Page 1

Service Training

Audi TT Coupé ´07 - Suspension System

Self-Study Programme 381

Page 2

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

The new TT by Audi is a thoroughbred sports car.

The suspension system is one of the features key to

meeting this high standard. The basic TT has a conventional steel-sprung suspension - the so-called

"dynamic suspension system". The new Audi magnetic ride system is optional. It is a semi-active suspension system with magneto-rheologically

controlled dampers.

Sport or comfort damper settings can be selected at

the touch of a button.

The S-line suspension by quattro-GmbH has been

developed to meet the growing customer demand

for vehicle customisation. This suspension is sportier than the dynamic suspension and reduces vehicle ride height by 10 mm.

381_064

Page 3

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Contents

Axles

Front axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Rear axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Brake system

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

System components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

ESP

System components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Operation and displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Steering system

Electromechanical steering system EPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Steering column . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Steering wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Audi magnetic ride

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Functional principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

System components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Special functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Function diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

CAN data exchange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Scope of service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Wheels/tyres

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Self Supporting Tires (SST) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Low tyre pressure indicator 36

Tyre pressure monitoring system (US spec) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

The self-study programme teaches the design and function of new vehicle models,

new automotive components or new technologies.

The self-study programme is not a repair manual!

All values given are intended as a guideline only and refer to the software version valid at the time of preparation of the SSP.

For maintenance and repair work, always refer to the current technical literature.

NoteReference

Page 4

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Axles

Front axle

Overview

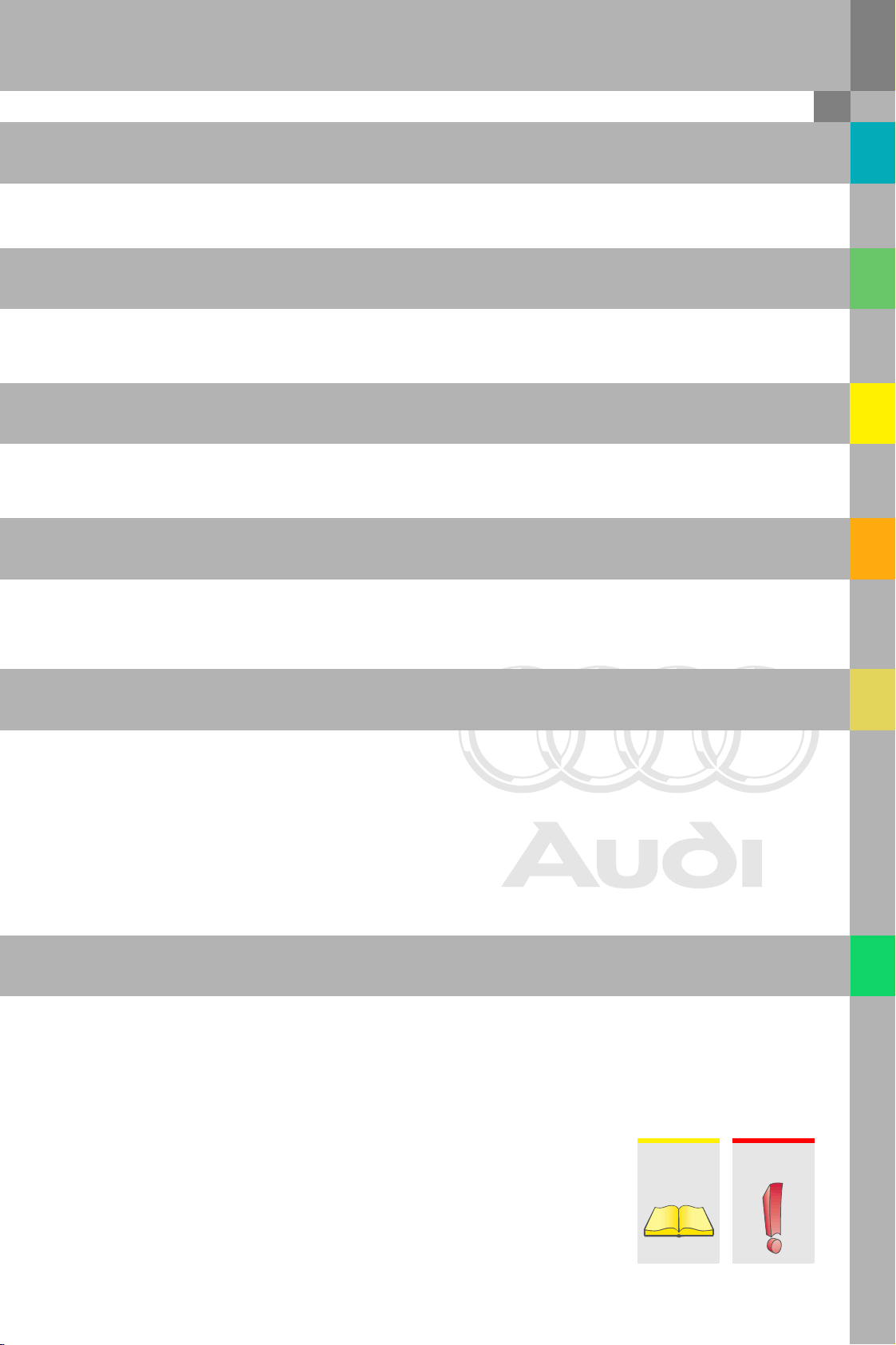

An improved version of the McPherson suspension

is employed. The design of the front axle is identical

to that of the Audi A3. Track width is 13 mm wider

on each side than the Audi A3.

Damper

Swivel bearing

Coupling rod

Detail modifications have been made to reflect the

particularly sporty character of the Audi TT. In addition to the tuning parts (springs, dampers and antiroll bars), the same axle components are used in all

TT suspension variants.

Spring

Ball joint

Anti-roll bar

Wishbone

Subframe

Wheel bearing

381_001

4

Page 5

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

System components

Subframe

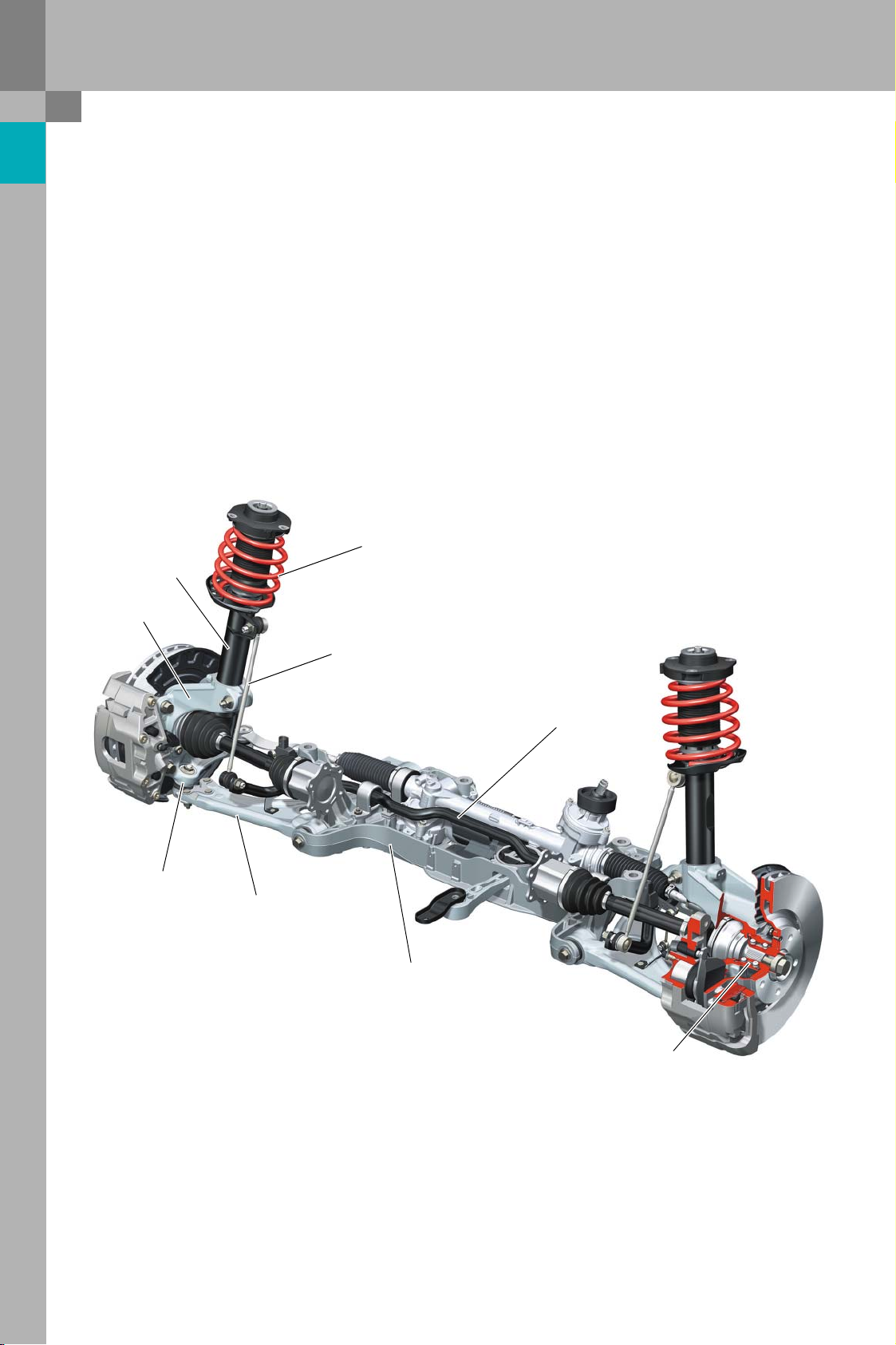

The aluminium subframe bears the wishbones, the

anti-roll bar and the steering gear of the electromechanical steering system. The two brackets for

mounting the wishbones are now common parts.

Swivel bearing

The Audi TT is living proof that sportiness and lightweight design go hand in hand. The illustration

shows the aluminium components of the front axle.

Brackets

Wishbone

Self-aligning support

Subframe

381_002

5

Page 6

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Axles

Swivel bearing, wheel bearing

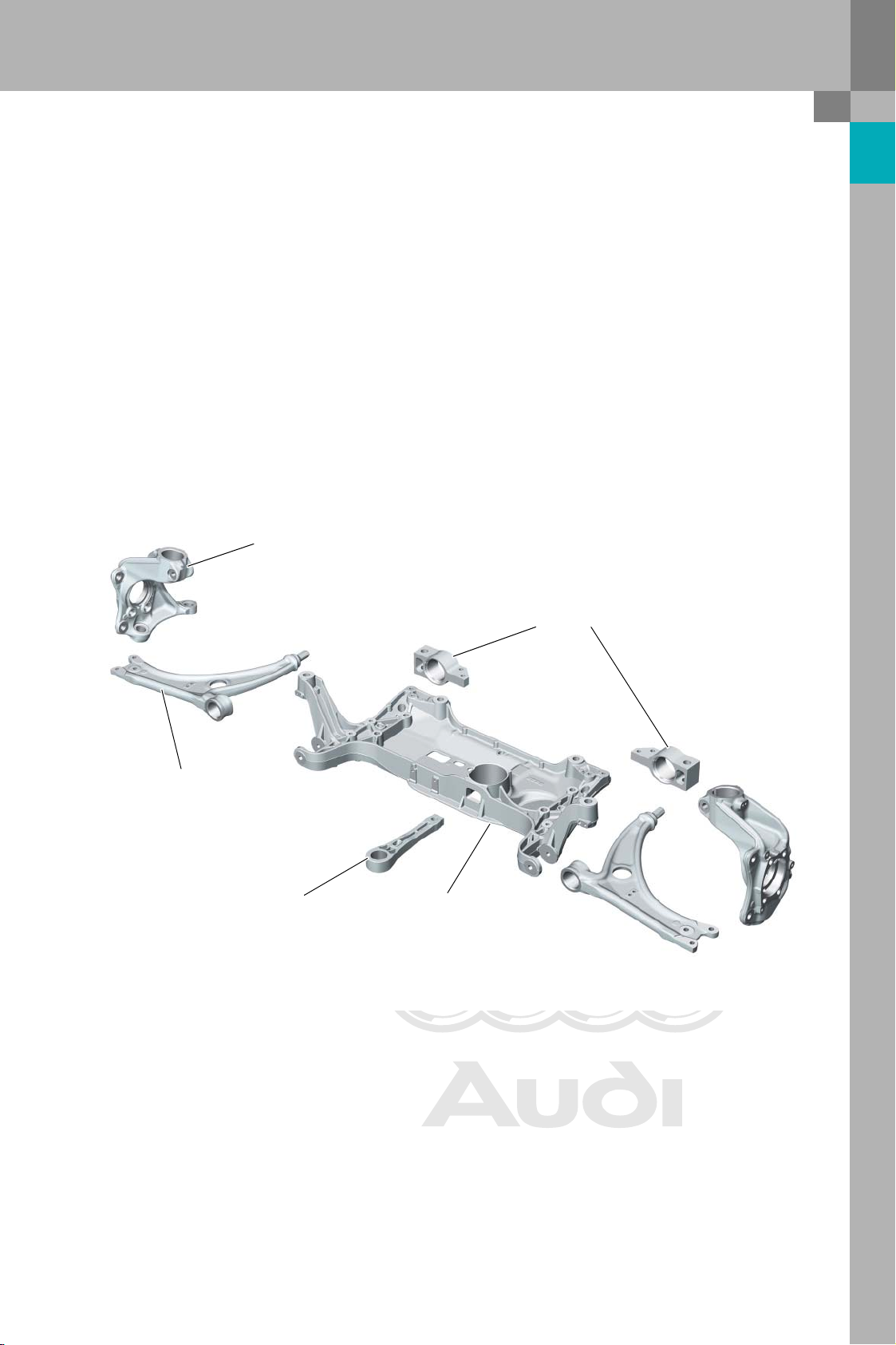

The aluminium swivel bearing manufactured using

Cobapress technology* is a new part.Its geometric

design allows a wider track width to be achieved.

Steel bushes are press fitted into the swivel bearing

at the track rod and ball joint mounting points.

The third generation wheel bearing is bolted to the

swivel bearing.

The wheel bearings are carry-over parts from the

Audi A3. The screws are now coated with a chromium-6 free material to protect the environment.

The suspension strut is connected to the swivel

bearing by a clamp coupling.

Suspension strut

Swivel bearing

Note

Note: Special tool 3424 must always be used to

widen the clamp when installing and removing

the damper!

Wheel bearing

381_003

*: The Cobapress process is a casting process in which the component subsequently undergoes a forging

process. The result is high strength and toughness.

6

Page 7

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

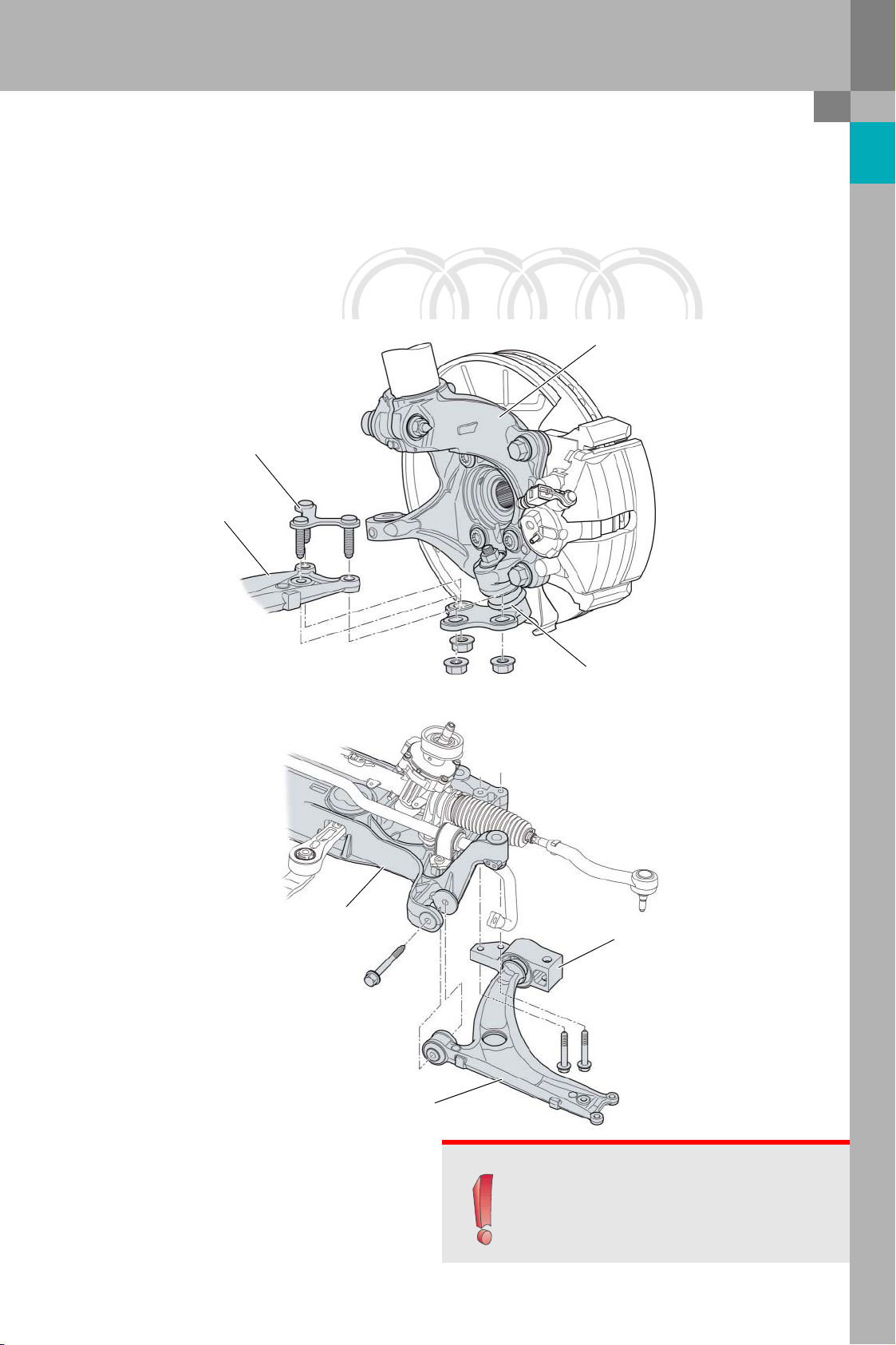

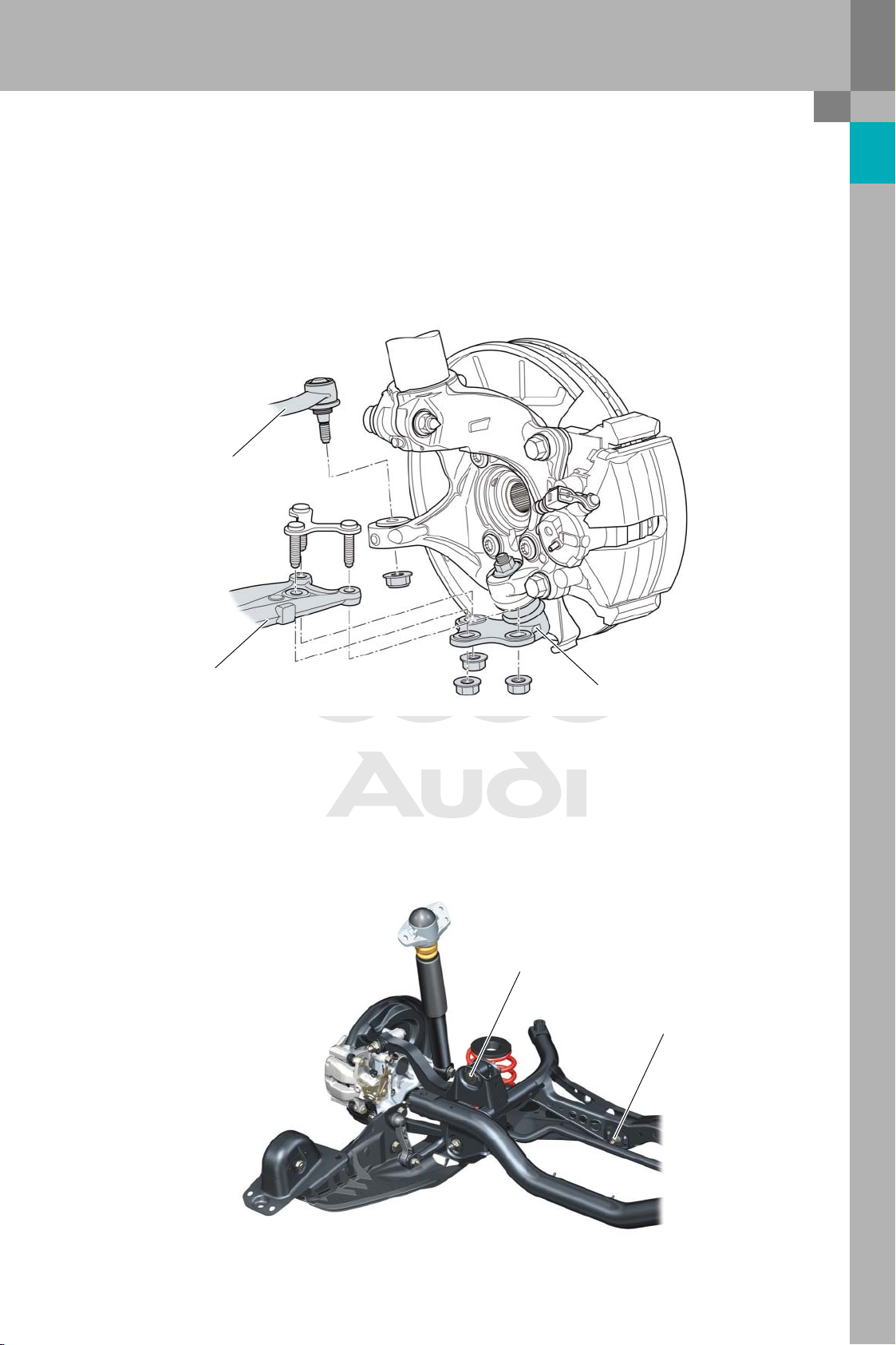

Wishbones, ball joint and bracket

The ball joint is connected to the wishbone at three

bolting points. Compared to the Audi A3, the fastening bolts are integral parts of a separate retaining

element. The bolts and retaining element are

inserted from above through the wishbone and ball

joint.

Retaining element

Wishbone

The wishbone is attached directly to the subframe at

the inside front and to the body at the inside rear by

means of an aluminium bracket.

Swivel bearing

Subframe

Wishbone

Ball joint

Bracket

381_004

381_005

Note

Note: after undoing the threaded connection

between the ball joint and wishbone, always

replace the retaining element.

7

Page 8

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

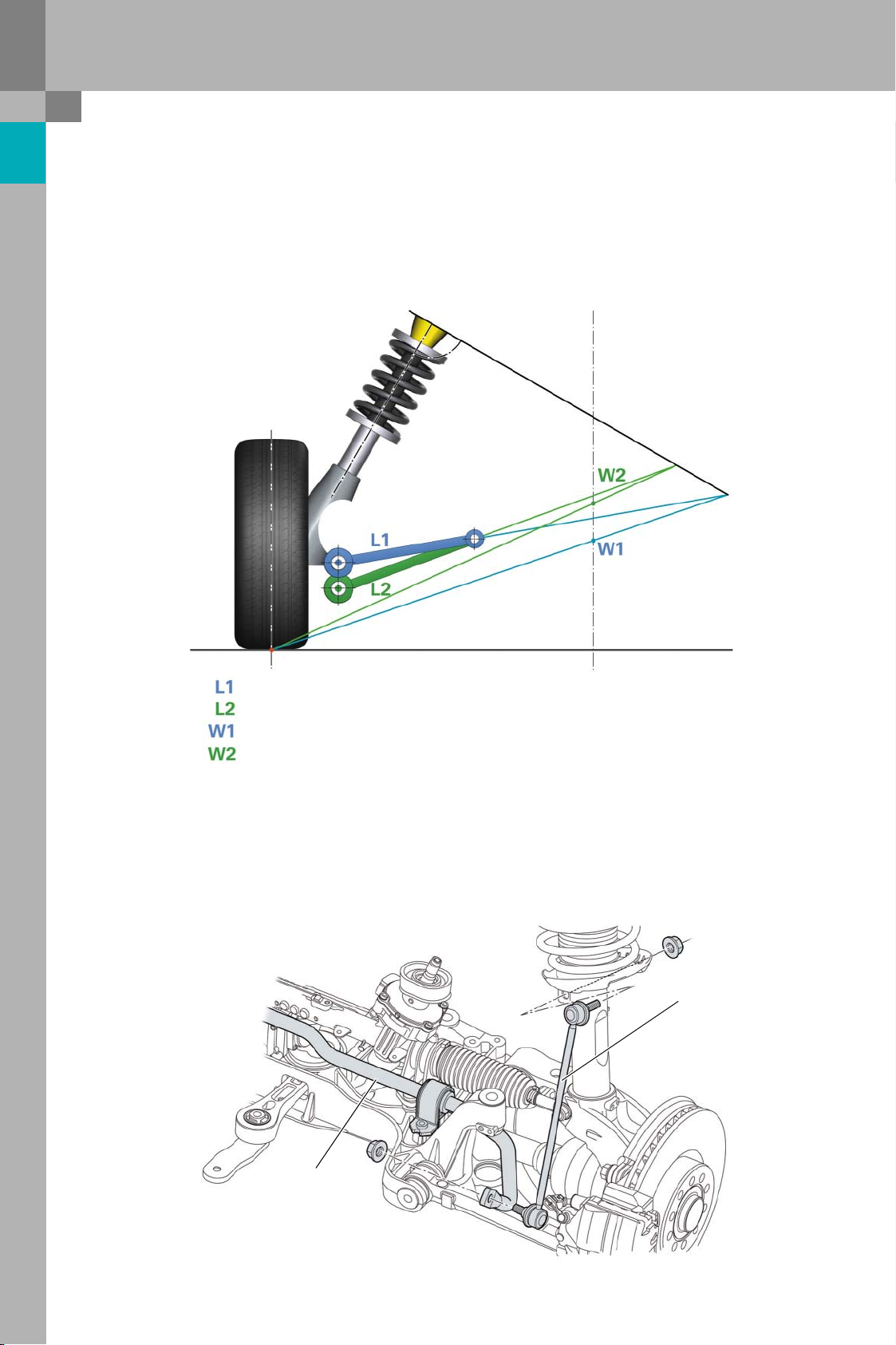

Axles

Wishbones, ball joint and bracket

The ball joint is in a lower position than on the Audi

A3. The result is a higher centre of roll. This

improves roll stabilisation and gives particularly

sporty handling.

The centre of roll is the level with the front axle in

the centre of the vehicle about which the body pivots when subjected to lateral forces, e.g. when cornering.

= position of the ball joint in the Audi A3

= lower position of the ball joint in the Audi TT

= position of the centre of roll in the Audi A3

= higher position of the centre of roll in the Audi TT

Anti-roll bar

A tubular anti-roll bar is used on models with frontwheel drive, while a solid bar is used on quattro

models.

The link rod is a carry-over part from the Audi A3.

381_006

Link rod

8

Anti-roll bar

381_007

Page 9

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

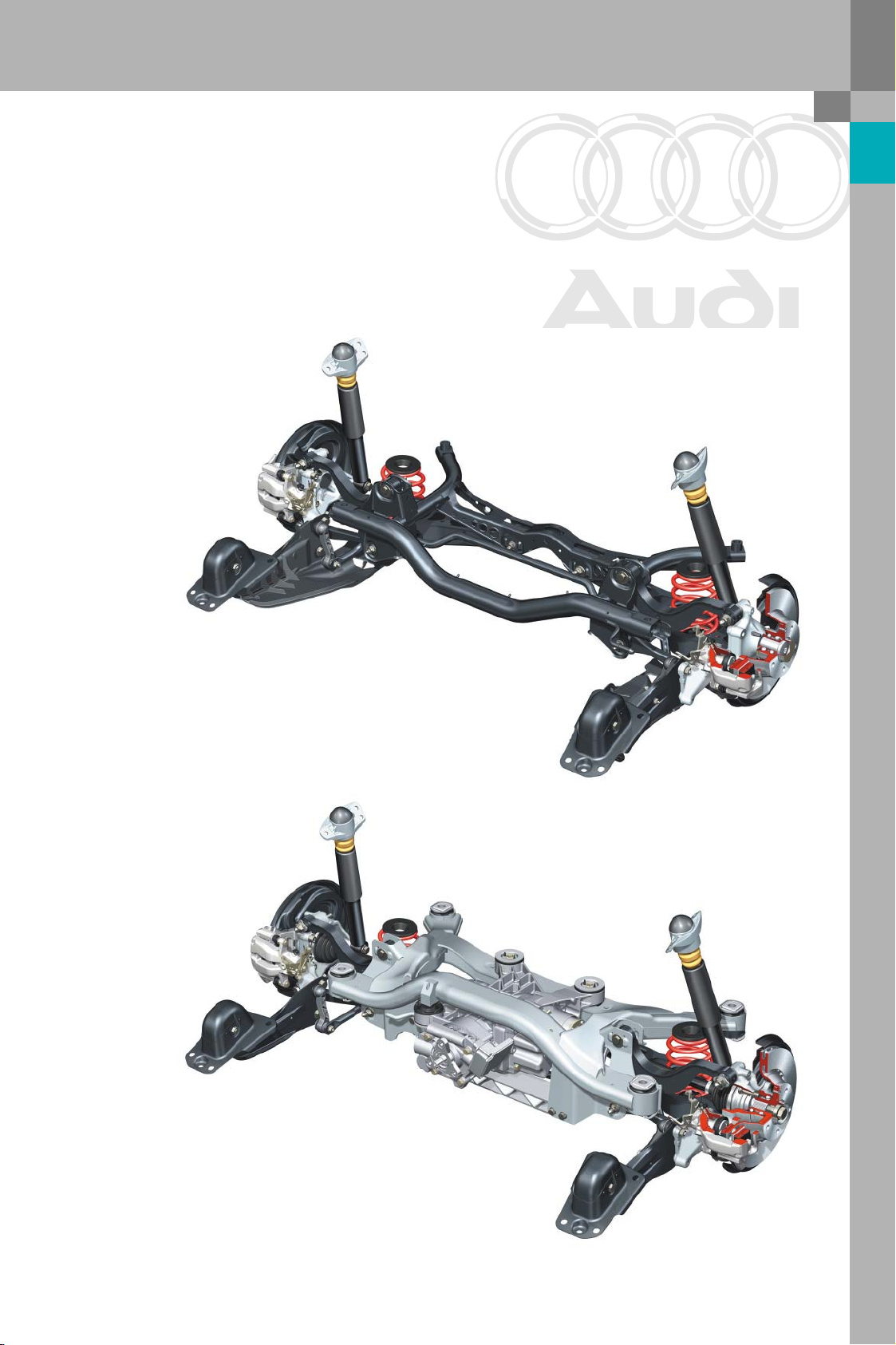

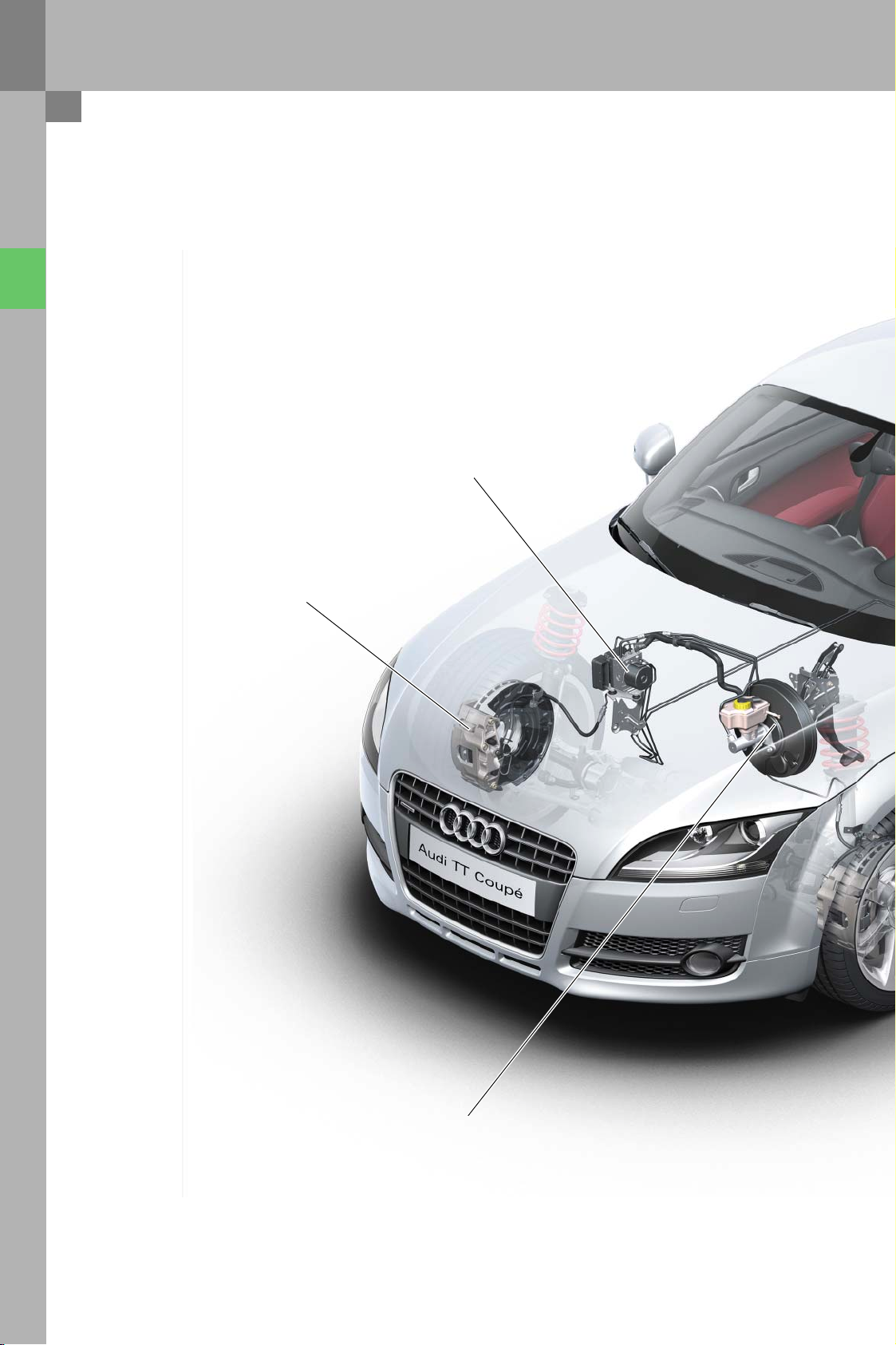

Rear axle

Overview

The rear axle of the Audi TT is basically identical in

design and function to the rear axle on the Audi A3 .

The wheel carriers, damper bearings and wheel

bearings are modified versions of the components

used in the Audi A3. Track width has been increased

by 15 mm on each side over the Audi A3.

Rear axle for front-wheel drive

The suspension and damping components (springs,

dampers and anti-roll bars) have been adapted to

the specific requirements of the Audi TT. Additional

stone chip protection is provided for certain markets. The trailing arms on these models are protected by plastic claddings.

Rear axle for quattro models

381_008

381_009

9

Page 10

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

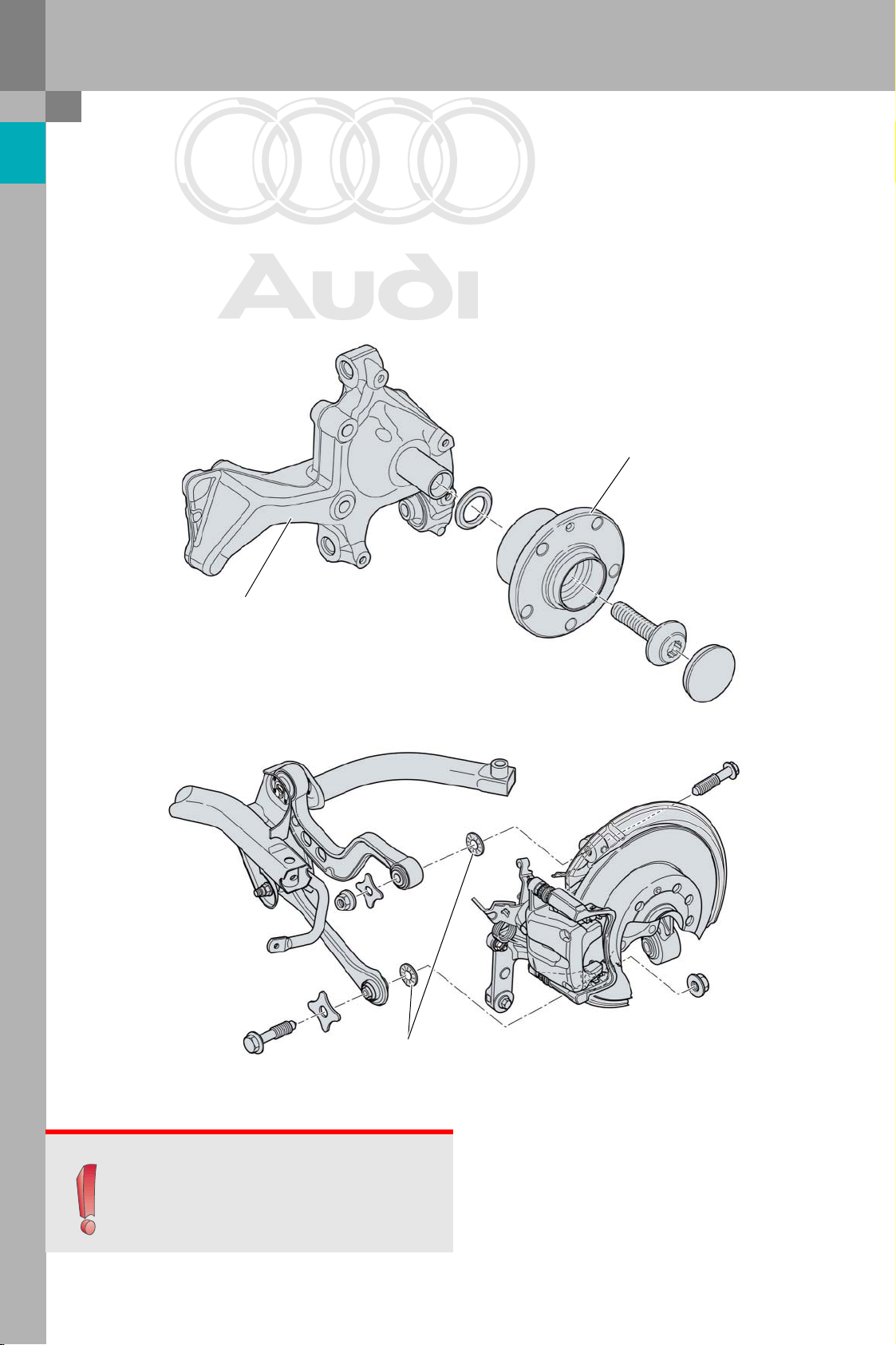

Axles

System components

Wheel carrier, wheel bearing

The wheel carrier has been modified geometrically

in order to increase track width. Front-wheel-drive

models use a second-generation wheel bearing

which is larger than the bearing on the Audi A3.The

diameter of the wheel carrier bearing journal has

been adapted to match the internal diameter of the

wheel bearing.

Wheel carrier

Ribbed washers are used for attaching the track

link, upper wishbones and damper to the wheel carrier.

These washers are required to achieve the necessary surface pressures.

Wheel bearing

381_010

Ribbed washers

381_011

Note

Note: Always replace the ribbed washers during

removal and installation of parts in the service

workshop.

10

Page 11

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Wheel alignment

Front axle

Toe and camber can be adjusted at the front axle.

The toe-out values are adjusted at the track rods.

Unlike on the Audi A3, left and right camber can be

adjusted separately.

Tra c k ro d

Wishbone

The camber is adjusted at the connection between

the wishbone and the guide bearing. For this purpose, the holes in the guide bearing are oblong in

shape.

Guide bearing

381_012

Rear axle

The camber and toe can be adjusted at the rear

axle.The adjustment procedure is the same as for

the Audi A3.

Camber adjustment

Toe adjustment

381_013

11

Page 12

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

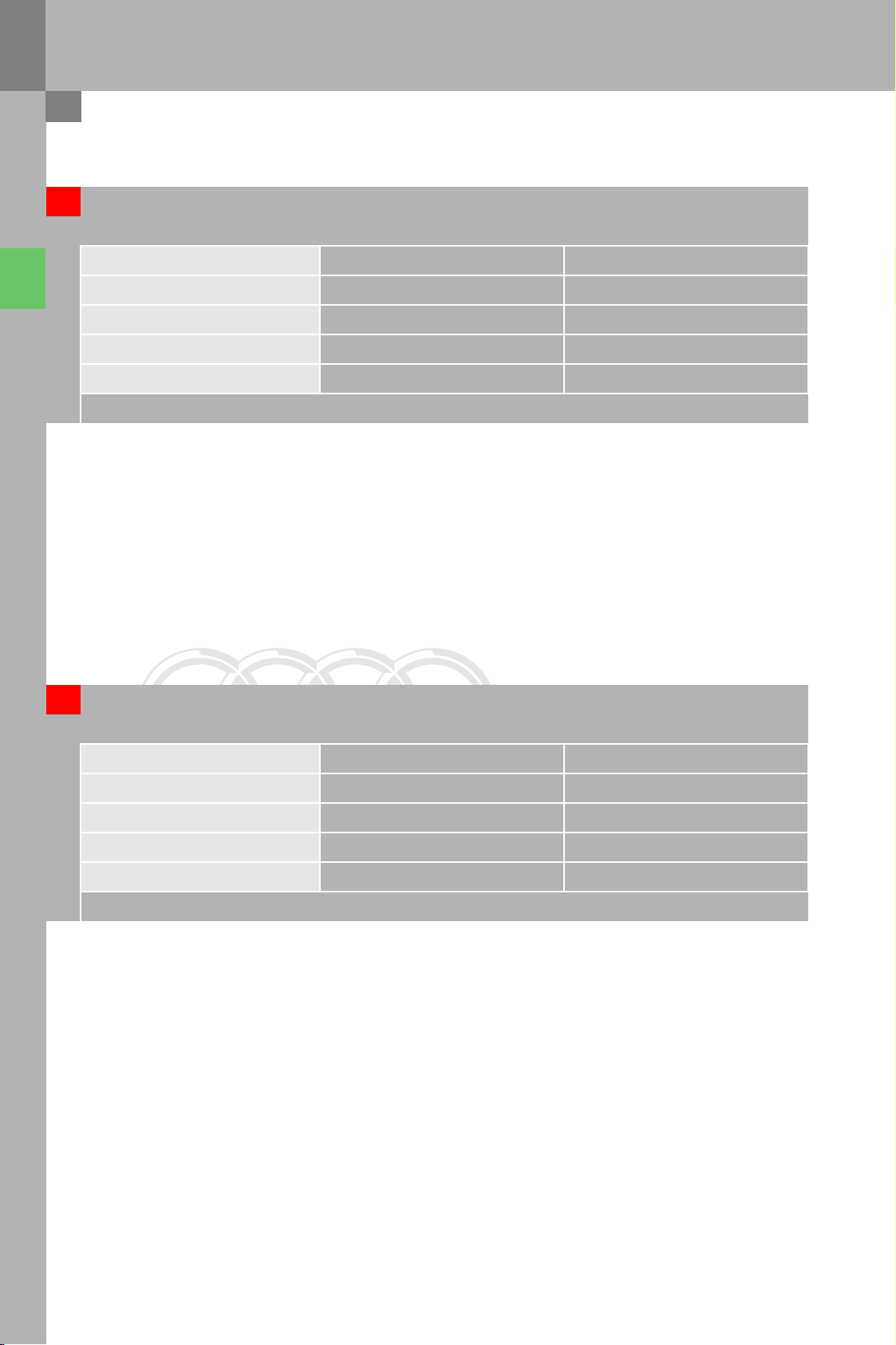

Brake system

Overview

optional Tyre Pressure Monitor

TEVES Mk60E1 with

Front axle brake caliper:

16" for all four-cylinder models

17" for all six-cylinder models

ESP:

10", 11", 7/8", with contactless brake

without dual rate characteristic

12

Brake servo:

light switch

Page 13

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Rear axle brake caliper:

16" for all four-cylinder models

17" for all six-cylinder models

381_014

13

Page 14

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Brake system

Front axle

Engine R4-4V 2.0l TFSI VR6 3.2l MPI

Minimum wheel size 16" 17"

Brake type FN3 FNR-G

Number of pistons 1 1

Piston diameter (mm) 54 57

Brake disc diameter (mm) 312 340

Rear axle

Engine R4-4V 2.0l TFSI VR6 3.2l MPI

Minimum wheel size 16" 17"

Brake type CII 38 CII 41

Number of pistons 1 1

Piston diameter (mm) 38 41

Brake disc diameter (mm) 286 310

14

Page 15

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

System components

Front axle wheel brake

The brake calipers are identical in design and

principle of operation to the brake calipers on the

Audi A3. A zinc-nickel coating is now applied. Brake

calipers are optionally available in a grey finish. The

brake discs for the 16" system have been adopted

from the Audi A3. The brake discs for the 17" system

are a modified version of the discs used on the Audi

A3. This change was necessary due to the modified

rim geometry of the SST wheels.

The Audi TT has new brake hoses with modified

holders on the swivel bearing compared to the Audi

A3.The 16" and 17" splash plates have been adopted

from the Audi A3. Break pad wear is measured in a

conventional fashion on the interior lining of the left

wheel brake. The 17" system is equipped with a

vibration damper. The damper is attached to the

brake caliper by the lower fastening bolt.

381_015

16" wheel brake

17" wheel brake

381_016

15

Page 16

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Brake system

Rear axle wheel brake

The brake calipers are identical in design and principle of operation to those on the Audi A3. The brake

carriers have been modified since the Audi TT has

wider rims than the Audi A3 and, because of this,

the requisite clearance for the handbrake cable

would not have been assured had the A3 brake carrier been adopted unchanged.

381_017

Compared to the Audi A3, the brake calipers have

been shifted 10 mm further inwards. Two new 16"

and 17" splash plates are used. The brake hoses

have been modified. In the Audi TT the transition

point from brake hose to brake line is located on the

side member (it is located on the subframe in the

Audi A3) .

16" wheel brake

381_018

17" wheel brake

16

Page 17

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Power brake unit / brake servo

In the case of the 16" systems, 10" single brake servos are used on left-hand-drive models and 7/8" tandem brake servos on right-hand drive models.

Vehicles with 17" systems are equipped with 11" single brake servos for left-hand-drive models and with

7/8" tandem brake servos for right-hand drive models.

For the Audi TT, no dual rate characteristic* was

applied to the brake servo.

The OHB-V function known from the Audi A3 * was

implemented on vehicles with 3.2l VR6 engine and

dual-clutch gearbox.

* dual rate and OHB-V are described in SSP 313

381_019

Like in Audi A3 models after November 2005, the

contactless brake light sensor is used on the Audi

TT. Brake light and brake test switches are no longer

required on the brake pedal.

The pedal assembly has been adopted from the

Audi A3.

Brake light sensor

381_020

17

Page 18

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

ESP

System components

ESP unit

The Audi TT features a new ESP generation by Continental-Teves with the designation Mk60E1.

As with the Mk25E1 in the current Audi Q7, the

Mk60E1 has analogised switch valves

(4 intake valves and 2 block valves) and an integrated pressure sensor. In the case of analogised

switch valves, the port cross-section is determined

by the activation current. Unlike systems with conventional switch valves with the valve positions

open and closed, more precise brake control is possible.

Note

Due to the use of linearised switch valves, it is

no longer possible to disconnect the control

unit from the hydraulic unit in the service workshop.

In the ESP control unit has the same integrated

functions as in the Mk60 control unit on the Audi

A3, however these functions have been adapted to

the Audi TT. The hill hold assist (hha) and driver

steering recommendation (dsr) functions will be

implemented at a later date. The Audi A3 system

has been modified with regard to the operation of

the ESP Off key.

381_022

Block valve

Inlet valve

Linearised switch valves

ESP hydraulic unit

(excerpt showing the hydraulic

control device for a wheel brake)

381_023

18

Page 19

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Sensor unit G419

The sensor unit comprises senders G200 (lateral

acceleration sender), G202 (yaw rate sender) and, on

models with quattro four-wheel drive, G251 (longitudinal acceleration sender) . The sensor unit has

been adopted from the Audi A3. The service procedures for calibrating the sensors are the same as for

the Audi A3.

Wheel speed sensors G44 - G47

381_024

The wheel speed sensors for wheel speed measurement have been adopted from the Audi A3.

Steering angle sender G85

The steering angle sender is identical in design and

function to the sender on the Audi A3.

381_026

19

Page 20

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

ESP

Operation and displays

The functions of button E256 for ESP and TCS were

extended as follows:

Briefly pressing the button (<3 s) deactivates only

the TCS function. TCS OFF improves traction when

starting from a stop on loose surfaces (e.g. on snow

or sand).

TCS OFF is active up to a road speed of 70 kph. TCS

is switched on automatically when this speed is

exceeded.In all-wheel-drive models, TCS is automatically switched off again when the vehicle's road

speed drops below 70 kph. In front-wheel-drive

models, TCS is not automatically switched off when

the vehicle's road speed drops below this threshold.

381_025

TCS OFF

381_027

If the button is pressed for longer than 3 s, the ESP

function is switched off.

When the brake is applied, TCS and ESP are

switched on again for the duration of the braking

manoeuvre and remain active until a stable driving

condition is restored.

The ESP function is activated automatically if faults

are diagnosed in the magnetic ride system or when

actuating the rear spoiler.

If the button is pressed for longer than 10 s, the ESP

function is switched on again and cannot be

switched off again until the ignition has been

turned off and on again.

ESP

SWITCHED

OFF

381_027a

ESP / TCS ON

381_027b

20

Page 21

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Electromechanical steering system EPS

The electromechanical steering system EPS which

has proved successful in the Audi A3 is also featured in the new Audi TT. The following modifications have been made compared to the Audi A3:

new track rod outer joint with

larger joint diameter and

modified journal geometry

Steering system

reduced steering angle, steering rack

shortened from 80 mm to 78 mm

new control unit due to new

control software without dsr fun ction

In the case of the Audi TT, the power steering assist maps

are determined by the powertrain type (front wheel drive

or quattro) In the case of the Audi A3, the weight of the

front axle is the determinant factor.

381_028

Reference

For detailed information on the design and

function of the EPS system, refer to SSP 313.

21

Page 22

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Steering system

Steering column

A mechanical steering column is used in the Audi

TT. The steering column is basically identical in

design and function to the steering column in the

Audi A3. The following modifications have been

made compared to the Audi A3:

Shear element for crash safety adapted to TT

Longer drive shaft

Steering wheel

A redesigned steering wheel is used in the Audi

TT.All models are fitted with three-spoke leatherbound steering wheels with integrated two-stage

airbag module. In addition to the standard version,

combinations are also available of multifunction,

Tiptronic and leather stitching in various colours.

The skeleton is made of magnesium. The diameter

of the steering wheel rim is 5 mm less than on the

Audi A3. As in the Audi A3, the airbag unit is bolted.

A new feature is the use cage nuts are used for tolerance compensation.The airbag module is centred

in the steering wheel with two locating pins.

Larger adjustment range:

Longitudinal adjustment: ± 30 mm

Height adjustment: ± 25 mm

381_029

381_030

22

Page 23

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Overview

The Audi TT is the first Audi to feature Audi magnetic ride - a new semi-active suspension system

with magneto-rheologically controlled dampers.

Sport or comfort damper settings can be selected at

the touch of a button.

Audi magnetic ride

Shock absorber damping

adjustment warning lamp K189

Shock absorber damping

adjustment valves N336-339

Shock absorber damping

adjustment button E387

ECD control unit (electronically

controlled damping) J250

Vehicle level senders

G76-78,G289

Audi magnetic ride improves driving dynamics and driving comfort for the following reasons:

– reduced body movement (pitch and roll)

– optimised vibration behaviour

– improved road-holding

– improved handling

381_031

23

Page 24

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi magnetic ride

Operating principle

The damping function is based on the magneto-rheological effect. The prerequisite for this is the use of

a special damping fluid. This magneto-rheological

fluid is a suspension consisting of a hydrocarbonbased synthetic oil in which soft magnetic particles

with a diameter of 3-10

µm are held in suspension.

Magneto-rheological fluid in

non-magnetised state

Magnetic particles Magnetic field

To stabilise the fluid, various additives are added.

Applying a magnetic field changes the properties of

the magneto-rheological fluid. The magnetic particles are aligned in the direction of the magnetic

field lines. This alters the flux voltage of the fluid.

Magneto-rheological fluid in

magnetised state

381_032

Piston bores

Magnetic coil not

activated

When the magnetic coils are not activated electrically, the magnetic particles are arranged irregularly

in the damper oil.During the piston stroke, the individual particles are forced with the fluid through the

piston bores. The particle-laden suspension damping fluid has a low resistance to the movement of

the piston. As a result the damping force is low.

Magnetic coil

activated

381_033

When the magnetic coil is activated electrically, the

magnetic particles are aligned with the magnetic

field lines. Thus, long particle chains form in the

vicinity of the piston.

These particle chains are aligned cross-wise before

the fluid enters the piston bores. During the piston

stroke, individual particles break up and are forced

with the fluid through the piston bores. To "break

up" these chains, force must be applied, i.e. work

must be done. The resistance which the piston must

overcome is greater than in the case of a non-energised magnetic coil, and is dependent on the

amount of electrical current and the strength of the

magnetic field.

This allows greater damping forces to be achieved.

24

Page 25

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

System components

Damper

The magneto-rheological dampers are much simpler in design than conventional dampers. The complex conventional damping valves are no longer

required. These have been replaced by bores in the

piston through which the fluid is displaced. In addition, single-tube dampers are used. The magnetic

coils are integrated in the pistons.

Connector

Power is supplied through the hollow piston rods

along discrete lines from control unit J250. Depending on engine type (4 cylinder or 6 cylinder engines),

different front axle dampers are used.A single

damper is used for all engine types on the rear axle.

Bores

Pistons

Cable to electrical control

device

Connector

Front axle damper Rear axle damper

381_034

25

Page 26

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi magnetic ride

Damper

Variable activation of the solenoid valve allows the

shock absorber damping force to be adjusted over a

wide range.

Comparison of the damping force characteristics of Audi magnetic ride and conventional dampers

Tension (rebound)

0

Damper force [N]

Damping force adjustments are made within milliseconds. This allows the damping force to be adapted to

requirements during the bump and rebound cycles.

Sport setting

Comfort setting

Compression (bump)

Adjustment range of Audi magnetic ride

Conventional damper

Damping speed [m/s]

ECD control unit (electronically controlled damping) J250

The control unit receives the measured data from

the vehicle level sender, as well as information on

the current driving condition from the ESP. The control unit processes the data and thus determines

the momentary activation currents for the dampers.

Each damper is activated individually. The dampers

are not activated when the vehicle is stationary. The

control unit is located under the front passenger

seat.

Sport setting

381_035

381_036

26

Page 27

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Vehicle level senders G76-78, G289

The vehicle level senders are identical in design and

function to those used in the Audi A6 and Audi A8.

The sampling rate is 800 Hz. Design and function

are described in detail in SSP 343. Measured data is

read in by control unit J250 across discrete lines,

processed and relayed to the headlight range control, control unit via the CAN bus.

Shock absorber damping adjustment button E387

Warning lamp K189

The button is used to select a damper setting. In

standard operation the dampers are configured for

comfort. A sport damping characteristic can be activated pressing the button. The LED indicator integrated in the button indicates that the sport setting

is active. Depending on dash panel variant, an additional text message may appear.The signal from the

button is read in by the control unit across a discrete line.

381_037

Warning lamp

System faults are indicated by a warning lamp in

the dash panel insert.The warning lamp is checked

whenever the ignition is turned on.

The warning lamp also comes on if the dash panel

insert has been coded incorrectly.

381_038

381_039

27

Page 28

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi magnetic ride

Special functions

Temperature model

The suspension damping becomes softer with

increasing magneto-rheological fluid temperature.

A software module for temperature compensation

is integrated in the control unit. The rising temperature is compensated by increasing the magnetic coil

activation current.

Likewise, the activation current is reduced at low

ambient temperatures.

Temperature is determined indirectly by measuring

the resistance of the magnetic coil.

A current of 3A is applied to the coil for the duration

The required voltage is determined and the resistance is calculated.

The basic value is the resistance measured in a vehicle which has been shut off for at least 6 hours. The

following measurements are correlated with the

basic value. Based on the change in resistance, the

control unit determines the actual temperature in

the shock absorber damper.In addition, the temperature of the control unit is calculated. This is done

by evaluating the electrical currents provided by the

control unit to activate the coils.

of 40 ms.

Temperature shut-off

The magnetic coil activation current must be

increased in order to compensate for the effect of

temperature increase in the dampers. However,

increasing the electrical current causes further

heating of the magnetic coil.Upwards of a defined

threshold temperature of (90°C), therefore, it is no

longer possible for the driver to select 'Sport' mode.

In 'Sport' mode, higher damping forces are produced by increasing the magnetic coil activation

current. Activating the 'Sport' mode would, therefore, cause a further increase in the already high

temperature in the suspension damper. The control

unit is shut down when its temperature exceeds

110°C.

Emergency operation in case of failure in electrical activation of the magnetic coil

In case of failure in electrical activation of multiple

magnetic coils, the magnetic coils of all suspension

dampers are no longer activated.

Suspension damper force characteristic of Audi magnetic ride

Tension (rebound)

0

Damper force [N]

In this case, the most comfortable suspension

damping characteristic is set.

Compression (bump)

28

Damping speed [m/s]

Adjustment range of Audi magnetic ride

Most comfortable damper setting

381_040

Page 29

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Shock absorber test

When the button is pressed for longer than 5 s, the

magnetic coils are activated by the application of a

constant electrical current.In this state, the shock

absorbers can be tested on the test bench.

The indicator LED in the button flashes when the

"shock absorber test" mode is active. The system

exists the mode automatically when the button is

pressed again, after ignition on/off or when driving

at a speed of at least 10 kph.

381_041

29

Page 30

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi magnetic ride

Function diagram

Posi tive

Earth

Powertrain CAN bus

Input signal

Output signal

381_042

J250 ECD control unit (electronically controlled damping)

G76-78,G289 Vehicle level senders

N336-339 Damper adjustment valves

E387 Shock absorber damping adjustment button

30

Page 31

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

CAN data exchange

J250 ECD control unit (electronically controlled

damping)

System status (2,5,8)

Activation of warning lamp, text display (8,5)

Position of button E387 (2,5,8)

Height front right, front left, rear right, rear left (4)

Automatic activation ESP (2,5,8)

J533 Diagnostic interface (8)

Date, time

Terminal 15 -counter

Mileage (km)

Time n ot in use

J519 Onboard power supply control unit (9)

Status of terminal 50

J220 Motronic control unit (1)

Momentary position of brake light switch, brake test

switch

Coolant temperature

Intake air temperature (ambient temperature)

Engine torque

Driver torque input

J104 ESP control unit (2)

ESP on or off

ESP system status

Momentary vehicle speed

ABS active

Lateral acceleration

Brake pressure

Yaw r a te

J527 Steering column electronics control unit (3)

G85 Wheel angle sender

Max. steering angle

Steering speed

Status of terminal 30

Information sent by control unit J250

Information received and evaluated

by control unit J250

J431 Headlight range control,

control unit (4)

(receiver only)

J285 Control unit with display in dash panel insert (5)

Time not in use of the vehicle

Status of combined light (terminal 58d)

Ambient temperature

VIN

381_043

Powertrain CAN bus

Dash panel insert CAN bus

Convenience CAN bus

31

Page 32

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi magnetic ride

Service work

Address

The system can be addressed in the diagnostic

tester under the address: 14 Wheel damping.

Coding

The coding tells the control unit the powertrain type

and engine type of the vehicle. The control unit

accepts the new coding after ignition on/off.

1 = heavy engine (6-cylinder)

3 = lightweight engine (4-cylinder)

3 = coupé with front-wheel drive

8 = coupé quattro

System initialisation - teaching in the new standard

position

The system initialisation must be performed when

the control unit J250 and/or one or more vehicle

level senders is replaced. The characteristic curves

of the vehicle level sender are stored in the control

unit

During the system initialisation procedure, the control unit is informed which vehicle ride heights at

the wheel positions match the actual measured values generated by the vehicle level sender. If these

assignments are known to the control unit, then all

measured values generated subsequently by the

vehicle level sender can be converted to vehicle ride

heights. The basic system initialisation procedure is

identical to the procedure for initialising the aas

systems in the A6 and A8. The system initialisation

can only be performed when the code control unit is

coded.

381_046

381_045

32

Page 33

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Final control diagnostics

The shock absorber dampers can be activated selectively in the final control diagnostics.

The shock absorber dampers are activated by applying a current of 2A.

Data blocks

The data blocks are used to check key system status

information.The temperature values calculated for

the dampers and control unit, for example, are represented in data block 28.

Cold starting

When control unit J250 or shock absorber dampers

are replaced, the control unit must determine the

electrical resistance values of the damper coils at

ambient temperature. The control unit saves these

values as "standard values" for purposes of temperature compensation (refer to "Special functions temperature model").

This function is activated automatically after ignition on, provided the vehicle has been out of use for

at least 3 hours (e.g. even after a a cold start in the

morning) . During this time not in use, the temperatures of the dampers have adjusted to the ambient

temperature. If the mechanic has fitted shock

absorber dampers which are already at ambient

temperature (e.g. parts sourced directly from the

spare parts warehouse), the resistance measurement function can be started immediately by activating the "Cold start" function with the diagnostic

tester.

Flashing

The control unit software can be flashed by an external data carrier (CD, online interface) .

33

Page 34

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Wheels and tyres

Overview

Engine Basic wheels Optional wheels Winter wheels

4-cylinder

6-cylinder

7.5J x 16 ET 45 (1)

Cast aluminium

wheel painted

225/55 R 16

8.5J x 17 ET 50 (2)

Forged aluminium

wheel painted

245/45 R 17

8J x 17 ET 47 (3)

Cast aluminium

wheel painted

225/50 R 17

9J x 18 ET 52 (4)

Cast aluminium

wheel painted

245/40 R 18

9J x 18 ET 52 (5)

Cast aluminium

wheel polished,

bicolor

225/50 R 17

9J x 18 ET 52 (6)

Cast aluminium

wheel painted

245/50 R 18

7J x 16 ET 47 (7)

Cast aluminium

wheel painted

225/50 R 17

7J x 17 ET 47 (8)

Forged aluminium

wheel painted

225/50 R 17

9J x 18 ET 52 (9)

Cast aluminium

wheel painted

245/40 R 18

also available optionally as SST wheel

381_047

34

Page 35

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Self Supporting Tires (SST)

SST tyres have run-flat capability because of their

modified design compared to conventional tyres.

Much stiffer tyre sidewalls enable the vehicle to

drive on for up to 50 km at a maximum speed of

80 kph even after a total loss of pressure.

Due to their modified tyre geometry, special wheels

with the designation EH2 (extended hump 2) are

used for SST tyres.To prevent inward displacement

of the tyre beads in case of loss of tyre pressure, the

bead seating has been modified substantially in

comparison with conventional wheels. The bead is

seated in a recess which supports the tyre towards

the inside of the rim.

The special 17" wheels on the Audi TT can be used

both for conventional tyres and for SST tyres. In the

case of the 18" wheels, conventional tyres are available in combination with conventional rims. SST

tyres are always combined with the low tyre pressure indicator.

381_048

Conventional wheel geometry

extended hump 2

Note

Tyres run in "limp home" mode must always be

replaced!

Special tools must be used to fit and remove

SST tyres.For detailed information, refer to the

"Workshop Equipment" catalogue

381_049

35

Page 36

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Wheels and tyres

Low tyre pressure indicator

Overview

In all markets except North America the Audi TT features a newly developed low tyre pressure indicator.

J285

J533

J793

Being an indirect measuring system, no tyre pressure sensors are installed in the wheels.

E492

J104

G44

G45

J285 Control unit with display in dash panel insert

J533 Data bus diagnostic interface

J793 Tyre pressure monitor control unit 2

E492 Tyre pressure monitor display button

J104 ESP control unit

36

G44-47 Wheel speed sensor

Dash panel insert CAN bus

Powe rtrain CA N bus

G46

G47

381_050

Page 37

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Design and function

Data processing in the Audi TT is performed by control unit J793, and is no longer an integral part of

the ESP control unit. The control unit is located

behind the dash panel insert.

Tyr e pre ssu re m on i tor di s play

control unit 2 J793

381_051

37

Page 38

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Wheels and tyres

Design and function

Using a new evaluation method, it is now possible

to detect simultaneous pressure loss to at multiple

wheels. Tyre pressures are monitored simultaneously using two different concepts.

1. Tyre circumference monitoring

– Tyre circumference decreases as a function of

loss of pressure. As a result the wheel must

rotate more quickly to cover the same distance as

a fully inflated tyre. Wheel speeds are transmitted to control unit J793 by the ESP control unit. In

the current Audi A3, the wheel speeds of the

diagonal wheels are added and both diagonal

sums are correlated with one another. In this

way, allowance is made for different wheel

speeds when cornering. In the Audi TT, the tyre

circumferences are compared axle by axle and

2. Tyre vibration monitoring

– Torsional vibration is excited in each tyre while

rolling, due to road surface unevenness. These

vibrations can be determined by evaluating the

wheel speed signals. When the tyre pressure

decreases, the vibration characteristics

change.This monitoring concept, which is an

additional feature compared to the Audi A3, it is

now possible to reliably detect simultaneous loss

of pressure at multiple wheels, as for example

occurs over time at all four wheels due to diffu-

sion.

side by side.

Allowance is made for yaw rate and steering

angle when cornering.

38

Page 39

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Operation and displays

Tyre pressure monitoring is activated with the SET

key. This function must always be activated when

tire pressures are changed or different wheels/tyres

are fitted to the vehicle. This can only be done when

the ignition is on and the vehicle stationary. The

SET key must be pressed for at least 5 seconds in

order to activate the tyre pressure monitoring

function.

381_061

Warnings are always indicated by the warning lamp

in the dash panel insert.

For this purpose, the warning lamp is activated in

two colours.

381_054

The following displays are possible:

– In the event of a rapid loss of pressure at a single

wheel (tyre damage), the red warning lamp is

activated. If the vehicle a driver information system, an additional text display appears indicating the position of the wheel affected.

– In case of slow loss of pressure, which occurs

gradually at multiple wheels due to diffusion, the

red warning lamp is also activated. In this case,

the optional text display appears but no positional information is given. The displays are activated when the tyre pressure drops below an a

coded minimum value.

– When system faults are detected, the yellow

warning lamp is activated.

39

Page 40

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Wheels and tyres

Operation and displays

The teach-in process is performed once after the

SET key is pressed for the low tyre pressure indicator. During the next trip, the control unit saves the

measured wheel speeds and the vibration characteristics of the wheels in various vehicle operating

states. The vehicle operating states are basically

defined by the following parameters: vehicle speed,

steering angle, transverse acceleration and yaw

velocity. These teach-in values subsequently make

up the target data which is used for monitoring.

After approximately 10 minutes of driving, it is

already possible to detect a breakdown (rapid loss

of pressure) . Approximately 60 minutes of driving

are required to detect diffusion loss (slow loss of

pressure).

381_061

Service work

Address

The system can be addressed in the

diagnostic tester under the address:

4C Tyre pressure monitor II.

Vehicle self-diagnostics

Select diagnostic

function

Display all diagnostic functions

02 - Query fault memory

05 - Clear fault memory

06 - End of output

07 - Encode control unit

Encoding the subbus system

08 - Read data block

16 - Access authorisation

Read out Challenge immobiliser IV

Activate immobiliser IV

Identification services

4C - Tyre pressure monitor II

8J0907274 8J0907274

J793 TPM+ H03 --- 0100

Coding 614100

Dealership number 98765

Goto Print

381_056

40

Page 41

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Coding

The coding tells the control unit the system variant,

powertrain type, gearbox type, wheel size and type

of tyre used on the vehicle. The control unit accepts

the new coding after ignition on/off.

Tyre type and size (16"-18", standard tyre, SST tyre)

Powertrain type (front, quattro, gearbox variant)

6 = PR No. 7K6 (= low tyre pressure indicator)

Data blocks

The data blocks are used to check key system status

information.

41

Page 42

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Wheels and tyres

Function diagram

381_057

Posi tive

Earth

Powertrain CAN bus

Input signal

Output signal

42

J793 Tyre pressure monitor control unit 2

J104 ESP control unit

E492 Tyre pressure monitor display button

A Signal from wheel speed sensor, rear right

B Signal from wheel speed sensor, rear left

C Signal from wheel speed sensor, front right

D Signal from wheel speed sensor, front left

Page 43

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

CAN data exchange

J793 Tyre pressure monitor control unit 2

System status (all)

Activation of warning lamp, text display (7,6)

J533 Diagnostic interface (7)

Date, time

Ter mina l 15 - coun ter

Mileage (km)

Reversing light switch

Tra il e r d ete cte d

J285 Control unit with display in dash panel

insert (6)

Displayed vehicle speed

Handbrake activated

Error status, ambient temperature

J220 Motronic control unit (1)

CCS status

Clutch switch

Coolant temperature

Engine torque

Engine speed

Gearbox variant

J104 ESP control unit (2)

ESP system status

ABS active

EBD, EDL and ESP intervention

TCS and EBC requ est

TCS shift control

Brake light sensor

Lateral acceleration

Yaw rat e

J527 Steering column electronics control unit (3)

G85 Wheel angle sender

max. steering angle

J217 Automatic gearbox control unit (4)

Selector mechanism active

Target gear or selected gear

Selector lever position/driving program

Torque converter lock-up clutch

Information sent by control unit J793

Information received and evaluated by

control unit J793

J492 Four-wheel drive control unit (5)

Error status

Clutch open

Clutch torque

Clutch stiffness

381_058

Powe rtrain CA N bus

Dash panel insert CAN bus

43

Page 44

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Wheels and tyres

Tyre pressure monitoring system (US spec)

Overview

The Audi TT for the North American market uses an

improved version of the tyre pressure monitoring

system as featured previously in the Audi A6 (USA)

.It is a direct measuring system with tyre pressure

sensors in the wheels.

J285

J533

J502

E492

G222

J285 Control unit with display in dash panel insert

J533 Data bus diagnostic interface

J502 Tyre pressure monitor contro l uni t

E492 Tyre pressure monitor display button

G222-225 Tyre pressu re sensors

44

G223

G224 G225

381_059

Dash panel insert CAN

Powertra in CAN bus

Page 45

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Design and function

In the Audi TT the rear tyre pressure monitor aerial

R96 is integrated in the tyre pressure monitor control unit J502.The control unit is fitted in the low

tyre pressure indicator behind the dash panel

insert. In the case of the tyre pressure monitoring

system, communication with the vehicle periphery

via the convenience CAN bus.

Tyre pressure monitoring

The aerial receives the radio signals from tyre pressure sensors G222-G226. The sensors operate at a

radio frequency of 315MHz. The sensors are identical in design and function to those on the Audi A6.

A new feature is the use of the valve body as a

transmitter antenna. The valve body and sensor can

no longer be separated. As with the current models

A4, A6 and Q7, the sensors do not start to transmit

until the wheels being to turn. To meet the countryspecific statutory requirements, the battery service

life is 10 years. The tyre pressure of the spare wheel

is not monitored. When the customer orders a fullsize spare wheel, the sensor is already installed in

the wheel if the vehicle is equipped with a tyre pressure monitoring system.

Tra il er

system J502

381_051a

381_060

The E492 button used in the tyre pressure monitoring system is identical to the button used by the low

tyre pressure indicator. Pressing the button displays

the actual tyre pressures as new target pressures.

As with the low tyre pressure indicator, the button is

connected to the control unit by discrete lines.

381_061

45

Page 46

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Wheels and tyres

Design and function

Tyre pressure warnings are indicated by the yellow

warning lamp in the dash panel insert. No positionrelated warning is given. Warnings are indicated in

accordance with country-specific statutory requirements at a residual tyre pressure of 75% or less.Tyre

pressures are determined taking into account the

tyre air temperature.

381_054

46

Page 47

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Service work

The main changes to the service work on the low

tyre pressure indicator are listed in the following.

Coding

The coding tells the control unit the system variant,

powertrain type, gearbox type, wheel size and type

of tyre used on the vehicle. The control unit accepts

the new coding after ignition on/off.

Target pressure ,Y bar

Target pressure X, bar

Tyre (standard, limp-home, extra load)

8 = PR No. 7K8 (= tyre pressure monitoring system)

Adaption

The control unit learns the new tyre pressure sensors automatically when the ignition is turned on

after the vehicle has been shut off for at least 20

minutes. When new tyre pressure sensor identification numbers are recognised, the fault indicator

lamp is activated. The driver enable monitoring of

the actual tyre pressures by pressing the SET key.

The system is now ready for operation again.

The tyre pressure sensor identification numbers

can be transmitted manually to the control unit

using the function "10 Adaption". This bypasses the

waiting period. Each identification number is indicated on the tyre pressure sensor housing.

Note

The handheld transmitters for the tyre pressure

monitoring system VAS 6287 cannot be used on

the tyre pressure monitoring system of the

Audi TT.

47

Page 48

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Vorsprung durch Technik www.audi.de

381

All rights reserved.

Technical specifications

subject to change without

notice.

Copyright

AUDI AG

I/VK-35

Service.training@audi.de

Fax +49-841/89-36367

AUDI AG

D-85045 Ingolstadt

Technical status: 05/06

Printed in Germany

A06.5S00.26.20

Loading...

Loading...