aroruA - 3.0 .veR

BCB.00029.5

®

is a trademark by Power-One - Product is subject to technical improvements

www.power-one.com

QUICK INSTALLATION GUIDE

Aurora® Power Service USA 877-261-1374

Aurora® Power Service France 00 800 00 28 76 72

Aurora® Power Service Germany 0800-2200211

Aurora® Power Service Italy 00 800 00 28 76 72

Aurora® Power Service Spain 00 800 00 28 76 72

Aurora® Power Service Middle East 00 800 00 28 76 72

Aurora® Power Service Australia +61 2 9735 3111

Aurora® Power Service China +86 755 2988 5888

Aurora® Power Service Singapore +65 6896 3363

Aurora® Power Service Malaysia +603-8025 9963

Model:

PVI-AEC-EVO

PVI-AEC-EVO-LIGHT

PVI-AEC-EVO

PVI-AEC-EVO LIGHT

Monitoring System

- USER MANUAL -

QUICK INSTALLATION GUIDE

SAVE THESE DOCUMENT IN A SAFE PLACE!

IMPORTANT SAFETY INSTRUCTION!

This manual contains important safety instruction that must be followed during the

installation and start-up of the device. It’s recommended to give special attention to the

installation instruction in order to reduce the risks pf electric shock and prevent damage

to the device.

Note: This document contains proprietary information of Power-One, Inc.

The contents of this document or any part thereof should not be reproduced or disclosed

to any third party whitout Power-One’s express written consent.

Note: Any changes / modification not approved by the responsible party could void the

user authority to operate the equipment.

BCB.00029.5

12-07-2013REV. 3.0

PVI-AEC-EVO / PVI-AEC-EVO LIGHT

QUICK INSTALLATION GUIDE

CONTENTS

A.

Product Description

B. Package Content

C.

D.

E.

F.

G.

H.

I.

L.

User Interface and Use of the Display

Pin-Outs of System Connectors

Power Supply Connections and System Start Up

Date and Time Settings

Connection of the RS485 Line and Inverter Acquisition Check

Configuration of the Analog Inputs

System Configuration for Connection to the LAN Network (Ethernet Port)

Internal Webserver access

2

3

4

5

6

7

7

11

14

17

Mac Address IdentificationM.

Firmware UpdatingN.

Appendices

1) Sensor Connection Diagrams

2) RS485 Cable Features

3) Display flow-charts

4) Compliance Requirements

20

21

1-EN

Monitoring System

A. Product Description

The PVI-AEC-EVO is a monitoring and checking system for photovoltaic systems made with Power-One Aurora

products. In thefollowing pages we willmake referenceto the“system”meaning both versions ofthe product.Whereas

thecharacteristicsof productaredifferent willbe specified.

The productallows toacquire parameters fromthe inverterand string-comb(in accordancewith the design ofthe

centralinvertermonitoring system)through theRS485linewiththePower-Oneproprietary protocol.

The system isequipped withtwoequivalent RS485 portsand each ofthem allowsa maximumof 62string inverters

or 62 55kW conversion modules (centralized modular inverters) to be acquired; It is also possible to use the

communicationport RS485/1(Ref.Par.D) toacquire parametersfrom powermeters equipped

withModbuscommunicationinterface.

Note: For PVI-AEC-EVOLIGHT,the max numberof string invertermanageable by the system is5, which can

beconnected onlybyRS485/2 (Ref.Par.D). Onlythe followings(in allof theirvariants) areallowed:

PVI-2000(-OUTD) UNO-2.0/2.5-I-OUTD PVI-3600

themodel

“ISKRAMECOMT831”

EN - ENGLISH

PVI-3.0/3.6/4.2-TL-OUTD PVI-3.8/4.6-I-OUTD PVI-5000/6000-TL-OUTD

PVI-10.0/12.5-TL-OUTD PVI-10.0/12.0-I-OUTD

( *): Compatibility isalso extended toprevious nationalversions (Ex:PVI-3.6-OUTD-UK)

**

*

In the PVI-AEC-EVO LIGHT the communication port RS485/1 (Ref. Par. D) can be used only to acquire

parametersfrom“ISKRAMECO MT831”power metersequipped withModbuscommunication interface.

The system is equipped with three analog inputs for the connection of sensors for the measurement of environmental

parameters: Power-Oneoffers inits cataloguea completerange ofradiation sensor,cell andambient temperature,speed

andwind direction.

The system alsohas six digitalinputs for acquiringstate signals(for example auxiliarycontacts ofpower switches)which

areassociated withstate alarmconditions.

With respect to the user interface, the system is equipped with a 2x16 character display and four keys as well as an

integratedwebserver withhtmlpages whichareaccessible throughLANconnection.

The initial system configuration (check that the inverter parameters are acquired, analog inputs configuration, LAN

network parameters configuration) can be carried out completely through the display and keys; for displaying the

detailed parametersof theinverters and/or ofthe string-combs,as wellas forthe advancedconfigurations it isnecessary

toaccess thepagesof theintegratedweb server.

ThePVI-AEC-EVOworks inconjunction withthe serviceweb portalAuroraVision:by registeringfor thisservice youwill be

ableto carryout monitoringandremote managementofsystems associatedwithyour account.

Theweb portalAuroraVisionis availableonthe website: www.Auroravision.net

2-EN

PVI-AEC-EVO / PVI-AEC-EVO LIGHT

QUICK INSTALLATION GUIDE

B. Package content

1

AURORA PVI-AEC-EVO / PVI-AEC-EVO LIGHT

2

Power Supply 100-240Vac 50-60Hz / 24Vdc

3

Power Supply connection cable

4

Quick Installation Guide

5

SD Card (assembled)

6

I/O Terminal Blocks Counterparts (assembled)

7

RS485 Terminal Blocks Counterparts (assembled)

8

Relais Terminal Blocks Counterparts (assembled)

9

Power supply Terminal Blocks Counterparts

(assembled)

1 2 4

STEP POWER

Input AC

100-240V

L(+) N(-)

3

--++

Output DC

24V 0.75A

DC

OK

5 6 7 8 9

Note: Checkthe packagecontentcorresponds totheabove list.

Pleasecheck thebox andeach singleitem insidehasno defect.In caseclaims tothe shippingcompany

andcommunicates quickly totheassistant technicalservice orto theCustomerserviceof Power-One.

3-EN

Monitoring System

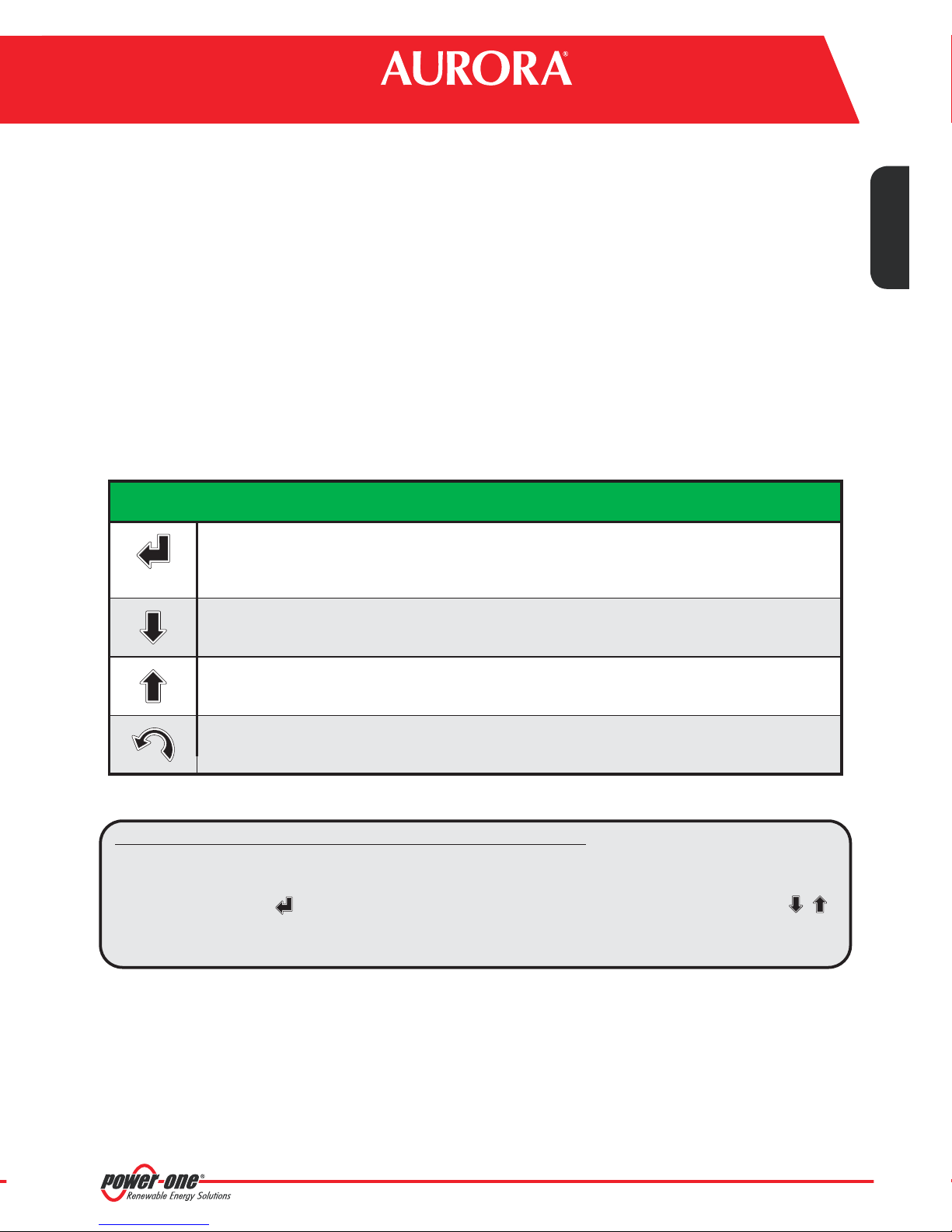

C. User interface and use of the display

Thesystem featuresa 2x16character display,four buttonsfornavigating menus,and threeLEDsto indicatedevicestatus.

Usingthe displayand thebuttons onthe frontpanel itis possibleto perform theinitial configurationof thesystem(check

ofparameter acquisitionfrominverter,analog inputconfiguration,and configurationof LANnetworkparameters).

For displaying the detailed parameters of the inverters and/or of the string-combs, as well as for the advanced

configurationsit isnecessary toaccess theinternalweb serverfollowing theproceduredescribedin paragraph“L”.

Alist offunctions accessiblefromthe displayis shownin thetablein Appendix3.

USE OF BUTTONS

'Enter' button. Used toconfirm an action,to accessthe main menuor the sub-menucorresponding to

theselectedentry(indicated bythe >symbol),orto gotothe nextdigit tochange.

'Down' button. Used to scroll down through the menu items, or to scroll the numerical scale in

descendingorder.

EN - ENGLISH

'Up' button. Used to scroll up through the menu items,or to scroll the numerical scale in ascending

order.

'Esc'button. Usedto returnto thepreviousmenu orto returnto thepreviousdigit tochange.

Accessto themain menu withadministratorprivileges

Toperformthe initialconfigurationit isnecessary toaccessthe variousdisplaymenus asadministrator.

Press the'ENTER' key ( ) and insert password : Toinsert the passwordpress the arrowkeys ( ) to

change thevalue and the'ENTER' key toconfirm the value. This passwordgives access toall the displaysetting submenusof thesystem.

0010

4-EN

PVI-AEC-EVO / PVI-AEC-EVO LIGHT

QUICK INSTALLATION GUIDE

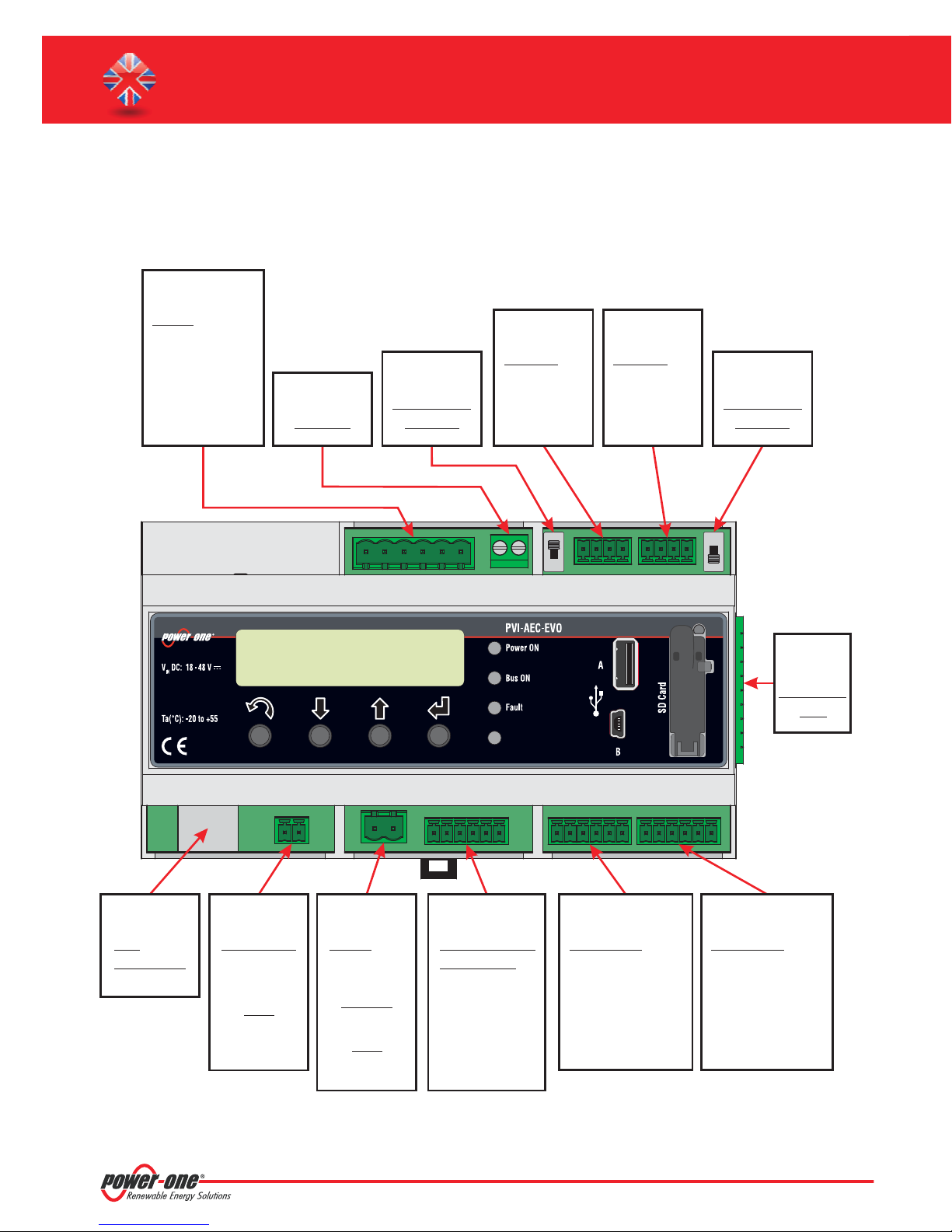

D. Pin-Out of System Connectors

Thediagram belowshowsthe pin-outof theconnectorswhich allowthesystem connection.

J5

RELAY

1) RELAY1-C

2) RELAY 1 - N.O

RELAY2-C

3)

4)

RELAY 2 - N.O

5)

RELAY3-C

6)

RELAY 3 - N.O

J12

GROUND

S2

120

Ω TERM.

RS485/1

J17

RS485/1

1) RTN

2) - T/R

3) +T/R

4) +5V

*

J15

RS485/2

1) RTN

2) - T/R

3) +T/R

4) +5V

S1

120

Ω TERM.

RS485/2

J7

LAN

IEEE802.3u

11122

J18

BATTERY IN

1) + Batt.

2) - Batt.

NOTE:

Only for dedicated

accessory

PVI-BATTERY-PACK

123456

J8

Vin DC

1) + Vcc

2) - Vcc

INPUT DC:

24 Vdc

(max. 48 Vdc)

0,3 A

NOTE:

Use the provided

power supply

5

3

6

4

J3

ANALOG INPUT

PT100/1000

1) PT_ALIM

2) PT_SENSE

3) PT_RTN

4) AIn_RTN

5) AIn 1

6) AIn 2

3

4

12

123456 1234562

J20

DIGITAL I/O

1) DO_RTN_PWM1

2) DO_ _PWM2

RTN

3) DO_PWM 1

4) DO_PWM 2

5) DIn 1

6) DIn_RTN

1234

J9

EXPANSION

BUS

J4

DIGITAL I/O

1) DIn 2

2) DIn 3

3) DIn 4

4) DIn_RTN

5) DIn 5 / CONT 2

6) DIn 6 / CONT 1

* In the PVI-AEC-EVO LIGHT model the RS458/1 port (J17) is not available as inverter communication port, but can be used only to

acquireparameters from powermeters equippedwith Modbuscommunicationinterface.ISKRAEMECO

5-EN

Monitoring System

E. Power Supply Connections and System Start Up

1. Connect the power supply to the power supply network (100/240V 50/60Hz): the "Power" led on the power

supply willlight up steadily.Check thatthe output voltageof the power supplyis 24Vdc.Disconnect the power

supplyfromthe powersupply network.

2. Connect theoutput of the powersupply tothe power supplyterminal blockof thePVI-AEC-EVO respecting the

polarity andusingthewiringprovided.

3. Connect thepower supplyto the powersupply network:After afirst starting phase(lasting about 30 seconds)

during whichthe systemis not able to receive anyinput from theuser,the green "PowerOn"led willremain lit.

The message“PVI-AEC-EVO...."(in the firstof the twolines) and date/time (in thesecond of the two lines)will

bedisplayed.

EN - ENGLISH

Output DC

24V 0.75A

DC

OK

STEP POWER

Input AC

100-240V

L(+) N(-)

L(+) N(-)

--++

12

+Vcc-Vcc

50-60 Hz

100-240 V~

Note: The system must be supplied with power supply and wiring provided; otherwise the CE

conformitywill notbe longervalid.

ONLY

6-EN

PVI-AEC-EVO / PVI-AEC-EVO LIGHT

QUICK INSTALLATION GUIDE

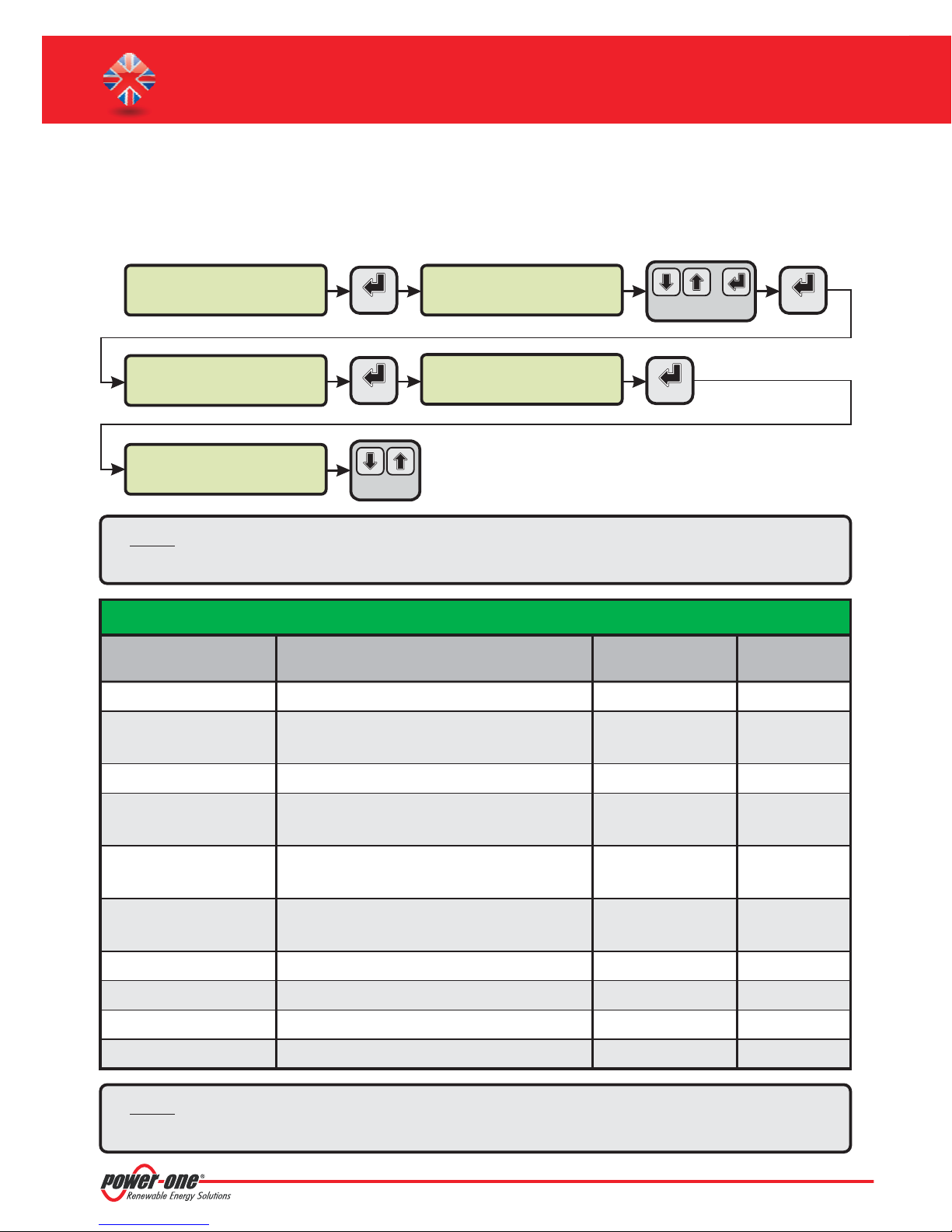

F. Date and time settings

1. Enterthe mainmenu asadministrator (Seepar.'C’).

2. Access the menu and then select the sub-menu. This enables to set the

correctdatein thesystem.

3. Return to themenu and then selectthe sub-menu. This enablesto setthe correcttime

inthesystem.

'SETTINGS' > 'DATALOGGER' 'SET DATE'

'DATALOGGER' 'SET TIME'

SET PIN TO 0010

PVI-AEC-EVO ......

12.00.00 01/01/11

>settings

change password

>set date

set time

>set time

network

ENTER ENTER

ENTER

ENTER

ENTER ENTER

menu pin

0***

>datalogger

io settings

>set date

01/01/11

>set time

12.00.00

CHANGE VALUE

ENTER

CHANGE VALUE

CHANGE VALUE

NEXT

DIGIT

NEXT

FIELD

NEXT

FIELD

ENTER

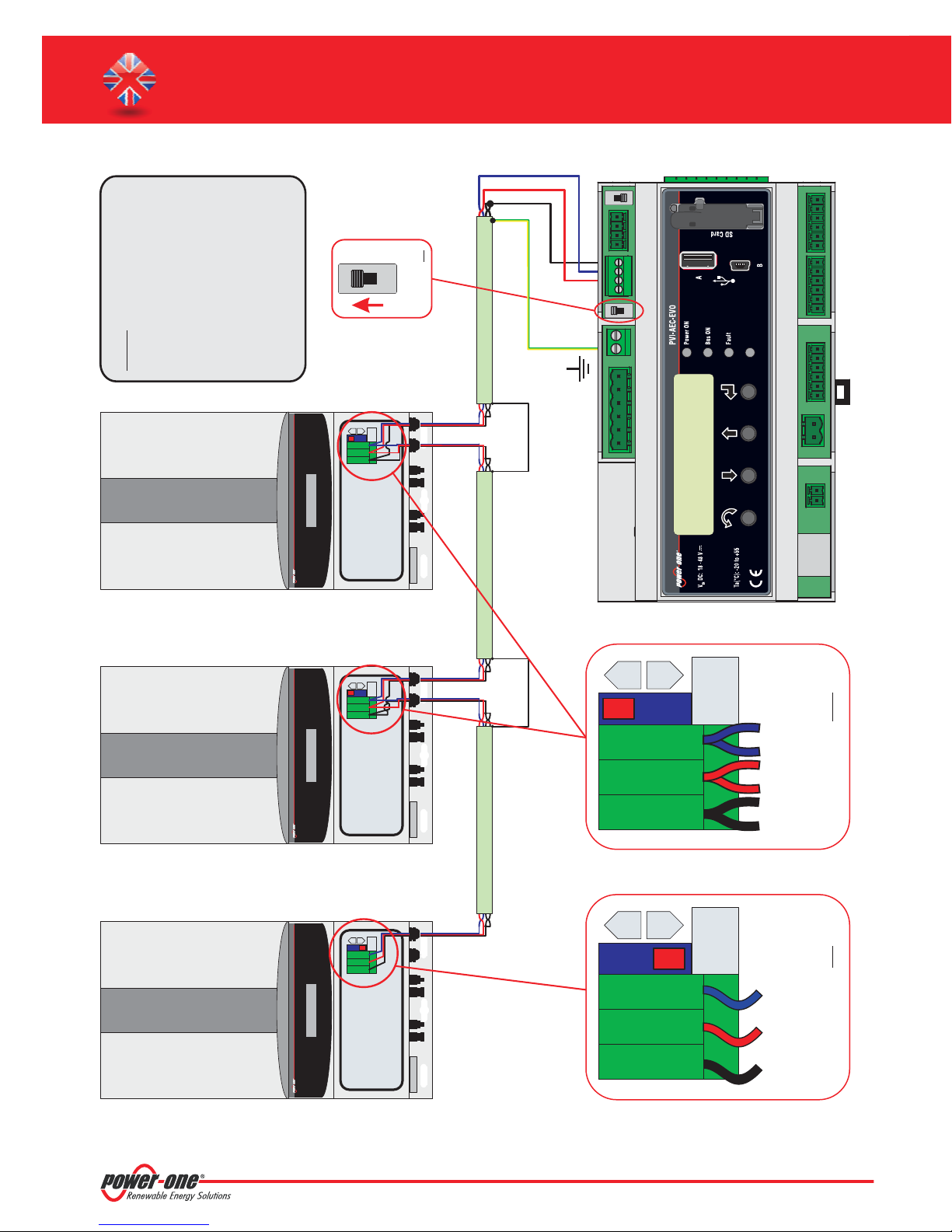

G. Connection of the RS485 line and inverter acquisition

check

TheconnectionoftheRS485 linemust becarried outrespecting thepin-outs ofthe J15 and/orJ17connectors.

Note: For PVI-AEC-EVO LIGHT, the only usable RS485 port for inverter monitoring is the RS485/2,

correspondentto connectorJ15.

I

t is recommended to connect the RS485 line when all the equipment is switched off (both the monitoring system

andtheinverters)and tostartupthemonitoring systemfirst andthen theinverters. Itisrecommended to:

Use a cable for RS485 applications with the following characteristics: 1 twisted pair+1conductor or two

l

twisted pairs,Screen and characteristic Impedance equal to 120 . For further informationon the cableto be

usedreferto Appendix2.

Makesure thesignals correspond.

l

Makesure thatall threelines(+T/R,-T/RandRTN)are connectedaccording tothediagramsin pages9-10.

l

l

Makesure thatthe communicationlinescreenis groundedaccording tothediagramsin pages9 -10).

Make sure that each element in the chain (each inverter or each 55kW module) has a RS485 address that is

l

differentfrom theothers.This addresscan be setviathedisplayof theinverter.

Ω

7-EN

Monitoring System

Note: For PVI-AEC-EVO LIGHT, the inverters must be set with addresses: 1,2, 3, 4,5. The configuration of

address1 correspondsto"AUTO"settings asinverter address.

Note: When connecting multiple units (string inverter or/and 55kW conversion modules) it is necessary

towire theRS485 communicationline accordingtothe daisy-chaindiagram (enter-exit).

Thelast inverterof thedaisy-chain mustbe 'terminated'byactivating thetermination resistanceof

the 120 communicationline throughswitching thedip-switch located onthe motherboardin the

stringinverters,and insideeach frameworkof thecentralinverters.

Note: The maximum number of units (string inverters or/and 55kW conversion modules) that can be

connected to a RS485 port of the PVI-AEC-EVO is 62.In order to connect a number of unitsgreater

than 62it isnecessary to usethe secondRS485/2 port respectingthe samewiring diagram usedfor

themain RS485/1port.

Ω

EN - ENGLISH

In the PVI-AEC-EVO LIGHT the number of inverters that can be acquired is limited to a maximum of 5

strings inverters which can be connected by RS485/2 (Ref. Par.D). Compatible models (in every their

variation) for the PVI-ACE-EVO LIGHT version are: PVI-2000(-OUTD); UNO-2.0/2.5-I-OUTD; PVI-3600;

PVI-3.0/3.6/4.2-TL-OUTD; PVI-3.8/4.6-I-OUTD; PVI-5000/6000-TL-OUTD; PVI-10.0/12.5-TL-OUTD;

PVI-10.0/12.0-I-OUTD.

Note: In case of mixed systems, the presence of both string inverters and central inverters on the same

RS485line ispermitted.Towire thisline followall thedirections above.

Note: All string inverters (except for models PVI-5000/6000-TL-OUTD) have a clamp that allows giving

continuityto thecable shieldofthe RS485line.

For single-phase inverters this clamp is indicated by the words LNK, for three-phase inverters it is

indicatedby SCLD.

Note: The centralized inverters have a clamp, which is located in the signal terminal block and marked

with “X23”, that allows to link to ground theshield of each singular portion of the communication

line independentlyfrom the other portionof communication line.(must notbe given continuity to

thecable shield).

Note: For further details on the wiring of the RS485 line and/or the activation of the termination

resistances,refer totheuser manualof stringinverters andtothe usermanual ofcentralinverters.

8-EN

PVI-AEC-EVO / PVI-AEC-EVO LIGHT

QUICK INSTALLATION GUIDE

-T/R

+T/R

RTN

1234

Note: Make sure that each

inverter in the chain has a RS485

address that is different from the

others. For PVI-AEC-EVO LIGHT,

the inverters must be set with

addresses: 1, 2, 3, 4, 5. The

configuration of address 1

corresponds to "AUTO" settings as

inverteraddress.

AURORA

AURORA

ON

Ω

120 TERM.

RESISTOR

Ω

ON

OFF

120

Term.

Resistor

-T/R

+T/R

RS485

RTN

Ω

ON

OFF

120

Term.

Resistor

-T/R

+T/R

RS485

RTN

OFF

12

3

4

ON

-T/R

+T/R

RTN

Ω

RESISTOR

120 TERM.

RS485

OFF

Ω

120 TERM.

RESISTOR

RTN +T/R -T/R

AURORA

ON

Ω

ON

OFF

120

Term.

Resistor

-T/R

+T/R

RS485

RTN

OFF

-T/R

+T/R

RTN

Ω

RESISTOR

120 TERM.

RS485

-T/R

+T/R

ON

Ω

120 TERM.

RESISTOR

RTN

9-EN

Monitoring System

EN - ENGLISH

Note: Make sure that each

OFF

Ω

120 TERM.

RESISTOR

55 kW module in the chain

has a RS485 address that is

1234

12

3

4

ON

Ω

120 TERM.

RESISTOR

-T/R

+T/R

RTN

different from the others.

X20 X21 X22 X23 X24 X25 X26 X27

A

D

OFF

Ω

120 TERM.

RESISTOR

ON

Ω

120 TERM.

RESISTOR

X20 X21 X22 X23 X24 X25 X26 X27

A

D

RTN +T/R -T/R

D

X20 X21 X22 X23 X24 X25 X26 X27

A

D

-T/R

+T/R

RTN

D

X20 X21 X22 X23 X24 X25 X26 X27

A

X20 X21 X22 X23 X24 X25 X26 X27

A

10-EN

PVI-AEC-EVO / PVI-AEC-EVO LIGHT

QUICK INSTALLATION GUIDE

After carrying out these checks, start up first the monitoring system and then the inverters. The system automatically

carries outa scan ofthe RS485 busand automaticallydetects theavailable inverters.Thepresenceof the inverterscan be

checkeddirectly fromthedisplay.

1. Enter themainmenu asadministrator(Seepar.'C’).

2. Access the menu (to displaythe string inverters) and/or

'ENERGY RACK'

'CURRENTVALUES'> 'ENERGY INVERTERS' 'CURRENTVALUES'>

(to displaythe 55kW conversionmodules). The numberof inverters detected duringthe scan will be

displayed;the listof themonitoredinverters identifiedby theSerialNumber (S/N)can bedisplayedby scrollingusing

thearrow keys( ).

SET PIN TO 0010

PVI-AEC-EVO ......

12.00.00 01/01/11

>CURRENT VALUE

SETTINGS

>ENERGY INVERTERS

ENERGY RACK

>ENERGY RACK

ENERGY PLANT

ENTER ENTER

ENTER

ENTER

ENTER

menu pin

0***

30 INVERTERS

>INVERTER SN 123456

RACK N. 1

>RACK SN 123456

CHANGE VALUE

CHANGE

INVERTER

CHANGE

RACK

NEXT

DIGIT

Note: The time necessary for the PVI-AEC-EVO to scan and acquire the inverters depends on the number of

inverterspresent onthe sameline (sometimesseveral minutes).

H. Configuration of the Analog Inputs

Theconnection ofthe analoguesensors mustbe carriedoutrespecting thepin-outs ofthe J3connector.

Thesystem hastwo0-10Vdc inputsand aPT100/1000input.

Note: To eachanalogue input(both 0-10Vdc and PT100/1000types) it ispossible toconnect only oneanalog

sensor. It istherefore notpossible toconnect multiplesensors onthe sameanalog input.

With respect tothe connection ofthe PT100/1000 sensors,the system isable tocarry outthe sensor readingthrough the

connectionof three-wires:

Asensor powersupplyline (PT_ALIM);

l

Areading line(PT_SENSE);

l

Apower supplyandreading closingline(PT_RTN).

l

11-EN

Monitoring System

The measurement is carried outbetween PT_SENSE and PT_RTN,therefore the element to be measured must bewired

betweenthese twosignals.

The PT100/PT1000 sensor is automatically recognised by the system and is therefore acquired without the need for

further settings.

Regarding theconnection of the sensorswith output range0...10Vdc,these mustbe powered andthe power supplycan

be taken directly from the system power supply; the grounding of the power supply and the grounding of the signal

readingis thesame.

For the sensor connection, beside the power supply, it is necessary to connect the signal proportionally to the quantity

measuredat oneofthe twoanaloginputsavailable(Aln1/Aln2).

Thegrounding ofthe signal to bemeasured (ifdifferentfrom thegrounding ofthe powersupply –within thePower-One

sensorrange onlyin thewind speedsensor PVI-AEC-WIND-COMPACT) mustbe connectedto theAln_RTN clamp.

After carrying out the connections it is necessary to configure the sensor in the system so that the correct quantity is

acquired:

1. Enter themainmenu asadministrator(Seepar.'C’).

EN - ENGLISH

2. Access themenu .

3. Select the item and then select the sensor model connected tothe AIn1 input of the system (the

'SETTINGS' >'IO SETTINGS'

“ANALOG INPUT1”

selectedmodel willbe identifiedwithan asterisk(*)).

4. Select the item and then select the sensor model connected to the AIn2input of the system (the

“ANALOG INPUT2”

selectedmodel willbe identifiedwithan asterisk(*)).

Note: Incase ofconnecting PT100/1000 sensorswith onlytwo terminals,connect a terminalto thePT_SENSE

clampand aterminalto thePT_RTN clamp,thenmake ajumper betweenPT_ALIM andPT_SENSE.

SET PIN TO 0010

PVI-AEC-EVO ......

12.00.00 01/01/11

>settings

change password

ENTER ENTER

ENTER

menu pin

0***

>io settings

UPGRADE FIRMWARE

CHANGE VALUE

ENTER

NEXT

DIGIT

>ANALOG INPUT1

ANALOG INPUT2

>ANALOG INPUT2

PULSE IN1

ENTER

ENTER

>ANALOG INPUT1

T1000-INTEGR *

>ANALOG INPUT2

RAD-13TC *

12-EN

CHANGE

SENSORS

CHANGE

SENSORS

ENTER

ENTER

PVI-AEC-EVO / PVI-AEC-EVO LIGHT

QUICK INSTALLATION GUIDE

Toreadthe measurementsof thesensors andtochecktheiraccuracy followthe instructionsbelow:

1. Enterthe mainmenu asadministrator (Seepar.'C’).

2. Access the menu . The quantity value will be displayed for each of the

analoginputs.

PVI-AEC-EVO ......

12.00.00 01/01/11

>CURRENT VALUE

SETTINGS

>T1000-INTEGR AN1

20.0 DEGC

'CURRENT VALUES' > 'ANALOG VALUE'

menu pin

ENTER ENTER

ENTER ENTER

CHANGE

INPUT

0***

>ANALOG VALUE

DIGITAL VALUE

SET PIN TO 0010

CHANGE VALUE

NEXT

DIGIT

Note: In the following table it is reported a list of the sensor which are present in thecatalogue “Power-one”.

Forthe connection ofthese sensors,please makereference todiagrams showninAppendix 1.

SENSORS WITH ANALOG OUTPUTS COMPATIBLE WITH PVI-AEC-EVO (POWER-ONE CATALOGUE)

MODELL TYPE

PVI-AEC-IRR

Radiation sensor (W/m --> V)

PVI-AEC-IRR-T Radiation sensor with integrated cell

temperature sensor

PVI-AEC-RAD-13TC

PVI-AEC-RAD-13TC-T

Radiation sensor (W/m --> V)

Radiation sensor with integrated cell

temperature sensor

2

2

(W/m --> V)

/°C

2

2

(W/m --> V)

/°C

DISPLAY

IDENTIFICATION CODE

IRR

IRR-T_Irr /

IRR-T_Temp

RAD-13TC

RAD-13-TC-T_Irr /

RAD-13-TC-T_Temp

OPERATIVE

RANGE

0-1200 W/m

0-1200 W/m

-20 to +80 °C

0-1300 W/m

0-1300 W/m

-25 to +90 °C

2

2

2

2

PVI-AEC-T100-ADH

Adhesive module temperature sensor

(back cell) PT100

PVI-AEC-T1000-INTEGR

Ambient temperature sensor connected to

PT100/0...10Vdc converter (°C --> V)

PVI-AEC-T1000-BOX

PVI-AEC-PYR-1300

PVI-AEC-WIND-COMPACT

PVI-AEC-WIND-DIR

Ambient temperature sensor PT100

Pyranometer ( --> V)W/m

Wind speed sensor (m/s --> V)

Wind direction sensor (° --> V)

Note: The system is predisposed for the connection to other sensors available: ZippZonen Pyranometer 0-

1600W/m and

2

Pyranometer0-2000W/m .

T100-ADH

T1000-INTEGR

T1000-BOX

2

Pirano_0-20mA

WIND-COMPACT

WIND-DIR

2

13-EN

-50 to +150 °C

-50 to +50 °C

-50 to +50 °C

0-1300 W/m

2

0-50m/s

0 - 360°

Monitoring System

I. System Configuration for connection to the LAN

Network (Ethernet Port)

The connectionto the PCof PVI-AEC-EVOcan bemade through directconnection viaEthernet cable,or connecting

bothdevicesto alocal networkLAN (viarouter,hub orswitch).

Incase of direct connection,it isenough toconnect thetwo devicesbetween themthrough aEthernet cable andset

thenetworkparameters ofPVI-AEC-EVO andof thePC tomakesure theyare compatiblebetweenthem.

Note: The IPaddress of the PCand the IP addressof the PVI-AEC-EVO must belongto the same groupbut

they ,for instance:

mustnot beidentical

PC IP ADDRESS:

PVI-AEC-EVO IP ADDRESS:

The subnet mask must be the same for both devices, for instance: 255.0.0.0

Incase ofconnection toa pre-existinglocal networkLAN,itisnecessaryto assignto PVI-AEC-EVOthe networkparameters

which have to be compatible with the local network to which the PVI-AEC-EVO is connected. Make reference to the

networkadministrator toobtain thecorrect parametersof thenetwork.

20.200.200.

20.200.200.

1

24

EN - ENGLISH

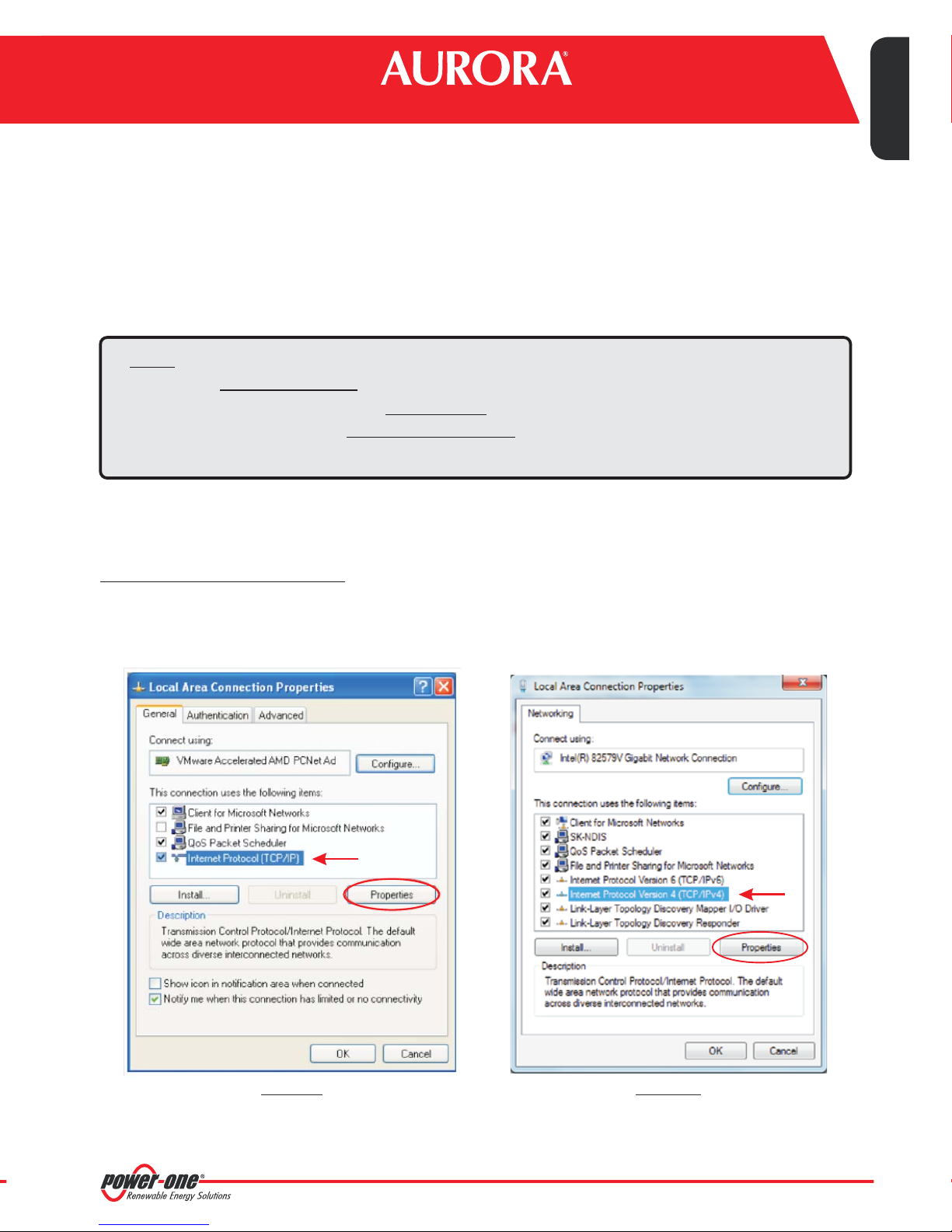

CHANGEOF PCNETWORK PARAMETERS

In order to change pc network parameters, please select and then click on

Connections”

“LocalArea Connection” “Properties”

: the new window will show the network connections; with the right button of your mouse click on

andselect ;asshowninthe followingfigure.

“Start” “Control Panel”, “Network

Windows XP Windows 7/8

Select (or in Windows 7/8) and click on“Internet Protocol (TCP/IP)” “Internet Protocol Version 4 (TCP/IPv4)”

“Properties”.

14-EN

PVI-AEC-EVO / PVI-AEC-EVO LIGHT

QUICK INSTALLATION GUIDE

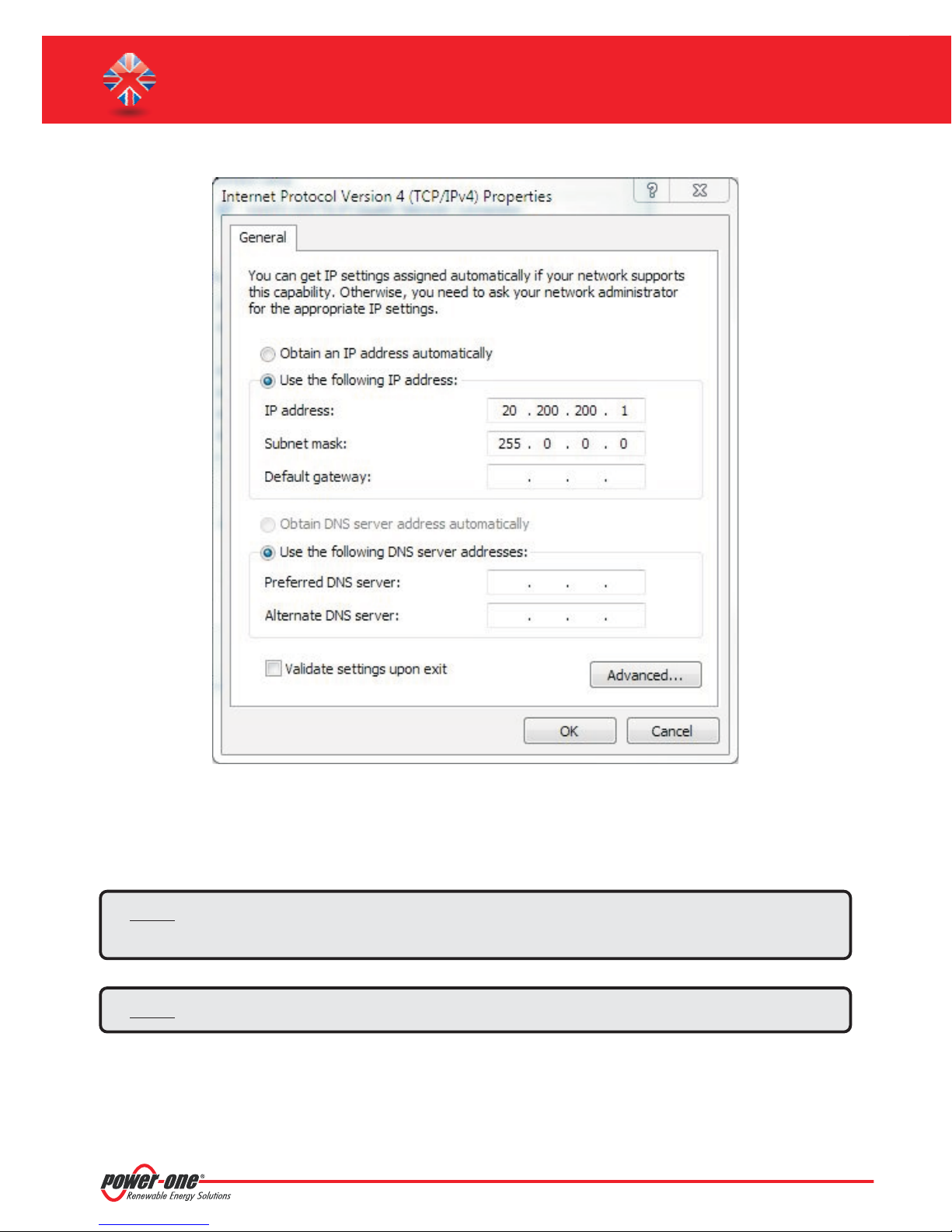

Select the option and insert the network parameters (IP address, Subnet Mask,

“Use the following IP address”

Gateway)compatible withthe networkparametersset inthe PVI-AEC-EVO.

DNSparametersfields canbe letempty.

Note: In case of direct connection between PVI-AEC-EVO and PC we suggest not to set “Gateway”

parameters.

Note: Thistype ofprocedureis tobe consideredonly anexample forthe mostpopularoperating systems.

15-EN

Monitoring System

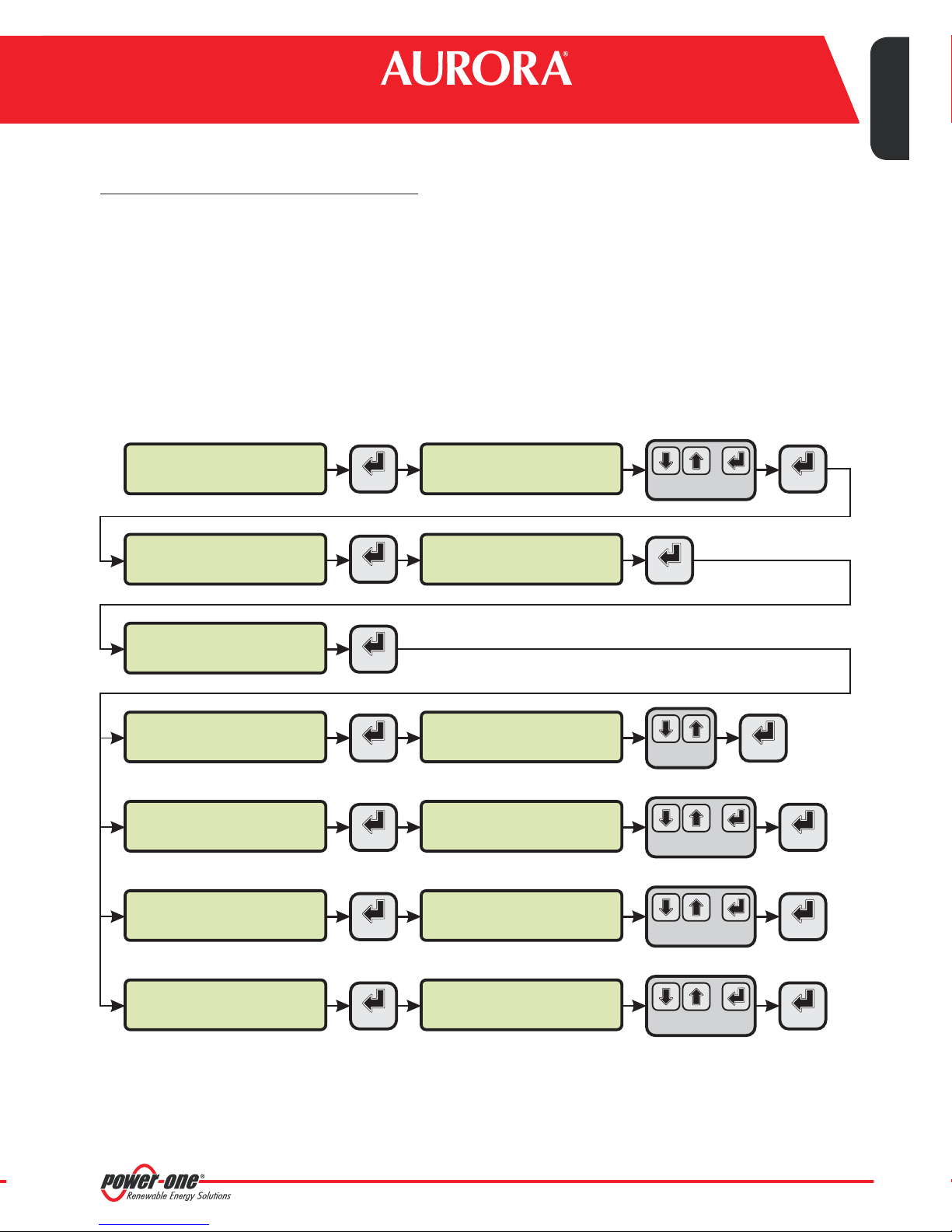

CHANGETHEPVI-AEC-EVONETWORK PARAMETERS

:in ordertochange thePVI-AEC-EVOnetworkparameters,please followthe procedurebelow:

Poweron thesystemandwaitfor thestartupphaseto complete(Ref.Par.'E’).

1.

Enterthe mainmenu asadministrator (Ref.Par.'C’).

2.

3. Access themenu .

“SETTINGS” > “NET WORK ”

Subnet mask,Gateway)may bemodified using the items ofthe menu.This allowsto configure the

systemfor connectionto theLAN networkand/or fordirectconnectiontoaPC.

4. At the end of the setting operations, return to the main screen, then switch off and switch on the system to

makethe settingstake effect.

The parametersfor connection to theLAN network (IP address,

"NETWORK"

SET PIN TO 0010

EN - ENGLISH

PVI-AEC-EVO ......

12.00.00 01/01/11

>settings

change password

>NETWORK

SET DATA

>IP method

ip setting

>IP SETTING

SUBNET MASK

>SUBNET MASK

ip gateway

menu pin

ENTER ENTER

0***

CHANGE VALUE

NEXT

DIGIT

>datalogger

ENTER

ENTER

io settings

ENTER

>IP method

ENTER ENTER

manual

CHANGE

METHOD

>IP SETTING

ENTER ENTER

XXX.XXX.XXX.XXX

CHANGE VALUE

NEXT

DIGIT

>subnet mask

ENTER ENTER

XXX.XXX.XXX.XXX

CHANGE VALUE

NEXT

DIGIT

>IP gateway

ip method

>IP gateway

ENTER ENTER

XXX.XXX.XXX.XXX

16-EN

CHANGE VALUE

NEXT

DIGIT

PVI-AEC-EVO / PVI-AEC-EVO LIGHT

QUICK INSTALLATION GUIDE

L. Internal Webserver access

In order to access to the Webserver pages of the system, after having done the connection of the system to the local

network LAN or direct connection to the PC, open an internet browser (e.g. Internet Explorer) and type into the

addressbar thefollowing address:

Note: Toaccess thewebserver pagesitis necessaryto inserta usernameand apassword:

USERNAME: admin PASSWORD: admin

After having done the access to the internal Webserver, go to the configuration page (CONFIG) of the system

(PLANT) andinserttheinstallationGPS coordinatesaccordingto oneof thefollowingformats:

Indicator Degrees Point Degrees (Hundredths of degree)

Latitude

Longitude

N43.33

E11.35

http://<system IP address>

N43 . 33

E11. 35

Degrees Indicator

Latitude

Longitude

*

The Double Quotation Mark ( ”) symbol must be inserted by entering twice the quotation mark(')symbol.

43N50’20”

11E23’30”

43

11

N

E

Minutes Quotation Mark Seconds Double quotation mark*

50

23

‘

‘

20

30

“

“

Note: Toset theGPS parameteris mandatoryto assurethe properworking ofmonitoring system.

17-EN

Monitoring System

Inordertoallow thePVI-AEC-EVOtocommunicate withthe AuroraVision webportal,accesstheconfigurationpage

(CONFIG) of the network (NETWORK) and check that in section 'DATA TRANSFER', under item 'IP Address Portal'

thereis theIP address .63.236.63.180

Note: If the setting 'IP Portal Address' does not correspond to 63.236.63.180, change it by entering the

above-mentioned address and press 'Confirm' to activate it. After this operation,reset the system

(ON-OFF).

Note: To make the system fully functioning it is essential that the same system is constantly connected

to the internet so that it is able to communicate with the Power-One server. This is essential to

graphicallyshows the dataon web pagesas wellas for sendingalarm and/or report messages.It is

essential that the LAN network in which the PVI-AEC-EVO is wired is such that it allows the

connection to the IP address 63.236.63.180 to be reached through port 80, so that the

PVI-AEC-EVO is ableto communicatewith theportal managementserver.

EN - ENGLISH

18-EN

PVI-AEC-EVO / PVI-AEC-EVO LIGHT

QUICK INSTALLATION GUIDE

19-EN

Monitoring System

M. MAC Address Identification

During the process of associationof PVI-AEC-EVO in AuroraVision you will beprompted toenter the MAC addressof the

PVI-AEC-EVOpresent inthesystem.

Itis possibletoobtain theMACAddressofyourPVI-AEC-EVO observingthe labelonthe rightside ofthe product.

TheMAC Addressis composedof12 characters(separatedby acolon)shownin red for examplein thefigure below.

PVI-AEC-EVO

P-1 P/N: 3I72001F100G Prod. Week 16/11

S/N: 3I72001F100G 000464VI1611

EN - ENGLISH

MAC ADDRESS: 00:50:C2:42:38:24

Alternativelyit's possibleto obtainthe MACAddress fromthe display:

1. Enter themainmenu asADMINISTRATOR(refer topar.“C”)

2. Enter the menu.

3. Using thearrowbuttons ( )moveto view

PVI-AEC-EVO ......

12.00.00 01/01/11

>INFORMATION

“INFORMATION” > “PRODUCT”

CURRENT VALUE

pN

3I72

“MACADDRESS” .

menu pin

ENTER ENTER

ENTER ENTER

CHANGE

MENU

0***

>PRODUCT

NETWORK

MAC ADDRESS

00:50:C2:42:38:24

SET PIN TO 0010

CHANGE VALUE

NEXT

DIGIT

20-EN

PVI-AEC-EVO / PVI-AEC-EVO LIGHT

QUICK INSTALLATION GUIDE

O. Firmware updating procedure via SD Card

It is possible to upgrade the firmware of the PVI-AEC-EVO either locally using the SD Card, or remotely using the web

portal AuroraVision.

Note: The firmware update via SD card should be carried out.only if it is not possible to update the firmware

viathe AuroraVision webportal

Note: For detailson theprocedure forthe firmware updatingthrough theweb portal AuroraVision,refer

tothe documentationon thewebsite .www.Auroravision.net

1. Access thedisplay byenteringthe userpassword0000.

2. Check andnotethe currentfirmwareversions installed:

FirmwareAVR: Information > Product > FirmwareAVR

FirmwareDisplay:

FirmwareIO:

3. Turnoff thePVI-AEC-EVOand waitatleast oneminute.

4. Disconnect allavailableconnections fromthePVI-AEC-EVO(RS458 line(s),LANconnection,sensors).

5. Remove theSD Cardfromthe slotonthePVI-AEC-EVO frontpanelby pressingtheSD Cardgently.

6. Insertthe SDCardinto theSDCard readerorinto totheSD Cardreaderslot ofthePC.

7. Delete thefoldersupgrade,web,langand configfromthe SDCard.

8. Copythe newfolders upgrade,web,lang andconfiginto therootof theSDCard.

9. Remove theSD Cardfromthe SDCardreader orfromthe SDCardreader slot.

10. Insert theSDCard intotheslot onthe PVI-AEC-EVOfront panelbypressing theSD Cardgently tolockit intoplace.

11. Turnon the PVI-AEC-EVOand wait aboutone minute.(N.B.: Powerfailure duringupdatemay cause seriousdamage

tothe device).

12. Enterthe displaybypushing theENTER buttonand insertthe password“0010”;push ENTERto confirm.

13. Followthe path: pressENTER to confirm;wait thecompleting of

upgrade(fewminutes).After theupgrade thesystemwill reboot:wait thecomplete reboot (date/timewill beshown

onthe display).

“SETTINGS > UPGRADE FIRMWARE> UPGRADE AVR”

Information > Product > FirmwareDisplay

Information > Product > FirmwareIO

14. Enterthe displaybypushing theENTER buttonand insertthe password“0010”;push ENTERto confirm.

15. Follow thepath press ENTERto confirm;wait thecompleting of

upgrade (few minutes). The upgrading process will be completed when the message will be

displayed.

“SETTINGS > UPGRADE FIRMWARE > UPGRADE ADC”

“Upgrade Success”

21-EN

Monitoring System

EN - ENGLISH

16. Followthe path pressENTER toconfirm;waitthe completing

of upgrade (few minutes).The upgrading process will be completed when the message will be

“SETTINGS >UPGRADE FIRMWARE>UPGRADE DISPLAY”

“Upgrade Success”

displayed.

17. Follow the path press ENTER to confirm; wait the completing of upgrade (few

minutes).The upgrading process will be completed when the message will be displayed again.

“SETTINGS > UPGRADE CONFIG”

“UPGRADE CONFIG”

PressESC toexit.

18. Switchoff thesystem,restoreallconnections (RS485line(s),LANconnection,sensors),thenswitchon thesystem.

22-EN

PVI-AEC-EVO / PVI-AEC-EVO LIGHT

GUIDA DI INSTALLAZIONE RAPIDA

INDICE

A. Descrizione del prodotto 2

B.

C.

D.

E.

F.

G.

H.

I.

L.

M.

Contenuto della confezione

Interfaccia Utente ed utilizzo del display

Piedinatura dei connettori del sistema

Collegamento dell’alimentazione del sistema

Impostazione di data ed ora

Collegamento della linea RS485 e verifica dell’acquisizione degli inverter

Configurazione degli ingressi analogici

Configurazione del sistema per la connessione in rete LAN (porta Ethernet)

Accesso alWebserver interno

Identificazione del MAC Address

3

4

5

6

7

7

11

14

17

20

N.

Aggiornamento Firmware

Appendici

1) Schemi di collegamento sensori

2) Caratteristiche cavo RS485

3) Display flow-charts

4) Requisiti di conformità

21

1-IT

Monitoring System

A. Descrizione del Prodotto

I sistemiPVI-AEC-EVO ePVI-AEC-EVO LIGHT sonosistemi dimonitoraggio e controllo degliimpianti fotovoltaicirealizzati

conprodotti Power-One. Nel seguitosi faràriferimento al"sistema" intendendoentrambe leversioni diprodotto,mentre

verràspecificato ilmodello nelcaso incuile lorocaratteristichesiano differenti.

Il prodottoconsente l'acquisizionedei parametri dainverter e stringcomb (secondol'architettura dimonitoraggio

degliinvertercentralizzati) attraversolineaRS485conprotocollo proprietarioPower-One.

Il sistemadispone di due porte RS485(equivalenti traloro) che permettono l'acquisizione,ciascuna, di 62 inverter

di stringa o di 62 moduli di conversione da 55kW (inverter centralizzati modulari); E’inoltre possibie utilizzare la

porta di comunicazione RS485/1 (rif. capitolo D) per l’acquisizione di parametri da contatori ISKRAMECO MT831

dotatidi interfacciacomunicazioneModbus.

Nota: Nella versione PVI-AEC-EVO LIGHT il numero di inverter monitorabili è limitato ad un massimo di 5

inverterdi stringa,collegabili unicamentealla portaRS485/2 (Rif.Par.D). I modellicompatibili (intutte

leloro varianti)sono iseguenti:

PVI-2000(-OUTD) UNO-2.0/2.5-I-OUTD PVI-3600

IT - ITALIANO

PVI-3.0/3.6/4.2-TL-OUTD* PVI-3.8/4.6-I-OUTD PVI-5000/6000-TL-OUTD*

PVI-10.0/12.5-TL-OUTD* PVI-10.0/12.0-I-OUTD

(*): La compatibilitàè estesaanche alleprecedenti versioninazionali ( Es: PVI-3.6-OUTD-IT )

Nella versionePVI-AEC-EVO LIGHT la porta di comunicazione RS485/1(Rif. Par.D) può essere utilizzata

unicamente per l’acquisizione di parametri da contatori ISKRAMECO MT831 dotati di interfaccia

comunicazioneModbus.

Il sistema dispone di tre ingressianalogici per il collegamento di sensori per lamisura dei parametri ambientali:PowerOne offre, a catalogo, una gamma completa di sensori di irraggiamento, temperatura ambiente e di cella, velocità e

direzionedel vento.

Ilsistema metteadisposizione anchesei ingressidigitaliper l'acquisizionedi segnalidistato (adesempiocontatti ausiliari

diinterruttori dipotenza)a cuisonoassociatecondizionidiallarme distato.

Relativamente all'interfaccia utente, il sistema dispone di un display 2x16 caratteri e quattro pulsanti oltre che di un

webserverintegrato dipaginehtml accessibileattraversoconnessione LAN.

La configurazione iniziale del sistema (verifica dell'acquisizione dei parametri da inverter,configurazione degli ingressi

analogici,configurazione deiparametri direte LAN)puòessere eseguitainteramenteattraverso ildisplayed ipulsanti;per

la visualizzazione dei parametridi dettaglio degli inverter e/o dellestringcomb nonchè per le configurazioni avanzate è

necessarioaccedere allepaginedi webserverintegrato.

Il PVI-AEC-EVOlavora inabbinamento al servizio diportale web AuroraVision: effettuando laregistrazione a taleservizio

saràpossibile effettuareilmonitoraggio elagestioneda remotodegli impiantiassociati alproprio account.

Ilportaleweb AuroraVision èdisponibilealla paginaweb: www.Auroravision.net

2-IT

PVI-AEC-EVO / PVI-AEC-EVO LIGHT

GUIDA DI INSTALLAZIONE RAPIDA

B. Contenuto della confezione

1

AURORA PVI-AEC-EVO / PVI-AEC-EVO LIGHT

2

Alimentatore 100-240Vac 50-60Hz / 24Vdc

3

Cablaggio connessione alimentatore

Guida di installazione rapida

4

SD Card (assemblata)

5

Controparti morsettiere I/O (assemblate)

6

Controparti morsettiere Rs485 (assemblate)

7

Controparte morsettiera Relè (assemblata)

8

Controparte morsettiera Alimentazione

9

(assemblata)

1 2 4

--++

Output DC

24V 0.75A

DC

OK

STEP POWER

Input AC

100-240V

L(+) N(-)

3

5 6 7 8 9

Nota: Verificareche ilcontenutodella confezione corrispondaalla listadicui sopra.

Controllare inoltre che non vi siano danneggiamenti alla confezione, al dispositivo e agli accessori in

corredo. In caso di non conformità si consiglia di presentare reclamo presso la ditta di trasporti e di

comunicaretempestivamenteal servizio diassistenza tecnicaoppureal customerservice di Power-One

ladifformità riscontrata.

3-IT

Monitoring System

C. Interfaccia Utente ed utilizzo del display

Il sistemadispone di un display 2x16 caratteri,quattro pulsantiper la navigazione neimenu e tre LEDche indicano

lostatodel dispositivo.

Attraversol’uso del display edei pulsantiposti sulpannello frontaleè possibile effettuarela configurazioneiniziale

del sistema (verifica dell'acquisizione dei parametri da inverter, configurazione degli ingressi analogici,

configurazionedei parametridi reteLAN).

Per la visualizzazione dei parametri di dettaglio degli inverter e/o delle stringcomb nonchè per le configurazioni

avanzateè necessarioaccedereal webserverinterno seguendola proceduradescritta nelparagrafo“L”.

Unalista dellefunzioni accessibilida displayèmostrata nellatabella presentein Appendice3.

UTILIZZO DEI PULSANTI

IT - ITALIANO

Pulsante “Enter”. Viene utilizzato per accedere al menu principale o al

sottomenu corrispondente alla voce selezionata (indicata dal simbolo >), o per passare alla cifra

successivada modificare.

Pulsante“Down”. Viene utilizzato per scorrere le voci dei menu verso il basso, oppure per scorrere la

scalanumerica inordinedecrescente.

Pulsante“Up”. Viene utilizzato per scorrere le voci dei menu verso l’alto,oppure per scorrere la scala

numericain ordinecrescente.

Pulsante“Esc”. Viene utilizzato per tornare al menu precedente o per tornare alla cifra precedente da

modificare.

Accessoal menuprincipale conprivilegidiamministratore

Perpotereffettuare leconfigurazioniiniziali, è necessarioaccedere comeamministratoreai varimenu deldisplay.

Premereil tasto“ENTER”( ) edinserire lapassword : per inserirelapassword premerei tastifreccia( )

permodificare ilvaloreed iltasto“ENTER”perconfermare ilvalore. Attraversoquesta passwordè possibileaccederea

tuttii sottomenudiimpostazione delsistema dadisplay.

per confermare un’ azione,

0010

4-IT

PVI-AEC-EVO / PVI-AEC-EVO LIGHT

GUIDA DI INSTALLAZIONE RAPIDA

D. Piedinatura dei connettori del sistema

Loschema diseguito riportala piedinaturadei connettorichepermettonola connessionedel sistema.

J5

RELAY

1) RELAY1-C

2) RELAY 1 - N.O

RELAY2-C

3)

4)

RELAY 2 - N.O

5)

RELAY3-C

6)

RELAY 3 - N.O

J12

GROUND

S2

120

Ω TERM.

RS485/1

J17

RS485/1

1) RTN

2) - T/R

3) +T/R

4) +5V

*

J15

RS485/2

1) RTN

2) - T/R

3) +T/R

4) +5V

S1

120

Ω TERM.

RS485/2

J7

LAN

IEEE802.3u

11122

J18

BATTERY IN

1) + Batt.

2) - Batt.

NOTE:

Only for dedicated

accessory

PVI-BATTERY-PACK

123456

J8

Vin DC

1) + Vcc

2) - Vcc

INPUT DC:

24 Vdc

(max. 48 Vdc)

0,3 A

NOTE:

Use the provided

power supply

5

3

6

4

J3

ANALOG INPUT

PT100/1000

1) PT_ALIM

2) PT_SENSE

3) PT_RTN

4) AIn_RTN

5) AIn 1

6) AIn 2

3

4

12

123456 1234562

J20

DIGITAL I/O

1) DO_RTN_PWM1

2) DO_ _PWM2

RTN

3) DO_PWM 1

4) DO_PWM 2

5) DIn 1

6) DIn_RTN

1234

J9

EXPANSION

BUS

J4

DIGITAL I/O

1) DIn 2

2) DIn 3

3) DIn 4

4) DIn_RTN

5) DIn 5 / CONT 2

6) DIn 6 / CONT 1

* Nel modelloPVI-AEC-EVO LIGHTlaportaRS485/1 (J17)non èdisponibileper l’acquisizionedegli inverter,maè utilizzabileunicamente

perl'acquisizione diparametrida contatoriISKRAEMECO dotatidi interfaccia dicomunicazione ModBus.

5-IT

Monitoring System

E. Collegamenti di alimentazione del sistema

1. Collegarel'alimentatore allaretedi alimentazione(100/240V- 50/60Hz):il led“Power”dell'alimentatoresi accenderà

stabilmente.Verificare che la tensione di uscita dell'alimentatore sia 24Vdc. Scollegare l'alimentatore dalla rete di

alimentazione.

2. Collegare l'uscita dell'alimentatore alla morsettiera di alimentazione del PVI-AEC-EVO (rispettando la polarità)

utilizzandoil cablaggiofornitoa corredo.

3. Collegare l'alimentatore alla rete di alimentazione: dopo una prima fase di avvio (della durata di circa 30

secondi), durante la quale il sistema non è in grado di ricevere input da parte dell'utente, il led verde“Power ON”

rimarrà stabilmenteacceso.A display saràvisibile la scritta“PVI-AEC-EVO....”(nella prima delledue righe) edata/ora

(nellaseconda delleduerighe).

IT - ITALIANO

Output DC

24V 0.75A

DC

OK

STEP POWER

Input AC

100-240V

L(+) N(-)

L(+) N(-)

--++

12

+Vcc-Vcc

50-60 Hz

100-240 V~

Nota: Il sistema deve essere alimentato con l'alimentatore ed il cavo fornito a corredo, pena il

decadimentodella certificazione CE.

unicamente

6-IT

Loading...

Loading...