Page 1

MM801

8.4" LCD OVERHEAD MONITOR

Installation Guide

ON OFF AUTO

POWER

MENU/

ENTER

Installation Guide

1

Page 2

Important Notice

An LCD panel and/or video monitor may be installed in a motor vehicle and visible to the

driver if the LCD panel or video monitor is used for vehicle information, system control,

rear or side observation or navigation. If the LCD panel or video monitor is used for

television reception, video or DVD play , the LCD panel or video monitor must be installed

so that these features will only function when the vehicle is in “park” or when the vehicle’s

parking brake is applied.

An LCD panel or video monitor used for television reception, video or DVD play that

operates when the vehicle is in gear or when the parking brake is not applied must be

installed to the rear of the driver’s seat where it will not be visible, directly or indirectly , to

the operator of the motor vehicle. It is unlawful in most jurisdictions for a person to drive

a motor vehicle which is equipped with a screen that is located in the motor vehicle at

any point forward of the back of the driver’s seat, or that is visible, directly or indirectly,

to the driver while operating the vehicle. In the interest of safety, the MM801 should

never be installed where it will be visible, directly or indirectly, by the operator of the

motor vehicle.

Installation Guide

2

Page 3

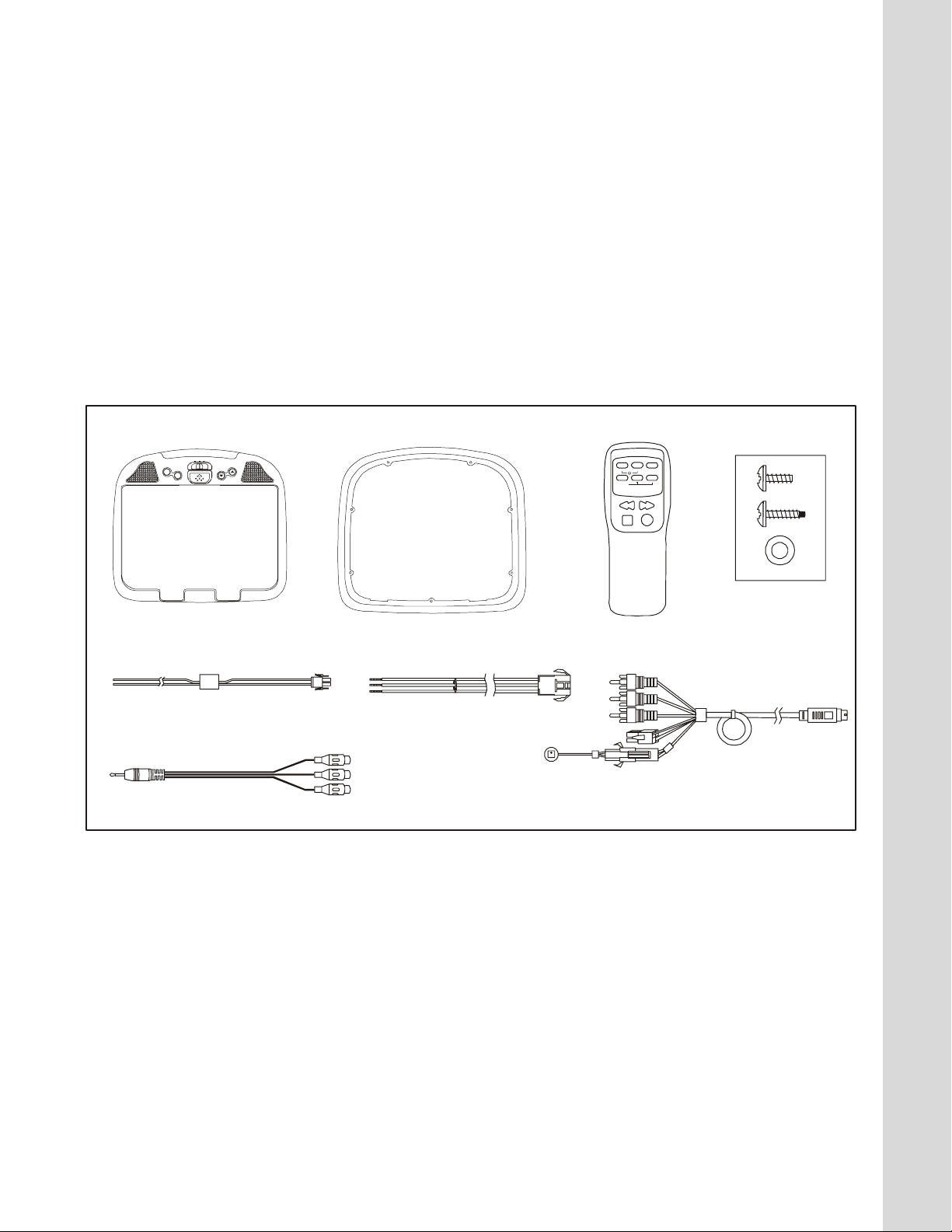

MATERIALS INCLUDED IN THIS PACKAGE:

V

1) MM801 Video Monitor (P/N 136D3649) – 1pc

2) Trim Ring (P/N 102C4007) – 1pc

3) Remote Control (P/N : 136B3650) – 1pc

4) Hardware Package:-

♦ #4 x 5/16” Screws – 7 pcs

♦ #8 x 5/8” Self Drilling Screws – 4 pcs

♦ #8 W ashers – 4 pcs

5) 2 Pin Power Wire Harness with choke (P/N 1 12B3143) – 1 pc

6) Dome light Harness (P/N 1 12B31 10) – 1 pc

7) Accessory Harness (P/N 8010730) – 1pc

8) A/V Adapter Cable (P/N 112B3227) – 1pc

Installation Guide

1. 2.

ON OFF AUTO

POWER

MENU/

ENTER

5.

8.

TOOLS REQUIRED:

3.

LCD

CP

MENU/

ENTER

REW FWD

PLAY

6. 7.

4.

SOURCE

+

STOP

#2 Phillips Screwdriver

#1 Phillips Screwdriver

Utility or Razor Knife or Shears

Wire Strippers

Upholstery hook tool (for removal of panels as necessary)

Electrical Tape

Masking Tape

Multimeter (to verify 12 volt DC and continuity: Do not use a test light or logic probe)

Marker pen – to mark headliner

Scribe (to mark trim ring if used)

Misc. electrical connectors (to connect to vehicle power source). Requirements will vary from vehicle to

vehicle.

3

Page 4

GENERAL INSTALLATION APPROACH:

1) Decide upon system configuration and options that will be installed (i.e.: what components, VCP,

Tuner, RF Modulator/external amp, remote headphones, DVD, etc.).

2) Review all manuals to become familiar with electrical requirements and hook ups.

3) Decide upon mounting locations of all components and method of mounting.

4) Prep the vehicle by removing any interior trim necessary to gain access to vehicle's wiring as well as

all areas where interconnecting wire harnesses will need to be located. If any access holes need to

be cut into the vehicle (headliner, other trim components etc.), this should be done now as well.

5) Route the wiring harnesses throughout the vehicle as necessary. (Refer to the Wiring Diagrams in

this manual as well as the wiring instructions for the individual components and accessory options

being installed). Be sure that all wiring is protected from sharp edges and is routed in such a manner

that it will not be pinched when all components and interior trim are fully installed. Be sure to leave

enough slack in the wiring at each component to allow working room.

6) Remove all A/V system components from their packaging and place them loosely in the vehicle at

their respective locations.

7) Connect all components together (electrically) and verify proper operation of all system functions.

Note: This is best done BEFORE components have been permanently mounted.

8) After verifying proper operation of the system, proceed to mount each of the components.

9) When all components are mounted, recheck function of entire system again to ensure that no wiring

was pinched or connected improperly during final installation.

Installation Guide

4

Page 5

VEHICLE PREPARATION:

1) Locate an accessory power source (+12v when key is in the ACC. and run positions, and 0v when key

is off). Also locate a good ground wire. Generally, these wires can be found at the ignition switch or

fuse-box.

2) The mounting method and location will vary from vehicle to vehicle, so this manual will only focus on

the installation of the video monitor and related console accessories.

3) Generally , the best location for the video monitor is where the vehicle's factory dome light is installed.

The monitor should be located in such a manner that it can be comfortably viewed by rear seat

passengers. NEVER INSTALL THE MONITOR IN A PLACE WITHIN THE DRIVER'S VIEW. THIS

IS NOT ONLY DANGEROUS, BUT IT IS ALSO ILLEGAL.

4) Once the mounting location of the monitor has been determined, there may be additional preparation

work necessary, depending on the vehicle structure and installation method. Some of the steps that

may be required are:

A) Removal of the vehicle's dome light.

B) The headliner may need to be trimmed.

Installation Guide

5

Page 6

TRIM RING INSTALLATION:

This page only covers special installation considerations for the trim ring installation.

If the video monitor is to be installed in a vehicle with the trim ring, it may need to be trimmed to fit the

contour of the vehicle headliner.

1) In this installation, the video monitor is mounted directly to the overhead cross-member in the roof

using the mounting screw bosses. These screw bosses should contact the cross-member directly (i.e.: no gap between the screw boss and the roof structure). Also, be sure that the screws

do not pierce the outer roof skin when fully fastened to the cross-member. The trim ring is

attached to the video monitor using the perimeter screw bosses. It is important that the screws

used in this installation are not overtightened, and that the video monitor and trim ring are mounted

in such a way that the assembly does not distort (or bend) when the mounting screws are tightened. An alternate method is to use a piece of plywood (5"x9"x3/4"). First secure the plywood

block to the cross-member, then screw the monitor into the plywood. See the drawing on p age 7.

2) It is best to mount the video monitor to the roof structure without the trim ring first. There should

be a gap between the headliner and the outer flange of the video monitor. The trim ring should be

cut to full this gap. Apply masking tape to the outer surface of the trim ring in the areas where the

cut will be made.

3) Mark the cut to follow the necessary contour of the roof. The suggested method of marking is as

follows:

A) First mark the narrowest point of the trim ring on the masking tape. Be careful to

consider not only left-right location, but fore-aft location.

B) Using the handle of a screwdriver, make a “transfer marking tool”. See diagram

below. Place the tool against the roof and the marker against the masking tape on

the mini-console. Trace the cut to be made around the entire perimeter of the trim

ring.

C) Cut the trim ring using a Dremel Tool.

D) Check the fit of the trim ring and make any minor adjustments necessary.

4) The trim ring can be painted or covered with a material that matches the headliner before assembling the trim ring to the video monitor.

5) The finished trim ring should be attached to the video monitor, then attach the assembly to the

roof.

Cut line

Lowest point mark

Tape marker to screwdriver. Starting at your mark

for the lowest point, trace the contour of the roof

Installation Guide

Headliner

6

Page 7

MOUNTING THE TRIM RING

Installation Guide

Roof

Roof Support

Headliner

5"x9"x3/4" Plywood

Block

(4) #8x1" self drilling

screws

Trim Ring

Video Unit

(4) #8 flat washers

(4) #8x3/4" self tapping

screws

7

Page 8

MM801

A

A

Dome

Light

1

Video Outp ut

Red: +12VDC

Accessory Ckt.

(Install 5A

Inline Fuse)

Black: Ground

IR LED:

Clean the IR Receiver Window on the front of the VCP.

Remove Adhesive Backing and Apply IR LED to IR

Window on the Face of the VCP.

Power Harness

item #5

Power

Connector 4 Pin

FUSE

DC IN

“Y” Adapter

for use with

Non-Stereo

Installations

RF OUT

Accessory

Harness

item #7

Red RCA (Audio Right)

NT.IN

White RCA (Audio Left)

OUT

Ye llo w RCA (Vide o)

udio Output

forFM Mod.

1) Insert the Circular Mini-Din Connector of the source Component Harness through the wire tie loop

on the main PCB and into the Mini-Din Connector on the main PCB.

2) Pull the wire tie loop tight and cut off the excess.

3) Connect the Power Harness to the mating connector on the Video Monitor .

4) Connect the power harness to the vehicle’s electrical system through an In-Line 5-Ampere fuse by

tapping into an accessory hot line.

5) Verify all functions of the System before final mounting of the finished assembly.

Installation Guide

8

Page 9

CONNECTING THE DOME LIGHTS

The dome lights in the video monitor require three connections to the vehicle's wiring. There are two

common types of dome light circuits used, positive or negative switched. Positive systems supply voltage to the interior lights to turn them on, negative switched systems apply ground to illuminate the bulbs.

To determine which system you have you must locate the wires at the dome light. On a positive switched

system, with all the doors closed and the lights out, both wires at the dome light will rest at ground. When

the light is activated, one of these wires will switch to +12 vdc. This is the vehicle's switching wire. On a

negative switched system, with all the doors closed and the lights out, both wires at the dome light will

rest at + 12vdc. When the light is activated, one of these wires will switch to ground. This is the switching

wire.

For positive systems, connect the violet / brown (Lamp auto) wire to the vehicle's switched wire. Then

connect the red / black (lamp on) wire to a fused constant 12 volt source and the black / red (lamp

common) wire to a good ground. Positive systems are commonly found on Ford vehicles.

For negative systems, connect the violet / brown (Lamp auto) wire to the vehicle's switched wire. Then

connect the red / black (lamp on) wire to a good ground and the black / red (lamp common) wire to fused

constant 12 volt source. Negative systems are commonly found on General Motors and import vehicles.

Note:

Some vehicles which incorporate transistorized control of the dome light circuit, such as the 1999

Dodge Caravan, may require that the violet / brown (Lamp auto) wire be connected to the door pin

switch wire, as the additional current draw of the Monitor's lights may not be supported by the output

of the vehicles body control computer.

Installation Guide

Positive Switched Dome lighting

To 3 pin

connector

on Monitor

Factory Dome light circuit

To

constant

+12vdc

9

Red / black - Lamp on

Black / red - Lamp common

Violet / brown - Lamp Auto

Factory Door ajar

switch or Body

Control computer

To

constant

+12vdc

Page 10

Negative Switched Dome lighting

To 3 pin

connector

Factory Dome light circuit

Red / black - Lamp on

Black / red - Lamp common

Violet / brown - Lamp Auto

Factory Door ajar

switch or Body

To

constant

To

constant

Troubleshooting:

SYMPTOM:

No power at Video Monitor

Power but no video or

sound

Picture, but no sound

REMEDY:

-Verify +12 VDC on Red wire at 2 pin Power Harness behind video

monitor. Verify ground connection with continuity test from known

good ground to black wire at 2 pin Power Harness

-Verify that the correct source is selected (i.e.: 1 or 2). Verify that the

source is on and playing a known good media (such as a videotape).

Verify connections at both ends of the source component harness.

-Verify that the headphones are turned on; check head phone batteries

-Verify that power is available to the FM Modulator; make sure modulator is tuned to the correct FM station

Installation Guide

10

Page 11

Installation Guide

This Page Intentionally Left Blank

11

Page 12

© Copyright 2004 AEC 150 Marcus Blvd. Hauppauge, NY 11788

128-7036

Loading...

Loading...