Page 1

AUO

Display Specification for B133EW07 V0

13.3” Wide (1280x800) TFT-LCD

LED Backlight with High Color Gamut

| Size: A | METRIC | Scale: NONE | Page 1 of 54

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD, DWG Number: 069-3542 Rev.01

www.jxlcd.com

www.jxlcd.com

Page 2

Revision History

DATE REV # Section # CHANGE DESCRIPTION

www.jxlcd.com

www.jxlcd.com

N

. | Size: A | METRIC | Scale: NONE | Page 2 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

Page 3

Table of Content

Revision History 2

1. General Description 6

2. ORDER OF PRECEDENCE OF DOCUMENTATION AUTHORITY 7

2.1. The Purchase Order 7

2.2. This Specification 7

2.3. Reference Documents 7

3. PHYSICAL DESCRIPTION 8

4. MECHANICAL REQUIREMENTS 9

5. ELECTRICAL REQUIREMENTS 11

5.1. Block Diagram 11

5.2. Display PCB Schematics 12

5.3. Display PCB Layout 13

5.4. Display Subsystem (PCB & TFT Panel) 13

5.4.1. Pin-Out (Single Channel LVDS Interface) 13

5.4.2. Connector Diagram 14

5.4.3. Color Input Data Reference 15

5.4.4. EDID Interface (Per Vesa EDID 1.x standard requirements) 17

5.4.5. Electrical Ratings 20

5.4.6. Signal Timing 22

5.4.6.1. Signal Impedance 22

5.4.6.2. Timing Data 22

5.4.6.3. Video Timing Diagram 23

5.4.7. Power Measurements (W/O backlight) 25

5.4.8. Power on-off sequence 26

5.4.9. Vcc Dip Condition 26

5.5. Near-Field Noise 27

5.6. Backlight Subsystem 27

6. OPTICAL REQUIREMENTS 30

6.1. Optical Specifications 30

6.2. Measuring Conditions 31

N

. | Size: A | METRIC | Scale: NONE | Page 3 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

www.jxlcd.com

www.jxlcd.com

Page 4

6.3. Definition 33

6.3.1. Center Point Luminance 33

6.3.2. Average Luminance 33

6.3.3. Luminance Uniformity 33

6.3.3.1. Global Luminance Uniformity: 33

6.3.3.2. Worst Neighbor Luminance Uniformity (The 4 points that are closest to the test point)

34

6.3.4. Contrast Ratio 34

6.3.5. White Color Uniformity 34

6.3.5.1. Panel to Panel White Color Uniformity 34

6.3.5.2. Max Color Difference with respect to the center within a panel 35

6.3.5.3. Max Color Difference between any two points within the panel 35

6.3.5.4. Max Color Difference between two neighbors 35

6.3.6. RGB Color Chromaticity 35

6.3.7. Viewing Angle 35

6.3.8. Gray Scale Inversion 36

6.3.9. Response Time 36

6.3.9.1. On and Off Response Time 36

6.3.9.2. Gray to Gray Response Time 36

6.3.10. Gray Scale Linearity or Gamma Value 37

6.3.11. Flicker 37

6.3.12. Cross-talk 38

6.4. Hot Spot Specifications: 38

7. ENVIRONMENTAL 40

7.1. Shock and Vibration 40

7.2. Temperature and Humidity 41

7.2.1. General Performance Requirements 41

7.2.2. Non-operational Testing 42

7.2.2.1. Low Temperature 42

7.2.2.2. High Temperature 42

7.2.2.3. High Temperature and High Humidity 42

7.2.2.4. Thermal Shock 42

7.2.3. Operational Testing 42

www.jxlcd.com

www.jxlcd.com

N

. | Size: A | METRIC | Scale: NONE | Page 4 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

Page 5

7.2.3.1. Low Temperature 42

7.2.3.2. High Temperature 42

7.2.3.3. High Temperature and High Humidity 42

7.2.3.4. Four Corner Test (72 hrs – operating) 42

7.3. Altitude 43

8. RELIABILITY 43

8.1. Resistance to Normal Abuse 43

8.1.1. Torsion Test 43

8.1.2. Test Conditions: 43

8.1.3. Test Set-up 44

8.1.4. Static Load Deflection and Breakage 44

8.2. Electrostatic Discharge (ESD) 44

8.3. MTBF 44

8.4. LCD Glass Strength 45

9. COSMETIC REQUIREMENTS 50

10. REGULATORY 51

10.1. Product Safety (Environmental, Ergonomics, Safety and Health) 51

10.2. RoHS Compliance and other Substance Regulations 51

10.3 Halogen Free 51

10.3. Environmental Markings and Recycling 51

10.4. Product Safety 52

10.5. Ergonomics 52

10.6. Electromagnetic Compatibility (EMC) 52

11 FACTORY/SERVICE REQUIREMENTS 54

12 REFERENCE DOCUMENTS 55

www.jxlcd.com

www.jxlcd.com

N

. | Size: A | METRIC | Scale: NONE | Page 5 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

Page 6

1. General Description

This document establishes the requirements for the display device for the B133EW07 V0

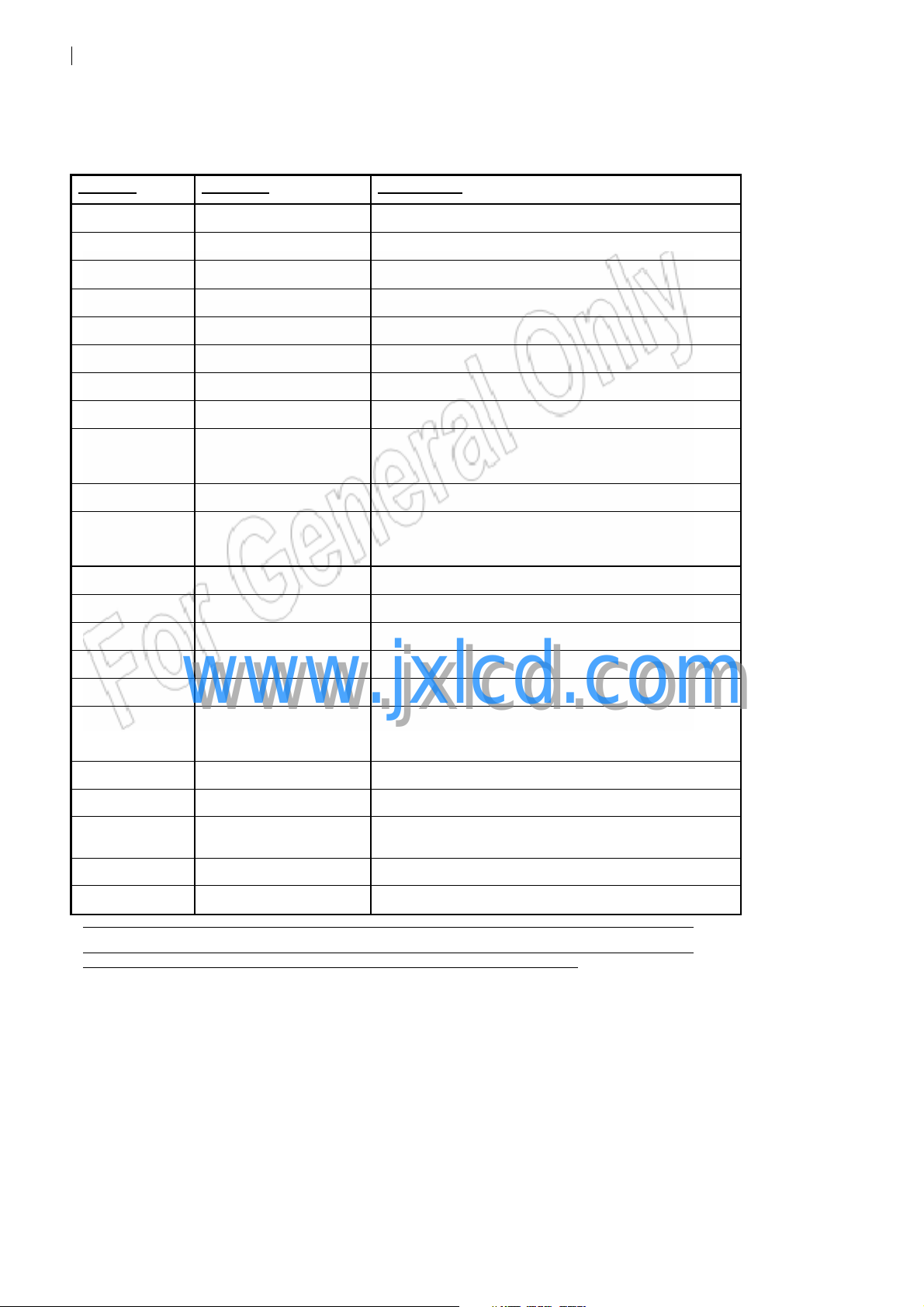

Category Parameter Specification

General

Electrical

Optical

Manufacturer AUO

Mfg. P/N B133EW07 V0

LCD TYPE Normally-White, Transmissive TN TFT-LCD

Diagonal 13.282” (33.74cm)

Pixel Format 1280 (RGB stripe, H) x 800 (V)

Pixel Pitch 0.2235(V) x 3x0.0745(H) mm

Color Depth 18-bits (6R, 6G, 6B), 262144 colors

Pooling requirement Rigid Post Spacer with strong pooling resistance

Packaging Protective film on front polarizer. Displays packaged

and air-tight sealed in anti-static bags.

Interface 3.3V single-channel LVDS

Power Consumption 4.36 W @ Black (typical, the logic plus the backlight

@94% duty cycle @23mA, 3.3V forward bias voltage)

Luminance 275 nits @ 94% duty cycle @23 mA (typical center)

White LED Backlight 6 strings, 9 LED per string. Nichia NNSW208

Hot Spots No visible hot spot at any angle

Viewing Direction 6:00 for worst dark inversion (pcb driver on the bottom)

Mechanical

N

. | Size: A | METRIC | Scale: NONE | Page 6 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

Contrast 500 typical

www.jxlcd.com

www.jxlcd.com

Top Polarizer Glossy Surface, 3H Hard Coating, LT4/ARC7 AR

coating

Diffuser Sheet Tsujiden D153GS (top) & Tsujiden D120 (Bottom)

BEF Sheet 2 X BEF2-G2 MR (Halogen free)

Reflector E6SR or equivalent (sulfur free)

LGP PMMA

Active Area 286.08 mm (H) x 178.80 mm (V)

Page 7

Minimum Viewing Area 288.08 mm (H) x 180.80 mm (V)

Environmental

Pre-Aging

2. ORDER OF PRECEDENCE OF DOCUMENTATION AUTHORITY

In the case of any conflict in any specification related to these parts, this order of precedence of

authority shall apply:

2.1. The Purchase Order

2.2. This Specification

2.3. Reference Documents

Module Outline Size 297.150 mm (H) x 192.150 mm (V)

Connector IPEX 20474-030E-12

Mating Connector IPEX 20472-030T-10

Weight 300 grams typical

Operating Temperature 0°C ~ +50°C

Storage Temperature -25°C ~ +65°C

Before shipment Minimum 2 hours at 50°C, panel on

www.jxlcd.com

www.jxlcd.com

N

. | Size: A | METRIC | Scale: NONE | Page 7 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

Page 8

:

3. PHYSICAL DESCRIPTION

3.1. Display Mode

Normally White, Transmissive, Twisted Nematic Liquid Crystal Displays

3.2. Pixel Configuration

RGB Vertical Stripe

3.3. Pixel Pitch

0.2235 mm x 0.2235 mm

3.4. Resolution

1280 (RGB stripe, H) x 800 (V)

3.5. Aperture Ratio

Minimum > 50%

3.6. Optimum Viewing Cone

6 o’clock worst dark inversion direction (PCB on the bottom)

3.7. Interface & Driving Scheme

3.3V single-channel LVDS (Flat Link) interface, requiring Hsync and Vsync

signals, along with DE (Data Enable) mode, 2-dot inversion

3.8. Front Surface Treatment

Low-reflection gloss surface, ~1% Reflectance, ≥3H hardness (Sumitomo LT4, or

Nitto Denko ARC7)

3.9 Environmental Requirements:

Any homogeneous component must meet Halogen-Free Specification, 069-1857.

www.jxlcd.com

www.jxlcd.com

N

. | Size: A | METRIC | Scale: NONE | Page 8 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

刪除

刪除

刪除刪除

Page 9

4. MECHANICAL REQUIREMENTS

4.1. Dimensions and Tolerances

The LCD module outline is described in the following table.

Dimension Min Typ Max Unit

Horizontal (H) 296.85 297.15 297.45 mm

Vertical (V) 191.85 192.15 192.45 mm

Depth (D) 3.08 3.38 3.68 mm

4.2. Weight

300 g (typical), 310 g (max)

4.3. Stack-up (tentative)

Mechanical Stack-up Part # Thickness /mm

Top Polarizer

(glossy, LT4 or ARC7) Sumika, SRW862APK-LT4

LCD Glass CF 0.5

LCD Glass TFT 0.5

Bottom Polarizer 0.215

Total Design Gap - 0.135

Upper Diffuser Tsujiden D131S 0.095

Upper BEF (Halogen Free) BEF II-GII MR 0.155

Lower BEF (Halogen Free) BEF II-GII MR 0.155

Lower Diffuser Tsujiden D120 0.12

Light Guide PMMA 0.72

White Reflector (Sulfur-free

www.jxlcd.com

www.jxlcd.com

reflector for PMMA

backlight) E6SR 0.188

Rear Bezel SUS 304 0.3

Tape 0.1

Total Typical Thickness w/o PCB 3.38

Maximum Tolerance 0.3

Total Maximum Thickness

PCB Thickness (8 Layer

PCB) 0.8

Maximum Component - 1

side (include Solder) 1.15

N

. | Size: A | METRIC | Scale: NONE | Page 9 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

(w/o PCB) 3.68

0.215

Page 10

Maximum Component - 2

side (include Solder) 0.2

Total Maximum PCB

Thickness 2.15

4.4. Exposed Areas and Restrictions

The display module shall not have exposed edges or components, which may cause injury

or damage during handling, inspection, assembly, and service. Exposed areas of the display

module (those not protected or shielded by construction) must be insulated and otherwise

protected to eliminate the possibility of electrical shorting or destructive ESD discharges

(per Section 7.2) during handling, inspection, assembly, and service.

www.jxlcd.com

www.jxlcd.com

N

. | Size: A | METRIC | Scale: NONE | Page 10 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

Page 11

I C

2

Panel

IF

ELECTRICAL REQUIREMENTS

4.5. Block Diagram

Connector

User

BUS

EDID

EDID

EDIDEDID

(EEPROM)

DC/DC

DC/DC

DC/DCDC/DC

Converter

E

DI

LV

DS

D

V

AVDD

GAMMA

VCOM

VON/VOFF

Backlight Driving Architecture

Buck

DC/DC

Generator

Controller

Controller

ControllerController

Gamma

Gamma

GammaGamma

VCOM

VCOM

VCOMVCOM

Timing

Timing

TimingTiming

SOURCE

SOURCE

SOURCESOURCE

DRIVE IC

DRIVE IC

DRIVE ICDRIVE IC

13.3” WXGA

(1280 x 800 × RGB)

GATE DRIVE IC

GATE DRIVE IC

GATE DRIVE ICGATE DRIVE IC

www.jxlcd.com

www.jxlcd.com

N

. | Size: A | METRIC | Scale: NONE | Page 11 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

Page 12

4.6. Display PCB Schematics

www.jxlcd.com

www.jxlcd.com

N

. | Size: A | METRIC | Scale: NONE | Page 12 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

Page 13

4.7. Display PCB Layout

Display Subsystem (PCB & TFT Panel)

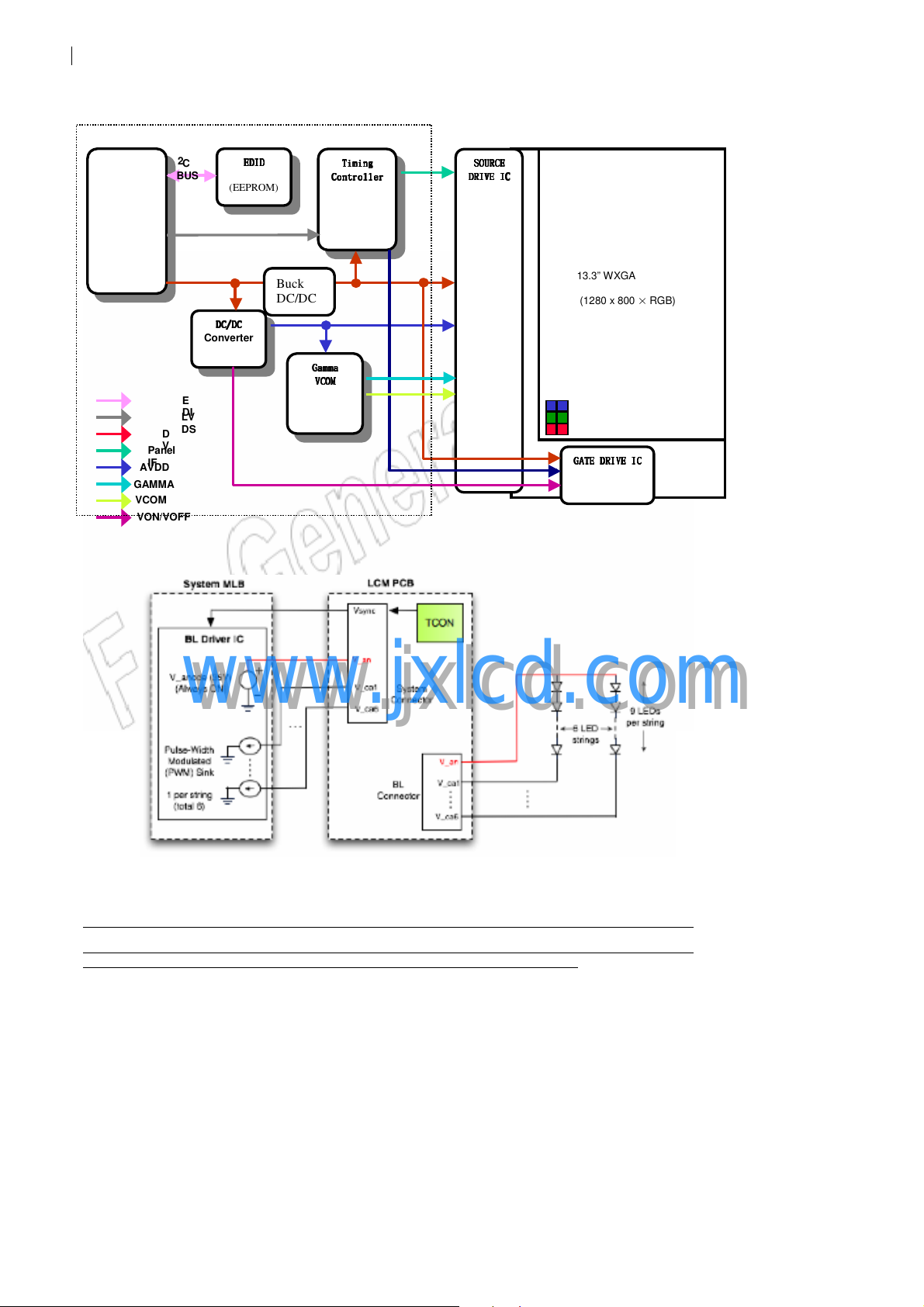

4.7.1. Pin-Out (Single Channel LVDS Interface)

Connector: IPEX 20474-030E-12 or equivalent (1.0 mm thickness, lock-in type, pin 1

starts from left on the front)

Matching Connector: IPEX 20472-030T-10 or equivalent (micro-coax type)

Interface Chips: (need update according the latest Configuration Sheet), integrated LVDS

and timing controller)

www.jxlcd.com

www.jxlcd.com

Single Channel LVDS Configuration

Pin Symbol Description Micro-coax cable gauge

(AWG)

1 GND Ground 40

2 Vcc Power Supply (+3.3V)

3 V

4 V

N

. | Size: A | METRIC | Scale: NONE | Page 13 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

Power Supply (+3.3V)

analog

DDC Power +3.3V 40

EDID

36

36

Page 14

5 Vsync Vsync 40

6 Clk

7 DATA

8 Rin0- Differential Data Input 40

9 Rin0+ Differential Data Input 40

10 GND Ground 40

11 Rin1- Differential Data Input 40

12 Rin1+ Differential Data Input 40

13 GND Ground 40

14 Rin2- Differential Data Input 40

15 Rin2+ Differential Data Input 40

16 GND Ground 40

17 Clkin- Differential Clock Input 40

18 Clkin+ Differential Clock Input 40

19 GND Ground 40

20 NC NC 40

21 Vdc(1 &2) LED Annold (Positive) 40

22 Vdc(3&4) LED Annold (Positive) 40

23 NC NC 40

24 Vdc1 LED Cathode (Negative) 40

25 Vdc2 LED Cathode (Negative) 40

26 Vdc3 LED Cathode (Negative) 40

27 Vdc4 LED Cathode (Negative) 40

28 Vdc5 LED Cathode (Negative) 40

29 Vdc6 LED Cathode (Negative) 40

30 NC NC 40

DDC Clock 40

EDID

DDC Data 40

EDID

www.jxlcd.com

www.jxlcd.com

4.7.2. Connector Diagram

N

. | Size: A | METRIC | Scale: NONE | Page 14 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

PIN #1

PIN #30

格格格格式化

式化::::

式化式化

格格格格式化

式化::::

式化式化

項目符號及編號

項目符號及編號

Page 15

4.7.3. Color Input Data Reference

The brightness of each primary color (red, green and blue) is based on the 6-bit gray

scale data input for the color. The higher the binary input, the brighter the color. The

table below provides a reference for color versus data input.

COLOR DATA REFERENCE

Input Color Data

Color Red

MSB LSB

R5 R4 R3 R2 R1 R0 G5 G4 G3 G2 G1 G0 B5 B4 B3 B2 B1 B0

Basic

Colors

Red

Green

Black

Red(63)

Green(63)

Blue(63)

Cyan

Magenta

Yellow

White

Red(00) Dark

Red(01)

Red(02)

Red(61)

www.jxlcd.com

Red(62)

www.jxlcd.com

Red(63) Bright

Green(00)Dark

Green(01)

Green(02)

Green(61)

Green(62)

Green(63)Bright

0

0

0

0

0

0

0

1

1

1

1

1

1

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

1

0

0

:

:

:

:

:

:

:

1

1

1

1

0

1

0

1

1

1

1

1

0

0

1

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

:

:

:

:

:

:

:

0

0

0

0

0

0

1

0

0

0

0

0

0

1

0

0

0

0

0

0

1

Green

MSB LSB

0

0

0

0

0

0

0

0

1

1

1

1

0

0

0

0

1

1

1

1

0

0

0

0

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

:

:

:

:

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

:

:

:

:

1

1

1

0

1

1

1

1

1

1

1

1

MSB LSB

0

0

0

0

1

0

0

1

1

1

0

1

1

0

1

1

0

0

0

0

0

0

:

:

0

0

0

0

0

0

0

0

1

0

0

0

:

:

1

0

0

0

1

0

0

0

0

1

1

1

0

1

0

0

0

:

0

0

0

0

0

0

:

0

0

0

Blue

0

0

0

1

1

1

0

1

0

0

0

:

0

0

0

0

0

0

:

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

0

0

0

1

1

1

0

0

0

0

0

0

0

0

0

:

:

:

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

:

:

:

0

0

0

0

0

0

0

0

0

N

. | Size: A | METRIC | Scale: NONE | Page 15 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

Page 16

BRG

R G BRG

B R G B R G

B

L

799

Blue(00) Dark

Blue(01)

Blue(02)

Blue

Blue(61)

Blue(62)

Blue(63) Bright

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

:

:

:

:

:

:

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

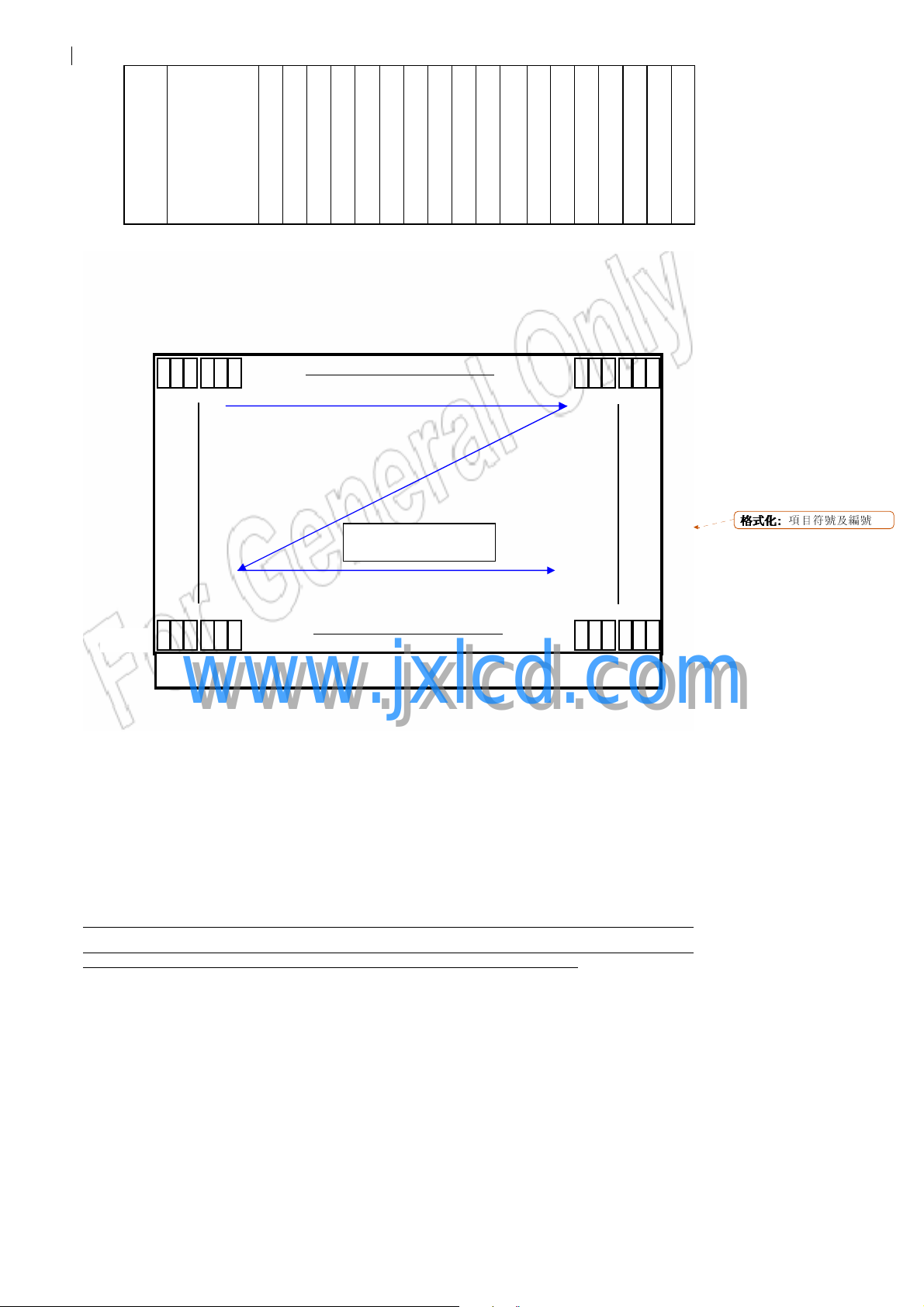

Pixel Format on the Display

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

0

0

1

0

:

:

:

:

:

:

:

:

:

:

:

:

0

0

0

0

0

0

1

1

1

1

0

1

0

0

0

0

0

0

1

1

1

1

1

0

0

0

0

0

0

0

1

1

1

1

1

1

in e 0

0

R G

B

R G B R G B

1279

Scan Direction

Flex Bonding Edge

www.jxlcd.com

www.jxlcd.com

格格格格式化

式化::::

式化式化

項目符號及編號

N

. | Size: A | METRIC | Scale: NONE | Page 16 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

Page 17

4.7.4. EDID Interface (Per Vesa EDID 1.x standard requirements)

Release

Address

HEX

00

01

02

03

04

05

06

07

08

09

0A

0B

0C

0D

0E

0F

10

11

12

13

14

15

16

17

18

19

1A

1B

1C

1D

1E

1F

20

21

N

. | Size: A | METRIC | Scale: NONE | Page 17 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

FUNCTION B133EW04

Header

Header

HeaderHeader

00 00000000 0

FF 11111111 255

EISA Manuf. Code

EISA Manuf. Code

EISA Manuf. Code EISA Manuf. Code

LSB

LSB

LSBLSB

Compressed ASCII

Compressed ASCII

Compressed ASCIICompressed ASCII

Product Code

Product Code

Product CodeProduct Code

hex, LSB first

hex, LSB first

hex, LSB firsthex, LSB first

32

32----bit ser #

bit ser #

3232

bit ser #bit ser #

Week of manufacture

Week of manufacture

Week of manufactureWeek of manufacture

Year of manufacture

Year of manufacture

Year of manufactureYear of manufacture

EDID Structure Ver.

EDID Structure Ver.

EDID Structure Ver.EDID Structure Ver.

EDID revision #

EDID revision #

EDID revision #EDID revision #

Video input definition

Video input definition

Video input definitionVideo input definition

Max H image size

Max H image size

Max H image sizeMax H image size

Max V image size

Max V image size

Max V image sizeMax V image size

Display Gamma

Display Gamma

Display GammaDisplay Gamma

www.jxlcd.com

www.jxlcd.com

Feature support

Feature support

Feature supportFeature support

Red/green low bits

Red/green low bits

Red/green low bitsRed/green low bits

Blue/white low bits

Blue/white low bits

Blue/white low bitsBlue/white low bits

Red x/ high bits

Red x/ high bits

Red x/ high bitsRed x/ high bits

Red y

Red y

Red yRed y

Green x

Green x

Green xGreen x

Green y

Green y

Green yGreen y

Blue x

Blue x

Blue xBlue x

Blue y

Blue y

Blue yBlue y

White x

White x

White xWhite x

HEX BIN DEC

FF 11111111 255

FF 11111111 255

FF 11111111 255

FF 11111111 255

FF 11111111 255

00 00000000 0

06 00000110 6

10 00010000 16

A1 10100001 161

9C 10011100 156

01 00000001 1

01 00000001 1

01 00000001 1

01 00000001 1

01 00000001 1

13 00010011 19

01 00000001 1

03 00000011 3

80 10000000 128

1D 00011101 29

12 00010010 18

78 01111000 120

0A 00001010 10

50 01010000 80

85 10000101 133

97 10010111 151

58 01011000 88

50 01010000 80

8E 10001110 142

27 00100111 39

27 00100111 39

50 01010000 80 Wx=0.313

Value Value Note

time 7/11/08 0:00

APP9CA1

APP9CA1

APP9CA1APP9CA1

0 00001(A) 10000(P)

10000(P)

9CA1 ( assigned code)

unused

unused

unusedunused

Week 1

Week 1

Week 1Week 1

19(2009

19(2009----1990=19)

19(200919(2009

1990=19)

1990=19)1990=19)

Digital Input

28.6cm

28.6cm

28.6cm28.6cm

17.9cm

17.9cm

17.9cm17.9cm

Gamma 2.2

Gamma 2.2

Gamma 2.2Gamma 2.2

no DPMS,Active

off,RGB color

Rx=0.640

Ry=0.340

Gx=0.310

Gy=0.610

Bx=0.150

By=0.060

Page 18

White y

White y

22

23

24

25

26

27

28

29

2A

2B

2C

2D

2E

2F

30

31

32

33

34

35

36

37

38

39

3A

3B

3C

3D

3E

3F

40

41

N

White yWhite y

Es

Established timing 1

tablished timing 1

EsEs

tablished timing 1tablished timing 1

Established timing 2

Established timing 2

Established timing 2Established timing 2

Manufacturer's

Manufacturer's

Manufacturer's Manufacturer's

Timing

Timing

TimingTiming

Standard timing #1

Standard timing #1

Standard timing #1Standard timing #1

Standard timing #2

Standard timing #2

Standard timing #2Standard timing #2

St

Standard timing #3

andard timing #3

StSt

andard timing #3andard timing #3

Standard timing #4

Standard timing #4

Standard timing #4Standard timing #4

01 00000001 1

Standard timing #5

Standard timing #5

Standard timing #5Standard timing #5

Standard timing #6

Standard timing #6

Standard timing #6Standard timing #6

01 00000001 1

Standard timin

Standard timing #7

Standard timinStandard timin

Standard timing #8

Standard timing #8

Standard timing #8Standard timing #8

Pixel Clock/10,000

Pixel Clock/10,000

Pixel Clock/10,000 Pixel Clock/10,000

Pixel Clock/10,000

Pixel Clock/10,000

Pixel Clock/10,000 Pixel Clock/10,000

Horiz. Active

pixels(Lower 8 bits) 00 00000000 0

Horiz.Blanking (Lower

Horiz. Active

pixels:Horiz. Blanking

(Upper4:4 bits)

www.jxlcd.com

www.jxlcd.com

Vert. Active

pixels:Vert. Blanking

(Upper4:4 bits)

Vert. Sync. Offset=xx

lines, Sync Width=xx

Horz. Ver. Sync/Width

(upper 2 bits)

g #7

g #7g #7

(LSB)

(LSB)

(LSB)(LSB)

(MSB)

(MSB)

(MSB)(MSB)

8 bits)

20 00100000 32

lines

54 01010100 84 Wy=0.329

00 00000000 0

00 00000000 0

00 00000000 0

01 00000001 1 unused

01 00000001 1

01 00000001 1

01 00000001 1

01 00000001 1

01 00000001 1

01 00000001 1

01 00000001 1

01 00000001 1

01 00000001 1

01 00000001 1

01 00000001 1

01 00000001 1

01 00000001 1

unused

Timing

52 01010010 82

1C 00011100 28

8F 10001111 143

50 01010000 80

2E 00101110 46

30 00110000 48

30 00110000 48

20 00100000 32

36 00110110 54

00 00000000 0

Descriptor #1

1280x800

1280x800

1280x800 1280x800

@60_mode:pixel

@60_mode:pixel

@60_mode:pixel @60_mode:pixel

clock=

clock=72.5

72.5MHz

clock=clock=

72.572.5

Horiz active=1280

Horiz active=1280

Horiz active=1280 Horiz active=1280

pixels

pixels

pixelspixels

Horiz

Horiz

Horiz Horiz

blanking=143pixels

blanking=143pixels

blanking=143pixelsblanking=143pixels

Vertcal activ

Vertcal active=800

Vertcal activVertcal activ

lines

lines

lineslines

Vertical blanking=46

Vertical blanking=46

Vertical blanking=46 Vertical blanking=46

lines

lines

lineslines

Horiz sync. Offset=48

Horiz sync. Offset=48

Horiz sync. Offset=48 Horiz sync. Offset=48

pixels

pixels

pixelspixels

Horiz sync. Pulse

Horiz sync. Pulse

Horiz sync. Pulse Horiz sync. Pulse

Width=32 pixels

Width=32 pixels

Width=32 pixelsWidth=32 pixels

Verti sync. Offset=3

Verti sync. Offset=3

Verti sync. Offset=3 Verti sync. Offset=3

lines,Sync Width=6

lines,Sync Width=6

lines,Sync Width=6 lines,Sync Width=6

lines

lines

lineslines

MHz

MHzMHz

e=800

e=800 e=800

. | Size: A | METRIC | Scale: NONE | Page 18 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

Page 19

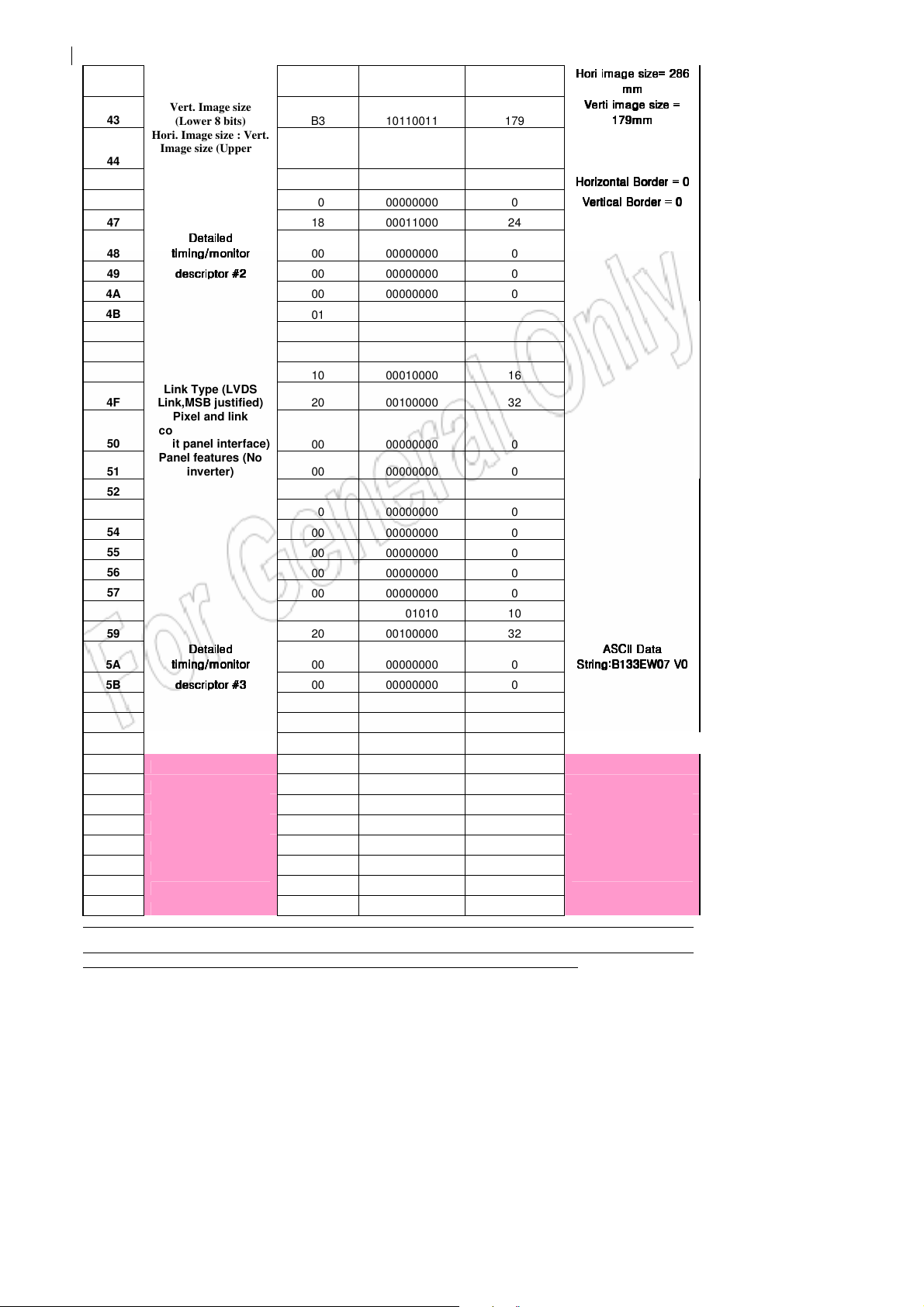

Hori image size= 286

Hori image size= 286

42

43

44

45

46

47

48

49

4A

4B

4C Version

4D edid signature

4E edid signature

4F

50

51

52

53

54

55

56

57

58

59

5A

5B

5C

5D

5E

5F

60

61

62

63

64

65

66

N

Hori. Image size

(Lower 8 bits) 1E 00011110 30

Vert. Image size

(Lower 8 bits) B3 10110011 179

Hori. Image size : Vert.

Image size (Upper 4

bits)

Detailed

Detailed

Detailed Detailed

timing/monitor

timing/monitor

timing/monitortiming/monitor

descriptor #2

descriptor #2

descriptor #2descriptor #2

00 00000000 0

Link Type (LVDS

Link,MSB justified)

Pixel and link

component format

(6-bit panel interface)

Panel features (No

inverter)

Detailed

Detailed

Detailed Detailed

timing/monitor

timing/monitor

timing/monitortiming/monitor

descriptor #3

descriptor #3

descriptor #3descriptor #3

www.jxlcd.com

www.jxlcd.com

33 00110011 51 3

57 01010111 87 W

10 00010000 16

00 00000000 0

00 00000000 0

18 00011000 24

00 00000000 0

00 00000000 0

01 00000001 1

00 00000000 0

06 00000110 6

10 00010000 16

20 00100000 32

00 00000000 0

00 00000000 0

00 00000000 0

00 00000000 0

00 00000000 0

00 00000000 0

00 00000000 0

00 00000000 0

0A 00001010 10

20 00100000 32

00 00000000 0

00 00000000 0

00 00000000 0

FE 11111110 254

00 00000000 0

42 01000010 66

31 00110001 49

33 00110011 51

45 01000101 69

30 00110000 48

37 00110111 55

Hori image size= 286 Hori image size= 286

mm

mm

mmmm

Verti image size =

Verti image size =

Verti image size = Verti image size =

179mm

179mm

179mm179mm

Horizontal Border = 0

Horizontal Border = 0

Horizontal Border = 0 Horizontal Border = 0

Vertical Border = 0

Vertical Border = 0

Vertical Border = 0 Vertical Border = 0

ASCII Data

ASCII Data

ASCII Data ASCII Data

String:B133EW07 V0

String:B133EW07 V0

String:B133EW07 V0String:B133EW07 V0

B

1

3

E

0

7

. | Size: A | METRIC | Scale: NONE | Page 19 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

Page 20

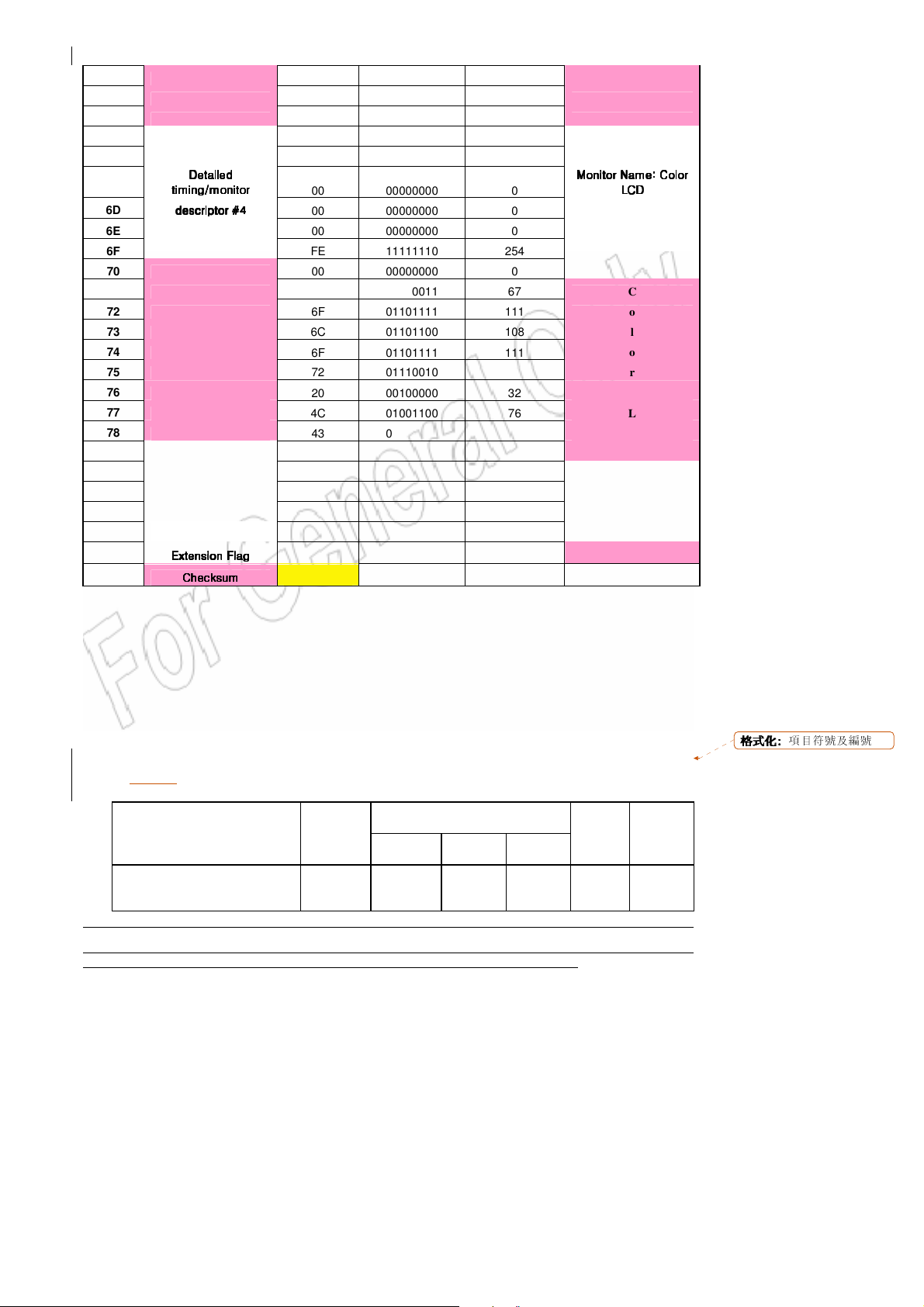

67

68

69

6A

6B

6C

6D

6E

6F

70

71

72

73

74

75

76

77

78

79

7A

7B

7C

7D

7E

7F

20 00100000 32

Detailed

Detailed

Detailed Detailed

timing/monitor

timing/monitor

timing/monitortiming/monitor

descriptor #4

descriptor #4

descriptor #4descriptor #4

6F 01101111 111 o

20 00100000 32

20 00100000 32

Extension Flag

Extension Flag

Extension FlagExtension Flag

Checks

Checksum

um

ChecksChecks

umum

56 01010110 86

30 00110000 48

0A 00001010 10

20 00100000 32

00 00000000 0

00 00000000 0

00 00000000 0

FE 11111110 254

00 00000000 0

43 01000011 67

6C 01101100 108

6F 01101111 111

72 01110010 114

4C 01001100 76

43 01000011 67

44 01000100 68

0A 00001010 10

20 00100000 32

20 00100000 32

00 00000000 0

13 00010011 19

V

0

Monitor Name: Color

Monitor Name: Color

Monitor Name: Color Monitor Name: Color

LCD

LCD

LCDLCD

C

l

o

r

L

C

D

www.jxlcd.com

www.jxlcd.com

4.7.5. Electrical Ratings

VALUES

PARAMETER SYMBOL

Min. Typ. Max.

Power Supply Input Voltage

N

. | Size: A | METRIC | Scale: NONE | Page 20 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

V

CC

3.0

3.3

3.6 V (DC)

UNIT NOTES

格格格格式化

式化::::

式化式化

項目符號及編號

Page 21

Power Supply Ripple

Power Supply Input Current

Differential Impedance

Power Consumption

Rush current

Notes: (1) The power supply ripple is measured whereas a black pattern is displayed;

(2) The specified current and power consumption are under the conditions at Vcc = 3.3 V, T =

25ºC, and fv = 60 Hz, f

(3) This impedance value is needed to a proper display and is measured from LVDS mating

connector to LVDS Rx

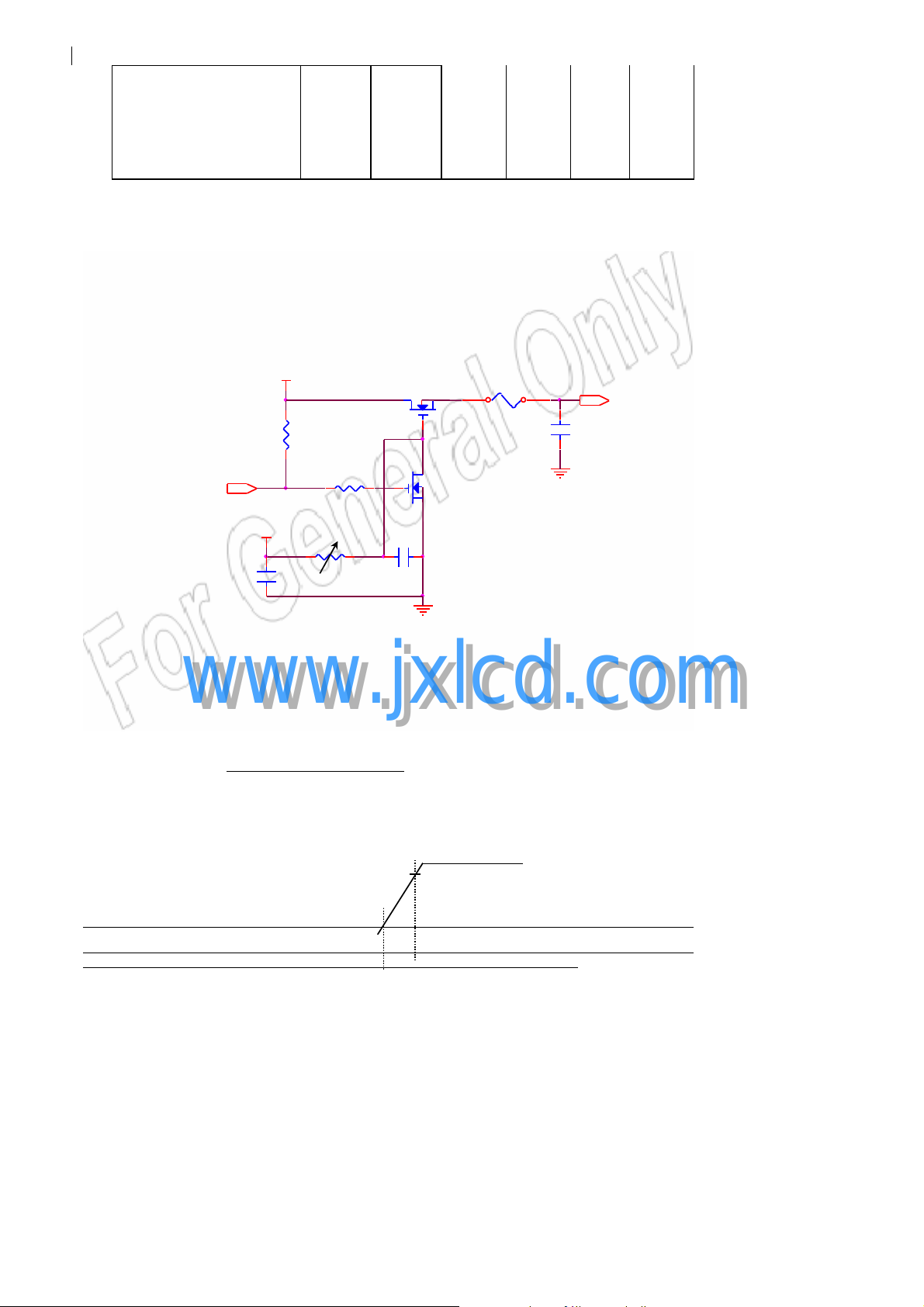

(4) The following is a typical Vcc circuit on the system side

3.3V

CONTROL SIGNAL

(HIGH to LOW)

12V

C3

1uF

www.jxlcd.com

www.jxlcd.com

Vcc rise time is about 470 µs

N

. | Size: A | METRIC | Scale: NONE | Page 21 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

I

CC

Zm

Pc

I

RUSH

=72.5MHz, whereas a mosaic pattern (typical) is displayed;

CLK

R1

47K

R2

1K

R3

47K

0.9Vcc

-

90

-

-

M1

2SK1059

C2

10000pF

M2

2SK1399

50

242

100

0.8

-

FUSE

273

110

0.9

1.5

C1

1uF

3.3V

470 µs

mV

mA

Ω

W

A

p-p

Vcc

1

2

3

2

4

(

LCD INPUT)

Page 22

4.7.6. Signal Timing

4.7.6.1. Signal Impedance

Defined in VESA standard for LVDS FPDI 2

4.7.6.2. Timing Data

This is the signal timing required at the input of the control ASIC concerned with

LVDS as a FlatLink or equivalent. All of the interface signal timing should be

satisfied with the following specifications based on the VESA timing guideline

(1280x800 @ 60 Hz) for its proper operation.

GND

The duration of the rush current is about 20 ms.

0.1Vcc

格格格格式化

式化::::

式化式化

格格格格式化

式化::::

式化式化

項目符號及編號

項目符號及編號

www.jxlcd.com

www.jxlcd.com

N

. | Size: A | METRIC | Scale: NONE | Page 22 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

Page 23

Video Timing Data

Signal Parameter Symbol Min Typ Max

D

Clock Period

CLK

Clock Frequency

Duty Ratio (% High)

Rise Time

Fall Time

DE

(Data Enable

Only)

(DTMG)

Data

H

H

sync

V

V

sync

Note: (1) When the WXGA+ controller sets DE Mode, and H

(DTMG) signal must be longer than 1 clock period (TC) at every horizontal sync period;

DE Setup Time

Data Setup Time

Data Hold Time

Horizontal Period

Horizontal Blank Period

Vertical Period

Vertical Blank Period

Back Porch

sync

H

Pulse Width

sync

H

Front Porch

sync

Horizontal Active Period

Back Porch

sync

V

Pulse Width

sync

V

Front Porch

sync

Vertical Active Period

www.jxlcd.com

www.jxlcd.com

T

T

T

H

T

Hfp

THD

V

TWV

Vfp

TVD

T

C

fC

Kdr

R CLK

F CLK

T

se

Tsd

Thd

TH

Tha

TV

wvb

bp

WH

bp

40

-

-

4

4

2

1280

800

sync

and V

13.79

72.50

50

4.42

4.42

-

-

-

1440

160

823

23

80

32

48

1280

14

6

3

800

are required. The duration of DE

sync

60

-

-

-

-

-

1280

800

Unit Note

ns

MHz

%

ns

ns

ns

ns

ns

TC

TC

TH

TH

T

C

TC

TC

TC

T

H

TH

TH

TH

1

1/T

TCh /TC

2

fV=59.94 Hz, 3

Display Period

Display Period

C

(2) Horizontal Period = One Line Scanning Time;

(3) The vertical period TV is related to the frame frequency fV, i.e., 60 Hz.

4.7.6.3. Video Timing Diagram

N

. | Size: A | METRIC | Scale: NONE | Page 23 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

格格格格式化

式化::::

式化式化

項目符號及編號

Page 24

1280 pixels

DE

DE

DEDE

DCLK

DCLK

DCLKDCLK

Da ta

Da ta

Da taDa ta

DE

DE

DEDE

T v d

Va lid

Va lid Dis play

Dis play Data

Va lidVa lid

Dis playDis play

T ch

T v

T hd

T h

Da t a ((((11111111 5555 2222p ix els )

Da t aDat a

T c

pix e ls )

pix e ls )pix e ls )

T w vb

T h s

90 %

50 %

DCLK

DCLK

DCLKDCLK

Display

Display

DisplayDis pla y

dat a

dat a

dat adat a

DE

DE

DEDE

N

. | Size: A | METRIC | Scale: NONE | Page 24 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

10 %

T r c lk

www.jxlcd.com

www.jxlcd.com

T ds

T e s

90 %

50 %

50 %

10 %

T fc lk

T dh

90 %

10 %

90 %

Page 25

4.7.7. Power Measurements (W/O backlight)

Pattern Min Typ Max Unit

格格格格式化

式化::::

式化式化

項目符號及編號

White To be updated

Mosaic 242 273 mA

V. Stripe To be updated

Black 273 303 mA

Note: (1) Display data pins and timing signal pins should be connected (GND = 0V);

(2) Operation conditions: fV = 60 Hz, f

(3) Power dissipation patterns are as follows.

(a) White screen (b) Mosaic (or checker) pattern

20x20 pixel black and white boxes

mA

mA

= 72.5 MHz, Vcc = 3.3 V;

CLK

Display Brightest Gray Level

Display Darkest Gray Level

(c) Vertical Stripe Pattern

sub-pixel vertical line on/off alternation,

www.jxlcd.com

www.jxlcd.com

N

. | Size: A | METRIC | Scale: NONE | Page 25 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

R G B R G B R G B

R G B R G B R G B

R G B R G B R G B

R G B R G B R G B

格格格格式化

式化::::

式化式化

項目符號及編號

Page 26

6

5

:

:

MacBook

4.7.8. Power on-off sequence

Power-on includes both system starting from power-off state and wake from sleep state;

power-off includes both system shutdown and entering sleep state.

Power on Power off Restart

刪除

刪除

刪除刪除

刪除

刪除

刪除刪除

MacBook

Power Supply for

LCD VCC

Interface Signal

(LVDS Signal of

Transmitter), Vi

Power for Lamp

90%

10%

0V

T

2

T

1

T3

Valid Data

ON

10

50

-

-

50

20

-

T

4

0V

OFF

Values Parameter

Min. Typ. Max.

T

1

T

2

T

3

T

4

www.jxlcd.com

T

5

www.jxlcd.com

T

6

T7

0.15

1

200

200

0

5

500

-

20

250

250

20

-

-

T

OFF

Unit

ms

ms

ms

ms

ms

ms

ms

T

90%

10%

T

7

4.7.9. Vcc Dip Condition

The Vcc dip is the Vcc voltage drop during panel start-up.

N

. | Size: A | METRIC | Scale: NONE | Page 26 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

格格格格式化

式化::::

式化式化

項目符號及編號

Page 27

:

5.4.8

(1) 2.5V ≤ Vcc < 3.0 V, Td ≤ 20 ms;

(2) For Vcc < 2.5V, Vcc should follow the power on-off sequence defined in 4.7.8

Vcc

td

刪除

刪除

刪除刪除

4.8. Near-Field Noise

The RF emissions from the panel (especially the LVDS input and Tcon) interfere with Wifi

operation.

Note that this spec compliance requirement is in addition to the legal EMI compliance

requirements.

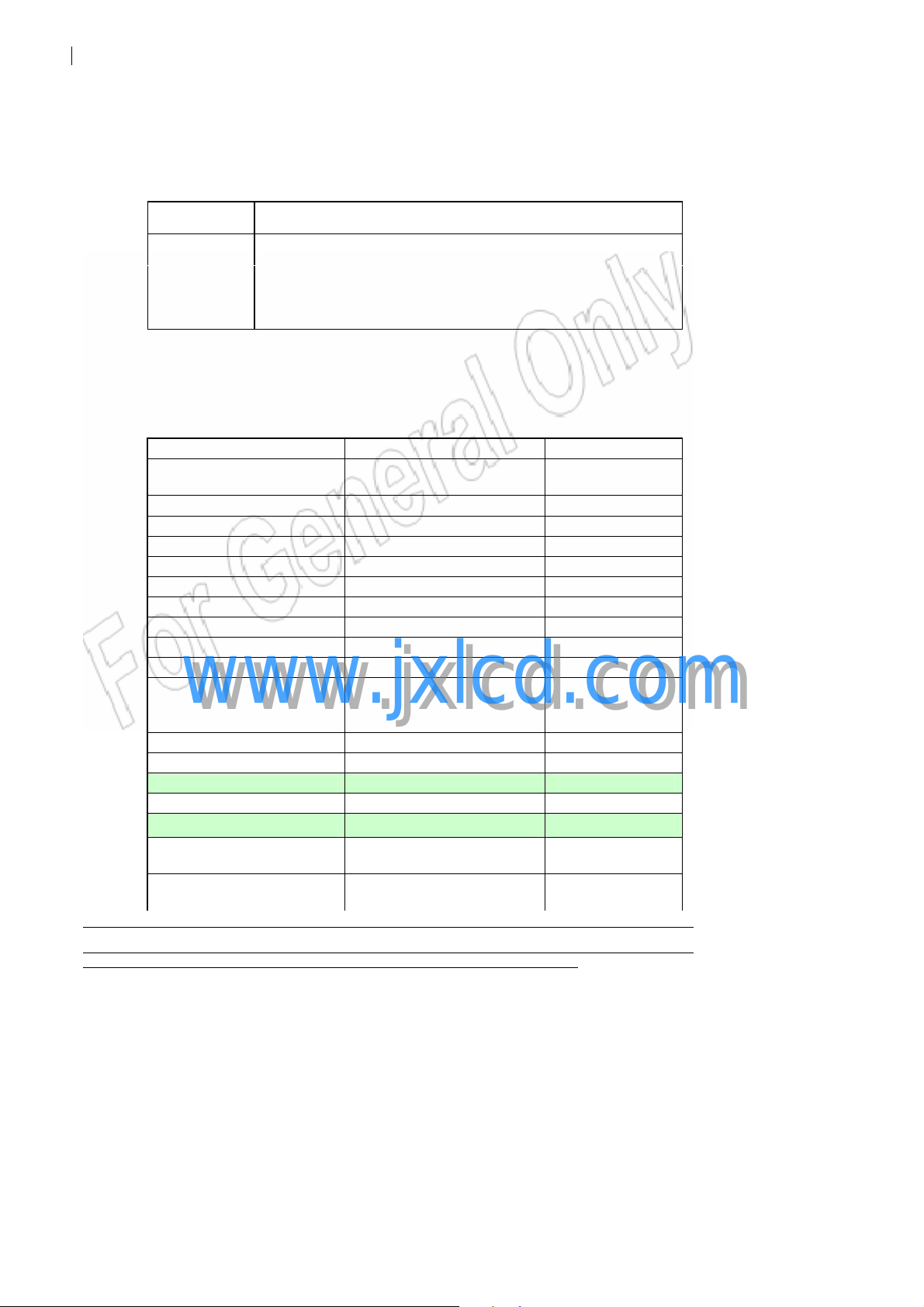

4.9. Backlight Subsystem

4.9.1. General Information

LED Manufacturer Nichia

LED Manufacturer Assembly P/N Nichia NNSW208

www.jxlcd.com

www.jxlcd.com

Number of LEDs 54

LED Ranks V630 and up

LED Brightness Bin 50 mcd per bin

LED Vf Bin Rank 1 (2.8-3.0 V) and 2 (3.0-3.2 V)

格格格格式化

式化::::

式化式化

格格格格式化

式化::::

式化式化

項目符號及編號

項目符號及編號

LED Forward Voltage Range for All 6

LED Series Lines

4.9.2. Backlight Synchronization Requirement (to avoid BL shimmering)

N

. | Size: A | METRIC | Scale: NONE | Page 27 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

(Characterized at LVDS Connector for 23 mA)

MAX: 28.8 V

格格格格式化

式化::::

式化式化

項目符號及編號

Page 28

Display Minimum

The Vsync/STV signal is a once-per-frame pulse that has a constant phase delay with

respect to the start of the frame. This signal is used by the backlight LED driver to

synchronize BL PWM with the frame update to avoid shimmering (waterfall) artifacts in

the image.

The minimum pulse width is 1 us.

4.9.3. Backlight Electrical Characteristics

The backlight brightness test shall be tested at 600Hz PWM 94% cycle & 23 mA peak current

with following percentage duty cycle

LED Current (%

duty cycle)

94% 28.8 V 3.73 250 275 300

N

. | Size: A | METRIC | Scale: NONE | Page 28 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

www.jxlcd.com

www.jxlcd.com

LED Forward

Voltage for any

LED string

Power (W)

Assuming 3.2V

max forward bias

Luminance (nits)

Display Typical

Luminance (nits)

Display

Maximum

Luminance (nits)

格格格格式化

式化::::

式化式化

項目符號及編號

Page 29

19% 28.8 V 0.75 50 55 60

5% 28.8 V 0.19 12 14 15

4.9.4. LED Connection

String LED1 LED2 LED3 LED4 LED5 LED6 LED7 LED8 LED9

1

2

3

4

5

6

1 7 13 19 25 31 37 43 49

2 8 14 20 26 32 38 44 50

3 9 15 21 27 33 39 45 51

4 10 16 22 28 34 40 46 52

5 11 17 23 29 35 41 47 53

6 12 18 24 30 36 42 48 54

格格格格式化

式化::::

式化式化

項目符號及編號

www.jxlcd.com

www.jxlcd.com

N

. | Size: A | METRIC | Scale: NONE | Page 29 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

Page 30

5. OPTICAL REQUIREMENTS

5.1. Optical Specifications

Supplier must submit optical measurement data from 20 samples for items marked critical in

Table 6.1.1. The optical performance will be based on supplier’s measurement data, visual

inspection of the samples, verification measurements, and specification correlation.

Table 6.1.1: Optical Characteristics

Parameter Symbol

Iso-Contrast Viewing Angle

CR ≥ 10

Contrast ratio CR Optimal 400 600 -- -- 1,2,3

Luminance Y I

Global Luminance Uniformity Optimal 50 -- % 1,2

Worst Neighbor Luminance

Uniformity

Gamma

Flicker F No Visual Flicker

Cross Talk D

Worst Low Level (dark)

Inversion Viewing Direction

Response (rise+fall time)

Gray to Gray Response time

www.jxlcd.com

www.jxlcd.com

θ

down 45 50

left/right 55/55 60/60

Optimal 80 -- % 1,2

γ

Optimal -- 2.0 % 1,2,3

SHA

PCB on the

τ

θ = 0°, Ta=25°C

on+off

τ

θ = 0°, Ta=25°C

G2G

Condition Min. Typ. Max. Unit Note

up 45 50 -- Degrees 1,2,3

=23 mA

LED

@94% duty cycle

-- -- 2.2 -- -- 1,2,3

bottom

220 250 -- cd/m2 1,2,4

-- -- -30 dB 1,2,3

-- 6:00 -- o’clock 1,2

-- 16 25 ms 1,2,3

-- 40 ms 1,2,3

x CIE 1931 0.297 0.313 0.329 -- 1,2,3 White Chromaticity

(all panels)

(Within one panel)

N

. | Size: A | METRIC | Scale: NONE | Page 30 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

y 0.313 0.329 0.345 -- 1,2,3

delta x 0.005 White Chromaticity

delta y 0.008

x CIE 1931 0.620 0.640 0.660 -- 1,2,3 Red Chromaticity

y 0.315 0.330 0.345 -- 1,2,3

Page 31

Parameter Symbol

Green Chromaticity

Max color difference within

one panel

Max color difference w.r.t.

Center within one panel

Max color difference from

panel to panel

Max color difference between

neigbors

Note 1: The testing conditions are specified in 6.2.

Note 2: The definitions of optical characteristics are shown in 6.3.

Note 3: Measured at center point. Equivalent performance over the entire panel required.

Note 4: Both center point and average of 160 points.

x CIE 1931 0.290 0.310 0.330 -- 1,2,3

Y 0.590 0.610 0.630 -- 1,2,3

X CIE 1931 0.120 0.150 0.170 -- 1,2,3 Blue Chromaticity

Y 0.040 0.060 0.080 -- 1,2,3

du’v’ white 0.005 1,2

du’v’ white 0.003 1,2

du’v’ white 0.008

du’v’ white 0.0025

Condition Min. Typ. Max. Unit Note

1,2

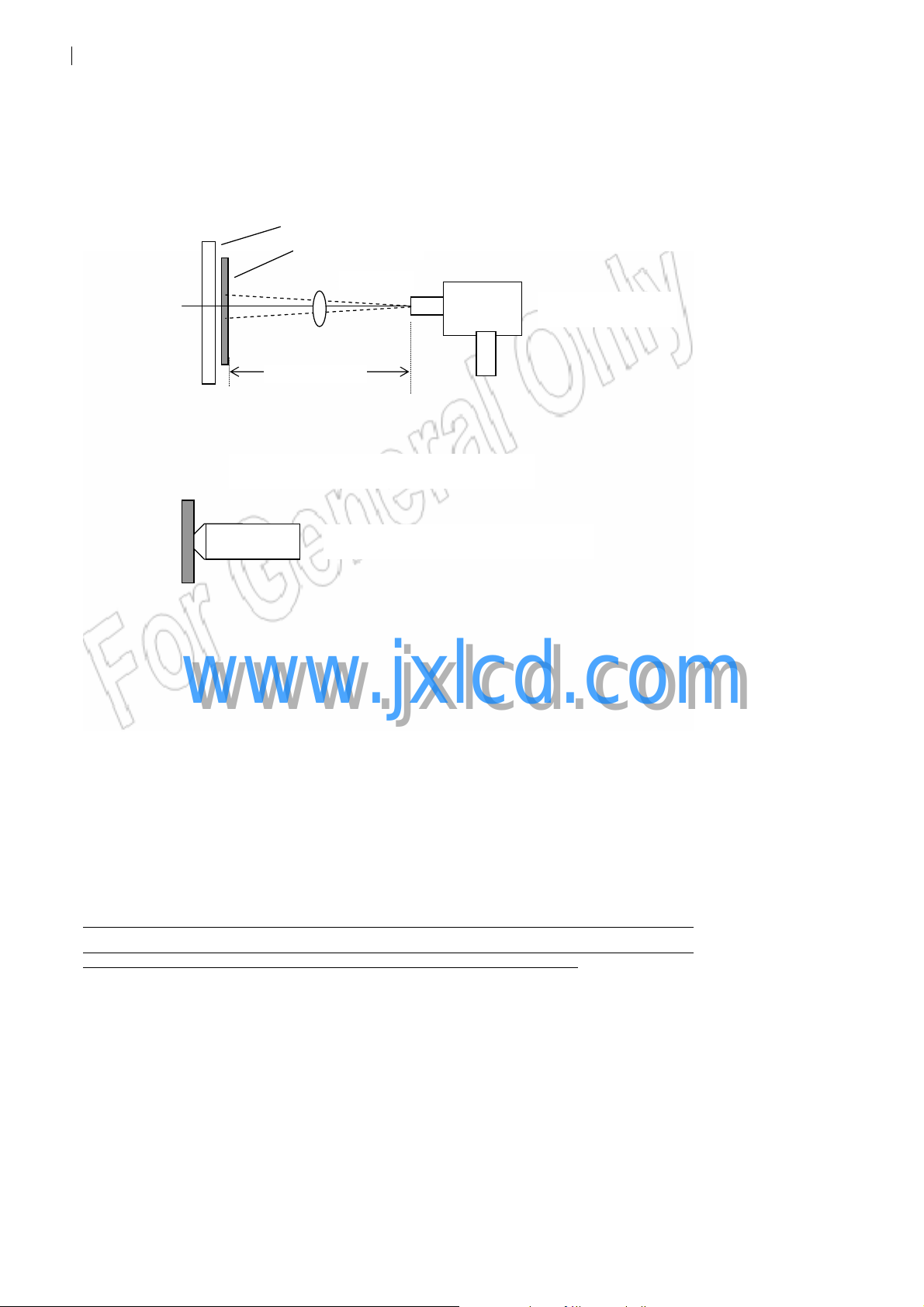

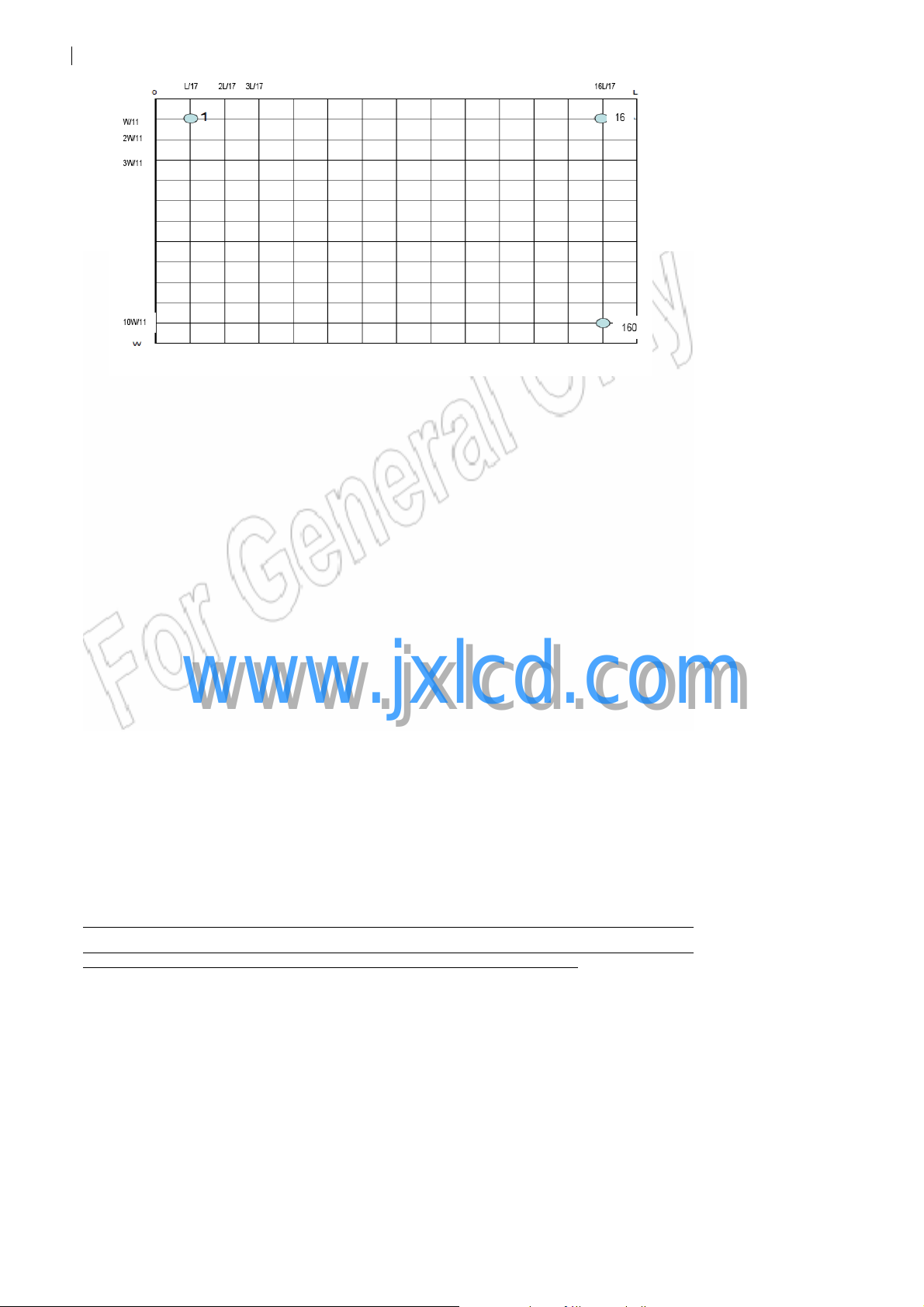

5.2. Measuring Conditions

The optical characteristics are determined after the unit has been ‘ON’ and stable for

approximately 30 minutes at the maximum brightness, in a dark environment at an

ambient temperature at 25°C ± 2°C. The electrical conditions include Vcc = 3.3 V, fv =

60 Hz, f

measuring equipments for luminance and color are CCD based imaging systems such as

Radiant Imaging Prometric 1400 system, or Colorimeter such as Photo Research PR650,

TOPCON BM-5A or similar. The measuring distance should be about 50 cm from the

LCD surface at normal unless otherwise specified. Measurements should be done on the

160 grid points as shown in the following figures. The measurement spot at the center is

approximately 12 mm in diameter from a distance of 400 mm by TOPCON BM-5A or

15 mm in diameter from a distance of 500 mm by PR 650.

Viewing angle measurements should be done by an Eldim EZ Color system or similar.

N

. | Size: A | METRIC | Scale: NONE | Page 31 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

= 72.5 MHz, IBL = 23 mA @94% duty cycle with 600Hz. Recommended

CLK

www.jxlcd.com

www.jxlcd.com

Page 32

Field = 2

°

The CIE 1931 or 1976 Standards will be used.

Luminance and Color Measurement

X-Y Stage

LCD Module

TOPCON BM-5A

or PR650 or CCD

400 or 500 mm

Viewing Angle Measurement

ELDIM EZ Color or equivalent

Figure 6-1: Optical Measurement Set-up

N

. | Size: A | METRIC | Scale: NONE | Page 32 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

www.jxlcd.com

www.jxlcd.com

Page 33

Figure 6-2: Measurement point location. L and W are the length and width of Active Area

respectively.

5.3. Definition

5.3.1. Center Point Luminance

Lct =(L

5.3.2. Average Luminance

L

5.3.3. Luminance Uniformity

5.3.3.1. Global Luminance Uniformity:

N

. | Size: A | METRIC | Scale: NONE | Page 33 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

72+ L73+ L88+ L89

= SUM(L1:L

Ave

where L1 to L

www.jxlcd.com

www.jxlcd.com

The entire display active area shall be scanned with the luminance measurement

with white screen set full brightness.

two kinds of data for brightness uniformity: Luminance Uniformity, and Worst

Neighbor Luminance Uniformity. The definitions are shown in below:

160

U = 100% - (L

where, L

)/4{Average Luminance value at point #72, 73, 88, 89}

) / 160

160

are the luminance values measured at point #1 to #160.

)/L

max-Lmin

= max {Luminance values at 160 points},

max

max

Page 34

L

= min {Luminance values at 160 points}

min

5.3.3.2. Worst Neighbor Luminance Uniformity (The 4 points that are closest to

the test point)

WNU=100%-Max(∆L1, ∆L2, ∆L3, ∆L4)/L0

Global WNU = min (WNU1, …WNU160)

5.3.4. Contrast Ratio

CR = Luminance at G

#72, 73, 88, 89}

5.3.5. White Color Uniformity

The entire display active area shall be scanned with the color coordinate

www.jxlcd.com

www.jxlcd.com

measurement with white screen set full brightness.

5.3.5.1. Panel to Panel White Color Uniformity

The center point (as defined by the average value at point #72, 73, 88, 89) white

color coordinate of any panel shall be within the box with 4 corners coordination

boundary listed in Table 6.1.

N

. | Size: A | METRIC | Scale: NONE | Page 34 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

/ Luminance at G

max

{Average contrast value at point

min

Page 35

5.3.5.2. Max Color Difference with respect to the center within a panel

On each panel, the maximum color difference between any of the 160 points and

the center point (defined as the average value at point #72, 73, 88, 89),

represented in delta u’v’.

5.3.5.3. Max Color Difference between any two points within the panel

On each panel, the maximum color difference between any two of the 143 points ,

represented in delta u’v’.

5.3.5.4. Max Color Difference between two neighbors

On each panel, the maximum color difference between any two neighboring

points on the panel, represented in delta u’v’

5.3.6. RGB Color Chromaticity

The entire display active area shall be scanned with the color coordinate

measurement with screen set to full brightness and solid R, G, B color

respectively. The measured color coordinate of any panel shall be within the box

with 4 corners coordination boundary listed in Table 6.1.

5.3.7. Viewing Angle

The viewing angle is defined as the viewing angle range under the condition at

CR > 10:1 .

φ

L

Normal Line

o

φ = 0

,

θ = 0

φ

H

o

θ

R

12 O’clock

direction

y

φ H = 90o

x'y'

o

θR =90

www.jxlcd.com

www.jxlcd.com

θ

L

o

θ L =90

6 O’clock

direction

φ L= 90o

N

. | Size: A | METRIC | Scale: NONE | Page 35 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

x

Page 36

Figure 6-4: Viewing angle definition

5.3.8. Gray Scale Inversion

Luminance vs. viewing angle curves are measured based on gray level 255, 223,

191, 159, 127, 95, 63, 32 and 0, in the viewing angle of left, right, up, down, with

PCB on the bottom side. Gray scale inversion happens when a higher gray scale

measures the same luminance or lower luminance than any of the lower gray scale.

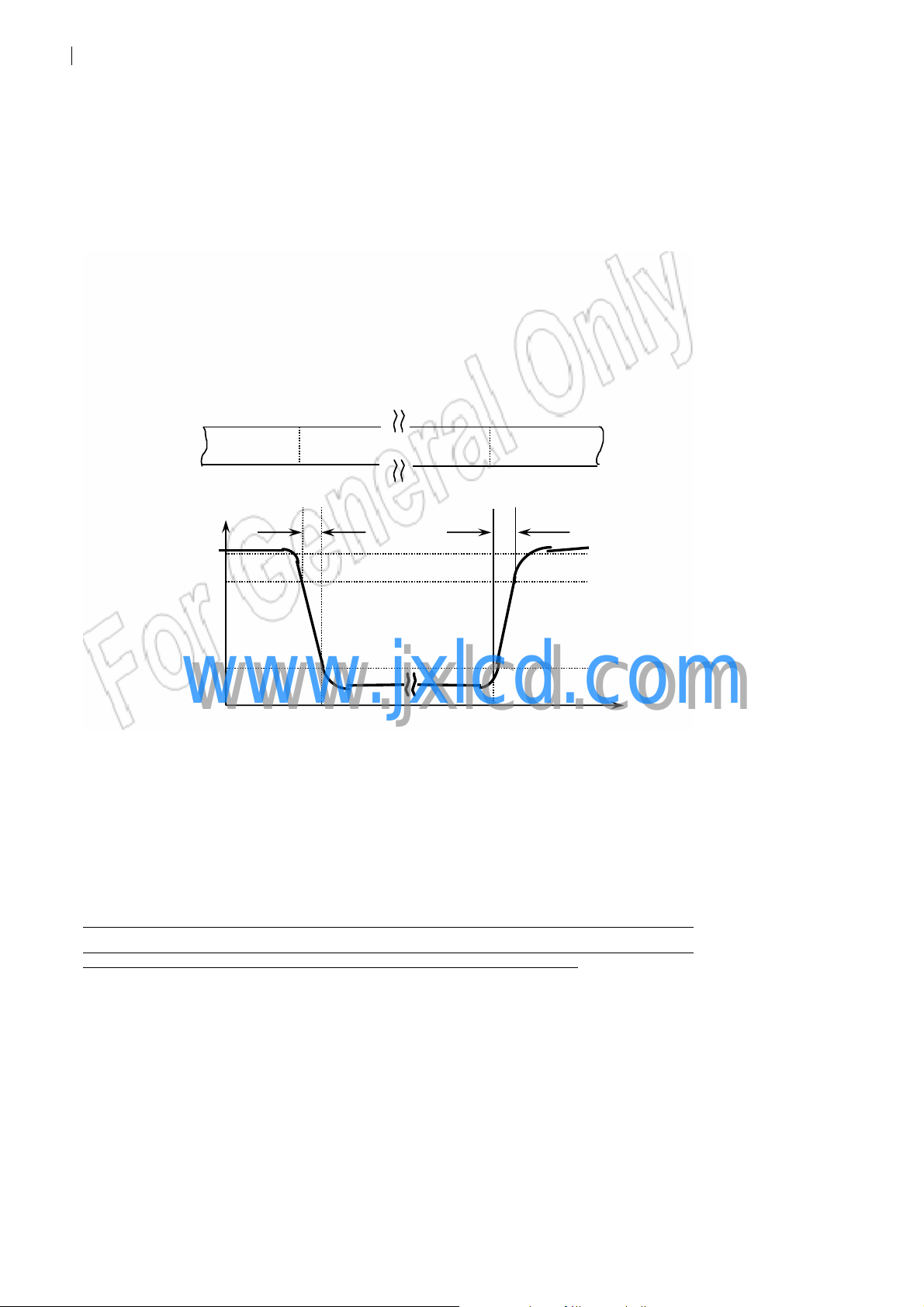

5.3.9. Response Time

5.3.9.1. On and Off Response Time

The On/Off response time, tR + tF, is defined in the following figure and shall be

measured by switching the input signal for “black” and “white”.

s

Display data

Optical

Response

5.3.9.2. Gray to Gray Response Time

White (TFT OFF)

100%

90%

10%

0%

www.jxlcd.com

www.jxlcd.com

Figure 6-5: Response Time Measurement

Gray to Gray Response Time is measured in a similar method. But instead of

switching display between black and white, panel is switched between two gray

scales. The maximum gray-to-gray response time is based on 9 levels of gray

t

R

Black (TFT ON)

White (TFT OFF)

t

F

Time

N

. | Size: A | METRIC | Scale: NONE | Page 36 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

Page 37

scales. The 9 levels are: gray level 255, 223, 191, 159, 127, 95, 63, 32 and 0.

Figure 6-6 shows an example of Gray to Gray Response Time measurement data.

Response護Tim

e

50

40

30

[ms]

20

10

255

223

191

Start Gray scale

159

127

95

63

32

0 0

32

63

127

95

159

Arrival Gray scale

0

255

223

191

Figure 6-6: Gray to Gray Response Time

5.3.10. Gray Scale Linearity or Gamma Value

The display luminance, LG, is measured at the different gray scales, G

min

, …, G

max

.

The exponential fitting is used to determine the gamma (γ) value, which should be

an intrinsic or uncorrected characteristic.

www.jxlcd.com

www.jxlcd.com

LG ~ Gϒ.

5.3.11. Flicker

No visual flicker will be allowed. The flicker level should be measured with

either vertical stripes or a checker pattern, defined in Sec. 5.3.6. The output signal

of a photometer is sent to an FFT analyzer. The flicker is essentially a ratio of the

powers in the frequency spectrum at 30 Hz (Px) and 0 Hz (P0), i.e.,

N

. | Size: A | METRIC | Scale: NONE | Page 37 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

Page 38

Black in surrounding

le = 127/255 in center

F = 10 Log (Px / P0).

5.3.12. Cross-talk

No visual cross-talk will be allowed. Two luminance values are measured at

center spot with 50 x 50 pixels. The cross-talk, D

D

= (LB – LA)/LB • 100%,

SHA

Where, LA = Luminance in Pattern A

LB = Luminance in Pattern B.

Pattern A

Gray Sca

5.4. Hot Spot Specifications:

The LED hot spot shall be inspected from 70 degree to -40 degree per the drawing

below. There shall be no visible hot spot or no worse than “limited sample” hot spot (if

, is defined as,

SHA

Pattern B

Gray Scale = 127/255 full screen

there is a “limited sample” set up.

www.jxlcd.com

www.jxlcd.com

N

. | Size: A | METRIC | Scale: NONE | Page 38 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

Page 39

www.jxlcd.com

www.jxlcd.com

N

. | Size: A | METRIC | Scale: NONE | Page 39 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

Page 40

:

e

6. ENVIRONMENTAL

The display modules shall meet all functional and cosmetic specifications after testing to the

nvironmental quality standards listed in this section. Additionally, the LCD modules in products

shall pass all the system testing requirements listed in the end of this document.

6.1. Shock and Vibration

7.1.1 There will be no functional or cosmetic defects following a shock to all 6 sides

delivering at least 200 G in a half sine pulse no longer than 2 ms to the display

module, secured by its designated mounting details, in accordance with MIL-STD-

202F Method 213B, test condition A.

7.1.2 There will be no functional defects following a shock delivering at least 260 g in a

half sine pulse no longer than 2 ms to each of 6 sides. Each of the 6 sides will be

shock tested with one each display, for a total of 6 displays. The displays are secured

by designated mounting details, in accordance with MIL-STD-202F Method 213B,

test condition A.

刪除

刪除

刪除刪除

7.1.3 There will be no functional or cosmetic defects following a shock delivering at least

60 G in a pulse 11 msec or longer to the display module, secured by its designated

mounting details, in accordance with MIL-STD-202F Method 213B, test condition A.

7.1.4 There shall be no functional or cosmetic defects following a vibration test,

conducted at 3.0 G from 5–150 Hz, 0.37 Oct/min with sine wave for 30 min./axis,

with the display secured by its designated mounting details, and conducted in

accordance with MIL-STD-202F, method 201A.

www.jxlcd.com

www.jxlcd.com

N

. | Size: A | METRIC | Scale: NONE | Page 40 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

Page 41

30%

6.2. Temperature and Humidity

Unless otherwise stated in this specification, the display module must meet functional

and cosmetic requirements after testing in accordance with Spec. # 080-0859, non-

operating and operating conditions.

For these tests, the following limits set forth in Specification #080-0859 shall be altered

to read.

6.2.1. General Performance Requirements

60

90%

80%

50%

-25 0 10 20 30

Note:

1) Maximum wet bulb temp operating temperature is 39°C.

2) Maximum wet bulb temp storage temperature is 48°C.

Wet Bulb

Temperature

39

30

20

10

0

www.jxlcd.com

www.jxlcd.com

Dry Bulb Temperature [°C]

50

48

40

40 50 60 70 80

40%

20%

10%

Humidity [%(RH)]

+

Storage

Operation

N

. | Size: A | METRIC | Scale: NONE | Page 41 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

Page 42

6.2.2. Non-operational Testing

6.2.2.1. Low Temperature

-25°C @ 500 hrs

6.2.2.2. High Temperature

65°C @ 500 hrs

6.2.2.3. High Temperature and High Humidity

60°C @ 500 hrs, R.H. = 75% ± 10%

6.2.2.4. Thermal Shock

Cycle display from -25°C to 65°C with 5-minute transfer time,

100 cycles at -25°C/65°C/-25°C.

6.2.3. Operational Testing

6.2.3.1. Low Temperature

0°C for 500 hours

6.2.3.2. High Temperature

50°C for 500 hours

www.jxlcd.com

www.jxlcd.com

6.2.3.3. High Temperature and High Humidity

50°C and 90% R.H. for 240 hours (Functional Check)

Maximum wet-bulb temperature at 39°C or lower without

condensation.

6.2.3.4. Four Corner Test (72 hrs – operating)

40°C @ 10% RH

40°C @ 90% RH

N

. | Size: A | METRIC | Scale: NONE | Page 42 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

Page 43

10°C @10% RH

10°C @ 90% RH

6.3. Altitude

72 hour storage

Operational: 15,000 Ft.

Non-Operational: 40,000 Ft.

7. RELIABILITY

7.1. Resistance to Normal Abuse

7.1.1. Torsion Test

Module is fixed by 4 mounting holes (A, B, & C) on stable supports. Tester is

connected to mounting hole on free floating module corner. Push/Pull test is

conducted on all four corners.

7.1.2. Test Conditions:

Applied Force 20 N

Cycles 10 K

Frequency (F=push / pull)1 Hz (1 cycle / sec.)

www.jxlcd.com

www.jxlcd.com

N

. | Size: A | METRIC | Scale: NONE | Page 43 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

Page 44

7.1.3. Test Set-up

7.1.4. Static Load Deflection and Breakage

Supplier shall demonstrate compliance per Specification 062-2208 Static

Breakage Test

7.2. Electrostatic Discharge (ESD)

Display modules are to be tested for ESD susceptibility per specification 062-

0302. The display modules must meet the Level 1 for the bare module, and Level

1 through III test requirements stated in the above referenced specification, when

assembled in a portable computer.

www.jxlcd.com

7.3. MTBF

N

. | Size: A | METRIC | Scale: NONE | Page 44 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

www.jxlcd.com

Supplier to demonstrate display module meets minimum 50,000 Hrs.@90%

Confidence Supplier to include any acceleration factors included in the

calculations. Power cycling frequency during this test is to be approved.

Page 45

7.4. LCD Glass Strength

The LCD glass strength (failure load) will be defined at a single 90% survival rate value on

Weibull distribution. Please provide the optimized loading performance in the similar chart

format below. The failure load of the 90% Weibull survival rate shall be higher than TBD N.

Probability Plot for bendload

Complete Data - LSXY Estimates

99

90

80

70

60

50

40

30

20

Percent

10

The 4 point bend test shall be used for the LCD glass strength test. The detailed fixture design/

shall follow the ASTM standard C158-02. The fixture is used in conduction with a load-

displacement machine, commonly known as Instron.

EXAMPLE ONLY

5

3

2

1

Bending Load (Newton)

bendload

Weibull

Table of Statistics

Shape

Scale 0.0024863

Mean 0.0023964

StDev 0.0002073

Median 0.0024227

IQR 0.0 002677

Failure 22

Censor 0

AD* 1. 220

Correlation 0.972

0.00280.00260.00240.00220.00200.0018

14.1433

www.jxlcd.com

www.jxlcd.com

N

. | Size: A | METRIC | Scale: NONE | Page 45 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

Page 46

Two orientations must be tested for this specification: orientation A (Figure 2.A) and orientation B

(Figure 2.B)

This test shall be performed on 30 samples, WITH current POLARIZERS laminated on both top

www.jxlcd.com

www.jxlcd.com

and bottom of the LCD glass, per applicable orientation as a First Article Inspection and when

settings, tooling, and equipment are modified. Supplier is responsible for monitoring glass strength

on an ongoing production basis. The test shall be conducted with a top rollers velocity of 1 mm/min.

As soon as the first plane breaks, the test shall be stopped to prevent the second plane from

breaking.

N

. | Size: A | METRIC | Scale: NONE | Page 46 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

Page 47

Orientation A. Longer plane parallel to ledge Orientation B. Shorter plane parallel to ledge

Figure 2. Display orientations measuring strength at edges

LCD glass strength data collection

Failure initiation site must be determined by visual inspection by selecting one of the different cases shown below

(Figure 3).

Case A) If the failure is starting from the bottom edge or close to it, enter letter A.

Case B) If the failure is starting from the top edge or close it, enter letter B.

Case C) If the failure is starting from the surface of glass, away from the edges and showing branching in both

directions, enter letter C.

Case D) When testing in orientation D (Figure 1.D), if the failure is starting at the epoxy region between the panes,

enter letter C edges of the glass (case D).

Case E) If during testing a snap is heard, but no crack is visible, enter letter E

Case O) If the failure does not match any of the above or cannot be easily recognized due to catastrophic breakage,

enter letter O.

www.jxlcd.com

www.jxlcd.com

N

. | Size: A | METRIC | Scale: NONE | Page 47 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

Page 48

a [mm] =

Site Case (A, B, C,

D, E, or O)

26

Initiation site

Initiation site

Initiation site

OR

OR

OR

Small branching

Small branching

Small branching

near edge

near edge

near edge

Case A. Failure from bottom edge (with or without slight branching near edge)

OR

Initiation site

Initiation site

OR

Small branching

Small branching

near edge

near edge

Initiation site

Initiation site

Case B. Failure from top edge (with or without slight branching near edge)

Initiation site

Initiation site

Initiation site

Epoxy

Epoxy

www.jxlcd.com

www.jxlcd.com

Approximate

Approximate

initiation site

initiation site

Ledge

Ledge

Failure

Failure

Approximate

Approximate

initiation

initiation

initiation site

initiation site

site

site

Case C. Initiation on surface of glass Case D. Failure at surface on epoxy region (Orientation D)

Figure 3 Surface crack initiation.

All failure loads and failure initiation sites will be entered in the following table below.

N

. | Size: A | METRIC | Scale: NONE | Page 48 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

Orientation a b c d (Circle one)

W [mm] = Llong [mm] =

Lshort [mm] = t [mm] =

Unit # Failure Load [N]

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

Failure Initiation

Page 49

N

. | Size: A | METRIC | Scale: NONE | Page 49 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

www.jxlcd.com

www.jxlcd.com

Page 50

8. COSMETIC REQUIREMENTS

Cosmetic Specification for Notebook Display, 062-7003E.

www.jxlcd.com

www.jxlcd.com

N

. | Size: A | METRIC | Scale: NONE | Page 50 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

Page 51

9. REGULATORY

9.1. Product Safety (Environmental, Ergonomics, Safety and Health)

Materials: specific chemical composition information or certifications necessary for the

product to enter countries, markets, and/or for component(s) material identification, or for

to respond to customer requests for information. The information may be in the form of,

but is not limited to, Material Safety Data Sheets, material specification sheets, health

hazard information, certifications, or other forms of documentation.

9.2. RoHS Compliance and other Substance Regulations

This product’s components, parts, and packaging shall be manufactured or assembled

based upon the following requirements.

10.2.1 The display module must comply with the European RoHS directive, As evidence

of such compliance, the supplier must provide a declaration of conformity in

accordance with RoHS Declaration of Conformity Procedure, 080-2153.

10.2.2 In addition to RoHS compliance, the display module and its manufacturing

process shall comply with Regulated Substances Specification, 069-0135.

10.2.3 The vendor shall provide a written statement declaring the average and maximum

amount of mercury in the display module.

10.3 Halogen Free

www.jxlcd.com

Flat panel display must be must be halogen-free in accordance with the Halogen-Free

Specification, 069-1857

9.3. Environmental Markings and Recycling

10.3.1 Flat panel display must be modular in design so that parts can be easily separated,

N

. | Size: A | METRIC | Scale: NONE | Page 51 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

www.jxlcd.com

without any special tools, for ease of proper recycling/disposal at the product's

end-of-life.

Page 52

10.3.2 Flat panel display plastic parts >25 grams must be marked according to ISO

11469 (except for the LGP (light guide panel) and optical films in the backlight).

9.4. Product Safety

Flat panel display assembly shall comply with Specification,

069-0279, Product Safety Requirements for Component Flat Panel Display

Assemblies.

9.5. Ergonomics

The flat panel display must comply with the ergonomic requirements of ISO 13406 parts

1 and 2. The vendor shall provide a written statement that the flat panel display, is

certified to comply with ISO 13406, parts 1 and 2.

9.6. Electromagnetic Compatibility (EMC)

10.6 Emissions

The final product must meet Class B Emission Standards for home electronic

device when configured within a system Spec. #062-0718. The display supplier

must provide all necessary support as required to meet this requirement. EMI

measurements are taken at the worst-case contrast setting.

www.jxlcd.com

10.6.1 Susceptibility

10.6.2 Spectrum Spreading Compatibility (SSC)

N

. | Size: A | METRIC | Scale: NONE | Page 52 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

www.jxlcd.com

Performance degradation due to external noise or RF will be considered as

specified in #062-0718 for Class B products.

10.6.2.1 Emissions

The final product must be compatible with spectrum spreading conditions

specified in 1.2.2 of this document. No failure or degradation in electronic

Page 53

functionality and optical performance is allowed with the spreading turned

ON compared to that when it is turned OFF.

10.6.2.2 Conditions for Spectrum Spreading

Spreading %: 0% (min.), 0.75% (typical), and 1.5% (max.)

Spreading type: center or down

Modulation Rate: 40 to 80 kHz.

www.jxlcd.com

www.jxlcd.com

N

. | Size: A | METRIC | Scale: NONE | Page 53 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

Page 54

11 FACTORY/SERVICE REQUIREMENTS

11.1 SQBR

Factory requirements are outlined in Supplier Quality and Business Requirements,

specification 070-1191.

11.6 SERVICE REQUIREMENTS

Service Requirements are outlined in specification 070-0385.

www.jxlcd.com

www.jxlcd.com

N

. | Size: A | METRIC | Scale: NONE | Page 54 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

Page 55

12 REFERENCE DOCUMENTS

www.jxlcd.com

www.jxlcd.com

N

. | Size: A | METRIC | Scale: NONE | Page 55 of 55

Title: Spec, Elec., Dspl., AUO, 13.3” TFT-LCD DWG Number: 069-3542 Rev.01

Loading...

Loading...