Aurora 151-302-0000, 151-301-0000, 151-301-0002, 151-301-0003, 151-301-0004 Technical Information

...Page 1

Technical

Information

no.

912-100-0123

page

1/8

Heater Mini

Content:

1 Safety advises

2 Device description

3 Function description

4 Operation

5 Installation

6 Technical data

7 Maintenance

8 Spare parts

9 Optional accessories

10 Fault diagnosis

A U R O R A

Konrad G. Schulz GmbH & Co. KG

Tel.: 0 62 84 / 92 02-0

info@aurora-eos.com

www.aurora-eos.com

The information on this document and the copyrights are ownership of

AURORA Konrad G. Schulz GmbH & Co. KG, Joachim Schulz str.4, D-69427 Mudau.

Transmission or duplication of this document or the utilization of the contents is not allowed without the

agreement of AURORA Konrad G. Schulz GmbH & Co. KG otherwise it is explicit allowed. Violation will be

prosecuted. All rights of patents, industrial designs and trademarks are reserved.

Please pay attention to ISO 16016.

We reserve the right to make technical modifications

author: 15.04.1999 KH

date/name

checked: 25.03.15 CK

date/name

released: 25.03.15 i.A.CK

date/name

a) 7726 14.05.01 KH e) 11717 11.07.06 KH i) 20613 11.11.13 KH

b) 8639 19.03.03 KH f) 12014 24.10.06 KH j) 21985 10.03.15 KH

c) 9708 28.06.04 KH g) 16415 05.10.10 KH

d) 11440 18.04.06 KH h) 19358 08.11.12 KH

Page 2

Technical

Information

no.

912-100-0123

page

2/8

1 Safety advises

Please consider the following advice for your own safety.

• Please have maintenance work and repairs exclusively carried out by authorised personnel.

• Do not grip into the unit and do not put objects inside.

• Maintenance work is to be carried out only when the blower-motor is not running. In order to

avoid injuries, the motor is to be separated from the current circuit.

• Attention! Danger of burning! Please do not get into contact with the heat exchanger and

its connections. Cooling tubes and cooling hoses can be hot and stand under pressure. Be

careful by touching them.

• This also applies for 2-speed versions to the resistor when working at the opened unit and

the construction part has not completely cooled down.

• Attention: cables may not affect the resistor!

• At maintenance work and repairs wear necessary protective clothing.

Advice for installation and maintenance work:

Please pay attention to the rules for the prevention of accidents.

2 Device description

The heater versions differences are the nominal voltage, the air outlets and the heat exchanger

connections.

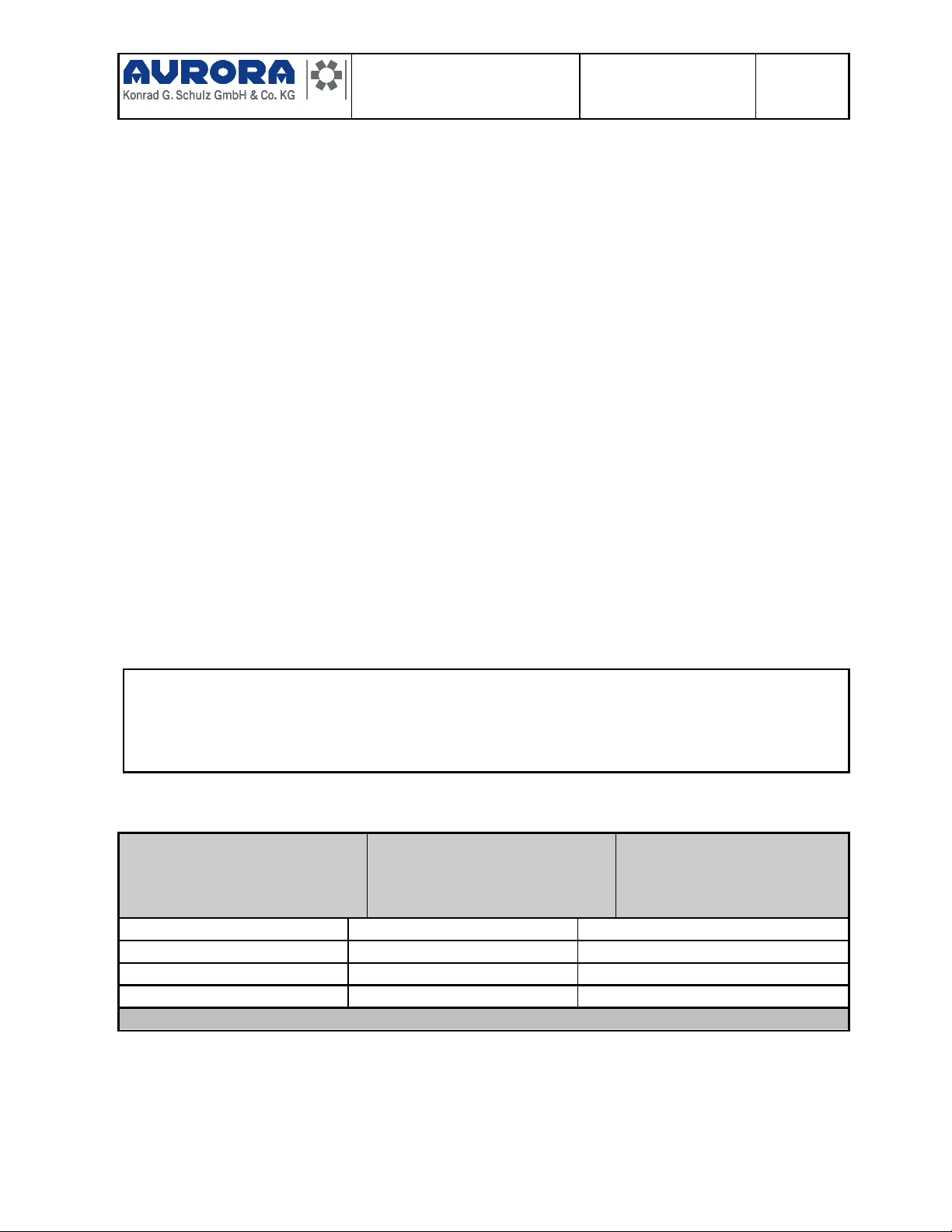

This technical information is valid for the following versions:

AURORA-part no. nominal

voltage

Air outlets

Heat exchanger connection-∅

151-301/302-0000 12V/24V 2 air grids 120x60 mm

∅12 straight connection

151-301-0001 12V 2 air grids 120x60 mm

∅12 straight connection

151-301/302-0002 12V/24V 2 air grids 120x60 mm

∅12 90° connection

151-301/302-0003 12V/24V 2 air grids 120x60 mm

∅12 90° connection

151-301/302-0004 12V/24V without air grids

∅12 straight connection

151-301/302-0005 12V/24V without air grids

∅12 straight connection

151-301/302-0006 12V/24V without air grids

∅12 90° connection

151-301/302-0007 12V/24V 2 air grids 120x60 mm

∅12 90° connection

151-301/302-0008 12V/24V 2 air grids 120x60 mm

∅15 straight connection

151-302-0009 24V 2 air grids 120x60 mm

∅12 straight connection

151-302-0010 24V 2 air grids 120x60 mm

∅15 straight connection

151-301/302-0011 12V/24V 2 air grids 120x60 mm

∅12 straight connection

151-301-0012 12V air outlet box with 2 oval

sockets

∅12 straight connection

151-301-0013 12V angular air outlet hood

∅12 straight connection

151-301-0014 12V air outlet hood with socket

∅70 mm

∅12 straight connection

151-301-0015 12V air outlet hood with socket

∅70 mm

∅12 straight connection

151-301/302-0016 12V/24V air outlet box with flap and 1

socket ∅70 mm

∅12 straight connection

Page 3

Technical

Information

no.

912-100-0123

page

3/8

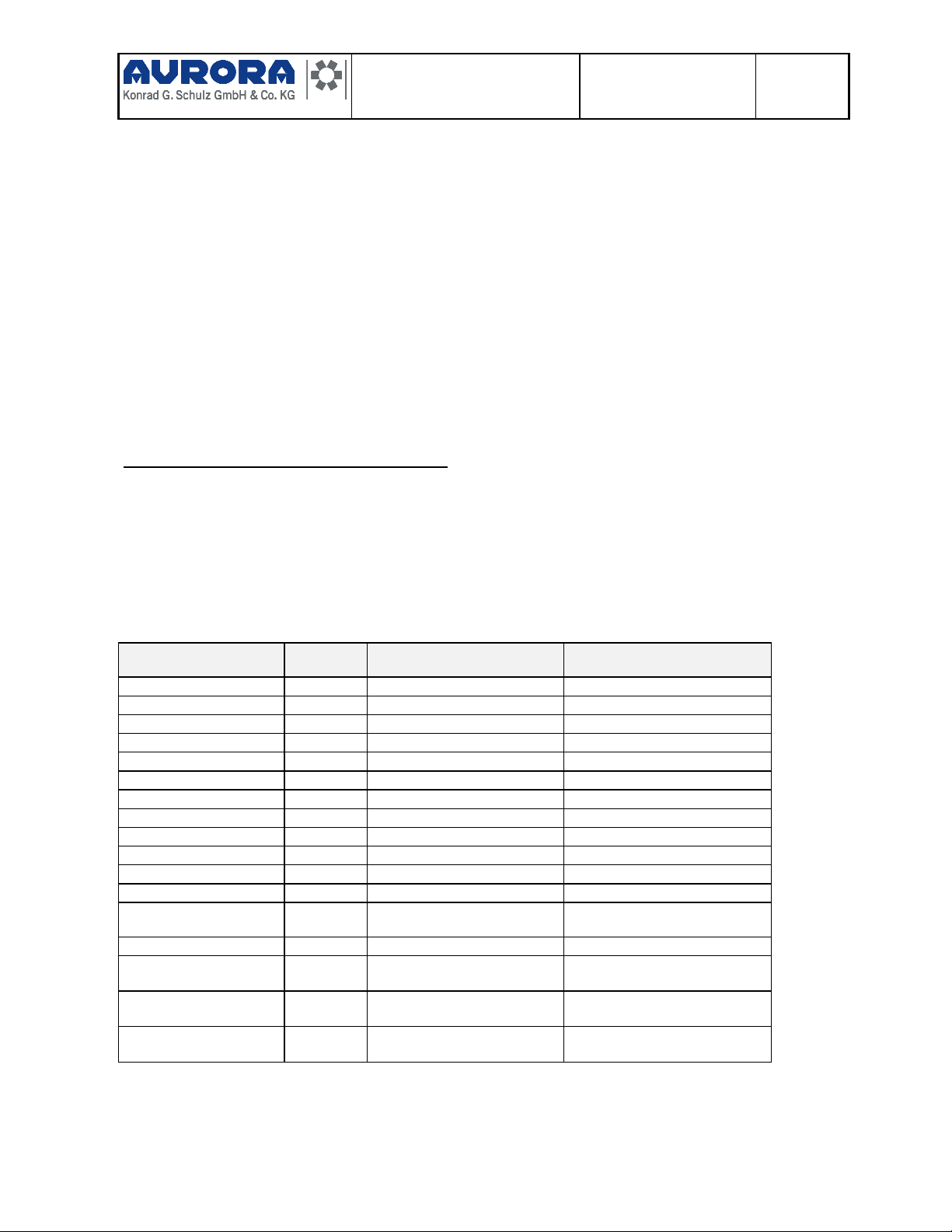

AURORA-part no. nominal

voltage

Air outlets

Heat exchanger connection-∅

151-301-0017 12V air outlet box with flap and 1

socket ∅55 mm

∅12 straight connection

151-301/302-0018 12V/24V air outlet box with flap and 1

socket ∅55 mm

∅12 straight connection

151-301/302-0019 12V/24V air outlet box with flap and 1

socket ∅55 mm

∅12 straight connection

151-301/302-0020 12V/24V air outlet box with flap and 2

sockets ∅42 mm

∅12 straight connection

151-301/302-0021 12V/24V air outlet box with flap and 2

sockets ∅55/∅42

∅12 straight connection

151-301/302-0022 12V/24V air outlet box with flap and 2

sockets ∅42 mm

∅12 straight connection

151-301/302-0023 12V/24V air outlet box with flap and 2

sockets ∅55/∅42

∅12 90° connection

151-301-0024 12V air outlet box with 1 socket

∅42 mm and 1 oval socket

78x55x3

∅12 straight connection

151-301-0025 12V air outlet box with flap and 1

socket 78x55x3mm

∅12 straight connection

151-301-0026 12V air outlet box with flap and 1

socket ∅55 mm

∅12 straight connection

151-301-0027 12V air outlet box with flap and 2

oval sockets

∅12 straight connection

151-301-0028 12V air outlet box with flap and 1

sockets ∅42 mm

∅12 straight connection

151-301/302-0029 12V/24V air outlet box with flap and 1

sockets ∅42 mm

∅12 straight connection

151-301-0030 12V air outlet box with flap and 2

sockets ∅42 mm

∅12 straight connection

151-301-0031 12V air outlet box with 1 socket

∅55 mm

∅15 90° connection

151-301-0032 12V 2 air grids 120x60 mm

∅12 straight connection

151-301-0033 12V 2 air grids 120x60 mm

∅12 90° connection

151-302-0034 24V 2 air grids 120x60 mm

∅12 straight connection

151-302-0035 24V 2 air grids 120x60 mm

∅12 straight connection

151-301/302-0036 12V/24V air outlet box with flap and 2

sockets ∅42 mm

∅12 straight connection

151-301-0037 12V/24V air outlet box with 1 socket

∅80 mm

∅12 straight connection

151-302-0038 24V 2 air grids 120x60 mm

∅12 straight connection

151-301/302-0039 12V/24V 2 air grids 120x60 mm Ø12 90° connection

151-301-0040 12V air outlet hood with round

nozzle RD 85.0

∅15 bent connection

151-302-0041 24V air outlet hood Ø70

∅15 straight connection

151-301/302-0042 12V/24V 2-speed with resistor

∅15 straight connection

151-301-0043 12V air outlet hood Ø70

∅15 bent connection

151-302-0044 24V air outlet hood Ø70

∅15 straight connection

151-301/302-0045 12V/24V 2-speed with resistor

∅15 straight connection

151-301-0046

12V 2-speed with resistor

air outlet hood Ø70

180° rotated from the

suction side

∅12 straight connection

Note: Some versions are no longer available

Page 4

Technical

Information

no.

912-100-0123

page

4/8

The Mini heaters are developed for the heating of cabins.

The heater can basically be operated with external or recirculating air. Therefore have the

requirements set into the vehicle according to the operation situation.

The heater is delivered by AURORA completely pre-mounted, the installation into the vehicle is

carried out by the customer.

The heat exchanger and the fan wheel with motor are integrated into the heater.

housing:

The housing is made from glass-fibre reinforcement polyamide PA6.

Blower function:

A direct current motor and a fan wheel, is used.

For the 2-speed version a resistor is integrated.

The different blower speeds are achieved using the pre-resistor.

The fan unit is protected against overload by a micro-temperature-fuse MTS (110°C) connected

to the resistor.

Heat exchanger-system:

A flat tube heat exchanger is used.

The water connection diameter is 12 mm (or. ∅ 15 mm for 151-301/302-0008, 151-301-0031,

151-301-0040, 151-302-0041, 151-301/302-0042, 151-301-0043, 151-302-0044 and 151301/302-0045).

Examples of different Mini-versions

Page 5

Technical

Information

no.

912-100-0123

page

5/8

3 Function description

The air is be sucked through the suction grid. The air flows through the heat exchanger and will

be lead through the air outlet grille and/or the sockets into the interior room.

The suction grid has the dimensions 113x113 mm.

The air direction can be changed by rotating the air outlet grille by 90°.

4 Operation

A AURORA control panel (accessories) can be used.

5 Installation

Please pay attention to the actual technical supplement to the general terms of sale and the

safety instructions in contact & Info of www.aurora-eos.com.

Please note: max. allowable pressure for flat tube heat exchangers: 2 bar abs.

The Mini can be installed in variable positions. Please pay attention to the air suction grille in

the installed position. The air suction grille shall not be disguised or closed.

For fixing, screws M5 in corresponding lengths can be used in connection with screw anchors

with an inner diameter of M5 (part number 497-900-0004, length 16 mm, to be set into drills

from the outside). The screw length differes according to vehicle. According fixing drills are on

the bottom or can be drilled at marked position on the housing. During setting the drills, please,

make sure that inside components are not damaged.

As an option fixing elements can be supplied by AURORA.

After installation of the Mini the electrical, the water side connection and optional the air

hose

connections have to be set.

Electrical connection for 2-speed versions:

12V: customer pre-fusing 3A necessary

24V:

customer pre-fusing 2A necessary

Attention: cables may not affect the resistor!

Page 6

Technical

Information

no.

912-100-0123

page

6/8

Connection sceme resistor:

View on plug please see drawing of the according version.

The warm air hoses are pushed over the heaters sockets (option).

It is essential to use appropriate hose clips for connecting the warm water hoses to the heat

exchanger with a tightening torque of approx. 3-3,5 Nm (if using AURORA-clips).

Check the system on leaks.

Check also the function of the fan unit and the air direction by switching on the blower (airflow

at the outlet nozzles or socket).

6 Technical data

Technical data for standard modells151-301/302-0000:

V

water

= 1000l/h

test voltage. 13 V / 26 V

•

V

air

[m³/h]

•

Q

80

[kW]

P

el

[W]

LP

[dB(A)] ±±±± 0,5

114 2,1 29 64

The technical data of the other versions are assimilable.

2-speed version:

12V:

Test result from 16.10.2006:

Test voltage 13V: [current + speed tolerance ±10%] at 23°C±5K, free blowing

speed 1 ca. 1,4A current consumption speed ca. 3665 1/min

speed 2 ca. 1,8A current consumption speed ca. 4470 1/min

Measurement under laboratory conditions

Page 7

Technical

Information

no.

912-100-0123

page

7/8

24V:

Test result from 16.10.2006:

Prüfspannung 26V: [current + speed tolerance ±10%] at 23°C±5K, free blowing

speed 1 ca. 0,7A current consumption speed ca. 3665 1/min

speed 2 ca. 0,9A current consumption speed ca. 4470 1/min

Measurement under laboratory conditions

Housing and air outlet hood orair outlet box made of polyamide PA6 GF35.

Frame and air grille are also made of polyamide PA6 GF35.

This granulate is certified to UL-HB concering burning behaviour:

Further information about burning behaviour of this material: See material specification 971820-0002.

EMC: Depending on version the motor has type approval regarding ECE R10 or the complete

Heater is type approved according directive 72/245/ECC.

7 Maintenance

CAUTION

Please pay attention to the safety advises (chapter 1) during all maintenance work.

Maintenance work is only carried out by wellinformed and authorised personnel.

The following checks should be carried out every month by the operator:

- Check of the fixing, leak control and laying of the hoses and fittings.

The hose fixings are to be tightened if necessary.

- Check electric connection pipes and plug connections on correct state and firm

position.

Cooling water circuit:

When refilling the cooling water quality has to be considered. When using AURORA water

valves the warranty expires when defects occur due to contamination in the water circuit. (see

TI 971-190-0003 anticorrosion/antifreeze solution. Please order in the case of need)

The air suction grid has to be checked on contamination and cleaned if necessary in regularly

intervals.

8 Spare parts

We can deliver the heat exchanger, the motor, the fan wheel, the resistor, the cable set or the

air grid as spare parts. For versions with hood the hood is also spare part. For the 2-speed

version a resistor is spare part. Please see spare parts list of the heaters.

More information about spare parts please see spare parts list of the respective heater.

9 Optional accessories

As well as the control panel and the water valve a comprehensive range of accessories have

been especially developed for the Mini.

Details upon request.

Page 8

Technical

Information

no.

912-100-0123

page

8/8

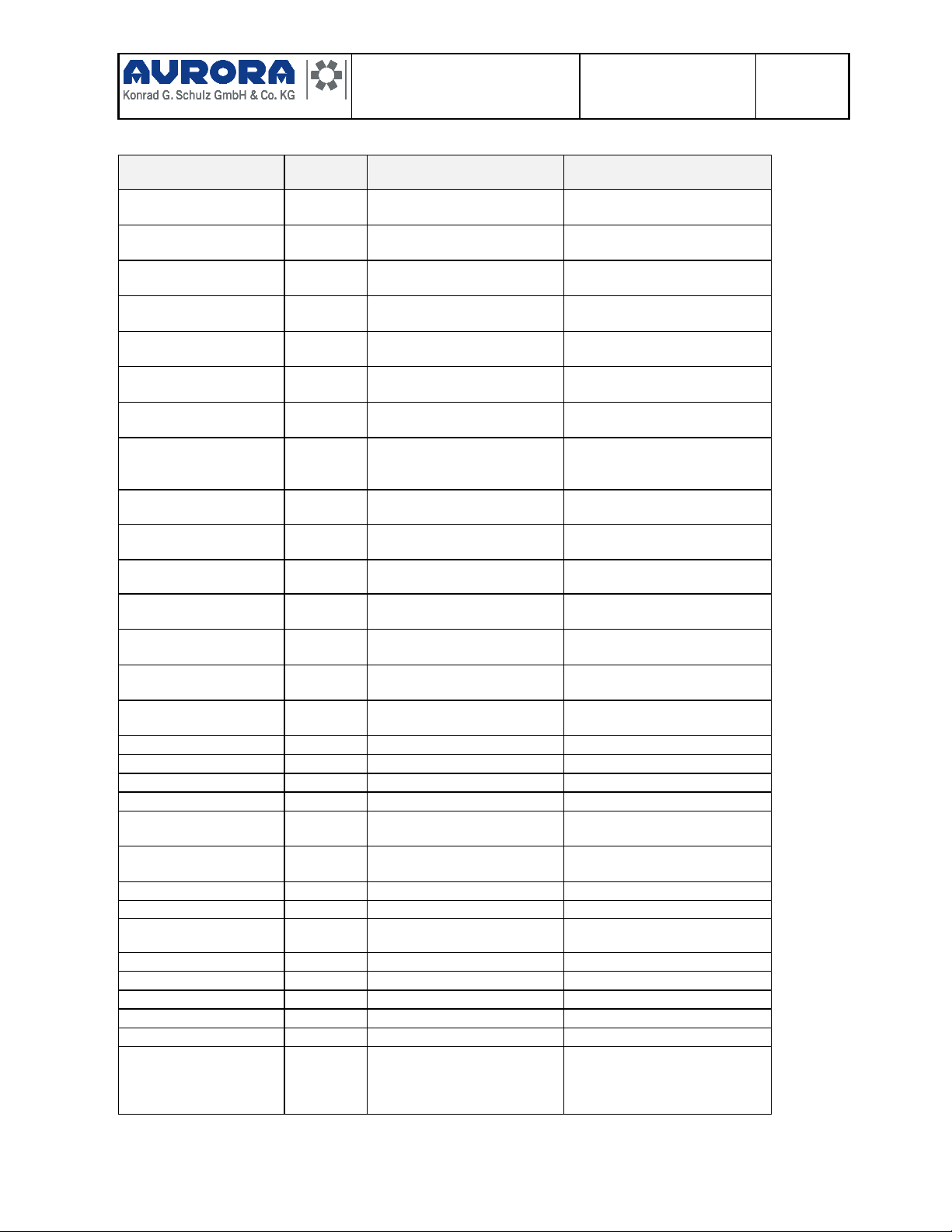

10 Fault diagnosis

Fault Cause Remedy

No air flow

Fuse defective or loose Check the seating of the fuse? If

necessary insert correctly. Renew

defective fuses.

Interruption of line Test lines on loose contacts or breaks

Blower motor defective replace motor

switch for blower defective change operation element

Mini will not operate

at all speeds (2speed versions)

Micro-temperature fusing (MTF)

has been triggered

Exchange resistor and check the blower

motor for the cause of functional faults

Switch for blower defective

change operation element

Connecting plug has become

loose

Check plug connection of unit for proper

seating. If not assemble it correctly

Check connection on switch

Resistor defective Exchange resistor

No or insufficient

heating power

Water supply temperature to

low

Wait until the motor is warm

Water valve will not open fully Check & renew water valve if necessary

incl. actuation operation, check flow

direction

Heat exchanger fins

contaminated

Check heat exchanger and clean it if

necessary

Water lines kinked or squashed Eliminate fault by installing correctly

Water escaping from

the unit

Hose connection has come

loose

Check hose seatings and tighten hose

clamps

Water hose damaged Install and connect new hose

Heat exchanger damaged Install and connect original replacement

part. Warning! Follow safety

instructions!

coolant system pressure too

high

reduce absolute coolant pressure

max. allowable pressure: 2 bar

Loading...

Loading...