Page 1

INSTALLATION GUIDE FOR:

PRO-O412/C

3-12 BAR COPPER ELEMENT DEFOGGER

WITH TIMER AND ON-OFF PANEL SWITCH

ADD PRO-OO20 FOR GRIDS NEEDING MORE BARS

Printed in U.S.A.

FORM NO.128-3881

Fig.2

IMPORTANT NEW INSTRUCTIONS

REVISED DEFOGGER GRID LAYOUTS AND WIRING METHODS

TO INSURE PROPER OPERA TION OF THIS DEFOGGER. THE FOLLOWING NEW INSTRUCTIONS MUST BE EXACTLY FOLLOWED.

1. Total grid current must not be less than 6 AMPS (the window will

not heat properly if it is below this).

2. Total grid current must not be more than 19 AMPS (the timer or

grid may fail or operate incorrectly if you exceed 19 AMPS).

3. Usethegrid examples provided in this manual as a guide butjfin

doubt, use the formula provided to calculate the actual grid

current your car will use.

=~4.This kit contains sufficiel1t ~aterials to make a grid upto 12bars

'{:Jc cby 5 feet wide. If your grid will exceed this. youiequiieaPRb-

~-'7!:0020accessory k!l -:'::~-,e;c-"';;"

HOW To SET-UP THE GRID PATTERN :

1- Measure your window to determine how many grid lines

(horizontal heating bars) your vehicle requires by the following

method (see Fig. 1 ).

A. Measure the height of the window at the edge of the window

since this is usually the smallest dimension (H).

B. Measurethe width of the window at the top and at the bottom

(W1 and W2).

C. Add W1 and W2 and divide by (2). This is the average width of

your window. -c c

Fig. 1

3. Determining the grid grouping required to achieve the idea[

current range of 6 AMPS to 19 AMPS.

A In our example we want 13 bars that will each be 38'c wide.

B. The formula to determine the current of this grid is:

a. ,012times the width (38") divided by the number ofbars in

each group (1) times the number of groups (13). This is

then divided into 13.2 volts (the average voltage of most

cars).

./ b. .012 (x) 38 = .456 (divided by) 1 = .456 (x) 13 = 5.9 (13.2

divided by 5.9 =2.2 AMPS)

As you can see this is way below the 6 AMP minimum,

c. Therefore. we cannot use 13 bars. So we now have a

choice, we can either delete one bar and make if a 12 bar

grid or we can close-up the spacing between bars by

overlapping the clear carrier tape and make it a 14 bar

grid.

d. For our example we will cfose-upthespacing and make it

a 14 bar grid. Now we can group the bars into groups of 2

bars each (14 is evenly divisible by 2). This will give us 7

groups of 2 bars each. (It is not divisible by 3 or 4.)

e. Using the formula we get

.012 (x) 38 (divided by) 2 (x) 7 = 1.59. We divide this into

13.2 and get 8.3 AMPS. This is within our 6 to 19 AMP

range.So our grid willfook like Fig. 3.

NOTE:

In our example the window is 18" high and W1 is 36" and

W2 is 40". So we add W1 (36") to W2 (40'1 and divide by (2)

36 + 40 = 76" divided by 2 = 38" "

Our average width is 38".

Our height is 18".

FIG. 3

2. Determine how many horizontal grid lines you require by the

following method (See Fig. 2).

A. The normal spacing between bars is 1%" (1.3751.

B. You must allow 5/a" clearance at the top and bottom of the

grid.

C. Therefore. divide the height of your window by 1 %" (1.375).

NOTE: In our example the height is 18". Divided by 1 %" we

get 13 lines.

D. Actually, we can fit 14 bars in 18" of height, but the top and

bottom bars would almost be touching the edges of the glass

area and this is not acceptable.

E. Now we want 13 bars but is this suitable for resistance

grouping to ~chieve the ideal current range of 6AMPS to 19

AMPS? For grouping, the number of lines must be evenly

divisible by 2, 3 or 4. As you can see, (13) is not evenly

divisible by any of these. Therefore. we can only use 13 bars

as single line groups provided it meets the current range of 6

AMPS to 19 AMPS. How we determine this will be explained

next

NOTE:

We have provided typical groupings for most windows on

the following pages. You will only need to use the formula

if your window doesn't work with one of the pictured

examples.

Page 2

Page 3

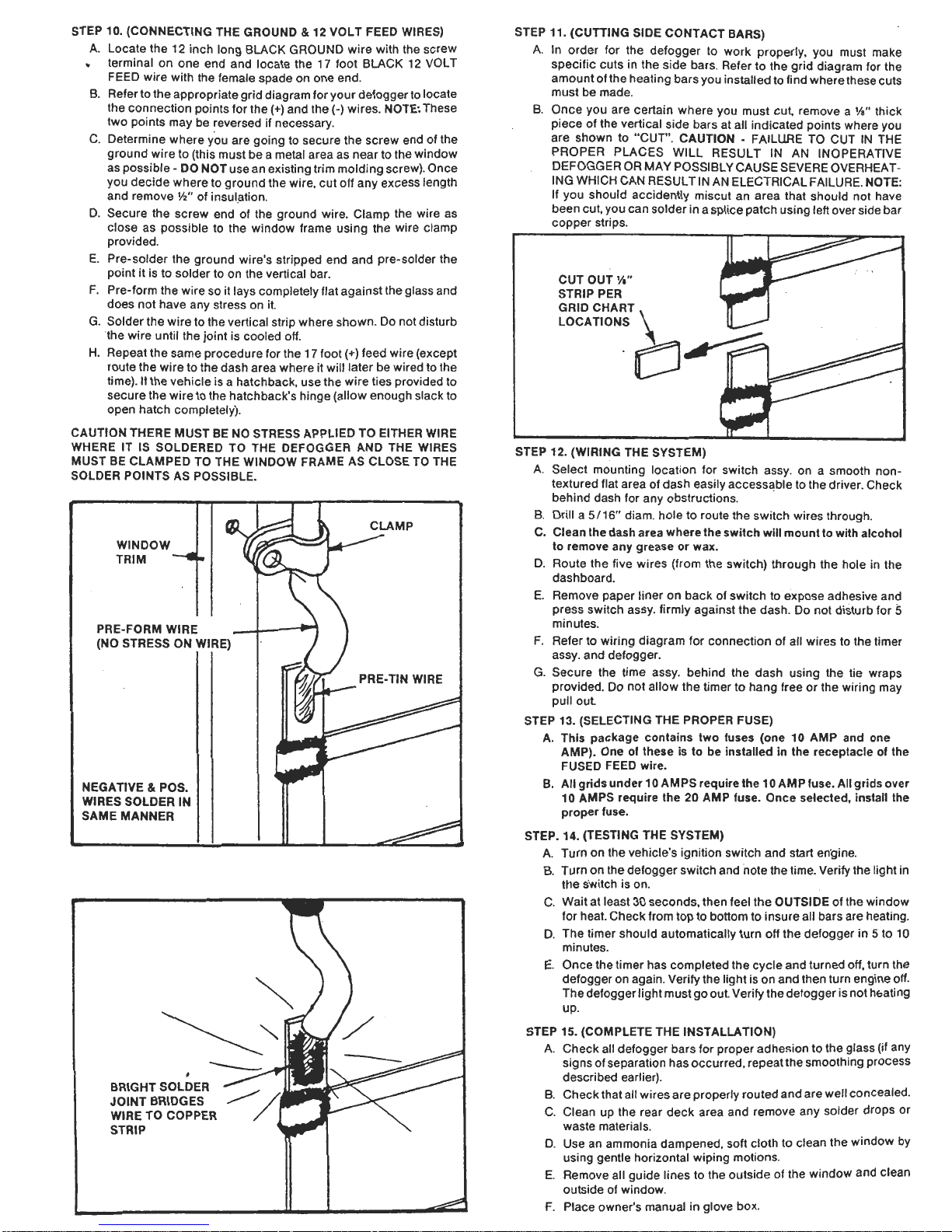

STEP 11. (CUTTING SIDE CONTACT BARS)

A. In order for the defogger to work properly. you must make

specific cuts in the side bars. Refer to the grid diagram for the

amount of the heating bars you installed to find where these cuts

must be made.

B. Once you are certain where you must cut, remove a Y." thick

piece of the vertical side bars at all indicated points where you

are shown to .'CUT". CAUTION -FAILURE TO CUT IN THE

PROPER PLACES WILL RESULT IN AN INOPERATIVE

DEFOGGER OR MA y POSSIBLY CAUSE SEVERE OVERHEAT ING WHICH CAN RESULT IN AN ELECTRICAL FAILURE. NOTE:

Jf you should accidently miscut an area that should not have

been cut, you can solder in a splice patch using left over side bar

copper strips.

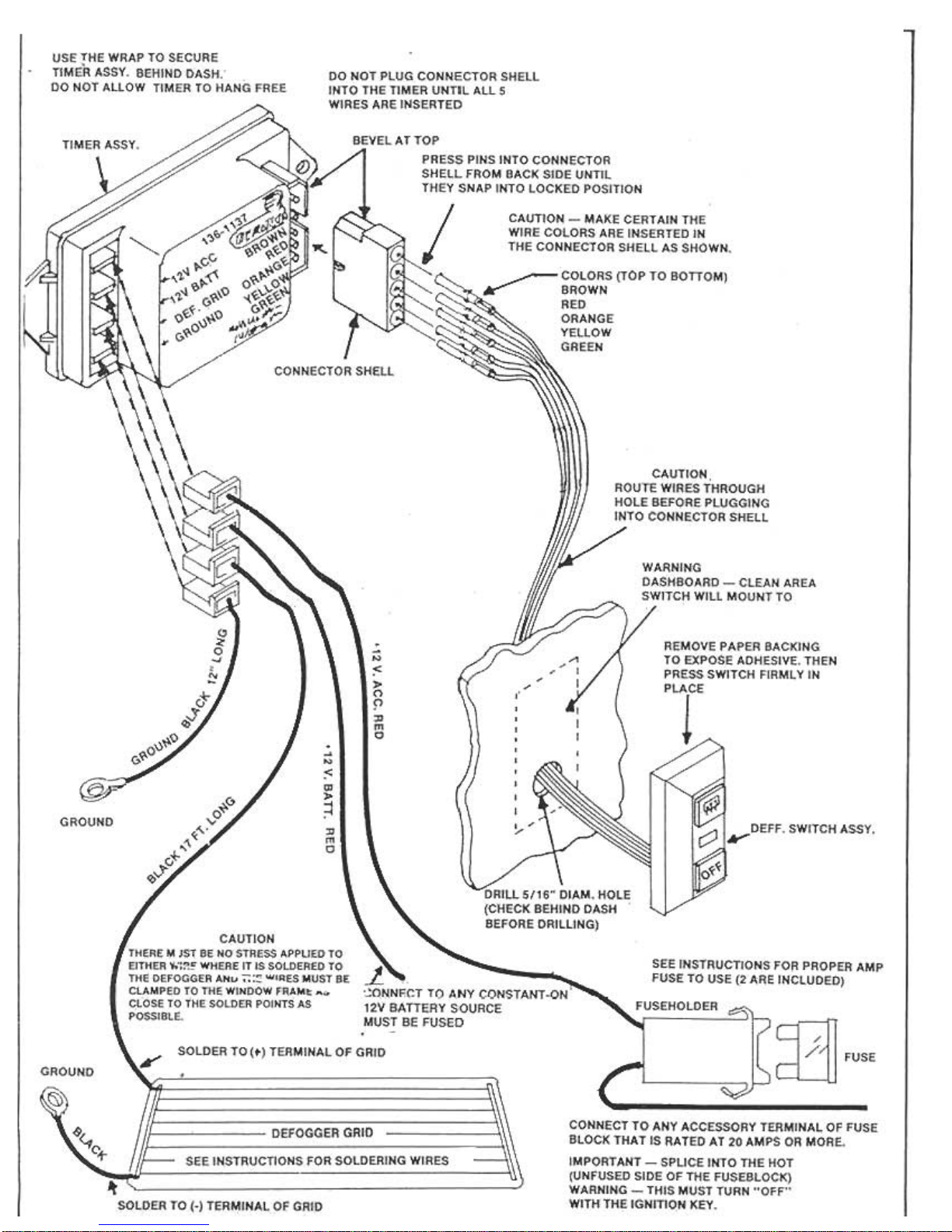

STEP 10. (CONNECTING THE GROUND & 12 VOLT FEED WIRES)

A. Locate the 12 inch long BLACK GROUND wire with the screw

terminal on one end and locate the 17 foot BLACK 12 VOL T

FEED wire with the female spade on one end.

B. Refer to the appropriate grid diagram for your defoggerto locate

the connection points for the (+) and the (-) wires. NOTE: These

two points may be reversed if necessary.

C. Determine where you are going to secure the screw end of the

ground wire to (this must be a metal area as near to the window

as possible -DO NOT use an existing trim molding screw). Once

you decide where to ground the wire. cut off any excess length

and remove V2' of insul.ation.

D. Secure the screw end of the ground wire. Clamp the wire as

close as possible to the window frame using the wire clamp

provided.

E. Pre-solder the ground wire's stripped end and pre-solder the

point it is to solder to on the vertical bar.

F. Pre-form the wire so it lays completely flat against the glass and

does not have any stress on it.

G. Solder the wire to the vertical strip where shown. Do not disturb

1he wire until the joint is cooled off.

H. Repeat the same procedure for the 17 foot (+) feed wire (except

route the wire to the dash area where it will later be wired to the

time). If the vehicle is a hatchback, use the wire ties provided to

secure the wire to the hatchback's hinge (allow enough slack to

open hatch completely).

CAUTION THERE MUST BE NO STRESS APPLIED TO EITHER WIRE

WHERE IT IS SOLDERED TO THE DEFOGGER AND THE WIRES

MUST BE CLAMPED TO THE WINDOW FRAME AS CLOSE TO THE

SOLDER POINTS AS POSSIBLE.

~

CLAMP

WINDOW

TRIM

-

PRE-FORM WIRE

(NO STRESS ON WIRE)

PRE- TIN WIRE

NEGATIVE & POS.

WIRES SOLDER IN

SAME MANNER

STEP 12. (WIRING THE SYSTEM)

A. Select mounting location for switch assy. on a smooth non-

textured flat area of dash easily accessable to the driver. Check

behind dash for any obstructions. .

B. Drill a 5/16" diam. hole to route the switch wires through.

C. Clean the dash area where the switch will mount to with alcohol

to remove any grease or wax.

D. Route the five wires (from the switch) through the hole in the

dashboard.

E. Remove paper liner on backotswitch to expose adhesive and

press switch assy. firmly against the dash. Do not disturb torS

minutes.

F. Refer to wiring diagram for connection of all wires to the timer

assy. and defogger.

G. Secure the time assy. behind the dash using the tie wraps

provided. Do not allow the timer to hang free or the wiring may

pull out

STEP 13. (SELECTING THE PROPER FUSE)

A. This package contains two fuses (one 10 AMP and one

AMP). One of these is to be installed in the receptacle of the

FUSED FEED wire.

B. All grids under 10 AMPS require the 10 AMP fuse. All grids over

10 AMPS require the 20 AMP fuse. Once selected, install the

proper fuse.

STEP. 14. (TESTING THE SYSTEM)

A. Turn on the vehicle's ignition switch and start en.gine.

B. Turn on the defogger switch and note the time. Verify the light in

the s.witch is on.

C. Wait at least 30 seconds, then feel the OUTSIDE of the window

for heat. Check from top to bottom to insure all bars are heating.

D. The timer should automatically turn off the defogger in 5 to 10

minutes.

E. Once the timer has completed the cycle and turned off, turn the

defogger on again. Verify the light is on and then turn engine off.

The defogger light must go out Verify the defogger is not h&ating

up.

STEP 15. (COMPLETE THE INSTALLATION)

A. Check all defogger bars for proper adhe!;ion to the glass (if any

signs of separation has occurred, repeat the smoothing process

described earlier).

B. Check that all wires are properly routed and are well concealed.

C. Clean up the rear deck area and remove any solder drops or

waste materials.

D. Use an ammonia dampened, soft cloth to clean the window by

using gentle horizontal wiping motions.

E. Remove all guide lines to the outside of the window and clean

outside of window.

F. Place owner's manual in glove box.

Page 4

STEP 6. (SMOOTHING THE HEATING BARS)

Proper adhesion of the heating bars to the glass is critical. Therefore,

before proceeding, you must re-smooth the heating bars by starting in

.the center of each bar and firmly pressing out each strip toward the

edges. Check the outside of the window to insure all lines appear as an

unbroken, solid dark line with no air bubbles or light spots.

STEP 7. (APPLYING THE VERTICAL CONTACT STRIPS)

Locate the small roll of the 318" wide copper contact strips.

A. Unroll a length that will overlap the top and bottom horizontal

bars by 1" (one inch) on each end. Cut the strip off the roll.

B. Using the vertical guideline for alignment, carefully peel away

the paper liner on the back of the copper strip (DO NOT REMOVE

IT COMPLETELY). The dark side applies to the glass.

C. Starting at the top corner, apply the strip to the window and

smooth it as you gradually remove the remainder of the paper

liner as you progress downward.

D. Repeat tilese steps for the other side of the window.

E Smooth out both strips in the same manner as the horizontal

bars.

STEP 9. (SOLDERING THE HORIZONTAL BARS TO THE VERTICAL

BARS)

A F,rst place a heayy drop cloth (not plastic) on the rear deck to

catch any possible solder drops. Use a standard 50 to 60 watt

electric soldering iron for all work.

B. You will be soldering each point where a horizontal bar overlaps

the vertical bar.

C. Use the following standard soldering techniques:

a.) Use 60/40 rosen core solder only -do not use acid core.

b.) The tip of the soldering iron must be clean and bright

c.) Test the iron for proper heat by touching a piece of solder to it

It must melt immediately.

d.) A good solder joint is made in the following manner:

m1.)Touch the tip of the iron to the point being soldered and

hold it there while you count to three slowly (one. ..two. ..

three. ..).

2.) TouCh the solder to the material being soldered (not to the

tip of the iron) and wait for it to flow completely around the

point being soldered.

3.) Remove the piece of solder from thejoint, then remove the

iron.

4.) Do not disturb the joint until it has cooled.

5.) Once cooled, inspect the solder joint It must appear as a

shiny, smooth puddle that bridges all the materials being

soldered, II it has bubbles in it, or it is lumpy and very dull

in color, it must be reheated.

[J

HOT

SOLDERING

IRON

/

SOLDER

/

/1

/

/

/

/

STEP 8. (OVERLAPPING & TRIMMING

A. Starting with the top horizontal bar, carefully Jift up the over-

lapping end and bend it back toward the center of the window,

overlapping the vertical bar-

8. Cut it so the end is even with the inside edge of the vertical bar

and 1hen press it firmly against the vel1ic31 bar. DO NOT CUT

AGAINST ELEMENT.

C. Repeat for all horizontal bars.

Page 5

STEP 1. (PREPARING THE WINDOW)

The inside of the window must be absolutely clean and dry. There is no

compromising of this procedure, for if you do, the defogger elements

will not adhere properly and will begin to peel at a later date.

A. The window must be at least 60-65° F. The adhesive on the

elements will not stick to cold or wet glass. Use a heat gun (or

hair dryer) to warm the window and repeat if the window begins

to cool down.

B. The best cleaning solution to use is "DENATURED ISO-PROPYL

ALCOHOL" which is available at drug stores. The window must

be cleaned twice. Use a clean cloth for each cleaning. Once the

window is completely cleaned, you must remove any residue by

cleaning it once more with AMMONIA based window cleaner

(DO NOT USE chemical cleaners such as "Formula 409" which

leave a soap residue on the glass). Allow the window to dry

thoroughly (use a heat gun if necessary). Avoid touching the

window once it is cleaned. At the same time clean the dash area

where you will mount the on-off switch.

C. II vehicle has a center mounted stop light that will interfere with

the installation of the grid, remove it until grid is installed. NOTE:

It is okay to run grid bars across the stop light area on the glass.

STEP 2. (MARKING THE MOUNTING AREA)

A. All markings must be made on the OUTSIDE of the window using

either a marking pencil or masking tape.

B. Your calculations will indicate the total height the required grid

will require. Using the height dimension provided, mark the top

and bottom horizontal reference lines making certain they are

parallel to eaCh other and to the top of the window.

C. Now mark the left and right vertical side guidelines.

NOTE: For best appearances, the vertical lines should be

parallel to the outside edges of the window.

D. You are now ready to install the defogger.

STEP 4.(APPL YING THE REMAINDER OF THE HORIZONTAL BARS)

Once the first bar is properly installed. you simply apply all additional

bars by the following method:

A. Apply the second strip so the top edge of the clear tape is flush

against the bottom edge of the first strip. Allow end overlaps as in

the first strip.

B. Smooth the second strip in the same manner as the first.

C. Repeat as many times as the application chart indicated for your

vehicle (8 bars. 10 bars. etc.). NOTE: For 14 to 20 bar grids. you

will find a second roll of heating elements in the PRO-0020 kit.

TOP REFERENCE LINE

SIDE REFERENCE LINE

BOTTOM REFERENCE LINE

STEP 5. (REMOVING THE CLEAR TAPE STRIPS)

Use care in removing the clear tape carrier strips to avoid pulling the

heating bar away from the window.

A. Start at one end and lift the clear tape while holding the heating

bar away from the window.

B. Bend the clear tape backward toward the direction you are

pulling to and slowly pull the clear tape away.

C. If the heating bar begins to pull away, immediately stop pulling

and press the bar against the window, then continue.

D. Repeat this procedure until all clear strips dre removed.

STEP 3. (APPLYING THE FIRST HORIZONTAL BAR)

You will find one 65 foot roll of horizontal heating element in this

package.

A. Beginning at the top of the window (use guide line). apply the first

strip in the following manner:

a.) Allow at least one inch of overlap beyond the side guide line.

Align the top edge pf the clear tape with the top guide line.

b.) Unroll one strip completely across the window, smoQthing it

as you progress across the window. CAUTION -DO NOT

STRETCH THE TAPE AS YOU APPL y IT, BUT IT SHOULD BE

TAUT.

c.) Once you have reached the opposite side of the window,

allow one iJIch of overlap and cut off the roll.

d.) You must now smooth the heating bar to insure proper

adhesion to the glass. Begin at the center Of the window and

work outward toward the edges. Do not attempt to smooth out

bubbles in the clear tape as it will be removed later. You are

only concerned with smoothing and applying firm pressure to

the heating bar. NOTE: The best method to use to verify

proper adhesion of the heating bar to the glass is to inspect it

from outside the vehicle. A properly adhered heating bar will

appear as an even. dark line. Any white spots indicate the

h.."tinn h"r n"Ati.. ..rlrlitinn..1 ..mnnthinn

Page 6

4 LINES PER GROUP

SOME UNUSUAL WINDOW APPLICATIONS

SPLIT DOOR VANS

J-UMPER WIRE (USE ELEMENT FEED WIRE PROVIDED)

0

1

20" WIDE

{X) 18" HIGH EACH

WINDOW

REQUIREMENT 12 BARS

EACH WINDOW IN GROUPS OF

2 LINES PER GROUP

TOTAL 24 BARS

TYPICAL CURRENT FOR 12.BAR GRIDS (4 LINES PER GROUP)

NOT RECOMMENDED UNLESS WINDOW IS MORE THAN 80" WIDE

80" WIDE WINDOW = 18 AMPS

TYPICAL CURRENT:

20" WIDE WINDOWS WITH A

TOTAL OF 24 BARS IN GROUPS

OF 2 = 12 AMPS.

HATCHBACKS

(ALL GLASS -NO METAL TO GROUND TO)

NOTE: SINCE HATCHBACKS ARE ALWAYS HINGED AT THE TOP

AND ALL GRip LAYOUTS HAVE THE (+) CONNECTION AND (-)

CONNECTION AT OPPOSITE ENDS OF THE GRID YOU CAN

EASILY BRING BOTH CONNECTIONS TO THE TO'P OF THE GRID

WHERE THE HINGES ARE.

~TO~12 FEED I rTO GROUND I

t ~ GRID ~INGES ~INGES

TOP OF GRID

~ .NEW GROUND

I CONNECTION

-EXTRA PIECE OF

SIDE BAR

NORMAL

CONNECTION

EXTRA PIECE OF SIDE BAR

MAINTAIN ';..'OF SPACE

BETWEEN SIDE BARS TO AVOID

SHORTING.

NOT SHOWN

TYPICAL CURRENT FOR 20-BAR GRIDS (4 LINES PER GROUP

NOT RECOMMENDED UNLESS WINDOW IS MORE THAN 50" WIDE.

50" WIDE WINDOW = 18 AMPS

TYPICAL CURRENT FOR 16-BAR GRIDS (4 LINES PER GROUP)

NOT RECOMMEDED UNLESS WINDOW IS MORE THAN 60" WIDE.

60" WIDE WINDOW = 18 AMPS

Page 7

Page 8

2 LINES PER GROUP

TYPICAL CURRENT FOR 4-BAR GRID (2 LINES PER GROUP)

80" WIDE WINDOW = 13 AMPS

60" WIDE WINDOW = 18 AMPS

6-BAR GRID

4. A final test of the formula:

A. Let's assume we decided to remove one bar from our 13 bar

grid and make it a 12 bar grid.

, B. Now you can see 12 is divisible by 1. 2.3 and 4. So let's

quickly check each grouping possibility to see what

happens:

a. Single grouping (1 bar per group) 12 groups of 1 bar each

.012 (x) 38 (divided by) 1 (x) 12 = 5.4 (13.2 divided by 5.4 =

2.4 AMPS)

This is below the limit

b. Two bar grouping (2 bars per group) 6 groups of 2 bars

each .012 (x) 38 (divided by) 2 (x) 6 = 1.3 (13.2 divided by

1.3 = 10.1 AMPS)

This is within the limits.

c. Three bar grouping (3 bars per group) 4 groups of 3 bars

each .012 (x) 38 (divided by) 3 (x) 4 = 0.6 (13.2 divided by

0.6 = 22 AMPS)

This is above the limits.

d. Four bar grouping (4 bars per group) 3 groups of 4 bars

each .012 (x) 38 (divided by) 4 (x) 3 = 0.3 (13.2 divided by

0.3 = 44 AMPS)

This is way above the limit

C. As you can see, if we had used 12 bars. the only possibility

would be to use 2 bar grouping to make 6 groups of 2 bars

each.

CUT

-J0

TYPICAL CURRENT FOR 6-BAR GRID (2 UNES PER GROUP)

80" WIDE WINDOW = 9 AMPS

40" WIDE WINDOW = 18 AMPS

SOME TYPICAL GRID PATTERNS

NOTE: YOU WILL SEE THAT AS THE WINDOW WIDTH

INCREASES, CURRENT DECREASES

0 3-BAR GRID

CUT 0,

CUT

1-00

TYPICAL CURRENT FOR 8-BAR GRID (2 LINES PER GROUP)

48. WIDE WINDOW= 12AMPS

TYPICAL CURRENT FOR 3-BAR GRIDS {1 LINE PER GROUP)

70" WIDE WINDOW = 6 AMPS

20" WIDE WINDOW = 18 AMPS

1 O-BAR GRID

~

CUT

G) , 4-BAR GRID

CUT D

CUT

CUT

CUT

cuL

G

CUT

-J0

TYPICAL CURRENT FOR 10-BAR GRID (2 LINES PER GROUP)

SO" WIDE WINDOW = 9 AMPS

15" WIDE WINDOW = 18 AMPS

TYPICAL CURRENT FOR 4-BAR GRIDS {1 LINE PER GROUP)

56" WIDE WINDOW = 6 AMPS

15" WIDE WINDOW = 18 AMPS

3 LINES PER GROUP

9-BAR GRID

@

CUT

CUT

.0

TYPICAL CURRENT FOR 9-BAR GRID (3 LINES PER GROUP)

80" WIDE WINDOW = 14 AMPS

60" WIDE WINDOW = 18 AMPS

0r;

ii

CUT

Loading...

Loading...