Page 1

AS6s

6.5” 2-Way In-Wall Speakers

Congratulations on your purchase of the

AudioSource AS6s In-Wall Speaker System. This

product is designed to reproduce the audio portion

of your home entertainment environment with

accuracy and detail that will satisfy the most

discriminating listener.

Please read this Installation Manual to ensure the

proper installation and performance of your AS6s

speakers.

Preparing for your Installation

Gather the necessary tools for you installation.

You will need the following tools:

1) A Keyhole or Drywall Saw

2) A Phillips Screwdriver

3) Masking Tape

4) A Pencil

5) A Bubble or Laser Level

6) A Tape Measure

7) A Stud Finder (recommended)

8) Your AS6s speakers

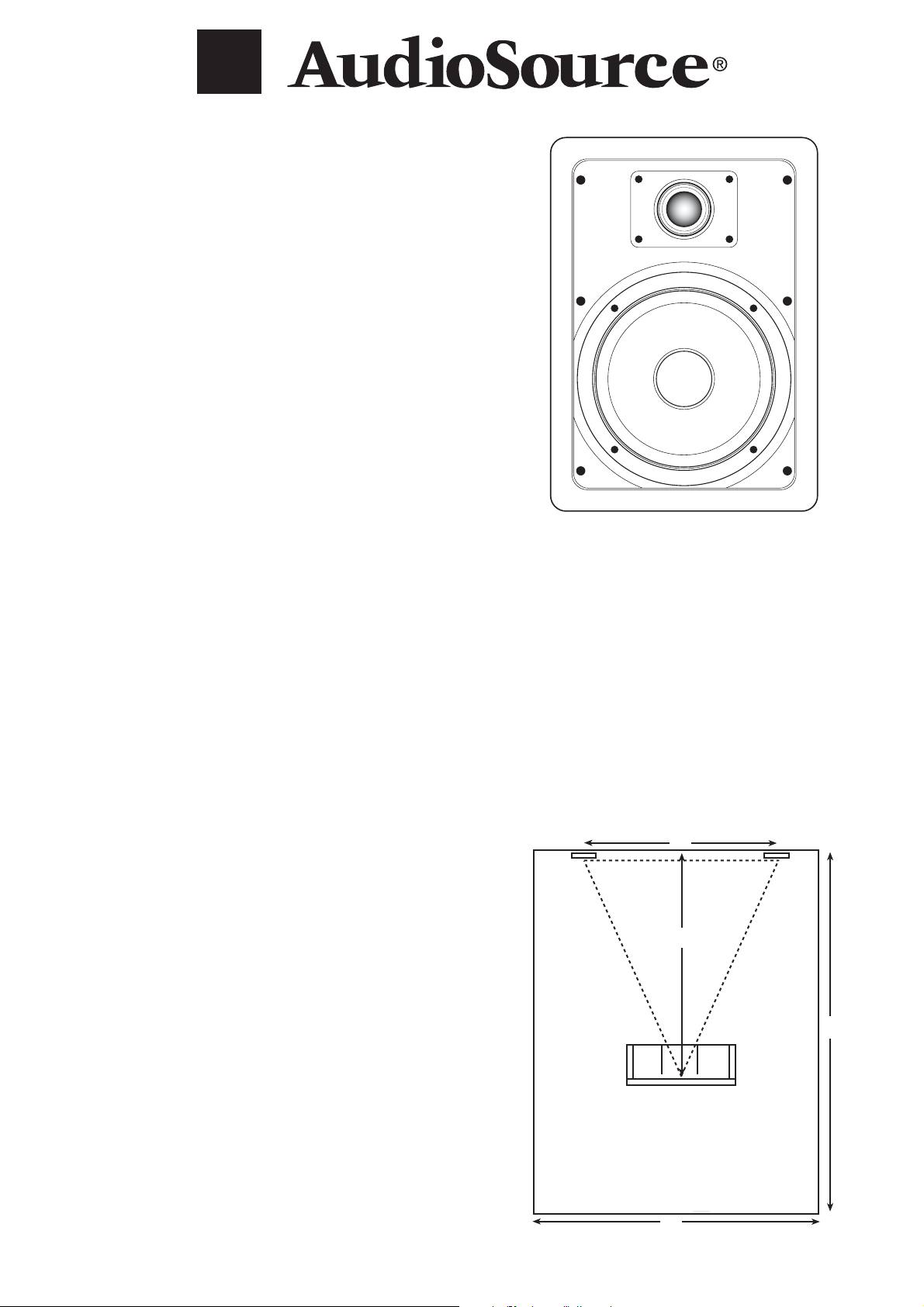

Placement

Plan your speaker placement carefully. Make certain

that electrical, plumbing and any other services will not

interfere within the walls where you plan to place your

speakers. The AS6s speakers can be mounted in the

walls or in the ceiling, but are typically used in walls.

The speakers should be located so that they provide

even coverage at you listening position. The distance

between the speakers should not be greater than the

distance from the speakers to the listening position.

(see fig. 1) If the room’s dimensions or furniture

placement prevent adhering to this requirement, the

tweeters in the AS6s speakers can be swiveled to aim

them at the desired listening position. Speaker height

should be maintained at ear level or just above. Again,

the tweeters may be aimed into the listening area.

New Construction

AS6s

Existing Construction

In most modern buildings the wall studs are positioned

on 16” centers, providing a space between the studs of

approximately 14 3/8”. The AS6s requires a mounting

hole 7 5/16” wide and 10 11/16” high. Additionally, you

should allow an extra 3/4” in all directions behind the wall

surface to allow room for the doglegs that retain the

frame to the wall surface to swing into position.

Use a stud finder to locate the vertical studs behind the

wall surface. Also, you should now check for

obstructions like cross bracing above and below the

desired speaker location.

11’

12.5’

20’

If you are installing your speakers in new construction

before the finished walls go up, AudioSource offers a

New Construction Bracket, part NCBI6 that provides a

stable frame that can be fastened to the wall studs on

16” or 24” centers. This allows the sheetrock or other

wall covering to be installed and cleanly leave the

opening for the AS6s speakers.

16’

Figure 1

Page 2

After selection of the mounting location, mark the hole to

be cut out. A template is provided in the speaker box.

Locate and level the template, then mark with pencil on

the wall surface. If you are unsure whether there are

obstructions behind the wall surface where the speakers

are to be mounted cut a small hole in the center of your

marked mounting location. Holding you drywall saw at a

45 degree angle (see Fig. 2) cut a square hole that you

can use to find any obstructions, should they exist.

ROOM

Figure 2

It is now time to connect the speaker wire to the AS6s.

Your speaker wire is usually coded to identify each

conductor as either positive or negative. This can be by

color coding, or one conductor may have a printed

marking or at least a rib along one edge that you will not

find on the other. Identify which type of polarity coding

that your wire is using. You must carefully observe that

the positive terminal of the speaker output on your

amplifier is connected to the positive terminal of the

AS6s speaker. Likewise, the negative terminal of the

amplifier’s speaker output should be connected to the

negative terminal of the AS6s speaker.

The 45 degree wedge shape of the removed surfacing

material will make replacement, if necessary, a much

easier task and yield a better finish when patching the

work.

Once it has been determined that there are no obstructions cut the hole to mount the speaker using the drywall

saw at a 90 degree angle to the wall surface. Cover the

raw edges of the wallboard with masking tape

(see Fig. 3). This will prevent the back pressure of the

speaker from blowing loose gypsum dust out and on to

the painted wall surface after installation. Do not allow

the tape to extend more than 1/4” beyond the edge of

the hole into the room. The frame of the AS6s will cover

and hide the tape.

Masking T.ape

ROOM

Figure 3

Next you will want to run your speaker wire to your

speaker locations. A UL rated CL3 speaker wire is

recommended when running wire inside your walls.

In many areas it may be required by code. When

running your speaker wire you should avoid having the

speaker wire run parallel to the 110V power lines to

avoid picking up hum and interference from the power

service. If the speaker wire needs to cross a 110V power

line at a right angle this is acceptable and should not

create a problem.

(+) Amp

(-) Amp

AS6s

6.5” Two Way In-Wall

100W / 8 ohm

Next make sure that the doglegs are positioned inside

the frame of the speaker.

Incorrect

Correct

AS6s

6.5” Two Way In-Wall

100W / 8 ohm

If you are uncomfortable with running the speaker wire

yourself in existing construction, it is recommended that

you retain a qualified custom home installation specialist

or electrician.

Installing the Speakers

Installation Tip! To further enhance the performance of

your AS6s speakers, the wall stud cavity where you plan

to place your speakers can be stuffed with a generous

quantity of fiberglass insulation. If uninsulated, stuff the

area above and under the speaker opening with 6” thick

insulation to a depth of approximately 2 feet beginning 1

foot above of and 1 foot below the speaker opening. If

the insulation is foil or paper backed, face the backing

away from the AS6s speaker. The addition of this

insulation will help to prevent the unwanted transfer of

sound into the otherwise large and resonant cavity of the

uninsulated wall.

With the grill removed, place the speaker in the wall

opening. Make sure that the speaker wire is not hanging

against the speaker where it can vibrate and rattle as the

speaker reproduces your music.

Next, one at a time, turn

1

each of the six screws that

operate the doglegs

counter clockwise a few

turns until you feel the

34

dogleg is loose from its

resting position. Now turn

the screw clockwise until

you feel the dogleg contact

5

the wall surface.

2

2

6

Page 3

Tighten all six of the mounting screws in the same

manner until the speaker is properly aligned and held

tight to the wall surface. Caution: Do not over tighten!

Painting the Speaker

Two paint shields are included in each AS6s speaker

package. Place the paint shield inside the frame to

protect the speakers. You can now safely paint the

speakers frame to match your wall surface if you desire.

Recommended Speaker Wire Gauges

The resistance of the speaker wire in your installation

can cause your speakers to perform at less than their

optimum quality level. Excess resistance caused by

using an undersized speaker wire can result in loss of

detail and definition in the bass region of your audio

program, as well as, a loss of dynamic range. Over

extremely long wire runs you may even experience a

loss of high frequency amplitude in the audio signal.

When painting the grill caution should be taken to ensure

that paint does not clog or congest the perforated

openings in the grill. This would prevent proper operation

of the grill by restricting the airflow from the individual

drivers in the speaker.

Aiming the Tweeter

Use you fingertips, placed carefully at the plastic edges

of the tweeter housing.

Press Here

Press

Here

Press

Here

To prevent this effect in your installation we have recommended speaker wire gauges that should not exceed

0.5 ohms resistance over the recommended length of

wire run.

For the AS6s speakers we suggest the following

minimum speaker wire gauge be used:

50’ or less - 16 Gauge 2-Cond. CL3

50’ - 150’ - 12 Gauge 2-Cond. CL3

150’ - 200’ - 10 Gauge 2-Cond. CL3

Press Here

Using gentle pressure swivel the tweeter to aim the axis

of the tweeter toward the listening area. You can use a

piece of music with a solid center imaged vocalist to

assist in correctly aiming the tweeter. When the

tweeters are properly aligned for the listening area you

will hear a coherent and stable center image from your

listening position. Usually, it is sufficient to aim the

tweeter only as it handles the frequencies that control

the direction of individual sounds in your audio program

material.

Removing the AS6s Speaker

Should it ever become necessary to remove the AS6s

speaker from the wall, simply remove the grill and turn

the six mounting screws counter-clockwise until the

doglegs lock out of position in their resting flange. The

speaker should easily come out of the wall for service or

replacement.

3

Page 4

AS6s Specifications

Woofer

Tweeter

Frequency Response

Impedance

Sensitivity

Power Capacity

Outer Dimension

Cut Out Dimension

Mounting depth

Two Year Limited Warranty

6.5” Poly Cone with Butyl Rubber Surround

Pivoting 25mm Ferro-Fluid Cooled Tweeter

50Hz to 20kHz

8 ohm

87dB

200 Watts Peak

8.5” x 12“ (215.9mm x 304.8mm)

7.3” x 10.8

“ (185.7mm x 274.6mm)

3.4” (85.75mm)

AudioSource a division of Rodin warrants this product against defects in materials and workmanship

for a limited period of time. For a period of two (2) years from date of original purchase, we

will repair or replace the product, at our option, without charge for parts. Customer must pay for all labor

charges associated with the removal and re-installation of speakers for the limited period and all parts and

labor charges after the limited warranty period expires. The limited warranty period for factory refurbished

products expires after ninety (90) days from date of original purchase. This limited warranty applies only to

purchases from authorized AudioSource Retailers or Distributors. This limited warranty is extended only to

the original purchaser and is valid only to consumers in the United States.

Consumers are required to provide a copy of the original sales invoice from an authorized AudioSource

Retailer or Distributor when making a claim against this limited warranty. This limited warranty only covers

failures due to defects in materials or workmanship that occur during normal use. It does not cover failures

resulting from accident, fire, flood, misuse, abuse, neglect, mishandling, misapplication, alteration, faulty

installation, modification, service by anyone other than AudioSource, or damage that is attributable to Acts of

God. It does not cover costs of transportation to AudioSource or damage in transit. The customer should

return their defective product, freight prepaid and insured, to AudioSource. only after

receiving a Return Authorization.

Repair or replacement under the terms of this warranty does not extend the term of this warranty. Should a

product prove to be defective in workmanship or material, the consumer's sole remedies will be repair or

replacement as provided under the terms of this warranty. If the defective product is discontinued

AudioSource may replace the product with an equivalent or superior product at its option. Any cost

of re-installation or repair of wall or ceiling surface is the sole responsibility of the customer and that cost

shall not be the responsibility of AudioSource. Under no circumstances shall AudioSource be liable

for loss or damage, direct,consequential or incidental, arising out of the use of or inability to use the

product. There are no express warranties other than described above.

Phoenix Gold International, Inc. 9300 North Decatur Street Portland, Oregon 97203

Tel: 503.286.9300 Fax: 503.978.3381 Tech Support: 800.950.1449

Web: www.phoenixgold.com Email: support@phoenixgold.com

4

8100.0329A

Loading...

Loading...