Page 1

Self-Study Program 990713

Audi TT RS with the 2.5L TFSI Engine

Page 2

Audi of America, LLC

Service Training

Printed in U.S.A.

Printed 6/2011

Course Number 990713

©2011 Audi of America, LLC

All rights reserved. Information contained in this manual is

based on the latest information available at the time of printing

and is subject to the copyright and other intellectual property

rights of Audi of America, LLC., its affi liated companies and its

licensors. All rights are reserved to make changes at any time

without notice. No part of this document may be reproduced,

stored in a retrieval system, or transmitted in any form or by

any means, electronic, mechanical, photocopying, recording or

otherwise, nor may these materials be modifi ed or reposted to

other sites without the prior expressed written permission of

the publisher.

All requests for permission to copy and redistribute

information should be referred to Audi of America, LLC.

Always check Technical Bulletins and the latest electronic

service repair literature for information that may supersede any

information included in this booklet.

Page 3

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Audi Space Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.5L TFSI Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Cylinder Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Material Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Crankshaft Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Cylinder Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Chain Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Oil Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Crankshaft Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Air Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Intake Manifold with Flaps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Exhaust System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Turbocharger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Exhaust System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Belt Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Engine Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Engine Load Sensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Sport Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Manual Transmission 0A6 . . . . . . . . . . . . . . . . . . . . . . . . . .37

Running Gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Drive Concept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Audi Magnetic Ride . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Brake System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Electronic Stabilization Program (ESP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

New Special Tools for the TT RS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Self-Study Programs for the Audi TT . . . . . . . . . . . . . . . . .46

Knowledge Assessment . . . . . . . . . . . . . . . . . . . . . . . . . . .47

i

Page 4

The Self-Study Program provides introductory information regarding the design

and function of new models, automotive components, or technologies.

The Self-Study Program is not a Repair Manual!

All values given are intended as a guideline only.

For maintenance and repair work, always refer to current technical literature.

iiii

Reference Note

!

Page 5

Introduction

The original Audi TT, named after the legendary

“Tourist Trophy” race in the United Kingdom,

was a milestone in automotive design. The

design followed pure geometry, with the central

theme being a circle refl ected in the wheel

arches, roofl ine arches, and both the front and

rear fascias of the vehicle.

TT_BodyShop_1

The Audi TT RS, developed by quattro GmbH,

breathes new life into old traditions. Thanks to

a turbocharged 2.5-liter fi ve cylinder engine,

permanent all-wheel drive, and a sporty yet

comfortable suspension and design, both the

RS Coupe and RS Roadster are uncompromising

sports cars.

The production of the Audi TT RS involves the

use of two factories. The Audi Space Frame (ASF)

body is constructed in Ingolstadt, Germany,

while fi nal assembly is completed in Györ,

Hungary.

TT_BodyShop_3

TT_BodyShop_2

1

Page 6

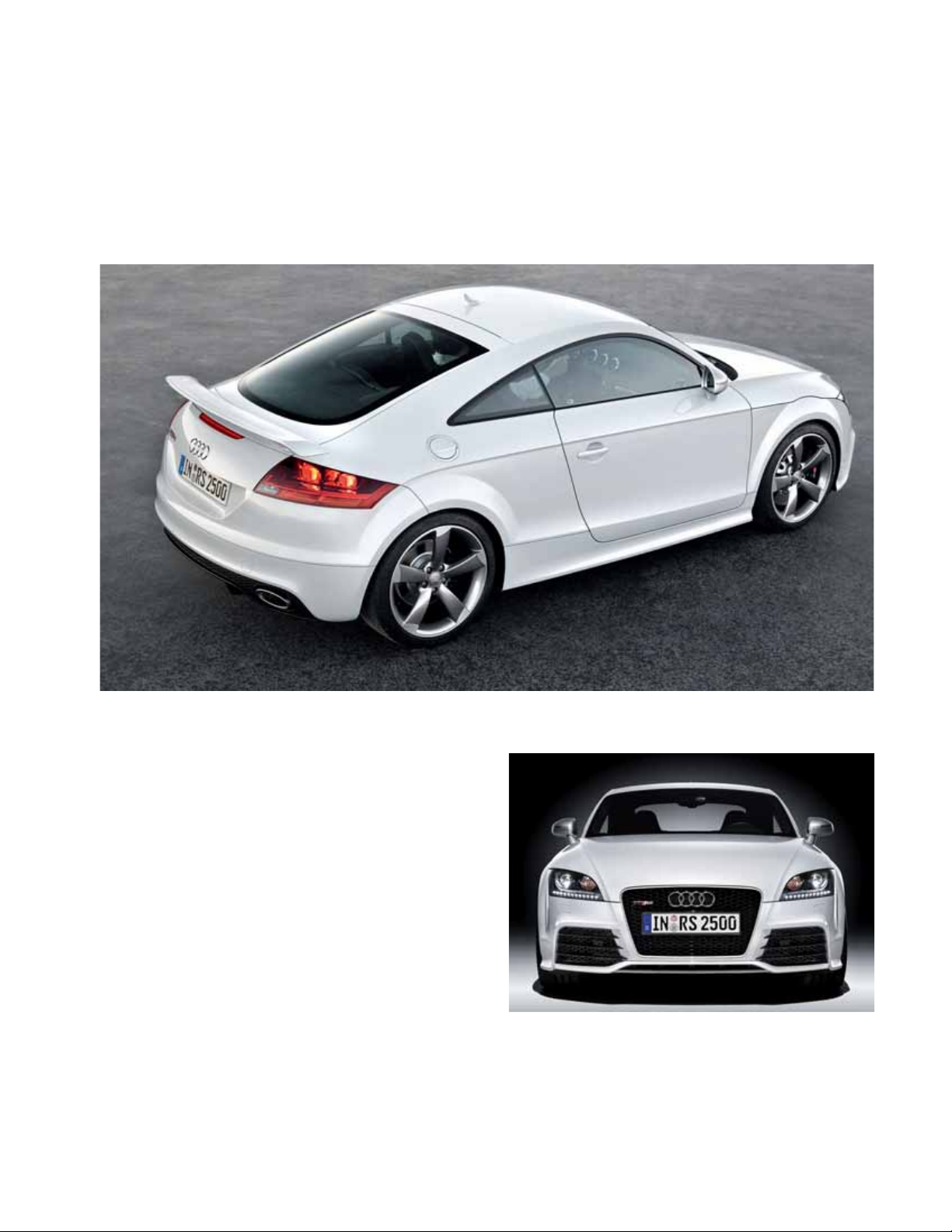

The TT RS is clearly the fl agship of the TT

model series. The muscular sheet metal body,

tautly curved surfaces, and sharp lines give an

impression of sculpture in motion.

From the side, the 18-inch wheels, large brakes,

and fl ared wheel openings of the TT RS instantly

catch the eye. Matte aluminum door mirror

covers are standard.

The front of the TT RS features the Audi marque

single frame grille. The insert is shiny black

bounded with a matte aluminum fi nish. Large

side air intakes with fl ared edges draw air into

the engine compartment.

The left intake routes air to the transmission,

while the right intake routes air to an auxiliary

radiator. The turbocharger draws in air through

the upper section of the grille while the

intercooler sits behind the lower segment of the

grille.

The front valance has been designed as a

splitter, and when coupled with the rear spoiler,

provides perfect aerodynamic balance.

451_011a

451_012

2

Page 7

The headlight design is a distinguishing Audi

characteristic. Xenon plus headlights, standard

on the TT RS, are accentuated by daytime

running lights comprised of 12 LEDs arranged in

a straight line.

451_013

Rear View

The rear bumper includes an integrated diffuser

insert that surrounds two large, oval tailpipes.

A wide, stationary spoiler increases downforce

on the rear axle, improving stability at high

speeds. The automatic spoiler featured on the

standard production TT is available on the TT RS

as an option.

451_014a

451_015

3

Page 8

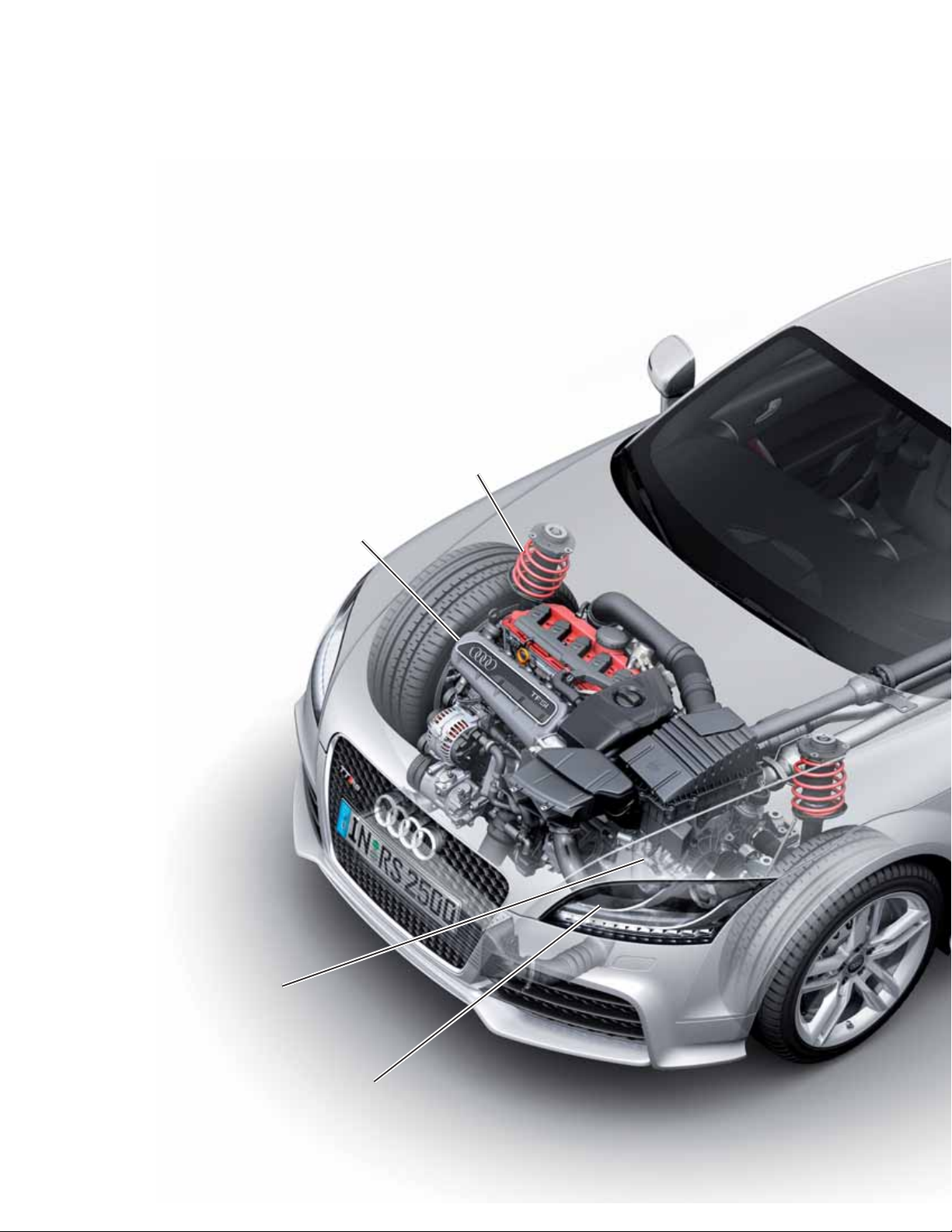

(10 mm lower than standard Audi TT)

2.5L TFSI engine with 335 hp

(250 kW) peak output

Sport suspension

ESP Sport Mode

Six-speed manual transmission

(0A6) with all-wheel drive

4

Xenon plus headlights

with LED DRLs

Page 9

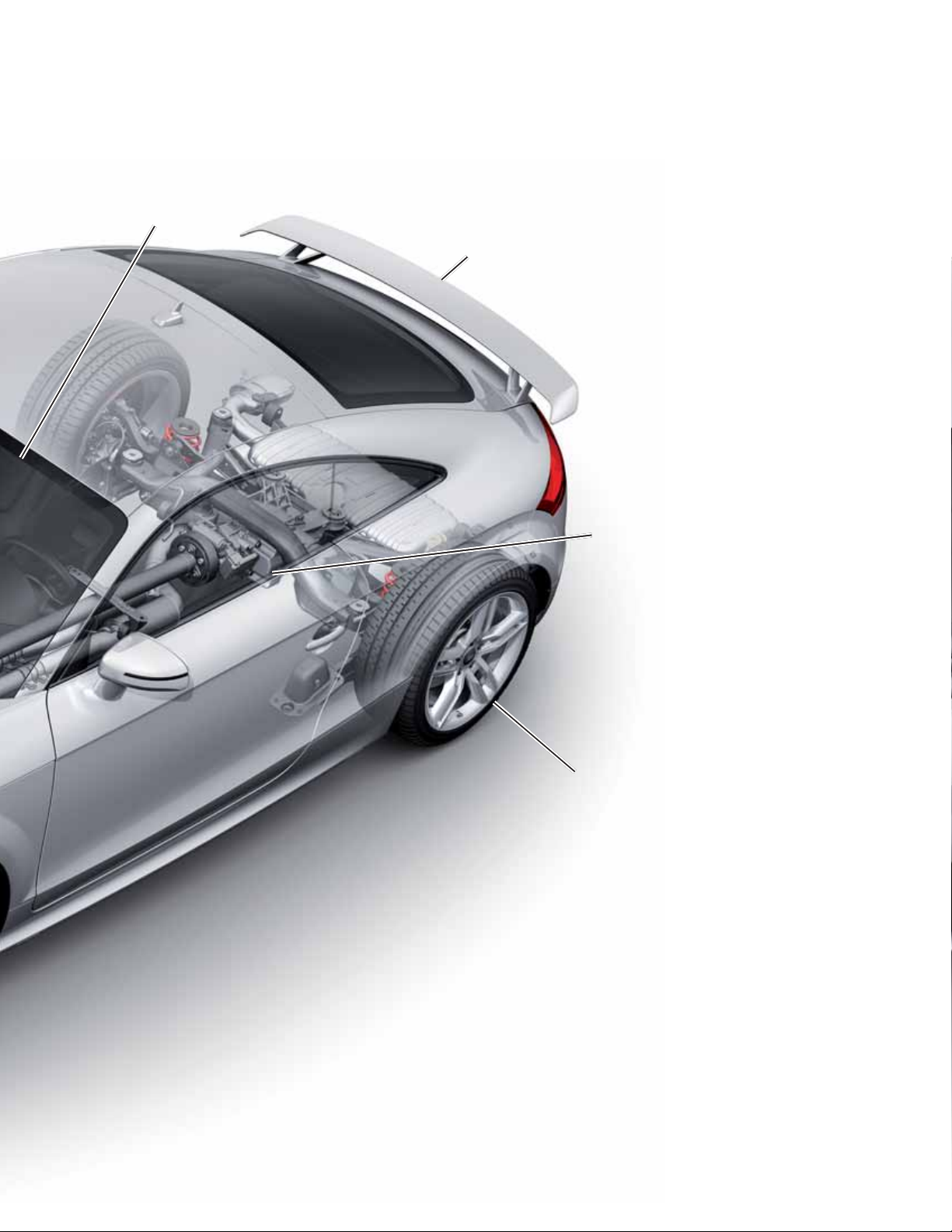

Heated sports seats trimmed

with leather / Alcantara

Optional rigid spoiler (adjustable

rear spoiler as found on the

standard TT is also available)

generation all-wheel drive clutch

Rear wheel drive via the 4th

451_008

18 inch alloy wheels

with 245/40 tires

5

Page 10

Body

Dimensions

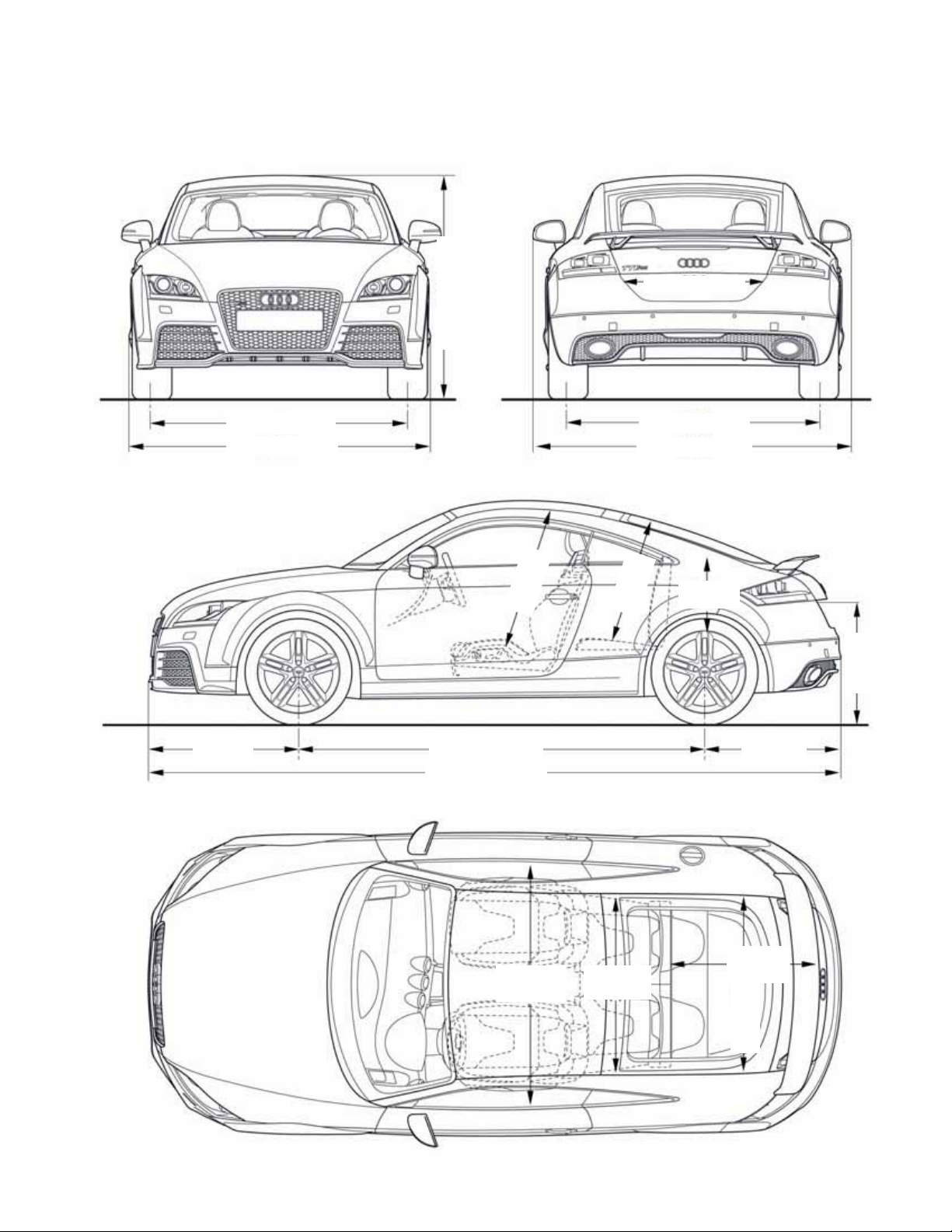

Audi TT RS Coupe

35.4 in (900 mm)

52.8 in (1342 mm)

61.2 in (1555 mm)

72.5 in (1842 mm)

35.8 in

(911 mm)

38.9 in

97.1 in (2468 mm)

165.2 in (4198 mm)

(990 mm)

60.8 in (1546 mm)

76.8 in (1952 mm)

32.6 in

(829 mm)

15.3 in

(390 mm)

32.4 in

(819 mm)

30.5 in

(777 mm)

32.1 in

60.3 in

(1532 mm)

6

47.4 in

(1532 mm)

(816 mm)

39.3 in

(1000 mm)

451_009

Page 11

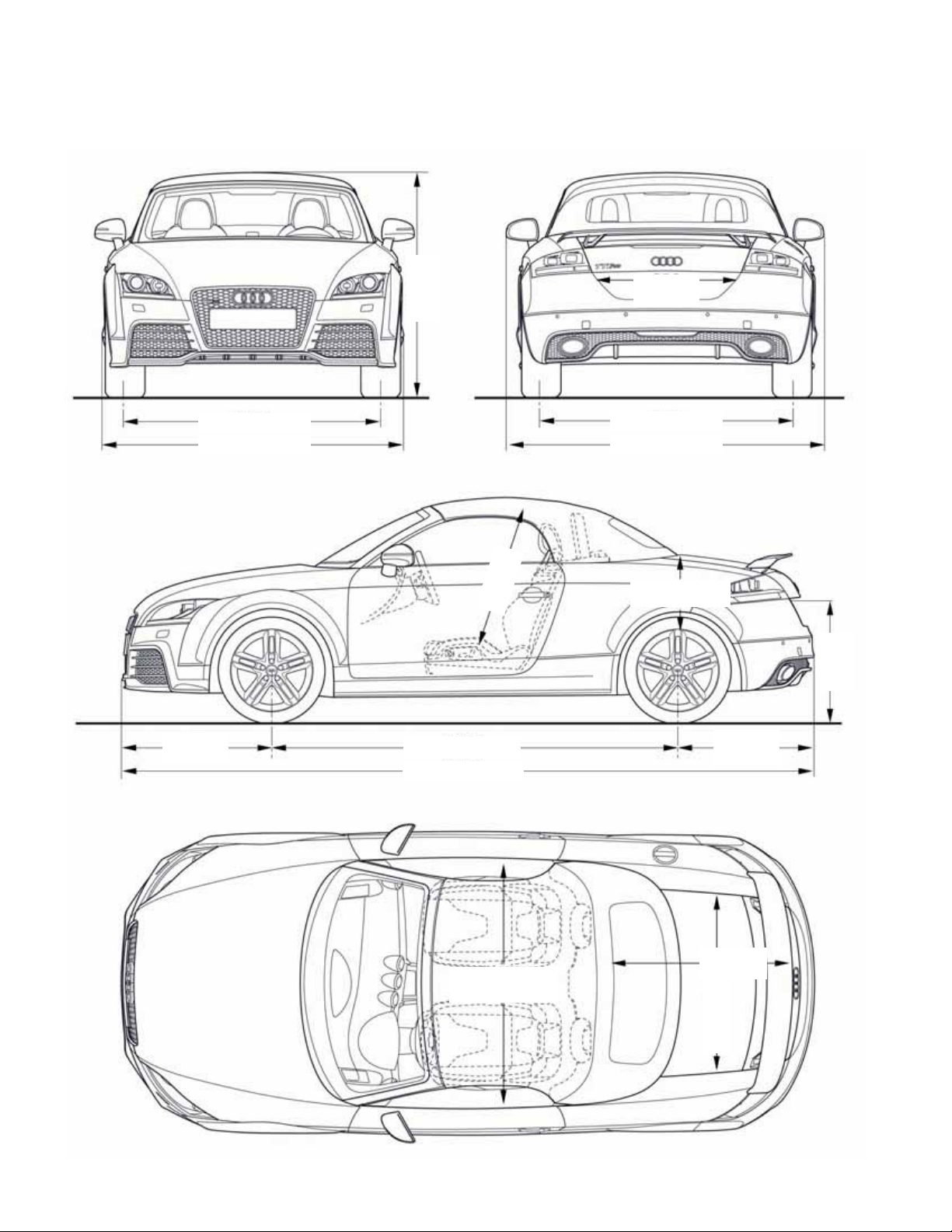

Audi TT RS Roadster

53.0 in

(1348 mm)

33.7 in

(856 mm)

61.2 in (1555 mm)

72.5 in (1842 mm)

35.8 in

(911 mm)

38.9 in

(990 mm)

97.1 in (2468 mm)

165.2 in (4198 mm)

60.8 in (1546 mm)

76.8 in (1952 mm)

9.6 in (245 mm)

32.2 in

(819 mm)

30.6 in

(778 mm)

53.2 in (1352 mm)

39.4 in

(1001 mm)

39.3 in

(1000 mm)

451_010

7

Page 12

Coupe Roadster

Curb weight

Maximum gross weight

Luggage capacity (seats folded down)

Fuel tank capacity

Drag coeffi cient

3196.6 lb (1450 kg)

4034.4 lb (1830 kg)

10.2 cu ft / 24.7 cu ft

(290 liter / 700 liter)

15.8 gal (60 liter)

0.32

3328.9 lb (1510 kg)

4034.4 lb (1830 kg)

8.8 cu ft (250 liter)

15.8 gal (60 liter)

0.34

8

Page 13

Notes

9

Page 14

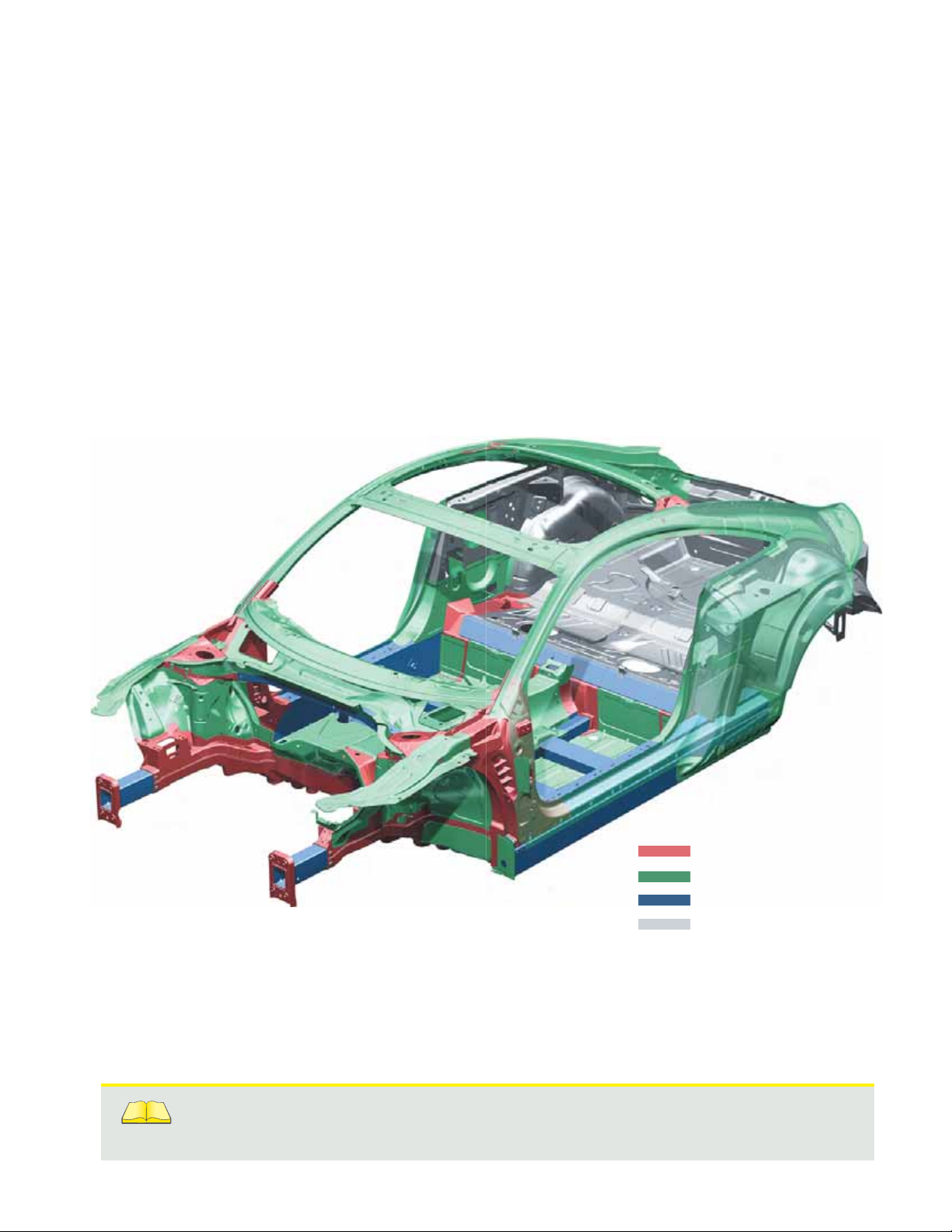

Audi Space Frame

Technical Design

The hybrid Audi Space Frame (ASF) fi rst used in

the 2008 TT is also used in the TT RS Coupe and

TT RS Roadster.

Sheet steel and aluminum sheet metal

components, aluminum castings, and aluminum

extruded sections form the TT RS body structure.

Vehicle weight distribution is optimized by

using sheet steel components in the rear facia,

improving driving dynamics and acceleration.

TT RS Coupe

Reference

For more information about the Audi Space Frame used in the Audi TT Coupe,

refer to Self-Study Program 994703, The 2008 Audi TT Body.

383_003

Aluminum castings

Sheet aluminum components

Aluminum extruded sections

Sheet steel components

10

Page 15

This ASF hybrid design guarantees maximum

rigidity and a balanced distribution of axle loads.

The body shell of the Coupe weighs 454.1 lb

(206 kg), while the body of the Roadster weighs

in at 553.3 lb (251 kg). Roadster weight is slightly

higher due to extra reinforcement.

TT RS Roadster

Reference

For more information about the Audi Space Frame used in the Audi TT Roadster,

refer to Self-Study Program 995703, The 2008 Audi TT Roadster.

391_039

Aluminum castings

Sheet aluminum components

Aluminum extruded sections

Sheet steel components

11

Page 16

2.5L TFSI Engine

Introduction

Audi’s fi ve-cylinder engines of the 1980s were

powerful, sporty engines that reinforced the

brand’s “Vorsprung durch Technik” commitment.

These fi ve-cylinder engines combined the

effi ciency of a four-cylinder with the power of

a six-cylinder, resulting in lighter and more

compact engine packages. A turbocharged

version was a sensation.

451_020

12

Page 17

Specifi cations

402.3 hp (300 kW)

362.0 hp (270 kW)

321.8 hp (240 kW)

Power in hp (kW)

Torque in lb ft (Nm)

281.6 hp (210 kW)

241.3 hp (180 kW)

201.1 hp (150 kW)

160.9 hp (120 kW)

80.4 hp (60 kW)

40.2 hp (30 kW)

Engine Code CEPA

Engine type

Five-cylinder inline engine

hp (kW)

442.5 lb ft (600 Nm)

398.2 lb ft (540 Nm)

354.0 lb ft (480 Nm)

309.7 lb ft (420 Nm)

265.5 lb ft (360 Nm)

221.2 lb ft (300 Nm)

177.0 lb ft (240 Nm)

lb ft (Nm)

88.5 lb ft (120 Nm)

44.2 lb ft (60 Nm)

0

2000 4000 5000 70001000 3000 6000

451_005

Displacement

Maximum power

Maximum torque

Valves per cylinder

Bore

Stroke

Compression ratio

Firing order

Fuel system

Fuel grade

Engine weight

Engine management

Exhaust emission standard

151.3 cu in (2480 cc)

335.2 hp (250 kW) @ 5400–6500 rpm

331.9 lb ft (450 Nm) @ 1600–5300 rpm

4

3.24 in (82.5 mm)

3.65 in (92.8 mm)

10 : 1

1-2-4-5-3

FSI (homogeneous) direct injection with demand-based high and low

fuel pressure regulation

Engine management without an air mass meter

91 AKI

403.4 lb (183 kg)

Bosch MED 9.1.2

LEV II

Emissions control

Sensors upstream and downstream of the catalytic converter

13

Page 18

Cylinder Block

Because of its very short overall length, this

engine lends itself very well to transverse

mounting.

451_025

19.4 in (494 mm)

20.07 in (510 mm)

22.04 in (560 mm)

23.1 in (589 mm)

23.2 in (591 mm)

451_026

14

Page 19

Material Selection

The cylinder block is made from high tensile

strength cast iron. The strength of this material

is needed because the connecting rod bearings

and main bearings have relatively small widths.

Cylinder block

Front sealing fl ange

Piston cooling jets are mounted in the cylinder

block.

Lower timing

case cover

Oil Level Thermal Sensor G266

Oil drain plug

Sheet steel

lower oil pan

Oil Pan

The oil pan is constructed from two parts. The

cast upper part acts as a baffl e plate and is

bolted to the crankcase. This upper part supports

the oil pump, which is bolted to the cylinder

block.

Cast upper oil pan

Check valve in the oil return line of the

positive crankcase ventilation system

451_037

The lower part of the oil pan is made from sheet

steel. It houses Oil Level Thermal Sensor G266

and the drain plug.

Both the front sealing fl ange and lower timing

case cover are sealed against the cylinder block

by a liquid sealant.

!

Note

The liquid sealants using during engine assembly and repair are specifi cally designated for various

components. Always check the latest technical literature and ETKA for correct application and

part numbers.

15

Page 20

Crankshaft Drive

The forged steel crankshaft is supported by six

main bearings.

Circlip

Connecting

rod bushing

Connecting rod

Piston

Wrist pin

A torsional vibration damper reduces radial

vibration by the pistons and crankshaft. The

damper, referred to as a viscodamper in repair

literature, uses a high viscosity silicone.

Crankshaft

Connecting rod

bearing shell

Connecting rod

bearing cap

Specifi cations

Center-to-center distance between cylinders

Block height

Connecting rod length

Crankshaft main bearings

Main bearing diameter

Connecting rod bearing diameter

451_027

3.46 in (88 mm)

8.66 in (220 mm)

5.66 in (144 mm)

6

2.28 in (58 mm)

188 in (47.8 mm)

16

Page 21

Pistons and Connecting Rods

To better respond to high loads, the pistons are

a “boxed” design. They have an asymmetrical

skirt with beveled box walls on the thrust and

counter-thrust sides. They are manufactured

from a high heat resistant alloy and have castin ring lands for the upper piston ring. Lower

weight and low oil consumption characteristics

were designed into these pistons.

N3, DSF** ring with

451_029

Mini headland rings

N1, asymmetrical, spherical,

N2, taper-face piston ring

tapered lands

steel nitride + PVD*

*PVD = Physical Vapor Deposition is a coating process in which

the coating material is physically vapor-deposited (by kinetic

or impact energy) on a material in a vacuum environment.

* *Top-beveled oil control ring with coil expander

451_027a

Optimized design with

large cross section

Reinforced

threads

M9 bolt

451_028

17

Page 22

Cylinder Head

The cylinder head is from the 2.5L 5-cylinder VW

engine, but to withstand the higher stresses of a

turbocharged engine, it was necessary to make

the following modifi cations:

– Different aluminum casting alloy

– Lower-set water jacket around the spark plug

– Tempered exhaust valve seats

– Attachment of a high-pressure pump to the

ladder frame

High-pressure

fuel pump

– Optimized exhaust cam contour

– Addition of an exhaust cam adjuster

– Sodium-fi lled exhaust valves for cooling

– Turbo-specifi c intake port (to produce the

required tumble air fl ow in the combustion

chamber)

Cam cover

Upper timing

case cover

Specifi cations

Intake valve diameter

Exhaust valve diameter

Intake valve lift

Exhaust valve lift

Intake camshaft adjustment range crank angle

Exhaust camshaft adjustment range crank angle

Cylinder head

Cylinder head gasket

451_006

1.33 in (33.85 mm)

1.10 in (28 mm)

0.42 in (10.7 mm)

0.39 in (10 mm)

42°

42°

18

Page 23

Chain Drive

The camshaft gears are located on the

transmission side of the engine. The drive

system is a two-stage arrangement using two

different chain types.

In the fi rst stage of the chain drive, the oil

pump and primary drive gear are driven by the

crankshaft. Attached to the primary drive gear

is the idler gear, which serves two purposes. It

drives both camshafts via the second chain, and

also provides a drive lug for operation of the

external vacuum pump.

A 3/8” gear chain is used in the primary drive

train to drive the oil pump and idler gear. It is

similar in design to the chain in the 2.0L R4 TFSI

engine and offers acoustic advantages over a

roller chain. A 3/8” roller chain is used in the

secondary drive.

The entire chain drive is lubricated by the oil

returning from both camshaft adjusters and by

a bore in the high pressure chamber of the chain

tensioner in the secondary drive. There is no

replacement interval for the chain drive.

Chain tensioner

Exhaust camshaft

adjuster

Intake camshaft

adjuster

Idler gear with lug for

driving vacuum pump

Primary

drive chain

Oil pump

sprocket

451_030

Tensioning rail

Secondary

drive chain

Tensioning rail

!

Note

Always replace timing case cover seals after performing work on the chain drive.

Refer to current technical literature for specifi cations.

19

Page 24

Oil Supply

High longitudinal and transverse acceleration

forces are to be expected when driving a

sport vehicle of this type. Because of this, the

engine lubrication system has been designed

to function reliably even in extreme driving

conditions.

The initial oil fi ll capacity of approximately 7.3 qt

(7.0 liter) is relatively high. In addition, the oil

pump intake is designed and installed to protect

against air induction under high longitudinal and

transverse acceleration forces.

Exhaust Camshaft

Adjustment Valve 1 N318

Oil Circulation System

A self-regulating oil pump circulates unfi ltered

oil from the oil pan through the oil fi lter module

and then through the oil cooler. The fi ltered oil

fl ows through passages to the lubrication points.

The oil cooler and fi lter are housed in a single

module mounted to the cylinder block. Oil check

valves for the cylinder block and cylinder head,

as well as an oil cooler bypass valve, are also

integrated into the module.

Camshaft Adjustment

Valve 1 N205

Filtered oil

Unfi ltered oil

Oil cooler

Turbocharger

Main oil

passage

Oil spray

jets

Bypass

Oil pump

451_032

Oil fi lter

module

Reference

For more details about the self-regulating engine pump, refer to Self-Study Program 922903,

The 2.0L 4V TFSI Engine with AVS.

20

Page 25

Crankcase Ventilation

The crankcase ventilation system of the 2.5L

TFSI engine is referred to as a “head ventilation”

system.

Single stage pressure

regulating valve

Fine oil

separator

Blow-by gases from the crankcase are directed

through riser channels integrated into the

cylinder block. The riser channels are protectively

located in the bearing saddle of main bearings

two, three, and four. The blow-by gases are

drawn into the camshaft cover through the

cylinder head, and are pre-cleaned as they pass

through the riser channels.

Oil return

Non-return

(check) valve

!

Blow-by gas

riser channels

Note

This sectional view does not show the positive crankcase ventilation (PCV) valve or the second

non-return (check) valve.

451_031

21

Page 26

The gas and oil spray mixture (blow-by) entering

the camshaft cover, fi rst fl ows into a relatively

large hollow chamber where oil droplets deposit

on the walls. The gas then fl ows to the fi ne oil

separator.

The fi ne oil separator consists of four

permanently open cyclone chambers and six

packets of up to nine cyclone chambers each

that can be activated or deactivated depending

on the blow-by gas fl ow rate.

Flow rate is dependent on engine speed, with

the cyclone chambers activated and deactivated

by locking springs with different spring

characteristics.

The separated oil from the camshaft cover and

fi ne oil separator is continuously recirculated to

the oil pan via return passages in the cylinder

head and cylinder block. Returned oil enters the

oil pan below the engine oil level.

In the extreme event of icing or malfunction,

the positive crankcase ventilation (PCV) valve in

the camshaft cover prevents high pressure from

damaging the engine. To avoid drawing oil from

the oil pan into the air intake system, a second

non-return (check) valve installed in the upper

part of the oil pan closes.

Cleaned blow-by gases are directed through a

single stage pressure regulating valve.

Depending on pressure in the intake manifold,

the gases fl ow through a non-return (check)

valve into the intake manifold downstream of the

throttle valve or upstream of the turbocharger

turbine.

A single stage pressure regulating valve is

integrated into the camshaft cover. The nonreturn (check) valves to the intake manifold or

turbocharger side are optimized for pressure

differential. Together with the pressure

regulating valve, they produce the partial

vacuum in the crankcase.

Locking springs with

different spring rates

Fine Oil Separator

Cleaned

blow-by gas

Separated oil

Cyclone

chamber

451_035

Blow-by

gas inlet

Cyclone chamber packets

(9 chambers per pack)

22

Permanently open

swirl chambers

Page 27

The positive crankcase ventilation (PCV) system

is used to purge the crankcase with fresh air at

part throttle. The system helps to separate fuel

and water that collects in the engine oil during

the combustion process.

If fuel and water are allowed to remain in

the oil pan, they can ice up at low ambient

temperatures, damaging the crankcase

ventilation system and engine. By admitting

air gathered downstream of the air fi lter, the

fuel and water are channeled out through the

camshaft cover.

Dry fresh air fl ows through the chain shaft and

into the crankcase, absorbing moisture and fuel

along the way. This helps prolong the useful life

of the lubricating oil.

The fresh air for crankcase ventilation is

extracted from the positive crankcase ventilation

line running to the exhaust turbocharger.

The PCV valve, which is integrated in the

camshaft cover, has the following tasks:

If a slight partial vacuum is present in the

crankcase during normal operation, it opens to

vent the crankcase. Fresh air fl ows from the line

downstream of the air fi lter and into the engine.

If a pressure of over 1.45 psi (100 mbar) develops

in the engine, excess pressure is relieved into

the line. This protects the crankcase seals.

A fault in the system or improper installation

of components are diagnosed by the ECM.

This is indicated to the driver via the MIL in the

instrument cluster.

Legend

A Throttle valve

B Camshaft

C Fine oil separator

D Pressure regulating valve

E Ladder frame

F PCV valve

G Diagnosis channel (closed)

H Turbocharger

I Intake manifold

J Cylinder head

K Cylinder block

L Extraction point in cylinder block

M Windage tray in upper oil pan

N Oil return line below oil level

O Oil pan

P Non-return (check) valves

!

451_040

Note

All components required for cleaning and ventilation are integrated in the cam cover. If one of these

components fails, the complete cam cover must be replaced.

23

Page 28

Cooling System

The cooling design is based on longitudinal

fl ow through cylinders 1 to 5. The coolant pump

is driven by a poly-vee belt and is designed to

control high thermal load, on the turbo engine.

To prevent the turbocharger from overheating

when the engine stops, the cooling system

is equipped with After-Run Coolant Pump

V51. When required, it is activated by ECM via

Auxiliary Engine Coolant Pump Relay J496.

451_007

Legend

A Breather pipe

B Expansion tank

C Heater heat exchanger

D Bleeder

E Exhaust turbocharger

F Coolant pump

G Coolant thermostat

24

H Engine oil cooler

I Engine Coolant Temperature Sensor G62

J Non-return (check) valve

K After-Run Coolant Pump V51

L Cooling Circuit Solenoid Valve N492

M Auxiliary cooler

N Cooler

Page 29

Air Supply

Fresh Air Intake

When designing the intake path, the primary

focus was on creating high effi ciency and

capacity.

air bypass line

Turbocharger intake line

with wastegate line

Turbocharger

Recirculating

The cross sections were optimally adapted to

available space, with air fl ow confi gured to be as

direct as possible.

Manifold Absolute Pressure Sensor G71

Intake Air Temperature Sensor G42

Air fi lter with

pulsation dampener

Cold air intake including

water separator

Intake manifold with

tumble fl ap system

Charge Air Pressure Sensor G31

Intake Air Temperature Sensor 2 G299

Throttle Valve Control

Module J338

Pressure tube upstream

of intercooler

Intercooler

The greatest pressure losses in a turbocharger

system occur at the intercooler.

The position of the intercooler at the lower front

of the vehicle allows maximum exposure to the

cooling air mass fl ow. This allows the fi ns of the

intercooler to be confi gured so that pressure

loss is reduced.

The total pressure loss along the air fl ow path

from the turbocharger outlet is only 1.9 psi

(135 mbar) at maximum fl ow.

451_034

Intercooler with

plastic shroud

451_069

25

Page 30

Intake Manifold with Flaps

The intake manifold is a two-part sand casting

comprised of the intake plenum and intake arm

gallery. A pneumatically actuated system of fl aps

is integrated in the intake gallery. Together with

the tumble intake port, this system produces

the turbulence necessary for optimum mixture

formation.

Intake manifold fl aps

Positive crankcase

ventilation system intake

Manifold Absolute Pressure Sensor G71

Intake Air Temperature Sensor G42

Air recirculation

channel

The fl ap position requested by the ECM is

measured by Intake Manifold Runner Position

Sensor G336. The ECM monitors this position.

When Intake Manifold Runner Control Valve N316

is not activated, the intake manifold fl aps are

completely closed.

Intake manifold,

upper part

Intake manifold,

lower part

Vacuum motor

Intake Manifold Runner

Position Sensor G336

Turbocharger

Recirculation Valve N249

Fuel rail

Injector

(six-hole)

Intake

manifold fl ap

451_038

Actuation of the intake

manifold fl ap shaft

26

Page 31

Exhaust System Overview

The exhaust system has the following

components:

– Turbocharger module

– Close-coupled pre-catalytic converter

– Twin-fl ow down pipes with isolating elements

– Two catalytic converters

– Two center muffl ers

– One rear muffl er with twin tailpipes

The exhaust turbocharger module is a derivative

of the four-cylinder TFSI engine. The illustration

below shows the separate connection between

the exhaust turbocharger and cylinder no. 3.

Compressor

intake manifold

!

Exhaust Gas Temperature

Sensor 1 G235

Separate cylinder connection

from exhaust turbocharger

Note

For the latest turbocharger mounting system, please refer to current technical literature.

451_036

27

Page 32

Turbocharger

The exhaust turbocharger, a type K16

turbocharger by Borg Warner Turbo Systems,

is notable for its high effi ciency over a wide

operating range.

It is large, with a compressor wheel that is

2.51 in (64 mm) in diameter at the outlet end.

At full throttle it can compress 10.24 cu ft

(7.0 liters) of air per second, producing relative

charge pressures of up to 17.4 psi (1.2 bar).

Heated Oxygen

Sensor G39

The exhaust turbocharger housing has a

separate oil supply, and is integrated with

the engine cooling circuit. When the engine

is switched OFF, After-Run Coolant Pump V51

dissipates the accumulated heat.

A sensor assisted exhaust gas temperature

regulation system ensures that a maximum

permissible exhaust gas temperature of 1796°F

(980°C) is not exceeded during operation.

To accomplish this, Exhaust Gas Temperature

Sensor G235 measures exhaust gas temperature

just before the turbine wheel.

Wastegate actuator

vacuum motor

Turbocharger Recirculation Valve N249

N249 is not located directly at the turbocharger

outlet. It is attached to the throttle valve body

upstream of the throttle valve.

The advantage of this design is that airfl ow is

not disturbed along the relatively long path to

the intake manifold via the intercooler. Turbine

speed losses are therefore minimized, which

results in the turbocharger therefore responding

very quickly after N249 is closed.

28

Wastegate Bypass

Regulator Valve N75

451_064

When N249 is opened, air is admitted into the

intake side of the turbocharger downstream

from the air fi lter via the air bypass.

Page 33

Exhaust System Components

To ensure compliance with LEV II exhaust

emission standards, it was necessary to position

the pre-catalytic converter as close as possible

to the turbocharger outlet, which is made of

ceramic material.

An oxygen sensor is integrated directly into

the turbocharger module at the outlet. Another

oxygen sensor is located directly downstream of

the pre-catalytic converter, and is non-linear.

Pre-catalyst

Isolating elements

Catalytic converters

Two additional catalytic converters are mounted

further downstream of the exhaust system.

A developmental goal for the dual fl ow

exhaust system was to minimize exhaust gas

backpressure, which resulted in large diameter

pipes being used.

Rear muffl er

Exhaust Flap

The left tailpipe has an exhaust fl ap. When this

fl ap is opened, the engine note becomes more

sporty. The fl ap is opened and closed by Exhaust

Door Valve 1 N321, which is characteristic mapcontrolled by the ECM.

If N321 fails, or there is a leak in the vacuum line

to the valve, the exhaust fl ap will stay open.

Center muffl er

451_071

451_052

Tailpipe

trims

29

Page 34

Belt Drive

Due to space limitations, the drive system for the

A/C compressor, alternator, and engine coolant

pump is a two-stage design.

A belt from the torsional vibration damper on the

crankshaft drives the A/C compressor, which has

twin belt pulleys.

Coolant pump

(track 2)

Crankshaft pulley

(track 1)

A second belt, driven by the A/C compressor,

drives the alternator, tensioner, and the engine

coolant pump.

Both belt tensioners are friction-damped. The

complete belt drive is designed for lifetime

operation.

Alternator

(track 2)

451_033

AC compressor

(tracks 1 and 2)

Alternator

(track 2)

Track 2

Track 1

AC compressor

(tracks 1 and 2)

451_065

30

Page 35

Fuel System

The TT RS fuel system is demand-controlled

on the high and low pressure sides. On the low

pressure side, the ECM regulates Fuel Pump

Control Module J538 and the delivery rate of the

fuel pump in the tank.

On the high pressure side, the ECM regulates

Fuel Metering Valve 290 directly at the highpressure pump. To monitor pressure levels in

the system, two fuel pressure sensors send their

respective signals to the ECM.

High-pressure

fuel pump

Low Fuel Pressure

Sensor G410

Fuel Metering

Valve N290

The central element of the fuel system is a

demand-controlled single-piston high-pressure

pump. This Generation III fuel pump by Hitachi

is driven by a three-lobe cam seated on the

exhaust camshaft.

The system operates at a maximum pressure of

1740.4 psi (120 bar). A pressure limiting valve in

the pump opens at a pressure of approximately

2103.0 psi (145 bar).

Fuel Pressure

Sensor G247

Fuel fi lter

To ECM

Fuel injectors 1–5

(N30–33 and N83)

Battery

positive

Fuel Pump Control

Module J538

Fuel Pump G6

451_003

!

Warning

Be very careful when working on the fuel system. It operates a extremely high pressures. To open the high

pressure side, always follow the instructions given in current technical literature.

31

Page 36

System Overview

Sensors

Charge Air Pressure Sensor G31

Intake Air Temperature Sensor 2 G299

Manifold Absolute Pressure Sensor G71

Intake Air Temperature Sensor G42

Engine Speed Sensor G28

Throttle Valve Control Module J338

EPC Throttle Drive Angle Sensor 1 G187

EPC Throttle Drive Angle Sensor 2 G188

Camshaft Position Sensor G40 (Intake)

Camshaft Position Sensor 3 (Exhaust)

Accelerator Pedal Position Sensor G79

Accelerator Pedal Position Sensor 2 G185

Clutch Position Sensor G476

Powertrain CAN data bus

Brake Light Switch F

Brake Pedal Switch F47

Sport Program Button E541

Fuel Pressure Sensor G247

Low Fuel Pressure Sensor G410

Knock Sensor 1 G61

Knock Sensor 2 G66

Oil Pressure Switch F22

Engine Coolant Temperature Sensor G62

Intake Manifold Runner Position

Sensor G336

Engine Control

Module J623

Data Link

Connector

Heated Oxygen Sensor G39

Oxygen Sensor After Three Way

Catalytic Converter G130

Exhaust Gas Temperature Sensor 1 G235

Auxiliary signals:

– J393 Door Contact Signal

32

– E45 Cruise Control System (ON/OFF)

Page 37

Actuators

Fuel Pump Control Module J538

Transfer Fuel Pump G6

Injectors for Cylinders 1–5

(N30–33 and N83)

Ignition Coils for Cylinders 1–5

(N70, N127, N291, N292, N323)

Throttle Valve Control Module J338

EPC Throttle Drive G186

Intake Manifold Runner Control

Valve N316

Engine Component Power Supply

Relay J757

Motronic Engine Control Module

Power Supply Relay J271

Wastegate Bypass Regulator Valve N75

EVAP Canister Purge Regulator Valve 1

Turbocharger Recirculation Valve N249

Fuel Metering Valve N290

Exhaust Door Valve 1 N321

Camshaft Adjustment Valve 1 N205

Exhaust Camshaft Adjustment Valve

1 N318

Coolant Circuit Solenoid Valve N492

Coolant Fan Control Module J293

Coolant Fan V7

Coolant Fan 2 V177

451_004

Oxygen Sensor Heaters Z19, Z29

Auxiliary Engine Coolant Pump

Relay J496

After-Run Coolant Pump Relay V51

33

Page 38

Engine Management

The Bosch MED 9.1.2 engine management

system calculates engine load from the

values of Manifold Absolute Pressure Sensor

G71 and Engine Speed Sensor G28. To meet

LEV II emission standards, the following

subassemblies, in combination with special

injection and catalytic converter heating

strategies, are used:

– Intake manifold with intake manifold fl aps

– Multi-port fuel injection and fl at pistons

– Close-coupled pre-catalytic converter

A secondary air injection system was not

needed.

Combustion Process

By optimizing spray parameters in combination

with a fl at piston crown shape, it was possible

to improve mixture formation compared to

the 2.0L TFSI engine, despite the approximate

25% increase in fl ow rate of the high-pressure

injectors.

Operating Modes

The following operating modes are possible:

– High pressure stratifi ed charging starting at

an ambient temperature of –14.8°F (–14.8°C)

– Catalytic converter heating and quicker engine

warm-up through double injection

– Camshaft timing and exhaust camshaft

duration adaptation to create high cylinder

scavenging rates, minimizing the amount of

residual gas in the cylinders when the engine

is warm and running at low rpm

– Matching of intake and exhaust pressures in

the upper rpm band to optimize fl ow rates and

minimize pressure losses

Flat-crown piston

451_053

Optimized tumble

intake port

Spray-optimized, six-hole,

high pressure injection

34

Page 39

Engine Load Sensing

Engine load is calculated from engine speed and

air mass values. Because no mass airfl ow sensor

is used, two identical combined temperature/

pressure sensors are used:

– Charge Air Pressure Sensor G31, Intake Air

Temperature Sensor 2 G299

– Manifold Absolute Pressure Sensor G71, Intake

Air Temperature Sensor G42

Two sensors are used because very different

pressures can exist simultaneously on either

side of the throttle valve assembly.

Also, the cast aluminum intake accumulates heat

and could potentially falsify the temperature

signal by temperature sensors G71/G42. The

temperature signal generated by G31/G299

upstream of the throttle valve is the most

reliable measurement.

Intake manifold

Throttle Valve Control

Module J338

Second Sensor

451_078

Charge Pressure Sensor G31,

Intake Air Temperature

Sensor 2 G299

First Sensor

Designation: Charge Pressure Sensor G31/Intake

Air Temperature Sensor G299

Task: Measurement of pressure and temperature

upstream of the throttle valve

This sensor is the boost pressure sensor and is

used to control boost pressure. Its signal is not

actually required at full open throttle because

boost pressure will be the same as pressure in

the intake manifold. However, in order to achieve

a better response, boost control (measured by

this sensor) becomes active even before the

throttle valve fully opens.

If the sensor fails, the charge pressure control

system will go into limp-home mode. This means

the engine will run as a normally aspirated

engine, with the MIL lighting up, and a DTC

stored in the ECM.

Intake Air Temperature

Sensor G42

Designation: Manifold Absolute Pressure Sensor

G71, Intake Air Temperature Sensor G42

Task: Measurement of pressure and temperature

in the intake manifold

This is referred to as the main charge sensor and

replaces the hot-fi lm air mass sensor. The air

mass fl owing through the engine is calculated at

all operating points of the engine from signals

generated by this sensor. The requisite amount

of fuel is then injected.

If this sensor fails, the engine will go into limphome mode, with engine power output reduced.

Air mass is then calculated in “alpha n mode,”

which is based on the throttle valve angle and

engine speed only. The MIL will light up and a

DTC will be stored in the ECM.

451_077

35

Page 40

Sport Mode

The following functions can be activated with

the Sport button:

– Direct accelerator response. A different

characteristic curve is selected by the engine

control module

– Modifi cation of exhaust system

characteristics. Vacuum motor for the exhaust

fl ap door is actuated by Exhaust Door Valve 1

– Sport driving mode of Audi magnetic ride is

activated

– Sport program indicator lamp K91 illuminates

Automatic Transmission Sport

Mode Indicator Lamp K91

451_045

Legend

E461 Front Center Console Control Head

E541 Sport Program Button

G76 Left Rear Level Control System Sensor

G77 Right Rear Level Control System Sensor

G78 Left Front Level Control System Sensor

G79 Accelerator Pedal Position Sensor

G185 Accelerator Pedal Position Sensor 2

G289 Right Front Level Control System Sensor

J250 Electronic Damping Control Module

36

J623 Electronic Control Module

K91 Automatic transmission Sport Mode Indicator Lamp

L156 Switch Illumination Bulb

N321 Exhaust Door Valve 1

N336 Left Front Damping Adjustment Valve

N337 Right Front Damping Adjustment Valve

N338 Left Rear Damping Adjustment Valve

N339 Right Rear Damping Adjustment Valve

S Fuses

Page 41

Manual Transmission 0A6

Manual Transmission 0A6 with all-wheel drive

Ratio including front axle drive i

Ratio spread

Front axle drive ratio

Weight with oil fi ll

Six-speed manual transmission 06A can handle up to 368.7 lb ft (500 Nm) of torque.

total

1st gear

2nd gear

3rd gear

4th gear

5th gear

6th gear

Reverse gear

1st – 6th gear

Output shaft – 1st/2nd gear

Output shaft – 3rd – 6th gear

Output shaft – reverse gear

13.45

8.12

5.51

4.16

3.36

2.83

14.41

4.75

64 : 17 = 3.765

64 : 22 = 2.09

64 : 20 = 3.200

187.3 lb (85 kg)

37

Page 42

Notes

38

Page 43

Drive Concept

The TT RS has the quattro permanent all-wheel

drive system as standard equipment. No frontwheel drive version is offered.

Running Gear

06A six-speed

transmission

Front axle

differential

Engine

Bevel gear

Prop shaft

Rear axle

differential

Generation IV all-

wheel drive clutch

Rear axle drive

451_001

39

Page 44

Generation IV All-Wheel Drive Clutch

The TT RS powertrain uses the Generation IV allwheel drive clutch. Power is transmitted via the

clutch plate set in the same way as the previous

Haldex generations. The major difference is that

clutch hydraulic pressure build-up is performed

by an electric pump on the Generation IV system.

All Wheel Drive Control Module J492 determines

torque to be transferred by controlling Haldex

Clutch Control Valve N373. Speed differences

between the front and rear axle are no longer

required to activate the all-wheel drive coupling.

Rear axle differential

drive pinion

Thanks to a high performance pressure

reservoir, all of this happens within a matter of

milliseconds.

To optimize TT RS axle load distribution, the

Generation IV clutch is mounted in front of the

rear axle differential.

Crown gear

All-wheel drive clutch

plate assembly

Drive shaft

All Wheel Drive

Control Module J492

All-wheel drive

clutch oil reservoir

451_063

Rear axle

differential

40

Page 45

451_048

Front Axle

The front suspension system, with a track width

of 61.06 in (1551 mm) is a MacPherson-type

design with triangular lower wishbones. The

pivot bearings, subframe, and wishbones are

made from aluminum. To increase rigidity, the

subframe is bolted to the body at six points.

Steering

The electromechanical power rack-and-pinion

steering system comes with variable servo

assistance. Its characteristics have been adapted

to the dynamic qualities of the TT RS.

Rear Axle

The four-link rear axle, with a track width of

60.8 in (1546 mm), is capable of absorbing

longitudinal and lateral forces separately thanks

to its sophisticated design.

The longitudinal links absorb the driveline and

braking forces, while the relatively soft mounts

permit excellent ride comfort.

The three links per wheel — the spring link, the

upper wishbone, and tie rod — are attached

rigidly to the subframe to enhance handling

dynamics.

The elastokinematic behavior of the high

strength steel control arms has been modifi ed

compared to non-RS TT models. Separate coil

springs and newly developed dampers provide

vertical support.

The body of the TT RS has also been lowered

0.39 in (10 mm) compared to non-RS TT models.

41

Page 46

Audi Magnetic Ride

Audi magnetic ride is offered as standard

equipment on the 2012 TT RS.

Function

Circulating inside its damper pistons is a

synthetic hydrocarbon fl uid containing minute

magnetic particles between three and 10

micrometers in size. When voltage is applied to

a coil, a magnetic fi eld is created in which the

orientation of particles changes.

Magneto-rheological fl uid

in a non-magnetized state

Magnetic particles

Piston orifi ces

These magnetic particles cluster transversely

to the direction of fl ow of fl uid, thus inhibiting

fl ow through the piston channels. This alters

the damping characteristic within a matter of

milliseconds.

Magneto-rheological fl uid

in a magnetized state

Magnetic fi eld

451_050

Magnetic coil not activated Magnetic coil activated

Operation

The system’s control module constantly

monitors the driver’s style and condition of the

road, adjusting its response accordingly. The

driver can change between Normal and Sport

modes at the touch of a button. In Normal mode,

when the fl uid has high viscosity, the suspension

of the Audi TT RS offers a well-balanced,

comfortable ride.

Reference

For further information about the Audi Magnetic Ride system, refer to Self-Study Program 993703,

The 2008 Audi TT Running Gear.

42

451_049

In Sport mode, when fl ow is inhibited, the

suspension is uncompromisingly fi rm, so the

car hugs the road with minimal body roll. The

specifi c stabilization of each wheel offers more

neutral self-steering behavior, resulting in a

more precise steering response.

Page 47

Brake System

All four wheels feature ventilated disc brakes.

The front brake discs are 14.5 in (370 mm) while

the rear discs are 12.2 in (310 mm). The front disc

friction surfaces are cross-drilled to promote

maximum heat dissipation.

Aluminum hub

Ventilated and

drilled brake discs

Electronic Stabilization Program

(ESP)

All four calipers are manufactured from

aluminum to reduce unsprung weight. The front

calipers are painted black and sport the RS logo.

Front Brake

Four-piston

brake caliper

451_047

The Electronic Stabilization Program is optimized

for dynamic driving but can be deactivated in

two stages using ASR/ESP Button E256 in the

center console.

First Stage (Sport Mode)

In the fi rst stage (Sport mode), traction control

is disabled and the brakes intervene somewhat

later than in normal operation. To select, push

the ESP OFF button briefl y. The ESP warning

light in the instrument cluster comes ON and

ESP Sport is displayed in the Driver Information

System. Driving stability is limited in Sport

mode.

Second Stage (complete shut down)

In the second stage, ESP is completely

deactivated. To select, push the ESP OFF button

for longer than three seconds. The ESP warning

lamp comes ON and ESP OFF is displayed in

the Driver Information System. When ESP is

deactivated, traction control is also deactivated.

451_046

TCS/ESP button

!

Note

ESP Sport mode should only be activated for agile handling and sporty driving if road,

weather, visibility, and traffi c conditions permit.

43

Page 48

Service

New Special Tools for the TT RS

T03000 Engine support

451_054

For removing and installing the engine in combination with

the engine and transmission support V.A.G. 1383 A

T03001 Engine support

451_055

For mounting the engine on the engine and transmission

support VAS 6095 or support clamp VW313

T03003 Wrench

T03004 Assembly sleeve

451_057

For setting the crankshaft to TDC

44

451_056

For replacing the crankshaft sealing fl ange on the belt pulley

side

Page 49

T03005 A Oil pump clamp

T03006 Locking pin

451_059

451_058

Oil pump clamp

T40057 Oil drain adapter

For draining engine oil out of the oil fi lter module

Chain tensioner clamp

T40226 Gauge

451_060

451_061

For transmission mounting

45

Page 50

Self-Study Programs for the Audi TT

SSP 991703 The 2008 Audi TT

Introduction

– Body

– Occupant Protection

– Engine

– Suspension System

– Electrical System

– Climate Control

– Infotainment

SSP 992703 The 2008 Audi TT

Electrical and Infotainment Systems

– Control Module Locations

– Topology and Networking

– Electrical and Comfort System Electronics

SSP 993703 The 2008 Audi TT

Running Gear

Service Training

The 2008 Audi TT

Vehicle Introduction

Self-Study Program 991703

Service Training

The 2008 Audi TT

Electrical and Infotainment Systems

Self-Study Program 992703

Service Training

– Axles

– Brake System

– Steering System

– Audi Magnetic Ride

– Other Features

SSP 994703 The 2008 Audi TT

Body

– Audi Space Frame (ASF)

– Joining Techniques and Production Processes

– Vehicle Safety Concept

– Dimensions

The 2008 Audi TT

Running Gear

Self-Study Program 993703

Service Training

The 2008 Audi TT Body

Self-Study Program 994703

46

Page 51

Knowledge Assessment

An on-line Knowledge Assessment (exam) is available for this Self-Study Program.

The Knowledge Assessment is required for Certifi cation.

You can fi nd this Knowledge Assessment at:

www.accessaudi.com

From the accessaudi.com Homepage:

– Click on the “ACADEMY” tab

– Click on the “Academy Site” link

– Click on the “CRC/Certifi cation” link

– Click on Course Catalog and select “990713 — Audi TT RS with the 2.5l TFSI Engine”

For assistance please call:

Audi Academy

Certifi cation Resource Center (CRC)

1-877-283-4562

(8:00 a.m. to 8:00 p.m. EST)

Or you may send an email to:

audicrchelpdesk@touchstone-group.com

Thank you for reading this Self-Study Program and taking the assessment.

47

Page 52

990713

All rights reserved.

Technical specifi cations subject

to change without notice.

Audi of America, LLC

2200 Ferdinand Porsche Drive

Herndon, VA 20171

Loading...

Loading...