Page 1

User Manual

All - In Se a l e r

v e r

D 552 AVT / D 552 AVTS

User Manual

www.audion.com

All-In Sealer

D 552 AVT / D 552 AVTS

D 552 AVT(S) ENG Rev.04

Page 2

All-In Sealer

D 552 AVT / D 552 AVTS

Original Instructions

All rights reserved.

No part of this publication may be reproduced and/or published by means of

print, photocopy, or in any other way, without prior written permission from

Audion Elektro BV.

Audion Elektro BV reserves the right to modify the machine and/or change the

operating manual without prior notice.

Audion Elektro BV is not liable for any damage caused by specifications

deviating from the standard version.

Although this manual was compiled with the utmost care, Audion Elektro BV

does not accept any liability for any mistakes it may contain and/or the

consequences of any incorrect interpretation of its contents.

Audion Elektro BV is not liable for any damage or problems resulting from the

use of parts other than original parts. If this manual does not provide

instructions for certain repairs, adjustments or maintenance, please contact your

dealer or Audion Elektro BV.

Page 3

Please read this operating

manual carefully before using

the sealer or carrying out

maintenance on it.

[*****]

The sealer is part of the Audion

product range. We also provide:

• Impulse sealers.

• Heat sealers.

• Continuous sealers.

• Vacuum sealers.

• Vacuum chambers.

• Shrink machines.

• Validatable sealers.

• Form, fill and seal machines.

Since its inception in 1947, Audion

has gained a lot of experience and

expertise with a wide variety of

sealing and packaging machines.

Our solutions for packaging

problems are unique. Our many

years of experience together with

our modern production, assembly

and testing methods ensure that our

packaging machines meet the

highest quality standards. We can

also customise the machines

according to your specific

requirements.

Audion is the right supplier for a

packaging machine that is geared to

your requirements.

[*****]

Page 4

All-In Sealer

D 552 AVT / D 552 AVTS

4 Table of Contents

Table of Contents

1 Introduction .......................................................................................................................... 6

1.1 Manufacturer .......................................................................................................... 6

1.2 Machine Type Plate ................................................................................................ 6

1.3 Warranty Conditions and Liability ......................................................................... 6

2 Safety .................................................................................................................................... 8

2.1 Symbols Used in This Manual ............................................................................... 8

2.2 User ......................................................................................................................... 8

2.2.1 Operating Personnel .......................................................................................... 8

2.2.2 Maintenance Personnel ..................................................................................... 8

2.3 Safety Instructions ................................................................................................. 9

2.3.1 General Safety Instructions ............................................................................... 9

2.3.2 What to do in case of Fire ................................................................................ 10

2.3.3 Use for Special Applications ........................................................................... 10

2.4 Safety Provisions .................................................................................................. 11

2.5 Safety symbols ..................................................................................................... 11

3 Installation .......................................................................................................................... 12

3.1 Unpacking the Sealer ........................................................................................... 12

3.2 Placing the Sealer ................................................................................................. 12

3.3 Connecting the Sealer .......................................................................................... 12

3.4 Adjusting the Sealer ............................................................................................. 13

3.4.1 Adjusting the Sealing Unit Height .................................................................. 13

3.4.2 Adjusting the Horizontal Distance for the Conveyor Belt .............................. 13

3.4.3 Adjusting the Conveyor Belt Height ............................................................... 14

4 Description of the Sealer ................................................................................................... 15

4.1 Function ................................................................................................................ 15

4.2 Overview of the Sealer ......................................................................................... 16

4.3 Control Panel ........................................................................................................ 17

4.3.1 Cool Run mode ................................................................................................ 18

5 Operation ............................................................................................................................ 19

5.1 Preparing the Sealer for Production .................................................................... 19

5.1.1 Switching on the Sealer .................................................................................. 19

5.1.2 Setting the Sealing Temperature and the Conveyor Belt Speed .................. 19

5.1.3 Switching on the heating, the cooling and the fan ........................................ 20

5.1.4 Starting the Sealer ........................................................................................... 21

5.2 Sealing .................................................................................................................. 21

5.3 Stopping the Sealer (STANDBY mode) ............................................................... 22

5.4 Emergency stop .................................................................................................... 22

5.4.1 Restarting After an Emergency Stop .............................................................. 23

5.5 Switching Off the Sealer Completely .................................................................. 23

6 Troubleshooting ................................................................................................................. 24

7 Maintenance ....................................................................................................................... 26

7.1 Maintenance Schedule ......................................................................................... 26

7.1.1 Daily maintenance ........................................................................................... 26

Page 5

Table of Contents 5

7.1.2 Weekly maintenance ....................................................................................... 26

7.1.3 Annual maintenance ........................................................................................ 26

7.2 Switching Off the Sealer and Opening the Protective Cover ............................. 27

7.3 Replacing the PTFE Belts ..................................................................................... 28

7.4 Replacing V-belts .................................................................................................. 30

7.5 Adjusting the V-belts ............................................................................................ 30

7.6 Replacing the heating elements .......................................................................... 31

7.7 Adjusting the Contact Force of the Heating Blocks ............................................ 33

7.8 Adjusting the Contact Force of the Press Rollers ............................................... 34

7.9 Adjusting the Contact Force for the Cooling Plates ............................................ 34

7.10 Adjusting the Contact Force of the After-press Rollers ...................................... 35

7.11 Adjusting the Conveyor Belt Tension.................................................................. 35

7.12 Motor Set-up......................................................................................................... 36

7.13 Correction factor ................................................................................................... 36

7.14 Reset to factory settings ...................................................................................... 36

8 Disposing of the Sealer ..................................................................................................... 37

8.1 WEEE Directive ..................................................................................................... 37

8.2 Correct Disposal for Reuse .................................................................................. 37

A Technical Information ........................................................................................................ 38

A.1. Dimension drawing .............................................................................................. 38

A.2. Technical Data ...................................................................................................... 39

B Electrical Diagram .............................................................................................................. 40

C Spare Parts ......................................................................................................................... 42

C.1. Wearing parts ....................................................................................................... 42

C.2. Exploded views .................................................................................................... 43

D Log ...................................................................................................................................... 55

D.1. Maintenance Log .................................................................................................. 55

E EC Declaration .................................................................................................................... 56

F Options .................................................................................................................................. 57

Page 6

All-In Sealer

D 552 AVT / D 552 AVTS

6 Introduction

1 Introduction

[*****]

1.1 Manufacturer

The sealer was manufactured by:

Audion Elektro BV

Hogeweyselaan 235

1382 JL Weesp

T

he Netherlands

Telephone:

+31 (0)294 491717

Fax:

+31 (0)294 491761

Email:

Export@audion.nl

Web:

www.audion.com

[*****]

1.2 Machine Type Plate

The sealer has a CE marking. This means that the sealer meets the fundamental

health and safety requirements of the European Communities.

1.3 Warranty Conditions and Liability

Subject to the limitations stated below, we provide a 12-month warranty for the

products we deliver. This warranty is limited to manufacturing defects and

therefore does not cover any malfunctions caused by any form of wear, or any

part of the delivered product that is subject to wear.

• The warranty we provide for parts or accessories purchased from third parties

is limited to the warranty the third-party provided to us.

• The warranty is void if the other party and/or any third parties engaged by

them use the product in a way it is not intended for.

• The warranty is also void if the other party, and/or any third parties engaged

by them carries out work and/or modifications on the delivered product.

• Any parts we replace in order to meet our warranty obligations become our

property.

Page 7

Introduction 7

• Should the other party not meet obligation resulting from the agreement

entered into between the parties in whole or in part or in a timely manner, we

are not obliged to provide warranty for as long as that situation continues.

We exclude all liability to the extent that the liability is not regulated by law. Our

liability will never exceed the total amount of the order in question.

Subject to the generally applicable legal rules of public order and good faith, we

are not obliged to pay compensation to the other party or any third party for

damages of any nature whatsoever, incurred directly or indirectly, including

trading loss and damage to movable or immovable property or persons.

In no case are we liable for any damage resulting from or caused by using the

delivered product or its unsuitability for the purpose for which the other party

purchased it.

Page 8

All-In Sealer

D 552 AVT / D 552 AVTS

8 Safety

2 Safety

[*****]

2.1 Symbols Used in This Manual

The following symbols are used in this user manual:

[*****]

A tip on how a task can be carried out more efficiently.

[*****]

Instructions for carrying out a task in the correct manner.

[*****]

Danger of injury to the user or damage to the sealer if the instructions

are not observed.

[*****]

2.2 User

[*****]

The sealer should only be operated by authorised personnel.

[*****]

Improper use of the sealer may lead to serious personal injury and

considerable material damage.

[*****]

Keep bystanders at a distance. Do NOT allow unauthorised personnel

to operate the sealer.

[*****]

2.2.1 Operating Personnel

The company using the machine has organised a training session to inform its

operating personnel of the potential risks of unprofessional behaviour while

carrying out their tasks.

[*****]

Installation, maintenance and repair require specialised knowledge,

which is why these tasks should only be performed by maintenance

personnel.

[*****]

Observe the safety instructions in this user manual. Failure to observe

the safety instructions may cause unacceptable risks.

The operating personnel must be familiar with all chapters of this user manual

with the exception of ‘Installation’ and ‘Maintenance’. Always observe the

following safety instructions before using the sealer or carrying out any

maintenance work.

2.2.2 Maintenance Personnel

These personnel’s professional training, knowledge and experience, and

knowledge of the manufacturer’s terms enable them to carry out the assigned

work and immediately recognise any risks that may arise.

[*****]

Observe the safety instructions in this user manual. Failure to observe

the safety instructions may cause unacceptable risks.

The maintenance personnel must be familiar with all chapters of this user

manual. Always observe the following safety instructions before using the sealer

or carrying out any maintenance work.

Page 9

Safety 9

2.3 Safety Instructions

The sealer meets the fundamental health and safety requirements of the

European Community. This means that the sealer can be operated and

maintained safely if all safety instructions are carefully observed. However,

improper or careless use can create dangerous situations.

[*****]

Observe the safety instructions in this user manual. Always remain

alert to dangerous situations and avoid any improper or careless use.

[*****]

2.3.1 General Safety Instructions

Observe the following general safety instructions:

• Tie back long hair.

• Do not wear loose clothing or jewellery.

• Always wear the personal protective equipment (PPE) prescribed by the

company, such as safety shoes, gloves and goggles.

[*****]

U

se the PPE required on the shop floor, such as safety shoes, gloves

and goggles and/or hearing protection, in particular when carrying out

maintenance work.

• Check the operation of the sealer every day.

• Keep your hands away from dangerous parts of the sealer.

• Always leave protective covers in place during production.

• Never bypass or deactivate any safety provisions.

• The sealer should never be operated or maintained by people who are under

the influence of alcohol, medication and/or drugs.

• Only use sealable material that is suitable for the sealer.

• The user is obliged to observe the normally applicable hygienic measures.

• If you are not sure whether the sealer is working properly, switch it off

immediately and consult the maintenance personnel.

• Both the user and the sealer must be supervised while the sealer is in use.

• Do not switch the sealer back on until the malfunction has been repaired.

• Should any liquid or foreign object enter the machine, switch off the sealer

and immediately remove the plug from the wall socket and have the sealer

checked by maintenance personnel before using it again.

Page 10

All-In Sealer

D 552 AVT / D 552 AVTS

10 Safety

• Should an unusual event occur, such as the development of smoke, remove

the plug from the socket immediately and have the sealer checked by

maintenance personnel before using it again.

• Remove the plug from the socket before carrying out any maintenance work.

• Never open the sealer’s housing while it is connected to the mains power.

• Do not use any water, abrasive cleaning agents, chemical solvents or other

liquids when cleaning the sealer.

2.3.2 What to do in case of Fire

[*****]

NEVER use water to extinguish a fire. This may result in lifethreatening situations because the sealer may be electrically live.

Should the sealer catch fire, never use water to extinguish the fire. Because the

machine is live, this may result in life-threatening situations. A fire extinguisher

must be within reach when the sealer is in use. The following types of fire

extinguishers are suitable to extinguish a burning sealer.

• Powder extinguisher.

• Foam extinguisher.

2.3.3 Use for Special Applications

[*****]

If the machine is used in a special environment, the company using the

machine must ensure that any instructions specific to that

environment are observed.

• If the machine is used in a sterile environment or cleanroom, the company

using the machine must ensure that any instructions specific to that

environment are observed.

• If the machine is used for the packaging of medical instruments, the company

using the machine must ensure that any instructions specific to that

environment are observed.

• If the machine is used for the packaging of food, the company using the

machine must ensure that any instructions specific to that environment are

observed.

Page 11

Safety 11

2.4 Safety Provisions

The sealer has the following safety provisions:

1. Safety covers.

− Electrical and mechanical parts in the housing are protected.

2. Metal parts are earthed.

− No dangerous voltage can develop between (external) metal parts and

the earth.

3. Fuse in 230 V circuit.

− If the maximum current is exceeded, the fuse will blow, cutting off the

power supply.

4. Emergency stop button

− In the event of a hazard, this can be used for switching off the sealer

immediately and completely.

2.5 Safety symbols

The following safety symbols have been applied on the All-In Sealer:

[*****]

Hot surfaces

On the front of the All-In Sealer on the cover.

There are heating elements and it may

therefore get hot.

[*****]

Page 12

All-In Sealer

D 552 AVT / D 552 AVTS

12 Installation

3 Installation

[*****]

3.1 Unpacking the Sealer

Check the following when unpacking the sealer:

1. Have all parts and accessories been delivered?

− Sealer

− User manual

[*****]

The sealer is packaged in environmentally friendly material that may

be disposed of as ordinary household waste.

[*****]

Keep the crate and the packaging material so that the sealer can be

transported safely again if necessary.

[*****]

3.2 Placing the Sealer

[*****]

1.

Move the sealer to the desired location.

2. Lock the wheels by pressing the brakes

down with your foot.

[*****]

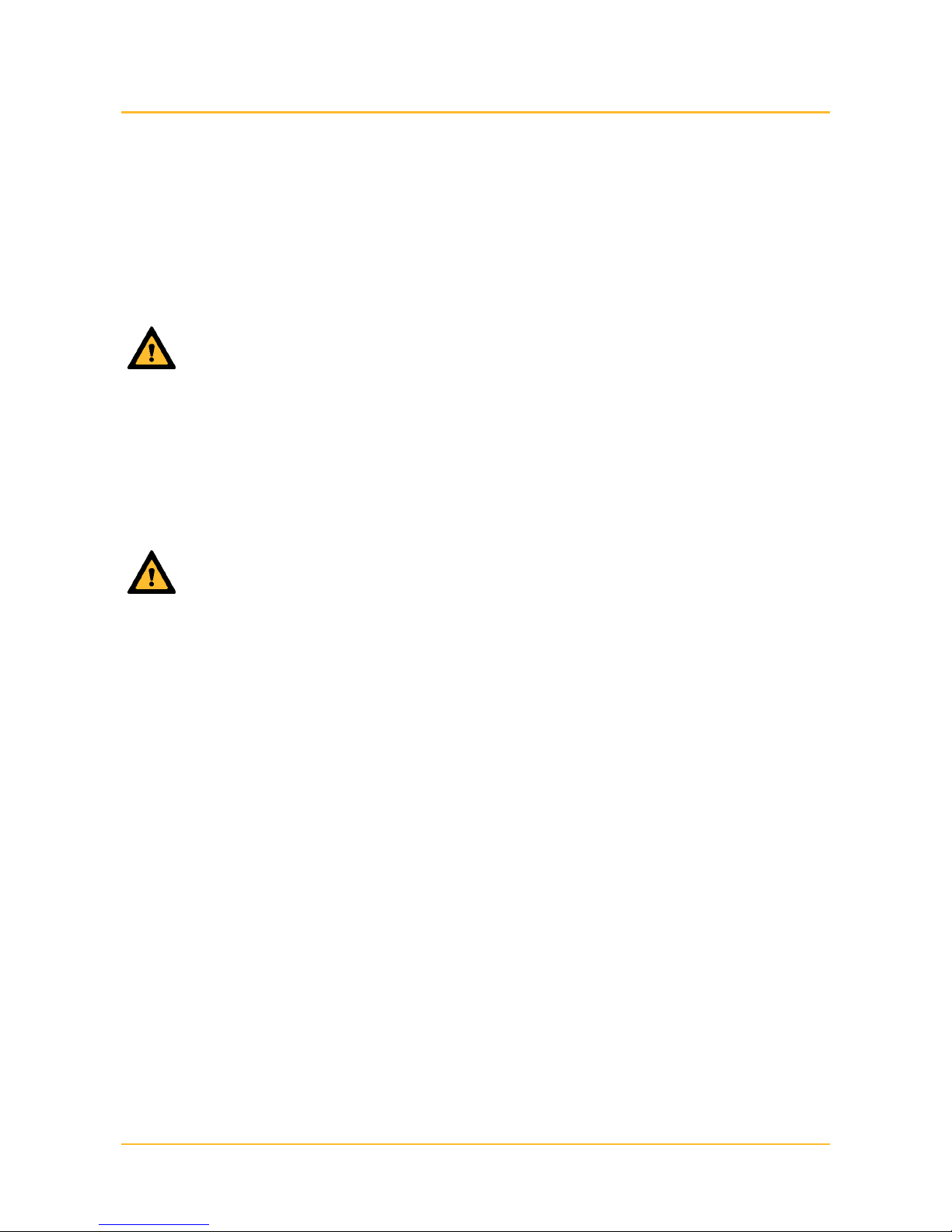

3.3 Connecting the Sealer

*****]

1.

Check that the main switch is in the ’0’

position.

Page 13

Installation 13

2.

Insert the plug in the wall socket.

[*****]

3.4 Adjusting the Sealer

The following adjustments can be made:

• The height of the sealing unit with respect to the conveyor belt; to adjust for

the height of the bags.

• The horizontal distance between conveyor belt and sealing unit; to adjust for

the positioning of the bags on the conveyor belt.

• The height of conveyor belt with respect to the floor, to adjust the working

height.

3.4.1 Adjusting the Sealing Unit Height

The sealing unit height can be adjusted as follows:

[*****]

1.

Set the sealing unit height by turning the

crank.

[*****]

The top of the bag to be sealed should b

e able to move freely along the

top of the infeed guide.

[*****]

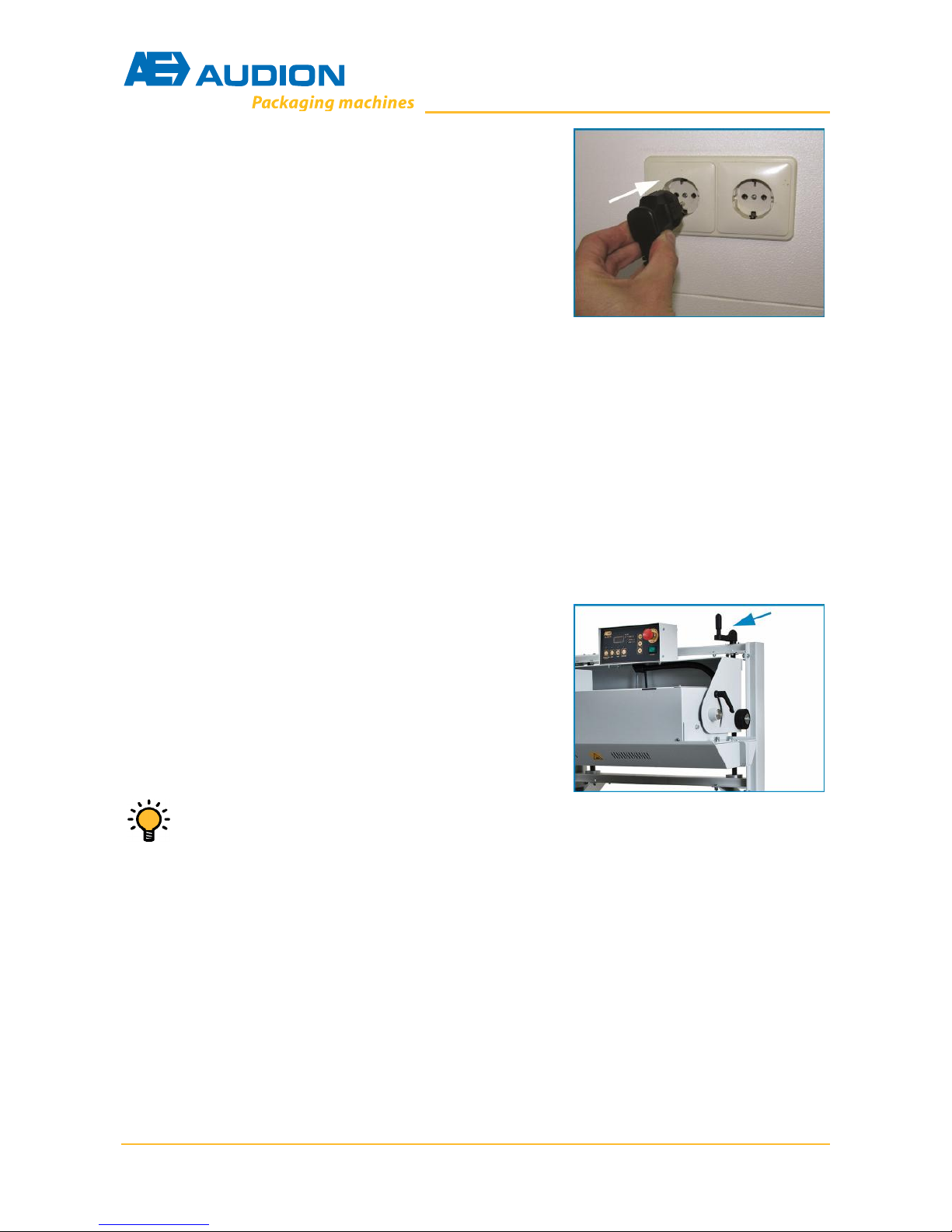

3.4.2 Adjusting the Horizontal Distance for the Conveyor Belt

The horizontal distance of the conveyor belt with respect to the sealing unit is

adjusted as follows:

[*****]

Page 14

All-In Sealer

D 552 AVT / D 552 AVTS

14 Installation

1.

Loosen the four locking

bolts a few turns.

2. Adjust the position of the conveyor belt

with respect to the sealing unit by shifting

the conveyor belt.

3. Tighten the locking bolts again.

[*****

The position of the conveyor belt must be set so that the bags that are

to be sealed are in the middle of the conveyor belt.

[*****]

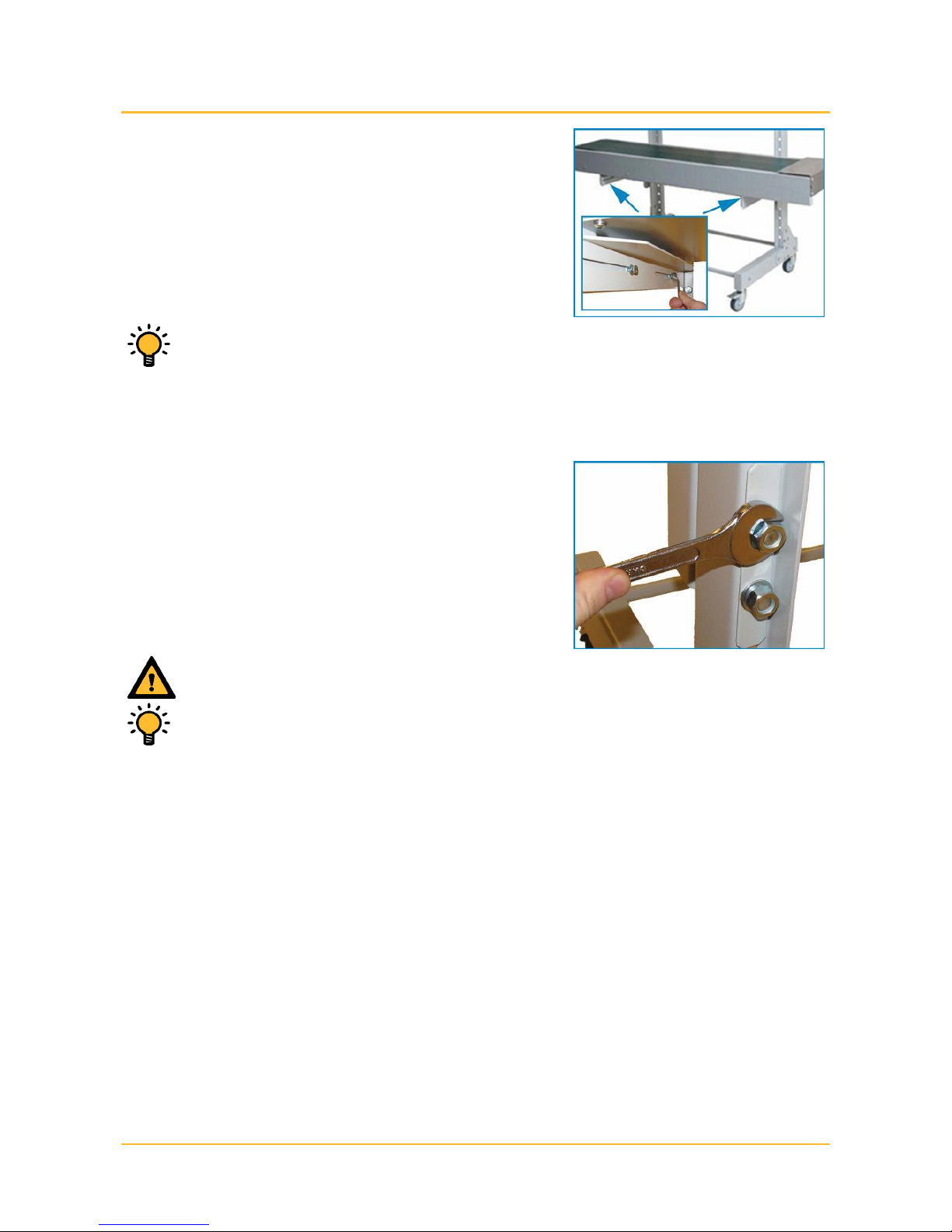

3.4.3 Adjusting the Conveyor Belt Height

The conveyor belt height can be adjusted with respect to the sealing unit as

follows:

[*****]

1.

Loosen the two mounting nuts at the back

of the conveyor belt brackets

2. Take the conveyor belt from the frame.

3. Position the conveyor belt on the frame at

the desired height.

4. Tighten the mounting nuts again.

[*****]

Make sure two persons take the conveyor belt from the frame and reposition it.

[*****]

The height of the conveyor belt must line up with the infeed and

outfeed belts.

[*****]

Page 15

Description of the Sealer 15

4 Description of the Sealer

[*****]

4.1 Function

The All-In Sealer is a band sealer for packaging a wide variety of products in large

quantities. The products are packaged in ready-to-use bags and then sealed. The

sealer can be used for sealing ready-made bags made of polyethylene (PE),

polypropylene (PP), thin PVC and various laminates with thicknesses of between

20µm and 150µm.

[*****]

Never use the All-In Sealer for any other purpose.

[*****]

The sealer is not suitable for the following applications:

• use in cleanroom environments

• use in medical or sterile environments

• use in explosive environments

• use with toxic, suffocating or irritant gases

• use in dusty environments

Page 16

All-In Sealer

D 552 AVT / D 552 AVTS

16 Description of the Sealer

4.2 Overview of the Sealer

[*****]

1. Housing

2. Control panel

3. Conveyor belt

4. Setting the distance and height of the sealing unit with respect to the

conveyor belt.

5. Frame with wheels

The sealer consists of a wheeled frame on which there is a conveyor belt and a

housing. The housing comprises the electrical and drive components; the

operating panel is mounted on top of the housing. During maintenance work, the

housing can be tilted to make the interior easily accessible.

The conveyor belt transports the bags that are to be sealed past the heating

blocks, the press rollers, the cooling plates and the after-press rollers that are

located inside the housing.

The height of the conveyor belt can be adjusted to let it line up seamlessly with

the infeed and outfeed belts. The vertical distance between the conveyor belt and

the housing can also be adjusted so that bags of various different heights can be

sealed. The horizontal position of the conveyor belt with respect to the sealing

unit can be adjusted to position the bags as centrally as possible on the conveyor

belt.

Page 17

Description of the Sealer 17

4.3 Control Panel

[*****]

[*****]

1.

Display

Gives the current sealing temperature, speed or

an error message. The setpoint value will be

shown while the settings are being adjusted.

2.

Prog

Press this to change the settings menu of the

sealer. A LED next to the button will show which

setting is being adjusted:

Temp, the sealing temperature.

Speed, the conveyor belt speed.

Sync., synchronising the sealing speed and the

speed of the conveyor belt.

3.

Up/Down

Press these to increase or reduc

e a setting.

4.

Emergency stop button

If a dangerous situation occurs, this will switch off

the sealer immediately and completely.

5.

Start/Stop

Press to start or stop the sealer. A LED above the

button shows whether the sealer is switched on or

off. If the current sealing temperature is above

80°C when the sealer is switched off, it will first

switch to ‘cool run’ mode.

6.

Heat

Press this to switch the heating on or off. A LED

above the button indicates whether the function is

switched on or off.

7.

Fan

Press this

to switch the fan on or off. A LED above

the button indicates whether the function is

switched on or off.

8.

Motor

Press this to switch the motor on or off. A LED

above the button shows whether the function is

switched on or off.

9.

Main switch

Switch for tur

ning the sealer on or off.

Page 18

All-In Sealer

D 552 AVT / D 552 AVTS

18 Description of the Sealer

4.3.1 Cool Run mode

The ‘cool run’ mode avoids burnt spots on the PTFE belts. After the machine has

been stopped, the heater is switched off; however, the fan and the motor will

continue to run. When the sealing temperature has dropped below 80°C, the

sealer is switched to standby mode. The fan and the motor will then also be

switched off.

Page 19

Operation 19

5 Operation

[*****]

5.1 Preparing the Sealer for Production

[*****]

5.1.1 Switching on the Sealer

Switch the sealer on as follows:

[*****]

1.

Set the MAIN SW

ITCH to ’1’.

2. Turn the EMERGENCY STOP BUTTON

clockwise if necessary to reset it.

[*****]

Put the plug in the socket first if necessary.

[*****]

5.1.2 Setting the Sealing Temperature and the Conveyor Belt Speed

The sealing temperature and conveyor speed can be adjusted as follows:

[*****]

1.

Press the

PROG

button until the TEMP LED

is lit.

2. Press the ARROW keys to raise or lower

the sealing temperature.

[*****]

The guideline sealing temperature is 100°C

[*****]

[*****]

3.

Press the PROG button until the SPEE

D

LED is lit.

4. Press the ARROW button to increase or

reduce the speed of the conveyor belt.

[*****]

The guideline value for the conveyor belt speed is 50.

[*****]

[*****]

Page 20

All-In Sealer

D 552 AVT / D 552 AVTS

20 Operation

5.

Press the PROG button until the current

sealing temperature is shown in the

display again.

[*****]

The TEMP LED will blink if the setpoint temperature differs from the

current sealing temperature by more than 5°C.

[*****]

Make a number of trial seals and readjust the sealing temperature and

speed as necessary.

[*****]

5.1.3 Switching on the heating, the cooling and the fan

Switch on the heating, the cooling and the fan as follows:

[*****]

1.

Press the HEAT button.

2. Press the MOTOR button.

[*****]

The heating and the transport motor must always be switched on

before use.

[*****]

[*****]

3.

Press the FAN button if necessary.

[*****]

If a paper or aluminium laminate film is being used, the FAN does not

have to be switched on.

Do be sure to switch on the fan when using PE films.

[*****]

Page 21

Operation 21

5.1.4 Starting the Sealer

Start the sealer as follows:

[*****]

1.

Press the START/STOP button.

2. Wait until the TEMP LED has stopped

blinking.

[*****]

The sealer has now reached the set temperature and is ready for

sealing.

[*****]

5.2 Sealing

Bags are sealed as follows:

[*****]

1.

Place the bags on the con

veyor belt and

guide the bag into the infeed guide.

[*****]

Make a number of trial seals first to check that the settings are

correct. Adjust the sealing temperature and conveyor belt speed as

necessary.

[*****]

Page 22

All-In Sealer

D 552 AVT / D 552 AVTS

22 Operation

5.3 Stopping the Sealer (STANDBY mode)

The sealer can be stopped and put in Standby mode after use as follows:

[*****]

1. Press the START/STOP button.

[*****]

The sealer now switches to Standby mode and the display shows "---".

If the sealing temperature is above 80°C, the sealer will first switch to

COOL RUN mode. The heating is switched off and the fan and motor

continue to run until the sealing temperature has dropped to below

80°C. The display will alternate between "c-r" and the current sealing

temperature.

The sealer is then switched to STANDBY mode.

[*****]

If the sealer is not going to be used for a lengthy period, it is better to

turn it off completely using the MAIN SWITCH.

[*****]

5.4 Emergency stop

In the event of an emergency, switch the sealer off completely as follows:

[*****]

1. Press the EMERGENCY STOP BUTTON.

[*****]

In emergency situations, always use the emergency stop button

immediately.

Do not use the emergency stop button to switch off the sealer under

normal circumstances.

[*****]

Page 23

Operation 23

5.4.1 Restarting After an Emergency Stop

The sealer can be restarted after an emergency stop as follows:

[*****]

Make sure that whatever caused the emergency stop has been

corrected before restarting the sealer.

[*****]

1.

Turn the EMERGENCY STOP BUTTON

clockwise to reset it.

2. Press the START/STOP button.

[*****]

The sealer is now ready to be used again. The ‘TEMP’ LED may possibly

be blinking; in that case, the sealer has to heat up again first.

[*****]

5.5 Switching Off the Sealer Completely

The sealer can be switched off completely as follows:

[*****]

1.

Set the MAIN SWITCH to '0'.

[*****]

Make sure that the sealer is in Standby mode before it is switched off

completely (see 'Stopping the Sealer (STANDBY mode)').

[*****]

Page 24

All-In Sealer

D 552 AVT / D 552 AVTS

24 Troubleshooting

6 Troubleshooting

[*****]

Troubleshooting may only be performed by authorised maintenance

personnel.

[*****]

In the event of a malfunction, always remove the plug from the socket

before attempting to solve the problem.

[*****]

If the problem cannot be solved using the following troubleshooting

table, please contact your dealer or Audion.

[*****]

[*****]

Problem

Cause

Solution

The sealer does not do

anything.

The main switch is set to

'0'.

Switch the sealer on.

The plug is not inserted

into the wall socket or

has not been inserted

properly.

Put the plug in the

socket

properly.

The power has been cut.

Check the power supply.

The emergency stop

button has been pressed.

Reset the emergency stop

button.

Internal fault.

Contact your dealer or

Audion.

The seal is not neat and

tidy.

The sealing temperature

is not set correctly.

Readjust the sealing

temperature.

The conveyor belt speed

is not set correctly.

Readjust the conveyor

belt speed.

The heating blocks and/or

the PTFE belts are dirty.

Clean the heating blocks

and/or the PTFE belts.

The seal is not be

ing

cooled properly.

Switch the cooling on.

The heating block, the

cooling plate and/or the

press rollers are still

raised.

Put the heating block,

cooling plate and/or press

rollers back in the lowest

position.

The PTFE belts are worn.

Replace the PTFE

belts.

The cooling is not

working

The fan is not on.

Switch the fan on.

The cooling plate position

is too high.

Adjust the cooling plate

correctly.

Internal fault

Contact your dealer or

Audion.

Error code E1

Incorrect frequency

setting (50 Hz or 60 Hz PCB jumpers.

Check the main frequency

and set the PCB jumpers

correctly.

Error code E2

Loose wire to the

temperature sensor

(Pt100).

Check the connections in

the temperature sensor

wiring (Pt100).

Error code E3

Short circuit in the

temperature sensor

(Pt100).

Replace the temperature

sensor (Pt100).

Page 25

Troubleshooting 25

The conveyor belt is not

moving.

The speed is set to '0'.

Set the speed higher.

Internal fault.

Contact your dealer or

Audion.

[*****]

Page 26

All-In Sealer

D 552 AVT / D 552 AVTS

26 Maintenance

7 Maintenance

[*****]

Maintenance should only be performed by authorised maintenance

personnel.

[*****]

Always remove the plug from the socket before carrying out any

maintenance work.

[*****]

Do not use any water, abrasive cleaning agents, chemical solvents or

other liquids when cleaning the machine.

[*****]

The maintenance schedule is based on normal use. The frequency of

maintenance must be increased if the machine is used intensively, or

under extreme conditions.

[*****]

Always keep a log of all maintenance work. An example is provided as

an annex.

[*****]

7.1 Maintenance Schedule

[*****]

7.1.1 Daily maintenance

[*****]

Daily maintenance should be carried out by the operating personnel

(see Foreword)

[*****]

Part

Work

PTFE belts

Check that the PTFE belts are clean. Clean

with a damp cloth if necessary.

He

ating blocks

check that the heating blocks are clean.

Clean with a damp cloth if necessary.

[*****]

7.1.2 Weekly maintenance

[*****]

Weekly maintenance should be carried out by authorised maintenance

staff (see Foreword).

[*****]

Part

Work

Drive

Check the

rotating parts and chains.

Lubricate as necessary.

V-belts

Check the V

-

belts for cracks and check the

tension.

Conveyor belt

Check the conveyor belt for cracks and check

its tension.

Cleaning

Clean the sealer with a damp cloth and mild

soap (for example, all-purpose cleaner).

[*****]

7.1.3 Annual maintenance

[*****]

Annual maintenance should be carried out by authorised maintenance

staff (see Foreword).

[*****]

Part

Work

Earthing system

Check that the earthing complies with NEN

3140 or EN 50110-1.

[*****]

Page 27

Maintenance 27

7.2 Switching Off the Sealer and Opening the Protective

Cover

Open the protective cover as follows:

[*****]

1.

Set the main switch to ’0’.

2. Remove the plug from the socket.

[*****]

Never carry out maintenance on the sealer while it is live.

[******]

3.

Loos

en the two locking handles at the side

a few turns.

4.

Tilt the housing so that the sealing slit is at

the front.

5. Tighten the two locking handles again.

[******]

6.

Loosen the two bolts near the infeed slit.

[******]

7.

Open the protective cover.

[*****]

Warning! The heating blocks may still be hot, even if the sealer has

been switched off for a while.

[******]

Page 28

All-In Sealer

D 552 AVT / D 552 AVTS

28 Maintenance

7.3 Replacing the PTFE Belts

[*****]

Warning! The heating blocks may still be hot, even if the sealer has

been switched off for a while.

[******]

Replace the PTFE belts as follows:

[*****]

1.

Move the cooling plate, the after

-

press

roller and the heating block to their

uppermost position.

[*****]

Pull the lifting pin up and turn the lifting plate in such a way that it

protrudes above the edge of the protective cover.

[******]

2.

Push the two tension rollers inwards until

they lock in place.

[*****]

When a tension roller is pushed inwards, the locking pin falls into a

recess, which prevents the tension roller from springing back.

[******]

3.

Remov

e the V

-

belts by pushing them off

the pulleys with a rotating motion.

Page 29

Maintenance 29

4.

Remove the old PTFE belts and put the

new ones in place.

[*****]

Make sure there are no creases or folds in the PTFE belts. This can

make them break during use.

[*****]

5.

Pull the

tension roller locking pins

upwards and let the tension rollers spring

back gently.

[*****]

Make sure that the PTFE belts run smoothly over the rollers.

[******]

6.

Place the V

-

belts back over the pulleys.

[*****]

Make sure that the V-belts run smoothly over the rollers, with the

serrated side facing outwards.

[******]

7.

Move the cooling plates, the after

-

press

roller and the heating block back to their

lowest position.

[*****]

Pull the lifting pin up and turn the lifting plate so that the lifting pin

can go back down all the way again.

[******]

Page 30

All-In Sealer

D 552 AVT / D 552 AVTS

30 Maintenance

7.4 Replacing V-belts

Replace the V-belts as follows:

[*****]

1.

Remove the V

-

belts by pushing them off

the pulleys.

2. Put the new V-belts back over the pulleys.

[*****]

Make sure that the V-belts run smoothly over the rollers, with the

serrated side facing outwards.

[******]

7.5 Adjusting the V-belts

The V-belts can be adjusted as follows:

[*****]

1.

Loosen the nut at the back of the shaft by

one full turn.

[*****]

Do not undo the nut completely, or else the tension roller will not stay

suspended.

[*****]

2.

Slide the tension roller to the left or right

to increase or decrease the V-belt tension

respectively.

3. Tighten the bolt at the back of the shaft

again.

[*****]

The long belts must be able to move up and down about 1 cm in the

middle; for the short belts, the play must be 0.5 cm.

[*****]

A V-belt that has to be tensioned frequently is worn and should be

replaced.

[******]

Page 31

Maintenance 31

7.6 Replacing the heating elements

Replace the heating elements as follows:

[*****]

1. Loosen the clamping screws in the

terminal block.

2. Pull the wires out of the terminal block.

3. Cut the tie-wraps away.

4. Move the heating block to its uppermost

position.

[*****]

Pull the lifting pin up and turn the lifting plate in such a way that it

protrudes above the edge of the protective cover.

[*****]

5. Loosen the mounting bolts.

6. Remove the heating block from the

machine.

7. Loosen the hex socket bolt at the back of

the heating block.

8. Take the heating element out of the

heating block.

9. Put a new heating element in place.

10. Carefully tighten the hex socket bolt at the

back of the heating block.

[*****]

Do not tighten the hex socket bolt too far, or the heating element may

get damaged.

[*****]

Page 32

All-In Sealer

D 552 AVT / D 552 AVTS

32 Maintenance

11.

Push the connecting wires through the

opening.

12. Put back the heating blocks.

13. Tighten the mounting bolts again.

[*****]

Note that the upper heating block should still be able to move up and

down a little bit after the mounting bolts are tightened.

[*****]

14.

Insert the connecting wires back in the

terminal block.

[*****]

15.

Tighten the terminal block screws again.

16. Fix the connecting wires in place again

with tie-wraps.

[*****]

Take care to connect the wires in the correct positions.

[*****]

Page 33

Maintenance 33

17.

Move the heating block back to its lowest

position.

[*****]

Pull the lifting pin up and turn the lifting plate so that the lifting pin

can go back down all the way again.

[*****]

7.7 Adjusting the Contact Force of the Heating Blocks

The heating blocks can be adjusted as follows:

[*****]

1.

Turn the adjuster

nut to

alter the contact

force.

[*****]

T

ry to keep the contact force as low as possible in order to minimise

wear and tear on the PTFE belts.

If necessary, the contact force can be increased for materials that are

difficult to seal. Always check that the bag does not get blocked or

stuck during sealing.

[*****]

Turn anticlockwise to increase the contact force and clockwise to

reduce it

[*****]

Note that the adjustment depends on the position (horizontal or

vertical) of the housing.

[*****]

Adjust both nuts equally.

[*****]

Page 34

All-In Sealer

D 552 AVT / D 552 AVTS

34 Maintenance

7.8 Adjusting the Contact Force of the Press Rollers

The press rollers can be adjusted as follows:

[*****]

1. Turn the adjuster nuts to set the contact

force.

[*****]

Try to keep the contact force as low as possible in order to minimise

wear and tear on the PTFE belts.

If necessary, the contact force can be increased for materials that are

difficult to seal. Always check that the bag does not get blocked or

stuck during sealing.

[*****]

Turn anticlockwise to increase the contact force and clockwise to

reduce it

[*****]

Note that the adjustment depends on the position (horizontal or

vertical) of the housing.

[*****]

7.9 Adjusting the Contact Force for the Cooling Plates

The cooling plates can be adjusted as follows:

[*****]

1. Tu

rn the adjuster nut to alter the contact

force

[*****]

[*****]

Try to keep the contact force as low as possible in order to minimise

wear and tear on the PTFE belts.

If necessary, the contact force can be increased for materials that are

difficult to seal. Always check that the bag does not get blocked or

stuck during sealing.

[*****]

Turn anticlockwise to increase the contact force and clockwise to

reduce it

[*****]

Note that the adjustment depends on the position (horizontal or

vertical) of the housing.

[*****]

Page 35

Maintenance 35

7.10 Adjusting the Contact Force of the After-press Rollers

The after-press rollers can be adjusted as follows:

[*****]

1.

Turn the adjuster nut to alter the contact

force.

[*****]

Try to keep the contact force as low as possible in order

to minimise

wear and tear on the PTFE belts.

If necessary, the contact force can be increased for materials that are

difficult to seal. Always check that the bag does not get blocked or

stuck during sealing.

[*****]

Turn anticlockwise to increase the co

ntact force and clockwise to

reduce it

[*****]

Note that the adjustment depends on the position (horizontal or

vertical) of the housing.

7.11 Adjusting the Conveyor Belt Tension

The conveyor belt can be adjusted as follows:

[*****]

1.

Loosen the two locking n

uts on the

underside of the conveyor belt a few turns.

2.

Turn the tension bolts to adjust the

tension.

3. Tighten the two locking nuts again.

[*****]

Turn clockwise to increase the conveyor belt tension and

anticlockwise to reduce it.

Make sure the tension is the same on both sides so that the conveyor

belt is not pulled out of line.

Page 36

All-In Sealer

D 552 AVT / D 552 AVTS

36 Maintenance

7.12 Motor Set-up

The machine has an automatic motor set-up function. This motor set-up function

must be carried out when a motor is replaced. During this set-up the motor will

run at full speed for a few seconds. Be aware that the machine can run safely for

a few seconds.

To perform a motor set-up follow the next steps:

• Select the ‘SPEED’ mode with the ‘PROG’ button.

• Press the ‘PROG’ button for 5 seconds till ‘SP1’ appears in the display.

• Start the set-up routine by pressing the ‘PROG’ button. The motor will run at

maximum speed for a few seconds.

• End the function by pressing the ‘PROG’ button for 5 seconds till the SPEED

settings appear on the display.

7.13 Correction factor

The machine has correction factors to adjust the motor if necessary. This factor

(%) will affect the motor output. If set at e.g. 90 the motor will run slower and set

at e.g. 110 the motor will run faster.

To perform a motor set-up follow the next steps:

• Select the ‘SPEED’ mode with the ‘PROG’ button.

• Press the ‘MOTOR’ and ‘PROG’ button simultaneous for 5 seconds till ‘CF1’

appears in the display.

• Press the ‘PROG’ button.

• Set the CF1 setting with the ‘UP’ or ‘DOWN’ button. (Minimum 85 and

maximum 115).

• Press the ‘PROG’ button to return to ‘CF1’.

• End the function by pressing the ‘PROG’ button for 5 seconds till the SPEED

settings appear on the display.

7.14 Reset to factory settings

The machine has a function to reset all settings to the original factory settings.

Note that if you reset the machine all settings prior made will be lost.

To perform a reset follow the next steps:

• Switch the main power OFF.

• Keep the ‘START/STOP’- and the ‘PROG’ button pressed, while the main power

is switched ON, until ‘rES’ appears in the display.

• Perform a motor set-up.

• Adjust the correction factor if necessary.

Page 37

Disposing of the Sealer 37

8 Disposing of the Sealer

[*****]

Correct disposal of machines and equipment helps protect the

environment and public health.

[*****]

8.1 WEEE Directive

[*****]

In accordanc

e with the European Directive on waste electrical and

electronic equipment (WEEE), the pictogram shown here indicates

that the machine or piece of equipment to which it has been applied

is to be collected separately from other waste and may not be

disposed of together with other waste.

[*****]

8.2 Correct Disposal for Reuse

The machine or piece of equipment is to be presented to a disposal station or, in

case of replacement, to the supplier of the replacement machine or piece of

equipment.

For more information, please contact the local agency responsible for the

collection of waste and the like, or the municipal waste depot.

[*****]

The owner of the machine or piece of equipment is responsible for the

correct disposal of the machine.

[*****]

Page 38

All-In Sealer

D 552 AVT / D 552 AVTS

38 Technical Information

A Technical Information

[*****]

A.1. Dimension drawing

Page 39

Technical Information 39

A.2. Technical Data

[*****]

General

Dimensions

See the dimensional drawing

Weight

120 kg

Ambient temperature

5 ºC to 40 ºC

Humidity

30% to 95% RH, non

-

condensing

Seal length

unlimited

Seal width

10 mm

Sealing

speed

Max. 10 metres per minute

IP value

IP20

Electrical

Voltage

230 V

- 16 A

Frequency

50-

60 Hz

Earthing

earthed

Power

1100 W

Mains power tolerance

< 10%

Fuse

4 AT

Length of power cable

± 1.8 m

Film

Min. film thickness

20 µm

Max. film thickn

ess 150 µm

Max. film insert

40 mm

Max. film width

unlimited

Bag dimensions

Max. weight (on conveyor belt)

10 kg

Max. bag length

420 mm

Max. volume

unlimited

Emissions

Noise

< 70 dB(A)

Hand/arm vibration

<2.5 m/s

2

[*****]

Page 40

All-In Sealer

D 552 AVT / D 552 AVTS

40 Electrical Diagram

B Electrical Diagram

[*****]

Maintenance to the electrical installation should only be performed by

authorised maintenance personnel.

[*****]

Always remove the plug from the socket before carrying out any

maintenance work.

[*****]

Page 41

Electrical Diagram 41

Page 42

All-In Sealer

D 552 AVT / D 552 AVTS

42 Spare Parts

C Spare Parts

[*****]

Only use original Audion parts for repairs and maintenance.

[*****]

Repairs and maintenance should only be performed by authorised

maintenance personnel.

[*****]

Always keep a set of recommended wear parts in stock so that a

defective part can be replaced quickly and the production process

resumed without delay.

[*****]

C.1. Wearing parts

*****]

Part

Qty per

machine

Item number

V-belt, large

2 685216

-14

V-belt, small

2 685205

-11

PTFE belt, width 25 mm

2

685206

-20

Heating element (PT100)

2

685209

-11

Set of wear

-

and-tear parts

2x V-belt, large

2x V-belt, small

4x PTFE belt, width 25 mm

2x heating element (PT100)

130-1203

[*****]

Page 43

Spare Parts 43

C.2. Exploded views

Page 44

All-In Sealer

D 552 AVT / D 552 AVTS

44 Spare Parts

Page 45

Spare Parts 45

Page 46

All-In Sealer

D 552 AVT / D 552 AVTS

46 Spare Parts

Page 47

Spare Parts 47

Page 48

All-In Sealer

D 552 AVT / D 552 AVTS

48 Spare Parts

Page 49

Spare Parts 49

Page 50

All-In Sealer

D 552 AVT / D 552 AVTS

50 Spare Parts

Page 51

Spare Parts 51

Page 52

All-In Sealer

D 552 AVT / D 552 AVTS

52 Spare Parts

Page 53

Spare Parts 53

Page 54

All-In Sealer

D 552 AVT / D 552 AVTS

54 Spare Parts

Page 55

Log 55

D Log

[*****]

Always keep a log of all maintenance work.

[*****]

Refer to the ’Maintenanc

e’ chapter for an overview of the maintenance

work to be carried out.

[*****]

Make a copy of the log and use it to sign off the maintenance work.

[*****]

D.1. Maintenance Log

[*****]

Maintenance*

Remarks/parts replaced

Date

Performed by

Initials

Weekly/

Monthly

Weekly/

Monthly

Weekly/

Monthly

Weekly/

Monthly

Weekly/

Monthly

Weekly/

Monthly

Weekly/

Monthly

Weekly/

Monthly

*Strike out that which does not apply.

[*****]

Page 56

All-In Sealer

D 552 AVT / D 552 AVTS

56 EC Declaration

E EC Declaration

Page 57

Options 57

Page 58

All-In Sealer

D 552 AVT / D 552 AVTS

58 EC Declaration

Loading...

Loading...