Page 1

Model APS 750a

Installation Manual

4 Channel Remote Car Starter

With Full Feature Alarm System

Installation Instructions

This Unit Is Intended For Installation In Vehicles With

12 V olt Negative Ground Electrical Systems,

Gasoline Engines, AndAutomatic Transmissions Only.

Kit Contents:

APS-750a Control Module

(2) - Three Button Anti Code Grabbing Transmitters

4 Channel Code Learning Receiver

On Board Extended Range Antenna

Six Tone Multi Tone Siren

(1) - Multi Pin Input/Output Harness

(1) - Six Pin Power Harness

(1) - Four Pin Auxiliary Output Harness

(1) - Two Pin LED Indicator

(1) - Two Pin Valet / Programming Switch

(1) - Two Pin Control Switch

(1) - Four Pin Shock Sensor Harness

(1) - Two Pin Door Lock Harness

(1) - Dual Stage Shock Sensor

(1) - Starter Inhibit Relay and Socket

(2) - 30 Amp In-line Fuse Holders With Fuses

(1) - Pin Switch Hardware Bag

(2) - Under Hood Caution Labels

(1) - Installation Manual

(1) - Operator's Manual

(1) - Limited Warranty

(2) - Window Decals

Page 2

The APS-750a Remote Start/Alarm System is designed to be used with Automatic Transmission Vehicles Only! The unit provides no output for glow plug pre-heat and may not be desirable for diesel

vehicles. If the diesel engine has a instant fire, (no glow plug pre-heat system), a tach signal input, and

an Automatic Transmission, this unit may be used. For diesel applications, consult your dealer for the

type of ignition system in your particular vehicle.

INSTALLATION OF THE MAJOR COMPONENTS:

CONTROL MODULE:

Select a mounting location inside the passenger compartment (up behind the dashboard). The mounting

location selected must be within 24" of the ignition switch wiring harness to allow connection of the 6 pin

main wiring harness.

Be certain that the chosen location will not interfere with proper operation of the vehicle. Avoid mounting

the module to or routing the wiring around the steering shaft/column, as the module or wiring may wrap

around or block the steering wheel preventing proper control of the vehicle. Secure the module in the

chosen location using cable ties or screws as necessary.

Do Not Mount The Module In The Engine Compartment, as it is not waterproof.

SIREN:

Select a location in the engine compartment that is not accessible from below the vehicle. The selected

location must be clear of hot or moving parts within the engine compartment The siren must be pointed

downward to prevent water retention and the flared end must be pointed away from and out of the engine

compartment for maximum sound distribution. Before securing the siren, check behind your chosen

location to assure that the mounting screws will not penetrate any factory wiring or fluid lines. Secure the

siren mounting bracket using #8 self taping screws or by first using the mounting bracket as a template,

scribe or mark the three bracket mounting holes. Drill the three marked holes using a 1/8" drill bit, than

mount the siren using #8 sheet metal screws.

HOOD AND TRUNK PIN SWITCHES:

The pin switches included in this package are intended for protecting the hood and trunk areas of the

vehicle. In all cases, the switch must be mounted to a grounded metal surface. When the pin switch is

activated, (hood/trunk open), it will supply a ground to the input wire activating the alarm. In addition, the

hood switch is required for the safety shut down of the remote start unit. If the vehicle is being worked on,

this hood switch prevents the remote start activation even if the RF command to start is issued. This

switch must be installed in all applications Failure to do so may result in personal injury or property

damage. Mount the switches in the hood and trunk locations away from water drain paths. If necessary,

the included brackets may be used to move the switch away from rain gutters or allow mounting to the

firewall behind the hood seal. In both cases the switch must be set up to allow the hood or trunk door to

depress the switch at least 1/4 inch when the hood or trunk is closed and fully extended when the hood

or trunk is opened. For direct mounting, a 1/4 inch hole must be drilled. Carefully check behind the

chosen location to insure the drill will not penetrate any existing factory wiring or fluid lines. Drill a 1/4"

hole in the desired location and thread the pin switch into it using a 7/16" nut driver or deep well socket.

If using the mounting bracket, first secure the bracket to the desired location and secure the pin switch in

the pre-threaded mounting bracket hole.

DASH MOUNTED L.E.D.:

The small Red LED included in the kit will serve as a visual indicator of the alarm's status and provide a

visual deterrent to a potential thief. The LED also provides important feed back information during the

transmitter and feature program modes. The LED should be installed in the dash in an area highly visible

so that it may be seen from the driver's seat as well as from outside the vehicle. Inspect behind the

chosen location to insure that the drill will not penetrate any existing factory wiring or fluid lines. Carefully

drill a 1/4" hole in the desired location and pass theconnector end of the LED through the hole and toward

the control module. Press the LED firmly into place until it is fully seated in the mounting hole.

2

Page 3

THE RANGE EXTENDER ANTENNA:

The range extender antenna provided with this unit allows routing from below the dash board for maximum

operating range. Choose a location above the belt line (dashboard) of the vehicle for best reception.

Special considerations must be made for windshield glass as some newer vehicles utilize a metallic

shielded window glass that will inhibit or restrict RF reception. In these vehicles, route the exposed, (non

shielded) end toward a rear window location for best reception. Secure the exposed end with double stick

tape or instant stick glue. After securing the exposed end of the antenna with the tape or glue, we advise

also securing a section of the antenna cable to a fixed support. This will prevent the antenna from

dropping down in case the double stick tape is exposed to extreme heat which may loosen it's gummed

surface.

VALET/PROGRAM/MANUAL OVERRIDE SWITCH :

Select a mounting location that is easily accessible to the operator of the vehicle. It is not necessary to

conceal the switch however concealment is recommended as it offers a higher level of security. The

switch can be mounted to the lower dash panel in the drivers area. Inspect behind the chosen location to

insure that adequate clearance is allowed for the body of the switch, and also that the drill will not

penetrate any existing factory wiring or fluid lines. Drill a 1/4" hole in the desired location and mount the

switch by passing it through the panel from the underside. Secure the switch using the nut, star washer,

and on/off face plate. It is suggested that the switch be oriented to allow the on position to be up toward

the driver and the off position to be down or away from the driver. Route the switch's connector toward the

control module.

CONTROL SWITCH:

Select a mounting location known and accessible to the operator of the vehicle. A lower dash panel, kick

panel, or glove box is desirable. Inspect behind the chosen location to insure that adequate clearance is

allowed for the body of the switch, and also that the drill will not penetrate any existing factory wiring or

fluid lines. Drill a 1/4" hole in the desired location and mount the switch by passing it through the panel

from the underside. Secure the switch using the nut, star washer, and on/off face plate. It is suggested

that the switch be oriented to allow the on position to be up toward the driver and the off position to be

down or away from the driver. Route the switch's connector toward the control module. Place the RED

rubber boot, included in the kit, over the switch handle to differentiate this switch from the valet/program

switch.

SHOCK SENSOR:

Select a centrally located, solid mounting surface for the shock sensor that will allow consistent operation

from all areas of the vehicle. The selected location must be within 18" of the control module to allow

routing and connecting of the 4 pin harness. Secure the shock sensor to the chosen location using two

#8 self taping sheet metal screws. The sensor can also be secured to an existing dash brace using cable

tie straps. Whichever mounting method is used be sure to allow access to the sensitivity adjustment

potentiometer for use later in the installation.

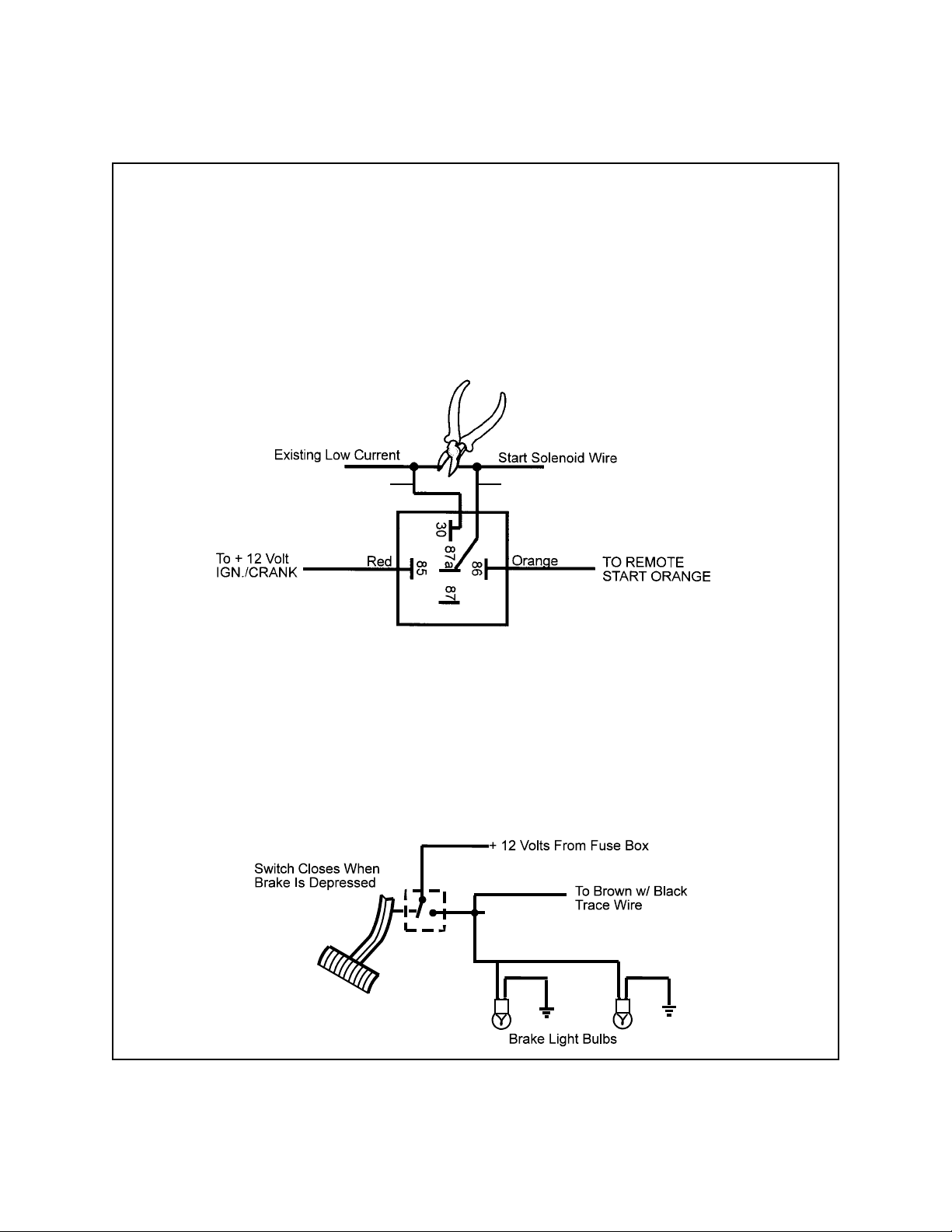

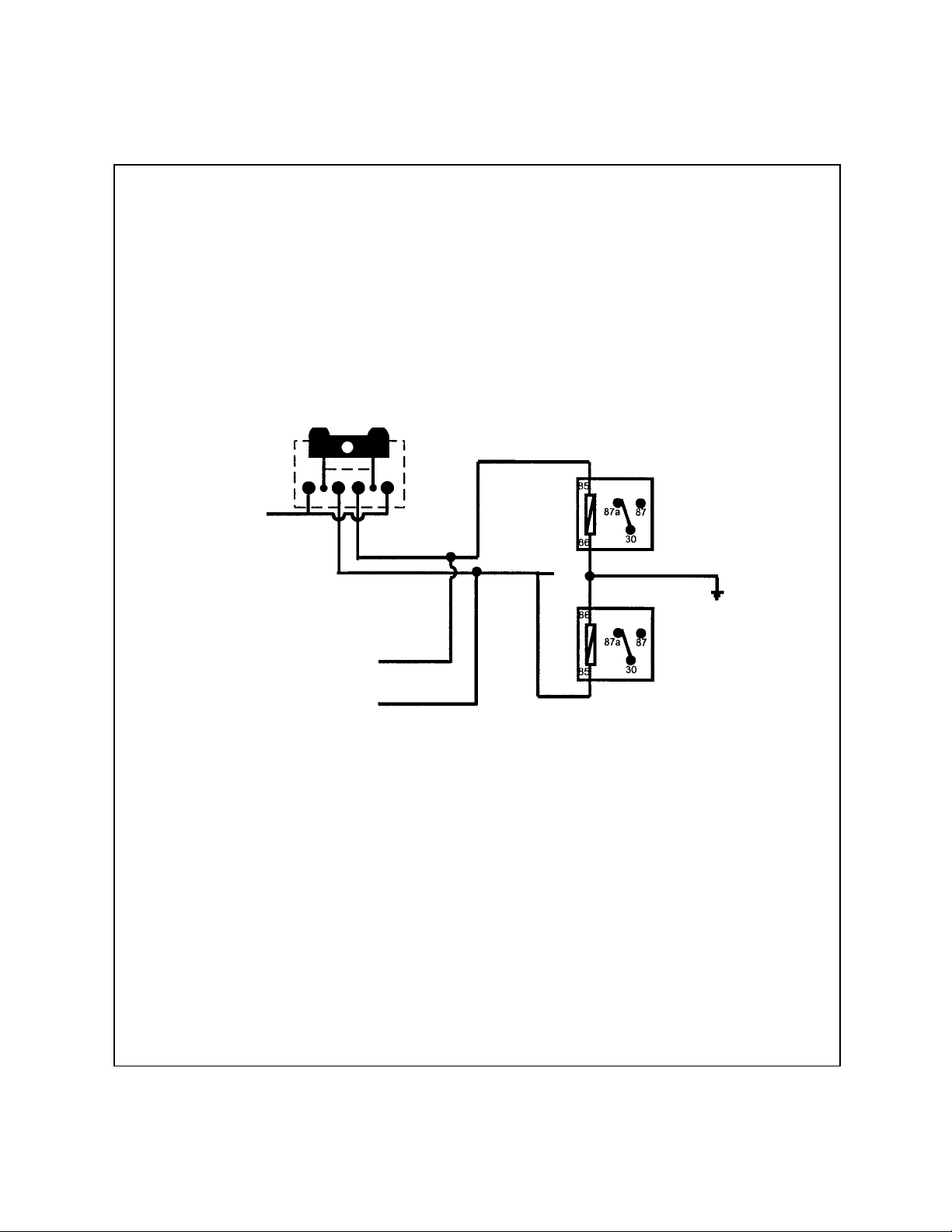

ST ARTERINHIBIT RELAY :

Select a mounting location within 12" of the ignition switch's low current start solenoid wire. Secure the

relay to an existing harness in the chosen location using a cable tie around the relay's wiring harness.

Caution! Do not wire tie the metal bracket to an existing wiring harness as vibration may cause chaffing

and shorting damaging the factory wiring. If an existing harness is not available then secure the relay's

metal mounting tab to an under dash metal brace with a #8 self taping sheet metal screw. Wire the relay

as per the diagram found later in this manual.

3

Page 4

The APS-750a is to be used in vehicles with AUTOMATIC TRANSMISSIONS only! Although this combi-

nation Alarm/Remote Start unit is a sophisticated system with many advanced features, IT MUST NOT

be installed into a vehicle with a manual operated transmission. Doing so may result in serious personal

injury and property damage.

IMPORT ANT!

DO NOTPLUG THE SIX PIN MAIN POWER HARNESS OR THE MUL TIPIN INPUT/ OUTPUTHARNESS

INTO THE CONTROL MODULE UNTIL ALL CONNECTIONS TO THE VEHICLE HAVE BEEN MADE.

AFTER SELECTING YOUR TARGET WIRES AS DEFINED BELOW, DISCONNECT THE NEGATIVE

BA TTERY CABLE FROM THE VEHICLE BATTERYPRIOR T O MAKING ANY CONNECTIONS.

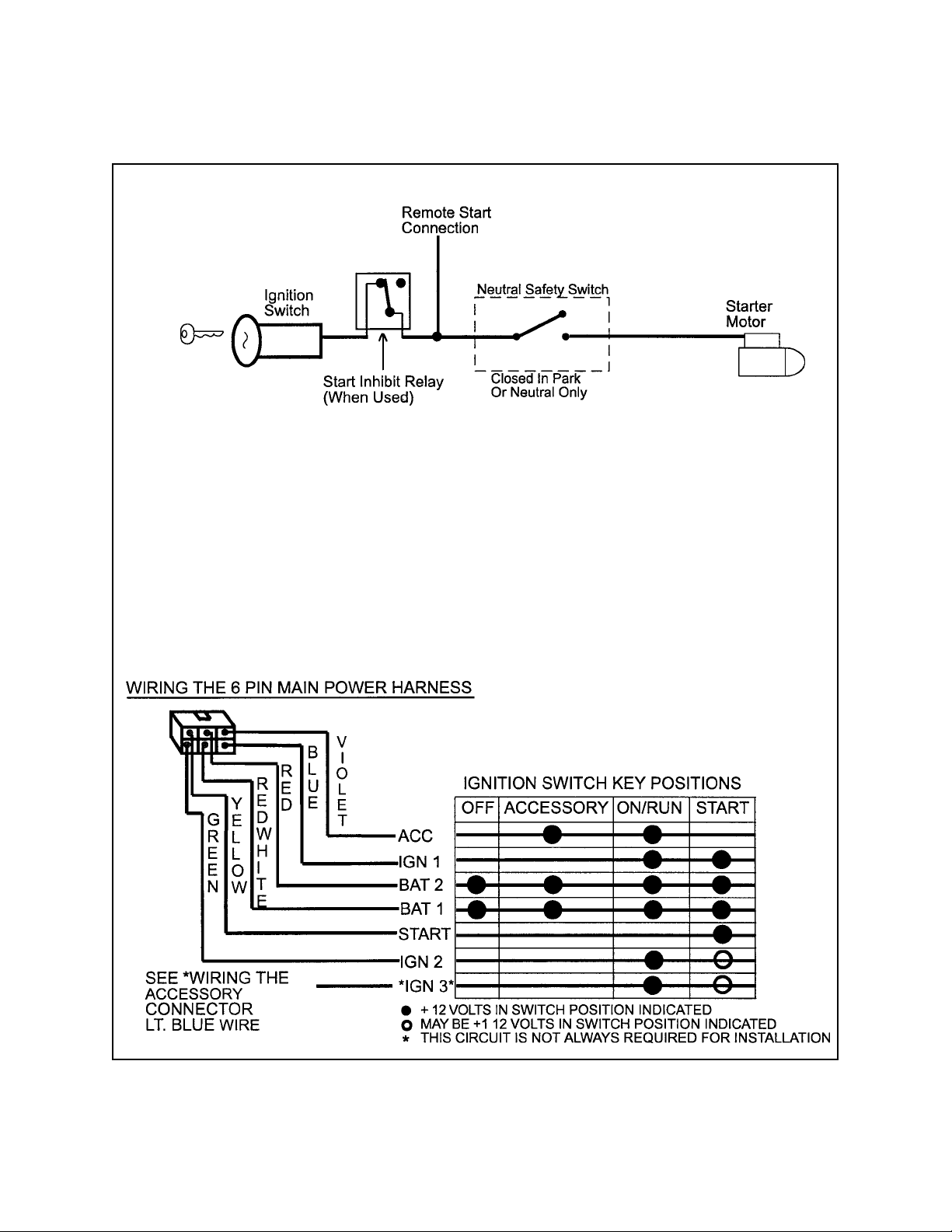

WIRING THE 6 PIN MAIN POWER HARNESS:

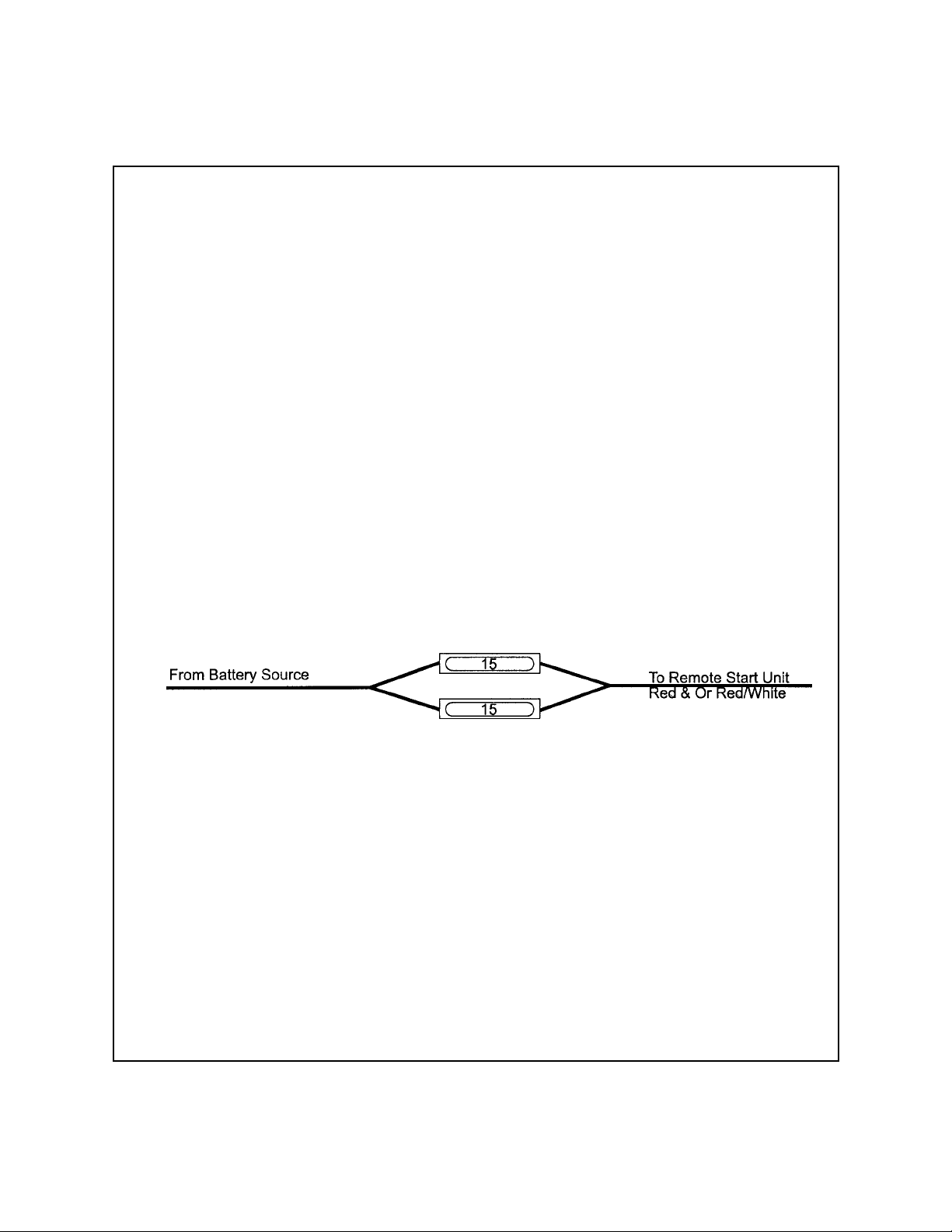

RED w/ WHITE Trace Wire: + 12 volts Battery 1 Source

Connect this wire toa+12VDCconstant source found at the vehicle's ignition switch using the 30 Amp

fuse and holder provided.

RED Wire: + 12 Volts Battery 2 Source

Connect this wire toa+12VDCconstant source found at the vehicle's ignition switch using the 30 Amp

fuse and holder provided, but NOT the same vehicle wire as used by the battery 1 source. Most vehicles

have more than one battery source supplying power to the ignition switch. Separate feed wires must be

used for the Red and Red/White wires. If your vehicle does not have two battery feed wires at the ignition

switch then it is possible to connect both wires to the vehicle's battery.

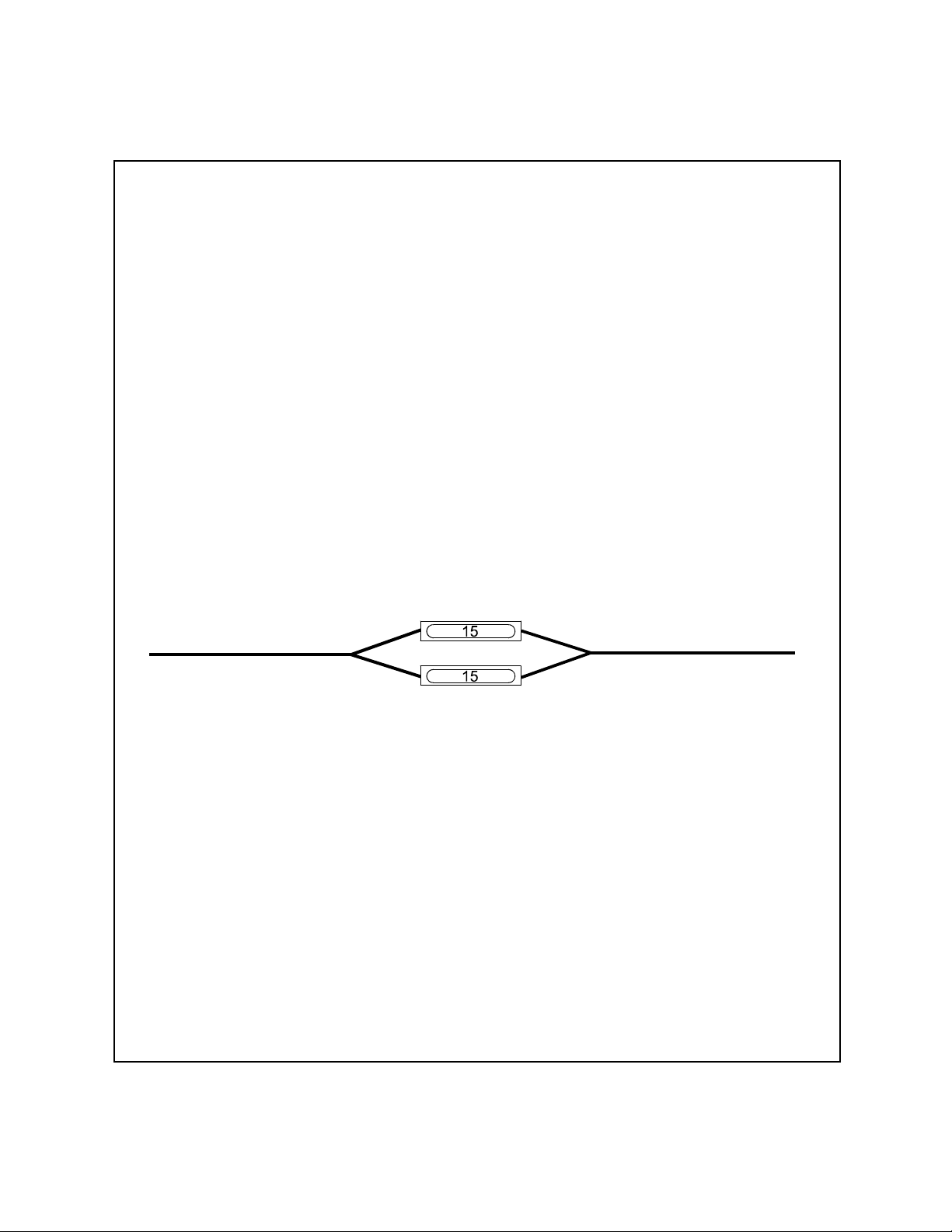

IMPORT ANT!

It is the responsibility of the installing technician to determine the load factor of the vehicles electrical

circuits when the vehicle is running and to adequately fuse the two power wires based on that load. If the

vehicle, running under load with the air conditioned, heater blower motor, and accessories exceed 24

Amps continuous, we recommend that two fuses be used in combination on each power wire as shown

below. For additional information seeTech Update issued 9/30/96.

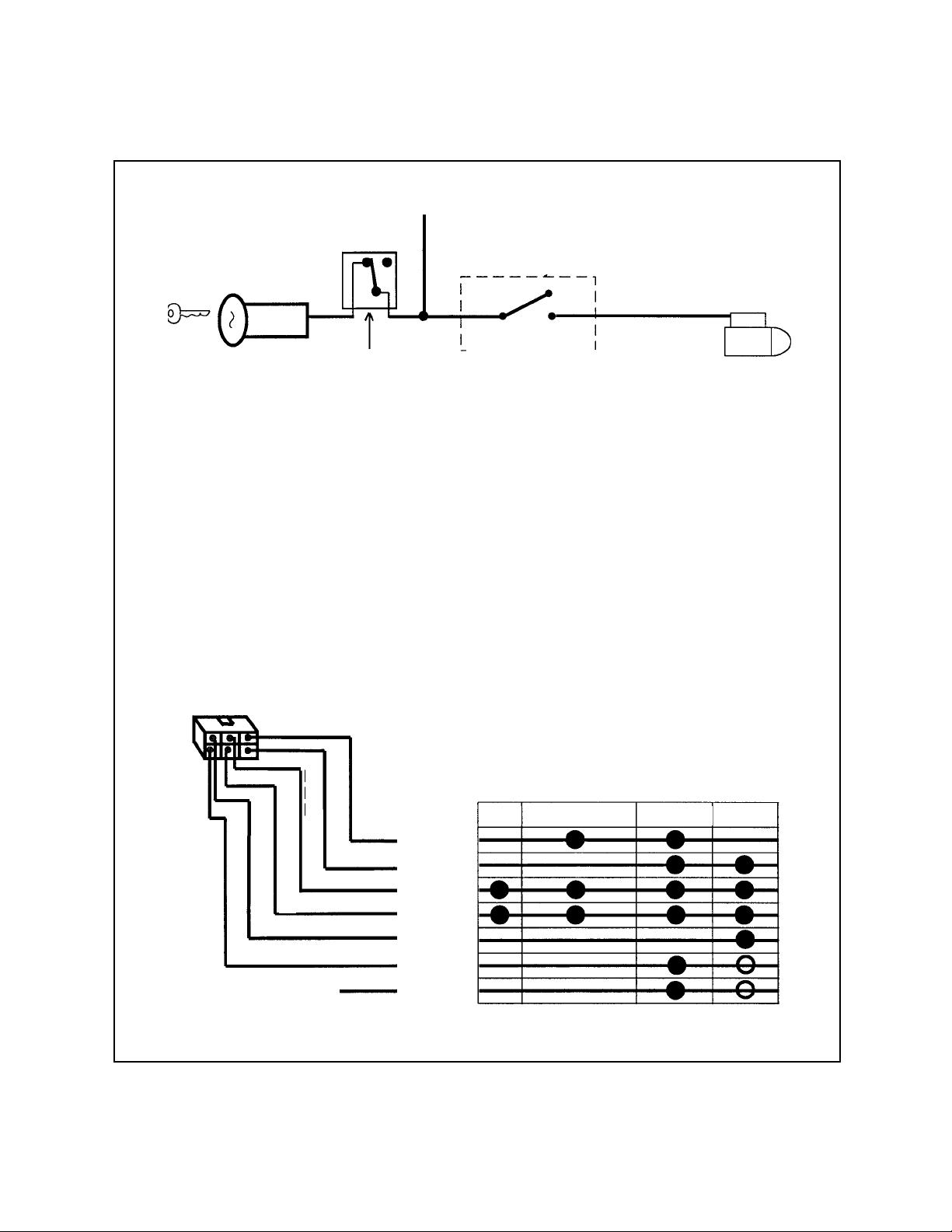

YELLOW Wire: Starter Output

Careful consideration for the connection of this wire must be made to prevent the vehicle from

starting while in gear. Understanding the difference between a mechanical and an electrical

Neutral Start Switch will allow you to properly identify the circuit and select the correct installation method. In addition you will realize why the connection of the safety wire is required for

all mechanical switch configurations.

Failure to make this connection properly can result in personal injury and property damage.

In all installations it is the responsibility of the installing technician to test the remote start unit and assure

that the vehicle cannot start via RF control in any gear selection other than park or neutral.

In both mechanical and electrical neutral start switch configurations, the connection of the Yellow wire will

be made to the low current start solenoid wire of the ignition switch harness. This wire will have +12 volts

when the ignition switch is turned to the start (crank) position only. This wire will have 0 volts in all other

ignition switch positions.

NOTE: This wire must be connected to the vehicle side of the starter cut relay (when used). For the

electrical neutral switch configuration, this connection must be made between the starter inhibit relay,

( when used ) and the neutral safety switch as shown in the following diagram.

Failure to connect this wire to the ignition switch side of the of the neutral safety switch can result in

personal injury and property damage.

SEE NEUTRALSTART SAFETY TEST FOR FURTHER DET AILS.

4

Page 5

YELLOW START WIRE DETAIL

BLUE Wire: Ignition 1 Output

Connect this wire to the ignition 1 wire from the ignition switch. This wire will show +12 volts when the

ignition key is turned to the to the "ON" or "RUN" and the "START" or CRANK" positions, and will have 0

volts when the key is turned to the "OFF" and "ACCESSORY" positions.

GREEN Wire: Ignition 2 Output

Connect this wire to the ignition 2 wire from the ignition switch. This wire will show + 12 volts when the

ignition key is turned to the "ON" or "RUN" position and is some cases the "STAR T"or CRANK" position.

This wire will show 0 volts when the key is turned to the "OFF" and "ACCESSORY" positions.

VIOLET Wire: Accessory Output

Connect this wire to the Accessory wire from the ignition switch. This wire will show + 12 volts when the

ignition switch is turned to the "ACCESSORY" or "ON" and "RUN" positions, and will show 0 volts when

the key is turned to the "OFF" and "START" or "CRANK" positions.

5

Page 6

WIRING CONNECTIONS: Multi Pin Accessory Input/Output Harness

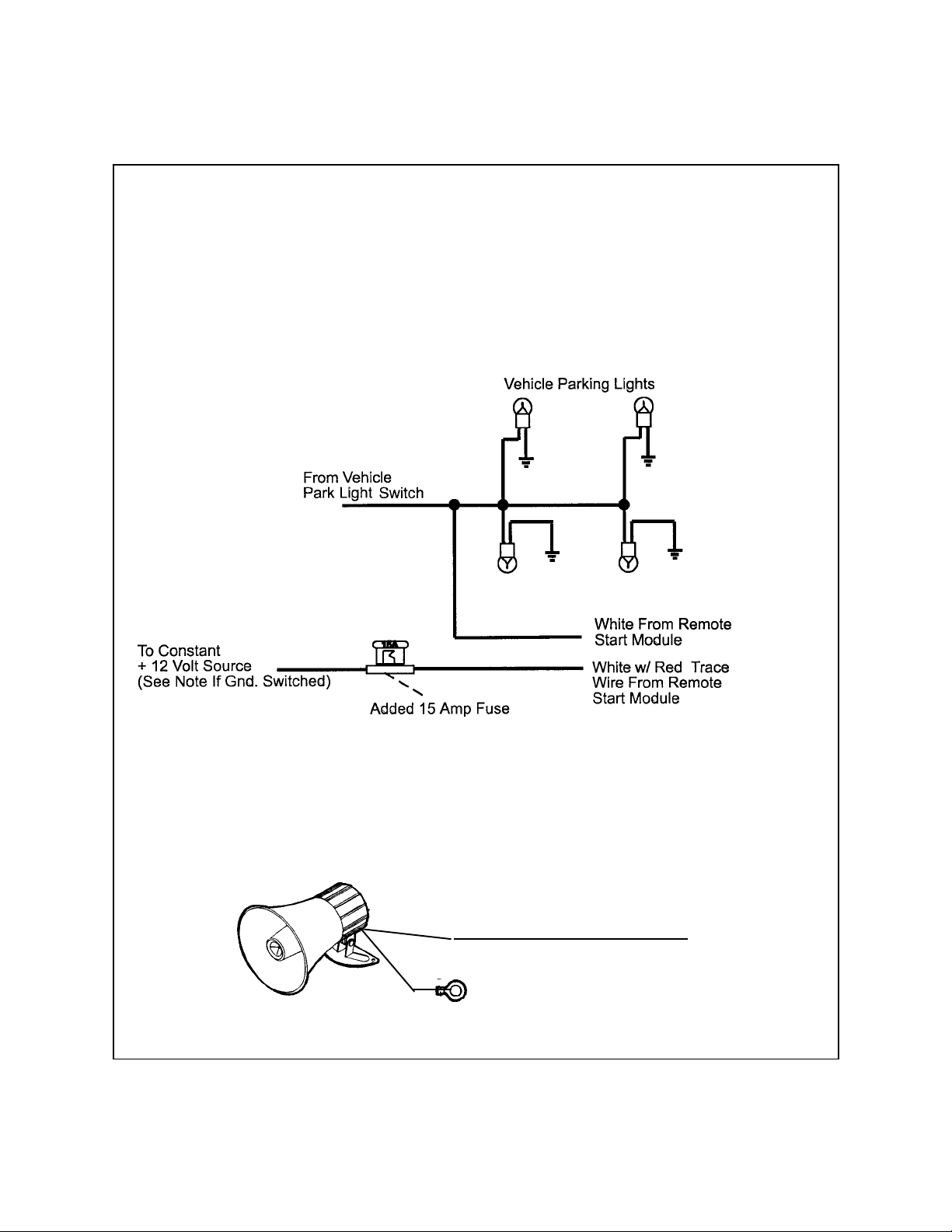

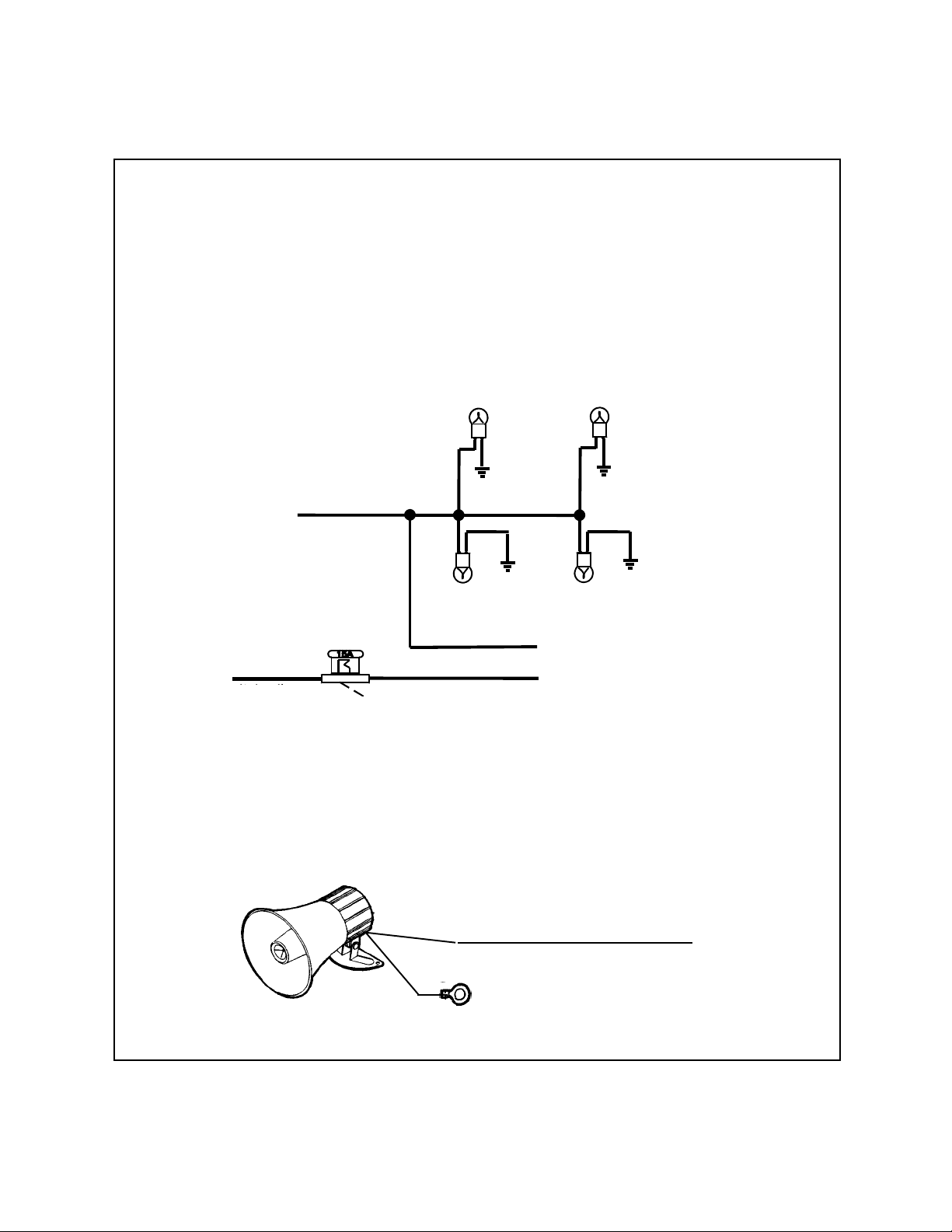

White w/ Red Trace Wire: Parking Light Flasher Feed

This wire is the common contact of the on board parking light flasher relay. If the vehicle you are working

on has +12 volt switched parking lights, connect this wire to a fused + 12 volt source. (Max. 15 Amps)

NOTE: If the vehicle's parking lights are ground switched, connect this wire to chassis ground.

White Wire: Parking Light Flasher Output

This wire is the normally open contact of the on board parking light flasher relay. Connect this wire to the

vehicle parking light feed wire. See diagram below for details on wiring positive switched parking light

circuits.

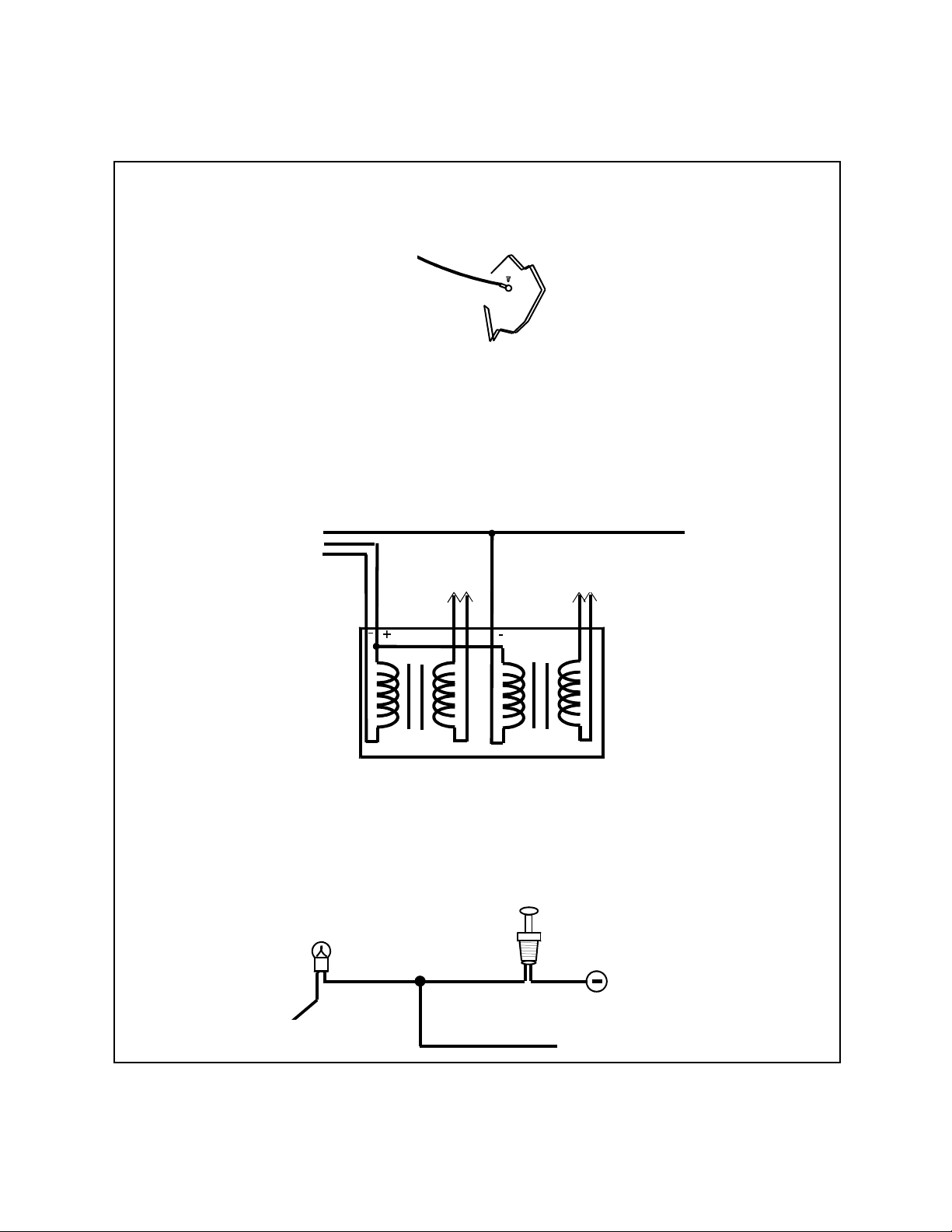

Parking Light Wiring Detail

White w/ Black Trace Wire: (+) Siren Output

This is the positive siren feed wire. Route this wire through a grommet in the firewall to the siren

location. Connect the White w/ Black Trace wire to the Red wire of the Siren. Secure the Black wire

of the Siren to a known chassis ground or solid clean metal surface.

Siren Wiring Detail

SIREN

BLACK

RED

TO WHITE w/BLACK WIRE OF MODULE

(-) TO VEHICLE'S CHASSIS GROUND

6

Page 7

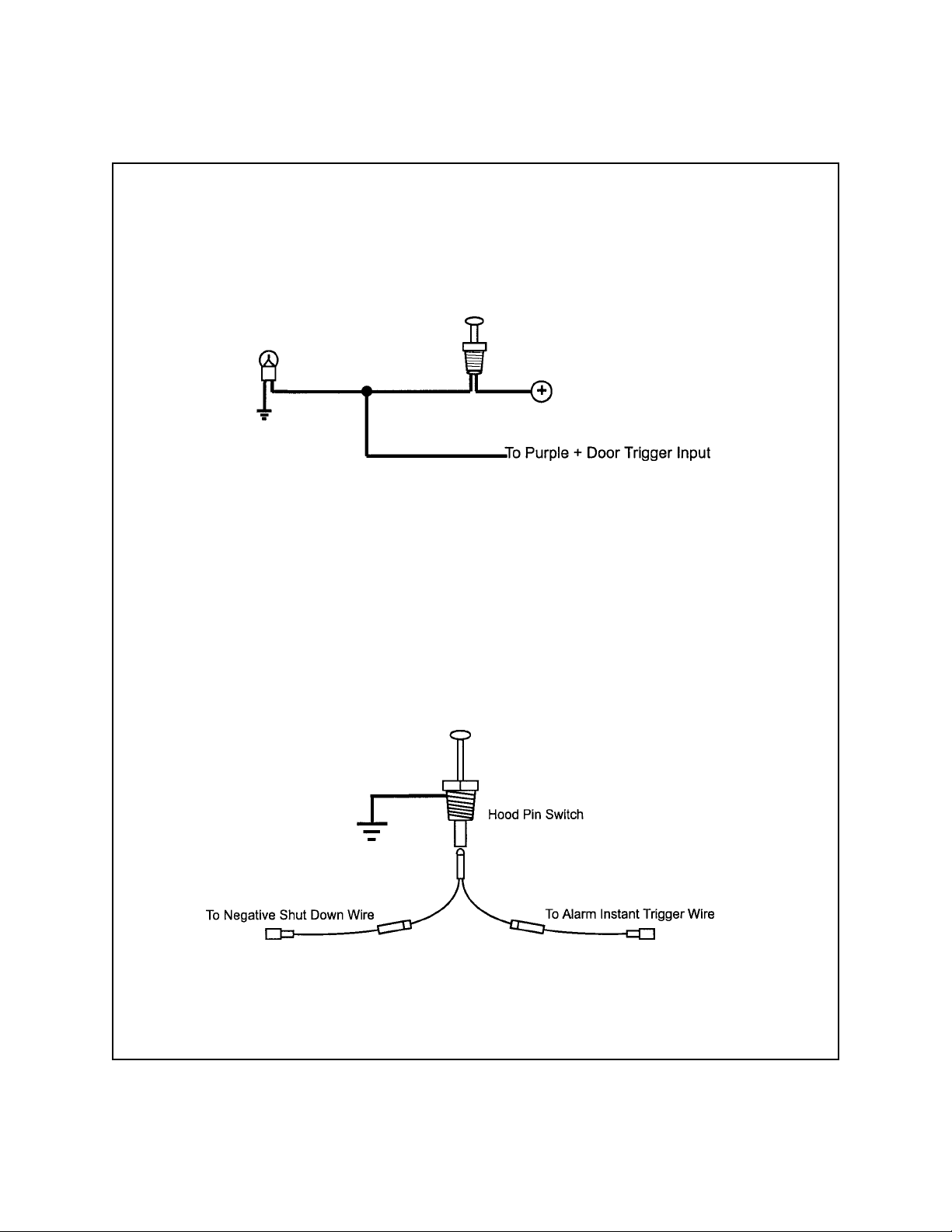

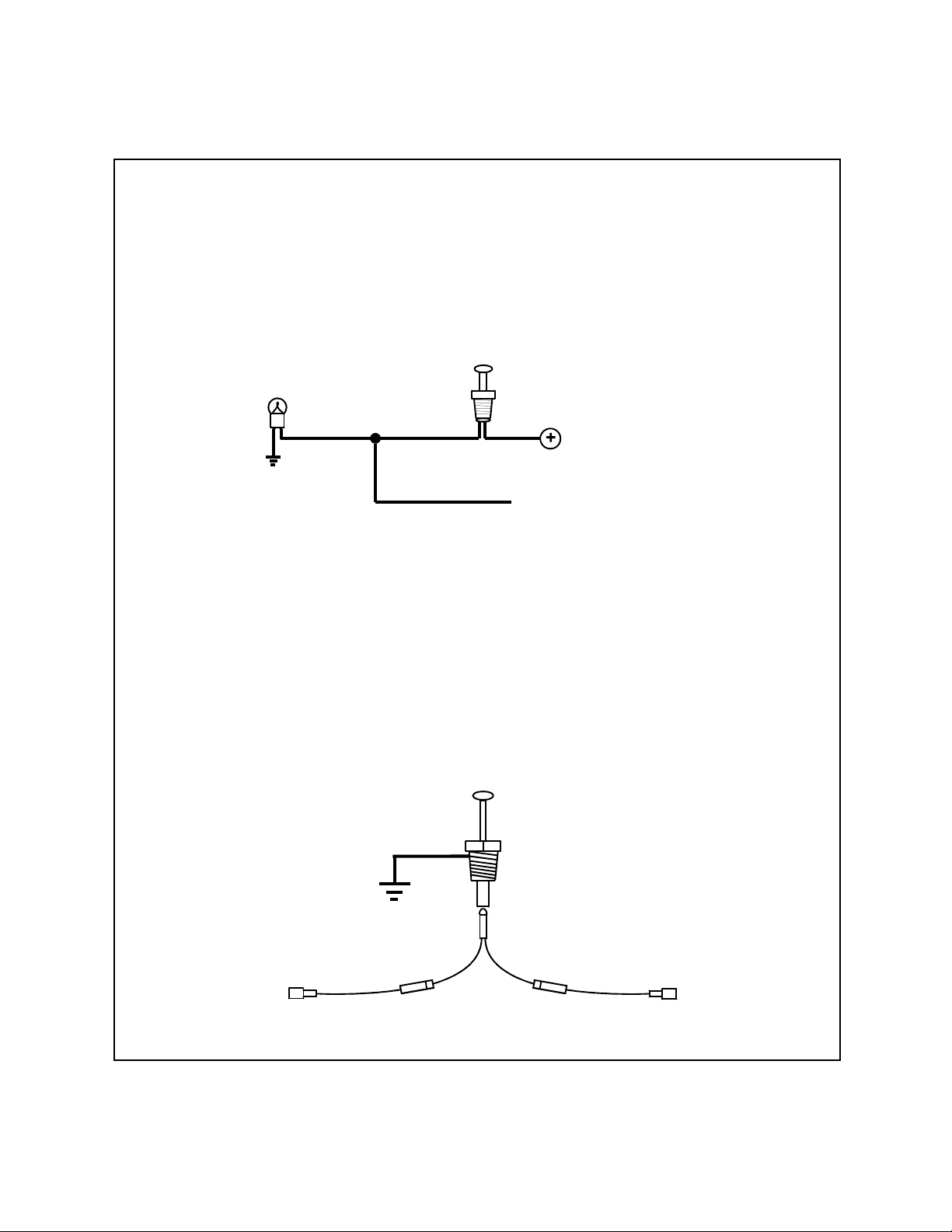

Purple Wire: (+) Door Trigger Input

If the vehicle's door courtesy light switches + 12 volts when the door is opened, (Most Fords and some

Imports), you must connect this wire to the positive output from one of the vehicle's door pin switches. In

most cases, the Purple wire will need to be connected to only one door switch no matter how many doors

the vehicle has as most door lighting circuits are wired in parallel. See below for wiring details.

Positive Door Switch Wiring Detail

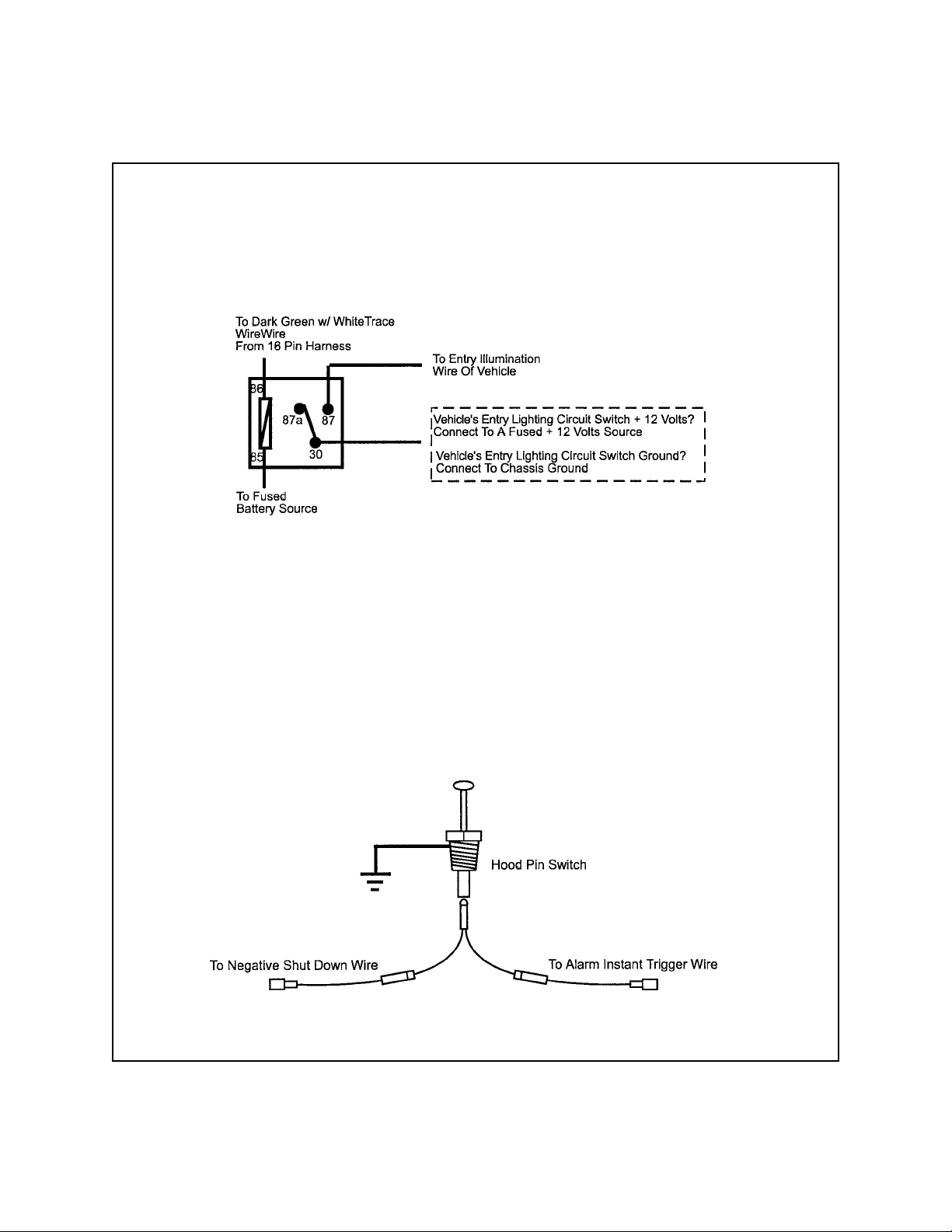

Dark Green Wire: (-) Instant Trigger Input

This is the instant on ground trigger input wire. This wire must be connected to the hood and trunk pin

switches previously installed.

Note: This wire will be shunted when remote control channel 2 is accessed, (trunk release). This wire will

remain shunted all the while there is ground present and for 5 seconds after the ground is removed. This

allows the operator to open the trunk via the remote transmitter without having to first disarm the alarm

system. See below for wiring detail.

Hood Pin Switch Detail

7

Page 8

Light Blue Wire: Ignition 3 Output

This wire provides a 300mA ground output that becomes active 3 seconds before the Remote Start Unit

initializes, and remains grounded while running plus an additional 4 seconds after the Remote Start Unit

turns off. In all of the applications described below, a relay will be required.

The Light Blue wire can be used to accommodate the following situations:

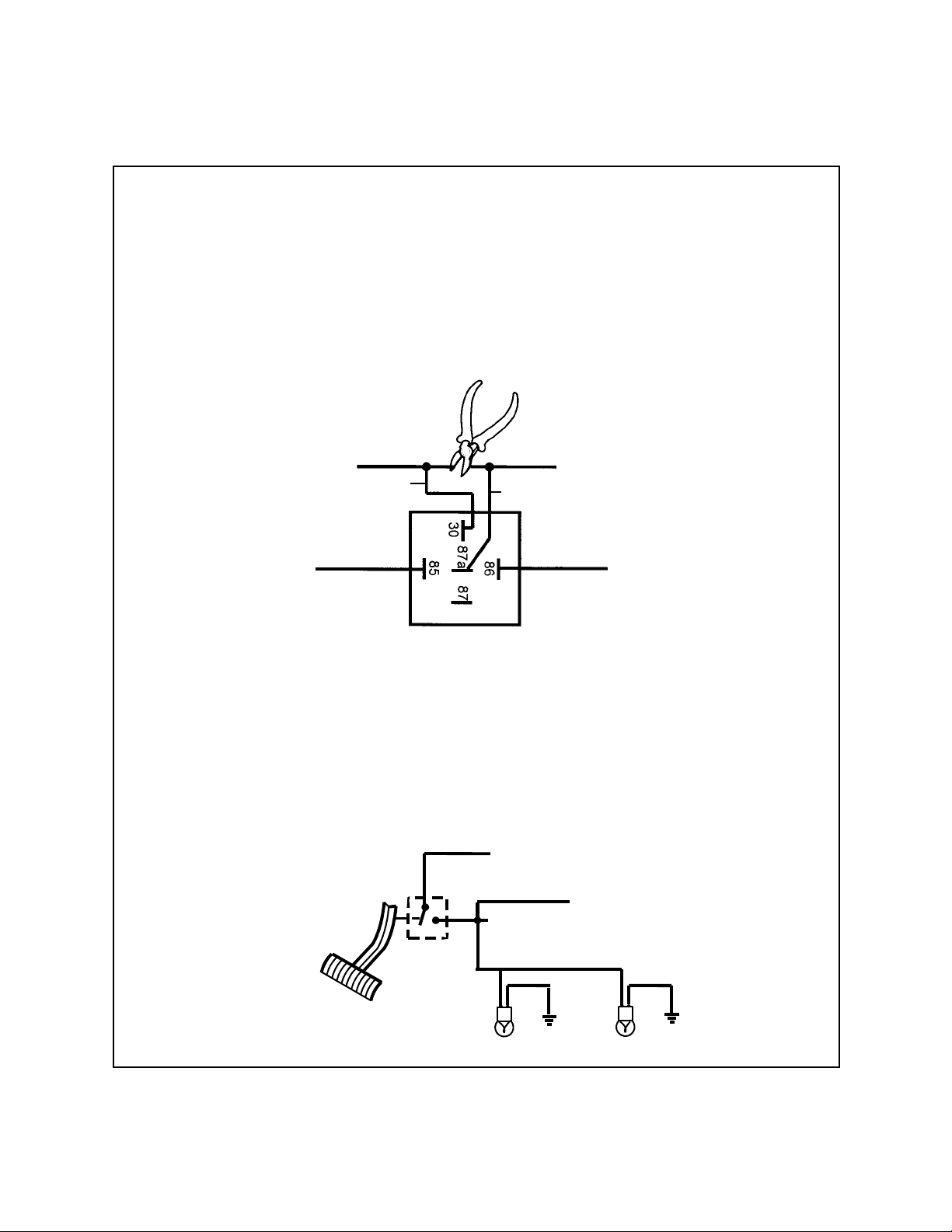

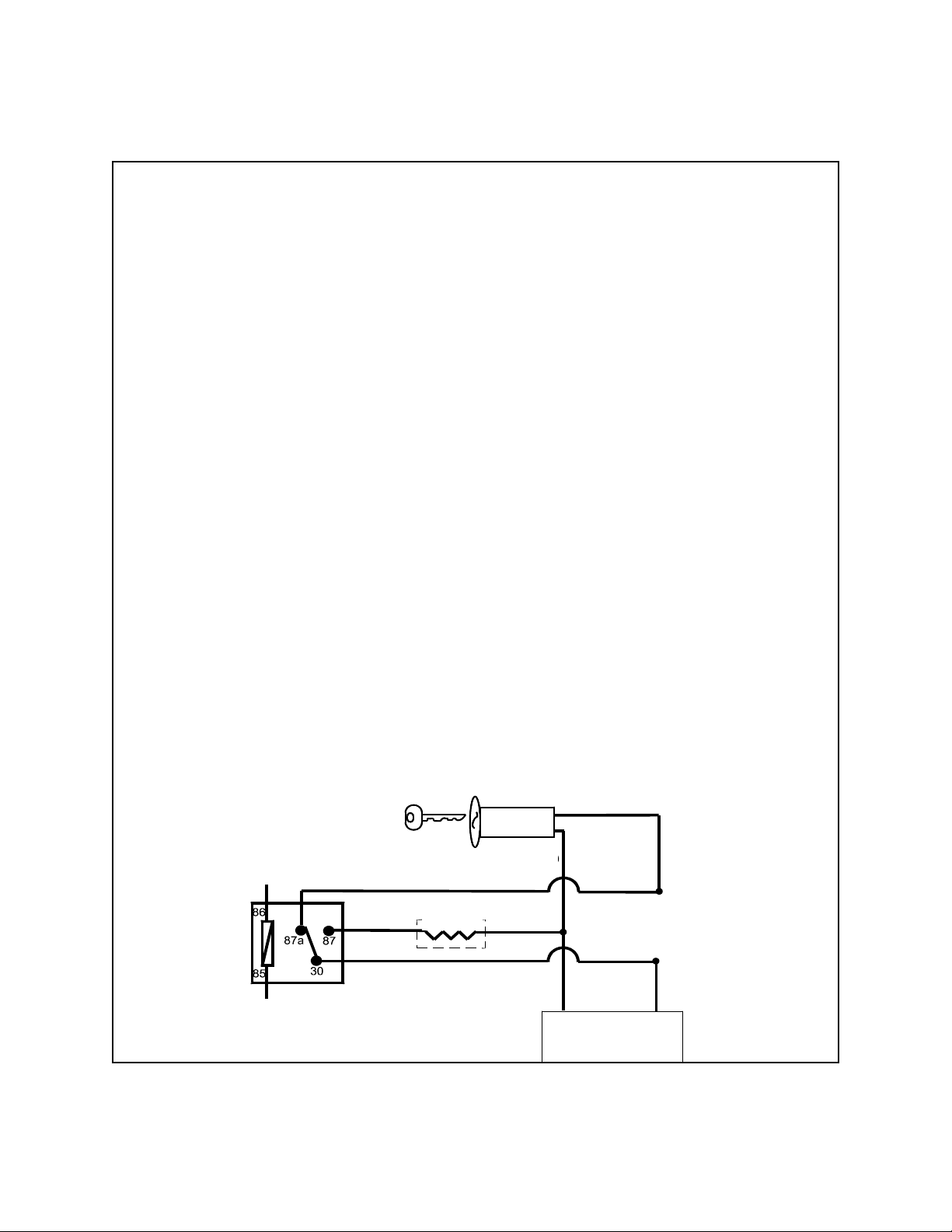

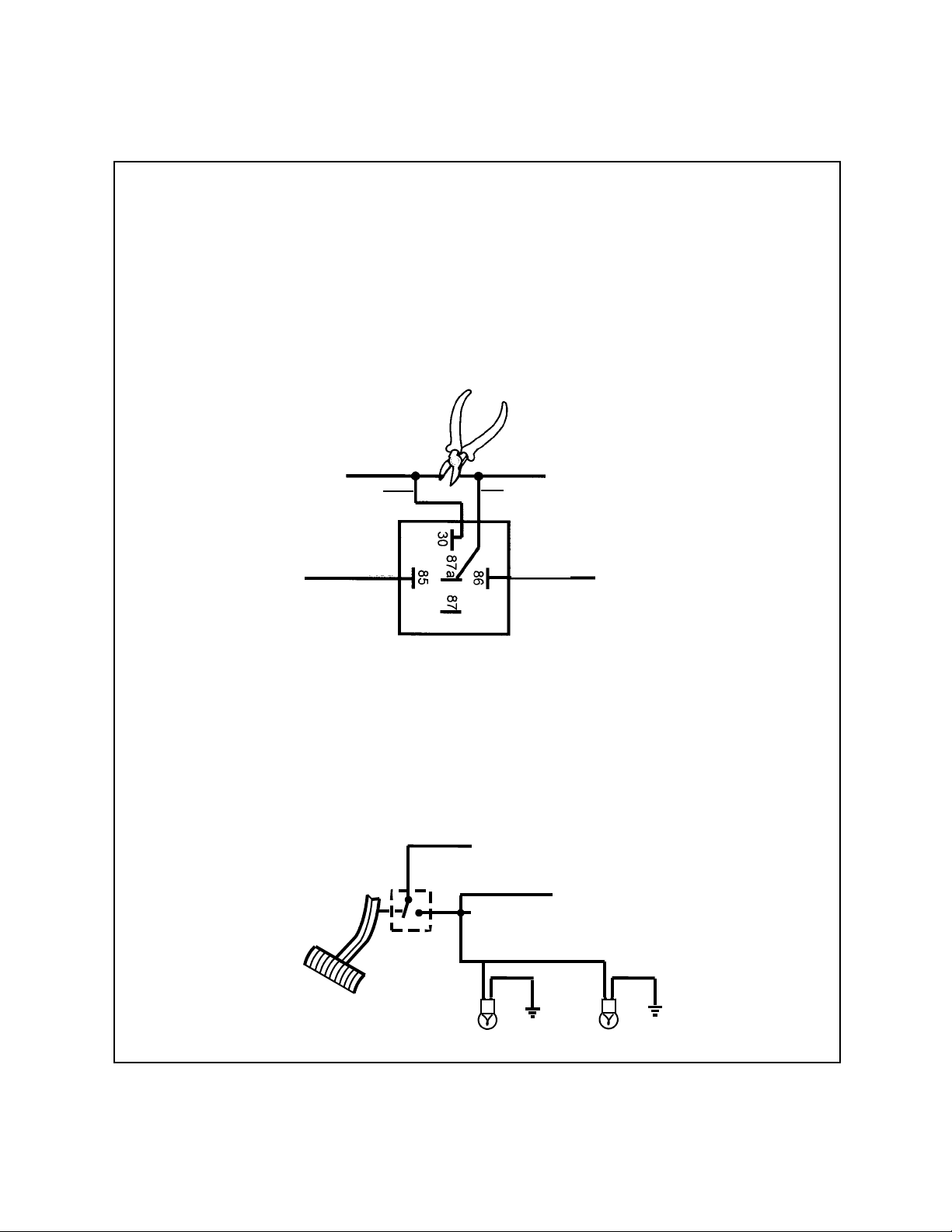

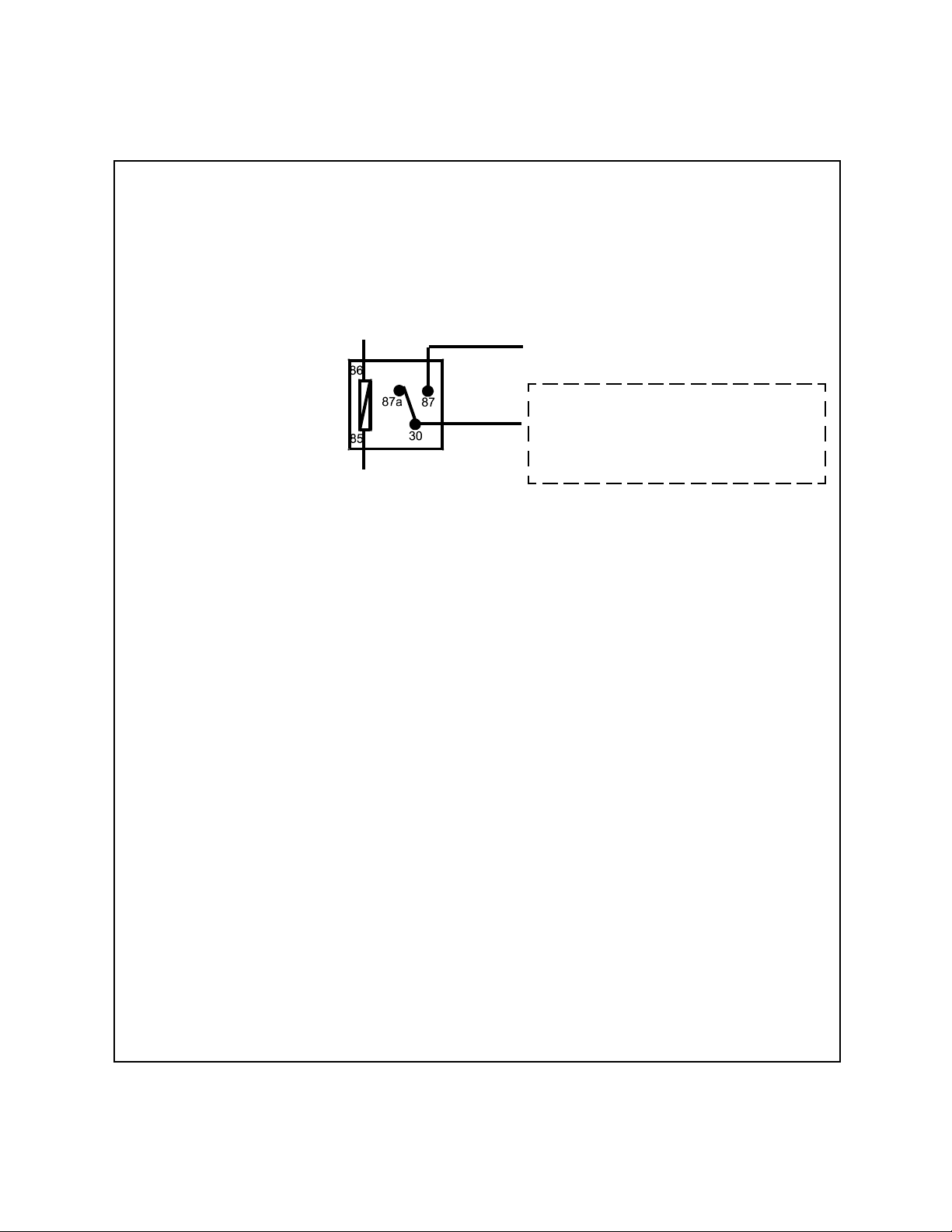

A. Shock Sensor By Pass:

If there is a Non Plug in Shock Sensor used with the alarm system and it is not shunted during the

Remote Start activation period, then vibration from the running vehicle can cause the alarm totrigger. In

this case, connect the Light Blue Wire to terminal #86 of a external relay. Connect terminal# 85 of the

relay to a fused + 12 volt battery source. Cut the shock sensor trigger wire and connect one end of the

cut wire to terminal #30 and the other end of the cut wire to terminal #87a. Just before the Remote Start

unit is activated, the relay contacts will open, preventing the shock sensor's operation until the Remote

Start unit shuts off.

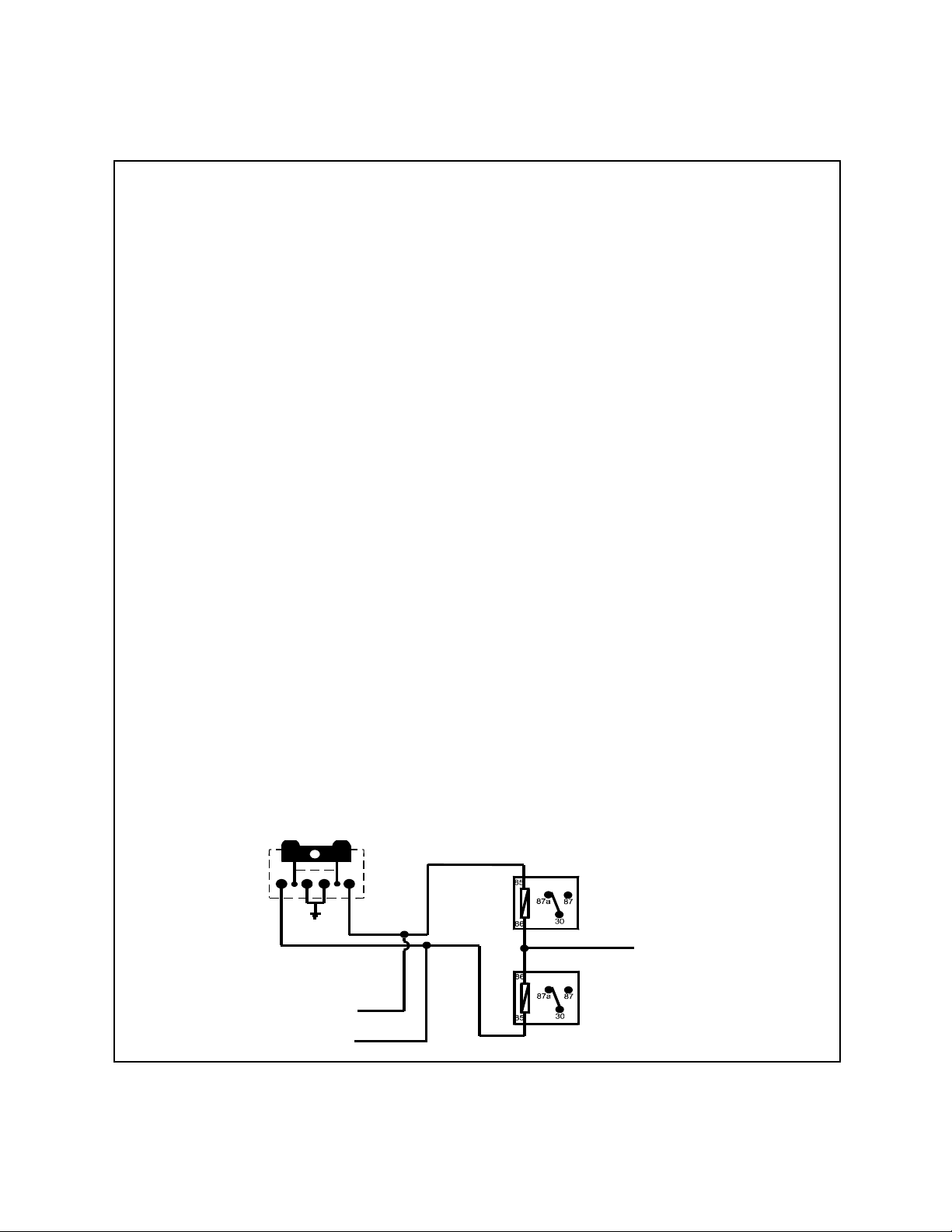

B. Ignition 3 Output:

Some newer vehicles use a third ignition wire which is required to start and keep the vehicle's engine

running. If this is the case, connect the Light Blue wire to terminal #86 of an external relay. Connect

terminal # 30Utoafused + 12 volt battery source rated for a minimum of 25 Amp. Connect

terminal # 87 to the third ignition wire in the vehicle.

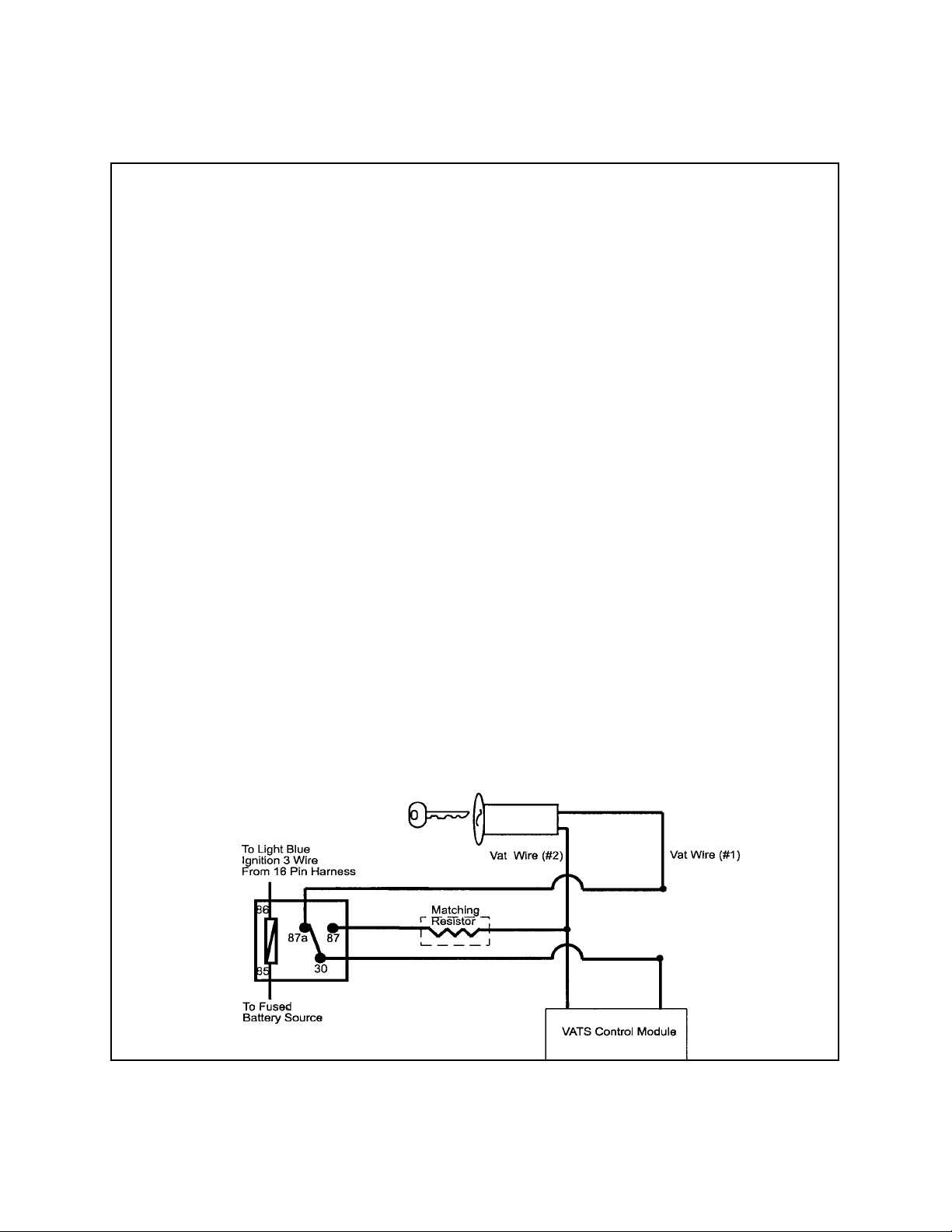

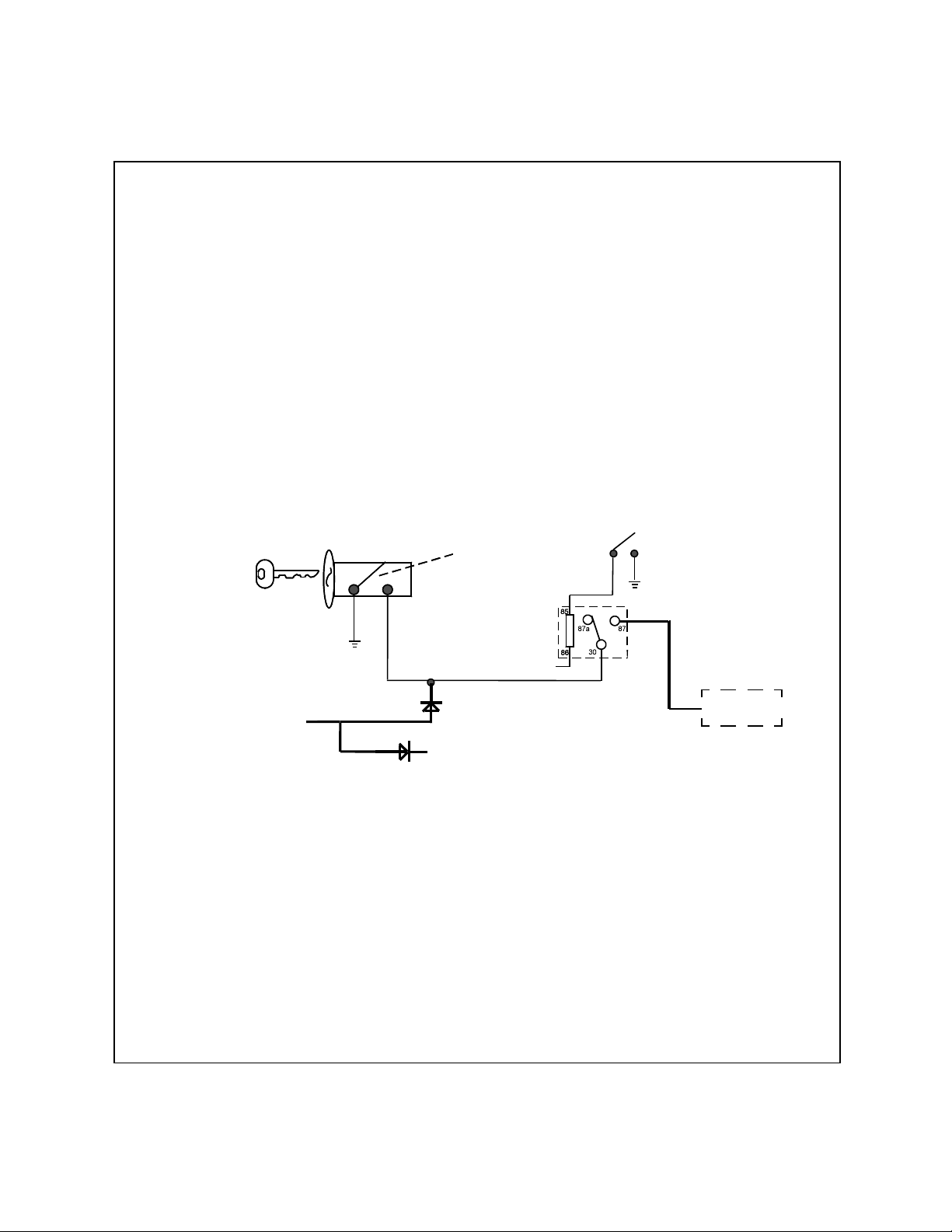

C. GM VATS Key Override:

If the vehicle has the General Motors VATS system installed, you will need to by-pass the system while

the vehicle is operating under the control of the Remote Start Unit. To Do This;

1. Measure the resistance of the resistor pellet on the ignition key then select a resistor within 5% of the

key's value from the resistor pack supplied.

2. Locate the pair of VATS wires in the vehicle, usually a pair of thin gauge wires running from the

ignition switch to the VATS control module.

NOTE: These wires are typically White w/ Black trace and Violet w/ Yellow trace, however in later model

Cadillacs, they are run through an orange sleeve, and are either both Black, both Yellow, or both White

wires. Consult the factory service manual for additional information.

3. Connect the Light Blue Wire from the Remote St artUnit to terminal #86 of an external relay. Connect

terminal #85 of the relay to a fused + 12 volt battery source.

4. Cut (#1) wire (as shown), and connect the ignition switch side of the cut wire to terminal #87a of the

relay. Connect the other side of the (#1) wire to terminal #30.

5. Connect the previously selected resistor from terminal #87 to the second (#2) wire (as shown).

NOTE: The above information and following diagram is for the GM VATS system only. For GM PASS

LOCK System you will require the Audiovox AS-PASS II Module.

General Motors VATS By-Pass Diagram

8

Page 9

Green w/ White trace Wire: Entry Illumination Ground Output

This wire provides a 30 second ground output (300 mA Max.) whenever the remote is used to disarm the

alarm or to unlock thedoors and provides a continuous pulsed output wheneverthe alarm is triggered. This

wire should be connected toan external relay, and wired to the vehicles interior entry lighting whenever the

optional Interior Illumination circuit is desired. See below for relay wiring details.

Entry Illumination Detail

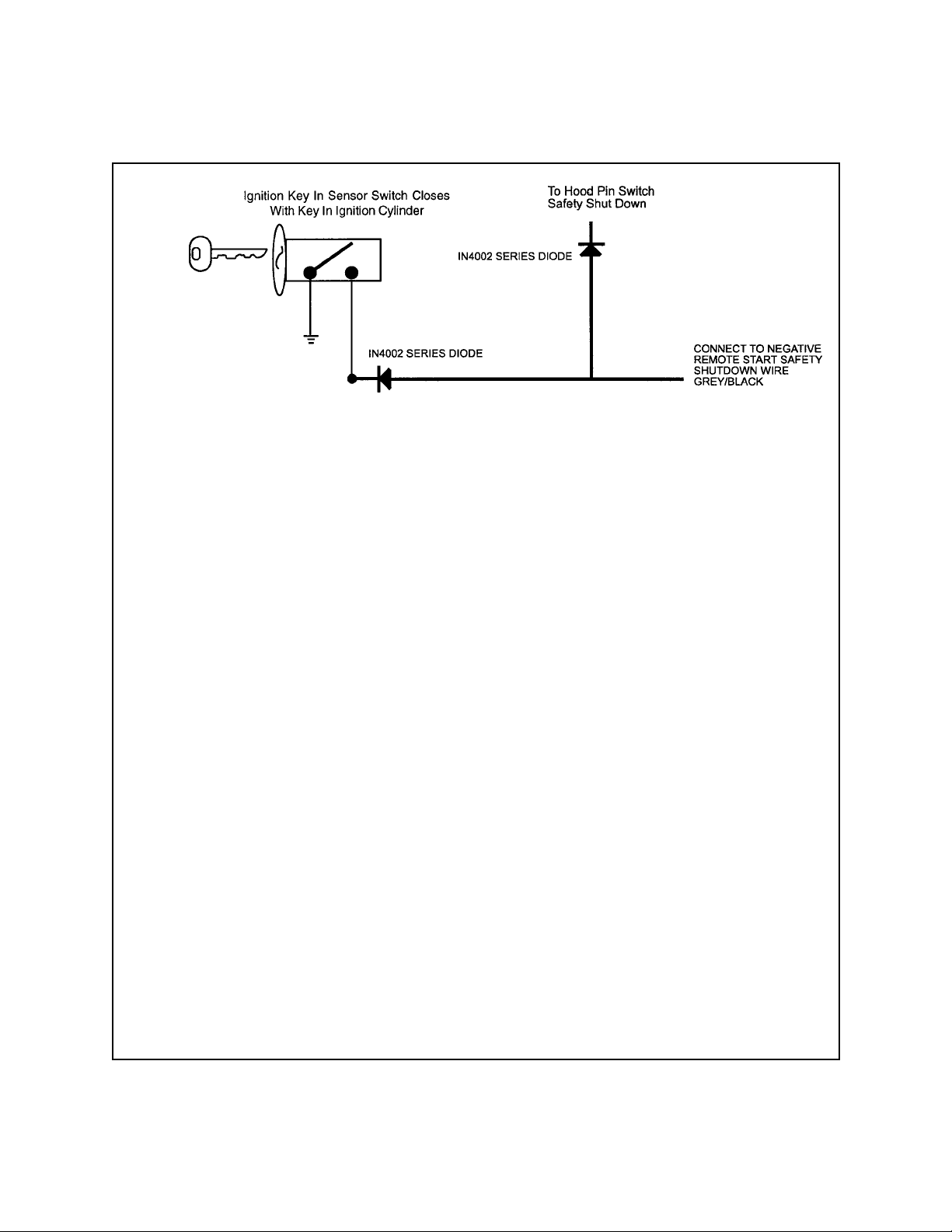

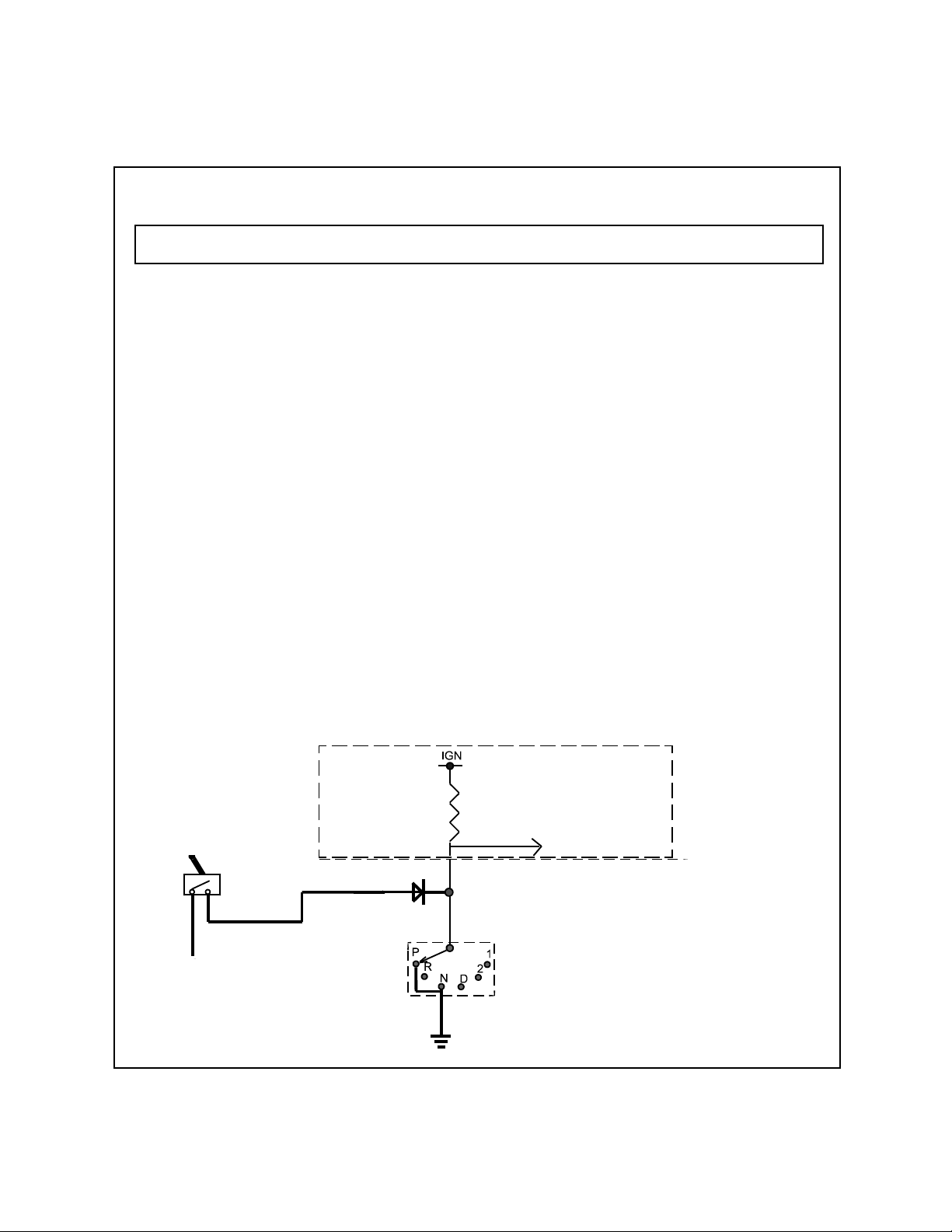

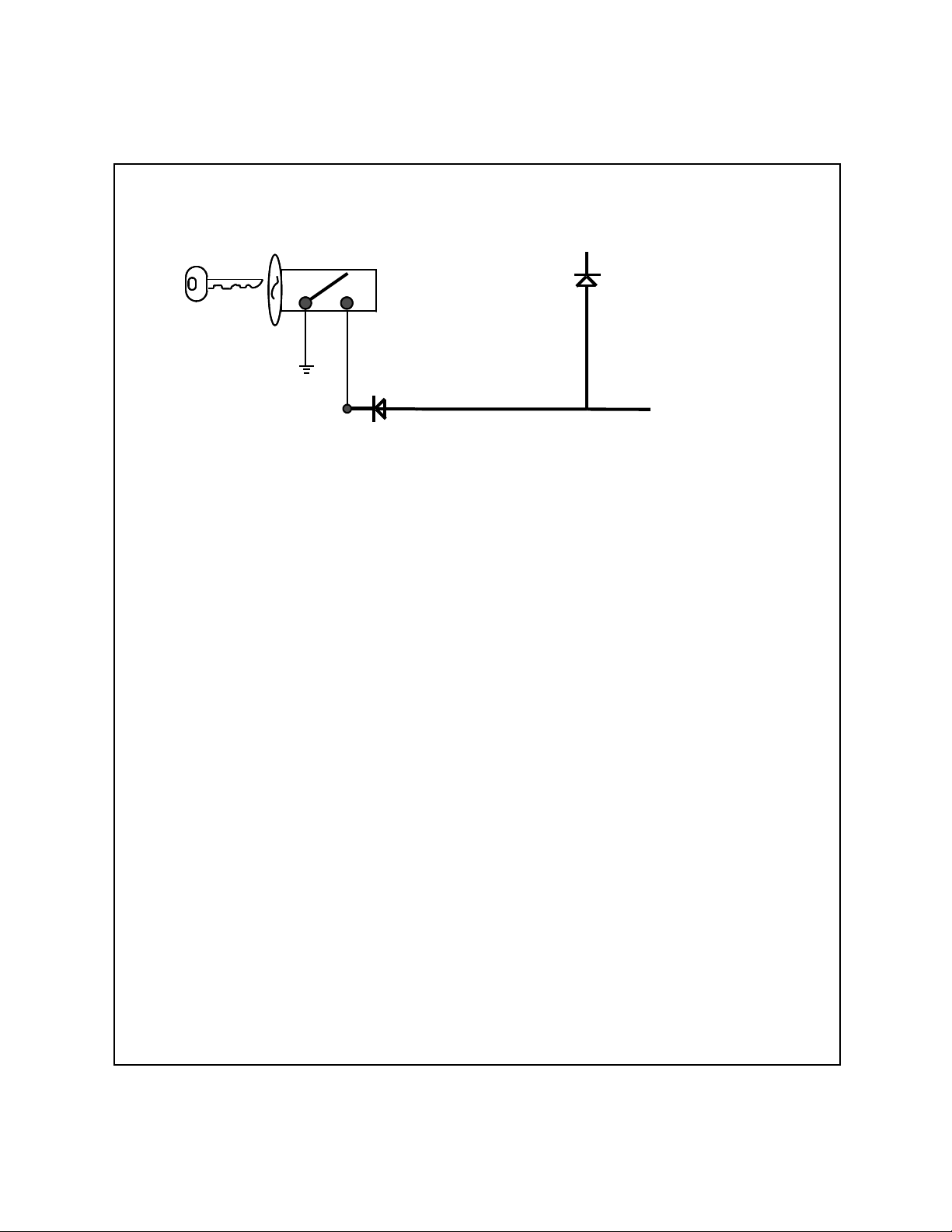

Grey w/ Black Trace Wire: Negative Inhibit Input

The Grey w/ Black Tracewire provides an instant shutdown for the RemoteStart Control Module whenever

it is grounded. Connect the Grey w/ Black trace wire to the hood pin switch previously installed. This wire

must be routed through a grommet in the firewall and connected to the hood pin switch. If the pin switch

is to be used with an alarm system, connect this wire using the diode assembly provided.

IMPORTANT! This connection is a safety wire and must be connected as shown and tested as specified.

Failure to do so may result in personal injury or property damage. See detail of wiring in the following

diagram. This wire may also be used if the vehicle brake light circuit switches ground to the brake lights.

An isolation diode must be used for ground switched brake light circuits and must be connected to the

output of the brake switch.

Grey w/ Black Trace Negative Inhibit Safety Shut Down Detail

9

Page 10

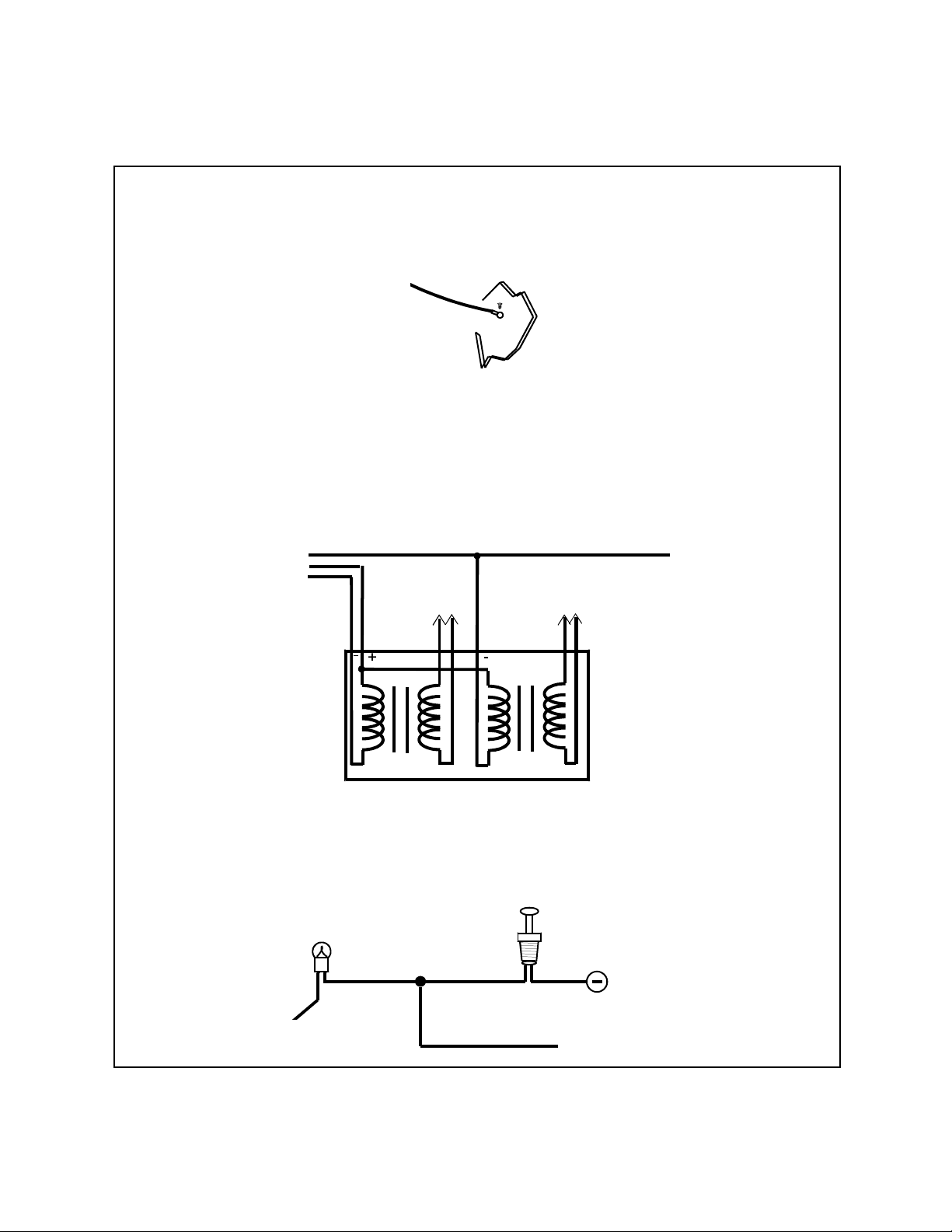

Orange Wire: Ground When Armed Output

This wire provides a 300 mA ground output when the alarm circuit is armed to control the starter inhibit

relay. Connect the Orange wire to terminal #86 (orange wire) of the relay provided. Connect terminal #85

(red wire) of the relay to an ignition wire in the vehicle that is +12 volts when the ignition switch is turned to

the on and start positions and off when the key is off. Locate and cut the low current start solenoid wire

found at the vehicles ignition switch harness. This wire will have + 12 volts when the ignition key is moved

to the start (crank) position and will have 0 volts in all other key positions. Connect one side of the cut wire

to terminal #87a ( Black wire) of the relay. Connect the other side of the cut wire to terminal #30 (White/

Black wire) of the relay. See below for detail of wiring, also see Yellow Start wire detail for connection to

vehicle considerations.

Starter Inhibit Wiring Detail

White/Black

Brown w/ Black Trace Wire: Positive Inhibit Input

The Brown w/ Black Trace wire provides an instant shutdown for the Remote Start Control module whenever it gets + 12 volts. If the Brake lights switch in the vehicle switches + 12 volts to the brake light circuit,

connect the Brown w/ Black trace wire to the output side of the brake switch. This will allow the Remote

Start to shut down if an attempt is made to operate the vehicle without the key while running under the

control of the Remote Start. In most vehicles, in order to shift into gear, the brake pedal must be depressed. The brake input will in turn cause the remote start unit to shut off. See detail in the following

diagram for wiring the brake light circuit.

Black

Brake Switch Positive Shutdown Detail

10

Page 11

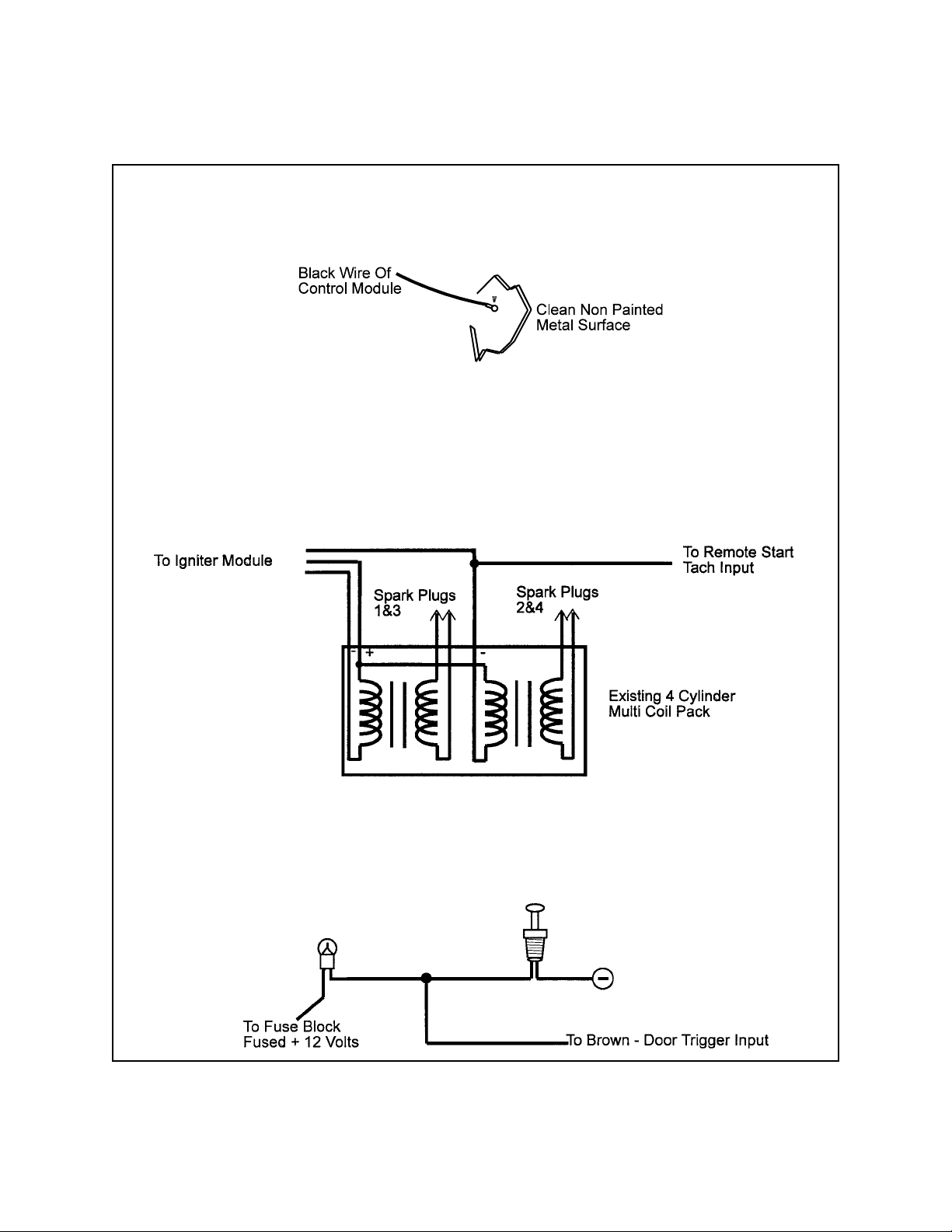

Black Wire: Chassis Ground Source

Connect the Black wire to a known vehicle ground source or to a solid clean metal part of the chassis. Be

certain to remove any paint or grease and secure this wire with a self taping screw and ring terminal.

Chassis Ground Connection Detail

Green w/ Orange Trace Wire: Tachometer Input Signal

This wire will continually monitor the engine tach rate while the unit is under power of the Remote Start

module. This wire will be routed to the vehicle ECM tach input or through the firewall into the engine

compartment and connect to the negative side of the ignition coil. This Remote Start unit learns the tach

rate of the vehicle and in most cases will operate properlyfrom one multi coil pack regardless of the number

of cylinders. If the vehicle has a single coil unit for each cylinder, it may be necessary to connect this wire

to more than one cylinder for proper tach reference. See multi coil wiring detail shown later in this manual

for additional information.

Tachometer Input Wiring Detail

Brown Wire: Negative Door Trigger

If the vehicle's door courtesy light switches ground when the door is opened, (Most GMs and Imports), you

must connect this wire to the negative output from one of the vehicle's door pin switches. In most cases the

Brown wire will need to be connected to only one door switch no matter how many doors the vehicle hasas

most door lighting circuits are wired in parallel. See below for wiring detail.

Negative Door Switch Wiring Detail

11

Page 12

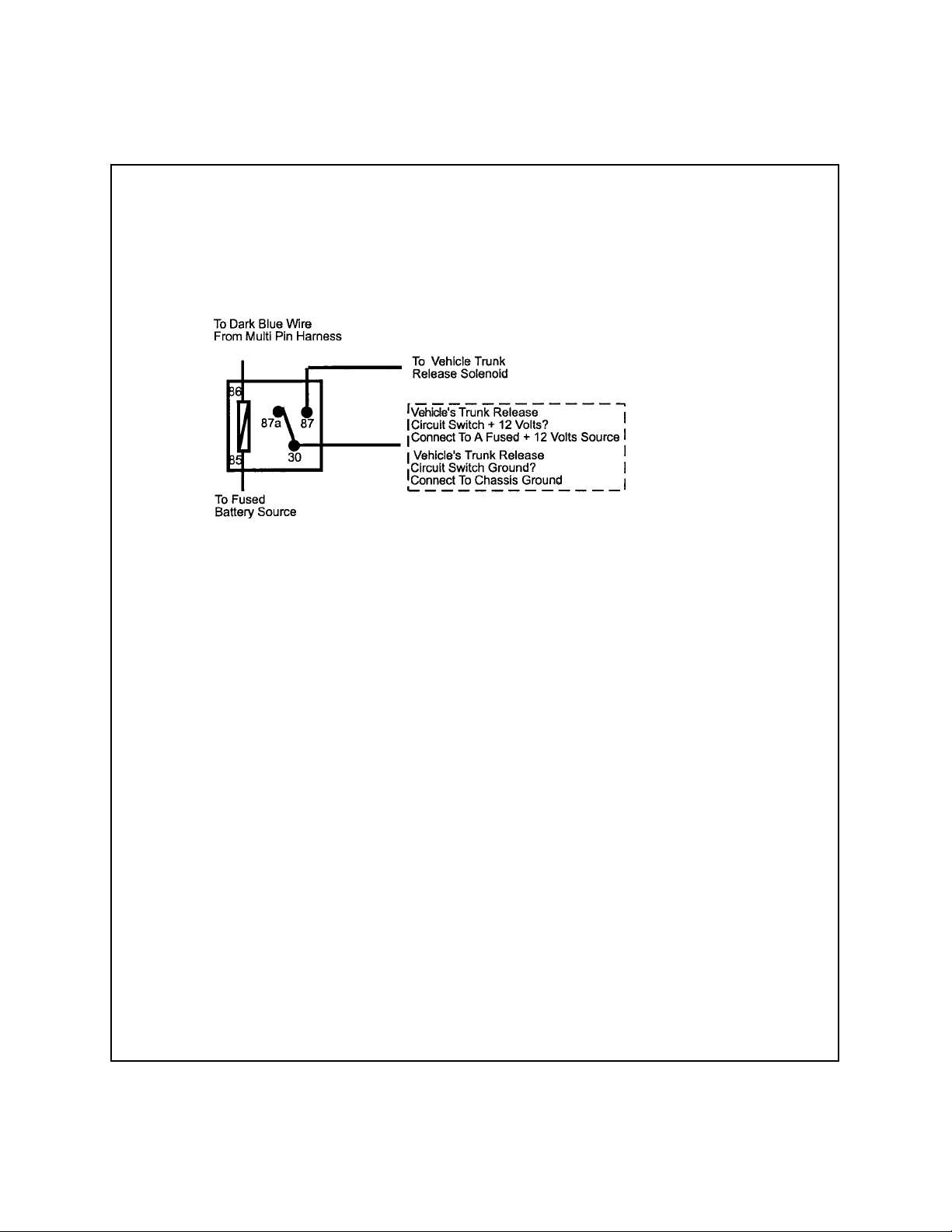

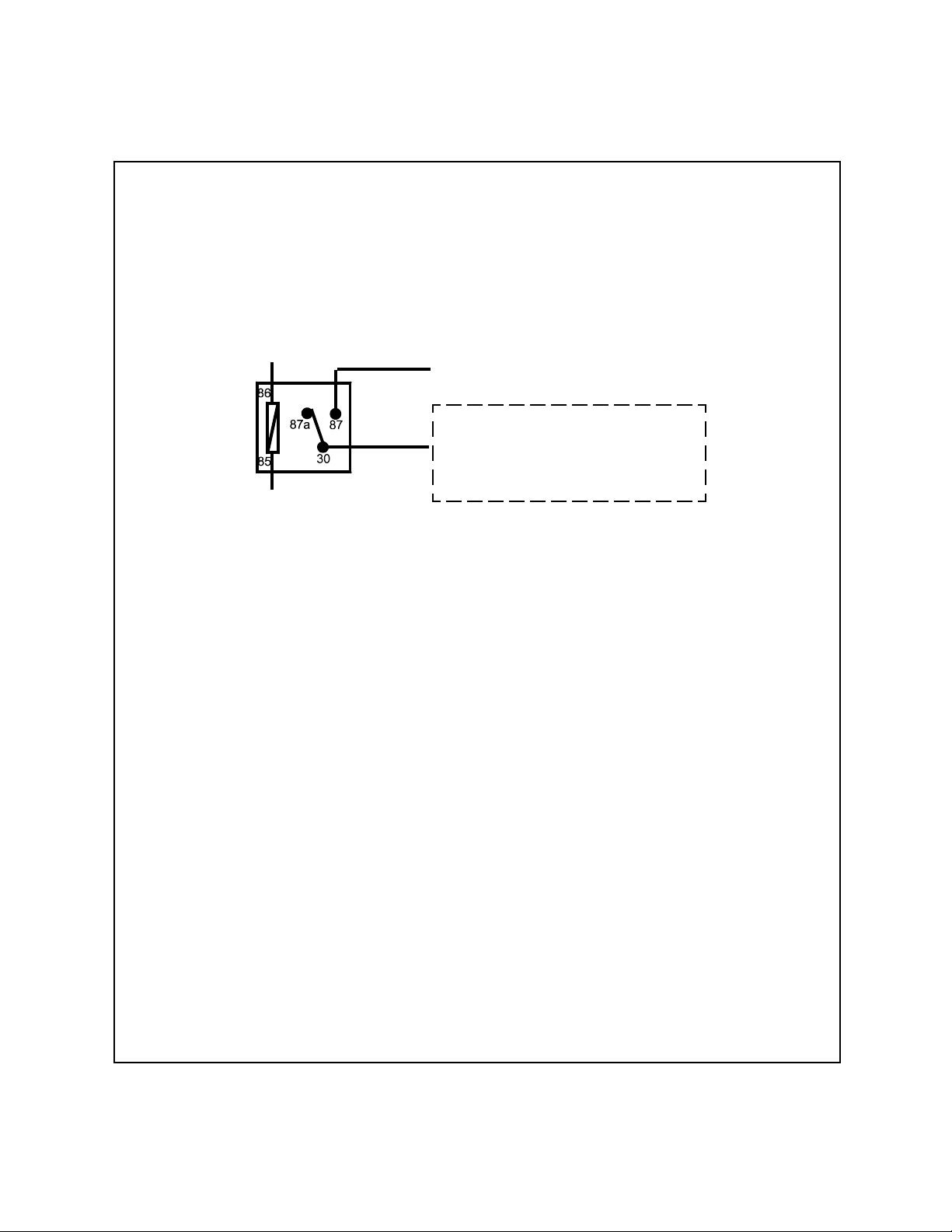

Dark Blue Wire: Delayed 300mA Pulsed Channel 2 Output

The DarkBlue wiresupplies a 300mA ground pulsed output whenever channel two of thereceiver isaccessed.

Pressing the pre-programmed transmitter button for three seconds will access channel two. This is a low

current output and must be connected to a relay to supply power to the trunk release or the circuit you wish

to control. Connect the Dark Blue wire to terminal # 86 of a VF45F11 P&B relay or equivalent. Connect

terminal # 85 of the relay to a fused + 12 volt source. Connect the common, normally open, and normally

closed contacts of the relay to perform the selected function of channel 2. See below for relay wiring detail.

Channel 2 Relay Wiring Detail

Green w/ Black Trace Wire: 300mA Latched Channel 3 Output

The Green w/ Black Trace wire supplies a 300 mA switched output whenever channel three of the receiver

is accessed. Pressing the pre-programmed transmitter button(s) will access channel three and will remain

active for as long as the transmitter button(s) is held. This is a low current output and must be connected

to a relay to supply power to the device you intend to control. Connect Green w/ Black Trace wire to

terminal #86 of a VF45F11 P&B relay or equivalent. Connect terminal #85 of the relay to a fused + 12 volt

source. Connect the common, normally open, and normally closed contacts of the relay to perform the

selected function of the channel 3 output.

WIRING THE 4 PIN AUXILIARY OUTPUT HARNESS

The auxiliary 4 pin connector provides low current outputs to control various functions in the vehicle during

different stages of the Remote Start unit's operation. Understanding these outputs and the time in which

they occur will allow you to determine if they are needed for the particular vehicle you are working on as well

as how to use them.

Black w Blue Trace Wire: Pulsed Ground Output Before Start

The Black w/ Blue Tracewire will provide a 300 mA pulsed ground output 3 seconds before the remote start

unit activates. Typical use for this output would be to disarm a factory theft deterrent system to prevent

false triggering of the factory alarm when the remote start unit engages.

Black w/ Light Green Trace Wire: Pulsed Ground Output After Start

The Black w/ Light Green Trace wire will provide a 300ma pulsed ground output after the vehicle is started

under control of the remote start unit. Typically this wire will be used to re-lock the vehicle doors if the doors

unlock automatically when the factory anti-theft system is disarmed.

Black w/ Red Trace Wire: Pulsed Ground Output After Shutdown

The Black w/ Red Trace wire will provide a 300 mA pulsed ground output after the remote start unit shuts

down. This output will occur regardless of whether the circuit times out or is manually terminated. Typically this output will be used to re-lock the vehicle doors if the doors unlock automatically when the ignition

circuit transitions to off.

Black w/ Yellow Trace Wire: Ground Output During Start (Crank)

The Black w/ Yellow Trace wire will provide a 300 mA ground output while the starter output of the remote

start unit is active. This output can be used to activate the Crank Low/Bulb Test wire found in some GM

vehicles. This wire is also referred to as the ECM wake up wire in some Chrysler vehicles.

NOTE: The outputs above are lowcurrent outputs and must be used with a relay if the circuit's requirement

is more than 300 mA.

12

Page 13

2 Pin Control Switch: (Red Connector)

The Black & Black w/White Trace wires loaded in the two pin red connector enable the operation of the

Remote Start unit. When the Black w/ White Trace wire is grounded, the remote start unit is operable.

When this wire is open from ground, the remote start is disabled. Route the twin lead Black & Black w/

White Trace wires from the control switch to the remote start unit and plug red two pin connector into the

mating red two pin connector shell of the control module.

4 Pin Shock Sensor: (White Connector)

The Red (+12 volt), Black (ground), Blue(pre-detect) and Green (full triggerwhen armed) wires loaded into

the white connector shell are the inputs/outputs of the shock sensor. Route the 4 wire harness from the

shock sensor to the remote start control unit and plug the 4 pin white connector into the mating 4 pin

connector shell of the control module. Note: While operating under the control of the remote start unit the

shock sensor will be shunted (by-passed). Once the remote start shuts down, the shock sensor will be

re-enabled.

2 Pin LED Harness: (White Connector)

The Red & Blue wires loaded into the two pin mini white connector control the anode and cathode of the

dash mounted LED. Route the twin lead Red and Blue wires from the LED to the remote start control unit

and plug the two pin connector into the mating white mini connector shell of the control module.

2 Pin Valet/Program Switch: (Blue Connector)

The Black & Grey twin lead wires loaded in the two pin blue connector are the ground supply and

program/valet input of the Remote Start unit. When the Grey wire is grounded, under certain conditions,

the unit will enter the valet mode. When the Grey wire is sequentially grounded under other conditions,

the unit will enter the various program modes. Route the twin lead Black and Grey wires from the valet/

Program switch to the remote start unit and plug the two pin connector into the mating blue connector

shell of the control module. Refer to the remote programming, feature programming and function programming shown later in this installation guide for operation of the valet/program switch.

2 Pin Door Lock/Unlock Harness: (White Connector)

The Red & Green Door Lock/Unlock output wires provide either a pulsed ground or pulsed + 12 volts to

control the vehicle door lock / unlock circuits. The output of these wires has a maximum switching

capability of 300mA. Many vehicles today have factory door lock relays which can be connected directly

to these outputs, however always confirm that the factory relays in your particular vehicle do not exceed

the rated 300mA output of the units door lock/unlock circuit. Plug the two pin connector of the door lock/

unlock harness into the mating connector shell of the control module. Determine the door lock circuit of

the vehicle you are working on and wire according to the diagrams shown.

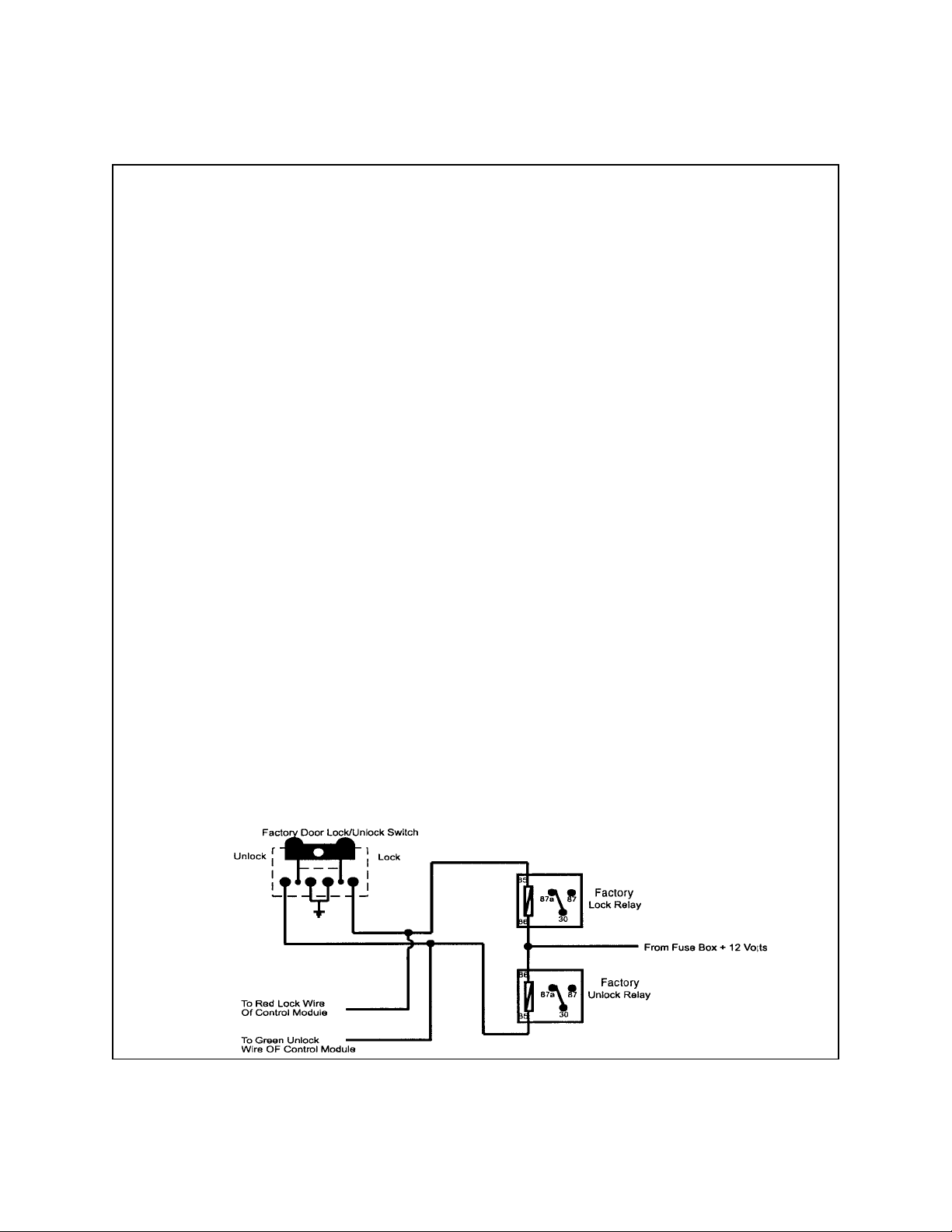

3 Wire Ground Switched Door Lock Circuits:

In this application, the Red wire of the two pin harness provides a ground pulse during the arming sequence, or pulsed ground lock output. Connect the Red wire to the low current ground signal wire from

the factory door lock switch to the factory door lock relay.

The Green wire of the two pin harness provides a ground pulse during the disarming sequence, or pulsed

ground unlock output. Connect the Green wire to the low current ground signal wire from the factory door

unlock switch to the factory door unlock relay. See Below For Wiring Detail.

3 WireGround Switched Door Lock/Unlock Wiring Detail

13

Page 14

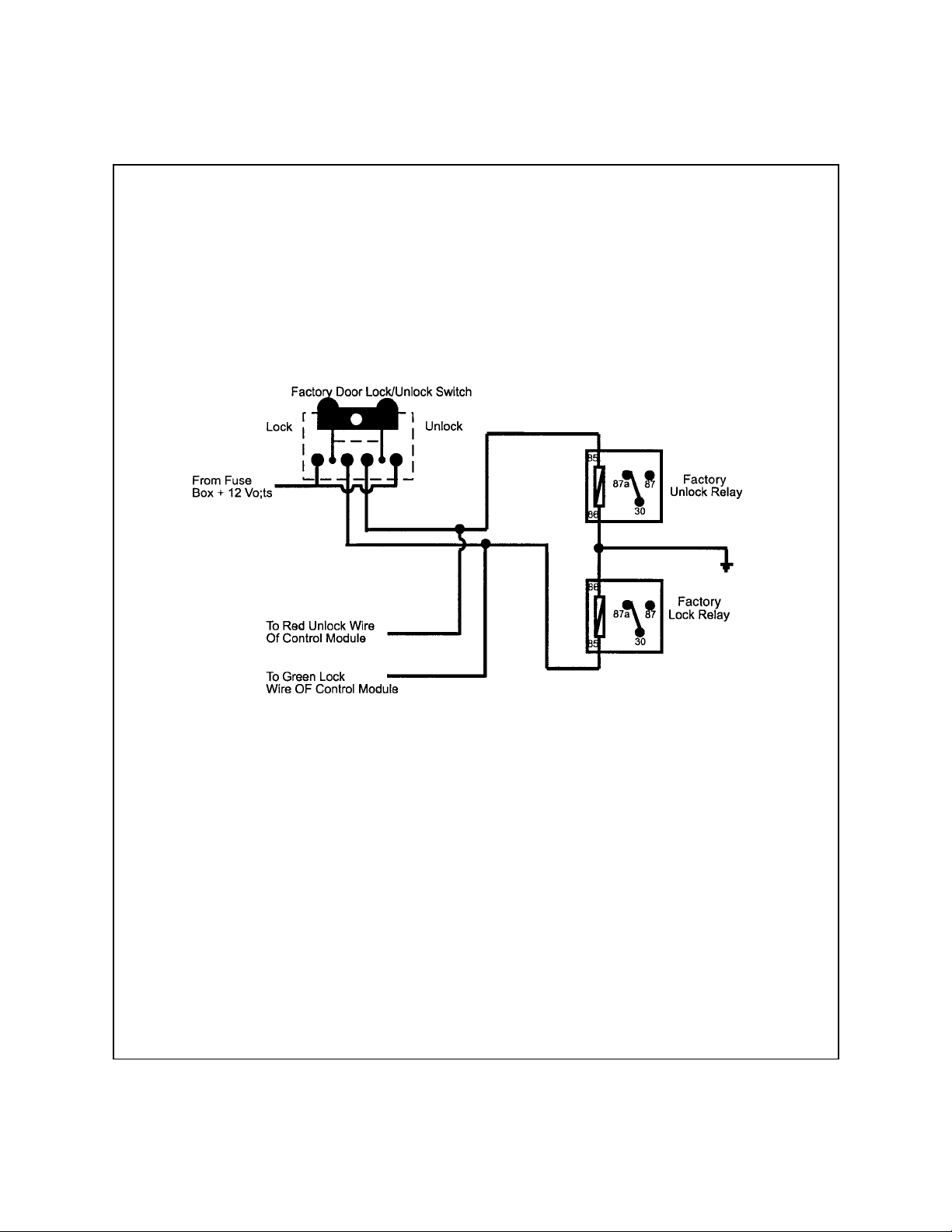

3 Wire Positive Switched Door Locks:

In this application, the Red wire of the two pin harness providesa+12volt pulse during the disarming

sequence, or pulsed 12 volt unlock output. Connect the Red wire to the low current 12 volt signal wire from

the factory door unlock switch to the factory door unlock relay.

The Green wire of the two pin harness providesa+12volt pulseduring the armingsequence, or pulsed12

volt lock output. Connect the Green wire to the low current 12 volt signal wire from the factory door lock

switch to the factory door lock relay. See Below For Wiring Detail.

3 Wire Positive Switched Door Lock/Unlock Wiring Detail

Note: For connection to Four Wire Polarity Reversal, 5 Wire Alternating 12 Volts, And All Other Door

Lock Circuits the Audiovox AS-9159 Door Lock Interface, (or equivalent 30 A automotive relays) must be

used. Refer to the Audiovox Door Lock Wiring Supplement for proper wiring of these circuits.

14

Page 15

NOTE: The Alarm Selectable Features and Remote Start Selectable Features programming steps following are

based on transmitter button 1 being programmed for channel 1 and transmitter button 2 being programmed for

channel 2.

RF Programmable Features:

Feature Selection 1 Chirp 2 Chirp Default

First 1 Second Door Locks 3.5 Second Door Lock 1 Second

Second Auto Lock On Auto Lock Off Auto Lock Off

Third AutoUnlock On Auto Unlock Off Auto Unlock Off

Fourth Passive Door Locks Active DoorLocks Active DoorLocks

Fifth Passive Arming ActiveArming Passive Arming

To Program The Alarm's Selectable Features:

First

Second

Third

Fourth

Fifh

NOTE: Once you've entered the program mode DO NOT allow more than 15 seconds to pass between steps, or

the programming mode will be terminated.

Action

Turn the ignition switch on

Flip the valet/program switch on then off 3 times

Within 3 seconds, turn the ignition switch off

and then on.

Press transmitter button 1 to change.

Or

Flip valet/program switch on then off

Press transmitter button 1 to change.

Or

Flip valet/program switch on then off

Press transmitter button 1 to change.

Or

Flip valet/program switch on then off

Press transmitter button 1 to change.

Or

Flip valet/program switch on then off

Press transmitter button 1 to change.

Or

Flip valet/program switch on then off

Or

Turn ignition switch off.

System Response

No Response

1 Chirp-LED 1 Flash

Short Chirp, then Long Chirp

1 Chirp = 1 second Locks

2 Chirps = 3.5 second Locks

2 Chirps = auto locks off

1 Chirp = auto locks on

2 Chirps = auto unlock off

1 Chirp = auto unlock on

2 Chirps = active locks

1 Chirp = passive locks

1 Chirp = passive arming

2 Chirps = active arming

Exit Program Mode

Exit Program Mode

LED FlashPattern

1 Flash Pause etc.

2 Flash Pause etc.

3 Flash Pause etc.

4 Flash Pause etc.

5 Flash Pause etc.

TIMED START PROGRAM:

The Remote Start unit has the ability to start the vehicle automatically at timed intervals. This feature is

useful in extremely cold climates where starting the engine is the only means to keep the battery charged

and fluids warm. The operator has the option to have the unit start every 2 or 4 hours for a maximum of 48

hours. Factory pre-set is to start at 4 hour intervals. To select 2 or 4 hour automatic start timer:

1. Start with the Enable switch (Red Handle) in the "On" Position.

2. Turn the ignition on then off.

3. Within 10 seconds of the key turning off, cycle the enable switch Off, On, Off, On ( 2 times) to select a

2 hour timed start interval. Cycle the enable switch Off, On, Off, On, Off, On, Off, On (4 times) to select

a 4 hour timed startinterval. The lights will flash and the siren will chirp 2Xor 4X dependant upon 2 or 4 hour

interval setting.

ALARM SELECTABLE FEATURES

NOTE: Once selected, 2 or 4, this timer interval will remain in memory until it is manually changed. To change, the

above sequence will have to be followed.

TIMED START OPERATION:

To begin the start timer, within 10 seconds of turning off the ignition switch, activate the RF command to

start 2 times. (Press button two 4 times). The lights will flash and the siren will chirp 4 times. Indicating

timed interval mode has been initiated. The vehicle will automatically start every 2 or 4 hours as programmed. To cancel the timed start mode start the vehicle either by RF or by the ignition key.

15

Page 16

REMOTE START SELECTABLE FEATURES

RF Programmable Features:

Feature Selection

First

Second

Third

Fourth

Fifth

Sixth

Seventh

Eighth

Park Lights Flash 1 x

RF start chirp confirm off

10 minute run time

Parking lights on steady

(No function)

(No function)

Ignition 2 off during crank

Diagnostics off

(No function)

Park Lights Flashes 2 x

RF start chirp confirm on

15 minute run time

Parking lights flash

Tach operation

(No function)

Ignition 2 on during crank

Diagnostics on

(No function)

Default

Off

10 Minutes

Steady

Tach

---------------Off during crank

Off

---------------

To Program The Remote Start Selectable Features:

1. Start with the valet/program switch in the "Off" position.

2. Turn the ignition key to the On position.

3. Flip the valet/program switch On, Off, On, Off, On, then Off.

4. Immediately turn the ignition key Off then press transmitter button 2 for 1 second.

5. Immediately turn the ignition key back On.

6. Flip the valet/program switch On, Off, On, then Off. The siren will emit 2 short and 1 long chirp verifying

you are in the feature program mode.

7. Use button 1 on the transmitter to advance to the feature you want to change. EXAMPLE- If you need to

change selectable feature 3, press and release button 1 on the transmitter 3 times in succession. The

parking lights will flash, andthe siren will chirp 3 times confirming that selected feature 3can be changed.

8. Use button 2 on the transmitter to change the selection of the programmable feature. If you are not sure

what the setting for any feature is, press button 2 one time, the parking lights will flash once or twice

indicating the features setting.

NOTE: Once you've entered the program mode DO NOT allow more than 15 seconds to pass between

steps, or the programming mode will be terminated.

Programming Tach Rate:

The APS-750a will learn the tach rate of the vehicle. To learn tach.

1. Start with the programming switch in the Off position.

2. Turn the ignition key to the On position.

3. Flip the valet/program switch On, Off, On, Off, On, then Off.

4. Immediately turn the ignition key Off.

5. Flip the valet/program switch On, then start the vehicle using the key.

6. When the unit senses the tach signal, the parking lights will begin to flash.

7. Flip the valet/program switch Off, The parking lights will turn on for three seconds to indicate that the

learned tach signal is stored and the unit is out of the tach learn mode.

NOTE: If the unit fails to learn tach rate due to an improper tachometer connection or a poor tach source, the

unit will go into a fail-safe mode. While in this mode, the remote start transmitter will not function and the

program switch will stop responding. This will be indicated by the LED turning on and off with each operation

of the program switch. To correct this situation, locate and connect the Green/Orange wire to the proper

tach signal, disconnect the power wire to the control module, repower the circuit, re-enter and learn the

proper tach signal.

Diagnostics:

Enter selectable feature #7 and turn on as described above.

NOTE: Diagnostic mode is a temporary mode. Once you have accessed the diagnostic mode, the unit will

pause for two seconds then begin to flash the last stored shut down code. This code will be displayed three

times in succession, then the unit will automatically exit the diagnostic on mode.

The parking lights will flash a number of times indicating the reason for the last remote start shutdown. The

light flash indications are as follows:

1 Flash 10 or 15 minute run timer expired

2 Flashes Low or no tach signal (RPM)

3 Flashes Positive or negative inhibit wire activation

4 Flashes Control switch moved to the off position

5 Flashes RF shutdown, Remote signal received

6 Flashes High tach signal (RPM)

16

LED Pattern

1 x Pause etc.

2 x Pause etc.

3 x Pause etc.

4 x Pause etc.

5 x Paues etc.

6 x Pause etc.

7 x Pause etc.

8 x Pause etc.

Page 17

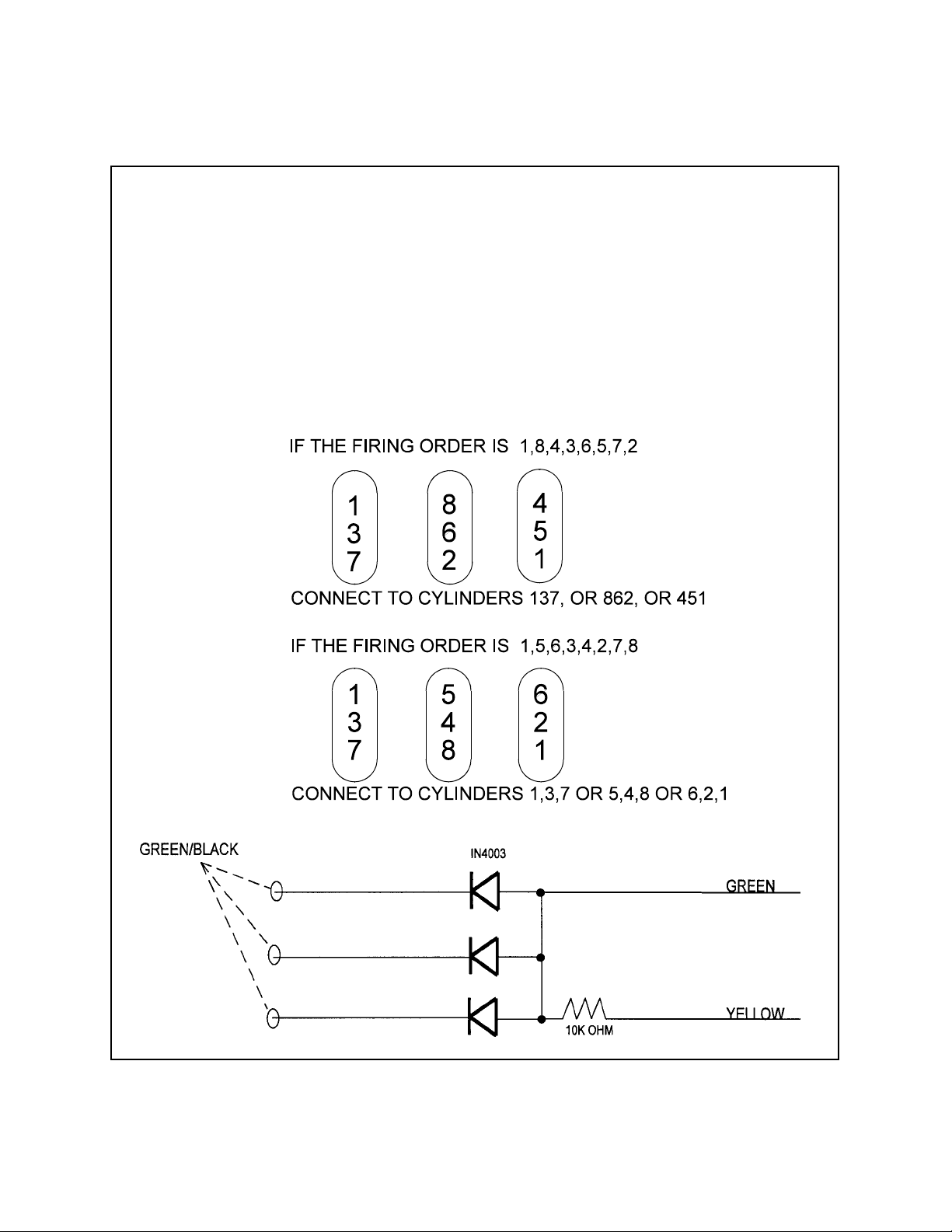

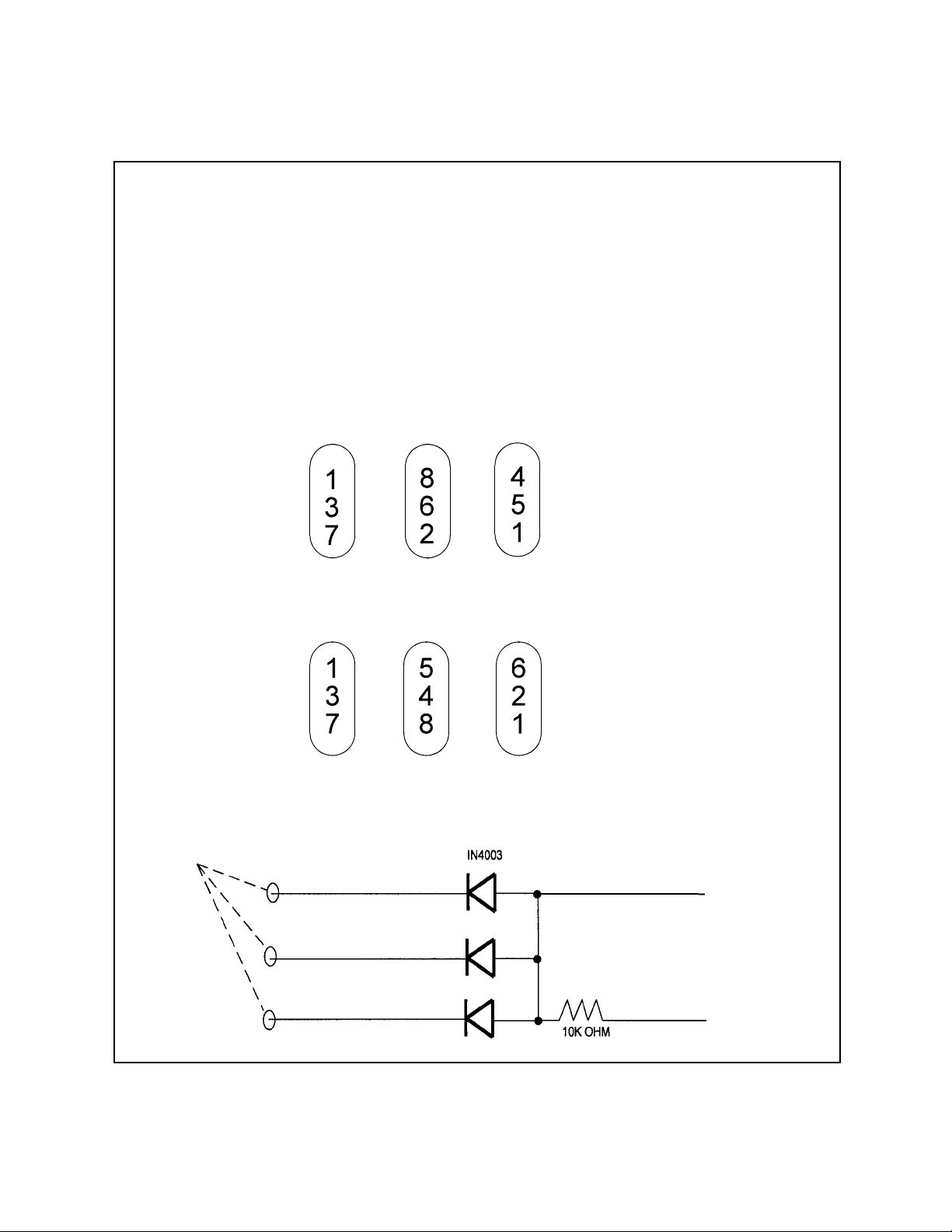

Multi Coil Pack Adaptor: (Optional)

The multi coil pack adaptor is designed for use with vehicles having multiple ignition coils where a single

point tach signal is unavailable.

To use the adaptor, the Green/Black wires must connect to the negative side of the ignition coil(s).

1. For vehicles utilizing independent coils per cylinder, connect the three Green/Black leads to alternate

coils. To achieve optimum performance the coil signals must be evenly distributed. This is accomplished by first mapping out the firing order of the engine in groups of as indicated below. Draw a circle

around any of the columns. The Green/Black wires should be connected to the negative (-) terminal of

the respective cylinder number which appears in any of the circles.

2. For vehicles utilizing 2 cylinder firing per coil pack, connect Green/Black to the tach side of each coil

pack. For 8 cylinder, four coil systems, connect to any of the three coils.

3. Connect the Yellow wire to a +12 volt ignition 1 source. This wire will have +12 volts with the ignition in

the on and start position and have 0 volts with the ignition in the off position.

4. Connect the Green wire to the (Green) or (Orange/Green) tach input of the Audiovox remote start unit.

17

Page 18

TESTING YOURINSTALLATION:

CAUTION!! The following procedure must be performed after the installation of an Audiovox Remote Start

Device. It is the responsibility of the installing technician to complete these tests. Failure to test the unit

in the following manner may result in personal injury, property damage, or both.

HOOD PIN SAFETY SHUT DOWN:

The intention of the hood pin safety shut down is to prevent the Remote Start unit from being activated while

a mechanic or vehicle owner is performing normal routine vehicle maintenance.

To test the integrity of this circuit:

1. With the drivers window in the down position, start the vehicle using the RF transmitter.

2. Reach inside the car and pull the hood release.

3. Raise the hood and confirm that the remote start unit shuts down.

If the unit fails this test, recheck your pin switch connection to the Gray/Black wire of the Audiovox Remote

Start Unit.

DO NOT RELEASE THIS VEHICLE TO THE CONSUMER UNTIL YOU CONFIRM THE

OPERATION OF THE HOOD PIN SAFETYSHUT DOWN FEATURE.

MANUAL SHUT DOWN / ENABLE CIRCUIT:

The intent of the manualshut down / enable circuit is to allowthe vehicle operator to prevent operation of the

Remote Start Unit regardless of the RF transmitter operation.

To test the integrity of the manual shut down / enable circuit:

1. Place the control switch in the on (Closed To Ground) position.

2. Start the vehicle using the RF transmitter.

3. The vehicle should start and run under the control of the remote start unit.

4. Move the switch to the off (Open From Ground) position, the vehicle should shut off.

If the unit fails this test, recheck your enable switch connection to the Ground and the Black/White wire of

the Audiovox Remote Start Unit. If you have a plug in enable switch, check that the two pin connector is

firmly seated in the mating connector on the control module.

DO NOT RELEASE THIS VEHICLE TO THE CONSUMER UNTIL YOU CONFIRM THE

OPERA TIONOF THE MANUAL SHUT DOWN/ ENABLE FEATURE.

NEUTRAL START SAFETYTEST:

The intent of the neutral start switch is to prevent the vehicle from starting while the gear selector is in any

position other than Park, or Neutral. When installing a Remote Start Device, it is imperative that the Yellow

Starter wire be connected to the ignition switch side of the Neutral Start Switch. Consideration for the

placement of a starter inhibit relay is important as well, and should be connected to the ignition switch side

of the Yellow Start Wire.

To test the integrity of the Neutral Start Safety Circuit:

1. Set the vehicle parking brake.

2. Block the drive wheels to prevent vehicle movement.

3. Temporarily disconnect the Brown/Black positive shut down wire from the vehicle's brake switch.

4. Sitting in the vehicle, start the engine using the vehicle's ignition key.

5. Step on the brake pedal and shift the gear selector into reverse.

6. Allow the transmission to shift. When you feel the engine pull, do not move the gear selector just turn

the ignition switch off. DO NOT attempt to remove the key.

7. Keeping the brake pedal depressed, activate the RF transmitter in an attempt to start the vehicle. The

car should not start.

8. Repeat the above test this time move the gear selector to the drive position. If the unit attempts to start,

failing this test, recheck your Yellow Wire's connection. This wire must be connected to the ignition

switch side of the Neutral Start Switch. If the vehicle you are working on does not have an Electrical

Neutral Safety Switch, it will be necessary to reconfigure the Remote Starts Wiring to accommodate

this vehicle. The information concerning the Mechanical Neutral Safety Switch provided below will help

you to determine if the vehicle you are working on has this type of safety switch and will provide alternate

wiring methods to accommodate this situation.

18

Page 19

CAUTION!

REMEMBER T ORECONNECT THE BROWN/BLACK WIRE TEMPORARILY

DISCONNECTED IN STEP 3

DO NOT RELEASE THIS VEHICLE TO THE CONSUMER UNTIL YOU CONFIRM THE OPERATION

OF THE NEUTRAL SAFETYSTART FEATURE.

MECHANICAL NEUTRAL SAFETY SWITCH CONSIDERATIONS:

Mechanical neutral safety switch configurations differ slightly in that they do not offer the same level of

safety when installing a remote start device. Often when the ignition switch is turned off while the gear

selector is in any position other than park or neutral, the mechanical function will not allow the key to be

turned to the start position or be removed from the ignition cylinder. This configuration prevents mechanical operation while the vehicle is in gear but offers no consideration for electrical operation. Because of

this potential problem, this installation requires the additional connection of a safety wire from the remote

start device to the vehicle Park/Neutral ECM Input or the vehicle key in sensor. This connection will

prevent remote start operation if the key is left in the ignition switch regardless of the gear selectors

position.

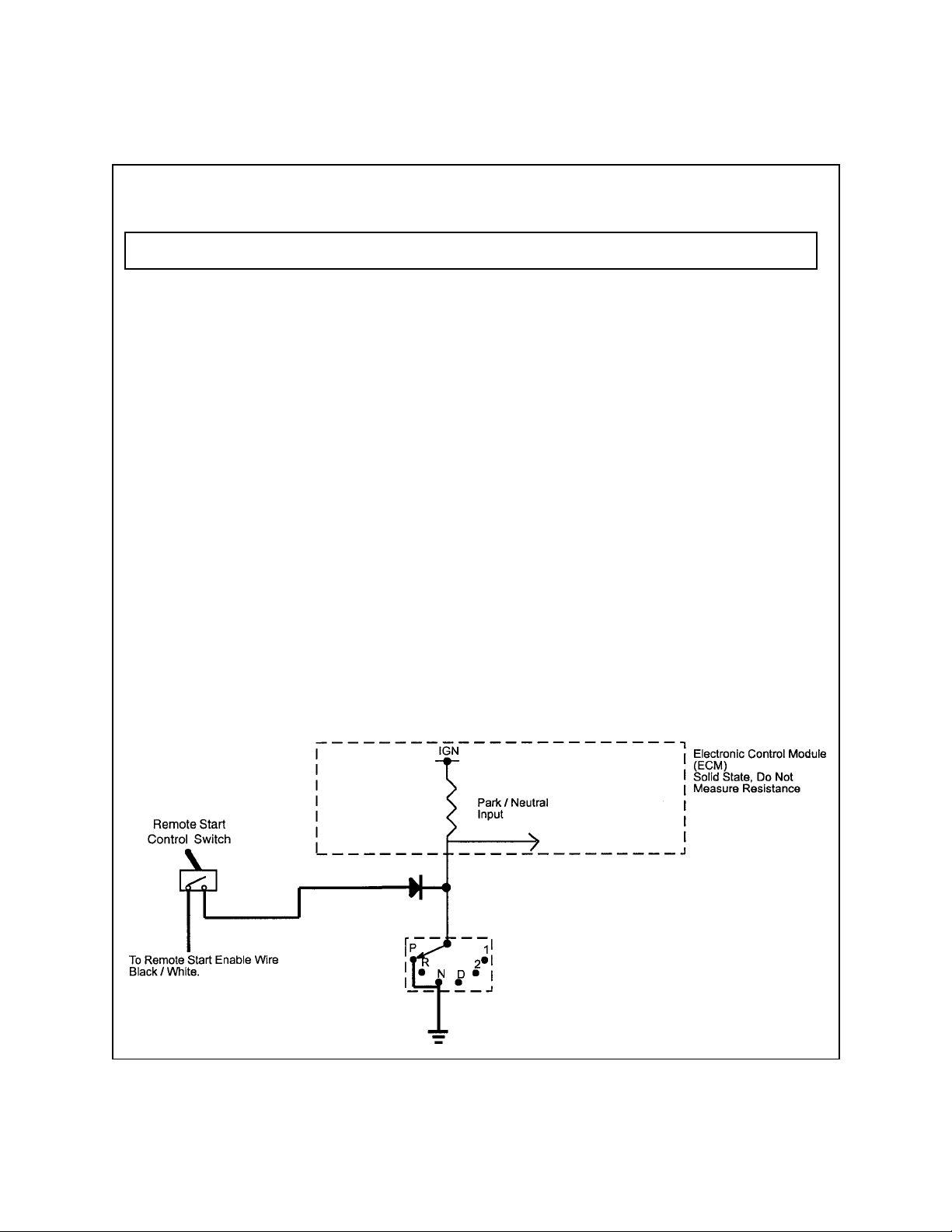

PARK / NEUTRAL ECM INPUT:

The Park / Neutral ECM input is the preferred method of installation. This not only maintains the integrity

of the factory circuit, it is also the easiest to install, providing the vehicle you are working on has this ECM

input.

The installation required for this application (shown below), indicates the slight reconfiguration of the

control switch wiring and the addition of a 4000 series diode. Shown is a typical GM Park/Neutral ECM

input circuit. To connect the Audiovox remote start unit to the GM Park / Neutral ECM input:

1. Locate the Orange / Black reference wire in the" C2" connector found at the ECM in GM B Body

vehicles or, locate the equivalent reference wire in the vehicle you are installing theAudiovox Remote

Start Unit in.

2. Connect the Cathode, (Striped) end, of a 4000 series diode to this reference wire.

3. Connect the Anode, (Non Striped) end, of the diode to one side of the Remote Starts enable switch.

4. Connect the other side of the enable switch to the Black/White enable input wire of the Remote Start

unit.

The reference diagram below shows a typical GM B Body ECM reference wire and how it is to be connected to the Remote Start Unit.

19

Page 20

KEY IN SENSOR CIRCUITS:

If the vehicle you are working on does not have or you cannot locate the ECM reference wire, there aretwo

alternatives available. Although not preferred, the vehicle Key In Sensor may be reconfigured to allow a

margin of safety and will prevent the vehicle with a Mechanical Neutral Start Switch from starting in gear.

AUDIOVOX ADVISES THAT YOU MAINTAIN THE FACTORY CIRCUIT WHENEVER POSSIBLE. The

following two circuits may be used only if the above circuit is not available.

NOTE: When completing an installation using either of the following key in sensor circuits, if the operator

inserts the ignition key while the vehicle is running under the control of the Remote Start, the vehicle will

shut down. This must be explained to the operator as it is in contrast to the normal operation of a vehicle

utilizing an electrical neutral start switch and is inconsistent with the operators manual.

Additional information concerning Key In Sensor methods 1 & 2 are listed below and should be reviewed

before considering either alternative.

Method 1 will allow the safety required for the remote start unit and prevent the vehicle from starting while

in any gear other than Park or Neutral while the key is in the ignition cylinder however, if the key is left in

the ignition switch and the door is left opened, the added relay will be energized causing a 150mA drain on

the battery.

Method 2 will allow the safety required for the remote start unit and prevent the vehicle from starting while

in any gear other than Park or Neutral while the key is in the ignition cylinder however, the original factory

key in chime module will not alert the owner that the key has been left in the ignition switch. In addition,

this may also effect other warning tones such as the light on reminder.

These situations should be carefully considered before altering the vehicle's wiring and must be fully

explained to the consumer.

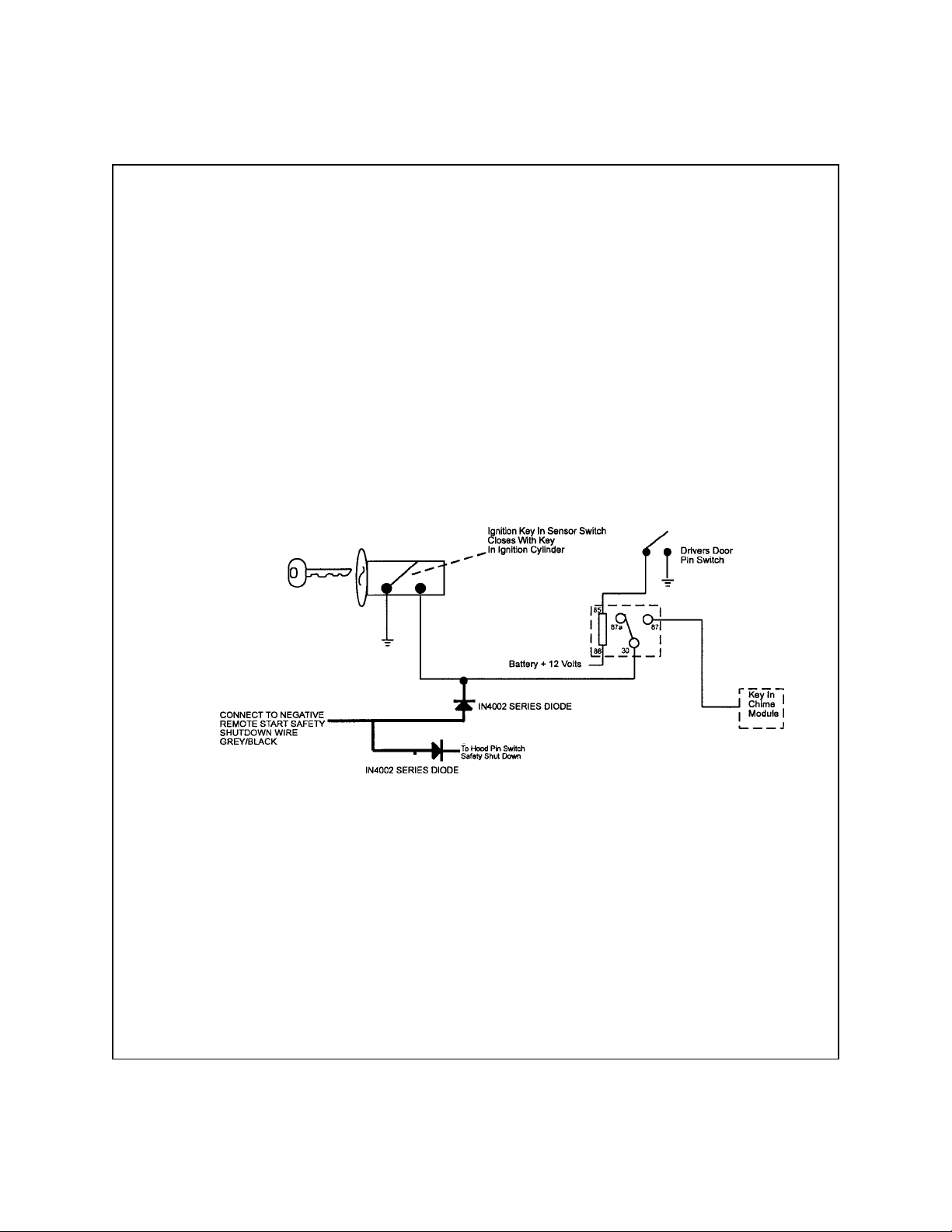

METHOD 1

To connect to the key in sensor as shown in method 1:

A. Locate the control wire that connects the drivers door pin switch to the key in sensor switch.

B. Cut this wire and connect the ignition cylinder side to chassis ground.

C. Locate the key in sensor switch wire that connects the chime module to the ignition cylinder .

D. Cut this wire and connect the ignition cylinder side to terminal 30 of a P&B VF45F11 or equivalent

relay.

E. Connect the cathode (striped) side of a 4002 series diode to this same wire, and connect the (non

striped) side to the negative shut down safety wire (Gray / Black) of the Audiovox Remote Start Unit.

F. Connect terminal 86 of the relay to a fused +12 volt constant battery source.

G. Connect terminal 87 of the relay to the Chime Module side of the previously cut wire in step D.

H. Connect terminal 85 of the relay to the Drivers Door side of the pin switch wire previously cut in step B.

NOTE: A second 4002 series diode may be required to maintain the integrity ofthe hood open, shut down

circuit. If this is the case, it must be installed as shown in the diagram above. The anode (Non Striped)

side must be connected to the Gray/Black wire of the Remote Start Unit. The cathode (Striped) side

must be connected to the hood pin switch. If the hood pin switch is also used for an alarm trigger input,

be certain to use the dual diode assembly packaged with the Audiovox Remote Start Unit as shown in

this installation guide. (Page 9)

20

Page 21

METHOD 2

To connect to the key in sensor circuit as shown for method 2:

A. Locate the control wire that connects the drivers door pin switch to the key in sensor switch.

B. Cut this wire and connect the ignition cylinder side to chassis ground.

C. Locate the key in sensor switch wire that connects the chime module to the ignition cylinder .

D. Cut this wire and connect the ignition cylinder side to the Remote Start Negative Safety Shut down

Wire Gray/Black, using a 4002 series diode as shown above.

NOTE: A second4002 series diode may be required to maintain the integrity ofthe hood open, shut down

circuit. If this is the case, it must be installed as shown in the diagram above. The anode (Non Striped)

side must be connected to the Gray/Black wire of the Remote Start Unit. The cathode (Striped) side

must be connected to the hood pin switch. If the hood pin switch is also used for an alarm trigger input,

be certain to use the dual diode assembly packaged with the Audiovox Remote Start Unit as shown in

this installation guide. (Page 9)

AFTER THECONNECTION OF THE NEUTRAL STAR TSAFETY WIRE AS INDICATED IN ANY OF THE

PREVIOUSALTERNATE CONFIGURATIONS, THISCIRCUIT MUSTBE TESTED FOR OPERATION.

Retest by following the steps outlined in the NEUTRAL START SAFETY TEST shown in this manual.

COMPLETING THE INSTALLATION:

After you have confirmed the operation of the Audiovox Remote Start unit and tested all the safety

features of the system:

1. If you have not done so already, place the red rubber handle cover over the handle of the control switch

for ease of identification. This will allow your customer to distinguish the Remote Start control switch

from the program switch.

2. Mount the control module up and behind the dash securing it in place with cable ties or screws. Be

certain that the chosen mounting location will not inhibit any of the controls of the vehicle.

3. Securely harness and tie all wiring up and away from all hot and moving parts that they may come in

contact with under the dash board or in the engine compartment areas.

CAUTION: Particularly avoid the area around the steering shaft and column, as wires can wrap around

these mechanisms and impair the safe operation of the vehicle.

4. Apply the Caution Labels supplied with this kit to a conspicuous area in the engine compartment.

Make sure to clean the surface before affixing the label.

5. Check the vehicle's wipers, lights, horn, etc.... to insure proper operation.

6. Replace all panels that were removed during installation, and retest the system.

7. Explain all activated features and safety systems associated with Remote Start Unit installed to the

customer.

21

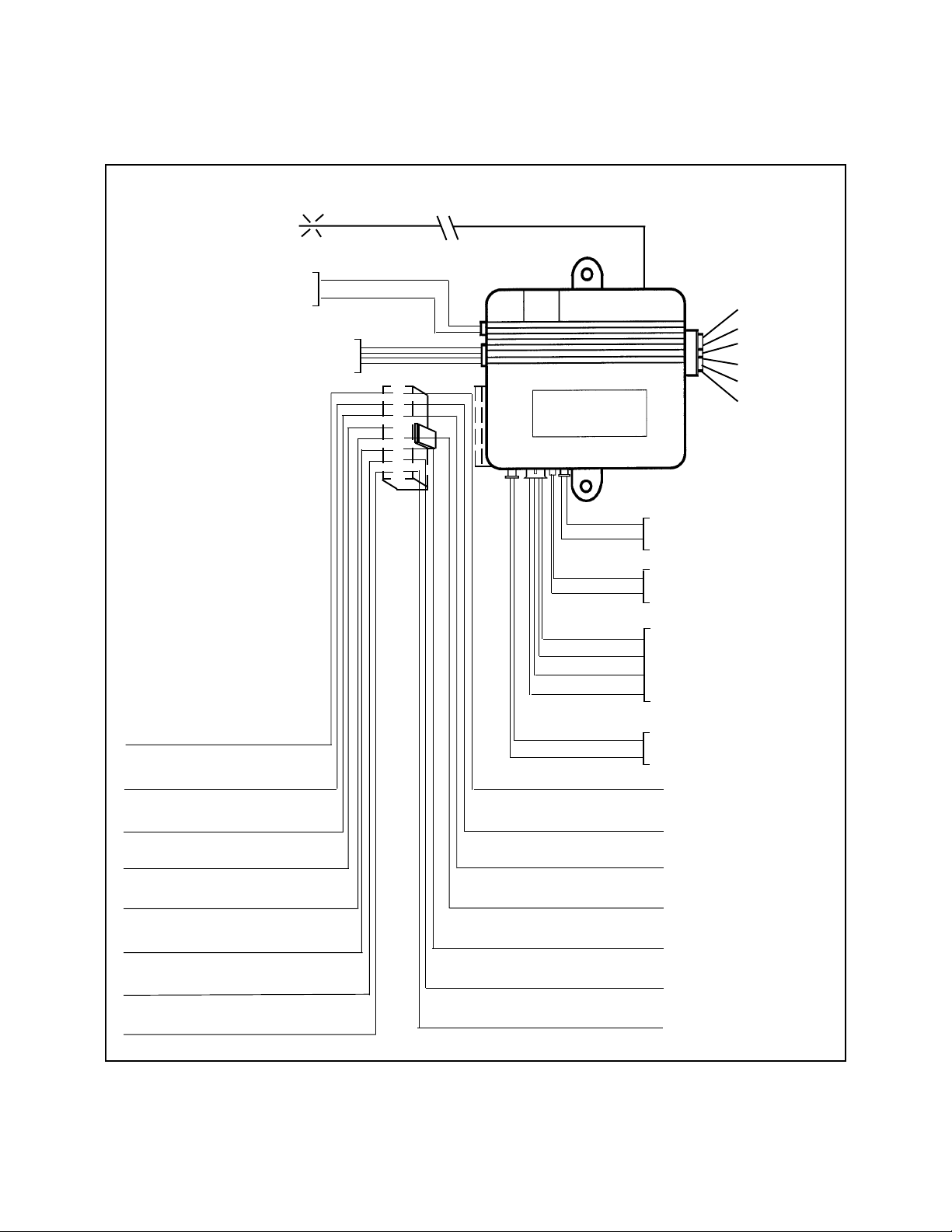

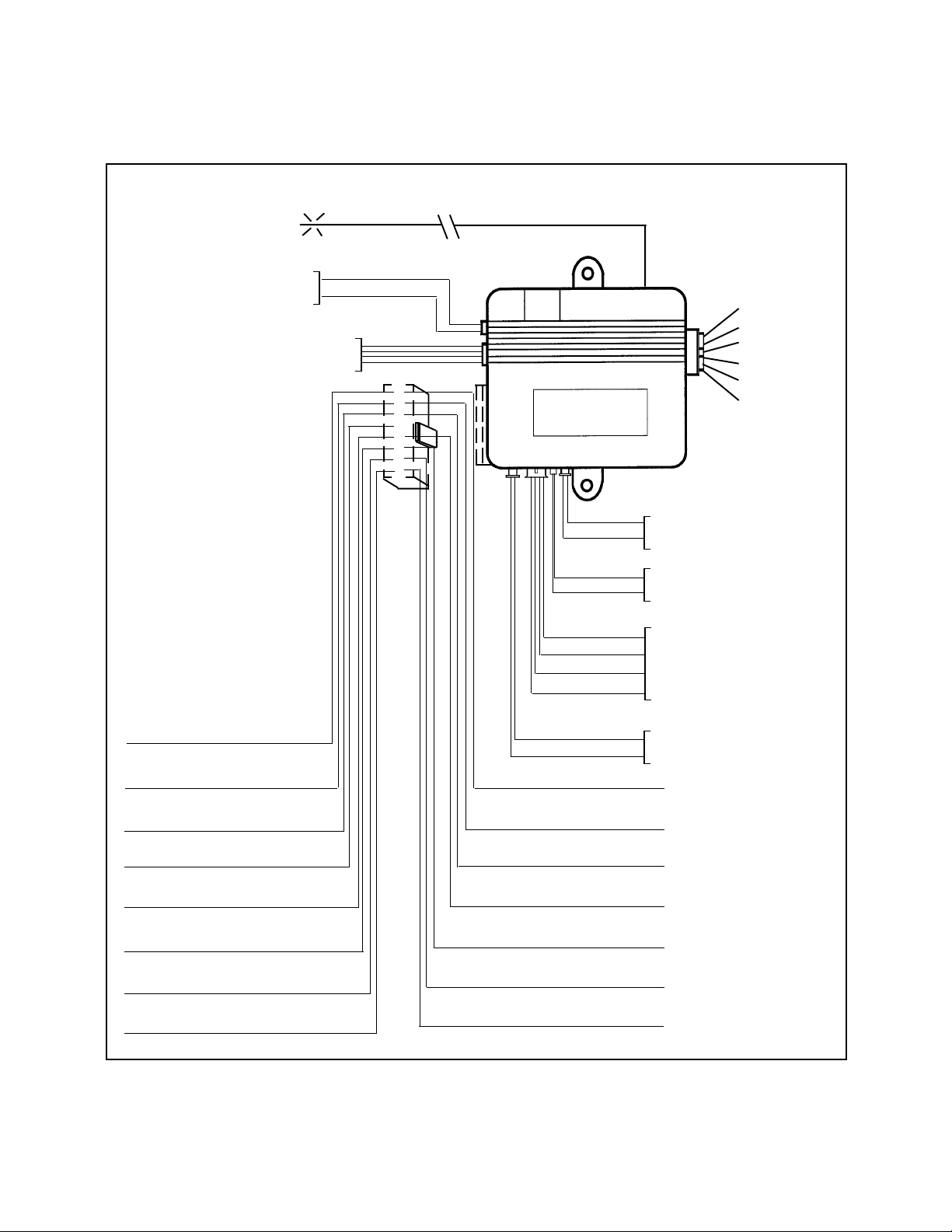

Page 22

ANTENNA WIRE

(See page 3)

V ALET/PROGRAMMING

SWITCH

(See page 13)

AUXILLIARY OUTPUTS

(See page 12)

MULTI-PINI/O HARNESS

(See page 6-12)

WIRING DIAGRAM

BLACK w/GRAY

GRA Y

CONTROL MODULE

APS-750a

6-PIN POWER

HARNESS

(See page4&5)

PURPLE

BLUE

RED

RED w/WHITE

YELLOW

GREEN

OUTPUT GREEN/BLACK (-)

TO CHANNEL 3CONTROL RELAY

OUTPUT DARK BLUE (-)

TO CHANNEL 2CONTROL RELAY

INPUT BROWN

FROM (-) DOOR TRIGGER

INPUT PURPLE

FROM (+) DOOR TRIGGER

INPUT BLACK

TO CHASSIS GROUND

INPUT BROWN/BLACK (+) SHUTDOWN

FROM BRAKE LIGHT SWITCH

OUTPUT ORANGE (-) CONTROL

TO STARTER INTERRUPT RELAY

INPUT GRAY/BLACK (-) SHUTDOWN

FROM HOOD SWITCH

GREEN

RED

RED

BLUE

RED

BLACK

GREEN

BLUE

BLACK w/WHITE

BLACK

OUTPUT GREEN w/WHITE

TO (-) DOME CONTROL RELAY

OUTPUT LIGHT BLUE

TO (-) IGNITION 3 CONTROL RELAY

INPUT DARK GREEN

TO (-) INSTANT TRIGGER

OUTPUT WHITE/ BLACK

TO (+) SIREN

INPUT GREEN/ORANGE

FROM TACHOMETER SIGNAL (-) COIL

INPUT WHITE/RED PARK LIGHTS

FROM +12 VOLTS OR GROUND SUPPLY

OUTPUT WHITE

TO PARK LIGHT +12VOLTSOR GROUND SWITCHED

(SEE WHITE/RED WIRE)

DOOR LOCKS

(See page 13)

L.E.D.

(See page 13)

SHOCK SENSOR

(See page 13 & 14)

CONTROL SWITCH

(See page 13)

Form No. 128-5402© 1998 Audiovox Corporation, Hauppauge, N.Y. 11788

Page 23

MODÈLE APS-750a

Manuel de l’installateur

Système de démarrage de véhicule

par télécommande à 4 canaux, avec

système d’alarme aux fonctionnalités complètes

Instructions pour l’installation

Cette unité est destinée à être installée uniquement sur les véhicules équipés de

systèmes électriques de 12 volts avec mise à la terre au négatif, de moteurs à essence

et de transmissions automatiques.

Le nécessaire comprend :

Module de commande APS-750a

(2) Émetteurs avec protection de codes, à trois boutons

Récepteur auto-adaptatif à quatre canaux

Antenne à portée étendue à bord du véhicule

Sirène à six tonalités modulées

(1) Faisceau entrée / sortie multibroches

(1) Faisceau sortie auxiliaire à six broches

(1) Faisceau d’alimentation à six broches

(1) Indicateur à DEL à deux broches

(1) Commutateur Valet / programmation à deux broches

(1) Commutateur de commande à deux broches

(1) Faisceau de détecteur de vibrations à quatre broches

(1) Faisceau de verrouillage de portes à deux broches

(1) Capteur de vibrations à deux positions

(1) Relais et douille d’inhibition du démarreur

(2) Porte-fusibles en ligne, avec fusibles 30 A

(1) Sac avec pièces pour contacteur de porte mâle

(2) Étiquettes d’avertissement à placer sous le capot

(1) Manuel de l’installateur

(1) Manuel de l’utilisateur

(1) Garantie limitée

(2) Décalcomanies à coller sur les vitres

23

Page 24

Le système d’alarme et de démarrage par télécommande APS-750a est conçu pourêtre utilisé uniquement sur desvéhicules

à transmission automatique ! L’unité ne fournit aucune sortiepour les bougies de préchauffage et n’est pas souhaitable sur

les véhicules diesel. Si le moteur diesel est à allumage instantané (aucunsystème de bougies de préchauffage), a uneentrée

de signal de tachymètre et une transmission automatique, il est alors possibled’utiliser l’unité. Pour les applications au diesel,

consulter votre revendeur pour déterminer quel est le type de système d’allumage de votre véhicule particulier.

INSTALLATION DES COMPOSANTS MAJEURS:

MODULE DE COMMANDE:

Choisir un emplacement de montage à l’intérieur du compartiment passagers (contre et derrière le tableau de bord). Cet

emplacement doit se trouver dans un rayonde 61 cm (24 po) du faisceaude conducteurs du commutateur d’allumage afin de

permettre le raccordement dufaisceau de câblage principal à six broches.

Il faut être sûr que l’emplacement choisin’interférera pas avec le bon fonctionnement duvéhicule. Éviter de monter le module

sur la colonne de direction ou de faire passer les fils autour de celle-ci car le module ou le câblage pourraient s’enrouler

autour du volant ou le bloquer et empêcher decontrôler le véhicule convenablement. Fixer le module à l’emplacementchoisi

à l’aide d’attaches de câble ou de vis, selon les besoins.

NE PAS monter le module dans le compartimentmoteur car il n’est pas étanche à l’eau.

SIRÈNE :

Choisir un emplacementà l’intérieur du compartimentmoteur qui nesoit pas accessible p arle dessous du véhicule. L’emplacement

choisi doit être dégagé des pièces chaudes ou mobiles du compartimentmoteur. La sirènedoit être pointée vers le bas pour

empêcher la rétention d’eau et l’extrémité qui s’élargit doit pointer au loin et vers l’extérieur du compartiment moteur pour

obtenir la répartition acoustique maximum. Avant defixer la sirène, vérifier le dos del’emplacement choisi pour s’assurer que

les vis de montage ne pourront pénétrer aucun des câblages montés enusine ou aucune des lignes de fluide.Fixer les pattes

de support de la sirène à l’aide de vis à auto-filetage nº 8 ou bien, se servird’abord d’une patte de support comme gabarit et

marquer les trois trous de montage de la patte. Percer les trois trousmarqués à l’aide d’une mèche de 1/8 po. puis monter la

sirène à l’aide de vis à tôle nº 8.

CONT ACTEURSMÂLES POUR CAPOTET COFFRE :

Les contacteurs mâles compris dans ce nécessaire sont prévus pour protéger le capot et le coffre du véhicule. Dans tous

les cas, le contacteur doit être monté sur une surface métalliquemise à la masse. Lorsque le contacteur est activé (capot ou

coffre ouvert), il fournit un courant de terre au fil d’entrée actionnant l’alarme. En outre, le contacteur de capot estnécessaire

à lasécurité de l’arrêt de l’unité de télécommande de démarrage. En cas de travail sur le véhicule, ce contacteur de capot

empêche l’activation du démarrage par télécommande,même sile signalde commandede démarrageRF aété émis. Ce

contacteur doit être installé dans toutes les applications. À défaut, il pourraiten résulter desdommages corporels et matériels.

Monter les contacteurs dans le capot ou le coffre en des endroits éloignésde tout trajet d’eau. Si nécessaire, on peut utiliser

les pattes de support fournies pour éloigner les contacteurs des gouttières de pluie et permettre de lesmonter sur la cloison

pare-feu, derrière le joint de capot. Dans les deux cas, le contacteur doit être installé pour que le capot ou le couvercle du

coffre puisse déprimer le contacteur d’au moins 1/4 po. lorsque le capot ou le coffre est fermé et pour que le contacteur soit

totalement en extension lorsque le capot ou le coffre est ouvert. Pour le montage direct, il faut percer un trou de 1/4 po.

Vérifier avec soin le dos de l’emplacement choisi pour s’assurer que la perceuse ne pourra pénétrer aucun des câblages

existants montés en usine ou aucune des lignes de fluide. Percer un trou de 1/4 po. à l’emplacement souhaité et visser le

contacteur mâle dans ce trou à l’aide d’un serre-écrou de 7/16 po. ou d’une douille profonde. Lorsqu’on utilise la patte de

support, il faut d’abord fixer la patte à l’emplacement souhaité puis fixerle contacteur mâle dans letrou pré-taraudé de la patte

de support.

DIODE ÉLECTROLUMINESCENTE (DEL) MONTÉESUR LE TABLEAUDE BORD :

La petite DEL rouge comprise dans le nécessaire sert d’indicateur visuel de l’état d’alarme et de moyen de dissuasion pour

le voleur potentiel. La DEL fournit aussi des renseignements de réaction importants au cours de la programmation de

l’émetteur et des fonctions et en modeprogrammé. La DEL doit être installée dansle tableau de bord à un endroit très visible,

tant du point de vue du conducteur que d’une personne située en dehors du véhicule. Inspecter le dos de l’emplacement

choisi pour s’assurer que la perceuse ne pourra pénétrer aucun des câblages existants montés en usine ou aucune des

lignes de fluide. Percer avec soin un trou de 1/4 po.à l’emplacement souhaité et faire passer l’extrémité du connecteur de la

DEL à travers le trou, dans la direction du module de commande. Appuyer fermement sur la DEL pour la mettre en place

correctement dans le trou de montage.

24

Page 25

ANTENNE D’EXTENSION DE PORTÉE :

L’antenne d’extension de portée fournie avec l’unité permet l’acheminer par le dessous du tableau de bord pour obtenir la

portée opérationnelle maximum. Choisir unemplacement au-dessus de la lignede ceinture (tableau de bord) du véhicule pour

obtenir la meilleure réception. Il faut tenir spécialement compte de la vitre du pare-brise car certains véhicules très récents

font usage d’un verre de pare-brise à écran métallique qui interrompt ou restreint la réception des radiofréquences (RF).

Dans ces véhicules, acheminer l’extrémité exposée (non blindée) vers une fenêtre arrière pour obtenir la meilleureréception

possible. Fixer l’extrémité exposée à l’aide de ruban adhésif sur deux côtés ou d’un bâtonnet de colle instantanée. Après

avoir fixé l’extrémité exposée de l’antenne avec le ruban adhésif ou la colle, nous conseillons de fixer aussi un section de

câble d’antenne à un support fixe. Ceciempêchera l’antenne de tomber si le rubanadhésif vient à être exposé à une extrême

chaleur etque l’adhésif se mette à perdre de son pouvoir.

COMMUTATEUR VALET / PROGRAMMATION /ASSERVISSEMENTMANUEL :

Choisir un emplacement de montage facile d’accès pour le conducteur du véhicule. Il n’est pas nécessaire de dissimuler le

commutateur,cependant, cette dissimulation est recommandée car elle of freun niveau plus élevé de sécurité. Le commut ateur

peut être monté sur le panneau inférieur du tableaude bord, dans la zone du conducteur. Inspecter le dos de l’emplacement

choisi pour s’assurerqu’il existe un dégagement suffisant pour le corps du commutateur et aussi, que la perceusene pourra

pénétrer aucun des câblages existants montés en usine ou aucune des lignes de fluide. Percer un trou de 1/4 po. à

l’emplacement souhaité et monter le commutateur en le faisant passer à travers le panneau, à partir du dessous. Fixer le

commutateur à l’aide de l’écrou, de la rondelle étoilée et du couvercle de protection. Il est suggéré d’orienter le commutateur

de sorte que la position de marche (ON) soit vers le haut, dans la direction du conducteur et la position d’arrêt(OFF) vers le

bas, dans la direction opposée au conducteur.Acheminer le connecteur du commutateurvers le module de commande.

COMMUTATEUR DE COMMANDE:

Choisir un emplacement de montage facile d’accèspour le conducteur du véhicule. Un panneauinférieur du tableau de bord,

une plinthe ou une boîte à gantssont à recommander.Inspecter le dos de l’emplacement choisi pour s’assurer qu’ilexiste un

dégagement suffisant pour le corps du commutateur et aussi, que la perceuse ne pourra pénétrer aucun des câblages

existants montés en usine ou aucune des lignes de fluide. Percer un trou de 1/4 po. à l’emplacement souhaité et monter le

commutateur en le faisantpasser à travers le panneau, à partir du dessous. Fixer le commutateur à l’aide de l’écrou, de la

rondelle étoilée et du couvercle de protection. Il est suggéré d’orienter le commutateur de sorte que la position de marche

(ON) soit vers le haut, dans la direction du conducteur et la position d’arrêt (OFF) vers le bas, dans la direction opposée au

conducteur.Acheminer le connecteur du commutateur vers le module de commande. Placer le capuchon en caoutchouc

ROUGE, inclus dans le nécessaire,sur la manette du commutateur pour le différencierdu commutateur Valet /programmation.

DÉTECTEUR DE VIBRATIONS :

Choisir, pour ledétecteur de vibrations, une surface de montage solide, centralementsituée, qui permette le fonctionnement

régulier en provenance de toutes les zones du véhicule. L’endroit sélectionné doit se trouver dans un rayon de 18 po. du

module de commande afin de permettre l’acheminement et la connexion du faisceau à quatre broches. Fixer le détecteur de

vibrations à l’endroit choisi, à l’aide de deux vis à tôlenº 8 à auto-taraudage. Le détecteur peut aussi être fixé surun montant

de support du tableau debord par des attaches decâble. Quelque soit la méthode de montage utilisée, il faut veiller à ménager

un accès au potentiomètre de réglage de sensibilité dont on fera usage ultérieurement au cours de l’installation.

RELAIS D’INHIBITION DU DÉMARREUR:

Choisir un emplacement de montage dans un rayon de 12 po. du fil du solénoïde pour faible courant de démarrage du

commutateur de contact. Fixer le relais à un faisceau existant dans l’emplacement choisi à l’aide d’attaches de câble fixées

autour du faisceau de câbles du relais. Attention ! Ne pasattacher la patte de support métallique à un faisceau existant avec

l’attache de câble car les vibrations pourraient causer un frottement et des court-circuitsendommageant le câblage d’usine.

S’il n’existe pas de faisceau existant disponible, fixer alors la patte de montagemétallique du relais à un montant de support

sous le tableau de bord à l’aide d’une vis à tôle nº8 à auto-taraudage. Câbler le relais selon le schéma de montage fourniplus

loin dans le manuel.

25

Page 26

L’APS-750a doit êtreutilisé uniquement sur les véhicules équipés de TRANSMISSIONS AUTOMATIQUES! Quoique l’unité

associant le système d’alarme et de démarrage par télécommande soit sophistiqué et comporte beaucoup de fonctions

avancées, IL NE DOIT PAS être installé sur un véhicule à changement de vitesse manuel. Il pourrait en résulter des

dommages corporels et matériels graves.

IMPORTANT!

NE PASBRANCHER LE FAISCEAU D’ALIMENTA TIONPRINCIP ALÀ SIXBROCHESNI LE FAISCEAU D’ENTRÉE / DESORTIEÀ

BROCHES MULTIPLESSUR LEMODULE DECOMMANDE TANTQUETOUTESLESCONNEXIONSAU VÉHICULE N’ONTPASÉTÉ

EFFECTUÉES.APRÈSAVOIRCHOISI LE CONDUCTEUR CIBLE COMME IL EST DÉFINI CI-DESSOUS, DÉBRANCHERLECÂBLE

NÉGATIFDEBA TTERIEDE LABA TTERIEDUVÉHICULEA V ANTD’EFFECTUER AUCUNE CONNEXION.

CÂBLAGE DU FAISCEAU D’ALIMENTATION PRINCIPAL À SIX BROCHES:

Fil BLANC à ligne ROUGE : + source 12 volts de la batterie 1

Connecter ce fil à une source de tension constante de +12 Vccau commutateur d’allumage du véhicule en utilisantun fusible

de 30 ampères et son porte-fusible fourni.

Fil ROUGE : + source 12 volts de la batterie 2

Connecter ce fil à une source de tension constante de +12Vcc trouvée à l’allumage du véhicule en utilisant un fusible de 30

ampères et son porte-fusible fourni, maisNON PAS le même fil du véhiculeque celuiutilisé par la source de batterie 1. La

plupart des véhiculesont plusieurs sources de batterie alimentant le commutateur d’allumage en énergie. Des fils d’alimentation

séparés doivent être utilisés pour les fils Rouge etRouge/Blanc. Si votre véhicule ne dispose pas de deuxfils d’alimentation

de batterie au commutateur d’allumage il est alors possible de connecter les deux fils à la batterie du véhicule.

IMPORTANT!

Le technicieninstallateur est responsable de déterminer le facteur de charge des circuits électriques du véhicule lorsque

celui-ci tourne et d’installer des fusibles adaptés aux deux fils d’alimentation en fonction de cette charge. Si le véhicule

tournant en charge avec l’air conditionné,le moteurde lasoufflante duradiateur etdes accessoiresdépasse 24 ampères

en courant continu, nous recommandons d’utiliser deuxfusibles en association sur chaque fil d’alimentation,comme indiqué

ci-dessous. Pour tous renseignements complémentaires, consulter la Mise à jour technique publiée le30/9/96.

Vers l’unité dedémarrage

En provenance de lasource de batterie

Fil JAUNE : sortie du démarreur

Il faut considérer soigneusement la connexion de ce fil pour éviter que le véhicule ne démarre lorsqu’il est en

prise. La compréhension de la différence entre un commutateur de démarrage au neutre mécanique et

électrique permet d’identifier correctement le circuit et de choisir la méthode d’installation correcte. En outre,

cela permet de réaliser pourquoi le connexion du fil de sécurité est requise dans toutes les configurations de

commutateur mécanique.

À défaut d’effectuer cetteconnexion correctement, il peut en résulter des dommages corporels et matériels.

Dans toutes les installations c’est letechnicien installateurqui estresponsable d’effectuerles testsde l’unitéde démarrage

par télécommande et d’assurer que le véhicule ne puisse pas démarrer au moyen de la commande à radiofréquence lorsqu’il

se trouve sur une vitesse autre que le frein de parking ou le neutre.

Dans les configurations du neutre tant mécaniques qu’électriques d’uncommutateur de démarrage, la connexion du fil Jaune

se fait au fil de courant faible du solénoïde de démarrage qui se trouve dans le faisceau du commutateur d’allumage.Ce fil est

sous tension de +12 volts lorsqu’on tourne la clé de contact seulement sur la position démarrage (CRANK). Ce fil est sous

tension de 0 volt à toutes les autres positions du commutateur d’allumage.

REMARQUE :Ce fil doit être connecté au côté véhicule du relais de coupure du démarreur (lorsque celui-ci est utilisé). Pour

la configuration au neutre électrique du commutateur,cette connexiondoit être faite entre le relais d’inhibition du démarreur

(lorsque celui-ci est utilisé) et le commutateur de sécurité au neutre, tel que l’illustre le schéma suivant.

Le défaut de connexionde ce fil au côté commutateur d’allumage du commutateur de sécurité au neutre peut entraîner des

dommages corporels et matériels.

VOIR LES TESTS DE SÉCURITÉDUDÉMARRAGEAUNEUTREPOUR PLUS DE DÉTAILS.

par télécommande

Rouge et/ou rouge/blanc

26

Page 27

DÉTAIL DU FILDE DÉMARRAGE JAUNE

Bouton commutateur

d’allumage

Connexion de démarrage télécommandé

Commutateur de

sécurité neutre

Moteur de

démarreur

Relais d’inhibition du

démarreur (lorsque

celui-ci est utilisé)

Fermé sur Parking ou

Neutre seulement

Fil BLEU : Sortie allumage1

Connecter ce fil au fil d’allumage 1 sortant du commutateur d’allumage. Ce fil indique une tension de +12 volts lorsqu’on

tourne la clé de contactsur les positions marche (ON/RUN) ou démarrage(STA R T/CRANK)et une tension de 0 volt lorsque

la clé est tournée sur les positions arrêt (OFF) et accessoires (ACCESSORY).

Fil VERT : Sortie allumage 2

Connecter ce fil au fil d’allumage 2 sortant du commutateur d’allumage. Ce fil indique une tension de +12 volts lorsqu’on

tourne la clé de contactsur les positions marche (ON/RUN) et danscertains cas la position démarrage(STA RT ou CRANK).

Le fil indique une tension de0 voltlorsque laclé esttournée surles positionsarrêt (OFF) et accessoires (ACCESSORY).

Fil MAUVE : Sortie accessoires

Connecter ce fil au fil d’accessoires sortant du commutateur d’allumage. Ce fil indique une tension de +12 volts lorsqu’on

tourne la clé de contact sur les positions accessoires (ACCESSORY) ou marche (ON/RUN) et une tensionde 0 volt lorsque

la clé est tournée sur les positions arrêt (OFF) et démarrage (START/CRANK).

CÂBLAGE DU FAISCEAU D’ALIMENTA TION À 6 BROCHES

M

B

R

R

O

O

U

U

J

G

A

V

U

E

N

R

E

T

G

E

E

B

L

A

N

C

VOIR *CâBLAGE DU

CONNECTEUR

D’ACCESSOIRES, FIL

BLEU CLAIR

A

L

U

E

V

U

E

POSITIONS DE LA CLÉ DE CONTACT

ARRêT

ACCESSOIRES

MARCHE

DÉMARRAGE

ACC

ALL 1

BA T2

BA T1

DÉMAR

ALL 2

*ALL 3*

+12 VOLTS SUR LA POSITION DE COMMUTATEUR INDIQUÉE

PEUT ÊTRE +12 VOLTS SUR LA POSITION DE COMMUTATEUR INDIQUÉE

* CE CIRCUIT N’EST PAS TOUJOURS NÉCESSAIRE POUR L’INSTALLATION

27

Page 28

CONNEXIONS DE CÂBLAGE : Faisceau entrée / sortie des accessoires à broches multiples

Fil Blanc avec ligne Rouge : alimentation des feux de positions clignotants

Ce fil est le contact commun du relais de feux de position clignotants d’origine. Si le véhicule sur lequel on travaillea des feux

de position activés par commutateur sous +12 volts, connecter ce fil à une source de +12 volts avec fusible. (Max. 15

ampères).

REMARQUE : si les feux de position du véhicule sont mis à la terre, connecter ce fil à la masse du châssis.

Fil Blanc : sortie des feux de position clignotants

Ce fil est le contact normalement ouvert du relais de feux de position clignotants d’origine. Connecter ce fil au fild’alimentation

des feux de position du véhicule. Voir le schéma ci-dessous pour plus de détails sur le câblage des circuits des feux de

position commutés positivement.

Détail du câblage des feux de position

Feux de position du véhicule

En provenance du commutateur

de feux de position

Blanc venant du module de

Versun source de tension

+12 voltsconstante

(voir Remarque si la terre

est commutée)

Fil Blanc avec ligne Noire : (+) sortie sirène

Il s’agit du fil d’alimentation positif de la sirène. Acheminer ce fil dans un passe-câble à travers la cloison pare-feu jusqu’à

l’emplacement de la sirène. Connecter le filBlanc avec ligne Noire au fil Rougede la sirène. Fixer le fil Noir de la sirène à une

mise à la masse connue duchâssis ouune surfacemétallique propreet pleine.

Fusible ajouté de

15 ampères

démarrage télécommandé

Blanc avec ligne Rouge, fil venant du

module de démarrage télécommandé

Détail du câblage de la sirène

Rouge

SIRENE

Noir

Vers le fil Blanc àligne Noire du module

(-) Vers la masse chaissis du vehicule

28

Page 29

Fil Violet: (+) entrée du déclencheur de porte

Si la lampe de courtoisie de la porte du véhicule fonctionne sous +12volts lorsqu’on ouvre la porte (la plupart des modèles

Ford et quelques importations), vous devez connecter ce fil à la sortie positive provenant de l’un des contacteurs de porte