Aurora of America 344A, 342A, 341A User Manual

INSTRUCTION AND REPAIR MANUAL

MODELS 341A, 342A AND 344A

6

SECTION 6 ITEM 340

DATED JUNE 1998

SUPERSEDES ITEMS 341, 342, 344

DATED MARCH 1992

© 1992 AURORA PUMP

NO. AURORA, ILLINOIS

NOTE

This repair manual is applicable to pump Models 341A,

342A and 344A. All photos illustrate Model 344A.

A

TTENTION: SAFETY WARNINGS:

Read and understand all warnings before installation or servicing pump.

OPERATIONAL LIMITS: *

Maximum Operating Pressure: 175 psi at Temperatures

to 150

O

F (65.6°C)

Maximum Operating Temperature: 225°F (107°C)

* See ASTM A126/ANSI B16.1 for pressure/temperature rat-

ings of flanges.

ELECTRICAL SAFETY:

HIGH TEMPERATURE SAFETY:

HIGH PRESSURE SAFETY:

SERVICE

Your Aurora pump requires no maintenance other than periodic

inspection, occasional cleaning and lubrication of bearings

(MODEL 344A only). The intent of inspection is to prevent

breakdown, thus obtaining optimum service life. The liquid end

of the pump is lubricated by the fluid being pumped and therefore does not require periodic lubrication. The motor, however

may require lubrication, in which case, the motor manufacturer’s recommendation should be followed.

LUBRICATION OF IMPELLER SHAFT BEARINGS

The MODEL 344A pump is available with three options for

lubricating the shaft bearings. They are:

1. Regreasable (standard)

2. Oil Lubrication

3. Sealed Bearings, Permanent Lubrication

Regreasable bearings will require periodic lubrication and can

be accomplished by using the zerk or lubrication fittings in the

cartridge cap and power frame. Lubricate the bearings at regular intervals using a grease of high quality. Polyurea base

Warning: Electrical Shock Hazard

All electrical connections are to be made by a qualified electrician in accordance with all codes and ordinances. Failure

to follow these instructions could result in serious personal

injury, death or property damage.

Warning: Electrical Overload Hazard

Insure all motors have properly sized overload protection.

Failure to follow these instructions could result in serious

personal injury, death or property damage.

Warning: Sudden Start-Up Hazard

Disconnect and lockout power source before servicing.

Failure to follow these instructions could result in serious

personal injury, death or property damage.

Warning: Hot Surface Hazard

If pumping hot water, insure guards or proper insulation is

installed to protect against skin contact to hot piping or

pump components. Failure to follow these instructions could

result in serious personal injury, death or property damage.

Warning: Spraying Water Hazard

When servicing pump replace all gaskets and seals. Do not

re-use old gaskets or seals. Failure to follow these instructions could result in serious personal injury, death or property damage.

Warning: High Pressure Hazard

The pump is rated at a maximum of 175 psi at 150°F. Do

not exceed this pressure. Install properly sized pressure

relief valves in system. Failure to follow these instructions

could result in serious personal injury, death or property

damage.

Warning: Expansion Hazard

Water expands when heated. Install properly sized thermal

expansion tanks and relief valves. Failure to follow these

instructions could result in serious personal injury, death or

property damage.

MODELS 341A-342A-344A

2

grease is recommended as lubricants for pumps operating in

both wet and dry locations. Mixing of different brands of grease

should be avoided due to possible chemical reactions between

the brands which could damage the bearings. Accordingly,

avoid grease of vegetable or animal base which can develop

acids, as well as grease containing rosin, graphite, talc and

other impurities. Under no circumstances should used grease

be reused.

Over lubrication should be avoided as it may result in overheating and possible bearing failure. Under normal application, adequate lubrication is assured if the amount of grease is maintained at 1/3 to 1/2 the capacity of the bearing and adjacent

space surrounding it.

In dry locations, each bearing will need lubrication at least

every 600 hours of running time or every 6 to 12 months,

whichever is more frequent. In wet locations the bearings

should be lubricated at least after every 300 hours of running

time or every 4 to 6 months, whichever is more frequent. A unit

is considered to be installed in a wet location if the pump and

motor are exposed to dripping water, to the weather, or to heavy

condensation such as is found in unheated and poorly ventilated

underground locations.

Oil lubricated bearings are optional on MODEL 344 pumps. A

fixed oil level is maintained with the power frame by an oiler

which allows visual indications of reserve oil.

At initial installation and before starting a unit that has been

shut down for repairs or for any extended length of time, run

enough 10W-30 weight motor oil through the oiler to maintain a

constant oil level to insure that the bearing will never be without an oil supply. Oil will have to be added at intervals to maintain a constant level in the oiler. This interval can only be determined by experience.

Under working conditions, oil will breakdown and need to be

replaced at regular intervals. The length of these intervals will

depend on many factors. Under normal operation, in clean and

dry locations, the oil should be changed about once a year.

However, when the pump is exposed to dirt contamination, high

temperatures (200°F. or above) or a wet location, the oil may

have to be changed every 2 to 3 months.

Use normal fire caution procedures when using any

petroleum cleaner.

REPAIRS

Before starting any work, insure the electrical power is locked

out, the system pressure has been lowered to 0 psi and temperature of the unit is at a safe level.

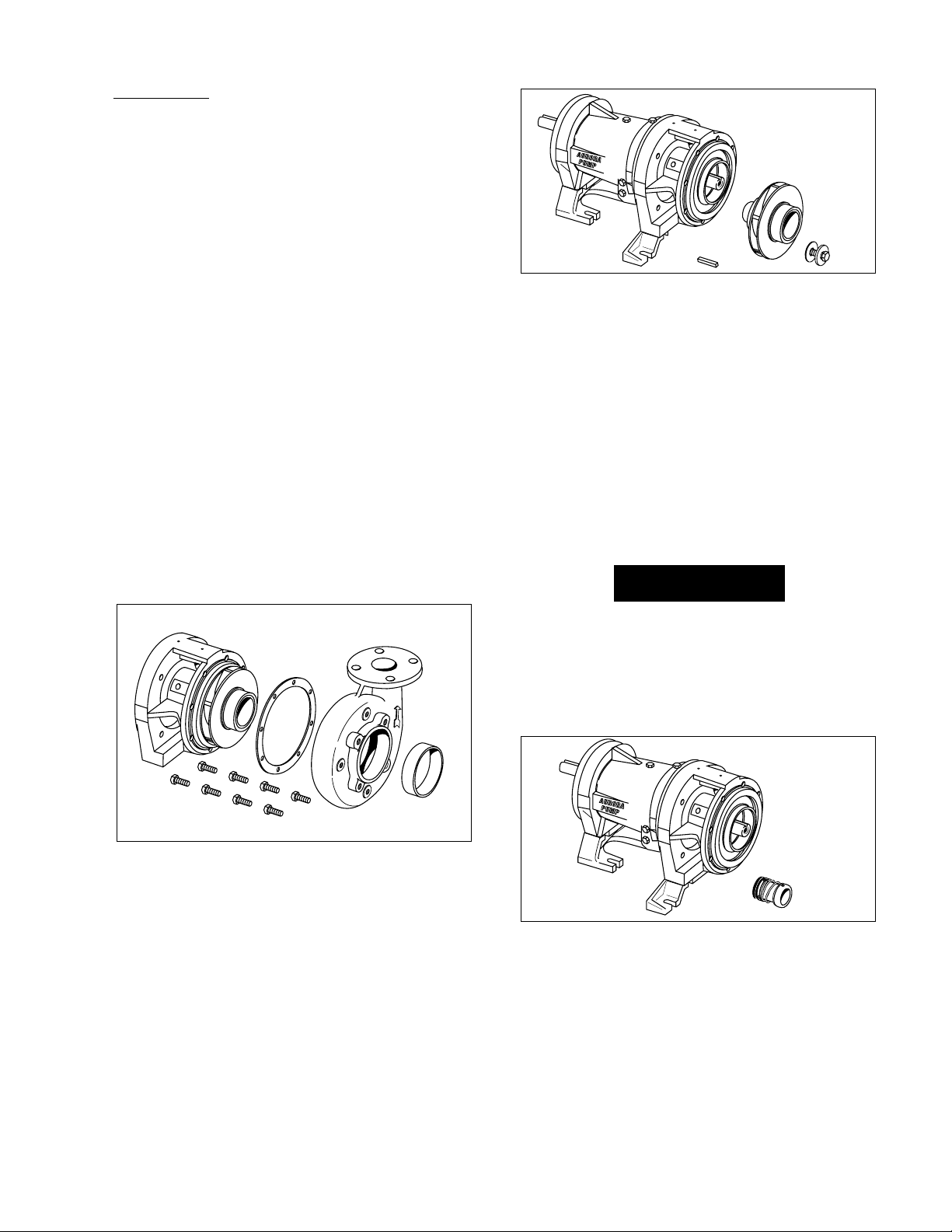

The pump may be disassembled using the illustrations and text

provided. Although complete disassembly is covered, it will seldom be necessary to completely disassemble your Aurora

pump.

The illustrations accompanying the disassembly instructions

show the pump at various stages of disassembly. The illustrations are intended to aid in the correct identification of the parts

mentioned in the text.

Inspect removed parts at disassembly to determine if they can

be reused. Ball bearings that turn roughly or show wear should

be replaced. Cracked castings should never be reused. Scored or

worn pump shafts should be replaced. Gaskets should be

replaced at reassembly simply as a matter of economy. They are

much less expensive to replace routinely than to replace singly

as the need arises.

CAUTION

A. Assembled Units.

Warning: Sudden Start-Up Hazard

Disconnect and lockout power source before servicing.

Failure to follow these instructions could result in serious

personal injury, death or property damage.

Warning: Hot Surface Hazard

If pumping hot water, insure guards or proper insulation is

installed to protect against skin contact to hot piping or

pump components. Failure to follow these instructions could

result in serious personal injury, death or property damage.

Warning: High Pressure Hazard

The pump is rated at a maximum of 175 psi at 150°F. Do

not exceed this pressure. Install properly sized pressure

relief valves in system. Failure to follow these instructions

could result in serious personal injury, death or property

damage.

Warning: Spraying Water Hazard

When servicing pump replace all gaskets and seals. Do not

re-use old gaskets or seals. Failure to follow these instructions could result in serious personal injury, death or property damage.

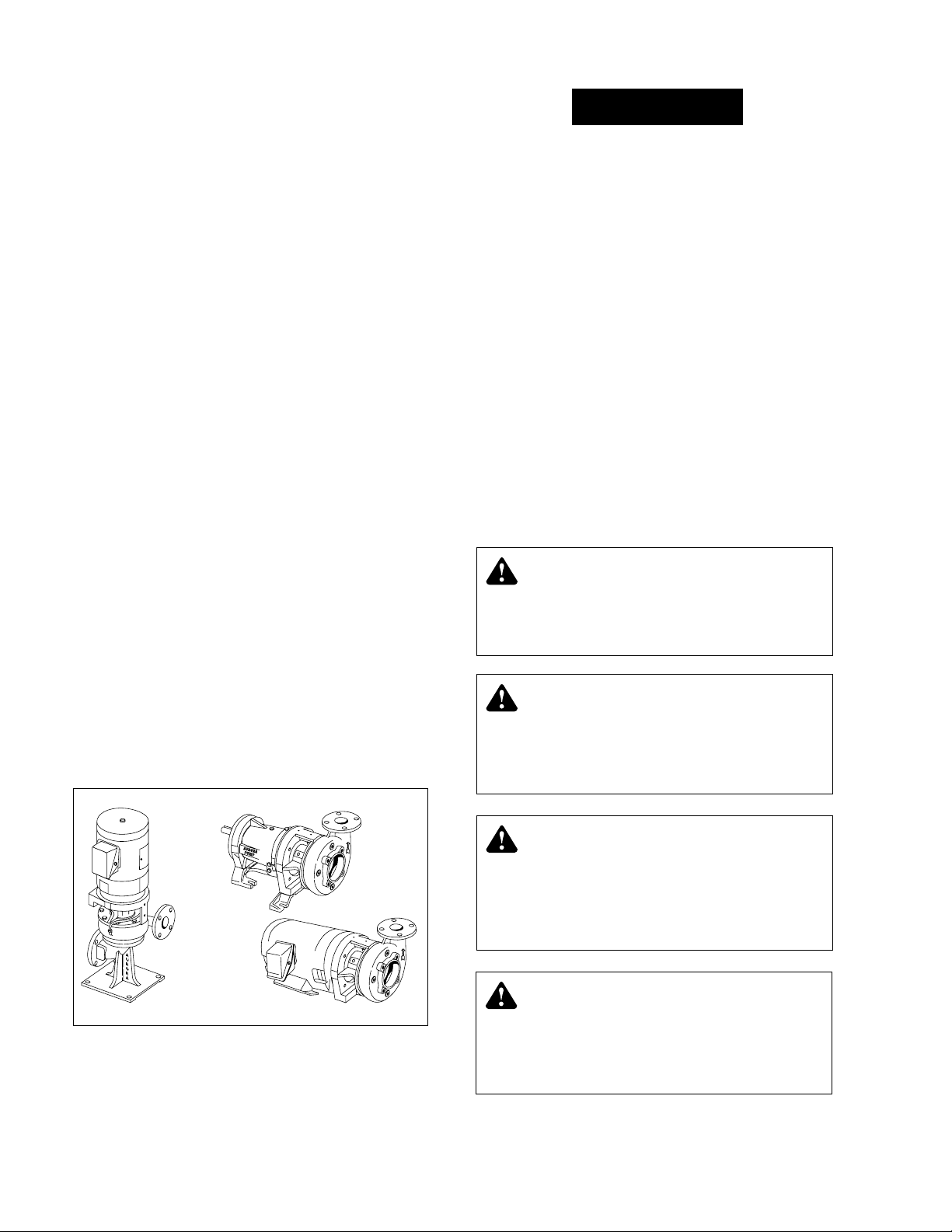

Model 344A

Model 342A

Model 341A

MODELS 341A-342A-344A

3

DISASSEMBLY

Disassemble only what is needed to make repairs or accomplish

inspection. (See Figure 2 for Model 341A, Figure 3 for Model

342A and Figure 3 for Model 344A.)

1. Disconnect and lockout power source to prevent drive unit

from being energized during disassembly.

2. Unscrew the two drain plugs (4) from the casing (6). On

Model 342A pumps, remove plugs (74 and 75) to drain

pump. Also unscrew the two plugs (4) from casing (6).

3. Remove all relief, cooling, flushing or drain lines from

pump, including compression connections (1 and 2) and

tubing (3). Break suction and discharge connections unless

it is intended to remove the power frame or motor assembly

and leave casing (6) in the line. On Model 342A pumps,

break discharge connections only, unless it is desired to

remove base (73). Remove capscrews (39) and lift pump

assembly from base (73). Remove gasket (72).

4. On Model 344A pumps, remove the flexible coupling from

between the pump and motor. Next unscrew the bolts that

hold support(s) (41 and 64) to the base and slide the pump

out to be worked on.

5. Remove capscrews (5) and pull casing (6) from bracket

(35). Remove gasket (8).

6. Unscrew impeller screw (9) and remove washer (9A), taking care not to damage gasket (9B) or capscrew seal (9C).

7. Slide impeller (11) and impeller key (12) from the shaft,

again taking care not to damage gasket (10) located behind

impeller. Remove gasket (10).

8. Wearing ring(s) (7 and 16) are pressed into their housings

with an interface fit and must be removed with a puller.

New ring(s) should be used for reassembly since it is likely

that during removal this fit will be lost. Do not remove

wearing rings if not being replaced.

9. Impeller wearing rings (optional - 14 and 15) are pressed

on and must be cut off if replacement is necessary. If they

are turned off in a lathe, take care not to cut into the

impeller.

10. Slide sleeve (25) with rotating parts of mechanical seal (27)

from the shaft. The sleeve should be carefully cleaned to

remove any residue that may be remaining in the seal area.

The rubber in seal (27) may have become partially adhered

to the sleeve. The sleeve must also be checked for abrasion

or corrosion that can occur when fluid residue penetrates

between the seal (27) and sleeve (25). The sleeve under the

seal may be polished lightly to a 32 RMS finish before

reassembly. Do not reuse a pitted sleeve. Pin (61) may be

removed if necessary.

The mechanical seal (see Figure 1) is a precision product

and must be treated as such. During removal, great care

must be taken to avoid dropping any part of the seal.

Take particular care not to scratch the lapped faces on the

washer or the sealing seat. If any wear of the seal faces is

noted, it is recommended to replace with a new seal during reassembly.

11. On Model 344A pumps, remove capscrews (39 and 62) and

washers (40 and 63) to take off support feet (41 and 64). On

Model 341A frame size 143 thru 184-JM only, unscrew capscrews (39) washers (40) and remove support (41) from

bracket (35).

12. Unscrew capscrews (32) to remove bracket (35) from frame

(57) or motor on Models 341A and 342A.

D. Mechanical Seal Removed.

CAUTION

C. Impeller and Key Removed.

B. Casing, Gasket, and Wearing Ring Removed.

Loading...

Loading...