Page 1

198

Service.

All rights reserved. Subject

to change.

AUDI AG

Dept.I/GS-5

D-85045 Ingolstadt

Fax +49.841/89-6367

740.2810.17.20

Technical status: 01/98

Printed in Germany

The 2.7-litre V6 Biturbo

Design and Function

Self-study Programme 198

For internal use only

Page 2

The 2.7-litre V6 biturbo .......

Turbocharged engines are already something

of a tradition at AUDI. The task now facing

AUDI’s engineers was to develop a worthy

successor to the 5-cylinder turbocharged

engine.

One of the key development goals for the

turbocharged engine was to achieve a good

level of dynamic response, particularly at the

bottom end of the rev band.

The goal of AUDI’s engineers was to realise a

high “basic torque level“ and a torque

characteristic that rises in direct proportion to

engine speed to its peak.

The term “basic torque level“

describes the torque which is

immediately available when the

throttle is opened (e.g. at part

throttle or in overrun).

SSP 198/77

........ a further milestone in engine development by Audi!

2

Page 3

Contents

Page

Engine .........................................................

Technical data, crankshaft, cylinder head,

camshaft timing, cooling circuit, engine

lubrication, overview of components, air ducting,

charging, exhaust system, pneumatically

controlled systems, charge pressure control, air

divert control in overrun, ACF system, crankcase

breather

Motronic ME 7.1..........................................

Subfunctions, system overview

Subsystems of the Motronic .....................

Torque-oriented engine management, torqueoriented functional structure, Electronic throttle,

exhaust gas temperature control

Sensors .......................................................

Additional sensors of the Motronic

4

31

33

49

Auxiliary signals/interfaces ...................... 57

Functional diagram..................................... 62

Self-diagnosis .............................................

Vehicle diagnosis, test and information system

VAS 5051, test box V.A.G 1598/31

Transmission ..............................................

Self-adjusting clutch, gearbox

This Self-study Programme provides you with information

regarding design and function.

The Self-study Programme is not a Workshop Manual!

Please refer to the Service Literature for all the relevant

maintenance and repair instructions.

64

66

New!

Important!/Note!

3

Page 4

Engine

The 2.7-litre V6 biturbo

This engine will also be used in the Audi S4

and Audi A6.

The engine used in the A6 has a comfortoriented setup, which means that it has

different torque and power output.

This effect was principally achieved by

modifying the software configuration of the

engine control unit.

A tuning protective device prevents

the S4 engine control unit being

installed in the A6!

This prevents misuse, which can

result in damage to the drivetrain!

An auxiliary heater is not available

as an option for the S4 and the A6,

due to the constraints on space.

BITURBO

SSP 198/01

4

Page 5

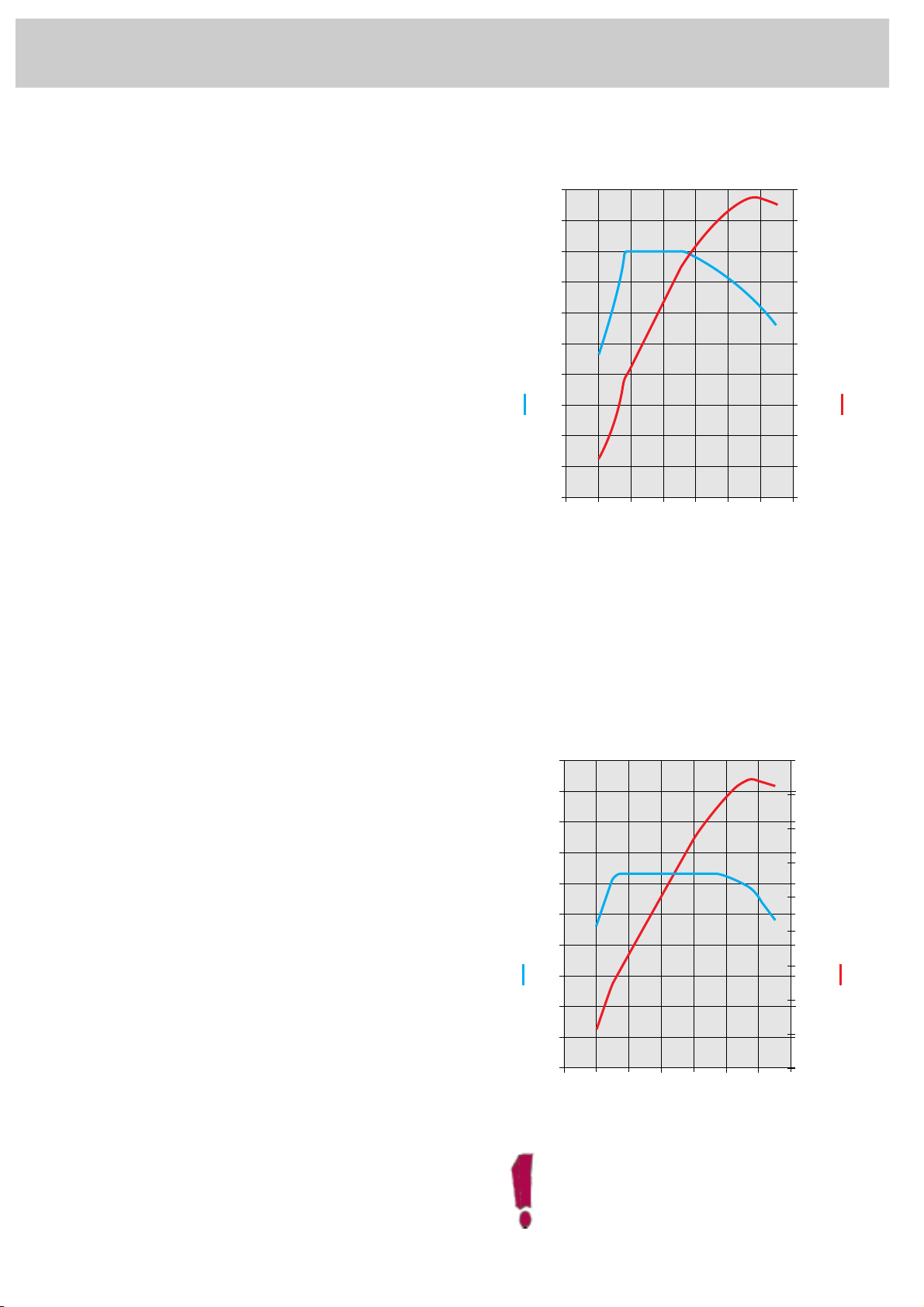

The technical data

•

Configuration:

V6 engine with 90° V-angle and twin

turbochargers

•

Engine code:

S4: AGB

A6: AJK

•

Output:

S4: 195 kW at 5800 rpm

A6: 169 kW at 5800 rpm

•

Torque:

S4: 400 Nm at 1850 to 3600 rpm

A6: 310 Nm at 1700 to 4600 rpm

•

Maximum speed:

6800 rpm

•

Compression ratio:

9.3 : 1

500

450

400

350

300

250

200

Torque [Nm]

150

100

50

0

0 1000 2000 3000 4000 5000 6000 7000

SSP 198/02

S4

200,0

180,0

160,0

140,0

120,0

100,0

80,0

60,0

40,0

20,0

0,0

Speed [rpm]

Figures obtained using 98 RON

unleaded premium fuel to

89/491/EEC.

Output [kW]

•

Displacement:

2671 cm

•

Bore:

3

81 mm

•

Stroke:

86.4 mm

•

Weight:

approx. 200 kg

•

Engine management:

Motronic ME 7.1

•

Firing order:

1-4-3-6-2-5

•

Fuel type:

S4: 98/95/91 RON

A6: 95/91 RON

•

Compliant with emission standard:

EU III-D

500

450

400

350

300

250

200

Torque [Nm]

150

100

50

0

0 1000 2000 3000 4000 5000 6000 7000

SSP 198/46

A6

180,0

160,0

140,0

120,0

100,0

80,0

Output [kW]

60,0

40,0

20,0

0,0

Speed [rpm]

Figures obtained using 95 RON

unleaded premium fuel to

89/491/EEC.

5

Page 6

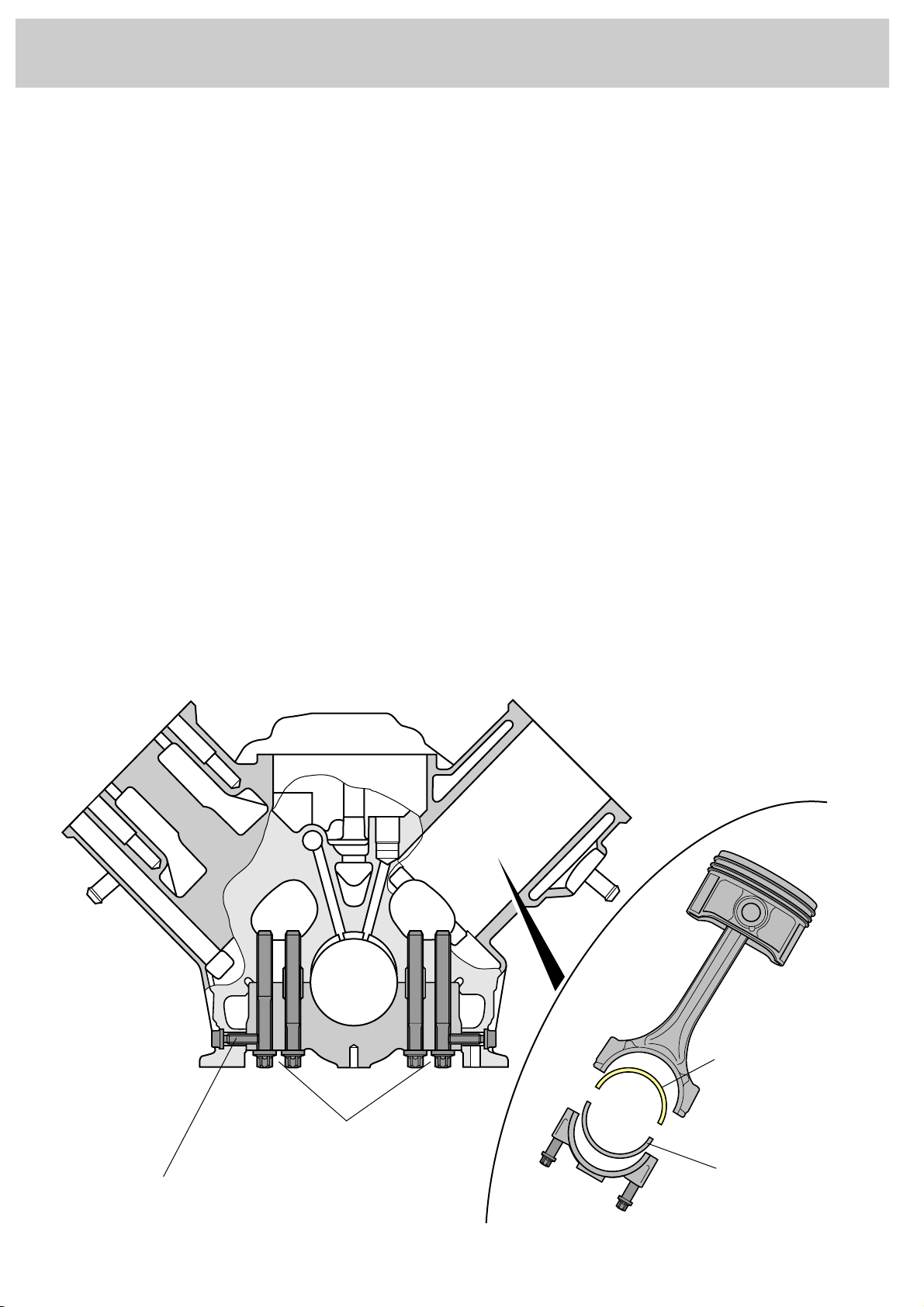

Engine

The crankshaft

The crankshaft is identical to that used in the

2.8-litre V6 engine.

The crankshaft bearing caps are attached to

the central crankcase by 4 bolts.

•

The 4-bolt connection reduces the load on

the bearing caps considerably.

The middle two crankshaft bearing caps are

also bolted to the side of the crankcase.

•

The lateral bolted connection helps to

improve acoustics.

The pistons are forged to enable them to

withstand the high loads to which they are

subjected.

Due to the high combustion pressures, a 2material bearing shell is installed on the

connecting rod side. The bearing cap has a 3material bearing shell.

Advantage:

The bearing shell has a high load-bearing

capacity

SSP 198/11

Lateral bolted connection

6

2-material

bearing shell

4-bolt connection

3-material

bearing shell

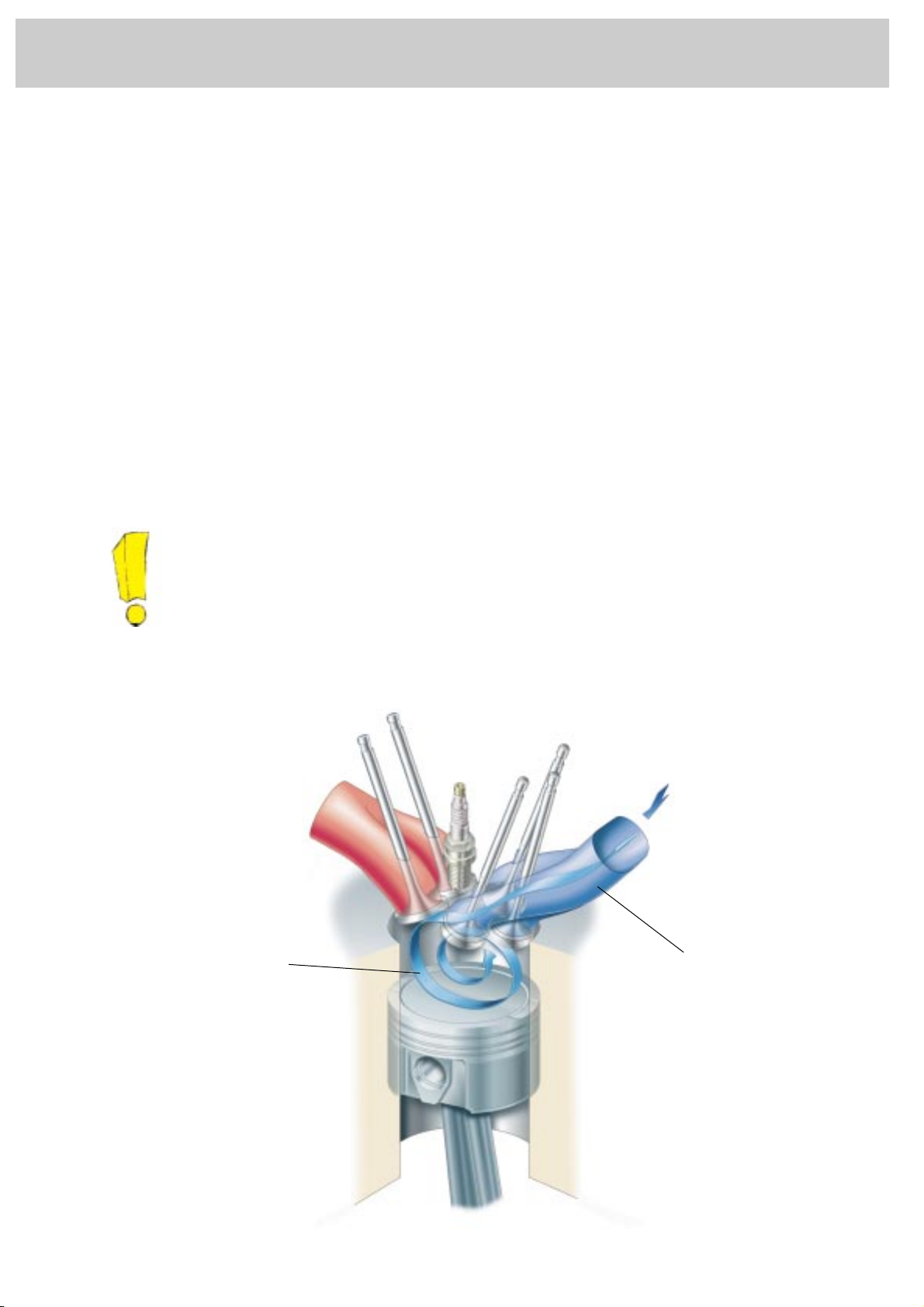

Page 7

Cylinder head

The cylinder heads are largely identical to

those used in the V6 naturally aspirated

engine. Common parts are used for both banks

of cylinders.

The mounting position of the right-hand

cylinder head is rotated through an angle of

180° in relation to the left-hand cylinder head.

The timing of the inlet camshafts is enginedependent.

To improve heat dissipation, the exhaust

valves are sodium-filled.

Tumble duct

In combination with five-valveper-cylinder technology, the inlet

duct is shaped as a so-called

“tumble duct“.

The shape of the inlet duct causes the drawnin air to tumble.

Advantages:

•

A good degree of swirl and high ignitability

fuel-air mixture are achieved

•

The tumble effect allows more efficient

combustion

For a turbocharged engine, the compression

ratio of 9.3 : 1 is high.

Advantage:

•

High ”basic torque level“ and fuel

economy

Tumble effect

Tumble duct

SSP 198/78

7

Page 8

Engine

The variable valve timing

The camshaft timing has been modified

compared to the 2.8-litre V6 engine to meet the

demands of turbocharging technology.

Variable valve timing with an adjustment angle

of 22° is used here for the first time in

turbocharged engines .

Advantage:

•

A torque increase of approx. 10% is

achieved at the bottom and top ends of the

engine speed range.

•

Better emission levels and fuel

consumption figures.

The variable valve timing is activated by the

Motronic by means of camshaft adjustment

valves N205 and N208.

The design and function of the

variable valve timing are already

described in Self-study Programmes

182 and 192.

Activation of the variable valve timing is

dependent on engine load and speed.

In the self-diagnosis, you can find out whether

the variable valve timing is active or not by

reading out the relevant measured value block

(refer to Workshop Manual).

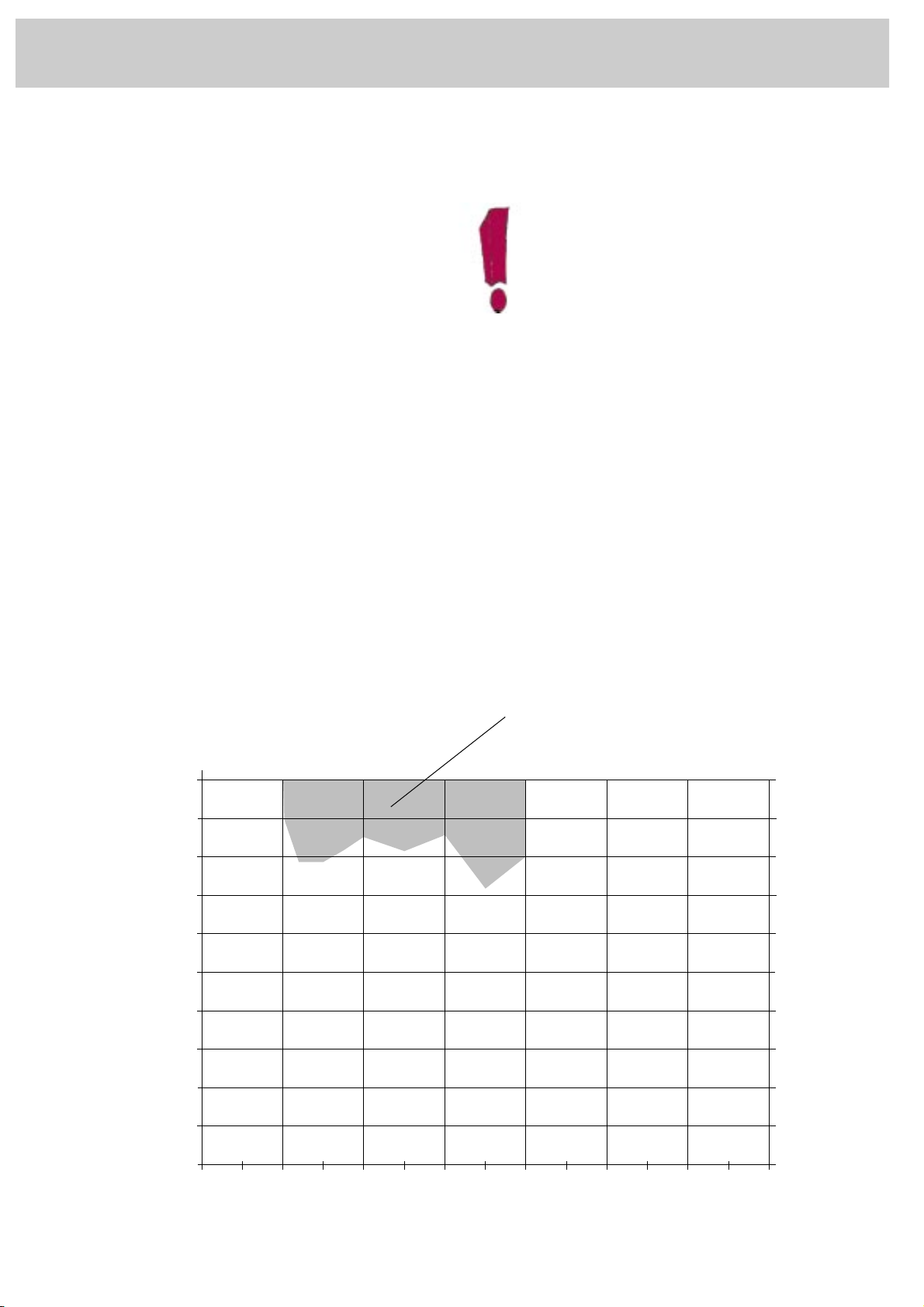

Diagram of variable valve timing

(shown using the 265 bhp engine as an

example)

Full throttle

Engine load in %

Variable valve timing active

= advance position

0

0 1000 2000 3000 4000 5000 6000 7000

SSP 198/45

8

Engine speed

Page 9

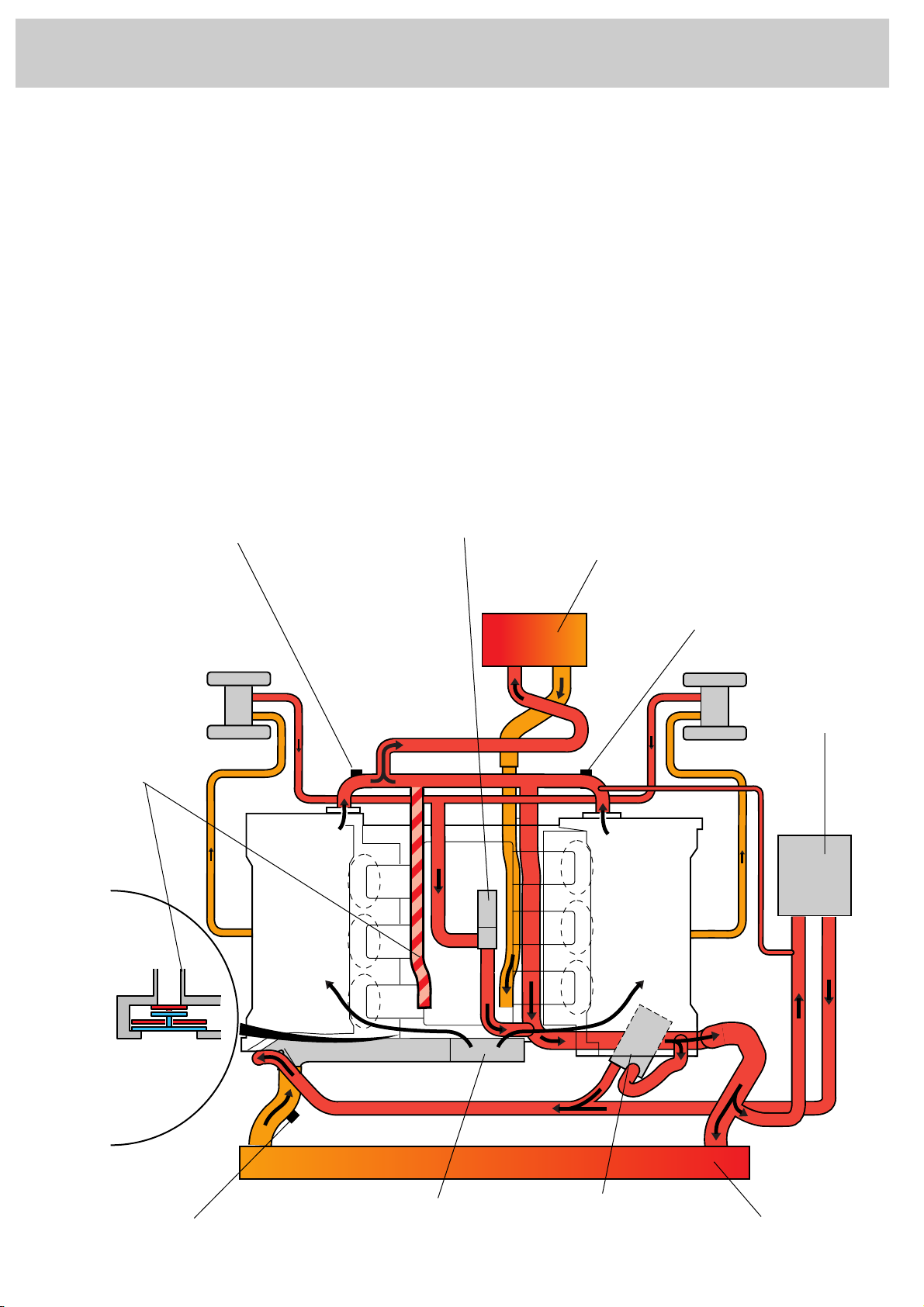

Cooling circuit

Both exhaust gas turbochargers are watercooled and integrated in the cooling circuit.

When the coolant thermostat is closed, the

coolant flows back to the coolant pump along

the short-circuit line as well as the heat

exchanger.

When the coolant thermostat is open, the

coolant flows back to the coolant thermostat

through the radiator (primary flow) or through

the oil cooler and expansion tank (secondary

flow).

Coolant temperature

senders G2 and G62

Continued coolant function pump

Located in the cooling circuit is a electrical

coolant pump.

This pump is required as a means of

protection against overheating of the coolant

under high thermal load, e.g. when the hot

engine is turned off.

Heat exchanger

Thermoswitch for F95

Short-circuit

line

Coolant

Expansion

tank

Radiator fan thermoswitch F18/F54

Coolant pump

SSP 198/03

Oil cooler

Radiator

9

Page 10

Engine

Electrical coolant circulation pump V51

Electrical coolant circulation pump V51 is

located in the engine’s V angle.

If the coolant temperature is too high,

thermoswitch for coolant circulation run-on

F95 activates the additional coolant function.

The high temperatures which occur at the

exhaust gas turbocharger produce vapour

bubbles which prevent coolant being drawn in

by pump V51.

When pump V51 starts up, the coolant flows

through the exhaust gas turbocharger and the

cylinder heads. The direction of flow in the

turbocharger cooling circuit is reversed by

this.

Rear coolant pipe

Due to this reversal of the direction of coolant

flow, coolant is drawn in via the cylinder heads

(large cross-sections), which means that any

vapour bubbles which develop are expelled

from the exhaust gas turbocharger lines.

The electrical coolant circulation pump again

draws in coolant along the rear coolant pipe,

thereby recirculating the coolant.

Thermoswitch for additional coolant

function F95

Radiator fan thermoswitch

F18/F54

SSP 198/10

10

Electrical

coolant

circulation pump

V51

Page 11

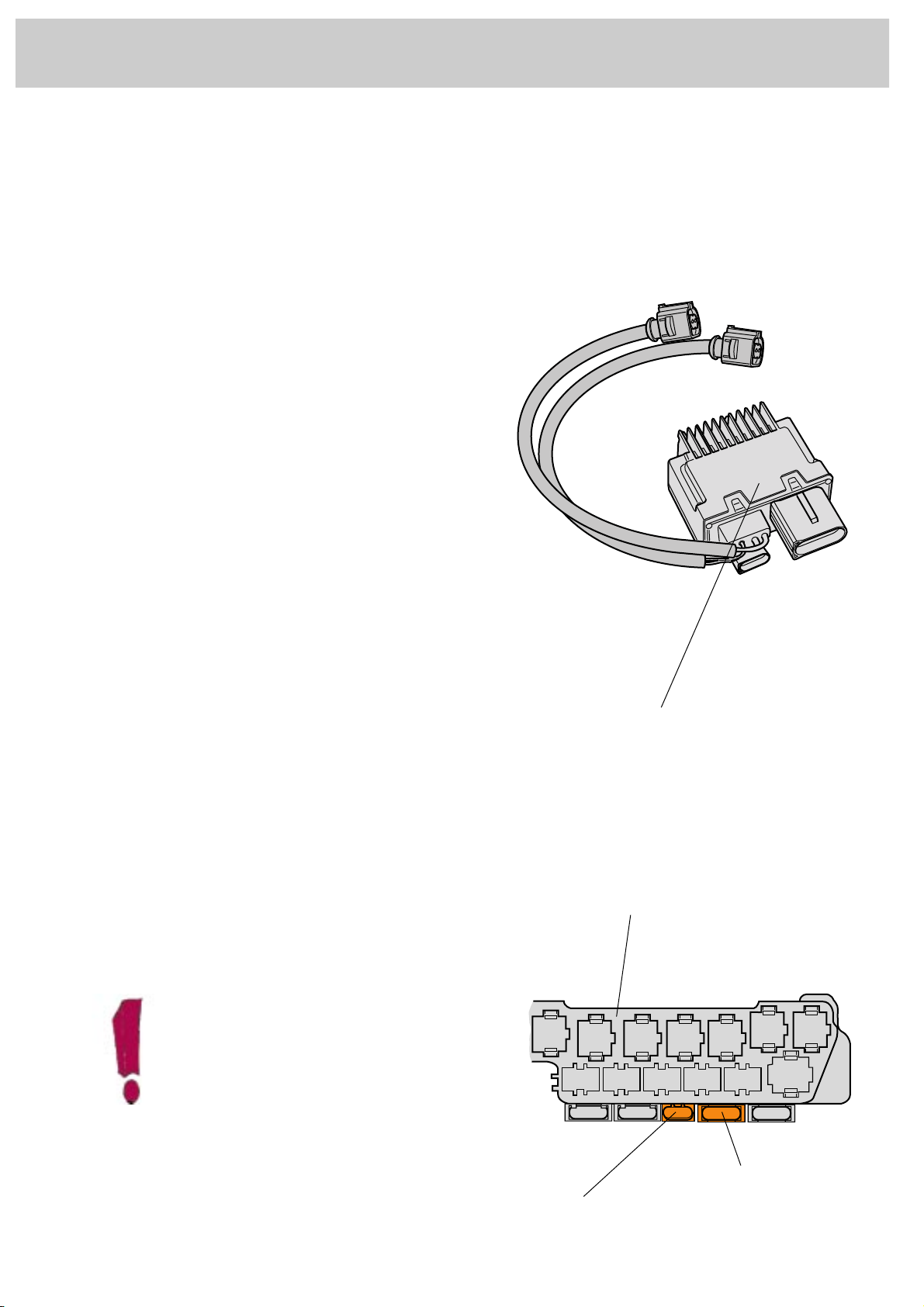

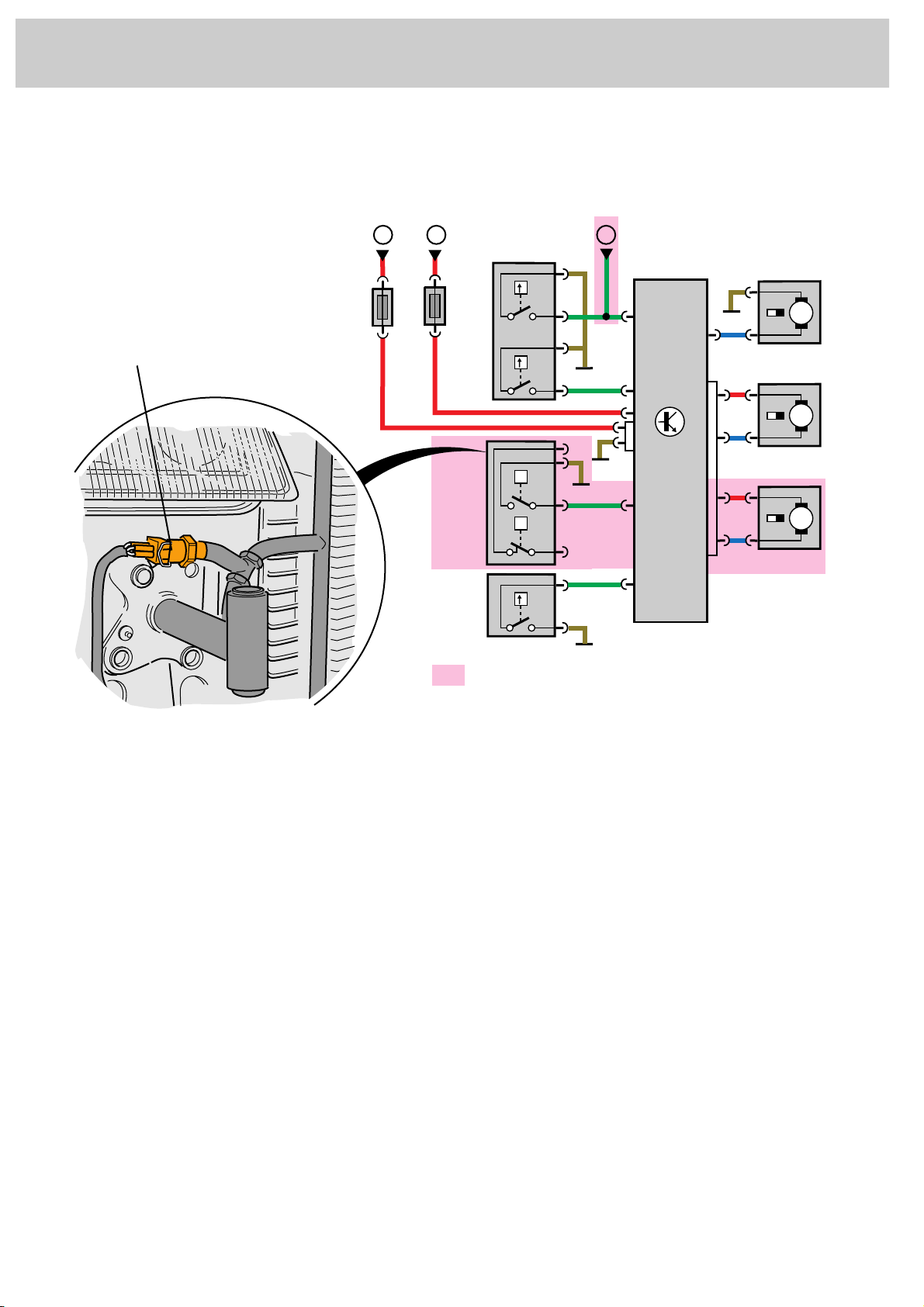

Fan control

The control unit for radiator fan V293 regulates

the output of the radiator fan and controls the

continued coolant circulation. The induced-air

fan V7 and the forced-air fan V177 are

activated simultaneously.

Forced-air fan V177 is located upstream of the

condenser, water cooler and visco fan. It

assists the visco fan.

The electronic power control

The various fan settings are executed by an

electronic power control.

The fan motors are operated periodically, the

length of the operating cycle depending on the

fan setting selected. Fan output level is

controlled via pulse-width-modulated outputs.

Should a fan fail, the radiator fan control unit

increases the speed of the fan motor still

available.

Advantages of the power control:

•

The series resistors previously used for

power control are no longer required.

•

Lower power consumption in lower fan

settings.

•

Safety functions.

The power supply is protected by a

fuse on the 8-socket relay plate. For

the correct fuse rating, please refer

to wiring diagram.

Vehicles equipped with an air

conditioner require a higher fuse

rating than vehicles without an air

conditioner.

SSP 198/50

Control unit for radiator fan

attached to front right

vehicle side member

8-socket relay plate

SSP 198/55

Fuse, terminal 30

Fuse, terminal 61

11

Page 12

Engine

Electric circuit of fan control:

1 23

F18

V293

*

_

M

Air-conditioning pressure switch F129

for vehicles with air-conditioning system:

*

F54

P

F129

P

*

F95

only for vehicles with air conditioner

Components:

V51

_

M

V7

_

M

V177

SSP 198/17

Integrated in the pressure switch for air

conditioner F129 is the high-pressure switch

for activating a higher fan setting.

The pressure switch is mounted below the

right-hand headlight behind the bumper.

F18/F54 Radiator fan thermoswitch

F95 Thermoswitch for continued coolant

function

F129 Pressure switch for air conditioner

(only for vehicles with air conditioner)

V293 Control unit for radiator fan

V7 Radiator fan (induced-air fan)

V51 Continued coolant circulation pump

V177 Fan 2 for radiator (forced-air fan)

(only for vehicles with air conditioner)

1 Terminal 30, positive supply via fuse

on 8-socket relay plate

2 Terminal 61, D+ (alternator) via fuse on

8-way relay

3 Fan activation (only for vehicles with

air conditioner)

12

Page 13

Function of fan circuit (for vehicles with air-conditioning system)

4 fan settings are possible:

The electrical coolant function.....

is activated by coolant pump thermoswitch

F95.

The fan motors and continued coolant

circulation pump V51 are activated.

The fan motors run at min. output (40%).

The continued coolant function is

only activated if the “engine not

running“ signal is picked up at

terminal 61. The continued coolant

function period is limited to 10

minutes.

Fan speed 1......

Fan speed 2......

Fan speed 3......

Fan speeds 1, 2 and 3 are only

activated if the “engine running“

signal is picked up at terminal 61.

is requested by radiator fan thermoswitch F18

or by the air-conditioning control panel.

The fan motors run at 50% output.

is activated by air-conditioning system

pressure switch F129.

The fan motors run at 85 % output.

is activated by radiator fan thermoswitch F54.

The fan motors run at full output.

13

Page 14

Engine

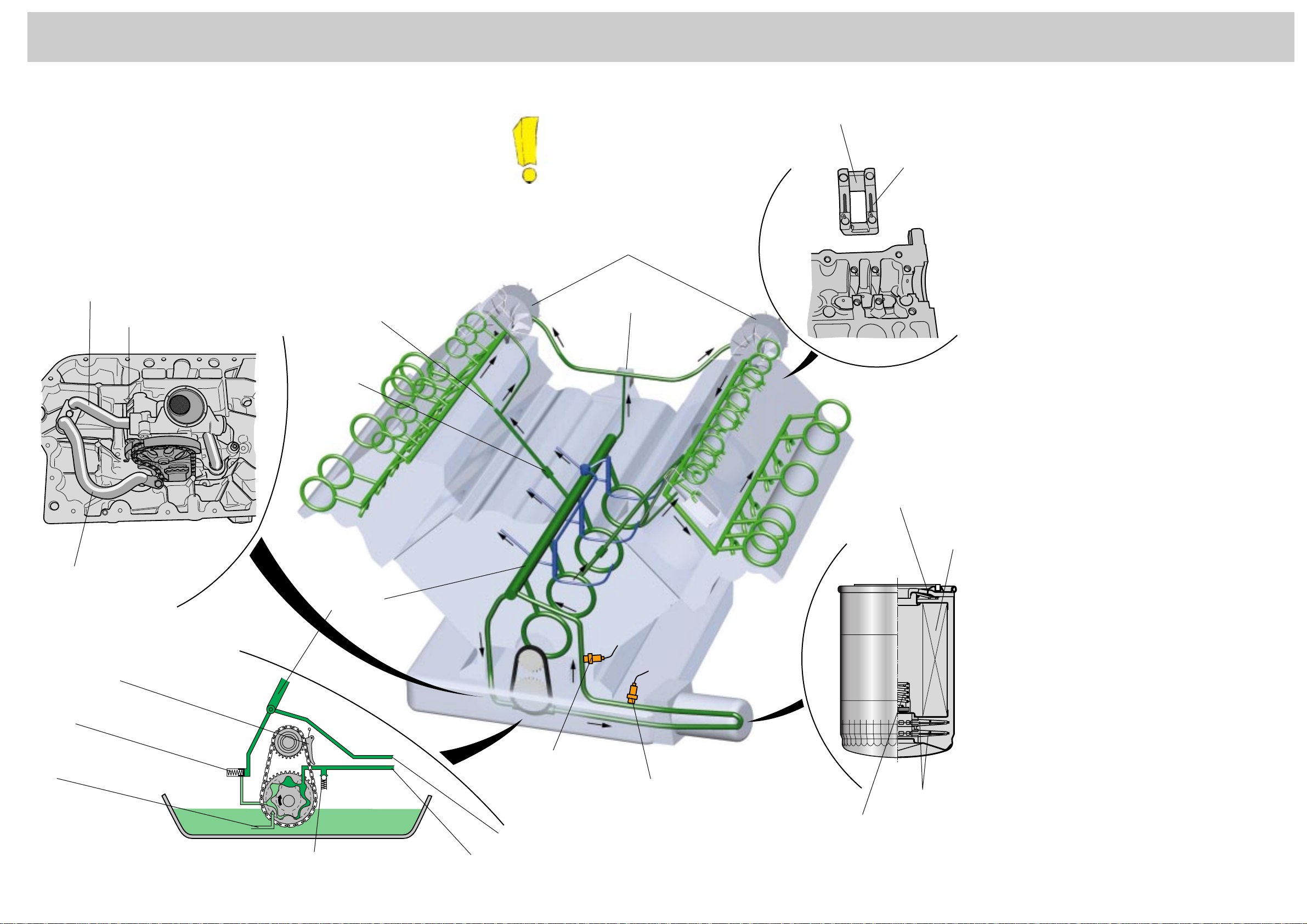

Engine lubrication

The oil circuit of the 2.7-litre V6 biturbo engine largely corresponds to that

of the 3rd V6 engine generation.

In addition, the two exhaust gas turbochargers are supplied with

pressurised oil from the main oil gallery via a distributor piece. The oil is

returned directly to the oil sump.

The oil cooler was adapted to withstand the higher thermal stresses in

comparison with a naturally aspirated engine.

to oil filter/oil cooler

Oil pressure relief valve

Oil retention

Restrictor

valve

A new feature of the biturbo is

the “integrated oil supply“ (see

next page).

Exhaust gas turbocharger

distributor piece

Bearing cap

Oil groove

Oil retention valves

Filter element

The oil circuit

A duocentric oil pump draws in the oil

through a coarse filter. Located in the

pressure chamber of the pump is a

pressure relief valve which protects

downstream components against

pressure peaks during cold starts.

The oil is fed to the oil filter via the oil

cooler. After passing an oil retention

valve, the oil flows through the filter

element. A bypass filter is connected in

parallel with the filter element.

The oil subsequently reaches the main

oil gallery. A branch line is routed to the

oil pressure control valve (clean oil

side).

The following components are supplied

with oil from the main oil gallery:

- the four crankshaft bearings

- the two exhaust gas turbochargers

via an oil distributor line

- the three pairs of piston spray jets via

a spray jet valve

- the cylinder head of cylinder bank 1

via an oil retention valve

from oil filter/oil cooler

Spring-loaded slipper

(chain tensioner)

Oil pressure

control valve

Induction filter

Main oil gallery

Oil pressure relief valve

Oil temperature

sender

from oil filter/oil cooler

to oil filter/oil cooler

The cylinder head of cylinder bank 2 is

supplied through a separate bore from

crankshaft bearing 2 via an oil retention

valve also.

First of all, the camshaft adjustment

valve is supplied with oil from the inlet

drilling in the cylinder head. After the oil

has passed by a restrictor, it is

channeled via the cylinder head main

gallery to the hydraulic valve tappets

and the camshaft bearings.

SSP 198/49

Oil pressure switch

Bypass filter

Bypass valve

14 15

Page 15

Engine

The component parts of the oil circuit

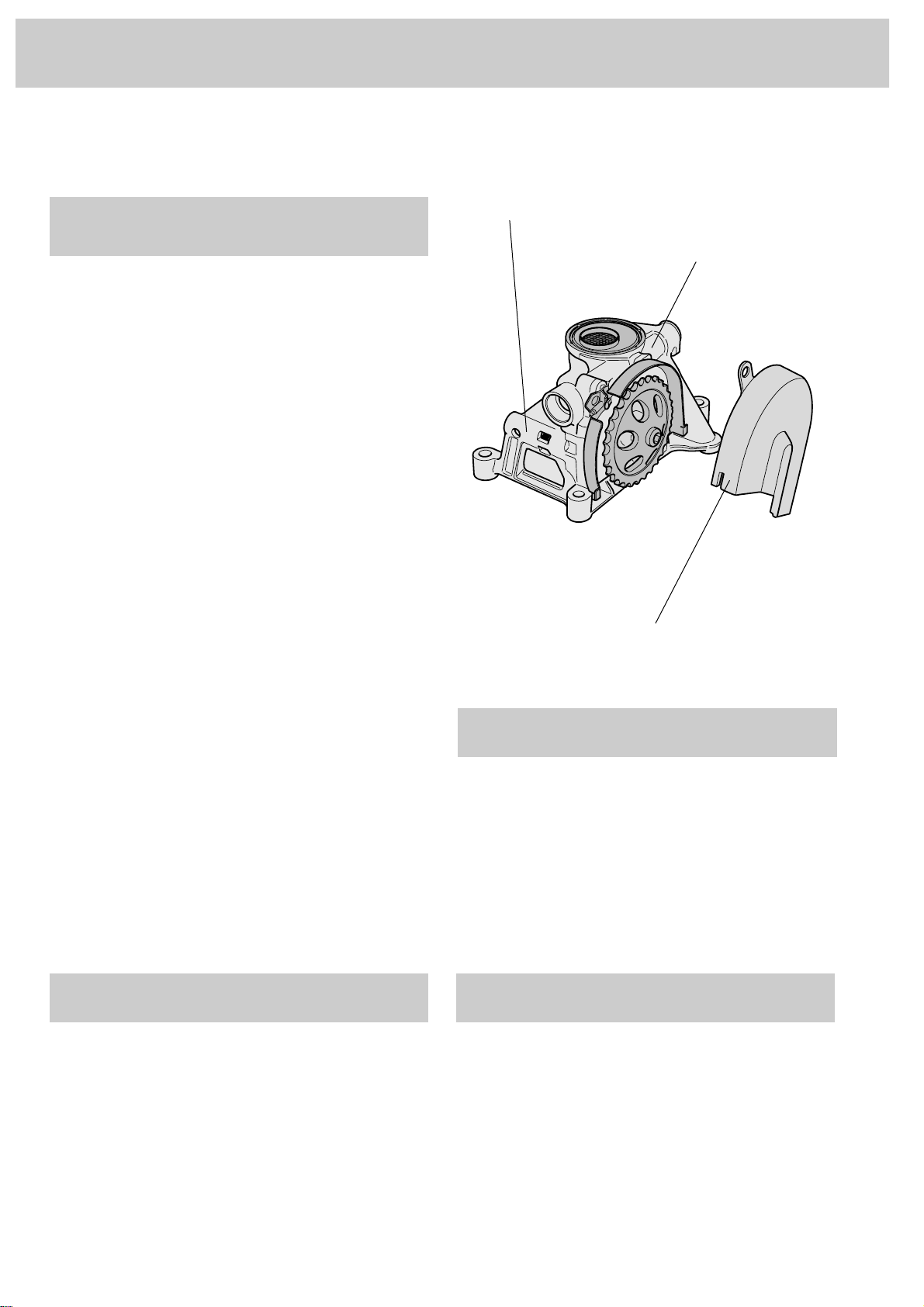

The oil pump ......

is an internal gear pump. It is attached to the

crankcase as a separate component.

The oil pump is designed in such a way that it

projects deep down into the oil sump and is

immersed completely in the engine oil when

the oil level is correct. This prevents the oil

pump running dry.

The oil pump, in combination with the

extremely short intake path, enables oil

pressure to build up more quickly and safely,

particularly during cold starts.

The oil pump is driven by the crankshaft by

means of a single chain.

A spring-loaded flat plate produces the

necessary tension.

Oil pressure limiting valve

Oil pressure control valve

SSP 198/57

A new feature of the oil pump is the chain

guard made from sheet steel. It encapsulates

both the chain wheel and the chain over a large

area.

This reliably prevents oil frothing and the

problems associated with this.

The oil cooler ......

is integrated in the primary flow. By increasing

the capacity and optimising the flow

resistance, the entire oil flow can be routed

through the oil cooler. Unlike the V6 naturally

aspirated engine, a bypass is not required.

Chain guard

The oil filter ......

contains an oil retention valve, the filter

element, a bypass filter and the filter bypass

valve. The latter has the task of maintaining

engine lubrication via the bypass filter if the

filter element becomes clogged up or if the oil

has a high viscosity.

The spray jets valve ......

opens up the oil flow to the piston spray jets if

the oil pressure is greater than 1.8 bar.

Reason: at low oil viscosity and low engine

speeds, the oil pressure would otherwise drop

below the minimum permissible level. That

aside, piston cooling is not necessary at low

engine speeds.

16

Page 16

The oil pressure control valve ......

regulates the engine oil pressure. It is

integrated in the oil pump housing. The oil

quantity “regulated“ by the oil pressure

control valve is fed to the suction side of the

oil pump.

This helps to optimise efficiency.

The oil pressure limiting valve ......

is a pressure relief valve. It is located inside the

oil pump housing and opens when the oil

pressure rises too high (cold start). If an

excessively high oil pressure builds up,

various component parts of the oil circuit (e.g.

oil filter, oil cooler) may be damaged. Also,

there is the possibility of the inlet and exhaust

valves opening or no longer closing, due to

“bulking“ of the hydraulic tappets. The knockon effect of this is that the engine can no

longer be started or cuts out.

The oil retention valves ......

prevent the oil running out of the oil filter and

the cylinder heads and back into the oil sump

while the engine is stationary.

The restrictors ......

prevent “flooding“ of the cylinder heads. At

high engine speeds, an excessively large

amount of oil enters the cylinder heads and

has to be returned to the oil sump via the oil

return drillings. The restrictors reduce the oil

flow and thereby ensure that return flow takes

place.

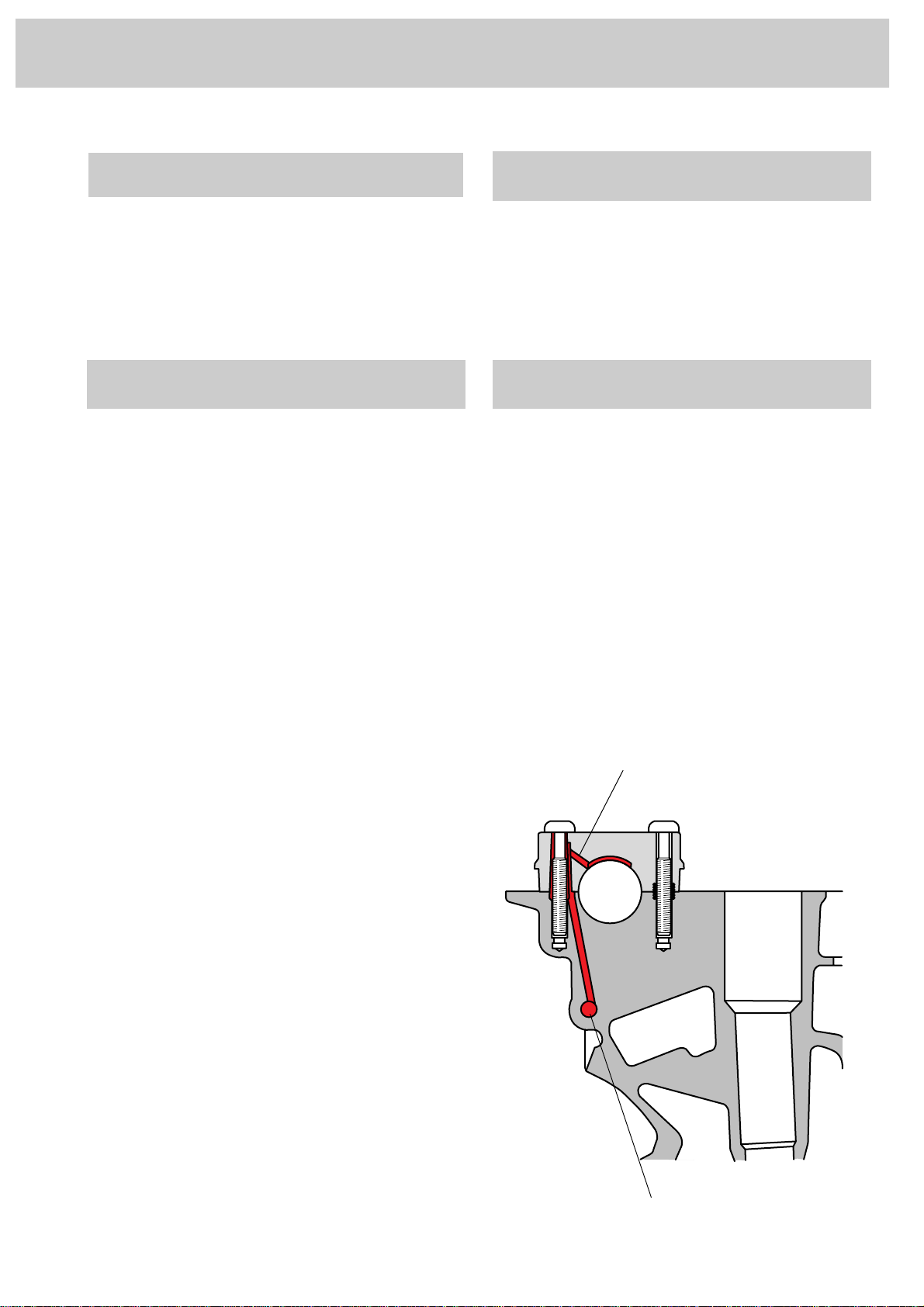

The “integrated oil supply“ ...

will also be adopted for all V6 5V naturally

aspirated engines.

Each camshaft bearing is supplied via a

drilling stemming from the cylinder head main

gallery.

The oil is fed along a bolt shaft in the bearing

cap to a transverse drilling.

A lubrication groove distributes the oil

throughout the camshaft bearing. It is no

longer necessary to run a pipe to the

individual bearing caps.

Advantages:

•

Fewer components

•

Quick and even oil supply

•

No additional installation work necessary

•

Lower cost

Transverse drilling

SSP 198/58

Cylinder head main gallery

17

Page 17

Engine

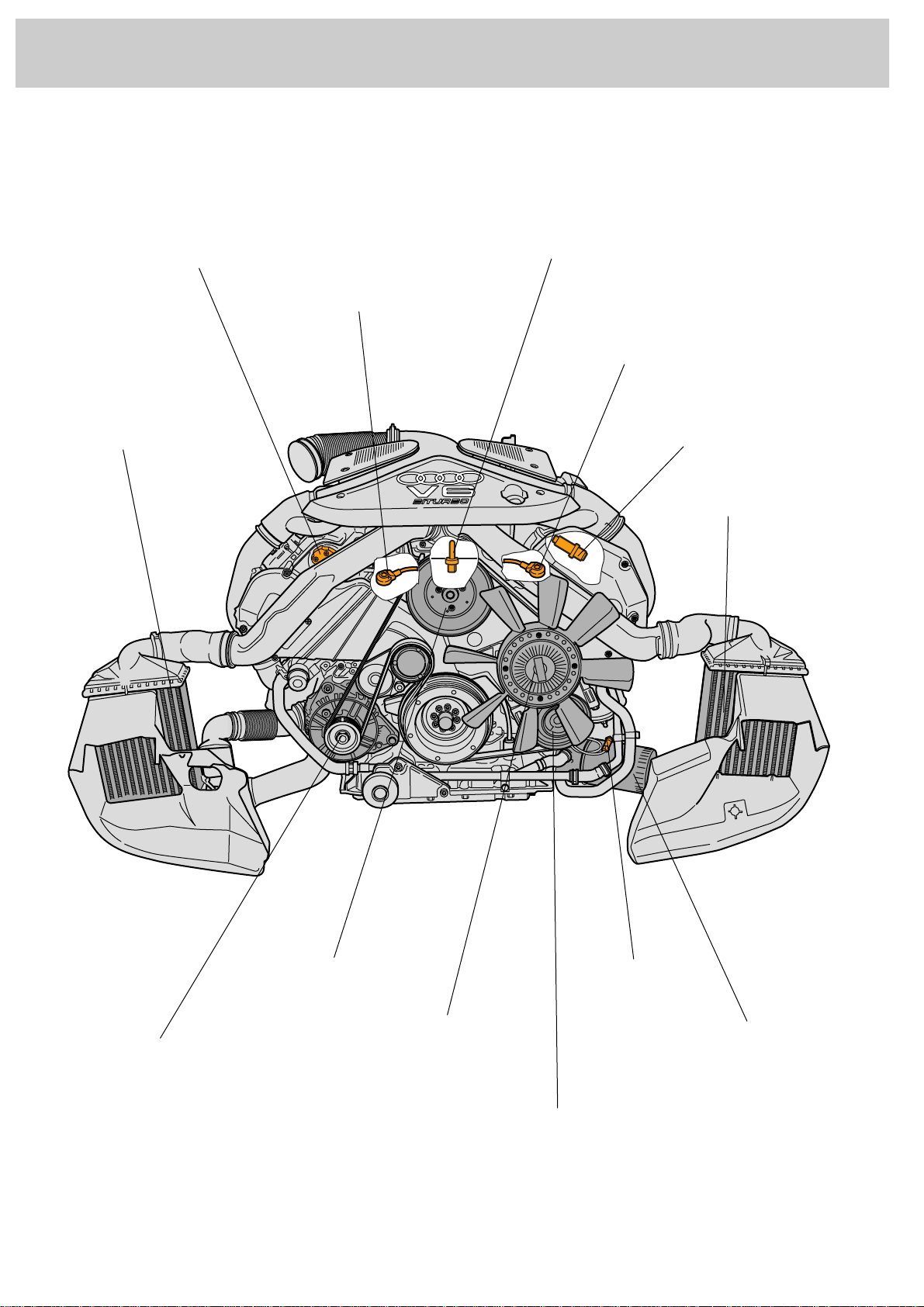

Front view of engine

Hall sender G163

Charge air cooler

Intake-air temperature

sender G42

Knock sensor G61

Knock sensor G66

Camshaft adjustment

valve N208

SSP 198/51

Charge air cooler

18

Alternator

Power assisted steering

pump drive

Visco fan

Oil pressure

switch

Oil filter

Air-cond. compressor

Page 18

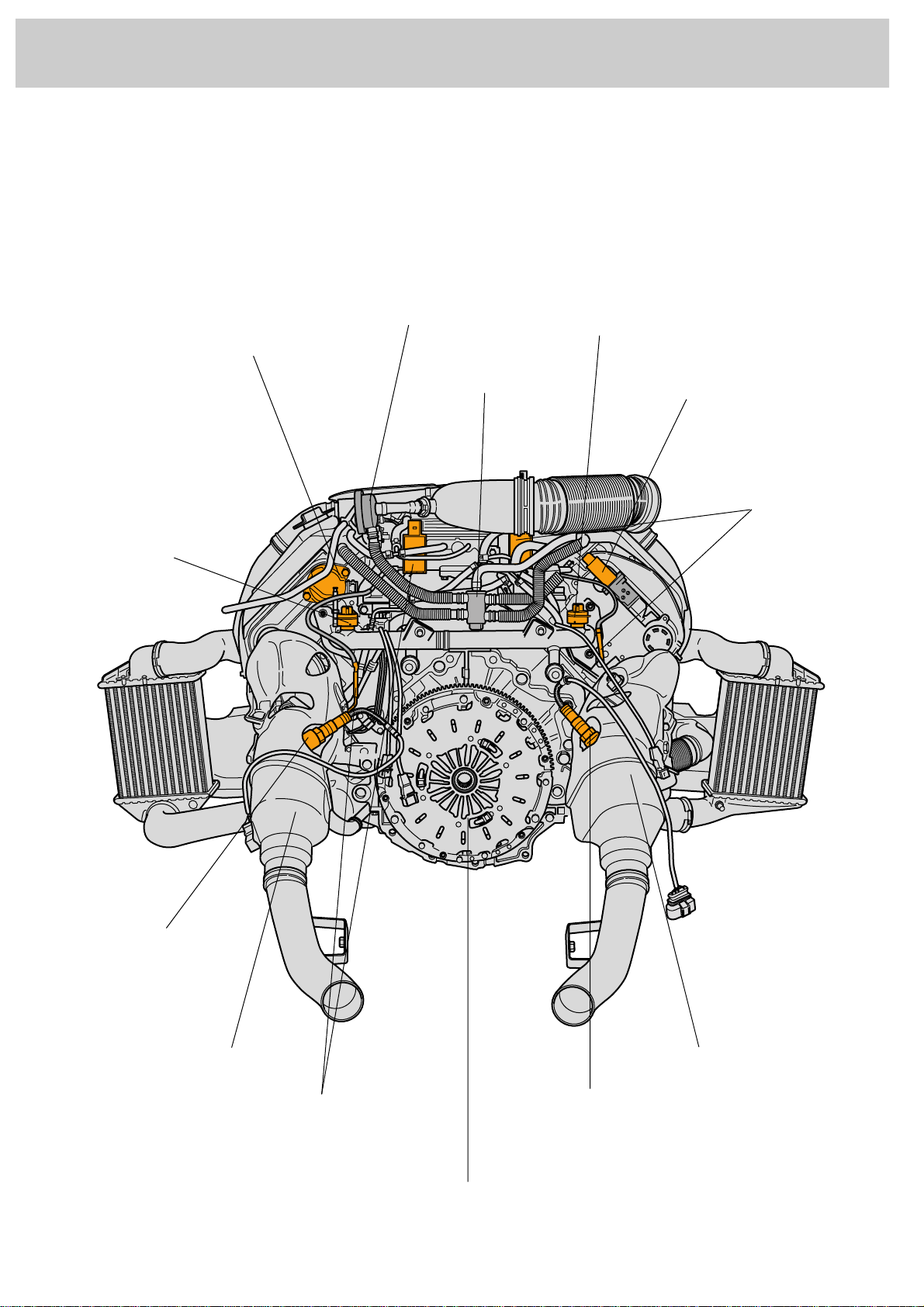

Rear view of engine

Hall sender G40

Thermoswitch for

continued cooling

function F95

Pressure limiting

valve

Distributor piece

Coolant temperature sender F18/F54

Camshaft adjustment

valve N205

Exhaust gas

temperature sender

G235 (with evaluation

electronics)

SSP 198/52

Lambda probe

G108

Prim. catal. converter Prim. catal. converter

Exhaust gas temperature

sender G236 (with

evaluation electronics)

SAC clutch pressure plate

Lambda probe G39

19

Page 19

Engine

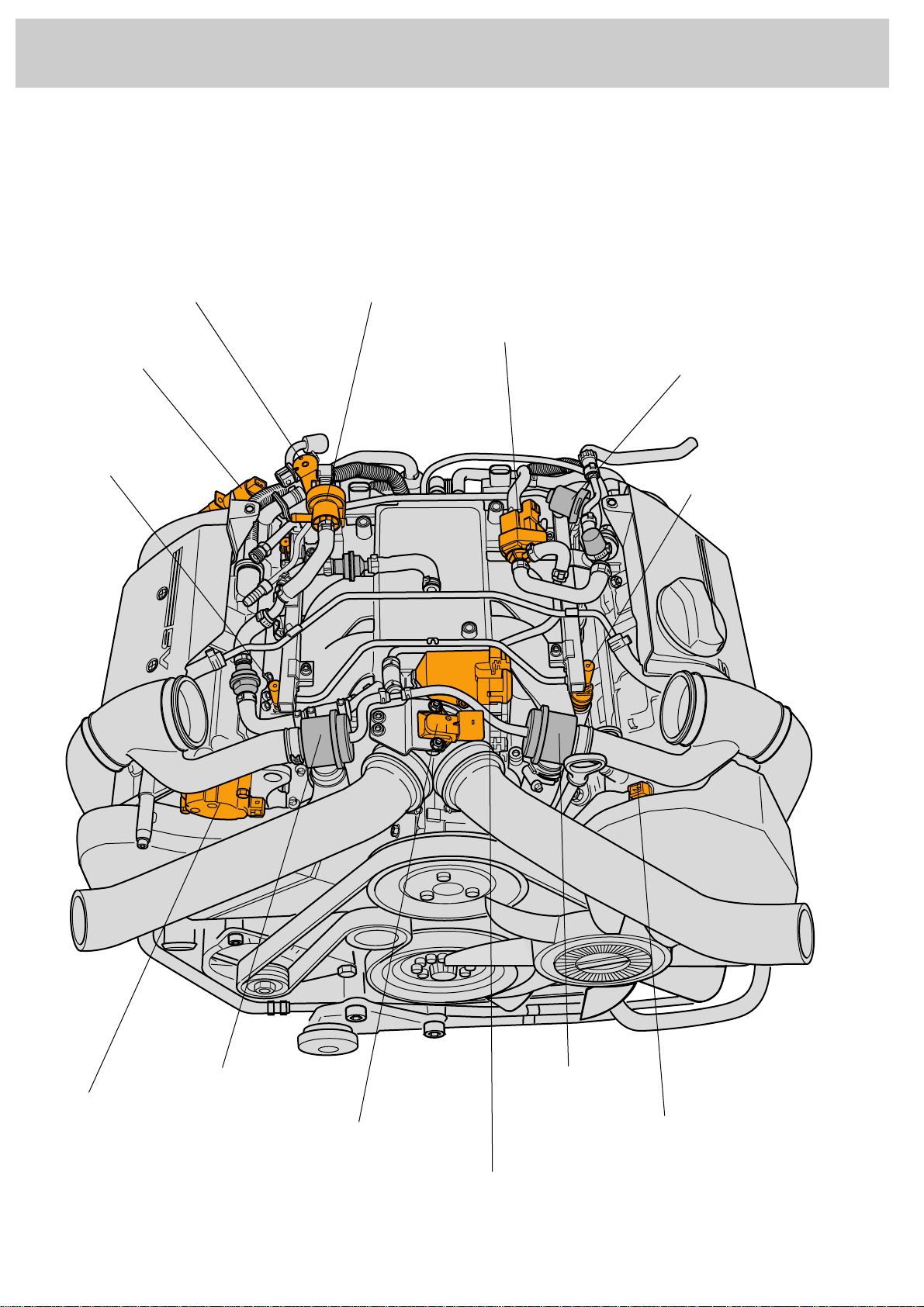

Top view of engine

Solenoid valve for charge

pressure control N75

Camshaft

adjustment valve

N205

Injector

Solenoid valve for

activated charcoal

Divert air valve for

turbocharger N249

Fuel pressure regulator

Injector

Hall sender G163

20

Divert air valve

Charge pressure

sender G31

SSP 198/54

Divert air valve

Camshaft adjustment

valve N208

Throttle valve

control part

Page 20

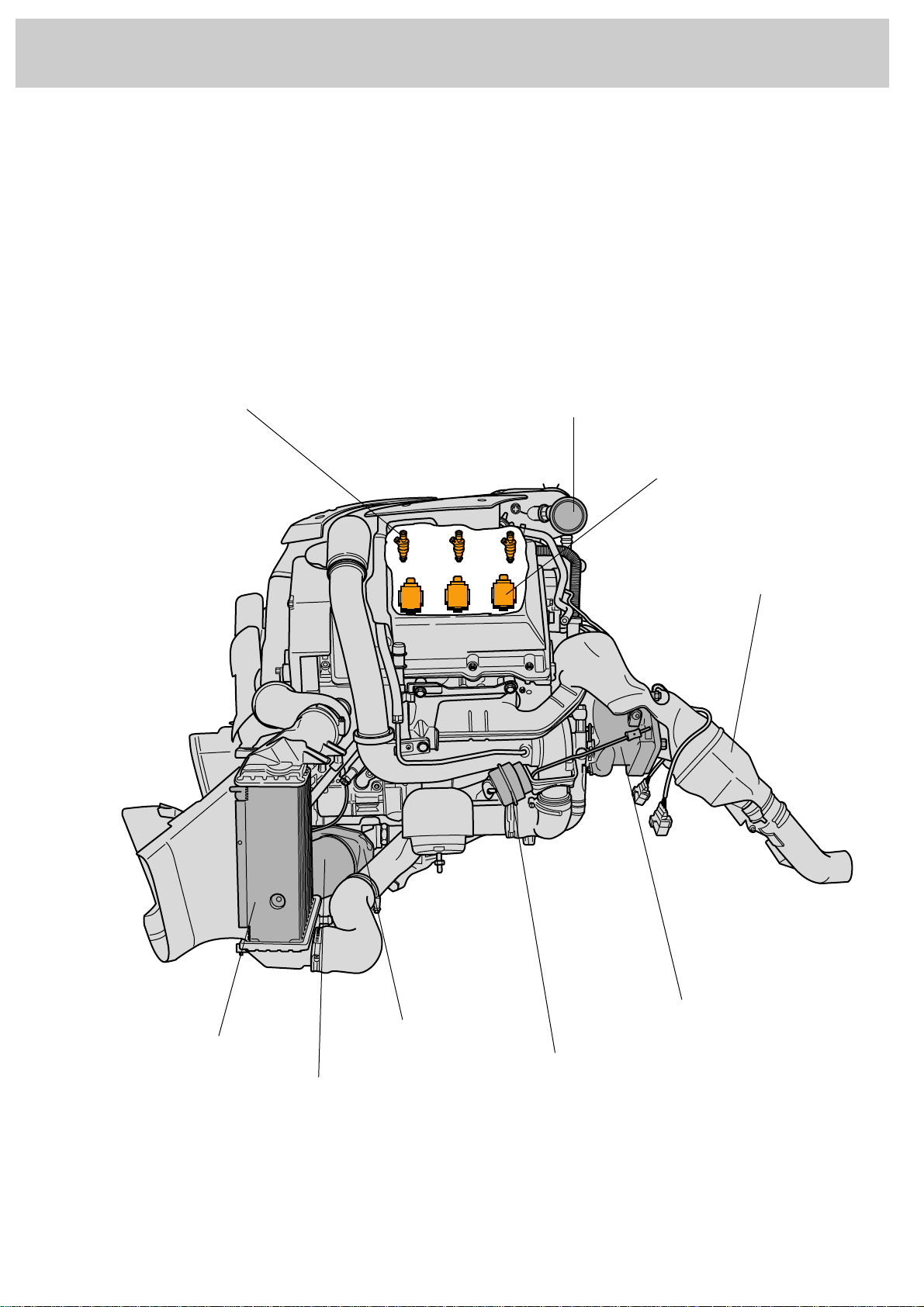

View of engine from left

Injector

Pressure control valve

Individual ignition coil

Prim. catal. converter

Charge air cooler

Oil filter

SSP 198/53

Exh. gas turbocharger

Oil cooler

Pressure unit for

wastegate flap

21

Page 21

Engine

Air ducting

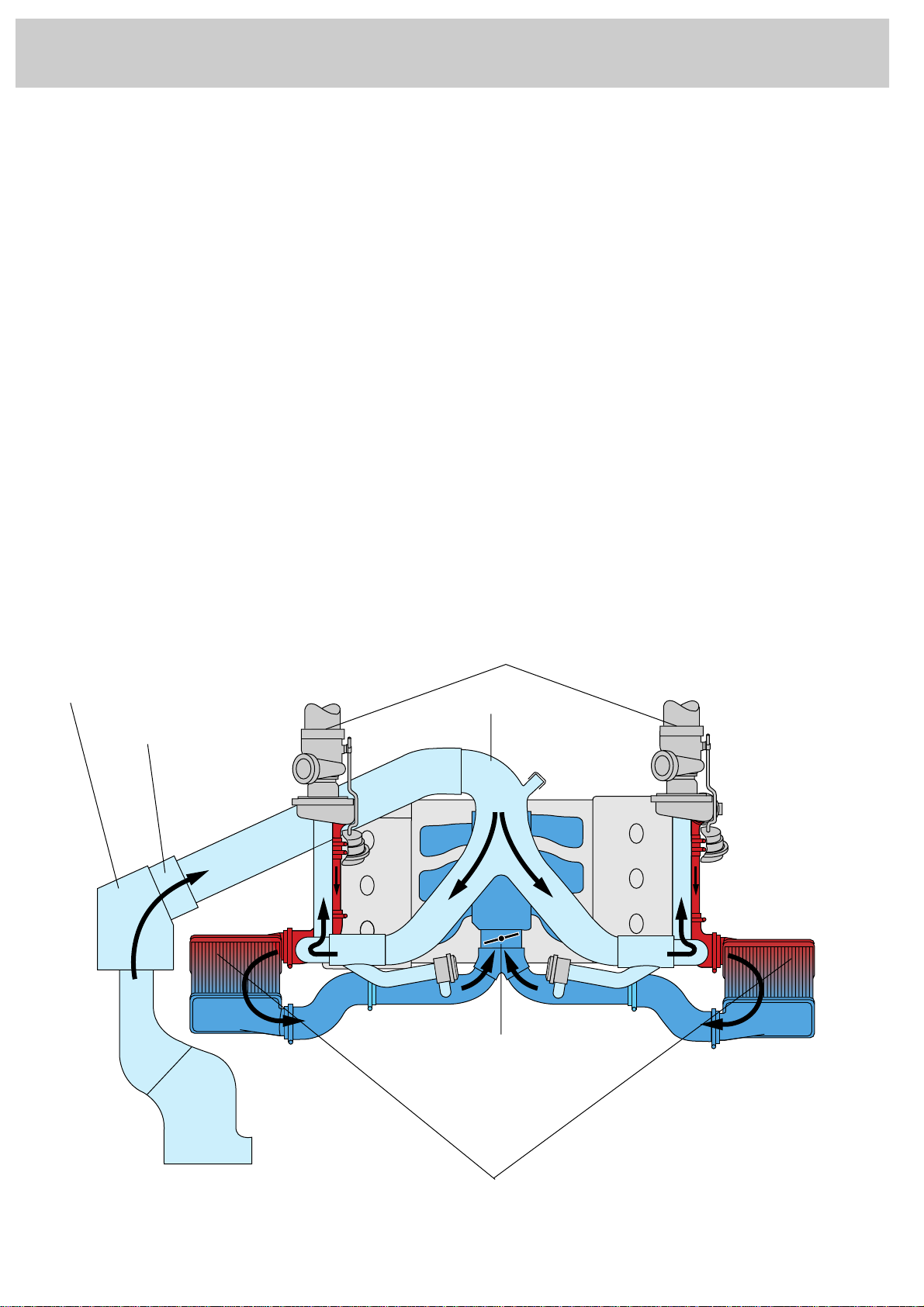

Fresh air is induced by the combined air filter

and air mass meter and distributed to the two

exhaust gas turbochargers by the air

distributor.

The air distributor is made of plastic.

Advantage:

•

Lower weight

•

The intake air is heated to a lesser degree

by the engine

The air, which is compressed and thus heated

by the exhaust gas turbocharger, is fed to the

charge air coolers.

Cooling air intakes in the bumper and air vents

in the wheel housing liners ensure that a

sufficient amount of air flows through the

charge air coolers.

Advantage of charge air cooling:

•

Cooled air has a higher density, and this

means improved volumetric efficiency.

•

The lower temperature reduces knock

tendency also.

The compressed air streams then converge

upstream of the throttle valve control part and

distributed to the individual cylinders in the

intake manifold.

Exhaust gas turbocharger

Air filter

Air distributor

Air mass meter

Throttle valve control part

SSP 198/04

22

Charge air cooler

Page 22

Charging

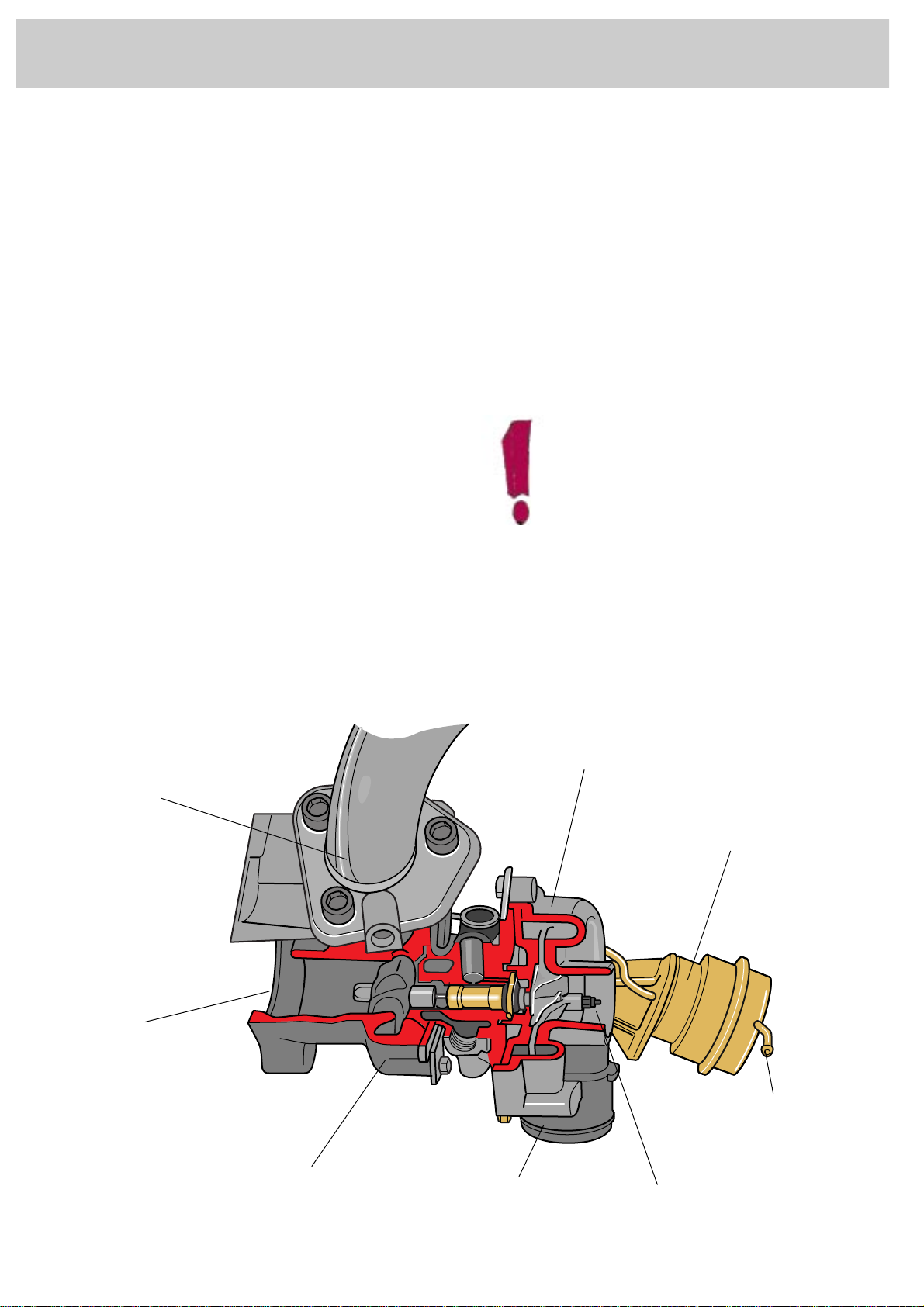

Two water-cooled exhaust gas turbochargers

with wastegate are used for charging.

The charge pressure of both exhaust gas

turbochargers is controlled via the common

charge pressure control valve N75.

Advantages of the biturbo technology:

•

The exhaust gas turbocharger is smaller,

which means better response due its

reduced mass.

•

Higher charge pressure at low engine

speeds.

•

The exhaust gas turbochargers are located

outside the V-angle due to the high

temperatures they reach. This advantage of

this arrangement is that the intake air is not

heated up additionally and the subassemblies are not subjected to so much

thermal stress.

•

Since the turbochargers are flanged

directly onto the exhaust manifold, the

exhaust gases travel less distance and

there is less temperature loss.

•

As a result, the catalytic converters are able

to heat up more quickly and the efficiency

of the exhaust gas turbocharger is

improved by the favourable air-flow.

The turbochargers must be replaced

in pairs

To maintain a synchronous air-flow

through the two chargers, it is

important to observe this instruction

to account for manufacturing

tolerances.

Service personnel are not permitted

to adjust the linkage to the wastegate

flap.

Exhaust manifold

to exhaust system

SSP 198/32

Turbine housing

Compressor housing

Charge press. side

of exh. gas turbocharger

Pressure unit for actuating

wastegate flap

Control pressure from

solenoid valve for

charge pressure

control

Intake side of exhaust

gas turbocharger

23

Page 23

Engine

Exhaust system

The exhaust manifolds are designed as pipe

elbows with insulated air gaps.

Advantage:

•

Less heat loss of the exhaust gas and less

heat radiation in the engine compartment

•

Weight saving

Located downstream of each exhaust gas

turbocharger is a primary catalytic converter

close to the engine (metal substrate) .

Advantage

•

The catalytic converters quickly reach a

state of readiness for operation after a cold

start

The large-surface area main catalytic

converters (ceramic substrate) are located

under the vehicle floor.

A new generation of probes is used

in this engine.

The “planar lambda probe“ is an

improvement on the finger-type

lambda probe (refer to chapter on

“Sensors”).

Advantage:

•

Short warm-up time

•

Less heating energy demand

•

Long service life

•

More stable control

characteristic

Wire mesh ring acting

as a spacer

Air-gap-insulated pipe elbow

Exhaust manifold

Inner pipes

Outer shell

Lambda probe

24

SSP 198/33

Prim. catal. converterMain catalytic converter

Page 24

Pneumatically controlled systems

In the Biturbo, 4 systems are pneumatically

controlled:

•

Charge pressure control

The Motronic ME 7.1 activates the solenoid

valve for charge pressure control N75 and

regulates the charge pressure via the

wastegate.

•

Divert air control in overrun

The Motronic ME 7.1 activates the electric

divert air valve for the turbocharger and

opens the pneumatic divert air valves using

this vacuum.

Divert air valve for

turbocharger N249

Non-return valve (divert

air control in overrun)

•

ACF system

The Motronic ME 7.1 activates the solenoid

valve for the activated charcoal canister

and regulates the fuel vapour feed rate to

the engine via the vacuum.

•

Crankcase breather

The crankcase breather controls the return

of oil vapours to the engine via two

mechanical valves.

Divert air valve

(pneumatic)

For exact the line routing, please refer

to the Workshop Manual.

Non- return valves (ACF system)

Solenoid valve for activated

charcoal canister N80

SSP 198/31

Distributor piecePressure control valve

Solenoid valve for charge

pressure control N75

25

Page 25

Engine

Charge pressure control

The air mass required to develop a specific

level of torque is determined by means of an air

mass calculation and produced by controlling

the charge pressure as required.

For safety reasons, the engine in the biturbo

regulates the charge pressure, and not the air

mass as is the case with the 1.8-litre 4-cylinder

turbocharged engine.

The charge pressure is measured by charge

pressure sender G31.

The Motronic regulates the charge pressure of

both turbochargers via the solenoid valve for

charge pressure control G31.

Charge pressure

Atmospheric pressure

If a defect occurs in one of the cylinder banks

(e.g. melting of the catalytic converter or

blockage of the exhaust system), a purely air

mass-oriented charging system would still try

to provide the computed air mass.

This would lead to an excessively high charge

pressure.

In any case, the charge pressure control

prevents an excessively high charge pressure

building up inside the intake system.

Control pressure

SSP 198/08

26

Solenoid valve for charge

pressure control N75

Charge pressure sender G31

Page 26

The solenoid valve for charge pressure control

N75 changes the opening time to atmospheric

pressure according to the signals it receives

from the engine control unit (duty cycle).

Thus, a control pressure is produced by

modulating the charge pressure and

atmospheric pressure. This pressure acts on

the pressure unit for the wastegate.

Turbine wheel

to catalytic converter

Wastegate flap

(open)

The wastegate is kept closed in a

depressurised state by a spring inside the

pressure unit . The entire exhaust gas flow is

routed via the turbine, and a charge pressure is

built up.

The control pressure counteracts this spring

force and opens the wastegate. Part of the

exhaust gas flow is fed from the wastegate

past the turbine, and the charge pressure stops

rising.

Impeller

Intake air

Exhaust gas from

combustion chamber

Control pressure from solenoid

valve for charge pressure control

pressure unit N75

If there is no flow, N75 is closed and the charge

pressure acts directly on the pressure unit. The

waste gate opens even if the charge pressure

is low.

If the charge pressure control fails, the charge

pressure is thus limited to a “basic charge

pressure“ in order to prevent the maximum

permissible charge pressure being exceeded.

This results in a loss of performance.

The “basic charge pressure“ is the charge

pressure (approx. 300 - 400 mbar) which is

achieved without regulation (mechanical

charge pressure).

charge pressure to solenoid valve

SSP 198/66

for charge pressure control N75

Solenoid valve for

charge pressure

limitation N75

Atmospheric

pressure from

distributor piece

Restrictor

SSP 198/67

to

combustion

chamber

Control

pressure to

pressure unit

Passage in no

flow state

Charge pressure from compressor housing

27

Page 27

Engine

Divert air control in overrun

To avoid pumping the exhaust gas

turbochargers when a sudden transition from

high load to overrun is made, two divert air

valves are used.

The Motronic also activates the

two pneumatic divert air valves by

means of an electrical changeover

valve, the divert air valve for

turbocharger N249.

Advantage:

•

Controlled opening of the

divert air valves reduces the

noise level in the induction

tract and reduces fuel

consumption.

Divert air valve for turbocharger N249

The divert air valve N249, in combination with

the vacuum reservoir, enables the divert air

valves to operate independently of the intake

manifold pressure.

The system is designed in such a way that the

pneumatic divert air valves continue to be

opened by the intake manifold pressure if the

electrically actuated divert air valve N249 fails.

Vacuum reservoir (inside

wheelhousing on the left)

Non-return valve

with flow

without flow

28

SSP 198/05

Divert air valve (pneumatic)

Page 28

ACF system

Integrated in the lines of the ACF systems are

the solenoid valve for activated charcoal

canister N80 and two non-return valves.

The engine control unit, assisted by solenoid

valve N80, regulates the return rate of the fuel

vapours from the ACF canister.

The Motronic operates the solenoid valve

cyclically using a pulse duty cycle.

The non-return valves control the return of fuel

vapours, depending on operating state.

ACF canister

Solenoid valve for activated charcoal canister N80

Vacuum in intake manifold:

Non-return valve 1 open. Fuel vapours return

to intake manifold.

charge pressure in intake manifold:

Non-return valve 2 open. Fuel vapours return

upstream of exhaust gas turbocharger.

For the exact line routing, please refer

to the Workshop Manual.

SSP 198/06

Non-return valve 1

Non-return valve 2

Vacuum in intake manifold

Charge pressure in intake manifold

29

Page 29

Engine

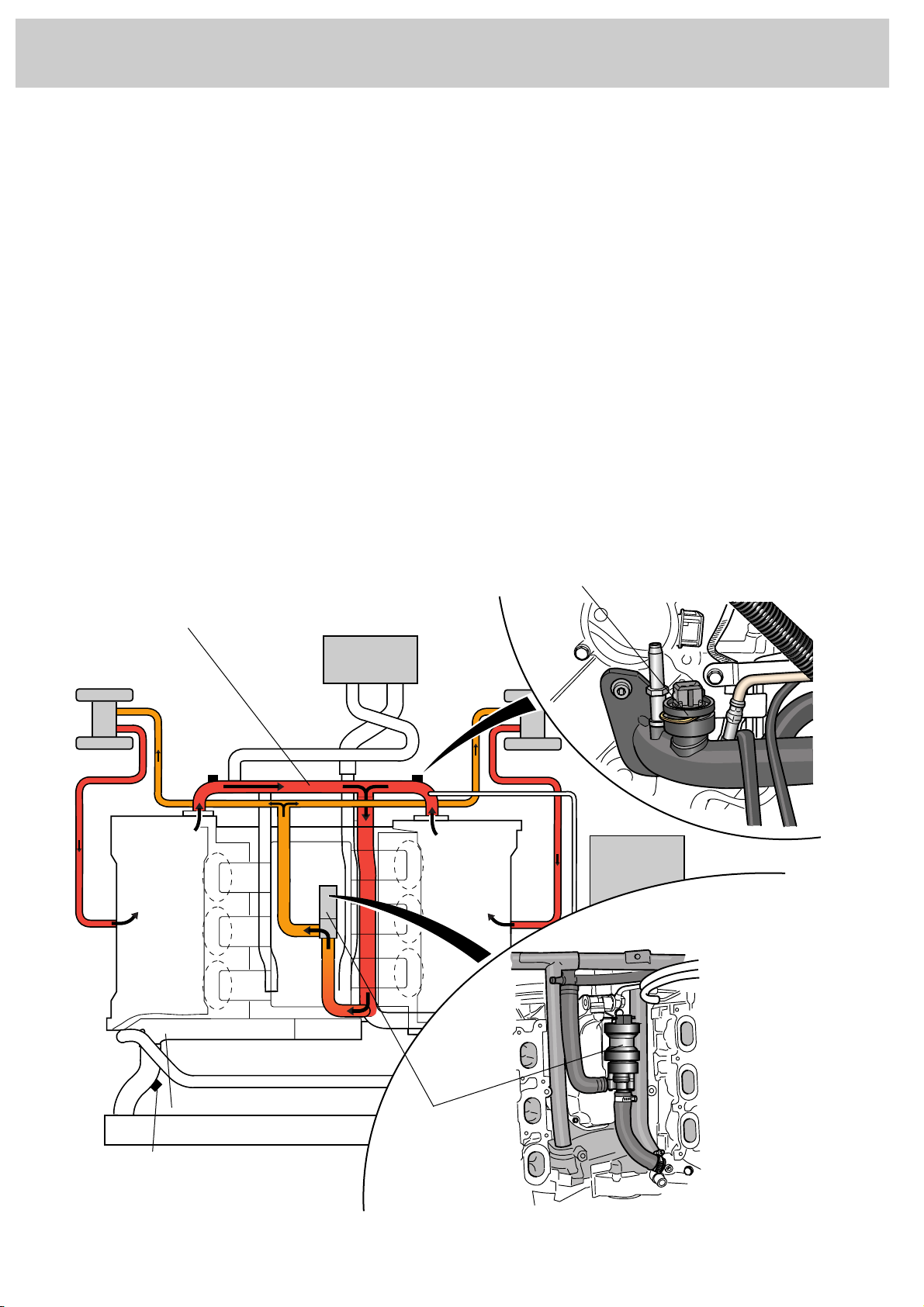

The crankcase breather ...

...comprises a distributor piece, a pressure

limiting valve, a non-return valve and the

associated hoses.

The oil vapours and “blow-by“ gases from the

cylinder heads and the crankcase converge in

the distributor piece.

The pressure limiting valve and the non-return

valve control the return of these vapours and

gases to the engine, depending on the intake

manifold pressure.

Vacuum in intake manifold:

The oil vapours and “blow-by“ gases return

via the non-return valve in the intake manifold.

charge pressure in intake manifold:

The oil vapours and “blow-by“ gases return

via the pressure limiting valve in the air

distributor.

The pressure limiting valve limits the vacuum

in the crankcase. If the vacuum in the

crankcase exceeds a defined value, the

diaphragm is drawn over the connection

against the force of the spring and closes the

connection. The valve is designed in such a

way that it allows a small quantity to pass

through when closed. This prevents the engine

oil being drawn into the intake tract and has no

adverse effects on engine breathing.

The term “blow-by“ gases refers to

the gases which escape from the

combustion chamber past the piston

rings.

Distributor piece

Air distributor

Pressure limiting valve

to air

distributor

from

distributor

piece

Connection

Diaphragm

SSP 198/07

30

Non-return valve

Page 30

Subfunctions of the Motronic

The Motronic consists of known and new subfunctions:

Sequential injection

Charge pressure control

(see chapter on “Engine” pp. 26 and 27)

Stereo lambda control

λ

Motronic ME 7.1

Mapped ignition

Cylinder-selective knock control

Static high-tension distribution with 6 individual ignition coils

ACF system

Torque-oriented engine management

Electrically actuated throttle valve (Electronic accelerator)

New

New

SSP 198/44

New

Cylinder bank-specific exhaust gas temperature control

New

Mapped variable valve timing (intake camshaft adjustment)

(see chapter on “Engine” p. 8)

31

Page 31

Motronic ME 7.1

Actuators

Sensors

Fuel pump relay J17 and

Hot-film air mass meter G70

fuel pump G6

Engine speed sender G28

Hall senders (bank 2) G40 and (bank 1)

G163

Lambda probes (bank 1) G39 and (bank 2) G108

Throttle valve control part J338

with angle sender (1) G187 and (2) G188 for

throttle valve drive G186

Intake air temperature sender G42

Coolant temperature senders G2 and G62

Charge pressure sender G31

Control unit for Motronic J220

SSP 198/14

Diagnosis

Injectors (bank 1) N30, N31, N32

Injectors (bank 2) N33, N83, N84

Output stage (bank 1) N122 and

ignition coils N (cyl. 1), N128 (cyl. 2)

and N158 (cyl. 3)

Output stage 2 (bank 2) N192 and

ignition coils N163 (cyl. 4), N164 (cyl. 5)

and N189 (cyl. 6)

Solenoid valve for activated charcoal

canister N80

Solenoid valve for

charge pressure control N75

Knock sensors (bank 1) G61 and (bank 2) G66

Accelerator position sender G79 and 2 G185

Exhaust gas temperature senders (bank 1)

G235 and (bank 2) G236

Brake light switch F and brake pedal

switch F 47

Clutch pedal switch F36

Auxiliary signals

Altitude sender F96 is

integrated in the engine

control unit.

EPC

Throttle valve control part J338

with throttle valve drive G186

Camshaft adjustment valve

(bank 1) N205 and (bank 2) N208

Divert air valve for turbochargers

Heater for lambda probe

(bank 1) Z19 and (bank 2) Z28

Fault lamp for electric

throttle control K132

Auxiliary signals

32

Page 32

Subsystems of the Motronic

Torque-oriented engine management

The Motronic ME 7.1 has a torqueoriented functional structure.

This is made possible by the new

electronic accelerator function.

External torque requests

• Driver inputs

Making allowance for efficiency and the

emissions standards, the engine control unit

coordinates the external and internal requests

and meets them by adjusting the available

control variables accordingly.

Internal torque requests

• Starting

• Idling speed control

• Catalytic converter

heating

• Power limiter

• Driving comfort

• Components

protection

• Engine governing

Control variables

influencing torque

• Driving

dynamics

• Driving

comfort

• Cruise control

system

SSP/198/15

Coordination of

torque and

efficiency requests

in engine control

unit

Throttle valve

angle

Charge pressure

Ignition angle

Injection cut-out

Injection time

33

Page 33

Subsystems of the Motronic

Torque-oriented

functional structure

In comparison with previously known

systems, the ME 7.1 is not confined to the

output of torque variables to the networked

control units (ABS, automatic gearbox), it also

uses these physical variables to calculate

control variables.

Nominal charging

moment

Prioritisation of

charging path

All - internal and external - torque demands

are combined, and a nominal torque is derived

from this.

To translate the nominal torque into actions,

the control variables are co-ordinated with

regard to consumption and emissions so as to

optimise torque control.

Nominal charge

Conversion of

torque into

charge

Throttle valve

Calculation of

throttle valve

opening

angle

External and

internal

torque

requests

SSP 198/75

Prioritisation

of crankshaft-

synchronous

path

Actual charge

Calculation of

efficiency and

torque reference

variables

Calculation of

crankshaft-

synchronous

intervention

Nominal inner

torque

Charge

pressure-

control

Nominal intake

manifold

pressure

Charge

pressure

(Wastegate)

Ignition angle

Injection cutout

Injection time

34

Page 34

The control variable calculation is subdivided

into two paths

Prioritisation of

charging path

Path 1

The charging path regulates the control

variables which influence charging:

• Throttle valve angle

• Charge pressure

Prioritisation

of crankshaftsynchronous

path

Path 2

All control actions which influence torque

regardless of charging are combined in the

crankshaft-synchronous path:

• Ignition angle

• Injection cut-out

• Injection time

The air mass necessary to develop a specific

torque is determined by means of a

“calculation model“ and is made available

along path 1 .

Path 2 is used to set the injection quantity or

cylinder cut-out necessary under the given

circumstances and the optimal ignition angle.

By and large, long-term torque requests are

fulfilled along path 1 .

Path 2 is particularly well suited to meeting

short-term torque requests, which usually

have a torque-reducing effect.

35

Page 35

Subsystems of the Motronic

Electrically actuated throttle valve (electronic accelerator)

With the Motronic ME 7.1, Audi is

using an electrically actuated

throttle valve for the first time.

There is no longer any need for a

mechanical accelerator cable

between the accelerator and

throttle valve. This has been

replaced by an electronic control

system (drive-by-wire).

The system comprises the following

components:

• Accelerator position sender

• Engine control unit

• throttle valve control part

CPU = Control Processing Unit

The accelerator position sender records the

accelerator pedal angle and transfers it to the

engine control unit.

The engine control unit adjusts the throttle

valve by means of an electric motor. A

continuous stream of feedback signals on the

position of the throttle valve is sent to the

engine control unit.

Extensive security measures in hardware and

software format - such as twin senders, safety

module and self-monitoring computer

architecture - are integrated in the electronic

accelerator .

Throttle valve control

part J338

Accelerator position sender

SSP 198/09

Accelerator position

senders G79 and

G185

Engine control unit

Input signals Output signals

CPU

Safety module

Throttle valve

drive G186

Angle sender for

throttle valve drive

G187 and G188

36

Page 36

The electronic accelerator controls the engine

output electronically and, over and above

intake-air control, offers the advantage that

functions such as idling speed control, cruise

control or engine governing can be executed

easily and comfortably.

.

Torque reduction

• Traction control system

• Engine governer

• Speed limiter

• Power limiter

• Cruise control system

• Driving dynamics control systems

The electronic accelerator is used for reducing

and increasing torque and does not adversely

affect exhaust emissions.

Torque increase

• Cruise control

• Engine braking torque control

• Load change damping

(Dash pot function)

• Idling speed control

• Driving dynamics control systems

The throttle valve can be opened regardless of

the accelerator position, and this serves to

reduce throttle losses.

The ideal combination of throttle valve crosssection and charge pressure produce the

necessary torque.

In this way, the throttle valve can be opened

fully while the accelerator pedal has not been

fully depressed.

With electronic accelerator, much improved

emissions and higher fuel economy are

achieved in specific load states.

Over and above this, any accelerator

characteristic can be programmed, e.g.

gradual acceleration when driving at low

speed.

37

Page 37

Subsystems of the Motronic

Accelerator position senders G79 and G185

The accelerator position sender transfers an

analog signal corresponding to the accelerator

position to the Motronic. To ensure that the

electronic accelerator functions reliably, the

accelerator position sender has two

independent potentiometers (G79 and G185).

They have different characteristic curves (see

diagram).

The control unit monitors the two senders G79

and G185 for proper functioning and

plausibility.

If a sender fails, the other sender serves as a

substitute.

The accelerator position sender transfers the

driver’s inputs to the Motronic and provides

kickdown information to the automatic

gearbox.

There is no separate switch for

kickdown information. Integrated in

the accelerator position sender is a

“mechanical pressure point “ which

conveys an authentic “kickdown feel”

to the driver.

When the driver operates the

kickdown, the full-load voltage of the

accelerator position sender is

exceeded. If a voltage defined in the

engine control unit is attained in the

process, this is interpreted as a

kickdown and transferred to the

automatic gearbox (via CAN-Bus).

The accelerator position senders for

the manual gearboxes and automatic

gearboxes are identical. Kickdown is

enabled or disabled via the

accelerator limit stop (refer to chapter

on “TDI engines”).

Lever

Ω

Resistance in

LL

SSP 198/25

G79

G185

Accelerator travel

38

SSP 198/12

Accelerator

Acc. position sender

Page 38

Self-diagnosis/emergency running

If a fault occurs in the accelerator position

sender or the wiring, two emergency running

programs can be run depending on fault type.

Emergency running program 1

If an accelerator position sender fails:

• Accelerator position limited to a defined value.

• If a full load is predefined, the power output is

increased slowly.

• In the case of implausible signals between G79

and G185, the lower value is used.

Prerequisite:

The idling speed position must be learnt once

by the intact sender.

• The signal supplied by brake light switch for

brake pedal switch F47 indicates the idling

speed.

• Comfort functions (CCS) are prohibited.

• The fault lamp for electric throttle control K132

comes on.

At idling speed, the accelerator

position senders G79 and G185 are

not diagnosed.

If the plug of the accelerator position

sender drops off, no fault is stored in

the control unit.

The fault lamp for electric throttle

control K132 does not come on.

The engine runs at idling speed and

does not respond to the accelerator

pedal.

Emergency running program 2

If both accelerator position senders fail, driver

input recognition is not possible:

• The engine only runs at idling speed.

• The fault lamp for electric throttle control K132

comes on.

Safety function:

For safety reasons, the throttle valve

is closed as far as a defined angular

position when both the accelerator

pedal and the brake pedal are

depressed.

If the brake is pressed first followed

by the accelerator pedal, the driver

input (torque request) is executed.

39

Page 39

Subsystems of the Motronic

throttle valve control part J338 with throttle valve drive G186, angle

senders 1 G187 and 2 G188 for throttle valve drive

The throttle valve control part comprises...

... throttle valve housing with throttle valve

... throttle valve drive G186 with reduction

gear

... angle senders for throttle valve drive

G187 and G188

Activated by the engine control unit, the

throttle valve drive controls the air-flow rate

necessary to develop the required torque.

Feedback on momentary throttle valve

position is provided by two potentiometers

G187 and G188.

For safety reasons, two angle senders

(redundancy) are used. They have opposite

impedance characteristics (see diagram).

If an angle sender fails, the second sender

maintains the electronic accelerator function

via an emergency running program.

Angle senders G187 and G188 cannot

be replaced separately. The throttle

valve control part may not be opened.

Redundancy means: superfluous,

non-essential.

Throttle valve drive G186

(Electric throttle control)

Throttle valve housing

with throttle valve

Ω

Resistance in

0 100%

Throttle valve opening in %

SSP 198/27

G188

G187

40

SSP 198/28

Angle senders for throttle valve

drive G187 and G188

Housing cover with electrical

connections

Page 40

Functional positions of throttle valve control part (linear representation)

The engine control unit recognises four key functional positions of the throttle valve control part.

• The lower mechanical limit stop

The throttle valve is closed. This

position is required to adapt the angle

sender.

• The lower electrical limit stop

is defined by the control unit and is

located just below the lower

mechanical limit stop. During

operation, the throttle valve closes no

further than the lower electrical limit

stop. This prevents the throttle valve

working its way into the throttle valve

housing.

Lower mechanical limit stop

SSP 198/24

Position of lower electrical limit stop

• The emergency running position

is the position of the throttle valve in

the deenergised state and ensures that

air flow is sufficient if any of the

relevant electronic accelerator functions

fails. Idling speed is higher - approx.

1000 rpm - and uneven.

Very limited vehicle operation is

possible.

SSP 198/22

Emergency running position

SSP 198/21

41

Page 41

•

Subsystems of the Motronic

• The upper electrical limit stop

is defined in the control unit does not

need to be learned.

As in the fully open position , the

shaft diameter is greater than

the thickness of the throttle

butterfly.

To enable the exact angular position of the throttle valve to be identified, angle senders for

throttle valve drive G187 and G188 must be learnt .

By moving the throttle valve into predefined positions, the values of the angle senders are stored

in the control unit (calibrated) and checked for plausibility. The state of the mechanics (terminals,

weak springs) in the throttle valve control part is determined by evaluating the throttle valve’s

reaction speed.

Position at upper electrical limit stop

SSP 198/23

Upper mechanical limit stop

Basic adjustment (adaption) ...

... involves not only learning the throttle

valve position, but also a complete check of

the throttle valve control part

... can be performed using the following

three methods:

manually - provided the ignition has been

switched on for at least 24 minutes without

operating the starter or accelerator.

• automatically - provided the need for adaption

is acknowledged.

• specifically - by initiating basic setting 04 in

measured value block 60 (refer to Workshop

Manual)

Adaption conditions

For basic setting (adaption), the test

conditions described in the

Workshop Manual must be met.

The basic setting routine will be

cancelled if the test conditions are

not fulfilled while it is in progress.

42

Page 42

Self-diagnosis/emergency running mode

If a fault occurs in the throttle valve control part or in the wiring, three emergency running

programs can be run, depending on fault type.

Emergency running program 1

If an angle sender for throttle valve drive fails

or an implausible signal is received:

• Torque-increasing requests on engine, e.g. CCS,

EBC (engine braking control) are suppressed.

• The fault lamp for electrical throttle control K132

comes on.

Prerequisite:

An intact angle sender and plausible

air mass flow. The air mass flow is

indicated by the air mass meter and

the charge pressure sender G31.

Emergency running program 2

If the throttle valve drive fails or malfunctions:

• The throttle valve drive is switched off and the

throttle valve goes into the emergency running

position. This results in considerable loss of

power, increased idling speed and possibly also

rough idling .

• Driver inputs are executed as far as possible via

the ignition angle and charge pressure. The

engine shows little response to the throttle.

• The fault lamp for electrical throttle control K132

comes on.

Emergency running program 3

If the throttle valve position is not clearly

recognisable and/or if the throttle valve is not

definitely known to be in the emergency

running position:

• The throttle valve drive is switched off and the

throttle valve goes into the emergency running

position. This results in considerable loss of

power, increased idling speed and possibly also

rough idling.

• The engine speed is limited to approx. 1200 rpm

by restricting the injection.

• The fault lamp for electric throttle control K132

comes on.

Prerequisite:

Emergency running program 2 is only

run if both angle senders for throttle

valve drive recognise the emergency

running position.

Repair work may not be performed on

the throttle valve control part J338! If

G186, G187 or G188 becomes faulty,

unit J338 must be replaced

completely and a basic setting

performed.

43

Page 43

Subsystems of the Motronic

Fault lamp for electric throttle

control K132

C

Faults in the Electronic Accelerator System are

detected by the self-diagnosis and indicated

via the separate EPC fault lamp. At the same

time, an entry is made in the fault memory.

When the ignition is turned on, the fault lamp

comes on and must go out again after 3

seconds if a fault state does not exist.

Fault lamp K132 is activated directly by the

engine control unit via an earth potential.

If a fault occurs in the Electronic Accelerator

System, an appropriate emergency running

program will be activated (refer to Accelerator

position sender and throttle valve control part).

EPC stands for E lectronic P ower

ontrol.

120

60

180

°C

SSP 198/47

EPC

90

120

4

3

5

2

EPC

1

12

93

6

60

°C

6

7

1/2

1/1

8

50

30

10

80

0

100

120

140

160

180

260

200

220

12

16

8

Volt

44

Page 44

In keeping with our policy of continuous product

improvement, the accelerator position sender

has been replaced by the accelerator pedal

module .

The accelerator pedal module has already been

used in other vehicle models within the Group.

The accelerator pedal module combines the

accelerator pedal and the accelerator position

sender as a unit.

The mechanics of the accelerator pedal module

are located inside the module housing.

Sensors G79 and G185 are located in the

housing cover.

For manual gearbox:

Stop buffer

For automatic gearbox:

Pressure element for

conveying the authentic

feeling of a kickdown

Advantages of the accelerator pedal module:

• Compact, lightweight, easy to assemble

• Modular technology

• Inexpensive to manufacture

Module housing

Housing cover and

sensors

SSP 198/34

45

Page 45

Subsystems of the Motronic

Exhaust gas temperature control

A new feature of Audi automobiles

is a function which monitors

exhaust gas temperature over the

entire engine speed range.

For turbocharged engines, the maximum

permissible exhaust gas temperature is a key

design criterion.

To protect the exhaust gas turbocharger and

the exhaust manifold, the exhaust gas

temperature should not exceed 1000 °C for a

lengthy period of time.

Since many of the components which

influence the exhaust gas temperature have

tolerances, thermodynamic adaptation

previously took place at 950 °C for safety’s

sake.

This was achieved by enriching the air/fuel

mixture.

The exhaust gas temperature is recorded in a

cylinder-bank-specific manner by the two

exhaust gas temperature senders G235 and

G236.

The Motronic controls the exhaust gas

temperature to 980 °C by enriching the air/fuel

mixture .

It is therefore possible to largely dispense with

the prophylactic enrichment process that has

been standard practice until now.

The mixture is only enriched...

... when necessary and

... to the extent necessary.

This means that engine operation with lambda

= 1 is possible up to high load and engine

speed ranges.

Advantage:

• Improved efficiency and reduction of fuel

consumption as well as exhaust emissions.

Exhaust gas temperature sender

G235

G236

SSP 198/26

Injectors

Engine control unit

46

Page 46

Exhaust gas temperature sender

G235 and G236

To facilitate exhaust gas temperature control,

the exhaust gas temperature must be recorded

to a high degree of accuracy.

An accuracy of ± 5 °C is achieved in the

measurement range from 950 °C to 1025 °C.

The exhaust gas temperature sender is located

inside the exhaust manifold upstream of the

exhaust gas turbocharger.

It comprises a measuring sensor and

evaluation electronics.

The measuring sensor and the control unit are

permanently connected by means of a

shielded, heat-resistant wire.

The evaluation electronics convert the signal

which the measuring sensor generates into a

pulse-width-modulated signal (PWM signal).

This is a square-wave signal with a fixed

frequency and a variable pulse duty factor.

The pulse duty factor is expressed as a

percentage . The measurement range extends

from

≥

10% to

A specific pulse duty factor is assigned to each

temperature (refer to diagram).

≤

90%.

evaluation electronics

Meas.

Substitute function and self-diagnosis:

A pulse duty factor of <1% or >99% is

recognised as a fault.

A fault is detected as of a certain enrichment

quantity.

If a sender fails, the charge pressure is reduced

to a safe level and an emergency enrichment

characteristic (engine speed-dependent) is

used.

SSP/198/13

Exhaust gas temperature sender

90%

70%

50%

30%

10%

Pulse duty factor

945°C

950°C

960°C

SSP 198/56

970°C

980°C

990°C

1000°C

1010°C

Exhaust gas temperature

1025°C

1030°C

47

Page 47

Notes

48

Page 48

Sensors

The following chapter presents the new features of the sensors, provided that they have not

already been described in the chapter on Subsystems of Motronic.

Charge pressure sender G31

The charge pressure sender is located

upstream of the throttle valve control part.

The Motronic supplies the sender with a

voltage of 5 volts and earth.

The signal which the sender generates is a

pressure- proportional voltage ranging from 0

to 5 volts.

At atmospheric pressure (at sea-level), the

voltage is approx. 2.5 volts.

The signal is used for charge pressure control.

The Motronic also needs information on

charge pressure so that it can take countermeasures if the maximum permissible

pressure is exceeded.

Substitute function and self-diagnosis:

If sender G31 fails, the charge pressure is

controlled via the characteristic curve (engine

speed-dependent). This will result in a

deficiency of engine power.

SSP 198/29

Charge pressure sender G31

The altitude sender F96 ....

... is integrated in the engine control unit, as is

normally the case with turbocharged engines.

... is required to control the charge pressure. In

conditions of decreasing air pressure (lower

density), the charge pressure is reduced to

prevent the turbocharger overspeeding.

... influences the air/fuel mixture composition

at engine start-up. The starting mixture is

leaned down with rising altitude.

Substitute function and self-diagnosis

If a signal fails, the charge pressure is reduced

to a safe level, which results in a deficiency of

engine power.

Adaption of the injection quantity at start-up

no longer takes place.

The fault message “Control unit defective“ is

displayed in the self-diagnosis.

49

Page 49

Sensors

Hot-film air mass meter G70

The hot-film air mass meter

operates on the same principle as

before.

In certain engine operating states,

pulsations occur in the intake tract,

reversing the air flow - and this

gives rise to measurement errors.

The hot-film air mass meter is designed in such

a way that it is able to recognise this returning

air flow (pulsation fault).

This more exact method of intake air

measurement in all operating states improves

engine management and reduces exhaust

emissions.

The hot-film air mass meter is a thermal

flowmeter. A partial airflow from the

measuring pipe is fed past the sensor element

through a measuring channel in the air mass

meter housing.

The ascertained temperature values are

evaluated in the evaluation electronics. The

Motronic applies a voltage proportional to the

air mass to the air mass meter. This voltage is

needed to calculate the injection period and of

actual engine torque.

Evaluation electronics

Meas.

channel

Sensor element

Substitute function and self-diagnosis:

The air mass meter detects air masses above

or below predefined limits. If the air mass

meter fails, the air mass is calculated on the

basis of a characteristic curve (throttle valve

angle and engine speed).

50

SSP 198/16

Hot-film air mass meter

Page 50

The measuring principle of the return flow

recognition

The sensor element is embedded in the

mounting plate.

The sensor element comprises a diaphragm

with a heating zone and two symmetrically

arranged temperature sensors T

and T2.

1

Temperature sensors T1 and T2 indicate a

temperature difference of ∆T.

In the case of a return air flow, the temperature

difference occurs at temperature sensor T

.

1

The amount and direction of this difference are

therefore dependent on the incoming flow.

The heating zone is set to an overtemperature

by means of a heating resistor and

temperature sensor T

.

2

If there is an incoming flow, the upstream part

of the diaphragm cools down along with the

temperature sensor T

.

1

The temperature of the upstream temperature

sensor T

is maintained due to the heated air in

2

the heating zone.

Temperature profile

Temperature difference

evaluation: ∆T = T

2

- T

1

1

• Advantage: the differential signal permits a

direction-dependent characteristic which

enables the Motronic to detect a return air flow.

without incoming flow

with incoming flow

Incoming flow

SSP 198/36

Mounting plate

0

Diaphragm

T

T

1

Heating zone

T

2

Sensor element

51

Page 51

Sensors

Lambda probes G39 and G108

The planar lambda probe is a further

development of the finger-type lambda probe

and has a transient response at lambda = 1.

There is a single lambda probe in the exhaust

pipe running to each of the primary catalytic

converters.

To ensure that the exhaust gases are treated

efficiently, it is important that the lambda

probe should react quickly. The lambda probe

should therefore reach its operating

temperature within as short a space of time as

possible. Its planar (= flat, elongated) design

makes this possible.

The probe heater is integrated in the sensor

element. It quickly reaches its operating

temperature despite its lower heating capacity.

Note:

At an exhaust gas temperature as low as 150

°C, the probe heater generates the necessary

minimum temperature of 350 °C.

The lambda control is ready to operate approx.

10 seconds after engine start-up.

A new generation of probes used in

the biturbo for stereo lambda

control.

Advantages:

• The warm-up period is short, which means

lower emissions during the warm-up phase

• Low heating power consumption

• More stable control characteristic

A porous, ceramic protective layer is sintered

onto the sensor element.

This layer prevents the sensor element being

damaged by residues in the exhaust gas.

It ensures that the sensor element will have a

long service life and meet the tough functional

demands.

Substitute function:

Controlled operation based on a characteristic

curve (cylinder bank-specific).

Sensor element

Section

SSP 198/37

52

Probe heater

Page 52

Hall senders G40 and G163

On V-engines with variable valve

timing, a Hall sender acting as a

camshaft sensor is attached to the

left- and right-hand cylinder banks.

To permit cylinder-selective knock control and

sequential injection, cylinder 1 must be

defined precisely.

The signal which Hall sender G40 supplies

together with the signal which engine speed

sender G28 generates (incremental sender for

engine speed and reference mark) enable

ignition TDC of cylinder 1 to be identified

(synchronization of cylinder 1).

After the simultaneous input of both signals,

initial injection and ignition are enabled.

Hall sender G40

By using Hall senders G163 and G40 as

camshaft sensors, the adjustment of both

camshafts can be monitored closely and

evaluated by the self-diagnosis.

Substitute function and self-diagnosis:

If Hall sender G40 fails, Hall sender G163 takes

on the task of synchronising first cylinder.

If both Hall senders fail, it is possible to start

the engine and the engine runs with substitute

functions.

SSP 198/35

Hall sender G163

53

Page 53

Sensors

Engine speed sender G28

The engine speed sender is an inductive

sender which records the engine speed and

the exact angular position of the crankshaft

(single-sender system).

Attached to the flywheel is a separate sender

wheel for the G28.

The sender wheel is designed as a segmented

wheel and is subdivided into 60 segments.

If the sender wheel moves past G28 , this

produces an alternating voltage whose

frequency changes as a factor of engine speed.

The frequency is the magnitude of the engine

speed.

To enable it to recognise the crankshaft

position, there is a gap of two segments in the

sender wheel.

Engine speed sender

The G28 recognises the engine speed.

Together with Hall sender G40, the G28

recognises the exact position of the engine

mechanics, i.e. ignition TDC of cylinder 1. The

injection and ignition timing are determined

using this information.

Substitute function and self-diagnosis:

The signal which G28 generates is checked

together with the signal supplied by the G40

for plausibility.

If the Motronic control unit does not detect any

segment gaps during 8 “phases“ of the G40,

an entry is made in the fault memory.

If the engine speed sender fails, it is not

possible to start or run the engine.

Since the G28 is an inductive sender,

the self-diagnostics are unable to

perform electrical tests (short circuit

to positive or negative or open

circuit).

Segment

gap

SSP 198/64

Sender wheel

Two mass flywheel

54

Page 54

Diagram of signal of engine speed sender and Hall sender using the oscilloscope function of

VAS 5051

Hall sender G40 (bank 2)

Engine speed sender G28

Sender wheel

Software reference mark

TDC of cylinder 1

72° before TDC of cylinder 1

Diagram of signal of engine speed sender and the two Hall senders

Hall sender G40

Hall sender G163 Hall sender G40

TDC of cylinder

1436251

SSP 198/59

Engine speed sender G28

SSP 198/60

Here, the signals which G40, G163 and G28 generate are shown combined for added

clarity. A two-channel oscilloscope does not allow all three signals to be represented.

The TDC mark of the belt pulley reflects the TDC of cylinder 3.

55

Page 55

Sensors

Brake light switch F and brake

pedal switch F47

Clutch pedal switch F36

Brake light switch F and

brake pedal switch F47

The information “brake operated“ is required

for the following functions:

• Function of cruise control system

• Safety interrogation of electronic accelerator

function (idling speed recognition during

emergency running mode of accelerator

position sender)

Brake light switch F and brake pedal switch F47

are combined as a unit. Both serve as

information senders for “brake operated“,

which means they are redundant (for safety

reasons).

Brake light switch F is open in the “off”

position and is supplied with voltage from

terminal 30. It serves as an additional

information input for the Motronic.

Brake pedal switch F47 is closed in the “off”

position closed and is supplied with voltage

from terminal 15. It serves exclusively as an

information input for the Motronic.

Substitute function and self-diagnosis:

The two switches are cross-checked for

plausibility by the self-diagnosis.

Please read the note on the “Safety function“

on page 39.

SSP 198/63

Clutch pedal switch F36 ...

... switches the cruise control system off.

... deactivates the load change functions during the gearshift operation. The load change

function is controlled via ignition angle intervention and throttle valve closing speed.

The clutch pedal switch is closed in the “off” position and is supplied with voltage from terminal

15.

Substitute function and self-diagnosis:

The F36 is not included in the self-diagnosis, which means that no substitute functions are

initiated.

56

Wrong settings, electrical malfunctions or maloperation (driver keeps foot on clutch

pedal) may result in load change jolts or engine speed overshoots.

Page 56

Additional signals/interfaces

Additional signals/interfaces to

Motronic ME 7.1

The Motronic receives a large number of

additional signals.

The following overview shows the signal

direction and meaning referred to the Motronic

control unit

Input

signal

•

•

Output

signal

Bidirec-

tional

•

•

Signal meaning

CAN-high, data bus signal for automatic gearbox

CAN-low, data bus signal for automatic gearbox

CCS, “set/decelerate“ signal for cruise control system

CCS, “Off“ signal for without cancellation cruise

control system

The term “interfaces“ is used to

describe the control unit connections

and wiring connections of the various

control units.

•

•

•

•

•

•

•

•

CCS, “On/Off“ signal for with cancellation cruise

control system (master switch)

CCS, “Resume/accelerate“ signal for cruise control

system

Road speed signal

Immobiliser/diagnosis signal

Air conditioner compressor “On/Off“ signal

Coolant temperature signal

Engine speed signal

Fuel consumption signal

57

Page 57

Additional signals/interfaces

The road speed signal ...

... is required for operation of the cruise control

system, speed limiter, load change measures,

idling speed stabilisation and internal safety

checks of the control unit (e.g. adaption

conditions).

Road speed signal (4 pulses)

1 revolution of wheel

... is a square-wave signal which is conditioned

by the dash panel insert. The frequency of this

signal changes as a factor of road speed.

The dash panel insert transfers 4 pulses per

revolution of the wheel.

Signal from speedometer sender (reed contact)

Coolant temperature signal

The engine control unit receives from the dash

panel insert a coolant temperature signal

calculated from the signal which coolant

temperature sender G2 generates and a

related temperature characteristic.

The signal is a “data message“ and is

connected to the earth potential when a

temperature of approx. 120 °C is exceeded.

In this case, the air conditioner’s operating and

display unit switches the compressor off along

the bidirectional wire designated “Airconditioner compressor On/Off“.

SSP 198/69

As of a temperature of 116 °C, the charge

pressure is reduced in order to counteract a

further rise in temperature.

If the temperature drops below a value of

approx. 116 °C, a data message is again

transferred and all actions previously

performed are reversed.

58

Page 58

The “Compressor On/Off“ interface ...

... serves to provide the engine control unit

with information on the circuit state of the

compressor.

... enables the engine control unit to switch off

the compressor or inhibit start-up.

... provides a link to the air conditioner’s

operating and display unit.

The interface as a signal input:

Shortly before switching on the magnetic

coupling, the air conditioner’s operating and

display unit applies voltage to the interface.

The engine control unit then increases the