Page 1

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Service

Workshop Manual

Audi TT 2007 ➤

Running gear, front-wheel drive and four-wheel drive

Edition 08.2010

Service Department. Technical Information

Page 2

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Service

List of Workshop Manual Repair GroupsList of Workshop Manual

Repair GroupsList of Workshop Manual Repair Groups

Re pa ir G ro up

00 - Technical data

40 - Front suspension

42 - Rear suspension

44 - Wheels, tyres, vehicle geometry

48 - Steering

Technical information should always be available to the foremen and mechanics, because their

careful and constant adherence to the instructions is essential to ensure vehicle road-worthiness and

safety. In addition, the normal basic safety precautions for working on motor vehicles must, as a

matter of course, be observed.

All rights reserved.

No reproduction without prior agreement from publisher.

Copyright © 2010 Audi AG, Ingolstadt A005TT00120

Page 3

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Running gear, front-wheel drive and four-wheel drive - Edition 08.2010

Contents

00 - Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Running gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 Wheels, tyres . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 Proper disposal of fluid-filled components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.1 Releasing gas in gas-filled shock absorbers (front) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.2 Releasing gas in gas-filled shock absorbers (rear) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.3 Releasing gas in Audi magnetic ride shock absorbers (front) . . . . . . . . . . . . . . . . . . . . . . 3

2.4 Releasing gas in Audi magnetic ride shock absorbers (rear) . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Checking shock absorbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.1 Leaks at shock absorbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2 Checking shock absorbers when removed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.3 Checking shock absorbers on shock tester . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

40 - Front suspension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1 General notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2 Contact corrosion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.3 Repairing threads in longitudinal member . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.4 Lifting suspension to unladen position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.5 Exploded views of front axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2 Subframe, anti-roll bar, wishbone, swivel joint, vehicle level sender . . . . . . . . . . . . . . . . . . 14

2.1 Exploded view of subframe, anti-roll bar, wishbone, swivel joint, vehicle level sender . . . . 15

2.2 Removing and installing subframe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.3 Servicing subframe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.4 Locating subframe in position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.5 Removing and installing anti-roll bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2.6 Removing and installing wishbone and mounting bracket . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.7 Renewing bonded rubber bush in wishbone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.8 Renewing mounting bracket for wishbone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.9 Removing and installing swivel joint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.10 Checking swivel joint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2.11 Removing and installing front left vehicle level sender G78 and front right vehicle level sender

G289 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3 Wheel bearing housing, wheel bearing unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.1 Exploded view of wheel bearing housing and wheel bearing unit . . . . . . . . . . . . . . . . . . . . 39

3.2 Removing and installing wheel bearing housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.3 Removing and installing wheel bearing unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4 Audi magnetic ride (AMR) - electronic damping control . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.1 Overview of Audi magnetic ride (AMR) - electronic damping control . . . . . . . . . . . . . . . . . . 45

4.2 Removing and installing electronically controlled damping control unit J250 . . . . . . . . . . 46

4.3 Procedure for re-adapting reference position with vehicle diagnostic, testing and information

system VAS 5051B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5 Suspension strut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.1 Exploded view of suspension strut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.2 Removing and installing suspension strut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.3 Servicing suspension strut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6 Drive shafts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6.1 General notes: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6.2 Loosening and tightening hexagon bolt securing drive shaft to wheel hub . . . . . . . . . . . . 56

6.3 Loosening and tightening twelve-point bolt securing drive shaft to wheel hub . . . . . . . . . . 56

Contents i

Page 4

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Running gear, front-wheel drive and four-wheel drive - Edition 08.2010

6.4 Removing and installing drive shaft (version with bolted flange on inner joint) . . . . . . . . . . 58

6.5 Removing and installing drive shaft with sliding CV joint (version with splines on inner

joint) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

6.6 Removing and installing drive shaft with triple roller joint AAR 3300i (with splines for stub

shaft on gearbox) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

6.7 Removing and installing drive shaft with triple roller joint AAR 3300i (with splines for insertion

in gearbox) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.8 Servicing drive shaft (sliding inner CV joint with 100 mm dia.) . . . . . . . . . . . . . . . . . . . . . . 74

6.9 Servicing drive shaft (sliding inner CV joint with 108 mm dia.) . . . . . . . . . . . . . . . . . . . . . . 82

6.10 Servicing drive shaft (sliding inner CV joint with splines, 100 mm dia.) . . . . . . . . . . . . . . . . 88

6.11 Checking outer constant velocity joint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

6.12 Checking inner sliding CV joint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

6.13 Servicing drive shaft with triple roller joint AAR 2600i . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

6.14 Dismantling and assembling drive shaft with triple roller joint AAR 2600i . . . . . . . . . . . . . . 100

6.15 Servicing drive shaft with triple roller joint AAR 3300i (with splines for insertion in gearbox)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

6.16 Servicing drive shaft with triple roller joint AAR 3300i (with splines for stub shaft on

gearbox) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

42 - Rear suspension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

1 General notes on rear axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

1.1 General notes: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

1.2 Contact corrosion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

1.3 Repairing damaged threads in longitudinal member (subframe to body) . . . . . . . . . . . . . . 117

1.4 Lifting suspension to unladen position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

1.5 Overview of rear axle (front-wheel drive) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

1.6 Overview of rear axle (four-wheel drive) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

2 Subframe, diagonal strut, lower transverse link, upper transverse link, track rod, vehicle level

sender (front-wheel drive) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

2.1 Exploded view of subframe, diagonal strut, lower transverse link, upper transverse link, track

rod, vehicle level sender (front-wheel drive) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

2.2 Removing and installing subframe with attachments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

2.3 Removing and installing diagonal struts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

2.4 Removing and installing lower transverse link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

2.5 Removing and installing upper transverse link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

2.6 Removing and installing track rod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

2.7 Removing and installing rear left vehicle level sender G76 and rear right vehicle level sender

G77 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

3 Wheel bearing housing, wheel bearing unit, trailing arm with mounting bracket, stone

deflector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

3.1 Exploded view of wheel bearing housing, wheel bearing unit, trailing arm with mounting

bracket, stone deflector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

3.2 Removing and installing wheel bearing housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

3.3 Renewing bonded rubber bush for wheel bearing housing . . . . . . . . . . . . . . . . . . . . . . . . 142

3.4 Removing and installing wheel bearing unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

3.5 Removing and installing trailing arm with mounting bracket . . . . . . . . . . . . . . . . . . . . . . . . 147

3.6 Servicing trailing arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

3.7 Removing and installing stone deflector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

4 Shock absorbers, coil springs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

4.1 Exploded view of shock absorbers, coil springs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

4.2 Removing and installing shock absorber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

4.3 Servicing shock absorbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

4.4 Removing and installing coil spring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

5 Anti-roll bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

5.1 Exploded view of anti-roll bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

5.2 Removing and installing anti-roll bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

ii Contents

Page 5

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Running gear, front-wheel drive and four-wheel drive - Edition 08.2010

6 Subframe, lower transverse link, upper transverse link, track rod, vehicle level sender (four-

wheel drive) - Coupé . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

6.1 Exploded view of subframe, lower transverse link, upper transverse link, track rod, vehicle

level sender (four-wheel drive) - Coupé . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

6.2 Removing and installing subframe with attachments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

6.3 Removing and installing subframe bushes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

6.4 Removing and installing lower transverse link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

6.5 Removing and installing upper transverse link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

6.6 Removing and installing track rod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

6.7 Removing and installing rear left vehicle level sender G76 and rear right vehicle level sender

G77 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

7 Subframe, diagonal struts, cross member, lower transverse link, upper transverse link, track

rod, vehicle level sender (four-wheel drive) - Roadster . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

7.1 Exploded view of subframe, diagonal struts, cross member, lower transverse link, upper

transverse link, track rod, vehicle level sender (four-wheel drive) - Roadster . . . . . . . . . . 181

7.2 Removing and installing diagonal struts - Roadster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

7.3 Removing and installing cross member - Roadster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

8 Wheel bearing housing, wheel bearing unit, trailing arm with mounting bracket . . . . . . . . 185

8.1 Exploded view of wheel bearing housing, wheel bearing unit, trailing arm with mounting

bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

8.2 Removing and installing wheel bearing housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

8.3 Renewing bonded rubber bush for wheel bearing housing . . . . . . . . . . . . . . . . . . . . . . . . 191

8.4 Removing and installing wheel bearing unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

8.5 Removing and installing trailing arm with mounting bracket . . . . . . . . . . . . . . . . . . . . . . . . 195

8.6 Servicing trailing arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

9 Shock absorbers, coil springs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

9.1 Exploded view of shock absorbers, coil springs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

9.2 Removing and installing shock absorber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

9.3 Servicing shock absorbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

9.4 Removing and installing coil spring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

10 Anti-roll bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

10.1 Exploded view of anti-roll bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

10.2 Removing and installing anti-roll bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

11 Drive shafts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

11.1 General notes: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

11.2 Loosening and tightening hexagon bolt securing drive shaft to wheel hub . . . . . . . . . . . . 210

11.3 Loosening and tightening twelve-point bolt securing drive shaft to wheel hub . . . . . . . . . . 211

11.4 Removing and installing drive shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

11.5 Servicing drive shaft with outer constant velocity joint, 90 mm diameter . . . . . . . . . . . . . . 214

11.6 Servicing drive shaft with outer constant velocity joint, 82 mm diameter . . . . . . . . . . . . . . 222

11.7 Checking outer constant velocity joint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

11.8 Checking inner constant velocity joint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

44 - Wheels, tyres, vehicle geometry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

1 Wheels, tyres . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

2 Tyre monitor display (TMD+) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

2.1 General notes: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

2.2 Removing and installing tyre pressure monitoring control unit 2 J793 . . . . . . . . . . . . . . . . 233

3 Tyre pressure monitoring system (TPM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

3.1 General notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

3.2 Tyre pressure monitoring system - exploded view of components . . . . . . . . . . . . . . . . . . 236

3.3 Operation of tyre pressure monitoring system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

3.4 Removing and installing tyre pressure monitor control unit J502 . . . . . . . . . . . . . . . . . . . . 238

3.5 Exploded view of tyre pressure sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

3.6 Removing and installing tyre pressure sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

3.7 Changing a tyre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Contents iii

Page 6

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Running gear, front-wheel drive and four-wheel drive - Edition 08.2010

4 Wheel alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

4.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

4.2 Wheel alignment must be checked: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

4.3 Explanatory notes on weight codes used in production (PR numbers) . . . . . . . . . . . . . . . . 244

4.4 Test requirements: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

4.5 Wheel alignment specifications, front-wheel drive and four-wheel drive (Coupé/Roadster)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

4.6 Measurement procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

4.7 Adjusting camber at front wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

4.8 Adjusting camber at rear wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

4.9 Adjusting toe setting at rear wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

4.10 Adjusting toe setting at front wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

48 - Steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

1 General repair instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

1.1 Steering box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

1.2 Gaskets and seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

1.3 Bolts and nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

1.4 Electrical components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

1.5 Guided Fault Finding, Vehicle Self-Diagnosis and Test Instruments . . . . . . . . . . . . . . . . . . 252

2 Steering wheel with airbag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

2.1 Steering wheel with airbag - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

2.2 Removing and installing steering wheel with airbag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

3 Steering column, mounting bracket with strut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

3.1 Steering column and mounting bracket with strut (LHD vehicles) - exploded view . . . . . . 255

3.2 Removing and installing steering column . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

3.3 Handling and transporting steering column . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

3.4 Checking steering column for damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

3.5 Removing and installing mounting bracket with strut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

3.6 Steering column and mounting bracket with strut (RHD vehicles) - exploded view . . . . . . 262

4 Electro-mechanical steering box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

4.1 Differences between steering boxes (generations 2 and 3) . . . . . . . . . . . . . . . . . . . . . . . . 264

4.2 Electro-mechanical steering box (LHD vehicles) - exploded view . . . . . . . . . . . . . . . . . . . . 266

4.3 Removing and installing electro-mechanical steering box . . . . . . . . . . . . . . . . . . . . . . . . . . 267

4.4 Exploded view - servicing electro-mechanical steering box . . . . . . . . . . . . . . . . . . . . . . . . 272

4.5 Removing and installing rubber boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

4.6 Removing and installing track rod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

4.7 Removing and installing bonded rubber bush for generation 2 steering box . . . . . . . . . . . . 281

4.8 Renewing sensor wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

4.9 Renewing and adjusting hydraulic thrust piece . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

4.10 Renewing and adjusting thrust piece at steering pinion end . . . . . . . . . . . . . . . . . . . . . . . . 291

4.11 Removing and installing steering pinion with steering moment sender G269 . . . . . . . . . . 298

4.12 Electro-mechanical steering box (RHD vehicles) - exploded view . . . . . . . . . . . . . . . . . . . . 302

iv Contents

Page 7

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Running gear, front-wheel drive and four-wheel drive - Edition 08.2010

00 – Technical data

1 Technical data

⇒ „1.1 Running gear“, page 1

⇒ „1.2 Steering“, page 1

⇒ „1.3 Wheels, tyres“, page 1

1.1 Running gear

Audi TT 2007 ➤

Front axle

Rear axle

Wheelbase mm 2467

Track width (front/rear)

1) Front/rear track width only applicable to tyre size 225/55/R16 on 7.5Jx16 ET45

rims (ET= rim offset)

1)

mm 1572 / 1558

Four-link suspension with separate spring/shock absorber layout

Front-wheel drive and four-wheel drive

MacPherson struts with bottom wishbones

Subframe

Anti-roll bar

Tubular anti-roll bar

1.2 Steering

Steering

box

Maximum steering angle at in‐

side wheel

Turning circle diameter approx. 10.9 m

Electro-mechanically assisted, maintenance-free rack-and-pinion steering

Front-wheel drive and four-wheel drive

36° 48'

1.3 Wheels, tyres

For general information on wheel/tyre combinations, winter tyres,

snow chains and recommended tyre makes, refer to ⇒ Wheel/

Tyre Guide .

1. Technical data 1

Page 8

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Running gear, front-wheel drive and four-wheel drive - Edition 08.2010

2 Proper disposal of fluid-filled compo‐

nents

⇒ „2.1 Releasing gas in gas-filled shock absorbers (front)“,

page 2

⇒ „2.2 Releasing gas in gas-filled shock absorbers (rear)“,

page 3

⇒ „2.3 Releasing gas in Audi magnetic ride shock absorbers

(front)“, page 3

⇒ „2.4 Releasing gas in Audi magnetic ride shock absorbers

(rear)“, page 4

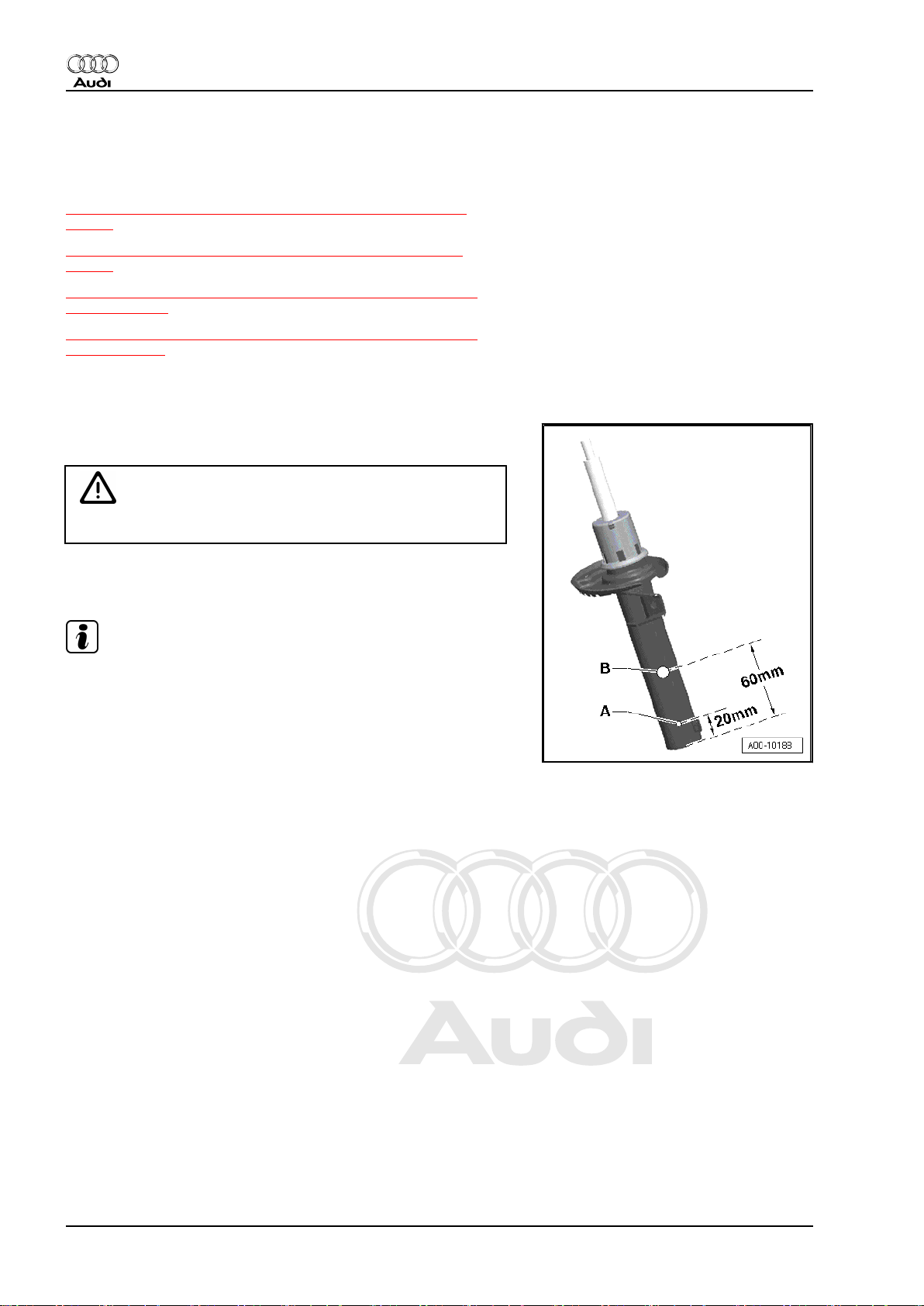

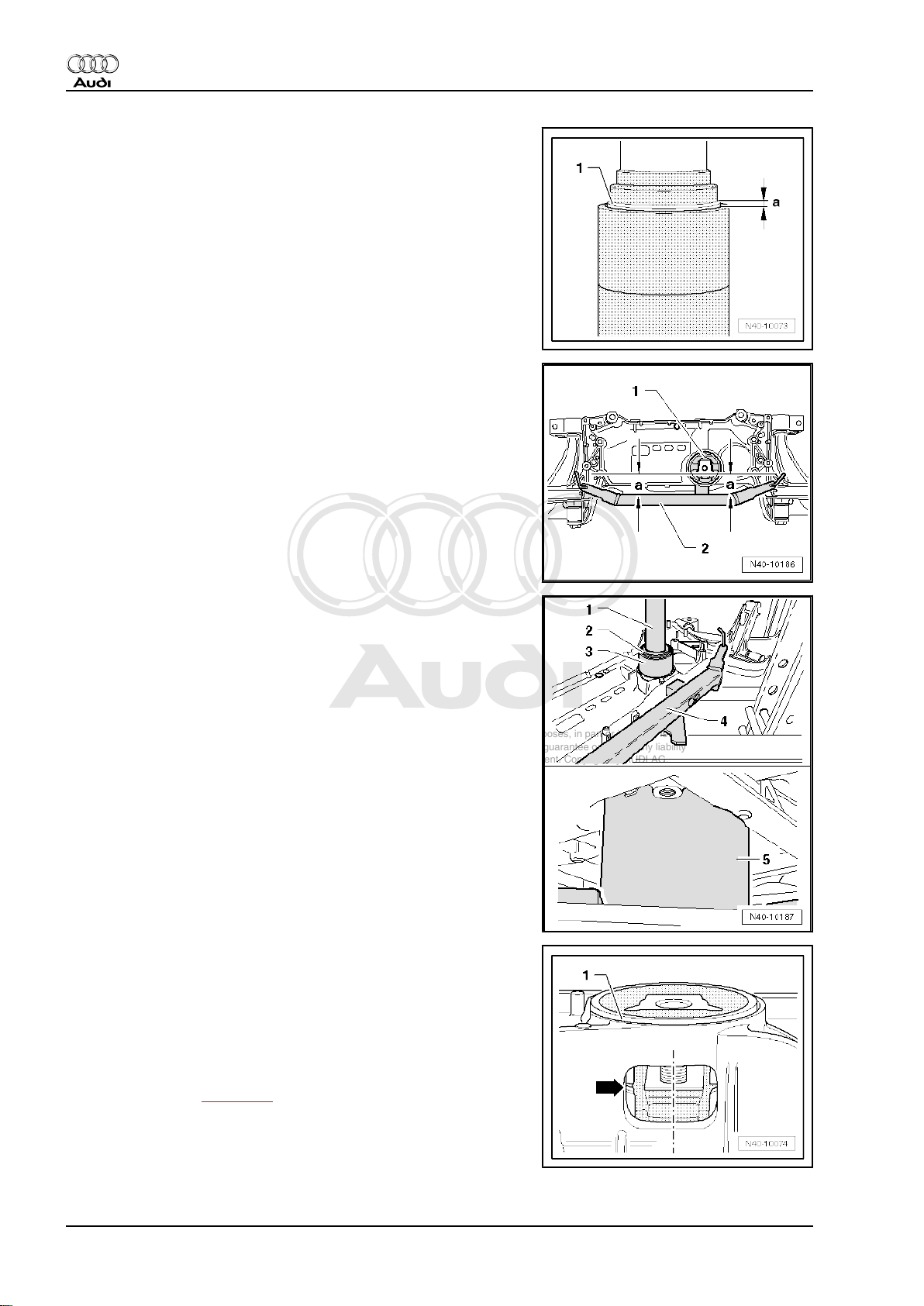

2.1 Releasing gas in gas-filled shock ab‐

sorbers (front)

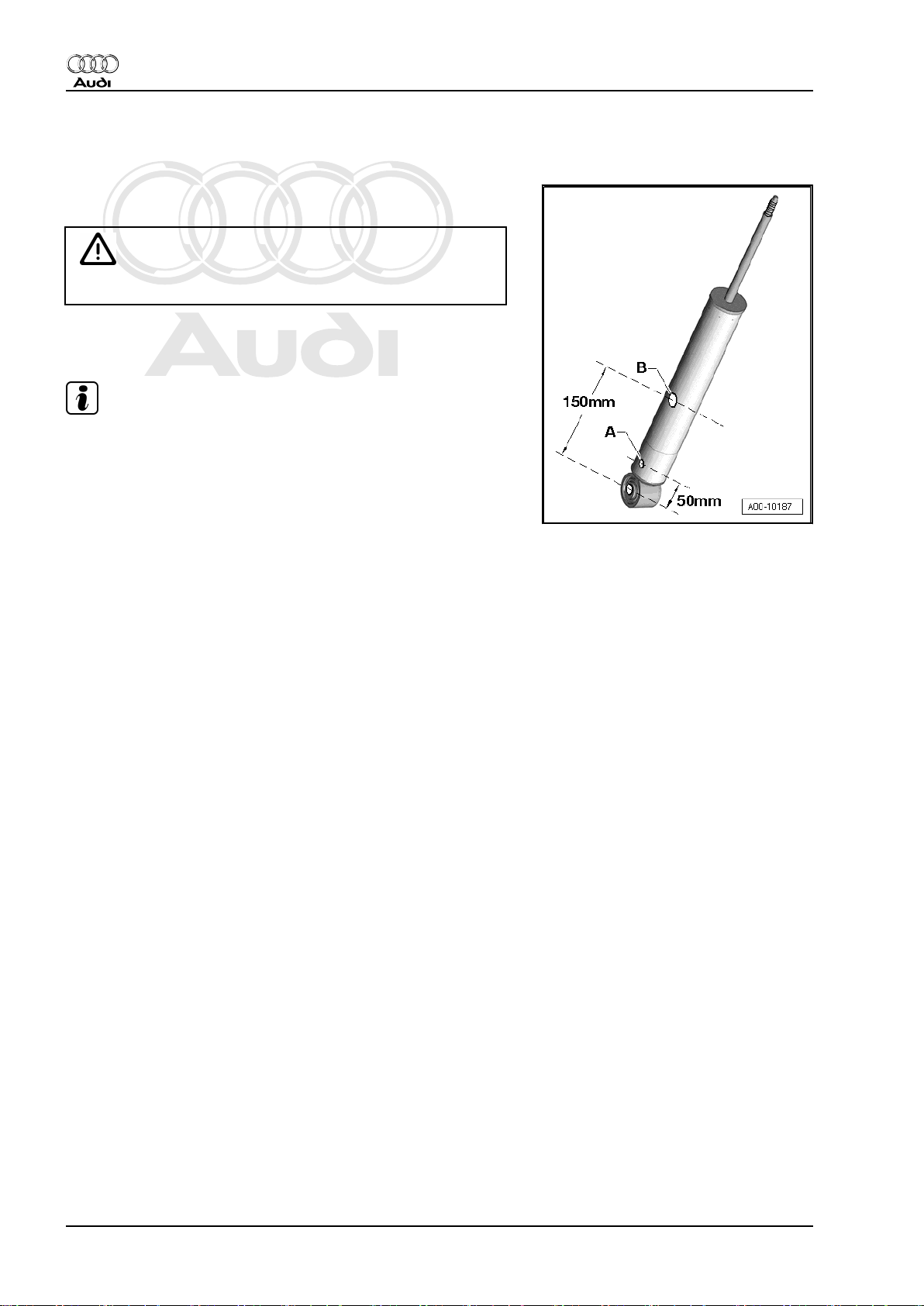

– Clamp gas-filled shock absorber vertically in vice, with piston

rod pointing downwards.

WARNING

Safety goggles must be worn when drilling.

– Drill a 3 mm ∅ hole -arrow A- through outer tube of shock ab‐

sorber.

Note

Gas will escape during drilling.

– Continue drilling until inner tube is fully penetrated (approx.

25 mm deep).

– Drill a second 6 mm ∅ hole -arrow B- through outer and inner

tubes of shock absorber.

– Hold shock absorber over a drip tray and move piston rod up

and down several times through entire stroke until no more

fluid comes out.

2 Rep. gr.00 - Technical data

Page 9

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Running gear, front-wheel drive and four-wheel drive - Edition 08.2010

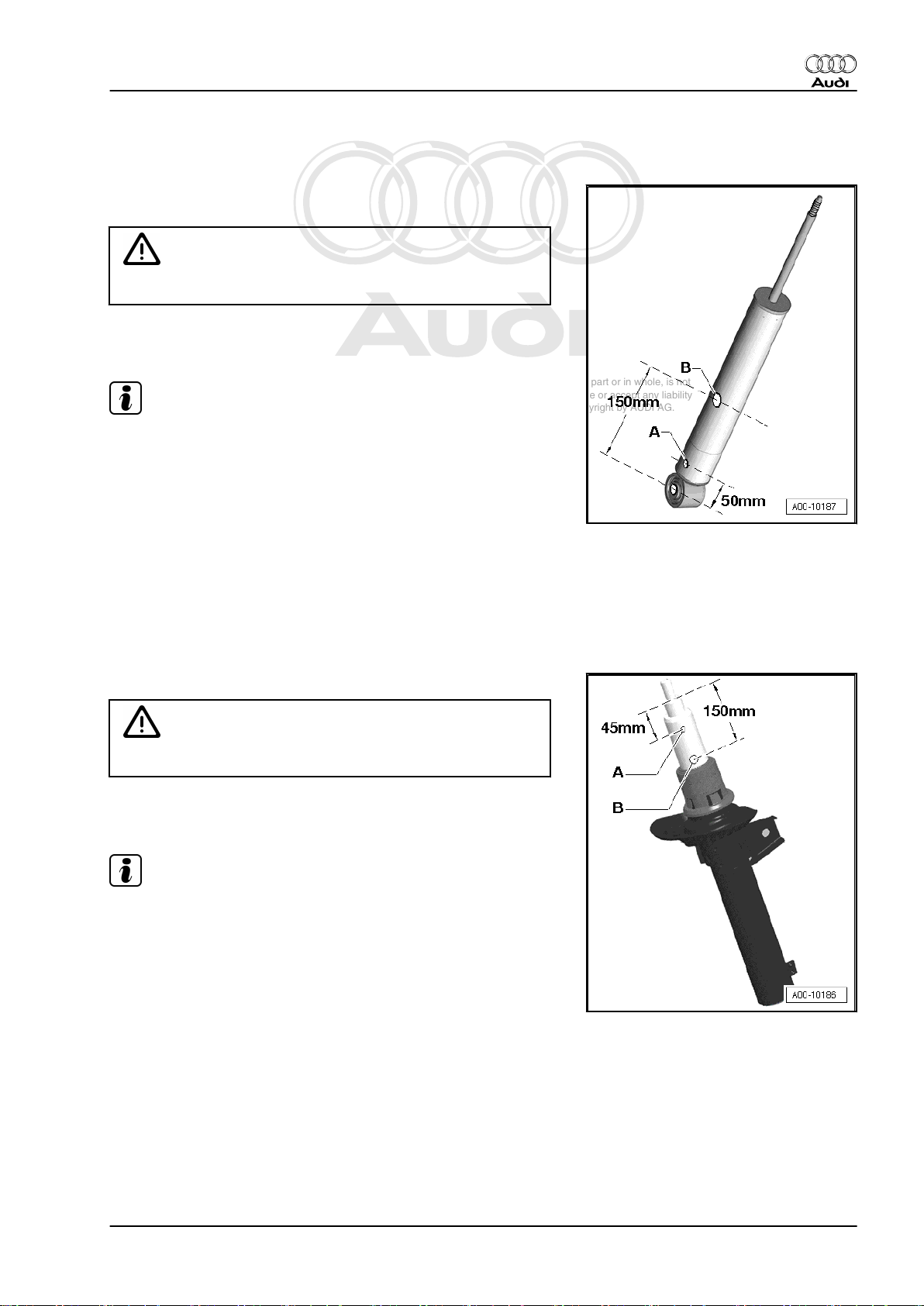

2.2 Releasing gas in gas-filled shock ab‐

sorbers (rear)

– Clamp gas-filled shock absorber vertically in vice, with piston

rod pointing downwards.

WARNING

Safety goggles must be worn when drilling.

– Drill a 3 mm ∅ hole -arrow A- through outer tube of shock ab‐

sorber.

Note

Gas will escape during drilling.

– Continue drilling until inner tube is fully penetrated (approx.

25 mm deep).

– Drill a second 6 mm ∅ hole -arrow B- through outer and inner

tubes of shock absorber.

– Hold shock absorber over a drip tray and move piston rod up

and down several times through entire stroke until no more

fluid comes out.

Audi TT 2007 ➤

2.3 Releasing gas in Audi magnetic ride shock absorbers (front)

– Clamp magnetic ride shock absorber vertically in a vice.

WARNING

Safety goggles must be worn when drilling.

– Drill a 3 mm ∅ hole -arrow A- through outer tube of shock ab‐

sorber.

Note

Gas will escape during drilling.

– Drill a second 6 mm ∅ hole -arrow B- through outer tube of

shock absorber.

– Hold shock absorber over a drip tray and move piston rod up

and down several times through entire stroke until no more

fluid comes out.

2. Proper disposal of fluid-filled components 3

Page 10

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Running gear, front-wheel drive and four-wheel drive - Edition 08.2010

2.4 Releasing gas in Audi magnetic ride shock absorbers (rear)

– Clamp magnetic ride shock absorber vertically in vice with pis‐

ton rod facing downwards.

WARNING

Safety goggles must be worn when drilling.

– Drill a 3 mm ∅ hole -arrow A- through outer tube of shock ab‐

sorber.

Note

Gas will escape during drilling.

– Drill a second 6 mm ∅ hole -arrow B- through outer tube of

shock absorber.

– Hold shock absorber over a drip tray and move piston rod up

and down several times through entire stroke until no more

fluid comes out.

4 Rep. gr.00 - Technical data

Page 11

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Running gear, front-wheel drive and four-wheel drive - Edition 08.2010

3 Checking shock absorbers

⇒ „3.1 Leaks at shock absorbers“, page 5

⇒ „3.2 Checking shock absorbers when removed“, page 5

⇒ „3.3 Checking shock absorbers on shock tester“, page 6

3.1 Leaks at shock absorbers

Shock absorbers are often replaced because of externally visible

leakage. Inspections on the test rig and in the vehicle have shown

that in the majority of cases this replacement is not justified.

Slight loss of fluid („sweating“) at the piston rod seal is not a rea‐

son for replacing a shock absorber. A shock absorber with slight

fluid leakage can be accepted as "OK" under the following con‐

ditions:

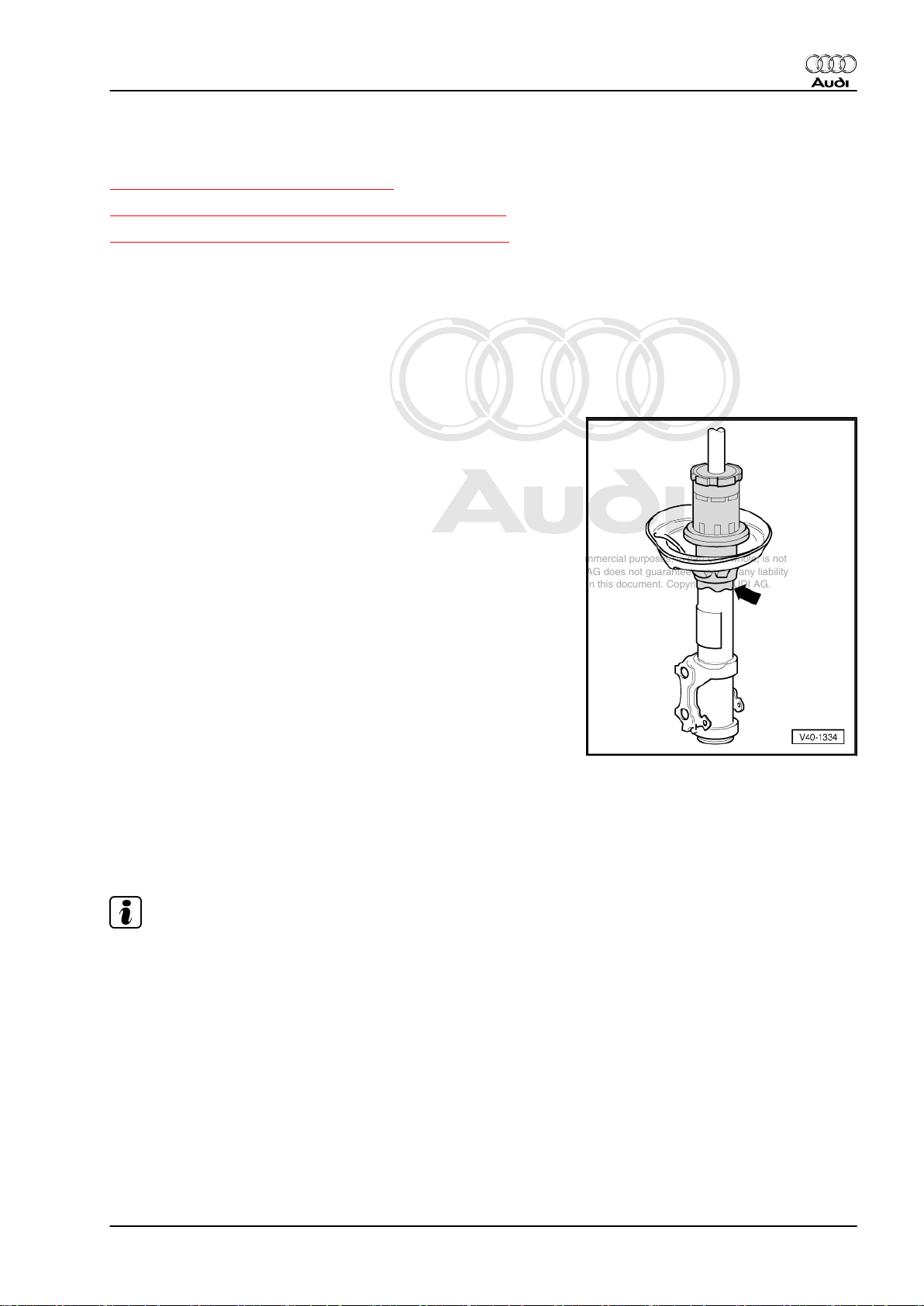

♦ Fluid seepage (as shown in the shaded part of the illustration)

is visible, but the fluid is dull and possibly dried by dust

♦ The fluid seepage extends only from the top shock absorber

seal (piston rod seal) down to the bottom spring plate

-arrow-.

Audi TT 2007 ➤

3.2 Checking shock absorbers when re‐

moved

Defective shock absorbers can be identified by loud rumbling

noises when driving, caused by wheel hopping, especially on bad

roads. Heavy fluid leakage is an additional visual indication.

Note

Shock absorbers are maintenance-free; shock absorber fluid can‐

not be topped up.

After removal, a shock absorber can be checked by hand as fol‐

lows:

– Compress shock absorber by hand.

♦ The piston rod should move smoothly over the entire stroke

with uniform resistance and without jolts.

– Release piston rod.

♦ If the shock absorber has sufficient gas pressure the piston

rod will return by itself to its original position.

3. Checking shock absorbers 5

Page 12

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Running gear, front-wheel drive and four-wheel drive - Edition 08.2010

Note

♦

If this is not the case, the shock absorber does not necessarily

need to be renewed. Provided there has been no major loss

of fluid, it will still be as effective as a conventional shock ab‐

sorber.

♦

Even without gas pressure, the shock absorber will provide full

damping effect as long as there has been no major loss of fluid.

However, it may produce more noise.

3.3 Checking shock absorbers on shock tester

The shock tester allows shock absorbers to be tested without re‐

moving them from the vehicle. The damping effect can be as‐

sessed on the basis of the pointer deflection or the print-out.

Special tools and workshop equipment required

♦ Boge shock tester or

♦ Sachs shock tester -V.A.G 1975- or

♦ Maha shock absorber tester -VAS 1990-

Note

♦

Temperature +10 ... +40 °C.

♦

Driver in vehicle.

♦

Vehicle stationary.

♦

Correct tyre inflation pressure.

♦

Wheels of vehicle in a central and straight position on the tyre

contact plates.

♦

Front wheels in straight-ahead position.

♦

Handbrake not applied, brake pedal not depressed.

♦

Ignition on.

♦

Test mode active on vehicles with Audi magnetic ride (AMR)

- electronic damping control.

Activating test mode for Audi magnetic ride (AMR) - electronic

damping control

– Press shock absorber damping adjustment button -E387-

⇒ page 45 in centre console and hold for over 5 seconds.

Diode in shock absorber damping adjustment button -E387flashes during test mode.

– The test mode is deactivated when shock absorber damping

adjustment button -E387- ⇒ page 45 is pressed again, when

the ignition is switched off, or when the vehicle is driven at a

speed of at least 10 km/h.

Test results

The condition of the shock absorbers can only be evaluated as

follows:

♦ Satisfactory damping effect

or

♦ Unsatisfactory damping effect

6 Rep. gr.00 - Technical data

Page 13

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Running gear, front-wheel drive and four-wheel drive - Edition 08.2010

Note

♦

It is not possible to obtain more detailed readings specifying

the exact degree of impairment of damping effect.

♦

A forecast of the remaining service life is not permissible.

♦

Test results will be falsified if the suspension contacts the

bump stops when the readings are taken.

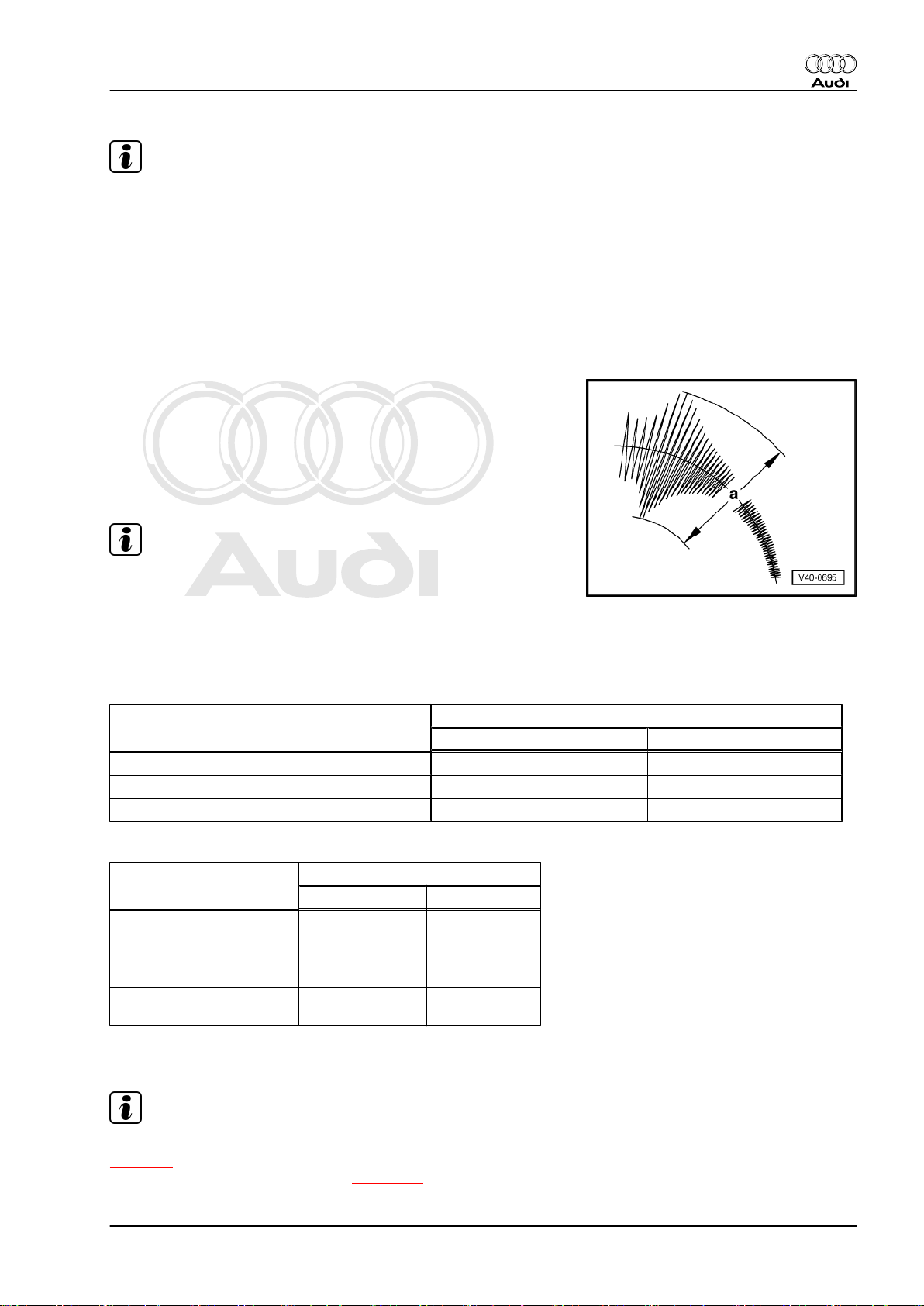

The following values apply only to tests conducted on the test

equipment listed above. If the stated values are exceeded, the

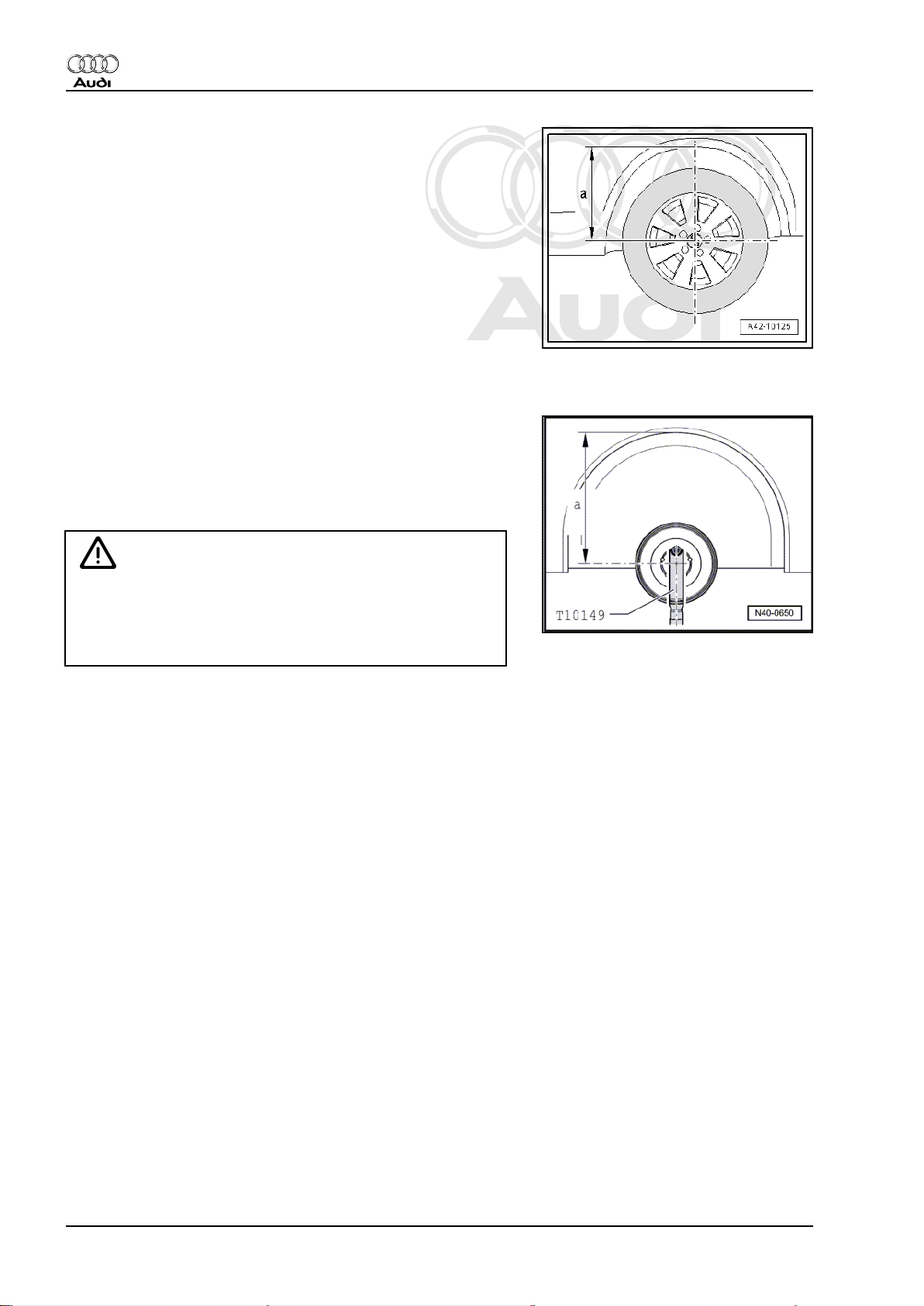

shock absorber action has deteriorated to such an extent that re‐

placement is recommended.

Example:

Maximum value = 70

♦ a = higher than 70: unsatisfactory damping effect

♦ a = lower than 70: satisfactory damping effect

Maximum values „a“ in mm

Audi TT 2007 ➤

Note

♦

If the reading is higher than the maximum value „a“ listed in

the table, the damping effect is unsatisfactory ⇒ renew the

shock absorber.

♦

If the reading is lower than the maximum value „a“ listed in the

table, the damping effect is satisfactory ⇒ the shock absorber

does not have to be renewed.

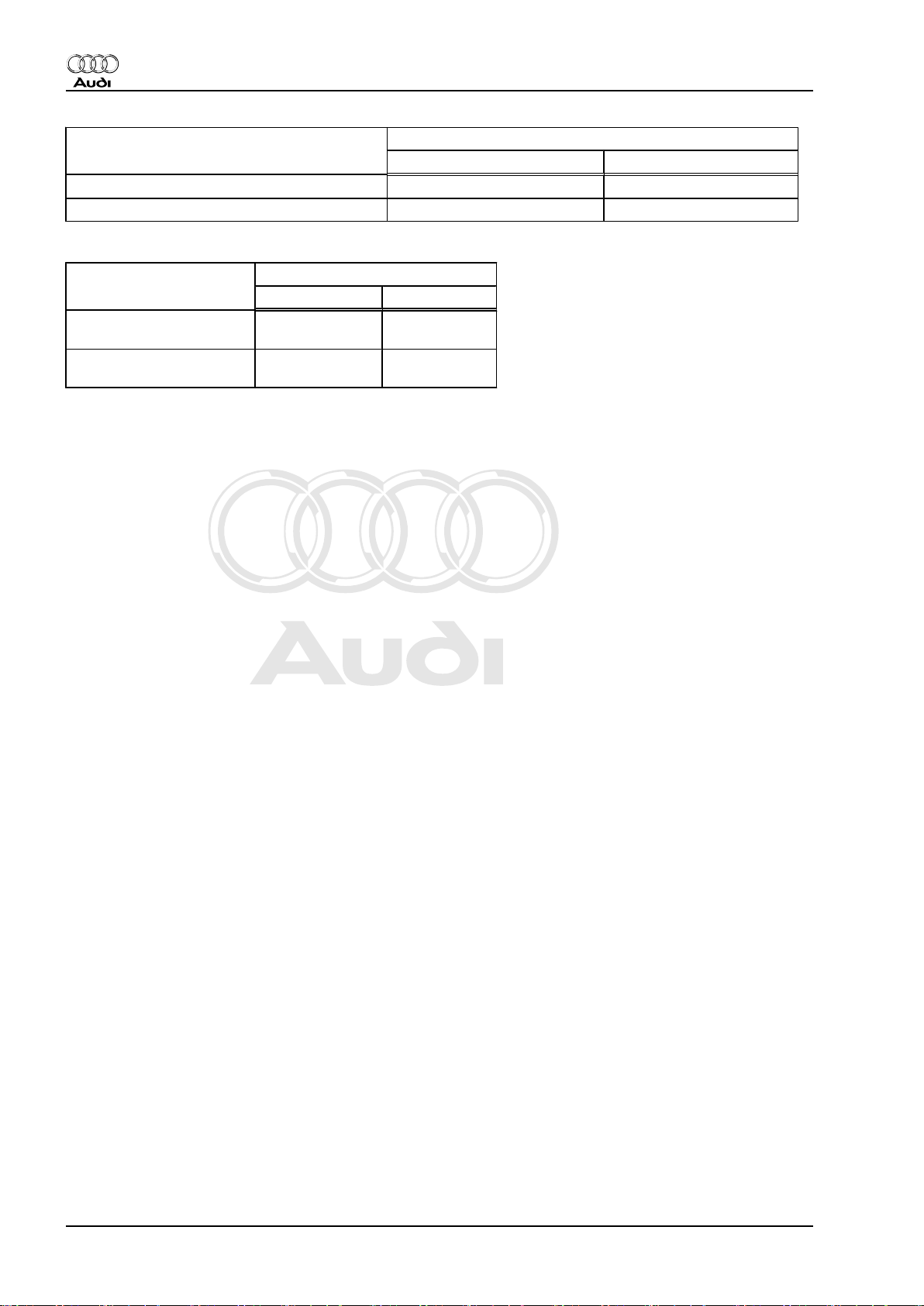

Front axle Damping effect

Inadequate Adequate

Standard running gear (1BA)

a = Greater than 60 a = Less than 60

Sports running gear (1BV) a = Greater than 60 a = Less than 60

Sports running gear (1BD) a = Greater than 60 a = Less than 60

Rear axle Damping effect

Inadequate Adequate

Standard running gear

(1BA)

a = Greater than60a = Less than

60

Sports running gear (1BV) a = Greater than60a = Less than

60

Sports running gear (1BD) a = Greater than60a = Greater

than 60

Vehicles with Audi magnetic ride (AMR) - electronic damping

control

Note

These values apply only when the test mode is activated

⇒ page 6 (in test mode, a diode flashes in the shock absorber

damping adjustment button -E387- ⇒ page 45 ).

3. Checking shock absorbers 7

Page 14

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Running gear, front-wheel drive and four-wheel drive - Edition 08.2010

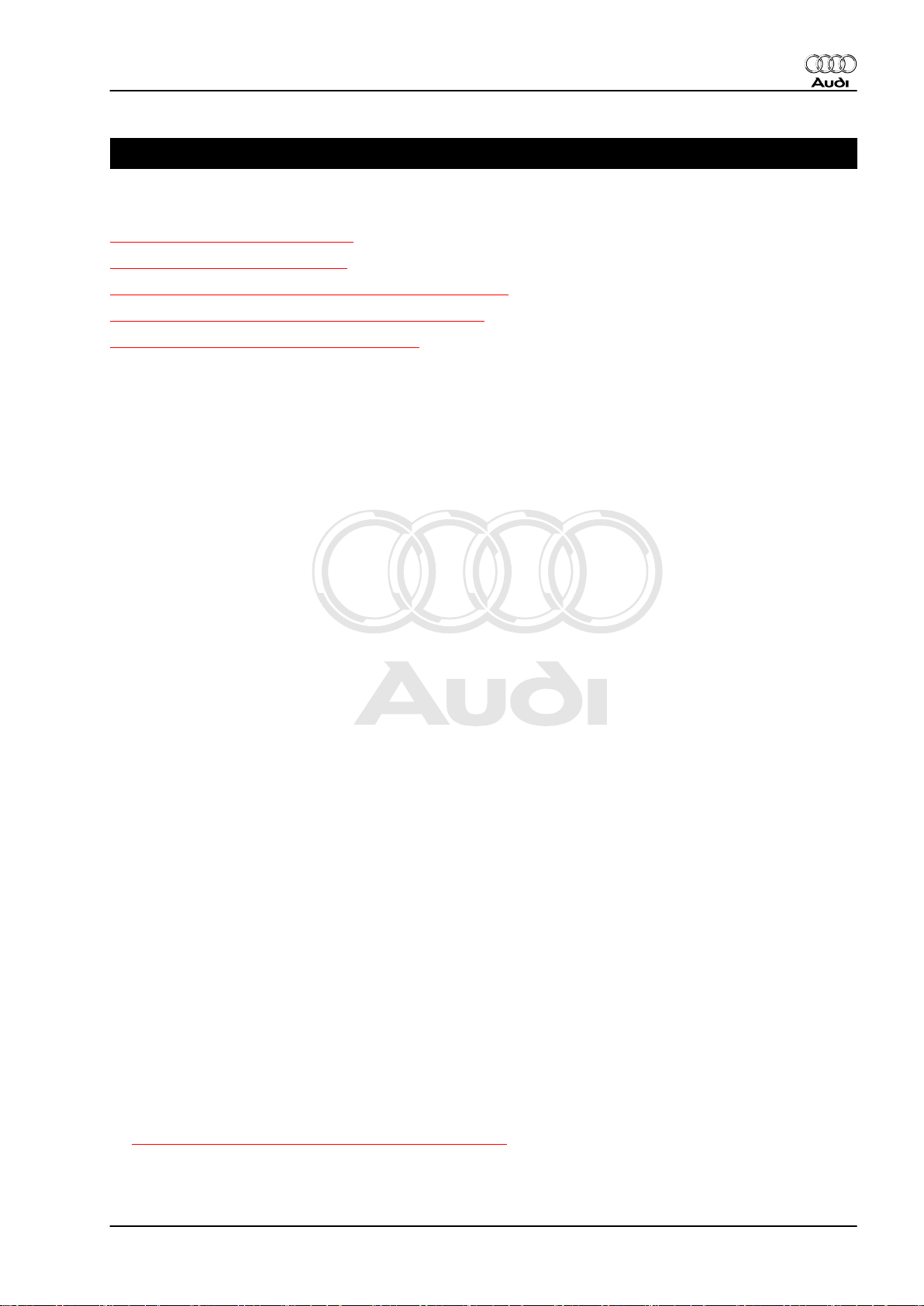

Front axle Damping effect

Inadequate Adequate

Sports running gear (1BL)

a = Greater than 50 a = Less than 50

Sports running gear (1BQ) a = Greater than 50 a = Less than 50

Rear axle Damping effect

Inadequate Adequate

Sports running gear (1BL)

a = Greater than50a = Less than

50

Sports running gear (1BQ) a = Greater than50a = Less than

50

8 Rep. gr.00 - Technical data

Page 15

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Running gear, front-wheel drive and four-wheel drive - Edition 08.2010

40 – Front suspension

1 General notes

⇒ „1.1 General information“, page 9

⇒ „1.2 Contact corrosion“, page 10

⇒ „1.3 Repairing threads in longitudinal member“, page 10

⇒ „1.4 Lifting suspension to unladen position“, page 11

⇒ „1.5 Exploded views of front axle“, page 13

1.1 General information

All contact surfaces must be cleaned when installing wax-coated

components. The contact surfaces must be free of wax and

grease.

Tightening torques refer to unoiled bolts and nuts.

Always renew self-locking bolts/nuts.

Always renew bolts and nuts which are tightened by turning

through a specified angle.

Load-bearing components and other suspension parts must not

be welded or straightened.

Do not subject coil springs to hammer blows or weld splashes and

do not make any new colour markings.

Do not perform welding or cutting operations (using power grind‐

ers) near the coil springs or suspension struts. Cover up coil

springs or suspension struts if necessary.

Make sketches or take photographs when unfastening or remov‐

ing and installing hydraulic or pneumatic pipes or electrical wires.

This ensures re-installation at the original location.

Any cable ties, brackets or fasteners removed during repair work

must be re-attached at their original standard locations.

Before fitting the outer joint in the wheel hub, apply a thin coat of

assembly paste to the splines on the outer joint ⇒ Electronic parts

catalogue .

When working on the vehicle, do not allow the drive shafts to hang

down under their own weight and never let the joints bend to such

an extent that they contact the end stop.

Do not attempt to move the vehicle without the drive shafts fitted;

this would result in wheel bearing damage. If the vehicle does

have to be moved, always note the following points:

– Fit an outer joint in place of the drive shaft.

– Tighten the outer joint to 120 Nm (twelve-point bolt) or 200 Nm

(hexagon bolt).

Bonded rubber bushes can only be turned to a limited extent. The

suspension must therefore always be in the unladen position or

the reference position when the suspension link attachments are

tightened.

♦ Lifting suspension to unladen position (vehicles with coil

springs)

⇒ „1.4 Lifting suspension to unladen position“, page 11

If the wheel alignment has to be checked and adjusted at a later

stage, all bolts and nuts which need to be slackened to make ad‐

justments should initially only be tightened to the specified torque

figure. After wheel alignment has been checked and adjusted,

Audi TT 2007 ➤

1. General notes 9

Page 16

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Running gear, front-wheel drive and four-wheel drive - Edition 08.2010

bolts and nuts must then be fully tightened by turning them

through the specified angle.

WARNING

All bolts and nuts must be fully tightened according to specifi‐

cations before the vehicle is driven on public roads.

1.2 Contact corrosion

Contact corrosion can occur if unsuitable fasteners (bolts, nuts,

washers ...) are used.

For this reason, all the fasteners on the vehicle have a special

surface coating.

In addition, rubber parts, plastic parts and adhesives are made of

non-conductive material.

Always install new parts as listed in the Parts catalogue if you are

not sure whether used parts can be refitted.

Note:

♦ We recommend using only genuine replacement parts; these

have been tested and are compatible with aluminium.

♦ We recommend the use of Audi accessories.

♦ Damage resulting from contact corrosion is not covered under

the warranty.

1.3 Repairing threads in longitudinal mem‐

ber

Under certain circumstances it is possible to repair the threads in

the captive nuts in the longitudinal member.

♦ Each thread can only be repaired once.

♦ If a second repair is needed, the captive nut must be renewed.

WARNING

Always wear safety goggles when drilling.

♦ Have all thread repairs checked by foreman or supervisor.

♦ The thread insert must be of the same length as the thread in

the body.

♦ Repair any damage to underseal ⇒ Body Repairs; Rep. gr.

00 ; Corrosion protection measures

10 Rep. gr.40 - Front suspension

Page 17

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Running gear, front-wheel drive and four-wheel drive - Edition 08.2010

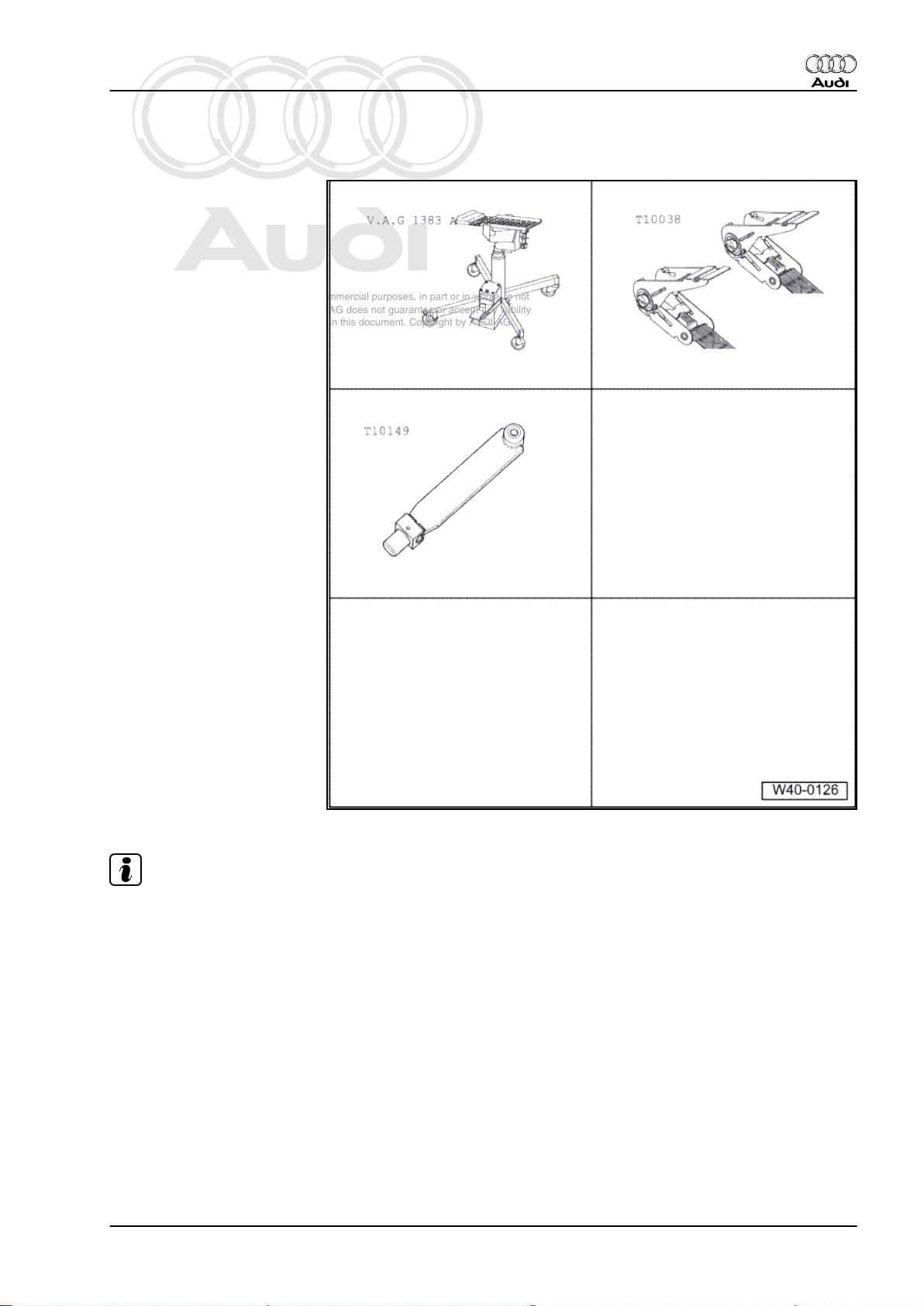

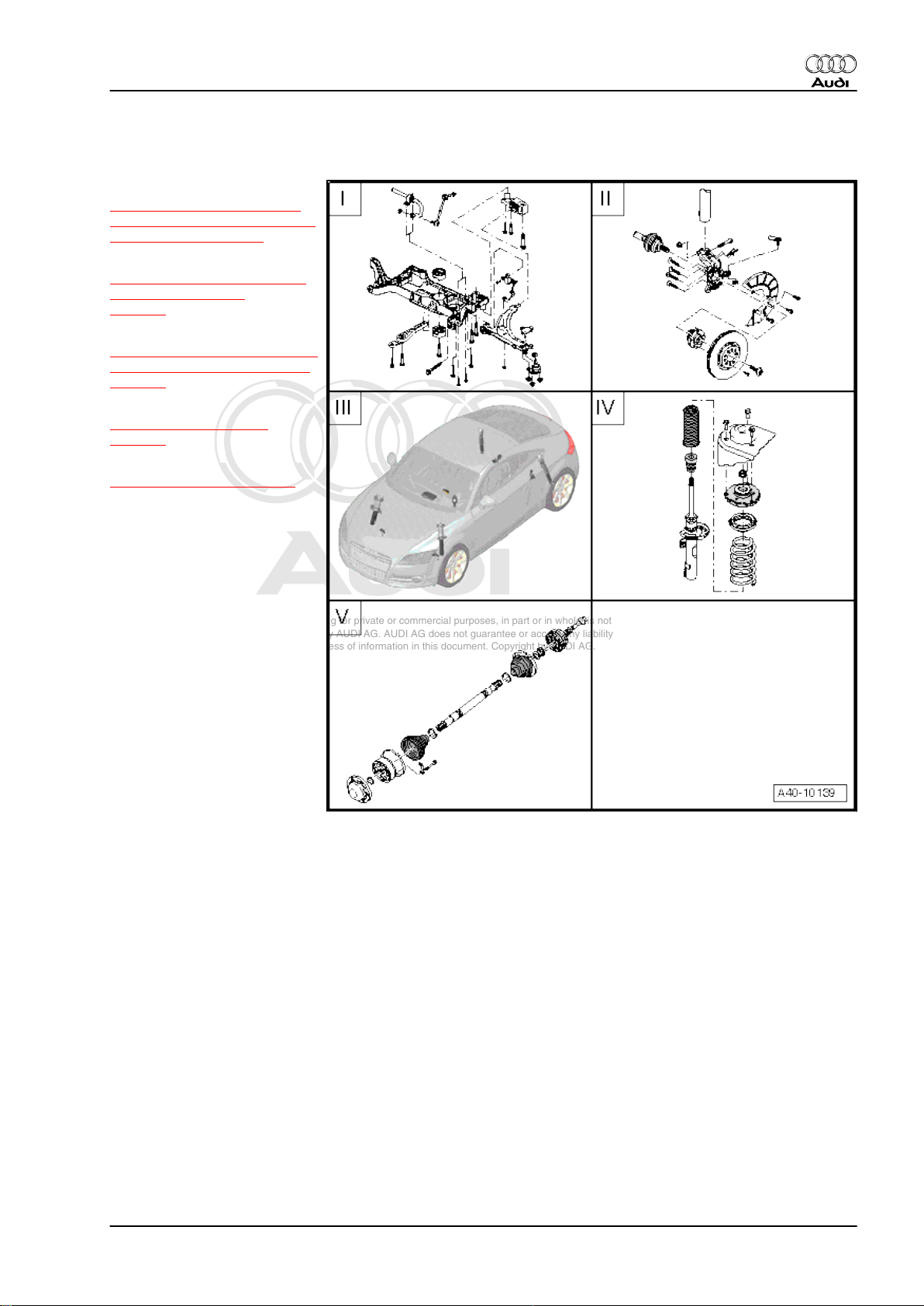

1.4 Lifting suspension to unladen position

Special tools and workshop

equipment required

♦ Engine and gearbox jack -

V.A.G 1383 A-

♦ Tensioning strap -T10038-

♦ Support -T10149-

Audi TT 2007 ➤

Note

All bolts on running gear components with bonded rubber bushes

must always be tightened with the suspension in the unladen po‐

sition (vehicle unladen).

Bonded rubber bushes can only be turned to a limited extent.

Therefore, before tightening the bolts, suspension components

with bonded rubber bushes must be brought into a position cor‐

responding to the normal position of the unladen vehicle while

driving (unladen position).

Otherwise, the bush would be subject to torsion loading and its

service life would be shortened.

This position can be simulated on the lifting platform by raising

the appropriate part of the suspension with the engine and gear‐

box jack -V.A.G 1383 A- and support -T10149- .

1. General notes 11

Page 18

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Running gear, front-wheel drive and four-wheel drive - Edition 08.2010

– Before commencing work, use measuring tape or similar to

measure dimension -a- from wheel centre to lower edge of

wheel housing.

This measurement must be taken with the suspension in the un‐

laden position (vehicle unladen).

– Make a note of the measured value. This will be needed when

tightening the bolts and/or nuts on the suspension.

Before raising wheel unit, secure vehicle to arms of lifting platform

using tensioning straps -T10038- .

If vehicle is not secured, there is a risk of it slipping off the lifting

platform.

– Turn wheel hub until one of the wheel bolt holes is at the top.

– Attach support -T10149- to wheel hub using wheel bolt.

– Raise wheel bearing housing with engine and gearbox jack -

V.A.G 1383 A- until distance -a- is obtained.

The bolts/nuts on the relevant suspension mountings must not be

tightened until the distance -a- between the wheel centre and the

lower edge of the wheel housing is the same as the distance

measured before commencing work.

WARNING

♦ Do not lift or lower the vehicle while the engine/gearbox

jack is under the vehicle.

♦ Do not leave engine and gearbox jack -V.A.G 1383 A- un‐

der vehicle for longer than necessary.

– Tighten relevant bolts/nuts.

– Lower wheel bearing housing.

– Pull out engine/gearbox jack from under vehicle.

– Remove support -T10149- .

12 Rep. gr.40 - Front suspension

Page 19

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Running gear, front-wheel drive and four-wheel drive - Edition 08.2010

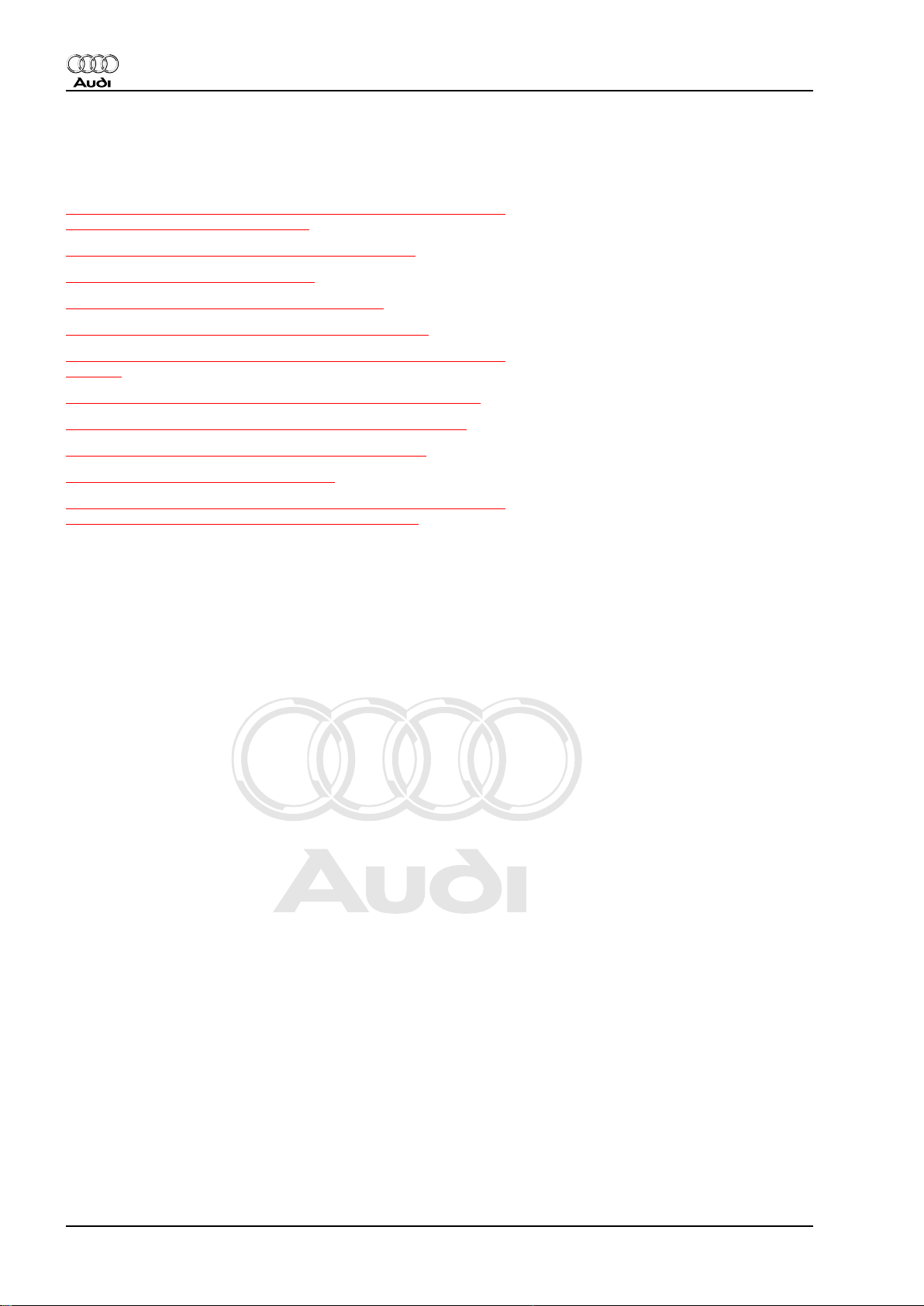

1.5 Exploded views of front axle

I -

⇒ „2 Subframe, anti-roll bar,

wishbone, swivel joint, vehicle

level sender“, page 14

II -

⇒ „3 Wheel bearing housing,

wheel bearing unit“,

page 39

III -

⇒ „4 Audi magnetic ride (AMR)

- electronic damping control“,

page 45

IV -

⇒ „5 Suspension strut“,

page 48

V -

⇒ „6 Drive shafts“, page 55

Audi TT 2007 ➤

1. General notes 13

Page 20

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Running gear, front-wheel drive and four-wheel drive - Edition 08.2010

2 Subframe, anti-roll bar, wishbone,

swivel joint, vehicle level sender

⇒ „2.1 Exploded view of subframe, anti-roll bar, wishbone, swivel

joint, vehicle level sender“, page 15

⇒ „2.2 Removing and installing subframe“, page 17

⇒ „2.3 Servicing subframe“, page 22

⇒ „2.4 Locating subframe in position“, page 25

⇒ „2.5 Removing and installing anti-roll bar“, page 26

⇒ „2.6 Removing and installing wishbone and mounting bracket“,

page 27

⇒ „2.7 Renewing bonded rubber bush in wishbone“, page 31

⇒ „2.8 Renewing mounting bracket for wishbone“, page 34

⇒ „2.9 Removing and installing swivel joint“, page 35

⇒ „2.10 Checking swivel joint“, page 37

⇒ „2.11 Removing and installing front left vehicle level sender G78

and front right vehicle level sender G289 “, page 37

14 Rep. gr.40 - Front suspension

Page 21

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Running gear, front-wheel drive and four-wheel drive - Edition 08.2010

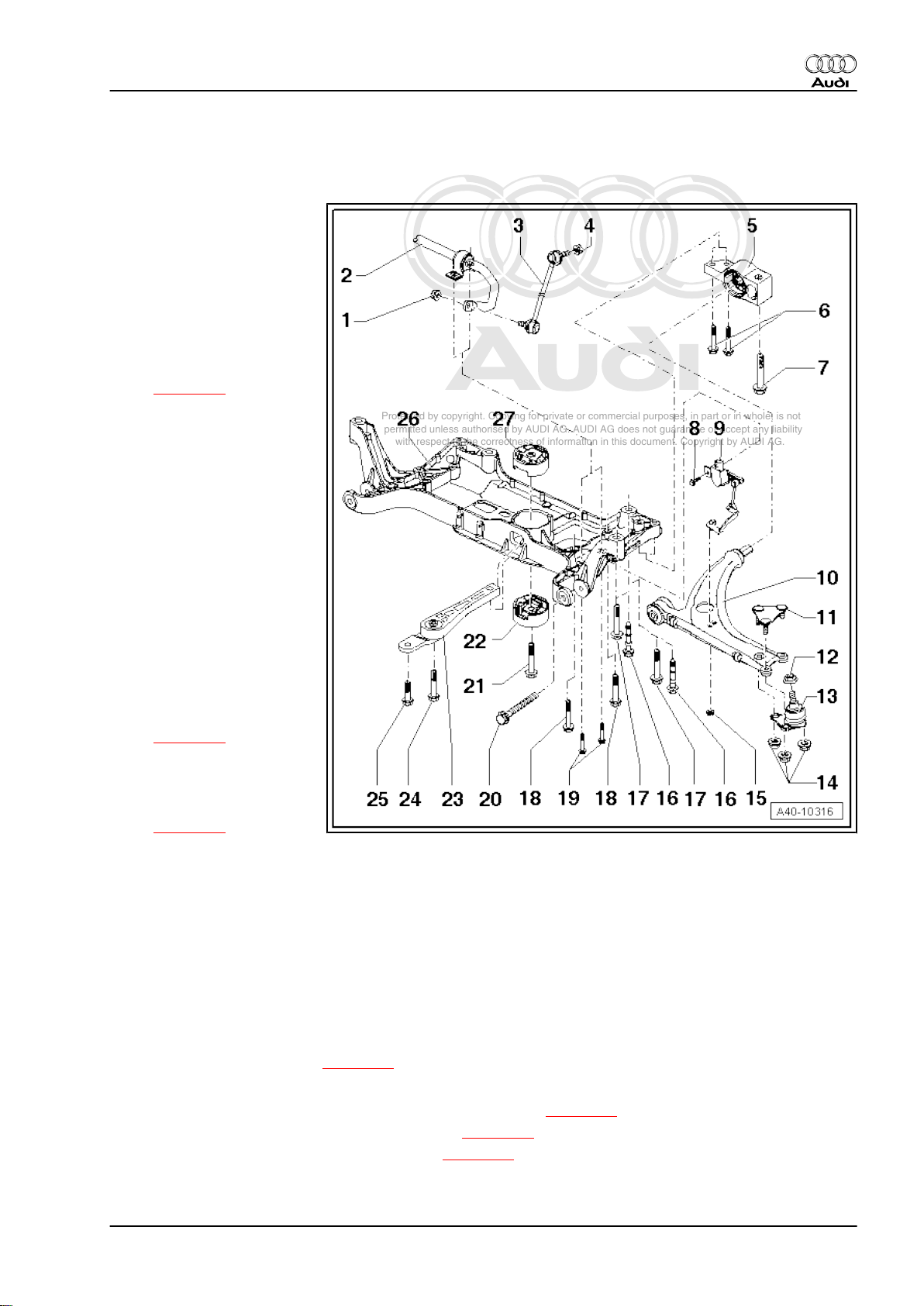

2.1 Exploded view of subframe, anti-roll bar, wishbone, swivel joint, vehicle level sender

1 - Nut

❑ 65 Nm

❑ When tightening, coun‐

terhold multi-point sock‐

et of joint pin

❑ Always renew if re‐

moved

2 - Anti-roll bar

❑ Removing and installing

⇒ page 26

❑ Different versions possi‐

ble. For correct version

refer to ⇒ Electronic

parts catalogue „ETKA“

3 - Coupling rod

❑ Link between anti-roll

bar and suspension

strut

4 - Nut

❑ 65 Nm

❑ When tightening, coun‐

terhold multi-point sock‐

et of joint pin

❑ Always renew if re‐

moved

5 - Mounting bracket

❑ Locating in position

⇒ page 26

❑ With bonded rubber

bush

❑ Renewing mounting

bracket for wishbone

⇒ page 34

6 - Bolt

❑ 50 Nm + 90°

❑ Always renew if removed

7 - Bolt

❑ 70 Nm + 90°

❑ Always renew if removed

8 - Bolt

❑ 9 Nm

9 - Front left vehicle level sender -G78- and front right vehicle level sender -G289-

❑ Removing and installing ⇒ page 37

10 - Wishbone

❑ Removing and installing wishbone and mounting bracket ⇒ page 27

❑ Renewing bonded rubber bush for wishbone ⇒ page 31

❑ Renewing mounting bracket for wishbone ⇒ page 34

11 - Retaining plate

❑ Always renew if removed

2. Subframe, anti-roll bar, wishbone, swivel joint, vehicle level sender 15

Page 22

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Running gear, front-wheel drive and four-wheel drive - Edition 08.2010

12 - Nut

❑ 20 Nm + 90°

❑ Always renew if removed

13 - Swivel joint

❑ Removing and installing ⇒ page 35

❑ Checking ⇒ page 37

14 - Nut

❑ 40 Nm + 45°

❑ Always renew if removed

15 - Nut

❑ 9 Nm

16 - Bolt

❑ 70 Nm + 90°

❑ Different country-specific versions are possible; for correct version, refer to ⇒ Electronic parts catalogue

„ETKA“

❑ Note different thread lengths

❑ Positioned with indentation on bolt head at rear underbody attachment point

❑ Always renew if removed

17 - Bolt

❑ 70 Nm + 90°

❑ Different country-specific versions are possible; for correct version, refer to ⇒ Electronic parts catalogue

„ETKA“

❑ Always renew if removed

18 - Bolt

❑ 50 Nm + 90°

❑ Attachment for steering box

❑ Always renew if removed

19 - Bolt

❑ 20 Nm + 90°

❑ Attachment for anti-roll bar

❑ Always renew if removed

20 - Bolt

❑ 70 Nm + 180°

❑ Always renew if removed

❑ Suspension must be in unladen position when tightening ⇒ page 11

21 - Bolt

❑ 100 Nm + 90°

❑ Do not tighten until pendulum support is bolted to gearbox

❑ Always renew if removed

22 - Bonded rubber bush (bottom) for pendulum support

❑ Removing and installing ⇒ page 22

23 - Pendulum support

❑ Bolt to gearbox first, then to subframe

❑ Different versions are possible; for correct version, refer to ⇒ Electronic parts catalogue „ETKA“

24 - Bolt

❑ Tightening torque for vehicles with manual gearbox ⇒ Rep. gr. 34

❑ Tightening torque for vehicles with automatic gearbox ⇒ Rep. gr. 37

16 Rep. gr.40 - Front suspension

Page 23

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Running gear, front-wheel drive and four-wheel drive - Edition 08.2010

25 - Bolt

❑ Tightening torque for vehicles with manual gearbox ⇒ Rep. gr. 34

❑ Tightening torque for vehicles with automatic gearbox ⇒ Rep. gr. 37

26 - Subframe

❑ Removing and installing ⇒ page 17

❑ Servicing subframe ⇒ page 22

❑ Locating subframe in position ⇒ page 25

❑ Different versions possible. For correct version refer to ⇒ Electronic parts catalogue „ETKA“

27 - Bonded rubber bush (top) for pendulum support

❑ Removing and installing ⇒ page 22

2.2 Removing and installing subframe

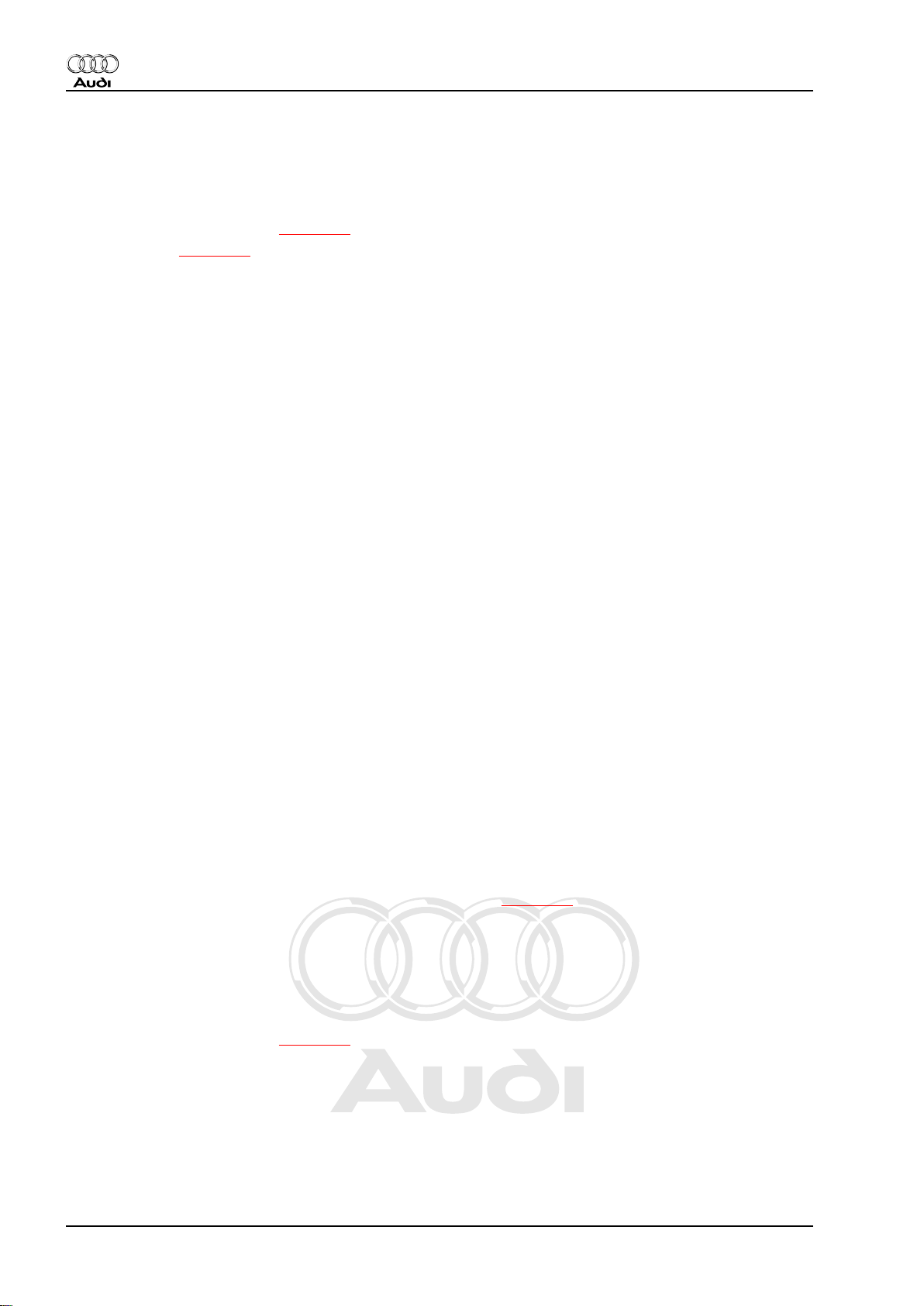

Special tools and workshop equipment required

♦ Locating pins -T10096-

♦ Engine and gearbox jack -V.A.G 1383 A-

♦ Torque wrench -V.A.G 1331-

2. Subframe, anti-roll bar, wishbone, swivel joint, vehicle level sender 17

Page 24

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Running gear, front-wheel drive and four-wheel drive - Edition 08.2010

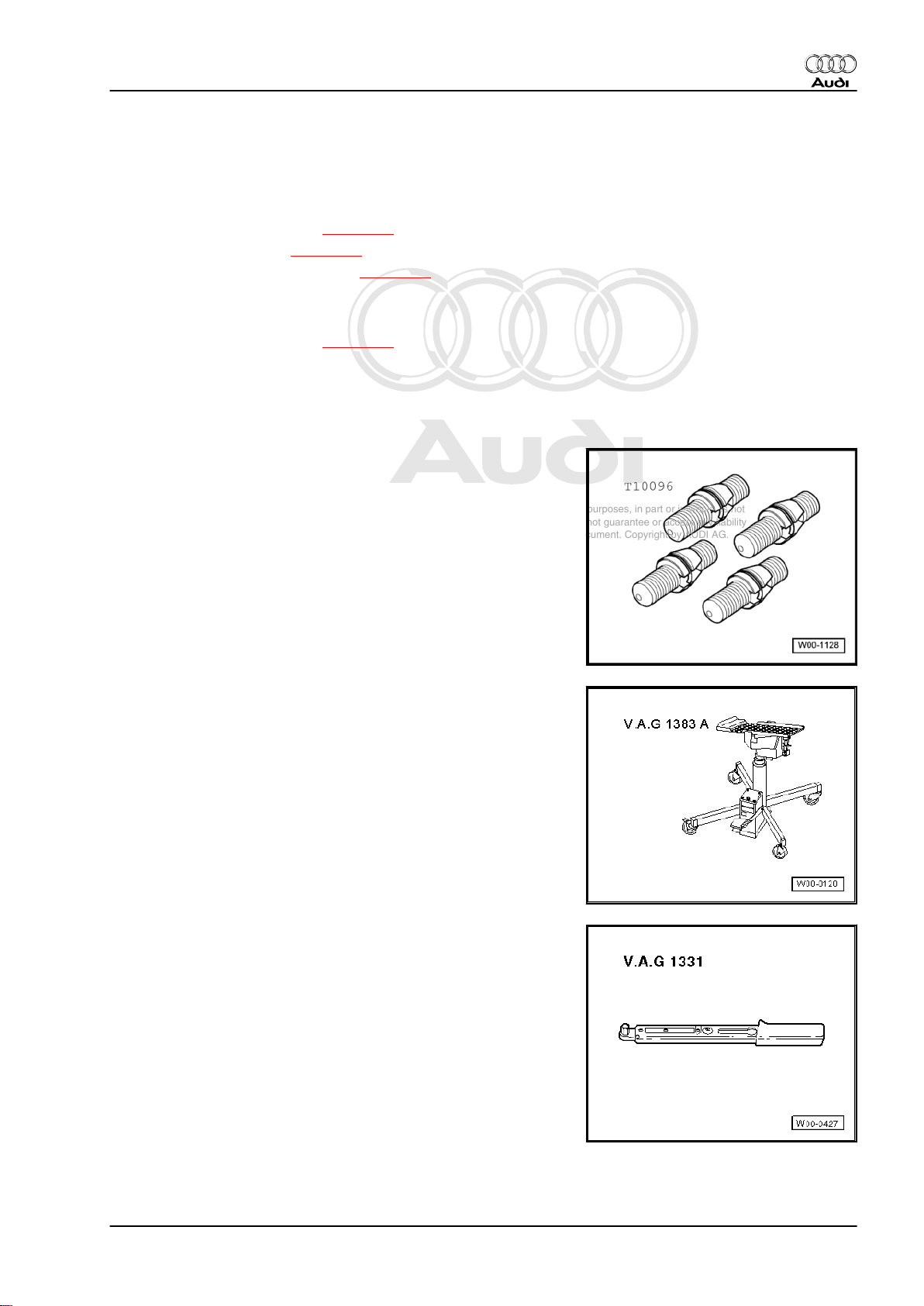

♦ Torque wrench -V.A.G 1332-

Removing

Note

The subframe is removed together with the anti-roll bar and wish‐

bones.

– Remove wheels.

– Detach noise insulation (bottom) ⇒ Rep. gr. 66 .

– Remove frame for noise insulation ⇒ Rep. gr. 50 .

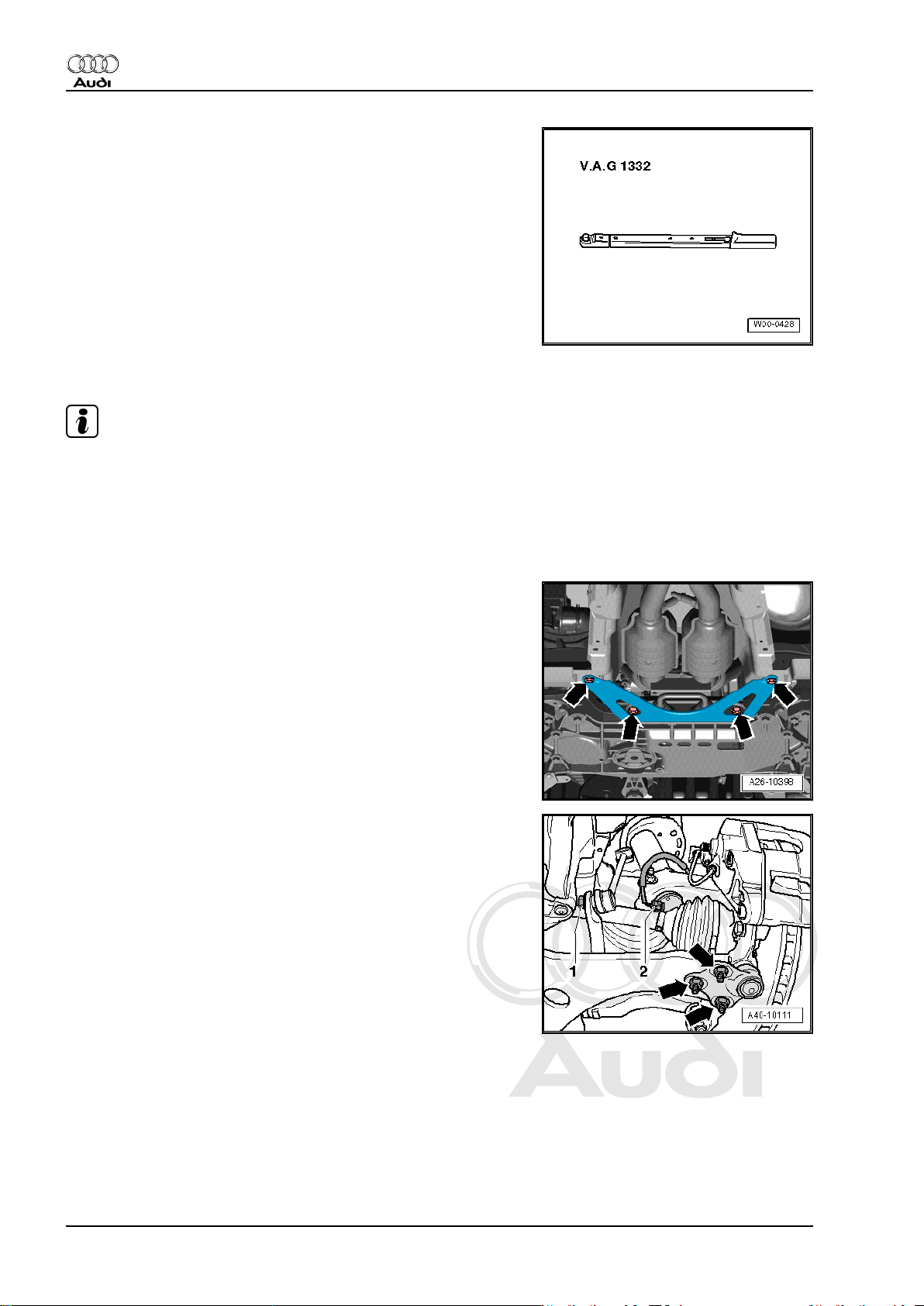

– Remove bolts -arrows- for exhaust bracket.

– Remove nut -1-.

18 Rep. gr.40 - Front suspension

Page 25

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Running gear, front-wheel drive and four-wheel drive - Edition 08.2010

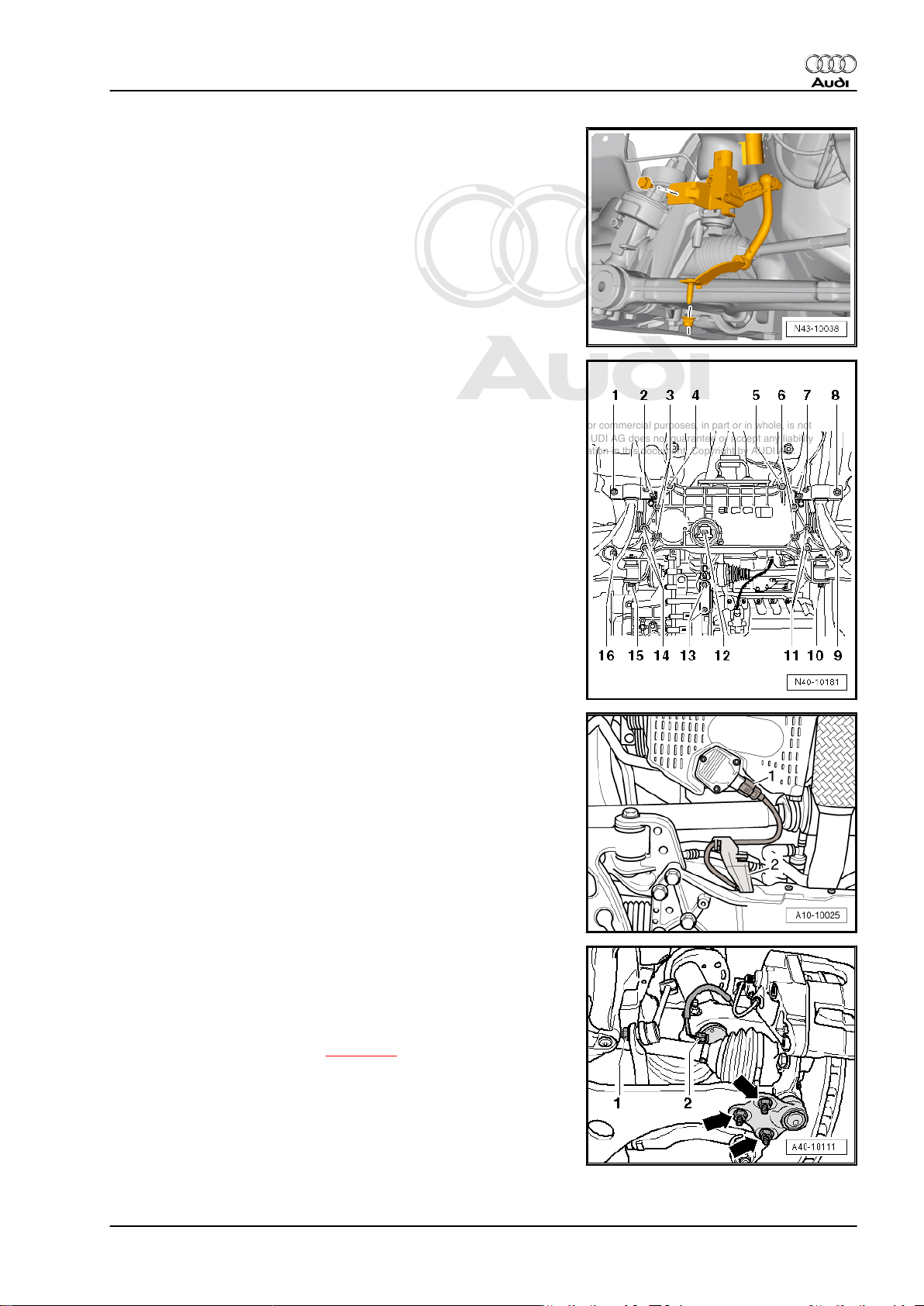

– On vehicles with vehicle level sender, unplug connector and

unscrew nut from linkage at wishbone.

– Unscrew bolts -13- and remove pendulum support from gear‐

box.

Audi TT 2007 ➤

– Unplug connector -1- for oil level and oil temperature sender

-G266- and unclip wiring from bracket -2-.

– Mark positions of nuts -arrows- with felt pen on both sides of

vehicle.

– Remove nuts -arrows- on both sides of vehicle.

– Pull wishbone out of swivel joint.

– Locate subframe in position ⇒ page 25 .

2. Subframe, anti-roll bar, wishbone, swivel joint, vehicle level sender 19

Page 26

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Running gear, front-wheel drive and four-wheel drive - Edition 08.2010

– Remove bolts -3- and -6- for steering box.

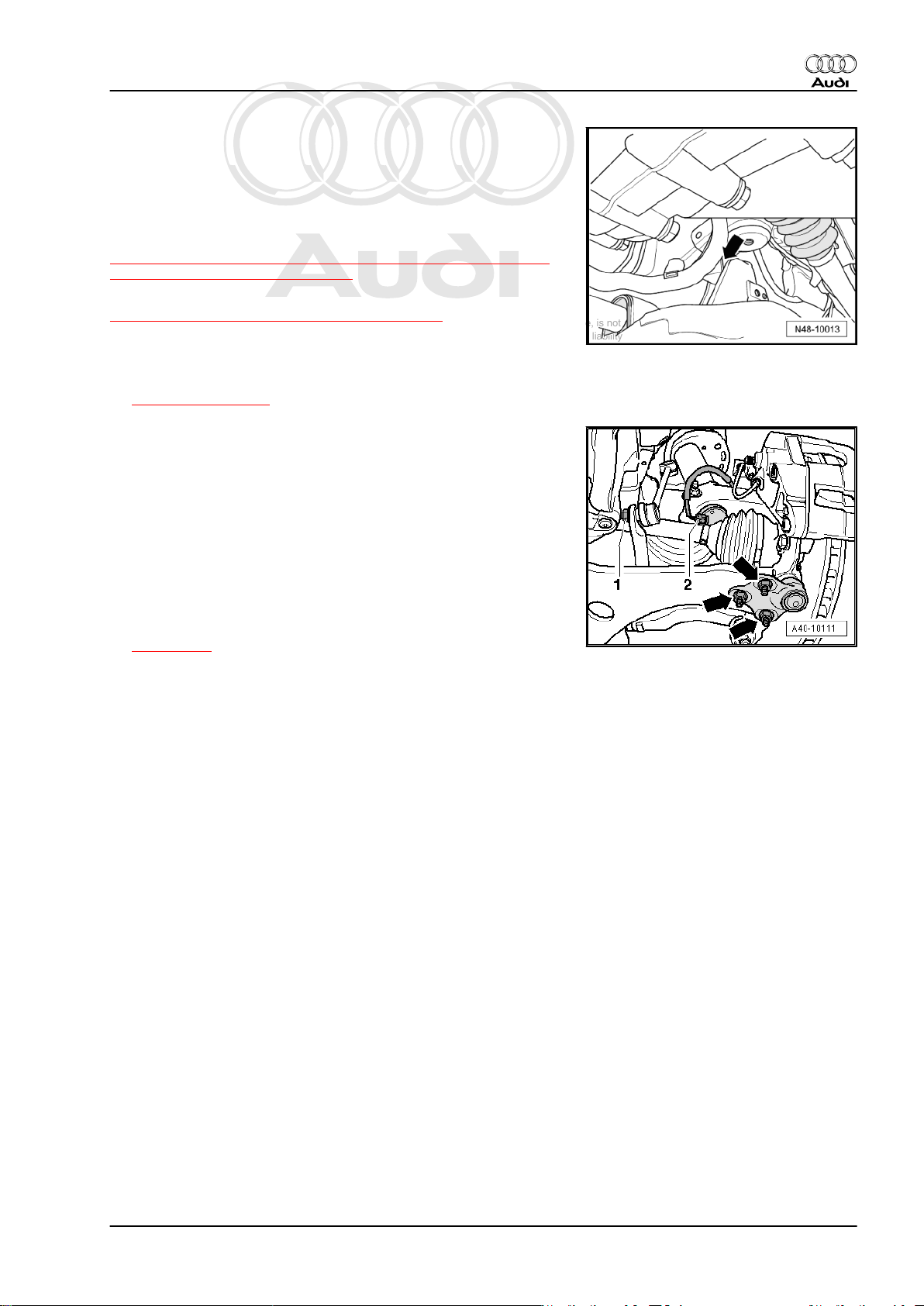

– Position engine and gearbox jack -V.A.G 1383 A- with suitable

wooden block -1- under subframe and press subframe up‐

wards lightly.

– Remove bolts -4- and -5-.

– Lower subframe with attached components approx. 30 mm

and pry threaded sleeves for steering box out of holes in sub‐

frame.

– Secure steering box to body.

20 Rep. gr.40 - Front suspension

Page 27

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Running gear, front-wheel drive and four-wheel drive - Edition 08.2010

– Detach cable guide from subframe -arrow-.

– Lower subframe with attached components.

Installing

Installation is performed in reverse sequence; note the following:

Tightening torques

⇒ „2.1 Exploded view of subframe, anti-roll bar, wishbone, swivel

joint, vehicle level sender“, page 15

Tightening torques

⇒ „4 Electro-mechanical steering box“, page 264

Threaded sleeves of steering box must be located in subframe

holes.

– Always renew retaining plate if removed

⇒ Item 11 (page 15) .

– Align position of nuts -arrows- according to markings made on

removal and tighten nuts.

– Install frame for noise insulation ⇒ Rep. gr. 50 .

– Install noise insulation ⇒ Rep. gr. 66 .

– On vehicles with electronic damping control (Audi magnetic

ride), re-adapt reference position ⇒ Vehicle diagnostic, testing

and information system VAS 5051.

– On vehicles with automatic headlight range control, carry out

basic adjustment of headlights ⇒ Rep. gr. 94 .

– Check and adjust wheel alignment as required, see chart

⇒ page 243 .

Audi TT 2007 ➤

2. Subframe, anti-roll bar, wishbone, swivel joint, vehicle level sender 21

Page 28

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Running gear, front-wheel drive and four-wheel drive - Edition 08.2010

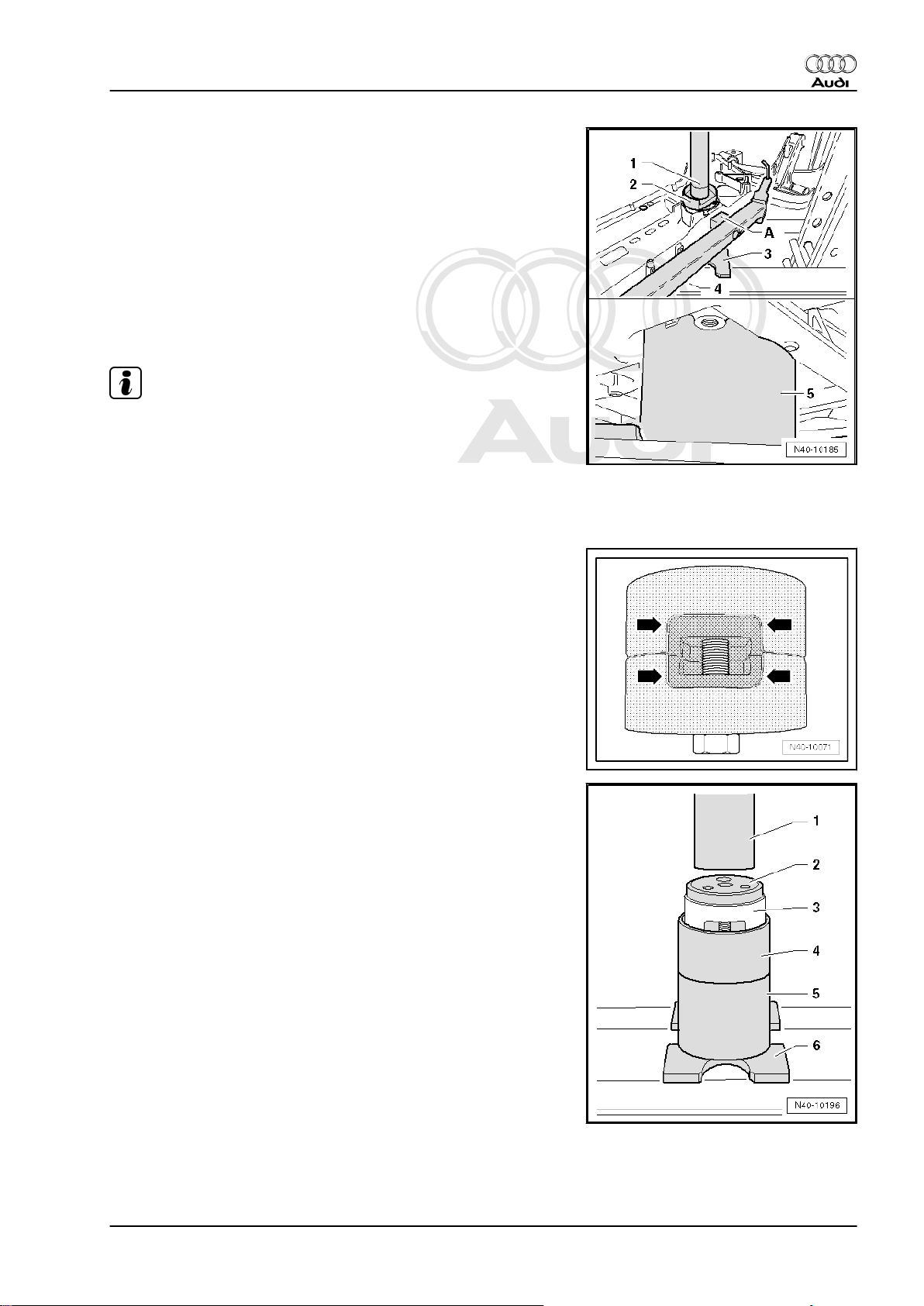

2.3 Servicing subframe

Special tools and workshop

equipment required

♦ Removal tool -3372-

♦ Thrust plate -VW 401-

♦ Press tool -VW 407-

♦ Press tool -VW 432-

♦ Assembly tool -T10214-

♦ Assembly tool -T10267-

♦ Tube from assembly tool -T10244/3-

– Remove subframe ⇒ page 17 .

– Detach pendulum support from subframe.

22 Rep. gr.40 - Front suspension

Page 29

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Running gear, front-wheel drive and four-wheel drive - Edition 08.2010

Pressing out bonded rubber bush

– Attach assembly tool -T10267- -4- to subframe. Secure re‐

taining pins of tool with locking pins.

1 - Press tool -VW 407-

2 - Thrust piece -3372/1-

3 - Thrust plate -VW 401-

4 - Assembly tool -T10267-

5 - Tube -T10244/3-

– Press out both bonded rubber bushes together as shown.

Note

♦

The flattened side of press tool -3372/1- must face the attach‐

ment -A- on assembly tool -T10267- , otherwise the attach‐

ment can be damaged.

♦

The tube -T10244/3- has two different internal diameters. The

subframe must be positioned on the larger diameter of the tube

-T10244/3- .

Audi TT 2007 ➤

Pressing in bonded rubber bush

– Bolt together both bonded rubber bushes with the genuine bolt

(the two recesses -arrows- must be exactly above each other).

– Insert the assembled bonded rubber bushes into the larger

diameter of tube -T10214/2- (with bolt head pointing down‐

wards).

1 - Press tool -VW 432-

2 - Press tool -T10214/3- without bolts.

3 - Bonded rubber bush

4 - Tube -T10214/2-

5 - Tube -T10214/1-

6 - Thrust plate -VW 401-

2. Subframe, anti-roll bar, wishbone, swivel joint, vehicle level sender 23

Page 30

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Running gear, front-wheel drive and four-wheel drive - Edition 08.2010

– Press in bonded rubber bushes -1- until dimension -a- is ob‐

tained.

Dimension -a- = 2 - 3 mm.

– Align tube -T10214/2- containing pressed-in bonded rubber

bushes on subframe. The corners of the inner core of the bush

-1- should lie parallel with the edge of assembly tool -T10267-

-2-.

The distance -a- must be identical on both sides to ensure parallel

alignment.

– Place subframe onto smaller internal diameter of tube -

T10244/3- .

– Press in bushes as far as stop (until a force of 20 kN is at‐

tained).

1 - Press tool -VW 407-

2 - Thrust piece -T10214/3-

3 - Tube -T10214/2-

4 - Assembly tool -T10267-

5 - Tube -T10244/3-

– Detach assembly tool -T10267- from subframe and check

pressed-in bonded rubber bushes for proper seating.

• The outer diameter -1- of the two bonded rubber bushes may

project up to 2 mm above the edge in the vicinity of the aper‐

ture for the pendulum support.

• The recesses of the bonded rubber bushes must be positioned

in the centre of the aperture in the subframe.

• There may be a gap -arrow- between the bonded rubber bush‐

es.

– Install subframe ⇒ page 17 .

24 Rep. gr.40 - Front suspension

Page 31

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Running gear, front-wheel drive and four-wheel drive - Edition 08.2010

2.4 Locating subframe in position

Special tools and workshop equipment required

♦ Locating pins -T10096-

♦ Torque wrench -V.A.G 1331-

Audi TT 2007 ➤

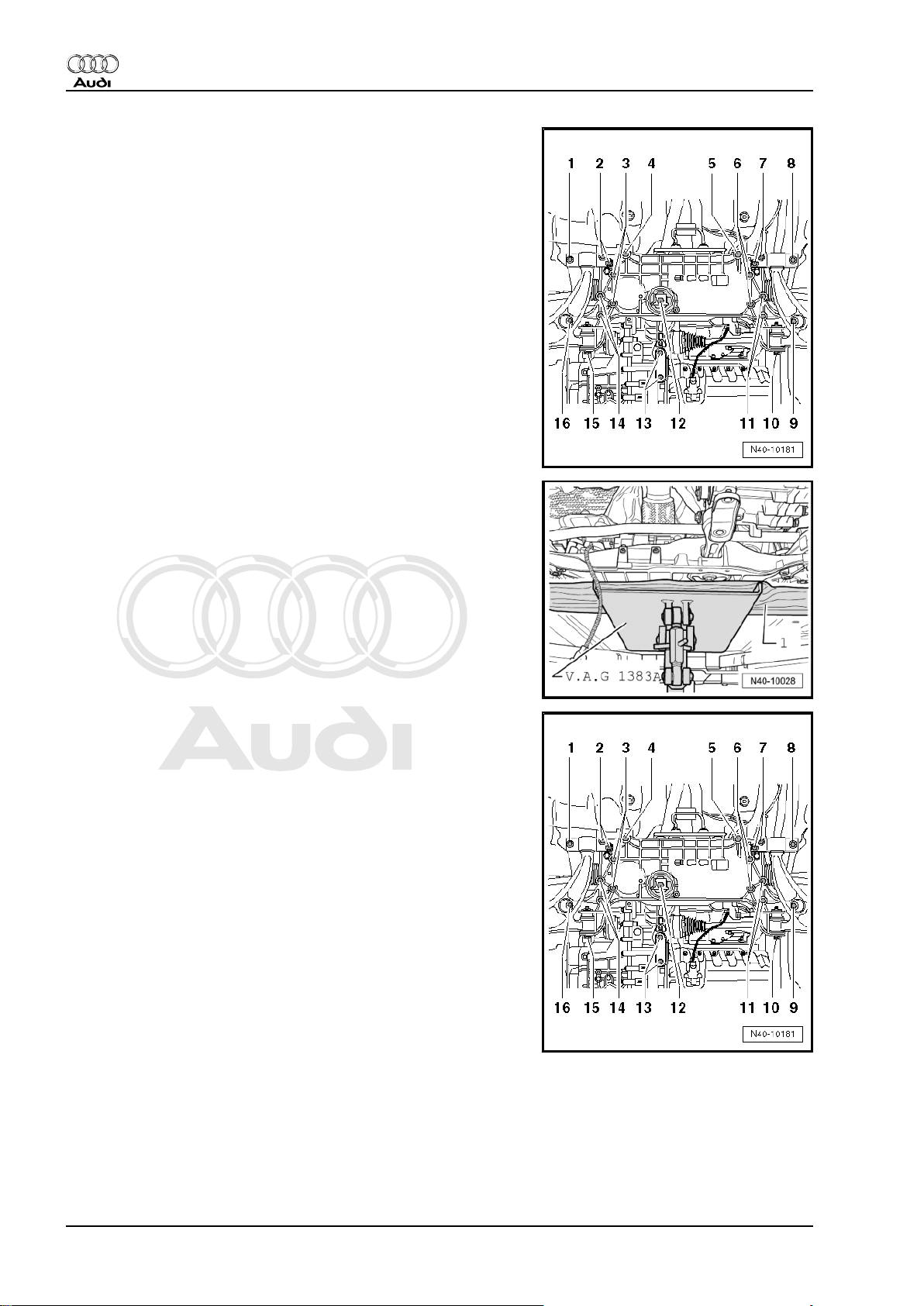

Installing locating pins -T10096-

The locating pins -T10096- must be screwed in one after the other

at positions -1-, -8-, -9- and -16- to locate the subframe with wish‐

bones in position.

– Screw in locating pins -T10096- in place of securing bolts and

tighten to 20 Nm.

2. Subframe, anti-roll bar, wishbone, swivel joint, vehicle level sender 25

Page 32

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Running gear, front-wheel drive and four-wheel drive - Edition 08.2010

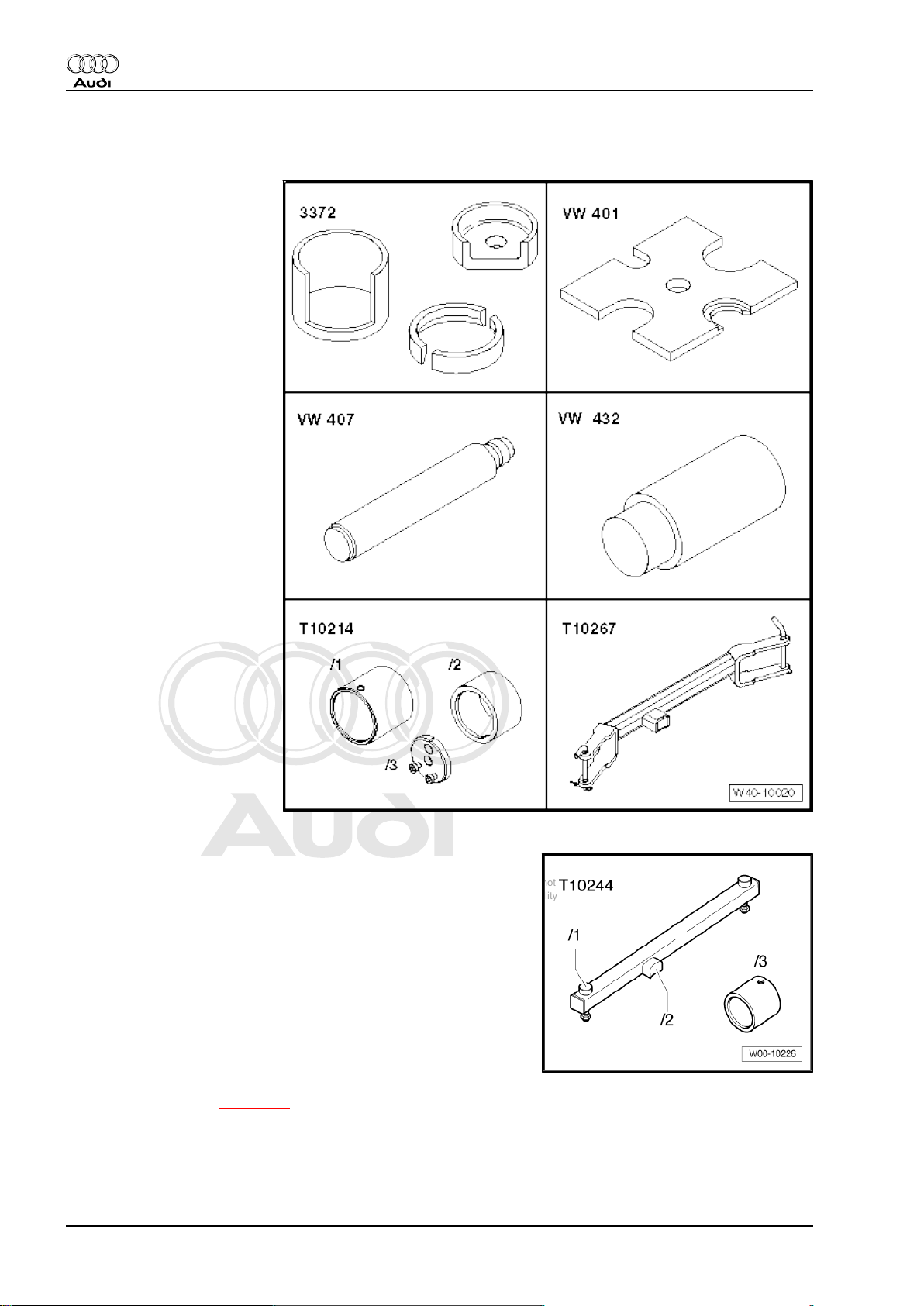

Locating mounting bracket in position

Locating subframe in position

The front axle is now fixed in position.

Removing locating pins -T10096-

Installation is carried out in the reverse sequence. When instal‐

ling, remove locating pins -T10096- one after the other and screw

in new securing bolts in their place.

Tightening torques

⇒ „2.1 Exploded view of subframe, anti-roll bar, wishbone, swivel

joint, vehicle level sender“, page 15

2.5 Removing and installing anti-roll bar

Special tools and workshop equipment required

♦ Locating pins -T10096-

♦ Engine and gearbox jack -V.A.G 1383 A-

26 Rep. gr.40 - Front suspension

Page 33

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Running gear, front-wheel drive and four-wheel drive - Edition 08.2010

♦ Torque wrench -V.A.G 1331-

♦ Torque wrench -V.A.G 1332-

Audi TT 2007 ➤

Removing

– Remove subframe ⇒ page 17

– Unbolt anti-roll bar from subframe -11 and 14-.

– Remove anti-roll bar.

Installing

Installation is performed in reverse sequence; note the following:

Tightening torques

⇒ „2.1 Exploded view of subframe, anti-roll bar, wishbone, swivel

joint, vehicle level sender“, page 15

Tightening torques

⇒ „4 Electro-mechanical steering box“, page 264

– Install subframe ⇒ page 17 .

– Always renew retaining plate if removed

⇒ Item 11 (page 15) .

2.6 Removing and installing wishbone and mounting bracket

Special tools and workshop equipment required

2. Subframe, anti-roll bar, wishbone, swivel joint, vehicle level sender 27

Page 34

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Running gear, front-wheel drive and four-wheel drive - Edition 08.2010

♦ Locating pins -T10096-

♦ Torque wrench -V.A.G 1332-

♦ Torque wrench -V.A.G 1331-

Removing

– Remove wheel.

– Detach noise insulation (bottom) ⇒ Rep. gr. 66 .

– On vehicles with vehicle level sender, unscrew nut from link‐

age at wishbone.

28 Rep. gr.40 - Front suspension

Page 35

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Running gear, front-wheel drive and four-wheel drive - Edition 08.2010

– Mark positions of nuts -arrows- with felt pen.

– Unscrew nuts -arrows-.

– Pull wheel bearing housing with swivel joint out of wishbone.

– Screw in locating pins -T10096- in place of bolt -1- (left-side)

and bolt -8- (right-side) and tighten locating pins to 20 Nm.

Caution

The locating pins -T10096- must not be tightened to more than

20 Nm, otherwise the threads of the locating pins will be dam‐

aged.

Audi TT 2007 ➤

– Remove bolts -1-.

2. Subframe, anti-roll bar, wishbone, swivel joint, vehicle level sender 29

Page 36

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Running gear, front-wheel drive and four-wheel drive - Edition 08.2010

– Unscrew bolt -15- on left side of vehicle or bolt -10- on right

side.

Note

If bolt -15- or -10- cannot be unscrewed, the subframe must be

removed on these vehicles ⇒ page 17 .

– Remove wishbone.

Installing

Installation is performed in reverse sequence; note the following:

Tightening torques

⇒ „2.1 Exploded view of subframe, anti-roll bar, wishbone, swivel

joint, vehicle level sender“, page 15

– Fit bolt -15- on left side of vehicle or bolt -10- on right side, and

tighten hand-tight.

– Always renew retaining plate if removed

⇒ Item 11 (page 15) .

– Align position of nuts -arrows- according to markings made on

removal and tighten nuts.

Note

♦

Bonded rubber bushes can only be turned to a limited extent.

The suspension mountings must therefore only be tightened

when the suspension is in the unladen position or reference

position.

♦

Lifting suspension to unladen position (vehicles with coil

springs) ⇒ page 11

30 Rep. gr.40 - Front suspension

Page 37

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Running gear, front-wheel drive and four-wheel drive - Edition 08.2010

– With vehicle in unladen position ⇒ page 11 , tighten bolt -15-

on left side of vehicle or bolt -10- on right side.

– On vehicles with electronic damping control (Audi magnetic

ride), re-adapt reference position ⇒ Vehicle diagnostic, testing

and information system VAS 5051.

– On vehicles with automatic headlight range control, carry out

basic adjustment of headlights ⇒ Rep. gr. 94 .

– Check and adjust wheel alignment as required, see chart

⇒ page 243 .

2.7 Renewing bonded rubber bush in wishbone

Audi TT 2007 ➤

Special tools and workshop

equipment required

♦ Assembly tool -T10219-

♦ Thrust plate -VW 402-

♦ Press tool -VW 411-

2. Subframe, anti-roll bar, wishbone, swivel joint, vehicle level sender 31

Page 38

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Running gear, front-wheel drive and four-wheel drive - Edition 08.2010

Pressing out bonded rubber bush

– Press out bonded rubber bush as shown.

1 - Press tool -VW 411-

2 - Tube -T10219/1-

3 - Thrust plate -VW 402-

Pressing in bonded rubber bush

Note installation position of bonded rubber bush: retaining

grooves -arrows- must be aligned symmetrically relative to axis

of wishbone.

Beads -1 and 2- face towards front of vehicle as shown in illus‐

tration.

• The bonded rubber bush must be applied at an angle to pre‐

vent damage when pressing in. The bush will then straighten

up as it is pressed in.

– Apply assembly lubricant ⇒ Electronic parts catalogue (diluted

1:20 with water) to outside of bonded rubber bush.

– Apply bonded rubber bush at an angle (towards wishbone).

Lip -arrow- must slide into hole as shown.

1 - Mandrel -T10219/2-

2 - Tube -T10219/1-

3 - Thrust plate -VW 402-

32 Rep. gr.40 - Front suspension

Page 39

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Running gear, front-wheel drive and four-wheel drive - Edition 08.2010

– Press in bonded rubber bush until core of bush -1- is level with

hole in wishbone -2-.

– Press back bush slightly in wishbone.

1 - Tube -T10219/1-

2 - Thrust plate -VW 402-

Audi TT 2007 ➤

Dimensions -a- and -b- must be equal.

2. Subframe, anti-roll bar, wishbone, swivel joint, vehicle level sender 33

Page 40

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Running gear, front-wheel drive and four-wheel drive - Edition 08.2010

2.8 Renewing mounting bracket for wishbone

Special tools and workshop

equipment required

♦ Press tool -VW 411-

♦ Thrust plate -VW 401-

♦ Thrust plate -VW 402-

♦ Tube -VW 426-

♦ Press tool -VW 412-

♦ Assembly tool -T10219-

Pressing mounting bracket off wishbone

Note

Hold wishbone while pressing it out

1 - Thrust plate -VW 401-

2 - Press tool -VW 411-

3 - Thrust plate -VW 402-

– Press off mounting bracket with bonded rubber bush from

wishbone.

34 Rep. gr.40 - Front suspension

Page 41

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Running gear, front-wheel drive and four-wheel drive - Edition 08.2010

Pressing mounting bracket onto wishbone

– Apply assembly lubricant ⇒ Electronic parts catalogue (diluted

1:20 with water) to hexagon flats of wishbone.

– Carefully press mounting bracket onto wishbone as far as it

will go.

1 - Press tool -VW 412-

2 - Tube -VW 426-

3 - Mounting bracket with bonded rubber bush

4 - Wishbone

5 - Tube T10219/1 from assembly tool -T10219-

6 - Thrust plate -VW 401-

2.9 Removing and installing swivel joint

Audi TT 2007 ➤

Special tools and workshop

equipment required

♦ Ball joint puller -3287 A-

♦ Angle wrench -V.A.G 1756-

♦ Ring spanner insert -

V.A.G 1332/10-