Page 1

INSTALLATION PROCEDURES

~NG CABLE (continued) I

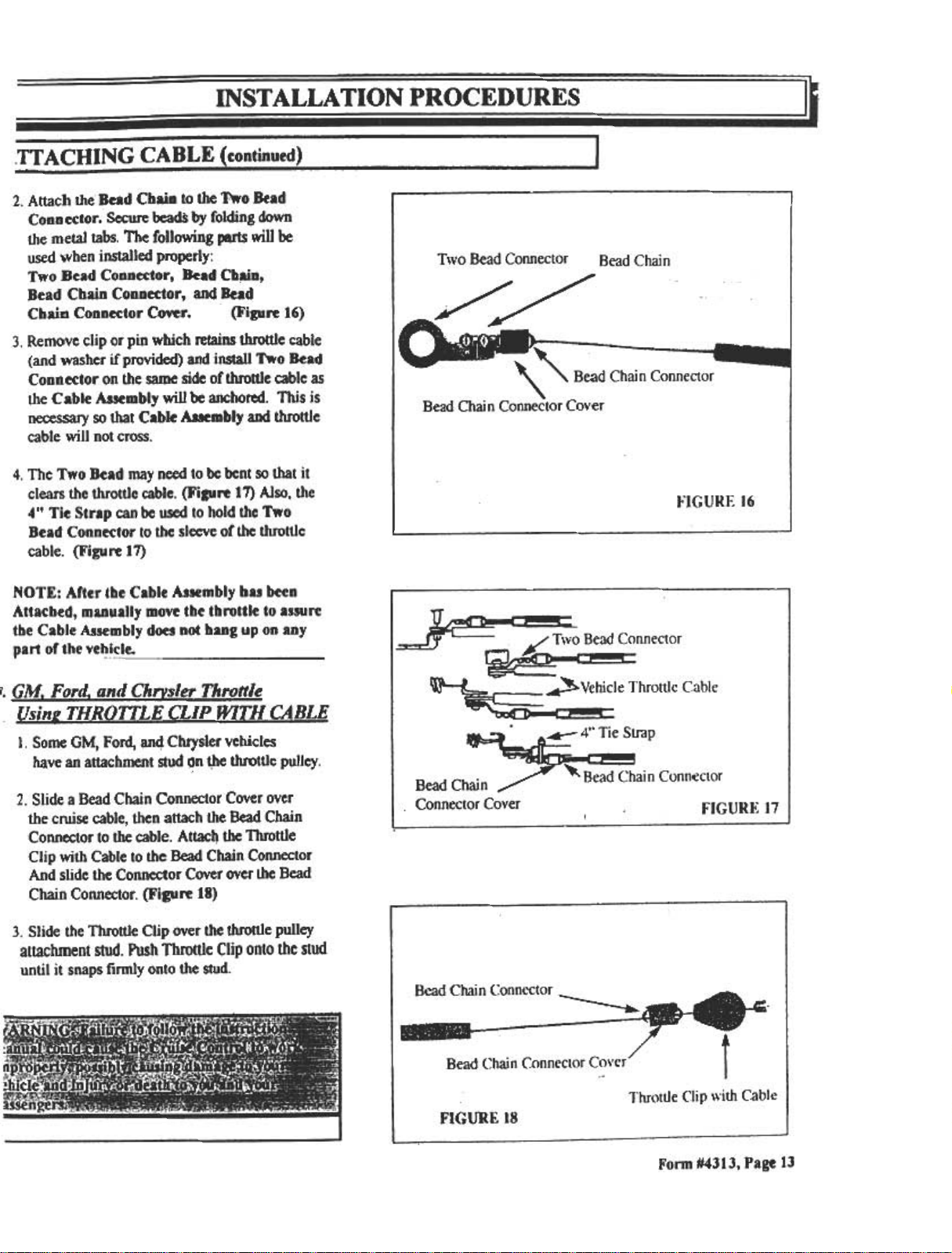

2. Attach the Bead CbaiD to the Two Bead

Connector; Secure beadS by folding down

the metal tabs. The following parts will be

used when installed properly:

Two Bead ConDector, Bead Cb~D,

Bead CbaiD CoDnector, and Bead

CbaiD CoDDector Cover. (Figure 16)

3. Remove clip or pin which retains throttle cable

(and washer if provided) and install Two Bead

Connector on the same side of throttle cable as

the Cable Assembly will be anchored. This is

necessary so that Cable Asaeinbly and throttle

cable will not cross.

4. The Two Bead may need to be bent so that it

clears the throttle cable. (Figure 17) Also, the

4" Tie Strap can be used to hold the Two

Bead Connector to the sleeve of the throttle

cable. (Figure 17)

NOTE: After the Cable Assembly has been

Attached, manually move the throttle to assure

the Cable Assembly does not hang up on any

part of the vehi~le.

1, GM. Ford. and Chrvsler Throttle

Usin~THRQ1TLE CLIP WlTHCABLE

I. Some OM, Ford. and Cbrysler vehicles

have an attachment stud qn ~e throttle pulley .

2. Slide a Bead Chain Connector Cover over

the cruise cable, then attach the Bead Chain

Connector to the cable. Attac~ the Throttle

Clip with Cable to the Bead Chain Connector

And slide the Connector Cover over the Bead

Chain Connector. (Figure 18)

3. Slide the Throttle Clip over the throttle pulley

attachment stud. Push Throttle Clip onto the stud

until it snaps firmly onto the Stud.

FIGURE 18

Throttle Clip with C-able

Form #4313, Page 13

Page 2

~nchoring Cable Assembly I

There are three (3) types of connectors used to anchor

the Cable Assembly:

A. Snap-ln Adapter

B. General Motors Blank Anchor

C. Threaded Tube Clamp

~

114" x 29

Cable

---7116" Box

End Wrench

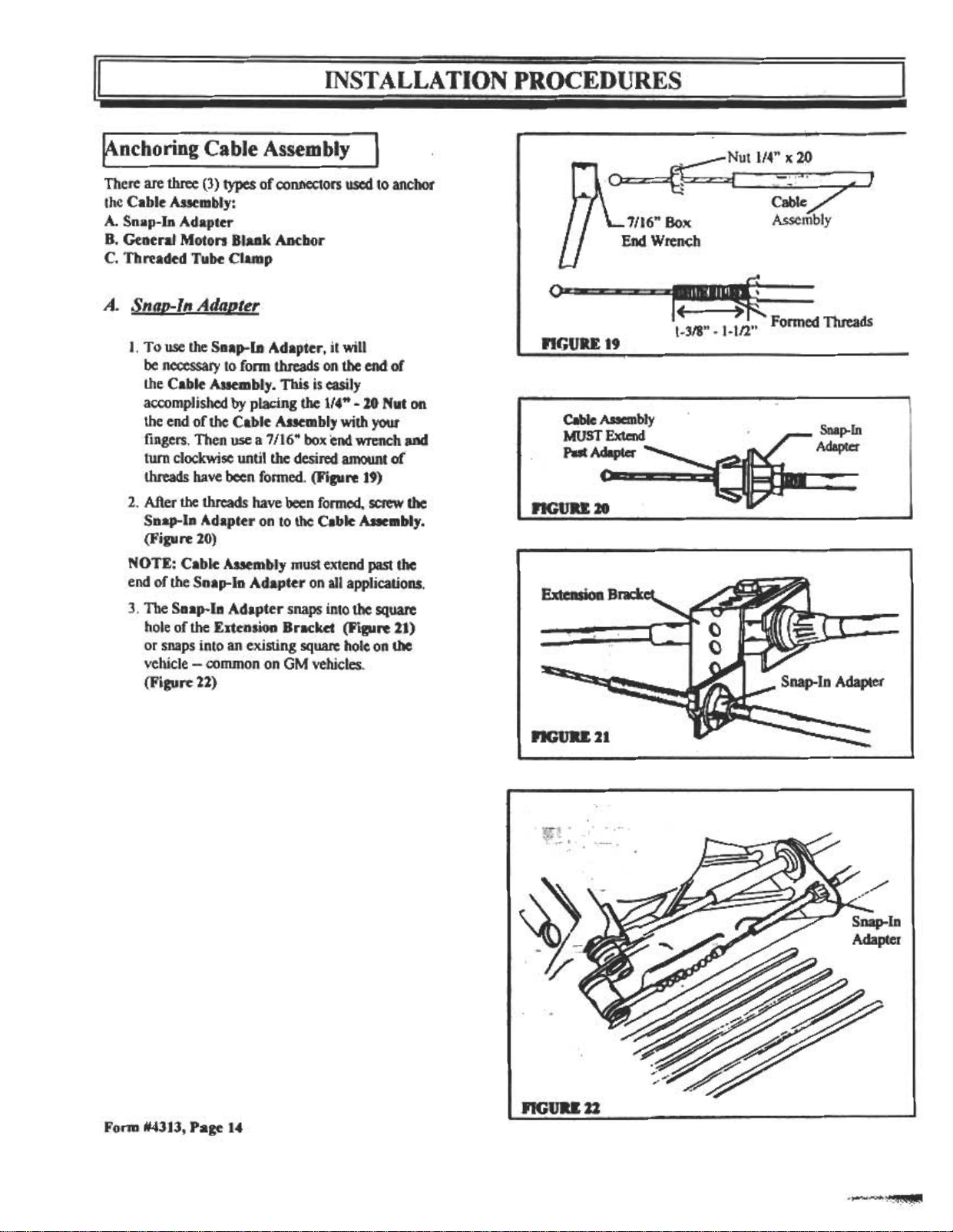

A. Snap-ln Adapter

I. To use the Snap-ln Adapter, it will

be necessary to fonn threads on the end of

the Cable Assembly. This is easily

accomplished by placing the 114" -10 Nut on

the end of the Cable Assembly with your

fingers. Then use a 7116" box end wrench and

turn clockwise until the desired amount of

threads have been Conned. (Figure 19)

2. After the threads have been formed, screw the

Snap-ln Adapter on to the Cable Assembly.

(Figure 20)

NOTE: Cable Assembly must extend past the

end of the Snap-In Adapter on all applications.

3. The Snap-ln Adapter snaps into the square

hole of the Enension Bracket (Figure 11)

or snaps into an existing square hole on the

vehicle -common on GM vehicles.

(Figure 21)

OZ~~~~:=

nGUU 19

Cable Assembly

MUST Extend

Put Adapter

nGUH 20

1-3/8" -1-1/2" Formed Threads

Snap-In

Adapter

FonD #4313, Page 14

:~."'""~

Page 3

INSTALLATION PROCEDURES

, ,

lDchoring Cable Assembly (Continued)

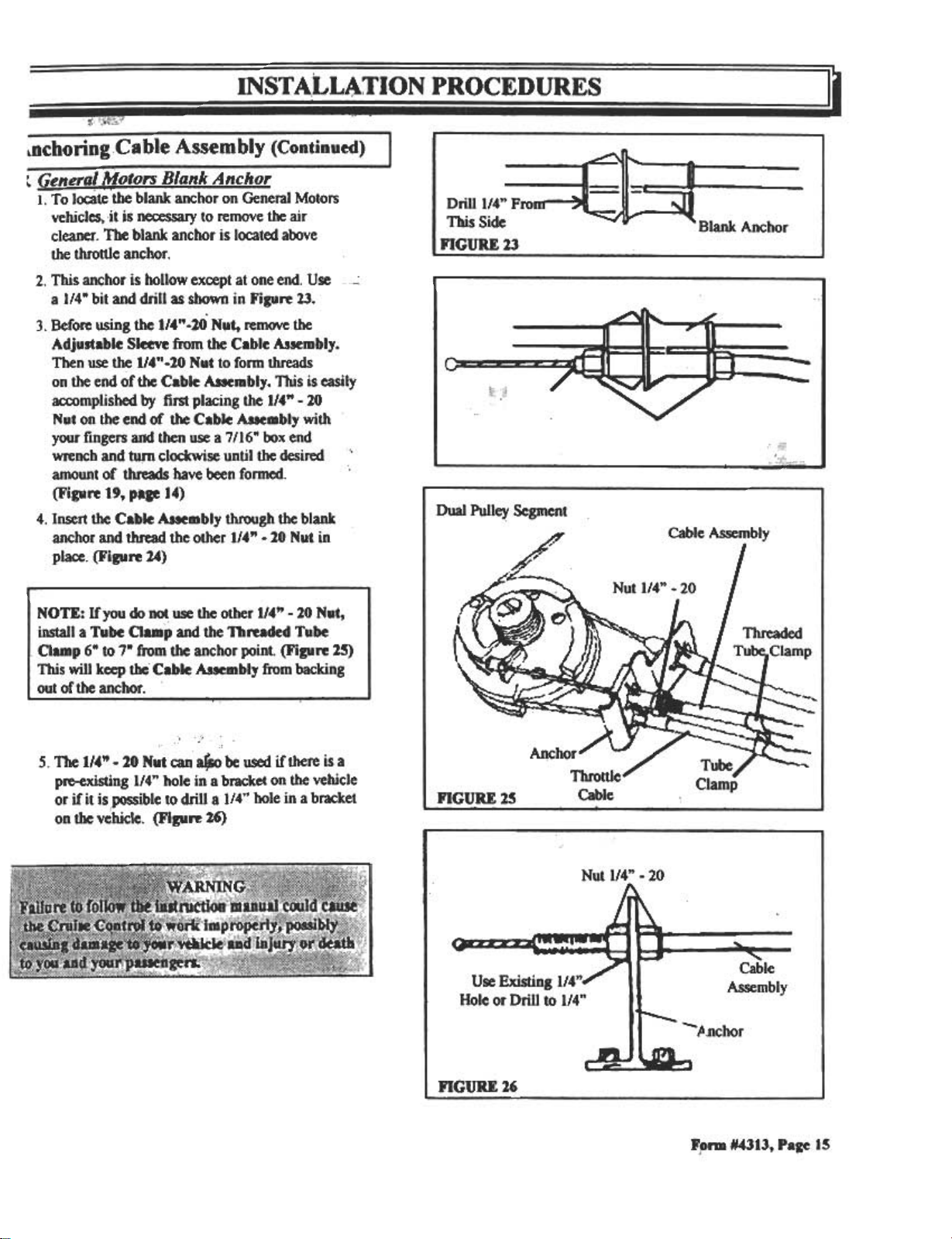

t General Motors Blank Anchor

--, .

1. To locate the blank anchor on General Motors

vehicl~, jljs necessary to remove the air

cleaner. The blank anchor is located above

the throttle anchor .

2. This anchor is hollow except at one end. Use

a 114" bit and drill as shown in Figure 23.

3. Before using the 114"-20 Nut, remove the

Adjustable Sleeve from the Cable A3sembly.

Then use the 114"-20 Nut to fonD threads

on the end of the Cable Assembly. This is easily

accomplished by first placing the 114" -20

Nut on the end of the Cable Assembly with

your fingers and then use a 7116" box end

wrench and tucfn clockwise until the desired ,

amount of threads have been formed.

(Figure 19, pa&e 14)

4. Insert the Cable Assembly through the blank

anchor and thread the other 114" -20 Nut in

place. (Figure 2.4)

I Drill 114"

This Side

FIGURE 23

Anchor

, -;, ,

5. The 114" -20 Nut cali .be used if there is a

pre-existing 114" hole in a bracket on the vehicle

or if it islX>SSible to drill a 114" hole in a bracket

on the vehicle. (FIgure 26)

I

Form 1#4313, Page 15

i

Page 4

.IN1 a'.' :.,;.-,. ,:.: ~

16~ p.n.n'.'~cb. m

ES" ~ I HbLiR'A Ul~, :~~U~R .

c T"rellMdT,,~a.. " ,:. ,

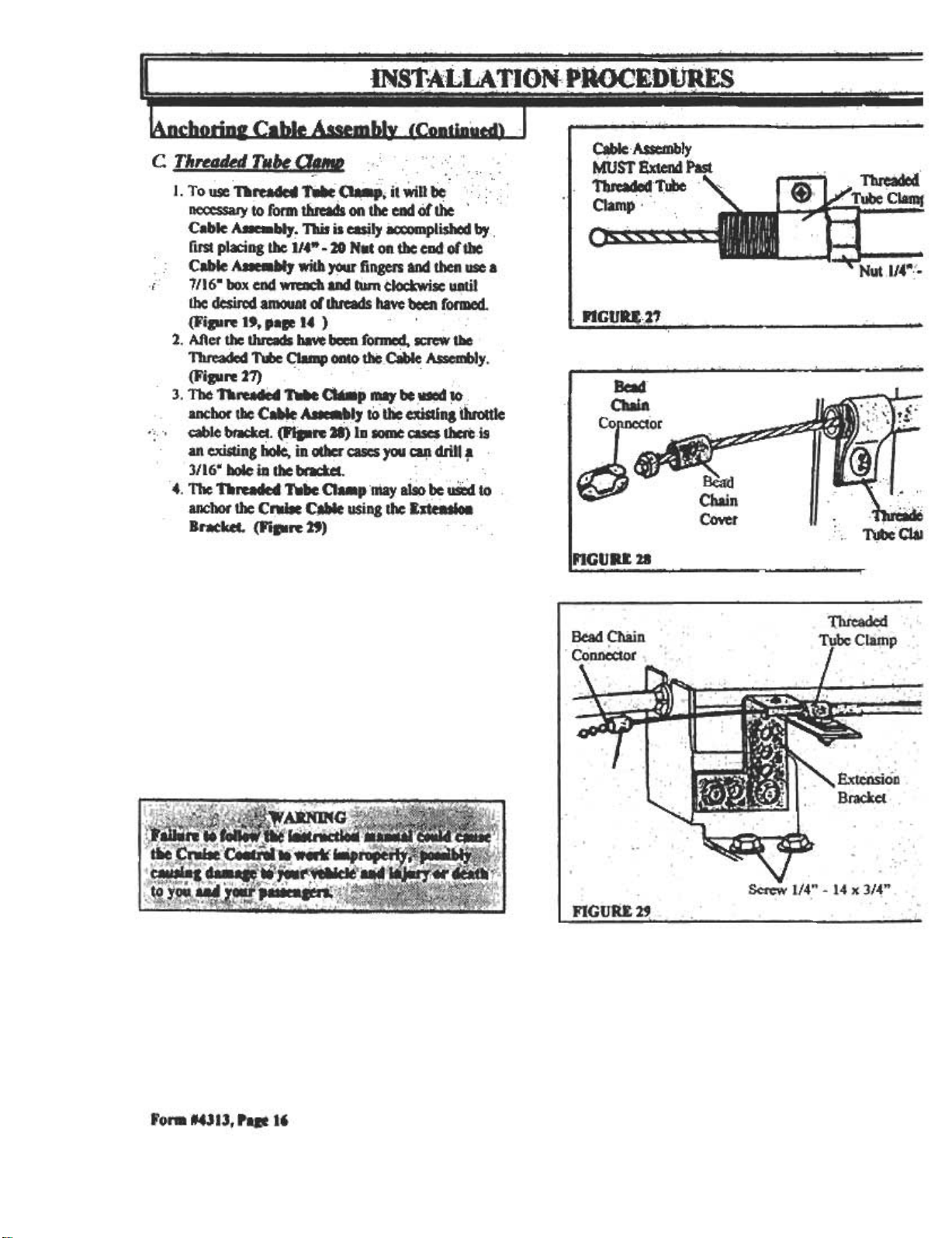

I. To ~ TbreadCd ~~P. it Win~ c: .

necessary to form threads on the end of' the .

-.,

" "

Cable AJIeIDbly.1bis is casJly accompliShed ~ .

first pl'M;ing the 1/4" -20 NMt on the end of1he

.: Cable AJIe8b1y with ~ fingers and then use a

i 7/16- box end wre..:h -turn clockwi~ ~til

the des~ aII1CMIDt ~ threads ~ve been formed.

(Fi.re 19, pa. 14 )

2. After the threads have been fonl1ed, a;rew the

Threaded ~ Clamp onto ~ c8b1e ~Iy.

(Ji'igure 27) .

.3. The r.rea.. T*aa8p -be.~ ~

.ancborthe C~ ~b'~ to ~WSUn.t1uottle

..:' ., cable ~. ~re 28) lD~ ~lhe.eis

an existing ~ in *r cases you ~dril' ~

3116- iW)Ie in the br'actel .

" ,:'

4. The nreaded T.bc a..pniay .be ua to

anchOr theCNile C.able using tIle: r.stt8si08

Bratket. (Fi..re 29) .

~Ie Assembly

MUST~ndPast

ThrCaded-rUbC

Clamp'"

nCURI.,21

Bead

Chain

nGtJRI. 18

Cflain

COvet

-.-"'

I ~.

4\.

~

/1iibe C..

~

~

.; .~ Clai

I ff:

.'..'

~

Fora 14313, Pa&e 16

Page 5

~arness Assembly I

Push Rubber Cover Grommet securely into place on

the cover of the Actuator Assembly. (Figure 30)

Straighten the Harness Assembly and find the 4 pin

mating connectors. Separate the 4 pin connectors. A

small screw driver may be needed.

Bamess Assembly needs a 314" hole to pass through

bulkhead. You may find one nearby such as the

speedometer cable hole or a small one you can file

larger. If you find the right size hole in the right

place, remove ru~r grommet. If not, drill, saw, or

punch a 314" hole in bulkhead. A hole a couple of

inches to the left or: slightly higher than the steering

column is usually a ~00d place. (FiEUre 31)

OTE: Check inside before drilling, sawing, or

linEso you don't dama!e anything.

From engine side, pass four pin connector and

VIOLET wire through hole. If you did not hook up

the BLUE TACH wire and GRAY VSS wire under

the hOOd, pass them through to the inside also.

Reattach 4 pin mating connectors and make

necessary wire connections. (See page 18)

,

~~

~

eat hole in bulkhead with Sealing Putty as shown

1 Figure 32.

)

FonD *4313, ..17

Page 6

" ,. ..\ f

ICruise Control Switch Installation I ,.' """;,,,!

'i'

If your Cruise Control switch is the type which clamps on the turn signal lever, req~ cutting the turn signalJever, or is

mounted on the instrument panel, follow instructions pack~~with it If you have a switch which replaces the cpntplete original

equipment turn signal lever, remove the existing lever and install the Cruise Control switch and lever assembly as instructed in

the vehicle shop servire manual.

I WIRING A Tf ACHMENTS TO VEH "~ ' ' c";

To find a place to get electrical power you will need to "ground" one lead of your test light or volt-ohm -.Find el~cal

..

ground by turning on the ignition switch and touching one lead to a 11« fused tenninal at fuse pan~l; toucbc~r lead to

unpainted metal part of vehicle. The metal you touch, if it makes (X)ntinuity , is ~d. Bracket for parking brake lever is usually

a good ground. Turn ignition switch off.

NOTE: Some fuse panels are behind shields which must be removed first. On other vehicles the screw that mounts the panel

must be removed to get to the fuses.

~.: ..

WIRE

I COLOR

~

BLACK

BROWN

RED

-~

VIOLET

GROUND

-

ACCESSORY POWER

CONSTANT POWER

GROUND

FUNCTION

-

~

WCATION

Vehicle puMIlM>int which is a clean ~nted metal

surface ,

NOTE: 00 NOr USE mE ENGINE AS A

GROUNDING POINT. 00 Nor CONNECf TO mE

EXTENSION BRACKET

F~ panel: fuse that bas + 12 volts when key is ON and

O wits when key is OFF or in the ST ART (CRANK)

position.

Hot side of brake switch -+ 12 volts

~ ~-

Cold side of brake switch -O resistance when brake is not

-

I p~-~l,~ wits or open resistance when brake is

BLUE

GRAY.

-consult Vehicle Shop Manual

TACHOMETER

.-,

VEHICLE SPEED SENSOR

See v~ TdlliCGIl,,/ormlltioll G,,- (FOnD #2482)

! or

consult Vehicle Shop Manual

See V~ TdlliCGIl"/omultio,, G"ide (FOnD #2482)

or

--

Form #4313, Page 18

Page 7

SELF DIAGNOSTICS PROCEDURES

, :~:~:~,';

otering'Diagnostics Mode:

I. Turn the Cnlile Control Switch to the OFF position

2. Turn the ignition switch to the OFF position

3. Press aDd hold the USUME/ACCEL slide switch wbile you turn the ignition switch to the ON position without

.-.rtIIIg tie -g;,.~ Now release the USUMVACCEL slide ~tch. (If you are using a 250-3592, 250-3593,

250-3742 or 250-3743 Cnlile Control S~ bIrD tbc ignition switch to the ON position wit1loll' starting the

-g;,.e, hold the USUMFJACCEL button... wbileyCMl turn the Cnlile Control Switch to the ON position.)

4. The Diagnostics LED should be off at this ~

!ltiag the Cnlile Control Switch, Brake Swid Wlri8c. ud Vehkie Speed SeDsor (VSS) Signal:

-If NOT- Pre8881Mi reIc8Ie SET/COAST button.

~ = t,.. =t=~: :i;.=;... =::;A I LED ~ IiIbt e8:h tiDIe 00tt00 is

~:r ; to entering ~cs mode I prc8Ied IIMI u when it is released. -IF NOT-

d tryasain jp ~ --I Check ~s ; en~ di;ostic mode and I

I ;~in-l'~ ~ ~'6 ~"6'.u~ .~ I

teck Swit£h .7:

OFF: N~ly OPEN switch

ON: NOmIaIly CLOSED switch

Bet iJIaXTectly. = andre-.enter I

~~. I

I

~ power to Actuator Assembly. if

me of the diagnostic commands are

nctionin~

beck Cruise Control Switch

i -IF' NOT-

~ ~ to en~ diagnostic ~ I

;d;y "~ ~ ~ aue ..."6' ~ I

IXDe vehicles need ; be pusbed D1<X'e than I

; (j)f;-; ~ --1'-- ..~~ w-.I

~ fo Ibc V~cle S.-I- ;.1

I I -

Press and Jel~ the

RESUMFJACCEL swit(:h. LED should

ligbt each time the switch is pressed

and to out when itis Jeleased.

IPYIS

D'YIS

-f

Test VEIDCLE SPEFD SENSOR

(VSS):

I A seccxtd perD1 is ~ to check

visual status of the LED. Push car at

least tiu'ec (3) feet f<XWlJd oc

b8CkW8I'd. LEDsbould Oesb at least

once.

OR

Check power to Actu~tor Assembly if none

of dIe diagnostic commands are fw1ctioning

I Check Cruise Control Switch I

IF NOT-

I Check steps to enterin~ diagnostic mode and I

I ~~ht-1'- e -.-e-.~:..~ ...:~ ~.~ I

I Check power to Red = I

Check power to Actuator Assembly, if none

of the diagnostic conunands are functioning

I Check Brake Switch ;d wiring to Brake I

I s~h~ u~.~.. ~ '6 .., ~ I

IF NOT-

I Check ,steps to enterin~ diagnostic mode and I

I ;;;~~in~l'~ .v W&.~& ~&e -.'"e'&V~~W U&~ -.-I

'., .

,

he ccxmectioo JX»int fM dac Vehicle Speed

«*X'illM)t~

,;"

T..AUXDJARY SPEED ~~Jt

lSignal Generat«):

A SCCOIMI perD1 is ~ to ch~k

visual status of die LED. One drive

wheel needs to be jKked-up, take care

10 ~ a suwcxt sta f« ~. Spin

wheel by ham.. fast u )'OU can. LED

I should flash.

I Check Programming Switch N 10, it should be I

I OFf I

I If switch is ON reset to OFF and re-enter I

I diagnostic mode I

You must spin the wheel at least 3 MPH or

faster in order to test an auxiliary signal

generator

Form #4313, Page 19

Page 8

If all 01 die previous functions are correct, check the T ACB Signal

I. Turn the Cnaile Coatrol Switch to the OFF position

2. Turn the ignition switch to the OFF position

3. Press and hold the RESUME/ACCEL slide switch while you turn the ignition switch to the ON position and start

lie .,.g;,.e. Now release the RESUME/ACCEL slide switch. (If you are using a 250-3592 or 250-3593 dash mount

Cnile Coatrol Switch, turn the ignition switch to the ON position and stl111 the engine, hold the RESUME/ACCE

.button 00wn while you turn the Cruise Control Switch to the ON position.)

4. The Diagnostics LED should be flashing. Rev the engine, the LED should flash faster at higher RPM's. If not:

.Check steps to entering diagnostic mode and tJy again

.Connection to T ACH Signal source is bad ~ 0-

.T ACH Signal connection point is not correct

CONTROL SWITCH TESTS

,. .* tat:

I. Unplug the S-pin connector from the Actuator Assembly.

2. Ground the test light lead and verify that the test light works by proving with a known po~er source.

TES:It'HART A (FOR ~LOSED CIRCUIT ~QNTROL sWITcm

IGNITION

SWRCB

; POSmoNS

j orr

I

, orr

OFr

On'

ON

CaANKor

-

CONTROL

SWITCH

POSITIONS

OFF

-

ON

ON

press and bold

SET/COAST

ON

press and bold

RESUMEI ACCEL

ON

-

ON

RED

OFF

~

ON

ON

ON

ON

ON

DARK

GREEN

OFF

ON

OFF

ON

ON

-

ON

YELLOW

OFF

OFF

ON

ON

2!!

OFF

BROWN

OFF

~

IGNmON

SWITCH

-POS~NS I

: iiij

OFf

orr

ON

C84NK or

,- NJI.1, ..ce 10

TEST CHART .

CONTROL

i POSITIONS

SWITCH

OFF

~

ON

press and bold

SET/COAST

ON

preu and bold

RF.SUME/ACCEL

ON

ON

(FOR OPEN CIRCUIT-~ONTROL swITcm

RED

-~

DARK

GREEN

OFF

-

-~N

~

ON

ON

ON

~c-- ON

OFF

OFF

"=-.

OFF ON

OFF

OFF

YELLOW

OFF

-

OFF

OFF OFF

OFF

-

OFF

BRO~

OFF

ON

Page 9

:" ~

-In

"~~

~l

~

¥

.~

211:

~~

~

~

~

0

.;I

c

)ooZ

<0

~~

.

~

":,;jE9~~ :

.~

y

" ,<2 Q -~

0

~

.

cO

~

1&1

..

~

,i

~

Go

Q

,

z c>(J,VJ~' -

~ rc,.r: li

0

~~

~8

~«

~o

~

,..

~

o~

IJftO

0 ...

,-

.I~

0.

...;J

u.

u.

~

z

0

-'

w

Q

Q

c

.

w

2

~

~

w

"

~O

<~

I~

00

~O

Fonn t431J, Page 21

~

~

Page 10

In the event that you need technical assistance with trouble shooting, please have the following

infonnation ready when calling our TechhicalService Department 910-277-1828. This inThfrnation

is important for a proper and speedy diagn~sis of the problems encountered.

Model Number of Cruise Control System pnnted on box and manufacturers code printedoii;the

Actuator Assembly

Vehicle Make Model and Year:

Engine and Transmission:

Ensure that the Brake Switch wiring connections are correct. "

Red wire of WirinrHarness Assembly is connected to "HOT SID~11(co.or):

Violet wire of Wirinl Harness Assembly is connected to "COLD StD~" (cblor):

Ensure that the Brown wire is connected to an "i&nition power sou'rce"

Speed Signal Source:

VSS (Vehicle Speed Signal): Gray wire connection point and wire color:

Alternative Speed Si&Dal Source (part *)" , :' ; I' r,

Tachometer Silnal: Blue wire connection point and color

Actuator Assembly prolramming switch settinls:

1 2 ,;3, 4

I "

"'

5r

..

6

8 9

7

10

ON

OFF

List the parts used for the throttle connection and cable anchoring. Refer to the Parts List all

Parts Diagram on Pages 4-5.

Form #4313, Pa&e 1.2

Page 11

36 M O NTH/36,000 MILE LIMITED W ARRANTY

AUDIOVOX CORPORATION (The Company) warrants to the original retail purchaser of this Cruise Product that should this

product or any part thereof, under normal use and conditiOns; be proven defective material or workmanship within 36 months

or 36,000 miles of the original purchase, such defect(s) will be repaired or replaced (at the Comoanv's ootion) without charge

for the parts.

To obtain repair or replacement within the ter8 fl ~ WarrMty, tk product is to be delivered with proof of warranty

coverage (e.g. dated bill of sale), specirl(.ati08 fl dded(1), sportatioD prepaid, to an approved warranty station or

the Company at the addreu shown below.

This Warranty does not cover costs incurred for removal or reinstallation of the prOOuct, or damage to vehicle electrical systems.

This Warranty does not apply to any prOOuctor part t1tCraJfwbich in the opinion of the Company has been damaged through

alteration, improper installation. mishandling. Ini-. MaIa:t. or I(x:ident.

This Warranty is in lieu of all other express warrIDtieI..li8iliIics. ANY IMPLIED WARRANTIES, INCLUDING ANY

IMPLIED W ARRANTY OF MERCHANT ABn..rrY ,SHAu. BE LIMrrED TO mE DURA TION OF TIllS WRITI'EN

WARRANTY. ANY AcnON FOR BREACH OF ANY W ARJANrY HERE UNDER INCLUDING ANY IMPLIED

W ARRANTY OF MERCHANT ABn.ITY MUST BE BROUGIrr WJ11DN A PERIOD OF 18 MONmS FROM DATE

OF ORIGINAL PURCHASE. IN NO CASE SHALL 11IE COMPANY BE LIABLE FOR ANY CONSEQUENTIAL OR

INCmENT AL DAMAGES FOR BREACH OF nus OR ANY' OTHER. w ARJANrY , EXPRESS OR IMPLIED,

WHATSOEVER No person or representative isa8i8laizccl to assume for the Company any liability other than expressed

herein in connection with the sale of this prOOuct.

THE EXTENT OF THE COMP ANY'S LIABUJTY UNDEJl nus W ARJANrY IS LIMITED TO THE REPAIR OR

REPLACEMENT PROvmED ABOVE AND. IN NO EVENT, S:HALL mE COMPANY'S LIABn.ITY EXCEED THE

PURCHASE PRICE PAID BY THE PURCHASER FOR "nIE PRODUCT.

Some states do not allow limitations on how long ...implied warranty lasts or the exclusion or limitation of incidental or

consequential damage so the above limitations or extlusions may not apply to you. This Warranty gives you specific legal

rights and you may also have other rights which vary from state to state.

,. ,0

INEASTERNU.S.A.: AUDIOVOXCORPORAnON.60ARKAY~HAUPPAUGE.NEWYORK 11788 Phone (516)231-6051

IN WESTERN U.S.A.: AUDIOVOX WESTCORPORAnON,16808MARQUARDTAVE. CERRffOS, CA 90701 Phone (213) 926-7758

OWNER'SW ARRANTY RECORD

(To be completed by selling dealer and retained by customer)

Customer's Name

Address

Dealer Name

Dealer Address

City

Date Purchased

Date Installed

Form #4313, Pa~e 23

Loading...

Loading...