Aussie RAPTOR 12, RAPTOR 16 Operator's Instruction Manual

July 2012 Raptor Electric Operator’s Manual 1

Australian Pump Industries

RAPTOR ELECTRIC

HYDRO-BLASTER

OPERATORS INSTRUCTION MANUAL

OPERATORS INSTRUCTION MANUAL

July 2012

ATTENTION: Operators must read this manual and understand it

completely before using the machine.

2 Raptor Electric Operator’s Manual July 2012

Australian Pump Industries

TABLE OF CONTENTS

Before attempting to operate your machine please read this Instruction Manual thoroughly following all

directions carefully. By doing so you will ensure safe operation of the unit and will enjoy long and trouble

free service from your heavy duty water blaster.

WARRANTY COVERAGE

The Aussie Eco-Clean Raptor has a two year warranty from date of purchase. This warrant y covers any defect which occurs due to

faulty workmanship or material under normal use. Please keep your receipt as proof of purchase. This warranty sp ecifically

excludes the following:

Damage resulting from debris or mineral deposits contained within the water supply to the machine.

Leaking hoses when the outer cover of the hose has been abraded or the hose has been kinked.

Damage to o-rings and valves, etc. caused by the use of cleaning chemicals or compounds.

Replacement of parts damaged due to fair wear and tear.

Misuse, negligence, alteration, accident or breakage.

Failure of the machine due to lack of normal maintenance services (The owner is responsible for the performance of

regular maintenance services, as specified in the Operator's Manual).

Damage and/or progressive damage caused by the failure to inform Australian Pump Industries Pty Ltd, or the closest

Authorised Australian Pump Agent or Distributor, within seven days of the defect becoming apparent.

Repair or modification by an unauthorised service person.

Australian Pump Industries Pty Ltd specifically excludes from warranty responsibilit y an y consequential loss or damage

including on-site servicing, loss of time, loss of use of the machine, hire costs of a replacement machine or

inconvenience..

Where possible return faulty goods to the place of purchase. No products can be returned to us without prior permission.

The reason for return must be clearly stated.

N.B. Warranty is not transferable to third parties in the event of sale of the machine within the warranty period. Please

note that any parts used in warranty repairs are guaranteed for a period limited by the original warranty of the parent

product.

Our goods come with guarantees that cannot be excluded under the Australian Consumer La w. You are entitled to a replacement

or refund for a major failure and for compensation for any other reasonably foreseeable loss or damage. You are also entitled to

have the goods repaired or replaced if the goods fail to be of acceptable quality and the failure does not amount to a major failure.

The benefits under the Aussie Pump warranty are in addition to other rights under Australian Consumer Law.

Safety First Page 3

Specifications Page 3

Safety Precautions Page 5

Personal Protective Equipment Page 6

Operator’s Hand Signals Page 7

Assembly & Operating Instructions Page 8

Troubleshooting Page 11

Accident Reporting Page 12

Emergency Medical Information Page 13

Spare Parts List Page 14

Warnings Page 15

Daily Checklist Page 15

Monthly Service Page 15

Grit Blaster Head Set Up Instructions Page 10

July 2012 Raptor Electric Operator’s Manual 3

Australian Pump Industries

SAFETY FIRST

WARNING: To comply with Australian and New Zealand standards, operator’s of 5000psi machines and

larger need to complete operational and safety training courses and be duly certified in order to comply with

Occupational Health & Safety requirements.

ATTENTION OPERATOR

Please read the Operating and Safety Instructions in this manual thoroughly before using your Aussie

Raptor water blaster. Please note that safety procedures must be followed carefully. Non-compliance can

result in severe injury or even death.

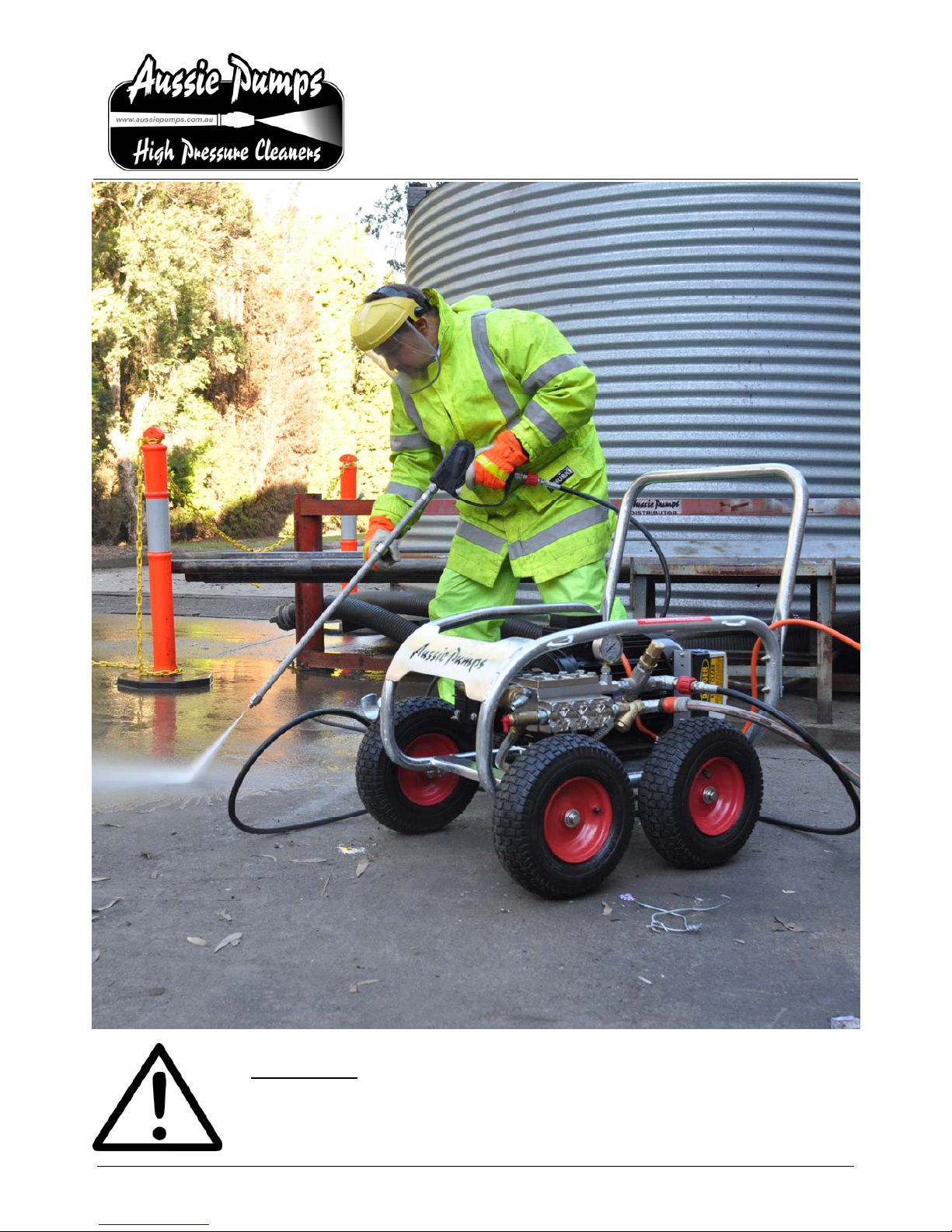

SAFETY CLOTHING

Wearing protective clothing is essential for the use of B-class machines (5000psi and above). Eye

protection, gloves, body protection, steel capped boots and ear protection equipment are essential. For

details see page 7.

WATER BLASTING OPERATION

While using the Aussie Predator, take special care to ensure the gun and nozzle are never pointed at any

person or animals. Severe injury or death may result. For details and other warnings see page 5.

BACTERIA WARNING

In the event that some person or persons may be sprayed by high pressure water, it is important medical

personnel be advised as unusual infections with microaerophilic organisms can occur. For details see

Emergency Medical Information page 14.

SPECIFICATIONS

Performance

Raptor 12 Raptor 16

Stock code ABRAPTOR/12EMOT ABRAPTOR/16EMOT

Pump pressure psi

7,300 (500 BAR) 7,300 (500 BAR)

EWP with turbo psi 12,000 12,000

Flow lpm

12 16

Motor Phase

Three phase Three phase

Power kW 4 pole, 12.5 4 pole, 15

Pump speed rpm 1450 1450

Pump type Penta Penta

Pump Model GHC12/50S GHC16/50S

Nozzle size 020 025

Accessories - Hose 10M 1/4” 1,000 BAR 10M 1/4” 1,000 BAR

Gun RL84 RL84

Lance RL800 RL800

Nozzle type Laser cut Laser cut

Weight kg 120 120

Boxed dimensions LxWxH (mm) 1000 x 720 x 820 1000 x 720 x 820

4 Raptor Electric Operator’s Manual July 2012

Australian Pump Industries

ACCESSORY INFORMATION

Ensure that all accessories are rated to 7,300 psi (500 bar) before using with the Aussie Raptor.

Suitable accessories available from Australian Pump Industries;

1) Aussie CTN500-020 (12 LPM version) or CTN500-025 (16 LPM version) 500 bar rated Turbo Master

turbo head. (1/4”M to 1/2” M nipple required to fit to lance.) Also available as a complete kit with lance,

gun, nozzle & nipple to allow quick coupling to hose (CTN500-_ _ _GLK)

2) Aussie Grit blast Kit

TPS450 500 bar grit blast head, 1/4” F BSP (C4700.18)

Probe 580mm, 20mm hose barb (C4604.01)

Note: Available as a complete kit with lance, gun, nozzle & nipple

to allow quick coupling to hose (TPS450/_ _ _GLK).

3) Aussie 500 bar gun, lance & shoulder rest.

RL84 500 bar spray gun, 1/2” F BSP (MPA30540000)

RL800 500 bar s/s 800mm single lance, 1/2”M (MPA30500080)

RL1250 500 bar s/s 1250mm single lance, 1/2”M (MPA30500092)

Shoulder rest, 300mm (MPA30501921)

HIGH PRESSURE WASH DOWN

The Aussie Raptor can be used for any high pressure water blasting application in construction, mining,

ship cleaning, dry docks, graffiti removal or for any other difficult task.

HIGH PRESSURE PISTON PUMPS

Your high pressure Udor pumping system is the heart of your water jetter. The pump has been specially

designed to be used with cold water (max 60ºC) for high pressure wash down applications. Your high

pressure Udor piston pump is designed to move a certain amount of water per revolution by its three solid

ceramic pistons.

High pressure is created once the pump outlet is restricted with a nozzle. All high pressure outlet

connections, hosing and equipment is rated over and above the maximum operating pressures of the

pump.

Please do not alter any valving on your pump; altering will void all warranty. For any malfunction of the

high pressure pumping system, please contact Australian Pump Industries or the Distributor you purchased

the unit from.

Because of safety/danger hazards with high pressure systems, only use approved high pressure hosing

and components when replacing or repairing your Raptor. For guidance on this, please contact Australian

Pump Industries or the Distributor you purchased the unit from.

Once wash down nozzles have worn, pressure loss will occur. Replacement of nozzles is necessary to

maintain constant and maximum efficiency of your Raptor. Using worn nozzles will reduce unloader valve

service life.

July 2012 Raptor Electric Operator’s Manual 5

Australian Pump Industries

WARNING… Do Not Alter Pressure Setting

Altering the high pressure unloader device and safety valve may result in severe injury or death. Warranty

will be void if any high pressure valve equipment has been altered by non-qualified staff. Over-speeding or

over-pressurizing of the pump system is dangerous and can severely reduce the operating life of the

machine. It may also result in injury or death!

SAFETY PRECAUTIONS - IMPORTANT

1. Never direct the spray jet at any person or animal.

2. Never direct spray jet at any surface that may contain asbestos material.

3. Never hold a finger over the high pressure nozzle.

4. Never direct the spray jet at the machine itself or any electrical equipment.

5. After use release the pressure in the high pressure hose by operating the pistol

trigger.

6. Electric cables should not be left in a position where water can come into contact

with the electric cable. Always keep electrical connections dry and off the ground

7. When not in use always switch off the engine and disconnect from water supply.

8. Certain components become very hot when in use. Switch off the blaster and

ALLOW TO COOL before touching.

9. Do not attempt any mechanical repair. If you have a problem with your machine

contact your local dealer or Aussie Pumps service division, phone 02 8865 3500

10. Never supply any liquid other than clean water to the water inlet.

11. Never pull the high pressure hose if it has formed kinks or nooses. Never pull the

hose over sharp objects.

12. Use only chemical cleaning agents (detergents) approved for power washing when

using the chemical injection facility.

13. Never use the chemical injection facility to introduce solvents, e.g. paint thinners,

petrol, oil, etc.

14. Do not attempt to disconnect any hose or coupling with pressure still in the hose.

15. Do not operate the machine whilst standing on ladders, use a platform tower or

scaffolding.

16. Children should not be allowed to use the machine.

17. We recommend the use of safety goggles when using the machine, particularly with

the sand blasting attachment, or any application where loose particles of stone or grit,

etc, may be blown around by the high pressure spray.

18. The electrical power voltage must agree with the voltage specified on label on base of

machine. [Note: Improper connection will damage machine and void warranty.]

19. The machine must be grounded. The plug must be plugged into an appropriate outlet

that is properly installed and grounded in accordance with all local codes and

ordinances.

20. Do not modify the plug provided with the machine. If plug does not fit your outlet

have a proper outlet installed by a qualified electrician.

21. Do not use any type of double adaptor or multiple socket power board with this

product.

22. Do not touch plug with wet hands.

23. To avoid damage to cable do not roll, crush or pull it. The power cable may only be

repaired or replaced by an trained electrician.

24. Disconnect the plug from power supply and relieve pressure to hose before

attempting any work on the machine.

Loading...

Loading...