Page 1

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Service

Workshop Manual

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4valve common rail, generation II)

Engine ID

Edition 05.2010

CFG

B

Service Department. Technical Information

Page 2

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Service

List of Workshop Manual Repair GroupsList of Workshop Manual

Repair GroupsList of Workshop Manual Repair Groups

Re pa ir G ro up

23 - Mixture preparation - injection

28 - Glow plug system

Technical information should always be available to the foremen and mechanics, because their

careful and constant adherence to the instructions is essential to ensure vehicle road-worthiness and

safety. In addition, the normal basic safety precautions for working on motor vehicles must, as a

matter of course, be observed.

All rights reserved.

No reproduction without prior agreement from publisher.

Copyright © 2010 Audi AG, Ingolstadt D3E8029B417

Page 3

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

Contents

23 - Mixture preparation - injection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1 Safety precautions and rules for cleanliness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Safety precautions for vehicles with start/stop system . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 Rules for cleanliness and instructions for working on fuel system . . . . . . . . . . . . . . . . . . . . 2

1.4 To avoid any risk of injuries to persons and/or damage to the injection and glow plug system,

always observe the following safety precautions: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.5 Checking vacuum system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Overview of fitting locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 System layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 Bleeding fuel system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5 Air cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1 Air cleaner - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.2 Removing and installing engine cover panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.3 Removing and installing air filter element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.4 Removing and installing air cleaner housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.5 Removing and installing air mass meter G70 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6 Intake manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.1 Intake manifold with attached components - exploded view . . . . . . . . . . . . . . . . . . . . . . . . 21

6.2 Removing and installing intake manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7 High-pressure pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.1 High-pressure pump - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.2 Removing and installing high-pressure pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.3 Performing first fuel filling operation after installing high-pressure pump . . . . . . . . . . . . . . 29

7.4 Checking fuel system for leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

8 Injectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.1 Injectors - exploded view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.2 Checking injectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8.3 Performing adaption of injector delivery calibration values . . . . . . . . . . . . . . . . . . . . . . . . 33

8.4 Checking return flow rate of injectors with engine running . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8.5 Checking return flow rate of injectors at starter cranking speed . . . . . . . . . . . . . . . . . . . . 36

8.6 Checking for injectors sticking open . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

8.7 Removing and installing injectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

9 Components of injection system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

9.1 Removing and installing throttle valve module J338 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

9.2 Installing high-pressure pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.3 Checking fuel pressure regulating valve N276 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

9.4 Checking fuel pressure (low pressure) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

9.5 Checking delivery rate of fuel pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9.6 Removing and installing fuel pressure regulating valve N276 . . . . . . . . . . . . . . . . . . . . . . 51

9.7 Removing and installing fuel pressure sender G247 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

9.8 Removing and installing fuel rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

10 Lambda probe and exhaust gas temperature senders . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

10.1 Lambda probe and exhaust gas temperature senders - exploded view . . . . . . . . . . . . . . . . 58

10.2 Removing and installing Lambda probe G39 with Lambda probe heater Z19 . . . . . . . . . . 58

10.3 Removing and installing pressure differential sender G505 . . . . . . . . . . . . . . . . . . . . . . . . 59

11 Engine control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

11.1 Wiring and component check with test box V.A.G 1598/42 . . . . . . . . . . . . . . . . . . . . . . . . 61

11.2 Removing and installing engine control unit J623 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

28 - Glow plug system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Contents i

Page 4

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

1.1 Removing and installing glow plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

1.2 Removing and installing automatic glow period control unit J179 . . . . . . . . . . . . . . . . . . . . 69

1.3 Removing and installing Hall sender G40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

1.4 Removing and installing engine speed sender G28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

ii Contents

Page 5

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

23 – Mixture preparation - injection

1 Safety precautions and rules for

cleanliness

⇒ “1.1 Safety precautions”, page 1

⇒ “1.2 Safety precautions for vehicles with start/stop system”,

page 1

⇒ “1.3 Rules for cleanliness and instructions for working on fuel

system”, page 2

⇒ “1.4 To avoid any risk of injuries to persons and/or damage to

the injection and glow plug system, always observe the following

safety precautions:”, page 3

⇒ “1.5 Checking vacuum system”, page 3

1.1 Safety precautions

Note the following if testers and measuring instruments have to

be used during a road test:

WARNING

Accidents can be caused if the driver is distracted by test

equipment while road-testing, or if test equipment is not prop‐

erly secured.

Persons sitting in the front passenger's seat could be injured if

the airbag is triggered in an accident.

• The use of test equipment while driving causes distraction.

• There is an increased risk of injury if test equipment is not

secured.

♦ Test equipment must always be secured on the rear seat

with a strap and operated from the rear seat by a second

person.

1.2 Safety precautions for vehicles with start/stop system

Risk of injury due to automatic engine start on vehicles with

start/stop system.

♦ On vehicles with activated start/stop system (this is indi‐

♦ Therefore it is important to ensure that the start/stop sys‐

WARNING

cated by a message in the instrument cluster display), the

engine may start automatically on demand.

tem is deactivated when performing repairs (switch off

ignition, if required switch on ignition again).

1. Safety precautions and rules for cleanliness 1

Page 6

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

1.3 Rules for cleanliness and instructions for working on fuel system

To prevent the high-pressure fuel pump from running while it is

empty and to ensure that the engine starts quickly after parts have

been renewed, it is important to observe the following:

♦ If components of the fuel system between the fuel tank and

the high-pressure fuel pump are removed or renewed, the ba‐

sic setting “Checking fuel system pressurisation pump” must

be performed to bleed the fuel system.

♦ If the supplementary fuel pump, fuel line (between fuel tank

and high-pressure fuel pump) or fuel filter is removed or re‐

newed, the basic setting “Checking fuel system pressurisation

pump” must be performed before the engine is started for the

first time.

♦ If the high-pressure fuel pump is removed or renewed, the ba‐

sic setting “Checking fuel system pressurisation pump” must

be performed before the engine is started for the first time.

Procedure for first fuel filling ⇒ page 29

• Clean tools and workbench etc. before working on the injection

system.

• Thoroughly clean all unions and surrounding areas before dis‐

connecting.

• When removing components, plug all open connections im‐

mediately with suitable clean sealing caps.

• Do not remove sealing caps from components until immedi‐

ately prior to installation. After removal, components should

be kept in new, sealable plastic bags (use the original new part

packaging if possible).

• Before installation, check the injectors and their surroundings

visually; they must be undamaged and free of lint. Make sure

the injector bores in the cylinder head are clean. Wipe out if

necessary using a clean cloth, taking care not to cause dam‐

age. Do not use sharp objects of any kind.

• If the high-pressure fuel lines are to be re-used, you must mark

them before removal. High-pressure fuel lines must always be

re-installed in their original positions (i.e. on the same cylin‐

der).

• The following components and seals/O-rings must always be

renewed when the injectors are removed and installed: “cop‐

per seal” and “O-ring for injector bore”.

• The following components and seals/O-rings must always be

renewed when an injector is renewed: “clamping piece”, “cop‐

per seal” and “O-ring for injector bore”.

• Always fit new copper seals for the injectors. Check all new O-

rings for damage before installing. Lubricate O-rings lightly

with assembly oil or clean engine oil before installing.

• Take care not to damage the injectors when removing the old

copper seals.

• Align the high-pressure fuel lines so they are free of tension.

Tighten all unions lightly to start with before tightening to final

torque.

• Never attempt to bend high-pressure fuel lines to shape.

• When working on any parts of the high-pressure fuel system,

tools may only be used for loosening and tightening pipe un‐

ions. All other components must always be removed and

installed by hand without using tools or other equipment.

2 Rep. Gr.23 - Mixture preparation - injection

Page 7

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

• Do not dismantle individual common rail components.

• If there is a fault, the complete components must be renewed.

• Do not bleed the common rail system by unfastening highpressure components after the engine has been started.

• When the engine is running, do not perform any repairs to the

common rail system; in particular, do not open or detach the

high-pressure pipes.

• All cable ties which are released or cut open when removing

must be refitted in the same position when installing.

• When the fuel system is open: Do not work with compressed

air if this can be avoided. Do not move the vehicle unless ab‐

solutely necessary.

• Also ensure that no diesel fuel comes into contact with the

coolant hoses. Should this occur, the hoses must be cleaned

immediately. Damaged hoses must be renewed.

1.4 To avoid any risk of injuries to persons

and/or damage to the injection and glow

plug system, always observe the follow‐

ing safety precautions:

♦ Persons wearing a pacemaker should not lean over the engine

compartment while the engine is running, as the injectors use

high voltage pulses.

♦ Do not open any fuel line connections while the engine is run‐

ning.

♦ Always switch off the ignition before connecting or discon‐

necting injection and glow plug system wiring or tester cables.

♦ Always switch off the ignition before cleaning the engine.

♦ Always switch off the ignition before connecting or discon‐

necting the battery, otherwise the engine control unit may be

damaged.

♦ Certain tests may lead to a fault being detected by the control

unit and stored. The event memory should therefore be inter‐

rogated and (if necessary) erased after completing the tests

and any repair work that may be required.

1.5 Checking vacuum system

Special tools and workshop equipment required

♦ Hand vacuum pump -VAS 6213-

Procedure

– Check all vacuum lines in the complete vacuum system for:

♦ Cracks

1. Safety precautions and rules for cleanliness 3

Page 8

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

♦ Traces of animal bites

♦ Kinked or crushed lines

♦ Lines porous or leaking

– Check vacuum line to solenoid valve and from solenoid valve

to corresponding component.

– If a fault is stored in the event memory, check all vacuum lines

leading to the corresponding component, and also check the

remaining vacuum lines leading to other components.

– If it is not possible to build up a vacuum with the hand vacuum

pump -VAS 6213- or if the vacuum pressure drops again im‐

mediately, check the hand vacuum pump and connecting

hoses for leaks.

4 Rep. Gr.23 - Mixture preparation - injection

Page 9

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

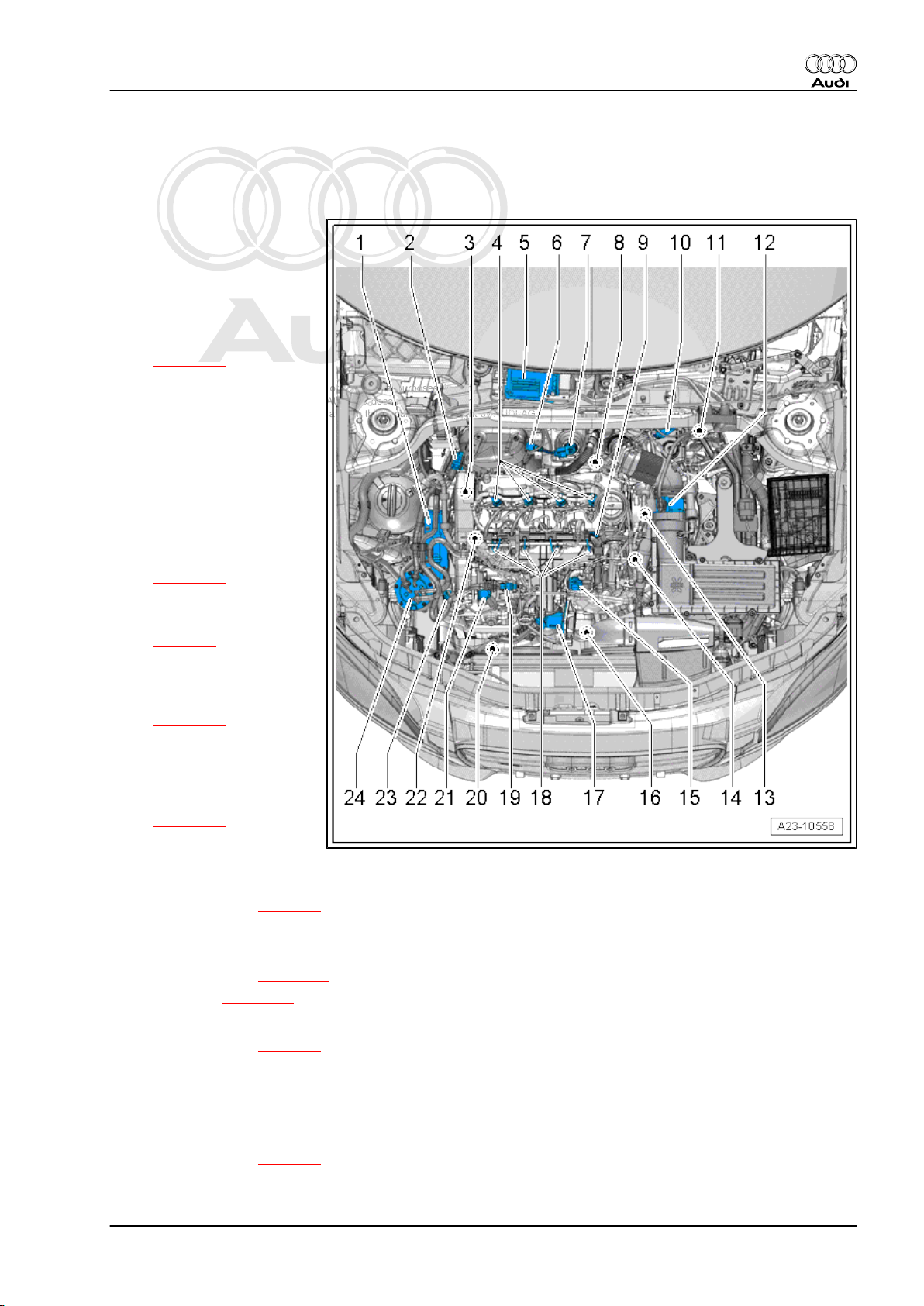

2 Overview of fitting locations

Components “A” to “H” are not shown in the illustration.

1 - Supplementary fuel pump V393-

❑ Exploded view ⇒ Rep.

Gr. 20

2 - Pressure differential sender

-G505-

❑ Exploded view

⇒ page 58

❑ Adaption must be per‐

formed after renewing

this component

3 - Hall sender -G40- (cam‐

shaft position sensor)

❑ Fitting location

⇒ page 10

❑ 10 Nm

4 - Injectors

❑ Exploded view

⇒ page 31

5 - Engine control unit -J623-

❑ Fitting location

⇒ page 7

6 - Lambda probe -G39- with

Lambda probe heater -Z19-

❑ Exploded view

⇒ page 58

❑ 50 Nm

7 - Position sender for charge

pressure positioner -G581-

❑ Fitting location

⇒ page 10

8 - Exhaust gas recirculation

control motor -V338- with exhaust gas recirculation potentiometer -G212-

❑ Integrated into exhaust gas recirculation cooler

❑ Fitting location ⇒ page 9

❑ Removing and installing ⇒ Engine, mechanics; Rep. Gr. 26

9 - Fuel pressure regulating valve -N276-

❑ Exploded view ⇒ page 43

❑ Checking ⇒ page 46

10 - Charge pressure control solenoid valve -N75-

❑ Fitting location ⇒ page 9

11 - Electrical connector

❑ For exhaust gas temperature sender 4 -G648❑ For exhaust gas temperature sender 1 -G235❑ For Lambda probe -G39❑ Fitting location ⇒ page 9

2. Overview of fitting locations 5

Page 10

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

12 - Coolant temperature sender -G62-

❑ Fitting location ⇒ page 10

13 - Air mass meter -G70-

❑ Exploded view ⇒ page 15

14 - Engine speed sender -G28-

❑ Fitting location ⇒ page 11

❑ 4.5 Nm

15 - Exhaust gas recirculation cooler change-over valve -N345-

❑ Fitting location ⇒ page 11

16 - Pump for exhaust gas recirculation cooler -V400-

❑ Fitting location ⇒ page 9

17 - Throttle valve module -J338- with throttle valve potentiometer -G69-

❑ Exploded view ⇒ page 21

18 - Glow plugs

❑ Glow plug 1 -Q10❑ Glow plug 2 -Q11❑ Glow plug 3 -Q12❑ Glow plug 4 -Q13❑ Removing and installing ⇒ page 67

❑ 17 Nm

19 - Fuel temperature sender -G81-

❑ In fuel supply line

❑ Fitting location ⇒ page 9

20 - Charge pressure sender -G31- with intake air temperature sender -G42-

❑ Fitting location ⇒ page 8

21 - High-pressure pump with fuel metering valve -N290-

❑ Exploded view ⇒ page 25

❑ Do not open fuel metering valve -N290❑ After renewing, first fuel filling operation MUST be performed (it is important not to allow pump to run

while it is still empty) ⇒ page 29

22 - Fuel pressure sender -G247-

❑ Exploded view ⇒ page 31

23 - Radiator outlet coolant temperature sender -G83-

❑ Fitting location ⇒ page 10

24 - Fuel filter

❑ Exploded view ⇒ Rep. Gr. 20

❑ Renewing ⇒ Rep. Gr. 20

A - Low heat output relay -J359- and high heat output relay -J360-

❑ Fitting location ⇒ Current flow diagrams, Electrical fault finding and Fitting locations

B - Brake light switch -F- and brake pedal switch -F47-

❑ Fitting location ⇒ page 7

C - Clutch position sender -G476-

❑ Fitting location ⇒ page 8

❑ Only fitted on vehicles with manual gearbox

D - Accelerator position sender -G79- and accelerator position sender 2 -G185-

❑ Fitting location ⇒ page 7

6 Rep. Gr.23 - Mixture preparation - injection

Page 11

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

E - Exhaust gas temperature sender 1 -G235-

❑ Exploded view ⇒ page 58

F - Exhaust gas temperature sender 3 -G495-

❑ Exploded view ⇒ page 58

G - Exhaust gas temperature sender 4 -G648-

❑ Exploded view ⇒ page 58

H - Particulate filter

❑ Combined with catalytic converter

❑ Adaption must be performed after renewing this component

❑ Removing and installing ⇒ Rep. Gr. 26

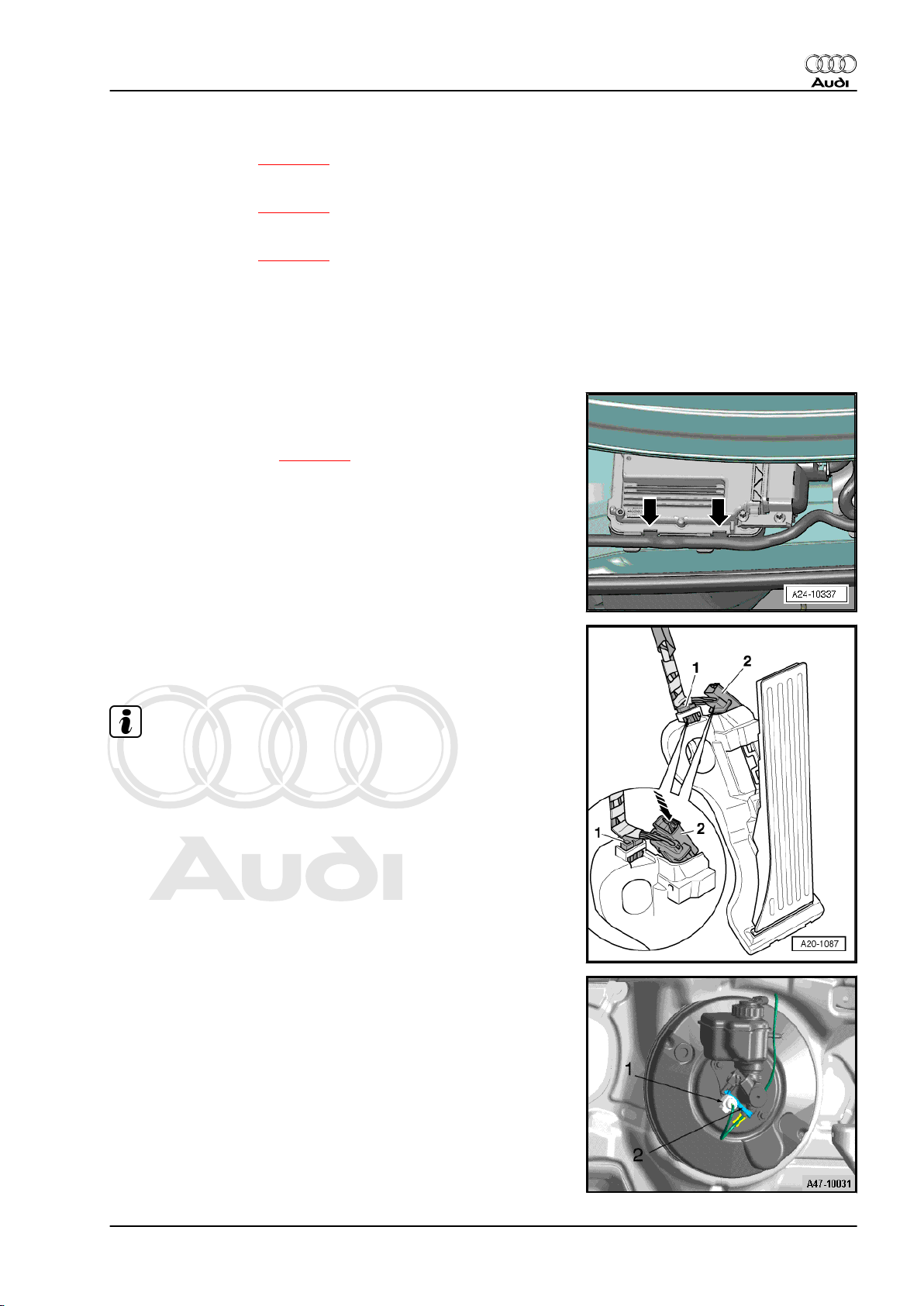

Fitting location of engine control unit -J623-

♦ In electronics box (plenum chamber)

Removing and installing ⇒ page 62

Fitting location: accelerator position sender -G79- and accelerator

position sender 2 -G185-

♦ Combined with accelerator pedal module

Note

The illustration shows the set-up for left-hand drive vehicles.

Removing and installing accelerator pedal module ⇒ Rep. Gr.

20

Fitting location of brake light switch -F- and brake pedal switch F47-

1 - Brake light switch -F- and brake pedal switch -F47-

♦ On brake master cylinder

Removing and installing ⇒ Rep. Gr. 47

2. Overview of fitting locations 7

Page 12

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

Fitting location of clutch position sender -G476-

♦ On clutch master cylinder-arrow-.

Removing and installing ⇒ Rep. Gr. 30

Integrated functions: clutch pedal switch for engine start -F194and clutch pedal switch -F36- (manual gearbox only)

Fitting location of fuel pump control unit -J538-

1 - Connector for fuel pump control unit -J538-

2 - Fuel pump control unit -J538-

3 - Fuel system pressurisation pump -G6-

Removing and installing ⇒ Rep. Gr. 20

Fitting location of charge pressure sender -G31- with intake air

temperature sender -G42-

1 - Charge pressure sender -G31- with intake air temperature

sender -G42-

♦ At air pipe (right-side)

Removing and installing ⇒ Rep. Gr. 21

8 Rep. Gr.23 - Mixture preparation - injection

Page 13

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

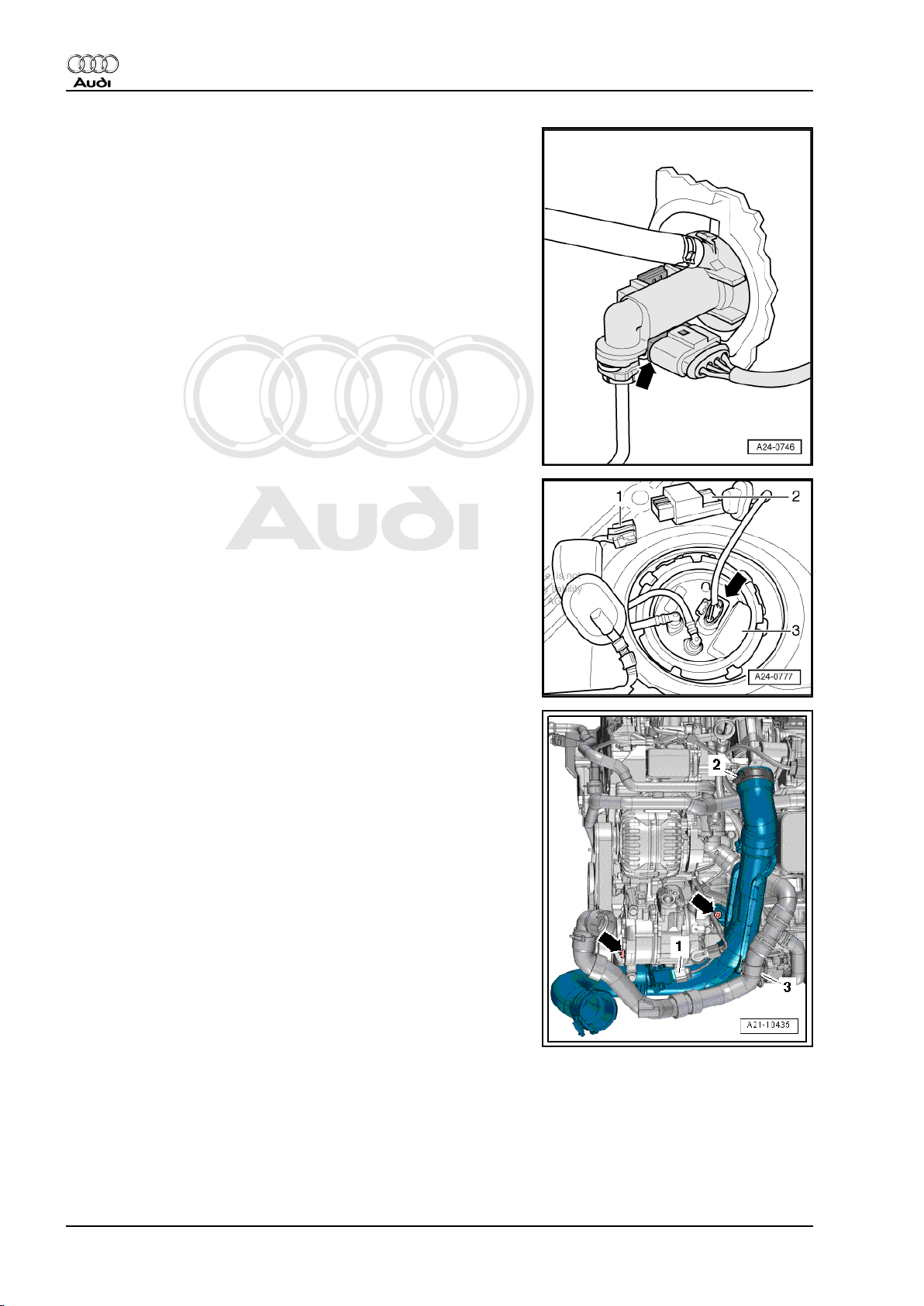

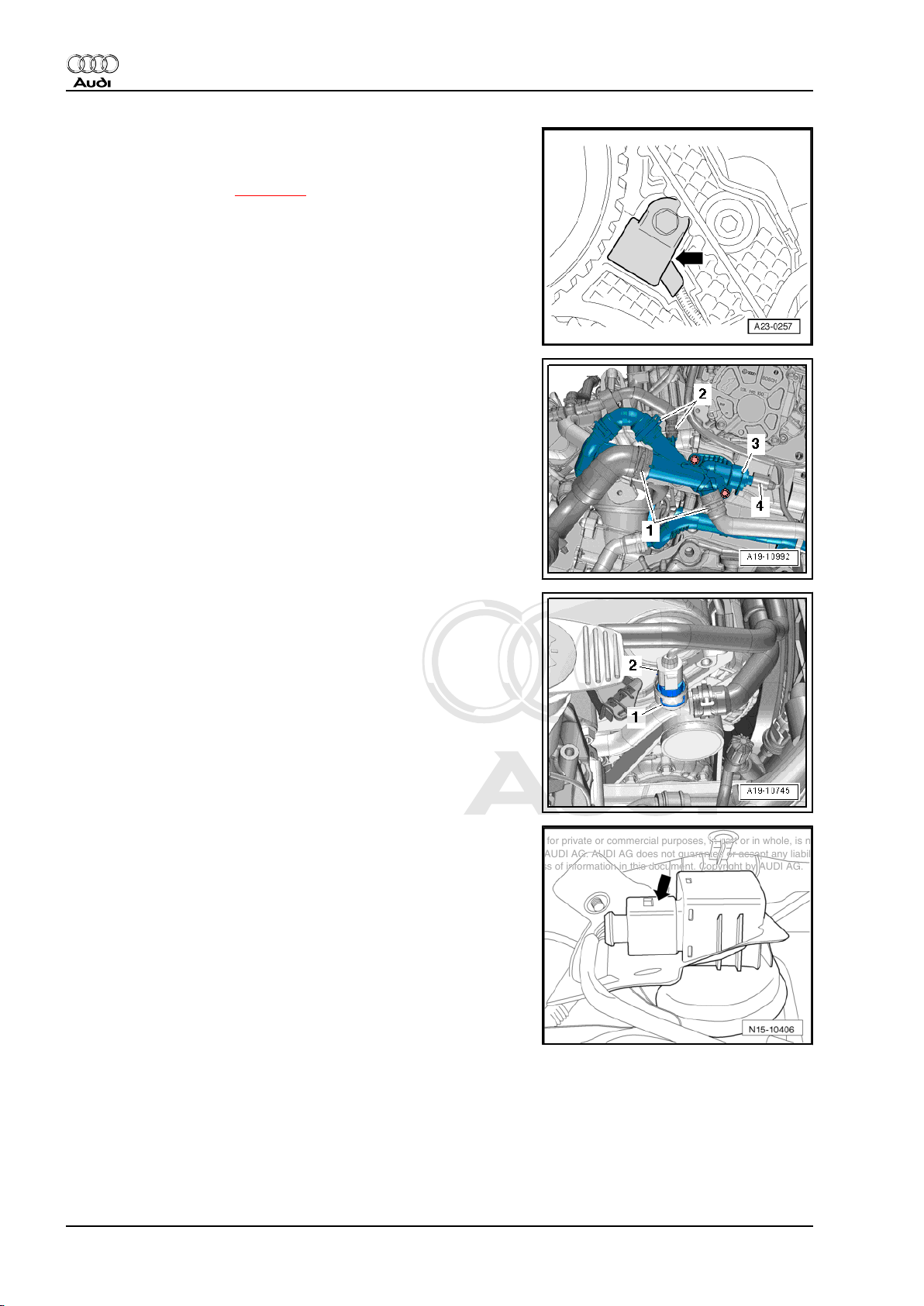

Components at rear of engine

2 - Exhaust gas recirculation control motor -V338- with exhaust

gas recirculation potentiometer -G212-

4 - Vacuum unit for exhaust gas recirculation cooling system

Electrical connectors

1 - For exhaust gas temperature sender 1 -G235-

2 - For exhaust gas temperature sender 4 -G648-

3 - For Lambda probe -G39-

4 - For exhaust gas temperature sender 3 -G495-

Fitting location of pump for exhaust gas recirculation cooler V400-

2 - Pump for exhaust gas recirculation cooler -V400-

♦ At front of engine

Removing and installing ⇒ Rep. Gr. 19

Fitting location of fuel temperature sender -G81-

4 - Fuel temperature sender -G81-

♦ In fuel supply line at high-pressure pump

2. Overview of fitting locations 9

Page 14

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

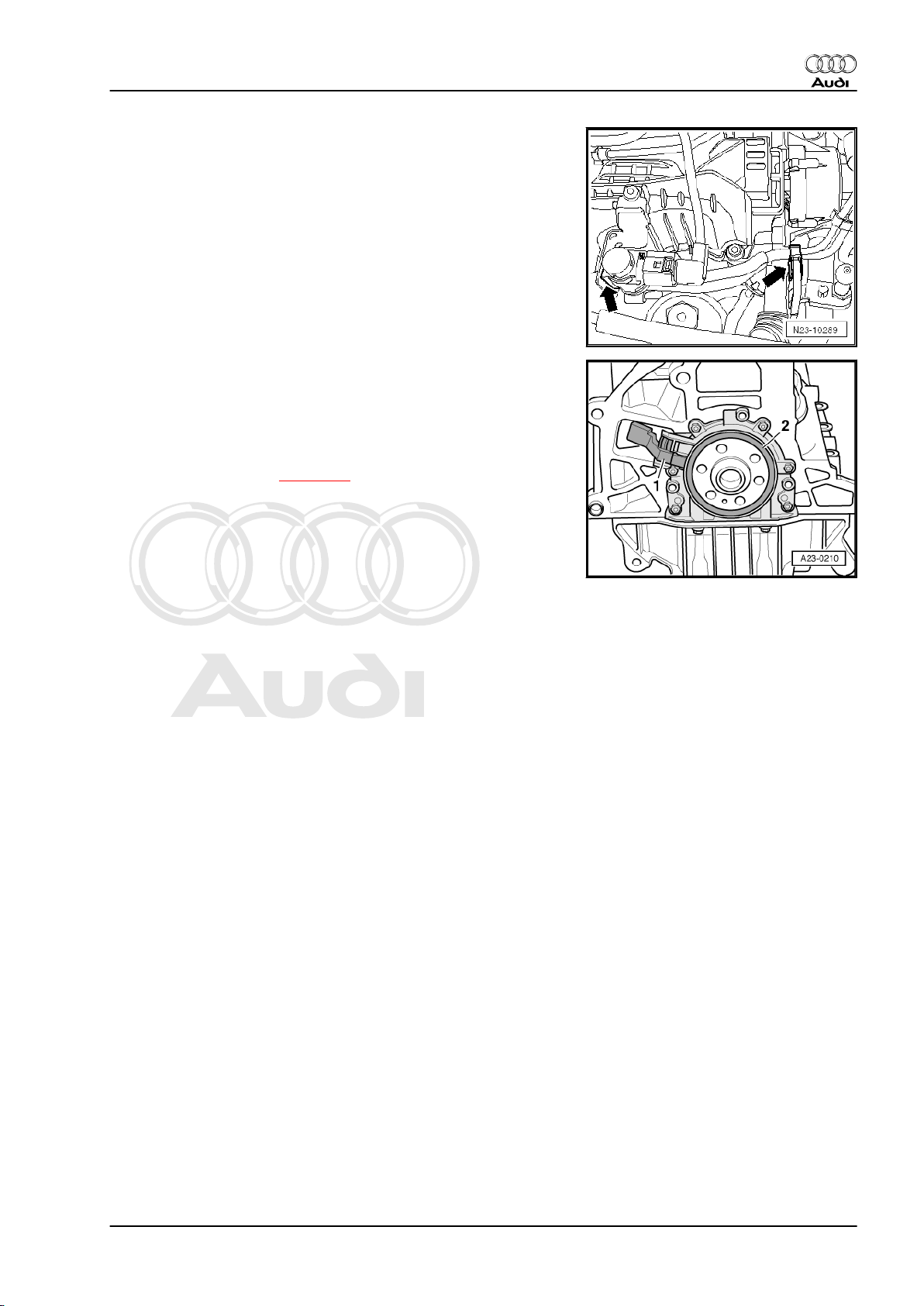

Fitting location of Hall sender -G40-

♦ Next to camshaft sprocket -arrow-

Removing and installing ⇒ page 69

Fitting location of coolant temperature sender -G62-

4 - Coolant temperature sender -G62-

♦ On right side of engine under exhauster pump

Removing and installing ⇒ Rep. Gr. 19

Fitting location of radiator outlet coolant temperature sender G83-

2 - Radiator outlet coolant temperature sender -G83-

♦ In coolant pipe (right-side) above alternator

Removing and installing ⇒ Rep. Gr. 19

Fitting location of position sender for charge pressure positioner

-G581-

♦ At rear of engine at turbocharger -arrow-.

10 Rep. Gr.23 - Mixture preparation - injection

Page 15

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

Fitting location of exhaust gas recirculation cooler change-over

valve -N345-

♦ On intake manifold -left arrow-.

Fitting location of engine speed sender -G28-

1 - Engine speed sender -G28-

2 - Sender wheel

♦ On flywheel side of engine.

Removing and installing ⇒ page 70

2. Overview of fitting locations 11

Page 16

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

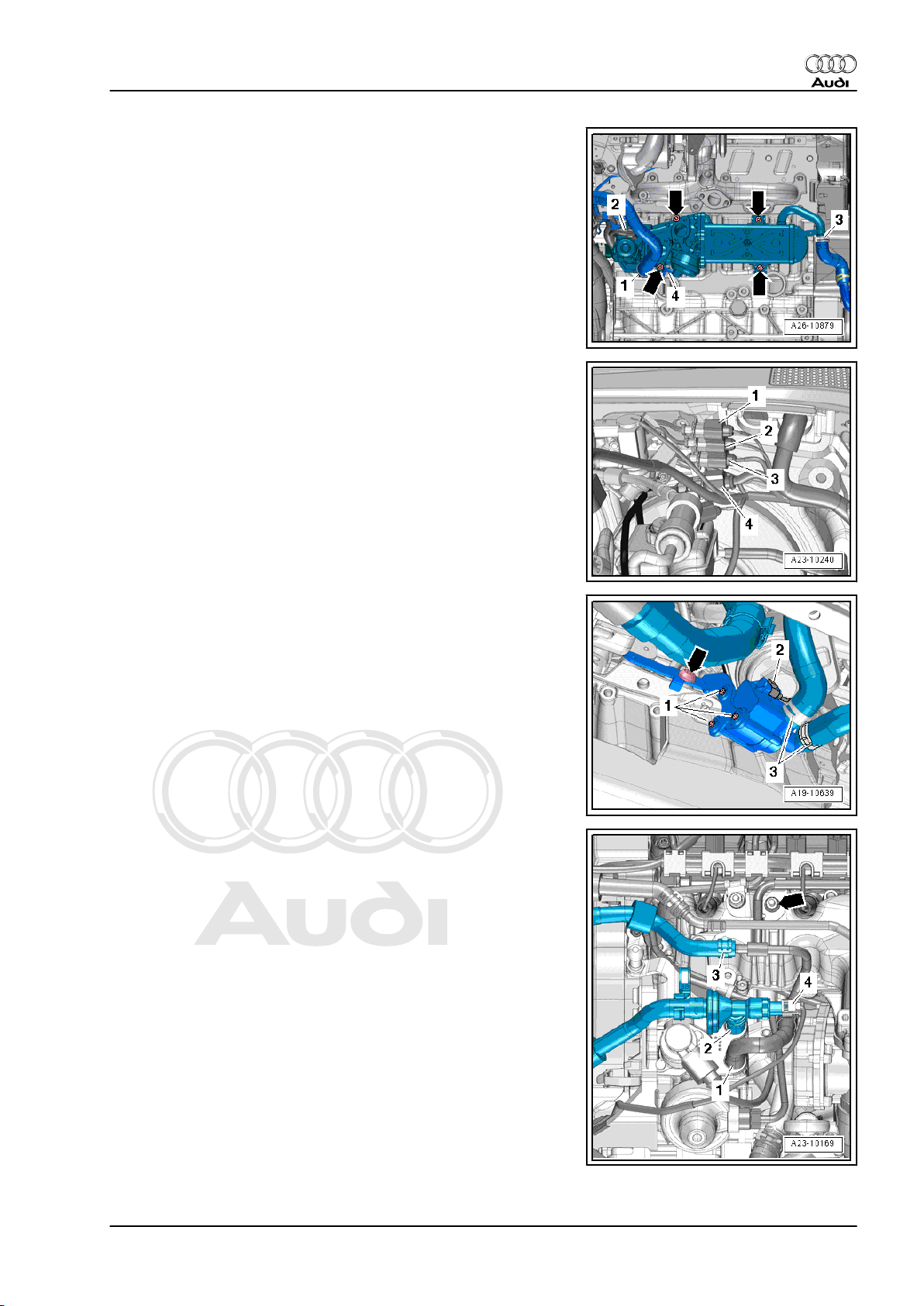

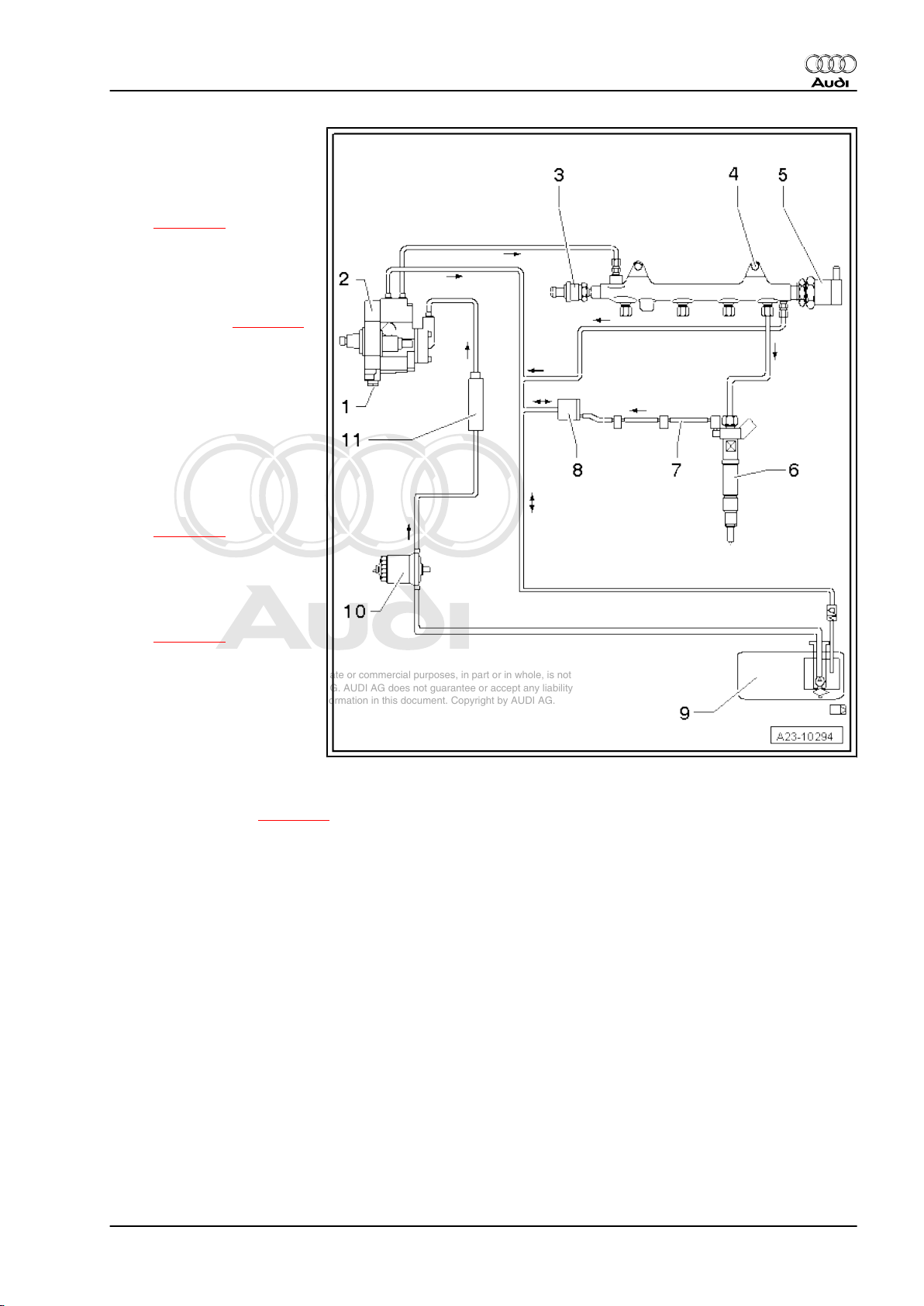

3 System layout

WARNING

♦ Always read rules for cleanliness and instructions for

working on fuel system ⇒ page 2 .

♦ Follow these instructions and rules for cleanliness before

starting work and while working on the fuel system.

Caution

The high-pressure fuel pump has very close tolerances and

must not be allowed to run without fuel. To prevent this and to

enable the engine to start quickly after parts have been re‐

newed, it is important to observe the following:

♦ If components of the fuel system between the fuel tank

and the high-pressure pump are removed or renewed, the

first fuel filling operation must be performed.

♦ If a fuel pump, fuel line (between fuel tank and high-pres‐

sure pump) or fuel filter is removed or renewed, the fuel

system must be bled before the engine is started for the

first time.

♦ If the high-pressure pump is removed or renewed, the fuel

system must be bled before the engine is started for the

first time.

Procedure for first fuel filling ⇒ page 29

Note

The high-pressure pump will be damaged if the first fuel filling

procedure is not performed.

12 Rep. Gr.23 - Mixture preparation - injection

Page 17

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

1 - Fuel metering valve -N290-

❑ Do not unscrew

2 - High-pressure pump

❑ Exploded view

⇒ page 25

❑ After renewing, first fuel

filling operation MUST

be performed (it is im‐

portant not to allow

pump to run while it is

still empty) ⇒ page 29

❑ After renewing high-

pressure pump or fuel

pressure regulating

valve -N276- , learnt val‐

ues must be re-adapted;

see “Guided Functions”

in vehicle diagnostic

tester

3 - Fuel pressure sender G247-

❑ Exploded view

⇒ page 31

4 - Fuel rail

5 - Fuel pressure regulating

valve -N276-

❑ Exploded view

⇒ page 31

❑ After renewing high-

pressure pump or fuel

pressure regulating

valve -N276- , learnt val‐

ues must be re-adapted;

see “Guided Functions”

in vehicle diagnostic

tester

6 - Injector

❑ Exploded view ⇒ page 31

7 - Fuel return line

8 - Not fitted

9 - Fuel tank

❑ With fuel system pressurisation pump -G6-

10 - Fuel filter

❑ Exploded view ⇒ Rep. Gr. 20

11 - Supplementary fuel pump -V393-

❑ Exploded view ⇒ Rep. Gr. 20

3. System layout 13

Page 18

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

4 Bleeding fuel system

Caution

If components of the fuel system between the fuel tank and the

high-pressure fuel pump are removed or renewed, the basic

setting “Checking fuel system pressurisation pump” must be

performed to bleed the fuel system.

If the supplementary fuel pump, fuel line (between fuel tank

and high-pressure fuel pump) or fuel filter is removed or re‐

newed, the basic setting “Checking fuel system pressurisation

pump” must be performed before the engine is started for the

first time.

Proceed as follows to fill fuel system with fuel:

– Connect a vehicle diagnostic tester.

– Switch on ignition.

– Select “Engine electronics” in vehicle self-diagnosis.

– Then select “Basic setting”.

– Select “Checking fuel system pressurisation pump” from the

list.

– Press “Start” button.

– The fuel pumps start running.

– The fuel pumps must run for approx. 1 minute to ensure that

the fuel system is filled sufficiently with fuel.

Note

To repeat basic setting, switch ignition off and on once. Then start

basic setting again.

– Start engine after filling fuel system.

– Run engine at moderate speed for several minutes and then

switch off.

– Check fuel system for leaks.

– Erase entry in event memory using diagnostic tester.

– After completing the repair, road-test the vehicle over a dis‐

tance of at least 20 km. Accelerate with full throttle at least

once. Then inspect the high-pressure section of the fuel sys‐

tem again for leaks.

Note

If there is any air left in the fuel system, the engine may switch to

the backup mode ('emergency running' mode) during the road

test. Switch off the engine and erase the event memory. Then

continue the road test.

– Interrogate event memory.

14 Rep. Gr.23 - Mixture preparation - injection

Page 19

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

5 Air cleaner

⇒ “5.1 Air cleaner - exploded view”, page 15

⇒ “5.2 Removing and installing engine cover panel”, page 16

⇒ “5.3 Removing and installing air filter element”, page 17

⇒ “5.4 Removing and installing air cleaner housing”, page 18

⇒ “5.5 Removing and installing air mass meter G70 ”, page 20

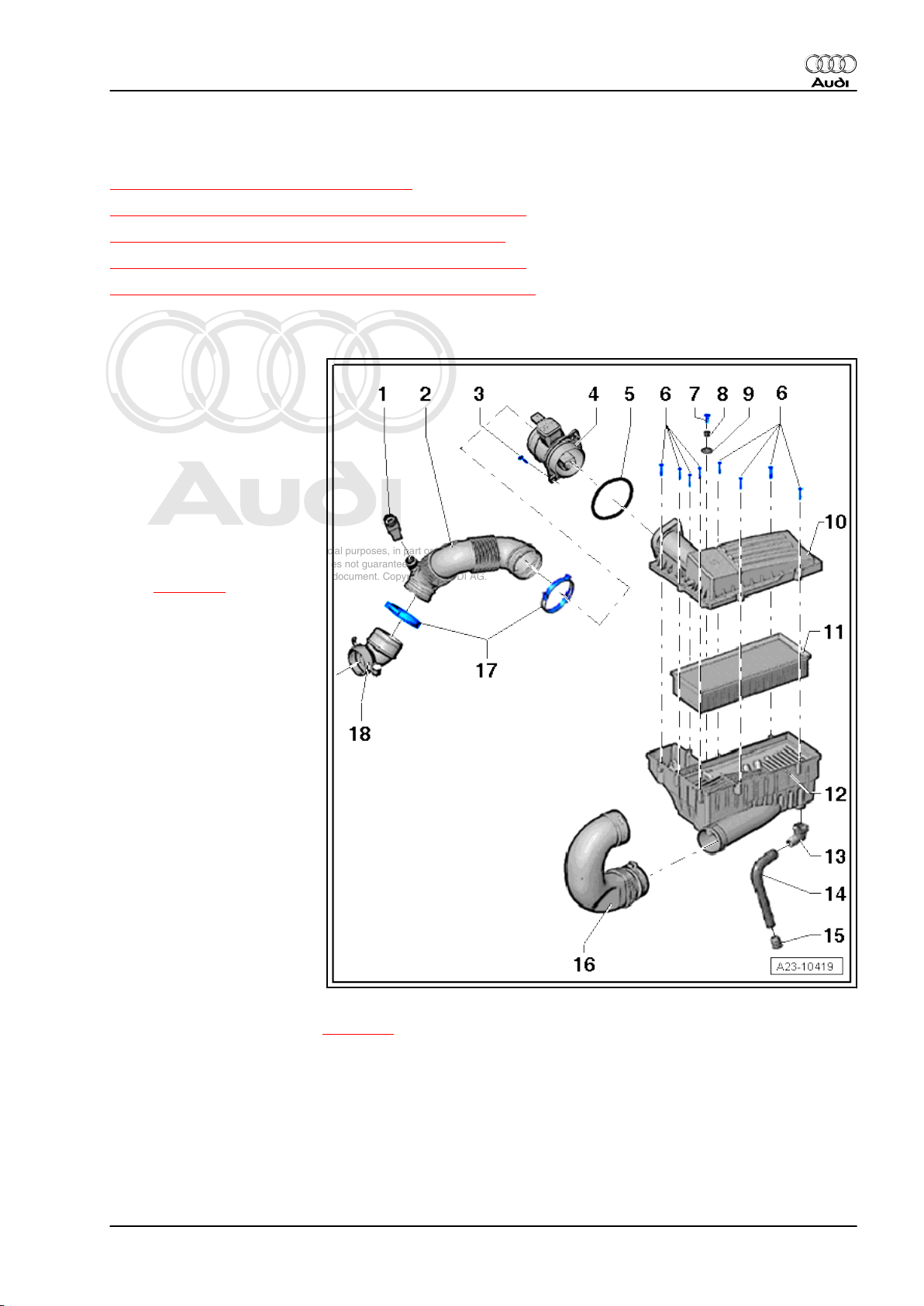

5.1 Air cleaner - exploded view

1 - Hose connection

2 - Air hose

❑ To turbocharger

❑ Check for dirt and accu‐

mulated leaves, etc.

3 - Bolt

❑ 2x

❑ 1.5 Nm

4 - Air mass meter -G70-

❑ Removing and installing

⇒ page 20

5 - O-ring

❑ Renew

❑ Use silicone-free lubri‐

cant when installing

6 - Bolts

❑ For air cleaner (top sec‐

tion)

❑ 1.5 Nm

7 - Bolt

❑ For air cleaner (bottom

section)

❑ 8 Nm

8 - Sleeve

9 - Washer

10 - Air cleaner (top section)

❑ Clean out dirt, leaves

and salt deposits

11 - Air filter element

❑ Always use genuine part for air filter element

❑ Removing and installing ⇒ page 17

❑ Observe change intervals ⇒ Maintenance ; Booklet 810

12 - Air cleaner (bottom section)

❑ Clean out dirt, leaves and salt deposits

❑ On vehicles for cold climates, air cleaner (bottom section) with hot-air-intake hose is installed

❑ Country-specific version with snow screen

13 - Connection for water drain hose

❑ Clean

5. Air cleaner 15

Page 20

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

14 - Water drain hose

❑ Clean

15 - Flutter valve

❑ Clean and re-install

16 - Intake air duct

❑ To lock carrier

❑ Clean out dirt, leaves and salt deposits

17 - Spring-type clip

18 - Connecting hose

❑ To turbocharger

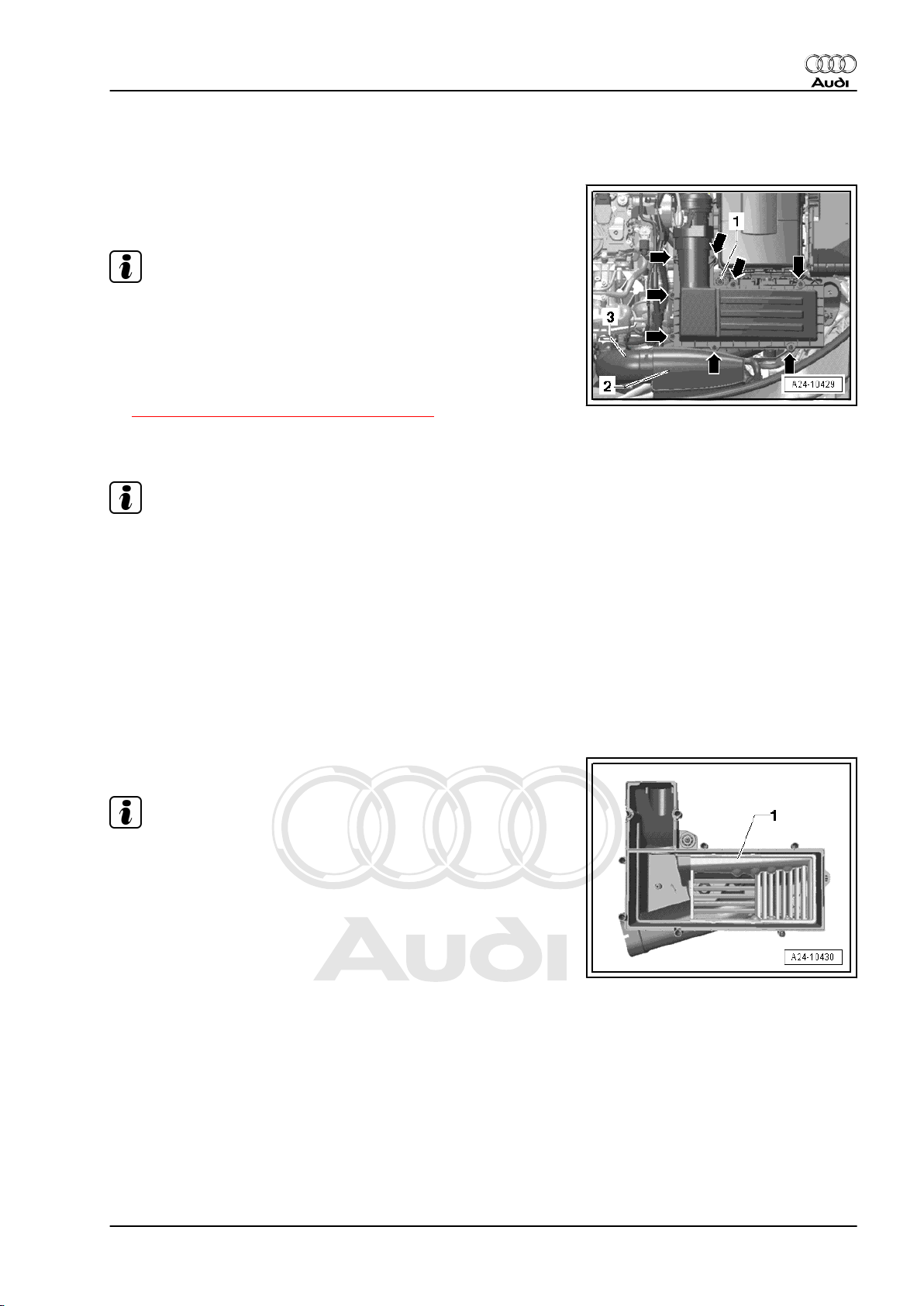

5.2 Removing and installing engine cover panel

Removing

– Carefully pull engine cover panel off retaining pins one after

the other -arrows-. Do not jerk the cover panel away, and do

not try to pull on one side only.

Installing

– To avoid damage, do not strike the engine cover panel with

your fist or with any kind of tool.

– Position engine cover panel on engine (note locations of oil

filler neck and oil dipstick).

– Press engine cover panel with both hands into the rubber

grommets at the rear and then into the grommets at the front.

16 Rep. Gr.23 - Mixture preparation - injection

Page 21

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

5.3 Removing and installing air filter ele‐

ment

Removing

– Remove bolts -arrows-.

Note

Disregard -items 1, 2, 3-.

– Lift up air cleaner (top section) and take out air filter element.

Installing

• Tightening torque

⇒ “5.1 Air cleaner - exploded view”, page 15

To ensure that the air mass meter functions properly, it is impor‐

tant to observe the following notes and instructions.

Note

♦

If the air filter element is very dirty or wet, dirt or water could

reach the air mass meter and affect the air mass value. This

would lead to loss of power, since a smaller injection quantity

is calculated.

♦

Always use genuine part for air filter element.

♦

The air cleaner housing MUST be clean.

♦

To prevent malfunctions, cover critical parts of the engine air

intake (air mass meter, air pipes, etc.) with a clean cloth when

blowing out the air cleaner housing with compressed air.

♦

Observe environmental requirements for disposal.

– Remove snow screen -1- and clean it.

Note

The snow screen is not fitted on all vehicles.

5. Air cleaner 17

Page 22

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

– Clean water drain -arrow- and air cleaner (bottom section).

– Clean salt residue, dirt and leaves out of air cleaner housing

(top and bottom sections) using a vacuum cleaner.

– Check for salt residue, dirt and leaves in air mass meter and

air intake hose (engine intake side).

– Check for dirt and leaves in air duct going from lock carrier to

air cleaner housing.

– When installing air filter element, check that it is properly cen‐

tred in retainer in air cleaner (bottom section).

– Fit the top section of the air cleaner carefully on the bottom

section, without using force. Make sure the top section of the

air cleaner is fitted straight on the air filter element (note posi‐

tion of sealing lip on air filter element).

– Ensure secure fit of intake hose at air mass meter.

The remaining installation steps are carried out in the reverse se‐

quence.

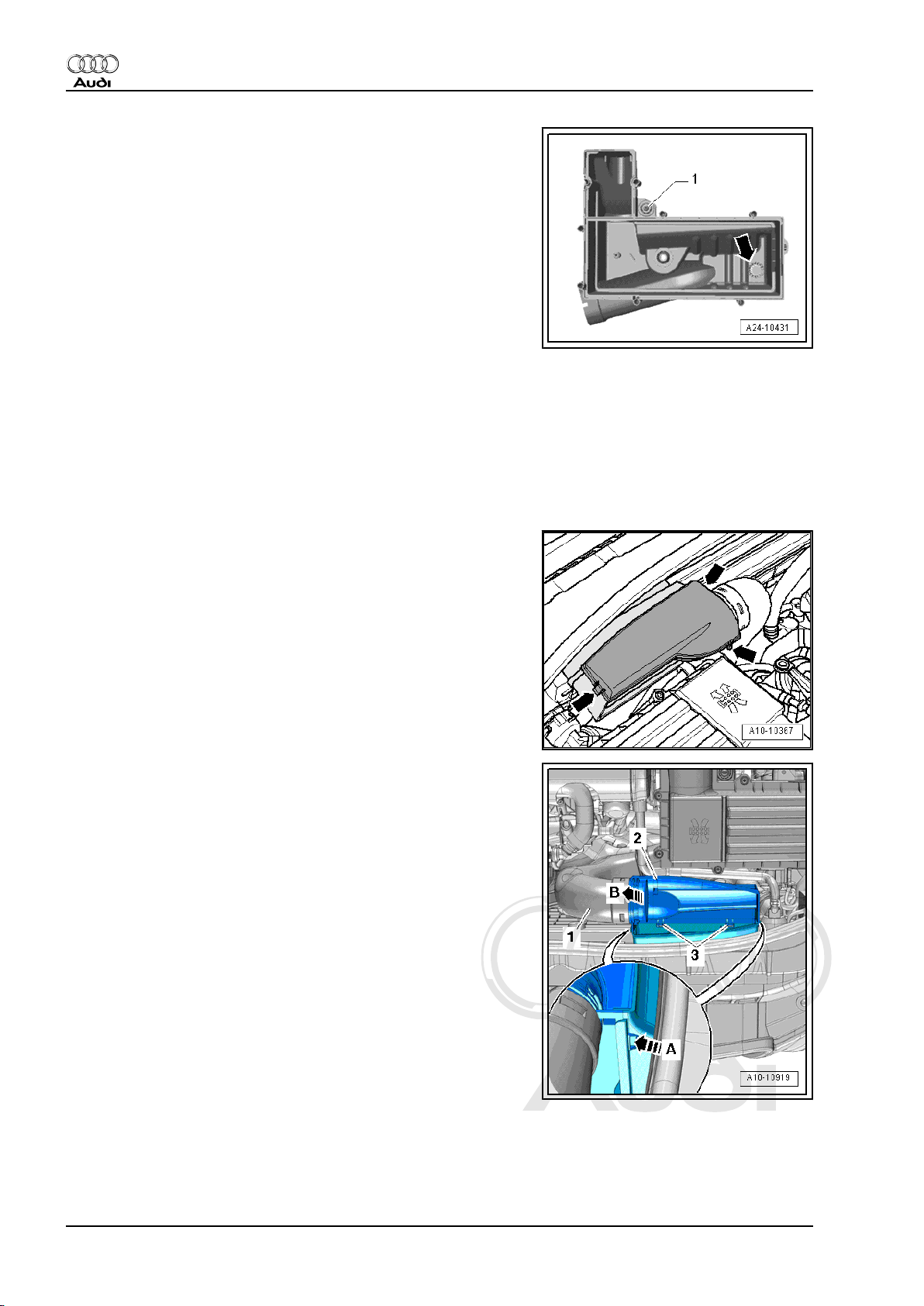

5.4 Removing and installing air cleaner housing

Removing

– Pull cover off air duct (release clips on sides) -arrows-.

– Release clips on left and right -arrow A- and unclip air duct at

bottom -2-.

– Swivel air duct (bottom) slightly to the rear and detach air duct

(bottom) from retainers -3-.

– Detach air pipe -1- from air duct (bottom) -arrow B-.

18 Rep. Gr.23 - Mixture preparation - injection

Page 23

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

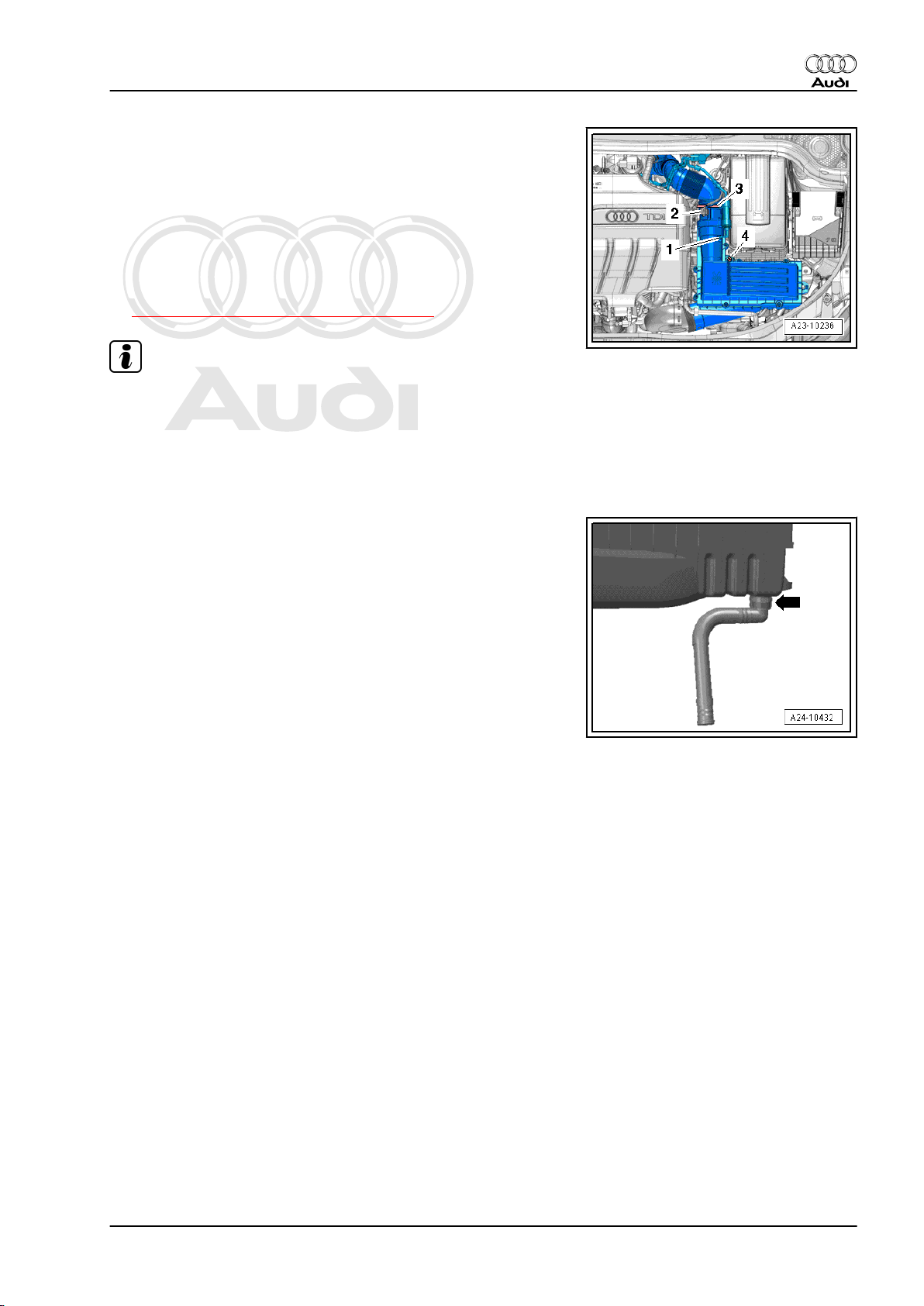

– Unplug electrical connector -2- from air mass meter -G70- .

– Detach hose -1-.

– Release hose clip -3- and detach air hose.

– Unscrew bolt -4- and remove air cleaner housing.

Installing

Installation is carried out in the reverse order; note the following:

• Tightening torque

⇒ “5.1 Air cleaner - exploded view”, page 15

Note

♦

Hose connections and air pipes and hoses must be free of oil

and grease before assembly.

♦

Use silicone-free lubricant when installing air hose.

♦

Secure all hose connections with the correct type of hose clips

(same as original equipment) ⇒ Electronic parts catalogue .

– Disconnect water drain hose -arrow- from air cleaner (bottom

section) and clean any dirt or leaves out of connection and

hose.

5. Air cleaner 19

Page 24

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

5.5 Removing and installing air mass meter

-G70-

Removing

– Remove air cleaner housing ⇒ page 18 .

– Remove bolts -arrows-.

– Carefully pull air mass meter -G70- out of guide on air cleaner

housing.

Installing

• Tightening torque

⇒ “5.1 Air cleaner - exploded view”, page 15

To ensure the proper function of the air mass meter -G70- it is

important to observe the following instructions.

Note

♦

If the air filter element is very dirty or wet, dirt or water could

reach the air mass meter and affect the air mass value. This

would lead to loss of power, since a smaller injection quantity

is calculated.

♦

Always use genuine part for air filter element.

♦

Always renew seal if damaged (air leaks in intake system).

♦

Use a silicone-free lubricant when installing the air hose and

seal.

♦

Hose connections and air pipes and hoses must be free of oil

and grease before assembly.

♦

Secure all hose connections with the correct type of hose clips

(same as original equipment) ⇒ Electronic parts catalogue .

– Check for salt residue, dirt and leaves in air mass meter and

air intake hose (engine intake side).

– Check for dirt in air duct leading to air filter element. If neces‐

sary, clean salt residue, dirt and leaves out of air cleaner

housing (top and bottom sections); wash out or use a vacuum

cleaner as required.

– Install air cleaner housing ⇒ page 18 .

20 Rep. Gr.23 - Mixture preparation - injection

Page 25

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

6 Intake manifold

⇒ “6.1 Intake manifold with attached components - exploded

view”, page 21

⇒ “6.2 Removing and installing intake manifold”, page 22

6.1 Intake manifold with attached components - exploded view

1 - Guide tube

❑ For oil dipstick

2 - Seal

❑ Renew

3 - Gasket

❑ Renew

4 - Bolt

❑ 8 Nm

5 - Fuel return line

6 - Bolt

❑ 9 Nm

7 - Intake manifold

❑ With intake manifold

flap motor -V157- and

intake manifold flap po‐

tentiometer -G336❑ Must not be dismantled

❑ Removing and installing

⇒ page 22

8 - Bracket

❑ For exhaust gas recircu‐

lation cooler change-

over valve -N345-

9 - Bolt

❑ 9 Nm

10 - Exhaust gas recirculation

cooler change-over valve N345-

11 - Gasket

❑ Renew

12 - Bolt

❑ 20 Nm

13 - Connecting pipe

❑ To exhaust gas recirculation cooler

14 - Clamp

❑ Renew

❑ 5 Nm

15 - Connection

❑ For exhaust gas recirculation

16 - Bolt

❑ 8 Nm

6. Intake manifold 21

Page 26

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

17 - Seal

❑ Renew

18 - Throttle valve module -J338-

❑ With throttle valve potentiometer -G69❑ Removing and installing ⇒ page 43

19 - Bolt

❑ 8 Nm

20 - Bolt

❑ 9 Nm

21 - Clip

6.2 Removing and installing intake manifold

Special tools and workshop equipment required

♦ Socket T30 -T10405-

Removing

WARNING

♦ Always read rules for cleanliness and instructions for

working on fuel system ⇒ page 2 .

♦ Follow these instructions and rules for cleanliness before

starting work and while working on the fuel system.

– Remove engine cover panel ⇒ page 16 .

– Loosen hose clip -arrow-.

– Detach electrical connectors at glow plugs ⇒ page 67 .

22 Rep. Gr.23 - Mixture preparation - injection

Page 27

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

– Take exhaust gas recirculation cooler change-over valve -

N345- -left arrow- out of bracket and move clear to one side.

Note

Disregard -arrow- on right-side of illustration.

– Remove bolts -2- and place coolant return line to one side.

– Remove bolts -arrows- and place fuel return line to one side.

– Remove bolt -2- and union nuts -1 and 3- and detach high-

pressure pipe.

– Remove fuel rail ⇒ page 55 .

6. Intake manifold 23

Page 28

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

– Unplug electrical connector -2- at throttle valve module -

J338- .

– Remove bolt -1- for dipstick guide tube.

Note

Disregard -arrows-.

– Open clamp -1- and detach.

Note

Disregard -item 2-.

– Unscrew intake manifold bolts -arrows- in diagonal sequence

starting from outside and working inwards using socket T30 T10405- .

– Carefully take out intake manifold.

Installing

Installation is carried out in the reverse order; note the following:

• Tightening torque

⇒ “6.1 Intake manifold with attached components - exploded

view”, page 21

Note

Renew seals and/or gaskets.

– Tighten intake manifold bolts in diagonal sequence, working

from inside to outside.

– Install air pipe ⇒ Rep. Gr. 21 .

– Install fuel rail ⇒ page 55 .

24 Rep. Gr.23 - Mixture preparation - injection

Page 29

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

7 High-pressure pump

⇒ “7.1 High-pressure pump - exploded view”, page 25

⇒ “7.2 Removing and installing high-pressure pump”, page 26

⇒ “7.3 Performing first fuel filling operation after installing highpressure pump”, page 29

⇒ “7.4 Checking fuel system for leaks”, page 30

7.1 High-pressure pump - exploded view

1 - Bracket for ancillaries

❑ Removing and installing

⇒ Rep. Gr. 13

2 - Bolt

❑ 2x

❑ Renew

❑ 20 Nm + 180° further

3 - Hub

❑ Use counterhold tool -

T10051- when loosen‐

ing and tightening

❑ To remove, use puller -

T40064-

4 - High-pressure pump

sprocket

5 - Bolt

❑ 3x

❑ Renew

❑ 20 Nm + 90° further

6 - Nut

❑ 95 Nm

7 - Bolt

❑ Renew

❑ 20 Nm + 45° further

8 - High-pressure pump

❑ With fuel metering valve

-N290- (do not open)

❑ After renewing, first fuel

filling operation MUST

be performed (it is im‐

portant not to allow

pump to run while it is still empty) ⇒ page 29

❑ After renewing high-pressure pump or fuel pressure regulating valve -N276- , learnt values must be re-

adapted; see “Guided Functions” in vehicle diagnostic tester

❑ Removing and installing ⇒ page 26

9 - Fuel supply hose

10 - Fuel return hose

11 - High-pressure pipes

❑ Between high-pressure pump and fuel rail

❑ Do not interchange

7. High-pressure pump 25

Page 30

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

Note

❑ Install free of stress

❑ Tightening torque ⇒ Item 9 (page 32)

7.2 Removing and installing high-pressure

pump

Special tools and workshop equipment required

♦ Counterhold tool -T10051-

♦ Puller -T40064- with T40064/1

Removing

Caution

♦ Always observe rules for cleanliness and instructions for

working on fuel system ⇒ page 2 .

♦ Follow these instructions and rules for cleanliness before

starting work and while working on the fuel system.

Running when dry causes irreparable damage to high-pres‐

sure pump.

♦ The high-pressure pump must first be filled with fuel before

the engine is started. The high-pressure pump must not

be allowed to run while still empty. First fuel filling

⇒ page 29

26 Rep. Gr.23 - Mixture preparation - injection

Page 31

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

– Remove toothed belt from camshaft and high-pressure pump

⇒ Rep. Gr. 15 .

– Remove bolts -2- and detach toothed belt sprocket from high-

pressure pump.

Note

Disregard -item 1-.

– Counterhold using counterhold tool -T10051- and remove nut

-1- at hub of high-pressure pump.

– Apply puller -T40064- with thrust piece -T40064/1- and pin -

T40064/2- as shown in illustration and pull hub off high-pres‐

sure pump. If necessary, counterhold using an open-end

spanner (24 mm).

7. High-pressure pump 27

Page 32

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

– Remove bolts -2- and place coolant return line to one side.

Note

Disregard -items 1, 3-.

– Remove bolts -arrows- and place fuel return line to one side.

– Remove bolt -2- and union nuts -1 and 3- and detach high-

pressure pipe.

– Unplug electrical connectors -1- and -3-.

– Detach fuel supply hose -2- and fuel return hose -4-.

28 Rep. Gr.23 - Mixture preparation - injection

Page 33

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

– Remove bolts -arrows- for high-pressure pump.

– Carefully take out high-pressure pump.

Installing

Installation is carried out in the reverse order; note the following:

• Tightening torques

⇒ “7.1 High-pressure pump - exploded view”, page 25

– Install toothed belt ⇒ Rep. Gr. 15 .

– Install high-pressure pipe ⇒ page 45 .

Caution

Running when dry causes irreparable damage to high-pres‐

sure pump.

♦ The high-pressure pump must first be filled with fuel before

the engine is started. The high-pressure pump must not

be allowed to run while still empty. First fuel filling

⇒ page 29

7.3 Performing first fuel filling operation af‐

ter installing high-pressure pump

Caution

Running when dry causes irreparable damage to high-pres‐

sure pump.

♦ The high-pressure pump must first be filled with fuel before

the engine is started. The high-pressure pump must not

be allowed to run while still empty.

Note

♦

When installing the high-pressure fuel pump, it is essential to

ensure that no dirt enters the fuel system.

♦

Only remove sealing plugs immediately prior to installation of

fuel pipes.

♦

There must be sufficient fuel in the tank.

– Connect vehicle diagnostic tester.

– Switch on ignition.

– Select “Engine electronics” in vehicle self-diagnosis.

– Then select “Basic setting”.

– Select “Checking fuel system pressurisation pump” from the

list.

– The fuel pumps start running.

– The fuel pumps must run for approx. 1 minute to ensure that

the high-pressure pump is filled with sufficient fuel.

– Start engine after filling fuel system.

– Run engine at moderate speed for several minutes and then

switch off.

7. High-pressure pump 29

Page 34

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

– Check fuel system for leaks.

– Erase entry in event memory using vehicle diagnostic tester.

– After completing the repair, road-test the vehicle over a dis‐

tance of at least 20 km. Accelerate with full throttle at least

once. Then inspect the high-pressure section of the fuel sys‐

tem again for leaks.

Note

If there is any air left in the fuel system, the engine may switch to

the backup mode ('emergency running' mode) during the road

test. Switch off the engine and erase the event memory. Then

continue the road test.

– Interrogate event memory.

7.4 Checking fuel system for leaks

– Run engine at idling speed for several minutes (do not press

accelerator) and then switch off. Fuel system will bleed itself

automatically.

– Check the entire fuel system for leaks.

Renew affected component if leakage still occurs after tightening

to correct torque.

– After completing the repair, road-test the vehicle. Accelerate

with full throttle at least once. Then check the high-pressure

section of the fuel system again for leaks.

Note

If there is any air left in the fuel system, the engine may switch to

the backup mode ('emergency running' mode) during the road

test. Switch off the engine and erase the event memory. Then

continue the road test.

30 Rep. Gr.23 - Mixture preparation - injection

Page 35

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

8 Injectors

⇒ “8.1 Injectors - exploded view”, page 31

⇒ “8.2 Checking injectors”, page 33

⇒ “8.3 Performing adaption of injector delivery calibration values”,

page 33

⇒ “8.4 Checking return flow rate of injectors with engine running”,

page 33

⇒ “8.5 Checking return flow rate of injectors at starter cranking

speed”, page 36

⇒ “8.6 Checking for injectors sticking open”, page 38

⇒ “8.7 Removing and installing injectors”, page 39

8.1 Injectors - exploded view

1 - Seal

❑ In cylinder head cover

❑ Removing and installing

⇒ Rep. Gr. 15

2 - Copper seal

❑ Renew

3 - O-ring

❑ Renew

4 - Injector

❑ The following compo‐

nents and seals/O-rings

must always be re‐

newed when the injec‐

tors are removed and

installed: “copper seal”

and “O-ring for injector

bore”.

❑ The following compo‐

nents and seals/O-rings

must always be re‐

newed when an injector

is renewed: “clamping

piece”, “copper seal”

and “O-ring for injector

bore”.

❑ When re-installing

“high-pressure injector

pipe” check taper seats

visually for damage,

scores and corrosion

(always renew if dam‐

aged)

❑ If they are to be re-in‐

stalled, the injectors,

high-pressure fuel pipes

and clamping pieces

must always be re-fitted on the same cylinder

❑ Removing and installing ⇒ page 39

5 - O-ring

❑ Renew

8. Injectors 31

Page 36

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

6 - Fuel return line

❑ To fuel tank

❑ Must not be kinked, damaged or clogged

❑ Do not dismantle

❑ After replacement, engine must be run at idling speed for approx. 2 minutes to bleed fuel system. Then

check fuel return lines for leaks

7 - Bolt

❑ Renew

❑ 8 Nm + 180° further

8 - Clamping piece

❑ If they are to be re-installed, the injectors and clamping pieces must always be re-fitted on the same

cylinder

❑ If an injector is renewed, the corresponding clamping piece must also be renewed

❑ Installation position ⇒ page 33

9 - High-pressure pipe

❑ Between fuel rail and injectors

Note

❑ Install free of stress

❑ Lubricate threads of union nuts with clean engine oil

❑ 25 Nm

10 - Bolt

❑ 22 Nm

11 - Fuel rail

❑ Removing and installing ⇒ page 55

12 - Fuel return hose

13 - Fuel pressure regulating valve -N276-

❑ Always renew after removing

❑ Removing and installing ⇒ page 51

❑ 80 Nm

❑ After renewing high-pressure pump or fuel pressure regulating valve -N276- , learnt values must be re-

adapted; see “Guided Functions” in vehicle diagnostic tester

14 - O-ring

❑ Renew

15 - High-pressure pipe

❑ Between high-pressure pump and fuel rail

Note

❑ Lubricate threads of union nuts with clean engine oil

❑ 25 Nm

16 - Bolt

❑ 8 Nm

17 - Fuel pressure sender -G247-

❑ Removing and installing

⇒ page 52

❑ 100 Nm

18 - Grommet

❑ In cylinder head cover

32 Rep. Gr.23 - Mixture preparation - injection

Page 37

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

Installation position of clamping piece

• One clamping piece is always used to secure two injectors.

• The bulge -arrow- of the clamping piece should point down‐

wards.

8.2 Checking injectors

There are three different tests for checking the operation of the

injectors.

• Checking adaption of “Injector delivery calibration values”

⇒ page 33

• Checking return flow rate of injectors with engine running

⇒ page 33

• Checking return flow rate of injectors at starter cranking speed

⇒ page 36

8.3 Performing adaption of injector delivery

calibration values

The “Injector delivery calibration values” function serves to correct

the injection rates for each cylinder of a common rail system in‐

dividually across the entire operating range.

The 7-digit adaption values -1- (details in illustration are only an

example) are marked separately on each injector. The values

may consist of letters and/or numbers.

Injector (view from above)

1 - Check sum

2 - Data matrix code

3 - Part number

When a new injector is installed, the adaption value must be writ‐

ten into the engine control unit.

When a new engine control unit is installed, the “Adaption values

for injectors” must be written into the new control unit.

Additionally, check that the “injector delivery calibration values”

are correctly entered for all the other injectors. Do NOT attempt

to re-enter these values if the correct values are already stored in

the engine control unit.

The adaption procedure is described in the “Guided Fault Find‐

ing”. (The procedure is also described under “Guided Functions”.)

8.4 Checking return flow rate of injectors

with engine running

A - Checking return flow rate of all injectors

Special tools and workshop equipment required

♦ Fuel-resistant measuring container

8. Injectors 33

Page 38

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

WARNING

♦ Always read rules for cleanliness and instructions for

working on fuel system ⇒ page 2 .

♦ Follow these instructions and rules for cleanliness before

starting work and while working on the fuel system.

– Remove engine cover panel ⇒ page 16 .

– Disconnect hose connection at fuel line.

– Seal off the open return connection with a plug -1-.

– Hold end of fuel return hose -2- (lengthen if necessary) in a

measuring container to measure the total return flow rate.

– Start engine and let it idle for 2 minutes.

• Specification for 2 minutes: 0 ml to 50 ml

– If specification is attained, increase engine speed to 2000 ...

2500 rpm for approx. 2 minutes and then check return flow rate

again.

• Specification for 2 minutes: less than 250 ml

Note

1000 ml = 1 litre

If specification is exceeded, this indicates that one or more injec‐

tors are defective. Check return flow rate from each injector

individually.

B - Checking return flow rate of individual injectors

Special tools and workshop equipment required

♦ Hose clamps for hoses up to 25 mm -3094-

34 Rep. Gr.23 - Mixture preparation - injection

Page 39

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

♦ Injection rate comparison meter -V.A.G 1348/2 B-

♦ 4 lengths of hose (made up in the workshop) to fit return line

connections on injectors

Each injector normally has a relatively low return flow rate. If the

return flow rate at one injector is relatively high compared to the

other injectors, that injector is probably defective.

– Clean all return line connections (e.g. with commercial clean‐

ing solution etc.) before removing.

– Dry all components after cleaning.

– Clamp off fuel return hose -arrow- using a hose clamp -3094- .

8. Injectors 35

Page 40

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

– Pull return line connections off injectors; to do so, press tabs

-1- and -2- down and at the same time pull release pin upwards

-arrow-.

Note

No dirt must be allowed to get into the disconnected return lines

or the open connections on the injectors.

– Connect hoses onto return line connections of all 4 injectors.

– Run the 4 hoses into injection rate comparison meter -V.A.G

1348/2 B- .

– Start engine and let it idle for several minutes.

Caution

Risk of damage to injectors when return lines are disconnec‐

ted.

♦ Do NOT press the accelerator during this test; the engine

must only run at idling speed.

– When the engine is warm and running at idling speed, the re‐

turn flow rates at each of the 4 return lines must not differ by

more than a small amount.

– If one injector has a significantly higher return flow rate than

the others it must be renewed ⇒ page 39 .

Installing fuel return lines

– Push return line connections carefully onto injectors. The

catch should engage audibly. Then press release pin down

carefully.

– Check fuel system for leaks ⇒ page 30 .

8.5 Checking return flow rate of injectors at starter cranking speed

If it is not possible to start engine, check return flow rate of injec‐

tors at starter cranking speed.

Special tools and workshop equipment required

♦ Injection rate comparison meter -V.A.G 1348/2 B-

♦ 4 lengths of hose (made up in the workshop) to fit return line

connections on injectors

36 Rep. Gr.23 - Mixture preparation - injection

Page 41

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

WARNING

♦ Always read rules for cleanliness and instructions for

working on fuel system ⇒ page 2 .

♦ Follow these instructions and rules for cleanliness before

starting work and while working on the fuel system.

Each injector normally has a relatively low return flow rate. If the

return flow rate at one injector is relatively high compared to the

other injectors, that injector is probably defective.

– Remove engine cover panel ⇒ page 16 .

– Clean all return line connections (with commercial cleaning

solution or similar) before removing.

– Dry all components after cleaning.

– Pull return line connections off injectors; to do so, press tabs

-1- and -2- down and at the same time pull release pin upwards

-arrow-.

Note

No dirt must be allowed to get into the disconnected return lines

or the open connections on the injectors.

– Unplug electrical connector -arrow- at fuel pressure regulating

valve -N276- .

Note

This prevents fuel from being injected when starter is operated.

– Connect the 4 hoses onto return line connections of all 4 in‐

jectors.

– Run the 4 hoses into injection rate comparison meter -V.A.G

1348/2 B- .

– Operate starter three times. (Wait approx. 20 seconds each

time after operating starter to prevent it from overheating.)

• Specification of return flow rate: 0 ml

– If fuel comes out of one injector, that injector must be renewed.

– Re-attach electrical connector on fuel pressure regulating

valve -N276- .

Installing fuel return lines

– Push return line connections carefully onto injectors. The

catch should engage audibly. Then press release pin down

carefully.

– Check fuel system for leaks ⇒ page 30 .

– Erase entry in event memory using vehicle diagnostic tester.

8. Injectors 37

Page 42

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

8.6 Checking for injectors sticking open

Special tools and workshop equipment required

♦ Tool insert, AF 17 -V.A.G 1331/6-

♦ Screw plug -T40204-

WARNING

♦ Always read rules for cleanliness and instructions for

working on fuel system ⇒ page 2 .

♦ Follow these instructions and rules for cleanliness before

starting work and while working on the fuel system.

– Erase entry in event memory using vehicle diagnostic tester.

– Remove engine cover panel ⇒ page 16 .

– Clean all connections (with commercial cleaning solution or

similar) before removing.

Note

♦

Make sure all parts are clean; no dirt must be allowed to enter

the fuel system.

♦

Check all cylinders in turn.

– Dry all components after cleaning.

Start with cylinder No. 1.

– Unscrew union nut for cylinder 1 on fuel rail. Also loosen union

nut on injector slightly. Seal off open connection on injector

pipe.

– Plug open connection using plug -T40204- .

• The electrical connector of the relevant injector must remain

connected.

– Erase all entries in the event memory.

– Perform test drive.

38 Rep. Gr.23 - Mixture preparation - injection

Page 43

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

Note

♦

The fault “positive fuel pressure control” should no longer be

indicated when the defective injector has been located.

♦

Other fault messages may possibly be stored in the memory.

These result from previous steps and can be disregarded.

– Interrogate event memory after road-testing vehicle. If a fault

relating to “positive fuel pressure control” is still indicated, re‐

peat the above steps for all connections until the fault is no

longer indicated after the road test.

Observe all instructions for connecting injector pipes.

– Lubricate threads of union nuts with fuel.

– Hand-tighten union nuts on high-pressure pipes. Make sure

that connections are not under tension.

– Install high-pressure pipes ⇒ page 45 .

8.7 Removing and installing injectors

Special tools and workshop equipment required

♦ Puller -T10055-

♦ Assembly sleeve -T10377-

♦ Puller -T10415-

8. Injectors 39

Page 44

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

Removing

WARNING

♦ Always read rules for cleanliness and instructions for

working on fuel system ⇒ page 2 .

♦ Follow these instructions and rules for cleanliness before

starting work and while working on the fuel system.

– Remove engine cover panel ⇒ page 16 .

Caution

♦ Mark cylinder numbers on injector units. They must al‐

ways be re-installed on the same cylinders.

♦ Observe rules for cleanliness when working on the injec‐

tion system.

♦ Plug open connections with suitable sealing caps imme‐

diately.

– Pull return line connections off injectors; to do so, press tabs

-1- and -2- down and at the same time pull release pin upwards

-arrow-.

– Unplug electrical connectors -arrows- at injectors.

– Unscrew union nuts on corresponding high-pressure pipe

(-1 to 4-) and detach corresponding high-pressure pipe.

– Unscrew bolt -1- for clamping piece.

40 Rep. Gr.23 - Mixture preparation - injection

Page 45

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

TDI injection and glow plug system (4-cyl. 2.0 ltr. 4-valve common rail, generation II) - Edition 05.2010

– Apply puller -T10055- with puller -T10415- as shown in illus‐

tration, and pull out injector upwards.

Note