Page 1

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Service

Workshop Manual

Audi TT 1999 ➤

Running gear, self-diagnosis

Edition 07.2004

Service Department. Technical Information

Page 2

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Service

List of Workshop Manual Repair GroupsList of Workshop Manual

Repair GroupsList of Workshop Manual Repair Groups

Re pa ir G ro up

01 - Self-diagnosis, electrical checks

Technical information should always be available to the foremen and mechanics, because their

careful and constant adherence to the instructions is essential to ensure vehicle road-worthiness and

safety. In addition, the normal basic safety precautions for working on motor vehicles must, as a

matter of course, be observed.

All rights reserved.

No reproduction without prior agreement from publisher.

Copyright © 2010 Audi AG, Ingolstadt A0057006120

Page 3

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Running gear, self-diagnosis - Edition 07.2004

Contents

01 - Self-diagnosis, electrical checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1 Self-diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Basic notes on self-diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Function of the individual systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Requirements for test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.5 Fault finding procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.6 Road test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.7 Connecting vehicle diagnostic, testing and information system VAS 5051 A . . . . . . . . . . 7

2 CAN bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Testing a “two-wire data bus system” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 ABS/EDL and ABS/EDL/TCS, ITT Mark 20 without ESP . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1 Electrical/electronic components and fitting locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 Faults displayed by warning lamps in instrument cluster . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.3 Performing self-diagnosis on the ABS/EDL and ABS/EDL/TCS, ITT Mark 20 without ESP

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.4 Interrogating fault memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.5 Fault tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.6 Final control diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.7 Basic setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.8 Erasing fault memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.9 End output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.10 Renewing and coding control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.11 Measured value block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.12 Login procedure or coding II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

3.13 Electrical check of ABS/EDL and ABS/EDL/TCS ITT Mark 20 without ESP . . . . . . . . . . . . 47

3.14 Connecting adapter V.A.G 1598/21 (test box) to ABS with EDL control unit J104 . . . . . . 48

3.15 Test table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4 ABS/EDL/TCS/ESP ITT Mark 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4.1 Retrofit installation of ESP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4.2 Electrical/electronic components and fitting locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4.3 Faults displayed by warning lamps in instrument cluster . . . . . . . . . . . . . . . . . . . . . . . . . . 62

4.4 Performing self-diagnosis of ABS/EDL/TCS/ESP ITT Mark 20 system . . . . . . . . . . . . . . . . 65

4.5 Interrogating fault memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4.6 Fault tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

4.7 Final control diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

4.8 Basic setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

4.9 Performing zero compensation of steering angle sender G85 . . . . . . . . . . . . . . . . . . . . . . 99

4.10 Erasing fault memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

4.11 End output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

4.12 Renewing and coding control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

4.13 Measured value block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

4.14 Login procedure or coding II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

4.15 Electrical check of ABS/EDL/TCS/ESP ITT MARK 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

4.16 Connecting test box V.A.G 1598 A with adapter cable (47-pin) V.A.G 1598/33 to ABS with

EDL control unit J104 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

4.17 Test table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

5 ABS/ESP, MK 60 Continental Teves Mark 60; Electronic Stabilisation Program, Continental

Teves Mark 60 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

5.1 This self-diagnosis system is described exclusively in the “Guided fault finding” . . . . . . . . 133

Contents i

Page 4

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Running gear, self-diagnosis - Edition 07.2004

ii Contents

Page 5

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Running gear, self-diagnosis - Edition 07.2004

01 – Self-diagnosis, electrical checks

1 Self-diagnosis

1.1 Basic notes on self-diagnosis

♦ The control unit of a system with self-diagnosis function de‐

tects any faults or malfunctions during vehicle operation and

stores them in a fault memory. This information will remain

available even if the system voltage fails.

♦ The self-diagnosis function enables faults to be traced quickly

and efficiently. The self-diagnosis functions available can be

implemented via vehicle diagnostic, testing and information

system -VAS 5051 A- or vehicle diagnosis and service infor‐

mation system -VAS 5052- .

Note

Audi TT 1999 ➤

This Workshop Manual describes how to perform self-diagnosis

using vehicle diagnostic, testing and information system VAS 5051 A- .

♦ The respective control unit and the vehicle diagnostic, testing

and information system -VAS 5051 A- must be able to ex‐

change data in order to communicate with each other. The

diagnostic connector is the interface for communication be‐

tween the control unit and vehicle diagnostic, testing and

information system -VAS 5051 A- .

Fault detection by ABS with EDL control unit -J104-

♦ The control unit detects any faults which may occur during ve‐

hicle operation and stores them in a fault memory.

♦ To commence fault finding, initiate self-diagnosis and inter‐

rogate the stored faults. It is necessary to interrogate the fault

memories of all vehicle systems with self-diagnosis capability

since the ABS with EDL control unit -J104- exchanges data

with the engine control unit as well as the steering angle send‐

er -G85- and the four-wheel drive control unit -J492- (if fitted).

Select function “00 - Interrogating fault memory - Complete

system” ⇒ page 7 .If faults are stored in any other systems,

check whether the stored faults affect the ABS/EDL/TCS/ESP

system by referring to the respective fault tables.

♦ After evaluating all received data, the ABS with EDL control

unit -J104- distinguishes between sporadic faults (occurring

intermittently) and static faults (permanently present for a de‐

fined period), and stores these faults in an internal memory.

♦ If a fault occurs, it is initially stored as being static. If the fault

does not reoccur over a certain period of time or while the ve‐

hicle is driven a certain distance, it is then stored as sporadic

fault.

♦ When interrogating the fault memory, sporadic faults are

marked as “sporadic” on the display.

♦ A fault is also stored as sporadic if the ignition is switched off

and on again while the fault memory is being interrogated, or

if the fault memory is not erased after performing repairs.

♦ Sporadic faults are erased automatically if they do not occur

again within the next 50 vehicle starts and driving off sequen‐

ces (road speed greater than 20 km/h).

1. Self-diagnosis 1

Page 6

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Running gear, self-diagnosis - Edition 07.2004

♦ The ABS with EDL control unit -J104- is able to detect whether

any of the required signals are not being transmitted via the

CAN bus.However, defective CAN bus wires (e.g. open circuit)

cannot be detected directly. The defective CAN bus wires can

only be traced after interrogating the fault memories of all con‐

trol units ⇒ page 9 .

♦ Sporadic faults affecting the CAN bus are erased automati‐

cally if they do not occur again within the next 15 vehicle starts

and driving off sequences (vehicle speed greater than 20 km/

h).

1.2 Function of the individual systems

1.2.1 Anti-lock brake system

The anti-lock brake system (ABS) prevents the wheels from lock‐

ing when the brakes are applied by the driver. Directional stability

and steerability are maintained in spite of high braking effect.

1.2.2 EDL - Electronic differential lock

The EDL system assists pulling away; it acts only on the front

wheels, even if the vehicle is equipped with four-wheel drive.An

electronically controlled brake application on the spinning driven

wheel provides a torque reaction point for the differential. This

enables the wheel with better traction to make use of the engine

power. The EDL is effective in both forwards and reverse direc‐

tions. The EDL control process is available up to a road speed of

80 km/h.

1.2.3 EBPD - Electronic brake pressure distri‐

bution

The Audi TT is not fitted with a mechanical brake pressure regu‐

lator. Specially developed software in the ABS with EDL control

unit -J104- provides electronic brake force distribution (EBPD)

and limits the brake pressure applied to the rear wheels.

1.2.4 TCS - Traction control system

♦ TCS (traction control system) is fitted only on vehicles with

front-wheel drive. The TCS limits the engine power to prevent

the driven wheels from spinning under acceleration. The sys‐

tem operates by reducing engine torque and is active at all

speeds. The EDL and TCS functions act together to assist ac‐

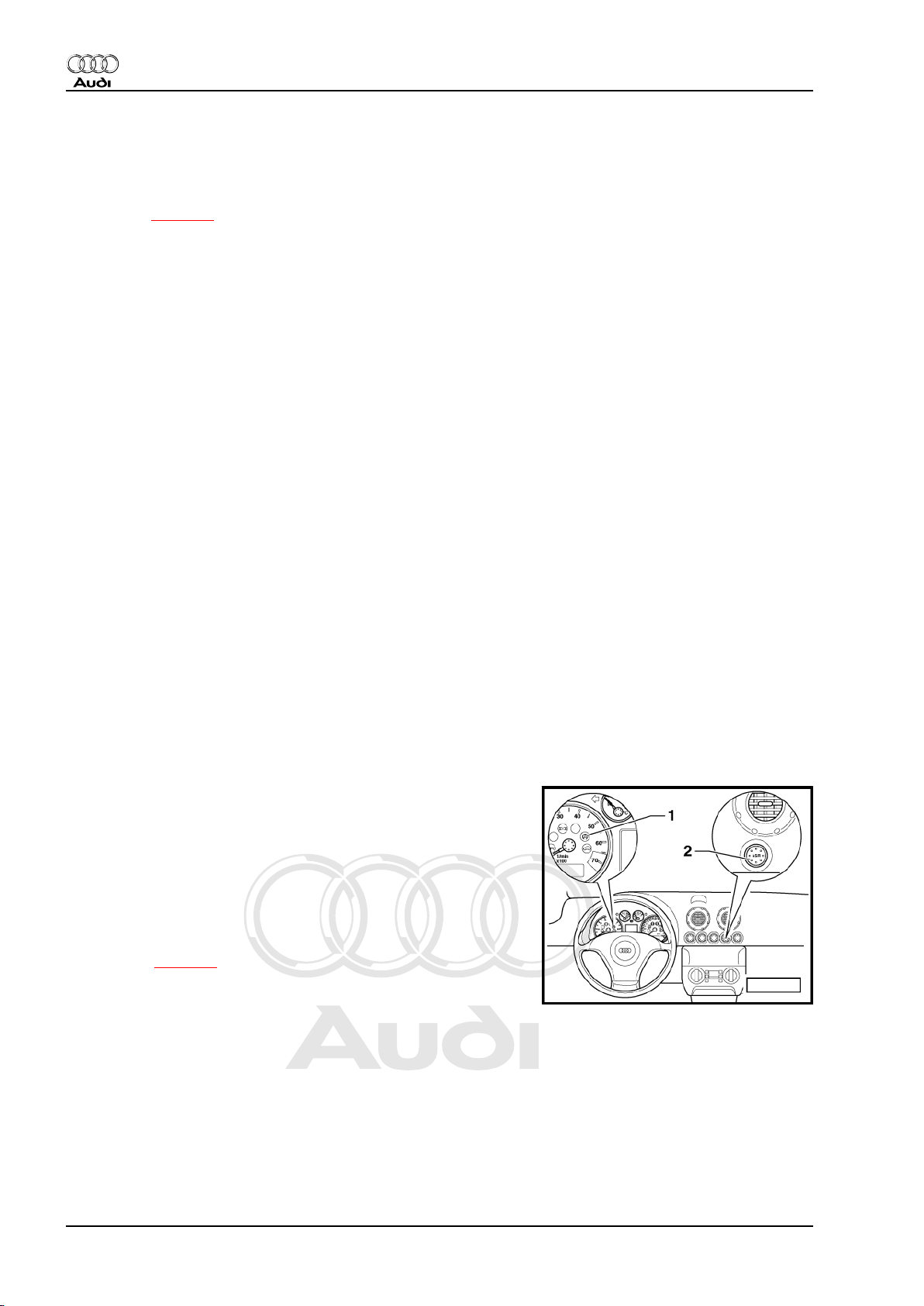

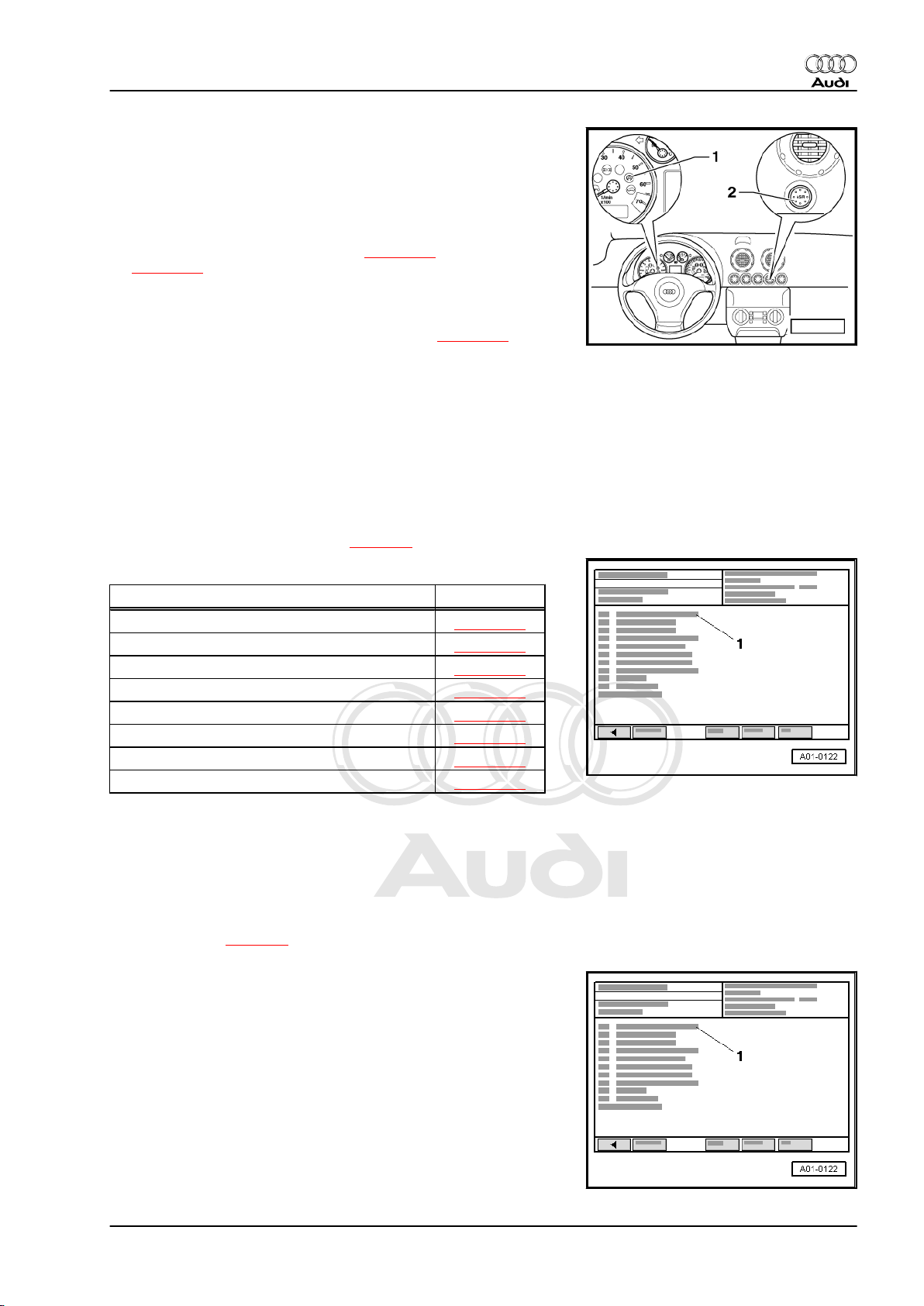

celeration. The warning lamp -1- flashes at a rate of three

times per second when the control function is working.

♦ The TCS requires an exchange of data between ABS with EDL

control unit -J104- and the engine control unit. The control

units communicate with each other. The data is transmitted via

CAN bus ⇒ page 9 .

♦ Depending on the engine version, the TCS also incorporates

an engine braking control (EBC). EBC prevents the driven

wheels from locking up due to excessive engine braking tor‐

que, for instance when the driver changes down from 3rd to

2nd gear. The engine braking effect is reduced via the elec‐

tronic idling stabilisation control.

♦ If required, the TCS function can be switched off (and on

again) by means of the button -2- (marked ASR) in the centre

of the dash panel. The TCS button has no influence on EBC.

The warning lamp lights up when the TCS is switched off. The

TCS is re-activated when the ignition is switched on again.

2 Rep. Gr.01 - Self-diagnosis, electrical checks

Page 7

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Running gear, self-diagnosis - Edition 07.2004

1.2.5 ESP - Electronic Stabilisation Program

The ESP is based on the existing on-board safety systems ABS/

EDL and ABS/EDL/TCS, with a number of additional capabilities.

ESP enhances the degree of control in critical dynamic condi‐

tions. In addition to the existing safety systems, ESP further

reduces the risk of skidding and improves steerability.

Caution

However, ESP is not able to overcome the physical limits of

the available road adhesion.

♦ The ESP is designed to stabilise the dynamic handling re‐

sponse of the vehicle by counteracting any tendency towards

oversteer or understeer. The functions of EBPD, ABS, EDL

and TCS are incorporated in the control system. However, the

characteristic function of the ESP is controlled brake applica‐

tion at individual wheels.

♦ The ESP function relies on an exchange of signals between

ABS with EDL control unit -J104- and the engine control unit,

the steering angle sender -G85- and the four-wheel drive con‐

trol unit -J492- (if fitted). The data is transmitted via CAN bus

⇒ page 9 .

♦ If required, the TCS function and the ESP function can be

switched off (and on again) by means of the button -2- (marked

ASR) in the dash panel. The control unit ignores the position

of the ESP switch when the driver presses the brake pedal.

ESP will remain active at all times during braking. Both func‐

tions, TCS and ESP, will be activated again automatically the

next time the ignition is switched on.

♦ When the TCS and ESP function are deactivated, the ESP and

TCS warning lamp -K155- -item 1- in the instrument cluster

lights up. The warning lamp flashes at a rate of three times per

second when the control function is actually working.

Audi TT 1999 ➤

Examples:

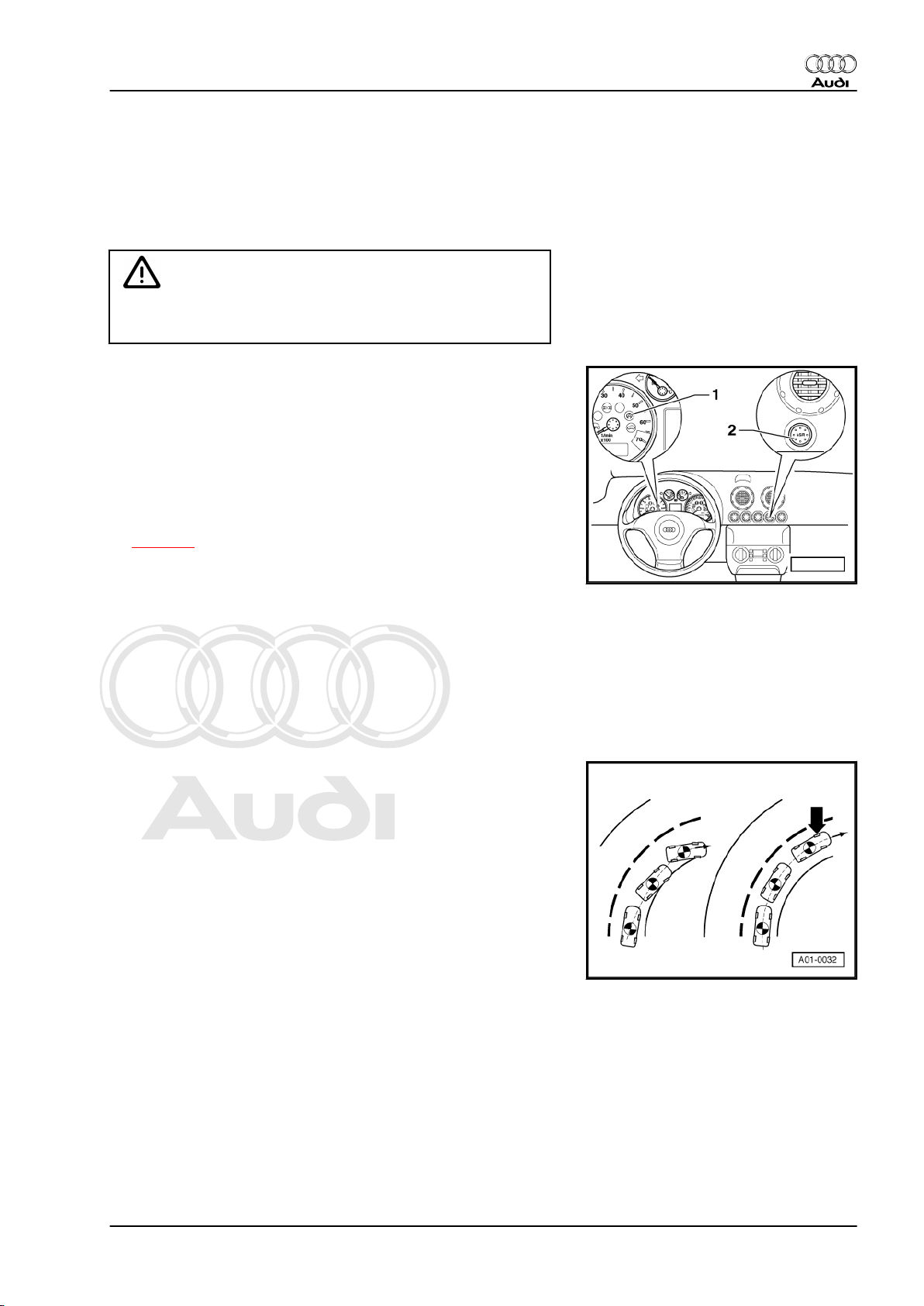

In an oversteer condition, the rear of the vehicle tends to break

away. The vehicle rotates further about its vertical axis than is

required to maintain course through the corner. The system coun‐

teracts this moment of vehicle oversteer by applying a controlled

braking force at the outside front wheel -arrow-.

1. Self-diagnosis 3

Page 8

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Running gear, self-diagnosis - Edition 07.2004

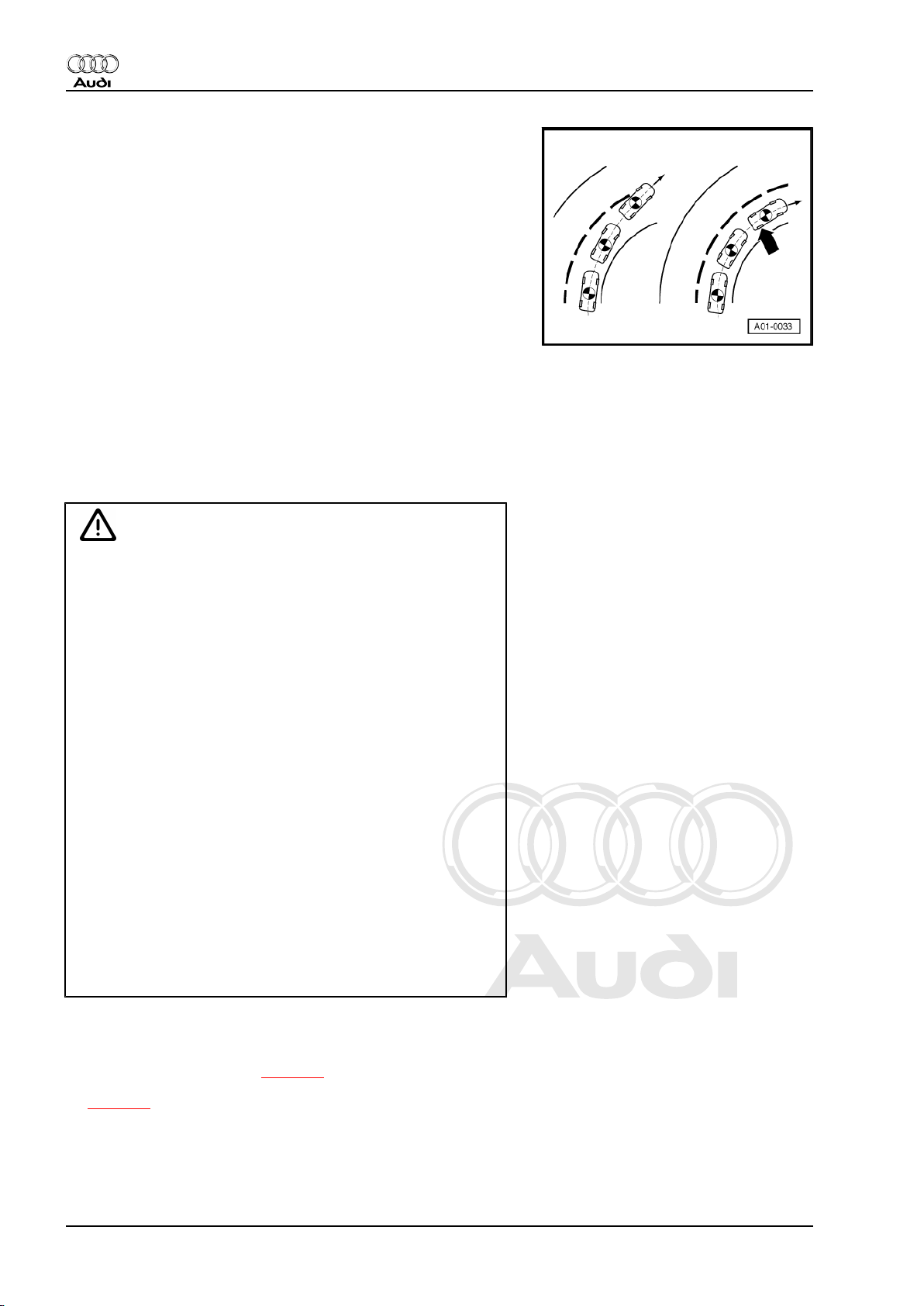

In an understeer condition the front end of the vehicle does not

follow the required corner radius. The vehicle breaks away to‐

wards the outside of the bend. The vehicle does not rotate far

enough about its vertical axis to maintain course through the cor‐

ner. The system increases the amount of rotation by applying a

controlled braking force at the inside rear wheel -arrow-.

1.3 Safety precautions

♦ The ABS/EDL/TCS and ESP are safety systems; knowledge

of the systems is essential for performing repair work

♦ Always switch off the ignition before carrying out installation

or repair work.

♦ Ensure that no brake fluid enters electrical connectors.

WARNING

♦ To avoid any risk of accident, observe the following pre‐

cautions when using test instruments while road testing

the vehicle:

Audi TT Coupé:

♦ Use only vehicle diagnostic, testing and information sys‐

tem -VAS 5051 A- or vehicle diagnosis and service infor‐

mation system -VAS 5052- to read measured value

blocks. The tester must always be secured on the rear

seat and operated from there by a second person.

♦ Due to the limited space, slide the front passenger's seat

forwards as far as it will go and (without pulling the release

lever) incline the backrest as far forwards as possible by

turning the adjuster knob. Do not operate the release lever

to tilt the backrest forward.

Audi TT Roadster:

♦ In the Audi TT Roadster, use only vehicle diagnosis and

service information system -VAS 5052- with the front pas‐

senger's airbag de-activated.

♦ Switch off the front passenger's airbag by means of the

key-operated switch in the glove box or via self-diagnosis

⇒ Body, self-diagnosis; Rep. Gr. 01 .

♦ Reactivate front passenger's airbag after testing is com‐

pleted.

♦ Do not drive the vehicle with the connector unplugged from the

control unit.

♦ During the final road test ⇒ page 6 , ensure that an ABS-

controlled brake application is performed at least once

⇒ page 4 .

1.4 Requirements for test

• When starting the self-diagnosis procedure, the vehicle must

be stationary and the ignition switched on (or engine running).

It is not possible to start self-diagnosis if the wheel speed is

4 Rep. Gr.01 - Self-diagnosis, electrical checks

Page 9

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Running gear, self-diagnosis - Edition 07.2004

above 2.75 km/h. Self-diagnosis will be terminated if road

speed exceeds 20 km/h.

• Power supply OK (min. 10.0 V).

• Fuses OK ⇒ Current flow diagrams, Electrical fault finding and

Fitting locations.

• Connector on ABS with EDL control unit -J104- correctly plug‐

ged-in (retainer is engaged).

• The tyres fitted to all wheels must be of the same (approved)

size; tyres inflated to prescribed pressure.

• Wheel speed sensors must be installed correctly ⇒ Brake

system; Rep. Gr. 45 .

• Mechanical/ hydraulic brake system components (including

brake light switch and brake lights) OK. Hydraulic connections

and pipes not leaking (visual check of hydraulic unit, brake

calipers, wheel cylinders, master brake cylinder).

• Wheel bearings and wheel bearing play OK.

• When testing the ABS/EDL/TCS and ESP systems, ensure

that the vehicle's electrics are not subjected to electromag‐

netic interference: keep the vehicle away from equipment with

a high current draw, such as electric welding units.

Audi TT 1999 ➤

1.5 Fault finding procedure

If a problem exists on the vehicle, perform the fault-finding pro‐

cedure in the following sequence:

– First switch on the ignition and observe the warning lamps.

This will give an initial indication of what to look for (vehicles

without ESP ⇒ page 14 , vehicles with ESP ⇒ page 62 ).

– Observe the test requirements detailed on ⇒ page 4 .

– Connect vehicle diagnostic, testing and information system -

VAS 5051 A- and select vehicle system “03 - Brake electron‐

ics” ⇒ page 7 .

– Check the control unit version ⇒ page 8 .

– Interrogate the fault memory (vehicles without ESP

⇒ page 17 , vehicles with ESP ⇒ page 65 ). If a fault is

present in the memory: print out the content of the fault mem‐

ory and then erase the fault memory.

– Conclude the transfer of data with the function “06 - End out‐

put”.

– Eliminate the fault using the fault tables.

– If a component is indicated as being defective, only renew it if

you are sure that the electrical wiring for that component is in

proper condition. The wiring must be able to transmit the nec‐

essary signals without interference or resistance. Check the

wiring for:

♦ Corrosion and loose contacts in the connectors and earth con‐

nections. If any of the plug contacts are bent, broken or cor‐

roded, use the wiring repair kit -VAS 1978- to fit new contacts.

♦ Open circuit in wiring or short circuit to positive/earth ⇒ Current

flow diagrams, Electrical fault finding and Fitting locations.

– Check that the connectors are plugged in correctly (with re‐

tainers engaged).

– After completing the repair, select vehicle system “03 - Brake

system” for a second time. Interrogate and erase fault mem‐

ory.

1. Self-diagnosis 5

Page 10

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Running gear, self-diagnosis - Edition 07.2004

– Conclude the transfer of data with the function “06 - End out‐

put”.

– Switch off ignition and detach diagnostic connector.

– Perform a road test ⇒ page 6 to check the function of the

system. If any of the warning lamps light up during the road

test, repeat the fault finding procedure.

WARNING

If the connector is not plugged into the ABS with EDL control

unit -J104- when the vehicle is moving, this may result in a

spurious (non-existent) fault being registered in the fault mem‐

ory of another control unit. The function of the brake system

will be impaired. The brake pressure at the rear wheels is no

longer controlled by the electronic brake force distribution func‐

tion. This can result in excessive braking at the rear, and the

tail of the vehicle may break out unexpectedly.

Note

For information on repairing common faults, refer to ⇒ Technical

Service Handbook.

1.6 Road test

Certain faults will only be detected by the self-diagnosis when the

vehicle is moving. Perform a road test to check the function of the

system.

WARNING

♦ To avoid any risk of accident, observe the safety precau‐

tions when using test instruments while road testing the

vehicle ⇒ “1.3 Safety precautions”, page 4 .

♦ If you drive the vehicle after a fault has been detected by

the self-diagnosis bear in mind that there is a risk of acci‐

dent. The function of the brake system will be impaired.

The brake pressure at the rear wheels is no longer con‐

trolled by the electronic brake force distribution function.

This can result in excessive braking at the rear, and the

tail of the vehicle may break out unexpectedly.

♦ The ABS/ESP function is deactivated when using vehicle

diagnostic, testing and information system -VAS 5051 Ain the mode “vehicle self-diagnosis” while road testing the

vehicle. However, this is not indicated by illumination of

the warning lamps. Self-diagnosis of ABS with EDL control

unit -J104- is terminated if a road speed of 20 km/h is ex‐

ceeded.

– Maintain a speed above 60 km/h for a period of 30 seconds.

After ensuring that it is safe to do so, apply the brakes hard

enough to activate ABS-controlled braking. This can be felt

from the pulsation at the brake pedal.

1.6.1 Special feature for four-wheel drive ve‐

hicles with Haldex coupling

♦ The longitudinal acceleration sender -G251- must be deacti‐

vated when testing the brake system on test rollers (vehicles

without ESP ⇒ page 35 , vehicles with ESP ⇒ page 90 ).

6 Rep. Gr.01 - Self-diagnosis, electrical checks

Page 11

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Running gear, self-diagnosis - Edition 07.2004

♦ After completion of the check, the longitudinal acceleration

sender -G251- must be reactivated by switching the ignition

off and back on again.

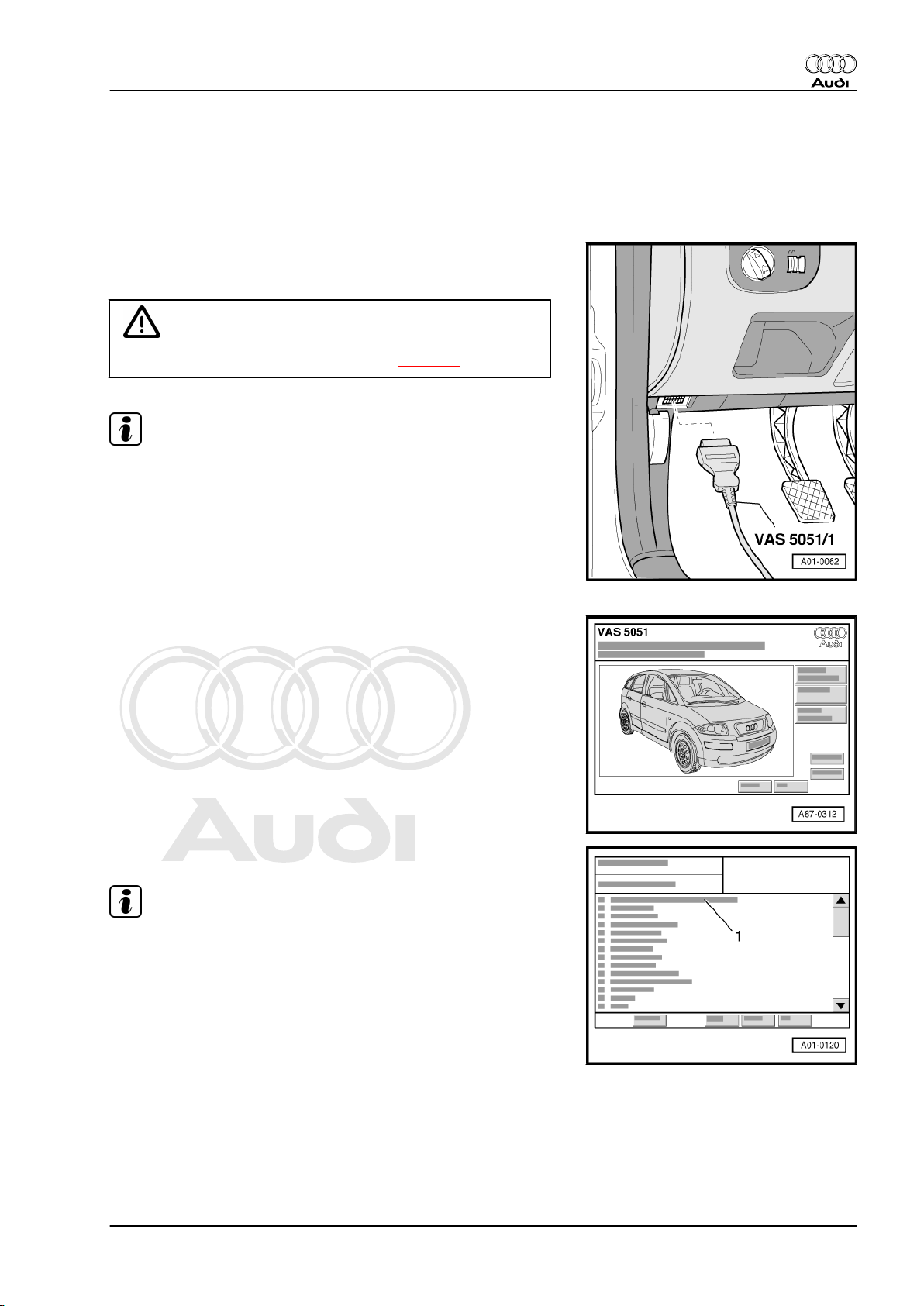

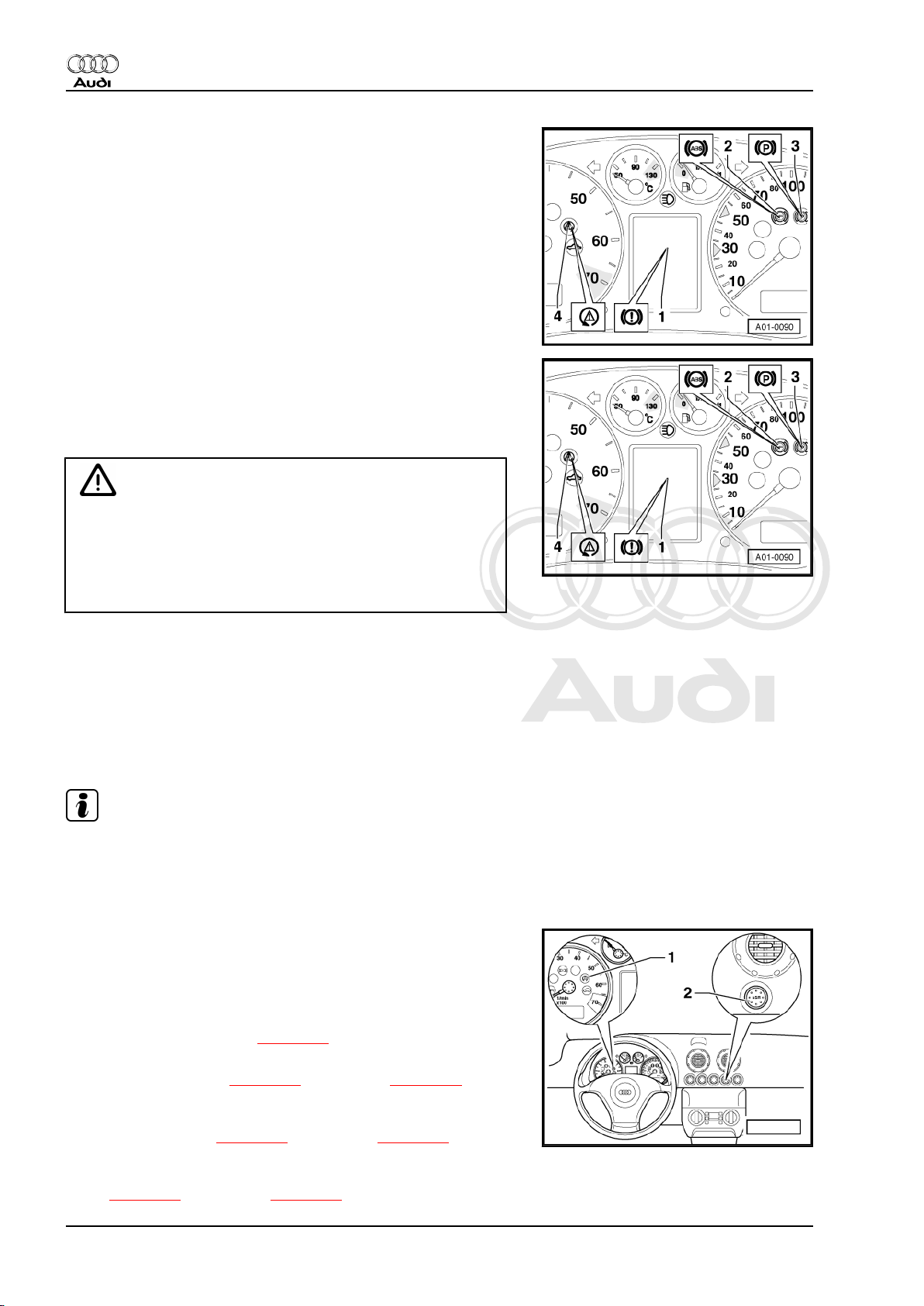

1.7 Connecting vehicle diagnostic, testing and information system -VAS 5051 A-

– With ignition switched off, connect vehicle diagnostic, testing

and information system -VAS 5051 A- with diagnosis lead VAS 5051 A/1- to diagnostic connection.

WARNING

Observe the relevant safety precautions ⇒ page 4 .

Note

Refer to ⇒ Operating instructions for vehicle diagnostic, testing

and information system -VAS 5051 A- if a fault is indicated on the

display.

Audi TT 1999 ➤

– Switch on ignition.

or

– Start engine.

Indicated on -VAS 5051 A- :

– Touch “Vehicle self-diagnosis” key.

Indicated on -VAS 5051 A- :

Note

Touching function “00 - Interrogate fault memory - complete sys‐

tem” in list -1- implements the automatic test sequence, i.e. fault

memory interrogation takes place for all vehicle systems with selfdiagnosis capability.

– From menu -1- select vehicle system “03 - Brake electronics”.

– Wait until next readout appears.

1. Self-diagnosis 7

Page 12

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Running gear, self-diagnosis - Edition 07.2004

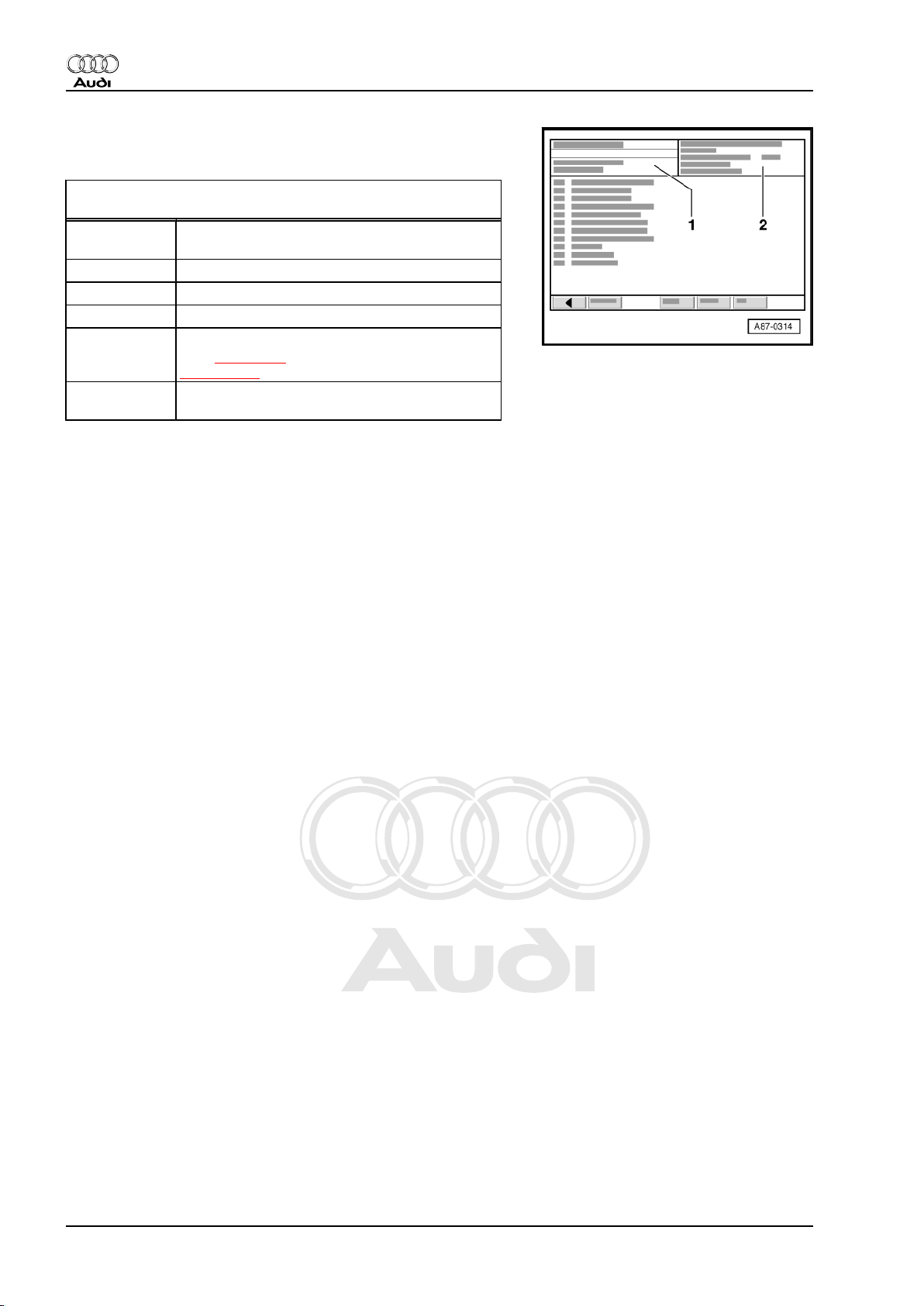

Indicated on -VAS 5051 A- :

2 - Control unit identification of ABS with EDL control unit -J104- .

Control unit identification

: ABS with EDL control unit -J104- (example)

03 - Brake

Vehicle system

electronics

8N0907379.. Part No.; Allocation ⇒ Parts catalogue

ESP System designation

CAN Data bus (CAN)

Code number

241

Control unit code (checking: vehicles without

ESP ⇒ page 39 , vehicles with ESP

⇒ page 103 ).

Dealership

number 12345

Dealership identifier of -VAS 5051 A- with

which coding was last performed

If the display “vehicle system not available” appears in display

zone -1-:

– Check:

♦ Voltage supply to diagnosis connector ⇒ Current flow dia‐

grams, Electrical fault finding and Fitting locations.

♦ Wiring connection between diagnosis connector and ABS with

EDL control unit -J104- ⇒ Current flow diagrams, Electrical

fault finding and Fitting locations.

8 Rep. Gr.01 - Self-diagnosis, electrical checks

Page 13

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Running gear, self-diagnosis - Edition 07.2004

2 CAN bus

Data bus:

A data bus is a system for the transmission and distribution of

data signals.

CAN:

A Controller Area Network is a bus system working with two wires.

They are referred to as bus wires. The bus wires transmit data

signals in serial form (one after the other) to the control units con‐

nected to the system.

These control units communicate with each other (i.e. exchange

data) via the CAN bus.

2.1 Testing a “two-wire data bus system”

Special tools and workshop equipment required

♦ Vehicle diagnostic, testing and information system -VAS 5051

A-

Test sequence:

– Refer to the appropriate current flow diagram to check how

many control units are connected to the CAN bus.

– Connect vehicle diagnostic, testing and information system -

VAS 5051 A- ⇒ page 7 and select function “00 - Automatic test

sequence”. When doing this the ignition must be switched on.

– Before testing the data bus wires make sure that there are no

faults in any of the control units which are connected to the

data bus. If a fault exists, the communication with other the

control units is affected.

Note

Audi TT 1999 ➤

A fault existing in or related to one of the control units does not

affect the data bus system directly, but results from a malfunction

of some kind in one of the systems. This may be a defective sen‐

sor, for example. The result is that the sensor signal can no longer

be processed for transmission via the data bus. A malfunction of

this kind has an indirect effect on the data bus system, and will

upset the communication with other control units which require

the signal from the affected sensor.

Procedure if a fault exists:

– Rectify the fault first.

– Print out the list of faults and erase the fault memories of all

control units (refer to “Interrogating fault memory” and “Eras‐

ing fault memory” for the relevant control unit.

– Conclude the transfer of data with the function “06 - End out‐

put”.

– Rectify the faults as described in the fault tables in the relevant

Workshop Manual.

When all faults have been rectified:

– If communication between the control units is still not working

properly, test the data bus wires.

– Distinguish between two possible configurations when tracing

faults in the bus wires.

2. CAN bus 9

Page 14

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Running gear, self-diagnosis - Edition 07.2004

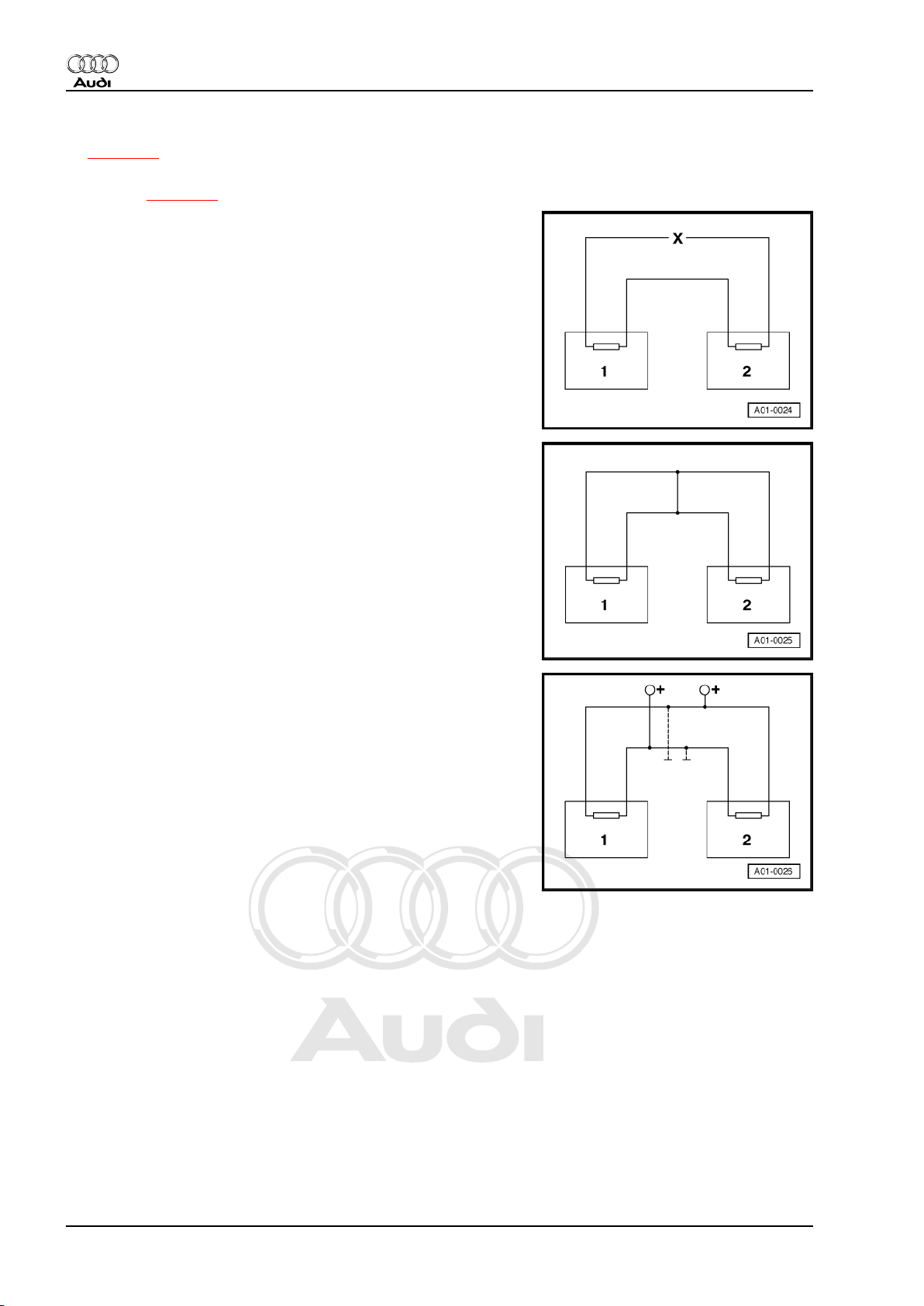

♦ Two control units communicating via a “Two-line bus system”

⇒ page 10 .

♦ Three or more control units communicating via a “Two-line bus

system” ⇒ page 11 .

2.1.1 Two control units communicating via a

“Two-line bus system”.

– Switch off ignition.

– Unplug multi-pin connectors at both control units.

– Check for an open circuit in the bus wires ⇒ Current flow dia‐

grams, Electrical fault finding and Fitting locations.

– Check for short circuit between the bus wires ⇒ Current flow

diagrams, Electrical fault finding and Fitting locations.

– Check for short to positive and short to earth in the bus wires.

If the cause of the fault cannot be found in the data bus wires:

– As a trial measure, renew the control unit which can be ex‐

changed with the least effort in terms of time and cost.

If the control unit communication via data bus is still not OK:

– Renew the second control unit.

10 Rep. Gr.01 - Self-diagnosis, electrical checks

Page 15

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Running gear, self-diagnosis - Edition 07.2004

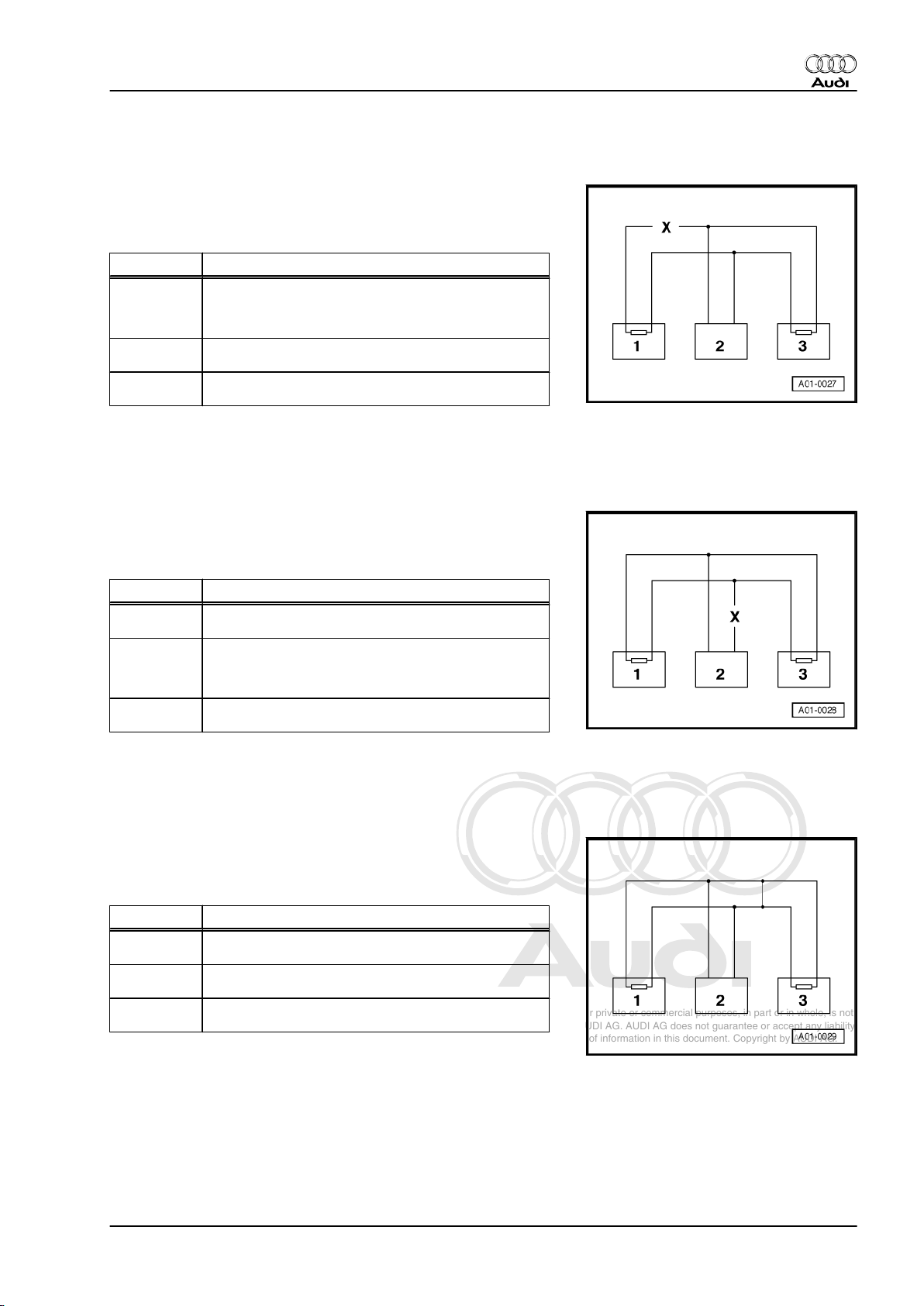

2.1.2 Three or more control units communi‐

cating via a “Two-line bus system”.

Example 1:

The faults stored in the fault memories indicate that the control

unit -1- has no connection to control units -2- and -3-.

Control unit Faults stored in fault memory

-1- ♦ No message from control unit -2-

♦ No message from control unit -3-

-2- ♦ No message from control unit -1-

-3- ♦ No message from control unit -1-

– Switch off ignition.

– Unplug electrical connectors on control units linked by data

bus wires and check bus wires for open circuit ⇒ Current flow

diagrams, Electrical fault finding and Fitting locations.

Audi TT 1999 ➤

Example 2:

The faults stored in the fault memories indicate that the control

unit -2- does not communicate with control units -1- and -3-.

Control unit Faults stored in fault memory

-1- ♦ No message from control unit -2-

-2- ♦ No message from control unit -1-

♦ No message from control unit -3-

-3- ♦ No message from control unit -2-

– Switch off ignition.

– Unplug electrical connectors on control units linked by data

bus wires and check bus wires for open circuit ⇒ Current flow

diagrams, Electrical fault finding and Fitting locations.

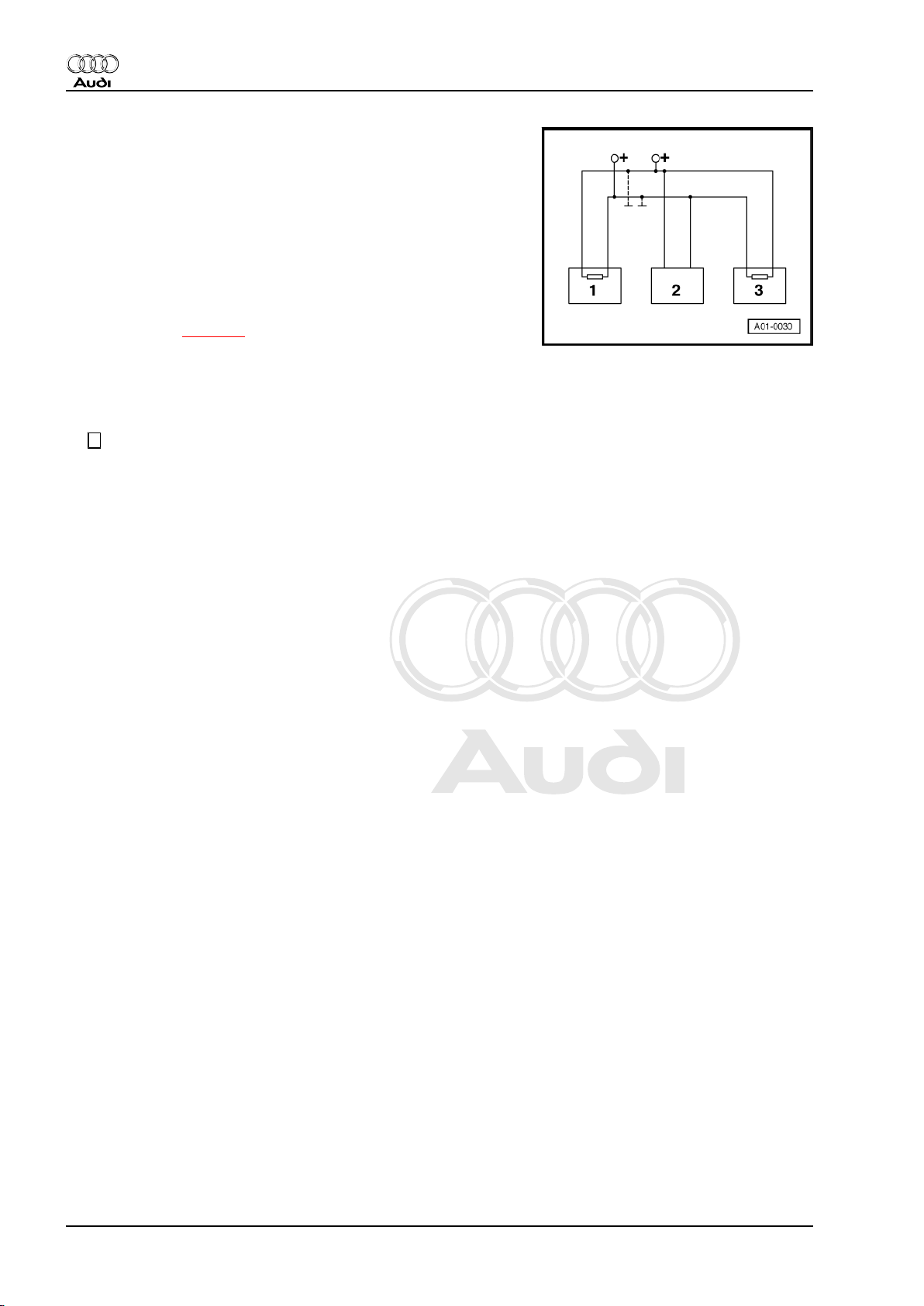

Example 3:

The faults stored in the fault memories indicate that none of the

control units can transmit or receive.

Control unit Faults stored in fault memory

-1- ♦ Control unit defective

-2- ♦ Control unit defective

-3- ♦ Control unit defective

– Switch off ignition.

– Unplug electrical connectors on control units linked by data

bus wires and check bus wires for short circuit ⇒ Current flow

diagrams, Electrical fault finding and Fitting locations.

2. CAN bus 11

Page 16

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Running gear, self-diagnosis - Edition 07.2004

– Check the bus wires for short to positive and short to earth.

– If the cause of the fault “Control unit defective” cannot be found

in the data bus wires, check whether one of the control units

is responsible for causing the fault.

• Electrical connectors on all control unit that communicate via

the CAN data bus are unplugged.

• Ignition switched off

– Connect one of the control units.

– Connect vehicle diagnostic, testing and information system -

VAS 5051 A- ⇒ page 7 .

– Switch on ignition and select the relevant vehicle system.

– Interrogate and erase the fault memory of the control unit

which has been just connected.

– Terminate function “05 - Erasing fault memory” by touching

← key.

– Conclude the transfer of data with the function “06 - End out‐

put”.

– Switch the ignition off and then on again.

– Leave the ignition switched on for 10 seconds. Then interrog‐

ate the fault memory of the control unit that has just been

connected.

If the fault “control unit defective” is indicated:

– Renew the control unit which has just been connected.

If the fault “control unit defective” is not indicated:

– Connect the next control unit and repeat the procedure.

12 Rep. Gr.01 - Self-diagnosis, electrical checks

Page 17

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Running gear, self-diagnosis - Edition 07.2004

3 ABS/EDL and ABS/EDL/TCS, ITT

Mark 20 without ESP

♦ The Audi TT without ESP is equipped with the ABS/EDL ITT

Mark 20 system or the ABS/EDL/TCS ITT Mark 20 system.

♦ The data signals are transmitted via CAN bus.

Note

ESP may have been retrofitted by AUDI AG on vehicles not orig‐

inally equipped with this system ⇒ page 59 .

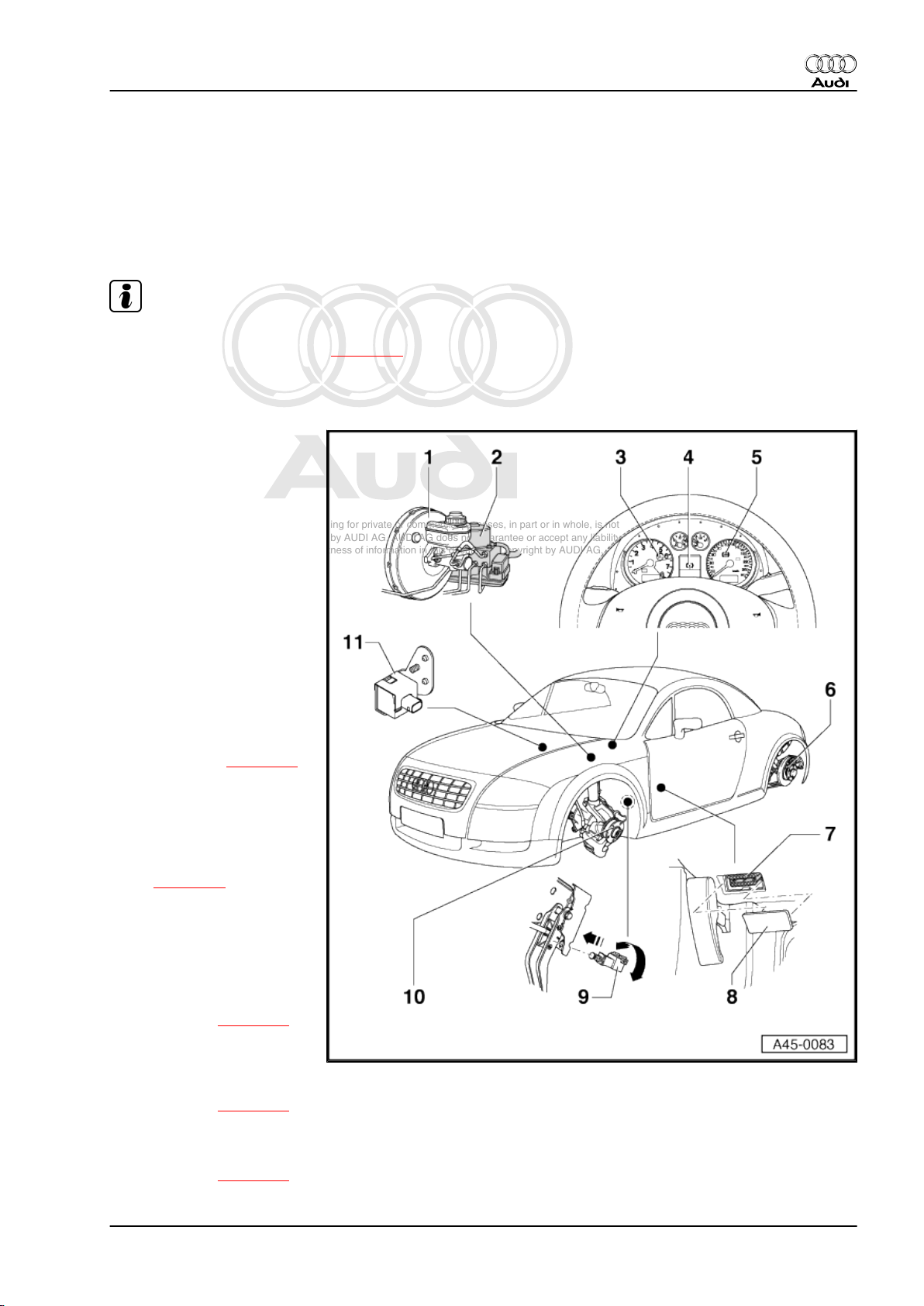

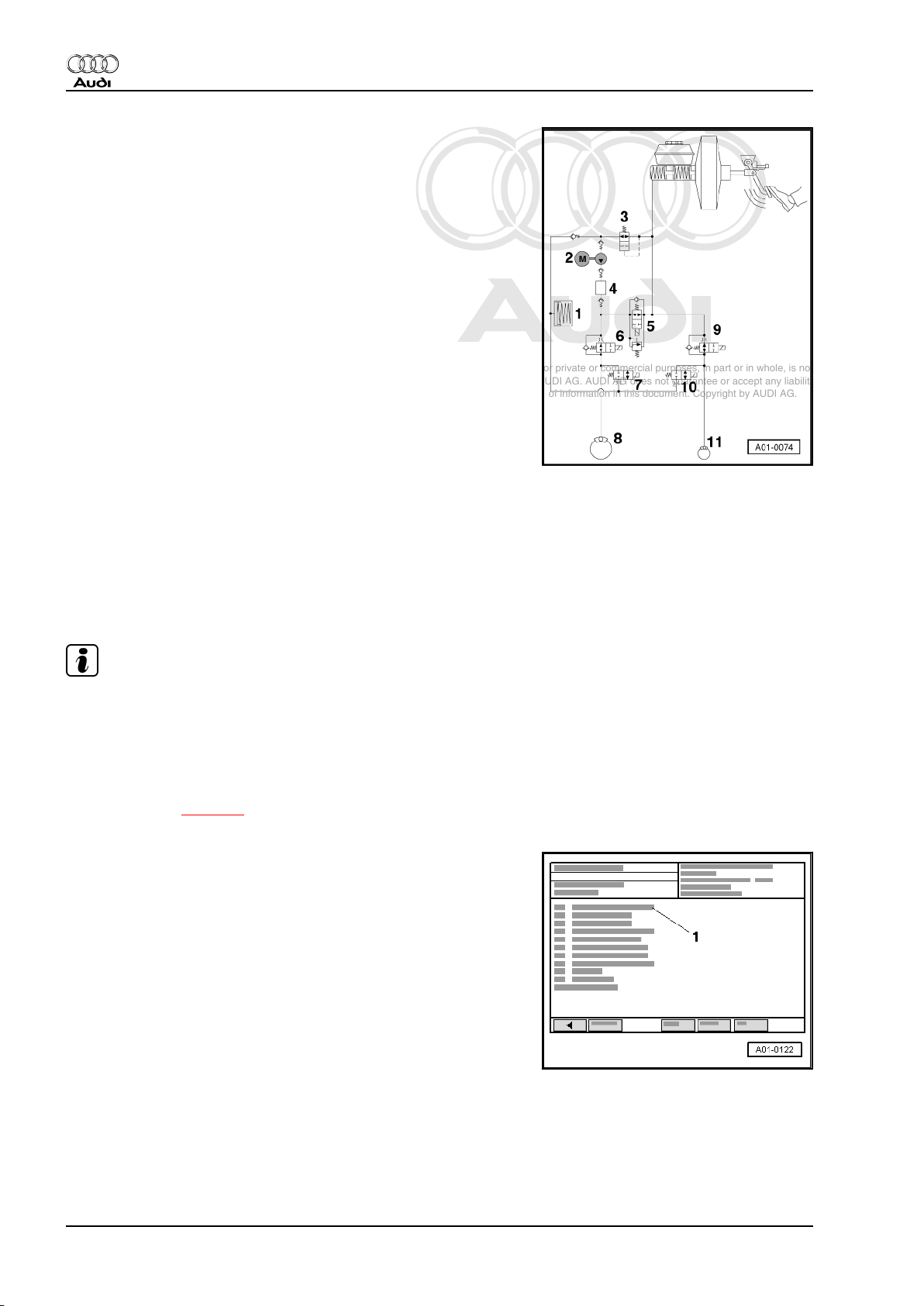

3.1 Electrical/electronic components and fitting locations

1 - Brake master cylinder and

brake servo

2 - Hydraulic control unit

❑ The hydraulic control

unit comprises the ABS

hydraulic pump -V64- ,

the ABS hydraulic unit N55- and the ABS with

EDL control unit -J104- .

❑ Fitting location: in en‐

gine compartment (leftside)

❑ Tested by self-diagno‐

❑ Only unplug 25-pin con‐

❑ Assignment of 25-pin

❑ Removing and installing

❑ Perform coding of ABS

3 - Traction control system

warning lamp -K86-

❑ Only on vehicles with

❑ Fitting location: in instru‐

❑ Function ⇒ page 14

4 - “Brake warning” symbol

❑ Appears in the display of

❑ Function ⇒ page 14

5 - ABS warning lamp -K47-

❑ Fitting location: in instrument cluster

❑ Function ⇒ page 14

sis

nector when the ignition

is switched off

connector ⇒ page 50

⇒ Brake system; Rep.

Gr. 45

with EDL control unit J104- after renewal

⇒ page 39

TCS

ment cluster

the driver information system

Audi TT 1999 ➤

3. ABS/EDL and ABS/EDL/TCS, ITT Mark 20 without ESP 13

Page 18

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Running gear, self-diagnosis - Edition 07.2004

6 - Rear left and rear right speed sensor and speed sensor rotor

❑ Rear left speed sensor -G46- and rear right speed sensor -G44❑ Removing and installing speed sensor, fitting speed sensor wires ⇒ Brake system; Rep. Gr. 45

❑ Checking speed sensor rotor ⇒ Brake system; Rep. Gr. 45

❑ Speed sensor rotor is welded to wheel hub; removing and installing wheel hub ⇒ Running gear, front-

wheel drive and four-wheel drive; Rep. Gr. 42

7 - Diagnosis connector

❑ Fitting location: in footwell (front left), next to release lever for bonnet.

8 - Diagnostics connection cover

9 - Brake light switch -F-

❑ Can be checked via reading measured value block ⇒ page 45

❑ Removing and installing ⇒ Brake system; Rep. Gr. 45

10 - Front left and front right speed sensor and speed sensor rotor

❑ Front left speed sensor -G47- and front right speed sensor -G45❑ Removing and installing speed sensor, fitting speed sensor wires ⇒ Brake system; Rep. Gr. 45

❑ Checking speed sensor rotor ⇒ Brake system; Rep. Gr. 45

❑ Speed sensor rotor is welded to wheel hub; removing and installing wheel hub ⇒ Running gear, front-

wheel drive and four-wheel drive; Rep. Gr. 40

11 - Longitudinal acceleration sender -G251-

❑ Four-wheel drive vehicles only

❑ Fitting location: on A-pillar (passenger side)

❑ Can be checked via reading measured value block ⇒ page 46

❑ Refer to ⇒ Brake system; Rep. Gr. 45 for removing and installing, then perform zero compensation in

basic setting ⇒ page 36

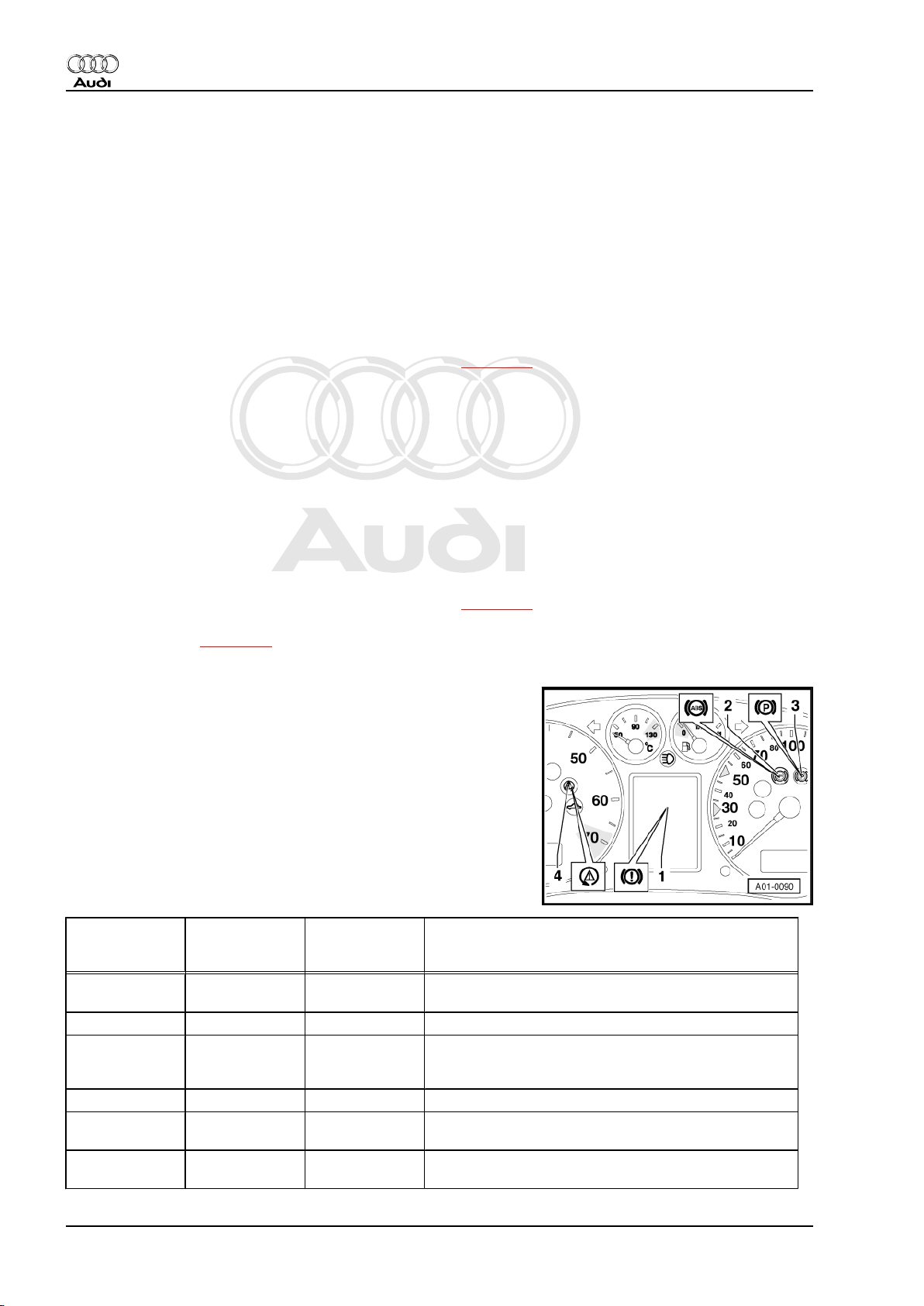

3.2 Faults displayed by warning lamps in in‐

strument cluster

1 - “Brake warning” symbol

2 - ABS warning lamp -K47-

3 - Handbrake warning lamp -K14-

4 - Traction control system warning lamp -K86- (only on vehi‐

cles with TCS)

“Brake warning”

symbol

On On On Test sequence after switching on ignition (first two sec‐

Off Off Off System OK (2 seconds after switching on ignition)

Off Off On TCS system failure or TCS system has been switched

Off Off flashes TCS control function is operating

Off On On ABS/EDL/TCS system failure (e.g. wheel speed sen‐

On On On ABS/EDL/TCS/EBPD system failure (e.g. several

ABS warning

lamp -K47-

Traction control

system warning

lamp -K86-

1)

Explanation

onds).

off via button; ABS, EDL and EBPD systems remain

functional.

sor defective), the EBPD remains fully functional.

wheel speed sensors defective)

14 Rep. Gr.01 - Self-diagnosis, electrical checks

Page 19

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Running gear, self-diagnosis - Edition 07.2004

“Brake warning”

symbol

ABS warning

lamp -K47-

Traction control

system warning

lamp -K86-

1)

Explanation

On Off Off Brake fluid level too low; all systems remain functional

1) Only on vehicles with TCS system

WARNING

There is a risk of accident if the ABS warning lamp -K47- and

the “brake warning symbol” both light up. The function of the

brake system will be impaired. As the brake pressure is no

longer controlled by the electronic brake force distribution the

rear wheels tend to brake excessively. Due to this the rear of

the vehicle may break away unexpectedly.

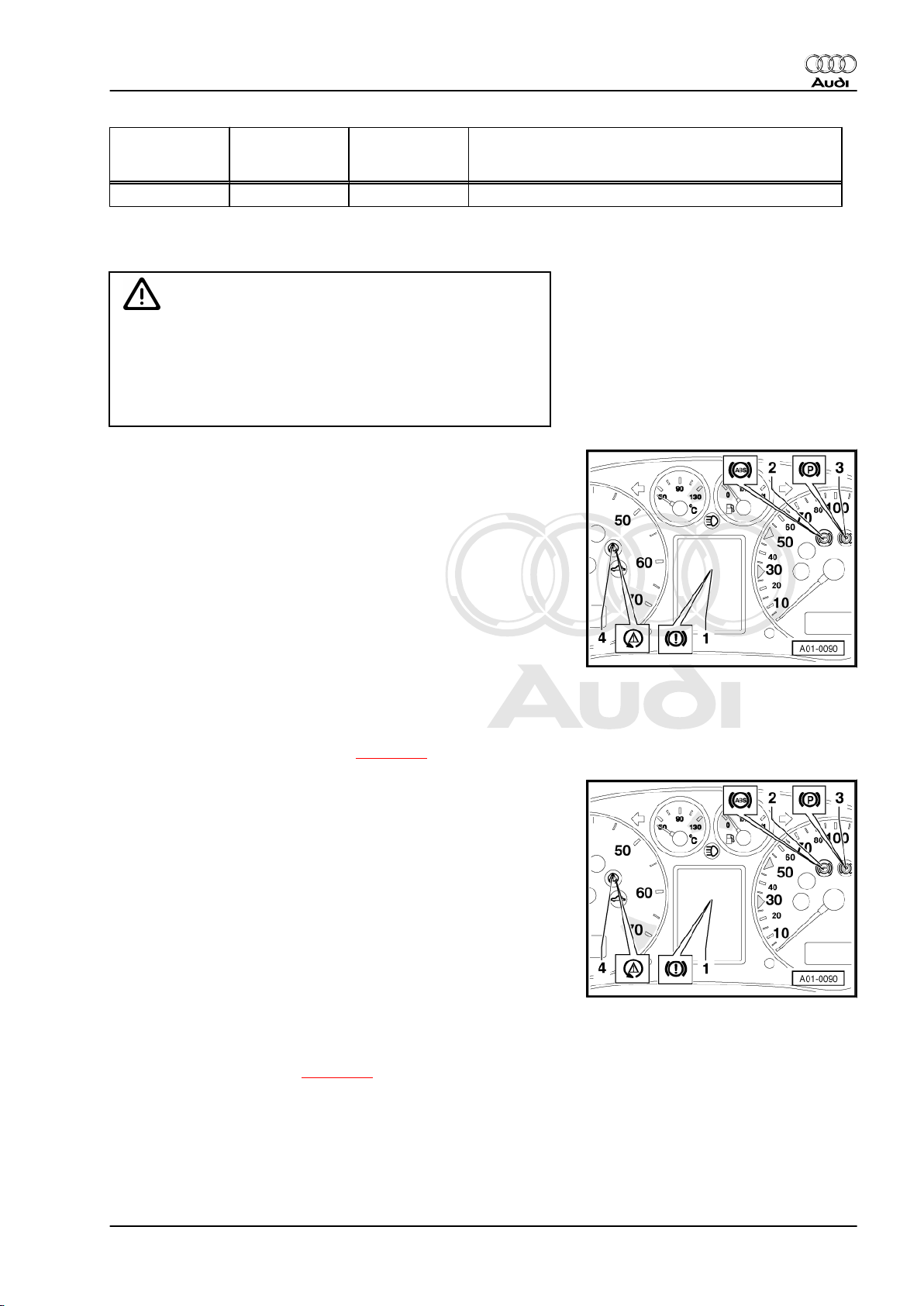

The ABS warning lamp -K47- -item 2- lights up during the test

sequence (self-test)

The system runs through an automatic test sequence when the

ignition is switched on: the ABS warning lamp -K47- is activated

by the ABS with EDL control unit -J104- and lights up for 2 sec‐

onds. During this period the control unit tests the following func‐

tions via self-test.

♦ The voltage supply is checked (min. 10.0 Volt).

♦ The control unit including the valve windings is checked.

♦ A speed sensor check (electrical test) is carried out; this is only

completed at 20 km/h.

♦ Control unit code is checked.

If the system does not perform the test sequence:

– Check voltage supply of ABS with EDL control unit -J104-

(perform electrical check, step 3 ⇒ page 51 ).

The ABS warning lamp -K47- -item 2- stays on after the test se‐

quence is completed

If a fault affecting only the anti-lock brake system is detected by

self-diagnosis, the ABS is switched off. The conventional brake

system remains fully functional.

The causes of the fault may be as follows:

♦ Voltage supply is below 10 Volts.

♦ A fault exists which affects only the ABS.

♦ A sensor fault has occurred after the last start (sporadic fault).

In this case the ABS warning lamp goes out automatically after

the vehicle is started again and the road speed exceeds 20 km/

h.

♦ Connection between ABS with EDL control unit -J104- and in‐

strument cluster is faulty or instrument cluster faulty (perform

electrical check, step 14 ⇒ page 55 ).

3. ABS/EDL and ABS/EDL/TCS, ITT Mark 20 without ESP 15

Page 20

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Running gear, self-diagnosis - Edition 07.2004

The ABS warning lamp -K47- -item 2- goes out after the test se‐

quence is completed,, but “brake warning symbol” -1- remains on

All systems remain functional.

The causes of the fault may be as follows:

♦ Brake fluid level too low.

♦ Fault in instrument cluster ⇒ Electrical system, self-diagnosis;

Rep. Gr. 01 or ⇒ Current flow diagrams, Electrical fault finding

and Fitting locations.

The ABS warning lamp -K47- -item 2- stays on after the test se‐

quence is completed and “brake warning symbol” -1- lights up

when vehicle speed first exceeds 10 km/h or engine speed first

exceeds 2000 rpm

The ABS system is defective and the EBPD system deactivated.

WARNING

There is a risk of accident if the ABS warning lamp -K47- and

the “brake warning symbol” both light up.The function of the

brake system will be impaired. As the brake pressure is no

longer controlled by the electronic brake force distribution the

rear wheels tend to brake excessively.Due to this the rear of

the vehicle may break away unexpectedly.

The causes of the fault may be as follows:

♦ The control unit is not coded (Code 00000), or is incorrectly

coded. In this case the ABS warning lamp -K47- will flash at a

rate of once per second. The “brake warning” symbol will also

flash when vehicle speed first exceeds 10 km/h or engine

speed first exceeds 2000 rpm after the ignition is switched on.

♦ A fault exists which affects the ABS and EBPD.

Note

If the ABS warning lamp -K47- and the “brake warning” symbol

do not light up but the brake system is not fully functional, the fault

must be traced in the conventional brake system ⇒ Brake system;

Rep. Gr. 46 and ⇒ Brake system; Rep. Gr. 47 .

Traction control system warning lamp -K86- -item 1- does not light

up after TCS is deactivated by pressing the traction control sys‐

tem switch -E132- -item 2-.

The causes of the fault may be as follows:

♦ Traction control system warning lamp -K86- defective (perform

electrical check, step 17 ⇒ page 57 ).

♦ Traction control system switch -E132- defective (perform elec‐

trical check, step 17 ⇒ page 57 and step 18 ⇒ page 57 ).

♦ Open circuit in vehicle power supply and wiring from ABS with

EDL control unit -J104- to instrument cluster (perform electri‐

cal check, step 17 ⇒ page 57 and step 18 ⇒ page 57 .

♦ Short circuit to positive in wiring from ABS with EDL control

unit -J104- to instrument cluster (perform electrical check, step

17 ⇒ page 57 and step 18 ⇒ page 57 ).

16 Rep. Gr.01 - Self-diagnosis, electrical checks

Page 21

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Running gear, self-diagnosis - Edition 07.2004

Traction control system warning lamp -K86- lights continuously

after ignition is switched on, and none of the malfunctions above

occur

The cause of the fault may be as follows:

♦ Short circuit to earth in wiring from ABS with EDL control unit

-J104- to instrument cluster (activation of TCS warning lamp)

(perform electrical check, step 17 ⇒ page 57 and step 18

⇒ page 57 ).

Vehicle with ABS/EDL has no EDL function

A possible cause of this fault is that the brake light switch is not

functioning. Check “measured value block 003” ⇒ page 45 .

Renewing brake light switch ⇒ Brake system; Rep. Gr. 45 .

3.3 Performing self-diagnosis on the ABS/ EDL and ABS/EDL/TCS, ITT Mark 20 without ESP

List of available functions

– With ignition switched off, connect vehicle diagnostic, testing

and information system -VAS 5051 A- with diagnosis lead VAS 5051 A/1- to diagnosis connector and select vehicle

system “03 - Brake electronics” ⇒ page 7 .

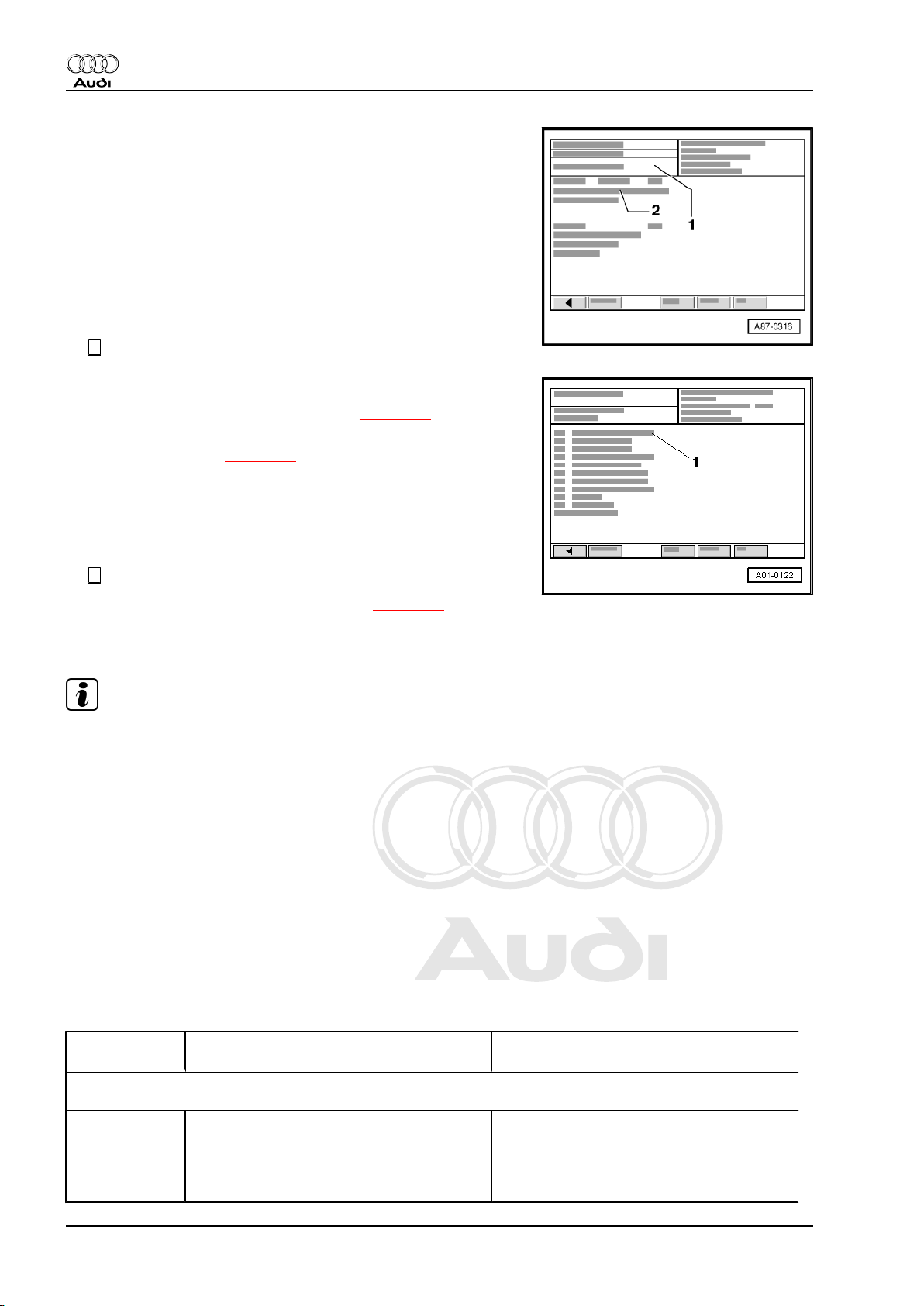

The following functions are available from the list -1-:

Audi TT 1999 ➤

Functions Page

02 Interrogate fault memory ⇒ page 17

03 Final control diagnosis ⇒ page 25

04 Basic setting ⇒ page 32

05 Erase fault memory ⇒ page 38

06 End output ⇒ page 39

07 Code control unit ⇒ page 39

08 Read measured value block ⇒ page 42

11

Login procedure/encoding II

2) The login procedure/encoding II is only required on four-wheel drive vehicles.

2)

⇒ page 46

The other functions displayed are currently not available, or can

be disregarded.

3.4 Interrogating fault memory

– Connect vehicle diagnostic, testing and information system -

VAS 5051 A- ⇒ page 7 and select vehicle system “03 - Brake

electronics”. When doing this the ignition must be switched on.

Indicated on -VAS 5051 A- :

– From list -1- select function “02 - Interrogate fault memory”.

3. ABS/EDL and ABS/EDL/TCS, ITT Mark 20 without ESP 17

Page 22

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Running gear, self-diagnosis - Edition 07.2004

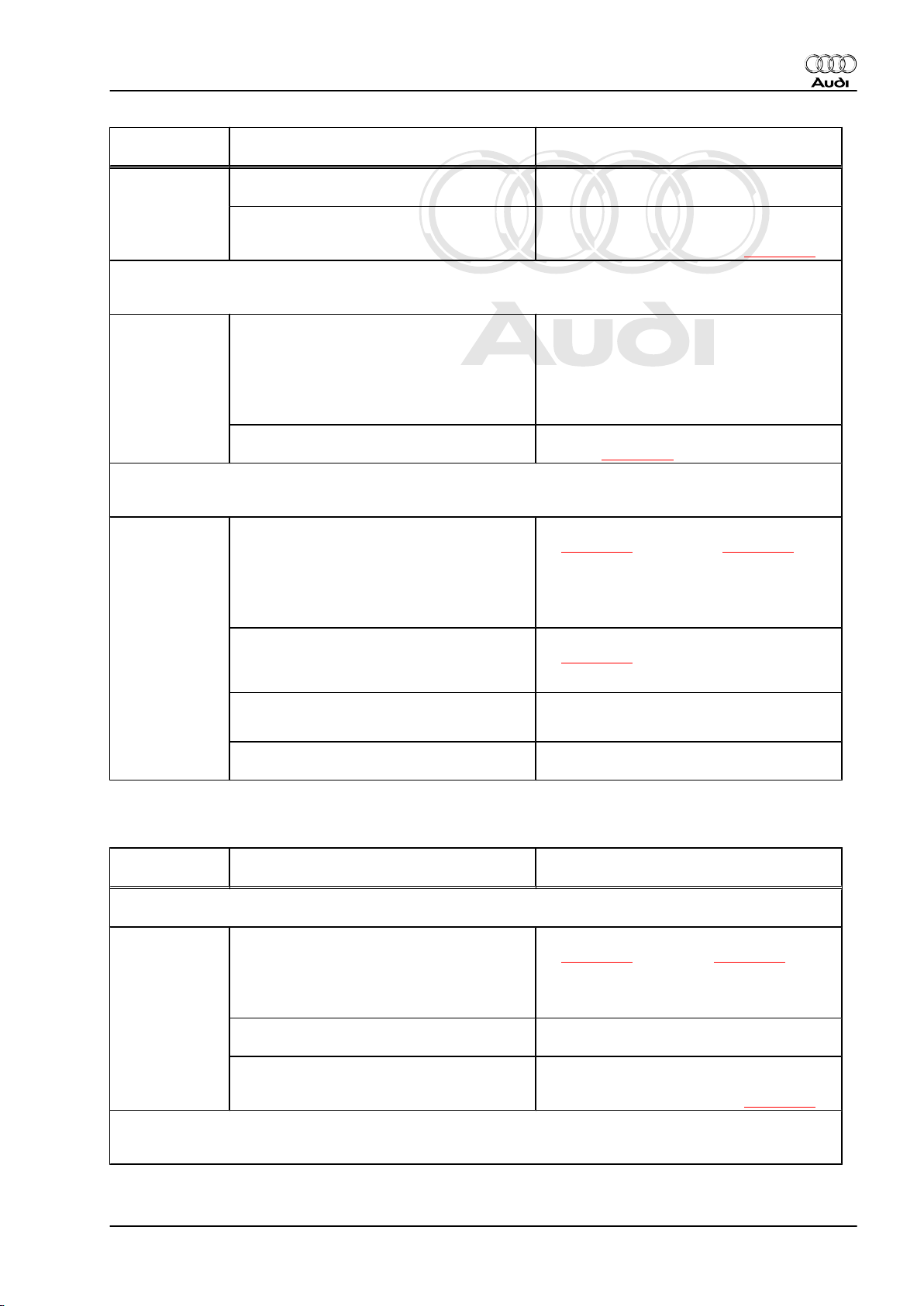

Indicated on -VAS 5051 A- :

-1- Content of fault memory No faults detected

or

X faults detected

-2- Fault Fault code

Fault location

Type of fault

A - If a fault was detected:

– Print out information on screen or self-diagnosis log.

– Terminate function “02 - Interrogate fault memory” by touching

← key.

Indicated on -VAS 5051 A- :

– Rectify fault(s) according to fault tables ⇒ page 18 .

– From list -1- select function “02 - Interrogate fault memory” and

erase fault memory ⇒ page 38 .

– From list -1- select function “06 - End output” ⇒ page 39 .

– Perform road test and interrogate fault memory again.

B - If no fault was detected:

– Terminate function “02 - Interrogate fault memory” by touching

← key.

– Select function “06 - End output” from list ⇒ page 39 .

3.5 Fault tables

Note

♦

The following table includes all faults which can be detected

by the ABS with EDL control unit -J104- and displayed by VAS 5051 A- when interrogating the fault memory.

♦

The contents of the fault memory remains stored until the

memory is erased; Erasing fault memory ⇒ page 38 .

♦

Faults are listed according to a 5-digit fault code, which ap‐

pears in the left-hand column of the fault table.

♦

Sporadic (intermittent) faults are identified as such by the word

“sporadic” appearing on the display.

♦

Check wiring and connectors going to the relevant compo‐

nents according to current flow diagram before renewing com‐

ponents indicated as faulty by -VAS 5051 A- . Also check earth

connections according to current flow diagram. This is partic‐

ularly important if faults are indicated as being “sporadic”.

Fault 00283

Display on -

VAS 5051 A-

00283

Front left speed sensor -G47-

♦ Open circuit, loose contact or short to

Possible cause of fault Fault remedy

positive or earth in speed sensor wire or

speed sensor

– Perform electrical check, step 6

⇒ page 52 and step 10 ⇒ page 54

♦ Speed sensor winding defective

18 Rep. Gr.01 - Self-diagnosis, electrical checks

Page 23

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Running gear, self-diagnosis - Edition 07.2004

Display on -

VAS 5051 A-

♦ Speed sensor or rotor damaged – Check speed sensor and rotor ⇒ Brake

♦ ABS with EDL control unit -J104- defec‐

tive

00283

Front left speed sensor -G47Mechanical fault

• This fault is

only detec‐

♦ Excessive air gap between speed sensor

and rotor.

ted above 20

km/h (carry

out test

drive).

♦ Outlet valves in hydraulic unit defective – Check hydraulic unit in final control diag‐

00283

Front left speed sensor -G47Signal outside tolerance

• This fault is

only detec‐

ted above 20

km/h (carry

out test

♦ Open circuit, loose contact or short to

positive or earth in speed sensor wire or

speed sensor

♦ Speed sensor winding defective

drive).

♦ Electrical interference from external in‐

terference sources (high frequency radi‐

ation, e.g. non-insulated ignition cable)

Possible cause of fault Fault remedy

system; Rep. Gr. 45

– Remove hydraulic control unit, renew

control unit ⇒ Brake system; Rep. Gr.

45 , then code control unit ⇒ page 39

– Check installation of speed sensor and

rotor ⇒ Brake system; Rep. Gr. 45

nosis ⇒ page 25

– Perform electrical check, step 6

⇒ page 52 and step 10 ⇒ page 54

– Read measured value block 001

⇒ page 44

♦ Excessive air gap between speed sensor

and rotor.

♦ Speed sensor or rotor damaged – Check speed sensor and rotor ⇒ Brake

Fault 00285

Display on -

Possible cause of fault Fault remedy

VAS 5051 A-

00285

Front right speed sensor -G45-

♦ Open circuit, loose contact or short to

positive or earth in speed sensor wire or

speed sensor

♦ Speed sensor winding defective

♦ Speed sensor or rotor damaged – Check speed sensor and rotor ⇒ Brake

♦ ABS with EDL control unit -J104- defec‐

tive

00285

Front right speed sensor -G45Mechanical fault

– Check installation of speed sensor and

rotor ⇒ Brake system; Rep. Gr. 45

system; Rep. Gr. 45

– Perform electrical check, step 5

⇒ page 52 and step 9 ⇒ page 54

system; Rep. Gr. 45

– Remove hydraulic control unit, renew

control unit ⇒ Brake system; Rep. Gr.

45 , then code control unit ⇒ page 39

3. ABS/EDL and ABS/EDL/TCS, ITT Mark 20 without ESP 19

Page 24

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Running gear, self-diagnosis - Edition 07.2004

Display on -

Possible cause of fault Fault remedy

VAS 5051 A-

• This fault is

only detec‐

♦ Excessive air gap between speed sensor

and rotor.

ted above 20

km/h (carry

out test

drive).

♦ Outlet valves in hydraulic unit defective – Check hydraulic unit in final control diag‐

00285

Front right speed sensor -G45Signal outside tolerance

• This fault is

only detec‐

ted above 20

km/h (carry

out test

♦ Open circuit, loose contact or short to

positive or earth in speed sensor wire or

speed sensor

♦ Speed sensor winding defective

drive).

♦ Electrical interference from external in‐

terference sources (high frequency radi‐

ation, e.g. non-insulated ignition cable)

♦ Excessive air gap between speed sensor

and rotor.

– Check installation of speed sensor and

rotor ⇒ Brake system; Rep. Gr. 45

nosis ⇒ page 25

– Perform electrical check, step 5

⇒ page 52 and step 9 ⇒ page 54

– Read measured value block 001

⇒ page 44

– Check installation of speed sensor and

rotor ⇒ Brake system; Rep. Gr. 45

♦ Speed sensor or rotor damaged – Check speed sensor and rotor ⇒ Brake

Fault 00287

Display on -

VAS 5051 A-

00287

Rear right speed sensor -G44-

♦ Open circuit, loose contact or short to

positive or earth in speed sensor wire or

speed sensor

♦ Speed sensor winding defective

♦ Speed sensor or rotor damaged – Check speed sensor and rotor ⇒ Brake

♦ ABS with EDL control unit -J104- defec‐

tive

00287

Rear right speed sensor -G44Mechanical fault

• This fault is

only detec‐

♦ Excessive air gap between speed sensor

and rotor.

ted above 20

km/h (carry

out test

drive).

system; Rep. Gr. 45

Possible cause of fault Fault remedy

– Perform electrical check, step 7

⇒ page 53 and step 11 ⇒ page 54

system; Rep. Gr. 45

– Remove hydraulic control unit, renew

control unit ⇒ Brake system; Rep. Gr.

45 , then code control unit ⇒ page 39

– Check installation of speed sensor and

rotor ⇒ Brake system; Rep. Gr. 45

♦ Outlet valves in hydraulic unit defective – Check hydraulic unit in final control diag‐

00287

Rear right speed sensor -G44Signal outside tolerance

20 Rep. Gr.01 - Self-diagnosis, electrical checks

nosis ⇒ page 25

Page 25

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Running gear, self-diagnosis - Edition 07.2004

Display on -

VAS 5051 A-

• This fault is

only detec‐

ted above 20

km/h (carry

out test

♦ Open circuit, loose contact or short to

positive or earth in speed sensor wire or

speed sensor

♦ Speed sensor winding defective

drive).

♦ Electrical interference from external in‐

terference sources (high frequency radi‐

ation, e.g. non-insulated ignition cable)

♦ Excessive air gap between speed sensor

and rotor.

♦ Speed sensor or rotor damaged – Check speed sensor and rotor ⇒ Brake

Fault 00290

Display on -

VAS 5051 A-

00290

Rear left speed sensor -G46-

♦ Open circuit, loose contact or short to

positive or earth in speed sensor wire or

speed sensor

♦ Speed sensor winding defective

♦ Speed sensor or rotor damaged – Check speed sensor and rotor ⇒ Brake

♦ ABS with EDL control unit -J104- defec‐

tive

00290

Rear left speed sensor -G46Mechanical fault

• This fault is

only detec‐

♦ Excessive air gap between speed sensor

and rotor.

ted above 20

km/h (carry

out test

drive).

Possible cause of fault Fault remedy

– Perform electrical check, step 7

⇒ page 53 and step 11 ⇒ page 54

– Read measured value block 001

⇒ page 44

– Check installation of speed sensor and

rotor ⇒ Brake system; Rep. Gr. 45

system; Rep. Gr. 45

Possible cause of fault Fault remedy

– Perform electrical check, step 8

⇒ page 53 and step 12 ⇒ page 55

system; Rep. Gr. 45

– Remove hydraulic control unit, renew

control unit ⇒ Brake system; Rep. Gr.

45 , then code control unit ⇒ page 39

– Check installation of speed sensor and

rotor ⇒ Brake system; Rep. Gr. 45

♦ Outlet valves in hydraulic unit defective – Check hydraulic unit in final control diag‐

♦ Excessive air gap between speed sensor

and rotor.

00290

Rear left speed sensor -G46Signal outside tolerance

• This fault is

only detec‐

ted above 20

km/h (carry

out test

♦ Open circuit, loose contact or short to

positive or earth in speed sensor wire or

speed sensor

♦ Speed sensor winding defective

drive).

nosis ⇒ page 25

– Check installation of speed sensor and

rotor ⇒ Brake system; Rep. Gr. 45

– Perform electrical check, step 8

⇒ page 53 and step 12 ⇒ page 55

3. ABS/EDL and ABS/EDL/TCS, ITT Mark 20 without ESP 21

Page 26

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Running gear, self-diagnosis - Edition 07.2004

Display on -

VAS 5051 A-

♦ Electrical interference from external in‐

terference sources (high frequency radi‐

ation, e.g. non-insulated ignition cable)

♦ Excessive air gap between speed sensor

and rotor.

♦ Speed sensor or rotor damaged – Check speed sensor and rotor ⇒ Brake

Fault 00668

Display on -

VAS 5051 A-

00668

Vehicle voltage, terminal 30

Signal outside tolerance

♦ Fuse defective

♦ Open circuit or short circuit to earth or

positive in voltage supply wiring

Possible cause of fault Fault remedy

– Read measured value block 001

⇒ page 44

– Check installation of speed sensor and

rotor ⇒ Brake system; Rep. Gr. 45

system; Rep. Gr. 45

Possible cause of fault Fault remedy

– Perform electrical check, step 1

⇒ page 51 and step 2 ⇒ page 51

Fault 01044

Display on -

VAS 5051 A-

01044

Control unit incorrectly coded

♦ An incorrect code number has been en‐

tered

♦ Coding bridge in wiring harness dam‐

aged

Fault 01130

Display on -

VAS 5051 A-

01130

ABS operation

Signal outside tolerance

• This fault is

only detec‐

ted above 20

km/h (carry

out test

drive).

♦ Electrical interference from external in‐

terference sources (high frequency radi‐

ation, e.g. non-insulated ignition cable)

♦ Open circuit, loose contact or short to

positive or earth in wiring

Possible cause of fault Fault remedy

– Check code ⇒ page 39

– Check wires in wiring harness; perform

electrical check, test step 13

⇒ page 55

Possible cause of fault Fault remedy

– Check all wiring and connections for

short to positive or earth.

– Erase fault memory

– Perform test drive at more than 20 km/h

22 Rep. Gr.01 - Self-diagnosis, electrical checks

– Interrogate fault memory again

If the fault is not rectified:

– Remove hydraulic control unit, renew

control unit ⇒ Brake system; Rep. Gr.

45 , then code control unit ⇒ page 39

Page 27

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Fault 01276

Audi TT 1999 ➤

Running gear, self-diagnosis - Edition 07.2004

Display on -

Possible cause of fault Fault remedy

VAS 5051 A-

01276

ABS hydraulic pump -V64Signal outside tolerance

• This fault is

only detec‐

ted above 20

km/h (carry

♦ Open circuit or short circuit to earth or

positive in internal wiring: ABS with EDL

control unit -J104- / ABS hydraulic pump

-V64out test

drive).

♦ ABS with EDL control unit -J104- defec‐

tive

♦ Pump motor defective – Renew hydraulic control unit ⇒ Brake

Fault 01279

Display on -

VAS 5051 A-

01279

Longitudinal acceleration sender -G251-

Possible cause of fault Fault remedy

3)

Electrical fault in circuit

♦ Open circuit, loose contact or short to

positive or earth in wiring

– Check ABS hydraulic pump -V64- via fi‐

nal control diagnosis ⇒ page 25

If ABS hydraulic pump -V64- starts running

during final control diagnosis:

– Perform electrical check, test step 1

⇒ page 51

– Check all wiring and connections for

short to positive or earth according to cur‐

rent flow diagram.

– Remove hydraulic control unit, renew

control unit ⇒ Brake system; Rep. Gr.

45 , then code control unit ⇒ page 39

system; Rep. Gr. 45

– Perform electrical check, test step 19

⇒ page 58

♦ Installation position of longitudinal accel‐

eration sender -G251- not OK

♦ Longitudinal acceleration sender -G251-

defective

3) Four-wheel drive vehicles only.

Fault 01312

Display on -

VAS 5051 A-

01312

Drive train data bus

defective

4)

♦ ABS with EDL control unit -J104- incor‐

rectly coded

♦ Engine control unit incorrectly coded – Check coding of engine control unit ⇒

– Check installation position ⇒ Brake sys‐

tem; Rep. Gr. 45

– Read measured value block 006

⇒ page 46

– Renew sender ⇒ Brake system; Rep. Gr.

45 , then perform zero compensation in

basic setting ⇒ page 36

Possible cause of fault Fault remedy

– Check code ⇒ page 39

Motronic injection and ignition system;

Rep. Gr. 01

3. ABS/EDL and ABS/EDL/TCS, ITT Mark 20 without ESP 23

Page 28

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Running gear, self-diagnosis - Edition 07.2004

Display on -

Possible cause of fault Fault remedy

VAS 5051 A-

4) If fault is displayed as sporadic fault: can occur when vehicle is started. This is

not a fault in the system; ignore and erase fault memory.

♦ Faults in CAN bus wiring – Check CAN bus wiring between engine

Fault 01314

Display on -

Possible cause of fault Fault remedy

VAS 5051 A-

01314

Engine control unit

No communication

• Signals are

transmitted

between

5)

When displayed as static fault:

♦ ABS with EDL control unit -J104- or en‐

gine control unit not CAN compatible

ABS with

EDL control

unit -J104and engine

♦ Fault in engine control unit – Interrogate fault memory of engine con‐

control unit

via CAN data

bus

When displayed as static and sporadic fault:

♦ Faults in CAN bus wiring

♦ High and Low CAN bus wiring inter‐

changed

♦ The output of one of the control units

communicating via the CAN bus is de‐

fective.

control unit and ABS with EDL control unit

-J104- ⇒ page 9

– Refer to control unit identification of ABS

with EDL control unit -J104- ⇒ page 8 and

engine control unit to check that correct

control units are installed. Allocation ⇒

Parts catalogue

trol unit ⇒ Motronic injection and ignition

system; Rep. Gr. 01 , rectify fault if nec‐

essary and erase fault memory

– Check CAN bus wiring between engine

control unit and ABS with EDL control unit

-J104- ⇒ page 9

– Check CAN Bus wiring for interchanged

connections according to current flow di‐

agram

– Check CAN bus wiring ⇒ page 9

5) Only on vehicles with TCS system

Fault 01324

Display on -

Possible cause of fault Fault remedy

VAS 5051 A-

01324

Four-wheel drive control unit -J492No communication

6) Four-wheel drive vehicles only.

6)

♦ Faults in CAN bus wiring – Check CAN bus wiring ⇒ page 9

Fault 65535

Display on -

Possible cause of fault Fault remedy

VAS 5051 A-

65535

Control unit defective

24 Rep. Gr.01 - Self-diagnosis, electrical checks

Page 29

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Running gear, self-diagnosis - Edition 07.2004

Display on -

Possible cause of fault Fault remedy

VAS 5051 A-

♦ ABS with EDL control unit -J104- defec‐

tive

3.6 Final control diagnosis

The final control diagnosis can be used to check the ABS hy‐

draulic pump -V64- and the correct functioning of the hydraulic

circuits (allocation of brake pipes to wheel brakes and function of

valves). This function will also detect interchanged connections

and leaks.

Note

♦

The vehicle must be raised until all wheels are free to turn.

♦

To avoid overloading the control elements they are only acti‐

vated for a period of 60 or 90 seconds. The final control test

will be terminated if the → key is not pressed within this period.

– Remove hydraulic control unit, renew

control unit ⇒ Brake system; Rep. Gr.

45 , then code control unit ⇒ page 39

Do not erase the fault memory of the defec‐

tive control unit. The data in the fault memory

will help to identify the malfunction

♦

The ABS warning lamp -K47- and the red “brake warning”

symbol flash during the final control diagnosis.

♦

After depressing the brake pedal several times the vacuum in

the brake servo will be exhausted. Therefore more pressure

must be applied to the brake pedal in order to attain the same

fluid pressure in the brake system as that attained with vac‐

uum.

♦

When vacuum in brake servo is exhausted it can happen that

the wheels do not lock: start engine and build up vacuum in

brake servo.

Meaning of abbreviations indicated on display

IFL = Inlet valve

OFL = Outlet valve

VBAT = Battery voltage; voltage at valve

0V = 0 Volt; No voltage at valve

Hydr-P = ABS hydraulic pump -V64-

3. ABS/EDL and ABS/EDL/TCS, ITT Mark 20 without ESP 25

Page 30

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Running gear, self-diagnosis - Edition 07.2004

Components of the ABS/EDL system

The hydraulic circuit is a schematic diagram of the ABS/EDL sys‐

tem. The diagram shows only one brake circuit.

1 - Low pressure accumulator

2 - ABS hydraulic pump -V64-

3 - EDL inlet valve (hydraulic)

4 - Noise damping chamber

5 - EDL change-over/separating valve (electrical) with integra‐

ted pressure limiting valve

6 - Front inlet valve

7 - Front outlet valve

8 - Front wheel

9 - Rear inlet valve

10 - Rear outlet valve

11 - Rear wheel

Test condition

• The wheels are locked individually during final control diagno‐

sis. For this test the mechanical and hydraulic components of

the brake system must be working properly. This means that

the master cylinder is able to build up pressure in all four wheel

brake cylinders and there are no leaks in the hydraulic pipes,

hoses and connections.

Note

If one of the wheels does not lock, perform a visual inspection of

the brake fluid reservoir, the master cylinder, the hydraulic unit

and the wheel cylinders.

Procedure

– Connect vehicle diagnostic, testing and information system -

VAS 5051 A- ⇒ page 7 and select vehicle system “03 - Brake

electronics”. When doing this the ignition must be switched on.

Indicated on -VAS 5051 A- :

– Release handbrake.

– Raise vehicle on lifting platform.

– From list -1- select function “03 - Final control diagnosis”.

26 Rep. Gr.01 - Self-diagnosis, electrical checks

Page 31

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Running gear, self-diagnosis - Edition 07.2004

Indicated on -VAS 5051 A- :

A - Final control test waiting, move on to next control element

1 - ABS hydraulic pump V64

– Touch → key.

Indicated on -VAS 5051 A- :

A - Final control diagnosis running, moving on permitted

1 - ABS hydraulic pump V64

• The ABS hydraulic pump -V64- - item 2- should start up audi‐

bly.

Note

♦

When you put your foot on the brake pedal you can feel it vi‐

brating. This is because the hydraulic pump -V64- is producing

pressure pulses in the brake pipes. The pressure pulses in‐

duce the vibrations that can be felt at the brake pedal.

♦

The pressure pulses in the brake pipes are not sufficient to

lock the wheels.

Audi TT 1999 ➤

– Touch → key.

Indicated on -VAS 5051 A- :

A - Final control diagnosis running, moving on permitted

2 - Operate brakes

– Depress brake pedal and and touch → within 10 seconds.

Indicated on -VAS 5051 A- :

A - Final control diagnosis running, moving on permitted

3 - IFL: 0V OFL: 0V Wheel FL locked

3. ABS/EDL and ABS/EDL/TCS, ITT Mark 20 without ESP 27

Page 32

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Running gear, self-diagnosis - Edition 07.2004

• Brake pedal must not give.

• When you press the brake pedal, brake fluid pressure will be

built up in all four wheel brake cylinders.

• The hydraulic EDL valve -3- closes, the front wheels -8- and

rear wheels -11- are locked.

Note

This test step in the final control diagnosis corresponds to

the“pressure build-up” phase during ABS-controlled braking.

– Touch → key.

Indicated on -VAS 5051 A- :

A - Final control diagnosis running, moving on permitted

4 - IFL: VBAT OFL: 0V Wheel FL locked

– Keep pressing the brake pedal.

• The hydraulic EDL valve -3- remains closed.

• The front inlet valve -6- is activated, which interrupts the supply

to the wheel brake cylinder; however, the fluid pressure is still

maintained in the wheel cylinder.

• The front left wheel -8- remains locked.

Note

This test step in the final control diagnosis corresponds to

the“maintain pressure” phase during ABS-controlled braking.

– Touch → key.

28 Rep. Gr.01 - Self-diagnosis, electrical checks

Page 33