Page 1

Se r v ic e .

For inter nal use only

Th e V 8 -5 V En g in e

Co n struc t io n Fe a t u re s a n d Fu n c t io n s

S e lf-S t u d y P r o g ra m m e 2 1 7

217

Page 2

AUDI h a s b e e n p rod uc in g a d va n ced 8-c ylin d e r

e n gin es s in ce 1988 . Their capacit y h as incr eased

from 3.6 l to 4 .2 l.

The V8 e n g in e in co m binat io n w ith Alum in iu m

Space Frame tech n o log y was the tech n ical b asis

fo r Audi's b reakth roug h into t h e lu xu ry cla s s .

Ste p s t o e n h a n ce th e value of the Audi A8 have

in cluded th e re d esign of t h e V8 e n g in e .

The new V8-5 V e n g in e s a re now a ls o available for

the Audi A6 m odel range.

2

SSP217_048

Page 3

3

En g ine - M o t ro n ic Sub sy ste m s

Va riab le inta ke m anifold ...................................................... 27

Seco n d a ry air s ys t e m ........................................................... 32

Co n t e n t

In t rod u c t io n

En g ine - M e c h a n ic s

Cra n kg e a r .............................................................................. 6

Engine m o u n ting .................................................................. 9

Engine lu b rica tion ................................................................ 10

Cooling cir cuit ....................................................................... 1 6

Cylin d e r he a d

Five -valve tech n o lo g y ............................................. 19

Roller rocke r ............................................................ 2 0

Cam s h aft adjuste r .................................................. 22

To o thed-b elt drive ; cylin d e r-h e a d s e a l ................. 2 4

Cylin d e r-h e a d cover s e a l ........................................ 25

Exhaust manifold .................................................... 26

Te chnica l dat a ....................................................................... 5

The self-study programme is not a repair manual!

The self-s tu dy prog ramm e pr ovide s you wit h in form a tio n

con cerning th e e ng ine 's co ns truc tio n fea tures and fu nction s.

New ! Caution!

Important !

Pa g e

Wh en ca rrying ou t m aint ena nc e and re p air work, it is e sse nt ial

to use th e la te st tec hnic a l literat u re .

En g ine M a n a g e m e n t

Syste m overview ................................................................... 36

Funct io n d ia g ra m ................................................................. 38

Qu ick-sta r t fu n ctio n s

Cam s h aft p osition sen sor ...................................... 40

Engine run -d o wn s e n s or ........................................ 4 1

Electron ic t h ro t tle fu n ctio n ................................................. 42

CAN b u s in t e rfac e s ............................................................... 44

Additio n a l s ignals / in t erfa c e s ............................................ 46

Se rv ice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 9

Page 4

4

New features

– Five -va lve c ylin d e r head with roller roc ke r

– Ca m s h a ft a d ju s tm ent

– 3-sta g e va riable in take m a n ifo ld

– En g in e m ana gem ent syste m, Bosch ME 7.1

– Ele ctro-hydra u lic engine m o u n ting

Modifications

– to crankcas e and crankgear

– to oil circ uit

– to coo lin g circu it

V 8 -5 V En g ine s

In t ro d u c t io n

SSP213_073

Ma jo r modific a tion s we re m a d e to the

V8 e n g in es d u ring th e c o u rs e of fu rth e r

d e ve lopm e n t.

Em p h asis was place d o n th e fo llo w in g

d e ve lopm e n t object ive s :

– com p lia n ce with fut u re exhaus t-e m is s io n

re g u la tions

– reduc tion of fu e l co n s um p tion

– in cre a s e in t orq u e a n d p o w er

– im provem e n t of com fo rt a nd co n ve n ie n ce

– reduc tion of e n g in e w e ig ht

– in cre a s e d u s e o f s h a red co m pon en ts fo r

the AUDI e n g in e ser ie s .

The followin g new featu re s a n d m odific a tions

h ave b e e n in corp o ra t e d in t h e V8 4-valve

e n gin e.

Page 5

5

Te ch n ic a l d a t a

The specified p owe r d ata is only

p ossible if 98 RON fue l is u sed.

A reduc tion in p o wer o utput m ust b e

e xp e cte d if 95 RON fu el is u s e d .

3.7 l V8-5V engine

4.2 l V8-5V engine

0

50

100

150

200

250

300

350

400

450

500

0

25

50

75

100

125

150

175

200

225

250

0 1000 2000 3000 4000 5000 6000 7000

0

50

100

150

200

250

300

350

400

0 1000 2000 3000 4000 5000 6000 7000

0

25

50

75

100

125

150

175

200

SSP217_004

SSP217_005

To rqu e (Nm )

Spee d (rpm )

Powe r outp u t (kW)

To rqu e (Nm )

Spee d (rpm )

Powe r outp u t (kW)

3.7 l 4.2 l

Engine co d e AQG AQF (A8)

ARS (A6)

De sign V8 e ngine wit h 90

o

V angle

Capac ity 36 97 cm

3

41 72 cm

3

Powe r outp u t 19 1 kW

26 0 hp

a t

60 00 rp m

22 8/220 kW

31 0/300 h p

a t

60 00 rp m

Spec if. ou tput 51 .6 kW/l

70 .3 hp/l

54 .6 kW/l

74 .3 hp/l

To rqu e 35 0 Nm a t

32 00 rp m

41 0 Nm a t

30 00 rp m

Spec if.

torque

94 .7 Nm /l 98 .3 Nm /l

Bore 84.5 m m 84.5 m m

Stroke 82 .4 m m 9 3.0 m m

Compression

ra t io

11 :1 11 :1

We ight 19 8 kg 20 0 kg

Engine

m a n agem ent

Mo tro nic ME 7.1

Fuel 98 /95 RON

Firin g

s equ en ce

1 - 5 - 4 - 8 - 6 - 3 - 7 - 2

Exhaus t-e m is s ion sta n d ard

EU 3

Page 6

6

En g in e - M e c h a n ic s

Cra n k g e a r

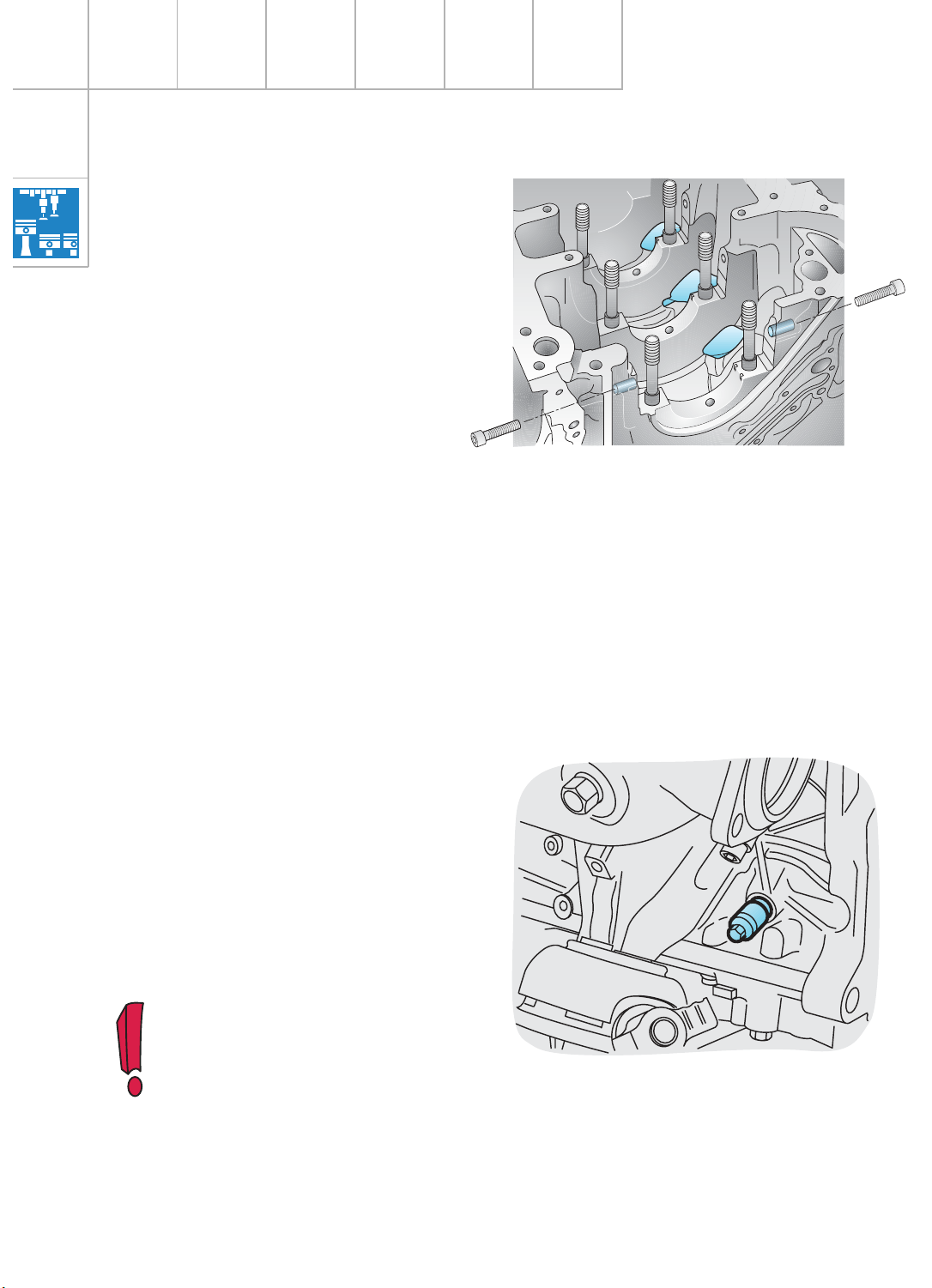

The crankcas e h a s b e e n a d a p ted to th e

m o d ifica t io ns m a d e t o the oil s u p p ly s ys t e m

a nd cooling cir cuit.

Cra cked-ste el co nr ods h ave b e e n u s e d fo r th e

3.7 l engine since 1995 and are n ow a ls o

b e in g u s e d fo r th e 4 .2 l e n g in e .

The co n rod s are s h a re d co m p o n e n ts used in

b oth th e 2 .4 l a n d 2.8 l e n g in e .

SSP217_054

SSP217_006

Page 7

7

Owing to th e design of t h e va lve re cesses, the

p is ton s a re s p e cifically in te nded for u se in the

a p p ro p riate c ylin d e r bank o n ly.

SSP217_055

SSP217_002

Page 8

8

En g in e - M e c h a n ic s

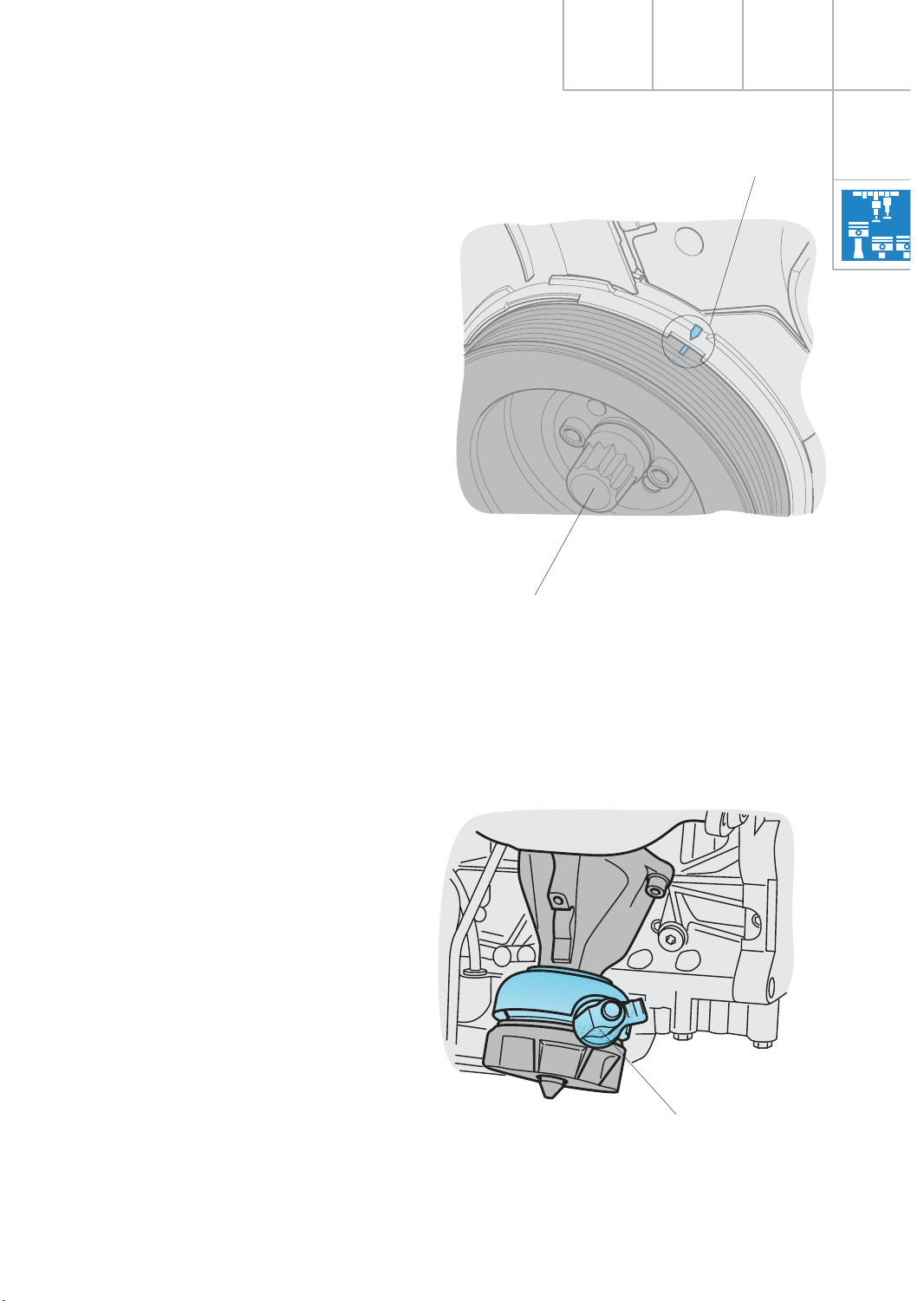

The lockin g m andre l (V.A.G 3242) u s e d fo r th e

V6 e n g in es is a ls o u s e d fo r lockin g th e

cra n ks h a ft. It is a p p lie d to the crank web of

the 4t h cylin d e r a n d is used for b a s ic engine

a d justment an d also as a cou n t erh o ld for

lo osening and tighte n in g t h e c entral b o lt of

the crankshaft.

SSP217_009

The 5th cylin d er m ust b e set t o

ig n ition TDC.

SSP217_007

Wid e , m illed ve n tilation re cess es above th e

thru s t b earin g s reduce pum ping losses.

Bolts are a ls o in s e rte d at t h e s id e o f th e t wo

fron t c ran ksha ft b ea ring caps to impro ve

ru n n in g smooth n e s s

(see SSP 198, page 6).

Page 9

9

The ce n t ra l bolt d o e s n o t h a ve to be

u nscrewed for t he vib rat io n d a m pe r to be

re m oved.

The m arking indicate s t h e ig n ition TDC of the

5t h c ylin d e r.

SSP217_050

Cent ra l bolt

Ma rking

En g in e m o u n t in g

To e n h a n ce driving co m fort , h ydra ulic engine

m o u n ts with e le c tric a l a ctivatio n a re used for

the 8-cylin d e r en gine s.

They funct io n in t h e w ay as d e s crib e d in

SSP 18 3/16.

The m ounts are a ctiva t e d b y t h e e n g in e

con trol unit accord in g t o e n g in e s p e e d a n d

ve h icle speed.

Elect ric a l c onn ec tion

SSP217_039

Page 10

10

En g in e - M e c h a n ic s

SSP217_010

A d u o centric oil pum p d riven b y the cra n ks h aft via a chain re p la c es the pre vio u s ly u s e d

e xtern a l g e a r oil pum p .

The duoc e n tric o il p u m p exte n d s d ee p into

the oil s um p . The lo w suct io n h e ig h t m e a n s

that t h e o il p ressure c an b u ild u p q u ickly,

e s p ecially with c o ld -star ts.

The oil-pressure c ontr ol va lve is lo cate d in the

oil p u m p ho u s in g . Th e “divert e d “ o il is led o ff

to th e in ta ke s ide of the oil p um p . This h e lp s

optimise the level o f e ffi ciency.

In the inta ke spindle shafts , the re are 5 o il

b ore s p e r tr ip le roller ro cke r. Thre e o il b o res

e ach sup ply one hydra u lic tappet. Two oil

b ore s s up ply the oil-spray b o re s inte g rat e d in

the ro lle r rocker to lubricate th e rollers . Th e

oil-spra y b o res are o n ly o p e n e d w h e n the

ro lle r ro ckers a re act u a ted. This res ult s in a

re d u c tion of the am ount of oil req u ired in the

cylin der h e a d .

Oil-le ve l s e n sor

Trip le ro ller roc ke r

The ro lle r rocke rs a re de sc ribed on

p a ges 20 a n d 21.

En g in e lub ric a t io n

Page 11

11

BA

A

B

B

P

A

A

SSP217_011

Thr ott le

Cylinder bank 1

Oil rete n tion valves

Spray je t valve

Byp ass valves

Oil fi lter m odule

Oil s um p

Oil p ressure co n tro l

va lve

Cam shaft

Cylinder bank 2

Oil fl ow (pre s suris e d )

Oil fl ow (non -p ressuris e d )

Thr ott le

Duoce n tr ic oil pump

Filter element

Oil c ooler

Slight modific a tion s have been m a d e to the

oil circ u it in the cylinder h e a d s .

The oil circuit for cylinder b ank 2 show n in the

illu s tra tion is the oil circuit th a t h a s b e e n

u sed s in ce th e in trod uct ion of the new model.

Cylin d e r ban k 1 show s t h e m o d ified oil

circuit.

Page 12

12

En g in e - M e c h a n ic s

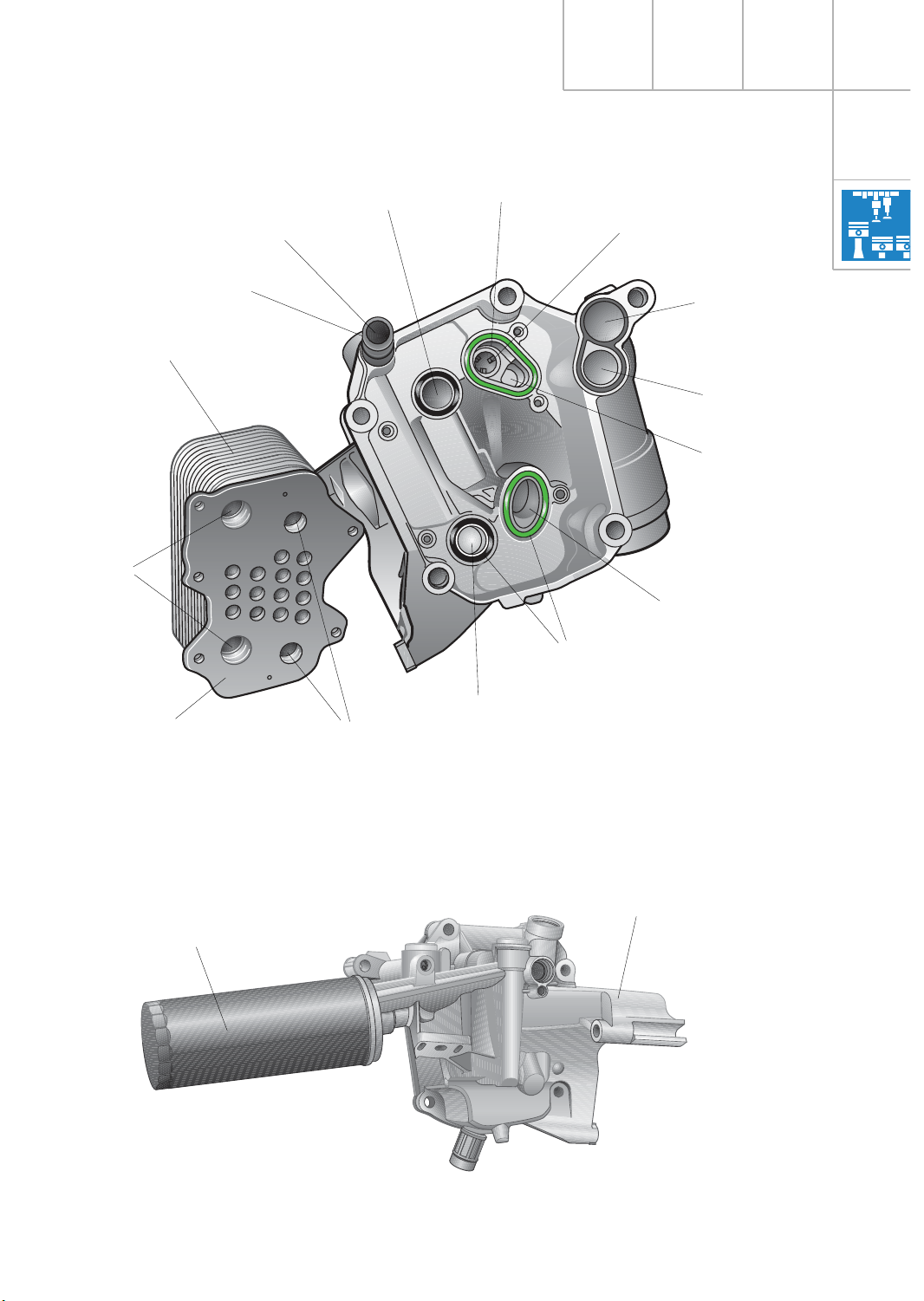

The oil filt e r module co n t ains the oil filte r

a nd o il c ooler. It is also used to ho ld th e

a ltern a tor.

SSP217_013

Oil c ooler byp ass valve

Alte rnat or m ou n t (par t

of o il m od ule )

Coola n t supply

Coola n t

re t urn

Oil s up ply

Oil retu rn

Oil filter module

(A8)

Oil p ressure swit ch

Dra in p lu g

Filter b yp ass

va lve

As was previo usly the cas e , th e o il co o le r is

d e sig n ed as a coolan t-to-oil h e a t e xch an g e r.

The “housing-le s s “ oil coo le r is b olted to t h e

oil filte r m odule using an O-ring seal to form a

s in g le u n it.

Page 13

13

SSP217_014

Oil c ooler

O-ring sea l

Sea ling su rfa ce

(Oil c oole r)

Coola n t supply

(fro m eng ine)

Oil d uc t

Coola n t

re t urn

Oil c ooler byp ass valve

Oil retu rn

(to e n g in e)

Oil s up ply

(fro m eng ine)

Oil c ooler

re t urn

Oil c ooler

s upply

Pla s tic c o nn ect ion

SSP217_003

Oil fi lter car trid g e

Alte rnat or

h older

For s p a ce re asons, the A6 o il filter m o d u le is

fitt ed with an oil filte r ca r trid g e .

Oil filter module

(A8)

Oil filter module

(A6)

Engine oil

Coola n t

Coola n t supply

Page 14

14

En g in e - M e c h a n ic s

The pitc h o f t h e in tern a l g ea r and the

e xtern a l runner h as n o fu n ction al

s ig n ifica n ce a nd is d e t erm ined by

p ro d u ction enginee rin g fa cto rs.

To e n s u re th a t the assembly

fu n ctio n s co rrect ly, the n arrow g e a rs

m u s t n ot ru n t ogeth e r on the same

p la n e.

SSP217_012

External ru n n er

Inte rn al gea r

Oil p ressure co n tro l va lve

Duocentric oil pump

Oil level sensor

The oil level s e n s or fun ctions as an in fo rm ation sender which a llo w s t he flexible servic e

in terva l to b e calcu late d and the oil le ve l to b e

d is p la ye d in th e d a s h p a n e l in s e r t.

Furt h e r in for m a tion can be found in SSP 207

(fro m page 84 o n ward s ) a n d SSP 213 (fro m

p a ge 55 o n ward s ).

SSP217_063

Oil le vel sen so r

Page 15

15

N o t e s

Page 16

16

En g in e - M e c h a n ic s

The flo w d ire c tion of the coo la n t h as b e en

cha n g e d in th e new V8 5-valve engines.

As with t h e V6 e n g in e s , t h e coolan t le a vin g

the cylinder h e ads m e rges in the re a r co o lant

p ip e from where it is t h e n le d o ff to th e

coo le r.

SSP217_015

Co o lin g c irc u it

(Exam p le : A8)

Retu rn fro m oil

coo le r

Heat e xch a nger / va lve

u nit

Coola n t tem per atu re

s ender G2 a nd G62

Radiato r fa n t herm o

s witch F18/F54

Coola n t pipe

(re tur n fo r h e a ter, oil

coo le r a nd expan sion

tan k)

Bre a the r pipe

Ne w coo la n t pipe to

cylinder head

(sm all coo lin g circ uit)

Page 17

17

Oil c ooler re turn

The new c o olant pipe alter s the coo la n t flow

in t he „s m a ll“ co o lin g c ircu it .

SSP217_016

Coola n t pipe

(re tur n fo r h e a ter, oil co o ler

a nd expans ion ta n k)

Ne w coo la n t pipe to

cylinder head

(sm all coo lin g circ uit)

To e xpa ns ion t a nk (A8)

Coola n t re turn

Heat e xch a nger (A6)

Bre a the r pipe

(to e xpa ns ion ta n k)

Coola n t supply

fo r h e a t exch anger

to veh icle radia to r

Coola n t re turn

Heat e xch a nger (A8)

to expa n s io n tan k (A6)

Coola n t tem per atu re

s ender G2 a nd G62

Coola n t pipe (re ar)

Page 18

18

Previous design:

The co o la n t ther m o s tat is co n n e cted to t h e

“sm a ll c oolant circu it “ via tw o h o le s in t h e

cylin der c ra n kc a se (see Fig. 217_017).

The holes are d irect ly connect ed to th e

cylin der-h ead wate r jacke t (1st c ylin d e r) and

the wa ter ja cket o f the cylinder c ra nkcas e. The

h eate d co o la n t flo w s from the 1s t c ylin d e r to

the co o la n t therm o s tat.

SSP217_018

En g in e - M e c h a n ic s

New design - m odified components:

– Cylin d e r head in b a n k 1 m o d ified

– Additio n a l c o olant pipe

– Re a r c o olant pipe m o d ified

The co n n e ctio n in th e cylin der head to th e

wate r jacke t (cylin d er c ra n kc a s e) has been

s p lit (see Fig. 217_019).

The co o la n t from the re a r c o olant pipe is

fo rked by the new co o la n t pipe (m ixture fr om

a ll cylin d e rs) and the n pas s e s t h ro u g h t h e

cylin der h e a d t o the tw o h o le s w h ich lead off

to th e c o olant th e rm ostat .

This ensure s u n ifo rm tempera ture c ontr ol.

The funct io n o f t h e c ylin d e r hea d is to

con nec t the co o la n t p ip e to the tw o h o le s

le adin g o ff to t he coola n t t herm os ta t.

SSP217_019

SSP217_017

Ne w coo la n t pipe

Ne w d esign

Fro m radiat or

To c oola nt p u m p

Coola n t the rm ost a t

Coola n t pipe

(re tur n fo r h e a ter, oil co o ler

a nd expans ion ta n k)

Page 19

19

The ro ckers a re m ade of d ie -c ast alum inium

in o rder to keep in ertia fo rce s as low a s

p ossible. As a re s u lt , t h e va lve g e a r is able to

fu n ctio n re lia b ly a t e n g in e s p e e d s o f u p to

72 00 rpm .

The use of ro lle r ro ckers h a s n o t only m ea nt a

con sider able re d u c tion in frict io n al lo s s e s in

the valve gear, b u t has also halved the oil

d e live ry ra te in t he cylin der h e a d s . This a ls o

h as a p ositive effe ct on th e d e g ree of

e fficie n cy.

Five -valve tech n o lo g y is now a ls o b e in g u s e d

in t he V8 engines.

Roller rocke rs a re being used for t h e firs t tim e

in t he e n hance d five -va lve c ylin d e r head.

This co n s id e rably re d u ces frict ional lo s ses in

the valve gear w hich , in turn , significantly

im p roves effic ie n cy.

SSP217_020

Cy lind e r he a d

Five-valve technology

Page 20

20

SSP217_023

En g in e - M e c h a n ic s

Roller rocker

Exhaust valve

Eve ry valve h as a h yd rau lic va lve lifter which

is in t egra ted in t h e ro cke r. The ro ckers a re

s upport e d b y a spindle shaft wh ic h is a ls o

u sed to supply oil to th e bea rings a n d the

h yd rau lic va lve lifters .

The tw o e xhau st valves are a ct uate d by a t win

ro lle r ro cker.

The single cam a ctu a tes the ro cker b y m ean s

of a roller lo cate d betw een the ro cker a rms.

SSP217_022

Spind le sha ft,

a lso use d to

s upply oil

Exhaus t va lve

20 .2˚

Roller lo cat e d b etw e en

ro cker a rm s

Twin

ro lle r rocke r

Single ca m

Oil s pr ay hole

The individual h yd ra ulic va lve lifters

can be re p la c ed witho u t the ro ckers

n e eding to be re m oved .

Page 21

21

Inlet valve

Tolerance compensation for inlet

triple RR (roller rocker)

To e n s u re uniform co m p ression

b e twe e n t h e two ca m s and ro lle rs

of t h e ro lle r ro ckers , th e s p in dle

s h aft of the in le t ro lle r ro cker is

con vex in s h a p e in o rder to

com pensate a lig nm ent and

com ponent t o le ra n c es. This

p re ve n t s t h e ro lle r ro ckers fro m

“tilting“.

SSP217_024

Double ca m

Hyd ra u lic va lve lift er

with s lide pad (hydraulic

va lve tapp et )

Oil d uc t

Spind le sha ft

Inlet va lve 2

14 .9˚

Inlet va lve 1 a n d 3

21 .6

o

SSP217_021

Cylin d er h e ad

The th ree inlet valves a re ac tuate d via a trip le

ro lle r ro cker.

A d o u b le cam a ctua t e s the ro cker b y means

of t wo ro lle rs betw e e n t he ro cker a rm s .

SSP217_025

Trip le ro lle r roc ke r

Cam s

Rollers

Spind le sha ft

a xis (ta rge t)

Spind le sha ft

a xis (act ual)

Ca m s haft axis

For the sake of c larit y, the

tolerance of the spin d le s h a ft

re la t ive t o the ca mshaft has

b e en g re a t ly e xa g g e ra t e d in

the illustr ation .

Page 22

22

En g in e - M e c h a n ic s

Camshaft adjust er

(cylinder b a n k 1 )

In the ca s e o f th e n e w V8 engines, a n

in terlo ck fu n ctio n a nd an oil re s e rvoir w e re

a d ded to th e p roven s ys t em d u ring the

cou r se of fur ther d e ve lo p m e n t.

Thes e new fea t u re s preve n t vib ra t ions in t h e

cha in drive w h ich has a p ositive effect o n

a cou s t ic b ehaviour d u ring th e s ta rt phas e .

The ca m shaft a d ju s t m e n t s ys t em , a featu re

in corp ora t ed in Audi's curre n t range of

e n gin es, is also used in the n ew genera tion o f

V8-5V en gines .

Wh e n the engine is s w itch e d o ff, n o oil

p re ssure is a pplied to the ch ain tension er a n d

camshaft adjuste r.

Owing to th e Fe rra ria effect in t h e chain d rive

when th e en gine is s tarted, vib ratio n s w h ich

g e nera te n oise occ u r un til s ufficient oil

p re s s u re has built up.

SSP217_026

Chain te n s ioner s lid e pad

Lockin g pins for

s tar ting phas e

Slide pad adju st e r

Cam shaft a d ju s tm ent

va lve N2 05

Hyd ra u lic cylinder with

s witching pisto n

The prin ciple o f c a m s h a ft

a d justment is describ ed in S SP 182.

Oil reser voir

Te n s ioning pisto n

Adjus te r pis to n

Page 23

23

BBA

A

BBA

A

B

A

BA

SSP217_027

Engine off:

If there is no oil p re s sure ,

a s p ring-loa d e d loc kin g

p in is p us he d into t h e

d e tent s lo t o f th e

a d justing pisto n . Th e

a d justing pisto n is th e n

lo cked.

Oil retu rn

Oil s up ply

Oil reser voir

Lockin g pin

Adjus tin g p is ton

SSP217_029

SSP217_028

The ca m s h aft adjuste r is locke d in th e

“Re tard p o s ition“.

Engine running:

On ce a d efi ne d o il p re ssure h as b een re ach ed,

it acts o n t h e s u rface o f th e loc kin g p in , i.e .

a gainst th e r esistan ce o f th e s p ring.

The lockin g p in re le ases the adjustin g pisto n

s o that t h e e n g in e c ontrol u n it can adjust th e

tim in g in t h e “Ad va n ce“ d ire c tion.

Cont ro l d uc ts

Lubricatio n a n d

b re a the r h ole

Engine start:

The adjust in g p is to n is lo cke d u n til s u fficie n t

oil p ress ure h as b uilt up. This pre ve n ts

vib rat io n s in th e chain d rive and, there fo re ,

n oise g e n era tion.

Oil reservoir

The oil re s e rvoir e n s ure s t h a t the pre s s ure

cha m ber o f t h e tensioner p is ton is filled

d urin g th e n on -p ressur is e d p h ase of t he

s tart in g cycle.

This also has a positive effect o n a c oustic

b e haviour w hen the engine is s tart e d .

A h o le in t h e top of t he oil rese rvo ir allow s a ir

to esca p e a n d s up plies th e c h a in with oil.

Retard set ting

(Bas ic a n d p o w er s e t ting)

Advance setting

(To rq u e s e t ting)

Page 24

24

En g in e - M e c h a n ic s

Toothed-belt drive

The to o thed-b e lt drive is id entica l to that of

the V6-5V e n g in e . The V8-5V e n g in e is a ls o

fitt ed with a stab ilising ro lle r.

The co mponent s are la rgely id e n tical to th ose

of t h e V6-5V e n g in e .

Cylinder-head seal

The new V8-5 V e n g in e s h a ve a multi-la ye r

m e tallic cylinder-head seal alre a d y u s e d in

the 4 an d 6-cylin d er e n g in e s . Th is s e a l

re p la c e s the soft seal used in p reviou s

m o d e ls .

SSP217_038

Sta b ilis in g ro lle r

It co n s is ts of 3 in d ivid u a l m et a llic la ye rs.

The tw o o u term o s t la ye rs are t re a t ed with a

s p e cial co a t in g .

Advantages:

– Ve ry good settlin g b e h a vio ur

– Im p rove d durability

SSP217_056

Coat in g

Ecc e n tr ic ro lle r

Page 25

25

The above-m entio n e d m eas u res m e ans that

the cylinder h e ad cover is not dire ctly co up led

with the cylinder h e a d . It is , t h e re for e, “in sulated“ against vibra tions g enera ted b y the

e n gin e.

SSP217_040

Cylin d e r h e a d

c ov er

De co u p lin g e lem ent

(shor t)

SSP217_043

The secu ring bolts m u s t b e tighte ned

u niform ly in t he s p e cifie d o rder to

p re ve n t d is t ort io n o f t h e c ylin d e r

h ead cover a n d to ensure that th e

s e al is c om p le tely air-tight.

Alwa ys re fe r to t he in fo rm atio n g iven

in t he re p a ir m a n ual.

Cylinder-head cover seal

The th in -w all cylin d e r h ea d co ve rs are m ad e

of a die-ca st magnesium a lloy. A seal con ce pt,

which deco uples the cylinder h ead cover from

the cylinder h e ad, im pro ve s the acou s t ics of

the engine.

The bolte d c o nnect io n s o f th e c ylin d e r hea d

cover h ave d e coup ling elem e n ts.

A s e a l, w h ich is s im ilar to a ra d ia l s h a ft o il

s e al, is us e d for the spark-p lu g s h a ft .

735

119

1012

648

1

2

Spac er s le e ve

Sea l cylinder head co ve r

De cou p lin g

e lem ent (lo n g )

Sea l

Pro filed ru b ber g ro m met

Spac er s le e ve

Page 26

26

En g in e - M e c h a n ic s

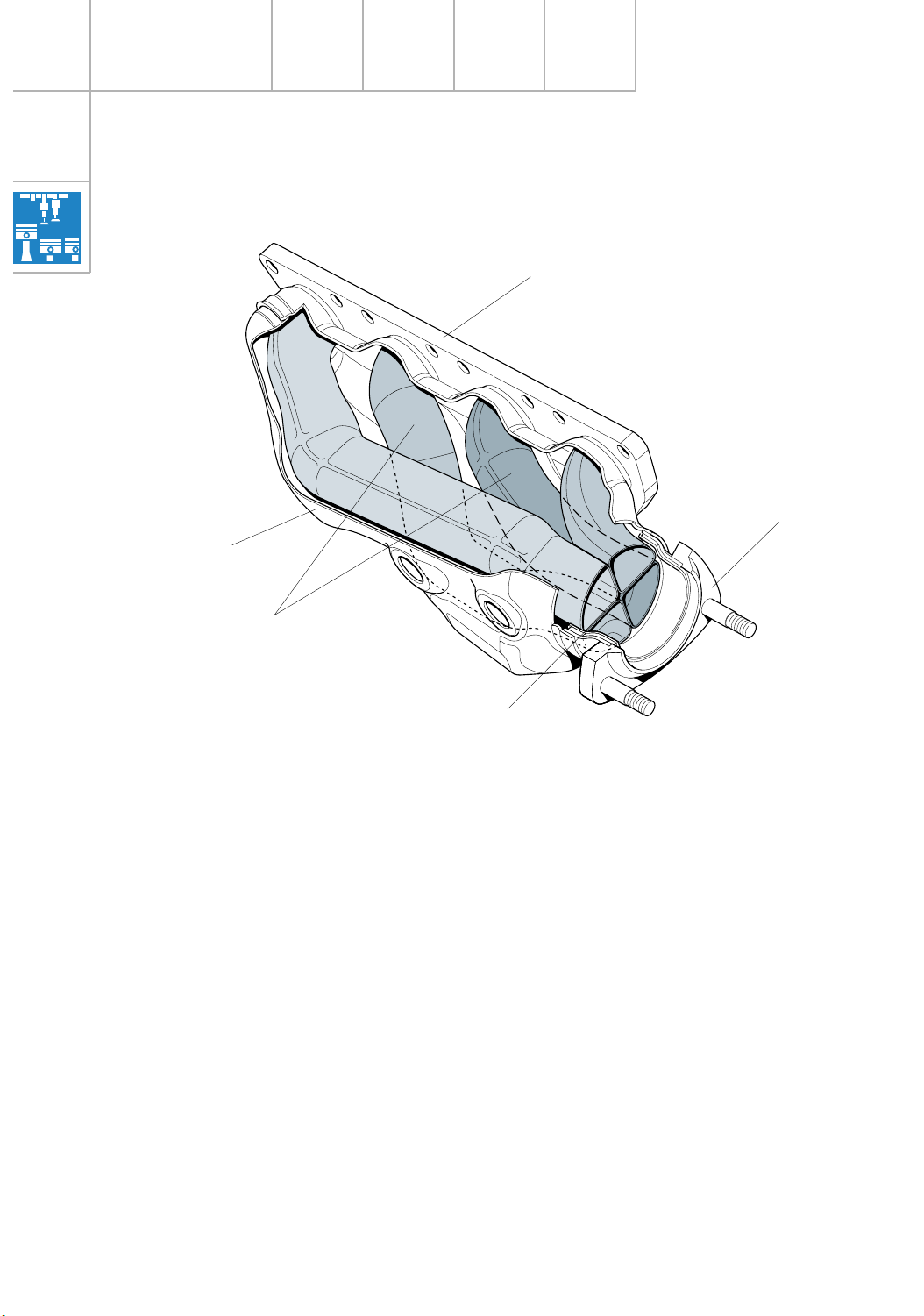

This pro tect s the in d ivid u a l c ylin d e rs

e ffe ctively against a n n o ying exhaust

vib rat io n s w h ich , in turn , has a positive

e ffe ct on engine-to rq u e c hara cte ristics .

The pipe sect io n s a n d a s s e m b ly o f th e airg ap-insulate d exhau s t m an ifold have been

m o d ified.

The exhaus t p ipes of the individ u al cylin d e rs

a re a s s e m b le d in a cloverle a f c onfig u ratio n

fo r e a ch cylinder b a n k (4 in 1 a rrangem ent).

Exhaust manifold

SSP217_036

Ma n ifo ld flan ge

(left-h an d c yl. b an k)

Conn ec tion for fron t

e xh aus t p ipe

Cloverle a f

a rran ge m en t

Individua l p ipes

res ha p e d fo r

in ter nal high

p re s s ure

Ou ter shell

Page 27

27

Increas ing to rque b y m ean s of va riable intake

m a n ifo ld s is a tradition at Audi. A thre e -s tage

va riab le inta ke m anifold m a d e o f a die-ca s t

m a g n e s iu m a llo y, a furt h e r d e ve lo p m ent o f

p re vio u s c o n cepts , is to be used for t he firs t

tim e .

The varia b le in t a ke m an ifold co n s is t s o f fou r

p rincip a l h o u s in g c om p o n ents wh ic h a re

b onded and b o lted to g e ther.

The co nce pt u ses two intake m a n ifo ld flaps to

p ro d u ce thre e d iffe rent inta ke m anifold

le n g ths (“re s o nance tu b e le n g t h s “). To u t ilis e

the pulsatio n s t o o p tim um e ffe c t, the in take

m a n ifo ld fl aps close th e resonance t u b e

openings b y m ea n s of a circum fe re n t ia l,

m o u ld e d -on s ealing lip .

SSP217_030

Holders fo r

in je cto rs

The varia ble in take m an ifo ld m us t not

b e d is m a n t le d . If n ec e s s a ry, t h e

e n tire a s s em b ly m ust b e co m plet e ly

re p la c e d.

Va ria b le int a k e m a n if o ld

Intake module

SSP217_031

Inta ke m an ifold fla p , s ta g e 3

F

r

o

m E

-th

r

o

t

t

l

e

v

a

l

v

e

s

y

s

t

e m

Inta ke a ir (inle t)

Inta ke m an ifold fla p ,

s tag e 2 (ope n)

Reson an ce tube, cyl. 5

(inlet s ide)

Va cuu m unit

Inta ke m an ifold fla p ,

s tag e 2

Va cuu m unit

Inta ke m an ifold fla p , s ta g e 3

En g in e - M o t ro n ic Su b sy st e m s

Page 28

28

En g in e - M o t ro n ic Su b sy st e m s

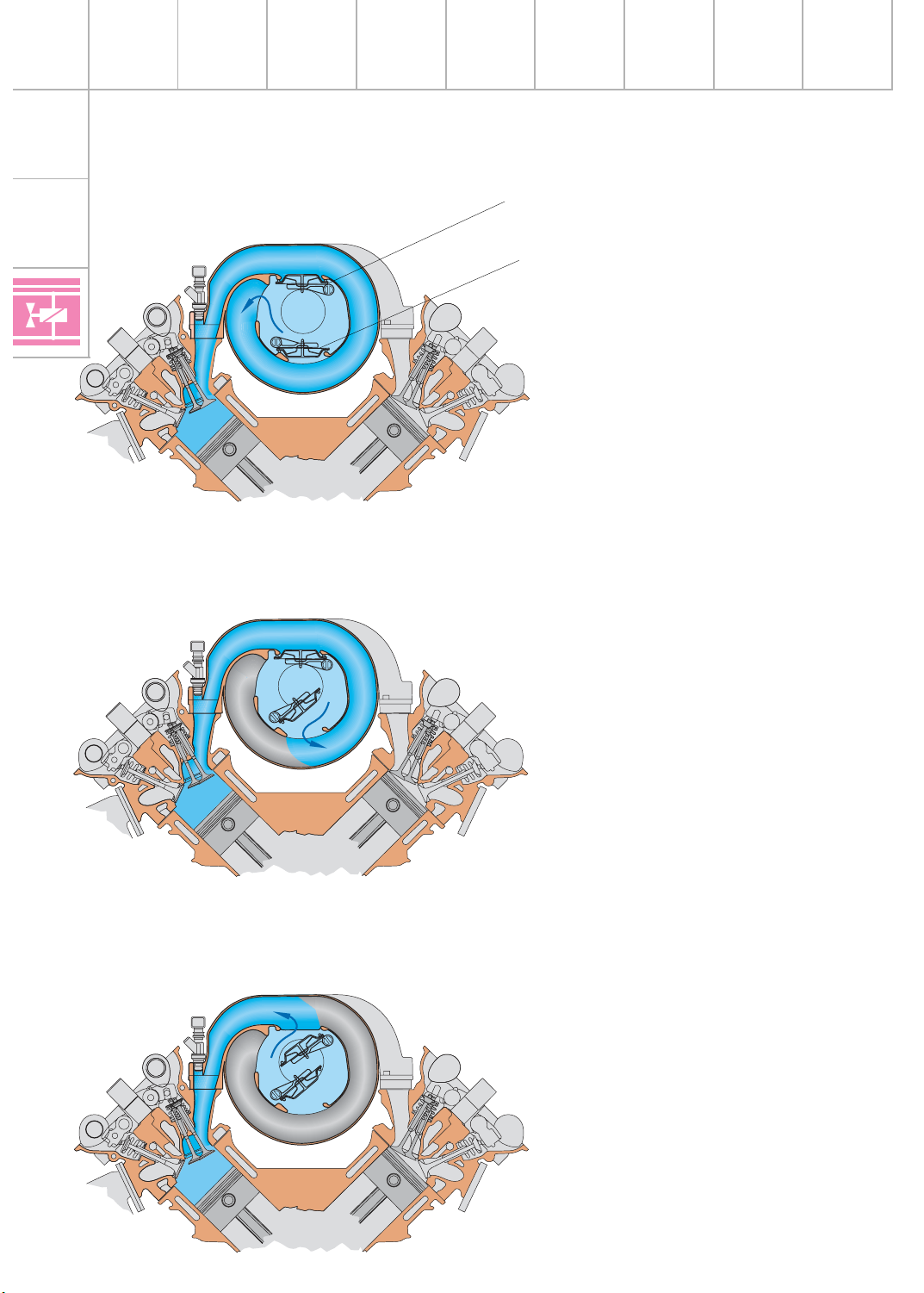

Stage 1

Lower speed range

Stage 2

Middle speed range

Stage 3

Upper speed range

In the upper s p eed ra n g e , th e s t a g e 3

in take m a n ifo ld flap is a ls o o p e n e d . The

in take air t a ke s t he s h ort e s t p ath to t h e

com bustio n c h am b e r.

Wh e n the engine is s w itch e d o ff, b oth

flap s are o p e n .

If the engine is id lin g , th e t w o va cuum

u nits are e va c uate d by th e appropria t e

in take m a n ifo ld changeover s olenoid

va lve s . The in take m a n ifo ld fl aps a re ,

there fore , clo s e d b e t ween th e idling

s p e ed a n d the s witching s p e e d.

SSP217_033

SSP217_034

SSP217_032

Inta ke m an ifold fla p

Sta g e 3

Inta ke m an ifold fla p

Sta g e 2

In the mid d le s p e e d ran ge, the inta ke

m a n ifo ld c hangeover s o lenoid va lve

N1 56 a llo ws atmospher ic p re s s u re into

the vacu u m unit of the sta g e 3 in take

m a n ifo ld fl ap.

The sta g e 2 in take m a n ifo ld fl ap is

opened and the intake path is s h ort e n e d .

Page 29

29

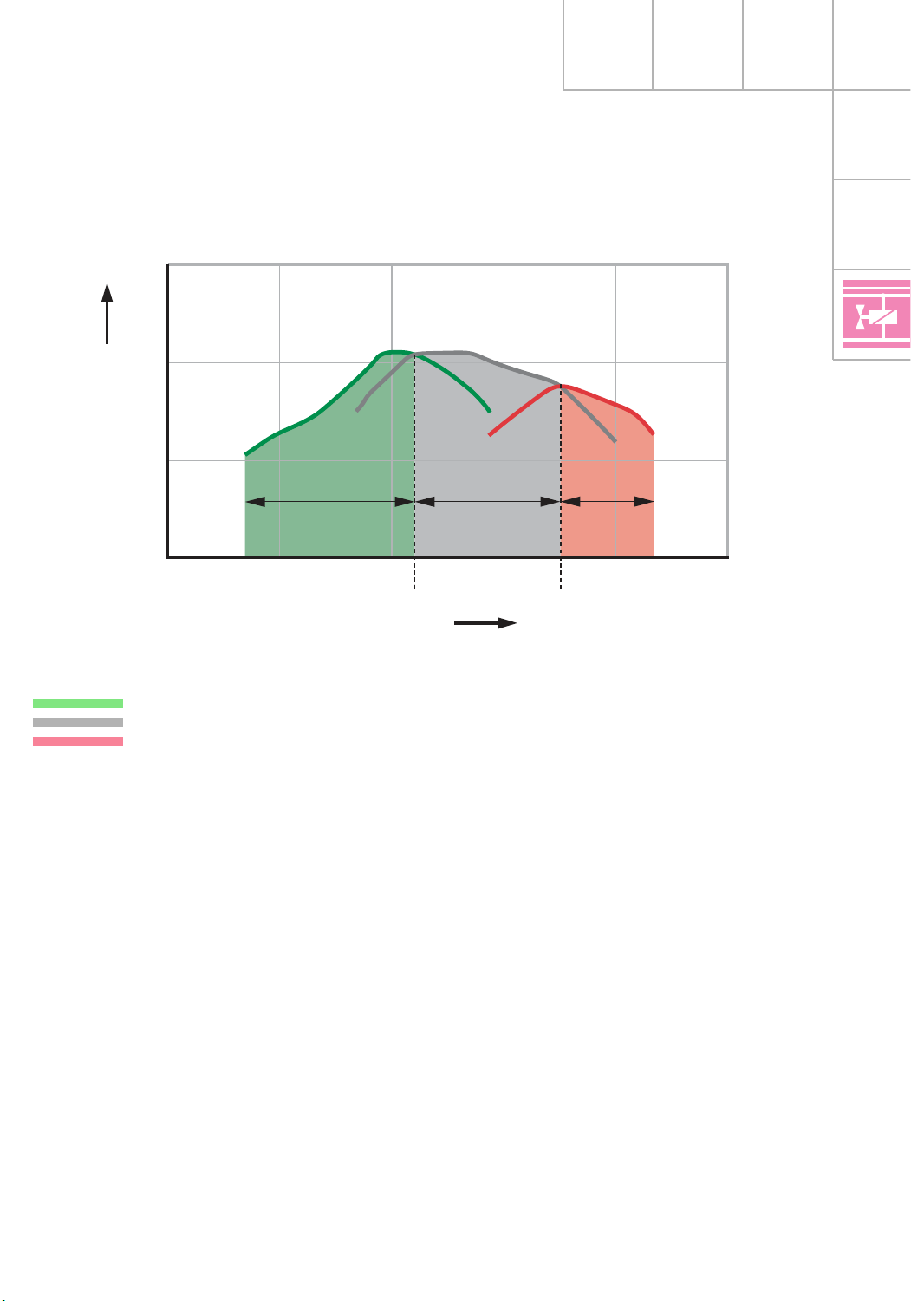

Effect of variable intake manifold on torque

The illustratio n explains th e co rrelatio n

b e twe e n t h e le n g th/cro ss s e ctio n o f th e

in take m a n ifo ld a n d e ngine speed and shows

the ch a racteris t ic torque cu rve p rod u c ed b y

the 3 st a g e s .

SSP217_035

Lowe r fu ll t hro tt le (s tag e 1)

Mid d le fu ll th ro ttle (st a ge 2)

Up p e r fu ll th rott le (sta g e 3)

Since t h e m aximum torq ue a cross the speed

ra n g e d ep en d s prim a rily o n the le n g th and

cro s s s e ctio n o f th e inta ke m anifold, the new

thre e -sta g e varia b le in t ake m a n ifo ld co m e s

closes t t o p rod u c in g the optimum characte ris tic to rqu e c u rve across th e spee d ra n g e.

De p ending o n the engine s p eed, a p p rop r iate

“res onance tu be le n gths“ are available for t h e

lo wer, m id d le a n d u p p e r speed ra n g e .

200

500

400

300

0 1500 3000

3360 5200

4500 6000 7500

Spee d

To rqu e

Page 30

30

En g in e - M o t ro n ic Su b sy st e m s

SSP217_051

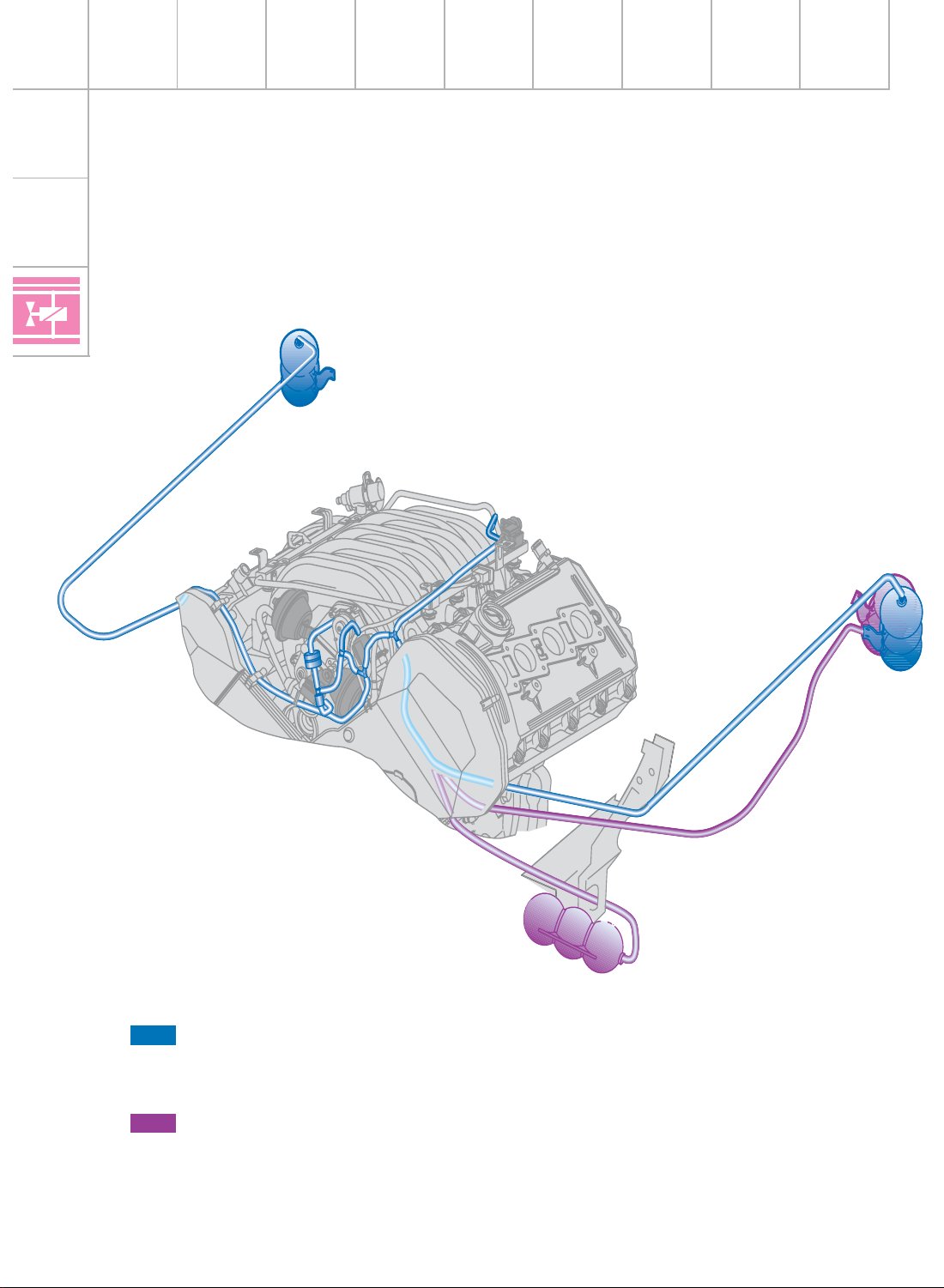

The vacu u m re quire d t o control th e varia b le

in take m a n ifo ld a n d t h e s e condary a ir system

is p rovided by two vacu u m reservo irs. If a

va cuum e xis ts in t he in take m a n ifo ld , th e

re s e rvoirs a re evacua t e d via a non -re t u rn

va lve .

Fittin g lo cat io n of va cuum re s e rvo ir,

Aud i A8

Fittin g lo cat io n of va cuum re s e rvo ir,

Aud i A6

Page 31

31

SSP217_052

Inta ke m an ifold ch a n geover

s oleno id va lve N261, sta g e 2

No n -re turn va lve

Va cuu m unit,

s tag e 2

Inta ke m an ifold ch a n geover

s oleno id va lve N156, sta g e 2

Fro m vac uum re s e rvo ir

Fro m vac uum

re s e rvoir

Va cuu m unit,

s tag e 3

Sec o ndar y a ir in let

va lve N1 12

Page 32

32

En g in e - M o t ro n ic Su b sy st e m s

Se c o n d a ry a ir sy ste m

Owing to th e high m ixture e n rich m ent d ur in g

the co ld -s t art a n d w a rm-up phase, an

in cre ased p ro p o rtio n o f unburn t h yd ro c a rb ons e xis ts in t he e xh a ust gas durin g t h is

tim e .

The ca t a lytic co n ve r ter cannot p roce s s t h is

h ig h p rop o r tion of h yd roc a rbon s beca u s e :

1. the re q u ired oper ating te m pera ture o f t h e

cata lyt ic convert er h a s n o t ye t b e en

re a ched and

2. a la m bda 1 m ixtu re m u s t e xis t to allow

com plete co n ve rsion.

Air in je ction down s t re a m of the outle t va lve s

causes oxygen enrichm e n t of the e xh a ust

g ases. As a re s u lt, t he h yd roc a rbon s an d th e

carb o n m on o xid e u n d e rgo post-o xid a tion

(after b urn in g ). Th e therm al energ y releas e d

d urin g this p ro ce ss also heats up the cat alytic

con vert er s o t h a t it re a ches its oper ating

tempera ture m ore quickly.

The seco n d a ry air s ys t em c onsists of

– t he s econ d a ry a ir p um p V101

– t wo co m binatio n va lve s A + B

– t he s econ d a ry a ir inlet va lve N112

J220

N112

G108

J299

V101

G39

G70

G62

SSP217_042

Energ is ed

No t energised

A

B

Page 33

33

SSP217_001

Sec o ndar y a ir in let va lve N112

Combina tio n va lve

Cylin d er b a n k 1

Conn ec tion for fres h air from

s eco n d ary a ir pum p V101

Combina tio n va lve

Cylin d er b a n k 2

Va cuu m fro m eng ine

Cont ro l line (vac u um o r a tm osph er ic

p re ssu re from seco n dary a ir in let valve

N1 12)

Fre sh air from s eco nd ary a ir p ump

V1 01

Page 34

34

En g in e - M o t ro n ic Su b sy st e m s

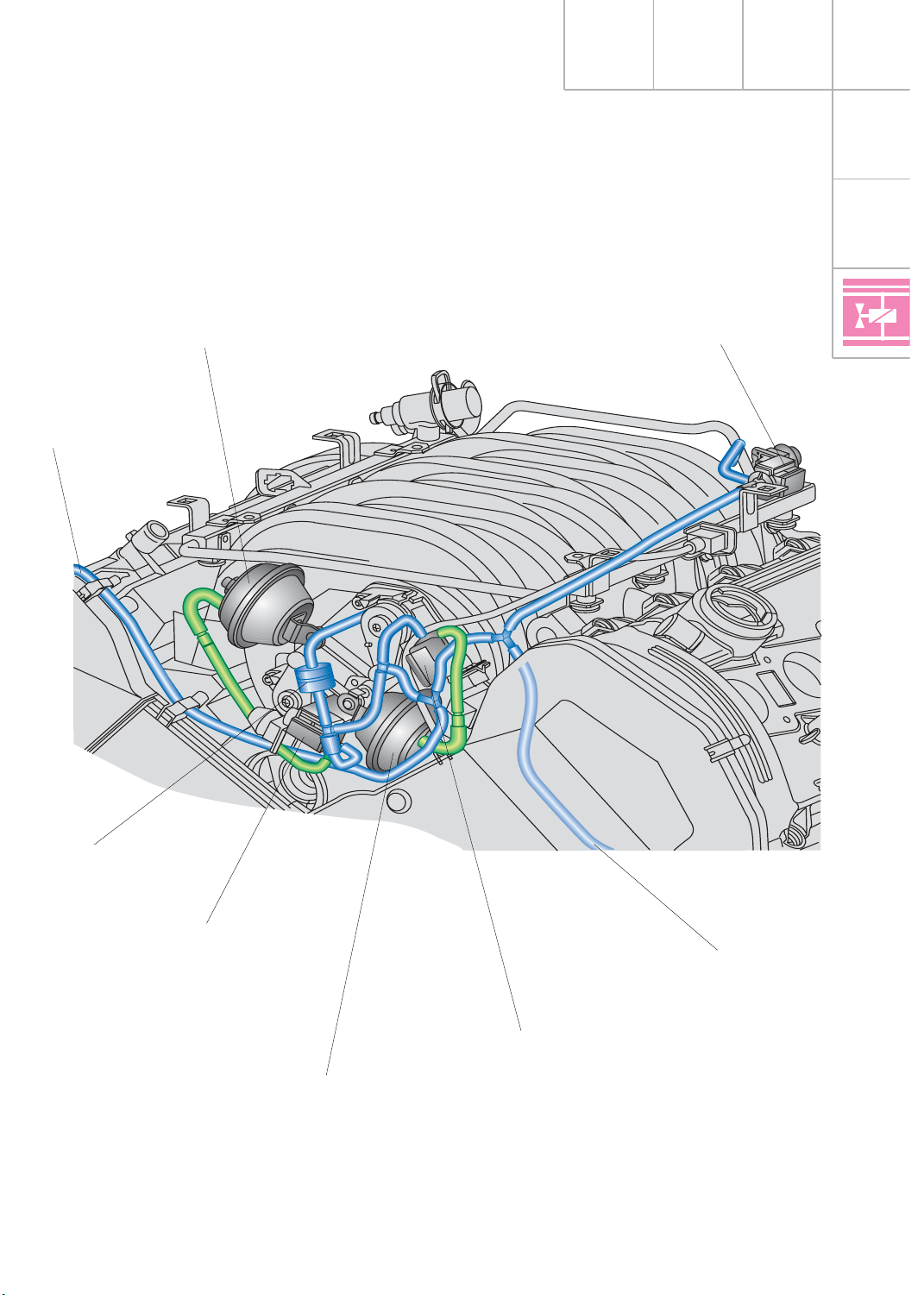

Combinat ion valve

The co m b in at io n va lve is bolte d to t he

s e con d a ry a ir d uc t of t h e cylin d er h e a d .

The vacu u m fro m th e s e c ondary a ir inlet

va lve c a uses the air channel betw e e n the

s e con d a ry a ir p um p and the seco n d a ry duct

of t h e cylin d e r h e a d t o o p en.

At th e s a m e tim e, the va lve p revents ho t

e xh a ust gas es fro m en te ring and then

d a m a g in g t h e s e con da r y a ir pum p.

Secondary air inlet valve N112

The seco n d a ry air in le t va lve is an elect ro p n e um a tic valve. It is act iva t ed b y t h e Mo t ro n ic con trol unit and co n t ro ls t h e com b in a tion

va lve .

It releases th e vacu u m s to re d in th e re s e rvoir

to open th e co m b in a t ion va lve .

Atm ospheric p re ssure is releas ed to clo s e t h e

com binatio n valve.

SSP207_016

Valve open

Fre s h a ir from

s e con d a ry air

p um p

To s e con da ry

a ir d u ct

Valve closed

Atm os phe ric

p re s s ure in c ontrol

lin e from s eco n d ary

a ir in let va lve

Exhaus t g a s

SSP207_019

SSP207_018

Va cuu m in

con tro l line fro m

s eco n d ary a ir inlet

va lve

Filter cap

Atm os phe re

To va c uum re se rvo ir

Energ is ed

No t energised

To c ombinat io n

va lve s

Page 35

35

The seco n d a ry air s ys t em is

d e scrib e d in S SP 2 07 .

SSP217_049

Air filte r box

Sec o ndar y a ir p um p,

Aud i A8

To c ombinat io n va lve

Secondary air pum p V101

The seco n d a ry air p u m p relay J 299 act iva ted

b y t he Mo tro n ic control unit co n n e cts th e

p ower s upply fo r th e s e c ondary a ir pum p

m o tor V101. The fre s h a ir m ixe d with th e

e xh a ust gas is d ra w n from the air fi lter

h ousing b y the s eco n d a ry air p u m p and

re le a s e d b y t h e com b in a tion valve.

The seco n d a ry air p u m p in the Au d i A8 has its

own air filte r.

The pump is in t e g ra t ed in t h e a ir filter

h ousing wher e it d ra w s in u n fi ltere d a ir.

The seco n d a ry air s ys t em is ac tive a t coo la n t

tempera ture s b e tween 0 a n d 55 ˚C.

The seco n d a ry air p u m p relay J 299 and the

s e con d a ry a ir inlet va lve N112 are a c tivate d

s im u lt aneous ly.

The syste m is s witch e d o ff afte r a d efin e d air

m a s s h as b e e n d raw n in by the m oto r

(inform atio n from t h e a ir m ass m e ter).

At idling speed, this occu rs after

a p p ro x. 60 - 90 s e conds.

The seco n d a ry air p u m p in th e Audi A6 d o e s

n ot have its own air filte r. It is m ounte d to t h e

lo ngitudinal m e m b e r an d dra ws the filt e re d

a ir fro m t h e a ir filt er b o x.

SSP217_057

Air filte r box

Sec o ndar y a ir p um p

Aud i A6

To c ombinat io n

va lve

Clean air in take

Page 36

36

Sy st e m o v e rv ie w

Motronic M E 7.1

Sensors

En g in e M a n a g e m e n t

Altit u de send er F96

(inte g ra te d in c ontrol un it)

Hot-film a ir m ass m ete r G70

Engine spe ed sen de r G28

Hall s e nder G40 (bank 2) a n d

Hall s e nder 2 G163 (b ank 1)

La m b da pro be G39 (bank 1) a n d

la m b d a pro b e G10 8 (b a n k 2)

Coola n t tem per atu re se nd er G2 an d G62

Kn ock s e nsor 1 G6 1 (b ank 1) a nd

kn ock se ns or 2 G6 6 (b ank 2)

Bra ke lig h t swit ch F and

b ra ke p e d al s witch F47

Clutc h p edal swit ch F3

(wit h m an ua l g ea rbox on ly)

Additio n al s ignals

– Air c onditio n e r req uirement s ig n a l

– Air c onditio n e r c ompre ssor,

b id ire ctio n a l

– Cra s h s ig n al

– CCS swit ch

Thr ott le va lve con trol un it J 338 with

thr ott le va lve d rive G186 (e le ct ric

thr ott le operatio n )

Angle se nd er -1- fo r th rot tle valve drive G1 87

Angle se nd er -2- fo r th rot tle valve drive G1 88

Pe dal send er /a cce le ra tor peda l m odule wit h

a cc e lera tor ped al pos itio n s e nder (1) G79

a nd

a cc e lera tor ped al pos itio n s e nder (2) G185

Mo tro nic

con tro l unit J 220

Cont ro l u nit fo r

ABS w ith EDL J 104

Aut om atic g e arb o x

con tro l unit J 217

* Com binatio n p ro cess or

in d ash pan el inse rt

J 218

* Air c onditio n er/Clim atron ic

operatin g an d displa y unit

E87

Ste e rin g an gle

s e n der G85

* No CAN b u s inte rfa ce

with Au di A6

Page 37

37

Active components

Fuel pum p re la y J 17 a n d

fu e l p u m p G6

Injec tor s N30, N31 , N32, N33

(bank 1)

Injec tor s N83, N84 , N85, N86

(bank 2)

Ignit io n coil N (1st c yl.), N 128 (2nd cyl.),

N1 58 (3rd cyl.), N1 63 (4t h cyl.)

Ignit io n coil N164 (5t h cyl.), N189 (6th c yl.),

N1 90 (7t h cyl.), N1 91 (8t h cyl.)

Act iva ted ch a rc oal filt er s ys tem s oleno id va lve N80

Sec o ndar y a ir p um p re la y J 29 9 an d

s eco n d ary a ir pum p m o to r V101

Sec o ndar y a ir in let va lve N112

Cam shaft a d ju s tm ent valve

N2 05 (bank 1) a n d N2 08 (bank 2)

Inta ke m an ifold ch a n geover

va lve N1 56

Inta ke m an ifold ch a n geover

va lve 2 N261

La m b da pro be heat in g Z19 (b ank 1) a nd

la m b d a pro b e heat in g Z28 (b a nk 2)

Thr ott le va lve con trol un it J 338

with t h ro ttle va lve drive G186

SSP217_046

Additio n al s ignals

– Air c onditio n e r c ompre ssor (ou t)

Diagnos is

Engine moun t 1 a nd 2

Page 38

38

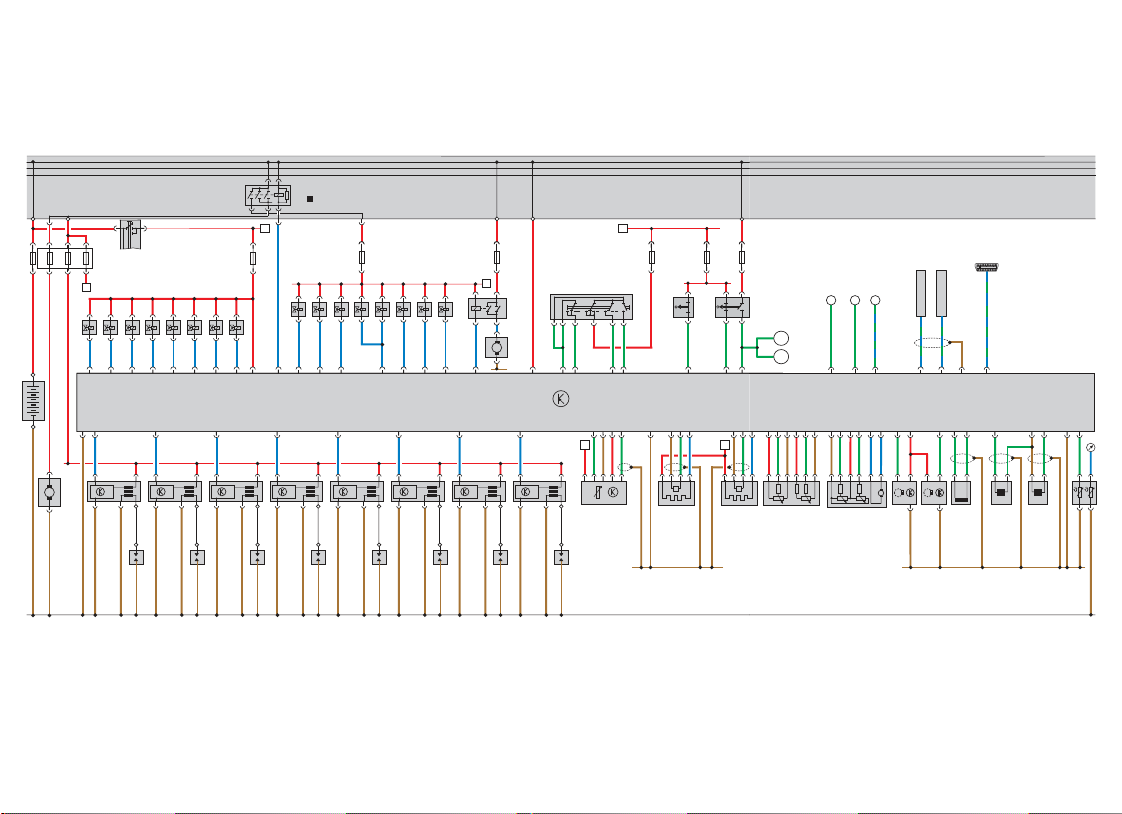

En g in e M a n a g e m e n t

Fu n c t io n d ia g ra m

4.2/ 3.7 l in A8 GP

Colour coding

= Po s itive

= Ea rth

= In put s ign al

= Ou t put s ign al

Component s

A Batt ery

E45 Cru is e con trol syste m

s witch

D Ignit io n /s tar ter swit ch

F Brake lig ht sw itch

F36 * Clutc h p edal swit ch

(wit h m an ua l g ea rbox on ly)

F47 Brake ped al sw itch fo r cruise co n trol

s ys tem

G2 Coola n t tem per atu re se nd er

G3 Coola n t tem per atu re ga ug e

G6 Fuel pum p

G28 Engine spe ed sen de r

G39 La m b da pro be

G40 Hall s e nder

G61 Kn ock s e nsor 1

G62 Coola n t tem per atu re se nd er

G66 Kn ock s e nsor 2

G70 Air m as s m et e r

G79 Acc elera to r pos it ion send er

G10 8 La m b da pro be 2

G16 3 Hall s e nder 2

G18 5 Acc elera to r pos it ion send er 2

G18 6 Thr ott le va lve d rive

(electric thrott le o peratio n )

G18 7 Angle se nd er 1 for th rott le va lve d rive

G18 8 Angle se nd er 2 for th rott le va lve d rive

J 17 Fuel pum p re la y

J 220 Mo t ro n ic co n trol u nit

J 299 Seco n dary a ir pum p re la y

M9 Bra ke lig h t bulb (le ft)

M10 Bra ke lig h t bulb (rig h t)

N Ignit io n coil (cylin de r 1)

N3 0 Injec tor (cylin der 1)

N3 1 Injec tor (cylin der 2)

N3 2 Injec tor (cylin der 3)

N3 3 Injec tor (cylin der 4)

N8 0 Act iva ted ch a rc oal filt er s ys tem s oleno id

va lve

N8 3 Injec tor (cylin der 5)

N8 4 Injec tor (cylin der 6)

N8 5 Injec tor (cylin der 7)

N8 6 Injec tor (cylin der 8)

N1 12 Sec o ndar y a ir in let va lve

N1 28 Ignit io n coil 2

= Bid ire ctiona l

Additional signals and connect ions

K dia gn os is co n nect ion

1 Cra sh signal (in ) from airb a g con trol un it

2 Air con ditio n er req u ire men t s ign al (in)

3 Air con ditio n er compressor signal (in -out )

CAN-BUS L } Co nnection to d a ta bu s

CAN-BUS H }

X}

Y } Conne ctions in fu n ct io n

Z } d iagra m

N1 44 Sole no id va lve (left) fo r ele ctro /h yd ra u lic

e ngine moun t ing

N1 45 Sole no id va lve (rig ht) for elec tro /h yd ra u lic

e ngine moun t ing

N1 56 Inta ke m an ifold ch a n geover valve

N1 58 Ignit io n coil 3

N1 63 Ignit io n coil 4

N1 64 Ignit io n coil 5

N1 89 Ignit io n coil 6

N1 90 Ignit io n coil 7

N1 91 Ignit io n coil 8

N2 05 Cam shaft a d ju s tm ent valve 1

N2 08 Cam shaft a d ju s tm ent valve 2

N2 61 Inta ke m an ifold ch a n geover valve 2

P Sp a rk plug co n n ect or

Q Spark p lu gs

S Fus e

ST Fu s e h older

V1 01 Sec ondar y a ir p um p m oto r

Z19 La m bd a probe hea t ing

Z28 La m bd a probe hea t ing 2

S204 Fittin g loc a tion in Audi A6: plen um cha mber

n e xt to b a tte ry

Fittin g lo cat io n in Aud i A8 : top rig h t

in lu ggag e co m p a rt m e n t

Page 39

30

15

X

4

J17

X

ST3

ST4

S

S6

E45

*

F36 FF47

ST2

S10

S9

J220

+

--+--+-+-

Y

m

l

G70

Z

λ λ

G39 G108 G79 G185

Z19 Z28

1 32

CAN - BUS H

CAN - BUS L

M9

M10

+ +

G188 G187MG186

G163 G40

G28 G66 G61 G2 G62

N86

X

S116

N261

N156 N208

N112

S117

N205 N80

S130

Y

N145

N144

J299

M

V101

31

30 15

S2 S3

S1

S204

D

ST4

Z

N32

N31

N33N30 N83

N85

N84

+

A

-

M

N N128 N158 N163 N164 N189 N190 N191

G6

30

15

X

G3

P

Q

31

P

Q

P

P

Q

Q

P

Q

P

Q

P

Q

P

Q

31

SSP217_044

Page 40

40

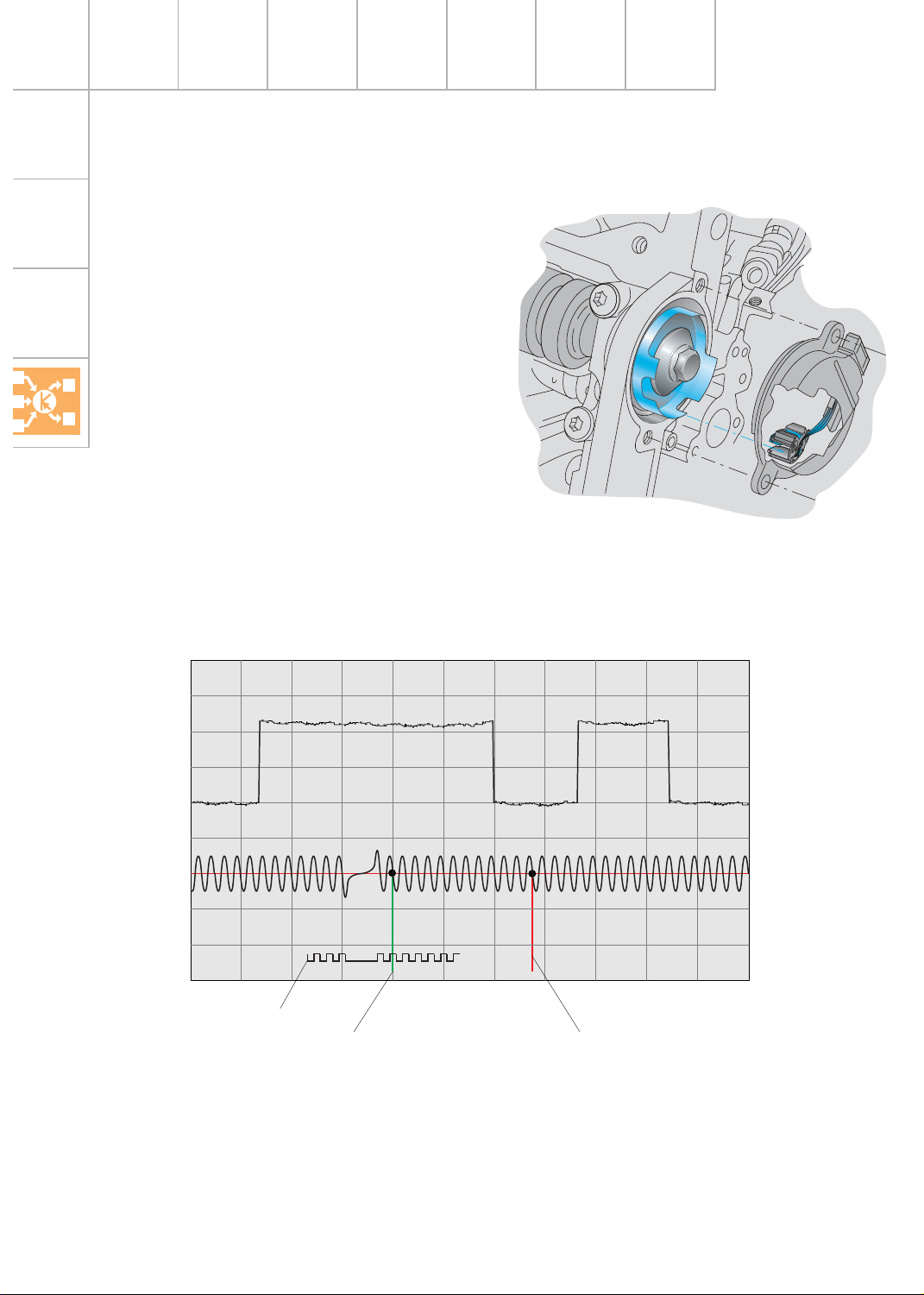

En g in e M a n a g e m e n t

Q u ick-st a r t f u n c t ion s

Camshaft position sensor G40 and G163

As with t h e V6-5V en gines , the new

V8-5V en gines also have two s e n s o rs for

d e term in in g th e p o s ition of t h e cam s haft

(G40 a n d G163).

The sender s ys tem with “qu ick-s tar t ro t or

ring“ alre a d y u s e d in th e 4- cylin d er 5-valve

e n gin es is im plemente d .

The quic k-s tart rot o r r in g h as two wid e a n d

two narro w s top s (tw o s m a ll a n d tw o la rge

windows ).

If a s top is in t h e Ha ll s e n s o r, t h e le ve l at t h e

s ig n al o u tput s e n s o r is high.

By u s in g d iffe rent sto p w id ths, it is p o s s ib le

to use th e s ignal fro m G40 tog et h e r w it h the

e n gin e s p e e d s e n d e r G2 8 to d e t erm ine the

camshaft positio n relative to t h e cra n ks h a ft

m o re quic kly.

SSP217_053

Wh e n the engine is s t art e d , t h e e n g in e c ontrol

u nit can thus dete rm ine the ignitio n TDC o f t h e

n e xt cylinder m ore quickly so tha t t h e e n g in e

s tart s m o re quickly (syn chronisatio n wit h the

1s t c ylin d e r is n o lo n g er n e c essary). Th is is

re fe rre d to as quick-s t art s ynch ro n is a t ion or

the quick-s tart fun ction.

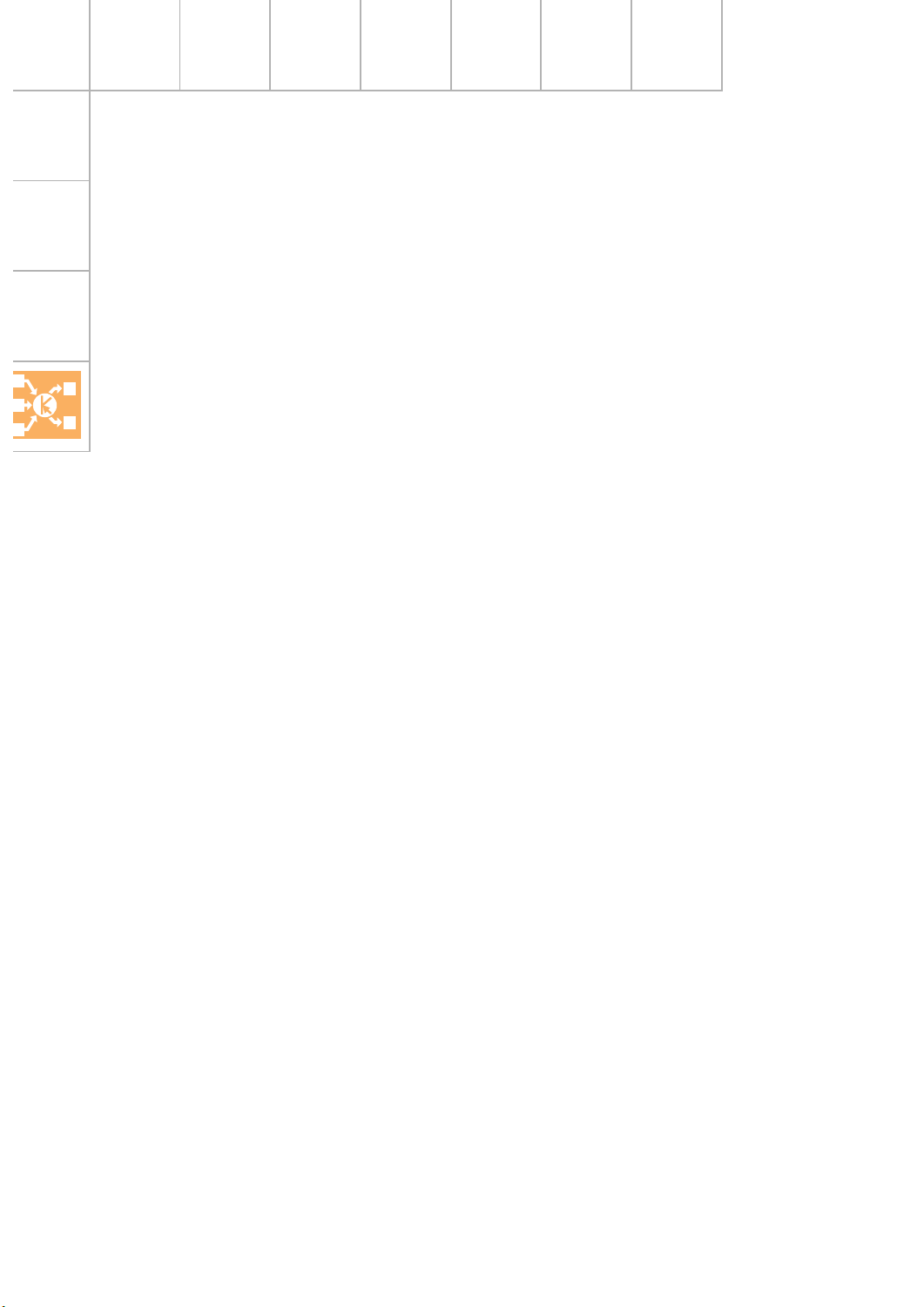

5 V/Div. 10 ms/Div

SSP217_062

Signal trace for engine speed sender G28 and Hall sender

G40 using oscilloscope function of VAS 5051

G40

G28

Sen de r whe el

Software re ference m ark

66o b e fo re TDC of 1st c ylin d e r

TDC of 1st c ylin d er

Automatic mode

*

Page 41

41

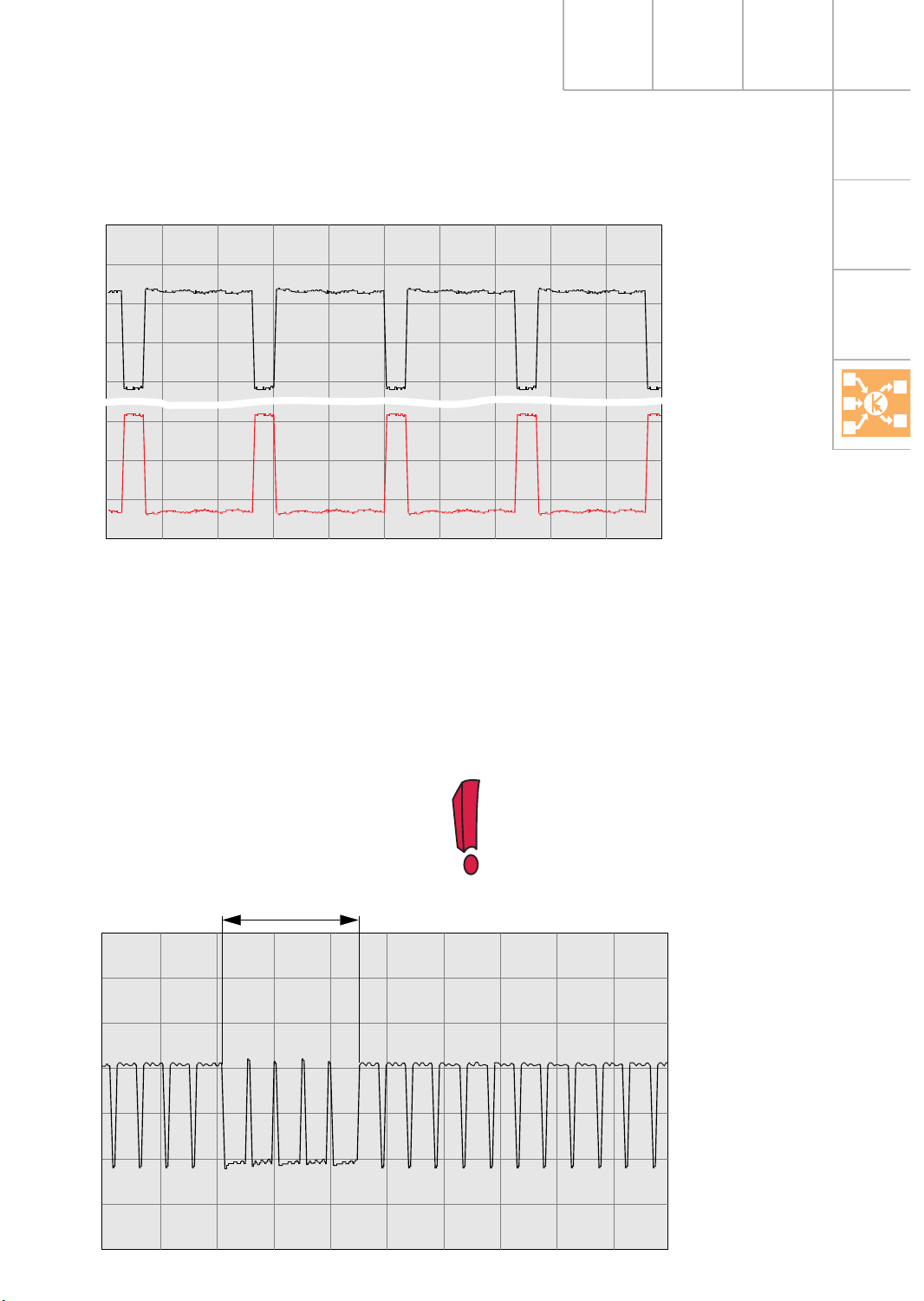

The ca m shaft pos itio n s en sor G16 3 is used to

m o n itor cam s haft adjustm ent a nd to

g e nera te a s u b s titu t e s ig n a l if th e G40 fails .

10 V/Div. 20 ms/Div

5 V/Div. 20 ms/Div

T

1

5 4 8 6 3 7 2

SSP217_061

The ca m shaft p os it io n s e n s o r G4 0 is

m o u n ted to c ylin d e r bank 2.

The ca mshaft pos itio n sensor G16 3 is

m o u n ted to c ylin d e r bank 1.

Engine run-down sensor

The ME 7.1 en gine m anagem ent system h as

a n e n g in e run-do w n s e n s o r. This d evice

s upport s t h e q uick-s tart fu n ction so th at fue l

in je ctio n c a n o ccu r before q u ick-sta r t

s yn chronisation .

The engine co n t ro l u n it rem ains a ctive for a

d e fin ed tim e after the ignition has been

s witc h ed off a n d , with t h e a id o f th e G2 8,

“m o n itors “ th e e n g in e a s it s lo w s to a s tan ds till.

The softw a re refere n ce m a rk is t he p oin t

from w h ich th e co ntrol unit co mm e n ces its

calcu la t ions to dete rm in e the ig n ition

p oint. It is about o n e t ooth afte r th e

h ard w a re refere n ce m a rk, w hich is

a p p ro xim ate ly 6 6˚ - 6 7˚ cr./shaft before

ig n ition TDC o f t h e 1st cylinde r.

Signal trace of engine speed sender G28, and

Hall sender G40 and G163

G16 3

G40

G28

Automatic mode

The positio n o f th e e n g in e m ech a n ics

(positio n o f th e next cylin d e r at ignitio n TDC)

is s tore d a n d is available th e next t im e th e

e n gin e is s ta rt e d . The ME 7.1 ca n im mediate ly

b e g in in je ction and has a fu e l m ixtu re re a d y,

which h a s a p os it ive e ffe ct o n s tart in g

b e haviour.

*

Page 42

42

En g in e M a n a g e m e n t

SSP217_041

Acc elera to r ped al

Kic kd own s wit ch

Ele c t ro n ic t h ro t t le f u n c t io n

Apart the following featu res, the elect ro n ic

thro ttle funct ions a re iden tic al to tho s e

d e scrib e d in S SP 1 98 .

The pedal sender is u s e d in th e Audi A8 a n d

the acc e le ra tor p e d a l m od ule in the Au d i A6

to dete rm in e the re q u ire ments of the drive r.

Pedal sender (Au di A8)

A s eparate s wit ch is used to pro vide kickdown

in fo rm a tio n.

It is loca te d in the fo otw ell and d oubles as the

a cce le rat o r p e d a l st o p .

The full-th rottle a nd kickdow n p os itio n s m ust

b e calibra t ed a cco rdingly.

The ME 7.1 en gine m anagem ent system h as

to a larg e e xt e n t b een d escrib e d in S SP 1 98 .

The new funct ions a n d fe a ture s o f t h e s yste m

u sed in t h e V8-5V e n g in e a re d e alt with b elow.

Page 43

43

If the acc e le ra to r ped al m od ule or the

e n gin e control unit is ch a n g e d , th e

s witc h in g p o in t of the kickdown

s witc h m u s t b e repro g ra m med using

the diagnostic teste r – see th e r epair

m a n u a l.

SSP217_060

100 %

0

G79

G185

5,0

20 % 40 %

60 % 80 %

Accelerator pedal module (Au di A6)

No s ep arate swit ch is used to pro vid e kic kd own inform at io n . In t h e case of a uto m at icg e arb o x veh icle s , th e a c celer ato r pedal sto p

is replace d b y a pre s s u re e lem ent. Th e

p re s s u re elem ent genera tes a “m e chanica l

p re s s u re point“ wh ic h g ive s t h e d river t he

“kickd own feeling“.

If the drive r activa t e s the kickdown , th e fullthro ttle volta g e o f th e a ccelerato r pedal

p osition senders is e xce e d e d . If a volta g e

d e fin ed in the engine co n t ro l un it is re a che d ,

this is in terp rete d a s a kickd o w n a n d t h e

in fo rm atio n is sent to t he a uto m atic g e a rb ox

via t h e CAN b u s . Th e kickd own swit ching

p oint can on ly be teste d u s in g d iagn os t ic

teste rs.

Kic kd own r ange

Acc elera to r ped al

fin al sto p

Full-th rot tle sto p

(m ech a n ical)

Driver to rqu e ran ge

Signa l volta g e (V)

Acc elera to r ped al travel

Page 44

44

CA N b u s int e rfa c e s

En g in e M a n a g e m e n t

ESP control unit

ASR r equest

ASR inte rventio n t o rq u e

(TARGET)

Bra ke p ed al sta t us

ESP in t erve n t io n

Road speed

MS R req u e s t

MS R in terve n t ion torque

CAN-high

CAN-low

Dash panel insert

Self-diagnosis info

Road speed

Mile a g e

Coola n t t e m p e rat u re

Oil t e m p e ratu re

Imm o b ilis e r

Steering angle sensor

Ste e ring wheel angle

(used for p reco n tro l o f th e

id lin g s p e e d c ontrol d e vice

a nd fo r ca lculatin g engine

tor que based on th e pow e r

re q u irem ents of the powe r

s teerin g s ys t e m )

Gearbox cont rol unit

Adapta tion re le a s e

Idle ch a rge co m pens at io n

Swit ch off com p re s s o r

Idling speed, targ e t s p e ed

Engine tor que (TARGET)

Em e rg en cy running p ro g ramm e s (in fo via self-diagnosis)

Ge ar change act ive / in a ctive

Selector le ve r positio n

To rqu e c o n ve rte r/g e arb o x

g uard

To rqu e c o n ve rte r clu t ch

s tatu s

Curre n t g e a r an d

targ e t gear

Engine control unit

Inta ke air tempera ture

Bra ke light s w itch

Bra ke p ed al swit ch

Thrott le va lve angle

Electron ic t h ro t tle warn in g

la m p in fo

Driver tor que ra n g e

Em e rg en cy running p ro g ramm e s (in fo via self-diagnosis)

Acc e le ra tor p e d a l p o s ition

CCS swit ch positio n s

CCS ta rget s pee d

Altit u d e in fo rm ation

Kickd own inform at io n

Swit ch off com p re s s o r

Compre s s o r ON/OFF

(ch e ck-back signal fro m

b id ire ctional in terfa ce)

Fuel con s u m ptio n

Coola n t t e m p e rat u re

Clutch p e d a l s w itch

Idle dete c tion

Engine s p e ed

Engine tor que (ACTUAL)

Imm o b ilis e r

Page 45

45

In the Au d i A8, dat a b e t ween th e en gine

con trol unit and th e ot h e r c o n trol u n its is ,

with th e e xce p tion of a fe w in t erfa ce s ,

e xchan ge d via the CAN s ys tem .

The syste m overvie w s h o ws the inform at io n

which is pro vid e d b y t h e e n g in e c ontrol u n it

via t h e CAN b u s , an d re ceived and u s ed b y

the co n n e cted co n t ro l u n it s .

The followin g tw o e xa m p le s simplify t h e

com ple xity of the CAN b u s n e twor k.

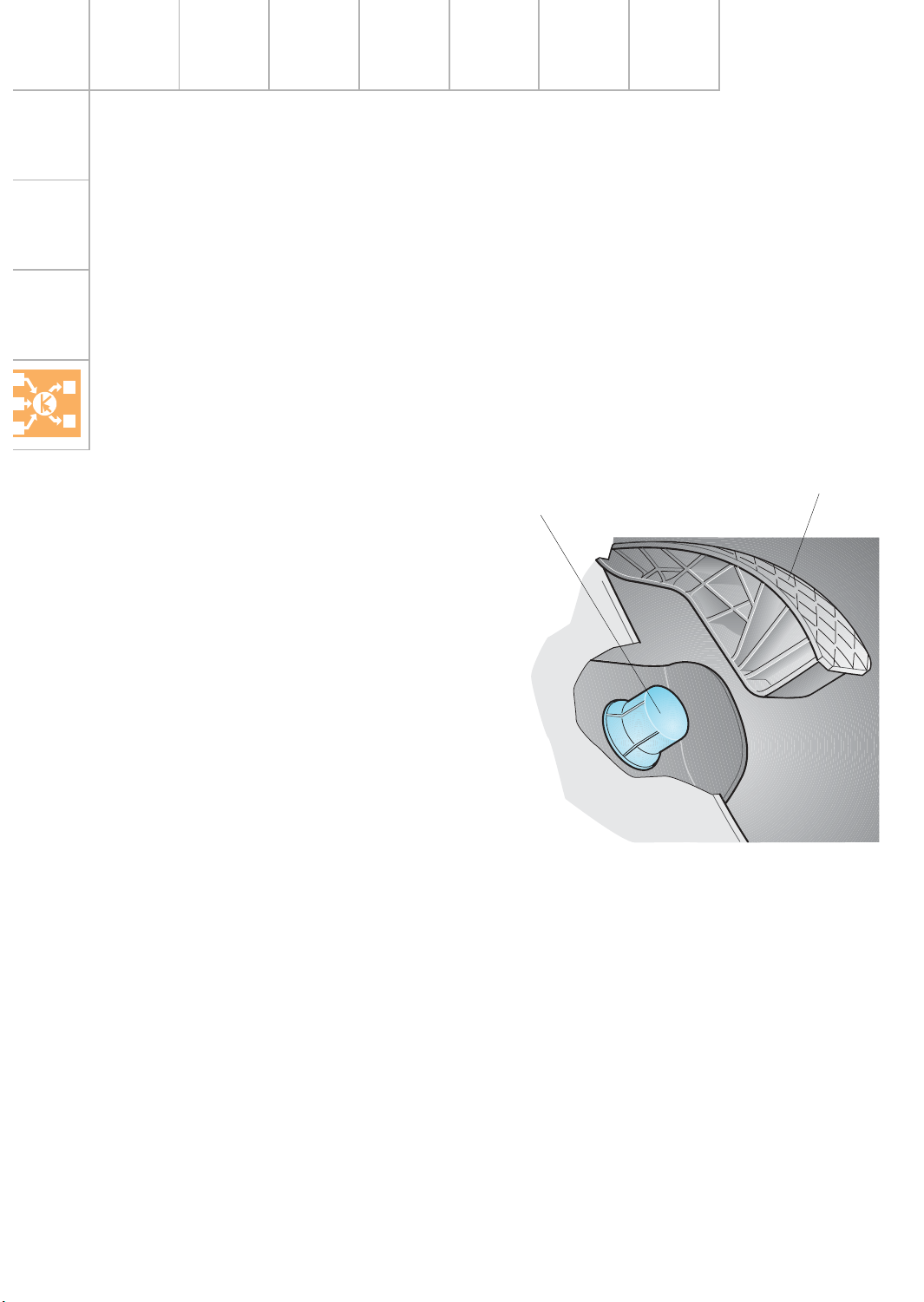

Selector lever lock:

De tailed inform at io n c once rning the

CAN d a t a b u s c an b e fo u n d in

SSP 18 6.

Kickdow n (for example, Audi A6):

Inform a t ion which is sent by

the engine co n t ro l un it.

Inform atio n which is re ce ived

a nd e va lu a ted by the engine

con trol unit.

Acc elera to r ped al mod ule

G79 /G185

Engine co n trol unit

J 220

Ge arb o x con trol un it

J 217

Bra ke lig h t swit ch

F/F47

Engine co n trol

u nit J2 20

Ge arb o x con trol un it

J 217

Sele ctor le ver lo ck

s oleno id N110

Page 46

46

En g in e M a n a g e m e n t

In the A6 , t h e re will be n o CAN d a ta e xch ange

with th e d a s h p a n e l in s e r t when pro d u ctio n

of t h e m o d e l b e g in s . For t h is rea s o n , t h e A6

h as the followin g inte rface s in additio n t o

thos e of the A8:

Pin 43 Im m obilis e r/self-diagnosis

Pin 19 Coolant te m p e ratu re signal

Pin 81 Fue l co n s u m p t ion s ig n a l

Pin 54 Roa d spee d signal

Pin 37 Engine speed signal

Pin 48 Warn in g la m p for e le ctronic

thro ttle

A d d itio n a l sig n a ls/

in t e rfa c e s

In the Au d i A8, th e fo llo w in g in t erfa c e s a ls o

e xis t fo r d a t a e xchange via CAN b u s :

Pin 67 Crash signal

Pin 43 K-lin e /d ia g n ostic c o n n ectio n

Pin 41 Com p re s s o r ON/OFF

Pin 40 Air c o n d itioner re q u irem ent signal

Mo s t of t h e in terfa c es a n d a d d itional signals

of t h e ME 7 .1 are d e s c rib ed in SSP 19 8. On ly

the new inte rface s an d additio n a l s ignals are

d e alt with b e lo w.

Page 47

47

SSP217_059

5 V/Div. 0,5 s/Div.

Recorder mode

Cra s h signal

w ith tr igger ing

Trig g e rin g ra nge

Crash signal

SSP217_058

T

5 V/Div. 0,1 s/Div.

In the event o f a crash where the belt

tension er s /a irbags are t rig g e red, the engine

con trol unit deac tivates act u ation of the fuel

p u m p re lay. Th is p reve n ts exces sive q ua ntitie s

of fu el escap ing if t h e fu el sys tem is d am aged.

The cras h s ignal is a s qu are -wa ve signal with a

s p e cific s ig n a l ratio (h ig h le ve l to lo w le ve l).

The signal is tra n s m it ted con t in u ously b y t he

a irb ag co n tro l u n it .

In the event o f a crash, the signal ra t io is

in ve rte d for a d e fined perio d o f tim e. Durin g

this perio d, the signal ra tio is in vert ed rela tive

to th e s ta n d a rd signal s o that t h e s u p p ly o f

fu e l is shu t o ff until th e e n g in e is re s tart e d .

In addition , th e “c ras h s h u t -off“ fault is

s tored.

The fault e nt ry can only be d e le ted

u sin g the diagnostic t ester.

Automatic mode

Sta n d ard s ig n al

Cra s h triggerin g

Signal traces for crash signal using oscilloscope

function of VAS 5051

Page 48

48

En g in e M a n a g e m e n t

Self-diagnosis

The cras h signal is checke d w ith re s p e ct to

the plausibility of the crash signal and

vo ltage.

Effect of fault

If the “cras h shu t -off“ fault is sto red in the

e n gin e control unit and is n ot erased, the fu e l

p u m p is not p rim e d w ith fu e l w hen the

ig n ition is s witc h e d o n (n o p re co m pre s s ion is

g e nera ted in t he fu e l s yste m ). This m ay re s u lt

in d e la ye d s t a rtin g of the engine.

Furt h e r in for m a tion con c e rn ing th e

fu e l s h u t-off s ys t e m c a n b e fo u n d

u nder Ve h icle Safet y in SS P 207 a n d

SSP 21 3.

The fuel s h ut-off s yste m will not b e

in corp ora t ed in t h e Au d i A6 a n d A8

u ntil m o d e l ye a r 2000.

Self-diagnosis

The air conditio n e r re quire m e n t in t erfa c e is

n ot m onito red b y the self-d ia g n osis s ys tem .

Effect of fault

The idling s p eed is n o t in cre ased which

re s u lt s in a re duct io n in t h e o u tput of co o l a ir

when th e en gine is id lin g .

The air condit ioner requirement interface

In the ca s e o f a high air conditio n e r outp u t

re qu ire m ent, th e idling s p e ed o f t h e e n g in e is

in cre ased to increas e t h e o u tput of co o l a ir

from the air conditio n e r co m pre ssor.

In som e cases , air c ondition ing re q uire m en ts

m a y b e suc h that th e “air c o nditione r re q u irem e n t“ in t erfa c e is a ls o s wit ch ed to “h ig h “ at

the air conditio n e r operating and dis p lay u n it

where upon the engine co n t ro l u n it is inform e d o f th e in creas e d o u tput re q uire m en t.

This ca n be te s t e d u s in g t h e “Re a d m ea s u re d

va lu e b lo ck“ fu n ction of the diagnosis te s t e r

(see re p a ir m anual).

It is im p o rta n t to note t h a t the funct io n fo r

in cre asing the idlin g s pee d is not a vailable fo r

a ll e n g in e va riants , eve n if th e s ig n a l is sent

to th e e n g in e co n tro l u n it.

Page 49

49

Se rv ic e

A n um b e r o f n e w s p ecial to ols are re qu ire d b y

the Se rvice depart m e n t fo r repairin g th e

V8-5V en gine.

Tensioning roller spanner

Order No .T400 09

Camshaft retainer

Order No .T400 05

SSP213_007

SSP213_008

SSP213_009

Thrust pad

fo r c ra n ksha ft o il seal

Order No .T400 07

Page 50

50

N o t e s

Page 51

De ar Re a d e r,

This self-stu dy p ro gr am m e has allowed yo u to fam ilia rise yours e lf wit h the n ew te ch nica l fe atu res

of t h e V8-5V e n g in e .

Ou r aim is to m a ke t h e conte n t o f t h e s e lf-s t u d y p rog ram m e m ate rial as in teresting as possible.

This is why we wa n t to g ive yo u t h e o p p ortu n ity to te ll us your o p in io n s a n d s u g g estion s for

fu ture s e lf-s t u d y p rog ram m e s .

The followin g qu e s tionnaire is inte n d e d to assist you in d oing this.

Send your com m e n ts a n d s u ggestio n s t o the fa x n u m b e r 0049/84 1 89 36 36 7 .

We thank yo u fo r your s u p p ort .

The Technical Training Service Team

51

Page 52

Loading...

Loading...