Page 1

ES933PMH

LESS THAN 2 TIMES “X”

DISTANCE “X”

100°

ANGLE OF

ACCEPTANCE

MIC A

2.5 TIMES

DISTANCE “X”

MIC B

100 °100°

Shield strands,

fully twisted

Yellow-Yellow

Red-Red

1

/8" strip reds

and yellows

1

/2"

1"

v+

SIG

GND

3

2

1

Terminal screws

RED/

RED

YEL / YEL

SHIELD

INPUT

AUDIO AUDIO +

SHIELD

OUTPUT

HYPERCARDIOID CONDENSER

HANGING MICROPHONE

DESCRIPTION

The ES933PMH is a wide-range

miniature condenser microphone with

a hypercardioid polar pattern. It is

designed for quality sound reinforcement, professional recording, television

and other demanding sound pickup

applications. The ES933PMH is

furnished with a vinyl-coated steel

hanger that allows it to be adjusted for

correct positioning. An included snapon foam windscreen effectively

reduces noise from wind or ventilation

air currents.

The ES933PMH is equipped with

UniGuard

®

RFI-shielding technology,

which offers outstanding rejection of

radio frequency interference (RFI). The

microphone is RoHS compliant – free

from all substances specified in the EU

directive on hazardous substances.

The microphone's hypercardioid polar

pattern provides a 100° angle of

acceptance. Additional interchangable elements with omnidirectional (360°), cardioid (120°) and MicroLine

®

(90°) pickup patterns

are available.

The microphone features a 50' (15.2 m) permanently attached

miniature cable. Its free end connects to the provided AT8534

wall/ceiling plate power module via TA3F-type connector. The

power module features a white-finished standard electrical cover

plate for easy, secure installation. The microphone can be powered

from any external 11V to 52V DC phantom power supply. Switches

in the power module permit a +10 dB gain setting for extra sensitive

pickup as well as a choice of flat response or low-frequency roll-off

(via integral 80 Hz high-pass UniSteep

®

filter) to help control

undesired ambient noise.

The microphone is enclosed in a rugged housing with a lowreflectance black finish. It is also available with white housing,

cable and hanger as the ES933PMWH.

INSTALLATION AND OPERATION

The combination of small size and excellent response makes the

ES933PMH ideal for suspension over choirs, instrumental groups

or theater stages. A uniform 100° angle of acceptance provides

well-balanced audio pickup. The microphone should be located

forward of the front-most source, above the rear-most source, and

“aimed” between them (Fig. 1). Increasing the height of the mic

above the sources will tend to equalize sound levels between

them, but may also increase pickup of background or reverberant

sound. Whenever possible, the distance from the mic to the rearmost source should be no more than twice the distance to the front

source, to maintain front-to-rear balance (Fig. 1).

The AT8534 wall/ceiling plate power module is designed to be

mounted in a standard metal U.S. single-gang electrical box. For

safety and best performance, use the electrical box

only for the

AT8534; do not include any AC power conductors. (Also route the

mic cable as far away from AC power cables as possible.)

Screw-terminal output connections of the AT8534 are the same as

those of an XLR-type plug: shield to Terminal 1, balanced signal

and phantom power to Terminals 2 and 3. Output is phased so that

positive acoustic pressure produces positive voltage at Terminal 2,

in accordance with industry convention.

cable shield to the box

. Double-check to make certain that all

Do not connect the output

input and output leads have no bare wires or loose strands that

could touch each other, the circuit board or the electrical box.

Then attach the power module plate to the electrical box.

Connect the TA3F-type connector from the microphone's cable to

the TA3M-type connector in the power module plate.

NOTE: Audio-Technica has developed a special RFI-shielding

mechanism that is an integral part of the connectors in the

Engineered Sound line. If you remove or incorrectly replace the

connector, you may adversely affect the unit's RFI immunity.

Audio-Technica offers a crimp tool (ATCT) and RFI shields for

TA3F-type, TA5F-type and XLRM-type connectors that enable you

to shorten the cable and correctly reinstall the connector while

maintaining the highest level of RFI immunity.

If you need to shorten the cable between the microphone and

power module, it can be done two ways:

a.If RF integrity must be maintained, the TA3F-type connector can

be removed from the cable end, the cable shortened and the

connector replaced using Audio-Technica's available crimp tool

and RFI shield for TA3F-type connector to maintain original RFI

shielding. (See note above.)

b.If RFI immunity is not required, the TA3M-type connector on the

plate can be removed and discarded (save the back nut and

washer). Assemble the included plastic ferrule into the hole left

from the TA3M-type connector, using the washer and nut from

the connector to secure the ferrule. Cut the cable to the desired

length plus a few inches. Thread the cable through the ferrule

and tie a knot in the cable behind the ferrule to secure it.

Carefully strip the ends of the cable and connect the wires to

the terminals formerly occupied by the TA3M-type connector.

Maintain color coding (Shield - S, Yellow - Y, Red - R) and

connect the microphone wires to the appropriate terminal

screws. (Fig. 3)

NOTE: The cable has two red wires and two

yellow wires. Twist the two red wires together and the two yellow

wires together. (Fig. 4)

(Continued on back)

Width of pickup is approximately 2.5 times the distance to the

closest performer. If additional mics are needed for wide sources,

they should be positioned apart laterally at least 2.5 times the

distance to the front source, to avoid phase cancellation (Fig. 2).

To orient the microphone in the proper direction, twist the housing

slightly in its wire holder (clockwise rotation moves the microphone

to the right; counterclockwise rotation moves it to the left).

The provided foam windscreen simply snaps over the head of the

microphone, effectively reducing noise from wind or ventilation air

currents.

®

An integral 80 Hz high-pass UniSteep

filter provides easy

switching from a flat frequency response to a low-end roll-off. The

roll-off position reduces the pickup of low-frequency ambient noise

(such as traffic, air-handling systems, etc.), room reverberation and

mechanically coupled vibrations. To engage the UniSteep

slide the switch toward the “bent” line.

A 10 dB gain switch is provided for situations that demand extra

sensitive pickup. The +10 position increases the microphone's

overall output by 10 dB. To engage the 10 dB gain, slide the switch

toward the +10 position.

®

filter,

Figure 1

Figure 3

Figure 2

Figure 4

Page 2

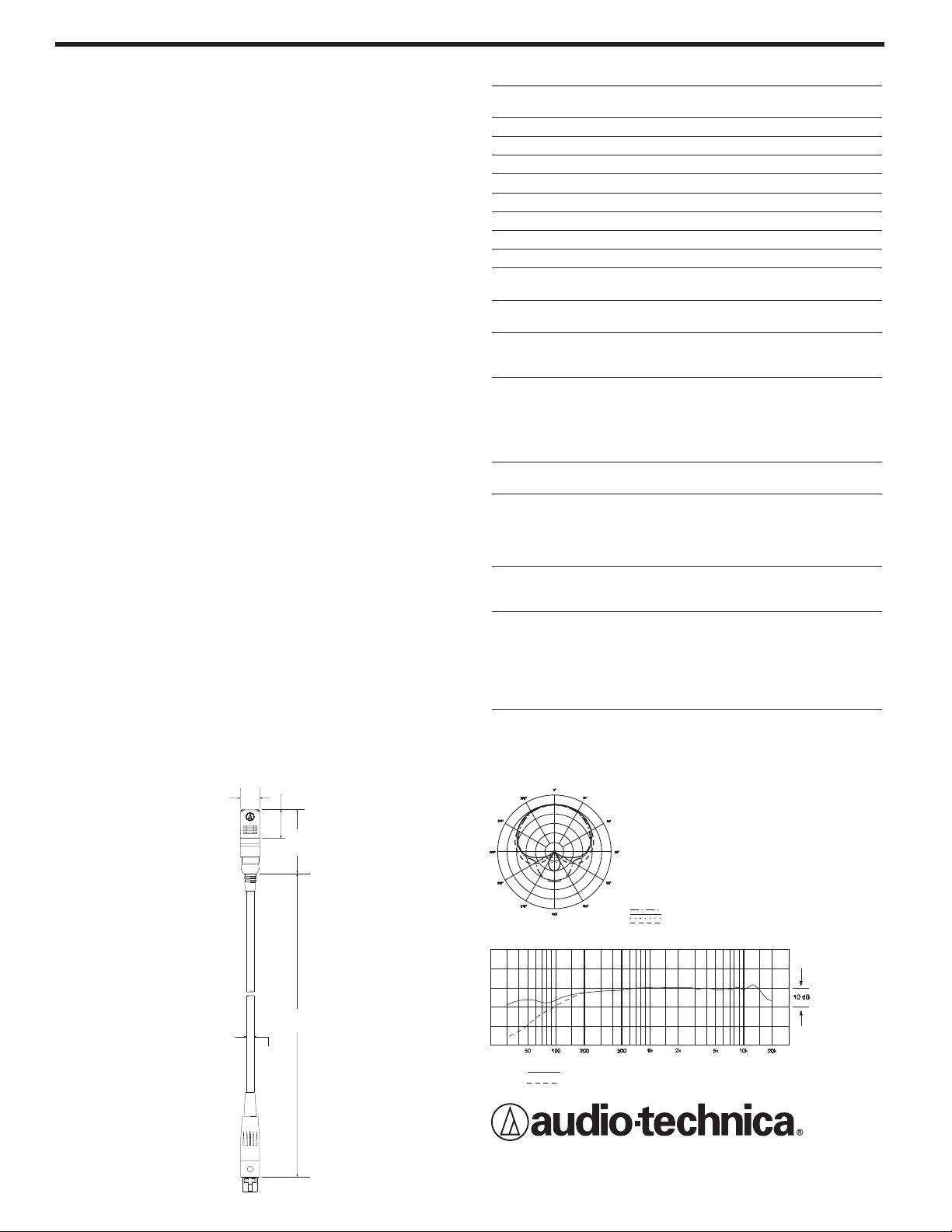

Frequency in Hertz

LEGEND

12" or more on axis

Frequency Response

Response in dB

Roll-off

8 kHz

Polar Pattern

SCALE IS 5 DECIBELS PER DIVISION

LEGEND

200 Hz

1 kHz

5 kHz

0.48"

12.3 mm

0.33"

8.4 mm

1.08"

27.5 mm

50'

15.2 M

0.13'

3.2 mm

While a modern condenser microphone is not unduly sensitive to

the environment, temperature extremes can be harmful.

Avoid leaving the microphone in the open sun or in areas where

temperatures exceed 110° F (43° C) for long periods of time.

Extremely high humidity should also be avoided.

ARCHITECTS AND ENGINEERS SPECIFICATIONS

The microphone shall be a fixed-charge condenser designed for

suspended installation in permanent applications. It shall have a

frequency response of 80 Hz to 20,000 Hz and a hypercardioid

polar pattern with uniform 100° angle of acceptance. It shall be

capable of accepting optional interchangeable elements for

additional polar patterns. It shall be capable of handling sound

input levels up to 128 dB with a dynamic range of 102 dB. Nominal

open-circuit output voltage shall be 10.0 mV at 1 kHz, 1 Pascal.

Output shall be low impedance balanced (200 ohms).

The microphone shall operate from an external 11V to 52V DC

phantom power source. It shall offer outstanding rejection of radio

frequency interference (RFI).The microphone shall be RoHS compliant.

The microphone shall have a permanently attached 50' (15.2 m)

miniature low-noise cable. Its free end shall connect to a provided

plate power module via a TA3F-type connector. An optional crimping

tool and crimp sleeves shall allow for shortening of the cable

without loss of RFI immunity.

The plate power module shall be designed to mount over a standard

single gang metal electrical box for ceiling or wall mounting. The

power module shall be provided with a switch for low-frequency

roll-off. The low-frequency roll-off shall be a tailored roll-off at 80

Hz to minimize pickup of unwanted mechanical noise. In addition,

the power module shall incorporate a switchable +10 dB gain

setting. The power module face plate shall be semi-gloss white

and mounting screws shall be included.

Output connections on the power module shall be screw terminals.

For suspended installations, the microphone shall be provided

with an adjustable steel wire hanger. The steel wire hanger shall

attach to the microphone body and allow for the positioning of

the microphone without the need for tools. Microphones using

goosenecks or other methods for positioning shall be

unacceptable. A snap-on foam windscreen shall be provided.

The microphone shall be 1.08" (27.5 mm) long with a head diameter

of 0.33" (8.4 mm). The microphone weight shall be 0.2 oz

(5.5 grams) without cable. The microphone case, cable and steel

hanger shall be finished in black [white].

The Audio-Technica ES933PMH [ES933PMWH] is specified.

ES933PMH SPECIFICATIONS

†

ELEMENT Fixed-charge back plate

permanently polarized condenser

POLAR PATTERN Hypercardioid

FREQUENCY RESPONSE 80-20,000 Hz

LOW-FREQUENCY ROLL-OFF 80 Hz, 18 dB/octave

OPEN CIRCUIT SENSITIVITY –40 dB (10.0 mV) re 1V at 1 Pa*

IMPEDANCE 200 ohms

MAXIMUM INPUT SOUND LEVEL 128 dB SPL, 1 kHz at 1% T.H.D.

DYNAMIC RANGE (typical) 102 dB, 1 kHz at Max SPL

SIGNAL-TO-NOISE RATIO

1

68 dB, 1 kHz at 1 Pa*

PHANTOM POWER 11-52V DC, 4 mA typical

REQUIREMENTS

SWITCHES

Flat, roll-off;

0 dB, +10 dB gain setting

WEIGHT

MICROPHONE

5.5 g (0.2 oz)

POWER MODULE 97 g (3.4 oz)

DIMENSIONS

MICROPHONE

27.5 mm (1.08") long,

8.4 mm (0.33") head diameter

POWER MODULE 71.0 mm (2.80") W x

115.5 mm (4.55") H x

36.0 mm (1.42") D

OUTPUT CONNECTOR Screw terminals

(power module)

CABLE 15.2 M (50') long (permanently

attached to microphone), 3.2 mm

(0.13") diameter, 2-conductor

shielded cable, terminated with

TA3F-type connector

OPTIONAL INTERCHANGEABLE ESE-O omnidirectional (360°);

ELEMENTS ESE-C cardioid (120°);

ESE-ML MicroLine®(90°)

ACCESSORIES FURNISHED

ES933PMH AT8109 two-stage foam

windscreen; AT8452 steel hanger

ES933PMWH AT8109(WH) two-stage foam

windscreen; AT8452(WH) steel

hanger

Both AT8534 power module

†In the interest of standards development, A.T.U.S. offers full details on its test

methods to other industry professionals on request.

*1 Pascal = 10 dynes/cm

1

Typical, A-weighted, using Audio Precision System One.

Specifications are subject to change without notice.

2

= 10 microbars = 94 dB SPL

Audio-Technica U.S., Inc., 1221 Commerce Drive, Stow, Ohio 44224

Audio-Technica Limited, Old Lane, Leeds LS11 8AG England

www.audio-technica.com

P51929 ©2007 Audio-Technica U.S., Inc. Printed in U.S.A.

Loading...

Loading...