Page 1

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Service

Workshop Manual

Audi TT 2007 ➤

Direct shift gearbox 02E, four-wheel drive

Edition 08.2008

Service Department. Technical Information

Page 2

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Service

List of Workshop Manual Repair GroupsList of Workshop Manual

Repair GroupsList of Workshop Manual Repair Groups

Re pa ir G ro up

00 - Technical data

30 - Clutch

34 - Controls, housing

35 - Gears, shafts

39 - Final drive - front differential

Technical information should always be available to the foremen and mechanics, because their

careful and constant adherence to the instructions is essential to ensure vehicle road-worthiness and

safety. In addition, the normal basic safety precautions for working on motor vehicles must, as a

matter of course, be observed.

All rights reserved.

No reproduction without prior agreement from publisher.

Copyright © 2010 Audi AG, Ingolstadt A005TT01520

Page 3

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

Contents

00 - Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1 Gearbox identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 Code letters, gearbox allocation, ratios, equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.1 Calculating ratio “i” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4 Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5 Notes on the direct shift gearbox 02E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.1 General notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.2 Safety functions of gearbox control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6 Notes on tow-starting and towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

7 Repair instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7.1 Contact corrosion! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8 Rules for cleanliness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

30 - Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1 Exploded view - servicing multiple clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.1 Removing and installing multiple clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

34 - Controls, housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2 Exploded view - selector lever handle with interlock button (side), selector lever display

illumination bulb L101 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.1 Removing and installing selector lever handle with interlock button (side) . . . . . . . . . . . . 30

3 Exploded view - selector lever handle with interlock button (front), selector lever display

illumination bulb L101 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.1 Removing and installing selector lever handle with interlock button (front) . . . . . . . . . . . . 33

3.2 Detaching selector lever boot from selector lever handle . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.3 Moving interlock button on selector lever handle into installation position . . . . . . . . . . . . . . 37

4 Removing and installing selector lever display illumination bulb L101 . . . . . . . . . . . . . . . . 39

5 Exploded view - selector mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.1 Manual release of selector mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.2 Checking selector mechanism and ignition key removal lock . . . . . . . . . . . . . . . . . . . . . . 43

5.3 Removing and installing selector mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.4 Removing and installing selector lever cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.5 Adjusting selector lever cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.6 Removing and installing tiptronic switch F189 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.7 Removing and installing selector lever lock solenoid N110 . . . . . . . . . . . . . . . . . . . . . . . . 52

5.8 Checking connectors on selector mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6 Overview - removing and installing gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.1 Removing gearbox - vehicles with 2.0 ltr. TFSI engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.2 Installing gearbox - vehicles with 2.0 ltr. TFSI engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.3 Removing gearbox - vehicles with 3.2 ltr. MPI engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

6.4 Installing gearbox - vehicles with 3.2 ltr. MPI engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

7 Transporting the direct shift gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

8 Securing gearbox to engine and gearbox support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

9 Exploded view - assembly mountings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

9.1 Removing and installing gearbox mounting and gearbox support - vehicles with 2.0 ltr. TFSI

engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

9.2 Removing and installing gearbox mounting and gearbox support - vehicles with 3.2 ltr. MPI

engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

9.3 Removing and installing pendulum support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Contents i

Page 4

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

10.1 Checking gear oil level and topping up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

10.2 Draining gear oil and filling up after repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

11 Exploded view - gear oil cooler and gear oil filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

11.1 Removing and installing gear oil cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

11.2 Removing and installing gear oil filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

12 Overview - removing and installing bevel box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

12.1 Removing and installing bevel box - vehicles with 2.0 ltr. TFSI engine . . . . . . . . . . . . . . . . 107

12.2 Removing and installing bevel box - vehicles with 3.2 ltr. MPI engine . . . . . . . . . . . . . . . . 110

35 - Gears, shafts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

1 Exploded view - oil pan, mechatronic unit, gear oil pump . . . . . . . . . . . . . . . . . . . . . . . . . . 116

1.1 Removing and installing oil pan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

1.2 Removing and installing mechatronic unit for dual clutch gearbox J743 . . . . . . . . . . . . . . 121

1.3 Removing and installing gearbox input speed sender G182 and clutch temperature sender

G509 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

1.4 Removing and installing gear oil pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

39 - Final drive - front differential . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

1 Exploded view - flange shaft and oil seals on gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

1.1 Removing and installing flange shaft (left-side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

1.2 Renewing oil seal for flange shaft (left-side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

1.3 Renewing oil seal between bevel box and gearbox (on gearbox) . . . . . . . . . . . . . . . . . . . . 131

1.4 Renewing oil seal for selector shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

2 Exploded view - flange shaft, oil seals and bracket on bevel box . . . . . . . . . . . . . . . . . . . . 136

2.1 Removing and installing flange shaft (right-side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

2.2 Renewing flange shaft oil seal (right-side) at bevel box (outer seal) . . . . . . . . . . . . . . . . . . 139

2.3 Renewing needle bearings (polygon bearings) for flange shaft (right-side) . . . . . . . . . . . . 141

2.4 Renewing oil seal between gearbox and bevel box (on bevel box) . . . . . . . . . . . . . . . . . . 142

2.5 Renewing oil seal for output flange on bevel box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

3 Overview - gear oil in bevel box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

3.1 Checking gear oil level and topping up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

3.2 Draining gear oil and filling up after repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

4 Propshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

5 Rear final drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

ii Contents

Page 5

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

00 – Technical data

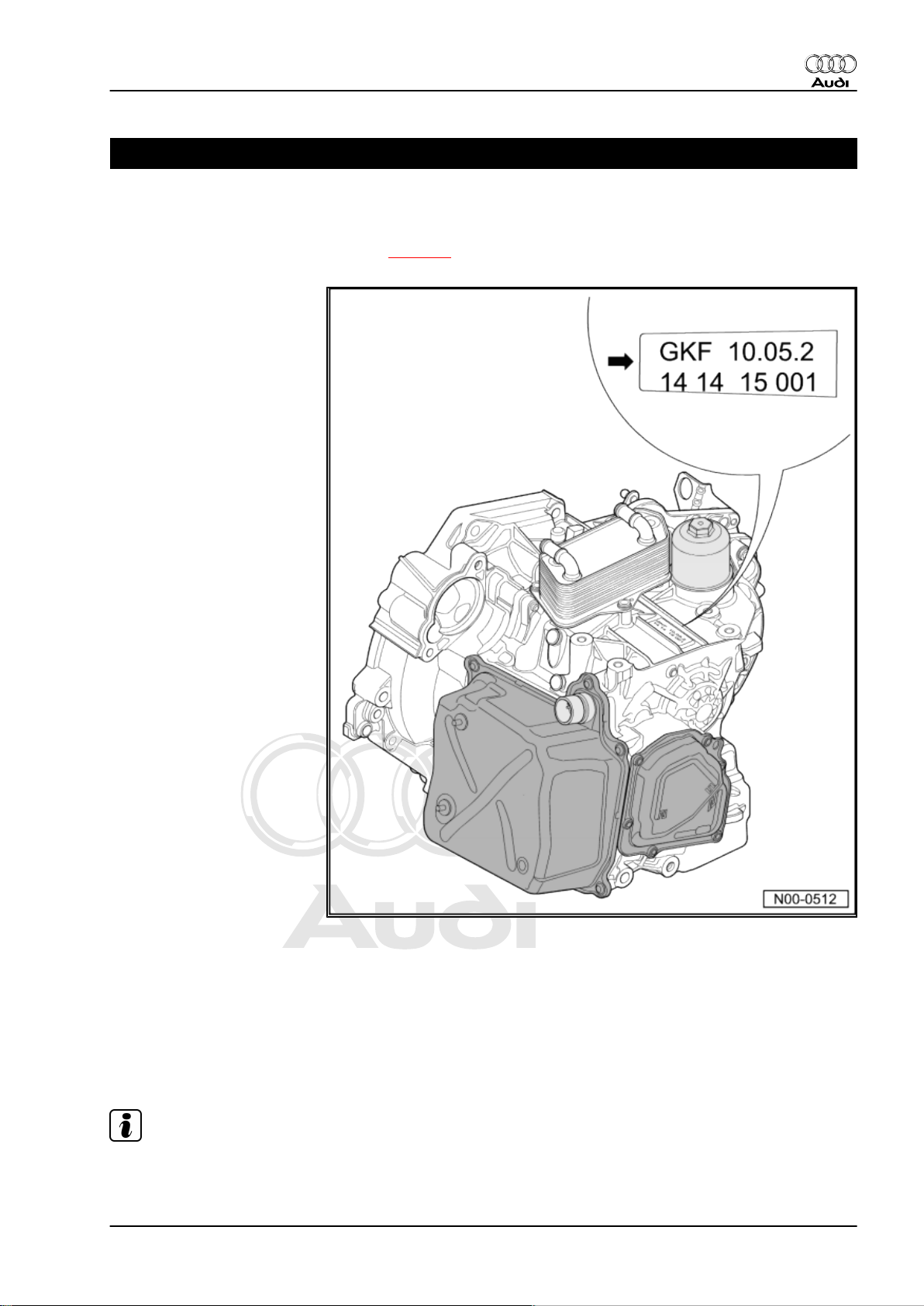

1 Gearbox identification

The “6-speed direct shift gearbox 02E (four-wheel drive)” is in‐

stalled in the Audi TT 2007 ▸. Allocation ⇒ page 2 .

Audi TT 2007 ➤

The gearbox code is located on the top of the gearbox, near the

gearbox oil cooler.

Example:

♦ GKF = gearbox code

♦ 10.05.2 = date of production: 10th May 2002

♦ The other figures are production-related.

Note

The gearbox code letters are also given on the vehicle data stick‐

ers.

1. Gearbox identification 1

Page 6

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

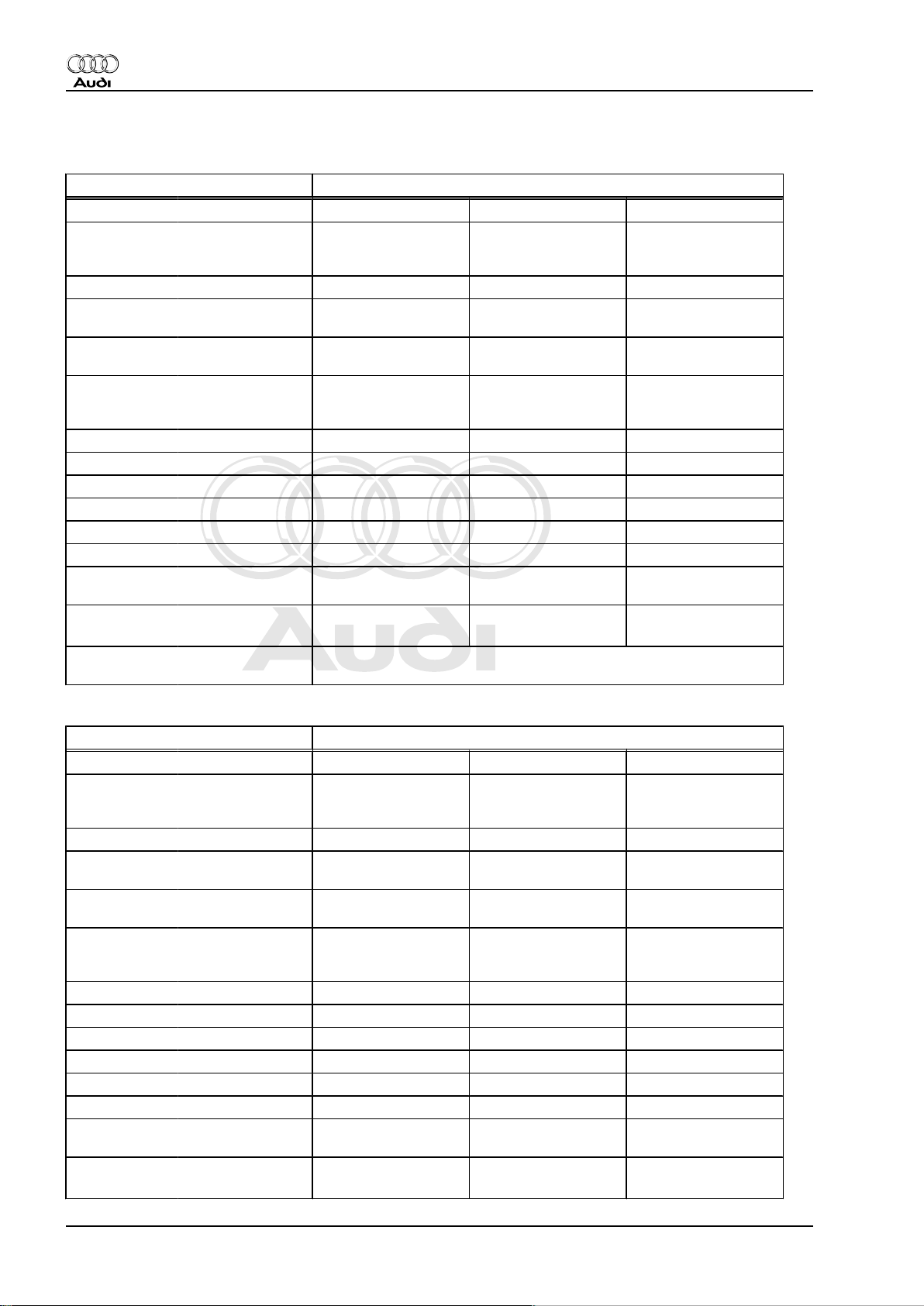

2 Code letters, gearbox allocation, ratios, equipment

Direct shift gearbox 02E four-wheel drive

Gearbox Code letters HXZ JFP JPZ

Allocation Model

Ratios Final drive I

Z2 : Z

1

Overall ratio

i

in top gear

ov.

Allocation: rear

final drive

Direct shift gearbox 02E four-wheel drive

Gearbox Code letters JUQ JYX KDE

Allocation Model

Ratios Final drive I

Z2 : Z

1

Overall ratio

i

in top gear

ov.

Manufac‐

tured

fro

m

05.06 05.08 11.06

to

Engine

Audi TT 2007 ▸ Audi TT 2007 ▸ Audi TT 2007 ▸

3.2 ltr. - 184 kW

6-cyl. MPI

2.0 ltr. - 147 kW

4-cyl. TFSI

72 : 15 = 4.800 69 : 17 = 4.059 72 : 15 = 4.800

for 1st to 4th gear

Final drive II

72 : 20 = 3.600 69 : 22 = 3.136 72 : 20 = 3.600

for 5th/6th gear

and reverse gear

1st gear

2nd gear

3rd gear

4th gear

5th gear

6th gear

Reverse

gear

44 : 15 = 2.933 45 : 13 = 3.462 44 : 15 = 2.933

44 : 24 = 1.833 43 : 20 = 2.150 44 : 24 = 1.833

39 : 30 = 1.300 41 : 28 = 1.464 39 : 30 = 1.300

39 : 40 = 0.975 41 : 38 = 1.079 39 : 40 = 0.975

34 : 33 = 1.030 35 : 32 = 1.093 34 : 33 = 1.030

33 : 40 = 0.825 35 : 38 = 0.921 33 : 40 = 0.825

22 : 14 x 32 : 15 =

3.352

22 : 14 x 33 : 13 =

3.352

2.970 2.888 2.970

Designation Rear final drive 02D and 0AV

Manufac‐

tured

fro

m

11.06 11.06 09.07

to

Engine

Audi TT 2007 ▸ Audi TT 2007 ▸ Audi TT 2007 ▸

3.2 ltr. - 184 kW

6-cyl. MPI

3.2 ltr. - 184 kW

6-cyl. MPI

72 : 15 = 4.800 72 : 15 = 4.800 72 : 15 = 4.800

for 1st to 4th gear

Final drive II

72 : 20 = 3.600 72 : 20 = 3.600 72 : 20 = 3.600

for 5th/6th gear

and reverse gear

1st gear

2nd gear

3rd gear

4th gear

5th gear

6th gear

Reverse

gear

44 : 15 = 2.933 44 : 15 = 2.933 44 : 15 = 2.933

44 : 24 = 1.833 44 : 24 = 1.833 44 : 24 = 1.833

39 : 30 = 1.300 39 : 30 = 1.300 39 : 30 = 1.300

39 : 40 = 0.975 39 : 40 = 0.975 39 : 40 = 0.975

34 : 33 = 1.030 34 : 33 = 1.030 34 : 33 = 1.030

33 : 40 = 0.825 33 : 40 = 0.825 33 : 40 = 0.825

22 : 14 x 32 : 15 =

3.352

22 : 14 x 32 : 15 =

3.352

2.970 2.970 2.970

3.2 ltr. - 184 kW

6-cyl. MPI

22 : 14 x 32 : 15 =

3.352

3.2 ltr. - 184 kW

6-cyl. MPI

22 : 14 x 32 : 15 =

3.352

2 Rep. Gr.00 - Technical data

Page 7

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

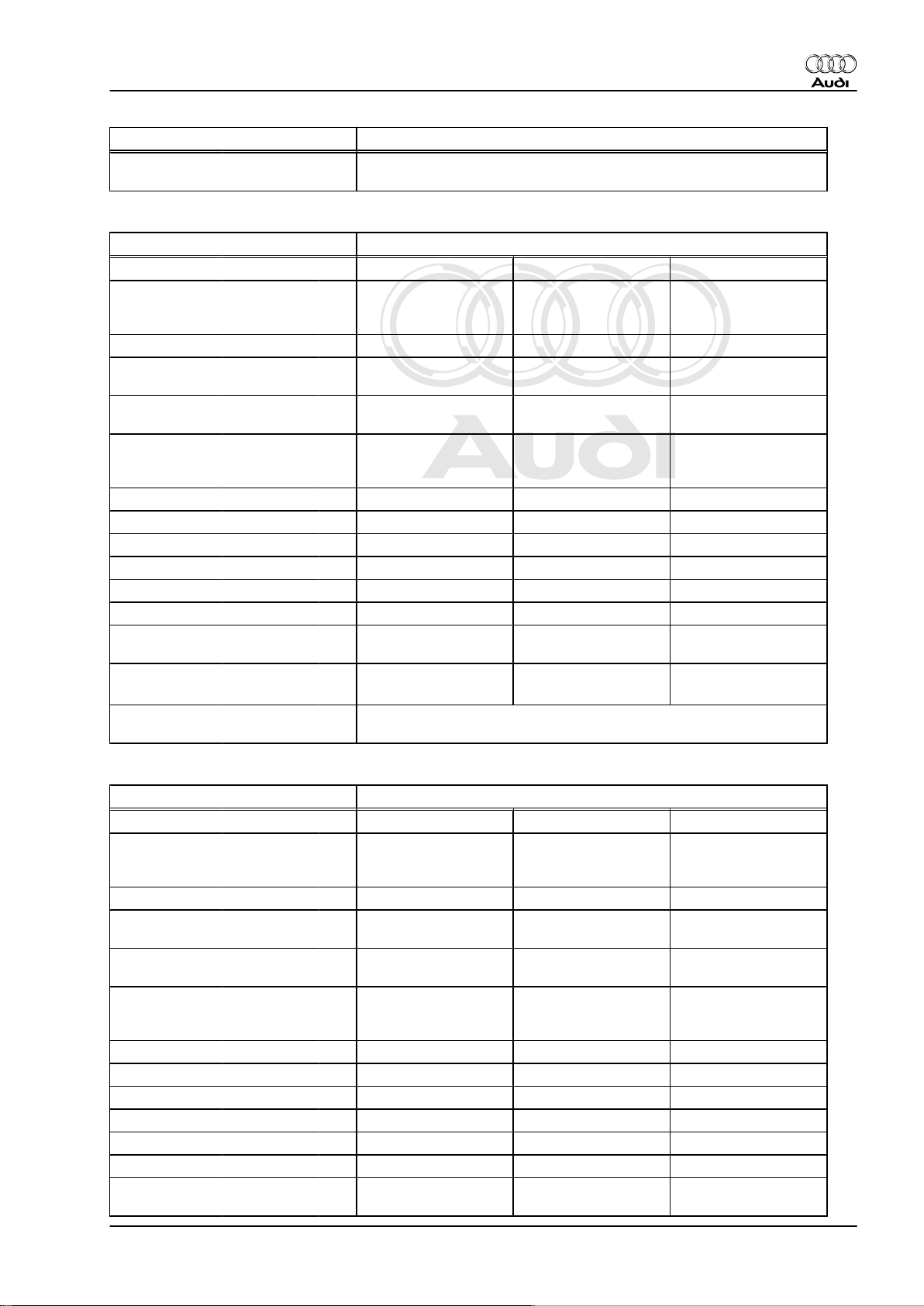

Direct shift gearbox 02E four-wheel drive

Allocation: rear

Designation Rear final drive 02D and 0AV

final drive

Direct shift gearbox 02E four-wheel drive

Gearbox Code letters KNL KNN KQA

Manufac‐

tured

fro

m

11.07 05.08 05.08

to

Allocation Model

Engine

Ratios Final drive I

Audi TT 2007 ▸ Audi TT 2007 ▸ Audi TT 2007 ▸

3.2 ltr. - 184 kW

6-cyl. MPI

2.0 ltr. - 195, 199 kW

4-cyl. TFSI

3.2 ltr. - 184 kW

6-cyl. MPI

72 : 15 = 4.800 62 : 13 = 4.769 72 : 15 = 4.800

for 1st to 4th gear

Z2 : Z

1

Final drive II

72 : 20 = 3.600 62 : 18 = 3.444 72 : 20 = 3.600

for 5th/6th gear

and reverse gear

Overall ratio

i

in top gear

ov.

Allocation: rear

1st gear

2nd gear

3rd gear

4th gear

5th gear

6th gear

Reverse

gear

Designation Rear final drive 02D and 0AV

44 : 15 = 2.933 38 : 13 = 2.923 44 : 15 = 2.933

44 : 24 = 1.833 45 : 23 = 1.957 44 : 24 = 1.833

39 : 30 = 1.300 35 : 25 = 1.400 39 : 30 = 1.300

39 : 40 = 0.975 32 : 31 = 1.032 39 : 40 = 0.975

34 : 33 = 1.030 28 : 26 = 1.077 34 : 33 = 1.030

33 : 40 = 0.825 27 : 31 = 0.871 33 : 40 = 0.825

22 : 14 x 32 : 15 =

3.352

22 : 14 x 27 : 13 =

3.264

22 : 14 x 32 : 15 =

3.352

2.970 3.000 2.970

final drive

Direct shift gearbox 02E four-wheel drive

Gearbox Code letters KRF LME

Manufac‐

tured

fro

m

01.08 01.08

to

Allocation Model

Engine

Ratios Final drive I

Audi TT 2007 ▸ Audi TT 2007 ▸

2.0 ltr. - 195, 200 kW

4-cyl. TFSI

62 : 13 = 4.769 62 : 13 = 4.769

2.0 ltr. - 155 kW

4-cyl. TFSI

for 1st to 4th gear

Z2 : Z

1

Final drive II

62 : 18 = 3.444 62 : 18 = 3.444

for 5th/6th gear

and reverse gear

1st gear

2nd gear

3rd gear

4th gear

5th gear

6th gear

Reverse

gear

38 : 13 = 2.923 38 : 13 = 2.923

45 : 23 = 1.957 43 : 24 = 1.792

35 : 25 = 1.400 32 : 27 = 1.185

32 : 31 = 1.032 29 : 35 = 0.829

28 : 26 = 1.077 25 : 29 = 0.862

27 : 31 = 0.871 24 : 35 = 0.686

22 : 14 x 27 : 13 =

3.264

22 : 14 x 27 : 13 =

3.264

2. Code letters, gearbox allocation, ratios, equipment 3

Page 8

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

Direct shift gearbox 02E four-wheel drive

Overall ratio

i

in top gear

ov.

Allocation: rear

3.000 2.362

Designation Rear final drive 02D and 0AV

final drive

2.1 Calculating ratio “i”

Example:

6th gear Final drive

Drive gear ZG1 = 40 ZA1 = 20

Driven gear ZG2 = 33 ZA2 = 72

i = Z2 : Z1 (Z1 = number of teeth on drive gear, Z2 = number of

teeth on driven gear)

iG = gear ratio = ZG2 : ZG1 = 33 : 40 = 0.825

iA = axle ratio = ZA2 : ZA1 = 72 : 20 = 3.6

iov = overall ratio = iG x iA = 0.825 x 3.6 = 2.97

4 Rep. Gr.00 - Technical data

Page 9

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

3 Capacities

Gearbox capacity

Capacities Direct shift gearbox 02E, four-wheel

drive

Initial filling 6.9 ltr.

Oil change approx. 5.5 ltr.

Change interval ⇒ Maintenance tables

Lubricant Gear oil for direct shift gearbox 02E

⇒ Electronic parts catalogue

Note

♦

Use only the correct type of gear oil for the direct shift gearbox

02E (available as a replacement part). Other types of lubricant

cause malfunctions and/or failure of the gearbox.

♦

You must also renew the gear oil filter when you change the

gear oil ⇒ page 105 .

Audi TT 2007 ➤

– Checking gear oil level and topping up ⇒ page 94

– Filling up with gear oil after repair ⇒ page 100

Bevel box capacity

Capacities Bevel box

Initial filling 0.9 ltr.

Oil change Filled for life, no change

Lubricant Gear oil ⇒ Electronic parts cata‐

logue .

Note

Use only the correct type of gear oil (available as a replacement

part) for the bevel box. Other types of oil cause malfunctions and/

or failure of the bevel box.

– Checking gear oil level and topping up ⇒ page 149

– Filling up with gear oil after repair ⇒ page 150

3. Capacities 5

Page 10

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

4 Safety precautions

Observe the following precautions if tests have to be performed

with the engine running.

WARNING

Accidents can be caused if a gear is inadvertently engaged

while the engine is running.

♦ Before working on the vehicle while the engine is running,

shift the selector lever into position “P” and apply the

handbrake.

Danger from toxic fumes!

♦ When the engine is running, the exhaust system must al‐

ways be connected to the exhaust gas extractor.

6 Rep. Gr.00 - Technical data

Page 11

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

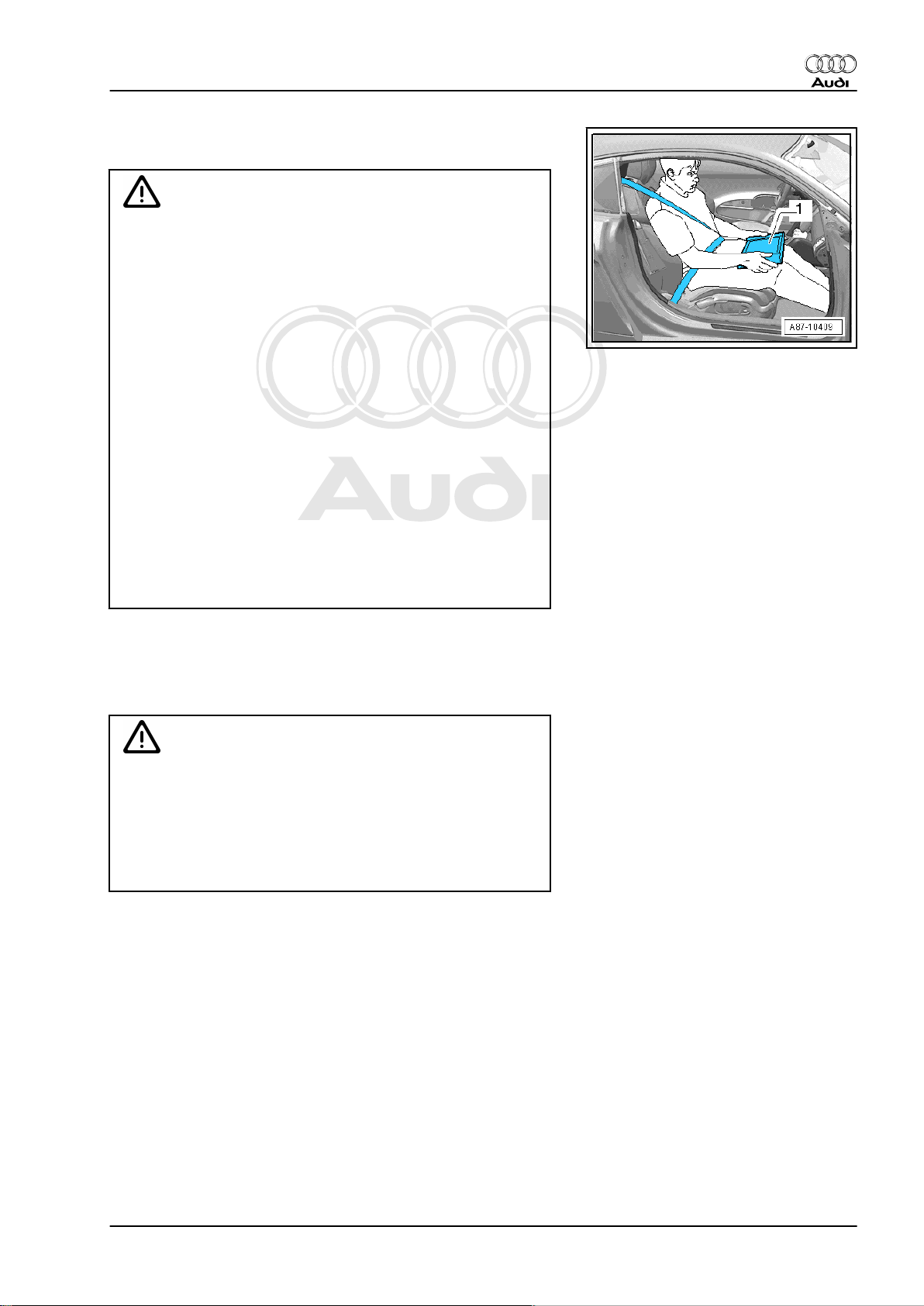

Observe the following precautions if test equipment has to be

used while road-testing the vehicle:

WARNING

Accidents can be caused if the driver is distracted by test

equipment while road-testing, or if test equipment is not se‐

cured.

Injuries can also be caused if the passenger's airbag is trig‐

gered in a collision.

• The use of test equipment while driving causes distraction.

• There is an increased risk of injury if test equipment is not

secured.

TT Coupé:

Always secure testing equipment to the rear seat with a strap

and have them operated from there by a second person.

TT Roadster:

♦ Move the passenger's seat to the rearmost position.

♦ Use only vehicle diagnosis and service information sys‐

tem -VAS 5052- or diagnosis system -VAS 5053- .

♦ Test equipment may only be operated by the passenger;

the tester -1- must be placed flat on the passenger's lap

as illustrated.

Audi TT 2007 ➤

Observe the following precautions to avoid possible injury and/or

damage to electrical and electronic components:

♦ Switch off ignition before disconnecting and connecting test

equipment.

Caution

When disconnecting the battery there is a risk of serious dam‐

age to electronic components:

♦ Observe the correct procedure for disconnecting the bat‐

tery.

♦ Always switch off the ignition before disconnecting the

battery.

4. Safety precautions 7

Page 12

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

5 Notes on the direct shift gearbox 02E

5.1 General notes

Gearbox

The direct shift gearbox 02E is a dual-clutch gearbox, also refer‐

red to as “S tronic”. It has the same basic construction as a 6speed manual gearbox. The engine torque is transferred to the

gearbox via the dual-mass flywheel. The two multi-plate "wet"

clutches are controlled hydraulically and actuated alternately so

that the gearbox is operated like an automatic gearbox, in other

words the gears are engaged automatically (but can also be se‐

lected manually via the tiptronic function). There is no clutch

pedal. For further information please refer to ⇒ Self-study pro‐

gramme No. 308 ; Direct shift gearbox 02E .

Selector mechanism

In selector lever position “P” the selector lever cable is used to

engage the parking lock mechanically. All other gearshift com‐

mands and selector lever positions are transmitted via the CAN

data bus from the selector lever -E313- (selector mechanism) to

the mechatronic unit for dual clutch gearbox -J743- .

Gear oil (gearbox and final drive)

The direct shift gearbox and front final drive have a common filling

of gear oil ⇒ page 94 .

Note

Use only the correct type of gear oil for the direct shift gearbox

02E (available as a replacement part). Other types of oil will cause

malfunctions and/or failure of the gearbox; for Part No. refer to ⇒

Electronic parts catalogue .

The bevel box has a separate oil filling ⇒ page 149 .

Note

Use only the correct type of gear oil (available as a replacement

part) for the bevel box. Other types of oil will cause malfunctions

and/or failure of the bevel box; for Part No. refer to ⇒ Electronic

parts catalogue .

Regulations for the disposal of oil

Drained oil must be disposed of properly.

♦ Improper disposal of used oil endangers the environment.

♦ It must not be mixed with solvents, brake fluid, coolant or sim‐

ilar.

♦ Please observe the information shown on the packaging of the

oil.

Variation of gear-change points for gradients

Additional gear-change maps automatically select the gearchange points for gradients according to accelerator pedal posi‐

tion and road speed.

• The gear-change map for extreme uphill gradients is matched

to the engine power.

8 Rep. Gr.00 - Technical data

Page 13

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

• The gear-change map for extreme downhill gradients is

matched to the engine braking effect.

• By selecting a gear directly via the tiptronic mode, it is possible

to make use of the engine braking effect available in a partic‐

ular gear, for instance when driving downhill with a trailer.

5.2 Safety functions of gearbox control unit

In the event of a failure of one or more components or sensors,

the control unit J743 will activate appropriate backup functions.

This enables the gearbox to continue operating without damage,

but will impair the operation and smoothness of the gearshifts.

Faults detected by the gearbox are classified in four different cat‐

egories.

1 - The fault is stored in the memory and one of the backup

programs is activated. The gear selection indicator in the

instrument cluster will continue to show the currently en‐

gaged selector lever position in the normal way. The driver

can continue to drive the vehicle (with certain restrictions),

and the condition is not critical to the safety of the vehicle or

to the gearbox itself. If at all, the driver will only notice the

fault if he experiences driveability problems, and will then

automatically contact an Audi Service Partner.

2 - Certain positions on the gear selection indicator in the in‐

strument cluster start to flash. This is to inform the driver that

this particular selector lever position is currently not availa‐

ble. Example: position "D" will start flashing if the selector

lever is moved from position "R" to position "D" while the

vehicle is still rolling backwards. To avoid damage to the

gearbox, the mechatronic unit for dual clutch gearbox -J743prevents 1st gear from being engaged while the vehicle is

moving backwards. 1st gear will only be engaged when the

vehicle comes to a standstill.

3 - The complete gear selection indicator lights up and flashes;

the currently engaged selector lever position is highlighted.

This shows the driver that a temporary critical fault in the

gearbox has been detected. Example: the gearbox has

been overloaded or overheated, for instance by towing an

excessively heavy load. The driver can continue to drive the

vehicle when the gearbox has cooled off, but will need to

avoid placing a heavy load on the transmission.

4 - The gear selection indicator flashes; the currently engaged

selector lever position is no longer indicated. This shows the

driver that a critical and permanent fault in the gearbox has

been detected. It may no longer be possible to use all gears,

so this condition is critical to the safety of the vehicle and to

the gearbox itself. This display is intended to warn the driver

that he should contact an Audi Service Partner.

Audi TT 2007 ➤

5. Notes on the direct shift gearbox 02E 9

Page 14

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

6 Notes on tow-starting and towing

Caution

Risk of damage to the gearbox.

♦ The selector lever must be in position “N” when the vehicle

is towed.

♦ The vehicle must not be towed further than 50 km or at a

speed in excess of 50 km/h.

Note

It is not possible to start the engine by tow-starting, for instance

if the battery is discharged or if the starter is not working.

10 Rep. Gr.00 - Technical data

Page 15

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

7 Repair instructions

Proper tools and the maximum possible care and cleanliness are

essential for satisfactory gearbox repairs. The usual basic safety

precautions also naturally apply when carrying out repair work.

A number of generally applicable instructions for the various re‐

pair procedures are summarised here. They apply to the work

described in this Manual.

Guided fault finding, vehicle self-diagnosis and testing system

♦ Before servicing the gearbox, the exact cause of the failure

must be determined using the functions “Guided Fault Find‐

ing”, “Vehicle Self-diagnosis” and “Test Instruments” ⇒ Vehicle

diagnosis, testing and information system VAS 5051.

Special tools

For a complete list of special tools used in this Workshop Manual

⇒ "Workshop equipment and special tools" .

Gearbox

♦ Do not run the engine or tow the vehicle with the oil pan re‐

moved or when there is no gear oil in the gearbox.

♦ When installing a replacement gearbox, check the gear oil

level and top up as required ⇒ page 94 : capacities

⇒ page 5 ; specification ⇒ Electronic parts catalogue .

♦ When installing gearbox, ensure that dowel sleeves are fitted

correctly.

Audi TT 2007 ➤

7. Repair instructions 11

Page 16

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

O-rings, oil seals and gaskets

♦ Renew O-rings, oil seals and gaskets.

♦ After removing gaskets and seals, always inspect the contact

surface on the housing or shaft for burrs resulting from removal

or for other signs of damage.

♦ Renew gaskets: completely remove the old gasket and clean

the sealing surfaces thoroughly.

♦ Lightly lubricate O-rings with gear oil before installation to pre‐

vent them being trapped and damaged during assembly.

♦ Lightly oil the outer circumference of oil seals and pack the

space between the sealing lips -arrow- about half-full with

sealing grease; for sealing grease refer to ⇒ Electronic parts

catalogue .

♦ Do not use any other lubricants where gear oil is specified.

Otherwise, there is a risk of problems occurring in the gearbox

hydraulics.

♦ The open side of the oil seal should face the side containing

the fluid.

♦ Observe rules for cleanliness ⇒ page 14 .

♦ After installation, check gear oil level and top up as required

⇒ page 94 and ⇒ page 149 .

Locking elements

♦ Do not overstretch circlips; renew if necessary.

♦ Circlips must be properly seated in the base of the groove.

Nuts, bolts

♦ Slacken bolts in reverse sequence to the specified tightening

sequence.

♦ Nuts and bolts which secure covers and housings should be

loosened and tightened in diagonal sequence and in stages if

no tightening sequence is specified.

♦ Renew self-locking nuts.

♦ Use a wire brush to clean the threads of bolts which are se‐

cured with locking fluid. Then install bolts with locking fluid; for

locking fluid refer to ⇒ Electronic parts catalogue .

♦ The tightening torques stated apply to non-oiled nuts and

bolts.

♦ Where instructions specify a torque setting plus an additional

angle, these bolts must be tightened to the specified torque

and then turned through the specified angle, e.g. 40 Nm + 90°

(90° = a quarter turn).

7.1 Contact corrosion!

Contact corrosion can occur if non-approved fasteners are used

on the vehicle (bolts, nuts, washers etc.).

For this reason, only fasteners with a special surface coating are

fitted.

Rubber or plastic parts and adhesives also consist of non-con‐

ductive materials.

If you are not sure whether used parts can be re-installed, always

fit new parts ⇒ Electronic parts catalogue .

12 Rep. Gr.00 - Technical data

Page 17

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

Please note:

♦ Use only genuine spare parts: these have been fully tested

and are compatible with aluminium.

♦ We recommend the use of accessories approved by Audi.

♦ Damage resulting from contact corrosion is not covered by the

warranty.

Audi TT 2007 ➤

7. Repair instructions 13

Page 18

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

8 Rules for cleanliness

♦ Carefully clean connection points and the surrounding area

with engine cleaner or brake cleaner and dry thoroughly before

opening.

♦ Seal off open lines and connections with clean plugs or sealing

caps immediately.

♦ Place removed parts on a clean surface and cover them over.

Use only lint-free cloths.

♦ Carefully cover or seal open components if repairs cannot be

completed immediately.

♦ Only install clean components: do not remove replacement

parts from packaging until just before installation.

♦ Protect unplugged electrical connectors against dirt and mois‐

ture and make sure connections are dry when attaching.

14 Rep. Gr.00 - Technical data

Page 19

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

30 – Clutch

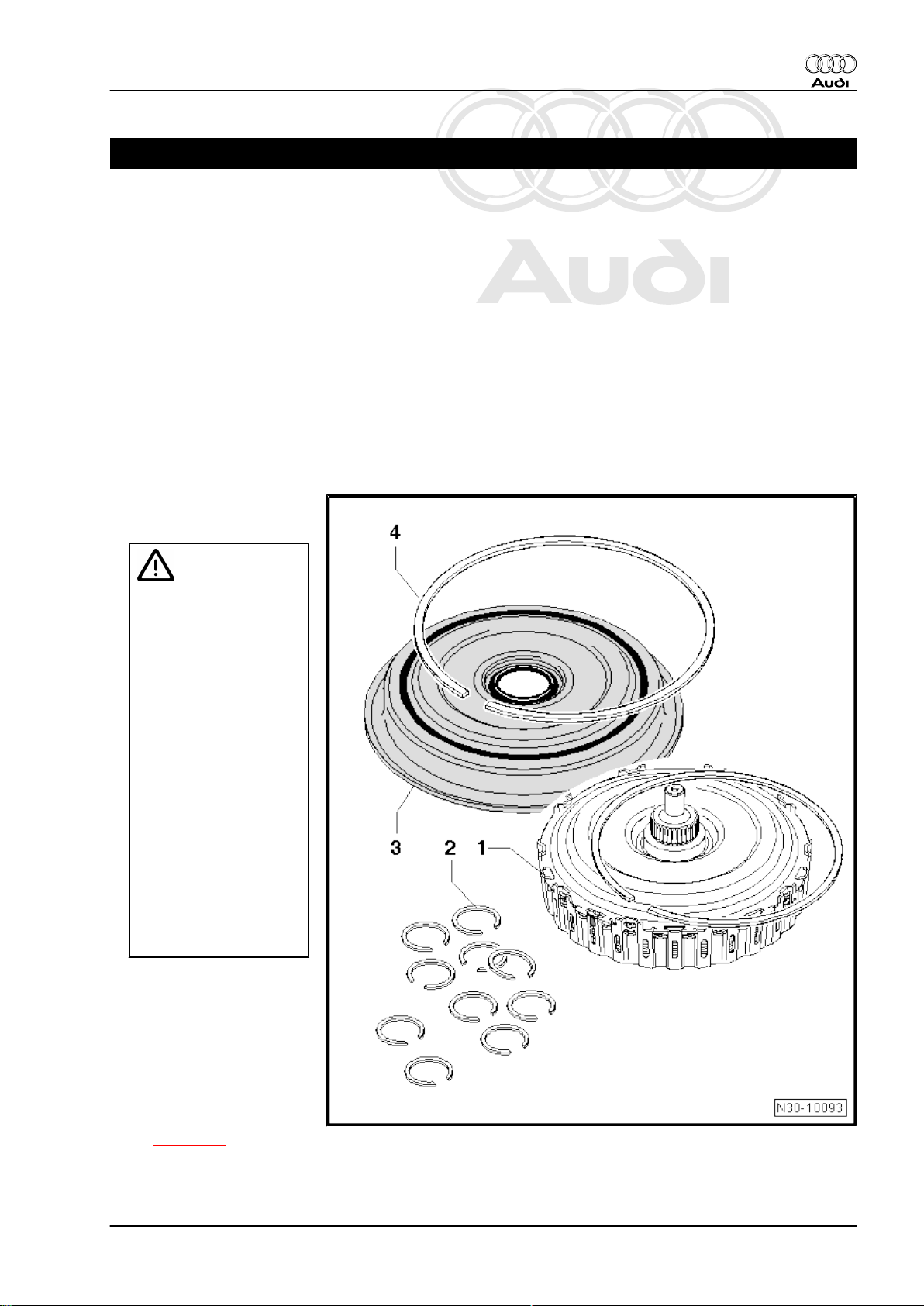

1 Exploded view - servicing multiple clutch

♦ The clutch in the direct shift gearbox 02E consists of two sets

of plates, or clutch packs, and is therefore referred to as a

“multiple clutch”. The larger clutch pack (located on the out‐

side) is designated “K 1” (clutch 1), and controls the torque

flow for reverse gear and gears “1”, “3” and “5”. The smaller

set of plates (on the inside) is designated “K 2” (clutch 2), and

controls the torque flow for gears “2”, “4” and “6”.

♦ Any work performed on the multiple clutch requires extra care

because all the parts are balanced and matched together in

production. If the components are rotated out of their original

positions when repairing, this will cause imbalance and impair

the smoothness of the gear-changes and reduce the service

life of the unit.

Replacement parts

1 - Multiple clutch

❑ With circlip

Audi TT 2007 ➤

Caution

The clutch plates can slip

out of position inside the

multiple clutch unit.

♦The multiple clutch unit

must not be dismantled

at present.

♦If the drive plate (which

forms the upper section

of the multiple clutch unit)

becomes detached from

the splines in the outer

plate carrier, the clutch

plates can slip out of po‐

sition in the clutch. It will

then no longer be possi‐

ble to adjust the clutch

correctly.

♦The drive plate included

with the replacement part

is not secured with the

large circlip; it is only a

close fit inside the clutch.

❑ Removing and installing

⇒ page 17

2 - Circlips

❑ 10x, with different thick‐

nesses for adjusting

multiple clutch

❑ Determining correct

thickness when instal‐

ling multiple clutch

⇒ page 22

3 - Clutch end cover

4 - Corrugated ring

1. Exploded view - servicing multiple clutch 15

Page 20

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

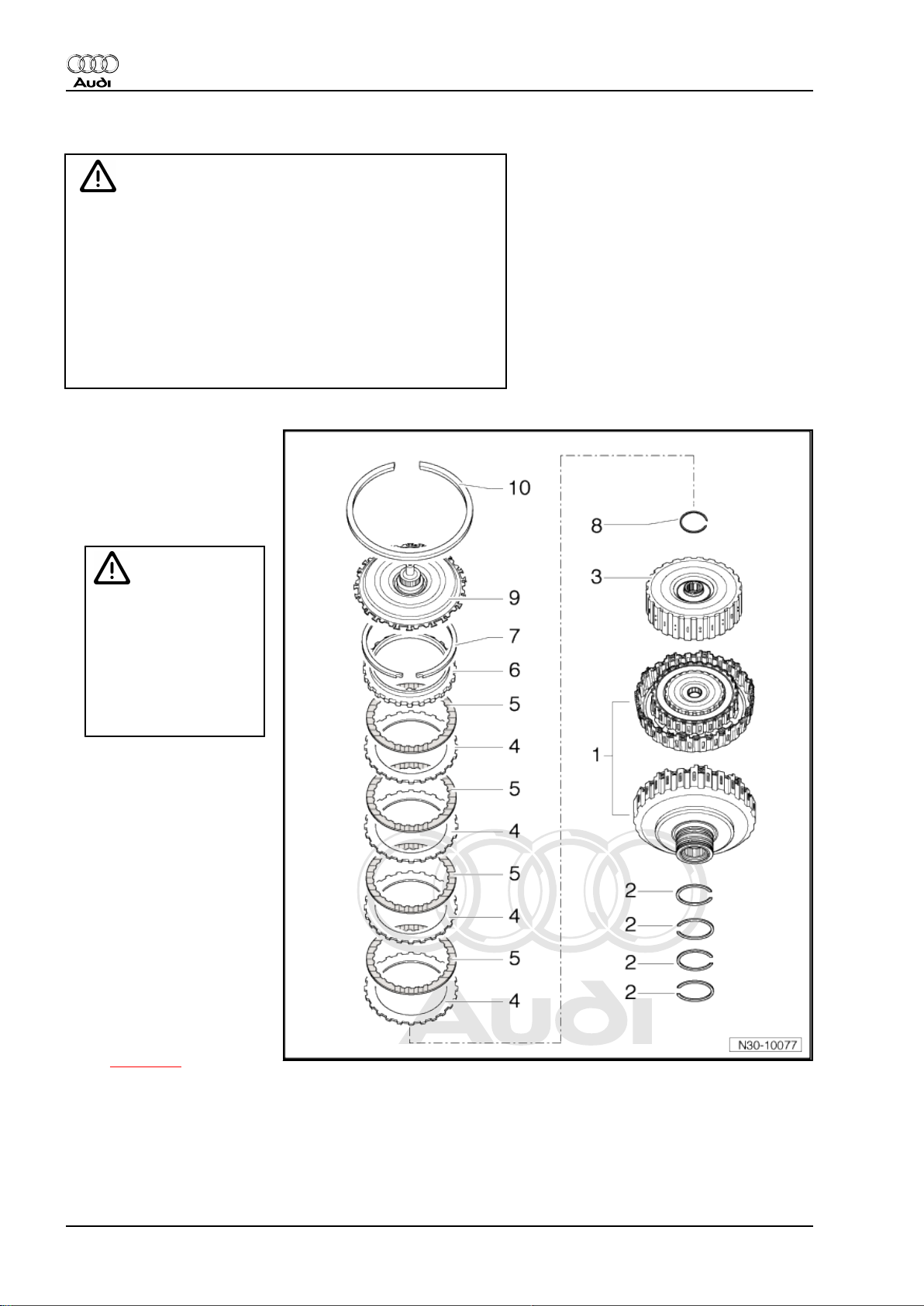

Component parts of dismantled multiple clutch

Caution

The clutch plates can slip out of position inside the multiple

clutch unit.

♦ This diagram showing the components of the multiple

clutch is for information only. The multiple clutch unit must

not be dismantled at present.

♦ If the drive plate becomes detached from the splines in the

outer plate carrier, the clutch plates can slip out of position

in the multiple clutch. It will then no longer be possible to

adjust the clutch correctly.

1 - Outer plate carrier with

clutch housing.

2 - Oil seals

❑ 4x

3 - Inner plate carrier

Caution

The clutch plates can slip

out of position.

♦If the inner plate carrier is

lifted or taken out, the

plates can slip out of po‐

sition inside the clutch. It

will then no longer be

possible to adjust the

clutch correctly.

4 - Outer plates

❑ 4x

5 - Inner plates

❑ 4x

6 - Thrust washer

7 - Circlip

❑ Fit a new circlip of the

same thickness if the

original circlip is re‐

moved in order to re-in‐

stall the clutch plates.

8 - Circlip

❑ Determining correct

thickness when instal‐

ling multiple clutch

⇒ page 22

9 - Drive plate

10 - Circlip

❑ Renew

16 Rep. Gr.30 - Clutch

Page 21

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

1.1 Removing and installing multiple clutch

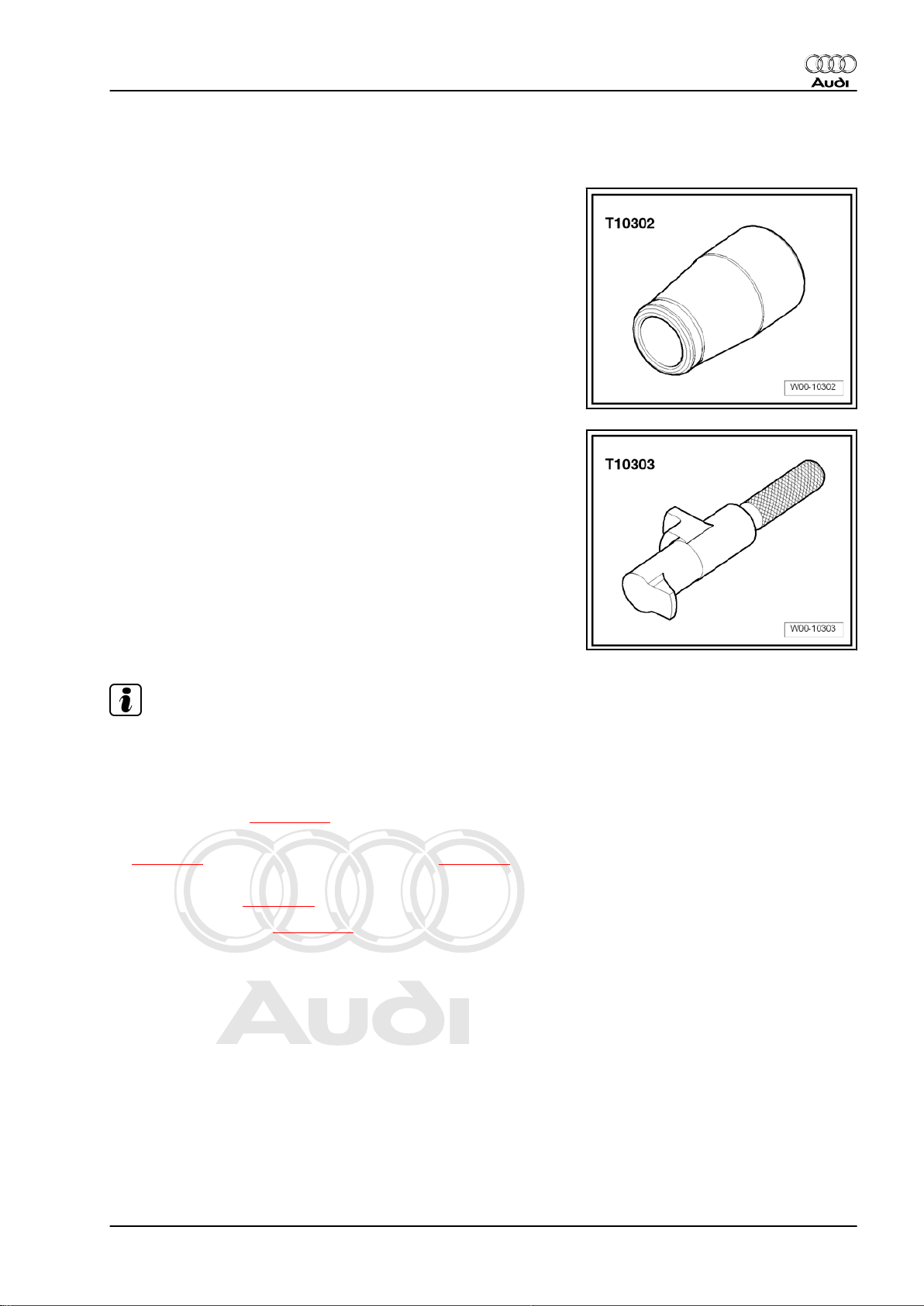

Special tools and workshop equipment required

♦ Assembly sleeve -T10302-

♦ Retaining pin -T10303-

Audi TT 2007 ➤

Note

Assembly sleeve -T10302- must be cleaned before use; do not

use an assembly sleeve if it is scratched.

Removing

– Drain off gear oil ⇒ page 100 .

– Remove direct shift gearbox: vehicles with 2.0 ltr. TFSI engine

⇒ page 53 , vehicles with 3.2 ltr. MPI engine ⇒ page 66 .

– Secure direct shift gearbox to engine and gearbox support in

vertical position ⇒ page 81 .

– Renew gear oil filter ⇒ page 105 .

1. Exploded view - servicing multiple clutch 17

Page 22

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

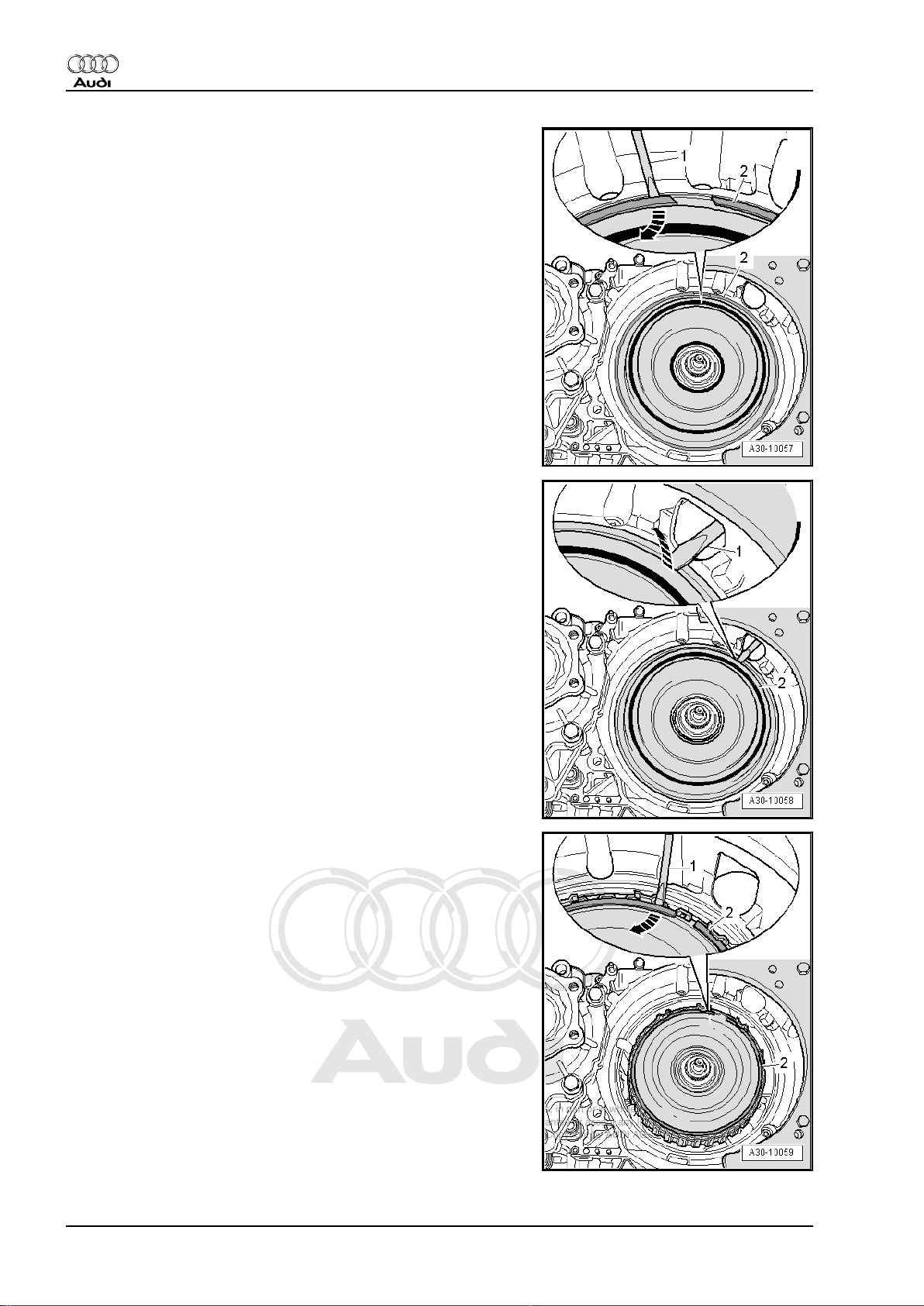

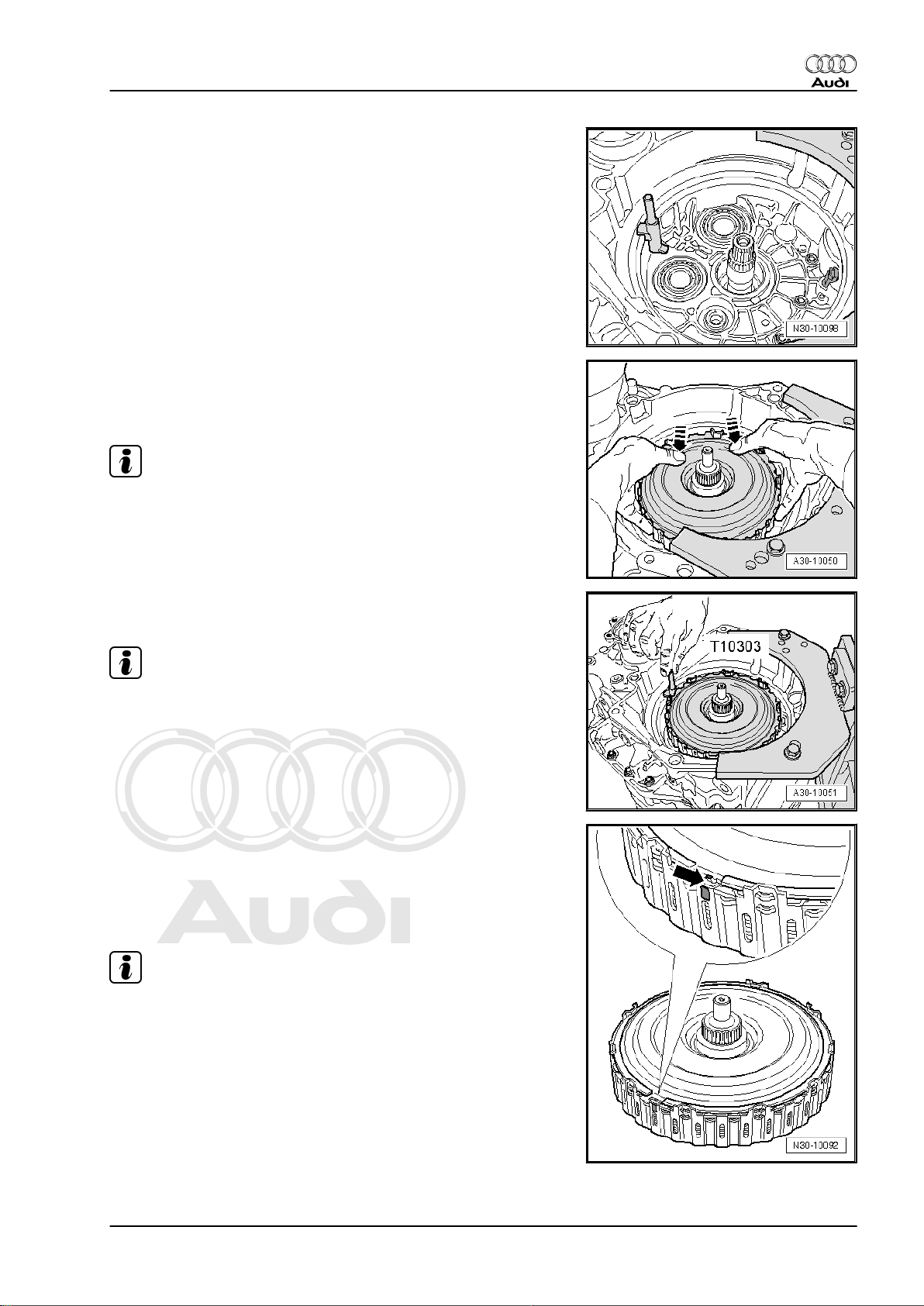

– Pry out and detach corrugated ring -2- for clutch end cover

using a screwdriver -1- -arrow-.

– Working through aperture for starter motor, pry out and detach

clutch end cover -2- using a screwdriver -1- or other suitable

lever -arrow-.

– Pry out circlip -2- for drive plate using a screwdriver -1-

-arrow-.

18 Rep. Gr.30 - Clutch

Page 23

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

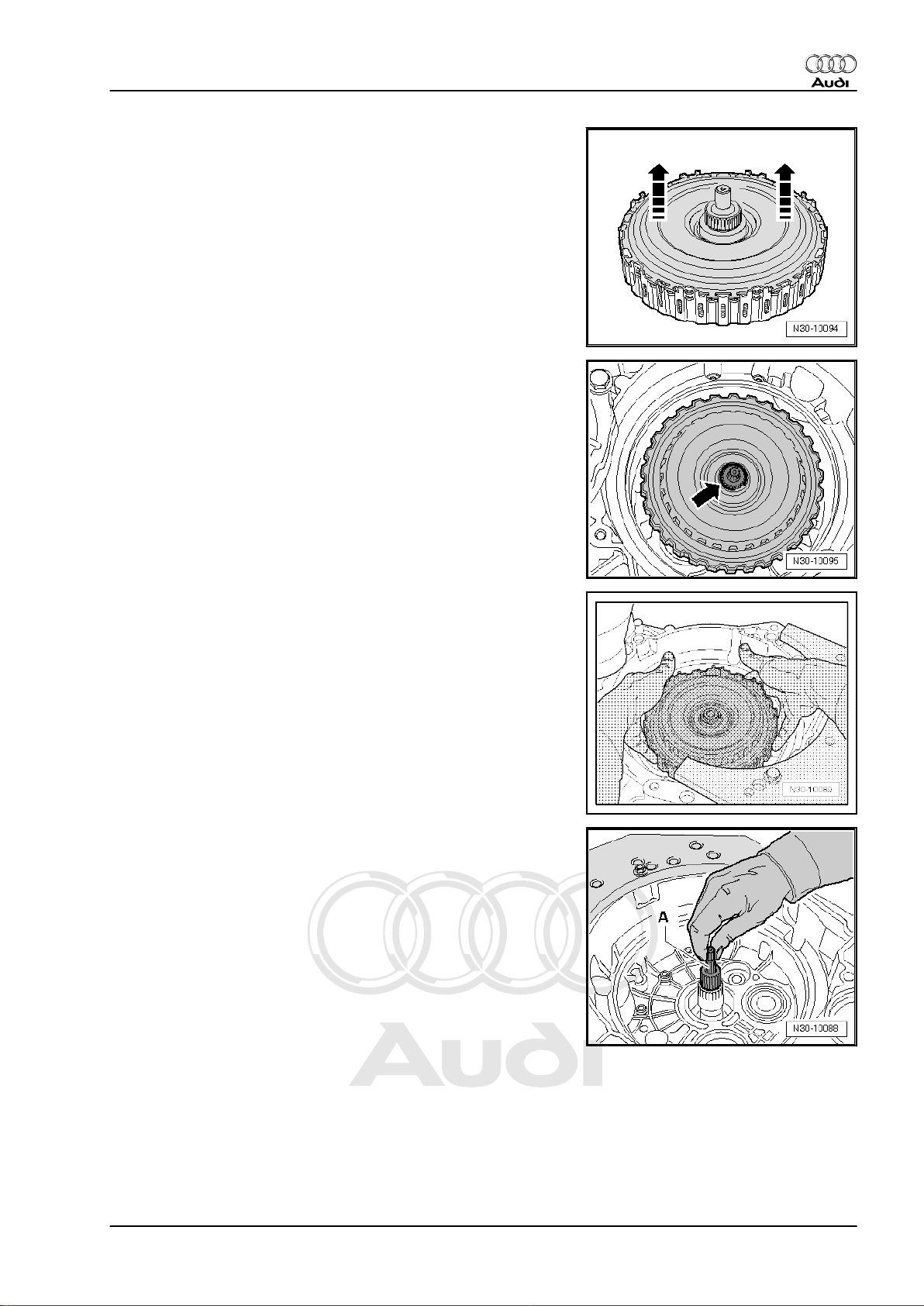

– Detach drive plate -arrows-.

– Pry out circlip -arrow- using a screwdriver or long-nose pliers.

Audi TT 2007 ➤

– Take multiple clutch out of gearbox.

– After removing multiple clutch, check whether clutch bell hous‐

ing was damaged during removal.

– Pull out pump shaft -A- and place to one side.

1. Exploded view - servicing multiple clutch 19

Page 24

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

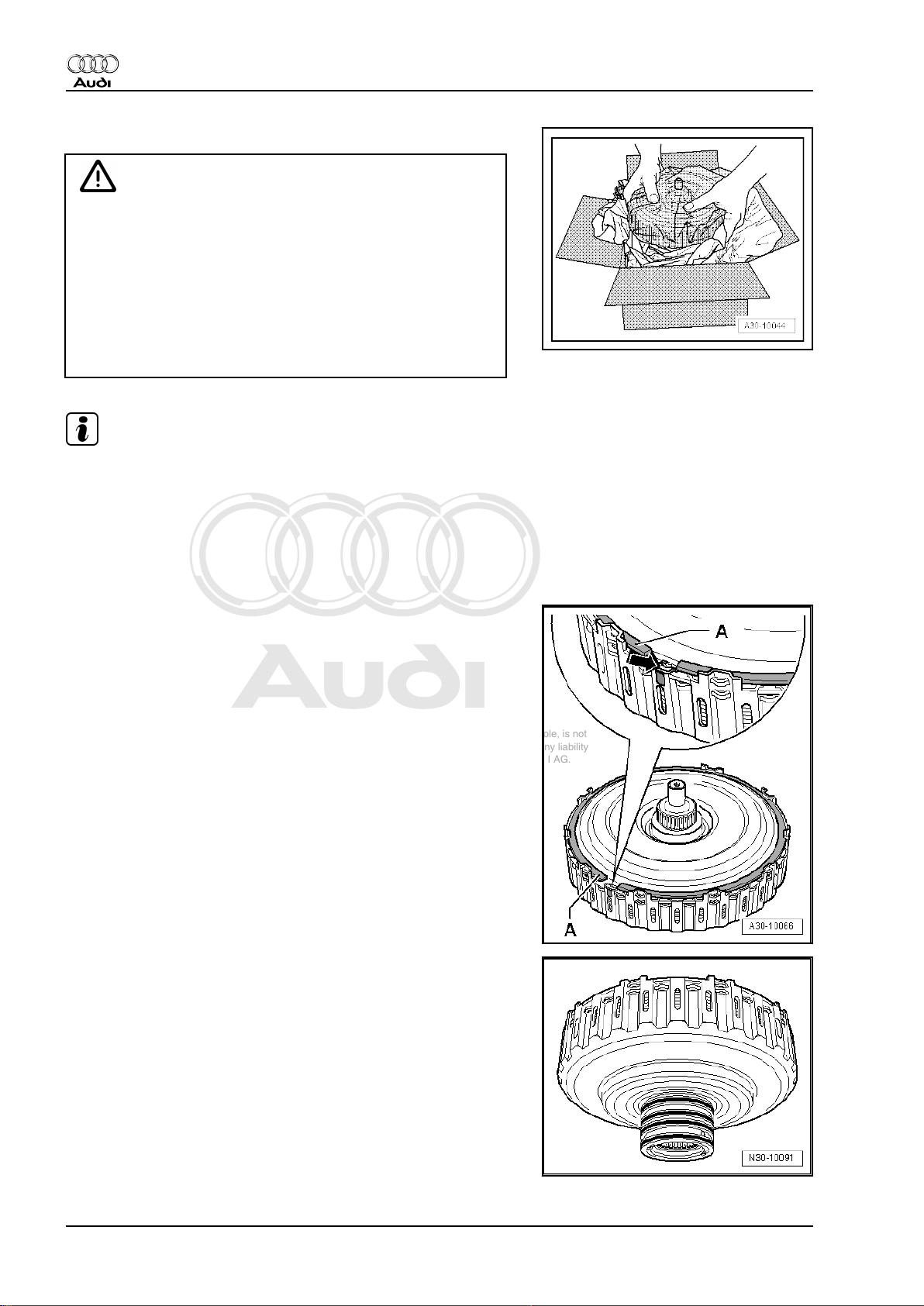

Installing

Caution

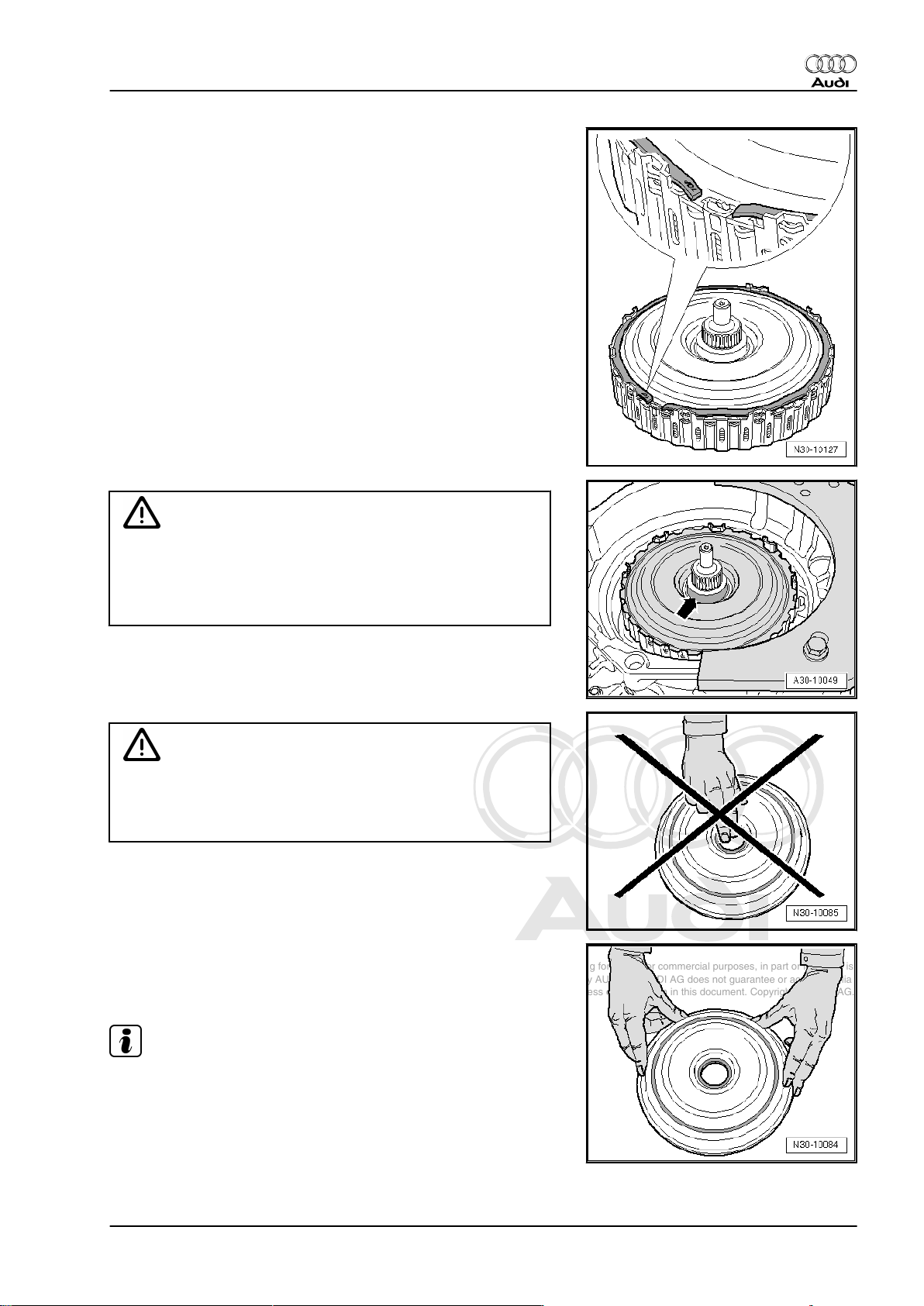

The clutch plates can slip out of position inside the multiple

clutch unit.

♦ If the drive plate becomes detached from the splines in the

outer plate carrier, the clutch plates can slip out of position

in the multiple clutch. It will then no longer be possible to

adjust the clutch correctly.

♦ To prevent the clutch plates from slipping inside the mul‐

tiple clutch unit, keep the drive plate pressed into the outer

plate carrier with both thumbs during all following steps.

Note

The circlip for the drive plate that is supplied with the replacement

parts is fitted at a later stage.

– Take new circlip for drive plate out of packaging and place to

one side.

– Take multiple clutch out of packaging, holding drive plate in

position.

– First fit old circlip -A- for drive plate from removed multiple

clutch.

• Installation position: the lug on the drive plate and the colourmarked splines on the outer plate carrier must be located

between the ends of the circlip.

– Using a screwdriver, check that circlip is fully engaged.

– Check that the 4 oil seals on the hub on the underside of the

multiple clutch are correctly seated; engage in position if nec‐

essary.

• Installation position: joints of seals should be offset

20 Rep. Gr.30 - Clutch

Page 25

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

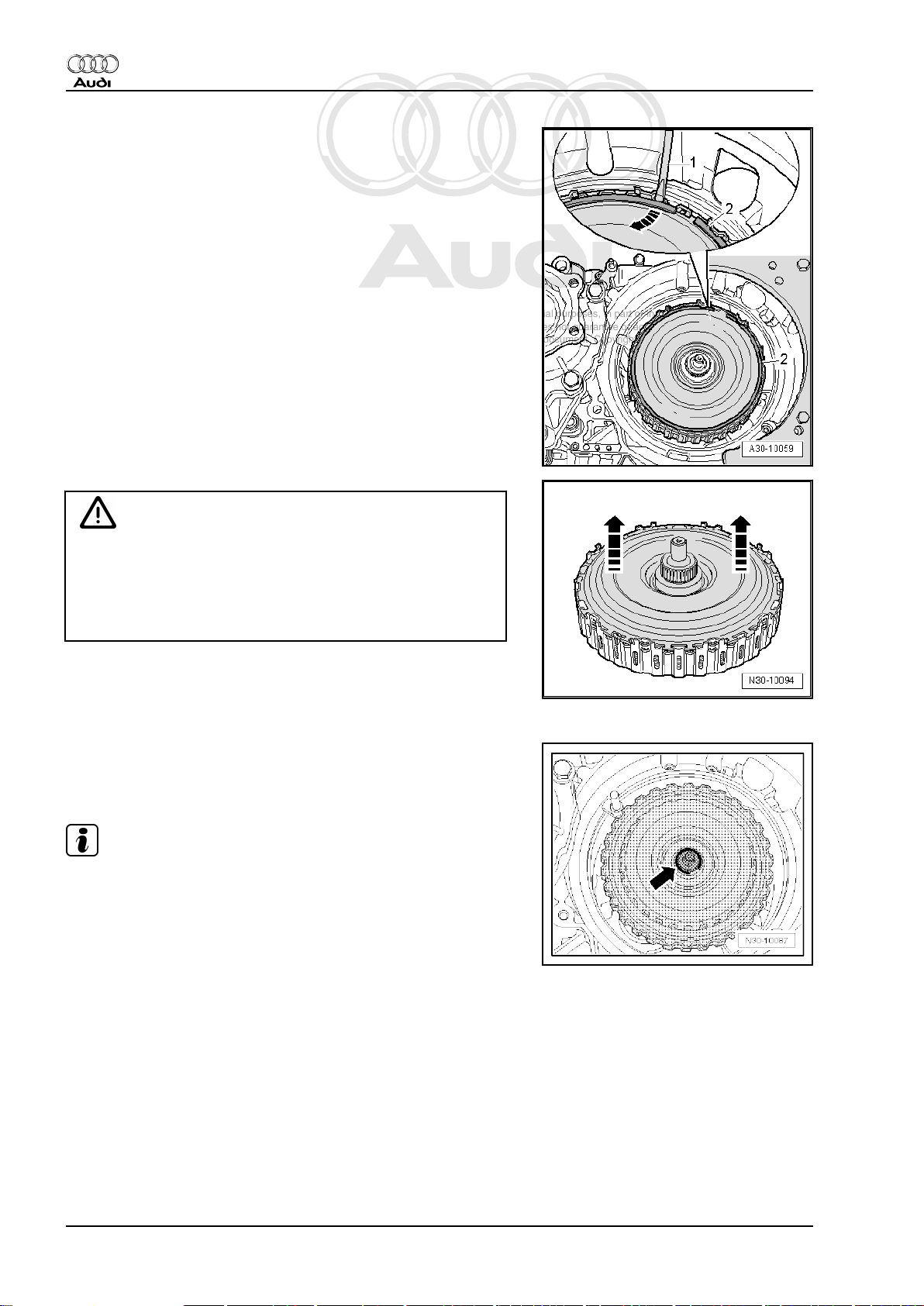

– Apply retaining pin -T10303- to seat of clutch end cover as

illustrated.

– Install multiple clutch in clutch bell housing (turn and move up

and down as required), at the same time keeping the drive

plate pressed into the outer plate carrier with both thumbs

-arrows-.

Note

Do not allow the multiple clutch to drop into the inner plate carrier.

Audi TT 2007 ➤

– Have a second mechanic hold the retaining pin -T10303- as

illustrated until the clutch end cover is installed.

Note

The multiple clutch must not be turned from this point onwards,

as this would turn the retaining pin -T10303- out of position.

– Check whether the projecting lug -arrow- on the drive plate is

positioned between the colour-marked splines on the outer

plate carrier.

– If no marking is provided, use waterproof pen to mark position

of drive plate in relation to outer rim of outer plate carrier as

illustrated so it can be re-fitted in the same position.

Note

When re-assembling, the lug on the drive plate must be located

again at this marked position.

1. Exploded view - servicing multiple clutch 21

Page 26

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

– Pry out old circlip -2- using a screwdriver -1- -arrow-.

Caution

The clutch plates can slip out of position inside the multiple

clutch unit.

♦ If the inner plate carrier is taken out or lifted, the plates can

slip out of position inside the clutch. It will then no longer

be possible to adjust the clutch correctly.

– Lift out drive plate -arrows-; if necessary lever it carefully out

of splines on outer plate carrier using a screwdriver.

– Place drive plate to one side.

Adjusting multiple clutch (determining thickness of circlip)

– Select the 2 mm thick circlip from the circlips supplied with the

unit.

Note

The 2 mm circlip is fitted provisionally for measurement purposes

and will be replaced later with the final circlip of the required thick‐

ness.

– Fit circlip of 2 mm thickness -arrow-.

22 Rep. Gr.30 - Clutch

Page 27

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

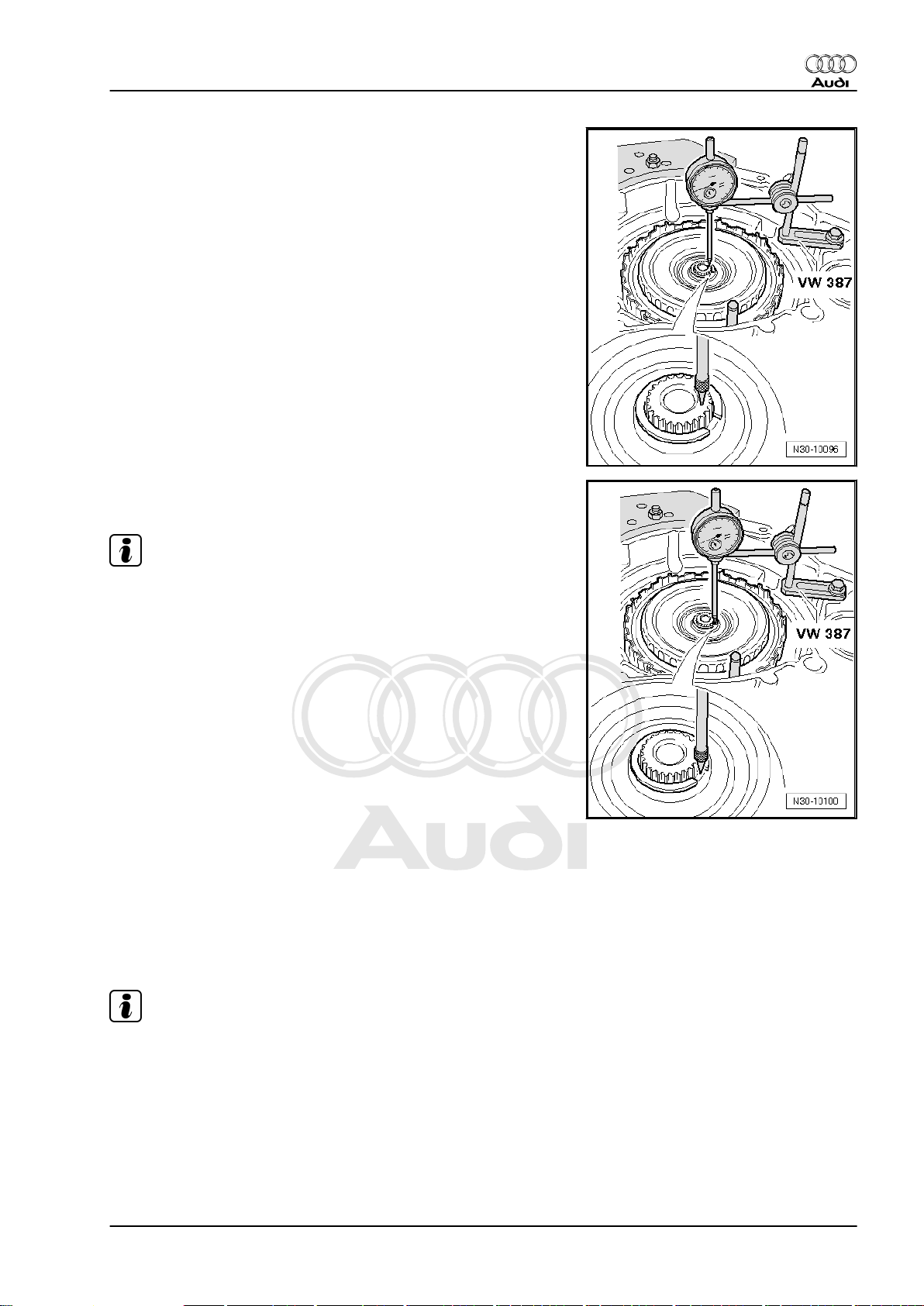

– Secure universal dial gauge bracket -VW 387- to gearbox

flange.

– For 1st measurement, apply tip of dial gauge to end of input

shaft as shown in illustration.

– Preload dial gauge to 2 mm and set to “0”.

– Lift up multiple clutch as far as it will go.

– Note reading on dial gauge (= axial clearance of input shaft).

– For 2nd measurement, apply tip of dial gauge to hub of inner

plate carrier as shown in illustration.

Audi TT 2007 ➤

Note

The tip of the dial gauge must not contact the circlip.

– Preload dial gauge to 2 mm and set to “0”.

– Lift up multiple clutch as far as it will go.

– Take reading and note down measured value.

The thickness of the new circlip is calculated according to the fol‐

lowing formula:

Circlip = 2nd measured value – 1st measured value + 1.85 (=

constant value)

The thickness of the new circlips is graduated in steps of 0.1 mm.

When selecting the required circlip, round up or down to the near‐

est 10th of a millimetre as required. In other words, values up to

0.049 are rounded down and values of 0.050 and above are roun‐

ded up.

Example:

♦ Calculated value for new circlip is 2.27 mm: round up to the

nearest 10th and select circlip with a thickness of 2.3 mm.

♦ Calculated value for new circlip is 2.24 mm: round down to the

nearest 10th and select circlip with a thickness of 2.2 mm.

Note

If the calculated thickness of the new circlip is exactly 2.0 mm, the

circlip fitted previously for taking the measurement does not have

to be removed.

1. Exploded view - servicing multiple clutch 23

Page 28

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

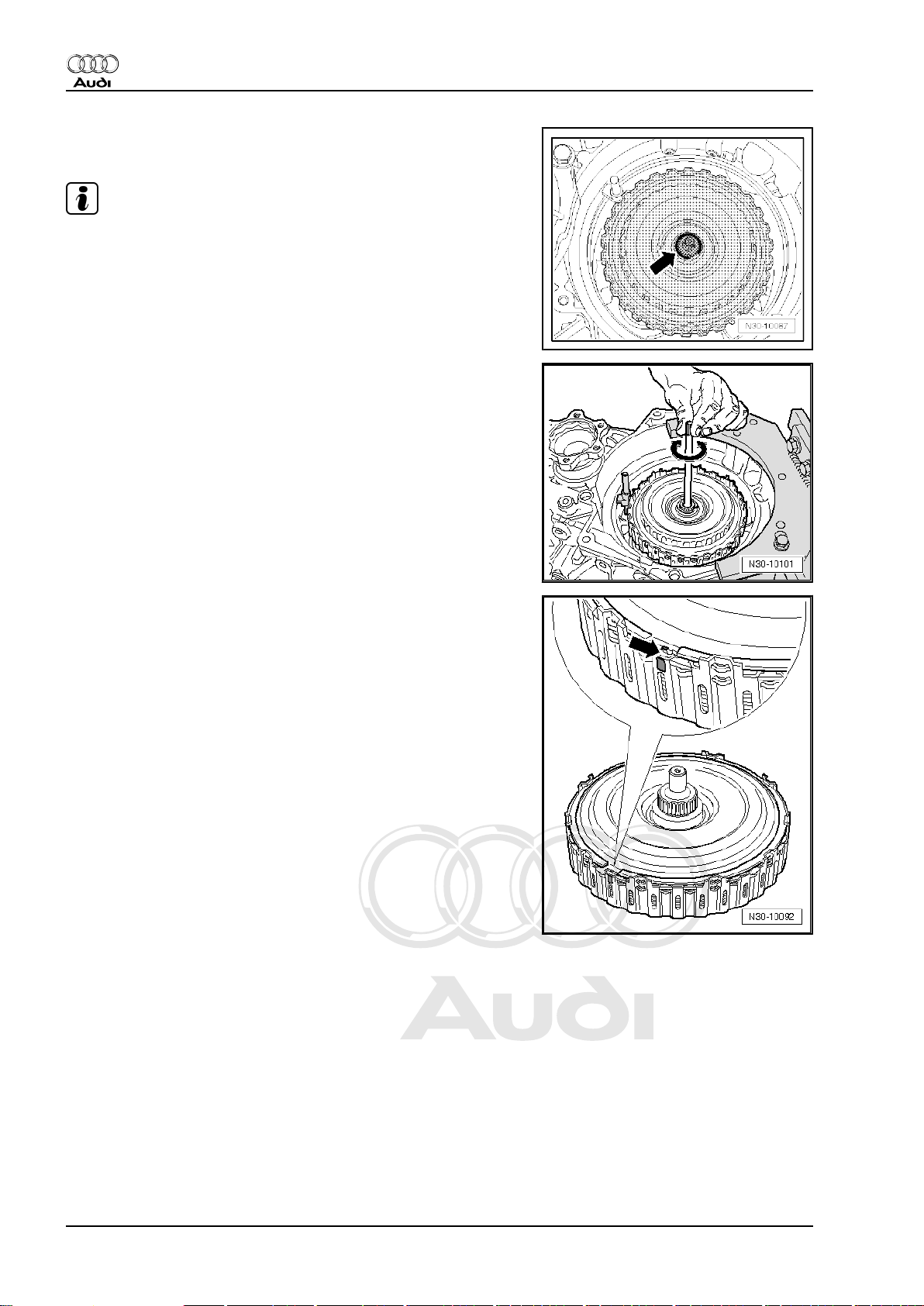

– Remove provisionally fitted circlip (2 mm) and fit new circlip

with thickness as calculated above.

Note

♦

Circlips must not be used more than once.

♦

The removed (provisional) circlip and all remaining circlips

should be disposed of.

– Install pump shaft. When installing, lift the shaft and turn it

slightly -arrow- so that it slides in and engages fully in the

splines.

– Install drive plate in multiple clutch.

• The projecting lug -arrow- on the drive plate must be posi‐

tioned between the colour-marked splines on the outer plate

carrier, or the marks made earlier in this procedure.

24 Rep. Gr.30 - Clutch

Page 29

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

– Fit new circlip for drive plate.

• Installation position: the lug on the drive plate and the colourmarked splines on the outer plate carrier (or the corresponding

marks made previously) must be located between the ends of

the circlip.

– Using a screwdriver, check that circlip is fully engaged.

– Take out retaining pin -T10303- between multiple clutch and

housing.

Audi TT 2007 ➤

Caution

Leakage can occur at the contact surface of the clutch end

cover.

♦ Thoroughly degrease running surface -arrow- on drive

plate for internal seal of clutch end cover.

– Clean the contact surface for the outer seal of the clutch end

cover.

Caution

Leakage can occur at the internal seal for the clutch end cover.

♦ To ensure that the internal seal remains absolutely free of

grease, do not touch the seal with your hands.

– Take the clutch end cover out of its packaging, only taking hold

of it on the outside as illustrated.

– Clean end of gearbox shaft.

Note

♦

Using gear oil, lightly lubricate the outer seal for the clutch end

cover only.

♦

If there are any stickers on the inside or the outside of the

clutch end cover, remove them thoroughly.

1. Exploded view - servicing multiple clutch 25

Page 30

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

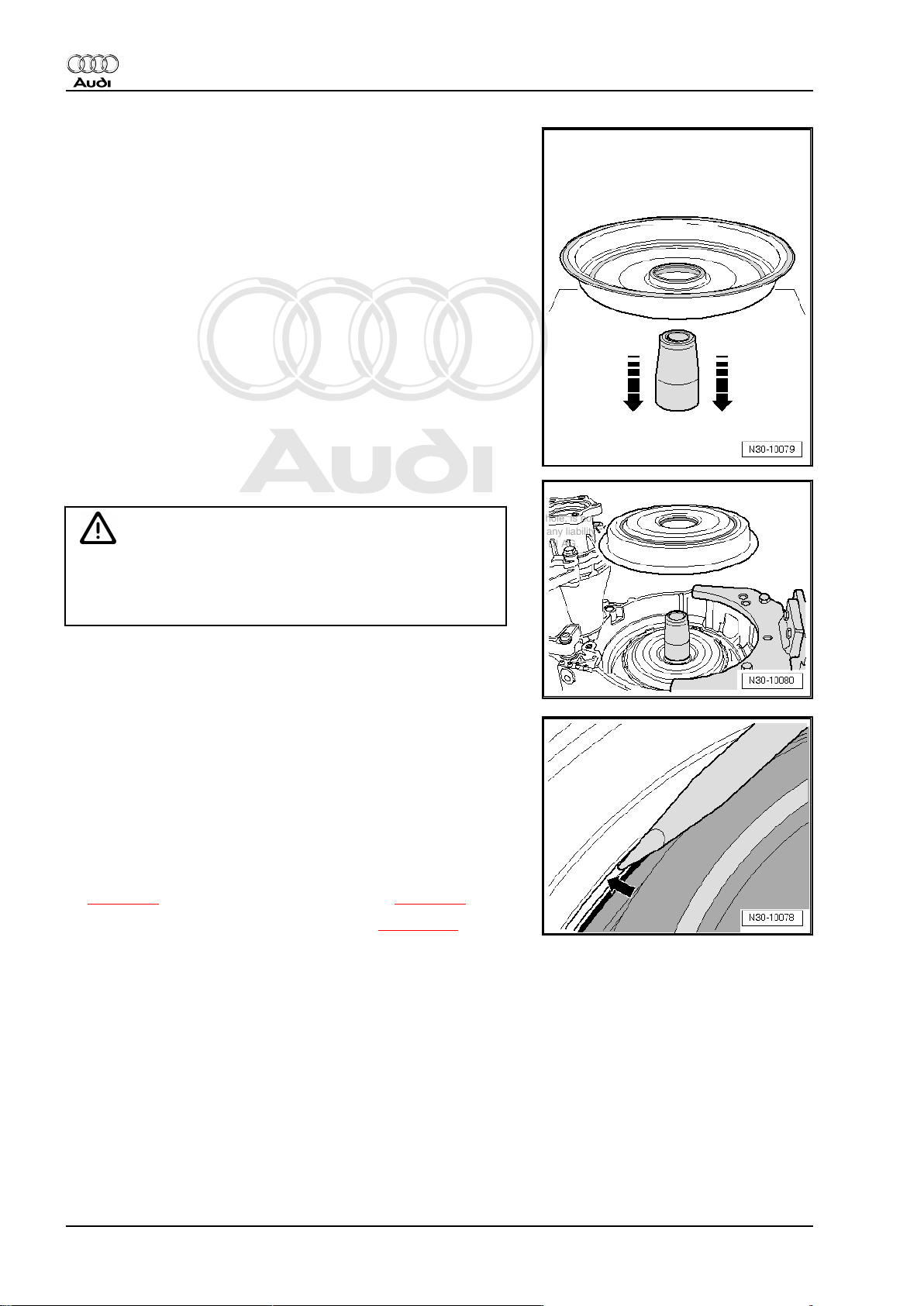

– Place assembly sleeve -T10302- on a flat surface.

– The internal seal in the new clutch end cover must be pre-

formed before installation; this is done by guiding the clutch

end cover, with the outside downwards, horizontally and uni‐

formly over the assembly sleeve -T10302- .

– Lift assembly sleeve -T10302- out of clutch end cover.

– Fit assembly sleeve -T10302- over end of multiple clutch shaft.

Caution

Clutch end cover can be damaged.

♦ Do not attempt to drive on the clutch end cover with a

hammer.

– Guide clutch end cover with the outside upwards horizontally

over assembly sleeve -T10302- and press cover uniformly on‐

to its seat.

– If necessary use a screwdriver to lever the clutch end cover

carefully into its seat as illustrated -arrow- so that the corru‐

gated ring can be fitted.

– Install corrugated ring for clutch end cover in gearbox housing,

always holding the ring in place on the opposite side so that it

remains in its groove.

– Using a screwdriver, check that corrugated ring is fully engag‐

ed.

– Install gearbox: vehicles with 2.0 ltr. TFSI engine

⇒ page 61 , vehicles with 3.2 ltr. MPI engine ⇒ page 74 .

– Fill up with gear oil for direct shift gearbox ⇒ page 100 .

– Connect vehicle diagnostic, testing and information system -

VAS 5051B- .

– Perform basic setting.

26 Rep. Gr.30 - Clutch

Page 31

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

34 – Controls, housing

1 Electrical/electronic components and fit‐

ting locations

Diagnostic connector

Fitting location: The diagnostic connector is located below the

knee padding on the left side of the steering wheel.

Audi TT 2007 ➤

Selector lever lock solenoid -N110-

Fitting location: the selector lever lock solenoid -1- is located in

the selector mechanism.

The solenoid is integrated in the selector mechanism; it is there‐

fore not possible to renew only the solenoid on its own. It can only

be removed or installed together with the selector mechanism

⇒ page 44 .

Mechatronic unit for dual clutch gearbox -J743-

Fitting location: the mechatronic unit for dual clutch gearbox J743- is bolted to the front of the gearbox housing and covered

by the gearbox oil pan.

The control unit is an integrated component of the mechatronic

unit for dual clutch gearbox -J743- .

♦ Is checked via self-diagnosis

Removing and installing mechatronic unit for dual clutch gearbox

-J743- ⇒ page 121 .

1. 27

Page 32

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

Gearbox input speed sender -G182- / oil temperature sender for

multi-plate clutch -G509-

Fitting location: the gearbox input speed sender -G182- and

clutch temperature sender -G509- -item A- are bolted to the gear‐

box housing below the mechatronic unit for dual clutch gearbox J743- .

♦ Checked via self-diagnosis

Removing and installing gearbox input speed sender -G182- and

clutch temperature sender -G509- ⇒ page 125 .

Selector lever -E313- with tiptronic switch -F189- , switch for se‐

lector lever locked in position P -F319-

Fitting location: the selector lever -E313- with tiptronic switch F189- and switch for selector lever locked in position P -F319- is

integrated in the printed circuit -B- of the selector mechanism.

These components cannot be renewed separately.

♦ Checked via self-diagnosis

Selector lever -E313- with tiptronic switch -F189- and switch for

selector lever locked in position P -F319- can only be removed

and installed together with selector mechanism ⇒ page 44 .

Selector lever position display -Y6-

Fitting location: integrated into instrument cluster

Note

The selector lever position display can only be renewed together

with the instrument cluster.

If the selector lever position display flashes or lights up, please

refer to safety functions of gearbox control unit ⇒ page 9 .

Removing and installing instrument cluster ⇒ Rep. Gr. 90

Selector lever display illumination bulb -L101-

Fitting location: in trim for selector lever boot -1-.

♦ Is checked via self-diagnosis

Removing and installing selector lever display illumination bulb L101- ⇒ page 39

28 Rep. Gr.34 - Controls, housing

Page 33

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

Brake light switch -F-

Fitting location: the brake light switch -arrow- is located on pedal

cluster.

♦ Is checked via self-diagnosis

Removing and installing brake light switch ⇒ Rep. Gr. 46

Note

To ensure a secure fit, the switch may only be fitted once.

Kickdown switch -F8-

An adapted value from accelerator position sender -G79- and ac‐

celerator position sender 2 -G185- (integrated in accelerator ped‐

al module) is stored in the engine control unit as the kickdown

signal.

♦ Is checked via self-diagnosis

♦ Signal is transmitted from engine control unit to gearbox con‐

trol unit via CAN bus.

Removing and installing accelerator pedal module ⇒ Rep. Gr.

20

Audi TT 2007 ➤

1. 29

Page 34

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

2 Exploded view - selector lever handle with interlock button (side), se‐

lector lever display illumination bulb -L101-

1 - Bolt

❑ 1 Nm

2 - Trim for selector lever boot

with selector lever display illu‐

mination bulb -L101-

❑ Removing and installing

⇒ page 39

3 - Guide

4 - Hose clip

❑ Removing and installing

⇒ “2.1 Removing and in‐

stalling selector lever

handle with interlock

button (side)”,

page 30

5 - Selector lever handle

❑ Removing and installing

⇒ page 30

2.1 Removing and installing selector lever handle with interlock button (side)

Special tools and workshop equipment required

♦ Hose clip pliers -V.A.G 1275-

30 Rep. Gr.34 - Controls, housing

Page 35

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

♦ Cable tie

Removing

Note

The selector lever handle is removed together with the selector

lever boot.

– Apply handbrake.

– Shift selector lever into position “N”.

– Use a cable tie to secure the interlock button in pulled-out po‐

sition -arrow-, as shown in the illustration.

– Unclip selector lever boot on both sides and lift it off -arrows-.

Audi TT 2007 ➤

– Turn selector lever boot -2- inside out over selector lever han‐

dle -3-.

– Release hose clip -1-.

– Pull off selector lever handle together with selector lever boot

-arrow-, taking care not to touch interlock button.

2. Exploded view - selector lever handle with interlock button (side), selector lever display illumination bulb L101 31

Page 36

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

Installing

Installation is carried out in reverse sequence; note the following:

Note

♦

To install the selector lever handle, the interlock button must

be pulled out as far as it will go and secured with either a cable

tie -arrow- or with the assembly aid supplied with the new han‐

dle.

♦

If the interlock button was not secured, do not attempt to pull

it out of the selector lever handle using mechanical tools. In‐

stead, apply a compressed air gun to the bottom of the handle,

blow out the interlock button and secure it in this position.

– Push selector lever handle fully onto selector lever.

• The interlock button faces the driver.

• The handle must engage in the annular groove on the selector

lever.

– Remove cable tie or assembly aid.

• The interlock button mechanism should engage in the vertical

groove on the selector lever. If not, press the interlock button

into the selector lever handle.

– Bring hose clip -1- into correct position.

• The lug -arrow- on the hose clip faces front right.

– Clamp selector lever handle -2- on selector lever by tightening

hose clip with hose clip pliers -V.A.G 1275- .

– Clip retainer frame -3- for selector lever boot onto trim for se‐

lector lever boot.

32 Rep. Gr.34 - Controls, housing

Page 37

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

3 Exploded view - selector lever handle with interlock button (front), se‐

lector lever display illumination bulb -L101-

1 - Bolt

❑ 1 Nm

2 - Trim for selector lever boot

with selector lever display illu‐

mination bulb -L101-

❑ Removing and installing

⇒ page 39

3 - Guide

4 - Selector lever boot

❑ Detaching selector lever

boot from selector lever

handle ⇒ page 35

5 - Selector lever handle with

interlock button (front)

❑ ⇒ “3.1 Removing and in‐

stalling selector lever

handle with interlock

button (front)”,

page 33

❑ ⇒ “3.3 Moving interlock

button on selector lever

handle into installation

position”, page 37

3.1 Removing and installing selector lever handle with interlock button (front)

Removing

Note

The selector lever handle is removed together with the selector

lever boot.

– Apply handbrake.

– Shift selector lever into position “N”.

– Unclip selector lever boot on both sides and lift it off -arrows-.

3. Exploded view - selector lever handle with interlock button (front), selector lever display illumination bulb L101 33

Page 38

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

– Turn selector lever boot -2- inside out over selector lever han‐

dle -3-.

– Turn locking ring in direction of -arrow- as far as stop.

• Raised lug -b- on locking ring is misaligned from lug -a-.

Caution

Risk of damage to the selector mechanism.

Do not touch the interlock button -1- on the selector lever han‐

dle when pulling off the handle.

Otherwise the selector lever handle or the pull rod of the se‐

lector mechanism will be damaged when the handle is pulled

off.

– Pull off selector lever handle together with selector lever boot

upwards -arrow-, taking care not to touch interlock button -1-.

Installing

Installation is carried out in reverse sequence; note the following:

– Turn locking ring in direction of -arrow- as far as stop.

• Raised lug -b- on locking ring is misaligned from lug -a-.

• Interlock button faces direction of travel.

Caution

Risk of damage to the selector mechanism.

The interlock button -1- must protrude from the selector lever

handle during installation. If the interlock button was pressed

in by mistake when the handle was removed, the interlock but‐

ton must be moved back to its installation position

⇒ page 37 .

If the interlock button has been pressed in and the handle is

installed with the interlock button in this position, the handle

and the pull rod of the selector mechanism -3- will be damaged

irreparably.

– Carefully press selector lever handle fully into selector lever,

taking care not to touch interlock button -1-.

• The handle must engage in the annular groove on the selector

lever.

34 Rep. Gr.34 - Controls, housing

Page 39

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

– Turn locking ring in direction of -arrow- as far as stop.

• It must be possible to turn the locking ring; press handle if

necessary.

• Lug -a- must align with raised lug -b- on locking ring.

Note

♦

The handle is not locked until the locking ring has been turned.

Only then can you press the interlock button on the handle.

♦

There may be increased resistance when you press the inter‐

lock button for the first time after installation.

– Press interlock button -1- on selector lever handle.

– Fold selector lever boot down and clip it in.

– Check selector mechanism ⇒ page 43 .

3.2 Detaching selector lever boot from se‐

lector lever handle

Audi TT 2007 ➤

Procedure:

– Remove selector lever handle ⇒ page 33 .

– Pull guide -1- off in direction of -arrow-.

3. Exploded view - selector lever handle with interlock button (front), selector lever display illumination bulb L101 35

Page 40

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

• Do not touch interlock button -A- when selector lever handle

has been removed.

– Hold upper end of selector lever boot -arrow 1-.

– Turn selector lever handle in direction of -arrow 2- and pull it

off -arrow 3-.

Installing selector lever boot with selector lever handle:

• Do not touch interlock button -A- when selector lever handle

has been removed.

– Insert selector lever handle in selector lever boot -arrow 1-

(with interlock button turned 90° out of position towards left).

– Hold upper end of selector lever boot -arrow 2-.

– Turn selector lever handle in direction of -arrow 3-.

– Clip guide -1- upwards into handle in opposite direction of

-arrow-.

– Install selector lever handle ⇒ page 33 .

36 Rep. Gr.34 - Controls, housing

Page 41

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

3.3 Moving interlock button on selector lever handle into installation position

Special tools and workshop equipment required

♦ Release tool -T40203-

Selector lever handle with interlock button (front):

• Installation position: the interlock button -1- must protrude

from the selector lever handle.

If the interlock button has been pressed in, it must be moved back

into its installation position so that the selector lever handle can

be installed.

Audi TT 2007 ➤

– Carefully insert release tool -T40203- into selector lever han‐

dle -1- as far as stop.

Note

For illustration purposes, the handle is shown without selector

lever boot.

• Recess on release tool -T40203- should face interlock button,

hook should point towards left.

3. Exploded view - selector lever handle with interlock button (front), selector lever display illumination bulb L101 37

Page 42

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

– Hold selector lever handle -A- and turn release tool -T40203-

180° in direction of -arrow 1-.

– Hold handle and carefully pull out release tool -T40203-

-arrow 2-.

• When pulling out release tool -T40203- , interlock button -Aon selector lever handle is pressed out and locked in position.

• Do not touch interlock button on selector lever handle before

installing handle so that interlock button is not pressed in

again.

38 Rep. Gr.34 - Controls, housing

Page 43

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

4 Removing and installing selector lev‐

er display illumination bulb -L101-

Special tools and workshop equipment required

♦ Removal wedge -3409-

Removing

– Apply handbrake.

– Shift selector lever into position “N”.

– Switch off ignition.

– Unclip selector lever boot on both sides and lift it off -arrows-.

Audi TT 2007 ➤

– Pull selector lever boot up and over handle.

– Using removal wedge -3409- , pry trim panel for centre console

out of centre console -arrows-.

– Unplug electrical connectors and remove trim panel for centre

console.

4. Removing and installing selector lever display illumination bulb L101 39

Page 44

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

– Remove bolts -arrows- and detach trim for selector lever boot

-1- together with selector lever display illumination bulb L101- .

Installing

Installation is carried out in reverse sequence; note the following:

Tightening torques:

• ⇒ “2 Exploded view - selector lever handle with interlock button

(side), selector lever display illumination bulb L101 ”,

page 30

• ⇒ “3 Exploded view - selector lever handle with interlock button

(front), selector lever display illumination bulb L101 ”,

page 33

– Make sure trim panel engages audibly in centre console.

40 Rep. Gr.34 - Controls, housing

Page 45

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct shift gearbox 02E, four-wheel drive - Edition 08.2008

5 Exploded view - selector mechanism

Note

Lubricate all bearings and moving surfaces with polycarbamide grease ⇒ Electronic parts catalogue .

1 - Support bracket

❑ For selector lever cable

2 - Bolt

❑ 20 Nm and then turn 90°

further

❑ 2x

❑ Renew

3 - Securing clip

❑ Renew

4 - Bolt

❑ 13 Nm

5 - Locking plate

❑ Renew

6 - Selector lever cable

❑ Do not bend or kink

❑ Do not grease cable eye

❑ Renew selector lever

cable if sleeves are

damaged

❑ Removing and installing

⇒ page 46

❑ Adjusting ⇒ page 50

7 - Nut

❑ 8 Nm

❑ 4x

❑ Selector mechanism to

body

8 - Buffer stop for selector lever

❑ Clipped onto selector

mechanism

9 - Shift unit

❑ With integrated printed circuit for selector mechanism ( selector lever -E313- )

Caution

Electronic components

of selector mechanism

can be damaged by elec‐

trostatic discharge.

♦Do not touch printed cir‐

cuit with bare hands.

❑ Incorporates tiptronic switch -F189- and selector lever lock solenoid -N110❑ Tiptronic switch -F189- and selector lever lock solenoid -N110- can be checked via “Guided Fault Finding”

⇒ Vehicle diagnosis, testing and information system VAS 5051

5. Exploded view - selector mechanism 41

Page 46

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability