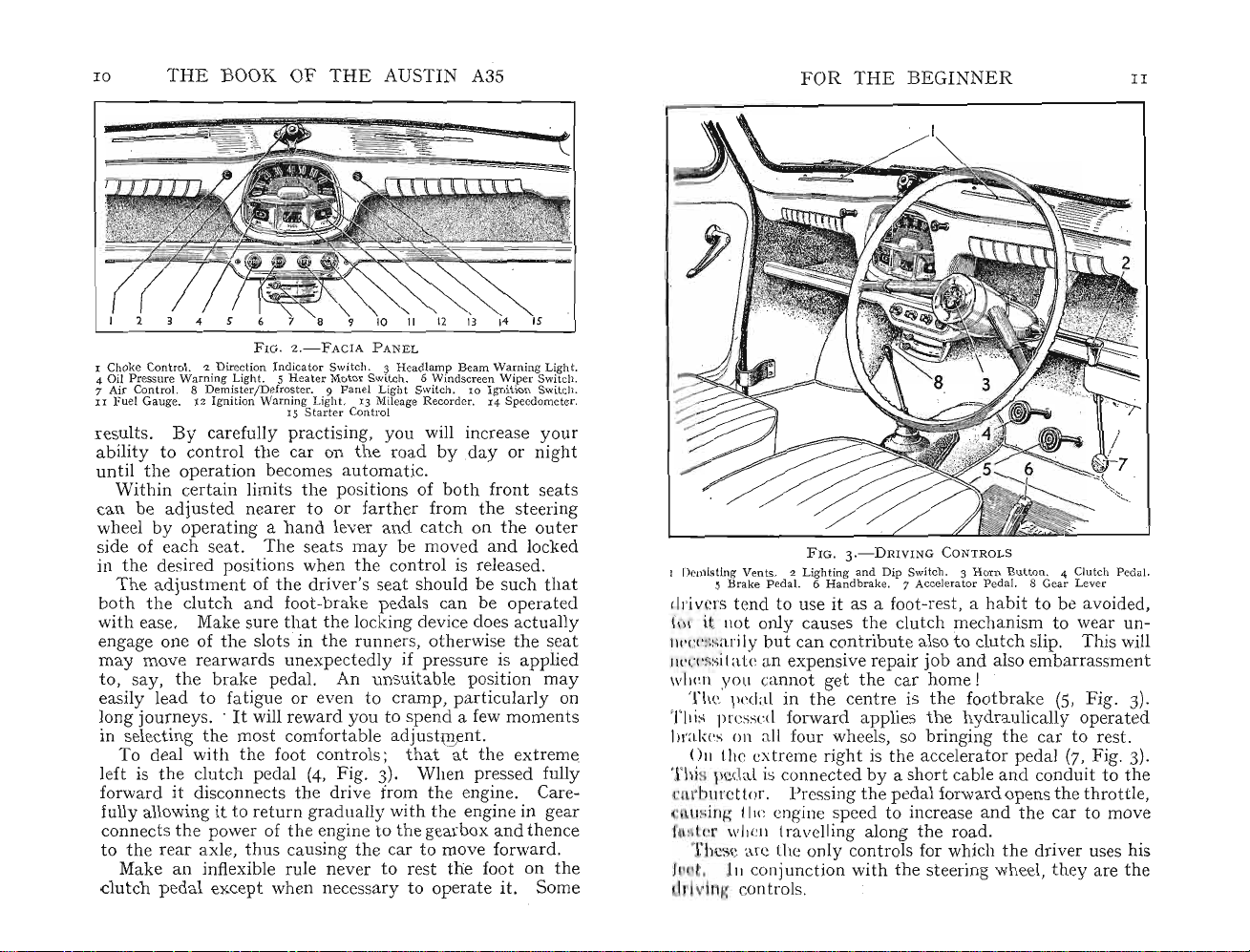

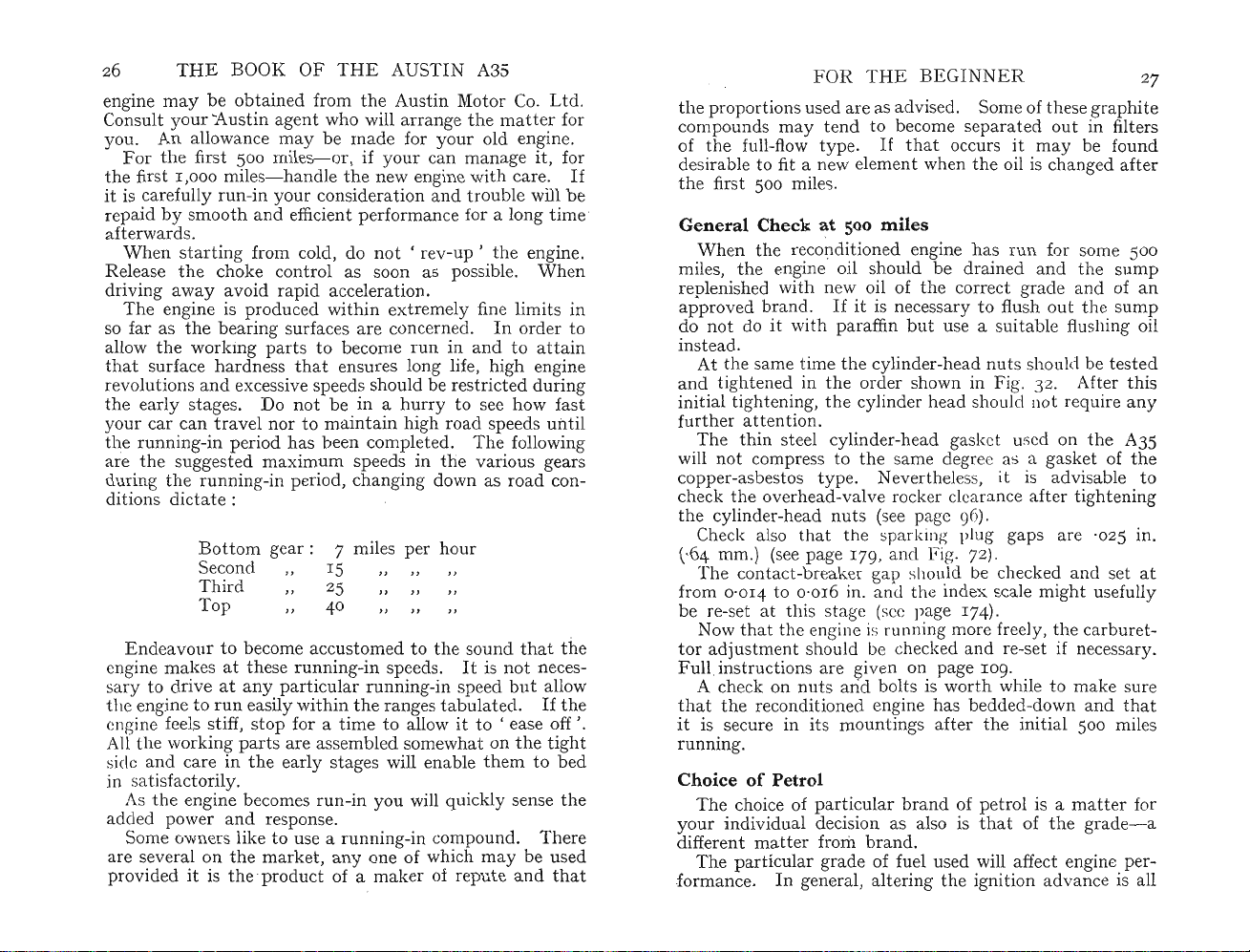

I Choke C

4 Oil Pr essure

7 Air C

II

re

abilit

untilth

can be

wheel

ontr

ol. 2 Dir ecti on Indicator Switch . 3 Headlamp Beam Warning Light .

War

ont

rol. 8 Demister/Defrost cr, 9

Fuel

Gaug

e. 12 Ignition Warn ing Ligh t. 13 Mileage Recorder. 14 Speedometer.

sults

. By carefully p

y to controlthe car on the roadby

e oper

Within

certain limitsthe positions of b

adjust

byopera

side of each seat.

F I G.2.-F

ning Li

ght.

ation

becomes aut omatic.

ed nearer to or f

ting a hand lever an d c

Th

in the desired positions when

The adjustment of

th th

bo

with ease . Make s

nga

e

maymove rearw

to, say, the b

easily leadto f

long j

e clutch and fo

urethatth

ge one ofthe slots inthe ru nners,otherwisethe s

ards

rake

pedal. An un

ati

ourn

eys. .Itwill rew

gue or even to

in selecting the most comfo

with

To deal

left is the clutch

the foot co

peda

forward it disconnects

ully

allowing it to ret

f

ctsthe power ofthe engine tothe gearbox andthence

conne

to

th

Make

clu

tchpeda

e rearax

le, thus causingthe car to move for

an

inflexible rule never to rest

l exc

ept

when necessar y to op

ACIA

PAN

EL

5 Heater Motor Switch. 6 Win dscreen Wiper Switch.

Pan

el Light Switch.10Ignition Switch.

15 Starter Control

ract

ising , you will increase yo

oth

arth

er from the s

atc

h on the

e seatsmay be moved and locked

the

drive

ot-b

thecontro

r's

seat s

rake

pedals can be operated

l is released.

hou

ld be such that

e lockin g device does actually

unexpect edly ifpres

suit

sur

able position

cramp,par

ard

you to spend a few moments

rta

ble adjus

ntro

ls;that

l (4, Fig. 3).

th

e dri ve fromthe engine. Care-

urn

grad

ually withth

tme

atthe ext reme

Wh

en pressed fully

e engine in gear

the

era

day

or ni

front

teer

e is applied

ticula

rly

nt .

ward

foot on

te it.

ur

ght

seats

ing

out

er

eat

may

on

.

the

Some

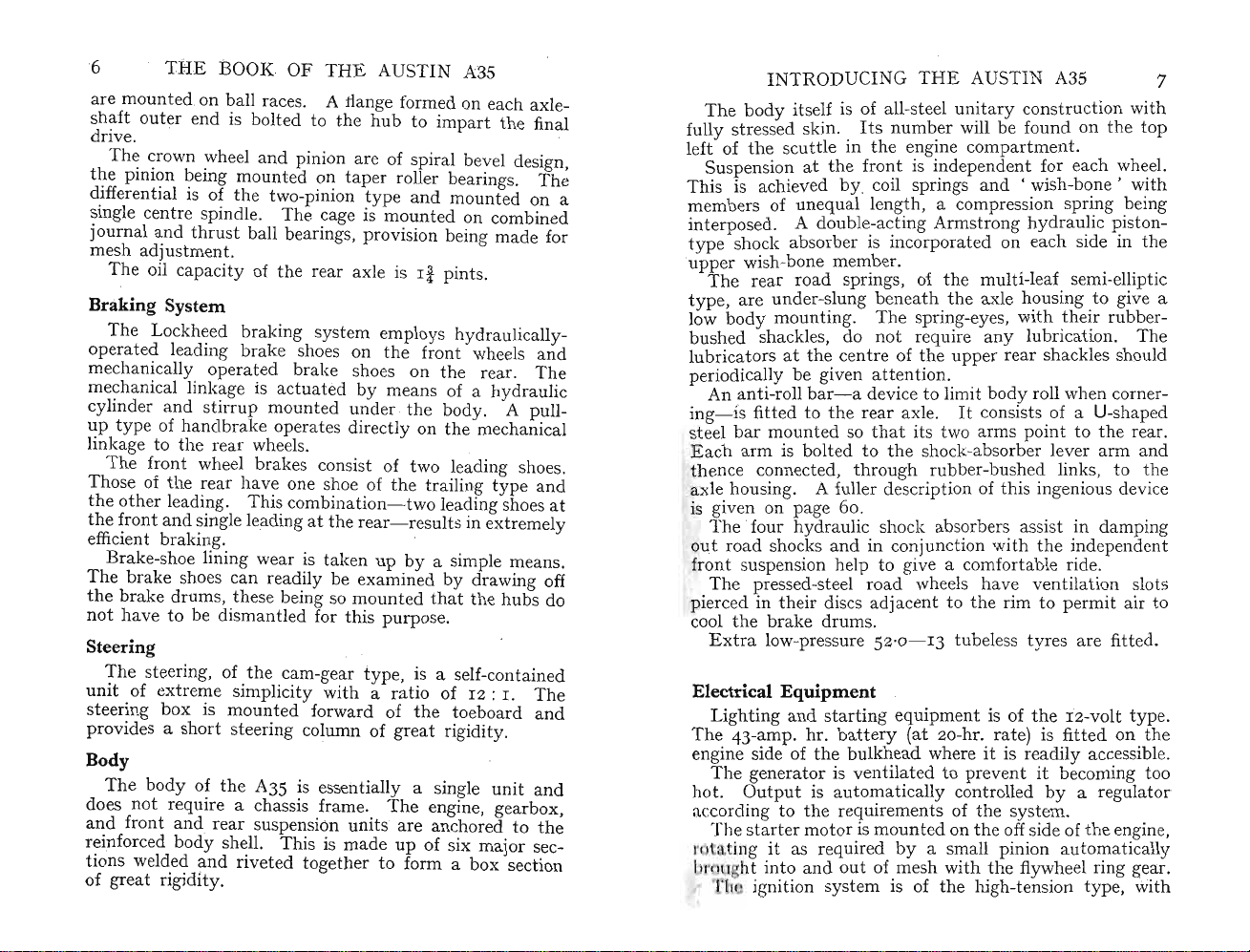

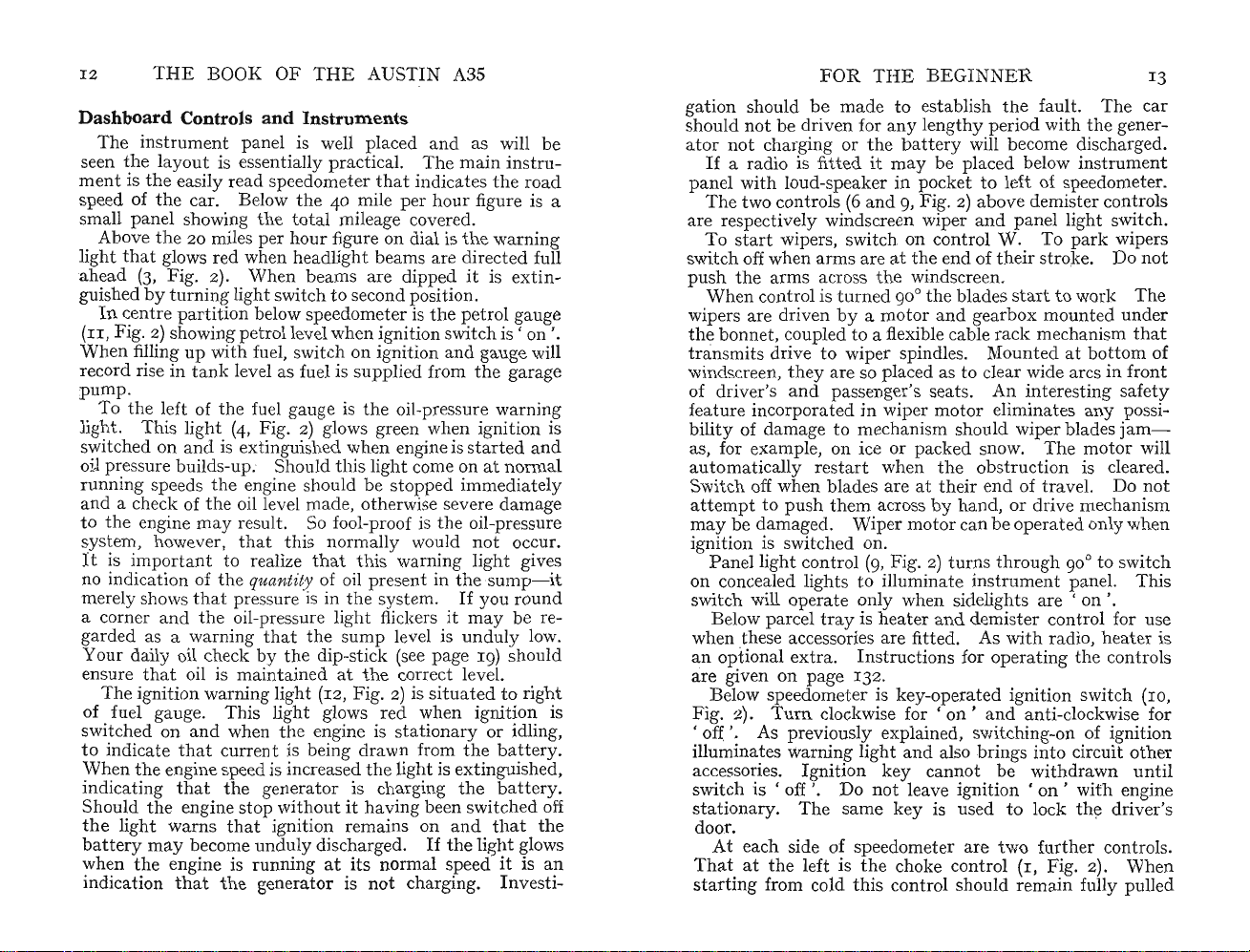

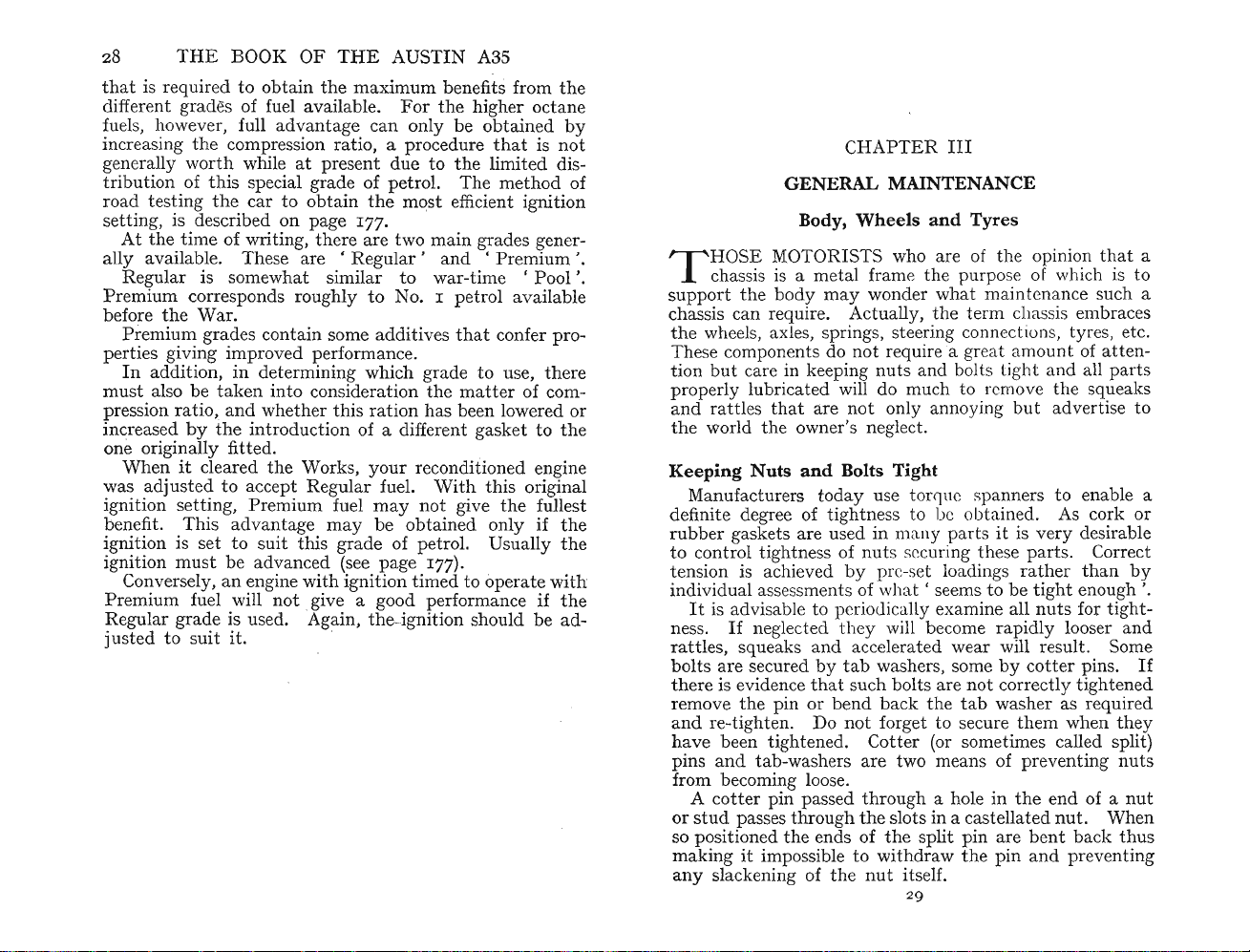

I emistlng Vents. 2 Lighting and Dip Switch. 3 Horn Bu tton. 4 Clutc h Pedal.

5 Brake P eda l. 6 H andbrake. 7 Accelerat or Pedal. 8 Gear Lever

d iv rs t end to use it as a foot-re st , a

r I' it not only causes

11

' assnriIy but can contribute also to cl

)\ l ' essitat an expensive rep

witin yo I annot get

'l'his I ross

The

I cdul in

FIG.3.-DRIVINGC ON TROLS

habit

to be avoided,

theclut

th

th

d.

e centre isthe fo

forward appliesthe hydr aulically o

ch mech

air

job

and

e car home!

ani

sm to wear

utc

h slip. This will

also

embarr

otbr

ake (5, Fig. 3).

un-

assm

perated

ent

I ruk 'S on all four wheels, so bringingthe car to rest.

n th extreme ri

Tid ' I dal is connected by a short cable

I'111'

tt

lIsing 1lie engine speed to increase

or.

l when travelling along

Tit's ar the only controls for which

.t. j

11

onjunct ion w

ghtisth

Pr

essingthe pedal fo

ith

the steering wheel, t

e accelerato r pedal (7, Fig. 3).

andconduittoth

rward

opens

the

thedri

thethrottl

car to move

ver

uses his

hey

are

the

the

road

and

.

n ntr ols.

e

e,

Page 11

12

THE

BOOK OF T

HE

AUSTIN A35

Dashboard Controls and Instruments

Th

e in

strum

ent

panel is well placed and as

th

e la

yout

seen

mentisth

speed of

the

small panel showing

Above

light

th

thatglows red when headli

ahead (3, Fig.

guished by

In

centre p

(II

, Fig. 2) showing

Wh

en filling up with fuel, switch on ignition and gauge will

is essentiallypractical. The

e easily read speedometerthat indi

car. Belowthe 40 mile per hour figure is a

th

e t

otal

mileage covered.

e 20 miles per h

2). When beams are dipped it is

turnin

g li

artition

pet

ourfigur

ght

switch to second position.

e on dial is the warning

ght

beams are directed full

below speedometer isthe petrol gauge

rol levelwhen ignition switch

record rise in tank level as fuel is supplied from

pump

.

th

e left of th e fuel gauge isthe oil-pressure warning

To

ght

light. This li

hed

switc

on and is extinguished when engineis

oil pressure builds-up. Should

running speeds

and a check of the oil level made,

to the engine

(4, Fig. 2) glows green when ignition is

thi

s li

ght

th

e engine should be stopped immediately

may

result. So fool-proof is the oil-pressure

come on at normal

oth

erwise severe damage

will

maininstru-

catesthe

ext

is'

th

e garage

sta

rted and

road

in-

on '.

system, however, that this normally would not occur.

It

is imp

no indic

ati

merely shows th

ortant

to realize

that

this warning li

on ofthe quantity of oil pres

at

pressure is inthe system.

ent

in the sump- it

If

you r

ght

gives

ound

a corner and the oil-pressure lightflickers it may be regarded as a warning

Your daily oil check by

ensure

thatoil is maintained at

Th

e ignition warning li

of fuel gauge. This li

switched on

to indicate

When

indicating

Should

the

light warns

ba

tterymay

when

indication

and

thatcurrent is being drawn from

th

e engine speed is increased the light is extinguished,

that

the

engine st op wi

become

the

engine is runningatits normal speed it is an

that

thatthe sump level is unduly low.

th

e dip-stick (see page 19) shou ld

ght

ght

the

correct level.

(12,

Fi

g. 2) is situated to ri

glows red when ignition is

whenthe engine is stationary or idling,

the

batt

the

generator is charging the

that

thoutitha

ignition remains on

undu

ly discharged.

the

gene

rat

or is

ving been switched off

not

If

charging. Investi-

batt

and

that

th

e lightglows

ght

ery.

ery.

the

be

FOR

THE

BEGI

NNER

gation should be made to establish

not

should

ator

If

pan

el with loud-speaker in pocket to left of speedometer.

Th

be driven for any len

not charging or

the

batt

ery will become discharged.

a radio is fitted it may be placed below

e two controls (6

and

9, Fig. 2) above demi

thefault

gthy

period withthe gener-

are respectively windscreen wiper and panel li

To

start

wipers, switch on control W. To

arm

switch off when

pushthe arms across

Wh

en control is

s areatthe

the

turn

ed 90°the blades start to work

wipers are driven by a motor

th

e bonnet, coupled to a flexible cable r

tran

smits drive to wiper spindles. Mounted at

end oftheir stroke. Do

windscreen.

and

gearbox

ack

. The car

instrument

stercontro

ght

park

mount

ed under

mechanism

bottom

switch.

wipers

not

The

that

windscreen, they are so placed as to clear wide arcs in front

of driver's

passenger's seats. An

int

eresting saf

ety

and

feature incorporated in wiper motor eliminates any possi-

bility of damage to mechanism should wiper blades

as, for example, on ice or packed snow.

autom

atically rest

Switch off when blades are at

att

empt

to pushthem across by hand, or drive mechanism

art

when the obstruction is cleared.

th

eir end oftravel. Do

Themotor

jam-

will

not

may be damaged . Wiper motor can be operated only when

tch

ignition is swi

Pan

el light control (9, Fig. 2)

on concealed lights to illumin

switch

will

Below parcel

th

when

ese accessories are fitted. As

an optional extra.

are

given on page 132.

ed on.

turnsthrou

at

e in

gh 90° to switch

strum

ent

pan

el. This

operate only when sidelights are ' on '.

tra

y is h

eaterand

Inst

ructions for operating

demister control for use

with

radio, heater is

the

controls

Below speedometer is key-operated ignition switch (ro,

2).

Turn

Fig.

clockwise

for'

on'

and

anti-clockwise for

, off,'. As previously explained, switching-on of ignition

into

circuit

the

other

until

driver's

illuminates warning light and also brings

accessories. Ignition key cannot be withdrawn

switch is

tation

s

ary.

'off'.

Do

not

Th

e same key is used

leave ignition ' on ' with engine

to

lock

door.

ter

At each side of speedome

atatthe

Th

starting from cold

left is

the

this

choke control (I, Fig. 2). When

control should remain fully pulled

are two further controls.

13

ls

of

Page 12

THE BOOK

u~til

out

push

for w

It

engine fires,

1D knob so

armi

ng-up.

is good practice to pu sh control home as soon as

possible, otherwise

engine will dilute

a greater

In

rate

than

a corresponding position to choke control,

(15, Fig. 2) is starter-motor control.

until

ignition is switched on. Start

disengages without any action on driver's

OF

THE

AU

STI

N A3S

Dir

ectly engine is running,partly

thata medium-rich mixture is

theundul

th

e oil and

y rich mi

contribu

xtur

e drawn

te to cylinder wear

normal.

but

Thi

s will not operate

er motor engages and

part,

ava

ilable

on ri

otherth

int

ght

an

pulling of cont rol outwards.

Two impor

control should never be op

or when car is in gear.

make a heavy drain on ba

This

can

tant

points to bear in

era

ted when engine is running

Apa

rt from the factthat

ttery

, the car will lurch forw

mind

arethat

thi

s would

thi

ard

be dangerous should anyone be standing in front,

Should engine fail to start or suddenly stop do not again

opera te control

may

be caused tothe ring g

untilithas come to rest, otherwise

ear

on flywheel or to starter-

dam

age

motor pinion drive.

If

engine does not start at first few turns, do not keep

starter in action for a

battery

will be

Instead, find

finding chart on

Combined lighting and dip swit ch is mo

extending to

th

e ri

ny

considerable length of

run

down.

out

what is wrong by referring to fault -

pa

ge 2

18

.

ght

below steering column (2, Fig, 3).

unt

ed on an arm

tim

e or

Turning this clockwise to first notch switches on side and

tail li

ghts;to second, headli

the

thir

d, headli

thelightattop

headli

ghts

when

th

ey are dipp ed.

Thehom

and can be op

Flasher indic

ght

s to full ahead. Aspreviouslyexplained,

of speedom

areatfull-ah

button

(3, Fig. 3) is in centre of

erat

ed when ignition switch is off.

ator

control is

and above speedometer. Move

ing ri

ght

and anti-clockwise for left. A warning li

ght

s in dipped positi

eter

ead

face is illuminated when

position and is extinguished

ste

ering wheel

mount

ed at

it

clockwise to show turn-

centr

on;

a nd

e of panel

ght

incorporated with switch shows when flashers are in

use.

FOR

THE BEGI NN

ER

15

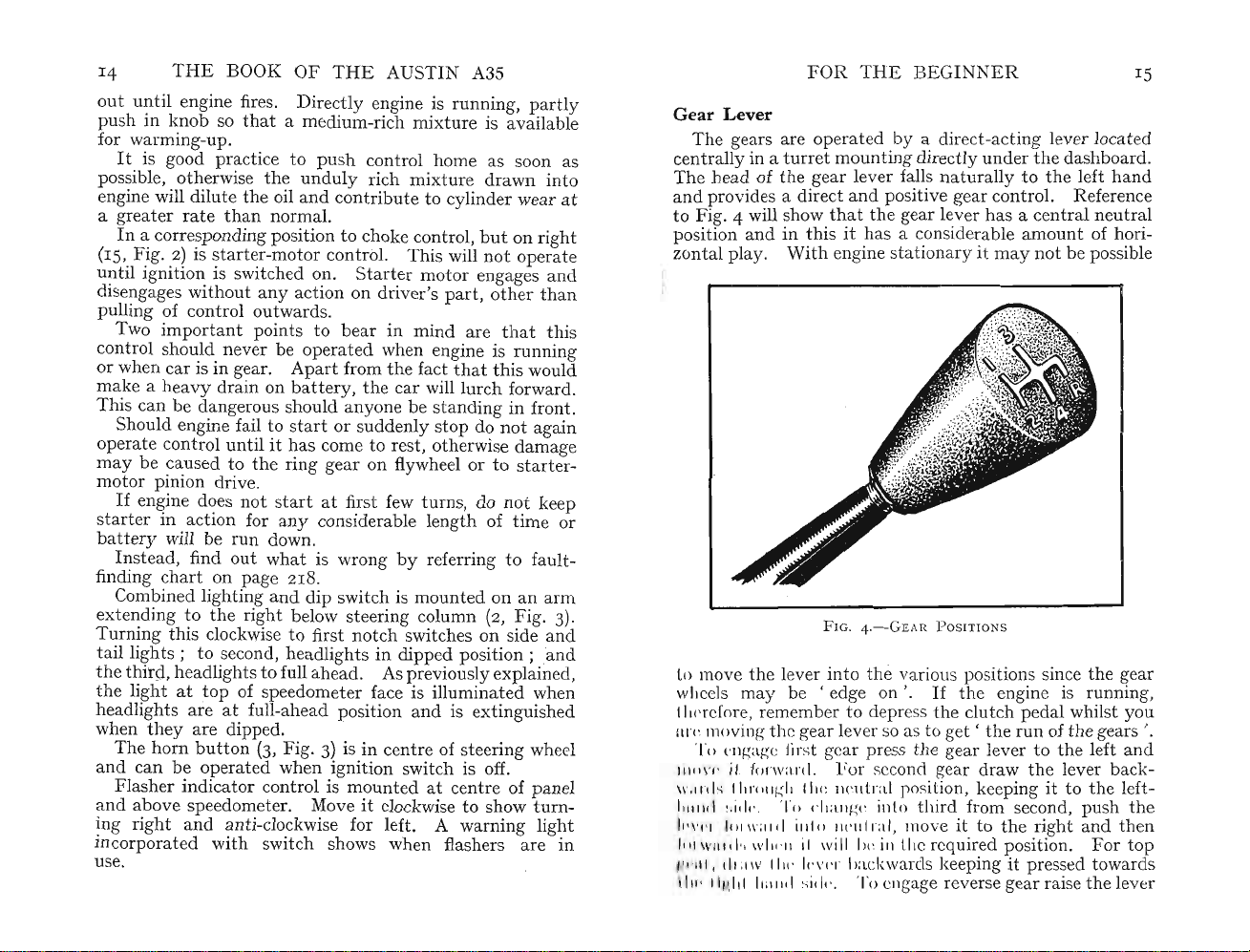

Gear Lever

The gears are operated by a direct-acting lever located

centrally in a

Th

o

at

e head of the gear lever falls n

andprovides a direct and positive gear control. Reference

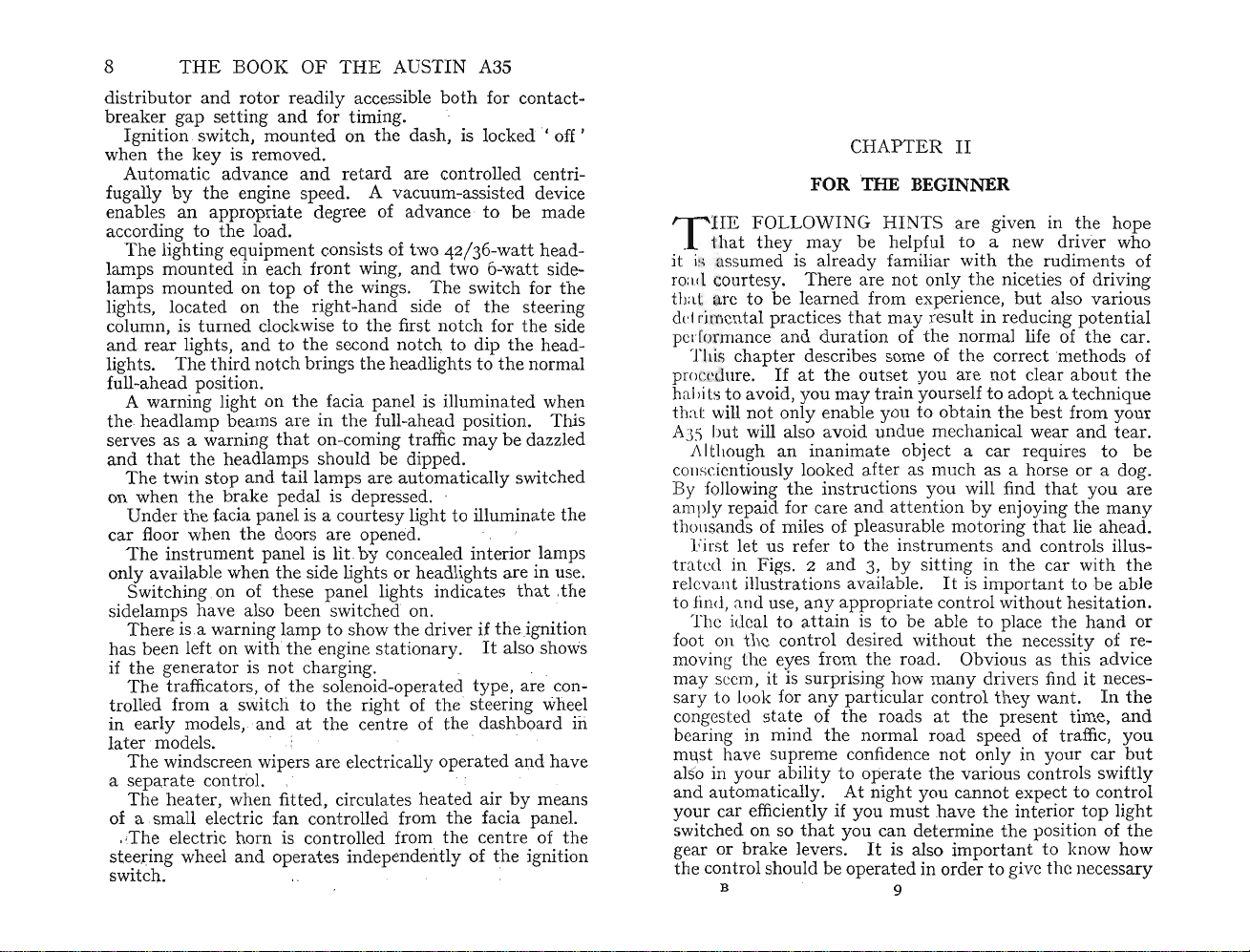

to Fig. 4 will show

position and in

zontal play.

turretmounti

that

ng directly under

the gear lever has a

thisithas a considerable

With

engine stationary it may

the

atur

ally tothe left h

centr

amount

not

dashboard.

and

al n

eutr

of hori-

be possible

al

s

.

FI

G. 4.

-G

EAR

POSITIO

NS

to move the lever

wheels may be

therefore. remember to depress

ur« moving the gear lever so as to get '

To

ellgage first gear press th e gear lever to

111" \' 1' il forward. For second gear draw

\1',11'1

1"

1111'011/-:

II

l1l1d

~.id(',

h'\,('1 1'

1

lllJ'l

IIII' IIMIII II:IIIII sid." To cngage reverse gear raise the lever

11

11

1\':11.1 iulo nt-ul r.rl, move it to

1Will .1'1 WIIl'II il will Iw ill the required position. For

l,

dllll

V II I., 1.,\,(,

11111

'1'" ('

int

o th e various positions since th e gear

'ed

ge on '.

If

th

e engine is

th

e clutch pedal whilst you

therunofth

th

e left and

th

e lever back-

(: ne

utr

al position, keepingitto the left-

lia

ng(: into third from second, push

th

e right

1'

backwards keeping it pressed towards

runn

ing,

e gears '.

the

and

then

top

Page 13

16

by pullingitupw

fully tothe ri

spn ng pressure

adjac

lever being pulled up and rearw

tothe rear wheels. A

position by.a

the

Sometimes, and particularly if the

with

r

ear

or by

clearing with the

to apply

brak

on.

gr

this m

in cases where

brake cannot readily be released,

brake p

the

THE

BOOK

ght

prev

The h

andbrake

ent

to his ri

tr.igger and a pawl.

pa

wl IS disengaged

some force,itis necess

wheel

brak

es either by pressing

wingthe h

th

e h

andbrak

Ther

dra

e are two

e pedalatth

The

leverage obtained on

eat

er t hanthat

eth

od ofapplication may befound helpful p

the

OF

THE

AUS

ard

s againstthe spring pressure, move

andthen rearw

ent

s its being engaged accide

lever is to

ght

hand.

ratch

andthe

ard

s. The resi

therightofth

lt

is of the pull-on type, the

ard

s to apply

et locksthe lever in

By

squeezing this trigger

handbr

br

ake has been applied

arytotakethe weight offthe

the

and

brak

tri

gger.

tip

s you may like to know.

e slightly h

e verysecurely, press downthe foot-

e same

tim

e pulling

the

developed by the

car is left on a g

thehand

foot-brake is

han

radient.

pr

edal;

thi

s will be found of assistance in releasing

pawl.

Th

e doors ofthe A35, either the two- or four-door

may be opened from either inside or

senger doors can be locked from

inside handles

upw

ards

beyond.

driver's door is locked from

key. When

raised, no doors

automatically

are raised. Remember to

to pre

vent

inside door

lt

is useful to make a

ignition key so

thus

locked,

can

the

sliding front door windows, whenthey

and

be opened. This position also locks

shut

anyone from insertinga stickto release one of

handlesand

so gain entrance to

noteofthe

that

you

may

ment without delay should

key can be obtained

The luggage

the

ignition

car

when necessary.

compartment

key

at

any

enabling you to leave your luggage in the

the

insidebyraisingthe

the

the

normal position.

outside

with

handles of other doors

all the windows suffici

be able to

the

need arise. A duplicate

time

through

boot

has

TIN

A3S

it

stan

ce by

nta

the

the

lly.

seat

brake

' on '

e driver's

ake is released.

foot-brake pedal

ard

er on and

If

then

you want

brake lever

rath

er

dbrak

e lever

If

arti

th

e hand-

and

cularlv

ess downthe foot-

mod

out

side.

Th

el,

e pas-

Th

withthe ign

ition

ently

the

the

car

.

code number of the

obtain

a replace-

your dealer .

a lock

that

accepts

capable

the

~un.

reta

17

the

in

FOR

THE

Th

ere are se

venient

roof above

and

helpful.

the

veralbod

y fittings

Forinstan

windscreen on

of being readily hin ged down,

lt

can

also be moved sideways within limits and ISspnng-

loaded to provide

it

in

the

desired position.

th

e necessary degree of friction to

BEGI

NNER

tha

t

will

ce, a visor fitted to

the

driver's side,

redu

ces glare from.

be found con-

and

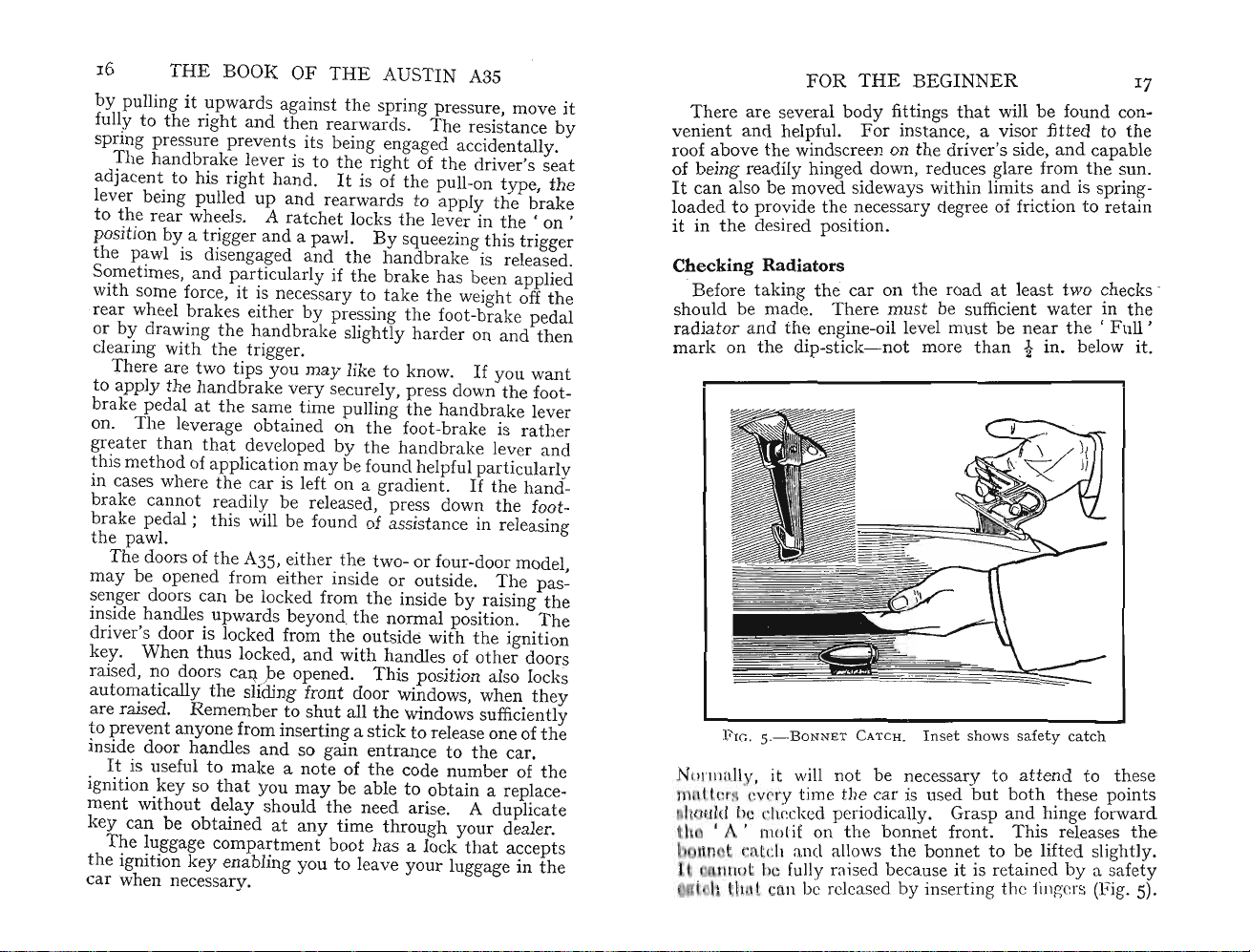

Checking Radiators

Before taking

should be made.

radi

ator

mark

and

on

the

the

car

on the r

Theremu

the

engine-oil levelmust be

dip-sti

ck-not

st be suffic

more

oadatleast two checks -

ient

wat

er in

the

n

e~r

the

'

than

t m, below It.

Fu~

,

e

Fro

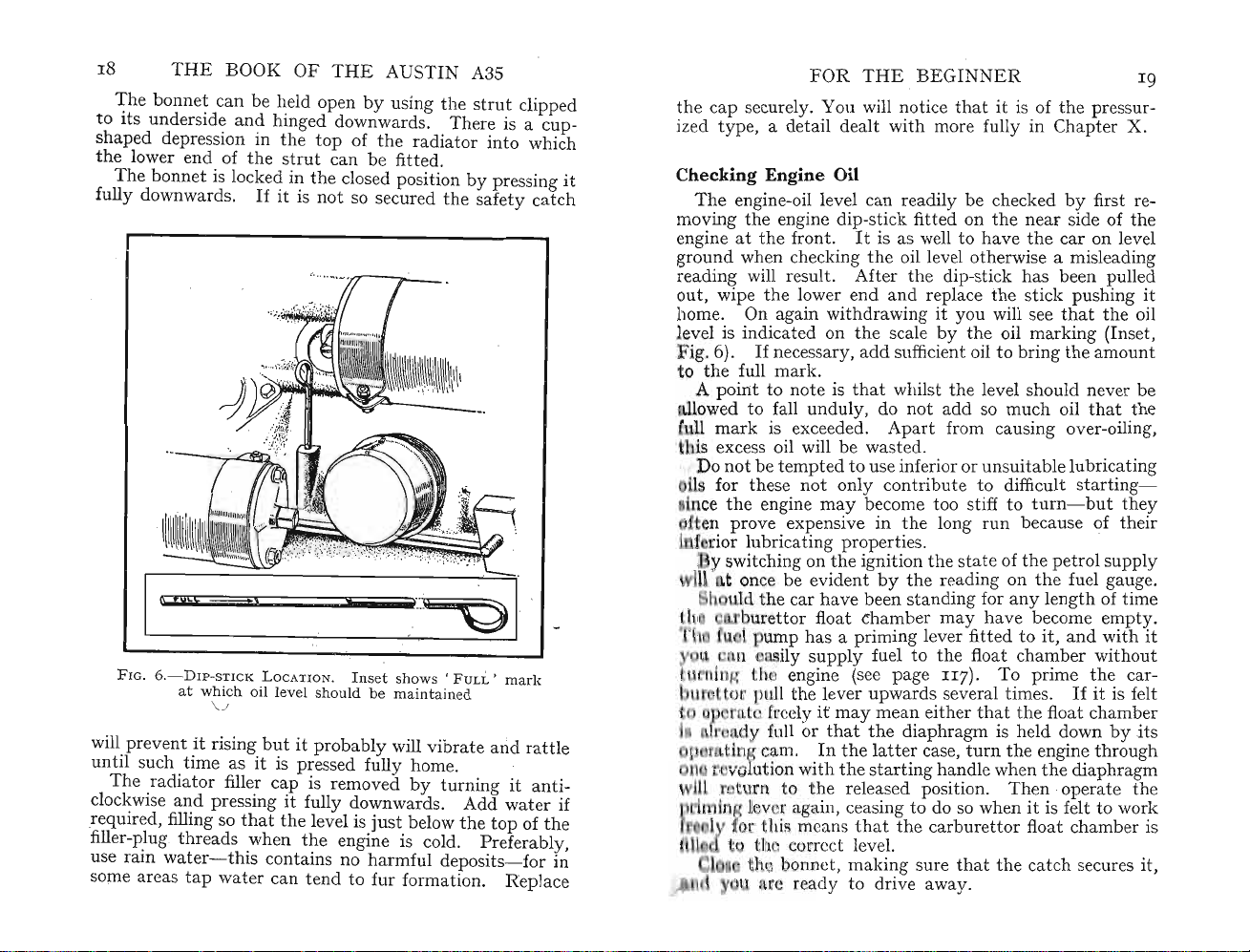

. 5.

-BoNNET

1'

111

11

. ' I' 'v ry t ime th e car is used

it will not be necessary to attend to

til l b h k d periodically. Grasp

mot

, .

if nthe bonnet front. This releases

CATCH. I n setsh

owssafetycatch

butboth

.these points

and

hinge forward

the

se

the

l It an 1 allowsthe bonnet to be lifted slightly.

I t b fully raised because it .is reta

in

ed by a

~afet

y

'h n b r leased by inserting the fing rs (FIg. 5)·

Page 14

18

to its

shapeddepr

th

e lower end ofthe strut can be fitted.

fully down

will prev

until such

The r

clockwise

required, filling so that

filler-plug

use rain

some areas

THE

BOOK

Thebonnet

under

can be held open by using

side

and

ession inthe

The

bonnet is locked in the closed position by pressing

ward

s.

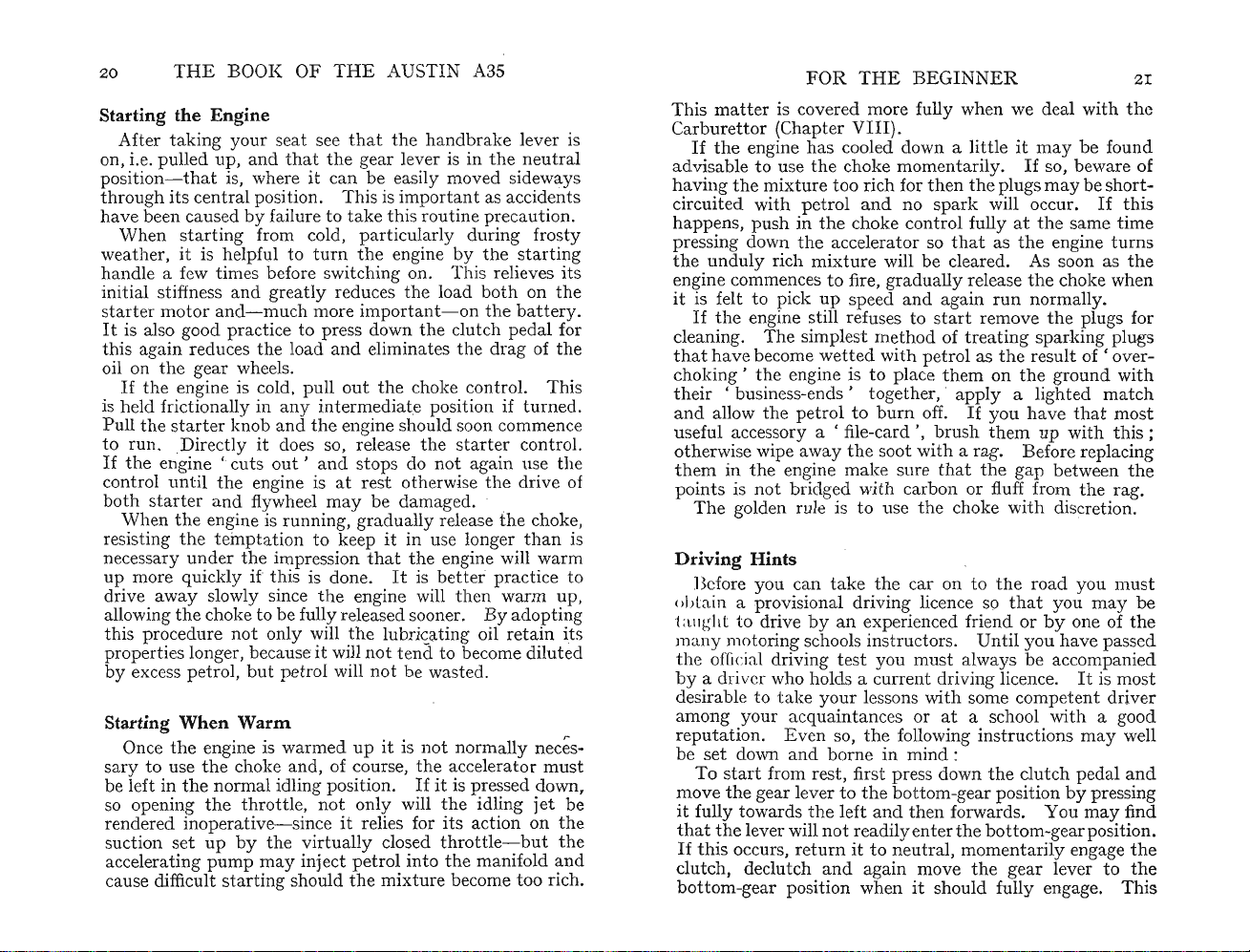

F IG.

6.-

D I P-STI CK L OCATI ON . Inset shows ' F U LL ' ma

atwhich oil level should be mainta

\J

ent

it rising

time

as it is pressed fully hom e.

adiator

water-

filler cap is removed

and

pressing it fully downwards. Add wat er if

thr

eads when

this contains no harmful deposits

tap

water

OF

THEAUSTIN

hinged downw

topoftheradiator

If

it is not so secured

but

it probably will vibrate

the

level is

the

just

engine is cold. Preferably,

can tend to fur formation. Replace

A35

the

stru

ard

s. There is a cup-

t clipped

into

the

safety catch

ined

and

by

turning it

belowthe

topofth

-for

which

rk

rat

tle

ant

in

FOR

THE

BEGIN

the cap securely. You will notice

ized type, a detail de

Chec

it

kingEngine

The

moving

engine-oil level can readily be checked by first re-

th

engineatth

e engine dip-stick fitted onthe near SIde of

e front.

ground when checking

reading will result. Aft er

out , wipethe lower end

alt

with

Oil

It

is as well to havethe

th

e oil level otherwise a misleading

th

and

home. On again withdrawing

vel is indicated onthe scale by

ig.6).

o

A po

owed to fall u

11

is excess oil will be

Do

If

necessary, add suffici

the

full mark.

inttonot

e is

nduly

that

whilstthe level should never be

, do

not

mark is exceeded. Apartfrom causing over-oiling,

wast

not

be t

empt

ed to use inferior or un

notonly

may

ce

for

the

th

ese

engine

n prove expensive in

ed.

contribute to diffic

become too stiff to

the

NER

thatit is of the pressur-

more fully in Chapter X.

the

car

on level

e dip-stick ha.s been I?ull

replacethe stick pushing l.t

it

you will see

the

ent

oil marking (

oil to bringthe

addsomuch

suitabl

long

run

that

the

Ins

amount

oil

that

the

elubricating

ult

star

ting-

turn-bu

t they

because of their

e.d

011

et,

ior lubricating properties.

switching on

once be evident

uld

th

ure

ump has a priming lever fitt ed to

n ily supply fuel to

ng h engine (see page

t 1ull the lever upwards several

t Ir ly

y full or

opl:)rn.tingcam.

u

i-

t

e

1l'II11

i n with

urn to

lng1 v r again, ceasing to do so when

r

thi:

th

e ignitionthe state ofthe petrol supply

by

the

reading onthe fuel gauge .

e car have been standing for any length of time

tt

or floatchamber may have become

it,

the

float chamber without

II

7). To primethe cartim

es.

and

If

empt

with

it

is fe

itmay mean eitherthatthe floatchamb er

that

thediaphra

Inthe

latt

th

th

e released position.

ma

ns thatthecarbur

er case,

e starting

gm is held down byits

turnthe engine

handl

e whenthe dia

Th

en operatethe

it

ettor

is felt to work

floatchamber is

throu

phra

gh

gm

y.

it

lt

th rre t level.

th bonnet , making sure that

th

e catch secures it,

ready to drive away .

Page 15

20

BOOK OF

THE

AUSTI N A3S

THE

Starting the Engine

After

tak

on, i.e. pulled up,

on-thatis,

positi

thr

ough its ce

hav

e been caused by failure to take this routme precaution,

When s

we

ath

han

ta

er, it is helpful to

dle a few times before switching on. This relieves its

andthatthe gear lever is in

whe.r~

ntral

it can ?e.

position. Thi s

rting from cold, particularly during fros

turnthe engine by the starting

initial stiffness and greatly reduces

ta

ing your seat see thatth

rter motor and- much

s

It

is also good practice to press downthe clutch pedal for

this again reduces

mor

e important- onthe ba

th

e load and eliminates the drag of

e handbrake lever is

the

e.asil

y moved

IS

I~port

the

load both onthe

sid~ways

~ntasaccId~

neutral

nts

tte

ry.

the

oil on the gear wheels. .

If

th

is held frictionally in any i

Pull

to run.

If

control

bothsta

resisting the temptation to .keep It m use l?nger. t

necessary under

up more quickly if this is done. It is b

drive away slowly since

allowingthe choke to befully released

e engine is cold. pull outthe choke control. This

nt

th

e starter knob

Dir

the engine

until

andthe engine should soon commence

ectly it does so, release the starter control.

'cu

ts out ' and stops do not again usethe

the engine is at rest otherwisethe drive of

ermediate position ifturned.

rter and flywheel may be damaged. .

When

th

e engine is

run

ning,

th

e impression t

th

g

ra~u~lly

hat

releasethe

the

engme will warm

ett

er practice to

e engine will then w

s?o

n~r.~yadoptI~g

chok~,

han

arm

"?-p,

this procedure not only willthe lubricatingOJI reta.m ItS

properties longer, because it will not tend to become dil

by excess petrol, but p

etr

ol will

not

be wasted.

ut

Starting When Warm

Once

the

engine is warmed up it is

ary

to usethe choke

s

and

, of course,the accelerator

be left inthe normal idling position.

the

so opening

throttle,

not

only will

not

normally neces-

If

it ispressed down,

the

idling

must

jet

rendered inoperative- since it relies for its action on the

suction set

accelerating

cause difficult

up

pump

star

bythe

may

ting should

virtu

inject

ally closed

petro~

into

the

mixtur

throttle-but

the

manifold ?-nd

e become too

th

nch.

ty

ed

be

IS

FOR

THE

BEGINNER

This

matter

Carburettor (Chapter

If

the

advisable t o use

having

circuited with petrol

happ

ens, push in

pr

essing down

theunduly

engine commences to fire, gradually

it is felt to pick

If

the

cleaning. The simplest me

thathave

choking ' the engine is to place them on

th

eir'business

and

allow the petrol to

useful accessory a

oth

erwise wipe away the soot with a rag. Before replacmg

th

em in the engine

points is not bridged with carbon or flu

Th

e golden rule is to use

is covered more fully when we deal with

VIII).

engine has cooled down a little it may be found

th

themixtur

the

rich mi

e choke momentarily.

e too rich for thenthel?lugsmay be

and

no sp

the

choke control fullyatthe

ark

accelerator so that asthe engme

xtur

e will be cleared. As soon as

up

speed and agam

will occur.

:ele

ase

run

If

so, beware of

s~me

the

choke when

normally.

engine still refuses to start ren::ovethe plugs for

th

become w

-ends'

ett

ed with petrol as

together, apply a li

od oftre

burn

'fi

make

le-car

off.

d',

surethat

the

atmg

spa

rkmg plugs

result of ' over-

th~

ground with

ght

ed m

have

that

up w

gap between

ff.

fron::the.rag.

brush

If

the

you

them

the

choke WIth discretion,

shor~

If

time

turns

atch

most

ith

th!s ;

2I

the

~hIS

the

the

Driving Hints

Before you can take

o

bta

in a provisional driving licence so

ta

ught to drivebyan experienced friend orbyone of

many

motoring schools in

theoffi

by

cial driving test you must always be accompamed

a driver who holds a current driving licence.

desirable to take

among

repu

be

move

it

e

that

If

your

tati

set

To st

the

fully towards

the

this

acquaintances or

on. Eve n so,the following instructions

down and borne in mind :

art

from rest, first press down

gear lever to

the

lever will

occurs,

return

clutch, declutch

the

car on to

the

road you

that

stru

ctors. U

your

lessons with some co

the

bottom-gear positionbypressing

at

ntil

you have

a school

the

clutch pedal

mpet

left andthen forwards. You

not

readily enter

the

bottom

it to neutral , momentarily engage

and

again move

the

gear lever to

you

may

be

the

must

pa

s~ed

It

is most

ent driver

with

a good

may

well

and

may

find

-gear position.

the

the

bottom-gear position when it should fully engage. This

Page 16

THE

22

BOOK OF

difficulty sometimes arises duetothe

eth

are

gear te

mesh. Allowing

alt

ers

their

'edge

the

rel

ati

ve positions

THE

AUSTIN A3S

fact

that

the

sliding

on'

to each

other

and

thus

cannot

clutch pedal to engage momentarily

and

so permits

them

engage.

Now release

thehandbr

wards slightly to ease

free

the

rat

chet

and

If

it is difficult to release

th

e foot-brake pedal to relievethe tension on

on

brak

e linkage. .

Pr

ess downthe accelerator slightly atthe same time

th

allowing

e clut ch pedal to come gently up

move forward as

not

e isthatthe simultaneous actuation-one up

-ofthe clutch and acceler

down

and

possibly uneven clutch engagement may ensue. Per-

push

the

severe, however, for it is only

mind

Bear in

clutch engagement

harmful for

thatthe hall-mark of a good driver is smooth

andthat

it

causes severe mechanical stress.

ake lever, first pullingitup-

the

pressure, squeeze

the

lever forwards

the

holding

the

and

rat

downwards .

chet,press firmly

and

clutch engages. The first

ator

pedals is

masteredby

harsh clut ch engagement is

trigger to

the

hand-

the

car will

point

and

one

not

easy

experience.

Gear Changing

When

th

e car is moving forward steadily it will be neces-

th

ght

e main bug-

th

e accelerator

tim

e pushing '

without

resistance

Whenthe

the

gears will

may

sary to change into second gear. One of

bears of

eliminated by

th

e novice-gear changing- is almost entirely

th

e synchromesh device.

To change from first to second gear, allow

return

to

down the clutch pedal as far as

unduehast

a ste

be felt

synchromesh device has come

to its closed position atthe same

it

ady

pre

but

e, move

ssure on

maintain

the

gear lever rearwards maintaining '

the

lever. A sli

the

pressure onthe knob.

into

will go. Then,

action

mesh and second gear will be engaged noiselessly. Allow

the

clutch pedaltoreturn

the

down

accelerator when

gently. At

the

car

will move forward

the

same time press

with

increased speed.

third

To change from second to

accelerator and depressthe clutch pedal. Move

lever deliberately forward into

similarly release

the

neutral position main-

the

gear

to

to

the

FOR

THE

taining a pressure to

forward into

and

control the speed ofthe car by

The

acceler

th

e gear lever rearwards

pr

essure on

a

Practi

third

final change

at

or pedal, depressingthe clutch pedal,

se gear changing in

the

speed. Allowthe clutch pedal to return

intotop

into

the

lever towardsthe right-hand side.

BEGIN NER

right throughthe

the

gate

accelerator pedal.

gear is effected by releasing the

and

top-gear position, maintaining

thismanneruntil

the

car moves

23

andthen

moving

forward smoothly and steadily after each gear change.

Carefully synchronize pedal movement to ensure smooth

ta

engagement in all circums

To Change

It

is equally necessary to learn how to change down

Down

to a Lower Gear

from a higher to a lower gear. This is essen

climbing a hill that normallythe car could

top

gear or whichever other gear may be in useatthe

tim

e. Also,

more slowly

In

changing down from top to third gear and from

to second adop t

pressure on

th

push

tra

ffic conditions may necess

th

an normally is permitted by top or

th

th

e gear lever

e following procedure. Maintainthe

e accelera

stea

nces.

tia

l

ascend

third

wh

gear.

not

ita

te travelling

thi

tor

and de-clutch. Simu

lta

neously,

dily into the desired position. The

synchromesh device again comes into action to give a silent

change. Release

th

e clutch pedal, controllingthe speed of

the car by using the accelerator pedal as necessary.

ent

A slightly differ

changing down from second to bo

is no synchromesh device. An easy change can be

however, by adopting

de-clutching '. Although this procedure

be complicated it is simple and you should

procedure should be adopted when

tt

om as in

thi

s casethere

mad

th

e technique known as ' double

may

appear to

pra

ctise until

you are proficient.

Pr

oceed as follow

(a) De-clutch. Move

th

e pressure on

(b)

Allow clutch to engage, with gear lever in neutral,

and

(c) Release

accel

move gear lever

s:

th

e gear lever

the

accelerat or.

eratethe

pre

ssure on accelerator pedal, de-clutch and

engine.

int

o first-gear positionatonce.

int

o n

eutr

al, releasing

~n

III

rd

e,

Page 17

THE

BOOK

(d)

Engage clutch, operate accelerator tomaintain

~

~.

Practisethis drill

cer

tai

n an d

pa

rticularly when ascending hills on which b

couldhave been used.

Tostop

cel

erator

Justbefore

dut

ch.

gear

intoneutral

rapi

the

car, firstof all take your foot offthe ac-

and

moveitover tothe fo

the

Wh

en s

OF

THE

AUSTIN A3S

desired

until

you can be sure of

d gear change in any circumstances,

ot-

brake t o

vehicle comes to a standstill depressthe

topp

ed applythehan

andthen release

the

clutch and fo

dbra

ott

ke,

makin

g a

om gear

the

left.

movethe

otb

rake,

Reversing

When

stationary.

is moving forwards will cause severe strain or

the

With'the

'd utch

will rise no further.

theright

intothe reverse position.

it forw

r

eturn

andagain

and gen

Almost

the steering is now reversed.

steering wheel tothe ri

temporarily the r

become familiar

l

earn

:practise re versing betweenthem- for instance, asifback -

In

novi so

pia.

mudguard and

carthat is ah ad of you. A li

show you how much room

engaging reverse gear the car

Any

attempt

transmi

It

into a line of parked vehicles. Nothing indicates

ssion

syst

car

station

and

lift

the

maintainingthe lift. Ne

ards

momentarily allowing the clutch p

as when engaging firstgear. De-clutch once more

movethe leverback

tly

acceleratewhenthe car will move backwards.

the

firstthing you will realize, of course, is

ear-t

withthese cha

how to

is a helpful idea to erect two guide marks

bac

k your carne

much

as inabi

not forget to allow for

bump

to go

int

em.

ary

and

the

gear lever

Th

ght

o move tothe left .

er w

upw

en move it

If

it

does not engage fully, move

wards.Engageth

Thatis to say,turningthe

causesthe front of

nged

atlyintoth

lity

to back his

hen

pulling

ttl

e practice

you

may

o reverse whenthe car

conditions,however,

mu

st always be

dama

engine

ardsuntilyou

through

xt,

the

runn

the

pullitrearwards

You

e desired

swing of

out

car

from

posit

and

neatly

will

allow.

the

v

ge to

ing, de-

feel it

gate

edal

e clutch

that

car-

will

soon

and

ion.

then

into

the

front

behind

ery

soon

the

to

to

to

.

a

FOR

THE

BEGINNER

Skidding

The

brak

efficient

except, of course, in emergency.

tyre

life as well as straining

Ev

•

never

of some

whenthe

unpleasant feeling

control.

first !

immediately releasethe

them

this factor is

What

sideways towards

roa

d. Often

the

steering wheel in

the skid develops.

direction you

Do

may

control inanisol

bus

drivers

to t eachthem

Tr

y to bearin

(I)

(2) Do

(3) Do not

(4) Do

es on

butitis

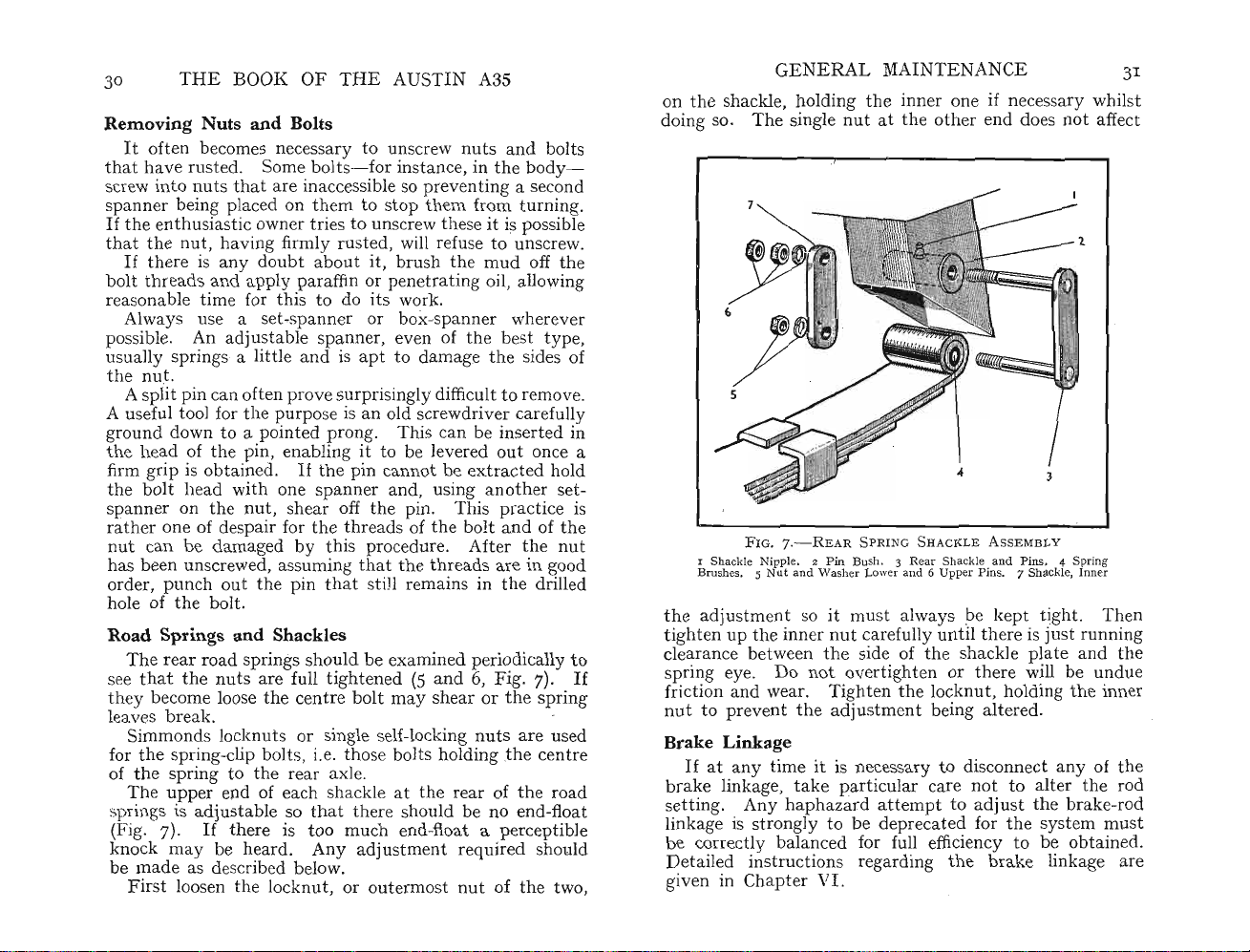

ery