Page 1

T420HW06 V4 Product Specification

Rev.0 0

Model Name: T420HW06 V4

Issue Date : 2010/11/19

(*)Preliminary Specifications

( )Final Specifications

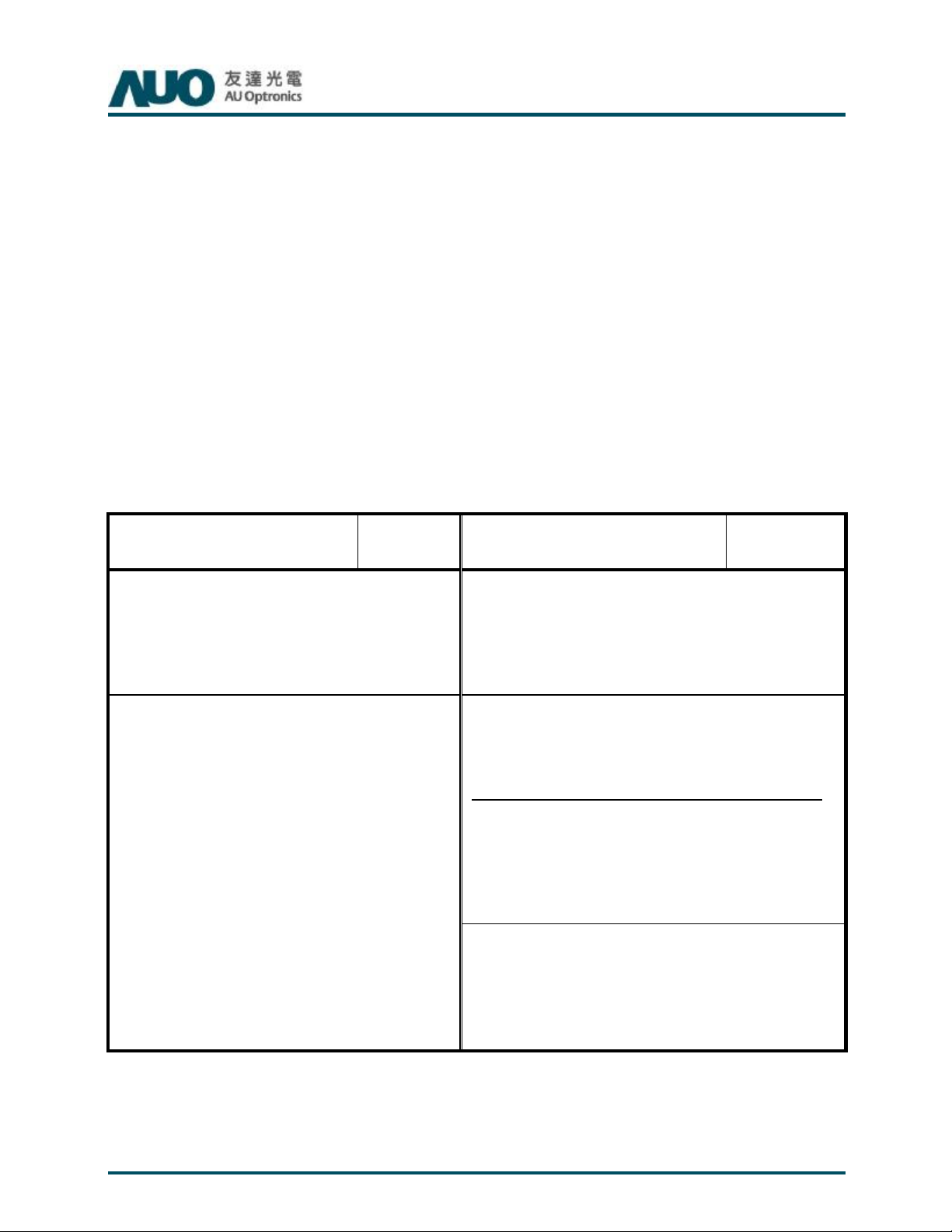

Customer Signature Date AUO Date

Approved By

_________________________________

Note

Approval By PM Director

Yen Ting Chiu

____________________________________

Reviewed By RD Director

Eugene CC Chen

____________________________________

Reviewed By Project Leader

Angus Liu

____________________________________

Prepared By PM

Cynthia Hung

____________________________________

© Copyright AUO Optronics Corp. 2009 All Rights Reserved. Page 1 / 32

Page 2

T420HW06 V4 Product Specification

Rev.0 0

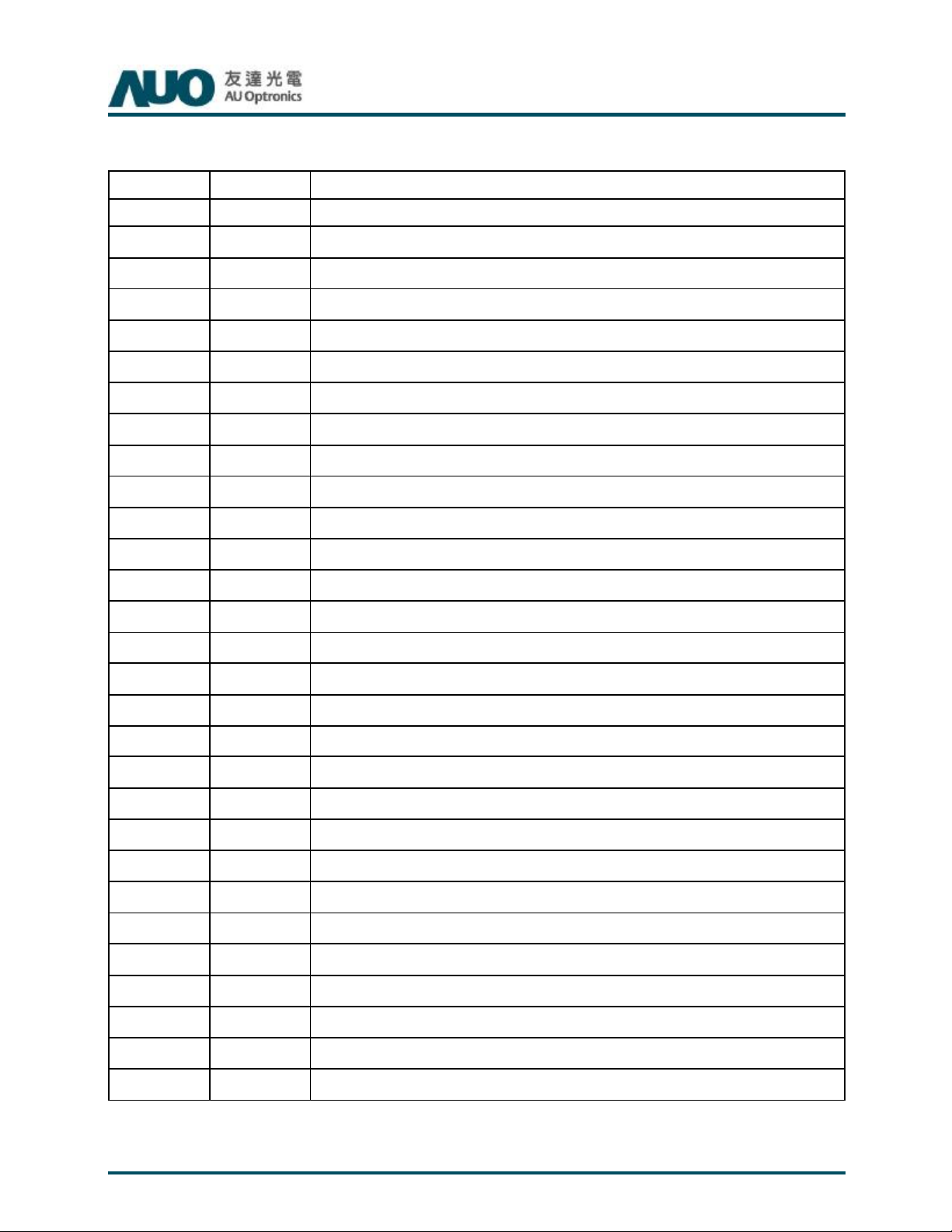

Contents

No

CONTENTS

RECORD OF REVISIONS

1 GENERAL DESCRIPTION

2 ABSOLUTE MAXIMUM RATINGS

3 ELECTRICAL SPECIFICATION

3-1 ELECTRIACL CHARACTERISTICS

3-2 INTERFACE CONNECTIONS

3-3 SIGNAL TIMING SPECIFICATION

3-4 SIGNAL TIMING WAVEFORM

3-5 COLOR INPUT DATA REFERENCE

3-6 POWER SEQUENCE

3-7 BACKLIGHT SPECIFICATION

4 OPTICAL SPECIFICATION

5 MECHANICAL CHARACTERISTICS

6 RELIABILITY TEST ITEMS

7 INTERNATIONAL STANDARD

7-1 SAFETY

7-2 EMC

8 PACKING

8-1 DEFINITION OF LABEL

8-2 PACKING METHODS

8-3 PALLET AND SHIPMENT INFORMATION

9 PRECAUTION

9-1 MOUNTING PRECAUTIONS

/9-2 OPERATING PRECAUTIONS

9-3 ELECTROSTATIC DISCHARGE CONTROL

9-4 PRECAUTIONS FOR STRONG LIGHT EXPOSURE

9-5 STORAGE

9-6 HANDLING PRECAUTIONS FOR PROTECT FILM

© Copyright AUO Optronics Corp. 2009 All Rights Reserved. Page 2 / 32

Page 3

Record of Revision

T420HW06 V4 Product Specification

Rev.0 0

Version

0.0 2010/11/19 First release

Date Page Description

© Copyright AUO Optronics Corp. 2009 All Rights Reserved. Page 3 / 32

Page 4

T420HW06 V4 Product Specification

Rev.0 0

1. General Description

This specification applies to the 42.0 inch Color TFT-LCD Module T420HW06 V4. This LCD module has a TFT

active matrix type liquid crystal panel 1,920x1,080 pixels, and diagonal size of 42.0 inch. This module supports

1,920x1,080 mode. Each pixel is divided into Red, Green and Blue sub-pixels or dots which are arranged in vertical

stripes. Gray scale or the brightness of the sub-pixel color is determined with a 8-bit gray scale signal for each dot.

The T420HW06 V4 has been designed to apply the 8-bit 4 channel LVDS interface method. It is intended to

support displays where high brightness, wide viewing angle, high color saturation, and high color depth are very

important.

* General Information

Items Specification Unit Note

Active Screen Size 42.02 inch

Display Area 930.24(H) x 523.26(V) mm

Outline Dimension 983.0(H) x 576.0(V) x 45.6(D) mm D: front bezel to T-con cover

Driver Element a-Si TFT active matrix

Bezel Opening 939 (H) x 531 (V) mm

Display Colors 8 bit + FRC, 16.7M Colors

Number of Pixels 1,920x1,080 Pixel

Pixel Pitch 0.4845 mm

Pixel Arrangement RGB vertical stripe

Display Operation Mode Normally Black

Surface Treatment Anti-Glare, 3H Haze=2%

Rotate Function Achievable Note 1

Note 1: Rotate Function refers to LCD display could be able to rotate.

© Copyright AUO Optronics Corp. 2009 All Rights Reserved. Page 4 / 32

Page 5

T420HW06 V4 Product Specification

2. Absolute Maximum Ratings

The followings are maximum values which, if exceeded, may cause faulty operation or damage to the unit

Item Symbol Min Max Unit Conditions

Logic/LCD Drive Voltage Vcc -0.3 14 [Volt] Note 1

Input Voltage of Signal Vin -0.3 4 [Volt] Note 1

Lamp Input Voltage VL - 1.5K Vrms Note 2

Operating Temperature TOP 0 +50 [

Operating Humidity HOP 10 90 [%RH] Note 3

Storage Temperature TST -20 +60 [

Storage Humidity HST 10 90 [%RH] Note 3

Panel Surface Temperature PST 65 [

Note 1: Duration:50 msec.

Note 2: Duration: 2 sec

Note 3 :Maximum Wet-Bulb should be 39 and No condensation.℃

o

C] Note 3

o

C] Note 3

o

C] Note 4

Rev.0 0

The relative humidity must not exceed 90% non-condensing at temperatures of 40 ℃or less. At temperatures

greater than 40, the wet bulb temperature must not exceed 39.℃℃

Note 4: Surface temperature is measured at 50℃ Dry condition

© Copyright AUO Optronics Corp. 2009 All Rights Reserved. Page 5 / 32

Page 6

T420HW06 V4 Product Specification

Rev.0 0

3. Electrical Specification

The T420HW06 V4 requires two power inputs. One is employed to power the LCD electronics and to drive the TFT

array and liquid crystal. The other is to power Back Light Unit.

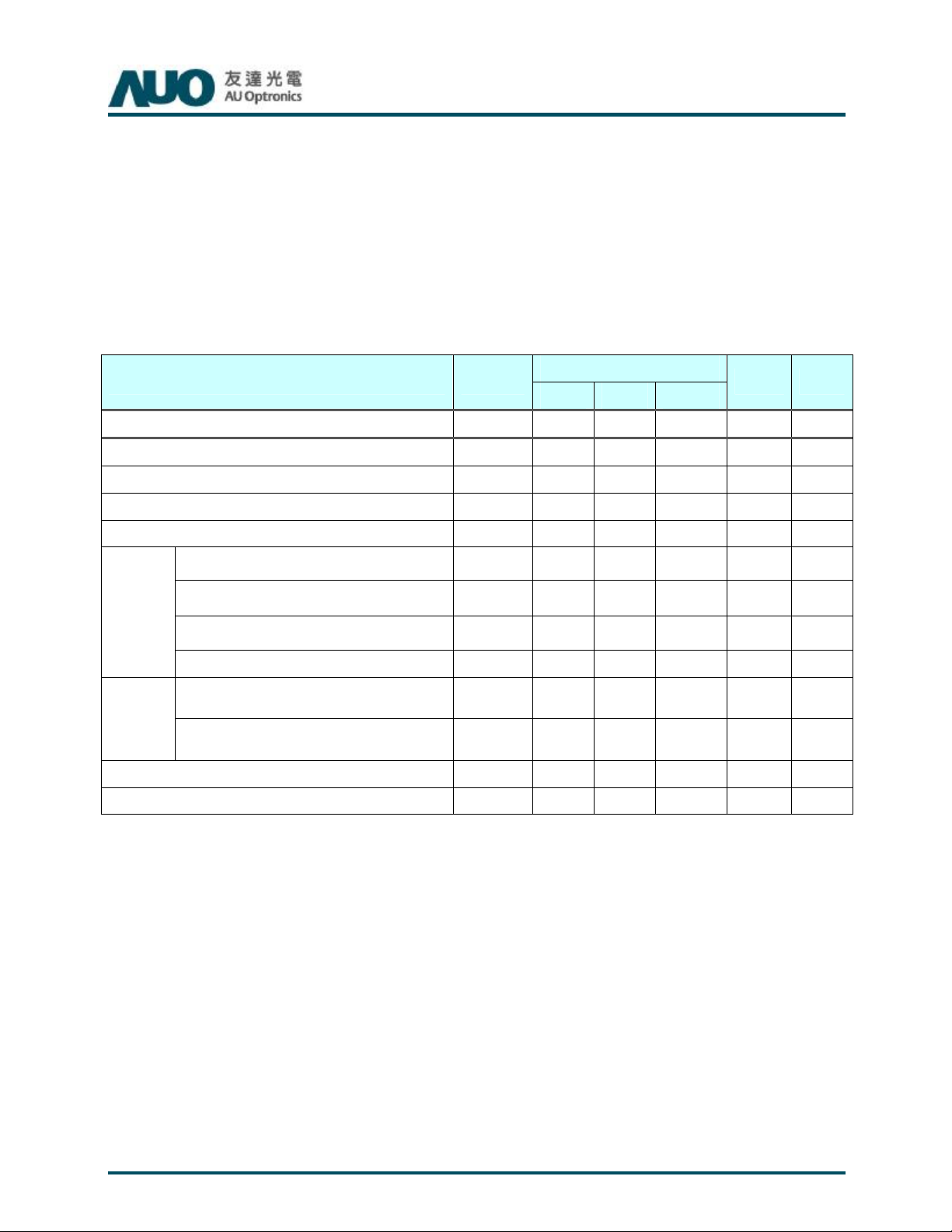

3.1 Electrical Characteristics

3.1.1: DC Characteristics

Parameter Symbol

Unit Note

Min. Typ. Max

LCD

Value

Power Supply Input Voltage V

Power Supply Input Current I

Power Consumption P

Inrush Current I

Input Differential Voltage

LVDS

Interface

Differential Input High Threshold Voltage

Differential Input Low Threshold Voltage

Input Common Mode Voltage V

CMOS

Interface

Input High Threshold Voltage

Input Low Threshold Voltage

Backlight Power Consumption P

10.8 12 13.2 VDC

DD

-- 1 1.5 A 1

DD

-- 18 Watt 1

C

-- -- 4 A 2

RUSH

∣VID∣

200 400 600 mVDC 3

VTH +100 -- +300 mVDC 3

VTL -300 -- -100 mVDC 3

1.1 1.25 1.4 VDC 3

ICM

VIH

(High)

VIL

(Low)

110 115 120 Watt

BL

2.7 -- 3.3 VDC 4

0 -- 0.6 VDC 4

Life time 5000 Hour 9,10

© Copyright AUO Optronics Corp. 2009 All Rights Reserved. Page 6 / 32

Page 7

s

µ

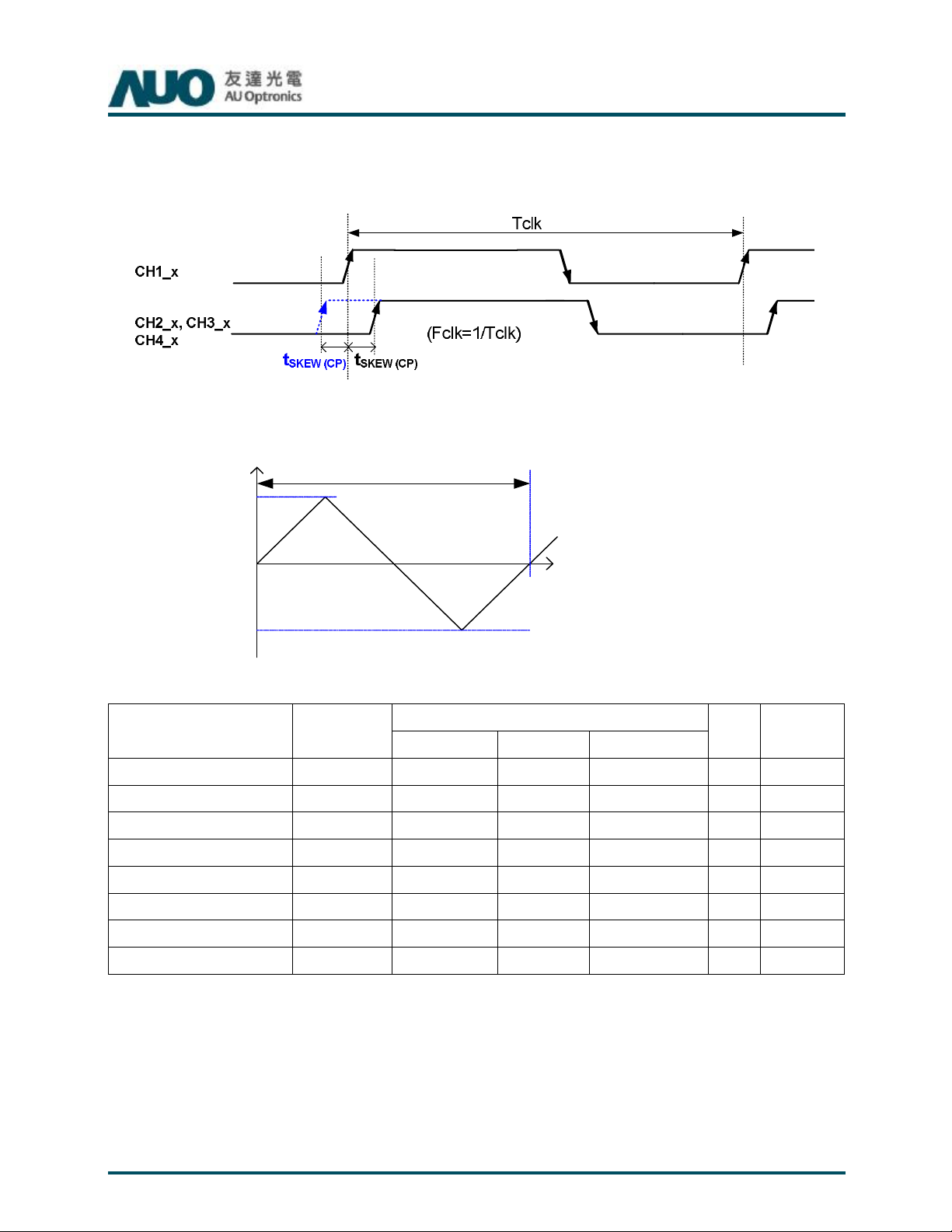

3.1.2: AC Characteristics

T420HW06 V4 Product Specification

Rev.0 0

Parameter Symbol

Input Channel Pair Skew Margin t

Receiver Clock : Spread Spectrum

LVDS

Interface

Modulation range

Receiver Clock : Spread Spectrum

Modulation frequency

Receiver Data Input Margin

Fclk = 85 MHz

Fclk = 65 MHz

Note :

1. V

2. Measurement condition : Rising time = 400us

= 12.0V, Fv = 120Hz, Fclk= 77.29MHz , 25 , Test Pattern : White Pattern℃

DD

GND

10%

Value

Unit Note

Min. Typ. Max

SKEW (CP)

Fclk_ss

-500 -- +500 ps 5

Fclk

-3%

--

Fclk

+3%

MHz 6

Fss 30 -- 200 KHz 6

tRMG

90%

-0.4

-0.5

V

DD

--

--

0.4

ns 7

0.5

400

3. V

= 1.25V

ICM

LVDS -

LVDS +

V

ICM

GND

0V

|VID|

|VID|

V

TH

|VID|

V

TL

© Copyright AUO Optronics Corp. 2009 All Rights Reserved. Page 7 / 32

Page 8

T420HW06 V4 Product Specification

4. The measure points of V

5. Input Channel Pair Skew Margin

Note: x = 0, 1, 2, 3, 4

6. LVDS Receiver Clock SSCG (Spread spectrum clock generator) is defined as below figures

and V

IH

are in LCM side after connecting the System Board and LCM.

IL

1/F

SS

Fclk_ss(max)

Rev.0 0

Fclk

Fclk_ss(min)

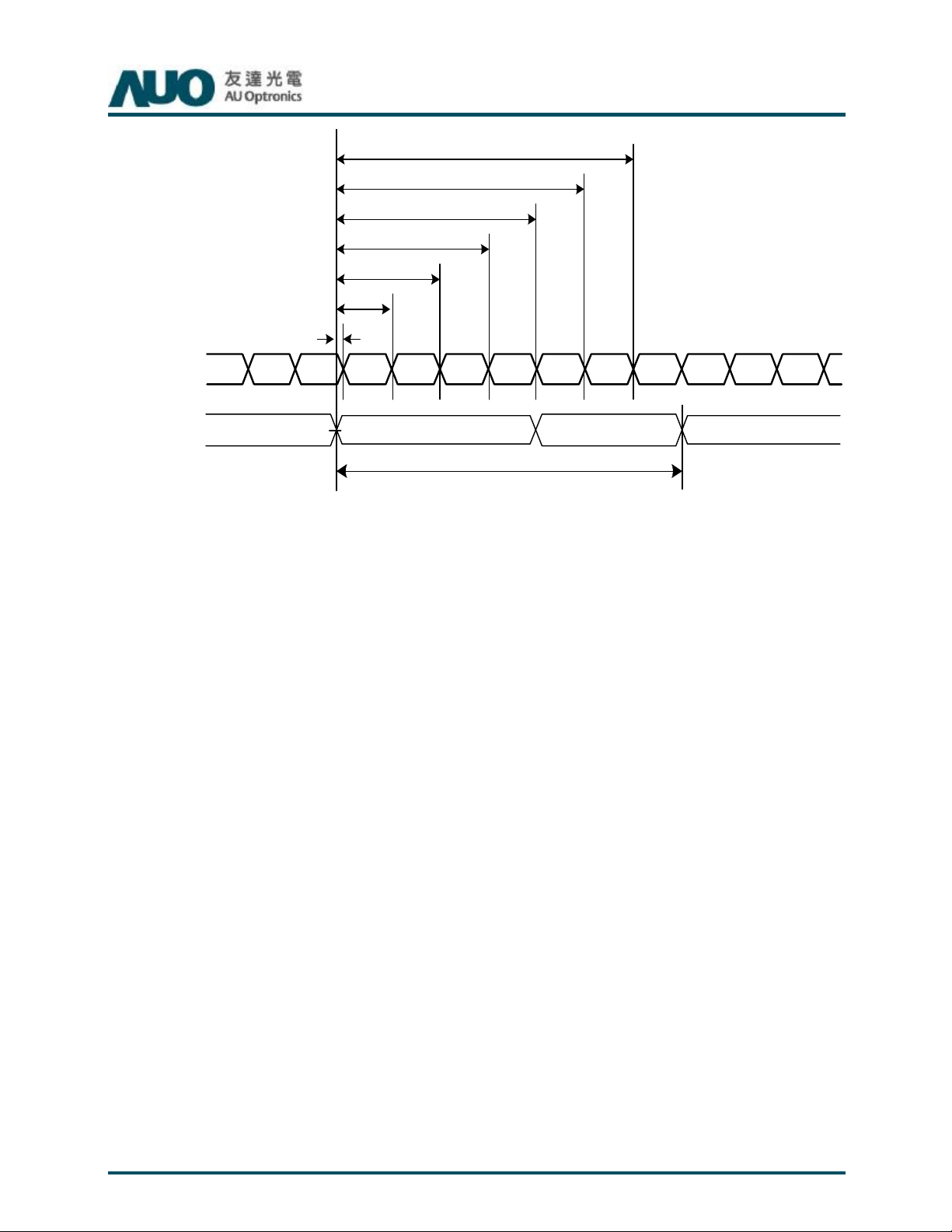

7. Receiver Data Input Margin

Parameter Symbol

Min Type Max

Input Clock Frequency Fclk Fclk (min) -- Fclk (max) MHz T=1/Fclk

Input Data Position0 tRIP1 -|tRMG| 0 |tRMG| ns

Input Data Position1 tRIP0 T/7-|tRMG| T/7 T/7+|tRMG| ns

Input Data Position2 tRIP6 2T/7-|tRMG|

Input Data Position3 tRIP5 3T/7-|tRMG|

Input Data Position4 tRIP4 4T/7-|tRMG|

Input Data Position5 tRIP3 5T/7-|tRMG|

Input Data Position6 tRIP2 6T/7-|tRMG|

Rating

Unit

2T/7 2T/7+|tRMG| ns

3T/7 3T/7+|tRMG| ns

4T/7 4T/7+|tRMG| ns

5T/7 5T/7+|tRMG| ns

6T/7 6T/7+|tRMG| ns

Note

© Copyright AUO Optronics Corp. 2009 All Rights Reserved. Page 8 / 32

Page 9

LVDS-Rx

Input Data

LVDS-Rx

Input Clock

tRIP2

tRIP3

tRIP4

tRIP5

tRIP6

tRIP0

tRIP1

T420HW06 V4 Product Specification

Rev.0 0

Rx1Rx0Rx6Rx5Rx4Rx3Rx2 Rx1Rx0Rx6Rx2Rx3

V

= 0V

diff

1/Fclk=T

8. Do not attach a conducting tape to lamp connecting wire. If the lamp wire attach to conducting tape,

TFT-LCD Module have a low luminance and the inverter has abnormal action because leakage current

occurs between lamp wire and conducting tape.

9. The relative humidity must not exceed 80% non-condensing at temperatures of 40 or less. At ℃

temperatures greater than 40, the wet bulb temperature must not exceed 39. When operate at low ℃℃

temperatures, the brightness of CCFL will drop and the life time of CCFL will be reduced.

10. Specified values are for a single lamp only which is aligned horizontally. The lifetime is defined as the time

which luminance of the lamp is 50% compared to its original value.

[Operating condition: Continuous operating at Ta = 25±2℃]

© Copyright AUO Optronics Corp. 2009 All Rights Reserved. Page 9 / 32

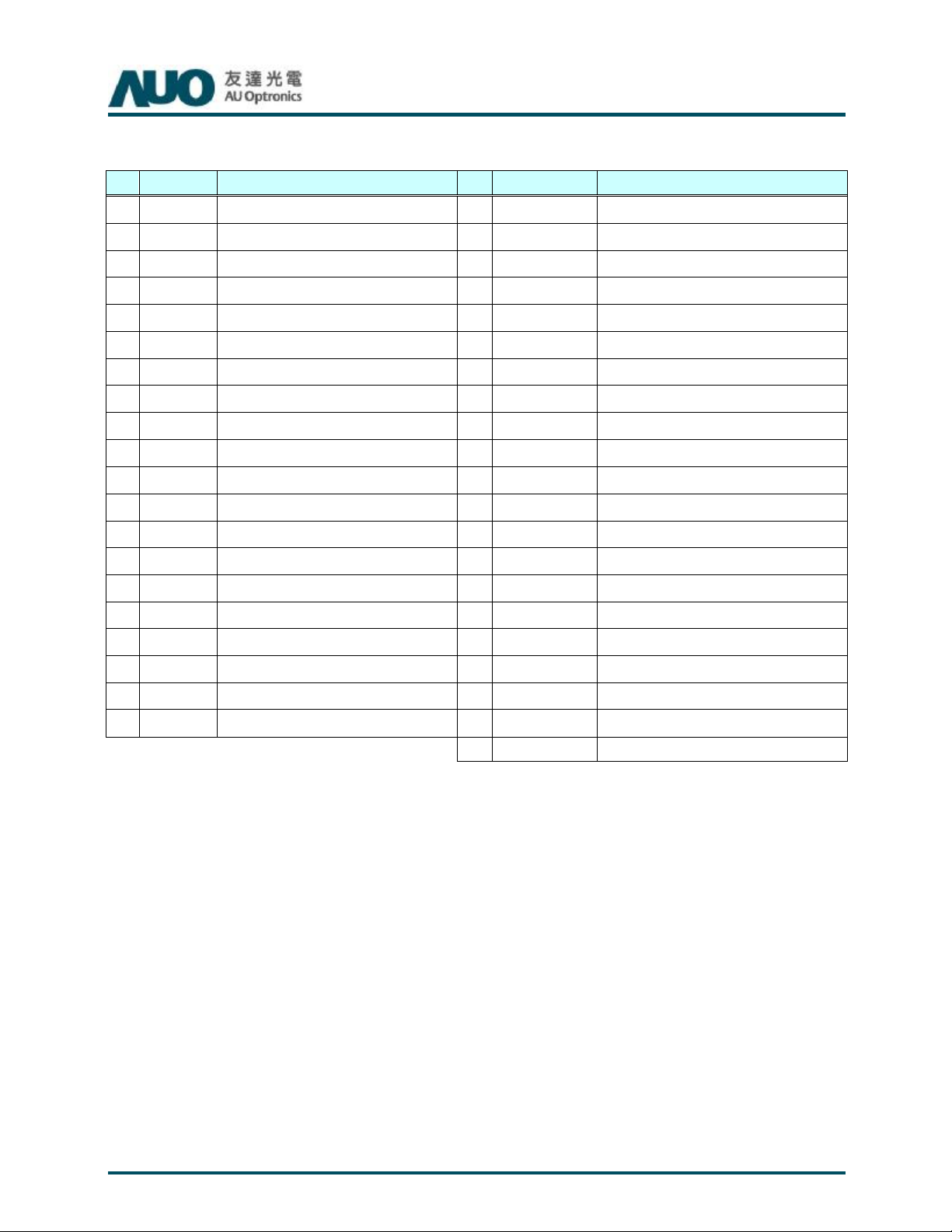

Page 10

T420HW06 V4 Product Specification

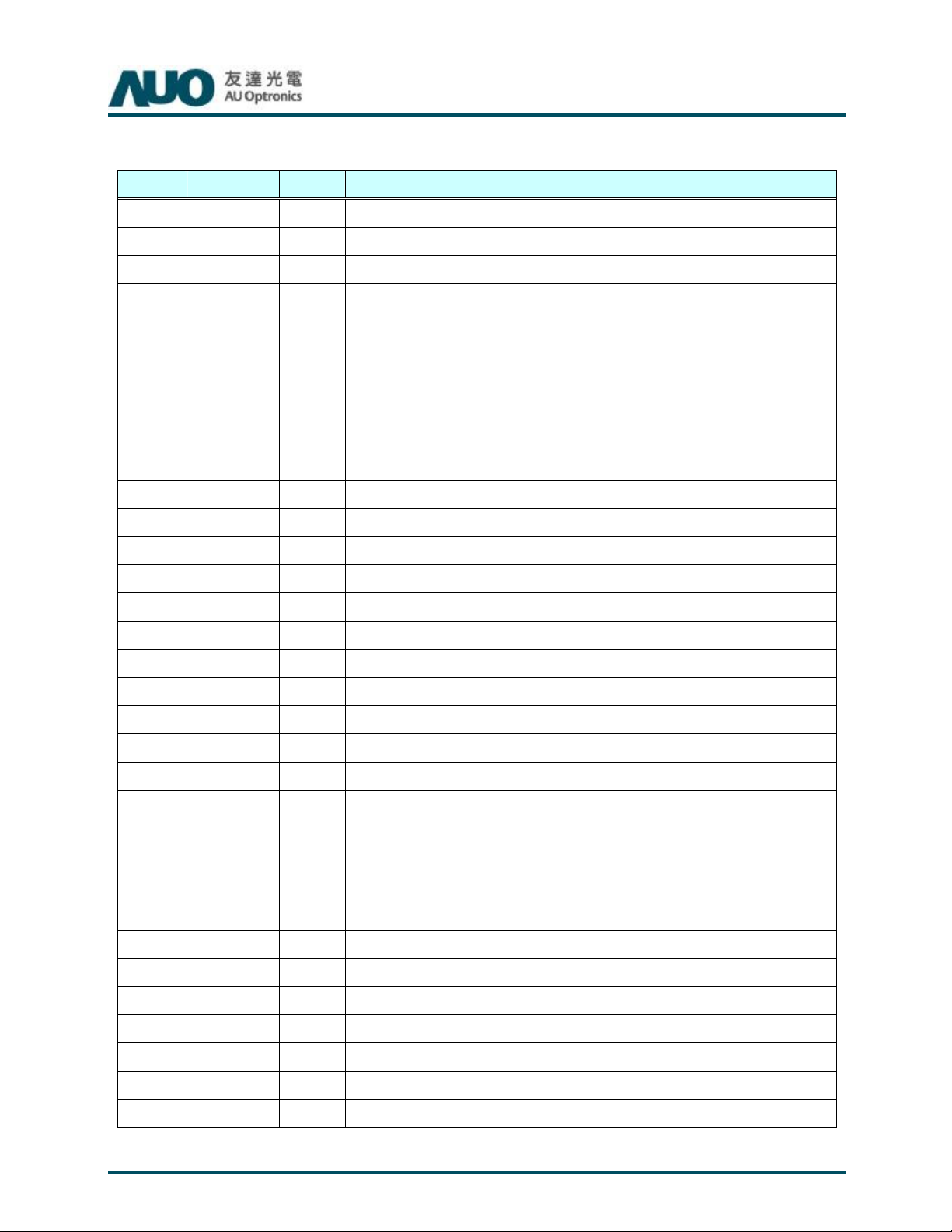

3.2 Interface Connections

l LCD connector: 187059-51221 (P-TWO, LVDS connector)

PIN Symbol Description PIN

1

N.C. No connection 21

N.C. AUO Internal Use Only

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

CH3_CLK-

17

CH3_CLK+

18

19

20

N.C. No connection 23

N.C. No connection 24

N.C. No connection 25

N.C. No connection 26

N.C. AUO Internal Use Only 27

N.C. No connection 28

GND Ground 29

CH3_0-

CH3_0+

CH3_1-

CH3_1+

CH3_2-

CH3_2+

GND

GND

CH3_3-

LVDS Channel 3, Signal 0- 30

LVDS Channel 3, Signal 0+ 31

LVDS Channel 3, Signal 1- 32

LVDS Channel 3, Signal 1+ 33

LVDS Channel 3, Signal 2- 34

LVDS Channel 3, Signal 2+ 35

Ground 36

LVDS Channel 3, Clock - 37

LVDS Channel 3, Clock + 38

Ground 39

LVDS Channel 3, Signal 3- 40

41

22

Note: N.C. : please leave this pin unoccupied. It can not be connected by any signal

Symbol Description

CH3_3+

CH3_4-

CH3_4+

GND

GND

CH4_0-

CH4_0+

CH4_1-

CH4_1+

CH4_2-

CH4_2+

GND

CH4_CLK-

CH4_CLK+

GND

CH4_3-

CH4_3+

CH4_4-

CH4_4+

GND Ground

GND Ground

LVDS Channel 3, Signal 3+

LVDS Channel 3, Signal 4-

LVDS Channel 3, Signal 4+

Ground

Ground

LVDS Channel 4, Signal 0-

LVDS Channel 4, Signal 0+

LVDS Channel 4, Signal 1-

LVDS Channel 4, Signal 1+

LVDS Channel 4, Signal 2-

LVDS Channel 4, Signal 2+

Ground

LVDS Channel 4, Clock -

LVDS Channel 4, Clock +

Ground

LVDS Channel 4, Signal 3-

LVDS Channel 4, Signal 3+

LVDS Channel 4, Signal 4-

LVDS Channel 4, Signal 4+

Rev.0 0

(Low/GND/High).

© Copyright AUO Optronics Corp. 2009 All Rights Reserved. Page 10 / 32

Page 11

24

25

T420HW06 V4 Product Specification

Rev.0 0

PIN Symbol Description PIN

1

2

3

4

N.C. AUO Internal Use Only 26

N.C. AUO Internal Use Only 27

N.C. AUO Internal Use Only 28

N.C. AUO Internal Use Only 29

LVDS 8/10bit Input Selection

5

BITSEL

Open/High(3.3V) : 10bits

30

Low(GND) : 8bits

6

7 LVDS_SEL

8

9

10

11

12

N.C. AUO Internal Use Only 31

Open/High(3.3V) for NS,

Low(GND) for JEIDA

32

N.C. AUO Internal Use Only 33

N.C. AUO Internal Use Only 34

N.C. AUO Internal Use Only 35 CH2_CLK- LVDS Channel 2, Clock -

GND Ground 36 CH2_CLK+ LVDS Channel 2, Clock +

CH1_0- LVDS Channel 1, Signal 0- 37

Symbol Description

N.C. AUO Internal Use Only

N.C. AUO Internal Use Only

CH2_0- LVDS Channel 2, Signal 0-

CH2_0+ LVDS Channel 2, Signal 0+

CH2_1- LVDS Channel 2, Signal 1-

CH2_1+ LVDS Channel 2, Signal 1+

CH2_2- LVDS Channel 2, Signal 2-

CH2_2+ LVDS Channel 2, Signal 2+

GND Ground

GND Ground

13

14

15

16

17

18

CH1_0+ LVDS Channel 1, Signal 0+ 38

CH1_1- LVDS Channel 1, Signal 1- 39

CH1_1+ LVDS Channel 1, Signal 1+ 40

CH1_2- LVDS Channel 1, Signal 2- 41

CH1_2+ LVDS Channel 1, Signal 2+ 42

GND Ground 43

19 CH1_CLK- LVDS Channel 1, Clock - 44

20 CH1_CLK+ LVDS Channel 1, Clock + 45

21

22

23

GND Ground 46

CH1_3- LVDS Channel 1, Signal 3- 47

CH1_3+ LVDS Channel 1, Signal 3+ 48

CH1_4- LVDS Channel 1, Signal 4- 49

CH1_4+ LVDS Channel 1, Signal 4+ 50

51

CH2_3- LVDS Channel 2, Signal 3-

CH2_3+ LVDS Channel 2, Signal 3+

CH2_4- LVDS Channel 2, Signal 4-

CH2_4+ LVDS Channel 2, Signal 4+

N.C. AUO Internal Use Only

N.C. AUO Internal Use Only

GND Ground

GND Ground

GND Ground

N.C. No connection

V

DD

V

DD

V

DD

V

DD

Power Supply, +12V DC Regulated

Power Supply, +12V DC Regulated

Power Supply, +12V DC Regulated

Power Supply, +12V DC Regulated

© Copyright AUO Optronics Corp. 2009 All Rights Reserved. Page 11 / 32

Page 12

LVDS Option = High/OpenèNS

Previous Cycle Current Cycle Next Cycle

Clock

T420HW06 V4 Product Specification

Rev.0 0

CHx_0+

CHx_0-

CHx_1+

CHx_1-

CHx_2+

CHx_2-

CHx_3+

CHx_3-

Note: x = 1, 2, 3, 4…

LVDS Option = LowèJEIDA

Previous Cycle Current Cycle Next Cycle

Clock

R0R5 G0G0R0R1 R2R3R4 R1

G1B0 B1B1G1G2 G3G4G5 G2

B2NA DEDEB2B3 B4B5NA B3

R6B7 NANAR6R7 G6G7B6 R7

CHx_0+

CHx_0-

CHx_1+

CHx_1-

CHx_2+

CHx_2-

CHx_3+

CHx_3-

G7

R2R7 G2G2R2R3 R4R5R6 R3

G3B2 B3B3G3G4 G5G6G7 G4

B4NA DEDEB4B5 B6B7NA B5

R0B1 NANAR0R1 G0G1B0 R1

Note: x = 1, 2, 3, 4…

© Copyright AUO Optronics Corp. 2009 All Rights Reserved. Page 12 / 32

Page 13

T420HW06 V4 Product Specification

Rev.0 0

3.3 Signal Timing Specification

This is the signal timing required at the input of the user connector. All of the interface signal timing should be

satisfied with the following specifications for its proper operation.

Timing Table (DE only Mode)

Signal Item Symbol Min. Typ. Max Unit

Period Tv 1090 1130 1392 Th

Vertical Section

Active Tdisp (v) 1080

Blanking Tblk (v) 10 50 312 Th

Period Th 540 570 580 Tclk

Horizontal Section

Clock Frequency Fclk=1/Tclk 64.8 77.29 80.74 MHz

Vertical Frequency Frequency Fv 94 120 122 Hz

Horizontal Frequency Frequency Fh 120 135.6 139.2 KHz

Notes:

(1) Display position is specific by the rise of DE signal only.

Horizontal display position is specified by the rising edge of 1st DCLK after the rise of 1st DE, is displayed on the

left edge of the screen.

(2)Vertical display position is specified by the rise of DE after a “Low” level period equivalent to eight times of

horizontal period. The 1st data corresponding to one horizontal line after the rise of 1st DE is displayed at the top

line of screen.

(3)If a period of DE “High” is less than 1920 DCLK or less than 1080 lines, the rest of the screen displays black.

(4)The display position does not fit to the screen if a period of DE “High” and the effective data period do not

synchronize with each other.

Active Tdisp (h) 480

Blanking Tblk (h) 60 90 100 Tclk

© Copyright AUO Optronics Corp. 2009 All Rights Reserved. Page 13 / 32

Page 14

3.4 Signal Timing Waveforms

T420HW06 V4 Product Specification

Rev.0 0

CH4

M-12

Pixel

Pixel

M-8

Pixel

M-4

Pixel

M

Invalid Data

Pixel

4

Pixel

8

Pixel

12

Pixel

16

Pixel

20

Pixel

24

CH3

M-13

Pixel

Pixel

M-9

Pixel

M-5

Pixel

M-1

Invalid Data

Pixel

3

Pixel

7

Pixel

11

Pixel

15

Pixel

19

Pixel

23

CH2

M-14

Pixel

M-10

Pixel

Pixel

M-6

Pixel

M-2

Invalid Data

Pixel

2

Pixel

6

Pixel

10

Pixel

14

Pixel

18

Pixel

22

CH1

M-15

Pixel

M-11

Pixel

Pixel

M-7

Pixel

M-3

Invalid Data

Pixel

1

Pixel

5

Pixel

9

Pixel

13

Pixel

17

Pixel

21

DE

Tdisp(h) Tblk(h)

CLK

RGB

Data

Line

N

Tclk

Invalid Data Invalid Data

Line

1

Line

2

Th

Line

3

Line

4

DE

Th

Tv

Tdisp(v)Tblk(v)

M-10

Pixel

M-8

Pixel

M-4

Pixel

M

Invalid Data

Pixel

M-9

Pixel

M-5

Pixel

M-1

Invalid Data

Pixel

Pixel

M-6

Pixel

M-2

Invalid Data

M-11

Pixel

Pixel

M-7

Pixel

M-3

Invalid Data

Line

N

N Line

M pixel

Pixel

4

Pixel

8

Pixel

3

Pixel

7

Pixel

2

Pixel

6

Pixel

1

Pixel

5

© Copyright AUO Optronics Corp. 2009 All Rights Reserved. Page 14 / 32

Page 15

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

T420HW06 V4 Product Specification

Rev.0 0

3.5 Color Input Data Reference

The brightness of each primary color (red, green and blue) is based on the 8 bit gray scale data input for the color;

the higher the binary input, the brighter the color. The table below provides a reference for color versus data input.

COLOR DATA REFERENCE

Input Color Data

Basic

Color

R

G

Color

MSB LSB

R7 R6 R5 R4 R3 R2 R1 R0 G7 G6 G5 G4 G3 G2 G1 G0 B7 B6 B5 B4 B3 B2 B1 B0

Black 0

Red(255) 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Green(255) 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0

Blue(255) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1

Cyan 0

Magenta 1

Yellow 1

White 1

RED(000) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

RED(001) 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

---RED(254) 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

RED(255) 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

GREEN(000) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

GREEN(001) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0

----

RED

MSB LSB

GREEN

BLUE

MSB LSB

GREEN(254) 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0

GREEN(255) 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0

BLUE(000) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

BLUE(001) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1

B

---BLUE(254) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 0

BLUE(255) 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1

© Copyright AUO Optronics Corp. 2009 All Rights Reserved. Page 15 / 32

Page 16

Power Sequence for LCD

T420HW06 V4 Product Specification

Rev.0 0

Power Supply For LCD

VDD (+12V)

GND

Interface Signal

(LVDS Data & CLK)

GND

Backlight on/off

control signal

(VBLON)

CMOS Interface Signal

GND

GND

Parameter

t1 0.4 --- 30 ms

t2 0.1 --- 50 ms

10%

90%

t1

t2

Valid Data

t3 t4

t8 t9

Values

Min. Type. Max.

90%

10%

t6

t5

10%

t7

Unit

t3 450 --- --- ms

t4 0

*1

--- --- ms

t5 0 --- --- ms

t6 --- --- ---*2 ms

t7 500 --- --- ms

t8 10 --- 50 ms

t9 0 --- --- ms

Note:

(1) t4=0 : concern for residual pattern before BLU turn off.

(2) t6 : voltage of VDD must decay smoothly after power-off. (customer system decide this value)

© Copyright AUO Optronics Corp. 2009 All Rights Reserved. Page 16 / 32

Page 17

T420HW06 V4 Product Specification

3.7 Backlight Specification

The backlight unit contains 10-I type CCFLs (Cold Cathode Fluorescent Lamp)

3.7.1 Electrical specification

Spec

Item Symbol Condition

Min Typ Max

Rev.0 0

Unit Note

Operating Voltage Vo - 760 960 1160 Vrms

Operating Current Io - 12.4 13.0 13.6 mArms

BL Total Power Dissipation PBL - - 115 - Watt

Striking Voltage Vstk

Striking Time Ts - 500 - 2000 msec

Operating Frequency fo - 53 55 57 kHz

PWM Operating Frequency F_PWM

PWM Dimming Duty Ratio D_PWM

Lamp Type Straight type

Number of Lamps 10 pcs

Note 1: Dimming range

At 0℃

At 25℃

-

-

1320 - -

Vrms

1660 - -

140 180 240 Hz

10 - 100 % Note 1&2

(Ta=25±5, Turn on for 45minutes℃ )

Note 2: Low dimming ratio operation

When PWM dimming duty ratio is operated lower than recommended value, feedback signal and all

protection functions should be confirmed by LIPS design. Display performance should also be confirmed by

customer’s implement.

© Copyright AUO Optronics Corp. 2009 All Rights Reserved. Page 17 / 32

Page 18

210%

2

210%

210%

3.7.2 Lamp specification

Item Symbol Condition

T420HW06 V4 Product Specification

Rev.0 0

Spec

Unit Note

Min Typ Max

Lamp voltage VL 760 960 1160 Vrms

Lamp current IL - 13 - mArms

Lamp frequency fL 35 80 kHz

Starting voltage

Delayed discharge time

Life time TL 50K - Unsymmetrical ratio UR - - 10%

Crest factor C.F.

The above characteristics are measured under the conditions:

Ambient temperature: 25±2℃, Relative Humidity: 65±20%RH.

Note 1: Waveform definition

Please light on the lamp with symmetrical voltage and current waveform (unsymmetrical ratio is less than

10%, crest factor within

I

I

p

p

Vs

TD - - 0.5 sec

At 0℃ - - 1820 Vrms

At 25℃ - - 1450 Vrms

−

±

).

Unsymmetrical Ratio = |Ip-I-p| / I

Unsymmetrical Ratio = |Ip-I-p| / I

Crest Factor = Ip(or I-p) / I

Crest Factor = Ip(or I-p) / I

Ip: High side peak value

Ip: High side peak value

+

rms

rms

hr

-

-

Note 1.

*100%

*100%

rms

rms

I-p: Low side peak value

I-p: Low side peak value

I

I

-p

-p

I

: Root mean square value

I

: Root mean square value

rms

rms

© Copyright AUO Optronics Corp. 2009 All Rights Reserved. Page 18 / 32

Page 19

3.7.3: Backlight Connector Pin Configuration

T420HW06 V4 Product Specification

Rev.0 0

T420HW06 V4

© Copyright AUO Optronics Corp. 2009 All Rights Reserved. Page 19 / 32

Page 20

T420HW06 V4 Product Specification

Rev.0 0

4. Optical Specification

Optical characteristics are determined after the unit has been ‘ON’ and stable for approximately 45 minutes in a

dark environment at 25°C. The values specified are at an approximate distance 50cm from the LCD surface at a

viewing angle of φ and θ equal to 0°.

Fig.1 presents additional information concerning the measurement equipment and method.

SR3 or equivalent

Parameter Symbol

Min. Typ. Max

Values

Unit Notes

Contrast Ratio CR 3200 4000 -- 1

Surface Luminance (White) L

Luminance Variation δ

320 400 -- cd/m2 2

WH

WHITE(9P)

-- -- 1.33 3

Response Time (G to G) Tγ -- 6.5 -- Ms 4

Color Gamut NTSC 72 %

Color Coordinates

Red R

R

Green G

G

Blue B

B

White W

W

0.640

X

0.330

Y

0.281

X

0.590

Y

X

Y

X

Y

Typ.-0.03

Typ.+0.03

0.144

0.060

0.280

0.290

Viewing Angle 5

x axis, right(φ=0°) θr -- 89 -- degree

x axis, left(φ=180°) θl -- 89 -- degree

y axis, up(φ=90°) θu -- 89 -- degree

y axis, down (φ=270°) θd -- 89 -- degree

Note:

© Copyright AUO Optronics Corp. 2009 All Rights Reserved. Page 20 / 32

Page 21

T420HW06 V4 Product Specification

Rev.0 0

1. Contrast Ratio (CR) is defined mathematically as:

Contrast Ratio=

2. Surface luminance is luminance value at point 5 across the LCD surface 50cm from the surface with all pixels

displaying white. From more information see FIG 2. When lamp current IH = 11mA. LWH=Lon5 where Lon5 is

the luminance with all pixels displaying white at center 5 location.

3. The variation in surface luminance, δWHITE is defined (center of Screen) as:

δ

WHITE(9P)

4. Response time Tγ is the average time required for display transition by switching the input signal for five

luminance ratio (0%,25%,50%,75%,100% brightness matrix) and is based on Fv=120Hz to optimize.

= Maximum(L

Surface Luminance of L

Surface Luminance of L

, L

on1

on2

,…,L

)/ Minimum(L

on9

on1

, L

on5

off5

on2

,…L

on9

)

Target Measured

Response Time

0% 25% 50% 75% 100%

0% 0% to 25% 0% to 50% 0% to 75% 0% to 100%

25% 25% to 0% 25% to 50%

Start

Tγ is determined by 10% to 90% brightness difference of rising or falling period. (As illustrated)

The response time is defined as the following figure and shall be measured by switching the input signal for

“any level of grey(bright) “ and “any level of gray(dark)”.

Any level of gray (Bright) Any level of gray (Dark) Any level of gray (Bright)

100%

90%

50% 50% to 0% 50% to 25%

75% 75% to 0% 75% to 25%

100% 100% to 0%

0%, 25%, 50%, 75%, 100%

100% to 25% 100% to 50% 100% to 75%

50% to 75% 50% to 100%

75% to 50%

25% to 75% 25% to 100%

75% to 100%

0%, 25%, 50%, 75%, 100%

Photodetector

Output

10%

0%, 25%, 50%, 75%, 100%

Time

T

γ(F)

© Copyright AUO Optronics Corp. 2009 All Rights Reserved. Page 21 / 32

T

γ(R)

Page 22

2 3 7

FIG. 2 Luminance

T420HW06 V4 Product Specification

Rev.0 0

V

H/2

H/6

1

H

V/2 V/6

5. Viewing angle is the angle at which the contrast ratio is greater than 10. The angles are determined for the

horizontal or x axis and the vertical or y axis with respect to the z axis which is normal to the LCD surface. For

more information see FIG3.

FIG.3 Viewing Angle

© Copyright AUO Optronics Corp. 2009 All Rights Reserved. Page 22 / 32

Page 23

T420HW06 V4 Product Specification

Rev.0 0

5. Mechanical Characteristics

The contents provide general mechanical characteristics for the model T420HW06 V4. In addition the figures in the

next page are detailed mechanical drawing of the LCD.

Item Dimension Unit Note

Horizontal 983.0 mm

Vertical 576.0 mm

Outline Dimension

Depth (Dmin) 35.5 mm to rear

Depth (Dmax) 49.5 mm to BLU emboss

Weight 9300 g typ

© Copyright AUO Optronics Corp. 2009 All Rights Reserved. Page 23 / 32

Page 24

Front View

T420HW06 V4 Product Specification

Rev.0 0

© Copyright AUO Optronics Corp. 2009 All Rights Reserved. Page 24 / 32

Page 25

Back View

T420HW06 V4 Product Specification

Rev.0 0

© Copyright AUO Optronics Corp. 2009 All Rights Reserved. Page 25 / 32

Page 26

6. Reliability Test Items

T420HW06 V4 Product Specification

Rev.0 0

1 High temperature storage test 3 60℃, 300hrs

2 Low temperature storage test 3 -20℃, 300hrs

3 High temperature operation test 3 50℃, 300hrs

4 Low temperature operation test 3 -5℃, 300hrs

5 Vibration test (non-operation) 3

6 Shock test (non-operation) 3

7 Vibration test (With carton) 3

Test Item Q’ty Condition

Wave form: random

Vibration level: 1.5G RMS

Bandwidth: 10-300Hz,

Duration: X, Y, Z 30min

One time each direction

Shock level: 50G

Waveform: half since wave, 11ms

Direction: ±X, ±Y, ±Z, One time each direction

Random wave (1.5G RMS, 10-200Hz)

30mins/ Per each X,Y,Z axes

Height: 25.4cm (ASTMD4169-I)

8 Drop test (With carton) 3

1 corner, 3 edges, 6 surfaces

(refer ASTM D 5276)

© Copyright AUO Optronics Corp. 2009 All Rights Reserved. Page 26 / 32

Page 27

7. International Standard

7.1 Safety

(1) UL 60950-1, UL 60065; Standard for Safety of Information Technology Equipment Including

electrical Business Equipment.

(2) IEC 60950-1 : 2001, IEC 60065:2001 ; Standard for Safety of International Electrotechnical

Commission

(3) EN 60950 : 2001+A11, EN 60065:2002+A1:2006; European Committee for Electrotechnical

Standardization (CENELEC), EUROPEAN STANDARD for Safety of Information Technology

Equipment Including Electrical Business Equipment.

7.2 EMC

(1) ANSI C63.4 “Methods of Measurement of Radio-Noise Emissions from Low-Voltage Electrical and

Electrical Equipment in the Range of 9kHz to 40GHz. “American National standards Institute(ANSI),

1992

(2) C.I.S.P.R “Limits and Methods of Measurement of Radio Interface Characteristics of Information

T420HW06 V4 Product Specification

Rev.0 0

Technology Equipment.” International Special committee on Radio Interference.

(3) EN 55022 “Limits and Methods of Measurement of Radio Interface Characteristics of Information

Technology Equipment.” European Committee for Electrotechnical Standardization. (CENELEC),

1998

© Copyright AUO Optronics Corp. 2009 All Rights Reserved. Page 27 / 32

Page 28

QTY : 7

Manufactured

XX/XX

MADE IN

XXXXX

8. Packing

8-1 DEFINITION OF LABEL:

A. Panel Label:

*xxxxxxxxxxxx-xxxx*

T420HW06 V4 Product Specification

Rev.0 0

Panel Unique ID

AUO Internal Use

XXXXX Model NO: T420HW06 V.4 XXXXXXX

Year

Week Factory Location AUO Internal Use

AUO Internal Use

Green mark description

(1) For Pb Free Product, AUO will add for identification.

AU Optronics

(2) For RoHs compatible products, AUO will add RoHS for identification.

Note: The green Mark will be present only when the green documents have been ready by AUO internal green

team. (definition of green design follows the AUO green design checklist.)

B. Carton Label:

T420HW06 V4

97.42T08.4XX

© Copyright AUO Optronics Corp. 2009 All Rights Reserved. Page 28 / 32

Page 29

1pcs Module/ESD Bag

Cushion top

Module

7pcs / 1 carton

”

H ” Tape

Cushion down

Cushion set

8-2 PACKING METHODS:

T420HW06 V4 Product Specification

Rev.0 0

© Copyright AUO Optronics Corp. 2009 All Rights Reserved. Page 29 / 32

Page 30

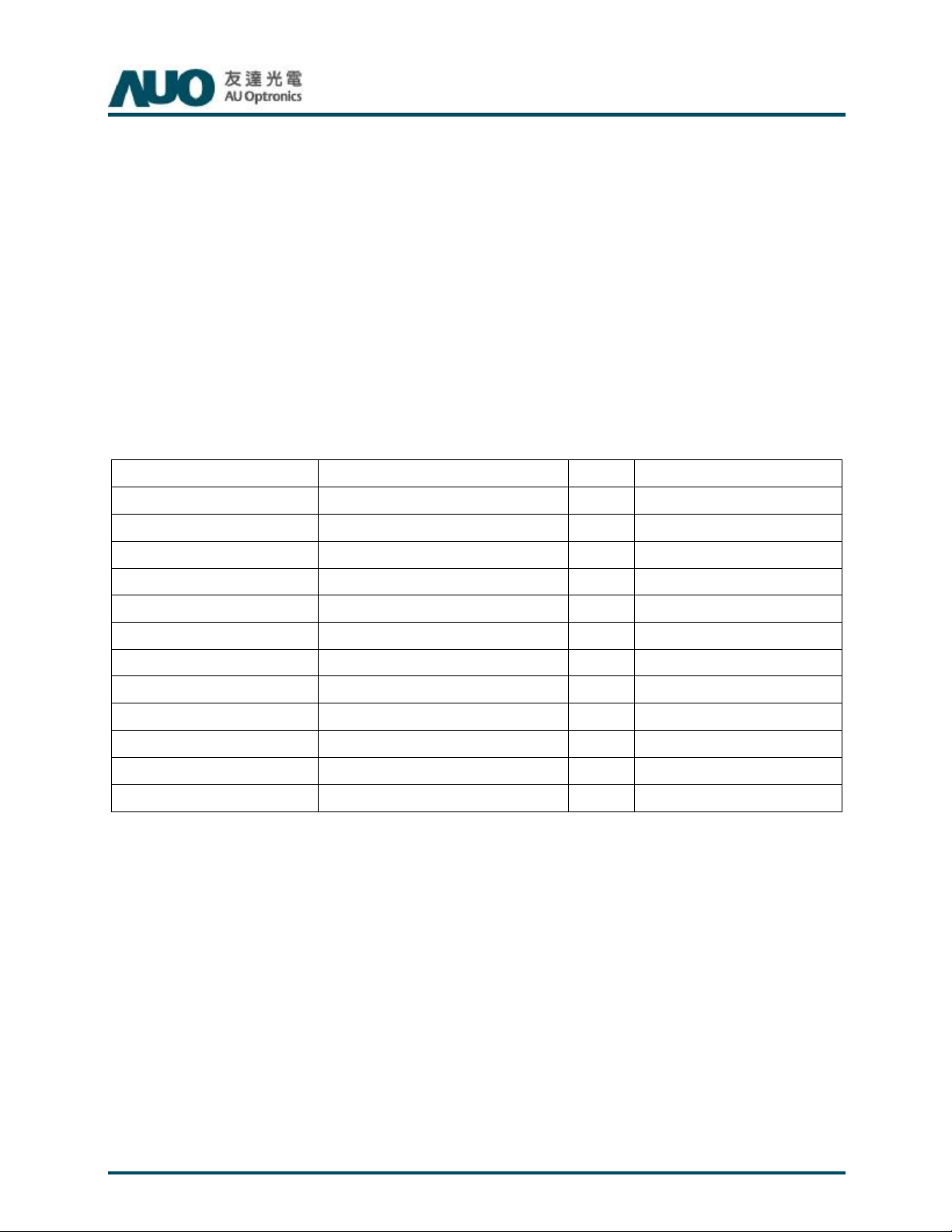

8-3 Pallet and Shipment Information

T420HW06 V4 Product Specification

Rev.0 0

Item

1 Packing BOX 7pcs/box 1060(L)*560(W)*680(H)

2 Pallet 1 1150(L)*1070(W)*138(H)

3 Boxes per Pallet 2boxes/pallet

4 Panels per Pallet 14pcs/pallet

Pallet after packing

Qty. Dimension Weight (kg)

14 1150(L)*1070(W)*818(H)

Specification

Packing Remark

80

16

180

Corner angle

Stretch film

Moisture-proof film

Label

PET band

Corner angle

Pallet

© Copyright AUO Optronics Corp. 2009 All Rights Reserved. Page 30 / 32

Page 31

T420HW06 V4 Product Specification

11. PRECAUTIONS

Please pay attention to the followings when you use this TFT LCD module.

9-1 MOUNTING PRECAUTIONS

(1) You must mount a module using holes arranged in four corners or four sides.

(2) You should consider the mounting structure so that uneven force (ex. twisted stress) is not applied

to module. And the case on which a module is mounted should have sufficient strength so that

external force is not transmitted directly to the module.

(3) Please attach the surface transparent protective plate to the surface in order to protect the polarizer.

Transparent protective plate should have sufficient strength in order to the resist external force.

(4) You should adopt radiation structure to satisfy the temperature specification.

(5) Acetic acid type and chlorine type materials for the cover case are not desirable because the former

generates corrosive gas of attacking the polarizer at high temperature and the latter cause circuit

broken by electro-chemical reaction.

Rev.0 0

(6) Do not touch, push or rub the exposed polarizer with glass, tweezers or anything harder than HB

pencil lead. And please do not rub with dust clothes with chemical treatment. Do not touch the

surface of polarizer for bare hand or greasy cloth. (Some cosmetics are detrimental to the polarizer.)

(7) When the surface becomes dusty, please wipe gently with absorbent cotton or other soft materials

like chamois soaks with petroleum benzene. Normal-hexane is recommended for cleaning the

adhesives used to attach front/ rear polarizer. Do not use acetone, toluene and alcohol because

they cause chemical damage to the polarizer.

(8) Wipe off saliva or water drops as soon as possible. Their long time contact with polarizer causes

deformations and color fading.

(9) Do not open the case because inside circuits do not have sufficient strength.

9-2 OPERATING PRECAUTIONS

(1) The device listed in the product specification sheets was designed and manufactured for TV

application

(2) The spike noise causes the mis-operation of circuits. It should be lower than following voltage:

V=±200mV(Over and under shoot voltage)

(3) Response time depends on the temperature. (In lower temperature, it becomes longer..)

(4) Brightness of CCFL depends on the temperature. (In lower temperature, it becomes lower.) And in

lower temperature, response time (required time that brightness is stable after turned on) becomes

longer.

(5) Be careful for condensation at sudden temperature change. Condensation makes damage to

polarizer or electrical contacted parts. And after fading condensation, smear or spot will occur.

(6) When fixed patterns are displayed for a long time, remnant image is likely to occur.

(7) Module has high frequency circuits. Sufficient suppression to the electromagnetic interference shall

© Copyright AUO Optronics Corp. 2009 All Rights Reserved. Page 31 / 32

Page 32

be done by system manufacturers. Grounding and shielding methods may be important to minimize

the interface.

9-3 ELECTROSTATIC DISCHARGE CONTROL

Since a module is composed of electronic circuits, it is not strong to electrostatic discharge. Make certain

that treatment persons are connected to ground through wristband etc. And don ’t touch interface pin

directly.

9-4 PRECAUTIONS FOR STRONG LIGHT EXPOSURE

Strong light exposure causes degradation of polarizer and color filter.

9-5 STORAGE

When storing modules as spares for a long time, the following precautions are necessary.

(1) Store them in a dark place. Do not expose the module to sunlight or fluorescent light. Keep the

temperature between 5 and 35 at normal humidity.℃℃

T420HW06 V4 Product Specification

Rev.0 0

(2) The polarizer surface should not come in contact with any other object. It is recommended that they

be stored in the container in which they were shipped.

9-6 HANDLING PRECAUTIONS FOR PROTECTION FILM

(1) The protection film is attached to the bezel with a small masking tape. When the protection film is

peeled off, static electricity is generated between the film and polarizer. This should be peeled off

slowly and carefully by people who are electrically grounded and with well ion-blown equipment or

in such a condition, etc.

(2) When the module with protection film attached is stored for a long time, sometimes there remains a

very small amount of glue still on the bezel after the protection film is peeled off.

(3) You can remove the glue easily. When the glue remains on the bezel or its vestige is recognized,

please wipe them off with absorbent cotton waste or other soft material like chamois soaked with

normal-hexane.

© Copyright AUO Optronics Corp. 2009 All Rights Reserved. Page 32 / 32

Loading...

Loading...