Page 1

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Service

Workshop Manual

Audi A3 2004 ➤

Audi TT 2007 ➤

Rear final drive 02D, 0AV, 0BR and 0BY

Edition 06.2009

Service Department. Technical Information

Page 2

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Service

List of Workshop Manual Repair GroupsList of Workshop Manual

Repair GroupsList of Workshop Manual Repair Groups

Re pa ir G ro up

00 - Technical data

39 - Final drive - rear differential

Technical information should always be available to the foremen and mechanics, because their

careful and constant adherence to the instructions is essential to ensure vehicle road-worthiness and

safety. In addition, the normal basic safety precautions for working on motor vehicles must, as a

matter of course, be observed.

All rights reserved.

No reproduction without prior agreement from publisher.

Copyright © 2010 Audi AG, Ingolstadt A005AA00320

Page 3

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A3 2004 ➤ , Audi TT 2007 ➤

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

Contents

00 - Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1 Rear final drive identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 Audi A3 2004 ▸ – Code letters, allocation, transmission ratios, capacities . . . . . . . . . . . . 3

2.1 Audi A3 with rear final drive 02D/0AV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Audi A3 with rear final drive 0BR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Audi TT 2007▸ – Code letters, allocation, transmission ratios, capacities . . . . . . . . . . . . . . 7

3.1 Audi TT with rear final drive 02D/0AV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Audi TT with rear final drive 0BR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.3 Audi TT RS with rear final drive 0BY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 Transmission layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5 General repair instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.1 Gear oil and oil for Haldex coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.2 Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.3 Contact corrosion! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6 Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.1 Safety precautions for Audi TT and Audi A3 Cabriolet . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.2 Safety precautions for Audi A3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

39 - Final drive - rear differential . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1 Exploded view – propshaft with detachable centre bearing (up to 05.07) . . . . . . . . . . . . . . 19

2 Removing propshaft with detachable centre bearing (up to 05.07) . . . . . . . . . . . . . . . . . . 27

2.1 Installing propshaft with detachable centre bearing (up to 05.07) . . . . . . . . . . . . . . . . . . . . 30

3 Exploded view – propshaft with non-detachable centre bearing (from 05.07 onwards) . . . . 34

3.1 Removing propshaft with non-detachable centre bearing (from 05.07 onwards) . . . . . . . . 35

3.2 Installing propshaft with non-detachable centre bearing (from 05.07 onwards) . . . . . . . . . . 40

4 Exploded view - propshaft (Audi TT RS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4.1 Removing and installing propshaft (Audi TT RS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5 Removing and installing flexible coupling (rear) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6 Connecting vehicle diagnostic, testing and information system VAS 5051B and checking

system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7 Checking function of Haldex coupling, rear final drive “02D/0AV” . . . . . . . . . . . . . . . . . . . . 54

7.1 Final drive“02D/0AV” – Checking function of open Haldex coupling on vehicles with manual

gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7.2 Final drive“02D/0AV” – Checking function of closed Haldex coupling on vehicles with manual

gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.3 Final drive“02D/0AV” – Checking function of open Haldex coupling on vehicles with dual

clutch gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7.4 Final drive“02D/0AV” – Checking function of closed Haldex coupling on vehicles with dual

clutch gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8 Checking function of Haldex coupling, rear final drive “0BR” and “0BY” . . . . . . . . . . . . . . 58

9 Electrical and electronic components and fitting locations, rear final drive “02D/0AV” . . . . 59

10 Exploded view – removing and installing four-wheel drive control unit J492 , rear final drive

“02D/0AV” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

10.1 Removing and installing four-wheel drive control unit J492 , rear final drive “02D/0AV” . . 62

11 Electrical and electronic components and fitting locations, rear final drive “0BR” and “0BY”

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

12 Exploded view – removing and installing four-wheel drive control unit J492 , rear final drive

0BD and 0BY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

12.1 Removing and installing four-wheel drive control unit J492 . . . . . . . . . . . . . . . . . . . . . . . . 68

13 Exploded view - removing and installing Haldex coupling . . . . . . . . . . . . . . . . . . . . . . . . . . 71

13.1 Removing and installing Haldex coupling (with final drive installed) . . . . . . . . . . . . . . . . . . 71

Contents i

Page 4

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A3 2004 ➤ , Audi TT 2007 ➤

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

14 Exploded view – dismantling and assembling Haldex coupling, rear final drive “02D/0AV”

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

14.1 Removing and installing oil filter for Haldex coupling, final drive “02D/0AV” . . . . . . . . . . . . 77

14.2 Removing and installing Haldex coupling pump V181 , final drive “02D/0AV” . . . . . . . . . . 78

14.3 Renewing grooved ball bearing for Haldex coupling, final drive “02D/0AV” . . . . . . . . . . . . 82

15 Exploded view – dismantling and assembling Haldex coupling, rear final drive “0BR/0BY”

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

15.1 Removing and installing Haldex coupling pump V181 , final drive “0BR/0BY” . . . . . . . . . . 89

16 Renewing oil seal for propshaft flange at rear final drive - final drive remains installed . . . . 93

17 Exploded view – Removing and installing rear final drive . . . . . . . . . . . . . . . . . . . . . . . . . . 96

17.1 Removing rear final drive (not TT RS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

17.2 Installing rear final drive (not TT RS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

18 Removing and installing rear final drive (Audi TT RS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

19 Renewing bonded rubber bushes in rear final drive - exploded view . . . . . . . . . . . . . . . . . . 107

20 Renewing flange shaft oil seals (right and left) - rear final drive remains installed . . . . . . . . 112

21 Checking oil level in Haldex coupling and topping up . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

21.1 Checking oil level in Haldex coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

21.2 Topping up oil in Haldex coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

22 Renewing high performance oil for Haldex coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

23 Checking gear oil in rear final drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

23.1 Checking gear oil level in rear final drive “02D/0AV” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

23.2 Checking gear oil level in rear final drive “0BR” and “0BY” . . . . . . . . . . . . . . . . . . . . . . . . 123

ii Contents

Page 5

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

00 – Technical data

1 Rear final drive identification

Note

♦

The “Haldex coupling” is incorporated in the final drive.

♦

The final drive and the “Haldex coupling” have separate oil

circuits.

♦

The final drive units “02D” and “0AV” are equipped with the

“Haldex coupling 2”. Identification ⇒ page 1 and

⇒ page 2 .

♦

Final drive units “0BR” and “0BY” are equipped with the “Hal‐

dex coupling 4”. Identification ⇒ page 2 .

Rear final drive units 02D, 0AV, 0BR and 0BY are fitted in con‐

junction with the following gearboxes:

♦ 6-speed manual gearbox 02Q, four-wheel drive

♦ 6-speed manual gearbox 0A6, four-wheel drive

♦ Direct shift gearbox 02E, four-wheel drive

Rear final drive allocation

♦ ⇒ “2 Audi A3 2004 ▸ – Code letters, allocation, transmission

ratios, capacities”, page 3

♦ ⇒ “3 Audi TT 2007▸ – Code letters, allocation, transmission

ratios, capacities”, page 7

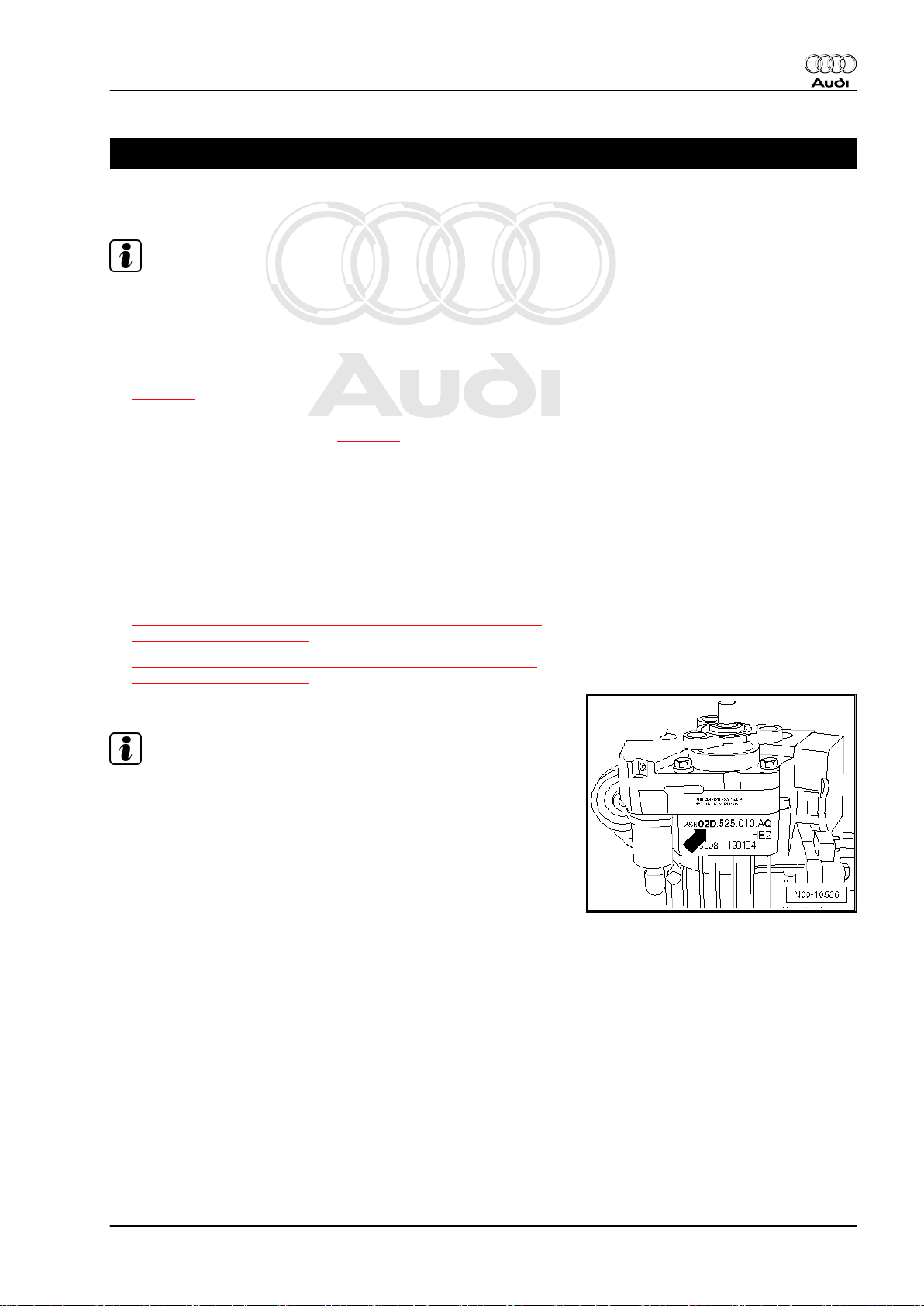

Rear final drive -02D-

Audi A3 2004 ➤ , Audi TT 2007 ➤

Note

♦

The identification -arrow- on the underside of the final drive

unit indicates which final drive version is installed.

♦

In this example: “Rear final drive 02D”

1. Rear final drive identification 1

Page 6

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A3 2004 ➤ , Audi TT 2007 ➤

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

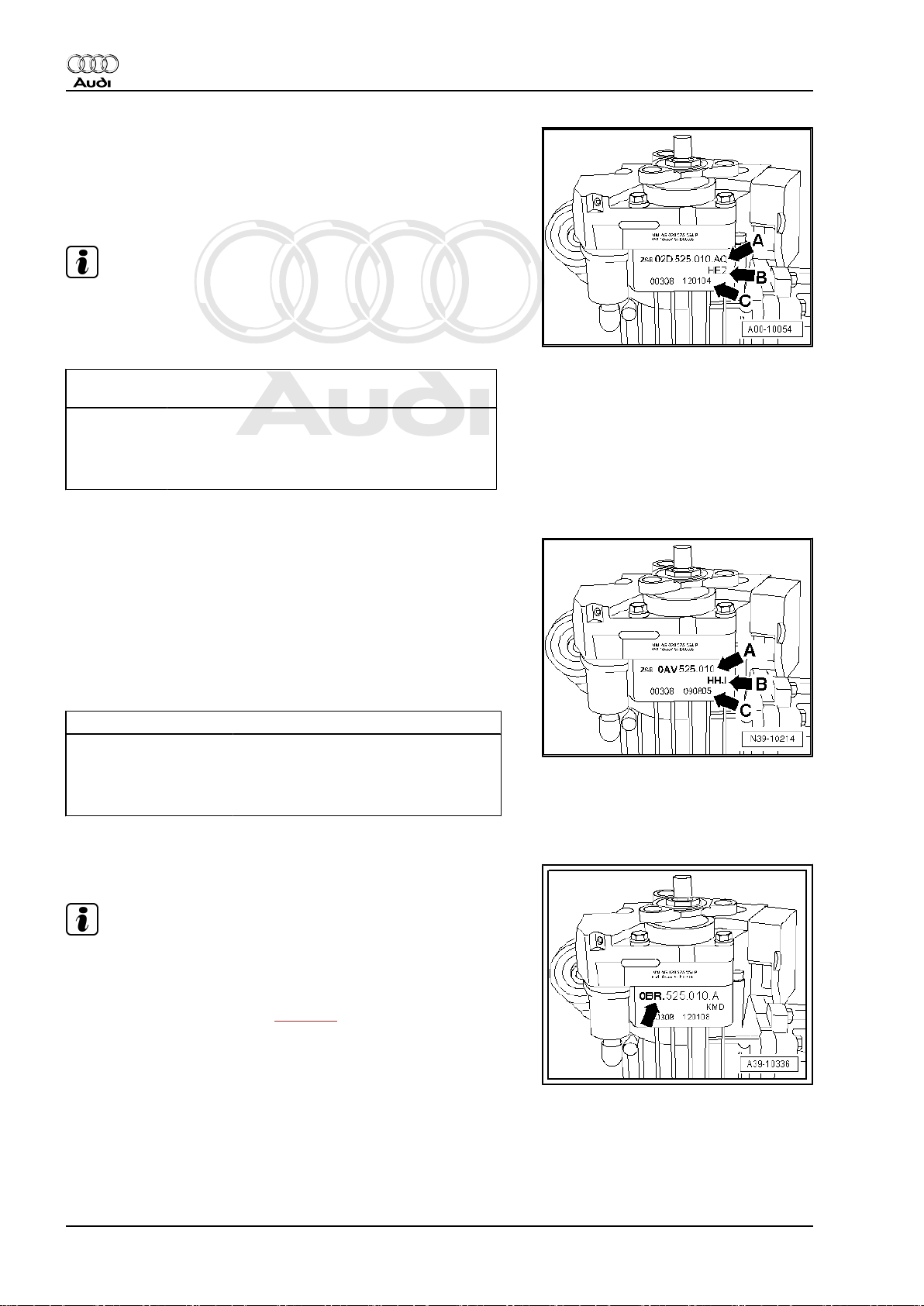

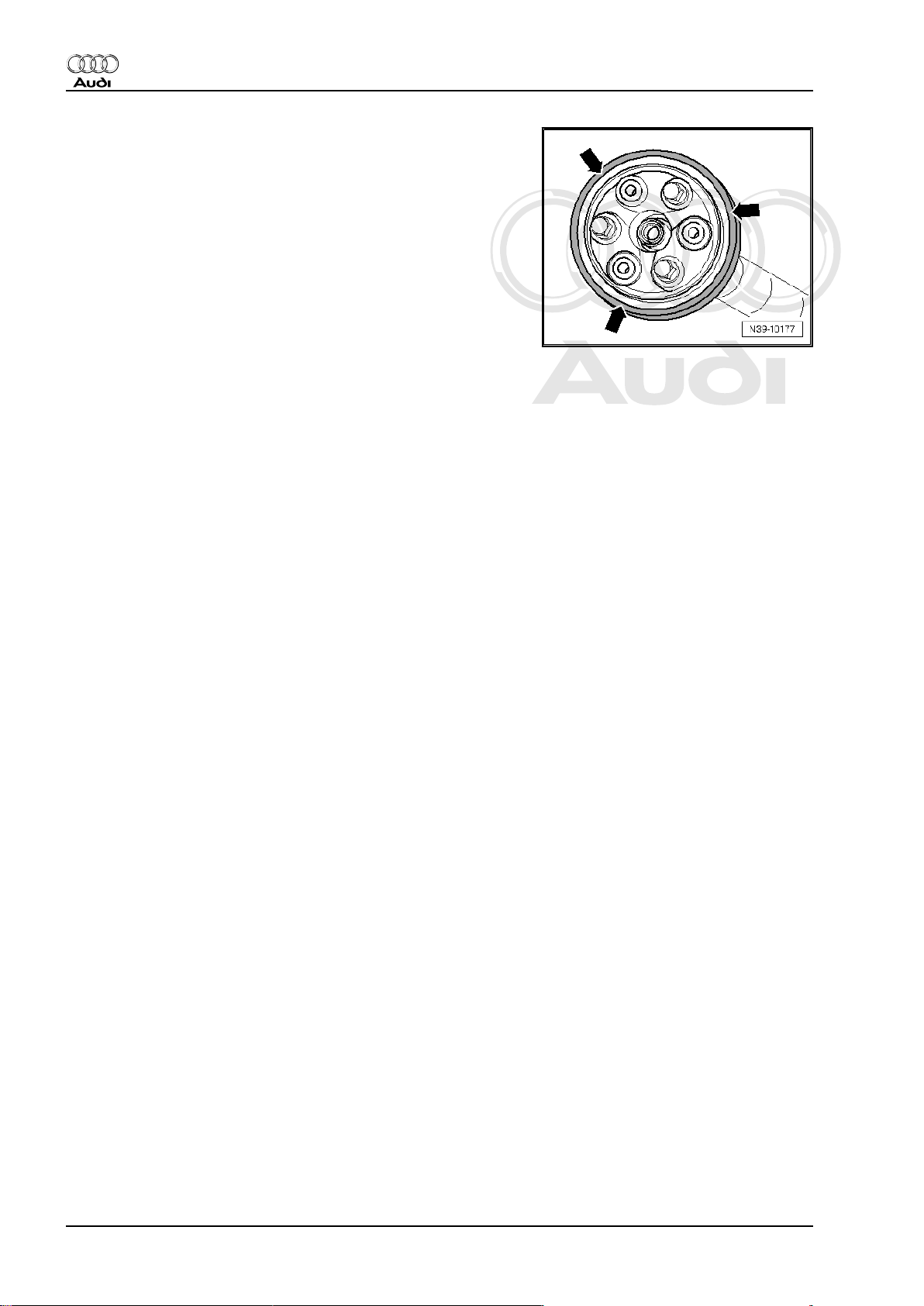

Example of identification markings on final drive “02D”

-Arrow A- Part number of final drive

-Arrow B- Code letters of final drive

-Arrow C- Production date of final drive

Note

If the code letters -arrow B- are not shown, the unit can be iden‐

tified via the Part No. -arrow A- ⇒ Electronic parts catalogue .

Example:

02D.

HEZ 12 01 04

525.010.AQ

I I I I I

I I I I I

Part No. Code let‐

ters

Day Month Year of manufacture

-2004-

Additional data are manufacture-related.

Example of identification markings on rear final drive “0AV”

-Arrow A- Part number of final drive

-Arrow B- Code letters of final drive

♦ If the code letters are not shown, the unit can be identified via

the Part No. ⇒ Electronic parts catalogue .

-Arrow C- Production date of final drive

Example:

HHJ 09 08 05

I I I I

I I I I

Code letters Day Month Year of manufacture

-2005-

Additional data are manufacture-related.

Rear final drive “0BR” or “0BY”

Note

♦

The identification -arrow- on the underside of the final drive

unit indicates which final drive version is installed.

♦

For further explanation of the identification markings on the

underside of the final drive ⇒ page 2 .

2 Rep. Gr.00 - Technical data

Page 7

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

2 Audi A3 2004 ▸ – Code letters, allo‐

cation, transmission ratios, capaci‐

ties

⇒ “2.1 Audi A3 with rear final drive 02D/0AV”, page 3

⇒ “2.2 Audi A3 with rear final drive 0BR”, page 5

2.1 Audi A3 with rear final drive 02D/0AV

Audi A3 2004 ➤ , Audi TT 2007 ➤

Rear final drive

02D

1)

Part No. 02D.525.010.AA 02D.525.010.AC 02D.525.010.AQ

Code letters FWR HEY HEZ

Manufactured from 07.03 11.04 01.04

to 01.04 12.04 08.04

Allocation Model Audi A3 2004 ▸ Audi A3 2004 ▸ Audi A3 2004 ▸

Engine 2.0 ltr. - 147 kW

2.0 ltr. - 103 kW TDI 2.0 ltr. - 147 kW TFSI

TFSI

Ratio: Z2 : Z

1

Final drive

3.2 ltr. - 184 kW

27 : 17 = 1.588 27 : 17 = 1.588 27 : 17 = 1.588

3.2 ltr. - 184 kW

(rear)

Drive shaft flange ∅ 100 mm 100 mm 100 mm

Capacity in final drive 0.95 litres

Capacity in Haldex coupling 0.85 litres

Oil change capacity in Haldex cou‐

pling

• Change intervals: ⇒ Mainte‐

0.65 litres

nance tables “ELSA”

1)

Rear final drive “02D” is equipped with “Haldex coupling 2”

The following data can be found in the ⇒ Electronic parts catalogue

♦ Specification of gear oil for rear final drive

♦ Specification of high performance oil for Haldex coupling

♦ Allocation of gearbox

Rear final drive

0AV

1)

Part No. 0AV.525.010 0AV.525.010.A 0AV.525.010.B

Code letters HHJ HHK HVY

Manufactured from 09.05 11.04 11.05

to 11.05 11.05 05.07

Allocation Model Audi A3 2004 ▸ Audi A3 2004 ▸ Audi A3 2004 ▸

Ratio: Z2 : Z

1

Engine 2.0 ltr. - 147 kW TFSI 2.0 ltr. - 103 kW TDI 2.0 ltr. - 147 kW TFSI

3.2 ltr. - 184 kW

Final drive

3.2 ltr. - 184 kW

27 : 17 = 1.588 27 : 17 = 1.588 27 : 17 = 1.588

(rear)

Drive shaft flange ∅ 100 mm 100 mm 100 mm

Capacity in final drive 0.95 litres

Capacity in Haldex coupling 0.85 litres

2. Audi A3 2004 ▸ – Code letters, allocation, transmission ratios, capacities 3

Page 8

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A3 2004 ➤ , Audi TT 2007 ➤

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

Rear final drive

0AV

1)

Part No. 0AV.525.010 0AV.525.010.A 0AV.525.010.B

Code letters HHJ HHK HVY

Oil change capacity in Haldex cou‐

0.65 litres

pling

• Change intervals: ⇒ Mainte‐

nance tables “ELSA”

1)

Rear final drive “0AV” is equipped with “Haldex coupling 2”

The following data can be found in the ⇒ Electronic parts catalogue

♦ Specification of gear oil for rear final drive

♦ Specification of high performance oil for Haldex coupling

♦ Allocation of gearbox

Rear final drive

0AV

1)

Part No. 0AV.525.010.C 0AV.525.010.D 0AV.525.010.E

Code letters HVZ JJN JYP

Manufactured from 11.05 11.06 06.07

to 05.07 01.08 02.08

Allocation Model Audi A3 2004 ▸ Audi A3 2004 ▸ Audi A3 2004 ▸

Ratio: Z2 : Z

1

Engine 2.0 ltr. - 103 kW TDI 2.0 ltr. - 147 kW TFSI

2.0 ltr. - 195 kW TFSI

2.0 ltr. - 125 kW TDI 3.2 ltr. - 184 kW 2.0 ltr. - 125 kW TDI

Final drive

27 : 17 = 1.588 27 : 17 = 1.588 27 : 17 = 1.588

2.0 ltr. - 103 kW TDI

(rear)

Drive shaft flange ∅ 100 mm 100 mm 100 mm

Capacity in final drive 0.95 litres

Capacity in Haldex coupling 0.85 litres

Oil change capacity in Haldex cou‐

0.65 litres

pling

• Change intervals: ⇒ Mainte‐

nance tables “ELSA”

1)

Rear final drive “0AV” is equipped with “Haldex coupling 2”

The following data can be found in the ⇒ Electronic parts catalogue

♦ Specification of gear oil for rear final drive

♦ Specification of high performance oil for Haldex coupling

♦ Allocation of gearbox

Rear final drive

0AV

1)

Part No. 0AV.525.010.K 0AV.525.010.L

Code letters KJS KJT

Manufactured from 09.07 02.08

to 06.08 06.08

Allocation Model Audi A3 2004 ▸ Audi A3 2004 ▸

Engine 2.0 ltr. - 147 kW TFSI

2.0 ltr. - 103 kW TDI

2.0 ltr. - 195 kW TFSI

3.2 ltr. - 184 kW 2.0 ltr. - 125 kW TDI

4 Rep. Gr.00 - Technical data

Page 9

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A3 2004 ➤ , Audi TT 2007 ➤

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

Rear final drive

0AV

1)

Part No. 0AV.525.010.K 0AV.525.010.L

Code letters KJS KJT

Ratio: Z2 : Z

1

Final

27 : 17 = 1.588 27 : 17 = 1.588

drive

(rear)

Drive shaft flange ∅ 100 mm 100 mm

Capacity in final drive 0.95 litres

Capacity in Haldex coupling 0.85 litres

Oil change capacity in Haldex

0.65 litres

coupling

• Change intervals: ⇒ Main‐

tenance tables “ELSA”

1)

Rear final drive “0AV” is equipped with “Haldex coupling 2”

The following data can be found in the ⇒ Electronic parts catalogue

♦ Specification of gear oil for rear final drive

♦ Specification of high performance oil for Haldex coupling

♦ Allocation of gearbox

2.2 Audi A3 with rear final drive 0BR

Rear final drive

Part No. 0BR.525.010

Code letters KMC

Manufac‐

from 07.08

tured

to

Allocation ModelAudi A3 2004

▸

En‐

gine

1.8 ltr. - 118

kW TFSI

2.0 ltr. - 147

kW TFSI

2.0 ltr. - 188

kW TFSI

2.0 ltr. - 195

kW TFSI

3.2 ltr. - 184

kW

2.0 ltr. - 103

kW TDI

Ratio: Z2 :

Z

1

Fi‐

nal

driv

27 : 17 =

1.588

e

(rear

)

Drive shaft flange∅100 mm

1)

0BR

Capacity in final

drive

Capacity in Hal‐

dex coupling

0.95 litres

0.85 litres

2. Audi A3 2004 ▸ – Code letters, allocation, transmission ratios, capacities 5

Page 10

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A3 2004 ➤ , Audi TT 2007 ➤

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

Rear final drive

Part No. 0BR.525.010

Code letters KMC

Oil change ca‐

1)

0BR

0.70 litres

pacity in Haldex

coupling

• Change inter‐

vals: ⇒ Main‐

tenance ta‐

bles “ELSA”

1)

Rear final drive “0BR” is equipped with “Haldex coupling 4”

The following data can be found in the ⇒ Electronic parts

catalogue

♦ Specification of gear oil for rear final drive

♦ Specification of high performance oil for Haldex coupling

♦ Allocation of gearbox

6 Rep. Gr.00 - Technical data

Page 11

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

3 Audi TT 2007▸ – Code letters, allo‐

cation, transmission ratios, capaci‐

ties

⇒ “3.1 Audi TT with rear final drive 02D/0AV”, page 7

⇒ “3.2 Audi TT with rear final drive 0BR”, page 8

⇒ “3.3 Audi TT RS with rear final drive 0BY”, page 9

3.1 Audi TT with rear final drive 02D/0AV

Audi A3 2004 ➤ , Audi TT 2007 ➤

Rear final drive

0AV

1)

Part No. 0AV.525.010.B 0AV.525.010.D 0AV.525.010.F

Code letters HVY JJN JUY

Manufactured from 11.05 11.06 03.07

to 05.07 - -

Allocation Model Audi TT 2007 ▸ Audi TT 2007 ▸ Audi TT 2007 ▸

Engine

3.2 ltr. - 184 kW 3.2 ltr. - 184 kW 3.2 ltr. - 184 kW

Ratio: Z2 : Z

1

Final drive

27 : 17 = 1.588 27 : 17 = 1.588 27 : 17 = 1.588

(rear)

Drive shaft flange ∅ 100 mm 100 mm 100 mm

Capacity in final drive 0.95 litres

Capacity in Haldex coupling 0.85 litres

Oil change capacity in Haldex cou‐

pling

0.65 litres

• Change intervals: ⇒ Mainte‐

nance tables “ELSA”

1)

Rear final drive “0AV” is equipped with “Haldex coupling 2”

The following data can be found in the ⇒ Electronic parts catalogue

♦ Specification of gear oil for rear final drive

♦ Specification of high performance oil for Haldex coupling

♦ Allocation of gearbox

Rear final drive

0AV

1)

Part No. 0AV.525.010.H 0AV.525.010.K 0AV.525.010.M

Code letters JZX KJS KJU

Manufactured from 08.06 12.07 12.07

to 11.06 - -

Allocation Model Audi TT 2007 ▸ Audi TT 2007 ▸ Audi TT 2007 ▸

Engine

3.2 ltr. - 184 kW 3.2 ltr. - 184 kW 3.2 ltr. - 184 kW

Ratio: Z2 : Z

1

Final drive

27 : 17 = 1.588 27 : 17 = 1.588 27 : 17 = 1.588

(rear)

Drive shaft flange ∅ 100 mm 100 mm 100 mm

Capacity in final drive 0.95 litres

Capacity in Haldex coupling 0.85 litres

3. Audi TT 2007▸ – Code letters, allocation, transmission ratios, capacities 7

Page 12

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A3 2004 ➤ , Audi TT 2007 ➤

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

Rear final drive

0AV

1)

Part No. 0AV.525.010.H 0AV.525.010.K 0AV.525.010.M

Code letters JZX KJS KJU

Oil change capacity in Haldex cou‐

0.65 litres

pling

• Change intervals: ⇒ Mainte‐

nance tables “ELSA”

1)

Rear final drive “0AV” is equipped with “Haldex coupling 2”

The following data can be found in the ⇒ Electronic parts catalogue

♦ Specification of gear oil for rear final drive

♦ Specification of high performance oil for Haldex coupling

♦ Allocation of gearbox

3.2 Audi TT with rear final drive 0BR

Rear final drive

Part No. 0BR.525.010 0BR.

Code letters KMC KMD

Manufac‐

from 01.08 01.08

tured

to

Allocation ModelAudi TT 2007▸Audi TT 2007

En‐

gine

2.0 ltr. - 195

kW TFSI

2.0 ltr. - 199

2.0 ltr. - 195

2.0 ltr. - 199

kW TFSI

Ratio: Z2 :

Z

1

3.2 ltr. - 184kW3.2 ltr. - 184

Fi‐

27 : 17 =

nal

1.588

driv

e

(rear

)

Drive shaft flange∅100 mm 100 mm

1)

0BR

525.010.A

-

▸

kW TFSI

kW TFSI

kW

27 : 17 =

1.588

Capacity in final

0.95 litres

drive

Capacity in Hal‐

0.85 litres

dex coupling

Oil change ca‐

0.70 litres

pacity in Haldex

coupling

• Change inter‐

vals: ⇒ Main‐

tenance ta‐

bles “ELSA”

1)

Rear final drive “0BR” is equipped with “Haldex coupling 4”

8 Rep. Gr.00 - Technical data

Page 13

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A3 2004 ➤ , Audi TT 2007 ➤

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

Rear final drive

Part No. 0BR.525.010 0BR.

0BR

1)

525.010.A

Code letters KMC KMD

The following data can be found in the ⇒ Electronic parts

catalogue

♦ Specification of gear oil for rear final drive

♦ Specification of high performance oil for Haldex coupling

♦ Allocation of gearbox

3.3 Audi TT RS with rear final drive 0BY

Rear final drive

Part No. 0BY.525.010

Code letters LEK

Manufac‐

from 01.09

tured

to

Allocation ModelAudi TT RS

2007▸

En‐

gine

2.5 ltr. - 250

kW TFSI

Ratio: Z2 :

Z

1

Fi‐

nal

driv

27 : 17 =

1.588

e

(rear

)

Drive shaft flange∅100 mm

1)

0BY

Capacity in final

0.95 litres

drive

Capacity in Hal‐

0.85 litres

dex coupling

Oil change ca‐

0.70 litres

pacity in Haldex

coupling

• Change inter‐

vals: ⇒ Main‐

tenance ta‐

bles “ELSA”

1)

Rear final drive “0BY” is equipped with “Haldex coupling 4”

The following data can be found in the ⇒ Electronic parts

catalogue

♦ Specification of gear oil for rear final drive

♦ Specification of high performance oil for Haldex coupling

♦ Allocation of gearbox

3. Audi TT 2007▸ – Code letters, allocation, transmission ratios, capacities 9

Page 14

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A3 2004 ➤ , Audi TT 2007 ➤

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

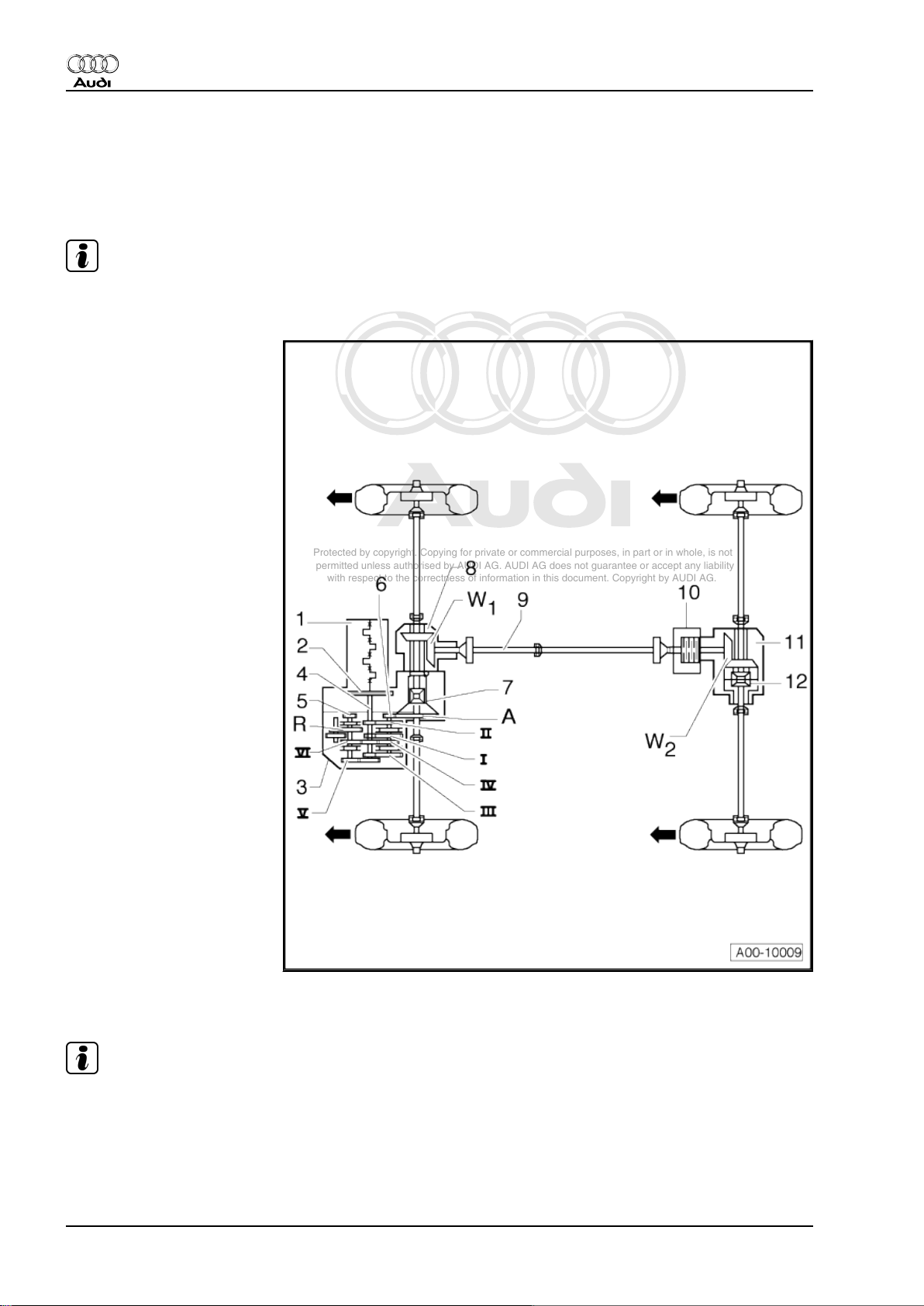

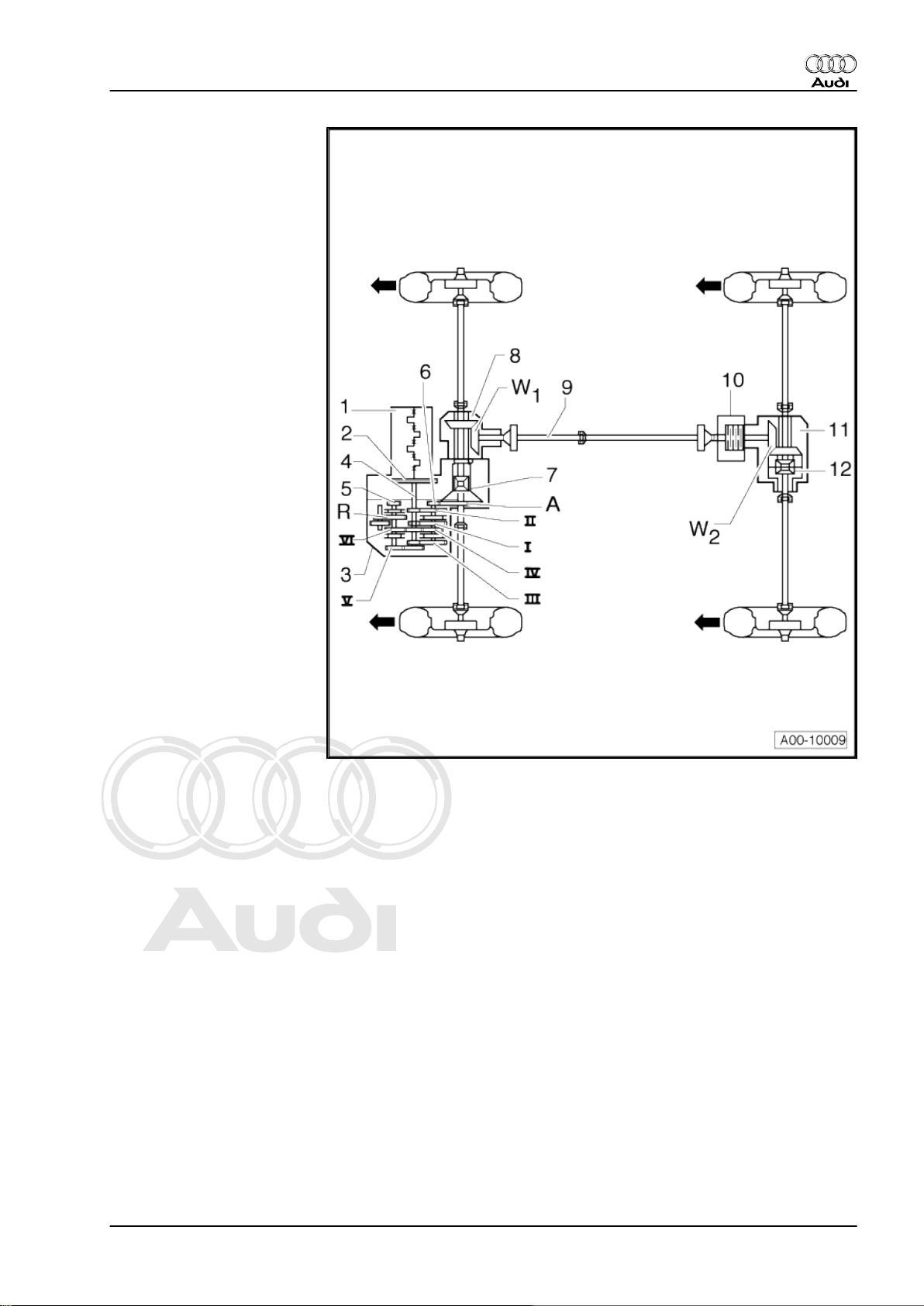

4 Transmission layout

♦ Illustrated with 6-speed manual gearbox 02Q, four-wheel drive

Identification

Note

Arrows point in direction of travel.

1 - Engine

2 - Clutch

3 - Manual gearbox or direct

shift gearbox

4 - Input shaft

5 - Output shaft for 5th, 6th and

reverse gear

6 - Output shaft for 1st - 4th

gear

7 - Differential

8 - Bevel box

9 - Propshaft

10 - Haldex coupling

11 - Rear final drive

12 - Differential

Ratio

Note

Arrows point in direction of travel.

10 Rep. Gr.00 - Technical data

Page 15

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

I - 1st gear

II - 2nd gear

III - 3rd gear

IV - 4th gear

V - 5th gear

VI - 6th gear

R - Reverse gear

A - Final drive

W 1 - Front bevel gears

W 2 - Rear bevel gears

Audi A3 2004 ➤ , Audi TT 2007 ➤

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

4. Transmission layout 11

Page 16

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A3 2004 ➤ , Audi TT 2007 ➤

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

5 General repair instructions

Proper tools and the maximum possible care and cleanliness are

essential for satisfactory repairs to the final drive. The usual basic

safety precautions also naturally apply when carrying out repair

work.

A number of generally applicable instructions for the various re‐

pair procedures are summarised here under the designation

“Components” ⇒ page 14 . They apply to the work described in

this Manual.

5.1 Gear oil and oil for Haldex coupling

Caution

The final drive and the “Haldex coupling” have separate oil cir‐

cuits.

♦ The Haldex coupling is filled with high-performance oil for

Haldex coupling . For part number, refer to ⇒ Electronic

parts catalogue .

♦ The final drive is filled with “gear oil”. For part number,

refer to ⇒ Electronic parts catalogue .

12 Rep. Gr.00 - Technical data

Page 17

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

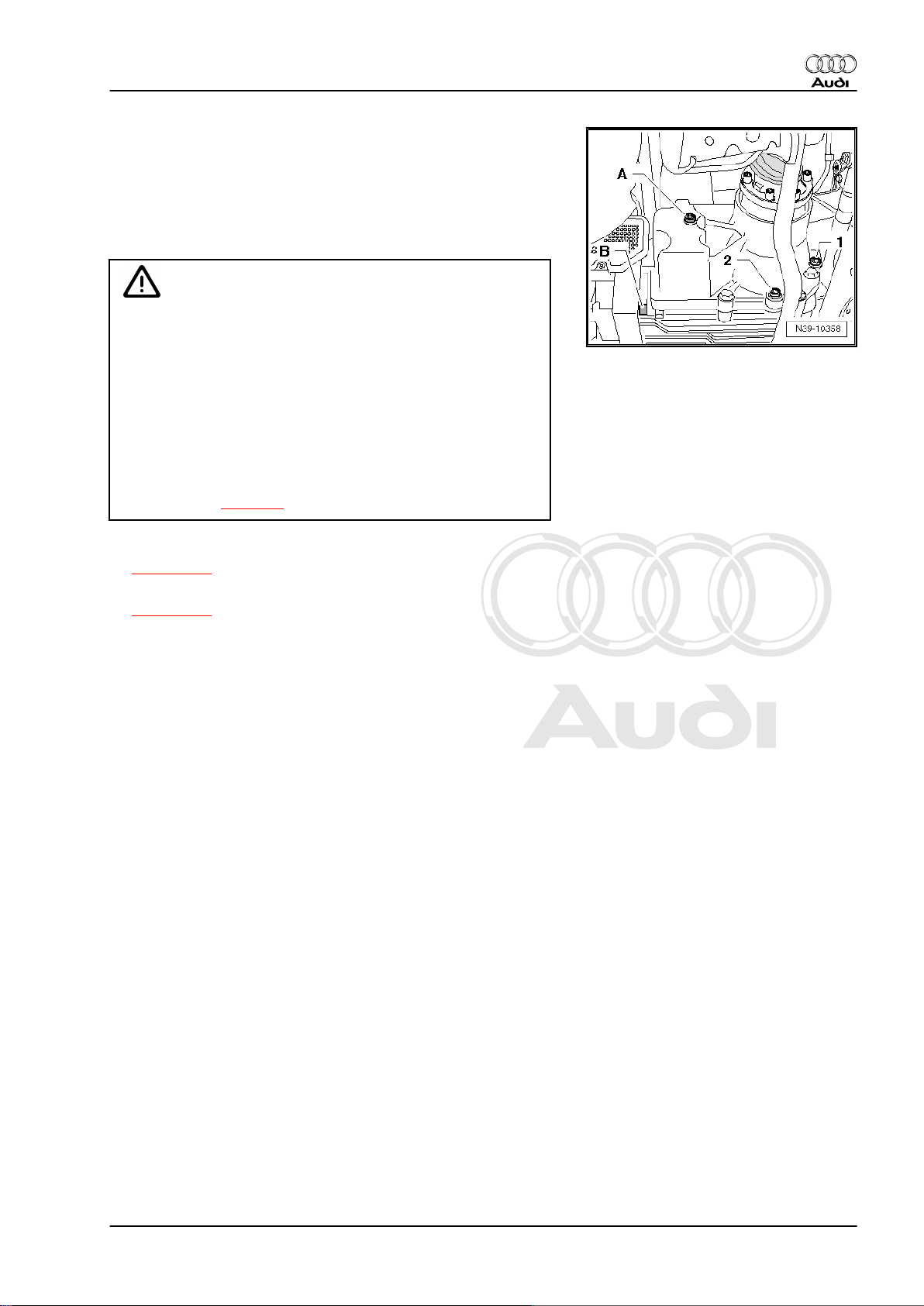

Location of oil filler plugs and drain plugs

A - Filler plug for high performance oil for Haldex coupling

B - Drain plug for high performance oil for Haldex coupling

1 - Filler plug for gear oil

2 - Drain plug for gear oil

Caution

Different types of high-performance oil for Haldex coupling

♦ The rear final drive units “02D/0AV” and “0BR/0BY” have

different “Haldex couplings” and therefore different types

of oil for the Haldex coupling.

♦ The two different types of oil for the Haldex couplings must

not be interchanged or mixed together.

♦ Part number for high performance oil for Haldex coupling

⇒ Electronic parts catalogue .

♦ Note the distinguishing markings for the different rear final

drive units ⇒ page 1 .

Audi A3 2004 ➤ , Audi TT 2007 ➤

♦ Checking oil level in rear final drive and topping up

⇒ page 123 .

♦ Checking oil level in Haldex coupling and topping up

⇒ page 115 .

♦ Do not use any “additives” in the oil.

♦ Do not re-use oil that has been drained off.

Regulations for the disposal of oil

Drained oil must be disposed of properly.

♦ Improper disposal of used oil endangers the environment.

♦ It must not be mixed with solvents, brake fluid, coolant or sim‐

ilar.

♦ Please observe the information shown on the packaging of the

oil.

5. General repair instructions 13

Page 18

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A3 2004 ➤ , Audi TT 2007 ➤

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

5.2 Components

Guided fault finding, vehicle self-diagnosis and testing system

♦ Before servicing the Haldex coupling, the exact cause of the

failure must be determined as precisely as possible via the

vehicle diagnostic, testing and information system -VAS

5051B- in the modes “Guided Fault Finding”, “vehicle self-di‐

agnosis” and “testing system”.

– Connecting vehicle diagnostic, testing and information system

- VAS 5051B- and selecting functions ⇒ page 53 .

WARNING

To avoid any risk of accident, observe the

⇒ “6 Safety precautions”, page 16 when road-testing the ve‐

hicle and using test equipment.

Special tools

For a complete list of special tools used in this Workshop Manual

⇒ "Workshop equipment and special tools" .

Rear final drive

♦ When renewing the rear final drive, check gear oil level and oil

level of the Haldex coupling and top up if necessary:

⇒ page 123 and ⇒ page 115 .

♦ Capacity, Audi A3 ⇒ page 3 .

♦ Capacity, Audi TT ⇒ page 7 .

♦ Specifications ⇒ Electronic parts catalogue .

♦ When installing mounting brackets as well as other waxed

components, the contact surfaces must be cleaned. The con‐

tact surfaces must be free of wax and grease.

O-rings, oil seals and gaskets

♦ Always renew O-rings, seals and gaskets.

♦ Thoroughly clean joint surfaces.

Before installation:

♦ Before installing oil seals, lightly oil outer circumference and

fill space between sealing lips -arrow- with a thin layer of

grease.

♦ The open side of the oil seals faces toward the side with fluid

filling.

After installation:

♦ Check gear oil level in rear final drive ⇒ page 123 .

♦ Check oil level in Haldex coupling and top up as necessary

⇒ page 115 .

Locking elements

14 Rep. Gr.00 - Technical data

Page 19

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

♦ Do not over-stretch circlips.

♦ Always renew circlips which have been damaged or over-

stretched.

♦ Circlips must be properly seated in the base of the groove.

♦ Renew spring pins. Position: the slit -A- should be in line with

the line of force -arrow-.

Nuts, bolts

♦ Nuts and bolts for securing covers and housings must be

slackened and tightened in diagonal sequence.

♦ Loosen and tighten particularly sensitive parts in diagonal se‐

quence and in stages, taking care to keep them straight.

♦ The tightening torques stated apply to non-oiled nuts and

bolts.

♦ Always renew self-locking bolts and nuts.

♦ For all threaded connections, ensure that (where applicable)

the contact surfaces and the nuts and bolts are not coated with

wax until after assembly is completed.

Bearings

♦ Install needle bearings so the lettering (side with thicker metal)

faces towards the installing tool.

♦ Lubricate all bearings in final drive with gear oil when installing.

♦ Always renew the tapered roller bearings on one shaft togeth‐

er as a set and use new bearings from a single manufacturer.

♦ Heat inner races to approx. 100° C before installing.

♦ Do not interchange the outer or inner races of bearings of the

same size (the bearings are paired).

Shims

♦ Measure shims at several points with a micrometer. Tolerance

variations make it possible to obtain the exact shim thickness

required.

♦ Check for burrs and damage.

♦ Install only shims which are in perfect condition.

Audi A3 2004 ➤ , Audi TT 2007 ➤

5.3 Contact corrosion!

Contact corrosion can occur if non-approved fasteners are used

on the vehicle (bolts, nuts, washers etc.).

For this reason, only fasteners with a special surface coating are

fitted.

Rubber or plastic parts and adhesives also consist of non-con‐

ductive materials.

If you are not sure whether used parts can be re-installed, always

fit new parts ⇒ Electronic parts catalogue .

Please note:

♦ Use only genuine spare parts: these have been fully tested

and are compatible with aluminium.

♦ We recommend the use of accessories approved by Audi.

♦ Damage resulting from contact corrosion is not covered by the

warranty.

5. General repair instructions 15

Page 20

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A3 2004 ➤ , Audi TT 2007 ➤

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

6 Safety precautions

⇒ “6.1 Safety precautions for Audi TT and Audi A3 Cabriolet”,

page 16

⇒ “6.2 Safety precautions for Audi A3”, page 17

6.1 Safety precautions for Audi TT and Audi A3 Cabriolet

Observe the following precautions if tests have to be performed

with the engine running.

WARNING

Vehicles with dual clutch gearbox: accidents can be caused if

a gear is inadvertently engaged while the engine is running.

♦ Before working on the vehicle while the engine is running,

shift the selector lever into position “P” and apply the

handbrake.

Danger from toxic fumes!

♦ When the engine is running, the exhaust system must al‐

ways be connected to the exhaust gas extractor.

16 Rep. Gr.00 - Technical data

Page 21

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

Observe the following precautions if test equipment has to be

used while road-testing the vehicle:

WARNING

Accidents can be caused if the driver is distracted by test

equipment while road-testing, or if test equipment is not se‐

cured.

Injuries can also be caused if the passenger's airbag is trig‐

gered in a collision.

• The use of test equipment while driving causes distraction.

• There is an increased risk of injury if test equipment is not

secured.

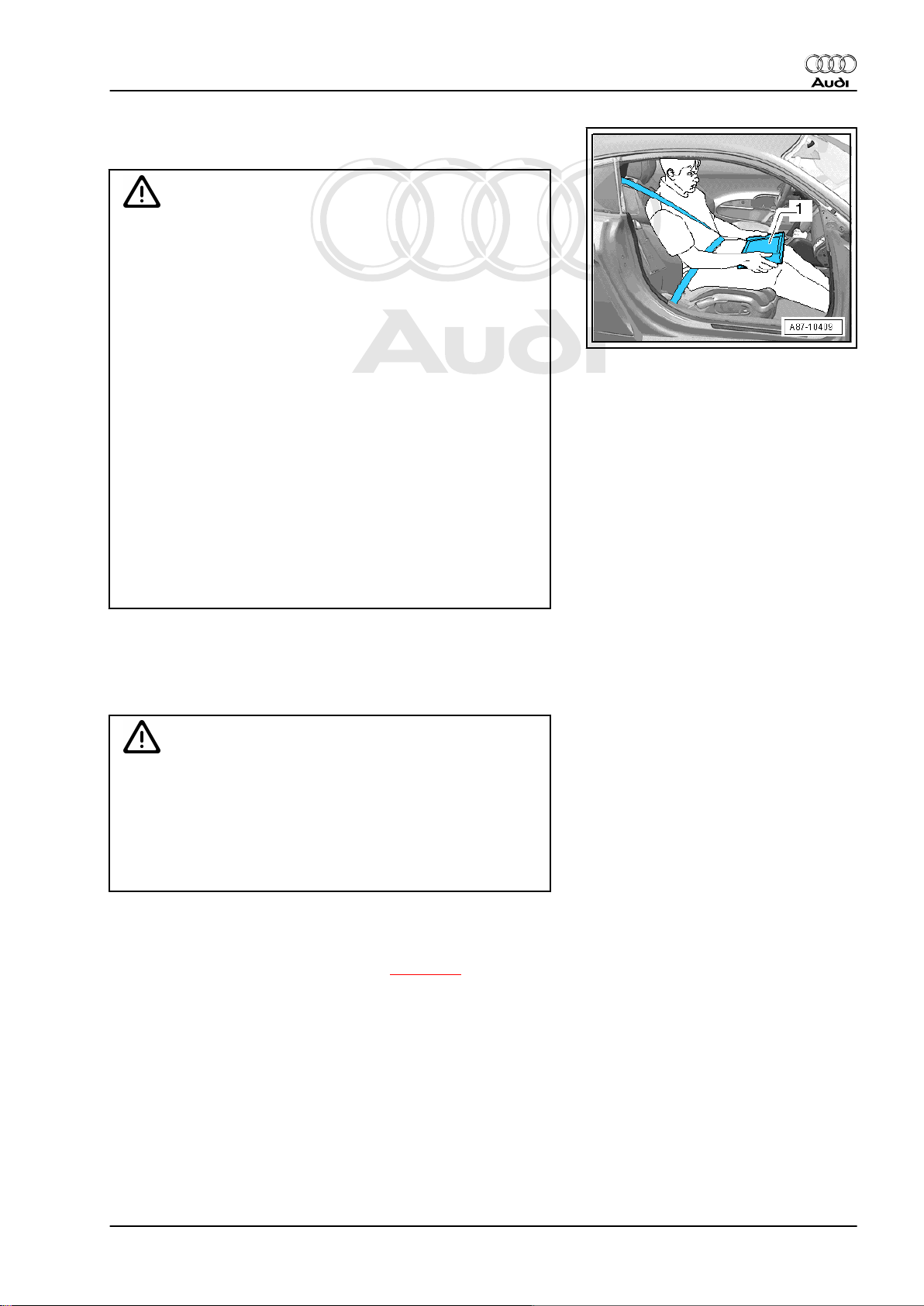

TT Coupé:

Always secure testing equipment to the rear seat with a strap

and have them operated from there by a second person.

TT Roadster:

♦ Move the passenger's seat to the rearmost position.

♦ Use only vehicle diagnosis and service information sys‐

tem -VAS 5052- or diagnosis system -VAS 5053- .

♦ Test equipment may only be operated by the passenger;

the tester -1- must be placed flat on the passenger's lap

as illustrated.

Audi A3 2004 ➤ , Audi TT 2007 ➤

Observe the following precautions to avoid possible injury and/or

damage to electrical and electronic components:

♦ Switch off ignition before disconnecting and connecting test

equipment.

Caution

When disconnecting the battery there is a risk of serious dam‐

age to electronic components:

♦ Observe the correct procedure for disconnecting the bat‐

tery.

♦ Always switch off the ignition before disconnecting the

battery.

6.2 Safety precautions for Audi A3

Safety precautions for Audi A3 Cabriolet ⇒ page 16

6. Safety precautions 17

Page 22

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A3 2004 ➤ , Audi TT 2007 ➤

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

Observe the following precautions to avoid possible injury and/or

damage to the vehicle:

WARNING

Vehicles with dual clutch gearbox: accidents and injury can be

caused if a gear is inadvertently engaged while the engine is

running.

♦ Before working on the vehicle while the engine is running,

shift the selector lever into position “P” and apply the

handbrake.

Danger from toxic fumes!

♦ When the engine is running, the exhaust system must al‐

ways be connected to the exhaust gas extractor.

Observe the following precautions if test equipment has to be

used when road-testing the vehicle.

WARNING

Accidents can be caused if the driver is distracted by test

equipment or if test equipment is not secured.

Injuries can be caused if the passenger's airbag is triggered in

a collision.

• The use of test equipment while driving causes distraction.

• There is an increased risk of injury if test equipment is not

secured.

♦ Always secure testing equipment to the rear seat with a

strap and have them operated from there by a second

person.

Observe the following precautions to avoid possible injury and/or

irreparable damage to electrical and electronic components:

♦ Switch off ignition before disconnecting and connecting test

equipment.

Caution

When disconnecting the battery there is a risk of serious dam‐

age to electronic components:

♦ Observe the correct procedure for disconnecting the bat‐

tery.

♦ Always switch off the ignition before disconnecting the

battery.

– Disconnect battery ⇒ Rep. Gr. 27 .

18 Rep. Gr.00 - Technical data

Page 23

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

39 – Final drive - rear differential

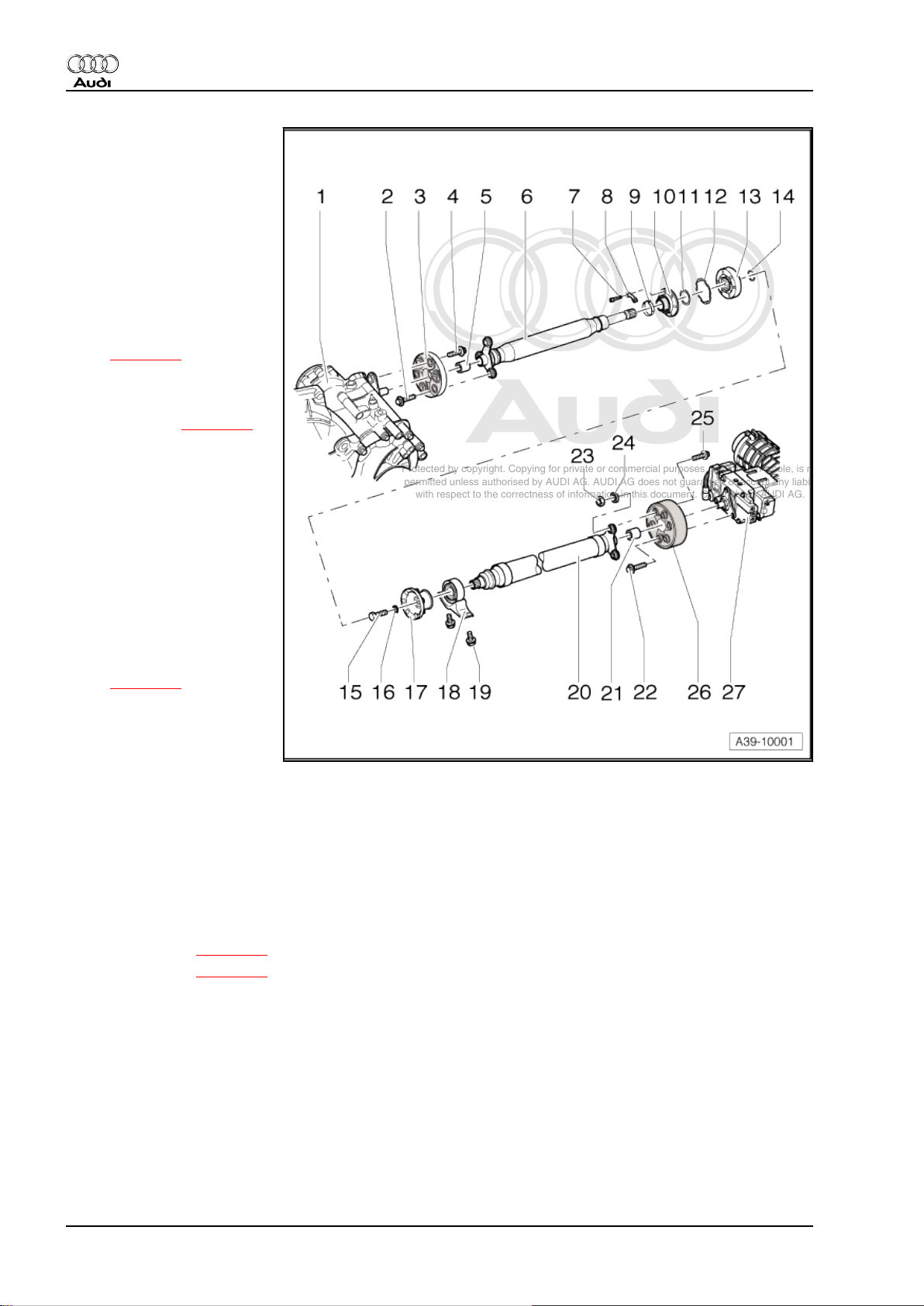

1 Exploded view – propshaft with de‐

tachable centre bearing (up to 05.07)

The propshaft with detachable centre bearing was installed as

follows:

♦ Audi TT up to vehicle identification number 8J-8-011 000

♦ Audi A3 up to and including model year 2007

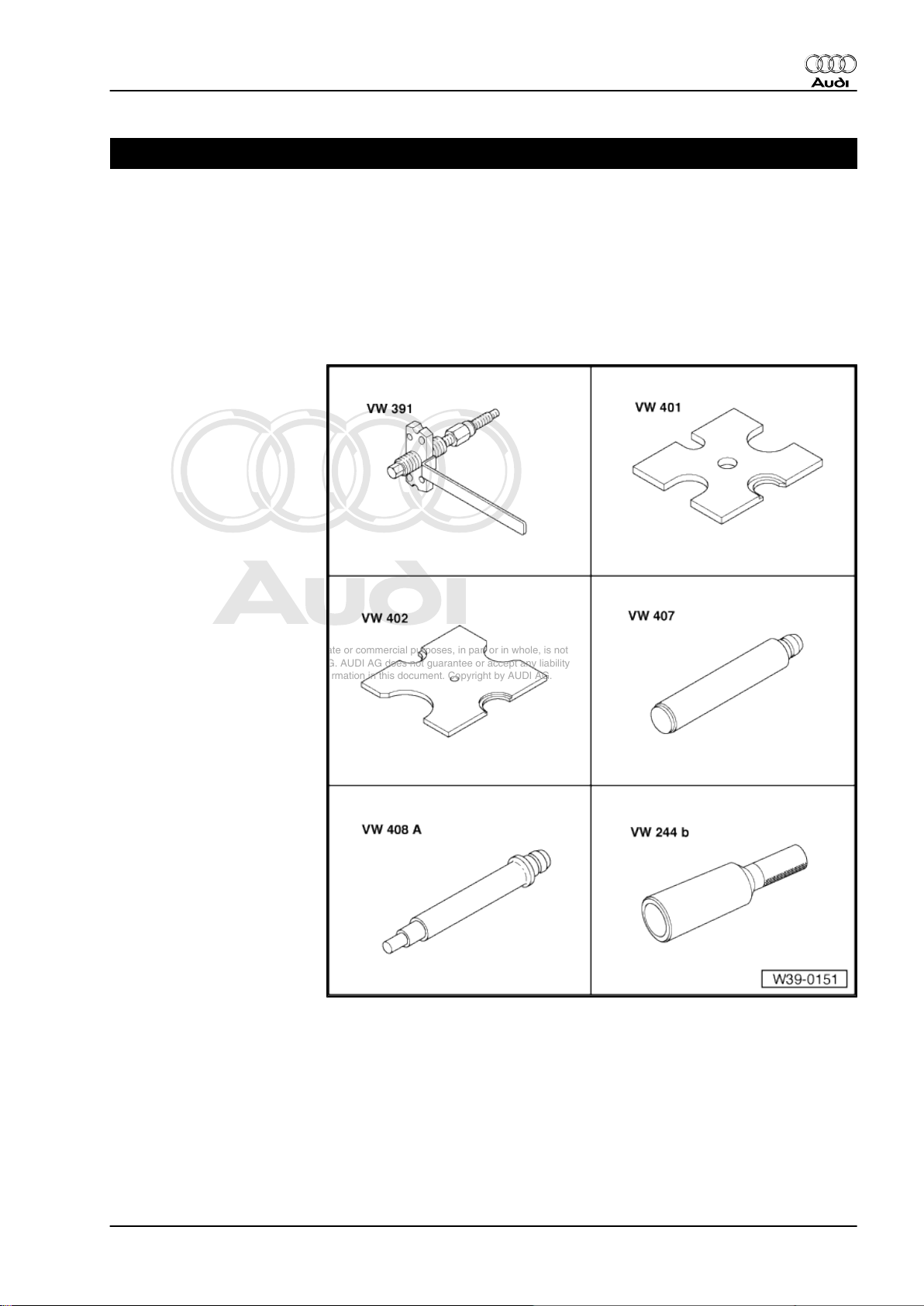

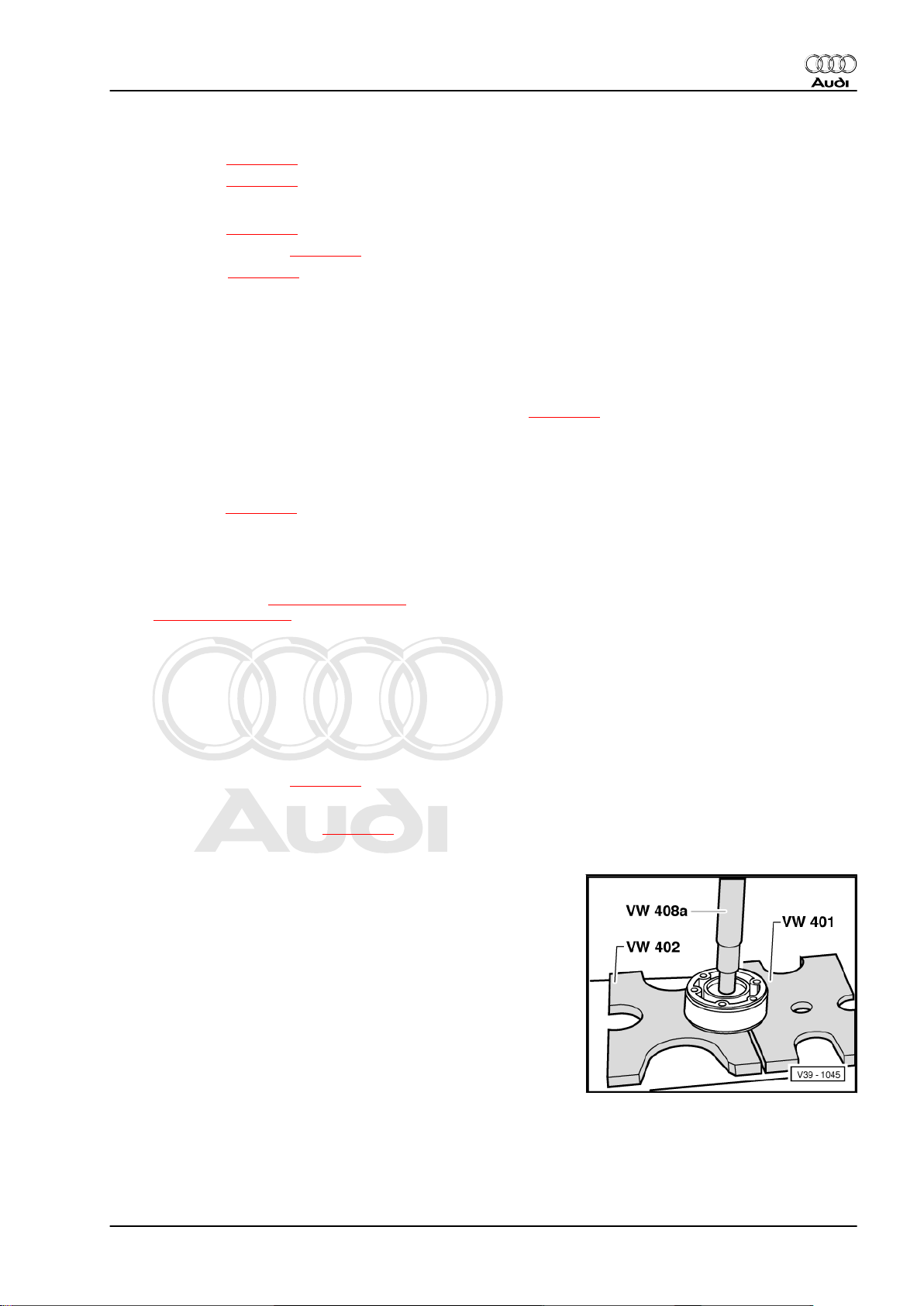

Special tools and workshop

equipment required

♦ Drive flange installing tool -

VW 391-

♦ Thrust plate -VW 401-

♦ Thrust plate -VW 402-

♦ Press tool -VW 407-

♦ Press tool -VW 408A-

♦ Drift sleeve -VW 244B-

Audi A3 2004 ➤ , Audi TT 2007 ➤

1. Exploded view – propshaft with detachable centre bearing (up to 05.07) 19

Page 24

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A3 2004 ➤ , Audi TT 2007 ➤

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

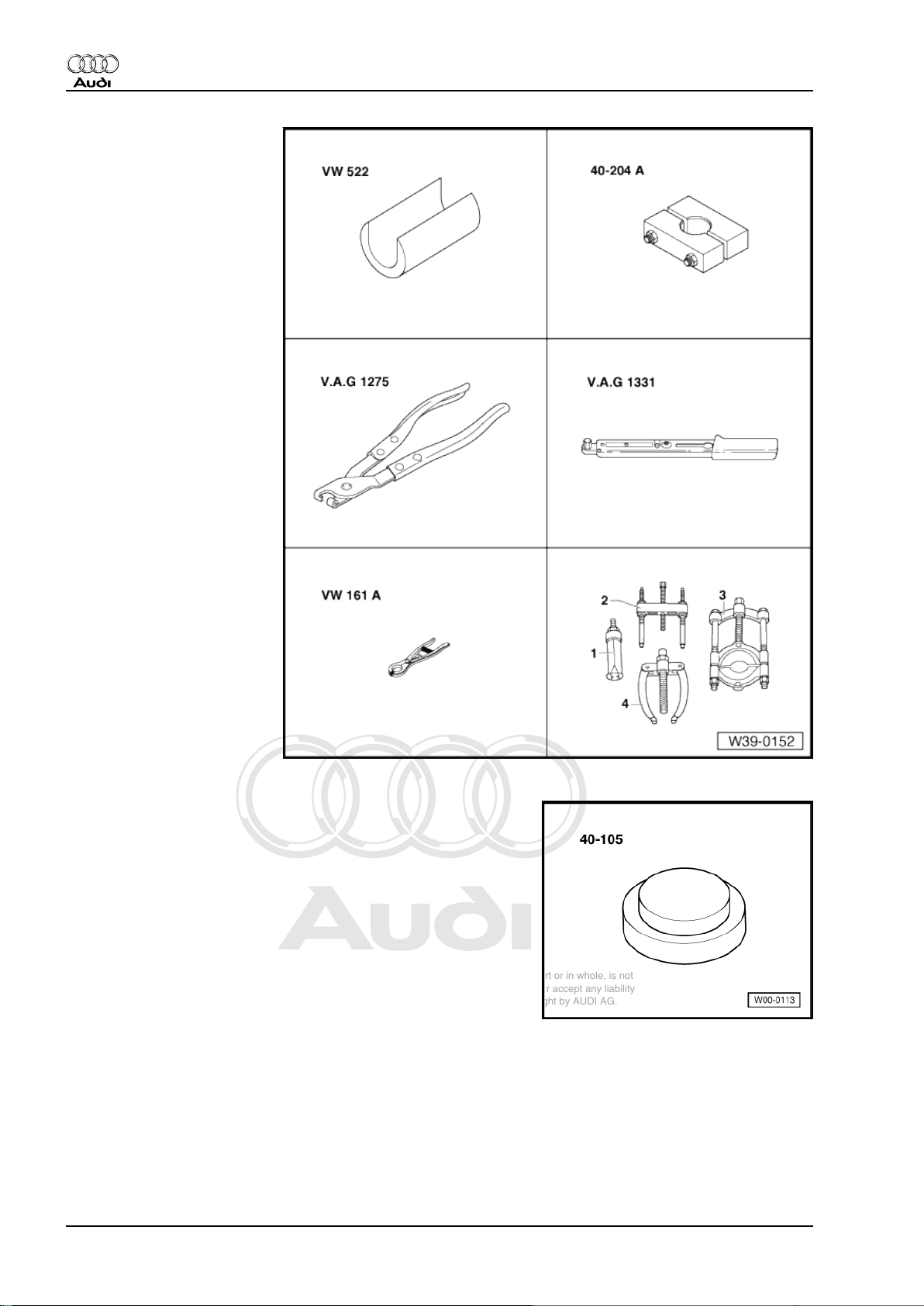

♦ Support sleeve -VW 522-

♦ Tensioner -40-204A-

♦ Hose clip pliers -V.A.G

1275/-

♦ Torque wrench -V.A.G

1331/-

♦ Circlip pliers -VW 161A-

♦ Puller -2 - Kukko 18/0-

♦ Splitter -3 - Kukko 17/1-

♦ Thrust plate -40 - 105-

20 Rep. Gr.39 - Final drive - rear differential

Page 25

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

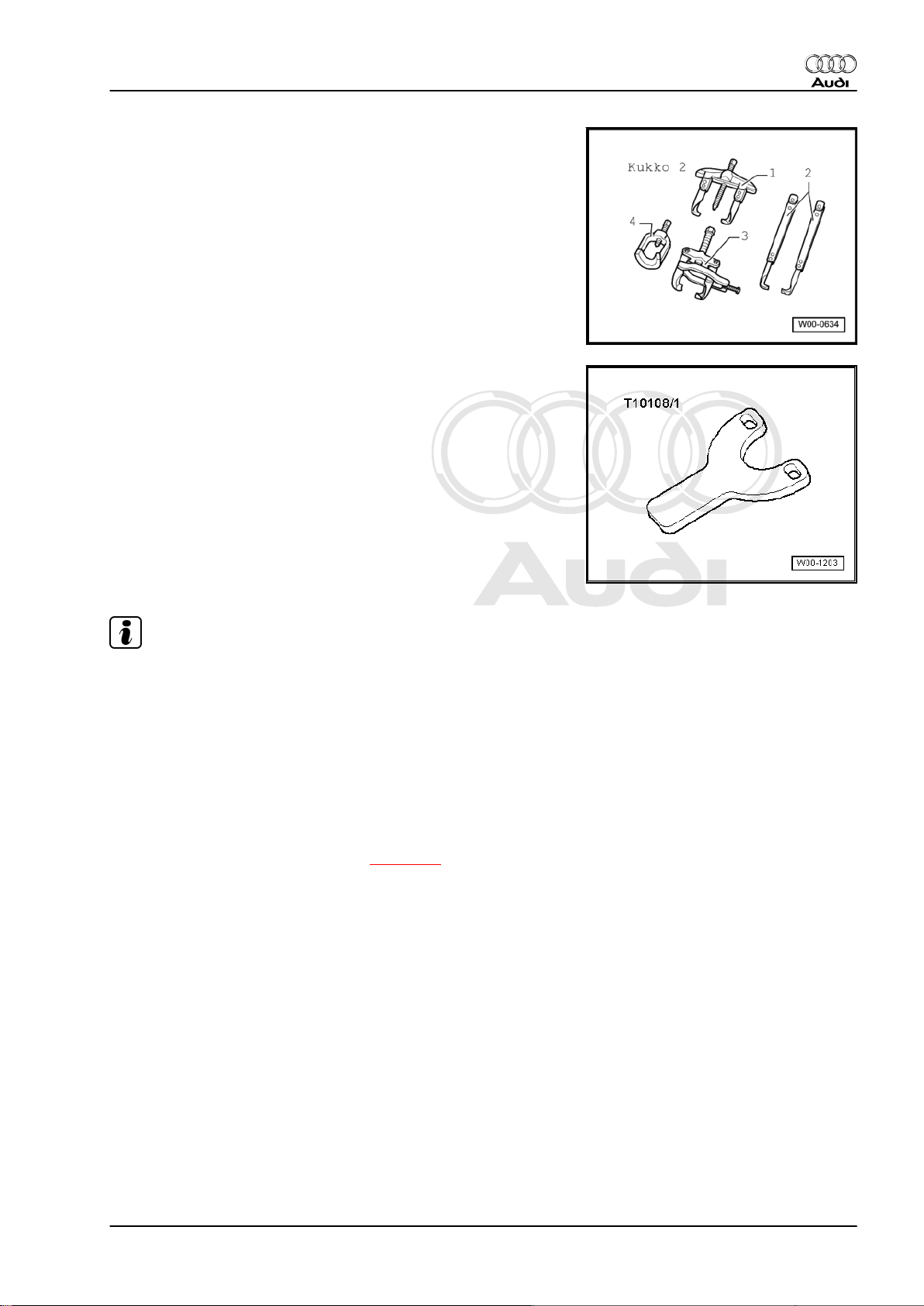

♦ Two-arm puller -1 Kukko 20/10-

♦ Support plate -T10108/1-

Audi A3 2004 ➤ , Audi TT 2007 ➤

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

Note

♦

In order to achieve the quietest possible running, only the

complete propshaft is balanced during manufacture. The bal‐

ancing of the complete propshaft or the individual propshaft

tubes cannot be carried out with workshop equipment. There‐

fore, if the front or rear propshaft tube is damaged, always

renew the complete propshaft.

♦

Do not bend propshaft; only store and transport fully extended.

♦

Before removing, mark the positions of all parts in relation to

each other. Reinstall in the same position to avoid excessive

imbalance, resulting in bearing damage and rumbling noise.

♦

Removing and installing propshaft ⇒ page 27

1. Exploded view – propshaft with detachable centre bearing (up to 05.07) 21

Page 26

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A3 2004 ➤ , Audi TT 2007 ➤

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

1 - Manual gearbox with bevel

box

2 - Bolt

❑ 50 Nm + 90°

❑ Always renew

3 - Flexible coupling with heat

shield

❑ Installation position:

open side of heat shield

points towards gearbox

❑ Removing and installing

⇒ page 27

4 - Bolt

❑ 60 Nm

❑ Allocation ⇒ page 31

5 - Centring sleeve

6 - Propshaft tube (front)

❑ Do not damage centring

sleeve -5- and seal in

centre of flange when

removing and installing

7 - Bolt

❑ 40 Nm

8 - Lock plate

9 - Clip

❑ Tensioning

⇒ page 24

10 - Boot for constant velocity

joint

❑ Drive off with a drift be‐

fore pressing off CV joint

❑ Check for damage

11 - Dished spring

❑ Inner diameter serrated

❑ Installation position: large diameter lies against CV joint

12 - Gasket

❑ Renew; pull off backing and stick onto joint

13 - Constant velocity joint

❑ Pressing off ⇒ page 23

❑ Pressing on ⇒ page 24

❑ Press 25 g G-6.3 grease from each side (in total 50 g) into joint. Regrease joint if necessary when

renewing boot

14 - Circlip

❑ Renew

❑ Remove and install using circlip pliers -VW 161A-

15 - Bolt

❑ 45 Nm

16 - Washer

❑ Always renew

22 Rep. Gr.39 - Final drive - rear differential

Page 27

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A3 2004 ➤ , Audi TT 2007 ➤

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

17 - Flange

❑ Pulling off ⇒ page 24

❑ Pulling on ⇒ page 25

18 - Centre bearing

❑ Pulling off ⇒ page 25

❑ Installation position ⇒ page 25

❑ Driving on ⇒ page 25

19 - Bolt

❑ 25 Nm

❑ Also secures heat shield

20 - Propshaft tube (rear)

❑ Do not damage centring sleeve -5- and seal in centre of flange when removing and installing

❑ Clamp in a vice to loosen and tighten bolt connections ⇒ page 24

21 - Centring sleeve

22 - Bolt

❑ 60 Nm

❑ Allocation ⇒ page 31

23 - Balancing nut

❑ 10 Nm

❑ Not fitted on all propshafts

❑ If the flange bolt ⇒ Item 25 (page 23) was loosened, the balancing nut and the balancing washer

⇒ Item 24 (page 23) must NOT be re-installed.

24 - Balancing washer

❑ Only fitted on balanced final drive units

25 - Bolt

❑ 50 Nm + 90°

❑ Always renew

26 - Flexible coupling with vibration damper

❑ Installation position ⇒ page 26

27 - Rear final drive

❑ Removing and installing ⇒ page 96

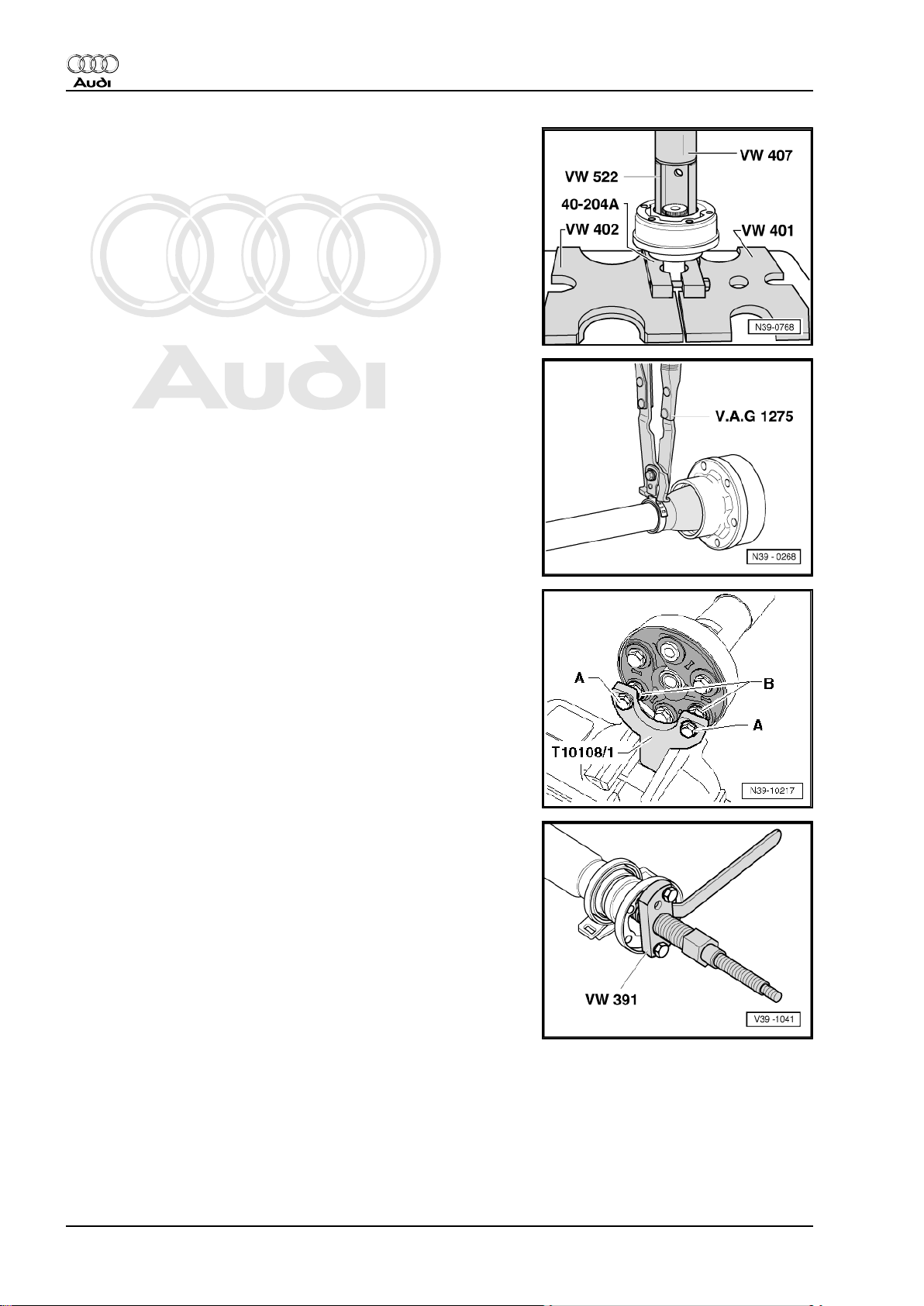

Pressing off constant velocity joint

1. Exploded view – propshaft with detachable centre bearing (up to 05.07) 23

Page 28

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A3 2004 ➤ , Audi TT 2007 ➤

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

Pressing on constant velocity joint

– Press on carefully.

– Tighten tensioner -V.A.G 40-204A- firmly; propshaft must not

move out of position in tensioner, as this will cause paint dam‐

age.

– If necessary, repair paint damage as follows: remove grease

residue with nitro thinner -L 001 600- . Apply 2-component

acrylic paint -ALN 769 041- with hardener -ALZ 009 001- .

Tightening clip

Refer to ⇒ Electronic parts catalogue for clip required in the event

of a repair.

Clamp rear propshaft tube into a vice using support plate T10108/1- .

– Secure support plate -T10108/1- to flexible coupling of prop‐

shaft tube.

– To do so, fit nuts -B- onto bolts -A- between support plate -

T10108/1- and flexible coupling.

A - Bolt M10 x 70 mm with nut

B - M12 nut

Pulling off flange

24 Rep. Gr.39 - Final drive - rear differential

Page 29

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

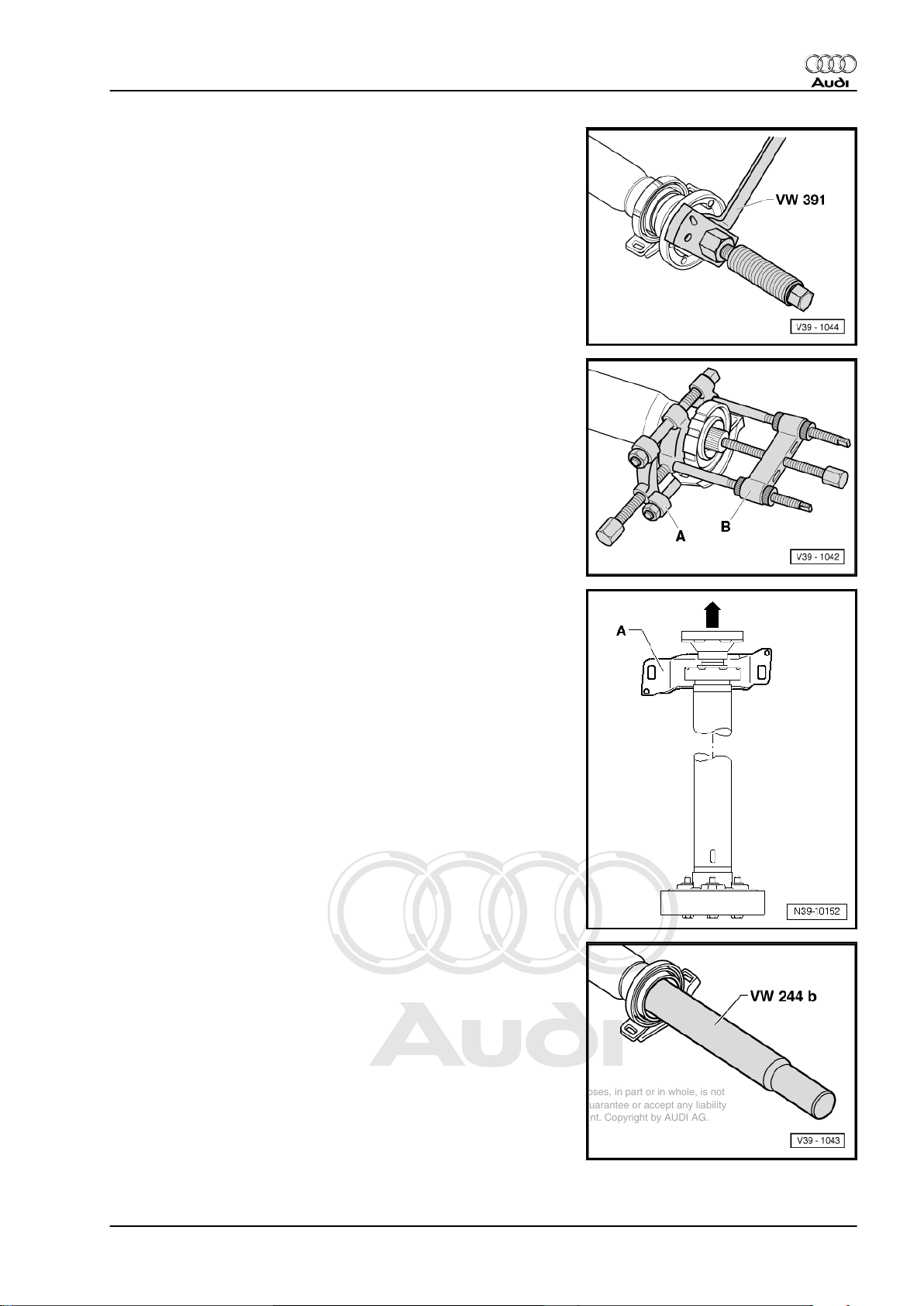

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

Pressing on flange

Pulling off centre bearing

– The rubber guide of the centre bearing must be cut and the

metal cover removed.

A - Splitter 12...75 mm , e.g. -Kukko 17/1-

B - Puller , e.g. -Kukko 18/0-

– Tighten splitter -A- with straight side of jaws behind centre

bearing.

– Then apply two-arm puller -B- to splitter .

– Pull centre bearing off propshaft tube.

Audi A3 2004 ➤ , Audi TT 2007 ➤

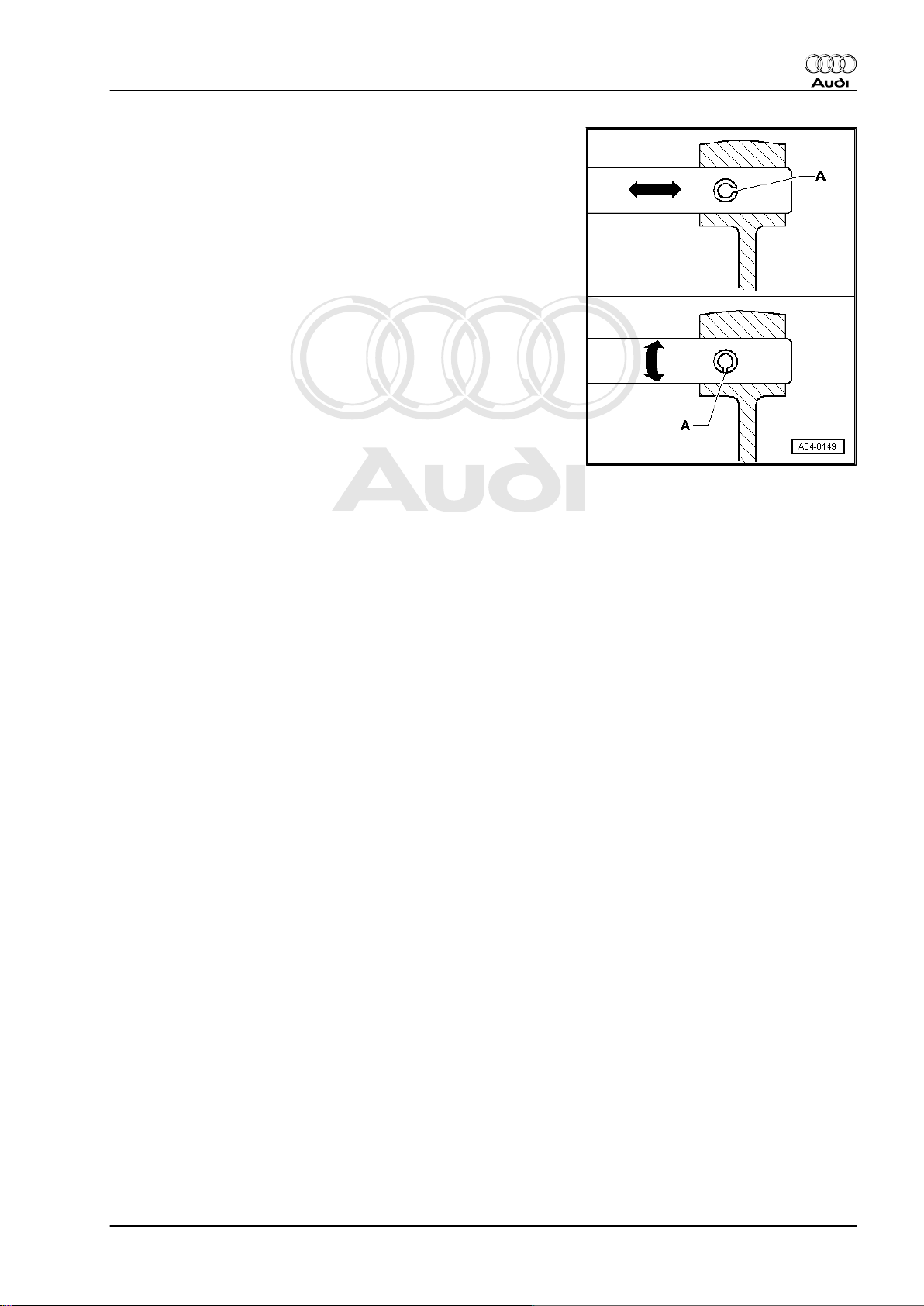

Installation position of centre bearing

The longer shoulder -A- points to left -arrow- (as seen in direction

of travel).

Driving on centre bearing

– Drive on centre bearing until limit stop.

1. Exploded view – propshaft with detachable centre bearing (up to 05.07) 25

Page 30

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A3 2004 ➤ , Audi TT 2007 ➤

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

Installation position of flexible coupling with vibration damper

The shoulder on the outer circumference -arrows- must point

away from the propshaft tube.

26 Rep. Gr.39 - Final drive - rear differential

Page 31

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

2 Removing propshaft with detachable

centre bearing (up to 05.07)

Special tools and workshop equipment required

♦ Engine/gearbox jack -V.A.G 1383 A- with universal support -

V.A.G 1359/2-

Removing

Audi A3 2004 ➤ , Audi TT 2007 ➤

Note

♦

Repairs on the propshaft should be carried out on a two pillar

hoist.

♦

Before removing, mark the positions of all parts in relation to

each other. Reinstall in the same position to avoid excessive

imbalance, resulting in bearing damage and rumbling noise.

♦

Do not bend propshaft; only store and transport fully extended.

Audi A3

– Remove noise insulation -arrows-.

Audi TT

– Remove centre noise insulation -fasteners 1 ... 4-.

2. Removing propshaft with detachable centre bearing (up to 05.07) 27

Page 32

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A3 2004 ➤ , Audi TT 2007 ➤

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

Vehicles with 4-cylinder engine:

– If fitted, remove cross member on underbody -arrows-.

– Disconnect exhaust system at clamp -1-.

– Tie up front exhaust pipe on underbody.

Caution

The flexible joints in the exhaust system can be damaged.

♦ The flexible joints in the front exhaust pipe must not be

bent further than 10°.

– Remove rear section of exhaust system ⇒ Rep. Gr. 26 .

Vehicles with 6-cylinder engine:

– Remove complete exhaust system ⇒ Rep. Gr. 26 .

Continued for all vehicles:

– Support propshaft with gearbox jack -V.A.G 1383 A- (use

wooden wedge -A- as an aid).

– Then unbolt heat shield -arrows-.

– Fit centre bearing again -arrows- after removing heat shield.

– Unbolt propshaft with flexible coupling from bevel box.

28 Rep. Gr.39 - Final drive - rear differential

Page 33

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

– Unscrew bolts -1 ... 3- and remove pendulum support.

– Check whether there are factory markings on the constant ve‐

locity joint/propshaft -arrow A- and -arrow B-. If not, please

apply colour markings.

Audi A3 2004 ➤ , Audi TT 2007 ➤

– Disconnect front propshaft tube from rear propshaft tube

-arrows-.

– Push front propshaft tube towards the front and swivel out from

flange of rear propshaft tube.

Note

Take care when swivelling out that the front propshaft tube is

pushed downwards as little as possible.

– Carefully detach front propshaft tube from centring pin on bev‐

el box.

Note

♦

The seal -arrow- in the flange of the propshaft must not be

damaged.

♦

Pull off propshaft horizontally from guide pin.

– Swivel front propshaft tube downwards and remove.

2. Removing propshaft with detachable centre bearing (up to 05.07) 29

Page 34

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A3 2004 ➤ , Audi TT 2007 ➤

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

– Check whether there is a factory marking (coloured dot) on the

flexible coupling and on the flange for the propshaft on the rear

final drive -arrows-.

– If not, mark position of flexible coupling and flange for prop‐

shaft on rear final drive in relation to each other -arrows-.

– Unbolt rear propshaft with flexible coupling and vibration

damper from rear final drive -arrows-.

– Unbolt centre bearing for propshaft from vehicle -arrows-.

– Carefully pull rear propshaft tube from centring pin.

Note

♦

Do not tilt propshaft when removing; pull off centring pin hori‐

zontally. Make sure that the seal in the centring sleeve

-arrow- does not become damaged.

♦

The flexible coupling and vibration damper cannot be separa‐

ted from each other.

2.1 Installing propshaft with detachable centre bearing (up to 05.07)

Installation is carried out in reverse sequence; note the following:

30 Rep. Gr.39 - Final drive - rear differential

Page 35

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

Note

♦

All parts of the propshaft marked in relation to each other must

be reinstalled in the same position.

♦

The seals -arrow- in flanges of the propshaft must not be dam‐

aged when removing and installing. If seals are damaged, the

propshaft must be renewed.

♦

Push propshaft horizontally onto the appropriate guide pin.

Installation position:

♦ Three projecting sleeves on the gearbox flange / rear final

drive flange and propshaft flange engage in mounting holes of

flexible coupling.

– Attach propshaft to rear final drive so that the markings

-arrows- align.

Audi A3 2004 ➤ , Audi TT 2007 ➤

Take note of the correct fitting locations for the various flange

bolts.

Flange bolt with Fitting location

small collar -arrow A- Propshaft to front final drive -A-.

Tightening torque

⇒ Item 4 (page 22)

large collar -arrow B- Propshaft to rear final drive -B-.

Tightening torque

⇒ Item 22 (page 23)

Make sure that the markings on the constant velocity joint/prop‐

shaft -arrow A- and -arrow B- are in line.

2. Removing propshaft with detachable centre bearing (up to 05.07) 31

Page 36

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A3 2004 ➤ , Audi TT 2007 ➤

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

– Secure front propshaft tube to rear propshaft tube -arrows-.

Tightening torque ⇒ Item 7 (page 22)

Stress-free installation of centre bearing:

• Make sure that all propshaft bolts have been tightened.

– Position the centre bearing in its elongated holes so that the

propshaft and centre bearing are not under stress.

– Tighten bolts with washers -1-. Make sure the bolts with wash‐

ers -1- are within the four centring tabs on heat shield -2-.

Tightening torque ⇒ Item 19 (page 23)

– First secure pendulum support to gearbox -arrows B and C-,

then on subframe -arrow A-.

Component

Pendulum support to: Gearbox

Nm

40 Nm + 90°

1)

-arrows B and C-

1)

Renew bolts

Subframe -arrow A-

100 Nm + 90°

1)

– Install exhaust system and perform stress-free alignment ⇒

Rep. Gr. 26 .

– If fitted, install cross member on underbody -arrows- ⇒ Rep.

Gr. 26 .

– Install noise insulation ⇒ Rep. Gr. 66 .

32 Rep. Gr.39 - Final drive - rear differential

Page 37

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

Note

♦

If droning noises occur during driving, note the following:

♦

Remove balancing nut and balancing washer -arrows-.

♦

Then, if necessary, unbolt propshaft with flexible coupling from

flange for propshaft on rear final drive, rotate one hole further

and screw in again.

♦

If the droning noises can still be heard, the propshaft must

again be rotated and screwed back on.

Audi A3 2004 ➤ , Audi TT 2007 ➤

2. Removing propshaft with detachable centre bearing (up to 05.07) 33

Page 38

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A3 2004 ➤ , Audi TT 2007 ➤

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

3 Exploded view – propshaft with non-

detachable centre bearing (from

05.07 onwards)

The propshaft with non-detachable centre bearing was intro‐

duced as follows:

♦ Audi TT (not TT RS) from vehicle identification number

8J-8-011 001 ▸

♦ Audi A3 from model year 2008 onwards, vehicle identification

number 8P-8-000 001▸

Note

♦

No repairs can be performed on the propshaft.

♦

The front propshaft tube cannot be separated from the rear

propshaft tube.

1 - Gearbox with bevel box

2 - Bolt

❑ 50 Nm + 90°

❑ Secures front flexible

coupling to propshaft

❑ Always renew

3 - Flexible coupling (front)

❑ Installation position:

open side of heat shield

points towards gearbox

4 - Bolt

❑ 60 Nm

❑ Secures flexible cou‐

pling to bevel box

5 - Propshaft

❑ Cannot be separated at

centre joint -arrow-

❑ Removing and installing

⇒ page 35

6 - Bolt

❑ 25 Nm

7 - Centre bearing

❑ Align so that compo‐

nents are free of stress

8 - Bolt

❑ 50 Nm + 90°

❑ Secures rear flexible

coupling to propshaft

❑ Always renew

9 - Bolt

❑ 60 Nm

❑ Secures flexible coupling to final drive

34 Rep. Gr.39 - Final drive - rear differential

Page 39

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

10 - Flexible coupling with vibration damper

❑ Heat shield faces towards propshaft

11 - Rear final drive

❑ Removing and installing ⇒ page 96

3.1 Removing propshaft with non-detacha‐

ble centre bearing (from 05.07 onwards)

Special tools and workshop equipment required

♦ Torque wrench -V.A.G 1332-

Audi A3 2004 ➤ , Audi TT 2007 ➤

♦ Engine and gearbox jack -V.A.G 1383 A-

Counterhold tool -T10172- with adapters -T10172/5-

Removing

Note

♦

Repairs on the propshaft should preferably be carried out on

a two-pillar hoist.

♦

Before removing, mark the positions of all parts in relation to

each other. Reinstall in the same position to avoid excessive

imbalance, resulting in bearing damage and rumbling noise.

♦

Do not bend propshaft; only store and transport fully extended.

♦

Always support the propshaft during removal; it must not be

allowed to “hang down” from one of the joints.

♦

Always keep the propshaft horizontal while pulling it off or fit‐

ting it on the joint flange.

3. Exploded view – propshaft with non-detachable centre bearing (from 05.07 onwards) 35

Page 40

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A3 2004 ➤ , Audi TT 2007 ➤

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

Audi A3

– Remove noise insulation -arrows-.

Audi TT

– Remove centre noise insulation -fasteners 1 ... 4-.

Audi TTS

– Remove front noise insulation -1- and -2- ⇒ Rep. Gr. 66 .

Vehicles with 4-cylinder engine:

– Unbolt bracket for exhaust system -arrows-.

TT Roadster with 4-cylinder engine:

36 Rep. Gr.39 - Final drive - rear differential

Page 41

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

– Unscrew bolts -arrows- and detach cross piece.

All vehicles with 4-cylinder engine:

– If fitted, remove cross member on underbody -arrows-.

Audi A3 2004 ➤ , Audi TT 2007 ➤

Caution

The flexible joints in the exhaust system can be damaged.

♦ The flexible joints in the front exhaust pipe must not be

bent further than 10°.

– Disconnect exhaust system at clamp -arrows-.

– Tie up front exhaust pipe on underbody.

– Remove rear section of exhaust system ⇒ Rep. Gr. 26 .

Vehicles with 6-cylinder engine:

– Remove complete exhaust system ⇒ Rep. Gr. 26 .

Continued for all vehicles:

– When loosening and tightening propshaft bolts, counterhold at

rear final drive using counterhold tool -T10172- and adapters

-T10172/5- .

3. Exploded view – propshaft with non-detachable centre bearing (from 05.07 onwards) 37

Page 42

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A3 2004 ➤ , Audi TT 2007 ➤

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

– Unbolt propshaft from bevel box -arrows-.

– Remove bolts -1- and -2- for pendulum support.

– Push engine/gearbox assembly forwards and secure in posi‐

tion with a suitable block of wood -A-.

– During this step, carefully detach propshaft tube from centring

pin on bevel box.

Note

♦

The seal -arrow- in the flange of the propshaft must not be

damaged.

♦

Pull off propshaft horizontally from guide pin.

38 Rep. Gr.39 - Final drive - rear differential

Page 43

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

– Support rear section of propshaft using engine and gearbox

jack -V.A.G 1383 A- .

A - Wooden block

– Secure propshaft against falling using belt from universal

gearbox support -V.A.G 1359/2- .

– Unscrew bolts securing centre bearing and heat shield

-arrows-.

– Detach heat shield.

– Check whether there is a factory marking (coloured dot) on the

flexible coupling and on the flange for the propshaft on the rear

final drive -arrows-.

– If not, mark position of flexible coupling and flange for prop‐

shaft on rear final drive in relation to each other -arrows-.

Audi A3 2004 ➤ , Audi TT 2007 ➤

– Remove bolts -arrows- securing propshaft to rear final drive.

– Pull propshaft off rear final drive and lay it on engine and gear‐

box jack -V.A.G 1383 A- .

3. Exploded view – propshaft with non-detachable centre bearing (from 05.07 onwards) 39

Page 44

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A3 2004 ➤ , Audi TT 2007 ➤

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

– Always make sure that you do not damage the bush -arrow-

when pulling off and refitting the propshaft.

Note

Do not tilt propshaft when removing; pull off centring pin horizon‐

tally. Make sure that the seal in the centring sleeve -arrow- does

not become damaged.

WARNING

To avoid damaging the protective sleeve in the centre bearing,

keep the propshaft as straight as possible during removal, in‐

stallation and storage.

Note

A second mechanic is required for the next steps when removing

the propshaft.

– Take out the propshaft towards the rear, keeping it as straight

as possible.

3.2 Installing propshaft with non-detachable centre bearing (from 05.07 onwards)

Installation is carried out in reverse sequence; note the following:

– Install all parts in the same relative positions, as marked before

removal.

– Attach propshaft to rear final drive so that the markings

-arrows- align.

– Tighten bolts securing propshaft. Tightening torques

⇒ Item 4 (page 34) and ⇒ Item 9 (page 34) .

Stress-free installation of centre bearing:

• Make sure that all propshaft bolts have been tightened.

– Position the centre bearing in its elongated holes so that the

propshaft and centre bearing are not under stress.

– Tighten bolts with washers -1-. Make sure the bolts with wash‐

ers -1- are within the centring tabs on heat shield -2-. Tight‐

ening torque ⇒ Item 6 (page 34)

40 Rep. Gr.39 - Final drive - rear differential

Page 45

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

– Secure pendulum support with new bolts. Tightening torques

⇒ Running gear; Rep. Gr. 40 .

Audi A3 2004 ➤ , Audi TT 2007 ➤

Component

Pendulum support to: Gearbox -1-

1)

Renew bolts

Gearbox -2-

Nm

40 Nm + 90°

40 Nm + 90°

1)

1)

– Install exhaust system ⇒ Rep. Gr. 26 .

– If fitted, install cross member on underbody -arrows- ⇒ Rep.

Gr. 26 .

– Install noise insulation ⇒ Rep. Gr. 66 .

3. Exploded view – propshaft with non-detachable centre bearing (from 05.07 onwards) 41

Page 46

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A3 2004 ➤ , Audi TT 2007 ➤

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

4 Exploded view - propshaft (Audi TT

RS)

Note

No repairs can be performed on the propshaft.

1 - Gearbox with bevel box

2 - Bolt

❑ 60 Nm

❑ Secures propshaft to

bevel box

3 - Propshaft

❑ Cannot be separated at

centre joint -arrow-

❑ Removing and installing

⇒ page 35

4 - Bolt

❑ 25 Nm

5 - Centre bearing

❑ Align so that compo‐

nents are free of stress

6 - Bolt

❑ 50 Nm + 90°

❑ Secures rear flexible

coupling to propshaft

❑ Always renew

7 - Bolt

❑ 60 Nm

❑ Secures flexible cou‐

pling to final drive

8 - Flexible coupling with vibra‐

tion damper

❑ Heat shield faces to‐

wards propshaft

9 - Rear final drive

❑ Removing and installing

⇒ page 103

4.1 Removing and installing propshaft (Audi TT RS)

Special tools and workshop equipment required

42 Rep. Gr.39 - Final drive - rear differential

Page 47

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

♦ Engine and gearbox jack -V.A.G 1383 A-

♦ Counterhold tool -T10172- with adapters -T10172/5-

Audi A3 2004 ➤ , Audi TT 2007 ➤

Removing

Note

♦

Repairs on the propshaft should preferably be carried out on

a two-pillar hoist.

♦

Before removing, mark the positions of all parts in relation to

each other. Reinstall in the same position to avoid excessive

imbalance, resulting in bearing damage and rumbling noise.

♦

Do not bend propshaft; only store and transport fully extended.

♦

Always support the propshaft during removal; it must not be

suspended from one of the joints.

♦

Always keep the propshaft horizontal while pulling it off or fit‐

ting it on the joint flange.

– Remove noise insulation panels -1- and -2- ⇒ Rep. Gr. 66 .

4. Exploded view - propshaft (Audi TT RS) 43

Page 48

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A3 2004 ➤ , Audi TT 2007 ➤

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

– Remove catalytic converters ⇒ Rep. Gr. 26 .

– Remove bolts -arrows- and detach cross piece -1-.

– Unscrew bolts -2- and detach bracket -3-.

Caution

The flexible joint in the starter catalytic converter can be dam‐

aged.

♦ The flexible joint must not be bent further than 10°.

– Remove rear section of exhaust system ⇒ Rep. Gr. 26 .

– When loosening and tightening propshaft bolts, counterhold at

rear final drive using counterhold tool -T10172- and adapters

-T10172/5- .

– Remove bolts -2, 3- for pendulum support.

Note

-Item 1- can be disregarded.

44 Rep. Gr.39 - Final drive - rear differential

Page 49

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Rear final drive 02D, 0AV, 0BR and 0BY - Edition 06.2009

– Check whether there is a factory marking (paint dot) on the

flexible coupling and on the flange for the propshaft on the rear

final drive -arrows-.

– If there is no marking, mark position of flexible coupling relative

to flange for propshaft on rear final drive.

– Remove bolts -arrows- securing propshaft to rear final drive,

counterholding with counterhold tool -T10172- .

Audi A3 2004 ➤ , Audi TT 2007 ➤

– Remove bolts -arrows- securing centre bearing and heat

shield, detach heat shield.

Note

-Item A- and -V.A.G 1383 A- can be disregarded.

4. Exploded view - propshaft (Audi TT RS) 45

Page 50

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability