Page 1

LCM641S

Roof Mount

Flip Down

Monitor

Video Only

US Patent #D 413,856

Owner’s Manual

And

Installation Guide

Audiovox Specialized Applications, LLC

23319 Cooper Dr.

Elkhart, IN 46514

1-800-688-3135

www.asaelectronics.com

Page 2

Features:

8010770)

- TFT Active Matrix Color LCD

- Built In Dome Lights

- “Hide Away” Screen When Not in Use

- Wide Viewing Angle (6.4” Diagonal)

- High Resolution (640 x 480)

- High Brightness (300 nit)

- Automatic Viewing Signal Sensing Turn-On Circuit

- Designed and Tested for Automotive Use

Installation may require Mini Console (Trim Ring) order no. 1181300

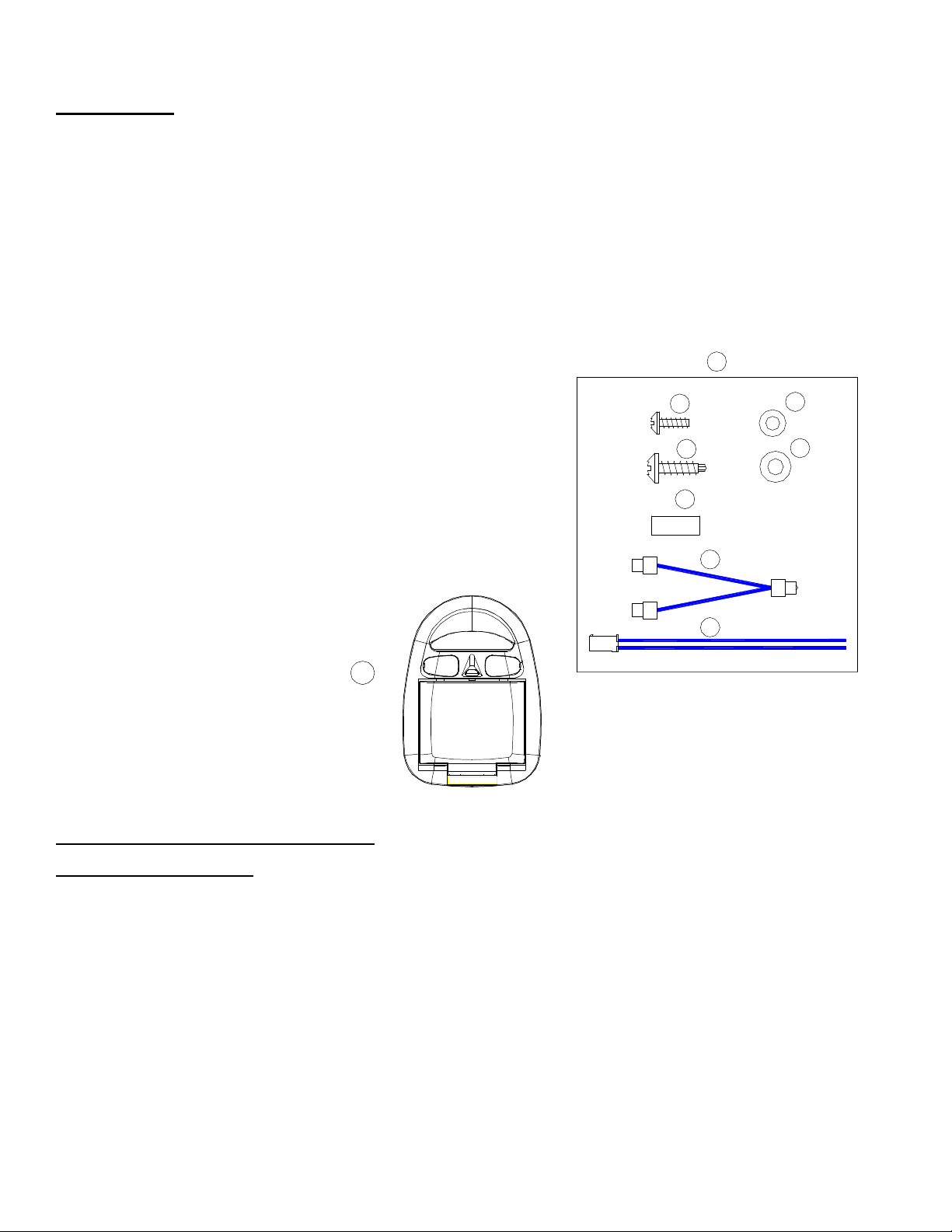

1) LCM641S Video Monitor – 1 pc.

2) Accessory kit (P/N 1186410) – 1 pc.

2a) #4 x 3/8” Screws – 11 pcs.

2b) #4 Washers – 11 pcs.

2c) #6 x 5/8” Self-drilling Screws – 4 pcs.

2d) #5 Washers – 4 pcs.

2e) Spacers – 8 pcs.

2f) Y-Adapter (P/N 0892165) – 1 pc.

2g) Cord, Power – 1 pc.

3) Owner’s Manual/ Installation Guide (P/N

1

2a

2c

2e

2

2b

2d

2f

2g

Materials in this Package:

Tools Required:

- #2 Phillips Screwdriver

- #1 Phillips Screwdriver

- Wire Strippers

- Utility Knife

- Masking Tape

- Multimeter (to verify 12VDC and continuity, do not use test light)

- Misc. electrical connectors (to connect to vehicle power source….will vary from vehicle to vehicle

- Marker Pen

- Electrical Tape

1

Page 3

Vehicle Preparation:

1) Locate vehicle power source. Generally this is best found near the vehicle’s fuse block, which is

usually (though not always) under the steering wheel area. Locate an accessory hot circuit to tap

into for video system power. Accessory hot means a circuit that is +12VDC when the ignition key

is in either the “ACC’Y” or “Run” positions, and 0 Volts DC when the ignition key is removed from

the vehicle.

2) Generally, the best location for the video monitor is where the vehicle’s dome light is traditionally

installed (center of roof, just behind the two front seats). The monitor should be located in such a

manner that it can comfortably be viewed by the rear seat passengers in the vehicle. The monitor

should NEVER be located in a position that would place it within the driver’s field of view. This is

not only hazardous for driving conditions (as it creates a distraction to the driver), but it is against

the law in many states. Check your state laws.

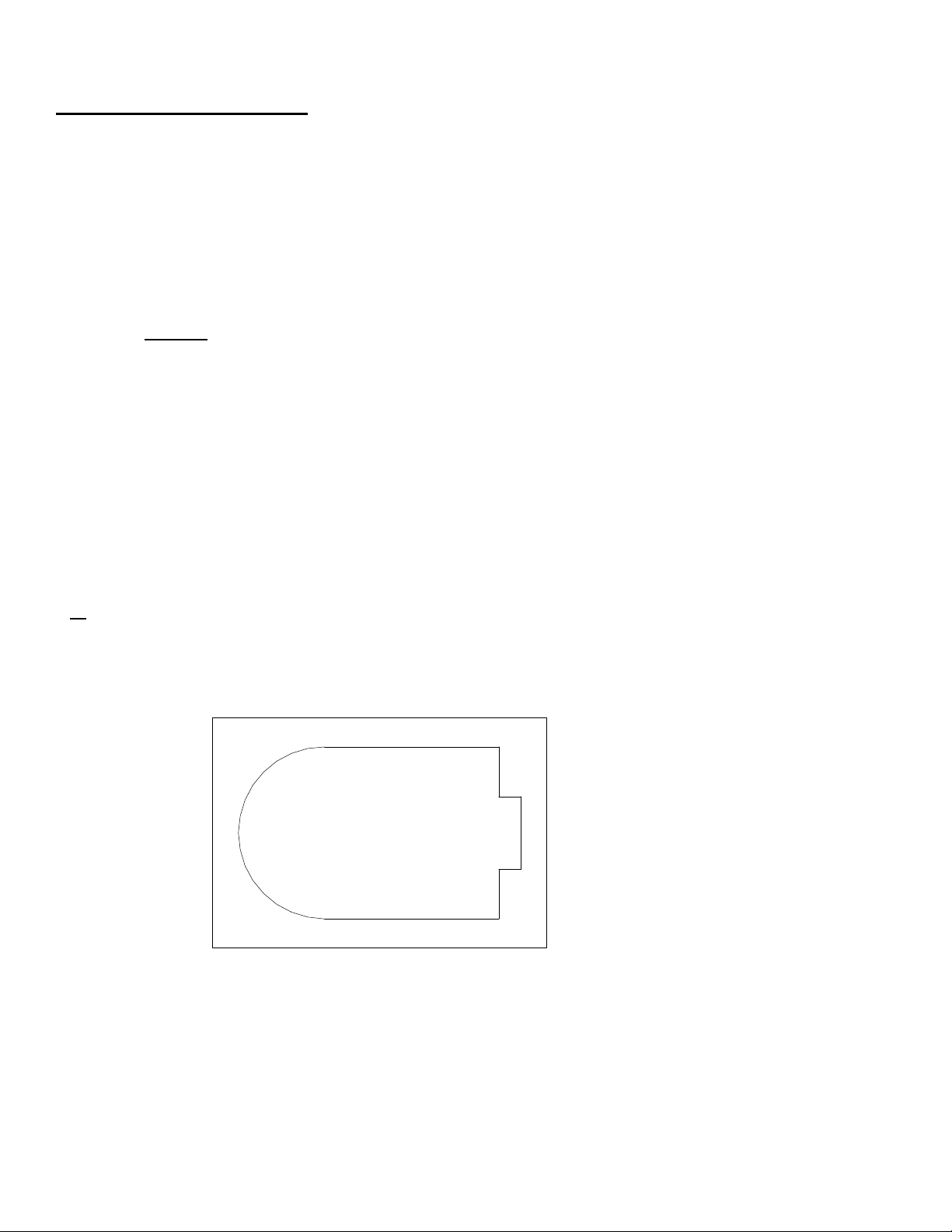

3) Once a monitor location has been determined, there may be prep work required for the headliner.

Some of the steps that may need to be taken depending upon your installation are:

a) Removing the vehicle’s dome light.

b) The headliner MAY have to be cut out per the diagram below.**

c) If the mini-console is being used, it will have to be trimmed to fit the contour of the

headliner. Refer to page 3.

NOTE: steps a-c listed above are not required in all installations….you may have to do

none, some, or all of these steps.

**IF your particular installation will require you to cut out the headliner, the box that this kit came in

can be used as a template. You can remove the shelf that the video monitor rests upon and trace the

opening onto the headliner for cutting.

Figure 1

2

Page 4

General Installation Approach:

B

A & B

1) Before beginning installation please refer to this warning in the manual.

2) Review this manual to become familiar with requirements and hook ups.

3) Decide upon mounting location and method of mounting.

4) Prep the vehicle by removing any interior trim necessary to gain access to vehicle power hook up

point as well as all areas where interconnecting wire harnesses will need to be located. If any

access holes need to be cut into the vehicle (headliner, or other trim components, etc.), this

should be done now as well. Refer to vehicle preparation section of manual.

5) Route all wire harnesses throughout the vehicle as necessary. (Refer to the wiring diagram

section of this manual.) Be sure that all wiring is protected from sharp edges and is routed in such

a manner that it will not be pinched when all components and interior trim are fully installed. Be

sure to leave enough slack in the wiring to allow working room.

6) Remove A/V system components from their packaging and place them loosely in the vehicle at

their respective locations.

7) Connect monitor (electrically) and verify proper operation of all system functions. Note: This is

best done BEFORE, and AFTER monitor has been permanently mounted.

8) After verifying proper operation of the system, proceed with mounting video monitor.

9) When the monitor is mounted, recheck function of the entire system again to ensure that no wiring

was pinched or connected improperly during final installation.

Rear Panel Features Hook Up Procedure

A- Perimeter Screw Bosses – Use these to A – Connect the power harness affix the unit to

various console/ trim to the mating connector on the

bezels. monitor.

B- Mounting Screw Bosses. – Use these B – Connect power harness to to

secure the unit to the roof structure of the vehicle’s electrical system

the vehicle and/or console assembly. by tapping into an accessory

(optional) hot line.

C – Connect to video source

using RCA connector .

D – Verify all functions of the

system before final mounting

of the finished assembly.

Figure 2 Figure 3

A

C

3

Page 5

Roof Structure

Optional Spacers

Screw Boss (ref "B", p3)

3a

3b

Note, If longer

screws are

substituted, care

should be taken to

prevent piercing the

roof, and be sure

that pan head

screws and

washers are used

to prevent screws

from pulling though

the screw boss.

3d

Perimeter Screw Boss (Ref "A", p3)

3c

Cut-Away View of Screw Bosses

Console Flange

Nylon spacers have

been supplied in kit

to place under

mounting screws

and/or screw

bosses. They can

be cut to size as

needed.

Figure 4

Full Size Console Installation:

This page covers special installation considerations for full size, custom console installation.

There are several “full size” custom consoles available for selected vehicles. Some of these vehicles

are the Chevy Suburban, Ford Expedition, and the Dodge Durango. These full size consoles

incorporate several additional features, and are particularly useful if the vehicle you are installing this

system into already has an OEM overhead console in the headliner.

Refer to the installation manual that comes with the console itself for complete installation

instructions. The diagram above shows a detail of the attachment of the console to the video pod.

4

Page 6

Mini Console Installation:

This page only covers special installation considerations for the mini console installation. If the video

monitor is to be installed with a custom full sized overhead console, turn to page 4 now.

If the video monitor is to be installed in a vehicle with the mini console (P/N 1181300), it may need to

be trimmed to fit the vehicle headliner.

1) In this installation, the video monitor is mounted directly to the overhead cross member in the roof

using the mounting screw bosses (item B on page 3). The screw bosses should contact the

crossmember directly (ie: no gap between the screw boss and the roof structure). Also, be sure

that the screws (2b on page 1) do not pierce the outer roof skin when fully fastened into the

crossmember. The mini console is attached to the video monitor using the perimeter screw

bosses (item A on page 3). It is important the screws used in this installation are not

overtightened, and the video monitor and mini console are mounted in such a way the assembly

does not distort (or bend) when the mounting screws are tightened.

2) It is best to mount the video monitor to the roof structure first without the mini console. There

should be a gap between the headliner and outer flange of the video monitor. The mini console

should be cut to fill this gap. Apply masking tape to outer surface of the mini consoe in the areas

where the cut will be made.

3) Mark the cut to be made following the necessary contour of the roof. Suggested method of

marking is as follows:

a) First mark the narrowest point of the mini console on the masking tape. Be carefull to

consider not only vertical location, but fore-aft location.

b) Using handle of a screwwdriver, make a “transfer marking tool” see Fig. 5 below. Place

tool against roof and the marker against the masking tape on the mini console. Trace the

cut to be made around the entire perimeter of the mini console.

c) Cut the mini console with a sharp utility knife or shears. Make cut in several passes over

marked line, each time cutting a little deeper. It is not necessary to cut completely through

plastic, cut need only be 50% of the wall thickness of plastic. The plastic will break cleanly

at the cut by bending back and forth several times.

d) Check the fit of trimmed console and make any minor adjustments necessary.

4) The mini console can be painted or covered with a material that matches the headliner before

assembling the mini console to the video monitor.

5) The finished mini console should be attached to the video monitor, then attach assembly to the

roof. See Fig.

Tape marker to screwdriver starting at

your mark for the lowest point, then

trace the contour of the roof

Lowest Point Mark

Figure 5

5

Cut Line

Headliner

Refer to Fig. 4 for detail on

attaching console to video

monitor and video monitor to

vehicle structure

Page 7

Specifications:

Video Input System: NTSC

Power Input: 12VDC; 850mA Current Draw

Video Input: 1V peak to peak Composite Video; 75Ω

Operating Temperature: 10°C to 60°C

Storage Temperature: -30°C to +80°C

Viewing Area: 6.4” Diagonal Measurement

Display type: Color TFT Active Matrix

Resolution: 640 x 480

Brightness: 300 nit

View Angle Range (left-right): ±60°

View Angle Range (top): 15°

View Angle Range (down): 35°

Contrast Ratio: 120 : 1

*Specifications may change without notice

Warning:

It is unlawful in most jurisdictions for a person to drive a motor vehicle which is equipped with a

television viewer or screen that is located in the motor vehicle at any point forward of the back of the

driver’s seat, or that is visible, directly or indirectly, to the driver while operating the vehicle. This

product should only be installed to the rear of the back of the driver’s seat where it will not be visible,

directly or indirectly, to the operator of the motor vehicle.

6

Page 8

Accessory List:

Description Part Number

AVT-988 9” Color Television with Remote (12V) AVT988

AVT-597 5” Color Television with Remote (12V) AVT597

AVT-1498 13” Color Television with Remote (12V) AVT1498

AVP-7000 Video Cassette Player (12V) AVP7000

AVP-7285 Video Cassette Player (12V) AVP7285

Wireless Headphone Kit: Includes 2 sets Wireless Headphones and Transmitter WRFKIT1

BPA-501-12 4 Amp Adapter for use with AVT-988 9” and

AVT-1498 13” Televisions

AC2A- 2 Amp Adapter for use with AVT-597 5” TV and

AVP-7000 Video Cassette Player

Unified Remote Control 0892325

VAC-21- 12 Volt Corded Vacuum VAC21

AVF-1 12 Volt Rechargeable Flashlight AVF1

HP-175 Headphones with Pivoting Ear Cup HP175

HP-275 Headphones with Volume Control on Cord HP275

HP-375 Studio Quality Headphones HP375

0891412

0891436

Unlike household electronics, all of our products have been specifically designed and tested for the

mobile environment and are only available through ASA. To order any of these products, please

contact Audiovox Specialized Applications at www.asaelectronics.com or 800-688-3135.

23319 Cooper Dr.

Elkhart, IN 46514

Manual P/N 8010770

Rev. D 12/00

Loading...

Loading...