Page 1

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Service

Workshop Manual

Audi TT 1999 ➤

Motronic injection and ignition system (6-cyl.)

Engine ID

Edition 12.2004

BHE BPF

Service Department. Technical Information

Page 2

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Service

List of Workshop Manual Repair GroupsList of Workshop Manual

Repair GroupsList of Workshop Manual Repair Groups

Re pa ir G ro up

24 - Mixture preparation - injection

28 - Ignition system

Technical information should always be available to the foremen and mechanics, because their

careful and constant adherence to the instructions is essential to ensure vehicle road-worthiness and

safety. In addition, the normal basic safety precautions for working on motor vehicles must, as a

matter of course, be observed.

All rights reserved.

No reproduction without prior agreement from publisher.

Copyright © 2010 Audi AG, Ingolstadt A0057007220

Page 3

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

Contents

24 - Mixture preparation - injection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1 Servicing Motronic injection system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Rules for cleanliness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.4 Overview - fitting locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.5 Dismantling and assembling air cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.6 Intake manifold - exploded view of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.7 Removing and installing intake manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.8 Wiring and component check on engine control unit with test box V.A.G 1598/31 . . . . . . 22

1.9 Removing and installing engine control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1.10 Checking system pressure, fuel pressure regulator and residual pressure . . . . . . . . . . . . 26

1.11 Dismantling and assembling fuel rail with injectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

1.12 Removing and installing injectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

1.13 Checking injection quantity and spray pattern of injectors; checking for leaks . . . . . . . . . . 32

1.14 Removing and installing Lambda probes (before catalytic converter) . . . . . . . . . . . . . . . . 34

1.15 Removing and installing Lambda probes (after catalytic converter) . . . . . . . . . . . . . . . . . . 36

28 - Ignition system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

1 Checking ignition system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

1.1 General notes on ignition system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

1.2 Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

1.3 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

1.4 Removing and installing parts of the ignition system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

1.5 Removing and installing ignition coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

1.6 Removing and installing spark plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Contents i

Page 4

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

ii Contents

Page 5

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

24 – Mixture preparation - injection

1 Servicing Motronic injection system

1.1 Safety precautions

To prevent injuries to persons and/or damage to the fuel injection

and ignition system, the following must be noted:

♦ Always switch off the ignition before connecting or discon‐

necting injection or ignition system wiring or tester cables.

♦ Certain tests may lead to a fault being detected by the control

unit and stored. Therefore, interrogate and, if necessary,

erase the fault memory after all repairs and tests.

♦ Always switch off the ignition before cleaning the engine.

♦ Always switch off the ignition before connecting or discon‐

necting the battery, otherwise the engine control unit may be

damaged.

Audi TT 1999 ➤

WARNING

The fuel system is pressurised. Before opening the system

place a cloth around the connection. Then dissipate pressure

by carefully unfastening the connection.

Note the following if testers and measuring instruments have to

be used during a road test:

WARNING

♦ To avoid any risk of accident, observe the following pre‐

cautions when using test instruments while road testing

the vehicle:

Audi TT Coupé:

♦ To read measured value blocks, use only the vehicle di‐

agnostic, testing and information system -VAS 5051 A- or

the vehicle diagnostic and information system VAS 5052- . Test equipment must always be secured on

the rear seat and operated from that position by a second

person.

♦ On account of the limited space available, the front pas‐

senger's seat is to be moved forwards as far as it will go

and the engaged backrest folded forwards as far as it will

go with the backrest adjuster handwheel. Do not operate

the release lever to tilt the backrest forward.

Audi TT Roadster:

♦ In the Audi TT Roadster, only use the vehicle diagnostic

and information system -VAS 5052- with the passenger's

airbag deactivated.

♦ Deactivate front passenger's airbag via the key switch in

glove box or the self-diagnosis ⇒ Body, self-diagnosis;

Rep. Gr. 01 ; Adaption .

♦ Reactivate front passenger's airbag on completion of

work.

1. Servicing Motronic injection system 1

Page 6

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

1.2 Rules for cleanliness

When working on the fuel supply/injection system, pay careful at‐

tention to the following “6 rules”:

♦ Thoroughly clean all unions and the adjacent areas before

disconnecting.

♦ Place parts that have been removed on a clean surface and

cover them over. Do not use fluffy cloths.

♦ Carefully cover or seal open components if repairs cannot be

carried out immediately.

♦ Only install clean components; replacement parts should only

be unpacked immediately prior to installation. Do not use parts

that have been previously unpacked and stored away loose

(e.g. in toolboxes, etc.).

♦ When the system is open: Do not work with compressed air if

this can be avoided. Do not move vehicle unless absolutely

necessary.

♦ Unplugged electrical connectors; keep them clean and dry.

Make sure connections are dry when attaching.

1.3 Technical data

Engine code letters BHE (3.2 ltr. / 4V / 184 kW

engine)

Idling speed

650 ... 750 rpm

1)

Cannot be adjusted; regulated by idling speed stabi‐

lisation

Speed governing by

approx. 6,500 rpm

deactivation of fuel injectors

Fuel pressure at idling

speed

Vacuum hose

connected

Vacuum hose

approx. 3.5 bar

approx. 4.0 bar

disconnected

Residual pressure after 10 minutes at least 3.0 bar

Injectors Spray pattern Two-hole nozzle / same for all injectors

1) Current values ⇒ Data sheets for exhaust emission test.

Injection quantity (30 sec.) 128 … 140 ml

BPF (3.2 ltr. / 4V / 184 kW

engine)

2 Rep. Gr.24 - Mixture preparation - injection

Page 7

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

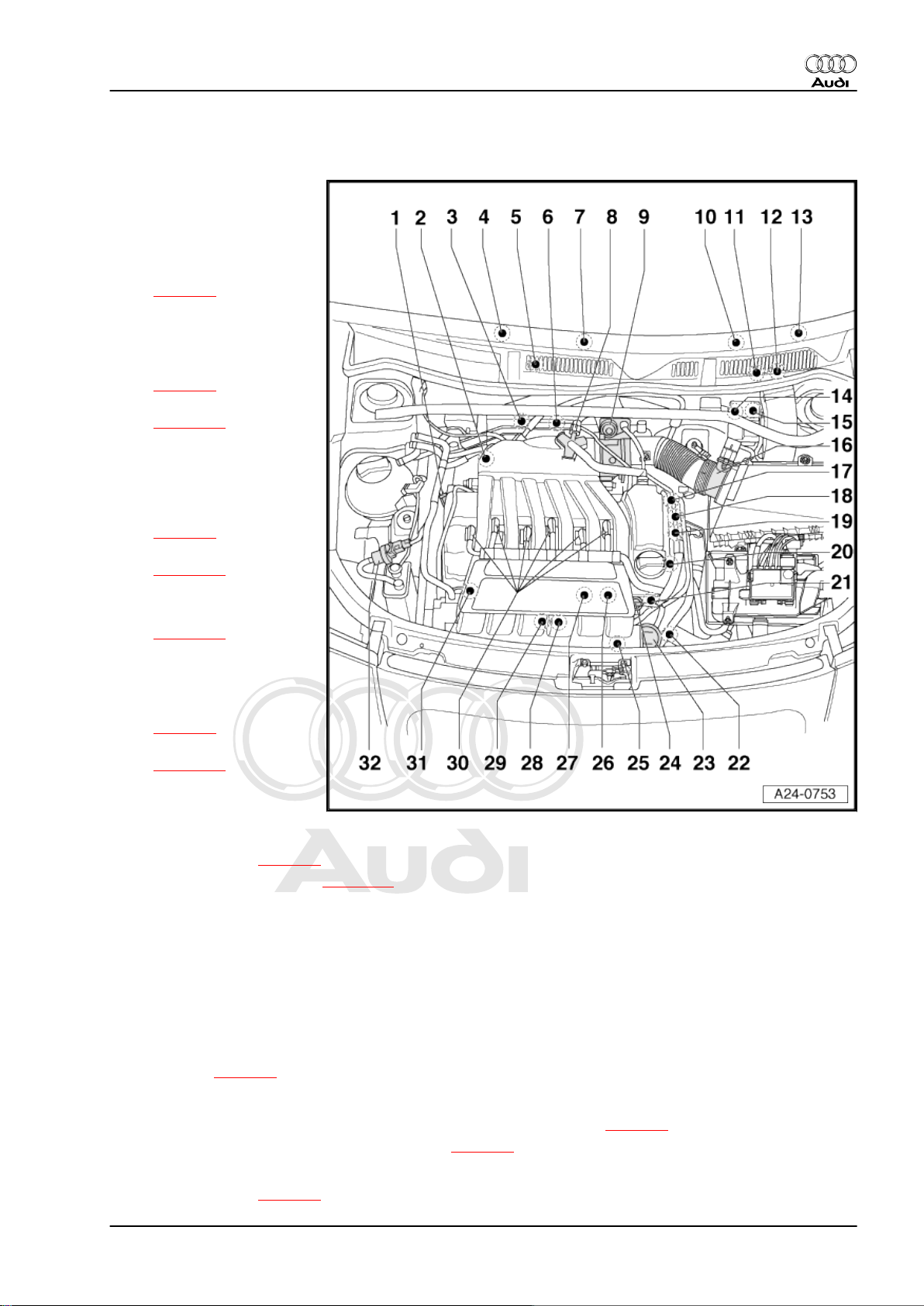

1.4 Overview - fitting locations

1 - 3-pin connector

❑ For knock sensor 1 -

G61-

2 - Knock sensor 1 -G61-

❑ Fitting location

⇒ page 8

3 - Lambda probe, before cat‐

alytic converter -G39- with

Lambda probe heater -Z19-

❑ Fitting location

⇒ page 6

❑ Removing and installing

⇒ page 34

4 - Lambda probe, after cata‐

lytic converter -G130- with

Lambda probe heater 1, after

catalytic converter -Z29-

❑ Fitting location

⇒ page 6

❑ Removing and installing

⇒ page 36

5 - Motronic control unit -J220-

❑ Removing and installing

⇒ page 23

6 - Lambda probe 2, before

catalytic converter -G108- with

Lambda probe 2 heater -Z28-

❑ Fitting location

⇒ page 6

❑ Removing and installing

⇒ page 34

7 - Lambda probe 2, after cat‐

alytic converter -G131- with

Lambda probe 2 heater, after

catalytic converter -Z30-

❑ Fitting location ⇒ page 6

❑ Removing and installing ⇒ page 36

8 - Heater element (crankcase breather) -N79-

9 - Throttle valve module -J338-

❑ Including throttle valve drive (electric throttle operation) -G186- , angle sender for throttle valve drive -

G187- and angle sender 2 for throttle valve drive -G188-

10 - Instrument cluster

❑ With exhaust emissions warning lamp -K83-

11 - Accelerator position sender -G79- and accelerator position sender 2 -G185-

Fitting location ⇒ page 5

12 - Brake light switch -F- / brake pedal switch -F47- , clutch pedal switch -F36-

❑ Fitting location of brake light switch -F- / brake pedal switch -F47- ⇒ page 5

❑ Fitting location of clutch pedal switch -F36- ⇒ page 6

13 - Fuel pump relay -J17-

❑ Fitting location ⇒ page 6

1. Servicing Motronic injection system 3

Page 8

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

14 - Secondary air pump relay -J299-

Fitting location ⇒ page 7

15 - Motronic current supply relay -J271-

16 - Air mass meter -G70-

17 - Hall sender 2 -G163-

❑ Black connector

18 - Exhaust camshaft control valve 1 -N318-

❑ Brown connector

19 - Inlet camshaft control valve 1 -N205-

❑ Black connector

20 - Hall sender -G40-

❑ Black connector

21 - Coolant temperature sender -G62-

❑ Fitting location ⇒ page 8

❑ If necessary, release cooling system pressure before removal

22 - Engine speed sender -G28-

❑ Fitting location ⇒ page 7

23 - Vacuum unit for intake manifold change-over

24 - Fuel pressure regulator

❑ Checking ⇒ page 26

25 - Secondary air pump motor -V101-

26 - Intake manifold change-over valve -N156-

❑ Fitting location ⇒ page 7

27 - Secondary air inlet valve -N112-

❑ Fitting location ⇒ page 7

28 - Knock sensor 2 -G66-

❑ Fitting location ⇒ page 8

29 - 3-pin connector

❑ For engine speed sender -G28❑ Fitting location ⇒ page 7

30 - Ignition coils with output stages

❑ Cylinder 1 ignition coil 1 with output stage -N70❑ Cylinder 2 ignition coil 2 with output stage -N127❑ Cylinder 3 ignition coil 3 with output stage -N291❑ Cylinder 4 ignition coil 4 with output stage -N292❑ Cylinder 5 ignition coil 5 with output stage -N323❑ Cylinder 6 ignition coil 6 with output stage -N324-

31 - Injectors

❑ Cylinder 1 injector, cylinder 1 -N30❑ Cylinder 2 injector, cylinder 2 -N31❑ Cylinder 3 injector, cylinder 3 -N32❑ Cylinder 4 injector, cylinder 4 -N33❑ Cylinder 5 injector, cylinder 5 -N83❑ Cylinder 6 injector, cylinder 6 -N84❑ Checking injection quantity and spray pattern; checking for leaks ⇒ page 32

❑ Removing and installing ⇒ page 30

4 Rep. Gr.24 - Mixture preparation - injection

Page 9

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

32 - Activated charcoal filter solenoid valve 1 -N80-

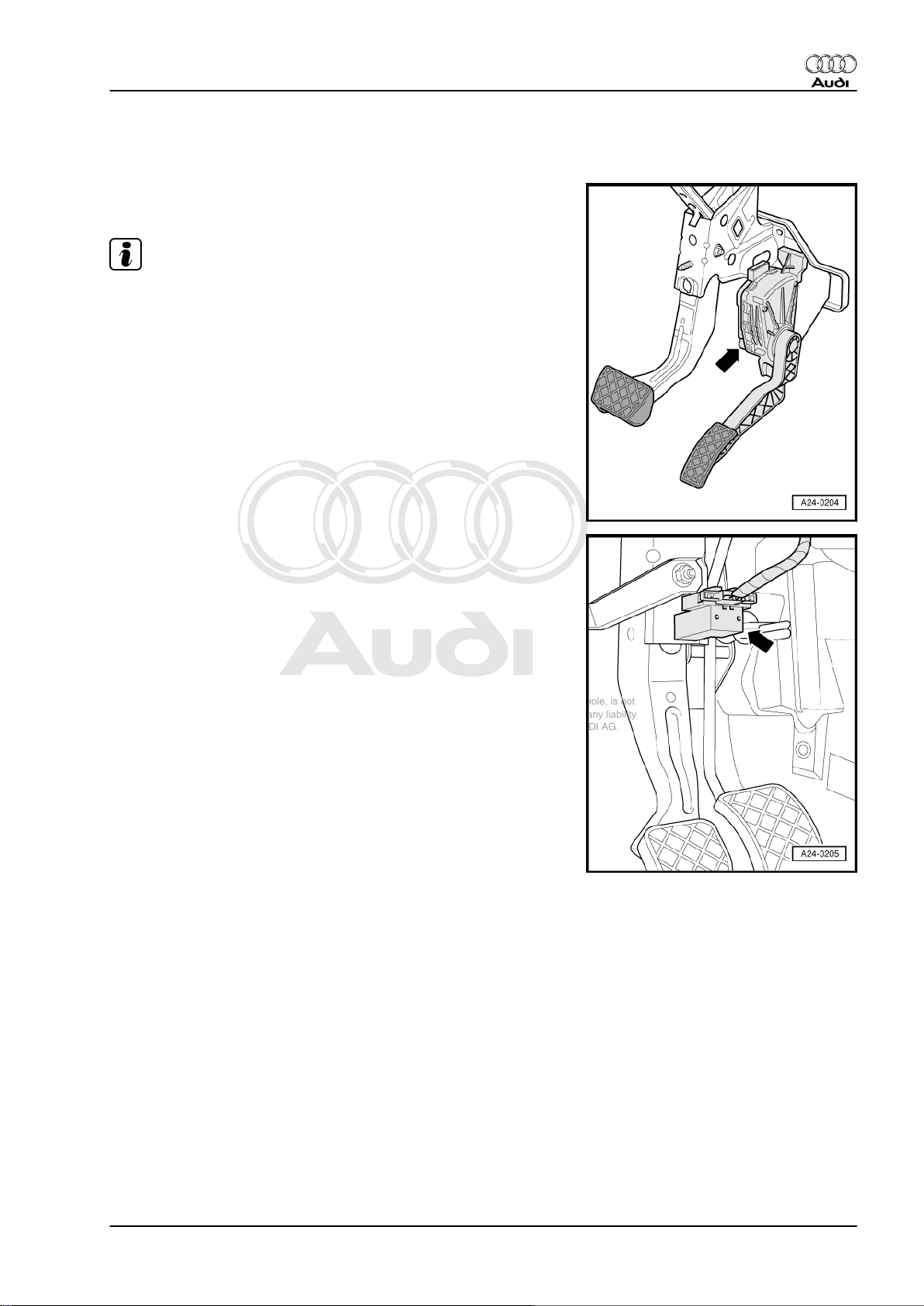

Fitting location of accelerator position sender -G79- and acceler‐

ator position sender 2 -G185-

Note

Diagram shows set-up on left-hand drive vehicles.

Audi TT 1999 ➤

Fitting location of brake light switch -F- and brake pedal switch F47-

♦ On pedal bracket

1. Servicing Motronic injection system 5

Page 10

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

Fitting location of clutch pedal switch -F36-

♦ On pedal bracket

Fitting location of Lambda probes before catalytic converter

♦ In front exhaust pipe

1 - Lambda probe 2, before catalytic converter -G108- with

Lambda probe 2 heater -Z28-

2 - Lambda probe, before catalytic converter -G39- with Lamb‐

da probe heater -Z19-

Fitting location of Lambda probes after catalytic converter

♦ In catalytic converter

1 - Lambda probe, after catalytic converter -G130- with Lamb‐

da probe heater 1, after catalytic converter -Z29-

2 - Lambda probe 2, after catalytic converter -G131- with Lamb‐

da probe 2 heater, after catalytic converter -Z30-

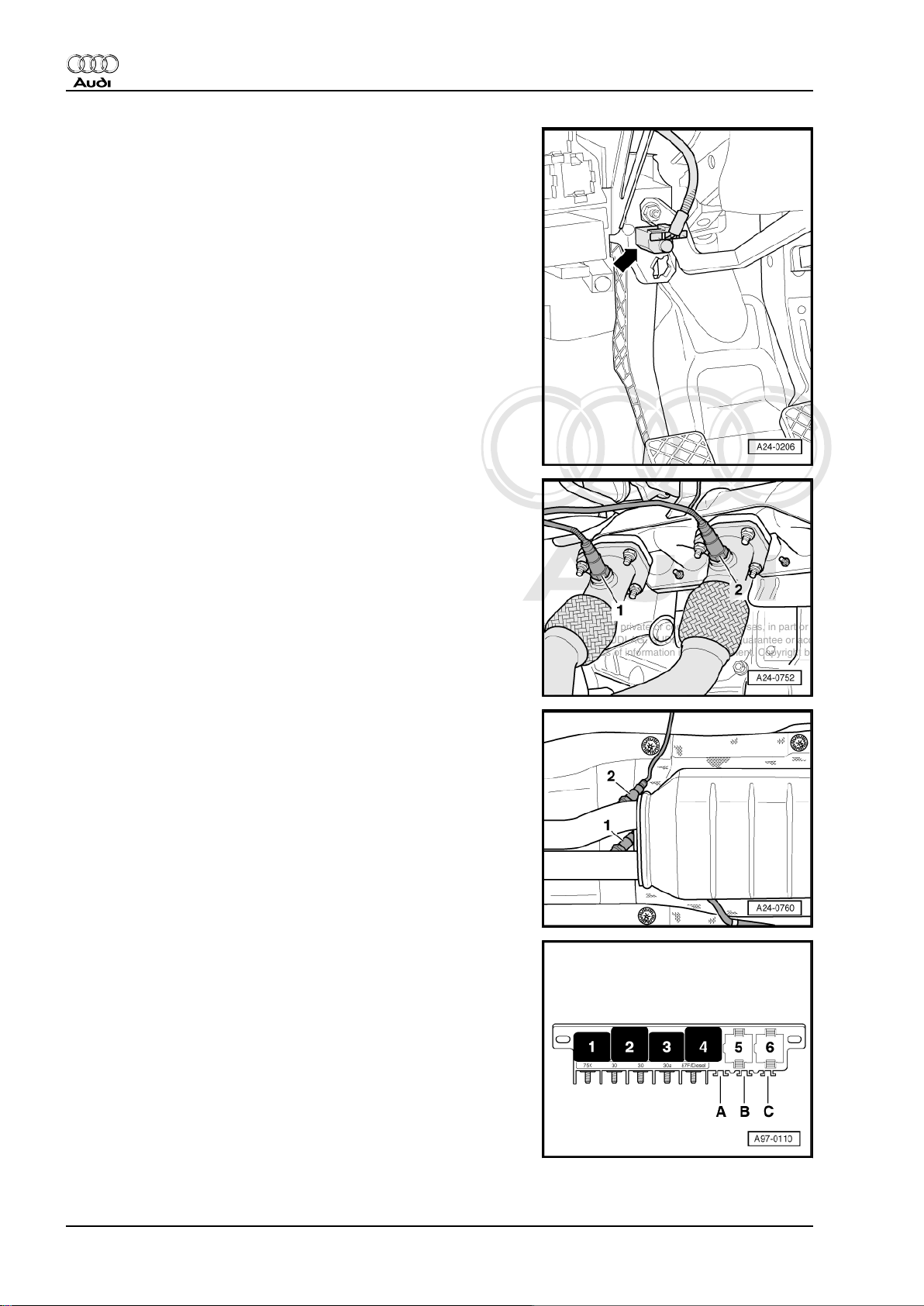

Fitting location of fuel pump relay -J17-

♦ In the micro central electrics (left-side) under the dash panel:

position 4.

6 Rep. Gr.24 - Mixture preparation - injection

Page 11

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

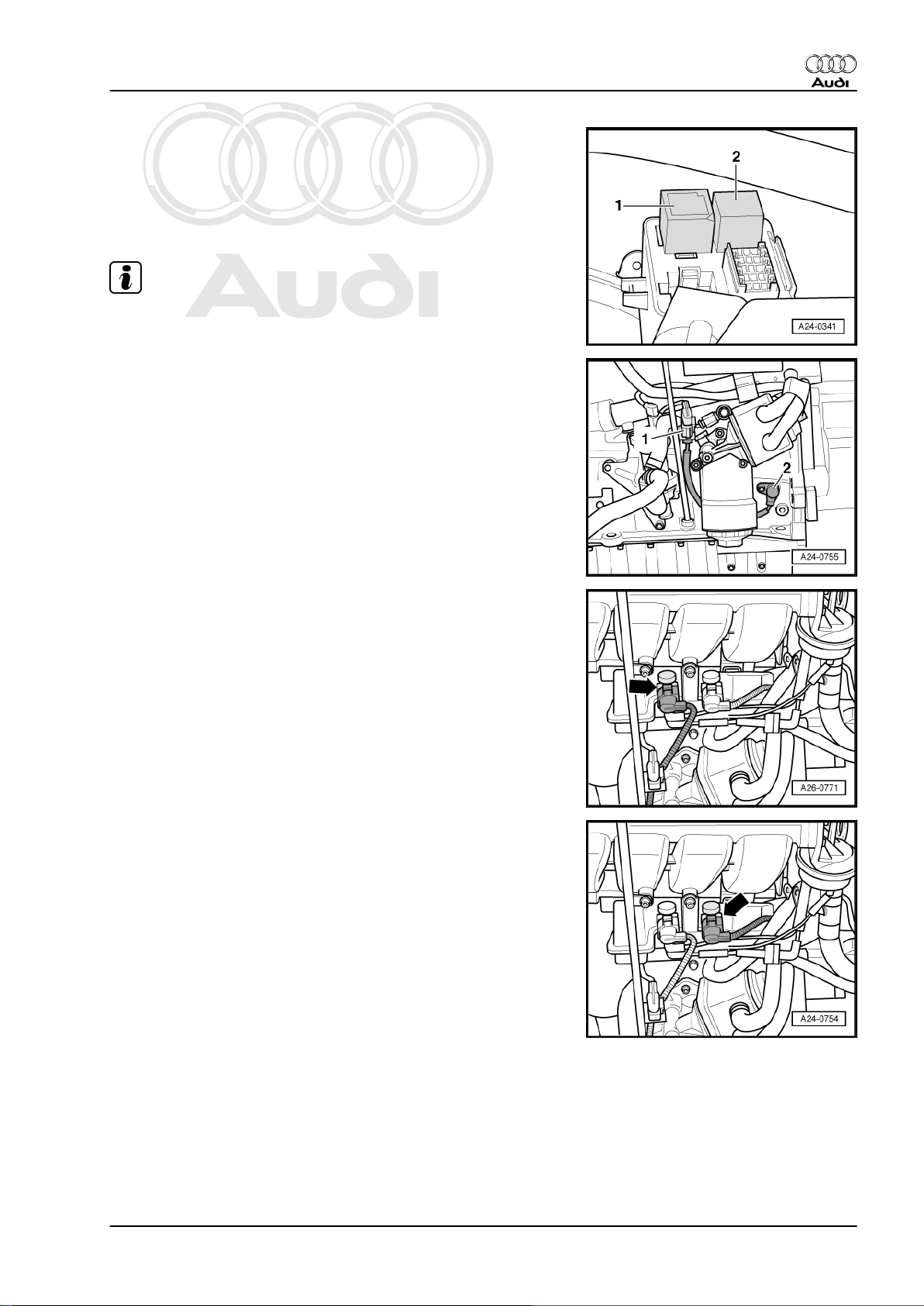

Fitting location: Motronic current supply relay -J271- and secon‐

dary air pump relay -J299-

♦ Beneath cover on left at bulkhead.

1 - Secondary air pump relay -J299-

2 - Motronic current supply relay -J271-

Note

To remove dust cover, detach relay carrier at bulkhead and lower.

Fitting location: engine speed sender -G28- with 3-pin connector

1 - 3-pin connector

2 - Engine speed sender -G28-

Audi TT 1999 ➤

Fitting location of secondary air inlet valve -N112-

♦ At vacuum reservoir (at front of engine)

Fitting location of intake manifold change-over valve -N156-

♦ At vacuum reservoir (at front of engine)

1. Servicing Motronic injection system 7

Page 12

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

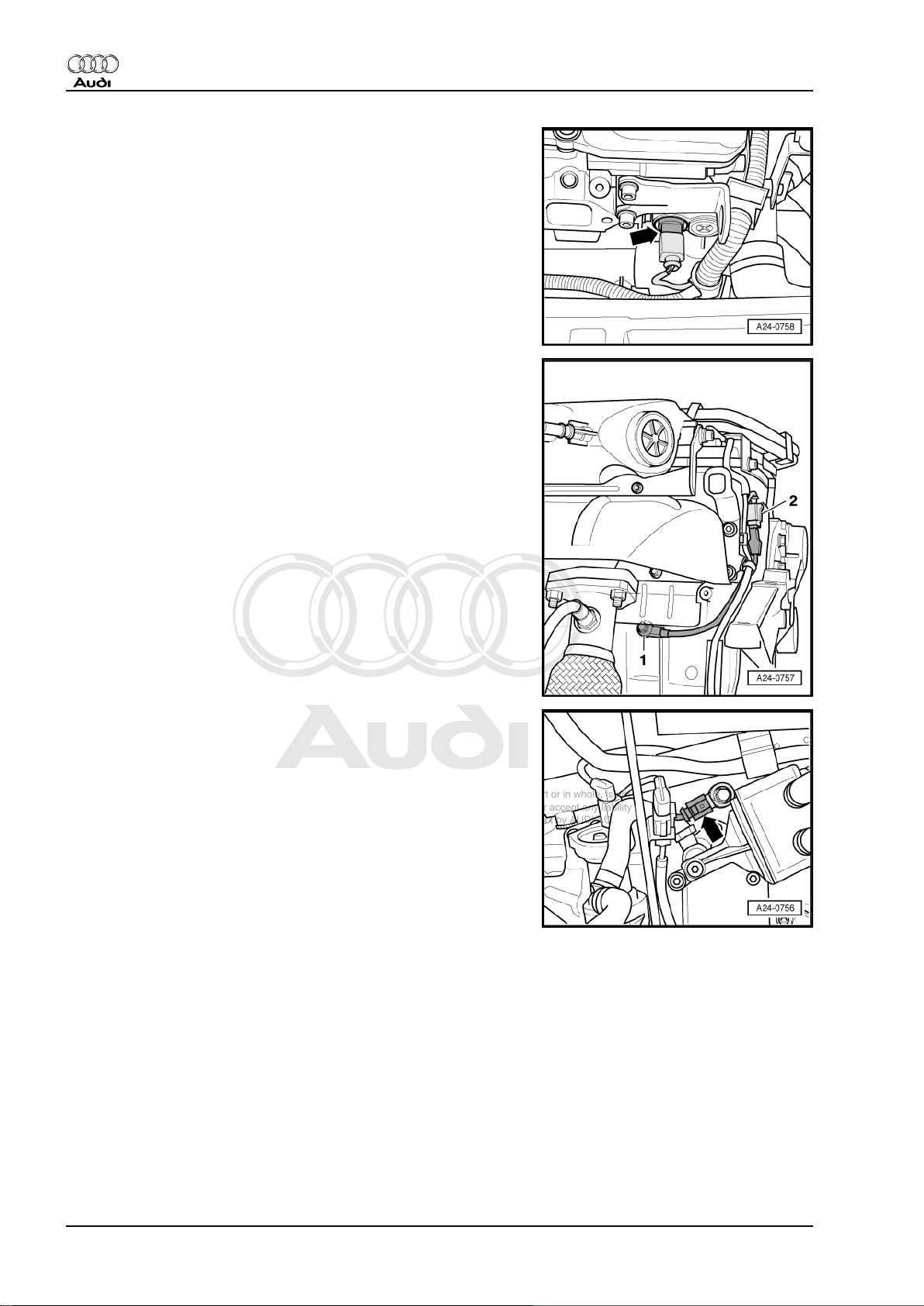

Fitting location of coolant temperature sender -G62-

♦ At front left on cylinder head

Fitting location: knock sensor 1 -G61-

♦ At rear right on cylinder block.

1 - Knock sensor 1 -G61-

2 - 3-pin connector

Fitting location: knock sensor 2 -G66-

♦ At front on cylinder block

8 Rep. Gr.24 - Mixture preparation - injection

Page 13

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

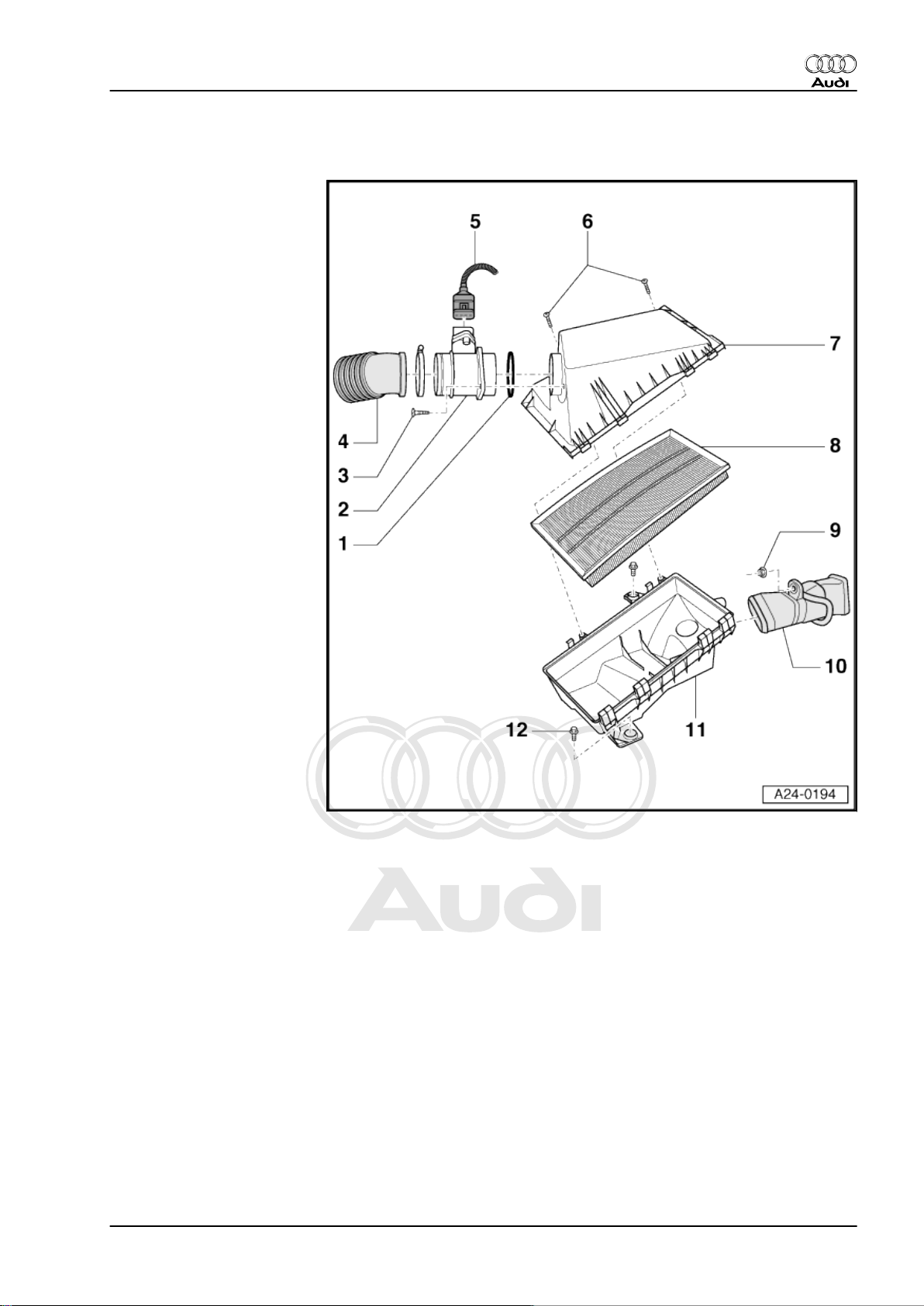

1.5 Dismantling and assembling air cleaner

1 - Seal

2 - Air mass meter -G70-

3 - Cross-head screw

4 - Air intake hose

5 - 5-pin connector

6 - Cross-head screw

7 - Air cleaner housing (top

section)

8 - Filter element

9 - Nut -10 Nm-

10 - Air intake connection

11 - Air cleaner housing (bot‐

tom section)

12 - Bolt, 10 Nm

Audi TT 1999 ➤

1. Servicing Motronic injection system 9

Page 14

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

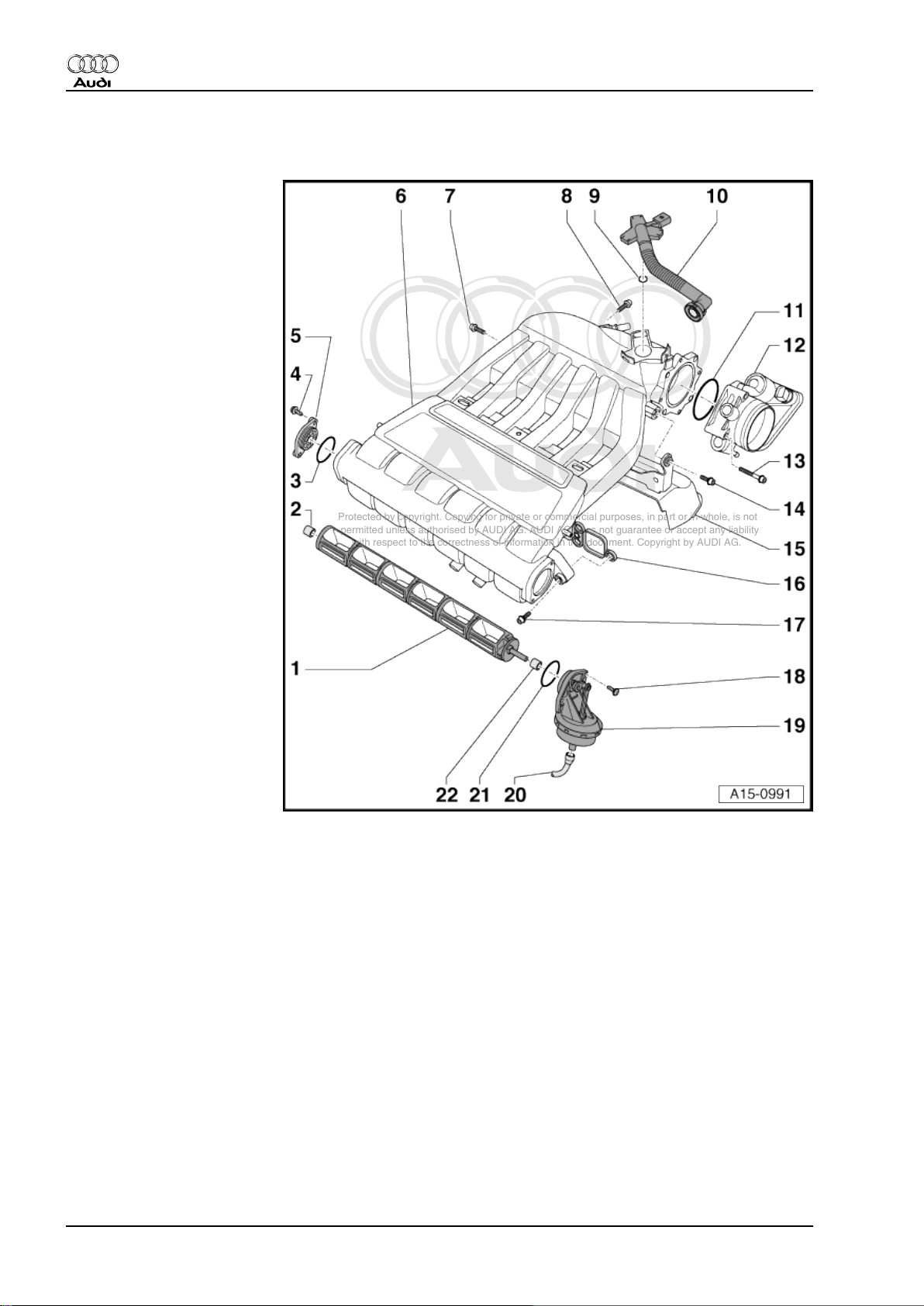

1.6 Intake manifold - exploded view of components

1 - Change-over barrel

2 - Bearing bush

3 - O-ring

❑ Renew

4 - Panel bolt

5 - Bearing cap

6 - Intake manifold

7 - 20 Nm

8 - 20 Nm

9 - Seal

10 - Connection for crankcase

breather

❑ With heater element

(crankcase breather) N79-

11 - O-ring

12 - Throttle valve module J338-

13 - 10 Nm

14 - 20 Nm

15 - Heat shield for exhaust

manifold

❑ With support for intake

manifold

16 - Gasket

❑ Renew

❑ Insert into manifold

17 - 13 Nm

18 - Panel bolt

19 - Vacuum unit

20 - Vacuum connection

❑ To intake manifold change-over valve -N156-

21 - O-ring

❑ Renew

22 - Bearing bush

1.7 Removing and installing intake manifold

Special tools and workshop equipment required

10 Rep. Gr.24 - Mixture preparation - injection

Page 15

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

♦ Drip tray for workshop hoist -VAS 6208- (TT Roadster only)

Removing

Note

All cable ties which are released or cut open when removing must

be fitted in the same position when installing.

Audi TT 1999 ➤

Caution

Observe notes on procedure for disconnecting the battery ⇒

Electrical system; Rep. Gr. 27 .

– With the ignition switched off, detach earth cable -arrow- at

battery (in luggage compartment, under floor cover).

– To remove fasteners -1- at lock carrier, press pin -2- in approx.

4 mm (do not push in completely). Then pull fastener out up‐

wards.

1. Servicing Motronic injection system 11

Page 16

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

– Remove covers (left-side) -1- and -2- at lock carrier and above

main fuse box -arrows-.

– Remove covers (right-side) -1- and -2- at lock carrier and

above coolant expansion tank -arrows-.

– Pull out oil dipstick.

Note

Before removing, mark direction of rotation of poly V-belt with

chalk or felt-tipped pen. If the belt runs in the opposite direction

when it is refitted, this can cause breakage.

– To release tension of poly V-belt, screw a bolt M8x40

-arrow- into the bore on tensioning element.

– Remove poly V-belt from alternator pulley.

– Unscrew upper securing bolt -2- for alternator.

12 Rep. Gr.24 - Mixture preparation - injection

Page 17

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

– Unscrew upper securing bolts -upper arrows- for radiator cowl.

– Disconnect secondary air hose at the position marked with an

-arrow-.

– Move air hose clear.

Audi TT 1999 ➤

TT Coupé:

– Remove centre noise insulation -fasteners 1 ... 3-.

TT Roadster:

– Release fasteners in wheel housing (left and right)

– Unscrew bolts -arrows 1 … 3-.

Note

Disregard -arrows A and B-.

1. Servicing Motronic injection system 13

Page 18

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

All models:

– Remove left noise insulation -arrows-.

– Remove right noise insulation -arrows-.

TT Roadster:

Note

Collect drained coolant in a clean container for re-use.

– Place drip tray for workshop hoist -VAS 6208- or -V.A.G 1306-

under engine.

– Turn drain plug -1- on radiator anti-clockwise, fit auxiliary hose

to connection if necessary.

– Remove lower coolant hose from radiator by pulling off retain‐

ing clip -2-.

All models:

– Remove tubular cross member -arrows-.

14 Rep. Gr.24 - Mixture preparation - injection

Page 19

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

– Unbolt pulley for power steering pump (counterhold with man‐

drel).

– Unscrew power steering pump from bracket -arrows-.

– Hang power steering pump on lock carrier with hydraulic ho‐

ses -1- and -2- attached.

– If fitted, unbolt bracket -2- for power steering pressure line.

– Unclip coolant hose -1-.

Audi TT 1999 ➤

– Unplug electrical connector -1- at secondary air pump motor -

V101- .

– Move wire clear.

– Unscrew bracket -2- for coolant hose.

– Unscrew bracket -3- for air filter for secondary air pump.

Note

Illustration shows vehicle with direct shift gearbox.

– Unscrew bolts -1- and -2- and remove secondary air pump with

bracket -A-.

1. Servicing Motronic injection system 15

Page 20

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

– Detach electrical connectors -1- for radiator fans at bottom of

radiator cowl.

– Unscrew lower securing bolts -lower arrows- for radiator cowl.

– Remove the radiator cowl with both fans from below.

– Unplug electrical connector -1- for magnetic clutch of air con‐

ditioner compressor.

WARNING

The air conditioner refrigerant circuit must not be opened.

Note

The air conditioner compressor can only be removed from bracket

with upper securing bolt still inserted. To do so, press the engine

simultaneously to the left side with an assembly lever (2nd me‐

chanic is required.) If required, loosen all bolts of the assembly

mounting 1 turn.

– Unscrew bolts -arrow- for air conditioner compressor.

– Tie up air conditioner compressor together with refrigerant ho‐

ses at front of longitudinal member (refrigerant hoses remain

connected).

– Unscrew lower securing bolt -1- for alternator.

– Remove alternator from bracket for ancillary units (electrical

wires remain connected).

– Unscrew clamp -3-.

– Unscrew wire -1- at alternator.

– Detach electrical connector -2-.

– Remove alternator.

16 Rep. Gr.24 - Mixture preparation - injection

Page 21

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

– Unhook connector -arrow- for engine speed sender -G28-

from bracket on guide tube for oil dipstick.

– Unscrew bolt -3- and pull out guide tube for oil dipstick -2-.

– Unscrew bolt -4- and detach vacuum reservoir -1- from mani‐

fold.

– Move vacuum reservoir to side (hoses remain attached).

Audi TT 1999 ➤

– Unscrew bolt -arrow- at bracket for coolant pump for continued

circulation -V51- .

– Unscrew bolts -1 ... 5- and detach bracket for ancillary units.

– Unscrew bolts -arrows- at front of intake manifold.

1. Servicing Motronic injection system 17

Page 22

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

– Detach electrical connectors at ignition coils by releasing tab

-arrow- with assembly tool -T10118- and carefully pulling con‐

nector.

– Attach puller -T10095 A- to ignition coils as shown in illustra‐

tion -arrow- and remove ignition coils one at a time.

– Remove body brace -1- -arrows-.

– Move electrical wire -arrow- clear.

– Loosen hose clips -1- and -2- and remove air hose between

air cleaner housing and throttle valve module -J338- .

18 Rep. Gr.24 - Mixture preparation - injection

Page 23

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

– Unplug electrical connectors -2- and -3-.

– Detach crankcase breather hose -1-.

– Unbolt throttle valve module -J338- from intake manifold

-arrows- and move clear to one side (coolant hoses remain

attached).

Audi TT 1999 ➤

– Disconnect vacuum hoses -1 ... 4- at rear of intake manifold.

Note

The other hoses remain attached on hose bracket.

– Unbolt hose bracket from intake manifold -arrows-.

– Remove rear securing bolts -arrows- for intake manifold.

1. Servicing Motronic injection system 19

Page 24

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

– Protect the intake manifold from damage with a clean cloth

-1-.

– Swing the intake manifold forwards -arrow-.

Note

Cover or plug the intake ports in the cylinder head with a clean

cloth or foam plastic to prevent small items from dropping in.

– Disconnect vacuum hose -arrow- at vacuum unit for intake

manifold change-over.

20 Rep. Gr.24 - Mixture preparation - injection

Page 25

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

– Unclip pipe guide -1- from fuel rail -2-.

– Disconnect vacuum pipe -3- from fuel pressure regulator.

– Unscrew bolts -arrows-.

– Remove fuel rail with fuel injectors from cylinder head and

move clear to one side (fuel lines remain attached).

– Swing intake manifold back to its fitting position and remove.

Installing

Installation is carried out in the reverse order; note the following:

Note

Renew gaskets.

– Install bracket for ancillary units ⇒ 6-cylinder engine, me‐

chanics; Rep. Gr. 13

– Drive back the respective bushes for securing bolts slightly to

facilitate installation of power steering pump, alternator and air

conditioner compressor.

– Install alternator ⇒ Electrical system; Rep. Gr. 27

– Install air conditioner compressor ⇒ Air conditioning system;

Rep. Gr. 87

– Install radiator cowl ⇒ 6-cylinder engine, mechanics; Rep. Gr.

19

– Install secondary air pump ⇒ 6-cylinder engine, mechanics;

Rep. Gr. 26

– Install power steering pump ⇒ Running gear, front-wheel drive

and four-wheel drive; Rep. Gr. 48 .

– Install body brace ⇒ Running gear, front-wheel drive and four-

wheel drive; Rep. Gr. 40 .

– Install tubular cross member ⇒ General body repairs, exterior;

Rep. Gr. 50 .

– Install poly V-belt ⇒ 6-cylinder engine, mechanics; Rep. Gr.

13

– Install noise insulation panels ⇒ General body repairs, exte‐

rior; Rep. Gr. 50 .

– Connect earth strap to battery ⇒ Electrical system; Rep. Gr.

27 .

Audi TT 1999 ➤

– Engine mountings must be adjusted (⇒ 6-cylinder engine,

mechanics; Rep. Gr. 10 ) if bolts for assembly mounting were

loosened.

TT Roadster:

– Fill cooling system ⇒ 6-cylinder engine, mechanics; Rep. Gr.

19 .

1. Servicing Motronic injection system 21

Page 26

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

Tightening torques

Component Nm

Intake manifold to cylinder head 13

Bracket for coolant pump for continued circula‐

tion -V51- to cylinder block

Intake manifold support to intake manifold 20

Throttle valve module -J338- to intake manifold 10

Vacuum reservoir to intake manifold 5

Guide tube for oil dipstick to intake manifold 5

20

1.8 Wiring and component check on engine

control unit with test box V.A.G 1598/31-

Special tools and workshop equipment required

♦ Test box -V.A.G 1598/31-

Note

♦

The test box -V.A.G 1598/31- is designed so that it can be

connected both to the wiring harness for the engine control

unit and to the engine control unit itself at the same time.

♦

The advantage of this is that the electronic engine control sys‐

tem remains fully functional when the test box is connected

(for example, for measuring signals when the engine is run‐

ning).

♦

The instructions for performing the individual tests indicate

whether or not the engine control unit itself also needs to be

connected to the test box.

♦

Always use adapter set -V.A.G 1594 A- to connect test equip‐

ment (e.g. voltage tester -V.A.G 1527 B- , hand-held multime‐

ter -V.A.G 1526 A- etc.).

Procedure

– Remove engine control unit ⇒ page 23 .

Note

If the test box -V.A.G 1598/31- only needs to be attached to the

81-pin connector, the protective housing for the engine control

unit does not need to be removed.

22 Rep. Gr.24 - Mixture preparation - injection

Page 27

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

– Connect test box -V.A.G 1598/31- to connectors on wiring

harness.

– Connect earth clip of test box to earth -arrow-.

– The instructions for performing the individual tests indicate

whether or not the engine control unit itself also needs to be

connected to the test box.

– Carry out test as described in relevant repair procedures.

– After completing test, re-install engine control unit

⇒ page 23 .

1.9 Removing and installing engine control unit

The 60-pin connector of engine control unit -1- is equipped with

a protective housing -4- that is secured with a locking plate -2and shear bolts -3-. To make it more difficult to unscrew the shear

bolts, the threads have additionally been coated with locking fluid.

The protective housing has to be removed before the 60-pin con‐

nector can be unplugged from the engine control unit (e.g. to

connect test box or replace engine control unit).

Audi TT 1999 ➤

Special tools and workshop equipment required

♦ Hot air blower (from wiring harness repair set -VAS 1978- )

♦ Nozzle for hot air blower from the wiring harness repair set -

VAS 1978-

♦ Vice-grip pliers (commercially available)

Removing

– When replacing engine control unit, select diagnosis object

“Renew engine control unit” in “Guided Fault Finding”.

For this purpose, use vehicle diagnostic, testing and information

system -5051 A- .

– Switch off ignition and remove ignition key.

1. Servicing Motronic injection system 23

Page 28

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

– Use screwdriver to pry off caps on wiper arms -arrows- and

slacken off hexagon nuts several turns.

– Detach wiper arms from wiper shafts by moving them slightly

backwards and forwards.

– Completely unscrew hexagon nuts and remove wiper arms.

– Pull off rubber seal -1- on plenum chamber cover.

– Detach plenum chamber cover -2- and lay aside (towards

windscreen).

– Detach electrical connectors for windscreen washer heating.

– Unclip cover -2-.

– Detach 81-pin connector -1- at engine control unit.

– Release retaining tab -arrow- and pull engine control unit for‐

wards out of the bracket.

Note

♦

The 60-pin connector -3- is secured with the protective hous‐

ing and remains attached when removing engine control unit.

♦

When the engine control unit is disconnected, the learnt values

are erased but the contents of the fault memory remain intact.

Caution

The following procedure must be followed exactly to prevent

any damage (burning) to wiring, connectors, insulation and

control units. Observe operating instructions for hot air blower.

24 Rep. Gr.24 - Mixture preparation - injection

Page 29

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

– Select settings on hot-air blower as shown in illustration, i.e.

set temperature potentiometer -2- to maximum heat output

and two-stage air flow switch -3- to position “3”.

Note

Then use hot air blower to heat threaded holes in protective hous‐

ing into which shear bolts have been screwed. This step reduces

inhibiting action of locking fluid on shear bolt thread and makes it

easier to unscrew these bolts.

– Place the engine control unit on a heat-resistant surface (con‐

nectors remain attached).

Caution

The shear bolts and protective housing also become very hot

when heating the threads of the locking mechanism. Take care

to avoid burns. It is also important to ensure that only the thread

is heated and none of the surrounding components if at all

possible. These should be covered if necessary.

Audi TT 1999 ➤

– Direct nozzle -1- of hot air blower at bolt -2- of locking mech‐

anism. You can rest the nozzle on the top section of the

protective housing.

– Switch on the hot air blower and heat the thread for approxi‐

mately 20 to 25 seconds.

1. Servicing Motronic injection system 25

Page 30

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

– Grasp head of bolt -2- with vice-grip pliers -1- and unscrew

shear bolt -arrows-.

– Repeat the procedure for the 2nd shear bolt.

Note

Be particularly careful here, as this shear bolt is in the immediate

vicinity of control unit connector.

– Release the retaining tab and detach the 60-pin connector for

engine control unit.

Installing

Installation is carried out in the reverse order; note the following:

– Reinstall the engine control unit into the protective housing.

– Clean threaded holes for shear bolts to remove any residue

from locking fluid. This can be done by using a thread tap.

– Use new shear bolts.

After installing a new engine control unit, the following operations

must be performed:

– Activate engine control unit in “Guided Fault Finding” under

diagnosis option “Replace engine control unit”.

For this purpose, use vehicle diagnostic, testing and information

system -VAS 5051 A- .

1.10 Checking system pressure, fuel pres‐

sure regulator and residual pressure

Fuel pressure is controlled by the fuel pressure regulator accord‐

ing to the intake manifold pressure. As a result, the pressure drop

at the injectors remains constant at all engine speeds and throttle

openings.

26 Rep. Gr.24 - Mixture preparation - injection

Page 31

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Special tools and workshop

equipment required

♦ K-Jetronic pressure gauge

-V.A.G 1318-

♦ Adapter set -

V.A.G 1318/17-

♦ Hose clip pliers -

V.A.G 1921-

Audi TT 1999 ➤

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

Test requirements

• Fuel pump relay OK.

• Fuel pump OK; checking: ⇒ Fuel supply system, petrol en‐

gines; Rep. Gr. 20 .

• Fuel filter OK

• Battery voltage at least 12.5 V

Checking system pressure

– Briefly open the fuel tank filler cap (to release pressure).

– Open cover of fuse holder and remove fuse 28 for fuel system

pressurisation pump -G6- .

WARNING

The fuel system is pressurised. Before opening the system

place a clean cloth around the connection. Then dissipate

pressure by carefully unfastening the connection.

1. Servicing Motronic injection system 27

Page 32

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

– Disconnect fuel supply pipe -1- by pressing release tab.

– Connect K-Jetronic pressure gauge -V.A.G 1318- with adapt‐

ers -V.A.G 1318/9- and -V.A.G 1318/17- to fuel supply pipe.

– Open cut-off valve on pressure gauge.

• Lever must point in direction of flow.

– Re-insert fuse 28 for fuel system pressurisation pump -G6- in

the fuse holder.

– Start the engine and run at idling speed.

– Measure the fuel pressure.

• Specification: approx. 3.5 bar

– Disconnect vacuum hose at fuel pressure regulator.

• Fuel pressure must increase to approx. 4.0 bar.

– Switch off ignition.

Checking for leakage and checking residual pressure

– Check leak-tightness and residual pressure by watching the

drop in pressure on the pressure gauge.

• After 10 minutes pressure must still be at least 3.0 bar.

If the residual pressure drops below 3.0 bar:

– Start the engine and run at idling speed.

28 Rep. Gr.24 - Mixture preparation - injection

Page 33

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

– Allow pressure to build up, then switch off ignition. At the same

time, close cut-off valve of K-Jetronic pressure gauge V.A.G 1318- (so that lever is perpendicular to direction of flow

-arrow-).

– Observe pressure drop on pressure gauge.

If the pressure now does not drop:

– Check fuel pump non-return valve

If the pressure drops again:

– Open cut-off valve on pressure gauge (lever points in direction

of flow).

– Start the engine and run at idling speed.

– Allow pressure to build up, then switch off ignition. At the same

time tightly clamp-off the return hose (with blue marking).

If the pressure now does not drop:

– Renew the fuel pressure regulator.

If the pressure drops again:

– Check pipe connections, O-rings on fuel rail and injectors for

leaks.

– Check pressure gauge for leaks.

Audi TT 1999 ➤

Note

Before removing the pressure gauge, release the fuel pressure

by opening the cut-off valve. Hold a container under the connec‐

tion.

1. Servicing Motronic injection system 29

Page 34

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

1.11 Dismantling and assembling fuel rail with injectors

1 - Fuel return hose

2 - Fuel supply hose

3 - Fuel rail

4 - Hexagon socket head bolt,

10 Nm

5 - Fuel pressure regulator

6 - O-ring

7 - O-ring

8 - Retaining clip

❑ Check for correct fit on

fuel rail

9 - O-ring

❑ Removing and installing

⇒ page 30

❑ Renew

❑ Lubricate with clean en‐

gine oil

10 - Retaining clip

❑ Check for correct fit on

injector

11 - O-ring

❑ Removing and installing

⇒ page 30

❑ Renew

❑ Lubricate with clean en‐

gine oil

12 - Injector

1.12 Removing and installing injectors

Removing

– Remove intake manifold ⇒ page 10 .

WARNING

The fuel system is pressurised. Before opening the system

place a cloth around the connection. Then dissipate pressure

by carefully unfastening the connection.

30 Rep. Gr.24 - Mixture preparation - injection

Page 35

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

– Disconnect fuel supply pipe -1- and fuel return pipe -2- by

pressing release tabs.

– Remove fuel rail together with injectors ⇒ page 30 . Fuel hoses

remain connected.

– Pull off retaining clip and detach injector.

Note

The fuel hoses must be detached before replacing fuel rail.

Installing

Installation is carried out in the reverse order; note the following:

• Renew the O-rings at all opened connections. (When renew‐

ing the front O-ring, ensure that the plastic cap is not removed

from the injector head. The O-ring must be pulled off over the

plastic cap).

• Lubricate the O-rings with clean engine oil.

• Make sure injectors are installed in correct position.

• Make sure retaining clips are properly connected.

• Position fuel rail with secured injectors on intake manifold and

press evenly into place.

Tightening torque

Audi TT 1999 ➤

Component Nm

Fuel rail to intake manifold 10

1. Servicing Motronic injection system 31

Page 36

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

1.13 Checking injection quantity and spray pattern of injectors; checking for leaks

Special tools and workshop

equipment required

♦ Remote control -

V.A.G 1348/3 A- with

adapter cable V.A.G 1348/3 - 2-

♦ Adapter set -V.A.G 1594 A-

♦ Injection rate tester -

V.A.G 1602-

♦ Test box -V.A.G 1598/31-

Test requirements

• Fuel pressure OK; testing ⇒ page 26

Test sequence

– Remove intake manifold ⇒ page 10 .

– Remove fuel rail together with injectors ⇒ page 30 . Fuel hoses

remain connected.

32 Rep. Gr.24 - Mixture preparation - injection

Page 37

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

Checking for leaks

– Open cover of fuse holder and remove fuse 28 for fuel system

pressurisation pump -G6- .

– Connect remote control -V.A.G 1348/3 A- with adapter cable

-V.A.G 1348/3 - 2- to contact 28a for fuel pump and to the

positive (+) battery terminal.

– Connect battery earth cable.

– Activate the remote control -V.A.G 1348/3 A- .

• The fuel pump should run.

– Visually check the fuel injectors for leaks.

• When the fuel pump is running, no more than 1 to 2 drops a

minute should escape from any one of the injectors.

If the fuel loss is greater:

– Renew defective fuel injector ⇒ page 30 .

Checking injection quantity

– Connect test box -V.A.G 1598/31- to wiring harness for engine

control unit ⇒ page 22 . The engine control unit is not connec‐

ted.

– Use leads from adapter set -V.A.G 1594 A- to bridge contacts

1 and 65 at test box.

Audi TT 1999 ➤

– Detach electrical connectors for fuel injectors by pressing re‐

taining tab in the direction of the -arrow-.

– Place a fuel injector in a measuring glass for injection rate

tester -V.A.G 1602- .

1. Servicing Motronic injection system 33

Page 38

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

– Connect one of the contacts of fuel injector to engine earth

using test lead and crocodile clamp from adapter set V.A.G 1594 A- .

– Connect second contact of fuel injector to remote control -

V.A.G 1348/3 A- using adapter cable -V.A.G 1348/3 - 2- .

– Connect crocodile clamp to positive (+) battery terminal.

– Use leads from adapter set -V.A.G 1594 A- to bridge contacts

1 and 65 at test box.

– If necessary, connect battery earth cable.

– Switch on ignition.

• The fuel pump should run.

– Press the remote control -V.A.G 1348/3 A- for 30 seconds.

– Carry out test for all fuel injectors using a new test glass each

time.

Note

Also check the spray pattern when testing the injection rate. The

spray pattern should be the same for all injectors.

– Once all 6 injectors have been actuated, place measuring

glasses on a level surface.

• Specification: 128 ... 140 ml for each injector

If the measured values for one or more of the fuel injectors do not

meet the specification:

– Switch off the fuel pump (switch off the ignition) and renew the

faulty injector ⇒ page 30 .

If the measured values for all the injectors are outside the speci‐

fication:

– Check fuel pressure ⇒ page 26 .

– Install injectors together with fuel rail ⇒ page 31 .

1.14 Removing and installing Lambda probes (before catalytic converter)

Special tools and workshop equipment required

♦ Lambda probe open ring spanner set -3337-

34 Rep. Gr.24 - Mixture preparation - injection

Page 39

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

Removing

– Remove body brace -1- -arrows-.

– Loosen the Lambda probe that is to be removed about 1 turn

(accessible from above).

1 - Lambda probe 2, before catalytic converter -G108- with

Lambda probe 2 heater -Z28-

2 - Lambda probe, before catalytic converter -G39- with Lamb‐

da probe heater -Z19-

Audi TT 1999 ➤

– Remove centre noise insulation -fasteners 1 ... 3-.

– Unbolt the protective cover -arrows-.

– Detach electrical connector for Lambda probe (before catalytic

converter) that is to be removed and move clear to side.

1. Servicing Motronic injection system 35

Page 40

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

– Unscrew the Lambda probe (before catalytic converter) from

below; ensure that the electrical wire is not damaged when

unscrewing.

1 - Lambda probe 2, before catalytic converter -G108- with

Lambda probe 2 heater -Z28-

2 - Lambda probe, before catalytic converter -G39- with Lamb‐

da probe heater -Z19-

Installing

Installation is carried out in the reverse order; note the following:

Note

♦

Threads of new Lambda probes are already coated with as‐

sembly paste; the paste must not get into the slots on the probe

body.

♦

If reinstalling the old Lambda probes, coat the threads with

high-temperature paste ⇒ Parts catalogue . The paste must

not get into the slots on the probe body.

♦

When installing, the Lambda probe wire must always be reat‐

tached at the same locations to prevent it from coming into

contact with the exhaust pipe.

♦

Secure the heat insulation sleeves in the original position

when installing.

Tightening torques

Component Nm

Lambda probe (before catalytic converter) in

front exhaust pipe

Body brace to body / bracket 20

55

1.15 Removing and installing Lambda probes (after catalytic converter)

Special tools and workshop equipment required

♦ Lambda probe open ring spanner set -3337-

36 Rep. Gr.24 - Mixture preparation - injection

Page 41

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

Removing

– Unbolt the protective cover -arrows-.

– Detach the electrical connector for the Lambda probe (after

catalytic converter) that is to be removed, and move the con‐

nector clear.

Lambda probe (right-side):

– Unscrew wire guide -arrows-.

Audi TT 1999 ➤

Continuation for both sides:

– Unscrew the Lambda probe (after catalytic converter); ensure

that the electrical wire is not damaged when unscrewing.

1 - Lambda probe 2, after catalytic converter -G131- with Lamb‐

da probe 2 heater, after catalytic converter -Z30-

2 - Lambda probe, after catalytic converter -G130- with Lamb‐

da probe heater 1, after catalytic converter -Z29-

Installing

Installation is carried out in the reverse order; note the following:

Note

♦

Threads of new Lambda probes are already coated with as‐

sembly paste; the paste must not get into the slots on the probe

body.

♦

If reinstalling the old Lambda probes, coat the threads with

high-temperature paste ⇒ Parts catalogue . The paste must

not get into the slots on the probe body.

♦

When installing, the Lambda probe wire must always be reat‐

tached at the same locations to prevent it from coming into

contact with the exhaust pipe.

Tightening torque

Component Nm

Lambda probe (after catalytic converter) in cat‐

55

alytic converter

1. Servicing Motronic injection system 37

Page 42

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

28 – Ignition system

1 Checking ignition system

1.1 General notes on ignition system

♦ Always switch off the ignition before connecting or discon‐

necting the battery, otherwise the engine control unit may be

damaged.

♦ A voltage of at least 12.7 V is required for proper operation of

electrical components.

♦ Certain tests may lead to a fault being detected by the control

unit and stored. The fault memory should therefore be inter‐

rogated and (if necessary) erased after completing the tests

and any repair work that may be required.

♦ If the engine starts, runs for a short period and then cuts out

after completing fault finding, repairs or component tests, this

may be due to the immobiliser disabling the engine control

unit. The fault memory must then be interrogated and, if nec‐

essary, the control unit must be adapted.

1.2 Safety precautions

Note the following to avoid injuries or damage to the fuel injection

system or ignition system:

♦ Do not touch or detach the ignition wires when the engine is

running or while starting the engine.

♦ The ignition must be switched off before disconnecting or con‐

necting ignition system wiring, high-voltage wires and test

leads.

♦ Certain tests may lead to a fault being detected by the control

unit and stored. Therefore, interrogate and, if necessary,

erase the fault memory after all repairs and tests.

♦ Always switch off the ignition before cleaning the engine.

1.3 Technical data

Engine code letters BHE (3.2 ltr. / 4V / 184 kW

engine)

Idling speed

Cannot be adjusted; regulated by idling speed stabili‐

sation

Speed governing by

deactivation of fuel injectors

Ignition timing

Not adjustable (determined by control unit)

Ignition system Multi-coil system with 6 ignition coils (output stages in‐

tegrated) connected directly to spark plugs via spark

Spark plugs

Firing order 1-5-3-6-2-4

2)

650 ... 750 rpm

approx. 6,500 rpm

plug connectors

Tightening torque 30 Nm

BPF (3.2 ltr. / 4V / 184 kW

engine)

2)

2) Current values ⇒ Data sheets for exhaust emission test.

38 Rep. Gr.28 - Ignition system

Page 43

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

1.4 Removing and installing parts of the ignition system

1 - Ignition coils with output

stages

❑ Cylinder 1 ignition coil 1

with output stage -N70-

❑ Cylinder 2 ignition coil 2

with output stage N127-

❑ Cylinder 3 ignition coil 3

with output stage N291-

❑ Cylinder 4 ignition coil 4

with output stage N292-

❑ Cylinder 5 ignition coil 5

with output stage N323-

❑ Cylinder 6 ignition coil 6

with output stage N324-

❑ Removing and installing

⇒ page 40

2 - 4-pin connector

❑ For ignition coils with

output stage

3 - Bracket

❑ For connector for knock

sensor 1 -G61-

4 - Bolt, 10 Nm

5 - 3-pin connector

❑ Black

❑ With gold-plated con‐

tacts

6 - Knock sensor 1 -G61-

7 - Bolt, 20 Nm

❑ To ensure correct operation of the knock sensor, it is important to adhere to the specified tightening

torque.

8 - Camshaft adjuster

❑ Exhaust side

❑ With sender wheel for Hall sender 2 -G163❑ After reinstalling, adjust valve timing ⇒ 6-cylinder engine, mechanics; Rep. Gr. 13

9 - Cover (upper) for camshaft timing chain

❑ Removing and installing ⇒ 6-cylinder engine, mechanics; Rep. Gr. 13

10 - Seal

❑ Renew

11 - Hall sender 2 -G163-

❑ For exhaust camshaft

12 - Bolt, 10 Nm

13 - 3-pin connector

❑ Black

❑ With gold-plated contacts

1. Checking ignition system 39

Page 44

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

❑ Mark before removing

14 - Hall sender -G40-

❑ For inlet camshaft

15 - Knock sensor 2 -G66-

16 - 2-pin connector

❑ Black

❑ With gold-plated contacts

17 - Camshaft adjuster

❑ Inlet side

❑ With sender wheel for Hall sender -G40❑ After reinstalling, adjust valve timing ⇒ 6-cylinder engine, mechanics; Rep. Gr. 13

18 - Spark plug

❑ Current values ⇒ Data sheets for exhaust emission test

❑ Removing and installing ⇒ page 41

❑ Tighten to 30 Nm

19 - Valve timing housing

❑ For variable valve timing

❑ Removing and installing ⇒ 6-cylinder engine, mechanics; Rep. Gr. 13

1.5 Removing and installing ignition coils

Special tools and workshop equipment required

♦ Puller -T10095 A-

♦ Assembly tool -T10118-

40 Rep. Gr.28 - Ignition system

Page 45

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

Removing

– Detach electrical connectors at ignition coils by releasing tab

-arrow- with assembly tool -T10118- and carefully pulling con‐

nector.

– Attach puller -T10095 A- to ignition coils as shown in illustra‐

tion -arrow- and remove ignition coils one at a time.

Audi TT 1999 ➤

Installing

Installation is carried out in the reverse order; note the following:

– Insert the ignition coils into the holes so that the flat edges align

with one another -arrows-.

1.6 Removing and installing spark plugs

Special tools and workshop equipment required

♦ Spark plug socket and extension -3122 B-

Removing

– Remove ignition coils ⇒ page 40 .

– Remove spark plugs with spark plug socket -3122 B- .

1. Checking ignition system 41

Page 46

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Motronic injection and ignition system (6-cyl.) - Edition 12.2004

Installing

Installation is carried out in the reverse order; note the following:

– Install ignition coils ⇒ page 40 .

Tightening torque

Component Nm

Spark plug in cylinder head 30

42 Rep. Gr.28 - Ignition system

Loading...

Loading...