Page 1

Manual Version 1.1 - August 2009

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 1

Page 2

Table of Contents

Section1: Introduction ............................................................................................................................................................. 3

Component Placement Breakdown..................................................................................................................................... 4

Electrical Safety Warning .................................................................................................................................................... 5

Section 2: First Steps .............................................................................................................................................................. 6

Installing the feet ................................................................................................................................................................. 6

IEC Section Installation ....................................................................................................................................................... 7

Mains Transformer Installation ............................................................................................................................................ 7

IEC Section.......................................................................................................................................................................... 8

Preparing the Secondary leads ......................................................................................................................................... 11

Section 3: Power Supply Board Construction ....................................................................................................................... 12

Installing the Components ................................................................................................................................................. 12

Section 4: Choke Installation and HT Wiring ........................................................................................................................ 14

Section 5: ECF80 Driver Board Construction ....................................................................................................................... 16

Parts List............................................................................................................................................................................ 17

Installing the Spacers and Valve Base .............................................................................................................................. 18

Installing the Resistors ...................................................................................................................................................... 19

Installing the Capacitors .................................................................................................................................................... 20

Section 6: EL34 Hardwired Section ...................................................................................................................................... 22

Parts List............................................................................................................................................................................ 23

Assembly ........................................................................................................................................................................... 23

Section 7: Layout Recap ....................................................................................................................................................... 30

Section 8: EL34 Board Filament Hook-Up ............................................................................................................................ 31

Section 9: EL34 Board To Output Transformer Wiring ......................................................................................................... 33

Section 10: HT and GND Connections to EL34 Board ......................................................................................................... 35

Section 11: Speaker Post Connections ................................................................................................................................ 37

Section 12: Driver Board Filament Hook-up ......................................................................................................................... 41

Section 13: ECF80 to EL34 Board Interconnections ............................................................................................................ 43

Section 14: RCA Connections and Final Earth ..................................................................................................................... 46

Section 15: Powering On and Testing .................................................................................................................................. 49

Power On Procedure ......................................................................................................................................................... 49

Appendix ............................................................................................................................................................................... 50

Resistor Color Code Reference......................................................................................................................................... 51

Mains Transformer Windings Diagram .............................................................................................................................. 52

Power Supply Board Schematic ........................................................................................................................................ 53

Driver Board Schematic..................................................................................................................................................... 54

Output Board Schematic ................................................................................................................................................... 55

Output Section Hardwiring Diagram .................................................................................................................................. 56

General Wiring Diagram .................................................................................................................................................... 57

Full Schematic ................................................................................................................................................................... 58

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 2

Page 3

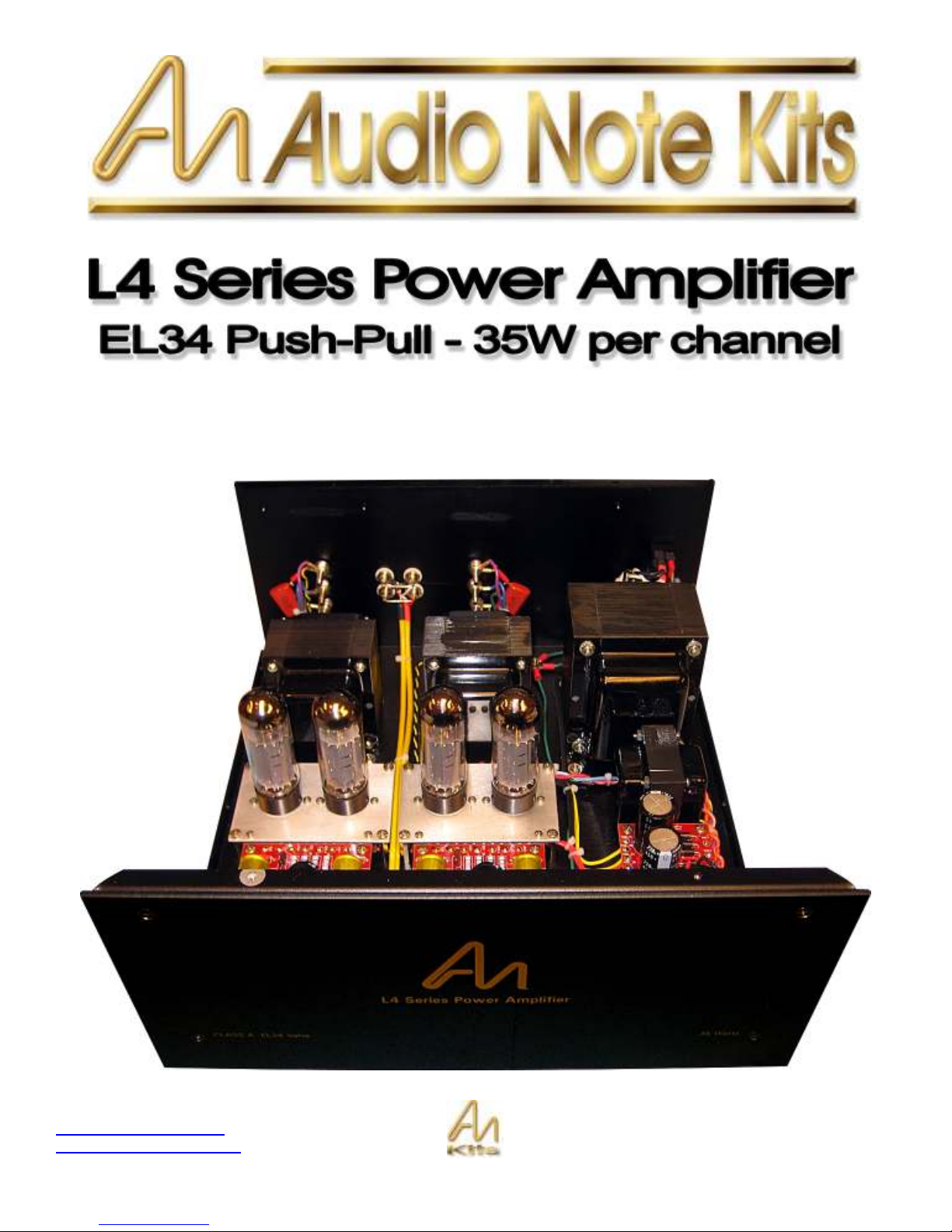

Section1: Introduction

Thanks for purchasing the AudioNote L4 Series EL34 Push-Pull Power Amplifier. Our goal is to provide you with the

highest quality Kit that you will build from scratch with these instructions. If you have any questions or comments during

the build feel free to contact us and we would be happy to help out.

You will need a soldering iron or soldering station with a sponge along with wire strippers and a Phillips screwdriver. A nut

driver or a pair of pliers would be useful as well. We have divided the manual up into a series of step-by-step instructions

for the successful build and debug of the kit. There are several places during the build that you will perform tests and/or

checks to make sure that you are on track. This way when you complete the kit you will know that all the major sections

are working.

You will find a number of component bags supplied with your kit. These bags will be referred to throughout this manual.

Here are some tips from working with many kit builders over the last few years:

Perform your work in small manageable chunks. Do not be in a hurry to listen to your finished kit.

Savor the build experience. Here’s a chance to really get to know your audio kit that will give you many hours of

enjoyment.

Better to work on a section and then spend the time to check over the section rather than just carrying on.

The kit building experience should be a pleasant one so find a place that you can build the kit with relative peace

so you can concentrate on the instructions.

If you plan for a long build stretch on a Saturday afternoon for example then take plenty of breaks with constant

re-checks of your work.

Whilst working through this manual, please feel free to give us your feedback and any other information that may allow us

to improve the build experience.

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 3

Page 4

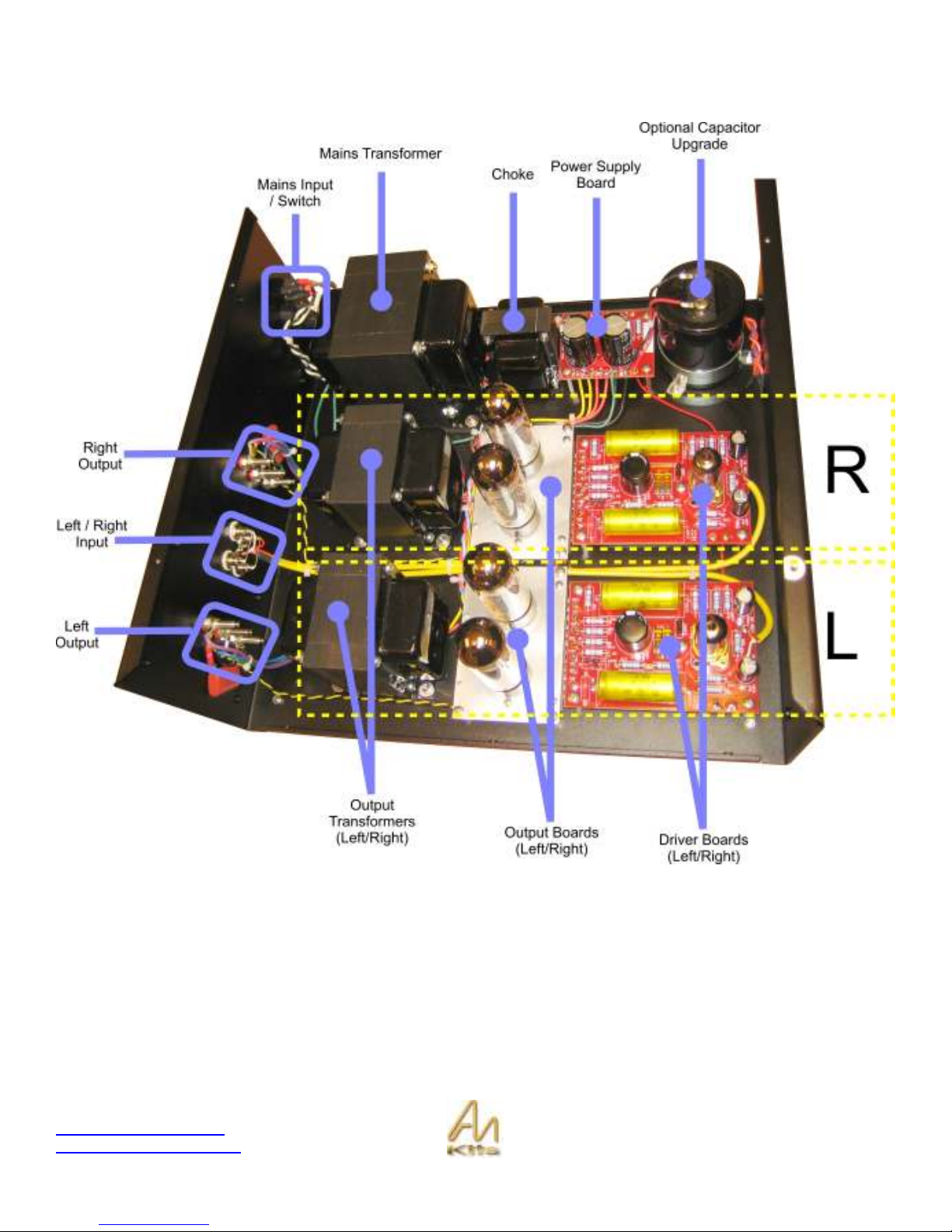

Component Placement Breakdown

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 4

Page 5

Electrical Safety Warning

There are sufficient voltages in this kit to give you a very nasty and harmful shock so be careful when powering

on, debugging, and probing around.

Please be aware of proper electrical safety.

Please contact AudioNote Kits via phone or email to discuss any precautions necessary when building the kit if

you feel unsure about what you are doing at any stage of the build.

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 5

Page 6

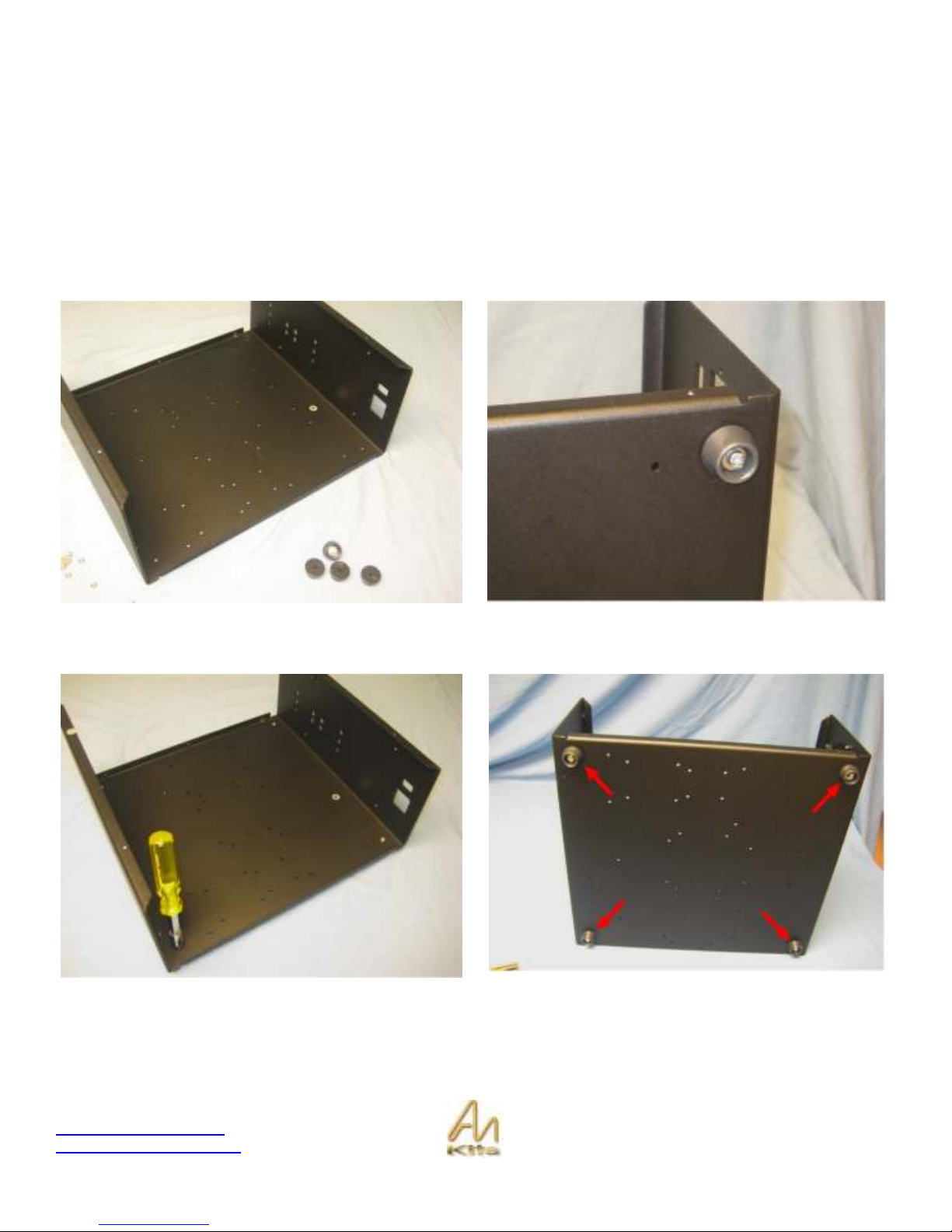

Section 2: First Steps

In this beginning section we will start by installing the 4 feet then we will install the Mains transformer and wire up the IEC

section.

Installing the feet

Our first task is to install the 4 rubber feet into the holes in the 4 corners of the chassis using the provided hardware in the

“Feet” Bag (found in the big Hardware bag). Use the M4 screw along with the big washer on the outside of the foot and

then a M4 nut and M4 black serrated washer against the chassis on the inside of the chassis!

Might be handy to use an M4 nut driver or something similar to tighten the nuts for the feet on the inside of the chassis as

shown below.

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 6

Page 7

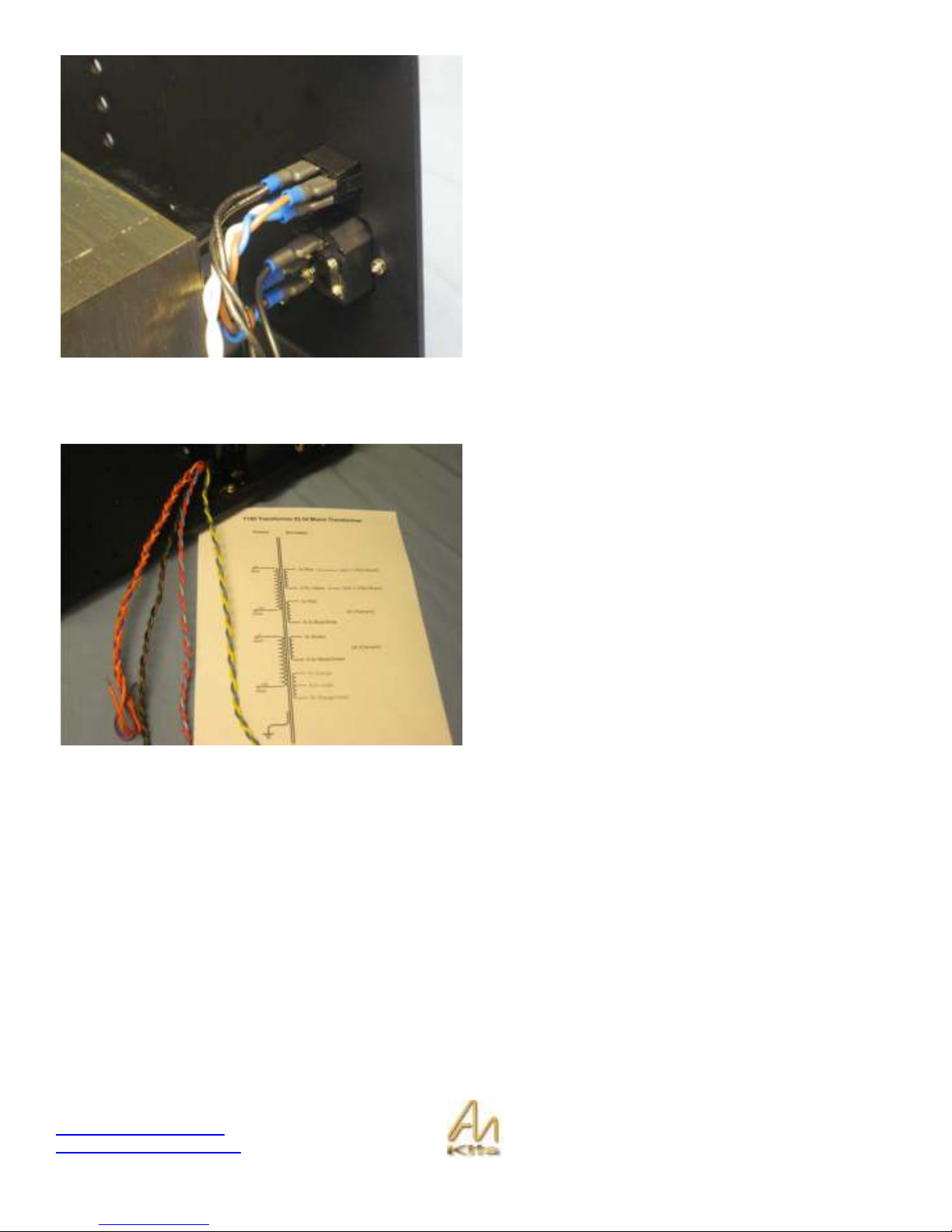

IEC Section Installation

Let’s install the input AC receptacle and rocker switch

known as the IEC socket & Rocker in the rear of the

chassis.

Shown opposite is the rocker switch slot above the fitted

IEC socket.

Mains Transformer Installation

Here you can see the correct installation of the IEC plug in

the rear of the chassis along with the Rocker switch.

2 rubber strips are used to isolate the

mains transformer from the chassis.

Lay down the two rubber strips so that

they are over the correct holes in the

chassis (these holes are about 100mm

apart).

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 7

Page 8

Place the Mains transformer carefully

over top. Note that the primary of the

Mains transformers (2 black + 2 white

+ 1 green wire) is placed towards the

back of the chassis while the

Secondaries are placed towards the

front.

The provided Hardware in the bag

marked “Mains transformer” will be

used to secure down the Mains

transformer – Prior to securing the

transformer in place we suggest you

hook up the IEC section with the

provided cables found in the “IEC”

Bag.

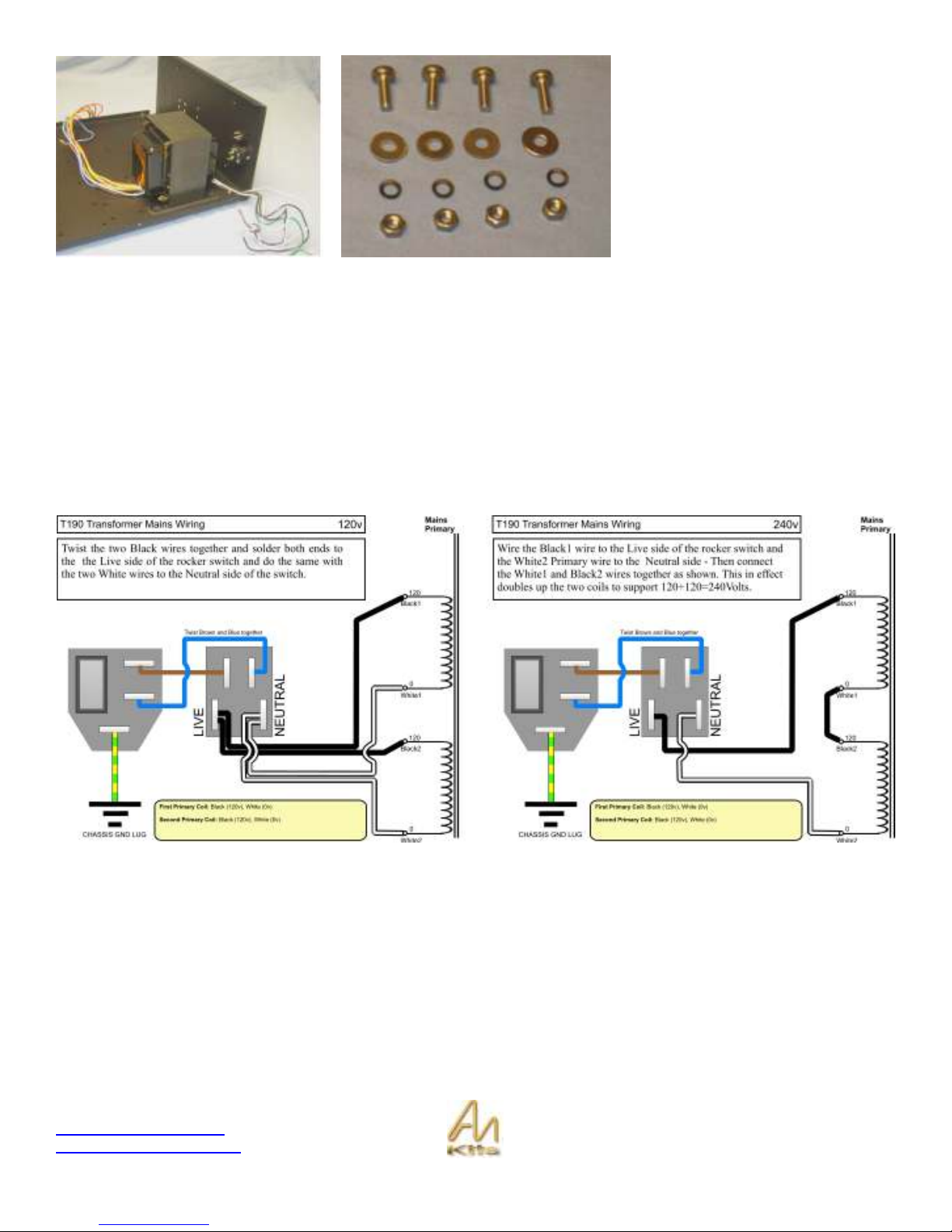

IEC Section

The supplied Mains Transformer is capable of being configured for different mains supply voltages. The examples here

are showing configuration for 120v operation. If you are in a region of the world that requires a different voltage then

please refer to the regional wiring chart shown below and derive the correct wiring from that instead.

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Mains wiring - Regional variations

Page 8

Page 9

Remember, the following example shows how to wire for 120v operation only.

The next step is trim the wires lengths once they have been

twisted such that the length would reach to the top of the

chassis (approx 7 or 8 inches).

* Applies to 120v operation only.

Take both black twisted wires and strip about ½ inch of

insulation – then twist the ends together – then TIN this end

by applying solder to it to make sure that it is nicely formed.

Then place a blue CRIMP on the end of the wire. Here’s the

tricky part – add solder so that the TINNed end of wire

adheres to the crimp – you will probably need to add a

surprising amount of solder to make sure there is a very

good connection along with quite a bit of heat.

Once the crimp has been added then you can place the

heat shrink over the exposed metal end of the crimp and

apply your heat gun.

REPEAT for the White twisted wires.

* Applies to 120v operation only.

If you live in a 120V AC world voltage

then we will twist the black wires

together as shown as well as twisting

the white wires.

We will also be working with the green

screen wire.

* Applies to 120v operation only.

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 9

Page 10

Now let’s deal with the green wire

coming out of the Mains Primary. This

is the ground lead that we will be

attaching to chassis ground.

Strip the wire and tin it and then solder

the ground lug to it.

This is where you will attach the earth wire to. You will secure it using an M4

16mm pan screw from under the chassis and use a nut to secure the ground lug

from the Mains transformer.

Note that the mains input earth will also be joining it shortly.

In order to complete the IEC wiring,

you will be using 2 pre-terminated

cables.

The first one is the earth cable shown

here. This connects to the IEC mains

socket’s earth lug, which is in turn

connected to the chassis earth lug

(discussed previously).

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Now use the twisted pair cable (shown

opposite) to complete the wiring

between the mains input socket and

the mains switch - refer to the wiring

diagram shown previously.

You will have to apply some pressure

to position the crimps correctly onto

the lugs.

Page 10

Page 11

Preparing the Secondary leads

The IEC section is now complete.

The picture opposite shows the completed wiring for 120v

operation.

* Applies to 120v operation only.

Pull out your insert sheet showing the Mains transformer

windings for the secondary.

The first step is to twist the wires according to the windings:

• Blue & Yellow

• Red & Blue/White

• Brown & Black/Green

• Orange & Violet & Orange/White (Braid these wires

– you may have to ask your wife!)

We will be using these twisted wires later – lets move on to

the Power Supply Board.

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 11

Page 12

Section 3: Power Supply Board Construction

Here are the parts for the Power Supply Board along with

the spacer hardware.

Quantity Description

4 1,000v 3A fast Diodes

2 220uF 450v Electrolytic Capacitors

1 330K 1W resistor

2 1M5 1W resistor

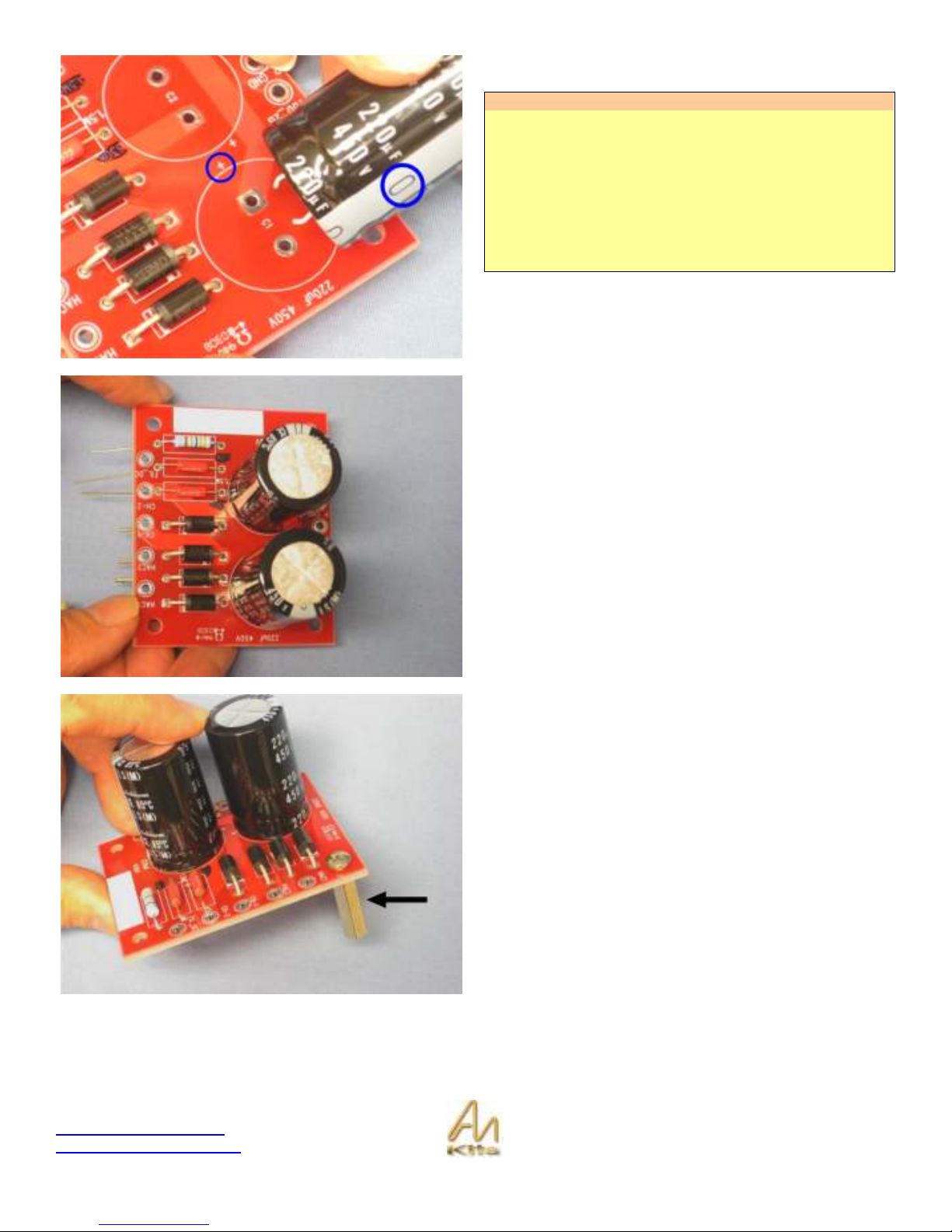

Installing the Components

IMPORTANT: The Diodes that we are

using have a stripe on one side that

you need to match with the PCB. They

must not be inserted the wrong way

around.

Bend the leads so that they can be

inserted into the PCB.

Next, install the 3 resistors.

Note that the board shown in the picture was a Beta board

with wrong stencil markings but as you can see the 330K

resistor is at the bottom of the board and the 2 x 1.5M are

above it.

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 12

Page 13

The next job is to install the Electrolytic Capacitors.

Quick Lesson on Electrolytic Capacitors

These capacitors have a Positive and Negative side to

them and need to be installed correctly or they will

BLOW up!

The Stripe on the side of the capacitor can designates

the NEGATIVE side.

You will also see the + sign marked on the PCB denoting

the positive side

Here you can see the capacitor being correctly installed in

the board.

Here you can see the Power Supply Board correctly

populated.

Check over the board for correct positioning and polarities

before finally soldering the components in place.

Finally, you can install the spacers on each corner of the

board and position the board into its correct location in the

chassis.

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 13

Page 14

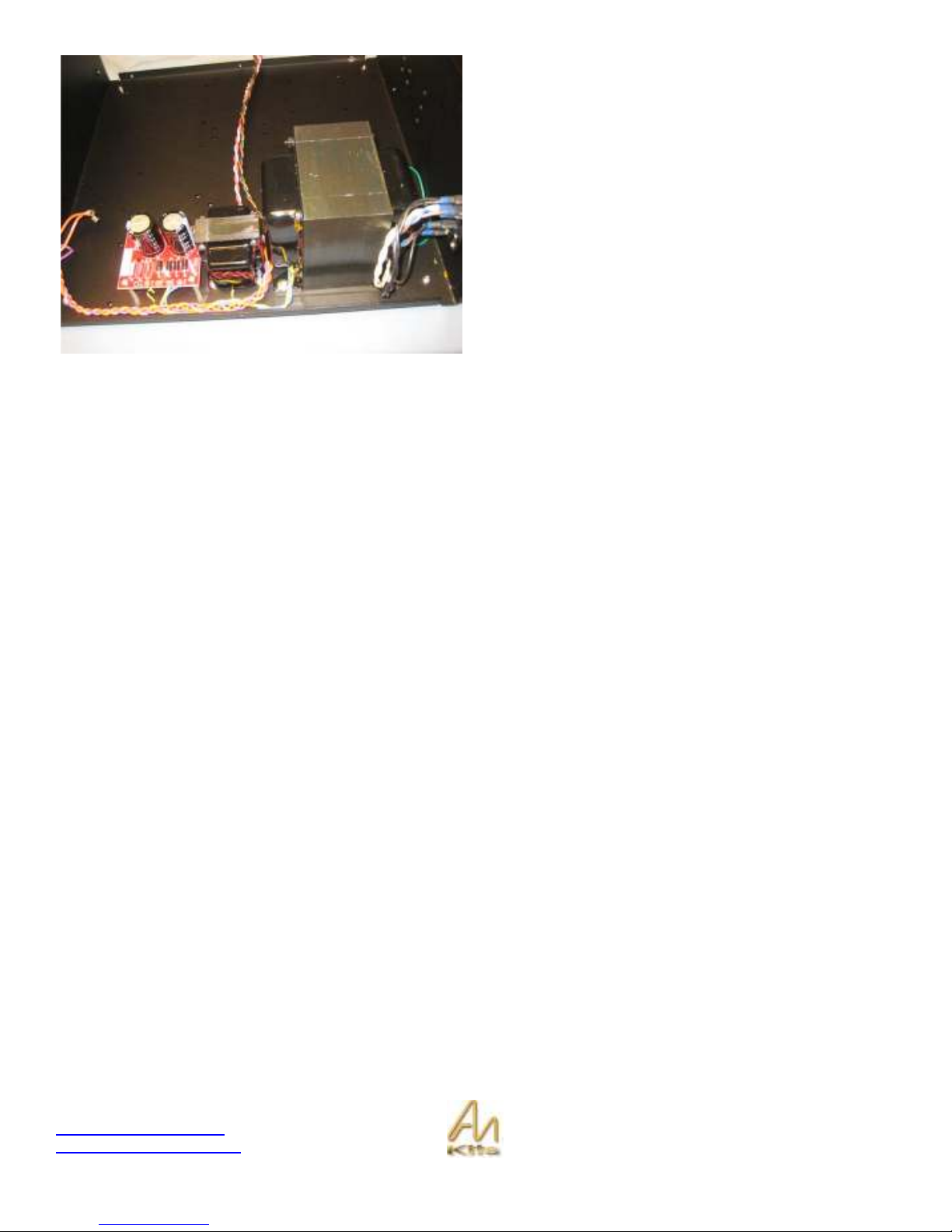

Section 4: Choke Installation and HT Wiring

Here is how the choke and the Power supply board will be

positioned in the chassis.

You will want to bring the Mains transformer secondary

leads through on this side of the chassis and position the

twisted filament wires from the secondary windings going

the other way into the amplifier.

Use the supplied hardware (M3 screws and nuts) to secure

the choke into position.

Trim and tin the Choke wires (yellow

and black) so that you can connect

them to the power supply board.

Insert them underneath the board if

you like and apply solder from the top

of the board – plenty of solder will be

used and then you can trim the extra

tinned wire poking through the board.

Connect the yellow and black wires

from the Choke into holes CH-1 and

CH-2 – it does not matter which wire

goes to which hole.

Now lets take the High Voltage wires (Yellow and Blue) and

trim to length.

Strip the end of the wires and tin.

Connect to HAC1 (High Voltage AC 1) and HAC2 (High

Voltage AC 2).

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 14

Page 15

Finally, bring the triple braided wire down the length of the

chassis for later use.

Now we can move onto the next stage of the build.

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 15

Page 16

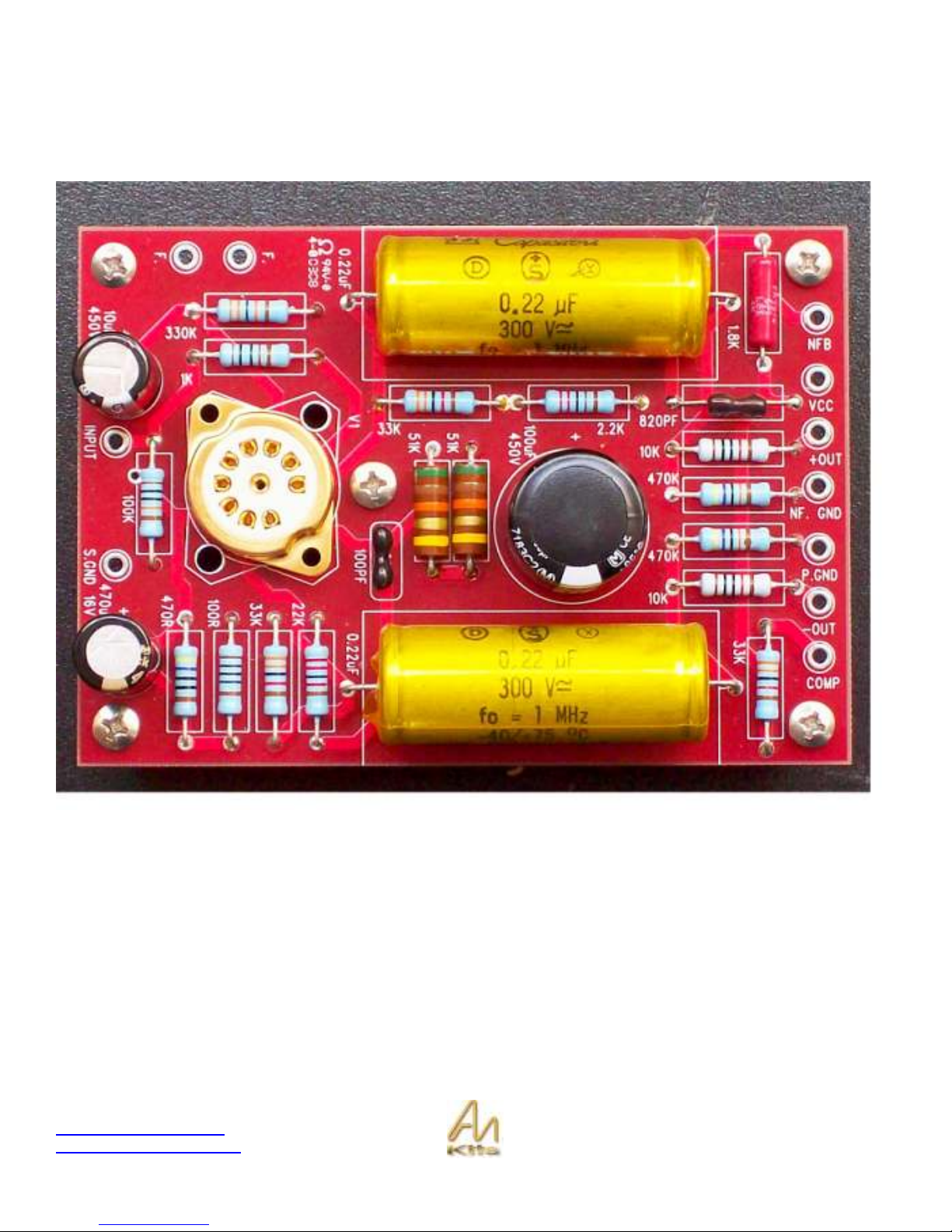

Section 5: ECF80 Driver Board Construction

In this section we will be building the first of the 2 Driver Boards, which contain the ECF80 tube. See the Appendix for the

schematic for this board.

The build of this board is quite straightforward and shouldn’t pose any problems. Just make sure that the three electrolytic

capacitors are inserted the correct way around - observing correct polarity.

SPECIAL NOTE: R12 and R13 have been moved from this board to the Output Board. Therefore, you should replace

these resistors with wire links!

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 16

Page 17

Parts List

Resistors

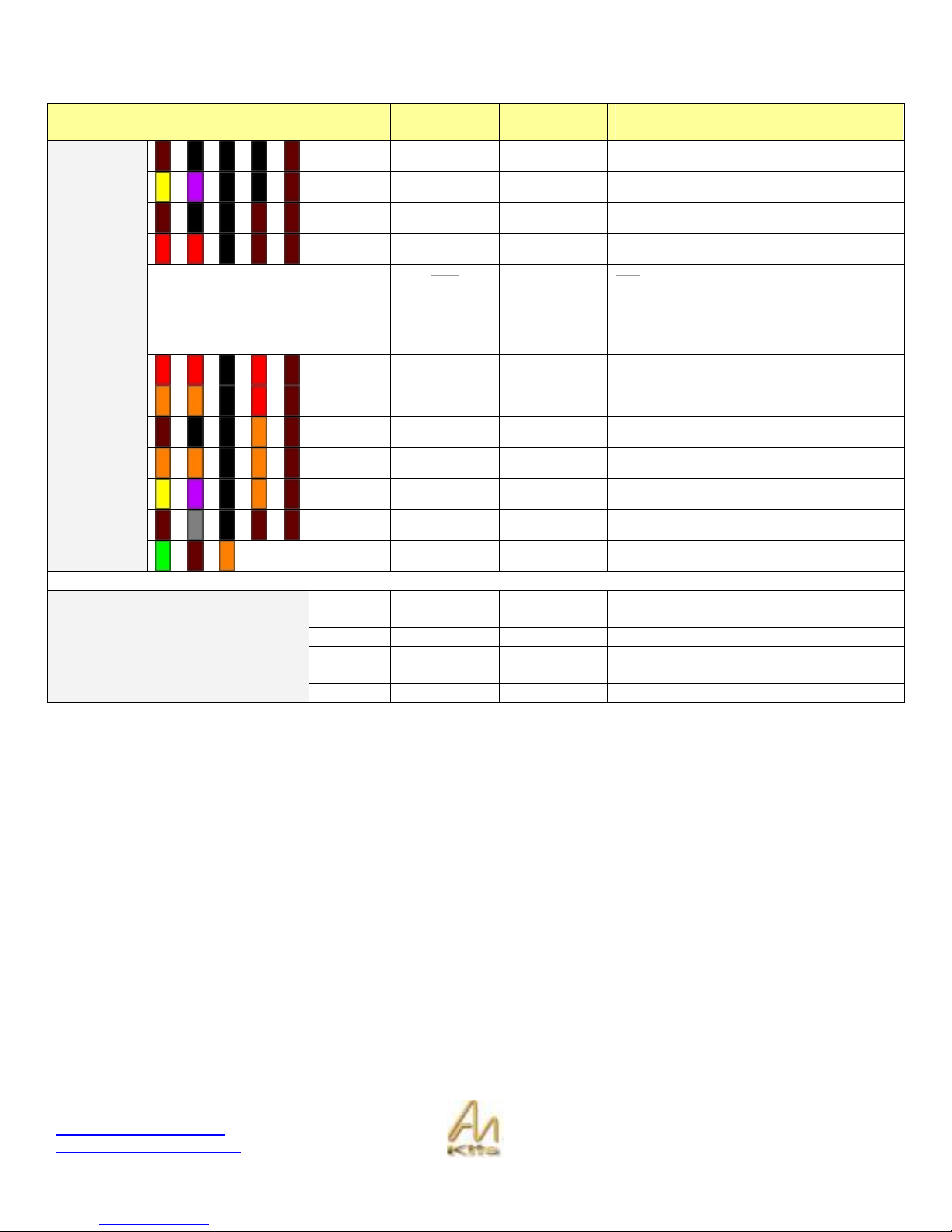

Quantity Value Designator Description

1 100R R6 1W

1 470R R5 1W

1 1K R2 1W

1 2K2 R15 1W

2 10K

R12, R13 1W

Wire links

1 22K R9 1W

3 33K R7, R8, R14 1W

1 100K R1 1W

1 330K R3 1W

2 470K R10, R11 1W

1 1.8K R16

2 51K R4a, R4b

The resistors that used to be here have

been moved to the Output Board for

performance reasons. W ire links should

now be used here in their place.

Capacitors

1 470uF 16v C2 ECF80 cathode

1 10uF 450v C1 ECF80

1 100uF 450v C3 HT / GND

2 .22uF 630v Input to EL34

1 100pF 630v C6 ECF80 input

1 820pF C7

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 17

Page 18

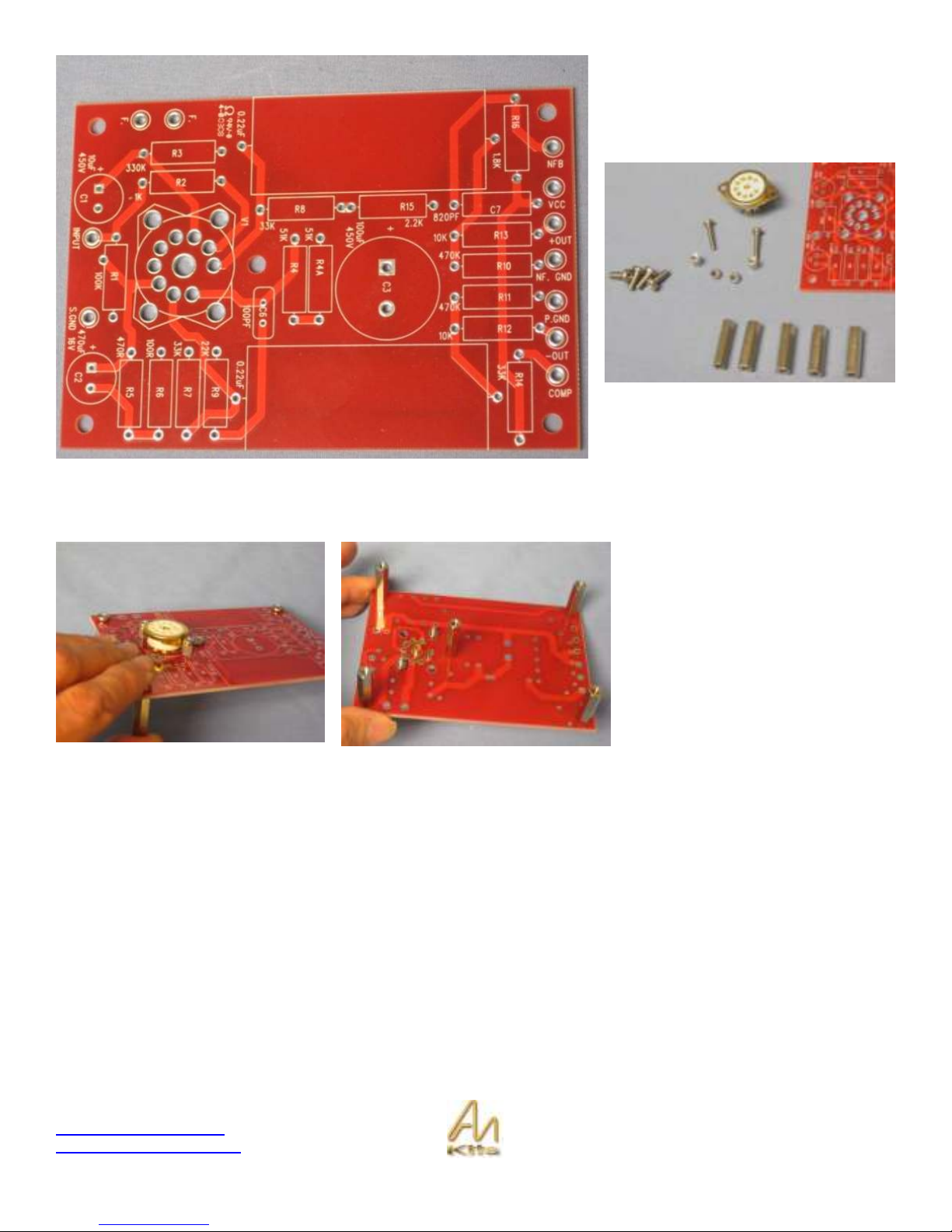

Installing the Spacers and Valve Base

Here is a reference picture of the

unpopulated board.

To begin construction you will need the

following hardware parts:

Install the 5 spacers and secure them

into position.

Using the M3 16mm screws, spacers

and M3 nuts, you can secure the valve

base into position on the board.

Then solder the pins of the valve base

on the underside of the board so that

they are connected to the PCB.

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 18

Page 19

Installing the Resistors

Install the resistors into their correct positions on the board.

Refer to the parts list on the previous page. It’s also a good

idea to use an OHM meter and refer to the color code chart

for inserting the correct resistors into position.

NOTE: In the picture opposite we have also installed the 2

x .22 film caps into position – you can do this later in the

capacitor section. For now just concentrate on the resistors.

NOTE: R12 and R13 should be replaced with wire links as

these resistors have been relocated to the Output board for

performance reasons.

You will want to bend the legs to fit into position and then

solder on the underside of the board.

Here you can see the underside of the board – good idea to

do a double check on your resistor values once they are

inserted prior to soldering into position – check with the

schematic and the color code chart to make sure it all

makes sense!

These two pictures show the

underside of the board with the valve

base soldered into position and the

resistor leads clipped!

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 19

Page 20

Installing the Capacitors

First, install the two large .22uF film capacitors at the top

and bottom of the board.

Next, install the 100uf electrolytic capacitor. You will see

the stripe on the side of the capacitor that denotes the

negative side (just like we did on the power supply board)

and you will see the + sign on the PCB on the positive side

of the capacitor.

Next install the Silver Mica film caps – these caps are not

polarized so it does not matter which direction they go in.

1 100pF 630v C6

1 820pF C7

NOTE that we made a change to this board and that the

board you are building may have C7 in another location on

the board.

Install the 10uF 450v electrolytic next (see picture

opposite). Here you can see it being inserted correctly.

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 20

Page 21

Finally, insert the 470uF 16v electrolytic capacitor into its

position (follow the same rules of Negative Stripe position).

That Basically completes the ECF80 driver board - You will

need to build another one now for the other channel! See

below how they will be positioned in the chassis.

Well done to get to this point – as you can see the amplifier is coming along nicely!

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 21

Page 22

Section 6: EL34 Hardwired Section

In this section we will be building

the hardwired section on the

aluminum plates where the

EL34’s reside – It’s a challenging

little section but also fun and

rewarding.

Here is what It will look like from

the topside.

The picture below shows what the

boards will be like from underside:

NOTE: Since these pictures were taken, we have relocated 2x 10K resistors from the Driver Board to here. Therefore the

White wires that can be seen above are now replaced with these relocated resistors.

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 22

Page 23

Parts List

Quantity Value Description

Resistors

2 250R 9W

2 10R

1 470R 6W

2 10K 1W (may not be shown in some pictures in this section)

2 47pF Silver Mica Capacitors

2 220uF 100v ELECTROL

Here is a picture of the parts that we will be using in this

section.

IMPORTANT: The top of the board has the countersunk

holes on the valve bases. Wiring will be done from the

underside.

Since this picture was taken, 2x 10K resistors have also

added. The instructions in this section have been amended

accordingly. However, some of the pictures shown in this

section may not take these newly introduced resistors please bear this in mind while building.

Assembly

Working on the underside of the board you will want to

secure the valve bases into position.

NOTE: The notch on the valve base must be pointing “up”

to the top of the board as in the picture opposite where the

6 holes are located on the aluminum plate.

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 23

Page 24

Position the 2x 250 ohm resistors on

the board over the holes as shown.

Use the supplied hardware to secure

the resistors into position.

Note that the nuts will be on the

underside of the board.

Install the supplied 'Tag Strip' into

position on the underside of the board.

Use the pan screws and the hex

spacers to secure the tag strip.

The last step before starting the wiring

is to install the spacers at the corners.

Please refer to the following diagrams that can be found in the Appendix while working in the remainder of this section:

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 24

Page 25

Install the two 10R resistors into

Basically if you look at the schematic you will see the 2x

position.

The trick here is to route the 10 ohm

red resistor through to the 250 ohm

resistor as shown.

Curl the leads around for good

mechanical connection then solder

into position and cut the remaining leg

off. ALWAYS hold the excess piece so

that it does not go flying off into space

as this can be dangerous.

You will see that we have a GROUND

that goes down the middle of the

board. Take the 20 guage Black PTFE

wire supplied and strip at least 1 inch

of insulation.

Then thread this through the two

resistors as shown in these pictures.

Do not solder yet...

Now before you solder we will want to add each 220uf 100v

Electrolytic capacitor – this is a little tricky so take your

time.

220uF capacitors situated on the cathode.

Please read through this section before starting to install

the capacitors.

We are going to position the two capacitors something like

the picture opposite.

Remember, these are electrolytic capacitors so they must

be connected with correct polarity in mind.

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 25

Page 26

Start by taking the Negative side of the capacitor (stripe

side) and bend the leg into position and thread it through

the resistor hole.

Then you can solder the resistor and the capacitor leg and

the stranded wire together – be careful not to burn the

casing the capacitor.

You can also temporarily bend the capacitor out of the way

so you can make the solder connection and then bend it

back.

Once that is successfully connected, you can bend the

positive leg over to Pin 1 of the valve base.

Note that this leg needs to touch both pins 1 and 8 so you

can bend the leg to touch both pins of the valve base and

then solder them both - refer to the graphic to show this

connection.

Then do the same thing with the other capacitor – its

definitely tricky but take your time.

Make sure the Negative side of the capacitor will connect to

the resistor lead and the positive side to the valve base pins

1 & 8.

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 26

Page 27

Now you can install the 47pf capacitor

into position – refer to the graphic.

On the graphic we have 12 positions

on the tag strip – make sure to align

the correct position with your

connections (in this case the 47pf cap

connects to position 11).

Wrap the leg around the valve base

post and solder and then cut off

excess lead.

Now install the second 47pf capacitor

as shown opposite (also refer to the

wiring diagram).

Now add the ground LEAD.

You will notice on the graphic that we

have 3 grounds in the middle of the

tag strip – positions 6 7 & 8 – let’s add

a piece of wire to connect all three as

shown here.

NOTE: These pictures are incorrect.

Recently we have replaced these

wires with 10K resistors that have

been relocated from the driver board*

So, connect a 10K resistor between

-OUT (position 9 on tag strip) and pin

5 on the left-hand valve base.

Connect the other between +OUT

(position 5) and pin 5 on the right-hand

valve base.

* Please note that other pictures in this section are incorrect also as they omit the 2x 10K resistors introduced in this last

step.

Copyright © 2006-2009 AudioNote Kits

Page 27

www.AudioNoteKits.com

audionotekits@rogers.com

Page 28

Use some red PTFE wire to connect pin 4 of one valve base to pin 4 of the other

base.

Connect the 470R 6W resistor into position (tag strip 4

position) with pin 4 of the left valve base.

That completes the component connection – now we will

finish up with the filament wiring.

We are now going to add the Filament

wire – the power supply will supply

6.3V AC voltage to this board via the

tag strip and this will connect to pins 2

& 7 of each EL34 – Lets start this

wiring by “paralleling” the pins 2 & 7 of

the two valve bases.

Start by cutting a short piece of the

green 16Guage wire and connecting

between pin 7 and pin 7 of each valve

base.

Do the same for pin 2 of each valve

base. It is preferable if you twist the

wire.

Then add the green filament wire to

the positions 2 & 3 on the tag strip –

cut off some strips of wire and solder

into position.

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 28

Page 29

Then you can twist these wires slightly and connect to pins

2 & 7 of the right EL34 valve base.

Congratulations! Well done if you have made it this far.

You will have to repeat this whole board build for the other

channel but I think a good nights sleep is in order!

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 29

Page 30

Section 7: Layout Recap

In this short section, we are going to review the layout of the internals of the amplifier. This will help you to understand the

wiring that you will have to perform later. For now, don’t screw any of the boards into place as you will need to have them

free in order to solder connections to them - often from the underside.

So, let’s have a quick look at the overall layout of the amplifier...

On the far left you can see the two

ECF80 driver boards installed into the

chassis – no need to secure any of

these boards as we will be wiring

underneath them later on.

In the next picture we have positioned

the EL34 Hardwire Boards into

position – note that the tag strip is

closest to the ECF80 driver board.

Here you can see the position of the

output transformers with the yellow

wires towards the center of the chassis

as these are the primaries – the green

blue purple wires are the secondaries

that will be connecting to the speaker

posts!

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Here, you can see the position of the optional Mundorf Cap

for the power supply!

Ok with that lesson under out belt let’s move on to the next

section!

Page 30

Page 31

Section 8: EL34 Board Filament Hook-Up

Now that we have nicely completed out EL34 hardwired boards we have to make some wiring connection to these boards.

Lay the boards out as shown in the

pictures opposite – also lay down the

two 6.3V filament supply twisted pairs

from the Mains transformer. We will be

connecting these filament wires to the

Boards. For the board closest to the

power supply you will want to trim the

filament wires to correct length to

reach the tag strip where the two

green filament wires are hooked up.

FILAMENT WIRES – A short lesson

We are using AC filament heating for the EL34’s and the

ECF80 tubes – Basically the Mains transformer

secondaries provides 6.3V AC to the tubes in order for

them to “light up” – Each channel has its own Mains

secondary to supply it.

So you will want to strip the red & blue/white wires and

insert them into the tag strip in positions 2 & 3 lining up with

the green filament wires.

DO not solder into position yet – the reason is that we are

going to add another twisted red black wire pair to the tag

strip in order to feed the filament voltage down to the

ECF80 board – read on...

Now with both sets of wires into

position go ahead and solder – make

sure that the stranded cable

completely soaks up the solder for

both wires and make a good

connection with the tag strip.

Once this step is completed you have

successfully wired in the filament wire

from the Mains transformer secondary

into the EL34 hardwired board and

also prepared the filament wire that

will be feeding the ECF80 driver board

later on.

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 31

Page 32

Repeat the step for the outer hardwired board- as shown

opposite.

Well done on completing the FILAMENT wiring section.

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 32

Page 33

Section 9: EL34 Board To Output Transformer Wiring

In this section we have to hook up

the red and black wires from the

Output transformer primary’ into

the EL34 Hardwired section.

On the diagram opposite, look at

the connections on pin 3 of each

valve.

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Start by taking the red and black wires from the output

transformer and twisting them. Then cut to the required

length.

Page 33

Page 34

Strip the ends of the red and black twisted and then tin the

end of the wires.

Connect the wires to their corresponding Pin 3 on each

valve base.

Please stick to the color-coding so that the 2 channels don’t

end up out of phase with each other!

Well done – that takes care of the output transformer primaries!

Repeat the connection of the red black twisted from the

output transformers for the other channel.

For the next step, please refer to the General Wiring

Diagram in the Appendix.

Finally, collect up the two yellow wires

from the output transformer primary.

These wires will connect into the

power supply board – route them

along the transformers over to the

power supply board – check out the

pictures of the completed unit to see

the routing of the wires.

Connect the two yellow wires hook up

to the VDD_1A and VDD_1B on the

power supply board.

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 34

Page 35

Section 10: HT and GND Connections to EL34 Board

Solder these to the Power Supply Board on pads VDD_2A

Before continuing, it would be a good idea to pull out the

General Wiring Diagram from the Appndix.

Take two lengths of RED 18 gauge 600v wire and strip the

ends.

& VDD_2B.

There is one red wire for each channel – Now connect the

RED wire into the tag strip position 4.

As you can see in the picture, I have wired into the same

side as the resistor (470R) this is because we are later

going to use the other hole on position 4 tag strip to

connect to the ECF80 board.

Repeat with the other channel and the other red wire –

leave a little slack in the wires as we will be eventually

turning over the boards.

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 35

Page 36

Now do the same thing but with 2 black wires – these will

be the High Voltage Grounds.

Wire these into PGND_A & PGND_B.

That completes the high voltage wiring!

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 36

Page 37

Section 11: Speaker Post Connections

Move the output transformers out of the way a little so we

can install speaker posts in the rear of the chassis.

We are going to install the 3 speaker

posts that go in the rear of the chassis.

Locate the 3 holes that are in a row.

Position the 2 red speaker posts on

the top 2 holes and the black speaker

post on the bottom hole – the speaker

posts are 8 (red), 4 (red) & 0 (Black).

Now take the three leads from the

output transformer (green, blue and

purple) and trim them so that they will

connect easily to the speaker posts –

remember the transformer has been

“moved” out of position so that we can

work back here.

Strip the ends and tin the wire leads.

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Take the ground lugs provided and

place on the ends of the tinned wire.

Solder the lugs in place (place your

soldering iron on the side closest to

the RING). You can use plenty of

solder and make sure there is a nice

smooth flow.

Position the rings on to the speaker

post – GROUND on the black, blue on

the middle and purple on the top.

Page 37

Page 38

If you check the EL34 schematic you will see that we have

a 10R resistor and a .1 cap in series between the GND and

the 8ohm speaker post. This is used in push pull amplifiers

as a filtering circuit.

We are going to make a little assembly along with the

feedback wires and then we can install on the speaker

posts! This picture shows the .1 cap, 10ohm resistor, GND

lugs and black yellow twisted wire that will be required.

Start by clipping the leads of the

capacitor and resistor and soldering

together as shown in the left-most

photo. You can then bend so that the

approximate distance will fit between

the two speaker posts.

Here you can see the next steps required to make the

assembly.

Trim the yellow black twisted wire and insert into the LUG –

then solder on the RING side – let plenty of solder flow so

that the wires are well connected inside – if you are unsure

you have not made a connection you could use an OHM

meter and check the other end of the wire and the GND lug

to make sure you have a good connection.

This is a critical part of the circuitry so if this is not properly

made the amplifier wont work properly!

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 38

Page 39

Here we are placing the assembly

onto the speaker posts – be sure to

position the resistor and the yellow

wire side on the 8 ohm post and the

cap and black wire on the ground post.

You can now use a nut to finalize each speaker post

connection.

Well done – now lets complete the wiring of the twisted

yellow and black on the other end...

Take the yellow black wire and trim the

ends.

Position your EL34 board as shown

and route the wire under the board.

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 39

Page 40

Solder the yellow wire into TAG position 1 – this is beside

the filament – remember you are looking at the board

upside down.

We will be connecting to that same terminal later from the

Driver Board.

Wire the black wire from the twisted yellow black into the

PGND position 6 7 or 8 – Note you may want to keep the

wire on the valve base side of the tag strip so that you can

use these holes when connecting to the ECF80 board later.

Well done once again – Now you just have to repeat the

process for the other channel! Maybe take a break or

charge ahead!

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 40

Page 41

Section 12: Driver Board Filament Hook-up

EXPLANATION: The filament wiring is basically AC right

off the Mains secondary – these filament wires go to the

EL34 hardwired board and then connect down to the

ECF80 board for each channel.

In order to have a very quiet amplifier, however, we need to

have the AC voltage 6.3V raised up about 30V DC – We do

this by connecting a single wire from the Power supply

board FIL_DC over to the FIL FIL section on the ECF80

driver board.

Connect the end of the Orange wire to the FIL_DC pad in

the Power Supply board.

So what you need to do is bring the twisted filament wires

from the Hardwired board over to the ECF80 board along

with the Orange wire from the power supply board FIL_DC.

But read on to see what else you have to do with this step

as you need to add one more wire...

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 41

Page 42

Where the orange wire (from FIL_DC)

connects to the ECF80 board you

need to add another orange wire to

connect over to the FIL on the other

ECF80 board.

To summarize:

The orange wire from FIL_DC connects over to the first

ECF80 board and then continues on through a second

orange wire over to the second ECF80 board – meanwhile

the red/black twisted wires from the hardwire boards are

soldered into the FIL FIL holes on each ECF80 driver

board.

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 42

Page 43

Section 13: ECF80 to EL34 Board Interconnections

We are now going to make the

connections between the hardwire

board and the ECF80 driver board.

Here is a graphic showing the tag

positions on the hardwire board

looking from the topside now along

with the connections that you are

going to be making in this section.

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Cut 7 short pieces of the solid core

gauge wire about 1 inch long and strip

off a ¼” of insulation on both ends.

Page 43

Page 44

Here you can see we have made the COMP connection

between TAG strip position 11 and the ECF80 board

COMP.

Now we have made all seven connections – it is well worth

double-checking this section – we will be doing some ohm

checks shortly also to make sure all is well.

With the inter-wiring complete you can secure down the

Hardwired EL34 board to the chassis and then secure the

ECF80 board into position also.

Well done – we have completed a channel.

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 44

Page 45

Let’s have a short lesson on using an OHM meter which is a most valuable tool

for checking and debugging with no power on!

When the probes are not touching we have an “open” circuit or in other words

there is no connection between the two points we are testing – on my meter you

can see it says OL for Overload or a resistance of many Mega ohms which is

the same as “not connected”.

Now I am touching the probes together and the meter is showing a very low

resistance of 4.7 ohms – this tells you that there is a connection –it might read 0

ohms or .5 ohms or 1 ohm also.

Now lets go make our first real ohm check...

I am checking between pin 5 of the EL34 valve base, which is connected to OUT and the ECF80 -OUT connection – reading 4 ohms.

So, a good exercise would be to use your schematic and see if you can make

some connections to check that everything is wired correctly.

Repeat the inter-wiring and testing on the second channel of the amplifier.

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

You can do a little wire cleanup at this point with the tie

wraps provided and your amplifier should look something

like this.

NOTE that we are using some different components on the

left and right channel in this prototype that we are building

for the manual – mainly the .22 caps – these caps can be a

fun source for making changes down the road for different

levels of upgrades.

Page 45

Page 46

Section 14: RCA Connections and Final Earth

One of our last steps now is to install the input AN-A cable – this is the shielded cable that will take the input audio signal

into the ECF80 driver boards.

The first step is to install the two RCA

posts in the back of the unit - making

sure that they do not short to the

chassis.

Once tightened, bend the earth lugs

up slightly as show in the central

picture.

Here you can see the prepared AN-A

cable.

One end has a red and a white lead.

These will connect to the RCA’s - the

red is the audio signal and the white is

the ground.

The other end has a red lead and a

GROUND – these will connect to the

ECF80 board.

The first step is to connect the end with the Red and White

leads to the RCA sockets.

The White lead connects to the RCA GND lug and the Red

lead connects to the central signal lug.

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 46

Page 47

The cable should be laid down the center of the amplifier as shown here.

The ends will connect to their associated Driver Board - make sure that the Left

input goes to the Left driver board (and similar for the Right channel).

Here you can see the AN-A cable connected to the ECF80

board.

The red lead connects to the INPUT signal and the copper

tinned lead connects to the S. GND input!

Well done – we have almost completed wiring of the

amplifier – One last thing to add is a ground lead from the

power supply to the chassis ground.

Connect this prepared cable from the chassis ground screw

behind the mains transformer and connect over to the

available P_GND on the power supply Board.

See the remaining two pictures for clarification...

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 47

Page 48

Now it’s safe to say that you have completed all the wiring for the L4 Amplifier - Congratulations!

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 48

Page 49

Section 15: Powering On and Testing

Installing the FUSE – Pull out the fuse drawer and flip it over – then push in the fuse into position and insert back in the

IEC receptacle.

The switch position above shows the unit OFF – when the 1 is pressed flush with the chassis the unit will turn ON.

Power On Procedure

If you have a Variac we will take advantage of it – it is a

very useful device for slowly turning on the power to your

amplifier.

If you do not have a Variac then you will have to be a little

more cautious and be in a position where you can switch off

at the slightest hint of anything not seeming correct.

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 49

Page 50

Appendix

The appendix contains auxiliary information. That is information that is either common to most project manuals or any last

minute pieces of information that did not make it into the manual in time. It may also contain pull-out circuit diagrams that

may be handy to have outside the manual etc.

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 50

Page 51

Resistor Color Code Reference

You can also find an 'Interactive Resistor Color Code Calculator' on our website (available from the Links page).

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 51

Page 52

Mains Transformer Windings Diagram

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 52

Page 53

Power Supply Board Schematic

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 53

Page 54

Driver Board Schematic

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 54

Page 55

Output Board Schematic

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 55

Page 56

Output Section Hardwiring Diagram

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 56

Page 57

General Wiring Diagram

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 57

Page 58

Full Schematic

Copyright © 2006-2009 AudioNote Kits

www.AudioNoteKits.com

audionotekits@rogers.com

Page 58

Loading...

Loading...