AURATON S14 User Manual

User manual

www.auraton.pl

S14

dla oprogramowania w ver. F03 oraz F0A

AURATON S14

AURATON S14 is a modern processor-based controller intended for work

with central heating (CH) and hot domestic water (HDW) circulating

pumps. The controller may work with a boiler stove fireplace in a CH

system and with a forced draft coal or fine c oal fired CH stove.

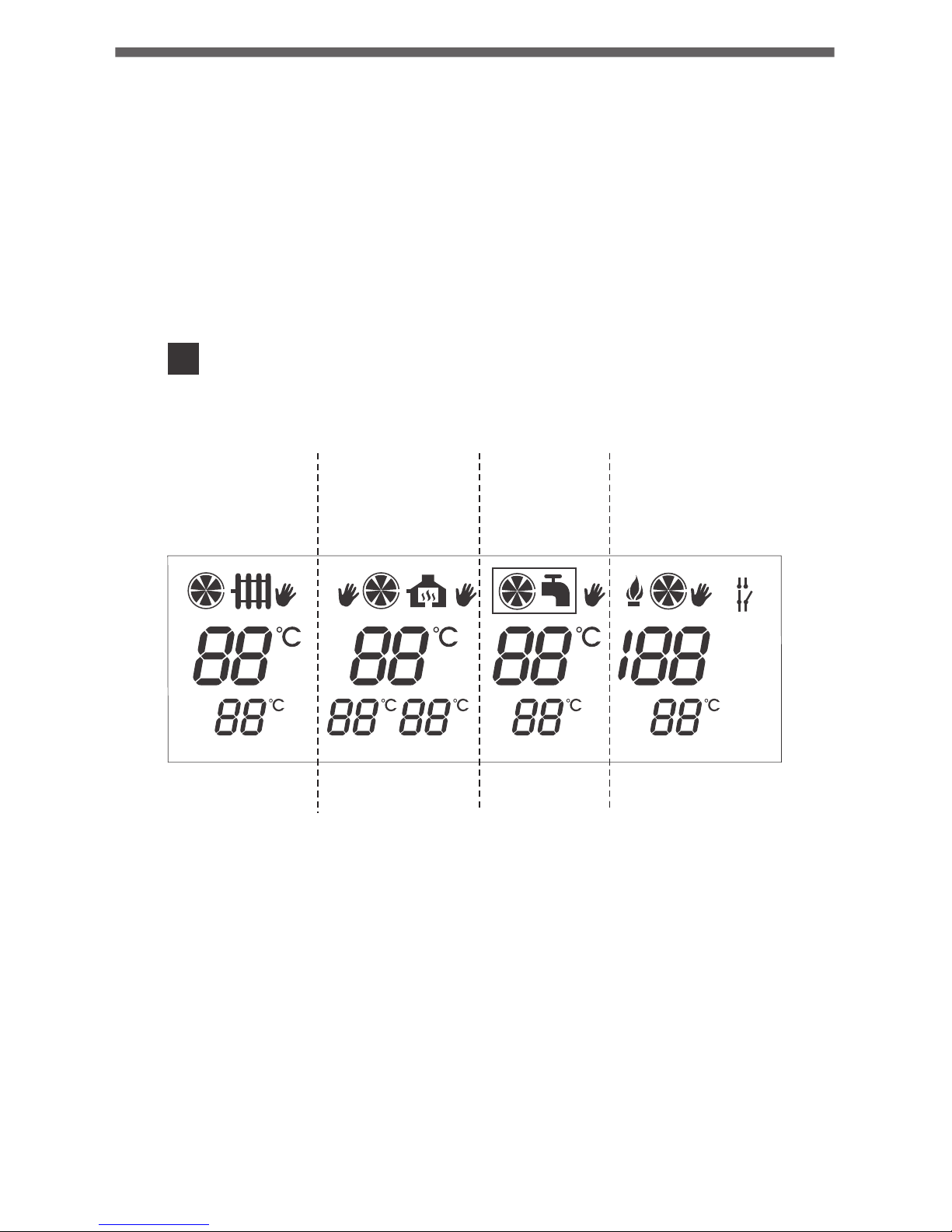

Description of the display

1

The display of the AURATON S14 controller is divided into four parts.

Each part corresponds to a separate device supported by the controller:

Part A: Control of the central heating (CH) pump,

Part B: Control of the central heating (CH) pump, the automatically

reset actuator, or the second central heating pump (in the

fireplace circuit),

Part C: Control of the hot domestic water (HDW) circulating pump,

Part D: Control of the fan (blower).

ON

OFF

S MIN

STOP LO

STOP HI

AUTO

%

A B C D

2

1

6

1. Temperature measured by individual sensors,

2. User's setting,

3. Counted operation time of the fan and the duration of the interval

between the blow-throughs,

4. Indicator of extinguished fire in the furnace,

5. Indicator of emergency shutdown of the fan,

6. Indicator of manual activation of the device ,

7. Indicator of ignition,

8. Indicator of fan power percentage value,

9. Indicator of forced operation (of the CH pump),

10. Indicator of sustained fire in the furnace.

3

1

6

7

8

9

10

3

4 52

ON

OFF

S MIN

STOP LO

STOP HI

AUTO

%

1. Temperature measured by individual sensors,

2. User's setting,

3. Counted operation time of the fan and the duration of the interval

between the blow-throughs,

4. Indicator of extinguished fire in the furnace,

5. Indicator of emergency shutdown of the fan,

6. Indicator of manual activation of the device ,

7. Indicator of ignition,

8. Indicator of fan power percentage value,

9. Indicator of forced operation (of the CH pump),

10. Indicator of sustained fire in the furnace.

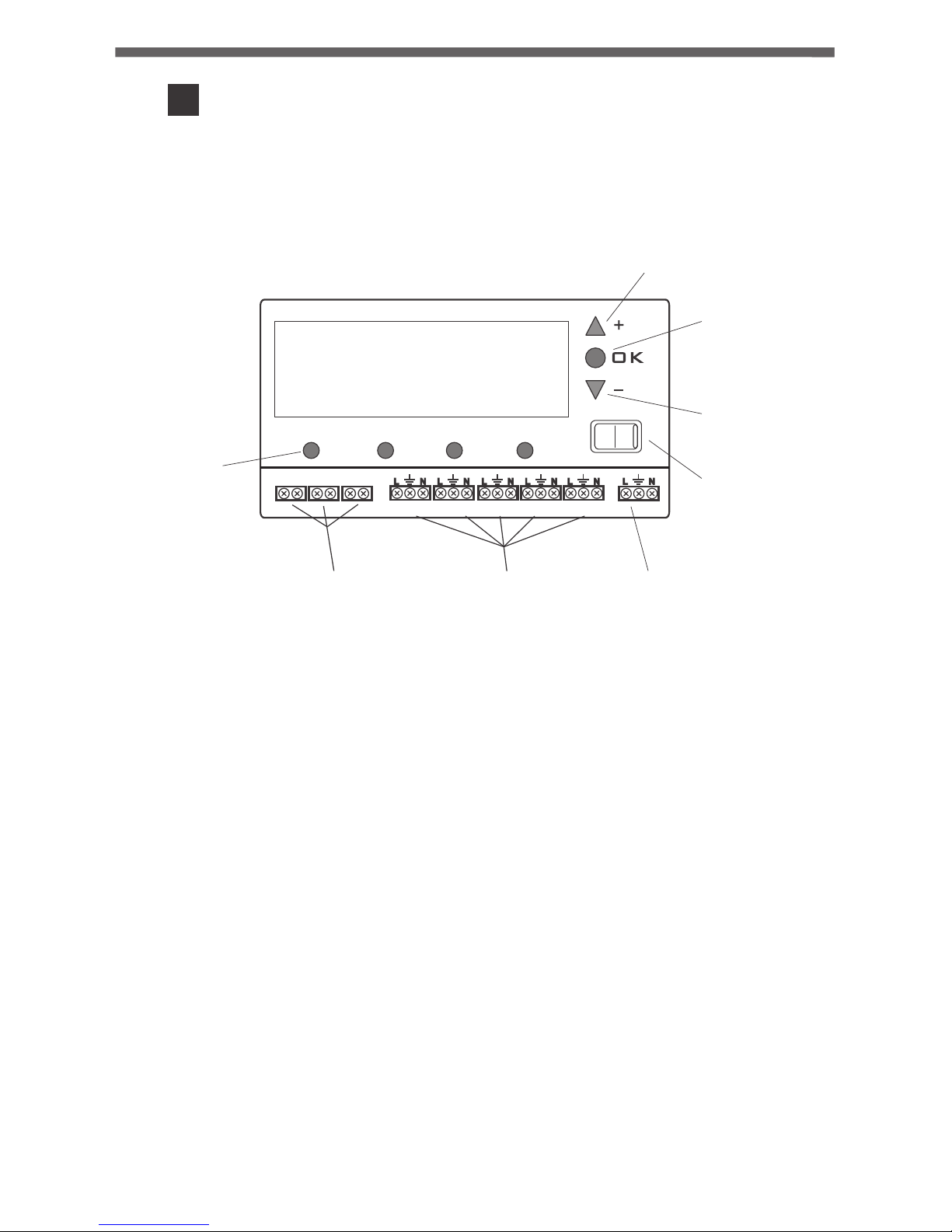

General comments

1. Buttons "A, B, C, D" for configuration of individual settings,

2. Terminals for connecting temperature sensors (SR1 through SR3),

3. Terminals for connecting actuators (OUT1 through OUT5),

4. Terminals for connecting the power supply,

5. "+" (plus) button - higher value,

6. "OK" button - approval,

7. "-" (minus) button - lower value,

8. Main power supply switch.

1. Before connecting the cables to the controller, remove the protective

plugs by cutting them off.

2. Only one sensor is provided (with an approx. 2.5 m long cable). If an

expanded functionality of the controller is required, additional

temperature sensors must be bought (option). If the length of the

cable is inadequate, a sensor with an approx. 15 m long cable can be

purchased.

4

1

2

3 4

5

6

7

8

0

I

A B C D

SR1 SR2 SR3

OUT1 OUT2 OUT3 OUT4 OUT5 IN

Description of buttons

and cable terminals

2

NOTE: In order to access the cable terminals, remove the front cover.

3

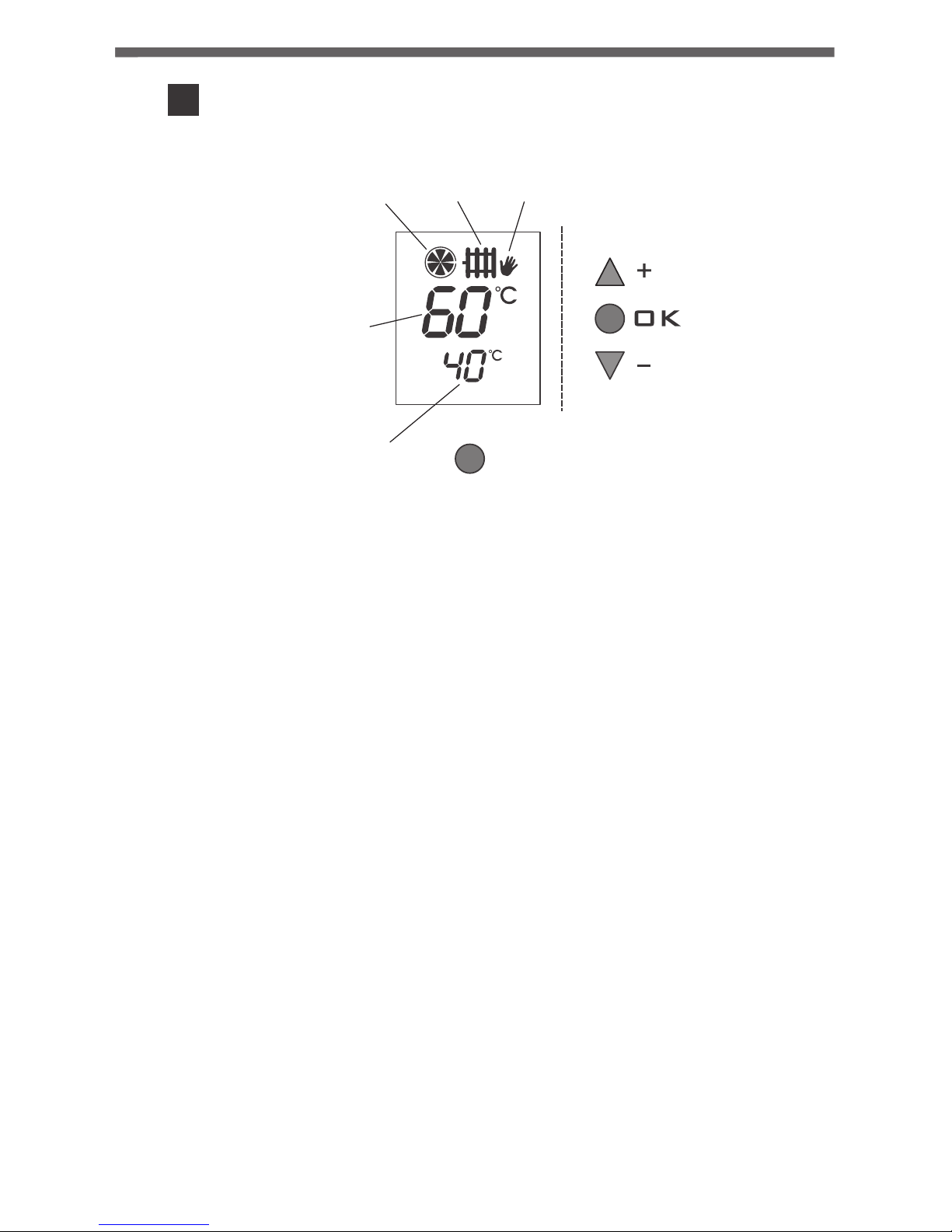

Description of the controller working

in a CH circuit (part A of the display)

The controller also has the GUARD functions which prevents the stalling

process in the rotor of the pump when it is not in use. Also, a built in

processor starts the pump for 30 seconds after the heating season is over.

In order for the system to work after the heating season, the controller

must be switched on.

1. CH pump operation indicator,

2. CH pump's sensor indicator,

3. Manual mode operation indicator,

4. Current temperature on the CH sensor (SR1),

5. Set temperature indicator.

The controller-pump assembly forces the water to circulate in a CH

system with a coal-fired boiler or a gas boiler without a system controlling

the operation of the pump. The controller's sensor measures the

temperature of the water on the supply side of the CH system.

In a CH system with a coal-fired boiler, the controller switches off the

circulation pump after the flame in the boiler is extinguished. Pumping of

water is not recommended when the flame is extinguished because the

air draft into the chimney causes faster cooling of the water in the boiler

faster than in the radiators. The optimum temperature can be set on the

controller's scale (most often approx. 40°C).

In a CH system with a gas boiler, the temperature must be lower than the

temperature set on the CH boiler's thermostat. If the temperature is set

above the dew point, it prevents condensation in the boiler during the

heating of the water in the CH system.

5

3

Description of the controller working

in a CH circuit (part A of the display)

The controller also has the GUARD functions which prevents the stalling

process in the rotor of the pump when it is not in use. Also, a built in

processor starts the pump for 30 seconds after the heating season is over.

In order for the system to work after the heating season, the controller

must be switched on.

A

1

2

3

4

5

1. CH pump operation indicator,

2. CH pump's sensor indicator,

3. Manual mode operation indicator,

4. Current temperature on the CH sensor (SR1),

5. Set temperature indicator.

The controller-pump assembly forces the water to circulate in a CH

system with a coal-fired boiler or a gas boiler without a system controlling

the operation of the pump. The controller's sensor measures the

temperature of the water on the supply side of the CH system.

In a CH system with a coal-fired boiler, the controller switches off the

circulation pump after the flame in the boiler is extinguished. Pumping of

water is not recommended when the flame is extinguished because the

air draft into the chimney causes faster cooling of the water in the boiler

faster than in the radiators. The optimum temperature can be set on the

controller's scale (most often approx. 40°C).

In a CH system with a gas boiler, the temperature must be lower than the

temperature set on the CH boiler's thermostat. If the temperature is set

above the dew point, it prevents condensation in the boiler during the

heating of the water in the CH system.

3.2.1. Switching the controller on

ut the switch n the "I" position. After the controller is switched

on, all segments of the display are lit for about 2 seconds and the software

version is displayed. Then the " symbol, the current sensor

temperature (4), and the set temperature (5) are shown on the display.

P i

"

[butt]

grzej]

3.1.3. Connecting the power supply cable of the pump

In the controller, the pump's cable must be connected to the OUT1

terminal. In the pump, connect the green or yellow-green wire

(grounding or protective zero) to the " " terminal and connect the blue

wire to the "N" terminal. Connect the brown wire to the "L" terminal.

3.1. Installation

3.1.1. Mounting the controller

The controller must be mounted on a wall or another support using two

screws (the concrete anchors with screws are delivered with the

controller). The cables extending from the controller must be fixed to the

wall with cable clips.

3.1.2. Mounting the sensor

Before installing the cables, remove the protective plugs by cutting them

off. In the controller, connect the temperature sensor to the SR1

terminals. Then install the sensor on an uncovered outlet pipe connected

to the CH boiler (as close to the boiler as possible).

NOTE: If a coal-fired boiler and a gas-fired boiler work in the same CH

system, the sensor should be installed in a location where the two

outlets merge and must be insulated.

3.1.4. Connection check

Check if the wire is connected properly and fix the lid of the pump motor's

compression box with screws.

3.1.5. Connecting the controller

NOTE: The wires and cables may be connected only when the

power supply is cut off.

After the wires are secured to prevent accidental ripping, connect the

power supply cable to a 230V AC/50 Hz power outlet with a grounding

pin.

NOTE: The ambient temperature in the place where the controller

is installed must not exceed 40°C.

3.2. Operation of the controller

0

I

3.2.3. Changing the temperature

Press the "A" button under the temperature setting. The digits begin to

blink and indicate the value of the current setting. Using the "+" (increase)

or "-" (decrease) button, set the desired temperature. After the

temperature value is set, approve it (within 10 seconds) by pressing the

"OK" button. Otherwise, the changed value will not be saved and the

controller will return to the previous setting.

3.2.4. Changing the hysteresis

Press the "A" button under the temperature setting. The digits begin to

blink and indicate the value of the current setting. Display the hysteresis

setting (HI) by pressing the "A" button again. Using the "+" or "-" button,

set the required hysteresis value in the range of 2°C to 10°C (with a 2°C

increment). After the value is set, approve it (within 10 seconds) by

pressing the "OK". Otherwise, the changed setting will not be saved and

the controller will return to the previous setting.

Example: If the temperature setting is 40°C and the hysteresis is 4°C, the

pump will start at 42°C and will stop at 38°C.

3.2.5. Changing the forced pump operation mode

Press the "A" button under the temperature setting. The digits begin to

blink and indicate the value of the current setting. Display the hysteresis

setting (HI) by pressing the "A" button again. After you press the "A"

button one more time, the value of 85°C will be displayed in the

temperature section and on the right side of the display the symbol of

forced pump operation ( ). Za pomocą przycisku „+” lub „–” will be

shown. Using the "+" or "-" button, select a setting where, after the

temperature exceeds 85°C, the pump is in continuous operation ( ) or

shuts down ( ).

After the pump operation mode is set, approve it (within 10 seconds) by

pressing the "OK" button. Otherwise, the changed setting will not be

saved and the controller will return to the previous setting.

^

3.2.6. Automatic operation

After this operation mode is set, the controller starts and stops the pump

depending on the set temperature. In the CH system, the pump is started

when the temperature in the location of the sensor exceeds the set value

and stopped when the temperature drops below the value set in the

controller, taking into account the hysteresis.

3.2.2. Description of the display

The top part of the display (4) shows the current temperature of the

sensor while the bottom part (5) shows the set temperature. Movement

of the blades on the indicator (1) indicates operation of the CH pump.

!

76

3.2.3. Changing the temperature

Press the "A" button under the temperature setting. The digits begin to

blink and indicate the value of the current setting. Using the "+" (increase)

or "-" (decrease) button, set the desired temperature. After the

temperature value is set, approve it (within 10 seconds) by pressing the

"OK" button. Otherwise, the changed value will not be saved and the

controller will return to the previous setting.

3.2.4. Changing the hysteresis

Press the "A" button under the temperature setting. The digits begin to

blink and indicate the value of the current setting. Display the hysteresis

setting (HI) by pressing the "A" button again. Using the "+" or "-" button,

set the required hysteresis value in the range of 2°C to 10°C (with a 2°C

increment). After the value is set, approve it (within 10 seconds) by

pressing the "OK". Otherwise, the changed setting will not be saved and

the controller will return to the previous setting.

Example: If the temperature setting is 40°C and the hysteresis is 4°C, the

pump will start at 42°C and will stop at 38°C.

3.2.5. Changing the forced pump operation mode

Press the "A" button under the temperature setting. The digits begin to

blink and indicate the value of the current setting. Display the hysteresis

setting (HI) by pressing the "A" button again. After you press the "A"

button one more time, the value of 85°C will be displayed in the

temperature section and on the right side of the display the symbol of

forced pump operation ( ). Za pomocą przycisku „+” lub „–” will be

shown. Using the "+" or "-" button, select a setting where, after the

temperature exceeds 85°C, the pump is in continuous operation ( ) or

shuts down ( ).

After the pump operation mode is set, approve it (within 10 seconds) by

pressing the "OK" button. Otherwise, the changed setting will not be

saved and the controller will return to the previous setting.

^

^.

^

3.2.6. Automatic operation

After this operation mode is set, the controller starts and stops the pump

depending on the set temperature. In the CH system, the pump is started

when the temperature in the location of the sensor exceeds the set value

and stopped when the temperature drops below the value set in the

controller, taking into account the hysteresis.

3.2.2. Description of the display

The top part of the display (4) shows the current temperature of the

sensor while the bottom part (5) shows the set temperature. Movement

of the blades on the indicator (1) indicates operation of the CH pump.

1. Current temperature on the

CH sensor (SR2)

2. Indicator of the set CH

temperature in the

fireplace circuit,

3. Indicator of the set

temperature of the

automatically reset

actuator or the second CH

pump,

4. Indicator of manual activation

of the CH pump,

5. CH pump operation indicator,

6. Indicator of operation of a tee valve or the second CH pump,

7. Indicator of manual activation of a tee valve or the second CH pump.

3.2.7. Manual mode - continuous operation

In order to manually switch on the circulating pump (regardless of the

current temperature at the SR1 (CH) sensor), press the "A" button and

hold it pressed for 3 seconds.

The display will show the hand symbol " " (3). If you wish to switch off

the pump's manual operation, press the "A" button again and hold it

pressed for 3 seconds.

NOTE: When only the SR1 sensor is connected, the remaining functions

of the controller are inactive, i.e. there is no indication of operation of

CH pumps in the fire place circuit and of the control of the pump in the

HDW circuit.

[h]

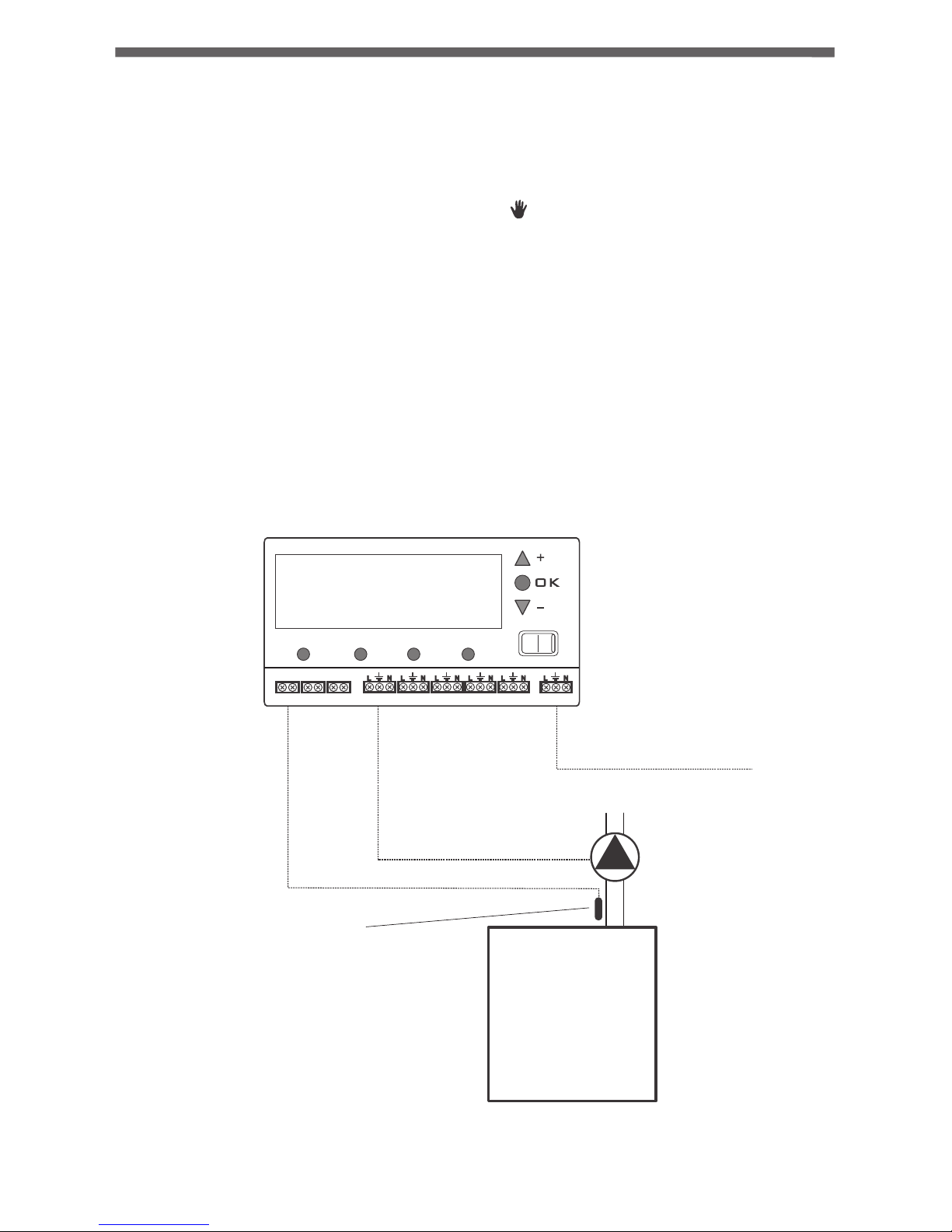

3.3. Diagram of connection of the controller with

the pump at the CH boiler

0

I

A B C D

SR1 SR2 SR3

OUT1 OUT2 OUT3 OUT4 OUT5 IN

CH

boiler

Pump

230V

mains power supply

Temperature sensor

(fix with a band)

4

Description of a controller working with

a CH pump and an automatically reset

actuator, or with a second CH pump -

a fireplace boiler stove circuit

(part B of the display)

AURATON S14 in a circuit with a boiler stove fireplace uses two control

outputs:

one for the water pump in the fireplace circuit;

ź

one for an actuated valve or the second pump, which is required for

ź

proper cooperation between the boiler stove fireplace with the CH

circuit.

After the power supply is switched on, temperature in the water jacket of

the boiler stove fireplace is measured (with the digital sensor); the

temperature signal can be divided into two independent channels.

Depending on the temperature of water in the fireplace circuit, the

controller automatically starts or stops the CH pump of the fireplace and

starts the valve or the second pump.

The AURATON S14 controller also has the GUARD functions which

prevents the stalling process in the rotor of the pump when it is not in use.

After the heating season, AURATON S14 automatically starts the pump

for 30 seconds every 14 days.

In order for the system to work after the heating season, the controller

must be switched on at all times.

98

1. Current temperature on the

CH sensor (SR2)

2. Indicator of the set CH

temperature in the

fireplace circuit,

3. Indicator of the set

temperature of the

automatically reset

actuator or the second CH

pump,

4. Indicator of manual activation

of the CH pump,

5. CH pump operation indicator,

6. Indicator of operation of a tee valve or the second CH pump,

7. Indicator of manual activation of a tee valve or the second CH pump.

4

Description of a controller working with

a CH pump and an automatically reset

actuator, or with a second CH pump a fireplace boiler stove circuit

(part B of the display)

4

6

7

1

5

B

2

3

AURATON S14 in a circuit with a boiler stove fireplace uses two control

outputs:

one for the water pump in the fireplace circuit;

ź

one for an actuated valve or the second pump, which is required for

ź

proper cooperation between the boiler stove fireplace with the CH

circuit.

After the power supply is switched on, temperature in the water jacket of

the boiler stove fireplace is measured (with the digital sensor); the

temperature signal can be divided into two independent channels.

Depending on the temperature of water in the fireplace circuit, the

controller automatically starts or stops the CH pump of the fireplace and

starts the valve or the second pump.

The AURATON S14 controller also has the GUARD functions which

prevents the stalling process in the rotor of the pump when it is not in use.

After the heating season, AURATON S14 automatically starts the pump

for 30 seconds every 14 days.

In order for the system to work after the heating season, the controller

must be switched on at all times.

Loading...

Loading...