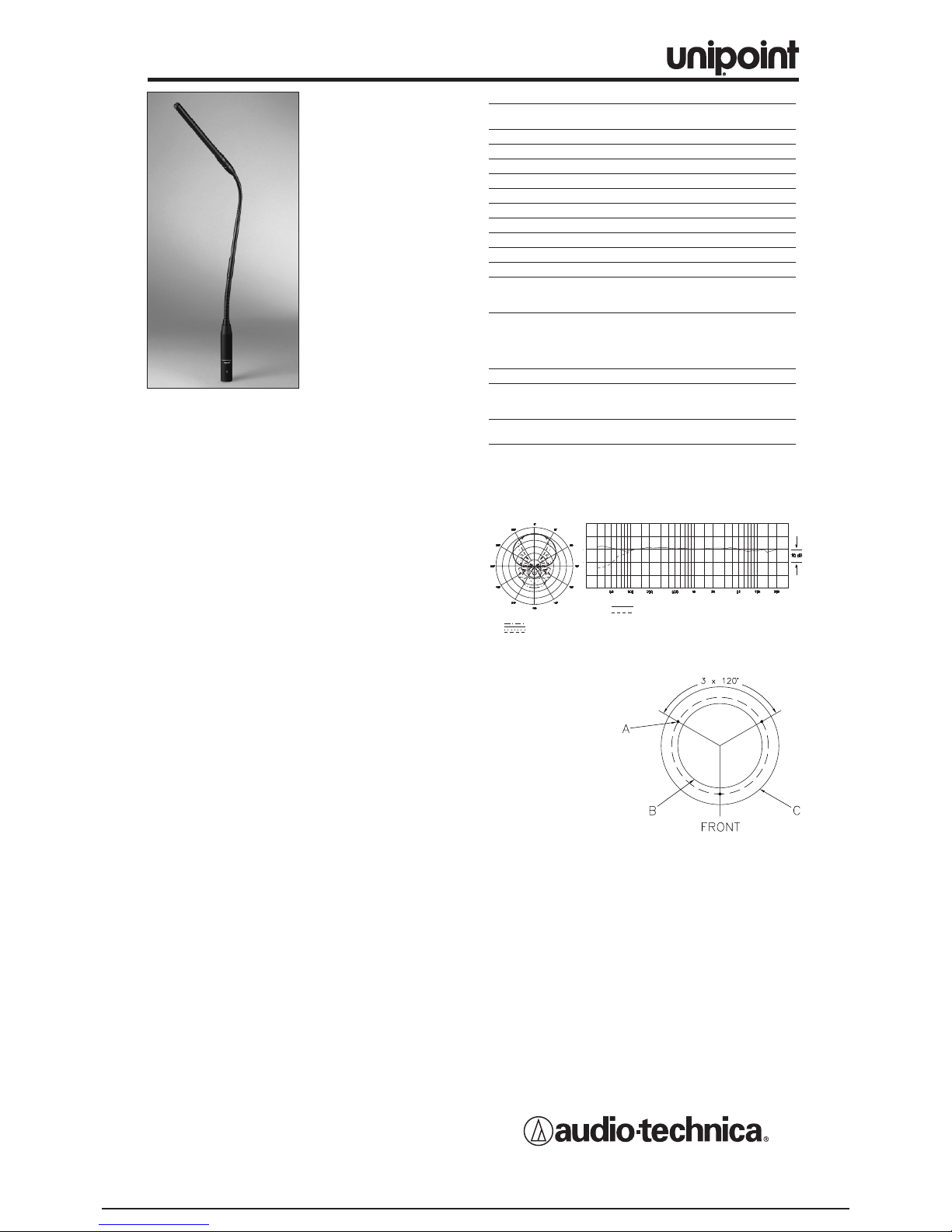

Audio Technica unipoint U857QLU, unipoint U857QU Specifications

• Designed for high-quality

sound reinforcement,

professional recording and

broadcasting

• UniLine

™

polar pattern

provides narrow 90°

acceptance angle

• Superior off-axis rejection for

maximum gain before

feedback

• UniGuard

™

RFI-shielding

technology offers outstanding

rejection of radio frequency

interference (RFI)

• Easy-to-adjust, rugged,

small-diameter, alternating

gooseneck with virtually no

“memory” permits quick

positioning into desired shape

• UniSteep

®

filter provides a

steep low-frequency

attenuation to improve sound

pickup without affecting voice

quality

• Self-contained electronics eliminate need for external power

module

• Accepts interchangeable elements to permit angle of

acceptance from 90° to 360°

• Two-stage foam windscreen yields dramatically improved

resistance to P-pops and other breath blasts

• Quick-mount design with 3-pin XLRM-type connector insert at

base plugs into any standard XLRF-type surface or cable

connector

•

Included shock mount attenuates noise, shock and vibration

transmitted through the mounting surface

The U857QU stands 19.17" (487.0 mm) from the table or podium; it

is also available in a 23.74" (603.0 mm) version as U857QLU. The

two models are identical in all other respects.

The U857QU requires 11V to 52V phantom power for operation.

Output from the microphone’s XLRM-type connector is low

impedance (Lo-Z) balanced. The signal appears across Pins 2 and

3; Pin 1 is ground (shield). Output phase is “Pin 2 hot” – positive

acoustic pressure produces positive voltage at Pin 2.

An integral 80 Hz high-pass UniSteep

®

filter provides easy

switching from a flat frequency response to a low-end roll-off. The

roll-off position reduces the microphone’s sensitivity to popping

in close vocal use. It also reduces the pickup of low-frequency

ambient noise (such as traffic, air-handling systems, etc.), room

reverberation and mechanically coupled vibrations.

A

void leaving the microphone in the open sun or in areas where

temperatures exceed 110° F (43° C) for extended periods.

Extremely high humidity should also be avoided.

8 kHz

Polar Pattern

SCALE IS 5 DECIBELS PER DIVISION

LEGEND

200 Hz

1 kHz

5 kHz

F

requency in Hertz

LEGEND

12" or more on axis

Roll-off

Frequency Response

Response in dB

Audio-Technica U.S., Inc., 1221 Commerce Drive, Stow, Ohio 44224

Audio-Technica Limited, Old Lane, Leeds LS11 8AG England

www.audio-technica.com

P51692 ©2005 Audi

o-Technica U.S., Inc. Printed in U.S.A.

U857QU/U857QLU

U857QU/ U857QLU SPECIFICATIONS

†

ELEMENT Fixed-charge back plate

per

manently polarized condenser

POLAR P

ATTERN

Line Cardioid

FREQ

UENCY RESPONSE

30-20,000 Hz

LO

W FREQUENCY ROLL-OFF

80 Hz, 18 dB/octa

ve

OPEN CIRCUIT SENSITIVITY –35 dB (17.7 mV) re 1V at 1 Pa*

IMPED

ANCE

250 ohms

MAXIMUM INPUT SOUND LEVEL 135 dB SPL, 1 kHz at 1%

T.H.D.

D

YNAMIC RANGE

(typical)

115 dB, 1 kHz at Max SPL

SIGNAL-TO-NOISE RATIO

1

74 dB, 1 kHz at 1 Pa*

PHANT

OM POWER REQUIREMENTS

11-52V DC

, 2 mA typical

SWITCH Flat, roll-off

WEIGHT

U857Q

U

5.7 oz (161 g)

U857QLU 5.9 oz (167 g)

DIMENSIONS

U857Q

U

19.17" (487.0 mm) long

U857QLU 23.74" (603.0 mm) long

BO

TH

0.48" (12.2 mm) head diameter

,

0.74 (18.9 mm) base diameter

OUTPUT CONNECT

OR

Integ

ral 3-pin XLRM-type

OPTIONAL INTERCHANGEABLE UE-C cardioid (120°);

ELEMENTS UE-H h

ypercardioid (100°);

UE-O omnidirectional (360

°)

A

CCESSORIES FURNISHED

A

T8154 two-stage foam

windscreen;

AT8662 shock mount

†

In the interest of standards development, A.T.U.S. offers full details on its test

methods to other industr

y professionals on request.

*1 Pascal = 10 dynes/cm

2

= 10 microbars = 94 dB SPL

1

Typical, A-weighted, using Audio Precision System One.

Specifications are subject to change without notice

.

UNILINE™CONDENSER QUICK-MOUNT

GOOSENECK MICROPHONES

Shock Mount Installation

AT8662 mounting dimensions

A.1/16" (1.5 mm) pilot

holes 3 places on

2.29" (58.2 mm) circle.

B. 2.0" (51.0 mm)

through-hole for mount

clearance

C. Outside edge of

flange, 2.79"

(71.0 mm) diameter

Drawing not actual size.

1. Find the center of the mounting location and mark it. Allow

enough clearance to accommodate the shock mount's flange

on the surface and make certain there are no physical

obstructions below the desired location.

2. Using 2.0" (51.0 mm) hole saw, drill the large through-hole for

the shock mount.

3. Set the shock mount into the hole and mark the location of the

three mounting screw holes.

Make certain to “center” the

mount in the large hole before marking the three small

mounting screw locations.

4. Using a 1/16" (1.5 mm) drill bit, drill three pilot holes for the

mounting screws.

5.

After installing the microphone, assure maximum shock

mounting effectiveness by providing some slack in the

connecting cable.

Loading...

Loading...