Page 1

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Service

Workshop Manual

Audi TT 2007 ➤

Heating and Air Conditioning

Edition 04.2009

Service Department. Technical Information

Page 2

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Service

List of Workshop Manual Repair GroupsList of Workshop Manual

Repair GroupsList of Workshop Manual Repair Groups

Re pa ir G ro up

80 - Heating

87 - Air conditioning system

Technical information should always be available to the foremen and mechanics, because their

careful and constant adherence to the instructions is essential to ensure vehicle road-worthiness and

safety. In addition, the normal basic safety precautions for working on motor vehicles must, as a

matter of course, be observed.

All rights reserved.

No reproduction without prior agreement from publisher.

Copyright © 2010 Audi AG, Ingolstadt A005TT00620

Page 3

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Heating and Air Conditioning - Edition 04.2009

Contents

80 - Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1 Notes on heater repair work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Contact corrosion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Notes on heater guided fault-finding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 Checking electrical components of heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.4 Checking of electrical components actuated by the heater . . . . . . . . . . . . . . . . . . . . . . . . 2

2 Components for control and regulation of heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 Components not located in passenger compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Components located in passenger compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Heater components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4 Checking actuation of temperature flaps and heat output . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.1 Checking heat output and actuation of temperature flaps . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5 Dismantling and assembling heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.1 Detaching electrical add-on components from heater/re-attaching . . . . . . . . . . . . . . . . . . 16

5.2 Dismantling and assembling heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.3 Dismantling and assembling air duct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

87 - Air conditioning system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1 Safety measures when working on vehicles with air conditioner and for handling

refrigerant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1.1 Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1.2 Draining refrigerant circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1.3 Working on refrigerant circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1.4 Painting work on vehicles with air conditioner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1.5 Further information on air conditioner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2 Notes on air conditioner repair work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.1 Contact corrosion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.2 Notes on air conditioner guided fault-finding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.3 Checking electrical components of air conditioner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.4 Checking of electrical components actuated by the air conditioner . . . . . . . . . . . . . . . . . . 26

3 Servicing work on refrigerant circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.1 Exploded view of refrigerant circuit components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.2 Removing and installing high-pressure sender G65 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.3 Checking pressure signal from high-pressure sender G65 . . . . . . . . . . . . . . . . . . . . . . . . 35

3.4 O-ring seals for refrigerant circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.5 Detaching air conditioner compressor from holder/attaching (vehicles with 4 or 6-cyl. engine)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.6 Detaching air conditioner compressor from holder/attaching (vehicles with 5-cyl. engine)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3.7 Checking cut-in signal for air conditioner compressor regulating valve N280 . . . . . . . . . . 45

4 Replacing air conditioner compressor pulley . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.1 Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.2 Replacing pulley (“Denso” air conditioner compressor, version “1”) . . . . . . . . . . . . . . . . . . 49

4.3 Detaching pulley (version “1”) from “Denso” air conditioner compressor/re-attaching . . . . 50

4.4 Replacing pulley (“Denso” air conditioner compressor, version “2”) . . . . . . . . . . . . . . . . . . 52

4.5 Detaching pulley from “Denso” air conditioner compressor/re-attaching (version “2”) . . . . 54

4.6 Replacing pulley (“Sanden” air conditioner compressor) . . . . . . . . . . . . . . . . . . . . . . . . . . 56

5 Components for control and regulation of air conditioner not located in passenger

compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

5.1 Components not located in passenger compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5.2 Checking, removing and installing passenger compartment forced air extractor . . . . . . . . 65

5.3 Removing/installing, checking and cleaning plenum chamber water drain . . . . . . . . . . . . 67

Contents i

Page 4

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Heating and Air Conditioning - Edition 04.2009

5.4 Checking, removing and installing cover and grille of fresh-air intake . . . . . . . . . . . . . . . . 68

6 Components for control and regulation of air conditioner located in passenger

compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.1 Components located in passenger compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.2 Removing and installing dash panel vent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

6.3 Cleaning evaporator of air conditioner with ultrasonic air conditioner cleaning unit VAS 6189

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

6.4 Removing and installing sunlight penetration photosensor G107 . . . . . . . . . . . . . . . . . . . . 77

6.5 Removing and installing air conditioner operating unit, Climatronic control unit J255 . . . . 78

6.6 Removing and installing dash panel temperature sensor blower V42 . . . . . . . . . . . . . . . . 82

6.7 Removing/installing and checking condensate drain hose . . . . . . . . . . . . . . . . . . . . . . . . . . 84

6.8 Removing and installing front left (or right) chest vent temperature sensor . . . . . . . . . . . . 85

7 Air conditioner unit components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

7.1 Removing and installing air recirculation flap control motor V113 . . . . . . . . . . . . . . . . . . . . 89

7.2 Preparing adapter lead for control motor actuation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

7.3 Removing and installing Central flap control motor V70 . . . . . . . . . . . . . . . . . . . . . . . . . . 91

7.4 Removing and installing right temperature flap control motor V159 . . . . . . . . . . . . . . . . . . 93

7.5 Removing and installing evaporator outflow temperature sender G263 . . . . . . . . . . . . . . 94

7.6 Removing and installing left footwell vent temperature sender G261 . . . . . . . . . . . . . . . . 95

7.7 Removing and installing right footwell vent temperature sender G262 . . . . . . . . . . . . . . . . 95

7.8 Removing and installing dust and pollen filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

7.9 Notes on dust and pollen filter with activated charcoal element . . . . . . . . . . . . . . . . . . . . . . 97

7.10 Removing and installing fresh air blower control unit J126 and fresh air blower V2 . . . . . . 98

7.11 Removing/installing and operation of air flow flap control motor V71 . . . . . . . . . . . . . . . . 101

7.12 Removing and installing defroster flap control motor V107 . . . . . . . . . . . . . . . . . . . . . . . . 107

7.13 Removing and installing left temperature flap control motor V158 . . . . . . . . . . . . . . . . . . 109

7.14 Removing and installing supplementary heater element Z35 . . . . . . . . . . . . . . . . . . . . . . 111

8 Removing and installing heat exchanger of air conditioner unit (heater) . . . . . . . . . . . . . . 114

8.1 Preparation for heat exchanger removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

8.2 Removing and installing heat exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

9 Block diagram of air distribution system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

9.1 Air routing and air distribution in passenger compartment . . . . . . . . . . . . . . . . . . . . . . . . . . 122

9.2 Air intake, air outlet and air routing in air conditioner unit (heater) . . . . . . . . . . . . . . . . . . 124

10 Checking cooling output of air conditioner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

10.1 Checking cooling output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

11 Checking heat output of air conditioner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

11.1 Checking heat output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

12 Servicing refrigerant circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

12.1 Servicing refrigerant circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

12.2 Detaching refrigerant pipes at air conditioner compressor/attaching . . . . . . . . . . . . . . . . 146

12.3 Removing and installing air conditioner compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

12.4 Detaching and re-attaching refrigerant pipes from condenser . . . . . . . . . . . . . . . . . . . . . . 151

12.5 Removing and installing condenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

12.6 Removing and installing receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

12.7 Removing and installing dryer cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

12.8 Detaching and re-attaching refrigerant pipes from expansion valve . . . . . . . . . . . . . . . . . . 166

12.9 Removing and installing expansion valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

12.10 Removing and installing air conditioner unit (heater) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

12.11 Removing and installing intake housing with recirculated-air and air-flow/fresh-air flap . . 176

13 Dismantling and assembling air conditioner unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

13.1 Detaching and re-attaching electrical add-on components from air conditioner unit . . . . . . 178

13.2 Dismantling and assembling air conditioner unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

13.3 Flap at outlet to defroster vents of air distribution housing of air conditioner . . . . . . . . . . . . 183

13.4 Dismantling and assembling evaporator housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

13.5 Removing and installing evaporator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

ii Contents

Page 5

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Heating and Air Conditioning - Edition 04.2009

13.6 Starting up air conditioner after charging refrigerant circuit . . . . . . . . . . . . . . . . . . . . . . . . 186

14 Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Contents iii

Page 6

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Heating and Air Conditioning - Edition 04.2009

iv Contents

Page 7

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Heating and Air Conditioning - Edition 04.2009

80 – Heating

1 Notes on heater repair work

WARNING

Remove the appropriate fuse(s) before working on wiring.

Note

Disconnect the battery -A- before starting electric welding work

on the vehicle ⇒ Electrical system; Rep. Gr. 27

♦ Contact corrosion ⇒ page 1

♦ Notes on heater guided fault-finding ⇒ page 1

♦ Checking electrical components of heater ⇒ page 2

♦ Checking of electrical components actuated by the heater

⇒ page 2

Audi TT 2007 ➤

1.1 Contact corrosion

Contact corrosion can occur if use is made of unsuitable con‐

necting elements, bolts, nuts, washers, rivets, plugs, grommets,

adhesives, etc.

For this reason, only connecting elements with a special surface

coating are fitted at the factory. In addition, rubber components,

plastic components and adhesives are made of non-conductive

materials. These tested, aluminium-compatible components are

also available as replacement parts ⇒ Electronic parts catalogue .

Important:

♦ Always fit new parts in cases of doubt about reusability.

♦ We recommend the use of genuine replacement parts only, as

these have been checked and are compatible with aluminium

⇒ Electronic parts catalogue .

♦ We advise using Audi accessories ⇒ Electronic parts cata‐

logue .

♦ Damage caused by contact corrosion is not covered by war‐

ranty.

1.2 Notes on heater guided fault-finding

♦ There are different versions of the heater operating unit, Cli‐

matronic control unit -J255- . When renewing, observe precise

allocation. ⇒ Electronic parts catalogue

♦ Heater self-diagnosis is to be performed by way of the “Guided

fault-finding” function using the vehicle diagnostic, testing and

information system ⇒ "Guided fault-finding" function of vehicle

diagnostic, testing and information system VAS 5051.

♦ At present heater operating units, Climatronic control unit -

J255- can be exchanged in the familiar manner, as component

protection is currently not active ⇒ "Guided fault-finding" func‐

tion of vehicle diagnostic, testing and information system VAS

5051 .

♦ If a heater operating unit, Climatronic control unit -J255- is to

be replaced, interrogate the encoding and adaption (of the

1. Notes on heater repair work 1

Page 8

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Heating and Air Conditioning - Edition 04.2009

heater operating unit, Climatronic control unit -J255- ) prior to

removal by way of the “Control unit replacement” function ⇒

"Guided fault-finding" function of vehicle diagnostic, testing

and information system VAS 5051 .

1.3 Checking electrical components of heat‐

er

The heater electrical components are identical to the air condi‐

tioner components. The electrical checks for the various heater

components are therefore performed in the same manner as for

the components of the air conditioner ⇒ page 25 and ⇒ "Guided

fault-finding" function of vehicle diagnostic, testing and informa‐

tion system VAS 5051.

Vehicles with no air conditioner (heater only) are not fitted with

various components which are required for control purposes on

vehicles with an air conditioner ( air conditioner compressor reg‐

ulating valve -N280- , right temperature flap control motor -V159- ,

temperature sensor blower -V42- etc.) ⇒ "Guided fault-finding"

function of vehicle diagnostic, testing and information system

VAS 5051 and ⇒ Current flow diagrams, Electrical fault finding

and Fitting locations.

Note

The “Electrical checks” function is not described in this Workshop

Manual. When implementing electrical checks by way of the “Gui‐

ded fault-finding” function, information is given on the functions to

be checked ⇒ "Guided fault-finding" function of vehicle diagnos‐

tic, testing and information system VAS 5051 .

1.4 Checking of electrical components ac‐

tuated by the heater

By the heater operating unit, Climatronic control unit -J255-

The vehicle electrical components actuated by the heater are

identical to those on vehicles with an air conditioner. The electrical

checks for the various components are therefore performed in the

same manner as for the components on vehicles with an air con‐

ditioner ⇒ "Guided fault-finding" function of vehicle diagnostic,

testing and information system VAS 5051 .

Operation and actuation of these components are identical on

vehicles with no air conditioner (heater only) and with an air con‐

ditioner ⇒ page 26 and ⇒ "Guided fault-finding" function of

vehicle diagnostic, testing and information system VAS 5051.

Note

Various electrical components in the vehicle (e.g. the heated rear

window -Z1- and the heated seats), which do not form part of the

heater, are actuated by the heater operating unit, Climatronic

control unit -J255- . Electrical checking of these components is to

be performed as described in the guided fault-finding routine (it is

identical for vehicles with and without an air conditioner)

⇒ page 26 and ⇒ "Guided fault-finding" function of vehicle di‐

agnostic, testing and information system VAS 5051.

2 Rep. Gr.80 - Heating

Page 9

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Heating and Air Conditioning - Edition 04.2009

2 Components for control and regula‐

tion of heater

Note

♦

In the event of a fault in the system, start by reading out the

fault memory of the heater operating unit, Climatronic control

unit -J255- ⇒ "Guided fault-finding" function of vehicle diag‐

nostic, testing and information system VAS 5051.

♦

If no fault is displayed, read out the measured value block of

the heater operating unit, Climatronic control unit -J255- and

actuate any problematic component by way of the “Final con‐

trol diagnosis” function ⇒ "Guided fault-finding" function of

vehicle diagnostic, testing and information system VAS 5051 .

♦

Electrical checking of the various components (control motors,

potentiometers and senders) is described in the guided faultfinding ⇒ "Guided fault-finding" function of vehicle diagnostic,

testing and information system VAS 5051.

♦ Perform the following operations on completion of repair work:

– Interrogate the fault memory of the heater operating unit, Cli‐

matronic control unit -J255- and erase any faults displayed ⇒

"Guided fault-finding" function of vehicle diagnostic, testing

and information system VAS 5051.

– Check the encoding of the heater operating unit, Climatronic

control unit -J255- ⇒ "Guided fault-finding" function of vehicle

diagnostic, testing and information system VAS 5051.

– If applicable, check the adaption of the heater operating unit,

Climatronic control unit -J255- ⇒ "Guided fault-finding" func‐

tion of vehicle diagnostic, testing and information system

VAS 5051.

– Perform basic setting of the heater operating unit, Climatronic

control unit -J255- ⇒ "Guided fault-finding" function of vehicle

diagnostic, testing and information system VAS 5051.

Audi TT 2007 ➤

♦ Components not located in passenger compartment

⇒ page 4

♦ Components located in passenger compartment

⇒ page 5

2. Components for control and regulation of heater 3

Page 10

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Heating and Air Conditioning - Edition 04.2009

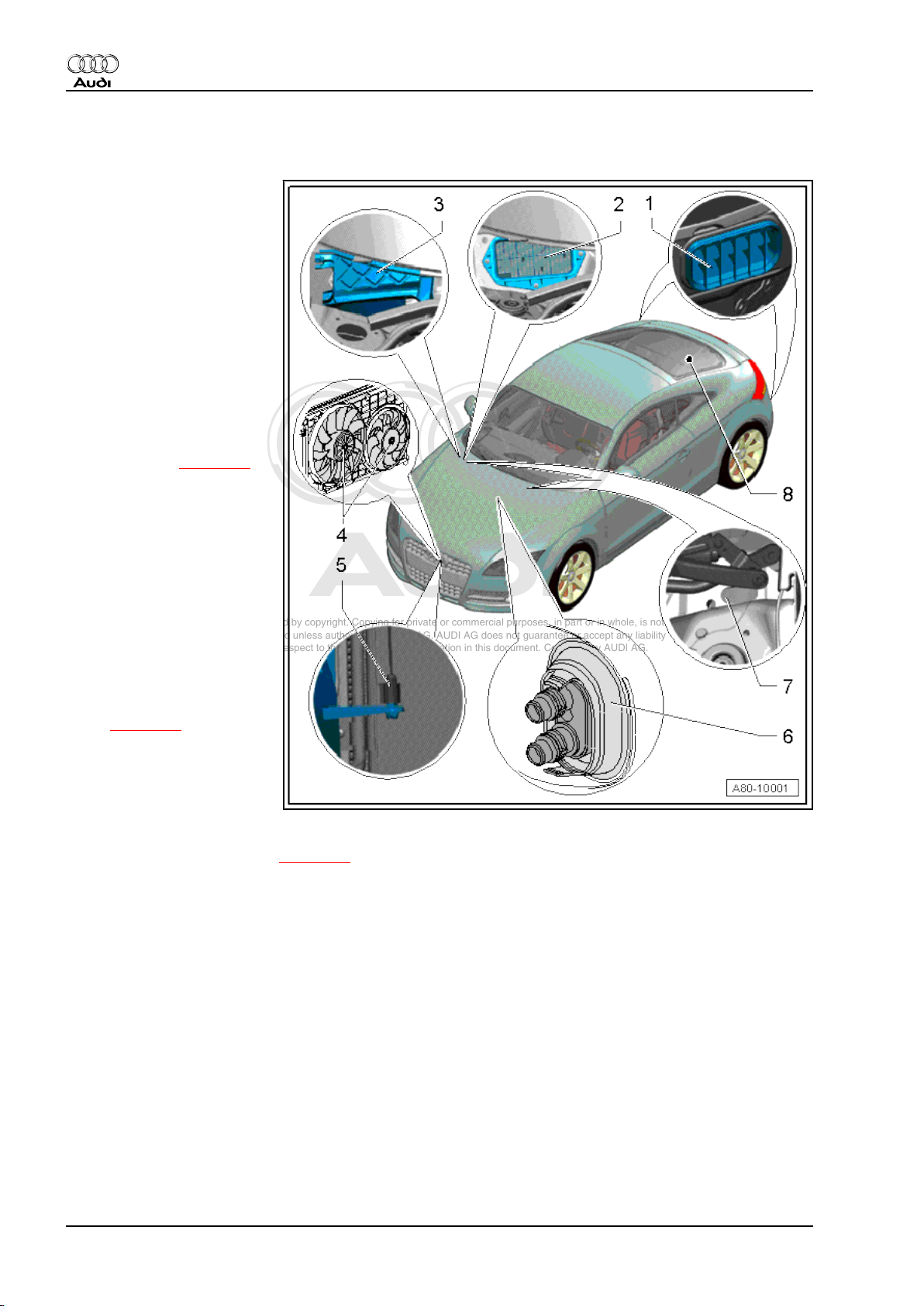

2.1 Components not located in passenger compartment

1 - Forced air extractor

❑ One forced air extractor

each is fitted on the left

and right beneath the

rear bumper.

❑ The sealing lips of the

vent frame must move

freely and close auto‐

matically.

❑ To ensure proper func‐

tioning of the passenger

compartment ventila‐

tion, the air ducts must

not be blocked by the

luggage compartment

lining.

❑ Checking ⇒ page 65

2 - Fresh-air intake grille

❑ Ensure correct position‐

ing, stops ingress of for‐

eign matter (e.g. leaves)

into the intake housing

of the heater.

❑ Check the bonded seal

for damage and proper

attachment. This seal

stops water running be‐

neath the intake grille in‐

to the intake housing of

the heater.

❑ Removing and installing

⇒ page 68

3 - Cover for fresh-air intake

❑ Check the bonded seal

for damage and proper

attachment. This seal

stops water running be‐

tween the lower frame of the windscreen and the cover into the intake housing of the heater.

❑ Removing and installing ⇒ page 68 and ⇒ General body repairs, exterior; Rep. Gr. 50

4 - Radiator fan -V7- and radiator fan 2 -V177-

❑ Different versions of the radiator fan -V7- and radiator fan 2 -V177- are fitted depending on the vehicle

equipment ⇒ Electronic parts catalogue

❑ In normal vehicle operation, the radiator fans are not actuated by the heater operating unit, Climatronic

control unit -J255- . The measured value block of the heater operating unit shows that the fans are not

being actuated; for checking refer to ⇒ "Guided fault-finding" function of vehicle diagnostic, testing and

information system VAS 5051 .

❑ The request for activation of the radiator fan(s) -V7- is only transmitted by the heater operating unit,

Climatronic control unit -J255- by way of the data bus to the engine control unit in the “Final control

diagnosis” function. With the engine running, the engine control unit then actuates the fan(s) ( radiator

fan -V7- and radiator fan 2 -V177- ) directly or by way of the radiator fan control unit -J293- ⇒ "Guided

fault-finding" function of vehicle diagnostic, testing and information system VAS 5051 and ⇒ Engine,

mechanics; Rep. Gr. 19 .

❑ With the engine running, the corresponding engine control unit switches e.g. the radiator fan -V7- and

the radiator fan 2 -V177- (directly or via the radiator fan control unit -J293- ) infinitely to the desired output

(depending on the engine type) ⇒ "Guided fault-finding" function of vehicle diagnostic, testing and in‐

formation system VAS 5051 and ⇒ Current flow diagrams, Electrical fault finding and Fitting locations.

4 Rep. Gr.80 - Heating

Page 11

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Heating and Air Conditioning - Edition 04.2009

5 - Ambient temperature sensor -G17-

❑ The measured value of the ambient temperature sensor -G17- is not used by the heater operating unit,

Climatronic control unit -J255- for heater regulation. Its measured value is however used to calculate the

permissible ON time for the heated rear window -Z1- .

❑ The measured value of the ambient temperature sensor -G17- is evaluated by the control unit with display

in dash panel insert -J285- and transmitted by way of the convenience data bus system to the heater

operating unit, Climatronic control unit -J255- ⇒ "Guided fault-finding" function of vehicle diagnostic,

testing and information system VAS 5051 .

Removing and installing:

– Remove the bumper cover ⇒ General body repairs, exterior; Rep. Gr. 50 .

– Unplug the connector at the temperature sensor and unclip the temperature sensor from the mount in

the air duct.

6 - Connections for coolant hoses to heating system heat exchanger

❑ Detaching coolant hoses from connections to heating system heat exchanger/attaching ⇒ page 114

(removing and installing air conditioner heat exchanger)

❑ For incorporation of heating system heat exchanger into engine coolant circuit, refer to ⇒ Engine, me‐

chanics; Rep. Gr. 19 .

7 - Plenum chamber water drains

❑ One water drain each is fitted on the left and right in the plenum chamber.

❑ Removing/installing grommet, checking and cleaning ⇒ page 67 .

8 - Heated rear window -Z1-

❑ The rear window heating request is transmitted by the heater operating unit, Climatronic control unit -

J255- via the convenience data bus. The heated rear window -Z1- is actuated by way of the onboard

supply control unit -J519- ⇒ "Guided fault-finding" function of vehicle diagnostic, testing and information

system VAS 5051 and ⇒ Current flow diagrams, Electrical fault finding and Fitting locations.

❑ Notes on operation of heated rear window ⇒ page 27

❑ Removing and installing rear window ⇒ General body repairs, exterior; Rep. Gr. 64 .

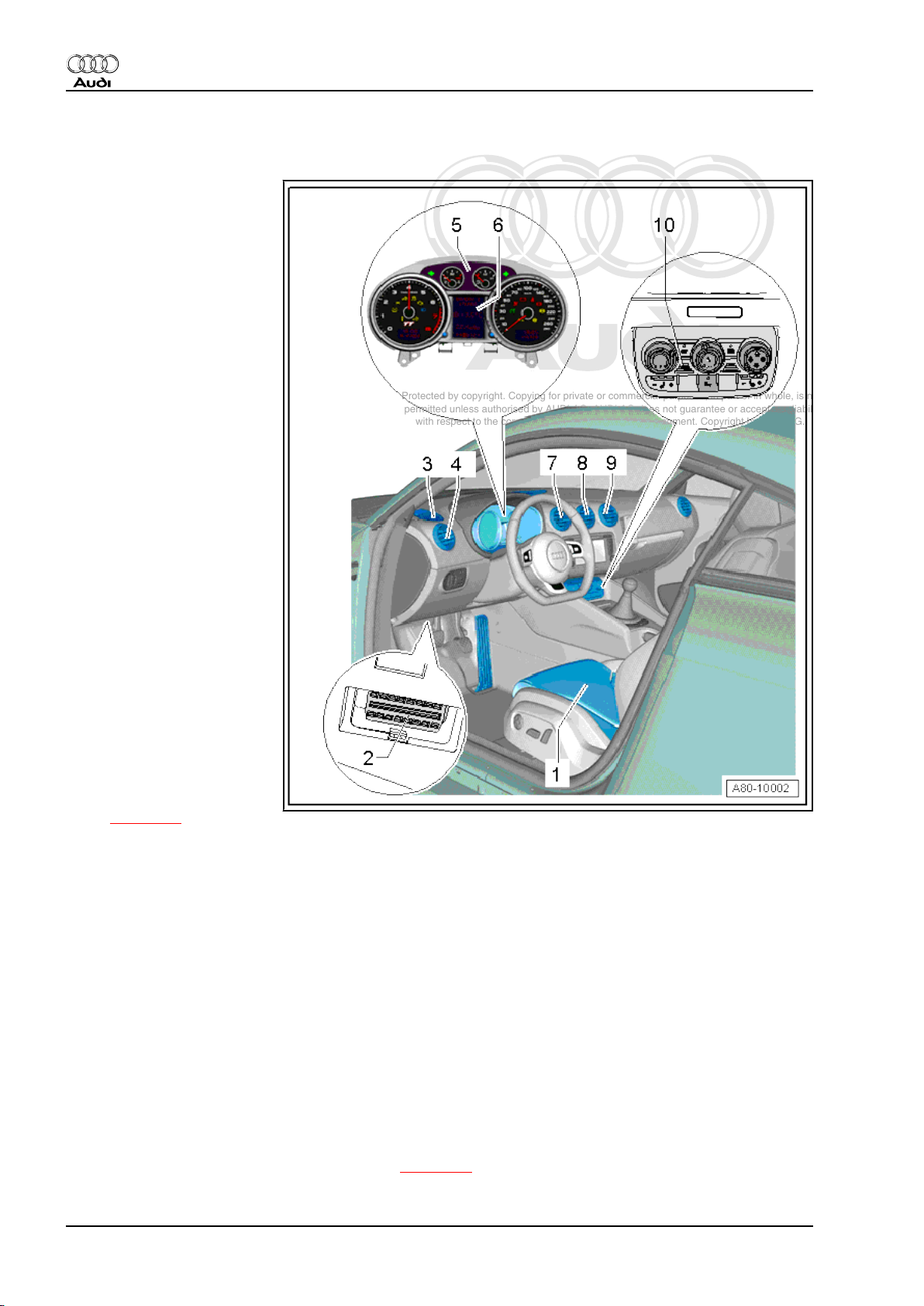

2.2 Components located in passenger com‐

partment

♦ Component group “1” (components on left side) ⇒ page 6

♦ Component group “2” (components on right side)

⇒ page 8

2. Components for control and regulation of heater 5

Page 12

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Heating and Air Conditioning - Edition 04.2009

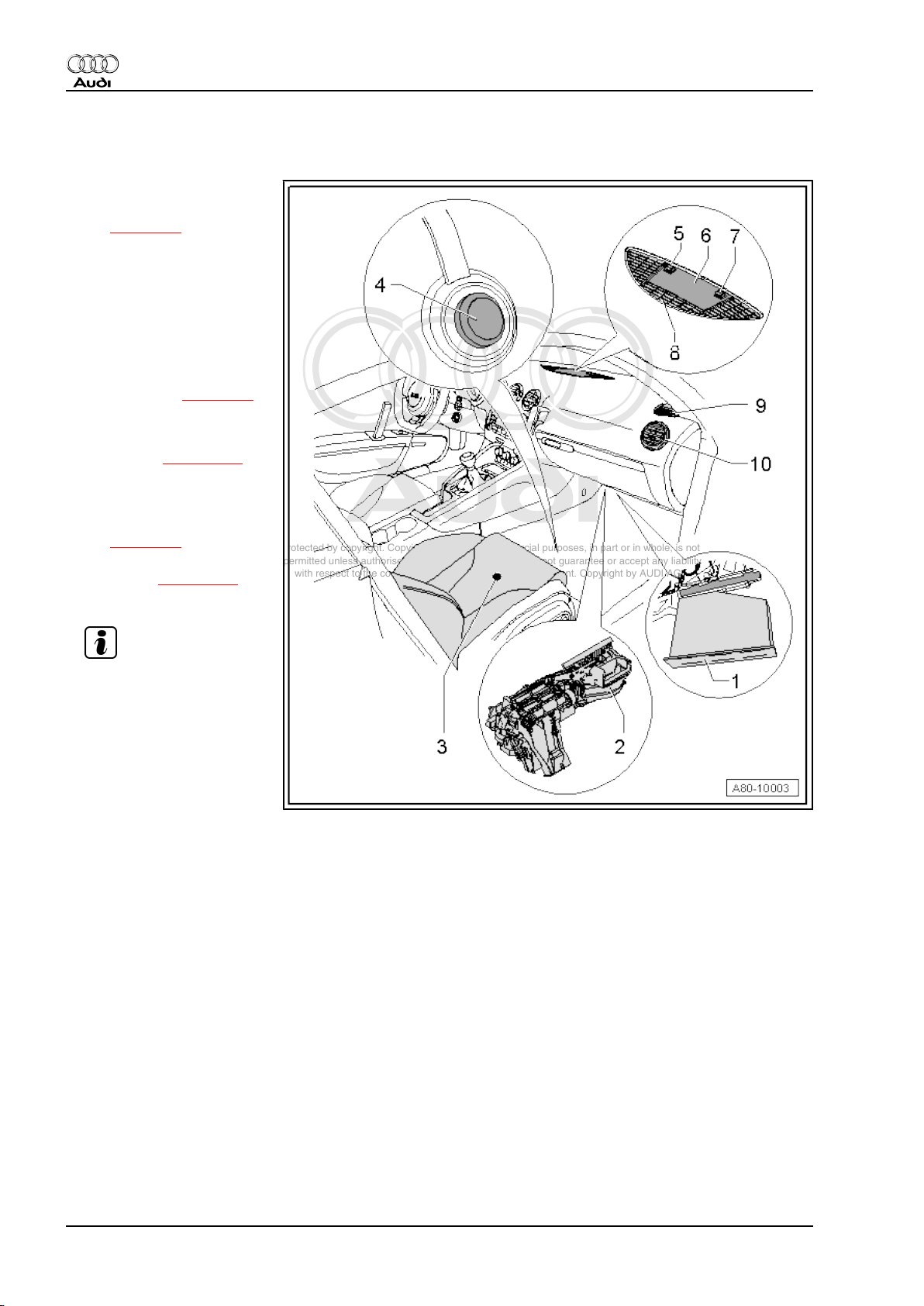

2.2.1 Component group “1” (components on left side)

1 - Front left seat temperature

sender -G344- and front left

seat heating -Z45-

❑ Not all vehicles feature

seat heating (optional

extra).

❑ Actuation of the seat

heating is indicated in

the measured value

block of the heater op‐

erating unit, Climatronic

control unit -J255- ; for

checking refer to ⇒

"Guided fault-finding"

function of vehicle diag‐

nostic, testing and infor‐

mation system

VAS 5051.

❑ Servicing seat heating

⇒ General body repairs,

interior; Rep. Gr. 74 .

2 - Diagnosis connection

❑ Heater self-diagnosis

procedure ⇒ "Guided

fault-finding" function of

vehicle diagnostic, test‐

ing and information sys‐

tem VAS 5051 .

3 - Defroster vent / left side

window

❑ Removing and installing

⇒ General body repairs,

interior; Rep. Gr. 70 .

4 - Left dash panel vent

❑ Removing and installing

dash panel vents

⇒ page 74 and ⇒ Gen‐

eral body repairs, interior; Rep. Gr. 70

5 - Control unit with display in dash panel insert -J285-

❑ With ambient temperature indicator -G106❑ The control unit with display in dash panel insert -J285- evaluates the measured value of the ambient

temperature sensor -G17- and then transmits this via the convenience data bus to the heater operating

unit, Climatronic control unit -J255- ⇒ "Guided fault-finding" function of vehicle diagnostic, testing and

information system VAS 5051 .

6 - Ambient temperature indicator -G106-

❑ The ambient temperature indicator -G106- is part of the control unit with display in dash panel insert -

J285- .

❑ The measured value of the ambient temperature sensor -G17- is evaluated by the control unit with display

in dash panel insert -J285- and transmitted by way of the convenience data bus to the heater operating

unit, Climatronic control unit -J255- ⇒ "Guided fault-finding" function of vehicle diagnostic, testing and

information system VAS 5051 .

❑ If the temperature reading is incorrect, check the measured value of the temperature sensor ⇒ "Guided

fault-finding" function of vehicle diagnostic, testing and information system VAS 5051.

7 - Centre left dash panel vent

❑ Removing and installing dash panel vents ⇒ page 74 and ⇒ General body repairs, interior; Rep. Gr.

70

6 Rep. Gr.80 - Heating

Page 13

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Heating and Air Conditioning - Edition 04.2009

8 - Centre dash panel vent

❑ Removing and installing dash panel vents ⇒ page 74 and ⇒ General body repairs, interior; Rep. Gr.

70

9 - Centre right dash panel vent

❑ Removing and installing dash panel vents ⇒ page 74 and ⇒ General body repairs, interior; Rep. Gr.

70

10 - Heater operating unit, Climatronic control unit -J255-

❑ Different versions, with or without seat heating switch, for assignment refer to ⇒ Electronic parts cata‐

logue

❑ Vehicles with 5-cyl. engine are only to be fitted with heater operating units with part number 8J0 819 043

as of index “D” ⇒ Electronic parts catalogue and ⇒ "Guided fault-finding" function of vehicle diagnostic,

testing and information system VAS 5051 .

❑ Removing and installing ⇒ page 78 (removing and installing air conditioner operating unit, Climatronic

control unit -J255- ).

❑ The heater operating unit, Climatronic control unit -J255- has neither an integrated dash panel temper‐

ature sensor -G56- nor a temperature sensor blower -V42- .

❑ Also heed the additional notes on the air conditioner operating unit, Climatronic control unit -J255-

⇒ page 78 .

❑ Heater operating unit, Climatronic control unit -J255- self-diagnosis is to be performed as described in

the guided fault-finding routine ⇒ "Guided fault-finding" function of vehicle diagnostic, testing and infor‐

mation system VAS 5051 .

❑ The buttons and rotary controls are illuminated by LEDs which cannot be replaced separately.

❑ The function indicator lamps in the buttons and rotary controls as well as the rotary controls and buttons

cannot be replaced separately.

2. Components for control and regulation of heater 7

Page 14

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Heating and Air Conditioning - Edition 04.2009

2.2.2 Component group “2” (components on right side)

1 - Dust and pollen filter

❑ Removing and installing

⇒ page 96

❑ Observe replacement

intervals ⇒ Mainte‐

nance tables

❑ Vehicles with no air con‐

ditioner (heater only)

are fitted with a dust and

pollen filter with no acti‐

vated charcoal element

⇒ Electronic parts cata‐

logue and ⇒ page 97

2 - Heater with attachments

❑ Air routing in heater and

vehicle ⇒ page 122 (air

routing is identical for

vehicles without and

with air conditioner).

❑ Heater components

⇒ page 10

❑ Removing and installing

heater ⇒ page 170 (re‐

moving and installing air

conditioner unit)

Note

3 - Front right seat temperature

sender -G345- and front right

seat heating -Z46-

❑ Not all vehicles feature

seat heating (optional

extra).

❑ Actuation of the seat

heating is indicated in

the measured value block of the heater operating unit, Climatronic control unit -J255- ; for checking refer

to ⇒ "Guided fault-finding" function of vehicle diagnostic, testing and information system VAS 5051.

❑ Servicing seat heating ⇒ General body repairs, interior; Rep. Gr. 74 .

4 - Sealing plug

❑ On vehicles with no air conditioner (heater only), the opening at the transmission tunnel for the air con‐

ditioner condensate drain must be sealed with a plug.

5 - Cap

❑ Removing and installing ⇒ General body repairs, interior; Rep. Gr. 70

❑ Vehicles with no air conditioner (heater only) are not fitted with a sunlight penetration photosensor -

G107- .

6 - Cover for centre dash panel loudspeaker

❑ Removing and installing cover ⇒ General body repairs, interior; Rep. Gr. 70

7 - Central locking system LED

❑ Removing and installing ⇒ General body repairs, interior; Rep. Gr. 70

8 - Defroster vent / windscreen

❑ Removing and installing ⇒ General body repairs, interior; Rep. Gr. 70

9 - Defroster vent / right side window

❑ Removing and installing ⇒ General body repairs, interior; Rep. Gr. 70

8 Rep. Gr.80 - Heating

Page 15

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Heating and Air Conditioning - Edition 04.2009

10 - Right dash panel vent

❑ Removing and installing dash panel vents ⇒ page 74 and ⇒ General body repairs, interior; Rep. Gr.

70

2. Components for control and regulation of heater 9

Page 16

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Heating and Air Conditioning - Edition 04.2009

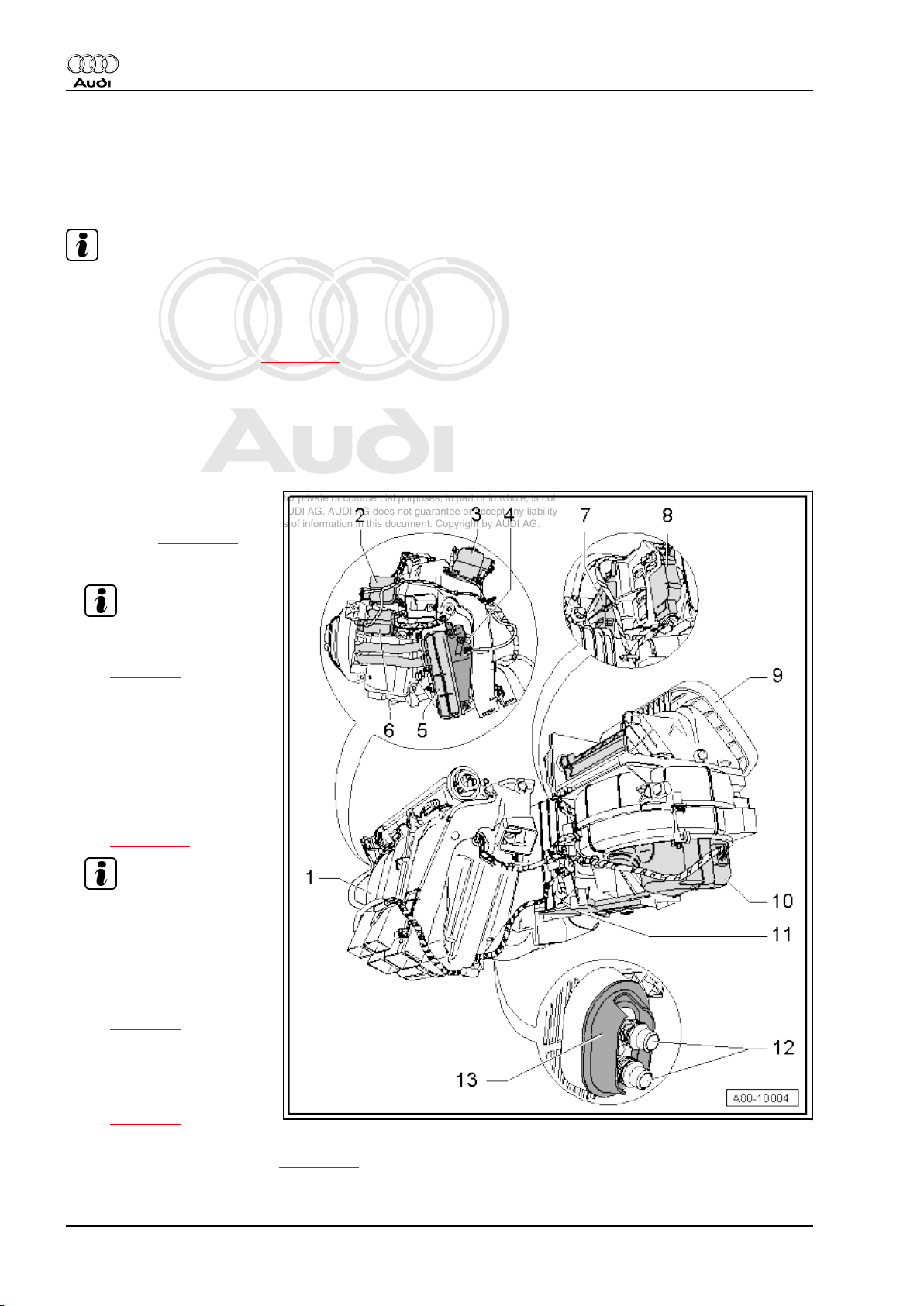

3 Heater components

Heed the notes on control and regulation of the heater compo‐

nents ⇒ page 3 .

Note

♦

The air routing in the heater and in the vehicle is the same as

for vehicles with an air conditioner ⇒ page 122 (block diagram

of air distribution).

♦

The heater is to be removed and installed in the same manner

as the air conditioner unit ⇒ page 170 (removing and installing

air conditioner unit).

♦

The colour indicated for the levers and the connecting ele‐

ments to the various control motors applies to left-hand drive

vehicles. On right-hand drive vehicles, these components

have a different colour.

1 - Heater with attachments

❑ Removing and installing

heater ⇒ page 170 (re‐

moving and installing air

conditioner unit)

Note

❑ Dismantling and assem‐

2 - Defroster flap control motor

-V107❑ With potentiometer for

❑ Colour code for lever:

❑ Removing and installing

3 - Central flap control motor V70-

❑ With potentiometer for

❑ Removing and installing

4 - Supplementary heater ele‐

ment -Z35-

❑ Only available for vehi‐

❑ Function, checking ⇒ page 29

❑ Removing and installing ⇒ page 111

bling heater

⇒ page 16

defroster flap control

motor -G135-

blue

⇒ page 107

Note

centre flap servomotor G112-

⇒ page 91

cles with diesel engine

⇒ page 29 .

10 Rep. Gr.80 - Heating

Page 17

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Heating and Air Conditioning - Edition 04.2009

5 - Heating system heat exchanger

❑ Removing and installing ⇒ page 114 (removing and installing heat exchanger of air conditioner unit)

6 - Left temperature flap control motor -V158-

❑ With potentiometer for left temperature flap control motor -G220❑ Colour code for lever: white

❑ Removing and installing ⇒ page 109

Note

7 - Air flow flap control motor -V71-

❑ With potentiometer for air flow flap control motor -G113❑ Removing and installing ⇒ page 101

8 - Air recirculation flap control motor -V113-

❑ With potentiometer for air recirculation flap control motor -G143❑ Removing and installing ⇒ page 89

9 - Intake housing with recirculated-air and air flow/fresh-air flap

❑ Removing and installing ⇒ page 176

10 - Fresh air blower control unit -J126- and fresh air blower -V2-

❑ Removing and installing

⇒ page 98

❑ Different versions; on the fresh air blowers -V2- fitted at the start of production, the fresh air blower control

unit -J126- and the fresh air blower -V2- form a cast assembly (cannot be replaced separately). Fresh

air blower control units -J126- and fresh air blowers -V2- which are bolted together (and can be replaced

separately) were gradually introduced in Model Year 2007 ⇒ page 98 and ⇒ Electronic parts catalogue .

❑ The fresh air blower -V2- features an integrated fresh air blower control unit -J126- . Depending on the

version, these two components can be replaced separately or only as an assembly.

❑ Checking ⇒ "Guided fault-finding" function of vehicle diagnostic, testing and information system

VAS 5051

11 - Dust and pollen filter

❑ Removing and installing ⇒ page 96

❑ Observe replacement intervals ⇒ Maintenance tables

❑ Vehicles with no air conditioner (heater only) are fitted with a dust and pollen filter with no activated

charcoal element ⇒ Electronic parts catalogue and ⇒ page 97

12 - Coolant pipes to heat exchanger

13 - Grommet

❑ For sealing the coolant pipe opening through the plenum chamber bulkhead to the engine compartment

3. Heater components 11

Page 18

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Heating and Air Conditioning - Edition 04.2009

4 Checking actuation of temperature

flaps and heat output

Note

♦

The Audi TT with no air conditioner (heater only) is only fitted

with one temperature flap control motor. The two temperature

flaps for the left and right side are linked by way of the shaft in

the heater air distributor housing and thus moved jointly by the

left temperature flap control motor -V158- ⇒ page 16 .

♦

As vehicles with no air conditioner (heater only) have no tem‐

perature sensors, there is no regulation of the outlet temper‐

ature. The left temperature flap control motor -V158- is set by

the heater operating unit, Climatronic control unit -J255- to a

position calculated on the basis of the temperature setting at

the rotary temperature control -A- and the learnt control motor

stop values.

♦ If the coolant circuit is not completely bled after filling, air may

accumulate in the heating system heat exchanger and thus

reduce the heat output. In addition, noise may occur or com‐

plaints may be received about differences in the temperature

of the air from the driver's and front passenger's vents.

Remedy:

– Perform a lengthy test drive at high engine speed (at least 10

minutes, engine speed above 2500 rpm). In doing so, select

a low gear to prevent excessive vehicle speed.

– In the event of complaints about poor heat output at certain

engine speeds, check incorporation of the heating system

heat exchanger into the coolant circuit. If the two coolant hoses

(supply and return) from the engine have been interchanged,

coolant will flow in the wrong direction through the heat ex‐

changer ⇒ Engine, mechanics; Rep. Gr. 19 .

♦ For checking heat output and actuation of the temperature

flaps, refer to ⇒ page 12 .

4.1 Checking heat output and actuation of

temperature flaps

Special tools and workshop equipment required

♦ Vehicle diagnostic, testing and information system -VAS 5051

A- (or vehicle diagnostic and service information system -VAS

5052- )

♦ Commercially available thermometer (for temperature meas‐

urement; if applicable use thermometer with 2 probes for

simultaneous measurement of temperature e.g. on right and

left)

♦ Test requirements ⇒ page 12

♦ Checking heat output ⇒ page 13 .

4.1.1 Test requirements:

♦ Coolant circuit bled in specified manner ⇒ Engine, mechanics;

Rep. Gr. 19

♦ All air ducts, covers and seals OK and properly installed.

♦ Air flow through dust and pollen filter not impeded by contam‐

ination.

12 Rep. Gr.80 - Heating

Page 19

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Heating and Air Conditioning - Edition 04.2009

♦ Engine warm

♦ Fault memory of heater operating unit, Climatronic control unit

-J255- interrogated and erased, basic setting performed and

encoding of heater operating unit, Climatronic control unit J255- checked ⇒ "Guided fault-finding" function of vehicle

diagnostic, testing and information system VAS 5051 .

♦ Adaption of heater operating unit, Climatronic control unit -

J255- checked ⇒ "Guided fault-finding" function of vehicle

diagnostic, testing and information system VAS 5051 .

♦ Vehicle not exposed to sunlight

4.1.2 Checking heat output

– Close bonnet.

– Close the doors, windows and rear lid.

– Open all dash panel vents.

– Start heater self-diagnosis ⇒ "Guided fault-finding" function of

vehicle diagnostic, testing and information system VAS 5051 .

– Measure the ambient temperature (temperature in the work‐

shop).

– Start engine.

Audi TT 2007 ➤

4. Checking actuation of temperature flaps and heat output 13

Page 20

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Heating and Air Conditioning - Edition 04.2009

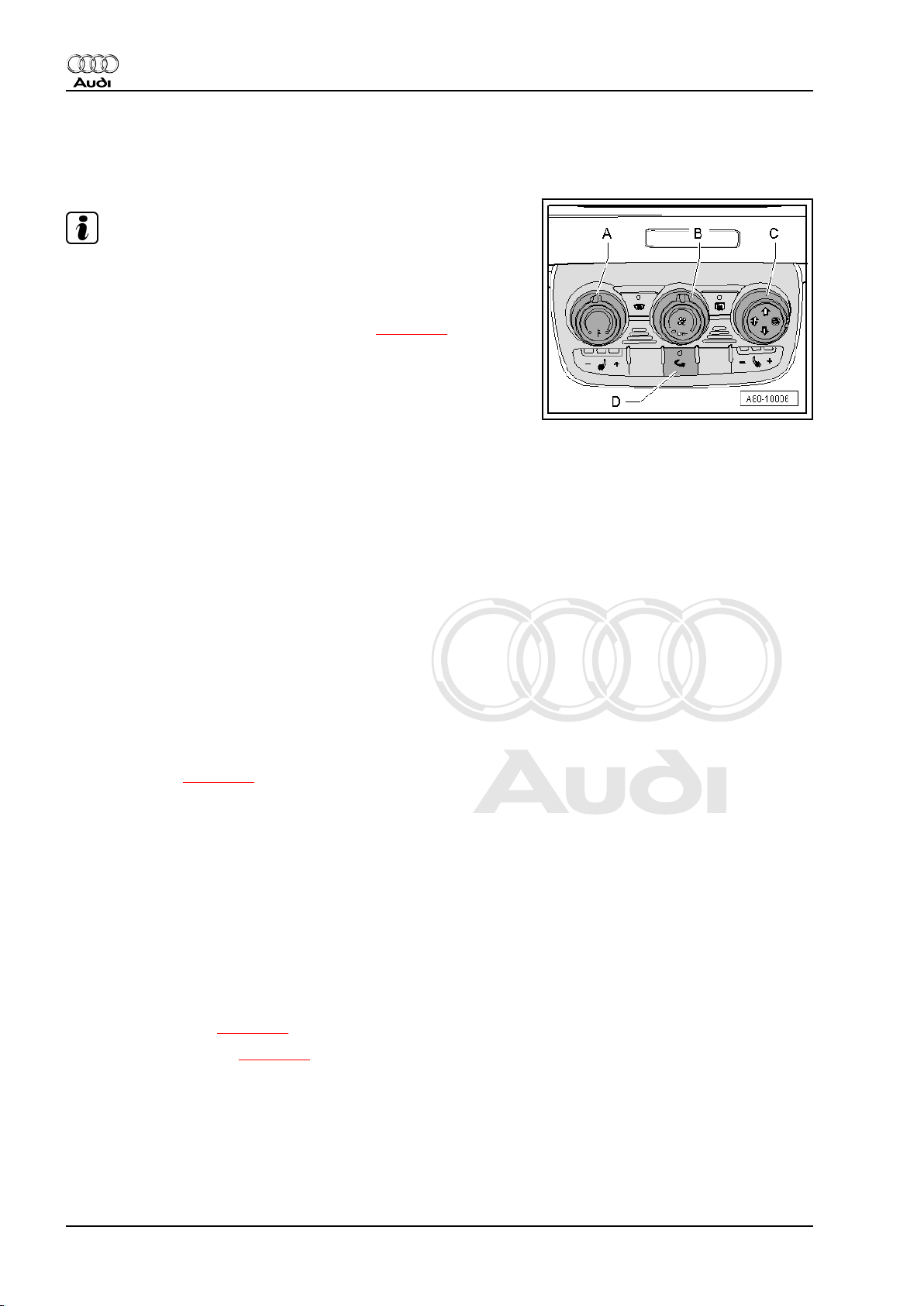

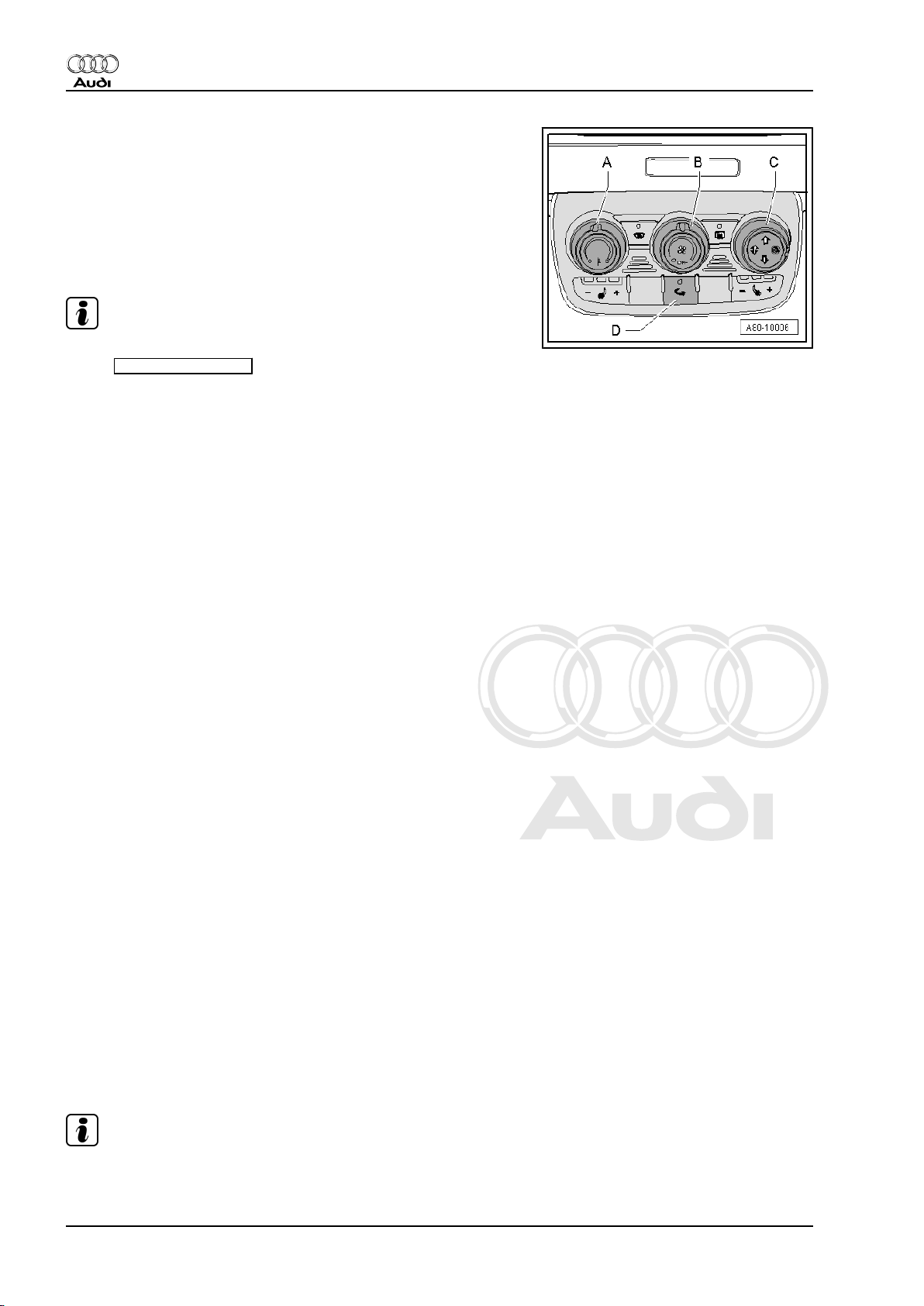

– Set the rotary temperature control -A- of the heater operating

unit, Climatronic control unit -J255- to the “cold” stop.

– Set the rotary air distribution control -C- of the heater operating

unit, Climatronic control unit -J255- such that air emerges from

the dash panel vents.

– Set the rotary fresh air blower speed control -B- of the heater

operating unit, Climatronic control unit -J255- to the “maximum

fresh air blower speed” stop.

Note

♦

The heater operates in fresh air mode, the indicator lamp in

the

recirculated air

♦

The fresh air blower runs at maximum speed.

button -D- does not light.

– Select the “Reading measured value block” function ⇒ "Gui‐

ded fault-finding" function of vehicle diagnostic, testing and

information system VAS 5051.

– Read out the measured value block with the display for the

position of the left temperature flap control motor -V158- ⇒

"Guided fault-finding" function of vehicle diagnostic, testing

and information system VAS 5051.

– Measure the temperature of the air emerging from the dash

panel vents on the left and right.

Specifications:

♦ The display shows that the left temperature flap control motor

-V158- is set to the “bottom” stop (“cold” stop).

♦ The temperature of the air emerging from the dash panel vents

on the left and right is max. 15 °C higher than the ambient

temperature previously measured (temperature increase in

heater less than 16 °C).

♦ The difference in the temperature of the air emerging from the

dash panel vents on the left and right is less than 8 °C.

– Set the rotary temperature control -A- of the heater operating

unit, Climatronic control unit -J255- to the “warm” stop.

– Read out the measured value block with the display for the

position of -V158- ⇒ "Guided fault-finding" function of vehicle

diagnostic, testing and information system VAS 5051.

– Measure the temperature of the air emerging from the dash

panel vents on the left and right.

Specifications:

♦ The display shows that the left temperature flap control motor

-V158- is set to the “top” stop (“warm” stop).

♦ The temperature of the air emerging from the dash panel vents

on the left and right increases to a value above 55 °C (at an

engine temperature of approx. 90 °C, depending on the in‐

stantaneous engine temperature).

♦ The difference in the temperature of the air emerging from the

dash panel vents on the left and right is less than 8 °C.

Note

The coolant flow through the heat exchanger (and thus the heat

output) is also governed by the engine speed.

14 Rep. Gr.80 - Heating

Page 21

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Heating and Air Conditioning - Edition 04.2009

– Set the rotary temperature control -A- of the heater operating

unit, Climatronic control unit -J255- to the “cold” stop.

– Read out the measured value block with the display for the

position of the left temperature flap control motor -V158- ⇒

"Guided fault-finding" function of vehicle diagnostic, testing

and information system VAS 5051.

– Measure the temperature of the air emerging from the dash

panel vents on the left and right.

Specifications:

♦ The display shows that the left temperature flap control motor

-V158- is set to the “bottom” stop (“cold” stop).

♦ The temperature of the air emerging from the dash panel vents

on the left and right drops within 5 minutes to a value max.15

°C higher than the ambient temperature previously measured.

Check the following if the readout does not match the specifica‐

tions:

♦ If the required heat output is not attained

– Bleeding of coolant circuit ⇒ Engine, mechanics; Rep. Gr. 19

– Incorporation of heating system heat exchanger into coolant

circuit ⇒ Engine, mechanics; Rep. Gr. 19

– Actuation and operation of the left temperature flap control

motor -V158- ⇒ "Guided fault-finding" function of vehicle di‐

agnostic, testing and information system VAS 5051.

– Foam seal for heating system heat exchanger ⇒ page 117

– Operation of temperature flaps in air distributor housing

⇒ page 124

– Thermostat (engine coolant may not warm up properly if ther‐

mostat is defective) ⇒ Engine, mechanics; Rep. Gr. 19

– Delivery of engine coolant pump ⇒ Engine, mechanics; Rep.

Gr. 19

♦ If the air emerging from the vents is too warm in the “cold”

setting

– Actuation and operation of the left temperature flap control

motor -V158- ⇒ "Guided fault-finding" function of vehicle di‐

agnostic, testing and information system VAS 5051.

– Operation of temperature flaps in air distributor housing

⇒ page 18

– The plenum chamber cover and the seal between the engine

compartment and the plenum chamber.

Audi TT 2007 ➤

4. Checking actuation of temperature flaps and heat output 15

Page 22

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Heating and Air Conditioning - Edition 04.2009

5 Dismantling and assembling heater

Removing and installing heater ⇒ page 170 (removing and in‐

stalling air conditioner unit)

Note

The heater is to be removed in the same manner as the air con‐

ditioner unit, with the exception of the work for those components

which are only fitted with an air conditioner.

♦ Detaching electrical add-on components from heater/re-at‐

taching ⇒ page 16 .

♦ Dismantling and assembling heater ⇒ page 18

♦ Dismantling and assembling air duct ⇒ page 20

5.1 Detaching electrical add-on compo‐

nents from heater/re-attaching

Note

The colour indicated for the levers and the connecting element to

the various control motors applies to left-hand drive vehicles. On

right-hand drive vehicles, these components have a different col‐

our.

16 Rep. Gr.80 - Heating

Page 23

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

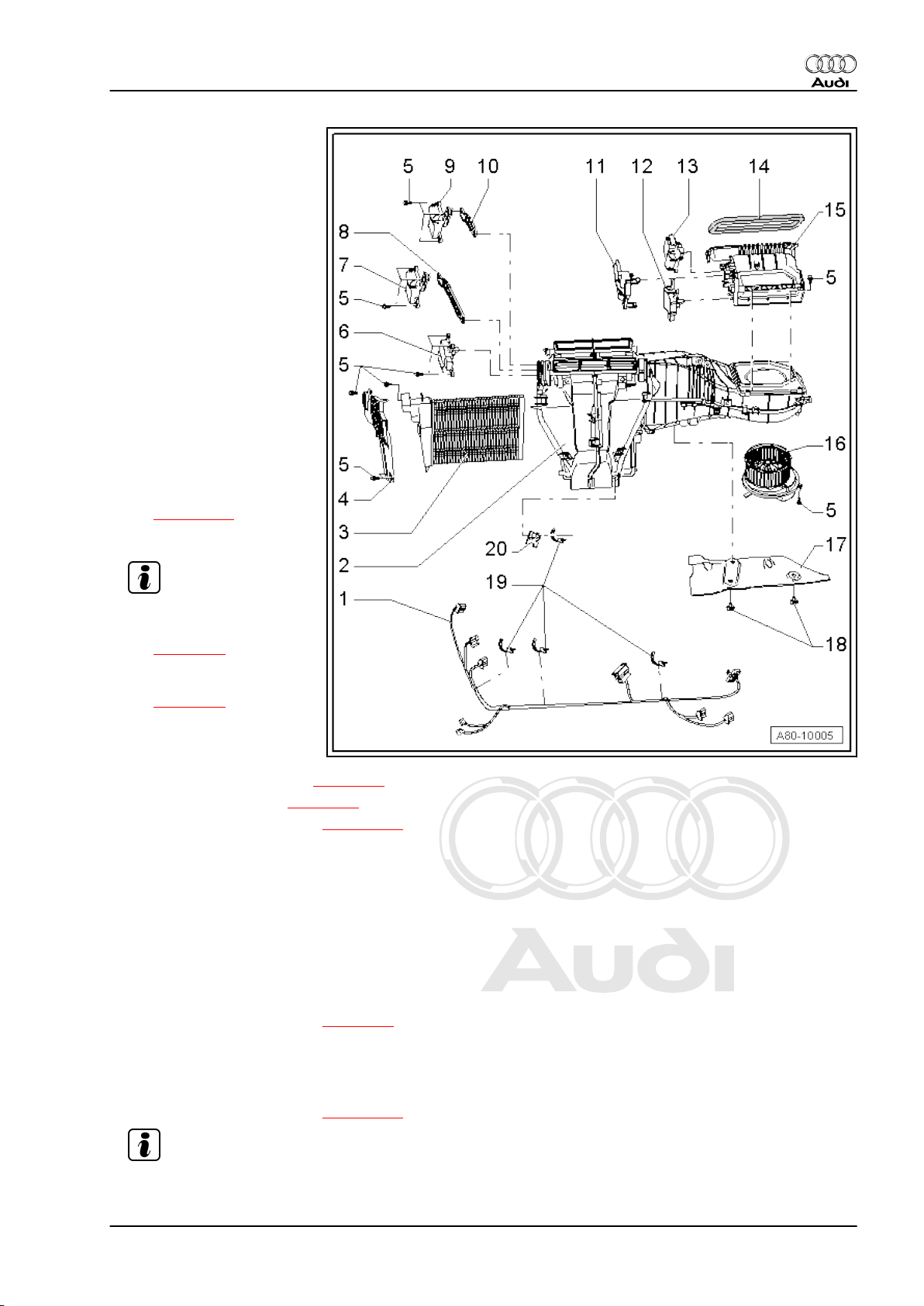

1 - Heater wiring harness

❑ Different versions (e.g.

with or without power

supply for supplementa‐

ry air heater element Z35- ) ⇒ Electronic

parts catalogue

❑ Mark assignment before

unplugging connectors

(identical connectors for

different control motors,

danger of interchange).

❑ Fasten the wiring har‐

ness to the attachment

points provided on the

housing (with cable ties

or at the mounts) such

that the harness cannot

come into contact with

moving parts.

2 - Heater

❑ Removing and installing

⇒ page 170 (removing

and installing air condi‐

tioner unit)

Audi TT 2007 ➤

Heating and Air Conditioning - Edition 04.2009

Note

❑ Dismantling and assem‐

bling heater

⇒ page 18

❑ Dismantling and assem‐

bling air duct

⇒ page 20

3 - Supplementary heater ele‐

ment -Z35-

❑ Only available for vehi‐

cles with diesel engine ⇒ page 29 .

❑ Function, checking ⇒ page 29

❑ Removing and installing ⇒ page 111

4 - Cover for coolant pipes and heat exchanger

❑ This illustration shows the version for vehicles with supplementary heater element -Z35- .

❑ Different versions for vehicles with/without supplementary heater element -Z35- (on vehicles with no

supplementary heater element -Z35- , the opening for the supplementary heater element -Z35- is sealed

with this cover) ⇒ Electronic parts catalogue

5 - Bolt

6 - Central flap control motor -V70-

❑ With potentiometer for centre flap servomotor -G112❑ Removing and installing ⇒ page 91

7 - Left temperature flap control motor -V158-

❑ With potentiometer for left temperature flap control motor -G220❑ Lever colour code: white

❑ Removing and installing ⇒ page 109

Note

5. Dismantling and assembling heater 17

Page 24

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Heating and Air Conditioning - Edition 04.2009

8 - Connecting rod to left temperature flap control motor -V158-

❑ Colour code: black

9 - Defroster flap control motor -V107-

❑ With potentiometer for defroster flap control motor -G135❑ Colour code for lever: blue

❑ Removing and installing ⇒ page 107

Note

10 - Connecting rod to defroster flap control motor -V107-

❑ Colour code: blue

11 - Cover and holder for air flow flap control motor -V71- and air recirculation flap control motor -V113-

❑ Removing and installing ⇒ page 101 (removing air recirculation flap control motor -V113- )

❑ Following installation, check both control motors held in position by this holder. Eliminate any clearance

if necessary by attaching a piece of foam to the inside of the attachment points of the holder

⇒ page 101 .

12 - Air recirculation flap control motor -V113-

❑ With potentiometer for air recirculation flap control motor -G143❑ Removing and installing ⇒ page 101

13 - Air flow flap control motor -V71-

❑ With potentiometer for air flow flap control motor -G113❑ Removing and installing

14 - Foam seal

❑ Provides seal between heater intake housing and vehicle

15 - Intake housing with recirculated-air and air flow/fresh-air flap

⇒ page 101

❑ Not to be further dismantled

❑ Removing and installing ⇒ page 176

❑ Different replacement part versions available ⇒ page 176

16 - Fresh air blower control unit -J126- and fresh air blower -V2-

❑ Removing and installing ⇒ page 98

❑ Different versions; on the fresh air blowers -V2- fitted at the start of production, the fresh air blower control

unit -J126- and the fresh air blower -V2- form a cast assembly (cannot be replaced separately). Fresh

air blower control units -J126- and fresh air blowers -V2- which are bolted together (and can be replaced

separately) were gradually introduced in Model Year 2007 ⇒ page 98 and ⇒ Electronic parts catalogue .

❑ The fresh air blower -V2- features an integrated fresh air blower control unit -J126- . Depending on the

version, these two components can be replaced separately or only as an assembly.

17 - Insulating mat

18 - Screw-type clips

19 - Cable tie

20 - Holder for wiring harness

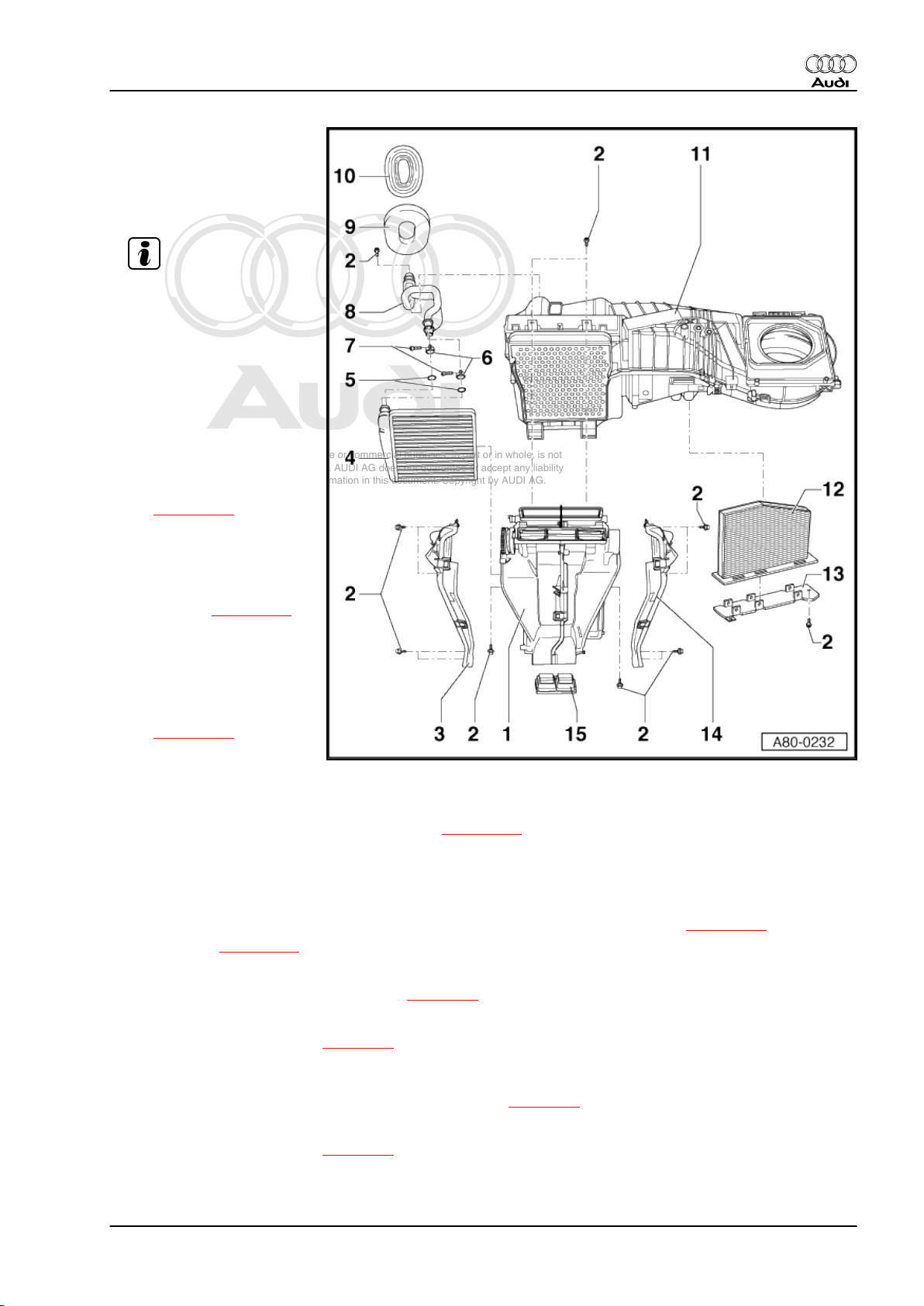

5.2 Dismantling and assembling heater

– Remove the heater ⇒ page 170 (removing and installing air

conditioner unit).

– Detach the electrical add-on components from the heater

⇒ page 16 .

18 Rep. Gr.80 - Heating

Page 25

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Heating and Air Conditioning - Edition 04.2009

1 - Heater air distributor hous‐

ing

❑ Different versions for

heater and air condition‐

er ⇒ Electronic parts

catalogue

Note

2 - Bolt

3 - Air duct to left footwell vent

❑ Different versions ⇒

Electronic parts cata‐

logue

❑ “Heater” version (with

no opening for fitting a

temperature sensor)

4 - Heating system heat ex‐

changer

❑ Removing and installing

⇒ page 114

5 - Sealing ring

❑ Renew

❑ Moisten slightly with

coolant and fit in correct

position

6 - Clamp

❑ Renew

⇒ page 114

❑ Ensure correct position‐

ing

❑ Removing and installing

⇒ page 114

7 - Bolt

❑ Tightening torque 2.5 Nm

8 - Coolant pipes

❑ Detaching from heat exchanger/attaching ⇒ page 114

9 - Foam spacer

❑ Fitted between grommet and heater

10 - Grommet

❑ Insert in the back wall of the vehicle plenum chamber before fitting the heater ⇒ page 170

❑ Installing ⇒ page 170

11 - Air duct

❑ Dismantling and assembling air duct ⇒ page 20

12 - Dust and pollen filter

❑ Removing and installing ⇒ page 96

❑ Observe replacement intervals ⇒ Maintenance tables

❑ Vehicles with no air conditioner (heater only) are fitted with a dust and pollen filter with no activated

charcoal element ⇒ Electronic parts catalogue and ⇒ page 97

13 - Dust and pollen filter cover

❑ Removing and installing ⇒ page 96

14 - Air duct to right footwell vent

❑ Different versions ⇒ Electronic parts catalogue

5. Dismantling and assembling heater 19

Page 26

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Heating and Air Conditioning - Edition 04.2009

❑ “Heater” version (with no opening for fitting a temperature sensor)

15 - Sealing plug

❑ Two different versions provided ⇒ page 122 .

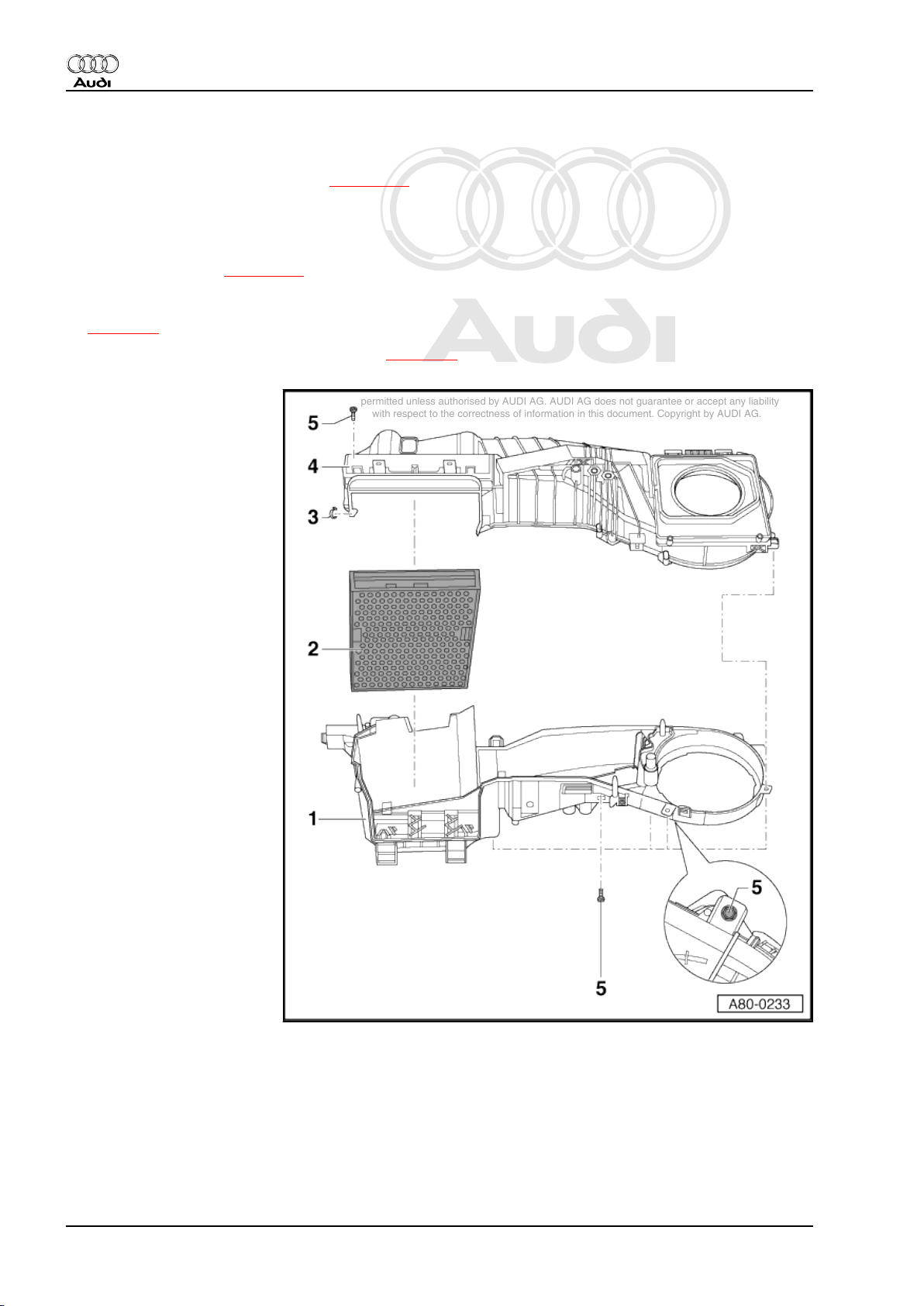

5.3 Dismantling and assembling air duct

– Remove the heater ⇒ page 170 (removing and installing air

conditioner unit).

– Detach the electrical add-on components from the heater

⇒ page 16 .

– Dismantle the heater to the extent required ⇒ page 18 .

1 - Bottom part of air duct

2 - Noise insulation

❑ Vehicles with no air con‐

ditioner (heater only)

are fitted with a foam

core (for noise insula‐

tion) instead of the

evaporator.

3 - Clip

4 - Top part of air duct

5 - Bolt

20 Rep. Gr.80 - Heating

Page 27

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Heating and Air Conditioning - Edition 04.2009

87 – Air conditioning system

1 Safety measures when working on

vehicles with air conditioner and for

handling refrigerant

The air conditioner assemblies and piping system are filled with

the following refrigerant:

1.1.1.2 tetrafluoroethane (CF3-CH2F or CH2F-CF3)

This refrigerant is currently known in Germany by the trade names

R134a, H-FKW 134a, SUVA 134a and KLEA 134a (other trade

names may be used in other countries).

♦ Safety precautions ⇒ page 21 .

♦ Draining refrigerant circuit ⇒ page 22 .

♦ Working on refrigerant circuit ⇒ page 22 .

♦ Painting work on vehicles with air conditioner ⇒ page 23 .

♦ Further information on air conditioner ⇒ page 23 .

Audi TT 2007 ➤

1.1 Safety precautions

The following safety measures are to be heeded in Germany for

this refrigerant (additional regulations may apply in other coun‐

tries).

The refrigerant circuit is to be drained first should repair work re‐

quire the refrigerant circuit to be opened ⇒ page 22 . All contact

with liquid refrigerant or refrigerant vapours should be avoided.

Should refrigerant nevertheless escape, avoid inhaling the resul‐

tant refrigerant/air mixture.

Extraction systems are therefore to be switched on and use made

of both rubber gloves and safety goggles.

Explanation:

Intensive exposure to refrigerant on unprotected parts of the body

will result in frostbite.

WARNING

Keep an eye-bath to hand.

Should liquid refrigerant come into contact with the eyes, rinse

eyes thoroughly with water for approx. 15 minutes.

Then apply eye drops and consult a doctor immediately even

if no pain is felt.

Always inform doctor of the type of refrigerant involved.

Should refrigerant come into contact with other parts of the body

despite compliance with all the pertinent safety measures, these

are similarly to be rinsed thoroughly with cold water without delay

for at least 15 minutes.

Although refrigerants do not represent a fire hazard, smoking,

welding, soldering and brazing are not permitted in areas exposed

to refrigerant.

1. Safety measures when working on vehicles with air conditioner and for handling refrigerant 21

Page 28

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Heating and Air Conditioning - Edition 04.2009

Explanation:

The high temperature of a naked flame or hot objects causes de‐

composition of refrigerant gas. Inhalation of the toxic decompo‐

sition products would cause dry coughing and nausea.

1.2 Draining refrigerant circuit

Refrigerant must not be allowed to escape into the environment.

It should be extracted from the refrigerant circuit by means of a

suction unit or an air conditioner service station. The refrigerant

removed is then either to be re-processed on site or returned to

the manufacturer for proper disposal (different or additional reg‐

ulations may apply in other countries). For this reason, the vehicle

is to be taken to a workshop equipped with the necessary tools

where the work can be performed by appropriately qualified per‐

sonnel. ⇒ Air conditioner - with refrigerant R134a

Explanation:

Should it escape into the earth's atmosphere, refrigerant R134a

will have a detrimental effect in terms of global warming.

Note

♦

Refrigerant R134a has far less of a greenhouse effect than

R12.

♦

Refrigerant R134a does not affect the earth's ozone layer

(R134a is an H-FC with no chlorine atoms). The depletion of

the ozone in the upper atmosphere is however only caused by

the splitting of carbon-chlorine bonds (as is the case, for ex‐

ample, with the refrigerant R12).

After draining the air conditioner, unplug the connector from the

air conditioner compressor regulating valve -N280- or from the

high-pressure sender -G65- .

Explanation:

The air conditioner compressor regulating valve -N280- is then no

longer actuated and the air conditioner compressor runs at idle.

The air conditioner compressor is designed such that lubrication

of the air conditioner compressor components is guaranteed by

way of an internal oil circuit at idle (provided there is sufficient

refrigerant oil in the air conditioner compressor).

1.3 Working on refrigerant circuit

Work on refrigerant circuit is only to be carried out in well venti‐

lated areas Care should be taken to ensure that there are no

inspection pits, shafts or cellar entrances within a radius of 5 me‐

tres. Extraction systems are to be switched on.

Explanation:

The refrigerant emerging is not only colourless and odourless, but

also heavier than air and thus displaces oxygen. Should refriger‐

ant gas nevertheless escape, this can result in an imperceptible

danger of asphyxiation in poorly ventilated areas and inspection

pits.

Note

The mixture of gas and air which forms when refrigerant gas es‐

capes must not be inhaled. Use is to be made of suitable work‐

shop extractors.

22 Rep. Gr.87 - Air conditioning system

Page 29

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Heating and Air Conditioning - Edition 04.2009

Welding, brazing and soldering are not permitted on sections of

the air conditioner when filled. This also applies to vehicle welding

and soldering work if there is a danger of air conditioner compo‐

nents becoming hot.

Explanation:

Exposure to heat creates considerable pressure in the system

which could cause it to burst.

Remedy:

Drain refrigerant circuit ⇒ page 22 .

Note

Damaged or leaking air conditioner components are not to be re‐

paired by welding or soldering, but should be replaced.

When servicing air conditioner, all open components and pipe

connections are to be immediately re-sealed.

Explanation:

Moisture will ingress into air conditioner components if they are

left open for a lengthy period. If this is the case, air conditioners

cannot be re-filled without having to replace parts of the system.

Audi TT 2007 ➤

1.4 Painting work on vehicles with air con‐

ditioner

When performing paintwork repairs, the temperature in the drying

booth or preheating zone must not exceed 80 °C.

Explanation:

Exposure to heat creates considerable pressure in the system

which could cause it to burst.

1.5 Further information on air conditioner

♦ The relevant current flow diagrams can be found in the Current

flow diagrams, Electrical fault-finding and Fitting locations

binder. ⇒ Current flow diagrams, Electrical fault finding and

Fitting locations

♦ A label in the engine compartment indicates the refrigerant

used as well as the capacity.

♦ For further information on repair work for vehicles fitted with

an air conditioner and on handling refrigerant, refer to ⇒ Air

conditioner with refrigerant R134a .

1. Safety measures when working on vehicles with air conditioner and for handling refrigerant 23

Page 30

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Heating and Air Conditioning - Edition 04.2009

2 Notes on air conditioner repair work

WARNING

Remove the appropriate fuse(s) before working on wiring.

Note

Disconnect the battery -A- before starting electric welding work

on the vehicle ⇒ Electrical system; Rep. Gr. 27

It is only permissible if so required by the pertinent safety regu‐

lations ⇒ page 21 , or if parts of the air conditioner refrigerant

circuit have to be replaced, to drain and open the air conditioner

refrigerant circuit ⇒ page 22 (draining refrigerant circuit).

The air conditioner refrigerant circuit must remain closed during

all other normal vehicle repair operations.

Service work which can be performed on the heater and air con‐

ditioner without opening the refrigerant circuit is described in this

Workshop Manual ⇒ page 60 .

Note

The connections for the senders/switches described in this Work‐

shop Manual are fitted with a valve which closes automatically

when the switches are unscrewed. These switches may therefore

be renewed in any VW/Audi workshop without draining the refrig‐

erant circuit.

Air conditioner service work for which the refrigerant circuit has to

be drained and which therefore cannot be performed at all VW/

Audi workshops is described as of ⇒ page 143 . Draining of the

refrigerant circuit requires the use of specific tools and such work

is also only to be performed by qualified personnel. For this rea‐

son, it may be necessary to take the vehicle to a workshop

equipped with the necessary tools where the work can be per‐

formed by appropriately qualified personnel ⇒ Air conditioner with

refrigerant R134a .

♦ Contact corrosion ⇒ page 24

♦ Notes on air conditioner guided fault-finding ⇒ page 25

♦ Checking electrical components of air conditioner

⇒ page 25

♦ Checking of electrical components actuated by the air condi‐

tioner ⇒ page 26

2.1 Contact corrosion

Contact corrosion can occur if use is made of unsuitable con‐

necting elements, bolts, nuts, washers, rivets, plugs, grommets,

adhesives, etc.

For this reason, only connecting elements with a special surface

coating are fitted at the factory. In addition, rubber components,

plastic components and adhesives are made of non-conductive

materials. These tested, aluminium-compatible components are

also available as replacement parts ⇒ Electronic parts catalogue .

24 Rep. Gr.87 - Air conditioning system

Page 31

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Heating and Air Conditioning - Edition 04.2009

Important:

♦ Always fit new parts in cases of doubt about reusability.

♦ We recommend the use of genuine replacement parts only, as

these have been checked and are compatible with aluminium

⇒ Electronic parts catalogue .

♦ We advise using Audi accessories ⇒ Electronic parts cata‐

logue .

♦ Damage caused by contact corrosion is not covered by war‐

ranty.

2.2 Notes on air conditioner guided faultfinding

♦ There are various versions of the air conditioner operating unit,

Climatronic control unit -J255- . When renewing, observe pre‐

cise allocation. ⇒ Electronic parts catalogue

♦ Air conditioner self-diagnosis is to be performed by way of the

“Guided fault-finding” function using the vehicle diagnostic,

testing and information system ⇒ "Guided fault-finding" func‐

tion of vehicle diagnostic, testing and information system VAS

5051.

♦ At present air conditioner operating units, Climatronic control

unit -J255- can be exchanged in the familiar manner, as com‐

ponent protection is currently not active ⇒ "Guided faultfinding" function of vehicle diagnostic, testing and information

system VAS 5051 .

♦ If an air conditioner operating unit, Climatronic control unit -

J255- is to be replaced, interrogate the encoding and adaption

(of the air conditioner operating unit, Climatronic control unit J255- ) prior to removal by way of the “Control unit replace‐

ment” function ⇒ "Guided fault-finding" function of vehicle

diagnostic, testing and information system VAS 5051 .

Audi TT 2007 ➤

2.3 Checking electrical components of air conditioner

Note

♦

The “Electrical checks” function is not described in this Work‐

shop Manual. When implementing electrical checks by way of

the “Guided fault-finding” function, information is given on the

functions to be checked ⇒ "Guided fault-finding" function of

vehicle diagnostic, testing and information system VAS 5051 .

♦

The temperature-dependent resistance values of the various

temperature sensors are stored in tables which can be called

up via the “Guided fault-finding” function ⇒ "Guided fault-find‐

ing" function of vehicle diagnostic, testing and information

system VAS 5051 .

♦ Wiring and component check using test box -V.A.G 1598 A-

⇒ page 25

2.3.1 Checking wiring and components with test box -V.A.G 1598 A-

Special tools, testers and other items required

♦ Test box (basic unit) -V.A.G 1598/14- with adapter -V.A.G

1598/11- and adapter -V.A.G 1598/12-

2. Notes on air conditioner repair work 25

Page 32

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Heating and Air Conditioning - Edition 04.2009

♦ Vehicle diagnostic, testing and information system -VAS 5051

A- with multimeter leads -VAS 5051/7- , probe -VAS 5051/8and current probe 50 A -VAS 5051/9-

♦ Voltage tester -V.A.G 1527 B-

♦ Adapter set -V.A.G 1594 C-

♦ Temperature measuring instrument (e.g. commercially avail‐

able thermometer)

♦ Current flow diagram for vehicle system to be checked ⇒ Cur‐

rent flow diagrams, Electrical fault finding and Fitting locations

Note

Electrical checking is to be performed as described in the guided

fault-finding routine ⇒ "Guided fault-finding" function of vehicle

diagnostic, testing and information system VAS 5051 .

2.4 Checking of electrical components ac‐

tuated by the air conditioner

Note