Aussie Scud 350, Scud 351, Scud 400, Ultra, Predator Plus Operation & Maintenance Manual

Aussie Pumps

Scud & Ultra Series High Pressure Blasters

OPERATION & MAINTENANCE MANUAL

Feb 2012

Covers:

Scud 350

Scud 351

Scud 400

Ultra

Predator Plus

IMPORTANT:

TO REDUCE RISK OF INJURY, READ

OPERATING INSTRUCTIONS CAREFULLY

BEFORE USING EQUIPMENT

Aussie Scud & Ultra … Operation & Maintenance Manual

2

Aussie Pumps

Feb 2012

Before attempting to operate your machine please read this Instruction Manual thoroughly following all

directions carefully. By doing so you will ensure safe operation of the unit and will enjoy long and trouble free

service from your heavy duty water blaster.

GUARANTEE … EXCLUSIVE 3 YEAR PUMP + 3 YEAR ENGINE WARRANTY

This Aussie Eco Clean product is guaranteed against faults in manufactur e for two years from purchase. The Bertolini pump

has a three year warranty, but must be serviced by an authorised service agent every six months to maintain this warranty.

Keep your receipt as proof of purchase and all service receipts. This guarantee is invalid if the product is found to h ave been

abused in any way, or not used for the purpose for which it was intended.

Routine maintenance is the owner=s responsibility. Failure to maintain the machine in lin e with the services outlined on the

back page will invalidate warranty. High pressure accessories carry a 3 month warranty.

Where possible return faulty goods to the place of purchase. No products can be returned to us without our prior permission.

The reason for return must be clearly state.

N.B. Warranty is not transferrable to third parties in the event of sale of the machine within the w arranty period.

Please note that any parts used in warranty repairs are guaranteed for a period limited by the original

warranty of the parent product.

Engine warranty is the responsibility of the engine manufacturer. Unit must be returned to authorised engine dealer

for evaluation of engine warranty. (Refer to engine handbook).

Battery warranty is covered by Federal/Ryde Batteries, call (02) 9879 5422 for your near est outlet.

Our goods come with guarantees that cannot be excluded under the Australian Consumer Law. You are entitled to a

replacement or refund for a major failure and for compensation for any other reasonabl y foreseeable loss or damage. You

are also entitled to have the goods repaired or replaced if the goods fail to be of accept able quality and the failure does not

amount to a major failure.

The benefits under the Aussie Pump warranty are in addition to other rights under Australian Consumer Law.

SAFETY PRECAUTIONS - IMPORTANT

1. NEVER direct the spray jet at any person or animal. Keep hands and feet clear of the cleaning

nozzle at all times.

2. NEVER direct spray jet at any surface that may contain asbestos material.

3. NEVER hold a finger over the high pressure nozzle.

4. NEVER direct the spray jet at the machine itself or any electrical equipment.

5. After use release the pressure in the high pressure hose by operating the gun trigger.

6. DO NOT attempt any mechanical repair. If you have a problem with your machine contact your local Aussie

Eco Clean Service Division, phone (02) 8865 3500.

7. NEVER supply any liquid other than water to the pump inlet.

8. DO NOT run dry

9. NEVER pull the high pressure hose if it has formed kinks or nooses.

10. NEVER pull the hose over sharp objects.

11. DO NOT attempt to disconnect any hose or coupling with pressure still in the hose.

12. DO NOT operate the machine whilst standing on ladders, use a pla tform tower or scaffolding.

13. Operate in well ventilated areas only.

14. DO NOT fill the fuel tank while engine is running

15. DO NOT try to repair a leak in the hose or connection while the system is unde r pressure.

16. DO NOT substitute any component part on this machine. Use of incorrect parts could cause

serious personal injury.

17. Children should NOT be allowed to use the machine.

18. We recommend the use of safety goggles and steel cap boots when using the machine.

AUSSIE ECO CLEAN SCUD & ULTRA SERIES OPERATING AND MAINTENANCE INSTRUCTIONS

* * W A R N I N G * *

AUSSIE SCUD SERIES HIGH PRESSURE WATER BLASTERS ARE DESIGNED

FOR PROFESSIONAL OPERATORS ONLY

IMPORTANT

INSTRUCT OPERATORS IN CARE AND USE OF THE MACHINE BEFORE USE!

Aussie Scud & Ultra … Operation & Maintenance Manual

3

Aussie Pumps

Feb 2012

C

D

B

A

ASSEMBLY AND PREPARATION FOR USE

Before proceeding with assembly of your new Aussie Eco AB high pressure blaster, check that all parts listed

below are included.

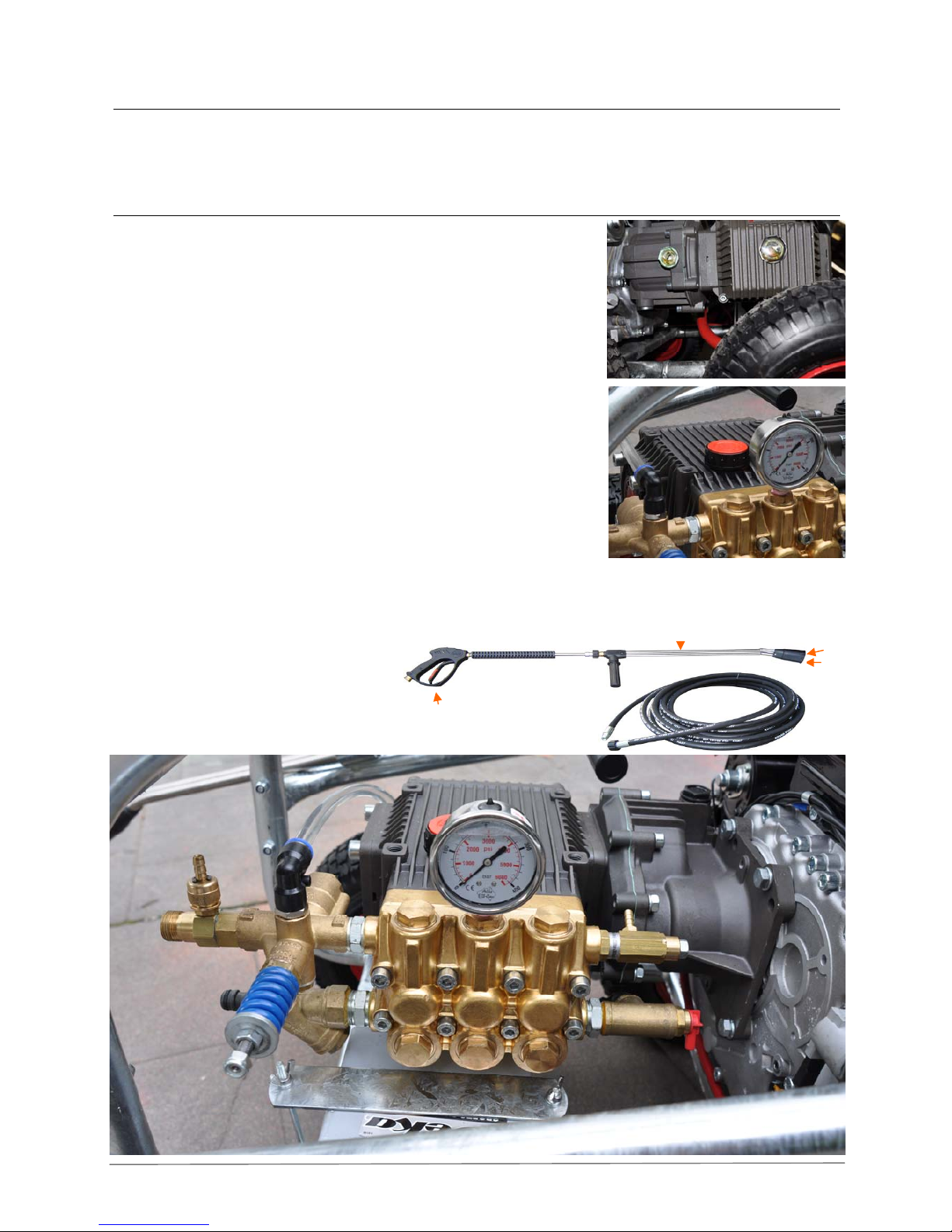

1 Gun handle assembly and high pressure hose

1 Lance and nozzle assembly

A. Machine Preparation (initial start-up)

1. Check the oil in the pump and gearbox.

Note separate reservoirs. With the machine on a level surface the oil

lever should cover the red spot in the oil level sight glass on the side

of the machine. If necessary, top up with SAE 75W-90. Do not mix

different grades of oil as this may affect the machines performance.

If alternative oil is used, first empty out oil by unscrewing drain plug

in bottom of machine.

2. Ensure breather plug is fitted to pump.

WARNING: Before operation ensure top mounted travel plug is

replaced by breather plug. Failure to fit breather and keep clean can

result in over pressuring of oil chamber (crank case) and can blo w oil

seals. This will void warranty.

3. Note that the gearbox has a separate oil reservoir. Gearbox oil is

SAE 90 gear oil.

4. Connect battery leads on electric start machines.

5. Check oil level in engine and fill with proper grade oil if necessary.

(SAE 10W-30 for Honda engines, check engine manual for other

makes)

6. Check fuel level and fill if necessary. (unleaded petrol)

7. Assemble gun/lance assembly.

HEAVY DUTY LANCE: To assemble the lance, insert Section B into Section A and screw together and check

nozzles have been fitted to end of lance (C & D).

Detergent injector

Unloader - factory set,

DO NOT adjust

Thermal dump

Safety valve

Aussie Safety Protection Kit

HP hose

connection

Supply hose

connection

Breather plug

Aussie Scud & Ultra … Operation & Maintenance Manual

4

Aussie Pumps

Feb 2012

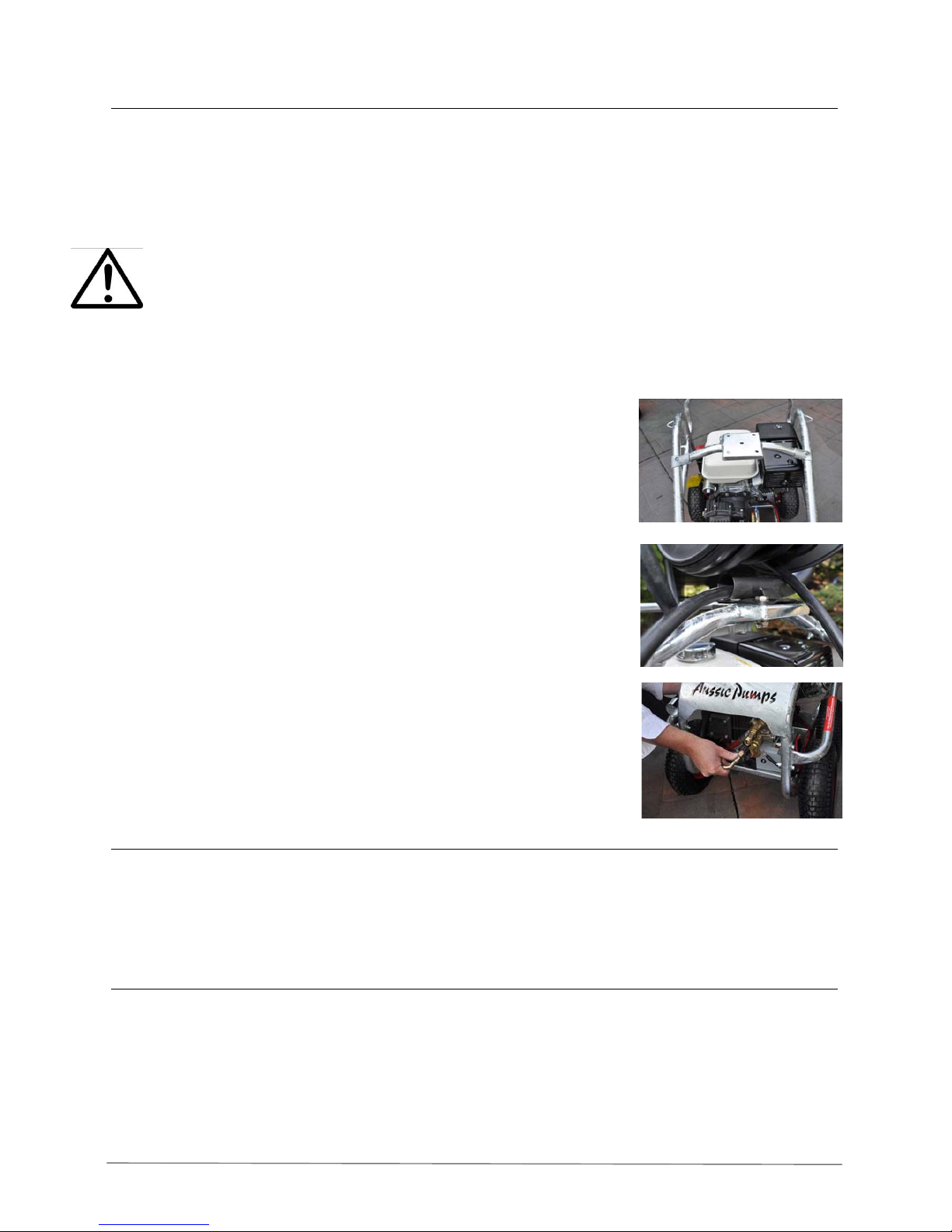

B. Hose Connections

1. Connect high pressure hose to machine outlet.

2. If optional low pressure downstream, in-line chemical injector is to be used, connect the injector tube to

the detergent inlet and place the other end of the tube, with the strainer attached, in the chemical

container (not supplied).

3. Connect gun/lance assembly to high pressure hose.

4. Check inlet water filter is clean then connect water supply hose to machine. Use a 25mm (minimum)

hose .

Incoming water supply must deliver double the flow of the machine. If questionable, check supply at

machine. If supply is insufficient, do not operate from this outlet. For residential use, the outlet closest to

the meter will usually deliver the highest flow rate. Connect only to clean town water supply.

Warning: Do not operate from tank or pond. Doing so will cavitate the pump causing damage. Cavitation

or pump starvation is not covered by warranty. Cavitation is a phenomenon causing vacuum pockets to

form within the pump that eventually implode under pressure pitting the internal pump surfaces.

Fitting instructions for optional hose reel

, Securely clamp the hose reel mounting bar across the top of the Scud

frame using the two sets of nuts and bolts supplied. Aussie Pumps

recommends using Loctite on the bolts to prevent them vibrating loose.

, Fit hose reel to the mounting bar using the four sets of nuts and bolts

supplied. Ensure all bolts are securely tightened and use Loctite to

prevent them vibrating loose.

The reel should be positioned so that it rotates fore/aft to aid fitting

whip hose.

, Connect whip hose to high pressure outlet on pump.

, Fit handle to reel.

, Fit gun to hose using C1500.24 nipple.

Start up machine (see below) and check for leaks. All leaks must be

rectified before using machine.

C. Before starting the machine

OPERATE IN WELL VENTILATED AREAS ONLY.

1. Ensure machine is level

2. Turn on water supply.

3. Pull gun trigger until water starts to flow in a steady steam then release trigger.

D. Starting the engine (for Honda , refer to engine manual for other engine options)

1. Ensure fuel valve is open

2. Move the choke on the engine to the closed position (see fig. 1). If engine is warm, move choke half-way.

3. Turn engine ON/OFF switch to ON

4. Hold the gun trigger on.

5. Start engine, either turn engine key or pull the recoil starter grip lightly until resistance is felt, then pull

briskly.

6. After engine starts, release the gun trigger and slowly open the choke.

7. Warm up engine for 3 minutes without load.

Loading...

Loading...