Page 1

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Service

Workshop Manual

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8

ltr., 2.0 ltr. 4-valve turbo with timing chain)

Engine ID

Edition 06.2010

CDAACCZACCTACESACET

A

Service Department. Technical Information

Page 2

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Service

List of Workshop Manual Repair GroupsList of Workshop Manual

Repair GroupsList of Workshop Manual Repair Groups

Re pa ir G ro up

24 - Mixture preparation - injection

28 - Ignition system

Technical information should always be available to the foremen and mechanics, because their

careful and constant adherence to the instructions is essential to ensure vehicle road-worthiness and

safety. In addition, the normal basic safety precautions for working on motor vehicles must, as a

matter of course, be observed.

All rights reserved.

No reproduction without prior agreement from publisher.

Copyright © 2010 Audi AG, Ingolstadt A005TT02120

Page 3

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

Contents

24 - Mixture preparation - injection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1 Safety precautions and rules for cleanliness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 General notes on self-diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 Safety precautions for vehicles with start/stop system . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4 Rules for cleanliness and instructions for working on fuel system . . . . . . . . . . . . . . . . . . . . 3

1.5 Important: Required procedure prior to opening high-pressure injection system . . . . . . . . 4

1.6 Checking vacuum system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Overviews - fitting locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Overview - fitting locations (engine codes CDAA, CCZA and CCTA) . . . . . . . . . . . . . . . . 8

3.2 Overview - fitting locations (engine codes CESA and CETA) . . . . . . . . . . . . . . . . . . . . . . 19

4 Air cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.1 Air cleaner - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.2 Removing and installing engine cover panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.3 Removing and installing air filter element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.4 Removing and installing air cleaner housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5 Intake manifold (engine codes CDAA, CCZA and CCTA) . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.1 Intake manifold - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.2 Fuel rail - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6 Intake manifold (engine codes CESA and CETA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.1 Intake manifold - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.2 Fuel rail - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.3 Removing and installing intake manifold with fuel rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7 High-pressure pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.1 High-pressure pump - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.2 Removing and installing high-pressure pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8 Injectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

8.1 Removing and installing injectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

8.2 Cleaning injectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

9 Components of injection system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

9.1 Removing and installing fuel pressure sender G247 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

9.2 Checking fuel pressure sender G247 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

9.3 Checking fuel pressure and residual pressure (up to high-pressure pump) . . . . . . . . . . . . 62

9.4 Removing and installing air mass meter G70 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

9.5 Removing and installing throttle valve module J338 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

9.6 Cleaning throttle valve module J338 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

9.7 Checking intake manifold change-over function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

9.8 Checking dual non-return valve of activated charcoal filter solenoid valve 1 N80 . . . . . . 68

10 Lambda probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

10.1 Lambda probes - overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

10.2 Removing and installing Lambda probe G39 and Lambda probe heater Z19 before catalytic

converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

10.3 Removing and installing Lambda probe after catalytic converter G130 and Lambda probe 1

heater after catalytic converter Z29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

11 Engine control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

11.1 Wiring and component check with test box V.A.G 1598/42 . . . . . . . . . . . . . . . . . . . . . . . . 75

11.2 Renewing engine control unit J623 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

28 - Ignition system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

1 General notes and safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

1.1 General notes on ignition system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Contents i

Page 4

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

1.2 Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

2 Servicing ignition system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

2.1 Test data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

2.2 Ignition system - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

2.3 Removing and installing ignition coils with output stages . . . . . . . . . . . . . . . . . . . . . . . . . . 84

2.4 Removing and installing knock sensor 1 G61 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

2.5 Removing and installing engine speed sender G28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

ii Contents

Page 5

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

24 – Mixture preparation - injection

1 Safety precautions and rules for

cleanliness

1.1 General notes on self-diagnosis

♦ The engine control unit has a self-diagnosis capability. Before

carrying out repairs and fault finding, the event memory must

be interrogated. The vacuum hoses and connections must al‐

so be checked (unmetered air).

♦ Fuel hoses in engine compartment must only be secured with

spring-type clips. O-type clips or screw-type clips must not be

used.

♦ A voltage of at least 11.5 V is required for proper operation of

the electrical components.

♦ Do not use sealants containing silicone. Particles of silicone

drawn into the engine will not be burnt in the engine and will

damage the Lambda probe.

♦ The vehicles are fitted with a crash/fuel shut-off system. This

system is designed to reduce the risk of a vehicle fire after a

crash by deactivating the fuel pump via the fuel pump relay.

♦ At the same time, this system also improves the engine's start‐

ing performance. When the driver's door is opened, the fuel

pump is activated for 2 seconds in order to build up pressure

in the fuel system ⇒ page 2 .

06.2010

1. Safety precautions and rules for cleanliness 1

Page 6

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

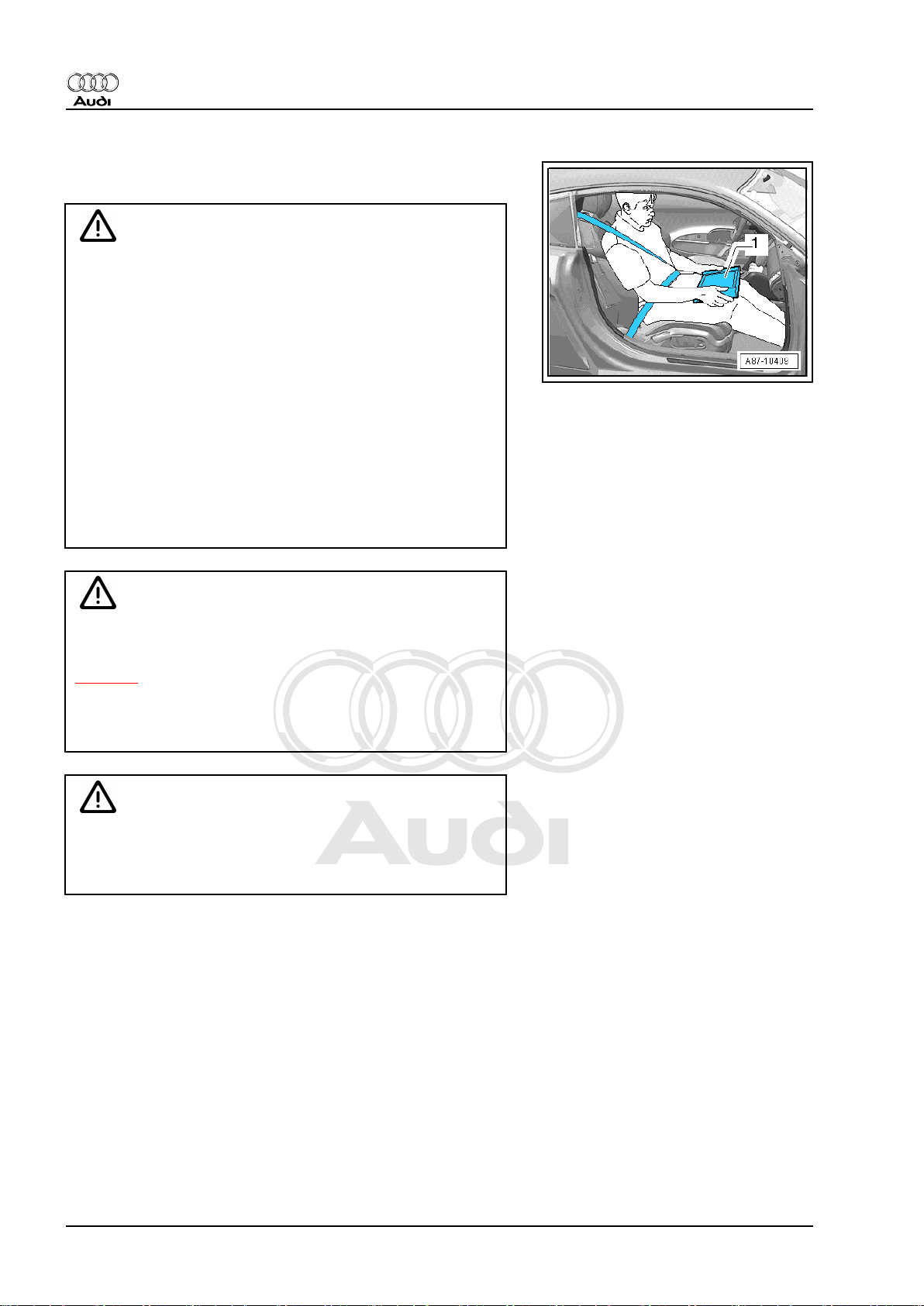

1.2 Safety precautions

Note the following if testers and measuring instruments have to

be used during a road test:

WARNING

Accidents can be caused if the driver is distracted by test

equipment while road-testing, or if test equipment is not prop‐

erly secured.

Persons sitting in the front passenger's seat could be injured if

the airbag is triggered in an accident.

• The use of test equipment while driving causes distraction.

• There is an increased risk of injury if test equipment is not

secured.

♦ Move the passenger's seat back as far as it will go.

♦ Use only vehicle diagnosis and service information sys‐

tem -VAS 5052 A- or diagnosis system -VAS 5053- .

♦ The test equipment -1- must rest flat on the passenger's

thighs (as shown in illustration) and must be operated by

the passenger.

WARNING

The fuel system is pressurised. The fuel pressure in the highpressure part of the injection system must be reduced to a

residual pressure prior to opening; for procedure see

⇒ page 4 .

The connection must be opened immediately after reducing

the pressure; wrap a cloth around the connection and allow the

residual pressure (approx. 6 bar) to dissipate.

Caution

To prevent damage to the electronic components when dis‐

connecting the battery:

♦ Observe notes on procedure for disconnecting the battery.

– Disconnect battery ⇒ Rep. Gr. 27 .

To prevent injuries to persons and/or damage to the fuel injection

and ignition system, the following must be noted:

2 Rep. Gr.24 - Mixture preparation - injection

Page 7

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

♦ For safety reasons, the battery must be disconnected before

opening the fuel system to prevent the fuel pump from being

activated by the contact switch on the driver's door.

♦ Persons wearing a cardiac pacemaker must at all times main‐

tain a safe distance from high-voltage components such as the

ignition system and gas-discharge headlights.

♦ Do not open any fuel line connections while the engine is run‐

ning.

♦ Always switch off the ignition before connecting or discon‐

necting injection or ignition system wiring or tester cables.

♦ If engine is to be operated at cranking speed without it starting

(e.g. compression test), unplug connectors from ignition coils

and remove fuse for electric fuel pump.

♦ Certain tests may lead to a fault being detected by the control

unit and stored. The event memory should therefore be inter‐

rogated and (if necessary) erased after completing the tests

and any repair work that may be required.

♦ If the event memory has been erased, you must generate the

readiness code again.

♦ Always switch off the ignition before cleaning the engine.

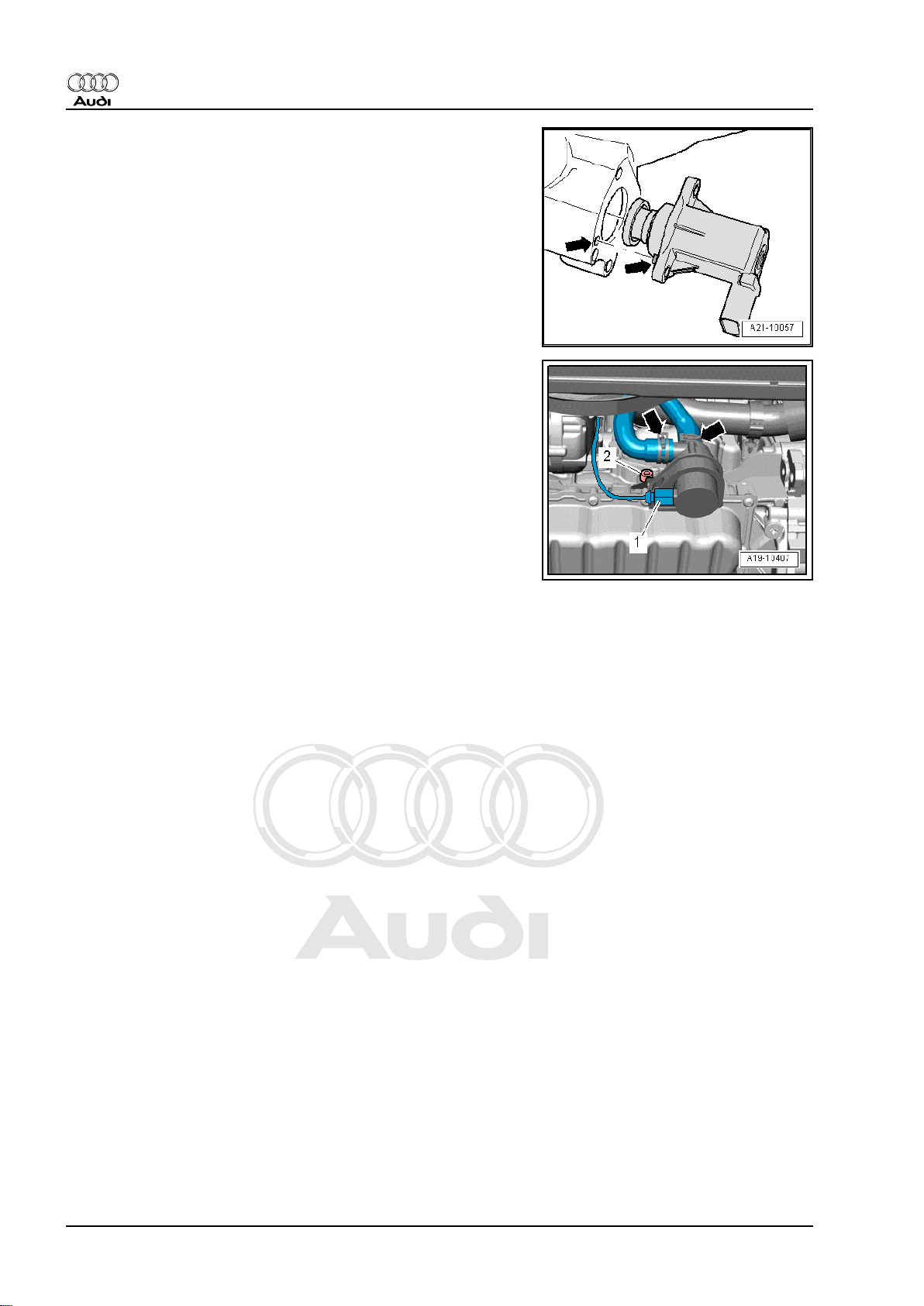

♦ If the engine has to be operated at the starting speed without

actually starting (e.g. to test compression pressure), detach

the four connectors from the ignition coils using assembly tool

-T40039- ⇒ page 84 . Also remove fuse for fuel pump control

unit -J538- .

Note

♦

The fuse is located in the fuse holder in the luggage compart‐

ment (right-side).

♦

Removing the fuse will interrupt the voltage supply “termi‐

nal 30” for the fuel pump control unit -J538- . ⇒ Current flow

diagrams, Electrical fault finding and Fitting locations

1.3 Safety precautions for vehicles with start/stop system

WARNING

Risk of injury due to automatic engine start on vehicles with

start/stop system.

♦ On vehicles with activated start/stop system (this is indi‐

cated by a message in the instrument cluster display), the

engine may start automatically on demand.

♦ Therefore it is important to ensure that the start/stop sys‐

tem is deactivated when performing repairs (switch off

ignition, if required switch on ignition again).

1.4 Rules for cleanliness and instructions for working on fuel system

Even small amounts of dirt can cause faults in the injection sys‐

tem. When working on the fuel supply/injection system, pay care‐

ful attention to the following basic rules:

1. Safety precautions and rules for cleanliness 3

Page 8

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

♦ Carefully clean connection points and the surrounding area

with engine cleaner or brake cleaner and dry thoroughly before

opening.

♦ Plug open lines and connections with suitable protective caps

immediately.

♦ Place parts that have been removed on a clean surface and

cover them over. Do not use fluffy cloths.

♦ Only install clean components; replacement parts should only

be unpacked immediately prior to installation. Do not use parts

that have been previously unpacked and stored away loose

(e.g. in toolboxes, etc.).

♦ When the system is open: Do not work with compressed air.

Do not move the vehicle unless absolutely necessary.

1.5 Important: Required procedure prior to opening high-pressure injection system

Caution

The injection system consists of a high-pressure section (max‐

imum approx. 150 bar) and a low-pressure section (approx. 7

bar).

Prior to opening the high-pressure section (e.g. when removing

the high-pressure pump, fuel rail, injectors, fuel pipes, etc.) the

fuel pressure in the high-pressure section must be reduced.

The procedure is described below.

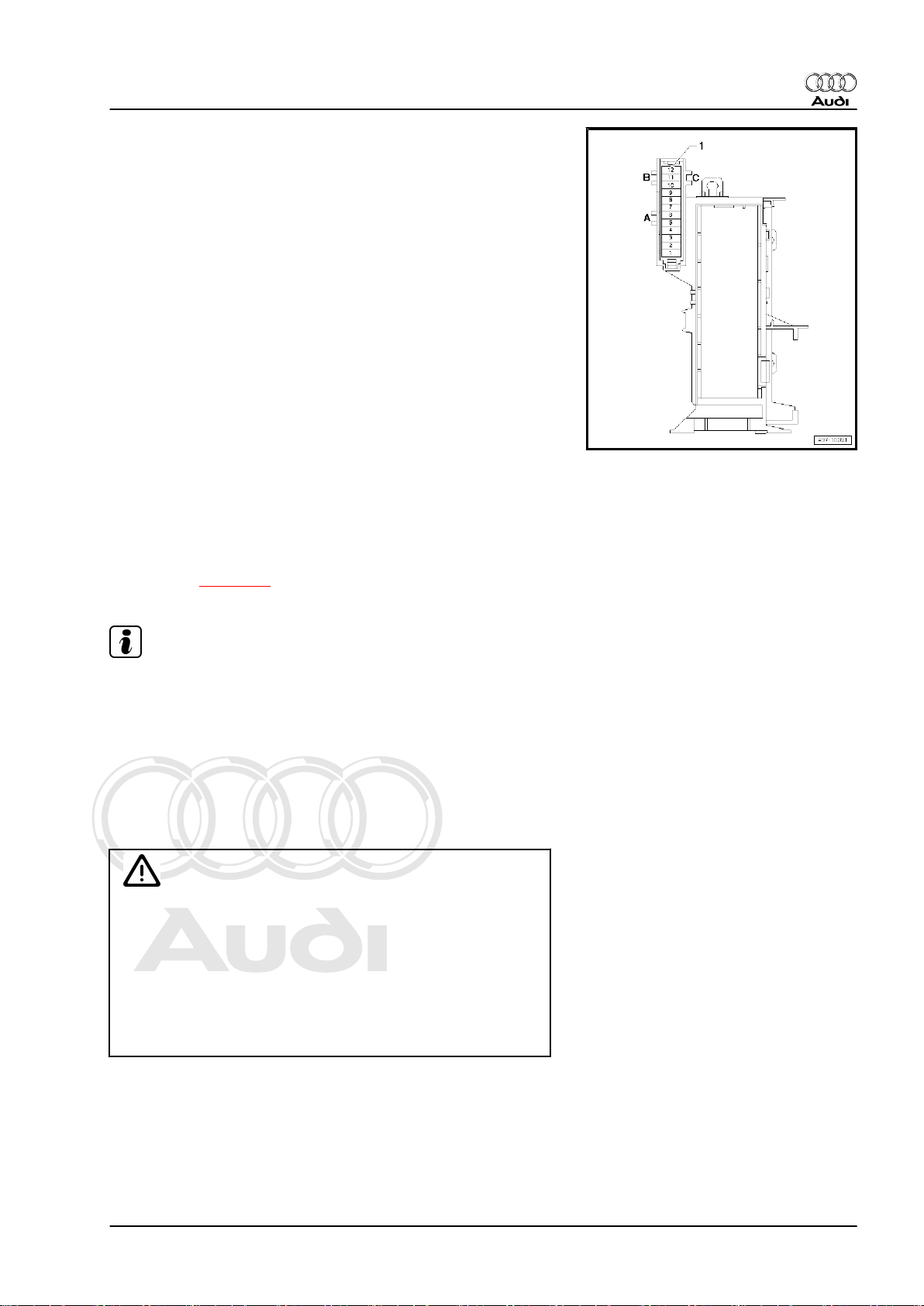

Reducing fuel pressure in high-pressure section

– Connect a vehicle diagnostic tester.

– Start engine and run at idling speed.

– Select “Engine electronics” in vehicle self-diagnosis.

– Then select function read “Measured values”.

– Select measured value block 140.

– With engine idling the fuel pressure is displayed in zone 3.

♦ Specification: between 35 and 45 bar

– The fuse is located in the fuse holder in the luggage compart‐

ment (right-side).

4 Rep. Gr.24 - Mixture preparation - injection

Page 9

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

– Remove luggage compartment trim (rear right) ⇒ Rep. Gr.

70 .

– With engine idling, pull out fuse for fuel pump control unit -

J538- ⇒ Current flow diagrams, Electrical fault finding and

Fitting locations.

– Observe fuel pressure displayed on tester.

• The fuel pressure will decrease very quickly because the me‐

chanical high-pressure pump is no longer being supplied with

fuel by the fuel system pressurisation pump -G6- .

– Switch off ignition as soon as fuel pressure has dropped to

approx. 8 bar.

Note

Fuel pressure must not fall below 6 bar, otherwise the engine will

stall (this could damage the catalytic converter).

WARNING

The fuel lines are still filled with fuel, however the fuel is no

longer under high pressure. Wear safety goggles and protec‐

tive clothing when opening the fuel system to avoid possible

injury and skin contact.

Before opening the high-pressure section, wrap a cloth around

the connection.

– The high-pressure system must be opened “immediately” after

reducing the fuel pressure; wrap a clean cloth around the con‐

nection. Catch the escaping fuel.

The following operations must be performed after completing re‐

pair work:

– Refit fuse.

– Erase event memory and generate readiness code in engine

control unit in “Guided Functions” mode.

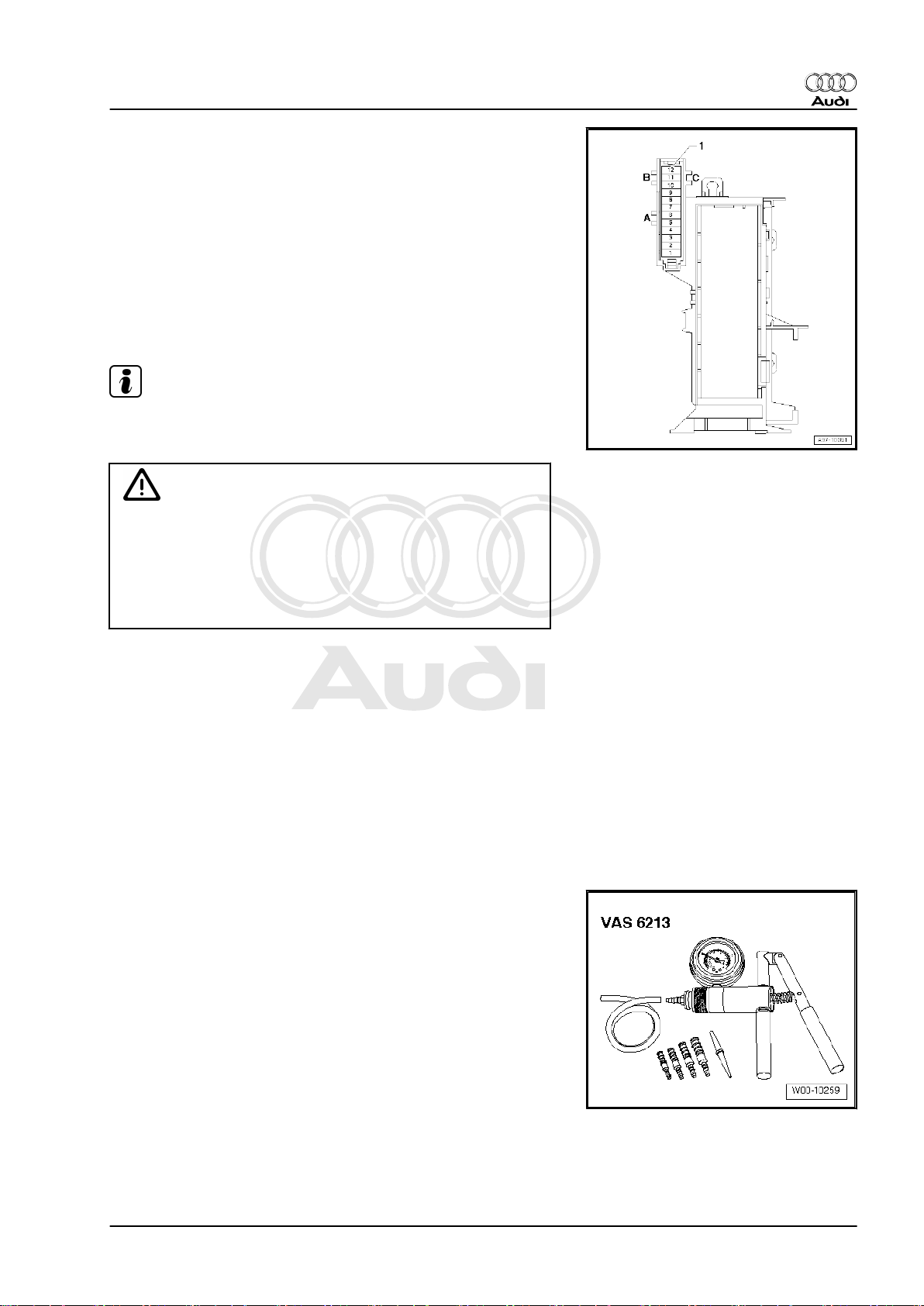

1.6 Checking vacuum system

Special tools and workshop equipment required

♦ Hand vacuum pump -VAS 6213-

Procedure

– Check all vacuum lines in the complete vacuum system for:

♦ Cracks

1. Safety precautions and rules for cleanliness 5

Page 10

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

♦ Traces of animal bites

♦ Kinked or crushed lines

♦ Lines porous or leaking

– Check vacuum line to solenoid valve and from solenoid valve

to corresponding component.

– If an entry is stored in the event memory, check the vacuum

lines leading to the corresponding component and also check

the remaining vacuum lines leading to other components.

– If it is not possible to build up pressure with the hand vacuum

pump -VAS 6213- or if the pressure drops again immediately,

check the hand vacuum pump and connecting hoses for leaks.

6 Rep. Gr.24 - Mixture preparation - injection

Page 11

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

2 Technical data

Engine data 1.8 ltr. and 2.0 ltr. turbo FSI engine

Idling speed is not adjustable; con‐

trolled by the idling speed stabili‐

sation

Maximum rpm governed by deac‐

tivation of fuel injectors

Fuel pressure Initial fuel pressure up to

high-pressure pump (gen‐

erated by electric fuel pump

Pressure in high-pressure

fuel circuit (generated by

mechanical single-plunger

pump) at a coolant temper‐

ature of approx. 85°C.

in fuel tank)

640 ... 800 rpm

6500 rpm

3.0 to 7.0 bar (identical for all operating

conditions)

approx. 40 bar at idling speed

approx. 150 bar in certain parts of operating

range.

2. Technical data 7

Page 12

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

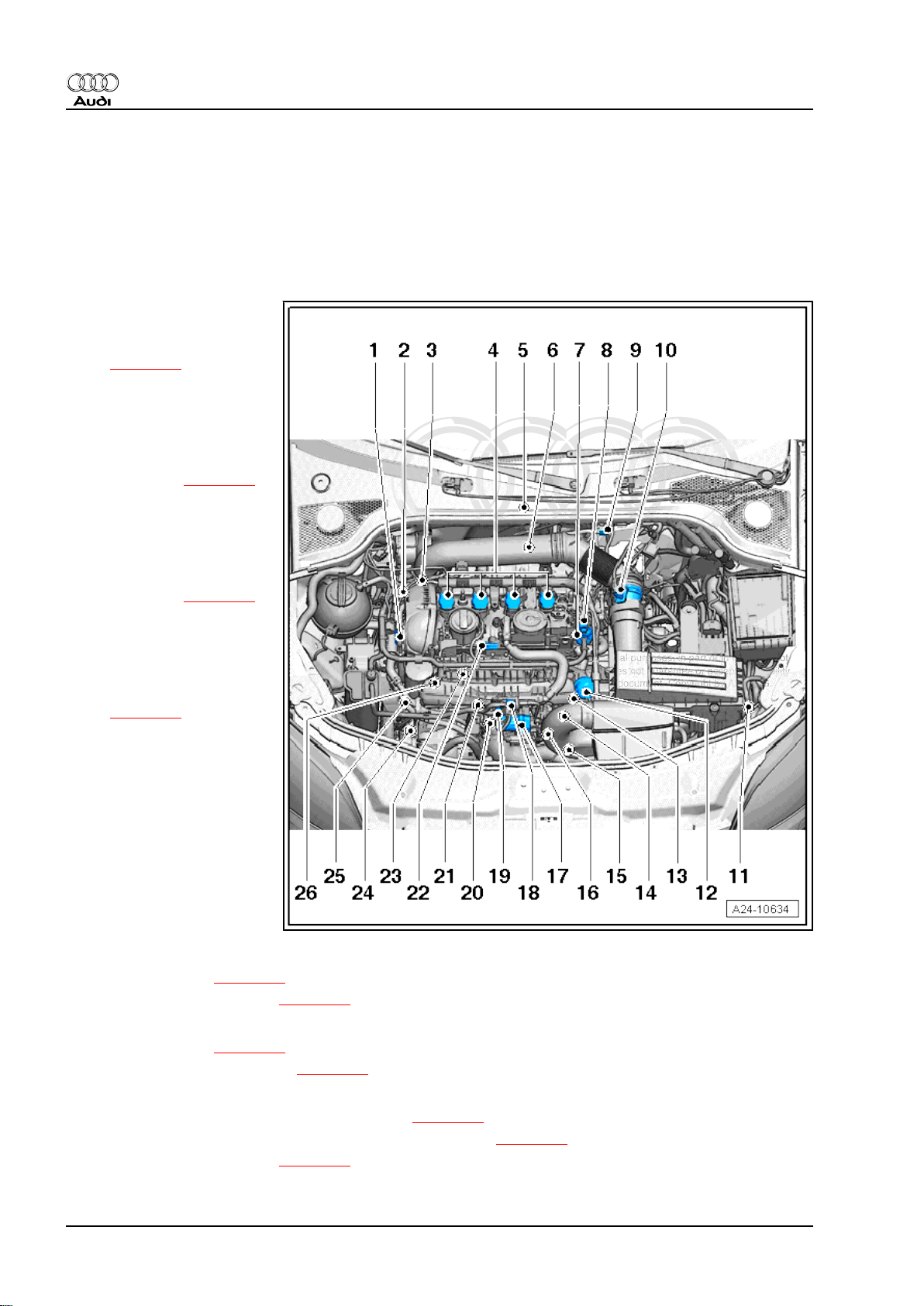

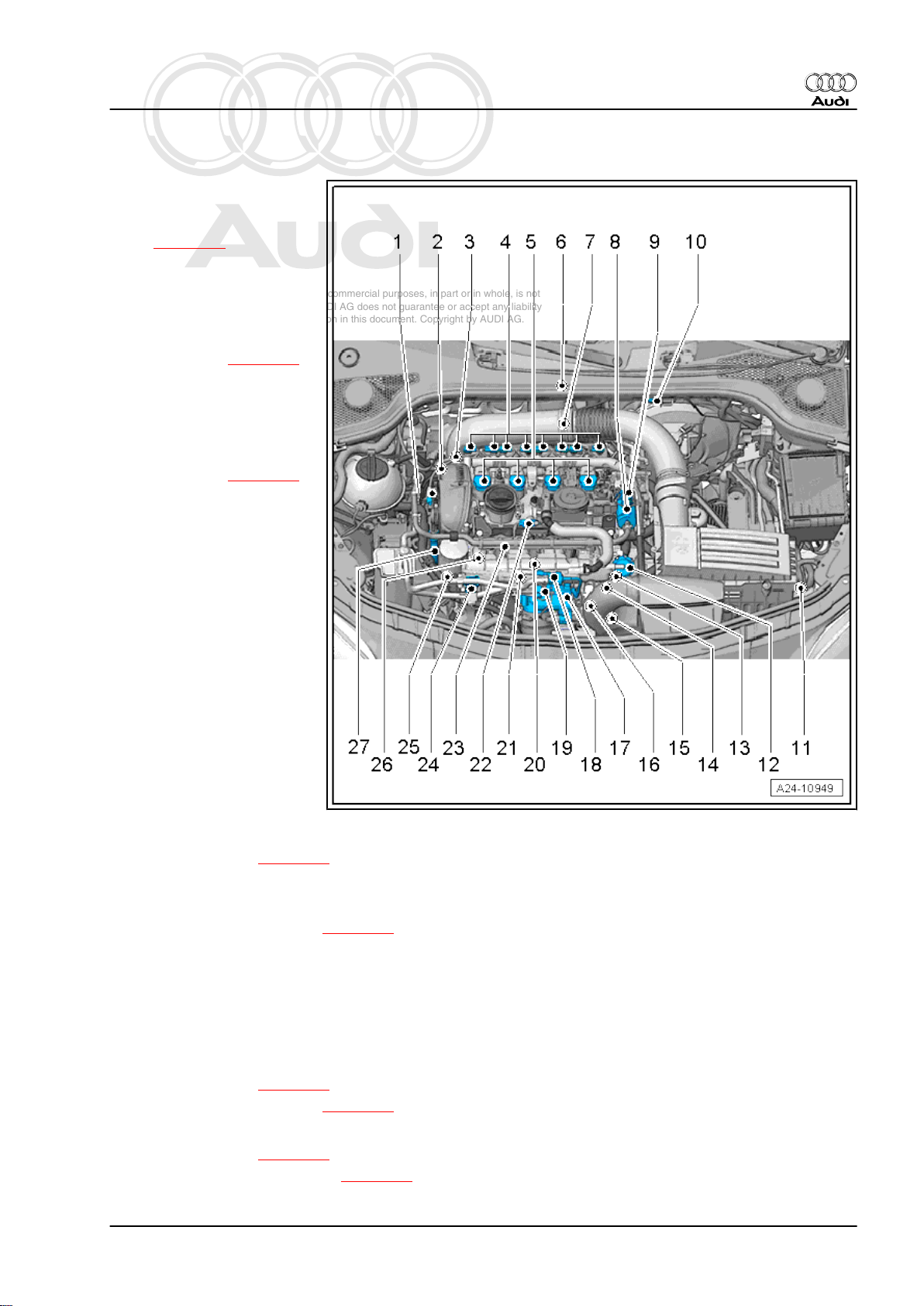

3 Overviews - fitting locations

3.1 Overview - fitting locations (engine co‐

des CDAA, CCZA and CCTA)

Components A to K are not shown in the overview.

1 - Camshaft control valve 1 N205-

❑ Fitting location

⇒ page 14

❑ Removing and installing

⇒ Rep. Gr. 15

2 - Charge pressure control

solenoid valve -N75-

❑ Located directly on tur‐

bocharger ⇒ page 17

❑ Removing and installing

⇒ Rep. Gr. 21

3 - Turbocharger air recircula‐

tion valve -N249-

❑ Located directly on tur‐

bocharger ⇒ page 17

❑ Removing and installing

⇒ Rep. Gr. 21

4 - Ignition coils with output

stages

❑ Removing and installing

⇒ page 84

❑ Ignition coil 1 with output

stage -N70-

❑ Ignition coil 2 with output

stage -N127-

❑ Ignition coil 3 with output

stage -N291-

❑ Ignition coil 4 with output

stage -N292-

❑ Puller -T40039- is re‐

quired for removing igni‐

tion coils from cylinder

head.

5 - Engine control unit -J623-

❑ Fitting location ⇒ page 11

❑ Removing and installing ⇒ page 77

6 - Lambda probe -G39- and Lambda probe heater -Z19-

❑ Fitting location ⇒ page 17

❑ Lambda probes - overview ⇒ page 71

7 - High-pressure pump

❑ Fitting location (engine code CDAA, 1.8 ltr.) ⇒ page 12

❑ Fitting location (engine codes CCZA and CCTA, 2.0 ltr.) ⇒ page 12

❑ Removing and installing ⇒ page 50

8 Rep. Gr.24 - Mixture preparation - injection

Page 13

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

8 - Fuel pressure regulating valve -N276-

❑ Fitting location (engine code CDAA, 1.8 ltr.) ⇒ page 12

❑ Fitting location (engine codes CCZA and CCTA, 2.0 ltr.) ⇒ page 12

9 - Electrical connector for Lambda probe -G39- and Lambda probe heater -Z19-

❑ Fitting location ⇒ page 16

10 - Air mass meter -G70- and intake air temperature sender 2 -G299-

❑ Removing and installing ⇒ page 65

11 - Radiator outlet coolant temperature sender -G83-

❑ Fitting location ⇒ page 16

12 - Vacuum unit for air flow control flaps (intake manifold flaps)

❑ Fitting location ⇒ page 13

13 - Intake manifold flap valve -N316-

❑ Fitting location ⇒ page 13

14 - Engine speed sender -G28-

❑ Fitting location ⇒ page 15

❑ Removing and installing ⇒ page 85

❑ 4.5 Nm

15 - Charge pressure sender -G31-

❑ Fitting location ⇒ page 16

16 - Electrical connectors

❑ From knock sensor 1 -G61- , fitting location ⇒ page 15

❑ From Hall sender -G40- , fitting location ⇒ page 15

❑ For injectors, fitting location ⇒ page 15

17 - Throttle valve module -J338- , throttle valve drive for electric throttle -G186-

❑ Throttle valve drive angle sender 1 for electric throttle -G187- and throttle valve drive angle sender 2 for

electric throttle -G188-

❑ After throttle valve module -J338- has been renewed, it must be re-adapted to engine control unit -J623- ,

see vehicle diagnostic, testing and information system -VAS 5051B-

18 - Activated charcoal filter solenoid valve 1 -N80-

❑ Fitting location ⇒ page 13

19 - Intake air temperature sender -G42-

20 - Knock sensor 1 -G61-

❑ Fitting location ⇒ page 13

❑ 20 Nm

❑ Removing and installing ⇒ page 85

21 - Coolant temperature sender -G62-

❑ Fitting location ⇒ page 15

❑ Removing and installing ⇒ Rep. Gr. 19

22 - Hall sender -G40- (camshaft position sensor)

23 - Fuel pressure sender -G247-

❑ 27 Nm

❑ Fitting location ⇒ page 13

❑ Removing and installing ⇒ page 59

24 - Valve for oil pressure control -N428-

❑ Fitting location ⇒ page 14

❑ Removing and installing ⇒ Rep. Gr. 17

3. Overviews - fitting locations 9

Page 14

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

25 - Oil pressure switch

❑ Oil pressure switch for reduced oil pressure -F378❑ Oil pressure switch -F22❑ Fitting location ⇒ page 14

❑ Removing and installing ⇒ Rep. Gr. 17

26 - Intake manifold flap potentiometer -G336-

❑ Fitting location ⇒ page 14

A - Diagnostic connector

❑ In driver's knee restraint

B - Fuel pump control unit -J538-

❑ Fitting location ⇒ page 11

C - Brake light switch - F- and brake pedal switch -F63-

❑ Fitting location ⇒ page 12

❑ Removing and installing ⇒ Rep. Gr. 45

D - Clutch position sender -G476-

❑ Only fitted on vehicles with manual gearbox

❑ Fitting location ⇒ page 12

❑ Removing and installing, see Power transmission, clutch ⇒ Rep. Gr. 30

E - Accelerator position sender -G79- and accelerator position sender 2 -G185-

❑ Fitting location ⇒ page 11

❑ On accelerator pedal (both senders are accommodated in one housing)

❑ If accelerator pedal module or engine control unit is renewed, kick-down function must be adapted on

vehicles with automatic gearbox

❑ Removing and installing ⇒ Rep. Gr. 20

F - Radiator fan control unit -J293-

❑ Fitting location ⇒ page 16

G - Injectors

❑ Removing and installing ⇒ page 53

❑ Injector, cylinder 1 -N30❑ Injector, cylinder 2 -N31❑ Injector, cylinder 3 -N32❑ Injector, cylinder 4 -N33-

H - Continued coolant circulation pump -V51-

❑ Fitting location ⇒ page 18

❑ Removing and installing ⇒ Rep. Gr. 19

I - Lambda probe after catalytic converter -G130- and Lambda probe heater 1 after catalytic converter -Z29-

❑ Fitting location ⇒ page 17

❑ Lambda probes - overview ⇒ page 71

J - Electrical connector for Lambda probe after catalytic converter -G130- and Lambda probe 1 heater after

catalytic converter -Z29-

❑ Fitting location ⇒ page 17

K - Relay and fuse holder in electronics box

❑ Relay and fuse assignment see ⇒ Current flow diagrams, Electrical fault finding and Fitting locations

10 Rep. Gr.24 - Mixture preparation - injection

Page 15

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

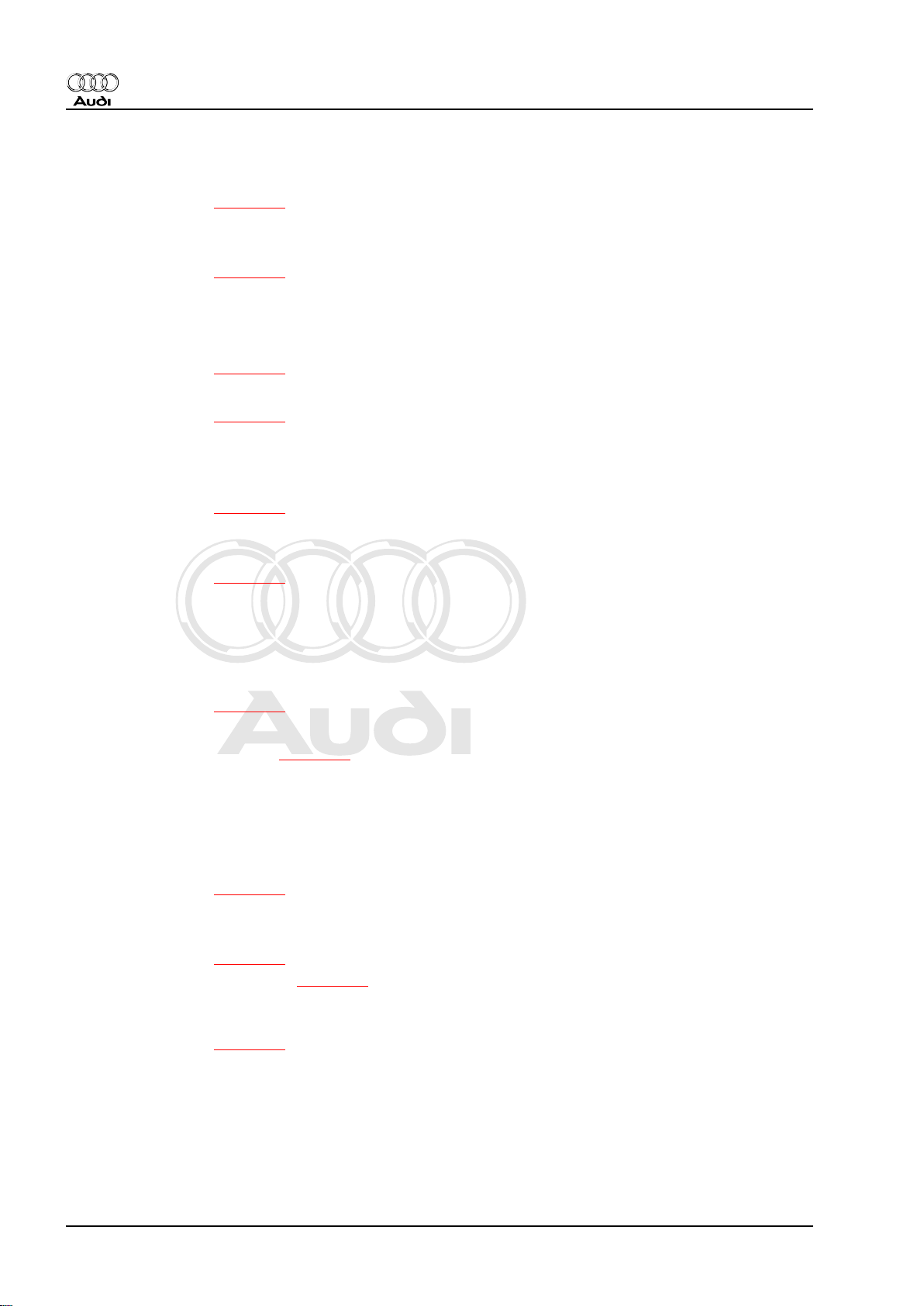

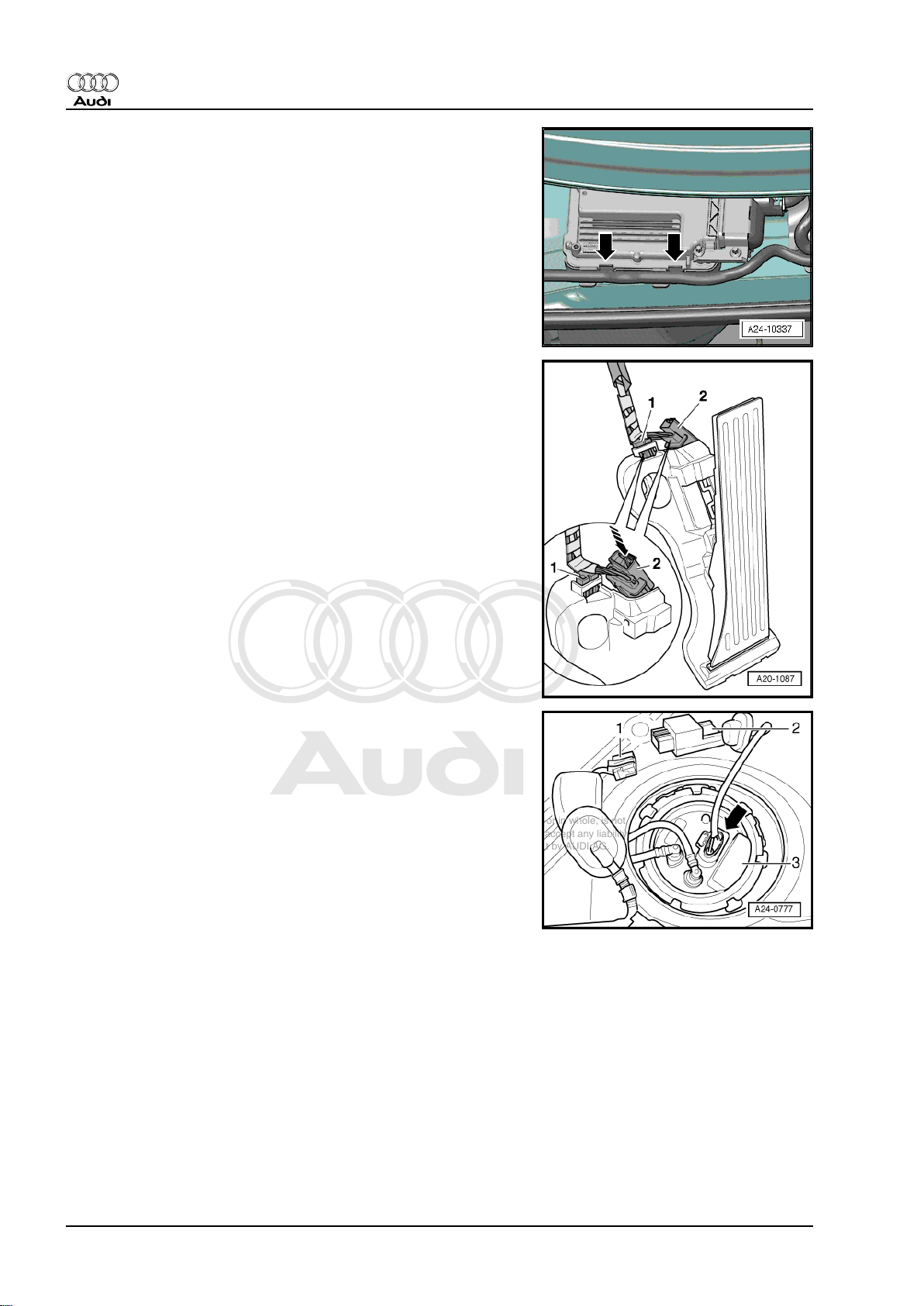

Engine control unit -J623-

Accelerator position sender -G79- and accelerator position send‐

er 2 -G185-

2 - Electrical connector for accelerator pedal module

Removing and installing ⇒ Rep. Gr. 20

Fuel pump control unit -J538- -2-

1 - Connector for fuel pump control unit -J538-

2 - Fuel pump control unit -J538-

3 - Fuel system pressurisation pump -G6-

3. Overviews - fitting locations 11

Page 16

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

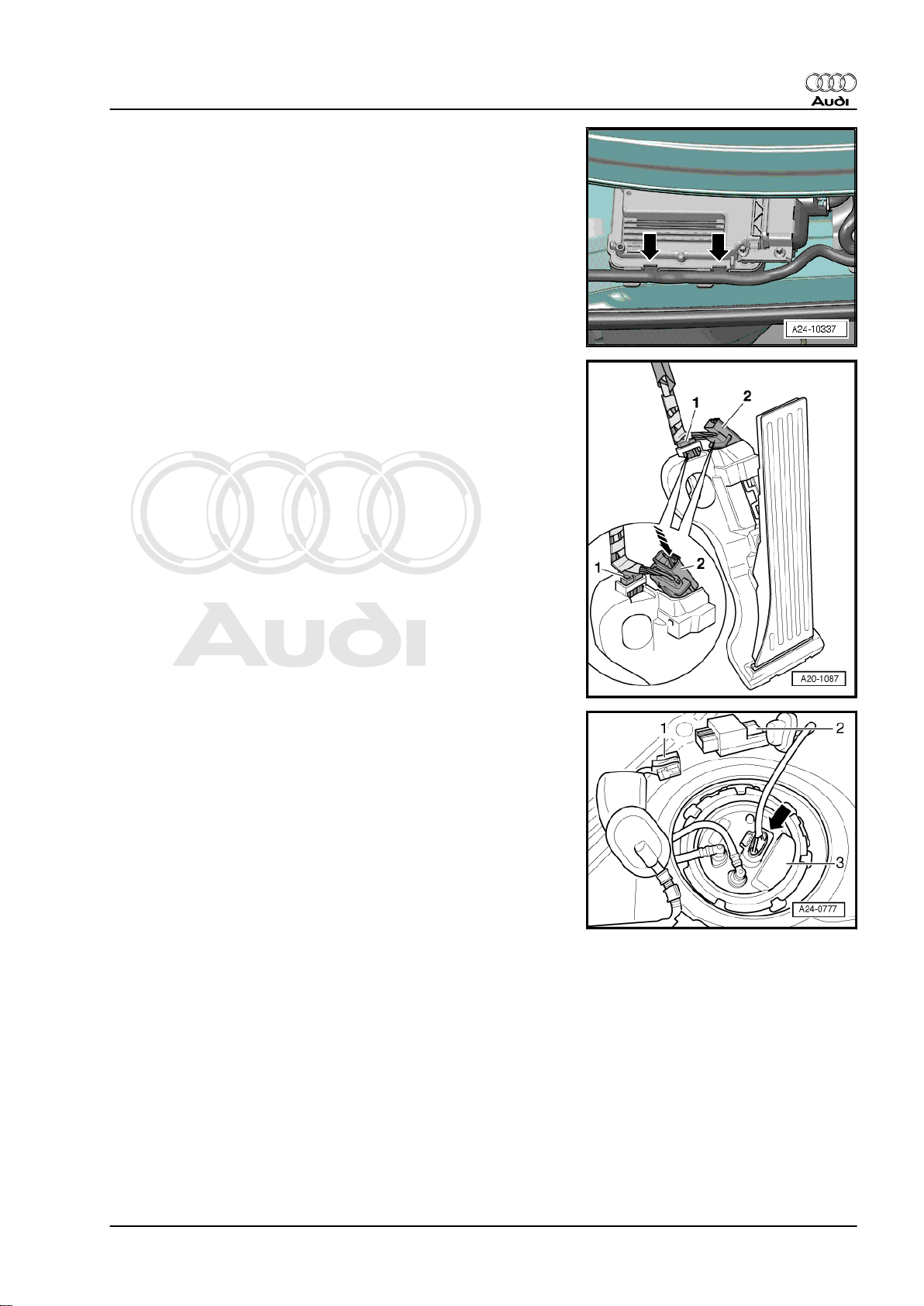

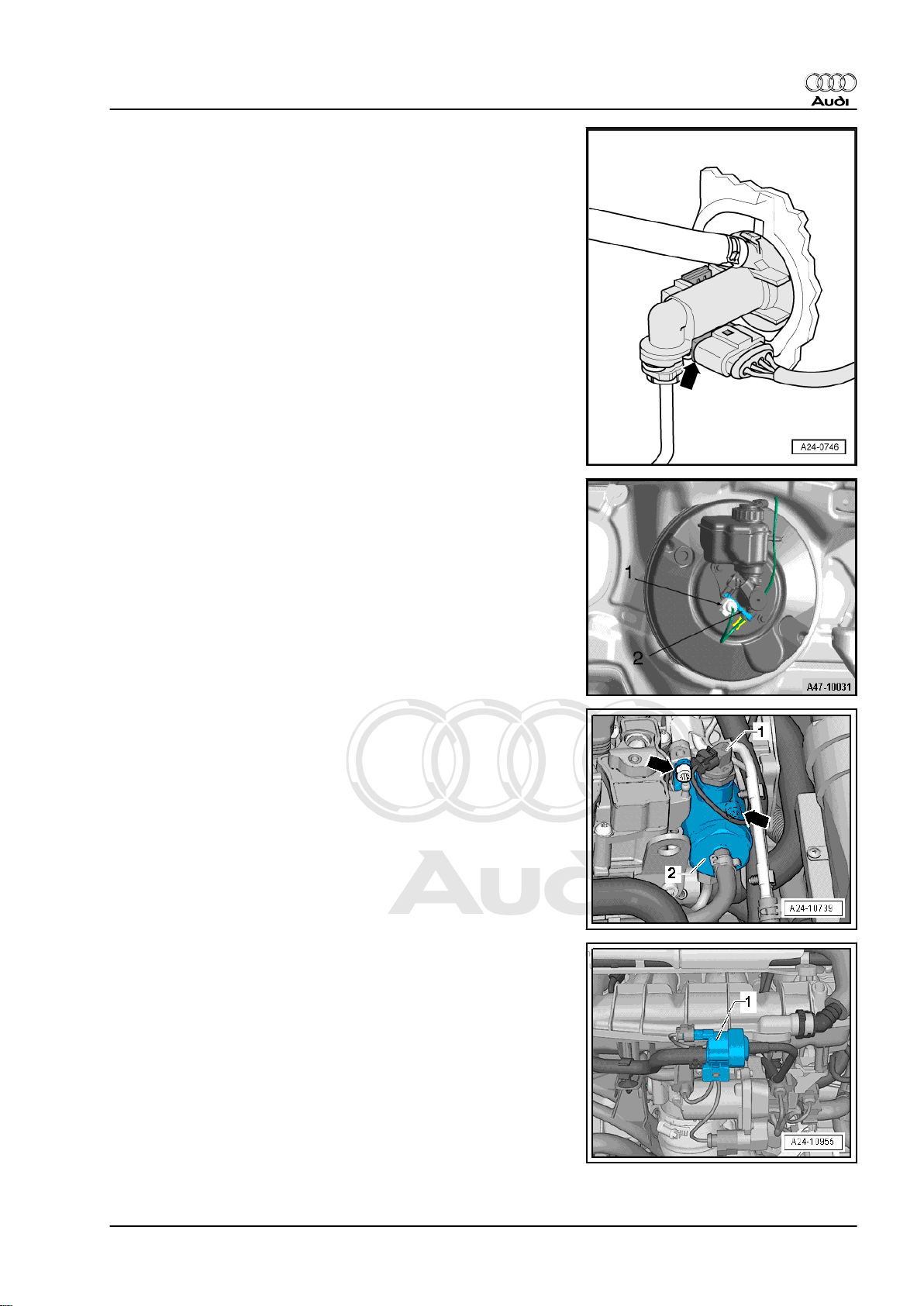

Clutch position sender -G476-

Removing and installing ⇒ Rep. Gr. 30

Brake light switch -F- and brake pedal switch -F63-

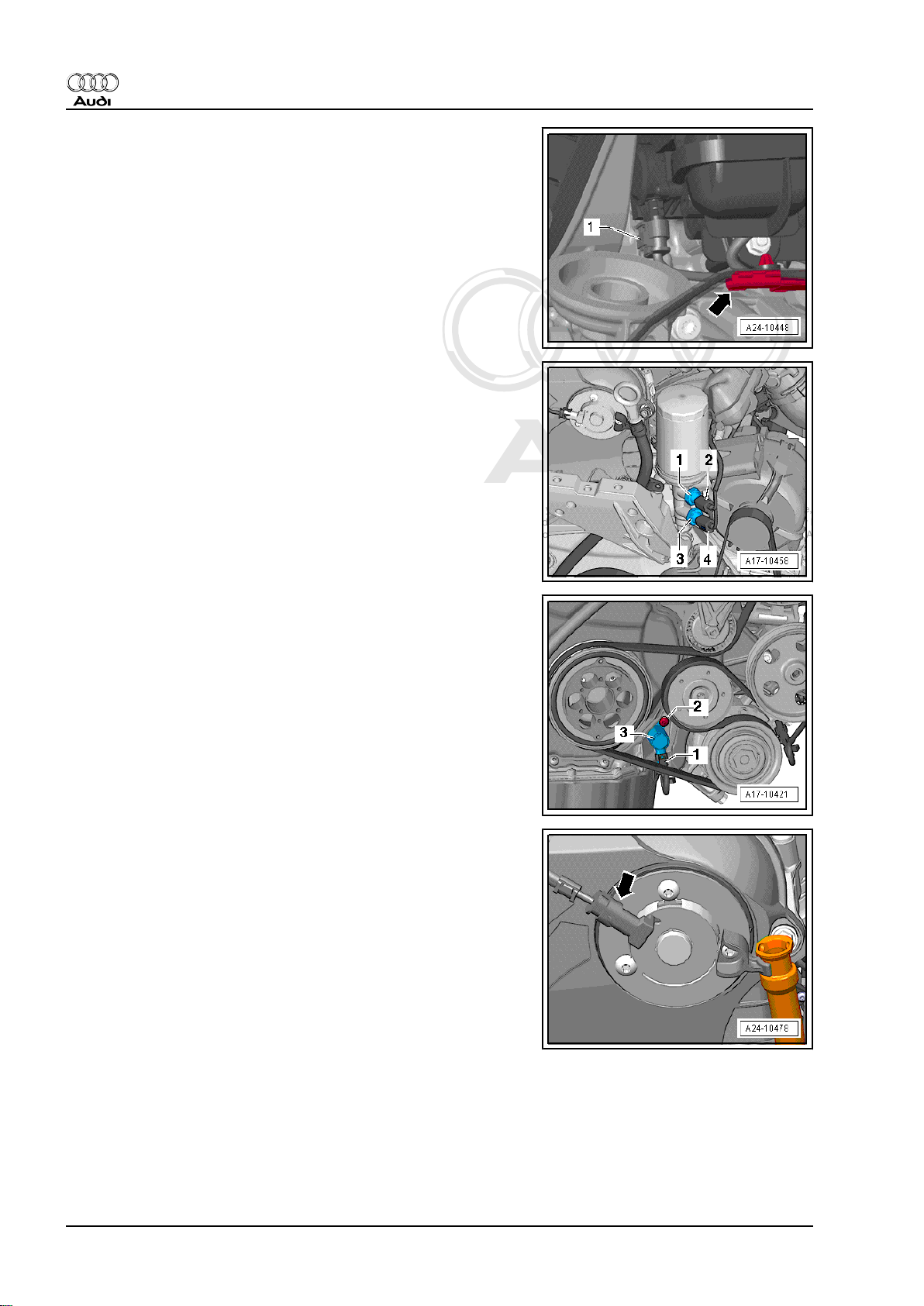

High-pressure pump -2-

1 - Fuel pressure regulating valve -N276-

Note

Illustration shows pump of engine code CDAA, 1.8 ltr.

High-pressure pump -2-

1 - Fuel pressure regulating valve -N276-

Note

Illustration shows pump of engine codes CCZA and CCTA, 2.0

ltr.

12 Rep. Gr.24 - Mixture preparation - injection

Page 17

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

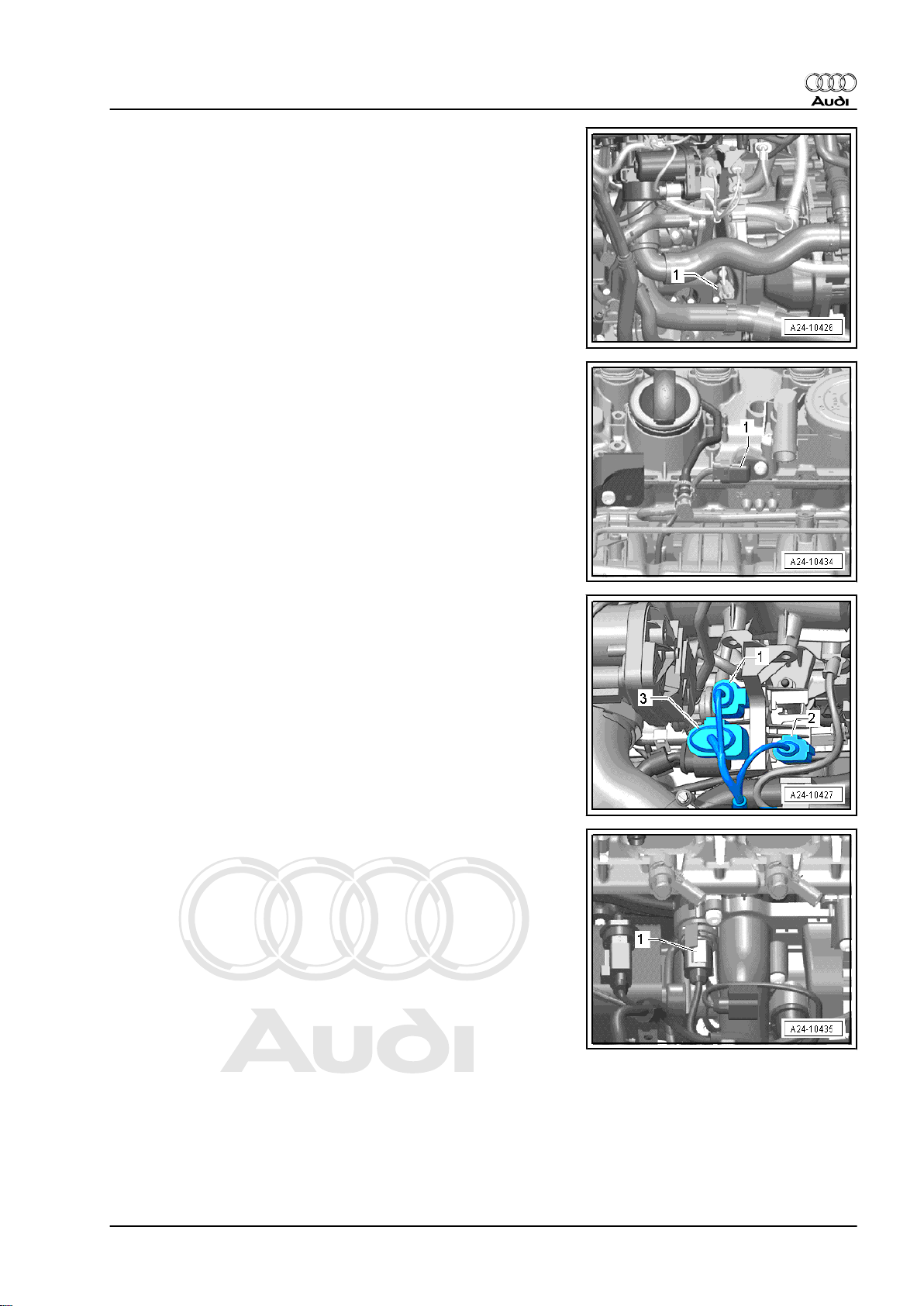

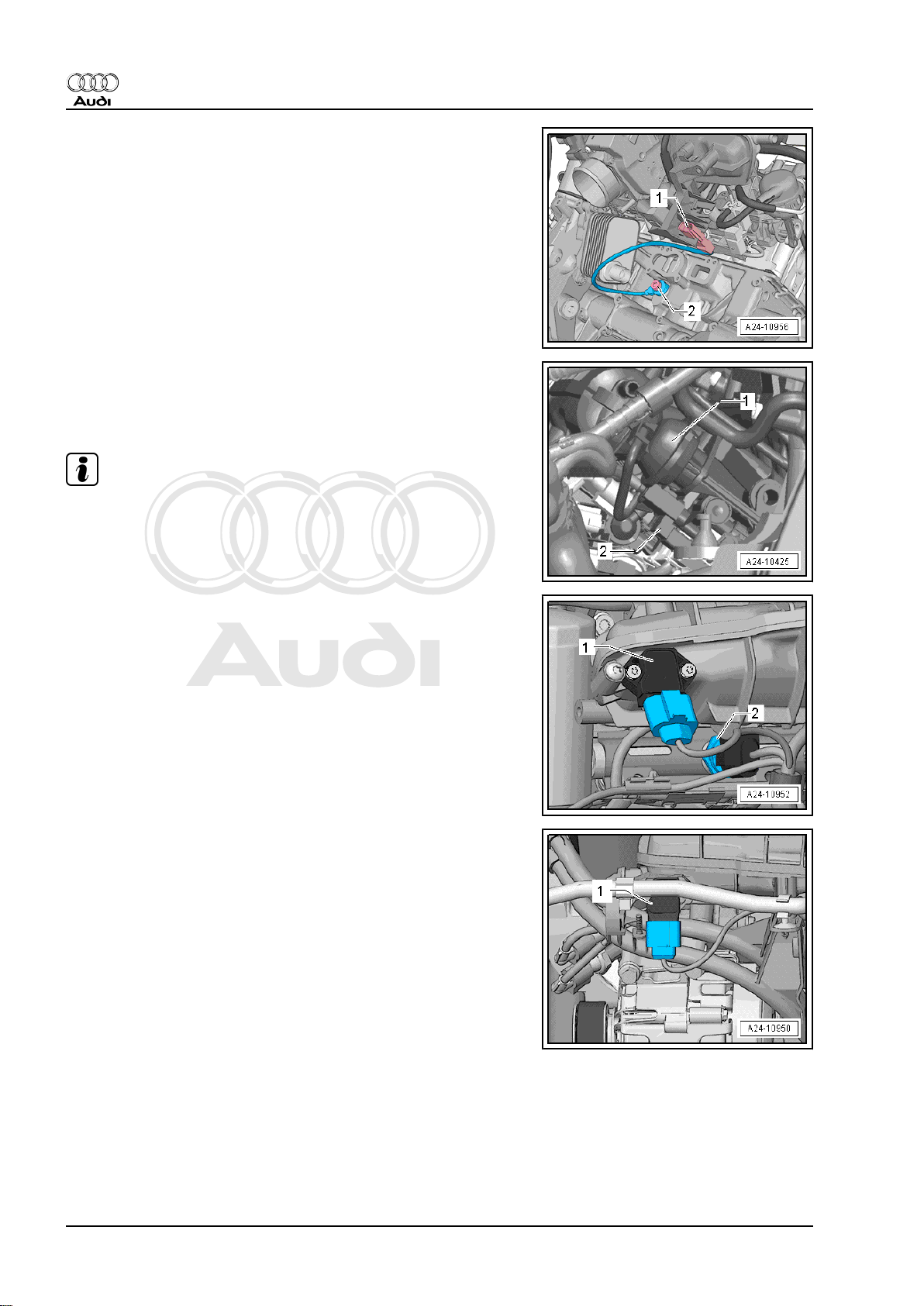

Activated charcoal filter solenoid valve 1 -N80- -1-

Fitting location of knock sensor 1 -G61-

1 - Electrical connector for knock sensor 1 -G61-

2 - Knock sensor 1 -G61-

Fitting location: below intake manifold and coolant pump

Intake manifold flap valve -N316- -2-

1 - Vacuum unit for intake manifold flaps

Note

Intake manifold flaps are the same as air flow control flaps.

Fuel pressure sender -G247- -1-

Removing and installing ⇒ page 59

3. Overviews - fitting locations 13

Page 18

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

Intake manifold flap potentiometer -G336- -1-

Oil pressure switch

1 - Oil pressure switch for reduced oil pressure -F378-

2 - Electrical connector for oil pressure switch for reduced oil

pressure -F378-

3 - Oil pressure switch -F22-

4 - Electrical connector for oil pressure switch -F22-

Valve for oil pressure control -N428- -3-

Camshaft control valve 1 -N205- -arrow-

Removing and installing ⇒ Rep. Gr. 45

14 Rep. Gr.24 - Mixture preparation - injection

Page 19

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

Engine speed sender -G28- -1-

Hall sender -G40- -1-

Electrical connectors

1 - From Hall sender -G40- and intake manifold flap potentiometer

-G336-

2 - From knock sensor 1 -G61-

3 - 8-pin connector for injectors

Coolant temperature sender -G62- -1-

Fitting location: below intake manifold in coolant pump

3. Overviews - fitting locations 15

Page 20

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

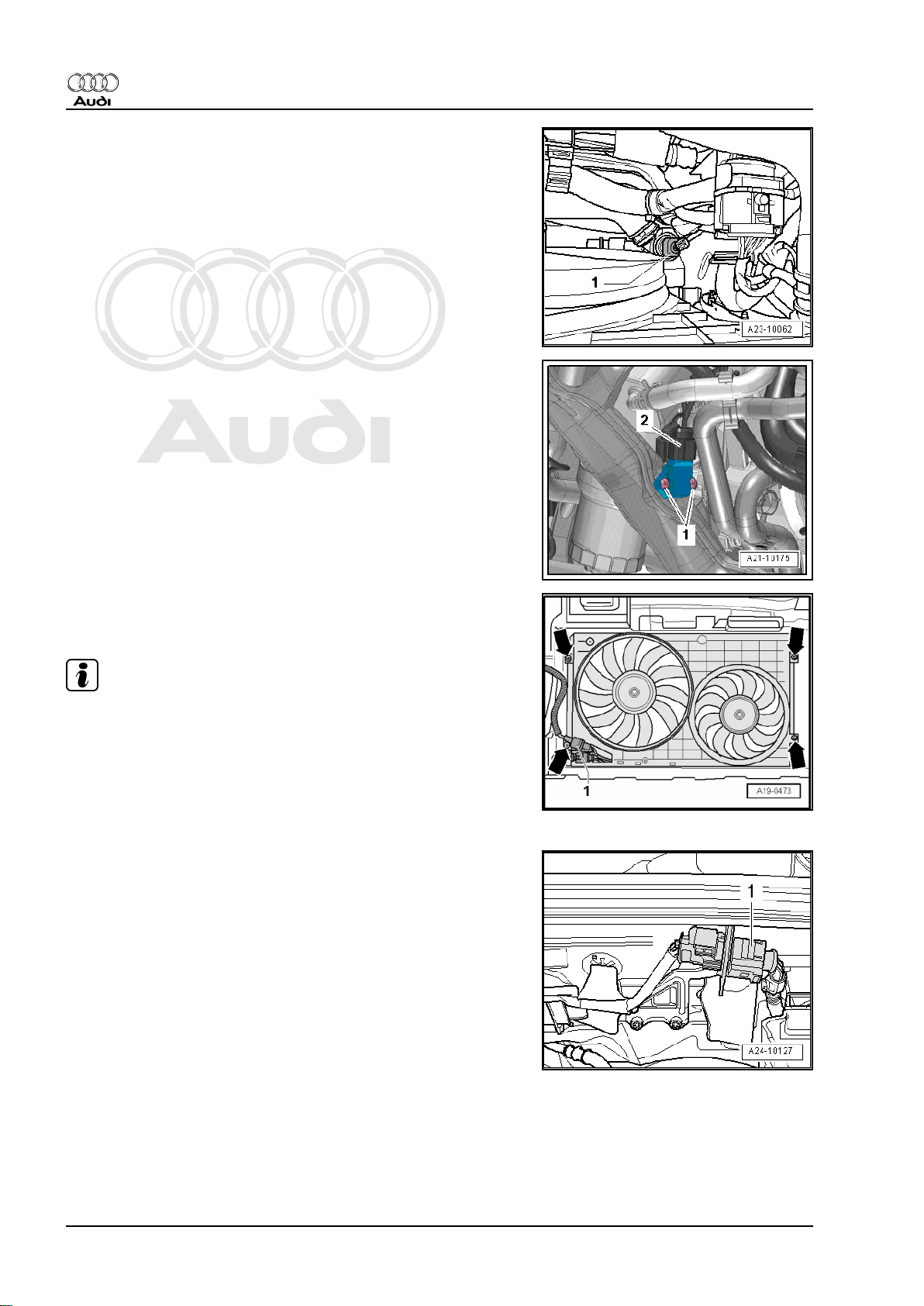

Radiator outlet coolant temperature sender -G83- -1-

Charge pressure sender -G31- -2-

Radiator fan control unit -J293-

1 - Connector for radiator fan control unit -J293-

Note

♦

The radiator fan control unit -J293- is integrated into the radi‐

ator fan -V7- .

♦

The fan shown in the illustration on the left is the radiator fan

-V7- .

♦

The fan shown in the illustration on the right is the radiator fan

on right of radiator -V35- .

Electrical connector

1 - For Lambda probe -G39- and Lambda probe heater -Z19-

16 Rep. Gr.24 - Mixture preparation - injection

Page 21

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

Fitting location of Lambda probe

1 - Lambda probe -G39- and Lambda probe heater -Z19-

Electrical connector (behind cover) for Lambda probe after cata‐

lytic converter -G130- and Lambda probe 1 heater after catalytic

converter -Z29-

Fitting location of Lambda probe

1 - Lambda probe after catalytic converter -G130- with Lambda

probe 1 heater after catalytic converter -Z29-

Note

The arrow in the illustration points in the direction of travel.

Components on turbocharger

1 - Removing and installing turbocharger ⇒ Rep. Gr. 21

2 - Tighten charge pressure control solenoid valve -N75- to 3 Nm

3 - Tighten turbocharger air recirculation valve -N249- to 7 Nm

(note installation position, refer to next illustration)

3. Overviews - fitting locations 17

Page 22

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

Pay attention to installation position of turbocharger air recircula‐

tion valve -N249-

Continued coolant circulation pump -V51-

Removing and installing ⇒ Rep. Gr. 19

18 Rep. Gr.24 - Mixture preparation - injection

Page 23

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

3.2 Overview - fitting locations (engine codes CESA and CETA)

1 - Camshaft control valve 1 N205-

❑ Fitting location

⇒ page 25

❑ Removing and installing

⇒ Rep. Gr. 15

2 - Charge pressure control

solenoid valve -N75-

❑ Located directly on tur‐

bocharger ⇒ page 29

❑ Removing and installing

⇒ Rep. Gr. 21

3 - Turbocharger air recircula‐

tion valve -N249-

❑ Located directly on tur‐

bocharger ⇒ page 29

❑ Removing and installing

⇒ Rep. Gr. 21

4 - Actuators for camshaft ad‐

justment

❑ Actuator 1 for camshaft

adjustment -F366-

❑ Actuator 2 for camshaft

adjustment -F367-

❑ Actuator 3 for camshaft

adjustment -F368-

❑ Actuator 4 for camshaft

adjustment -F369-

❑ Actuator 5 for camshaft

adjustment -F370-

❑ Actuator 6 for camshaft

adjustment -F371-

❑ Actuator 7 for camshaft

adjustment -F372-

❑ Actuator 8 for camshaft adjustment -F373❑ Fitting location ⇒ page 26

❑ Removing and installing ⇒ Rep. Gr. 15

5 - Ignition coils with output stages

❑ Removing and installing ⇒ page 84

❑ Ignition coil 1 with output stage -N70❑ Ignition coil 2 with output stage -N127❑ Ignition coil 3 with output stage -N291❑ Ignition coil 4 with output stage -N292❑ Puller -T40039- is required for removing ignition coils from cylinder head.

6 - Engine control unit -J623-

❑ Fitting location ⇒ page 22

❑ Removing and installing ⇒ page 77

7 - Lambda probe -G39- and Lambda probe heater -Z19-

❑ Fitting location ⇒ page 28

❑ Lambda probes - overview ⇒ page 71

3. Overviews - fitting locations 19

Page 24

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

8 - High-pressure pump

❑ Fitting location ⇒ page 23

❑ Removing and installing ⇒ page 50

9 - Fuel pressure regulating valve -N276-

❑ Fitting location ⇒ page 23

10 - Electrical connector for Lambda probe -G39- and Lambda probe heater -Z19-

❑ Fitting location ⇒ page 28

11 - Radiator outlet coolant temperature sender -G83-

❑ Fitting location ⇒ page 27

12 - Vacuum unit for air flow control flaps (intake manifold flaps)

❑ Fitting location ⇒ page 24

13 - Intake manifold flap valve -N316-

❑ Fitting location ⇒ page 24

14 - Engine speed sender -G28-

❑ Fitting location ⇒ page 26

❑ Removing and installing ⇒ page 85

❑ 4.5 Nm

15 - Charge pressure sender -G31-

❑ Fitting location ⇒ page 27

16 - Electrical connectors

❑ From knock sensor 1 -G61- , fitting location ⇒ page 27

❑ From Hall sender -G40- , fitting location ⇒ page 27

❑ For injectors, fitting location ⇒ page 15

17 - Throttle valve module -J338- , throttle valve drive for electric throttle -G186-

❑ Throttle valve drive angle sender 1 for electric throttle -G187- and throttle valve drive angle sender 2 for

electric throttle -G188-

❑ After throttle valve module -J338- has been renewed, it must be re-adapted to engine control unit -J623-

using a vehicle diagnostic tester

18 - Activated charcoal filter solenoid valve 1 -N80-

❑ Fitting location ⇒ page 23

19 - Intake air temperature sender -G42-

20 - Knock sensor 1 -G61-

❑ Fitting location ⇒ page 24

❑ 20 Nm

❑ Removing and installing ⇒ page 85

21 - Coolant temperature sender -G62-

❑ Fitting location ⇒ page 27

❑ Removing and installing ⇒ Rep. Gr. 19

22 - Hall sender -G40- (camshaft position sensor)

23 - Fuel pressure sender -G247-

❑ 27 Nm

❑ Fitting location ⇒ page 24

❑ Removing and installing ⇒ page 59

24 - Intake manifold pressure sender -G71-

❑ Fitting location ⇒ page 24

25 - Oil pressure switch

❑ Oil pressure switch for reduced oil pressure -F378-

20 Rep. Gr.24 - Mixture preparation - injection

Page 25

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

❑ Oil pressure switch -F22❑ Fitting location ⇒ page 25

❑ Removing and installing ⇒ Rep. Gr. 17

26 - Intake manifold flap potentiometer -G336-

❑ Fitting location ⇒ page 25

27 - Valve for oil pressure control -N428-

❑ Fitting location ⇒ page 25

❑ Removing and installing ⇒ Rep. Gr. 17

A - Diagnostic connector

❑ In driver's knee restraint

B - Fuel pump control unit -J538-

❑ Fitting location ⇒ page 22

C - Brake light switch - F- and brake pedal switch -F63-

❑ Fitting location ⇒ page 23

❑ Removing and installing ⇒ Rep. Gr. 45

D - Clutch position sender -G476-

❑ Only fitted on vehicles with manual gearbox

❑ Fitting location ⇒ page 23

❑ Removing and installing, see Power transmission, clutch ⇒ Rep. Gr. 30

E - Accelerator position sender -G79- and accelerator position sender 2 -G185-

❑ Fitting location ⇒ page 22

❑ On accelerator pedal (both senders are accommodated in one housing)

❑ If accelerator pedal module or engine control unit is renewed, kick-down function must be adapted on

vehicles with automatic gearbox

❑ Removing and installing ⇒ Rep. Gr. 20

F - Radiator fan control unit -J293-

❑ Fitting location ⇒ page 28

G - Injectors

❑ Removing and installing ⇒ page 53

❑ Injector, cylinder 1 -N30❑ Injector, cylinder 2 -N31❑ Injector, cylinder 3 -N32❑ Injector, cylinder 4 -N33-

H - Continued coolant circulation pump -V51-

❑ Fitting location ⇒ page 29

❑ Removing and installing ⇒ Rep. Gr. 19

I - Exhaust flap 1 valve -N321-

❑ Fitting location ⇒ page 30

J - Lambda probe after catalytic converter -G130- and Lambda probe heater 1 after catalytic converter -Z29-

❑ Fitting location ⇒ page 29

❑ Lambda probes - overview ⇒ page 71

K - Electrical connector for Lambda probe after catalytic converter -G130- and Lambda probe 1 heater after

catalytic converter -Z29-

❑ Fitting location ⇒ page 28

3. Overviews - fitting locations 21

Page 26

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

Engine control unit -J623-

Accelerator position sender -G79- and accelerator position send‐

er 2 -G185-

2 - Electrical connector for accelerator pedal module

Removing and installing ⇒ Rep. Gr. 20

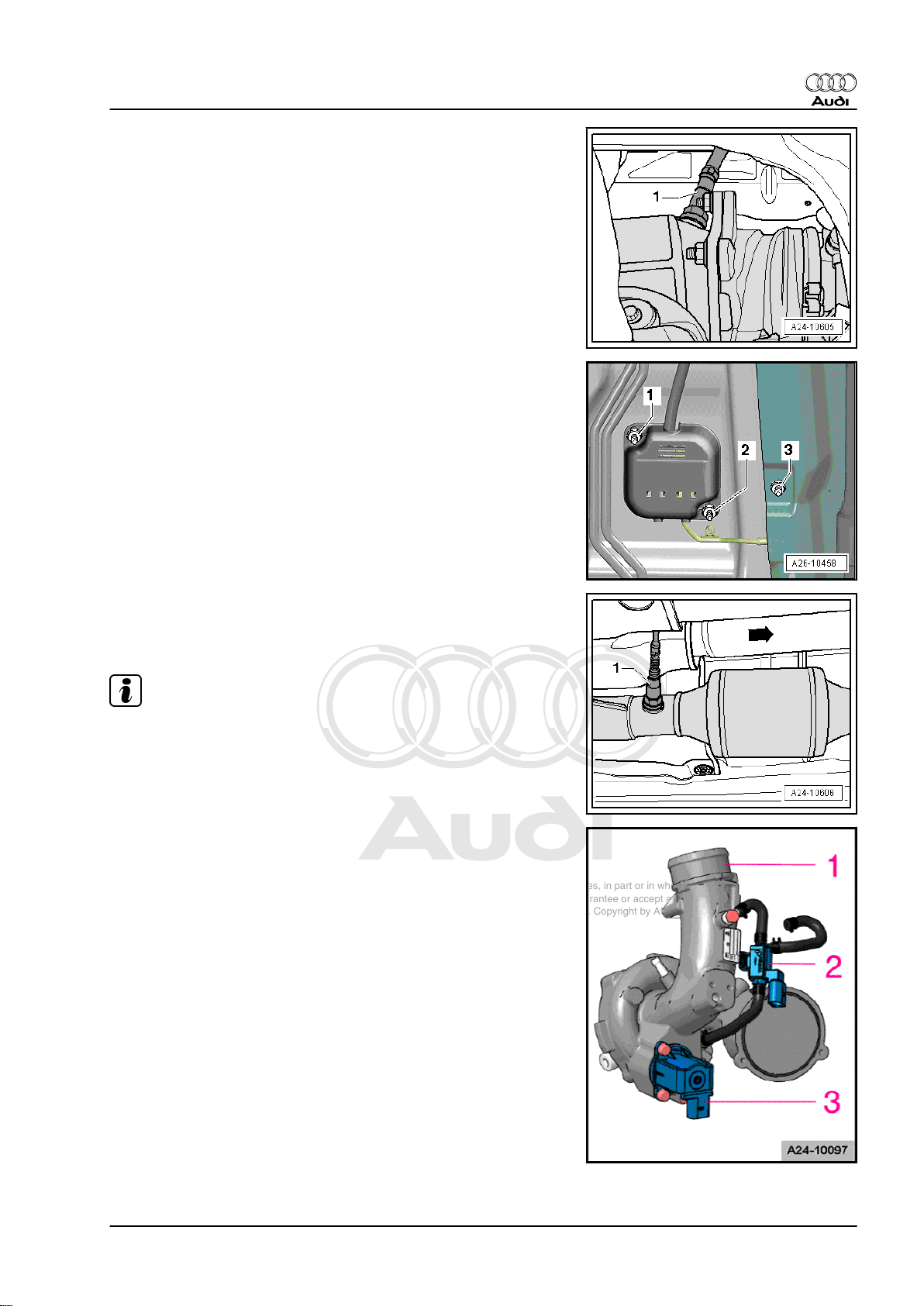

Fuel pump control unit -J538- -2-

1 - Connector for fuel pump control unit -J538-

2 - Fuel pump control unit -J538-

3 - Fuel system pressurisation pump -G6-

22 Rep. Gr.24 - Mixture preparation - injection

Page 27

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

Clutch position sender -G476-

Removing and installing ⇒ Rep. Gr. 30

Brake light switch -F- and brake pedal switch -F63-

Removing and installing ⇒ Rep. Gr. 45

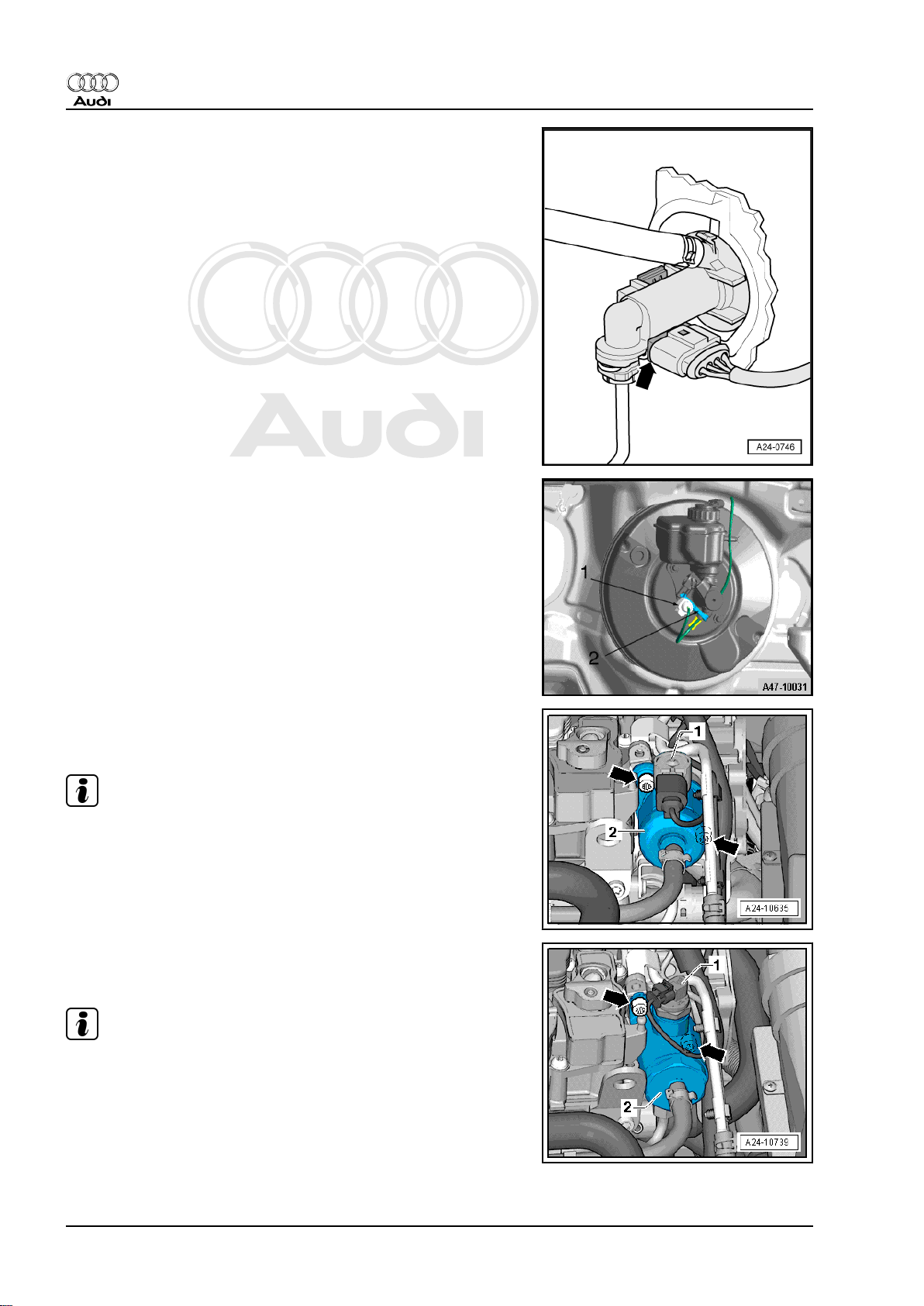

High-pressure pump

1 - Fuel pressure regulating valve -N276-

2 - High-pressure pump

Activated charcoal filter solenoid valve 1 -N80- -1-

3. Overviews - fitting locations 23

Page 28

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

Fitting location of knock sensor 1 -G61-

1 - Electrical connector for knock sensor 1 -G61-

2 - Knock sensor 1 -G61-

Fitting location: below intake manifold and coolant pump

Intake manifold flap valve -N316-

1 - Vacuum unit for intake manifold flaps

2 - Intake manifold flap valve -N316-

Note

Intake manifold flaps are the same as air flow control flaps.

Intake manifold pressure sender -G71- -1- and fuel pressure

sender -G247- -2-

1 - Intake manifold pressure sender -G71-

2 - Fuel pressure sender -G247-

Intake manifold pressure sender -G71- -1-

24 Rep. Gr.24 - Mixture preparation - injection

Page 29

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

Intake manifold flap potentiometer -G336- -1-

Oil pressure switch

1 - Oil pressure switch for reduced oil pressure -F378-

2 - Electrical connector for oil pressure switch for reduced oil

pressure -F378-

3 - Oil pressure switch -F22-

4 - Electrical connector for oil pressure switch -F22-

Valve for oil pressure control -N428- -3-

Camshaft control valve 1 -N205- -arrow-

3. Overviews - fitting locations 25

Page 30

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

Ignition coils

1 - Ignition coil 1 with output stage -N70-

2 - Ignition coil 2 with output stage -N127-

3 - Ignition coil 3 with output stage -N291-

4 - Ignition coil 4 with output stage -N292-

5 - Actuator 2 for camshaft adjustment -F367- (for cylinder No. 1)

6 - Actuator 1 for camshaft adjustment -F366- (for cylinder No. 1)

7 - Actuator 3 for camshaft adjustment -F368- (for cylinder No. 2)

8 - Actuator 4 for camshaft adjustment -F369- (for cylinder No. 2)

9 - Actuator 6 for camshaft adjustment -F371- (for cylinder No. 3)

10 - Actuator 5 for camshaft adjustment -F370- (for cylinder No.

3)

11 - Actuator 7 for camshaft adjustment -F372- (for cylinder No.

4)

12 - Actuator 8 for camshaft adjustment -F373- (for cylinder No.

4)

Engine speed sender -G28- -1-

Hall sender -G40- -1-

26 Rep. Gr.24 - Mixture preparation - injection

Page 31

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

Electrical connectors

1 - From Hall sender -G40- and intake manifold flap potentiometer

-G336-

2 - From knock sensor 1 -G61-

3 - 8-pin connector for injectors

Coolant temperature sender -G62- -1-

Fitting location: below intake manifold in coolant pump

Radiator outlet coolant temperature sender -G83- -1-

Charge pressure sender -G31- -2-

3. Overviews - fitting locations 27

Page 32

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

Radiator fan control unit -J293-

1 - Connector for radiator fan control unit -J293-

Note

♦

The radiator fan control unit -J293- is integrated into the radi‐

ator fan -V7- .

♦

The fan shown in the illustration on the left is the radiator fan

-V7- .

♦

The fan shown in the illustration on the right is the radiator fan

on right of radiator -V35- .

Electrical connector

1 - For Lambda probe -G39- and Lambda probe heater -Z19-

Fitting location of Lambda probe

1 - Lambda probe -G39- and Lambda probe heater -Z19-

Electrical connector (behind cover) for Lambda probe after cata‐

lytic converter -G130- and Lambda probe 1 heater after catalytic

converter -Z29-

28 Rep. Gr.24 - Mixture preparation - injection

Page 33

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

Fitting location of Lambda probe

1 - Lambda probe after catalytic converter -G130- with Lambda

probe 1 heater after catalytic converter -Z29-

Note

The arrow in the illustration points in the direction of travel.

Components on turbocharger

1 - Removing and installing turbocharger ⇒ Rep. Gr. 21

2 - Tighten charge pressure control solenoid valve -N75- to 3 Nm

3 - Tighten turbocharger air recirculation valve -N249- to 7 Nm

(note installation position, refer to next illustration)

Pay attention to installation position of turbocharger air recircula‐

tion valve -N249-

Continued coolant circulation pump -V51-

Removing and installing ⇒ Rep. Gr. 19

3. Overviews - fitting locations 29

Page 34

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

Exhaust flap 1 valve -N321- -1-

30 Rep. Gr.24 - Mixture preparation - injection

Page 35

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

4 Air cleaner

4.1 Air cleaner - exploded view

1 - Spring-type clip

2 - Air hose

❑ To turbocharger

❑ Check air intake hose

for dirt and leaves

3 - Air mass meter -G70-

❑ 1.5 Nm

❑ Removing and installing

⇒ page 65

4 - Bolts

❑ For air cleaner (top sec‐

tion)

❑ 1.5 Nm

5 - Bolts

❑ For air cleaner (top sec‐

tion)

❑ 1.5 Nm

6 - Air cleaner (top section)

❑ Clean any salt residue,

leaves and dirt out of air

cleaner (top section)

7 - Filter element

❑ Always use genuine

part for air filter element

❑ Removing and installing

⇒ page 32

❑ Observe change inter‐

vals ⇒ Maintenance ;

Booklet 810

8 - Bolt

❑ For air cleaner (bottom

section)

9 - Snow screen

❑ Not installed in all vehicles

10 - Air cleaner (bottom section)

❑ Clean any salt residue, leaves and dirt out of air cleaner (bottom section)

11 - Connection for water drain hose

❑ Clean connection

12 - Water drain hose

❑ Clean water drain hose

13 - Flutter valve

❑ Clean and re-install

14 - Intake air duct

❑ To lock carrier

4. Air cleaner 31

Page 36

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

❑ Clean any leaves and dirt out of intake air duct

4.2 Removing and installing engine cover panel

Removing

– Carefully pull off engine cover panel. Do not jerk the cover

panel away, and do not try to pull on one side only.

Installing

– Press engine cover panel back carefully into its retainers.

– To avoid damage, do not strike the engine cover panel with

your fist or with any kind of tool.

4.3 Removing and installing air filter ele‐

ment

Removing

– Unscrew bolts -arrows- from air cleaner (top section).

Note

Disregard items 1 to 3.

– Lift up air cleaner (top section) and take out air filter element.

Installing

Note

♦

Always use genuine part for air filter element.

♦

Hose connections and hoses for charge air system must be

free of oil and grease before assembly. Do not use any lubri‐

cants containing silicone when assembling.

♦

The air cleaner housing must be clean.

♦

Secure all hose connections with the correct type of hose clips

(same as original equipment) ⇒ Parts catalogue

♦

To prevent malfunctions, cover all critical parts of the engine

air intake tract (air mass meter, intake pipes, etc.) with a clean

cloth when blowing out the air cleaner housing with com‐

pressed air.

♦

Please observe requirements for disposal.

– Check for salt residue, dirt and leaves in air mass meter and

air intake hose (engine intake side).

– Check for dirt in air intake hose from air duct.

32 Rep. Gr.24 - Mixture preparation - injection

Page 37

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

– Remove snow screen -1- and clean it.

Note

The snow screen is not fitted on all vehicles.

– Clean water drain -arrow- and air cleaner (bottom section).

– When installing the air filter element, check that it is properly

centred in the retainer in the air cleaner (bottom section).

– Fit the top section of the air cleaner carefully on the bottom

section, without using force. Make sure the top section of the

air cleaner is fitted straight on the air filter element (note posi‐

tion of sealing lip on air filter element).

The remaining installation steps are carried out in the reverse se‐

quence.

4.4 Removing and installing air cleaner housing

Removing

– Unscrew bolts -arrows- from air cleaner (top section).

– Lift up air cleaner (top section) and take out air filter element.

– Remove air duct leading from lock carrier to air cleaner hous‐

ing -2 and 3-.

– Slacken bolt -1-.

– Carefully lift air cleaner (bottom section).

Installing

4. Air cleaner 33

Page 38

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

– Remove snow screen -1- and clean it.

Note

The snow screen is not fitted on all vehicles.

– Clean water drain -arrow- and air cleaner (bottom section).

– Disconnect water drain hose -arrow- from air cleaner (bottom

section) and clean any dirt or leaves out of connection and

hose.

– When installing the air filter element, check that it is properly

centred in the retainer in the air cleaner (bottom section).

– Fit the top section of the air cleaner carefully on the bottom

section, without using force. Make sure the top section of the

air cleaner is fitted straight on the air filter element (note posi‐

tion of sealing lip on air filter element).

The remaining installation steps are carried out in the reverse se‐

quence.

34 Rep. Gr.24 - Mixture preparation - injection

Page 39

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

5 Intake manifold (engine codes

CDAA, CCZA and CCTA)

5.1 Intake manifold - exploded view

1 - Screw for intake air temper‐

ature sender -G42-

❑ 5 Nm

2 - Intake air temperature

sender -G42-

3 - Activated charcoal filter sol‐

enoid valve 1 -N80-

❑ With dual non-return

valve; checking

⇒ page 68

4 - Intake manifold

❑ Removing and installing

⇒ page 42

5 - Vacuum unit for air flow

control flaps (intake manifold

flaps)

6 - Bolts for high-pressure

pump

❑ 10 Nm (engine code

CDAA, 1.8 ltr.)

❑ 20 Nm (engine codes

CCZA and CCTA, 2.0

ltr.)

7 - Connecting piece for fuel

supply pipe

❑ From fuel tank

8 - Fuel pressure regulating

valve -N276-

9 - High-pressure pump

❑ With fuel pressure regu‐

lating valve -N276-

❑ An electric fuel pump

(fitted in fuel tank) supplies fuel to the mechanical high-pressure pump

❑ When installing the high-pressure fuel pump, it is essential to ensure that no dirt enters the fuel system.

❑ The fuel system must not be under pressure when installing the high-pressure pump; procedure for

reducing fuel pressure ⇒ page 4

❑ Fuel pipes must be free of tension when installed.

❑ Removing and installing ⇒ page 50

10 - Roller tappet

❑ May remain lodged in exhauster pump when high-pressure pump is removed; it can be taken out

11 - Connecting piece for fuel supply pipe to fuel rail

❑ Renew

❑ 25 Nm

12 - High-pressure fuel pipe

❑ Fuel pipes must be free of tension when installed.

5. Intake manifold (engine codes CDAA, CCZA and CCTA) 35

Page 40

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

❑ 20 Nm

13 - Intake manifold flap valve -N316-

14 - Injectors

❑ Renew O-ring and teflon ring

❑ Ensure correct installation position.

❑ Removing and installing ⇒ page 53

15 - Intake manifold support

16 - Bolt for intake manifold support

❑ 20 Nm

17 - Securing nut for intake manifold support

❑ 10 Nm

18 - Bolts for throttle valve module -J338-

❑ 5 Nm

19 - Throttle valve module -J338- , throttle valve drive for electric throttle -G186-

❑ Throttle valve drive angle sender 1 for electric throttle -G187- and throttle valve drive angle sender 2 for

electric throttle -G188-

❑ After throttle valve module -J338- has been renewed, it must be re-adapted to engine control unit -J623-

using a vehicle diagnostic tester

20 - Seal

❑ Renew

36 Rep. Gr.24 - Mixture preparation - injection

Page 41

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

5.2 Fuel rail - exploded view

1 - Injector

❑ With combustion cham‐

ber ring seal (teflon ring

seal): always renew

❑ Renew O-rings

❑ Ensure correct installa‐

tion position.

❑ Removing and installing

⇒ page 53

2 - Support ring

3 - Fuel rail

❑ Removing and installing

⇒ page 42

❑ Tighten to 8 Nm

4 - High-pressure pump

❑ With fuel pressure regu‐

lating valve -N276❑ An electric fuel pump

(fitted in fuel tank) sup‐

plies fuel to the mechan‐

ical high-pressure pump

❑ When installing the

high-pressure fuel

pump, it is essential to

ensure that no dirt en‐

ters the fuel system.

❑ The fuel system must

not be under pressure

when installing the high-

pressure pump; proce‐

dure for reducing fuel

pressure ⇒ page 4

❑ Fuel pipes must be free

of tension when instal‐

led.

❑ Removing and installing ⇒ page 50

5 - Roller tappet

6 - Fuel pressure regulating valve -N276-

7 - Bolts for high-pressure pump

❑ 10 Nm (engine code CDAA, 1.8 ltr.)

❑ 20 Nm (engine codes CCZA and CCTA, 2.0 ltr.)

8 - Connecting piece for fuel supply pipe

❑ Renew

❑ 25 Nm

9 - Union nut for fuel supply pipe

❑ 20 Nm

10 - Air flow control flaps (intake manifold flaps)

11 - Gasket

❑ Renew

12 - Intake manifold

❑ Removing and installing ⇒ page 42

5. Intake manifold (engine codes CDAA, CCZA and CCTA) 37

Page 42

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

13 - Vacuum unit for air flow control flaps (port separator plates)

14 - Throttle valve module -J338- , throttle valve drive for electric throttle -G186-

❑ Throttle valve drive angle sender 1 for electric throttle -G187- and throttle valve drive angle sender 2 for

electric throttle -G188-

❑ After throttle valve module -J338- has been renewed, it must be re-adapted to engine control unit -J623-

using a vehicle diagnostic tester

❑ 7 Nm

15 - Bolts for intake manifold

❑ 9 Nm

16 - Intake manifold flap potentiometer -G336-

❑ Intake manifold flap potentiometer -G336- must be re-adapted to engine control unit -J623- if it has been

renewed. Use vehicle diagnostic tester to do so.

17 - Fuel pressure sender -G247-

❑ 27 Nm

❑ Lubricate threads lightly with clean engine oil

❑ Fitting location ⇒ page 13

❑ Removing and installing ⇒ page 59

38 Rep. Gr.24 - Mixture preparation - injection

Page 43

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

6 Intake manifold (engine codes CESA

and CETA)

6.1 Intake manifold - exploded view

1 - Screw for intake air temper‐

ature sender -G42-

❑ 5 Nm

2 - Intake air temperature

sender -G42-

3 - Activated charcoal filter sol‐

enoid valve 1 -N80-

❑ With dual non-return

valve; checking

⇒ page 68

4 - Intake manifold

❑ Removing and installing

⇒ page 42

5 - Vacuum unit for air flow

control flaps (intake manifold

flaps)

6 - Bolts for high-pressure

pump

❑ 20 Nm

7 - Connecting piece for fuel

supply pipe

❑ From fuel tank

8 - Fuel pressure regulating

valve -N276-

9 - High-pressure pump

❑ With fuel pressure regu‐

lating valve -N276❑ An electric fuel pump

(fitted in fuel tank) sup‐

plies fuel to the mechan‐

ical high-pressure pump

❑ When installing the

high-pressure fuel pump, it is essential to ensure that no dirt enters the fuel system.

❑ The fuel system must not be under pressure when installing the high-pressure pump; procedure for

reducing fuel pressure ⇒ page 4

❑ Fuel pipes must be free of tension when installed.

❑ Removing and installing ⇒ page 50

10 - Roller tappet

❑ May remain lodged in exhauster pump when high-pressure pump is removed; it can be taken out

11 - Connecting piece for fuel supply pipe to fuel rail

❑ Renew

❑ 25 Nm

12 - High-pressure fuel pipe

❑ Fuel pipes must be free of tension when installed.

❑ 20 Nm

6. Intake manifold (engine codes CESA and CETA) 39

Page 44

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

13 - Intake manifold flap valve -N316-

14 - Injectors

❑ Renew O-ring and teflon ring

❑ Ensure correct installation position.

❑ Removing and installing ⇒ page 53

15 - Intake manifold support

16 - Bolt for intake manifold support

❑ 20 Nm

17 - Securing nut for intake manifold support

❑ 10 Nm

18 - Bolts for throttle valve module -J338-

❑ 5 Nm

19 - Throttle valve module -J338- , throttle valve drive for electric throttle -G186-

❑ Throttle valve drive angle sender 1 for electric throttle -G187- and throttle valve drive angle sender 2 for

electric throttle -G188-

❑ After throttle valve module -J338- has been renewed, it must be re-adapted to engine control unit -J623-

using a vehicle diagnostic tester

20 - Seal

❑ Renew

21 - Intake manifold pressure sender -G71-

22 - Bolts for intake manifold pressure sender -G71-

❑ 5 Nm

40 Rep. Gr.24 - Mixture preparation - injection

Page 45

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

6.2 Fuel rail - exploded view

1 - Injector

❑ With combustion cham‐

ber ring seal (teflon ring

seal): always renew

❑ Renew O-rings

❑ Ensure correct installa‐

tion position.

❑ Removing and installing

⇒ page 53

2 - Support ring

3 - Roller tappet

4 - Fuel pressure regulating

valve -N276-

5 - High-pressure pump

❑ With fuel pressure regu‐

lating valve -N276❑ An electric fuel pump

(fitted in fuel tank) sup‐

plies fuel to the mechan‐

ical high-pressure pump

❑ When installing the

high-pressure fuel

pump, it is essential to

ensure that no dirt en‐

ters the fuel system.

❑ The fuel system must

not be under pressure

when installing the high-

pressure pump; proce‐

dure for reducing fuel

pressure ⇒ page 4

❑ Fuel pipes must be free

of tension when instal‐

led.

❑ Removing and installing

⇒ page 50

6 - Bolts for high-pressure pump

❑ 20 Nm

7 - Bolts

❑ 9 Nm

8 - Connecting piece for fuel supply pipe

❑ Renew

❑ 25 Nm

9 - Union nut for fuel supply pipe

❑ 20 Nm

10 - Bolts

❑ 9 Nm

11 - Vacuum unit for air flow control flaps (intake manifold flaps)

12 - Throttle valve module -J338- , throttle valve drive for electric throttle -G186-

❑ Throttle valve drive angle sender 1 for electric throttle -G187- and throttle valve drive angle sender 2 for

electric throttle -G188-

6. Intake manifold (engine codes CESA and CETA) 41

Page 46

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

❑ After throttle valve module -J338- has been renewed, it must be re-adapted to engine control unit -J623-

using a vehicle diagnostic tester

❑ 7 Nm

13 - Intake air temperature sender -G42-

❑ Tighten to 5 Nm

14 - Intake manifold

❑ Removing and installing ⇒ page 42

15 - Intake manifold pressure sender -G71-

❑ Tighten to 5 Nm

16 - Intake manifold flap potentiometer -G336-

❑ Intake manifold flap potentiometer -G336- must be re-adapted to engine control unit -J623- if it has been

renewed. Use vehicle diagnostic tester to do so.

17 - Gasket

❑ Renew

18 - Air flow control flaps (intake manifold flaps)

19 - Fuel pressure sender -G247-

❑ 27 Nm

❑ Lubricate threads lightly with clean engine oil

❑ Fitting location ⇒ page 13

❑ Removing and installing ⇒ page 59

20 - Fuel rail

❑ Removing and installing ⇒ page 42

❑ Tighten to 8 Nm

6.3 Removing and installing intake manifold with fuel rail

After the fuel rail has been removed or renewed, intake manifold

flap potentiometer -G336- must be adapted to engine control unit

-J623- . Use vehicle diagnostic tester to do so.

Special tools and workshop equipment required

♦ Assembly tool -T10118-

42 Rep. Gr.24 - Mixture preparation - injection

Page 47

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

♦ Hose clip pliers -V.A.G 1921-

♦ Socket Torx T30 -T10347-

♦ Oil filter tool -3417-

Removing

– Remove engine cover panel.

Note

♦

The combustion chamber (teflon) ring seal and the O-ring

must always be renewed.

♦

Intake manifold - exploded view ⇒ page 35

♦

Fuel rail - exploded view ⇒ page 37

WARNING

The fuel system is pressurised. The fuel pressure in the highpressure part of the injection system must be reduced to a

residual pressure prior to opening; for procedure see

⇒ page 4 .

– Disconnect negative terminal from battery.

– Clean joint between intake manifold and cylinder head.

6. Intake manifold (engine codes CESA and CETA) 43

Page 48

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Direct petrol injection and ignition system (4-cyl. 1.8 ltr., 2.0 ltr. 4-valve turbo with timing chain) - Edition

06.2010

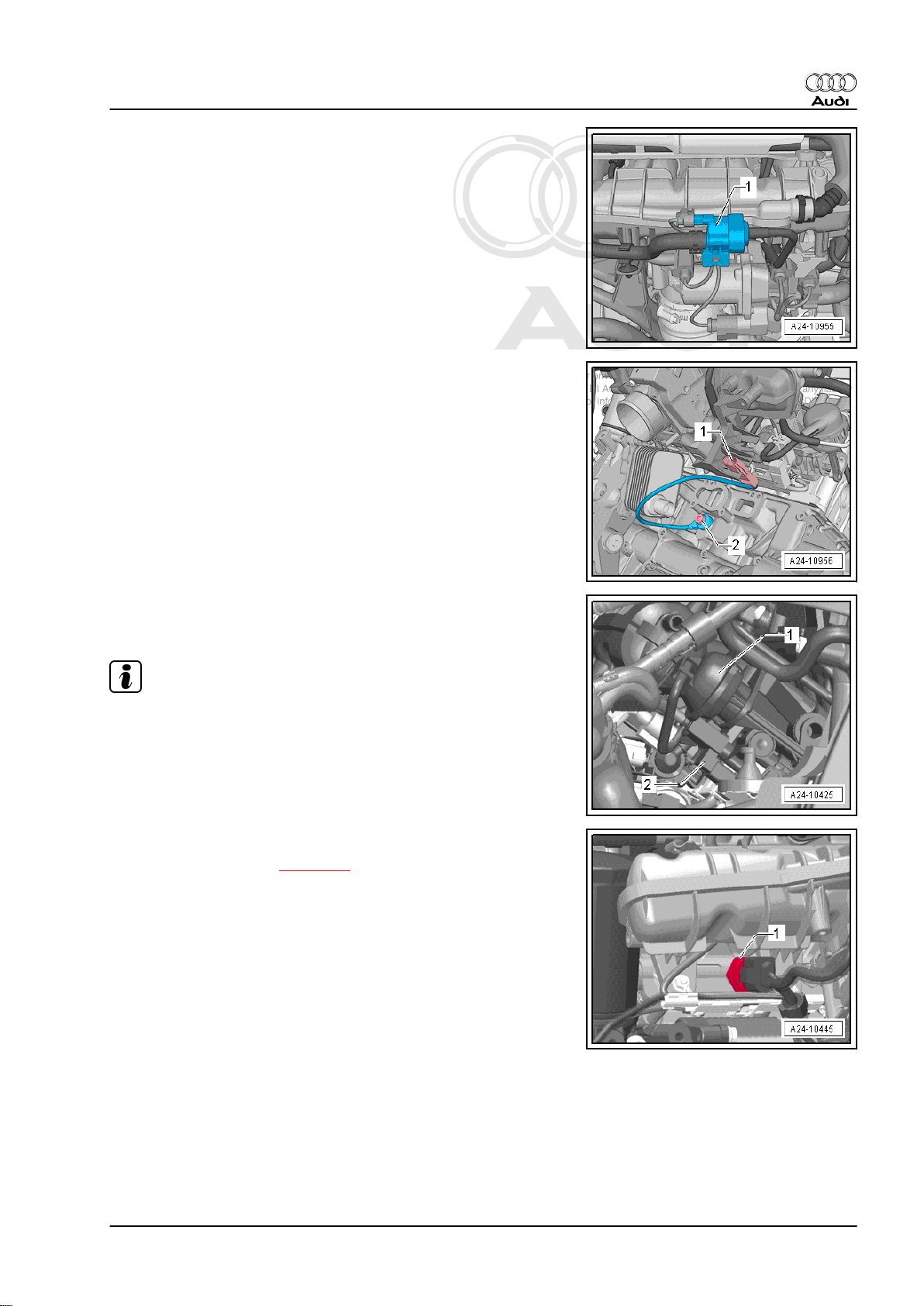

– Pull cover off air duct (release clips on sides) -arrows-.

– Unclip air duct at the bottom by releasing clips -arrows-.

– Detach air duct at bottom together with air hose.

– Disconnect vacuum line -arrow- leading to activated charcoal

filter.

– Unplug following electrical connectors:

1 - Intake air temperature sender -G42-

2 - Activated charcoal filter solenoid valve 1 -N80-

3 - Throttle valve module -J338-

Unplug electrical connector -1- at Hall sender -G40- .

– Remove noise insulation ⇒ Rep. Gr. 66 .

44 Rep. Gr.24 - Mixture preparation - injection

Page 49