Page 1

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Service

Maintenance

Audi TT 1999 ➤

Edition 06.2007

Service Department. Technical Information

Page 2

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Maintenance

He ad in g

1. Overview of engines

2. Delivery Inspection

3. LongLife Service

4. Oil Change Service

5. Inspection Service

6. Description of work

7. Type plate, vehicle identification number

8. Lifting the vehicle

9. Tow-starting/towing

10. Vehicle tests carried out as part of inspection services and maintenance

Service

Technical information should always be available to the foremen and mechanics, because their

careful and constant adherence to the instructions is essential to ensure vehicle road-worthiness and

safety. In addition, the normal basic safety precautions for working on motor vehicles must, as a

matter of course, be observed.

All rights reserved.

No reproduction without prior agreement from publisher.

Copyright © 2010 Audi AG, Ingolstadt A0357015220

Page 3

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Maintenance - Edition 06.2007

Contents

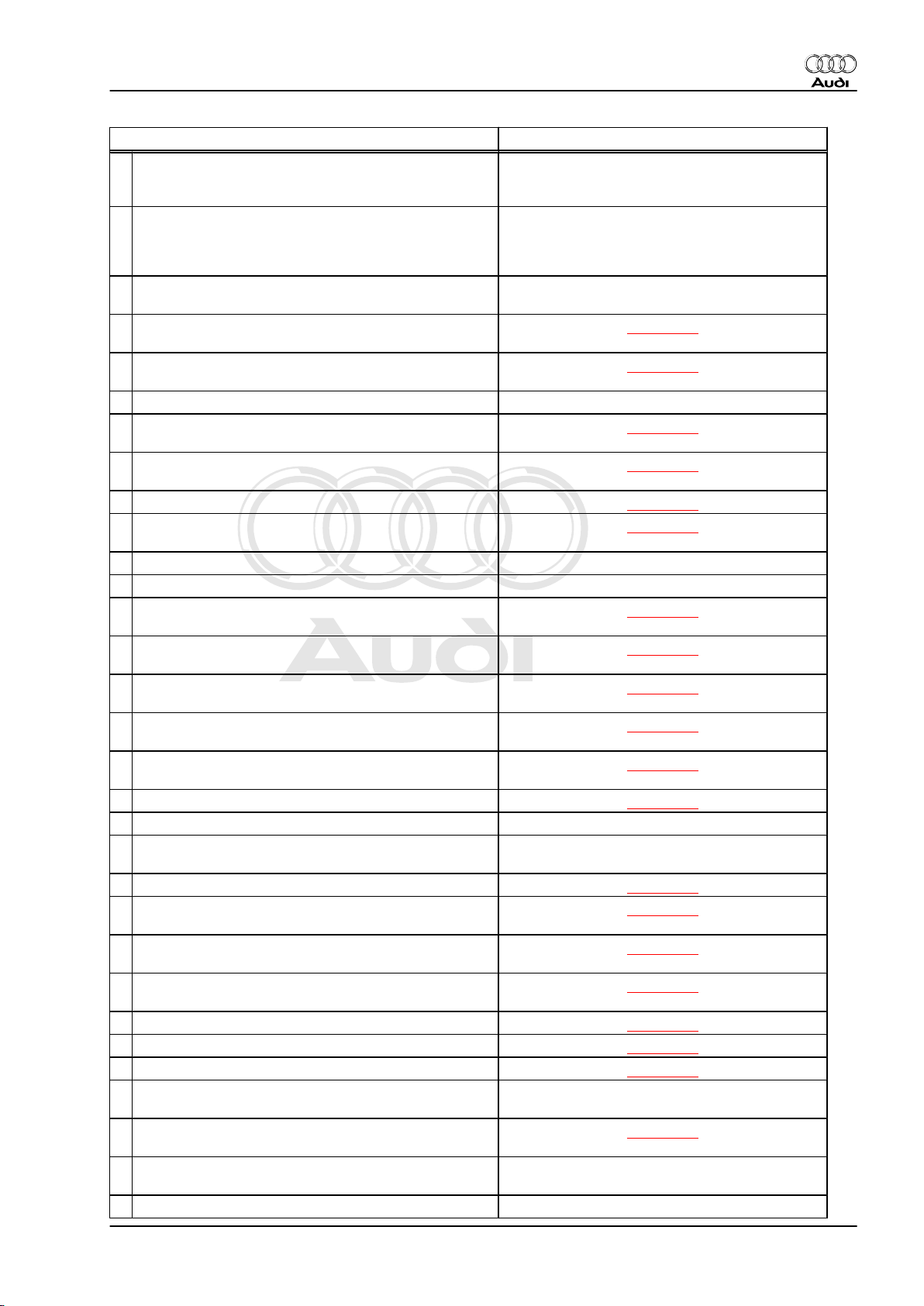

1 Overview of engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 Delivery Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3 LongLife Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4 Oil Change Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5 Inspection Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6 Description of work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.1 Battery: performing load test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.2 Battery: checking "no load" voltage before starting the engine for the first time (only applies

to stock vehicles) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.3 Battery: checking that battery cables are securely fitted . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.4 Battery: checking electrolyte level, topping up with distilled water if necessary . . . . . . . . . . 16

6.5 Lights, electrical equipment, switches, displays and other driver-operated controls: checking

operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.6 Tyres: checking condition, wear pattern, tread depth and correcting inflation pressures. . . 21

6.7 Brake system: visual check for leaks and damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.8 Brake fluid level (depends on brake pad wear): checking . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.9 Brake fluid: changing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.10 Brake pads: checking thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.11 Direct shift gearbox (DSG): changing oil and renewing oil filter . . . . . . . . . . . . . . . . . . . . 30

6.12 Electric windows: checking positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.13 Vehicle keys: checking operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.14 Interrogating fault memory for all systems: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.15 Noise insulation: removing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.16 Haldex coupling: changing oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.17 Haldex coupling: renewing oil filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.18 Haldex coupling: checking oil level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.19 Hydraulic system: checking for leaks, checking hydraulic fluid level and topping up if

necessary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.20 Instrument cluster: setting the language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.21 Air conditioner: checking operation and setting temperature to 22 °C . . . . . . . . . . . . . . . . 36

6.22 Cooling system: checking antifreeze and topping up with coolant if necessary . . . . . . . . . . 37

6.23 Poly V-belt: renewing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.24 Air cleaner: cleaning housing and renewing filter element . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.25 Bonnet arrester hook: lubricating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.26 Engine cover panel: removing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.27 Engine (from above and below) and engine compartment: visual check for leaks and

damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.28 Engine oil: draining or extracting, changing oil filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.29 Engine oil: filling up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.30 Engine: checking oil level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.31 Road test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.32 Wheel bolts: tightening to specified torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.33 Tyre repair kit: checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.34 Radio (Chorus, Concert): switching off transport mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.35 Radio: activating anti-theft coding by entering fixed code number . . . . . . . . . . . . . . . . . . . . 49

6.36 Dust and pollen filter: renewing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.37 Manual gearbox/final drive: checking oil level, topping up with oil if necessary . . . . . . . . . . 50

6.38 Windscreen wiper/washer system and headlight washer system: checking jet settings and

operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.39 Windscreen wiper/washer system: checking jet settings, adjusting jets if necessary . . . . 50

6.40 Headlight washer system: checking jet settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.41 Headlights: checking settings and adjusting if necessary . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.42 Windscreen and headlight washer system: topping up with washer fluid . . . . . . . . . . . . . . 58

6.43 Wiper blades: checking park position and checking for damage . . . . . . . . . . . . . . . . . . . . 58

Contents i

Page 4

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Maintenance - Edition 06.2007

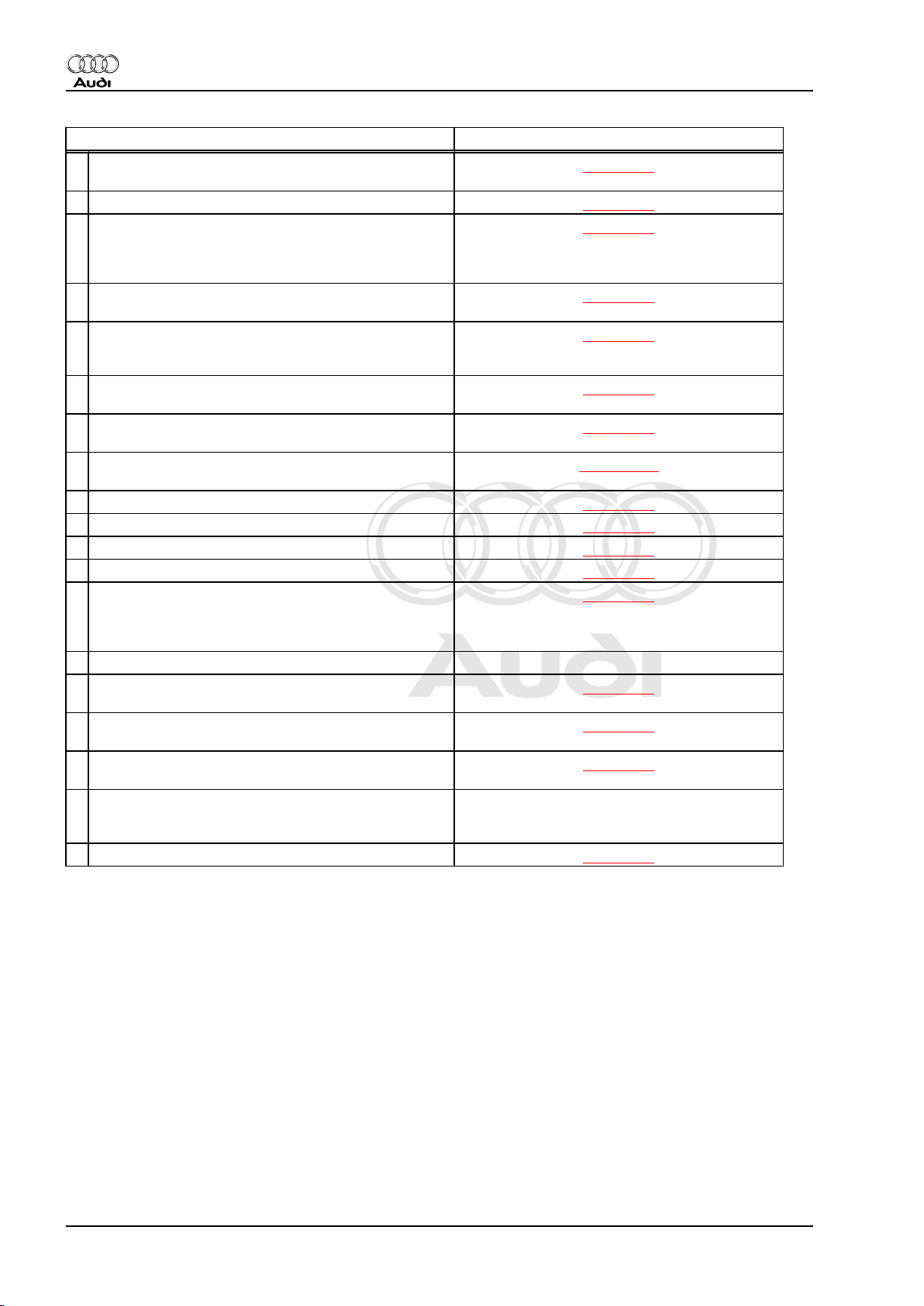

6.44 Service interval display: resetting Inspection Service (fixed intervals), up to chassis No. 8NY1

049 999 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6.45 Service interval display: resetting LongLife Service (from chassis No. 8NY1 050 000

onwards) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

6.46 Service interval display: resetting Inspection Service (fixed intervals), from chassis No.

8NY1 050 000 onwards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

6.47 Track rod ball joints: checking play, security and boots . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

6.48 Door arresters and lock cylinders: lubricating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

6.49 Transport locks: removing locking elements for front and rear axles . . . . . . . . . . . . . . . . . . 98

6.50 Underseal: visual check for damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

6.51 Plenum chamber: checking and cleaning water drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

6.52 Winter tyres (factory-fitted) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

6.53 Toothed belt: renewing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

6.54 Clock: setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

6.55 Spark plugs: renewing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

7 Type plate, vehicle identification number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

8 Lifting the vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

9 Tow-starting/towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

10 Vehicle tests carried out as part of inspection services and maintenance . . . . . . . . . . . . . . 111

ii Contents

Page 5

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Maintenance - Edition 06.2007

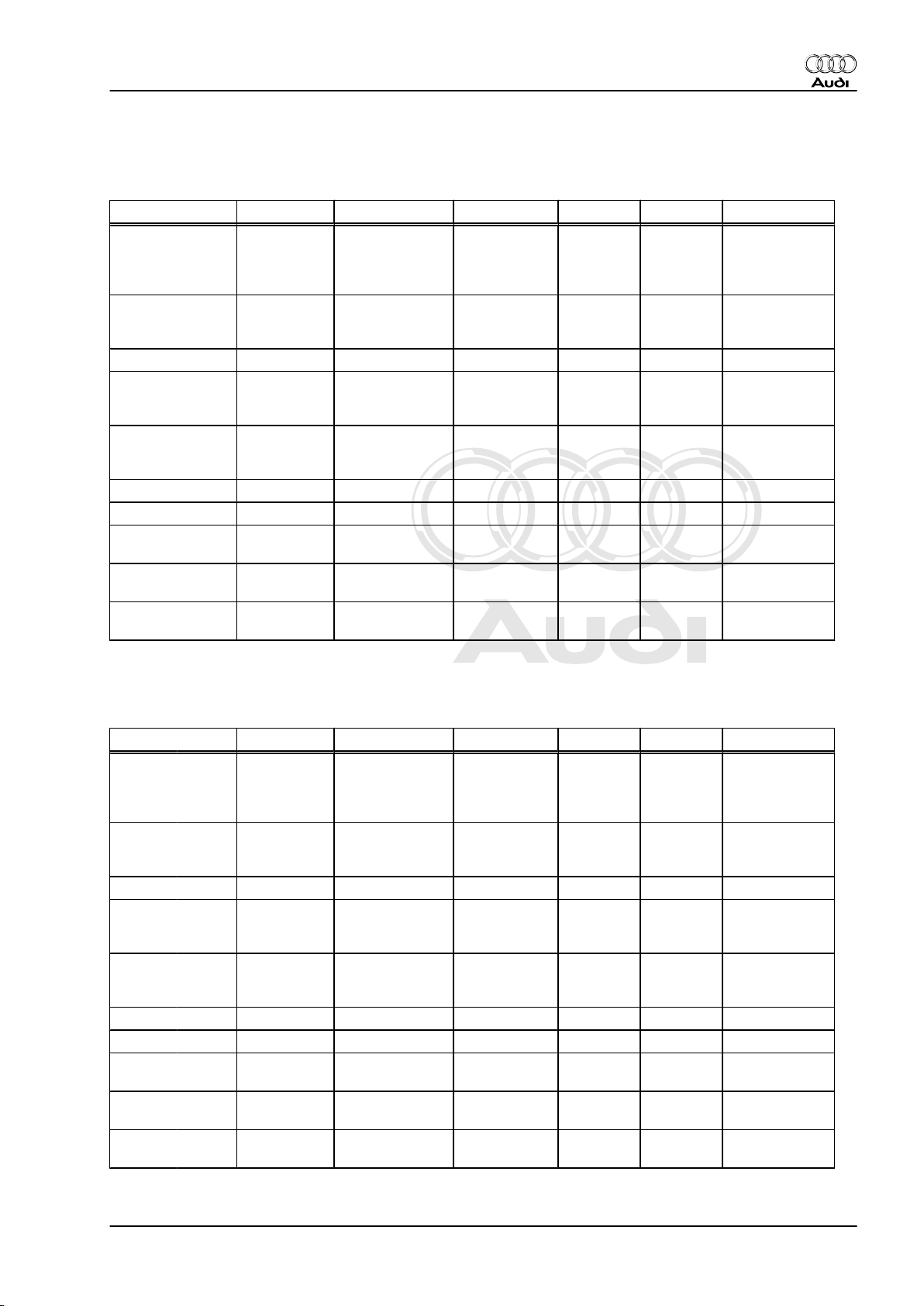

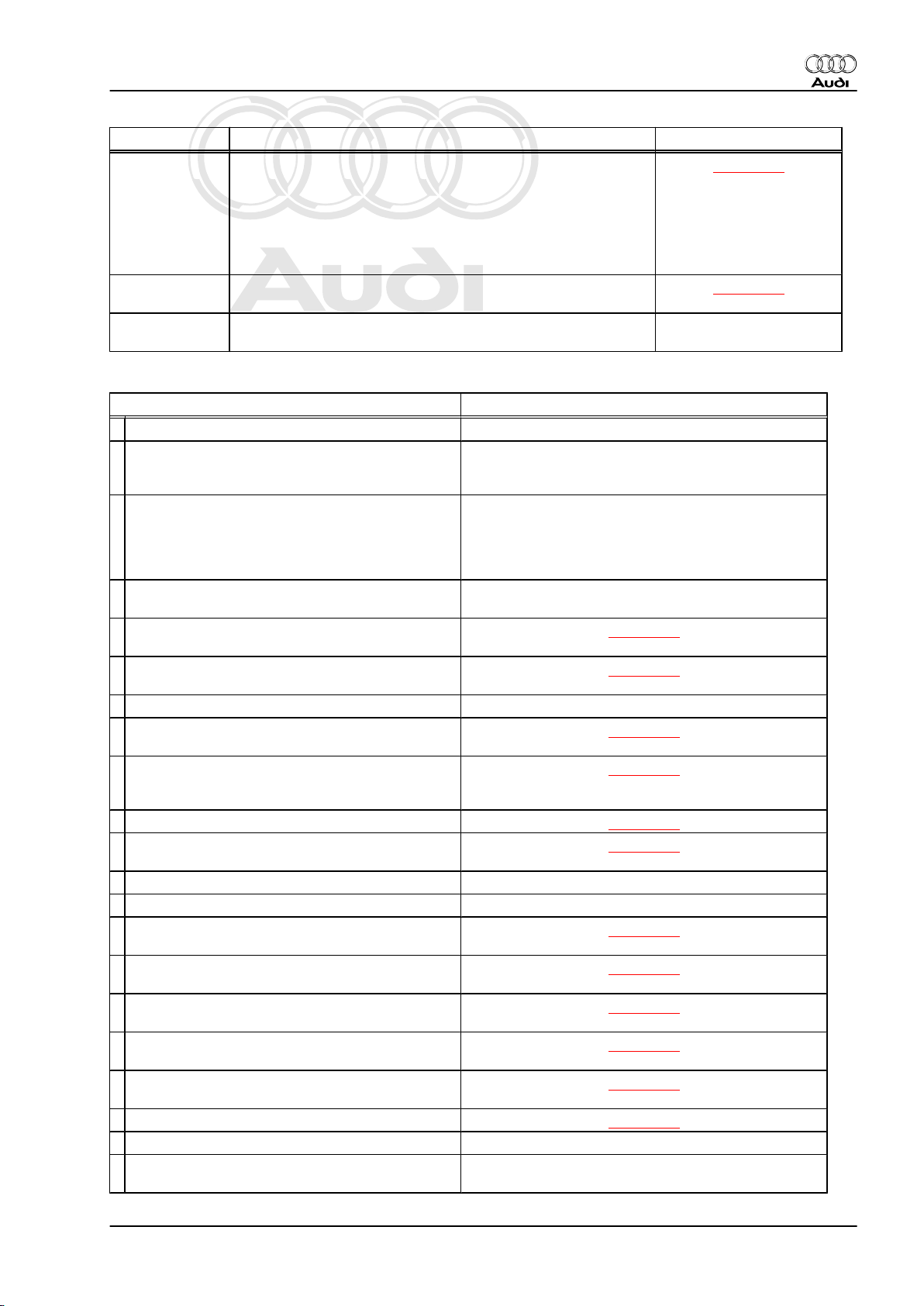

1 Overview of engines

Petrol engines

Engine code AJQ APP AUQ ARY AUM BVP

kW at

rpm

rpm

EU II + D3 EU II + D3 EU IV EU III EU IV EU IV

4 / 5 4 / 5 4 / 5 4 / 5 4 / 5 4 / 5

132/

5500...6000

235/

2000...4600

132/

5500...6000

235/

2000...4600

132/

5500...6000

235/

1950...5000

132/

5500...600

0

235/

1950...500

0

110/

5500...570

0

210/

1750...460

0

1950...4700

9.5 9.5 9.5 9.0 9.5 9.3

Bosch

Motronic

1)

98

Super plus

Bosch

Motronic

1)

98

Super plus

Bosch

Motronic

1)

98

Super plus

Bosch

Motronic

1)

98

Super plus

Bosch

Motronic

2)

95

(unleaded)

Motronic

(unleaded)

120/

5700

225/

Bosch

95

Exhaust

emis‐

sions

standard

No. of cylinders /

valves per cylin‐

der

Capacity ltr. 1.781 1.781 1.781 1.781 1.781 1.781

Power

output

Torque Nm at

Bore ∅ mm 81.0 81.0 81.0 81.0 81.0 81.0

Stroke mm 86.4 86.4 86.4 86.4 86.4 86.4

Compression ra‐

tio

Fuel injection / ig‐

nition

RON min.

2)

1) Unleaded RON 95 can also be used, but will result in a slight loss of power.

2) Unleaded RON 91 can also be used, but will result in a slight loss of power.

Engine code BVR APX AMU BAM BFV BHE

Exhaust

EU IV EU II + D3 EU III EU III EU III EU IV

emis‐

sions

standard

No. of cylinders /

4/5 4 / 5 4 / 5 4/5 4/5 6/4

valves per cylin‐

der

Capacity ltr. 1.781 1.781 1.781 1.781 1.781 3.189

Power

output

kW at

rpm

140/

5700

165/

5500...6000

165/

5500...6000

165/

5500...600

176/

5700

184/

6300

0

Torque Nm at

rpm

240/

1980...5400

280/

2200...5500

280/

2200...5500

280/

2200...550

0

320/

2300...500

0

320/

2800...3200

Bore ∅ mm 81 81.0 81.0 81.0 81 84.0

Stroke mm 86.4 86.4 86.4 86.4 86.4 31.9

Compression ra‐

9.3 9.0 9.0 9.0 8.9 11.3

tio

Fuel injection / ig‐

nition

RON min.

Bosch

Motronic

3)

98

Super plus

Bosch

Motronic

3)

98

Super plus

Bosch

Motronic

3)

98

Super plus

Bosch

Motronic

3)

98

Super plus

Bosch

Motronic

3)

98

Super plus

Bosch

Motronic

98

Super plus

3)

1. Overview of engines 1

Page 6

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Maintenance - Edition 06.2007

3) Unleaded RON 95 can also be used, but will result in a slight loss of power.

2 1. Overview of engines

Page 7

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Maintenance - Edition 06.2007

2 Delivery Inspection

Work to be completed Page

In the case of stock vehicles: perform steps

specified in Technical Service Handbook; “In‐

spection and Maintenance”; Chapter 6

Battery: checking that battery cables are secure‐

ly fitted

Battery: performing load test ⇒ page 14

Engine (from above) and engine compartment:

visual check for leaks and damage

Cooling system: coolant must be filled to max.

level

Windscreen and headlight washer system: must

be filled to max. level

Engine: checking oil level and topping up if nec‐

essary

Brake system: brake fluid must be filled to max.

level

Hydraulic system: checking fluid level ⇒ page 34

Transport locks: removing locking elements for

front suspension struts

Please note: If there is a “warning” notice (orange

tag) attached to the interior mirror, the locking el‐

ements for rear suspension struts (on both sides)

must also be removed.

Underside of vehicle, mechanical units, steering,

boots, brake system, hoses, fluid reservoirs: vis‐

ual check for leaks and damage (without disman‐

tling noise insulation)

Underside of vehicle (underbody): visual check

for damage

Tyre pressure on all 4 wheels and spare wheel:

check (note: 3.5 bar when car leaves factory)

Wheel bolts: tightening to specified torque ⇒ page 46

Electric windows: checking positions ⇒ page 30

Clock: setting ⇒ page 100

Air conditioner: checking operation and setting

temperature to 22 °C

Radio or Radio/Navigation System Plus (Chorus,

Concert): Deactivating transport mode

Radio: sticking label with serial number and fixed

code number (see vehicle data sticker) onto radio

card

(included with radio operating instructions)

Radio: activating anti-theft coding by entering

fixed code number

Radio: storing local radio stations on station but‐

tons (on RDS radios, do not store until station

name appears on display)

Telephone: sticking label with serial number in

telephone operating instructions

Instrument cluster: setting the language ⇒ page 35

Service interval display: resetting ⇒ page 64

Passenger's airbag: checking key switch on / off,

must be set to “on”.

(see Owner's Manual)

⇒ page 16

⇒ page 41

⇒ page 37

⇒ page 51

⇒ page 51

⇒ page 45

⇒ page 22

⇒ page 98

⇒ page 98

⇒ page 22

⇒ page 36

⇒ page 46

⇒ page 49

Audi TT 1999 ➤

2. Delivery Inspection 3

Page 8

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Maintenance - Edition 06.2007

Work to be completed Page

All control units: interrogating fault memory

(Enter “00” for address word “Automatic test se‐

quence”)

Windscreen washer jets: adjusting height of

⇒ page 50

spray area

Protective seat covers and plastic sheeting for

carpet: removing

Floor mats: fitting

Cleanliness of vehicle interior: checking front and

rear seats, interior trim, carpeting/mats, windows

Fitting wheel covers/hub trim caps, roof aerial,

telephone aerial (components stored in luggage

compartment)

Transport protection: removing protective edge

strips on doors

Cleanliness of vehicle exterior: checking paint‐

work, trims, windows, wiper blades

Audi sticker: enter next service (and date for

brake fluid change) and affix sticker on left of

dash panel or on door post (B-pillar)

Service Schedule: removing vehicle data sticker

from spare wheel well or luggage compartment

floor and sticking into Service Schedule under

“Warranty entitlement record”. Entering Delivery

Inspection.

Owner's literature: checking that it is complete

and preparing for handover to customer

Vehicle keys: checking operation ⇒ page 30

Road test ⇒ page 45

4 2. Delivery Inspection

Page 9

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

3 LongLife Service

Vehicles built model year 2000 > -Y-

Note

♦

Belgium

♦

Denmark

♦

Germany

♦

Finland

♦

France

♦

Gibraltar

♦

Greece

♦

Great Britain

♦

Ireland

♦

Iceland

♦

Italy

♦

Canary Islands

♦

Luxembourg

♦

Malta

♦

Netherlands

♦

Norway

♦

Austria

♦

Portugal

♦

Sweden

♦

Switzerland/Liechtenstein

Audi TT 1999 ➤

Maintenance - Edition 06.2007

♦

Spain/Andorra

♦

Cyprus

♦

Japan (from August 2002)

♦

Czech Republic (from 2003)

Extended servicing intervals

♦ Vehicles with petrol engine/ turbocharged petrol engine: max.

30,000 km (20,000 miles) or max. 2 years, oil grade 2

♦ The oil grade must be entered in the instrument cluster.

LongLife engine oil

New VW standard (specially developed, resistant to ageing) ac‐

cording to specification:

-VW 503 00- or -VW 504 00- for petrol engines / turbocharged

petrol engines (110 / 120 / 132 / 140 / 184 kW)

-VW 503 01- or -VW 504 00- for turbocharged petrol engines

(165 / 176 kW)

3. LongLife Service 5

Page 10

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Maintenance - Edition 06.2007

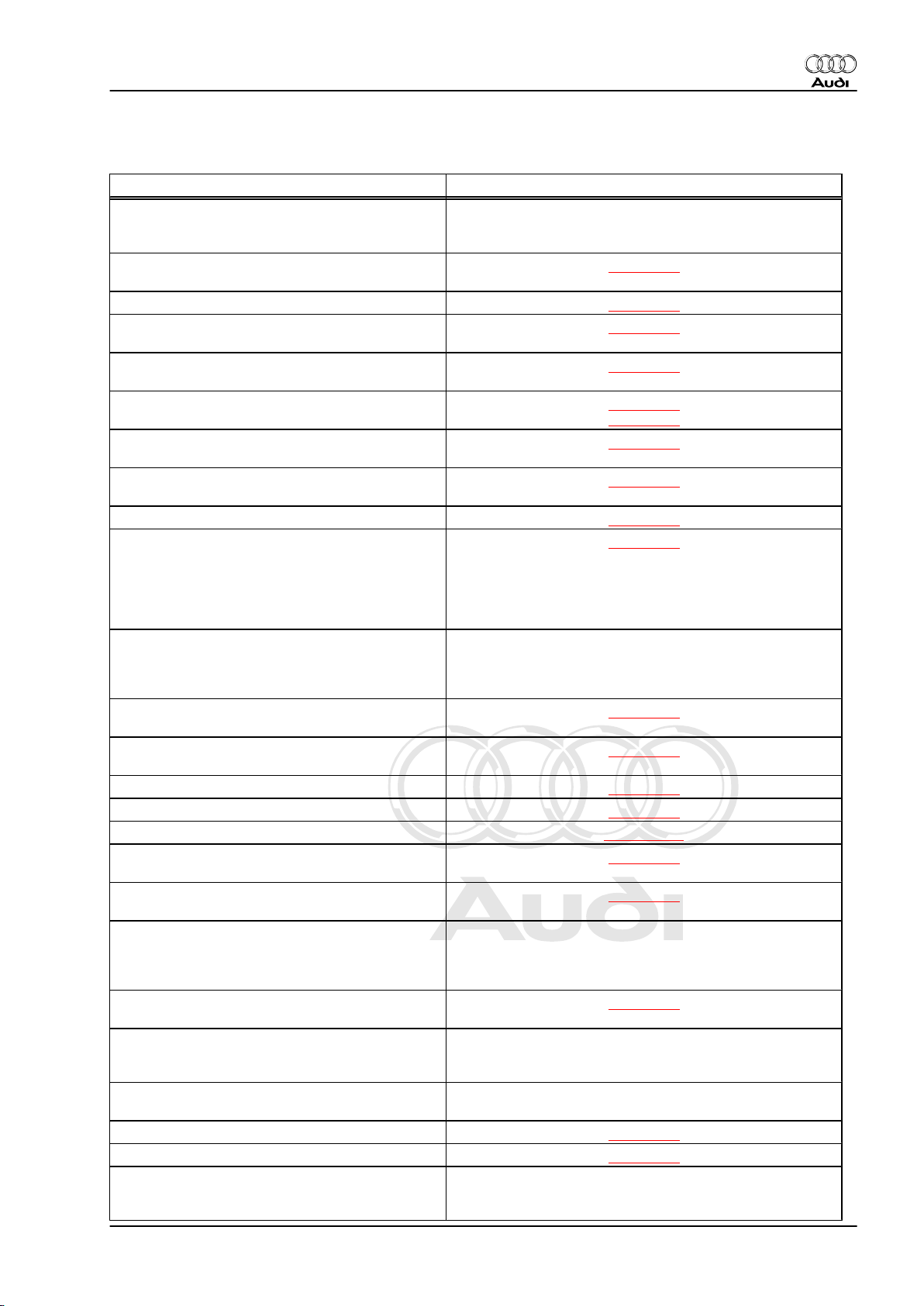

Work to be completed

The order of the individual servicing operations is optimised

as a result of long-standing experience. It is therefore essen‐

tial to comply with the stated order to avoid unnecessary

delays.

The order in which operations are described here is based on

that specified for the Inspection Service, which is the type of

service performed most frequently.

Please inform the customer if any faults or defects which need

repairing are identified during an Inspection Service.

Interval Work to be completed

according to

All work to be completed except for jobs marked "XX"

service interval

display

every 60,000 km

All work to be completed including jobs marked "XX"

(40,000 miles)

every 30,000 km

(20,000 miles)

In addition to LongLife Service:

♦ Change oil for Haldex coupling

♦ Direct shift gearbox (DSG) tiptronic: changing oil and re‐

newing oil filter (only on vehicles with chassis no.

8N_41000189 to 8N_1009705)

every 60,000 km

(40,000 miles)

In addition to LongLife Service:

♦ Direct shift gearbox (DSG) tiptronic: changing oil and re‐

newing oil filter

♦ Haldex coupling: changing oil and renewing oil filter

every 120,000

km

(80,000 miles)

In addition to LongLife Service:

– Poly V-belt and toothed belt: renewing

♦ 1.8 ltr. 165 kW turbocharged engines from model year 2001

onwards

♦ 1.8 ltr. 176 kW turbocharged engines

every 180,000

km

(115,000 miles)

In addition to LongLife Service:

– Poly V-belt and toothed belt: renewing

♦ 1.8 ltr. 132 kW turbocharged engines from model year 2001

onwards

♦ 1.8 ltr. 110 kW turbocharged engines

♦ 1.8 ltr. 120 kW turbocharged engines

♦ 1.8 ltr. 140 kW turbocharged engines

⇒ page 33

⇒ page 30

⇒ page 30

⇒ page 99

⇒ page 99

every 180,000

km

(115,000 miles)

or every 5 years

In addition to LongLife Service:

– Poly V-belt and toothed belt: renewing

♦ 1.8 ltr. 132 kW turbocharged engines up to model year

2000

♦ 1.8 ltr. 165 kW turbocharged engines up to model year

2000

every 24 months In addition to LongLife Service:

– Brake fluid: changing

Work to be com‐

pleted B

Work to be completed Page

Electrical system

6 3. LongLife Service

⇒ page 99

⇒ page 23

Page 11

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Maintenance - Edition 06.2007

Work to be completed Page

Front lighting - checking operation: side lights, dipped

headlights, main beam headlights, fog lights, turn sig‐

nals, hazard warning lights

Rear lighting - checking operation: brake lights (incl.

3rd brake light), rear lights, reversing lights, rear fog

light, number plate lights, turn signals, hazard warn‐

ing lights, luggage compartment light

Interior lights and glove box lights, warning and indi‐

cator lamps, horn: checking operation

Self-diagnosis: interrogating fault memory with fault

⇒ page 31

reader -V.A.G 1551- or -VAS 5051Service interval display: resetting LongLife Service

⇒ page 64

(from chassis No. 8NY1 050 000 onwards)

Vehicle, from outside

Door arresters, lock cylinder and bonnet arrester

⇒ page 97

hook: lubricating

Windscreen wiper/washer system and headlight

⇒ page 50

washer system: checking jet settings and operation

Wiper blades in park position: checking ⇒ page 58

Only in the case of “juddering” wiper blades: checking

⇒ page 58

setting angle

Wiper blades: checking for damage

Tyres

Tyre on spare wheel: checking condition and wear

⇒ page 21

pattern; entering tread depth

Tyre (front left): checking condition and wear pattern;

⇒ page 21

entering tread depth

Tyre (rear left): checking condition and wear pattern;

entering tread depth

Tyre (rear right): checking condition and wear pattern;

entering tread depth

Tyre (front right): checking condition and wear pat‐

⇒ page 21

⇒ page 21

⇒ page 21

tern; entering tread depth

Tyre repair kit: checking expiry date ⇒ page 46

Vehicle, from below:

Engine, gearbox, final drive, steering and boots: vis‐

ual checks for leaks and damage

Engine oil: draining or extracting, changing oil filter ⇒ page 42

Manual gearbox/final drive: checking oil level, topping

⇒ page 50

up with oil if necessary

Haldex coupling: changing oil (four-wheel drive) / ad‐

⇒ page 33

ditional work

Haldex coupling: renewing oil filter (four-wheel drive) /

⇒ page 34

additional work

Brake system: visual check for leaks and damage ⇒ page 22

Brake pads: checking thickness ⇒ page 29

Underseal: visual check for damage ⇒ page 98

Exhaust system: visual check for leaks and damage,

check that parts are properly secured

Track rod ball joints: checking play, security and

⇒ page 97

boots

Swivel joints: checking play, checking boots for leaks

and damage

Engine compartment

Audi TT 1999 ➤

3. LongLife Service 7

Page 12

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Maintenance - Edition 06.2007

Work to be completed Page

Engine (from above) and engine compartment: visual

⇒ page 41

check for leaks and damage

Engine oil: filling up ⇒ page 44

Battery: checking electrolyte level, topping up with

⇒ page 16

distilled water if necessary

Battery with magic eye: checking display, topping up

with distilled water if necessary

Windscreen and headlight washer system: topping up

⇒ page 58

with washer fluid

Cooling system: checking antifreeze and coolant lev‐

⇒ page 37

el / antifreeze specified value -25°C; actual value

(measured value):

XXHydraulic system: checking for leaks, checking hy‐

⇒ page 34

draulic fluid level and topping up if necessary

XXAir cleaner: cleaning housing and renewing filter ele‐

⇒ page 40

ment

XXSpark plugs: renewing ⇒ page 100

Dust and pollen filter: renewing ⇒ page 49

Plenum chamber: checking water drain ⇒ page 99

Poly V-belt: renewing - additional work ⇒ page 39

Toothed belt: renewing - additional work ⇒ page 39

Brake fluid: changing (every two years) - additional

⇒ page 23

work

Note: Never remove strainer from brake fluid reser‐

voir

Final jobs

Tyre pressures on all 4 wheels and spare wheel:

⇒ page 22

checking

Headlights, ellipsoid headlights: checking settings

and adjusting if necessary

Gas discharge headlights: checking settings and ad‐

⇒ page 51

⇒ page 53

justing if necessary

Sticker: enter next service (and date for brake fluid

change) and affix sticker on left side of dash panel or

on door post (B-pillar)

Road test ⇒ page 45

8 3. LongLife Service

Page 13

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

4 Oil Change Service

Audi TT 1999 ➤

Maintenance - Edition 06.2007

Work required

Page

every 15,000 km

(10,000 miles)

or 12 months

Engine oil: draining or extracting, changing oil filter ⇒ page 42

Brake pads: checking thickness of disc brake pads ⇒ page 29

Engine oil: filling up ⇒ page 44

Service interval display: resetting (on vehicles up to chassis No.

⇒ page 59

8NY1 049 999)

Service interval display: resetting Inspection Service (from

⇒ page 81

chassis No. 8NY1 050 000 onwards)

4. Oil Change Service 9

Page 14

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Maintenance - Edition 06.2007

5 Inspection Service

Fixed service interval

♦ Vehicles with petrol engine/ turbocharged petrol engine: max.

15,000 km (10,000 miles) or max. 1 year; oil grade 1.

♦ The oil grade must be entered in the instrument cluster.

Inspection Service

In the case of fixed service intervals the following engine oils ac‐

cording to VW standards must be used:

-VW 501 01- , -VW 502 00- or -VW 504 00- for petrol engines /

turbocharged petrol engines

Work to be completed

The order of the individual servicing operations is optimised

as a result of long-standing experience. It is therefore essen‐

tial to comply with the stated order to avoid unnecessary

delays.

The order in which operations are described here is based on

that specified for the Inspection Service, which is the type of

service performed most frequently.

Please inform the customer if any faults or defects which need

repairing are identified during an Inspection Service.

Interval Work to be completed

according to

All work to be completed except for jobs marked "XX"

service interval

display

every 60,000 km

All work to be completed including jobs marked "XX"

(40,000 miles)

every 30,000 km

(20,000 miles)

In addition to Inspection Service:

♦ Change oil for Haldex coupling

♦ Direct shift gearbox (DSG) tiptronic: changing oil and re‐

newing oil filter (only on vehicles with chassis no.

8N_41000189 to 8N_1009705)

every 60,000 km

(40,000 miles)

In addition to Inspection Service:

♦ Direct shift gearbox (DSG) tiptronic: changing oil and re‐

newing oil filter

♦ Haldex coupling: changing oil and renewing oil filter

every 120,000

km

(80,000 miles)

In addition to LongLife Service:

– Poly V-belt and toothed belt: renewing

♦ 1.8 ltr. 165 kW turbocharged engines from model year 2001

onwards

♦ 1.8 ltr. 176 kW turbocharged engines

every 180,000

km (115,000

miles)

In addition to LongLife Service:

– Poly V-belt and toothed belt: renewing

♦ 1.8 ltr. 132 kW turbocharged engines from model year 2001

onwards

♦ 1.8 ltr. 110 kW turbocharged engines

♦ 1.8 ltr. 120 kW turbocharged engines

♦ 1.8 ltr. 140 kW turbocharged engines

⇒ page 33

⇒ page 30

⇒ page 30

⇒ page 99

⇒ page 99

10 5. Inspection Service

Page 15

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Maintenance - Edition 06.2007

Interval Work to be completed

every

180,000 km

(115,000 miles)

/ every 5 years

In addition to LongLife Service:

– Poly V-belt and toothed belt: renewing

♦ 1.8 ltr. 132 kW turbocharged engines up to model year

2000

♦ 1.8 ltr. 165 kW turbocharged engines up to model year

2000

every 24 months In addition to Inspection Service:

– Brake fluid: changing

Work to be com‐

pleted B

Work to be completed Page

Electrical system

Front lighting - checking operation: side lights,

dipped headlights, main beam headlights, fog

lights, turn signals, hazard warning lights

Rear lighting - checking operation: brake lights

(incl. 3rd brake light), rear lights, reversing lights,

rear fog light, number plate lights, turn signals,

hazard warning lights, luggage compartment

light

Interior lights and glove box lights, warning and

indicator lamps, horn: checking operation

Self-diagnosis: interrogating fault memory with

fault reader -V.A.G 1551- or -VAS 5051-

Service interval display: resetting LongLife Serv‐

⇒ page 31

⇒ page 64

ice (from chassis No. 8NY1 050 000 onwards)

Vehicle, from outside

Door arresters, lock cylinder and bonnet arrester

⇒ page 97

hook: lubricating

Windscreen wiper/washer system and headlight

⇒ page 50

washer system: checking jet settings and opera‐

tion

Wiper blades in park position: checking ⇒ page 58

Only in the case of “juddering” wiper blades:

⇒ page 58

checking setting angle

Wiper blades: checking for damage

Tyres

Tyre on spare wheel: checking condition and

⇒ page 21

wear pattern; entering tread depth

Tyre (front left): checking condition and wear pat‐

⇒ page 21

tern; entering tread depth

Tyre (rear left): checking condition and wear pat‐

⇒ page 21

tern; entering tread depth

Tyre (rear right): checking condition and wear

⇒ page 21

pattern; entering tread depth

Tyre (front right): checking condition and wear

⇒ page 21

pattern; entering tread depth

Tyre repair kit: checking expiry date ⇒ page 46

Vehicle, from below:

Engine, gearbox, final drive, steering and boots:

visual checks for leaks and damage

⇒ page 99

⇒ page 23

5. Inspection Service 11

Page 16

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Maintenance - Edition 06.2007

Work to be completed Page

Engine oil: draining or extracting, changing oil fil‐

⇒ page 42

ter

Manual gearbox/final drive: checking oil level,

⇒ page 50

topping up with oil if necessary

Haldex coupling: changing oil (four-wheel drive) /

⇒ page 33

additional work

Haldex coupling: renewing oil filter (four-wheel

⇒ page 34

drive) / additional work

Brake system: visual check for leaks and dam‐

⇒ page 22

age

Brake pads: checking thickness ⇒ page 29

Underseal: visual check for damage ⇒ page 98

Exhaust system: visual check for leaks and dam‐

age, check that parts are properly secured

Track rod ball joints: checking play, security and

⇒ page 97

boots

Swivel joints: checking play, checking boots for

leaks and damage

Engine compartment

Engine (from above) and engine compartment:

⇒ page 41

visual check for leaks and damage

Engine oil: filling up ⇒ page 44

Battery: checking electrolyte level, topping up

⇒ page 16

with distilled water if necessary

Battery with magic eye: checking display, topping

up with distilled water if necessary

Windscreen and headlight washer system: top‐

⇒ page 58

ping up with washer fluid

Cooling system: checking antifreeze and coolant

⇒ page 37

level / antifreeze specified value -25°C; actual

value (measured value):

XXHydraulic system: checking for leaks, checking

⇒ page 34

hydraulic fluid level and topping up if necessary

XXAir cleaner: cleaning housing and renewing filter

⇒ page 40

element

XXSpark plugs: renewing ⇒ page 100

Dust and pollen filter: renewing ⇒ page 49

Plenum chamber: checking water drain ⇒ page 99

Poly V-belt: renewing - additional work ⇒ page 39

Toothed belt: renewing - additional work ⇒ page 39

Brake fluid: changing (every two years) - addi‐

⇒ page 23

tional work

Note: Never remove strainer from brake fluid res‐

ervoir

Final jobs

Tyre pressures on all 4 wheels and spare wheel:

checking

Headlights, ellipsoid headlights: checking set‐

⇒ page 22

⇒ page 51

tings and adjusting if necessary

Gas discharge headlights: checking settings and

⇒ page 53

adjusting if necessary

Sticker: enter next service (and date for brake

fluid change) and affix sticker on left side of dash

panel or on door post (B-pillar)

12 5. Inspection Service

Page 17

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Maintenance - Edition 06.2007

Work to be completed Page

Road test ⇒ page 45

Audi TT 1999 ➤

5. Inspection Service 13

Page 18

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Maintenance - Edition 06.2007

6 Description of work

6.1 Battery: performing load test

The battery load test provides information on the condition of the

battery.

Special tools and workshop equipment required

♦ Battery tester -VAS 5097 A-

Note

It is not necessary to remove the battery when using battery tester

-VAS 5097 A- . The battery does not have to be disconnected.

Carrying out load test

– Switch off ignition.

– Read operating instructions for battery tester.

– Connect the clamps of the test leads to battery terminals as

described in operating instructions for the tester.

The clamps must make good contact with the battery terminals.

– As the load current differs depending on the battery, the cur‐

rent must be set on the tester according to battery capacity ⇒

Operating instructions for battery test equipment.

– Perform a battery load test as described in the operating in‐

structions.

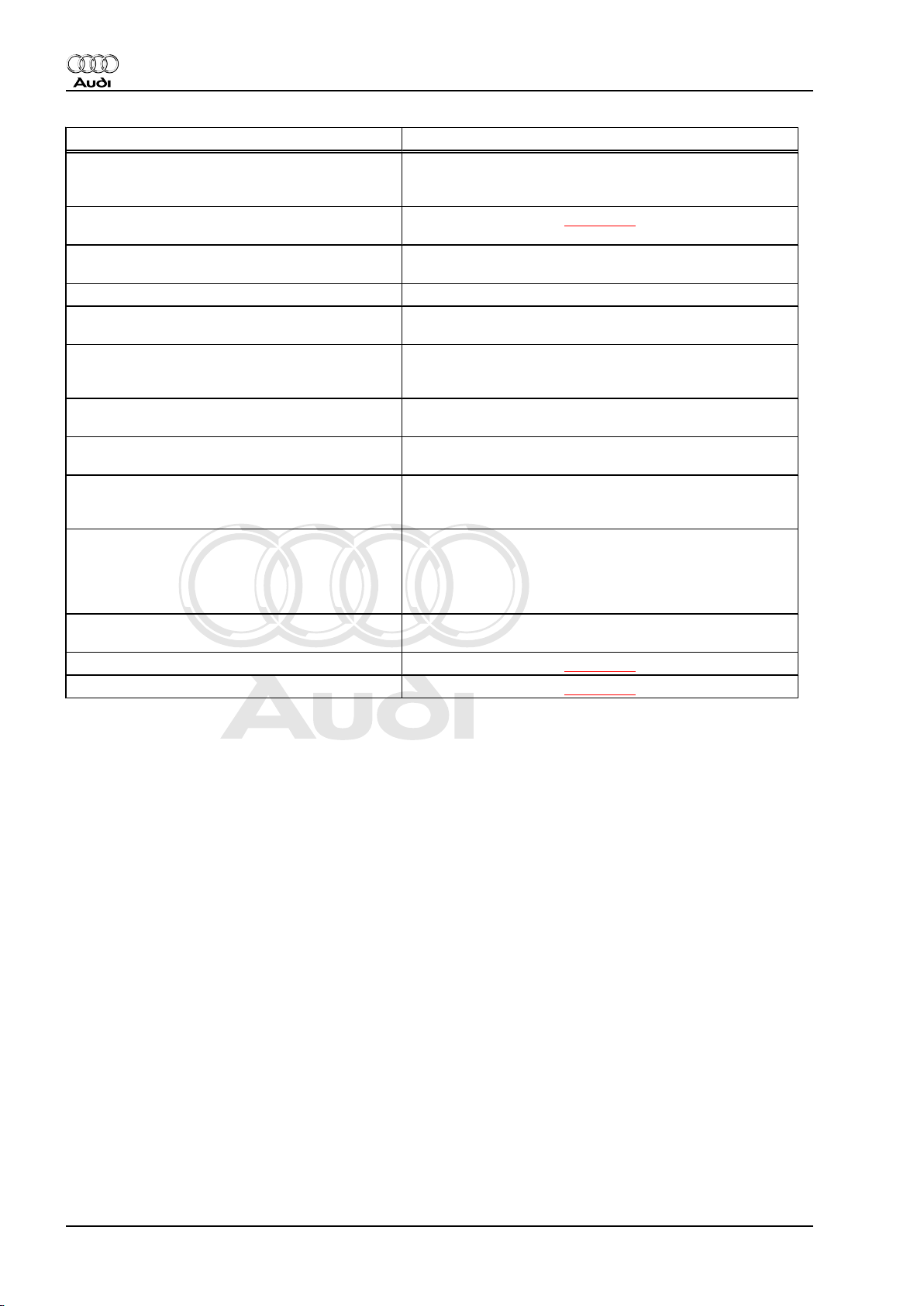

Test equipment display during load test

Please note the test results shown on the display of the tester.

Table:

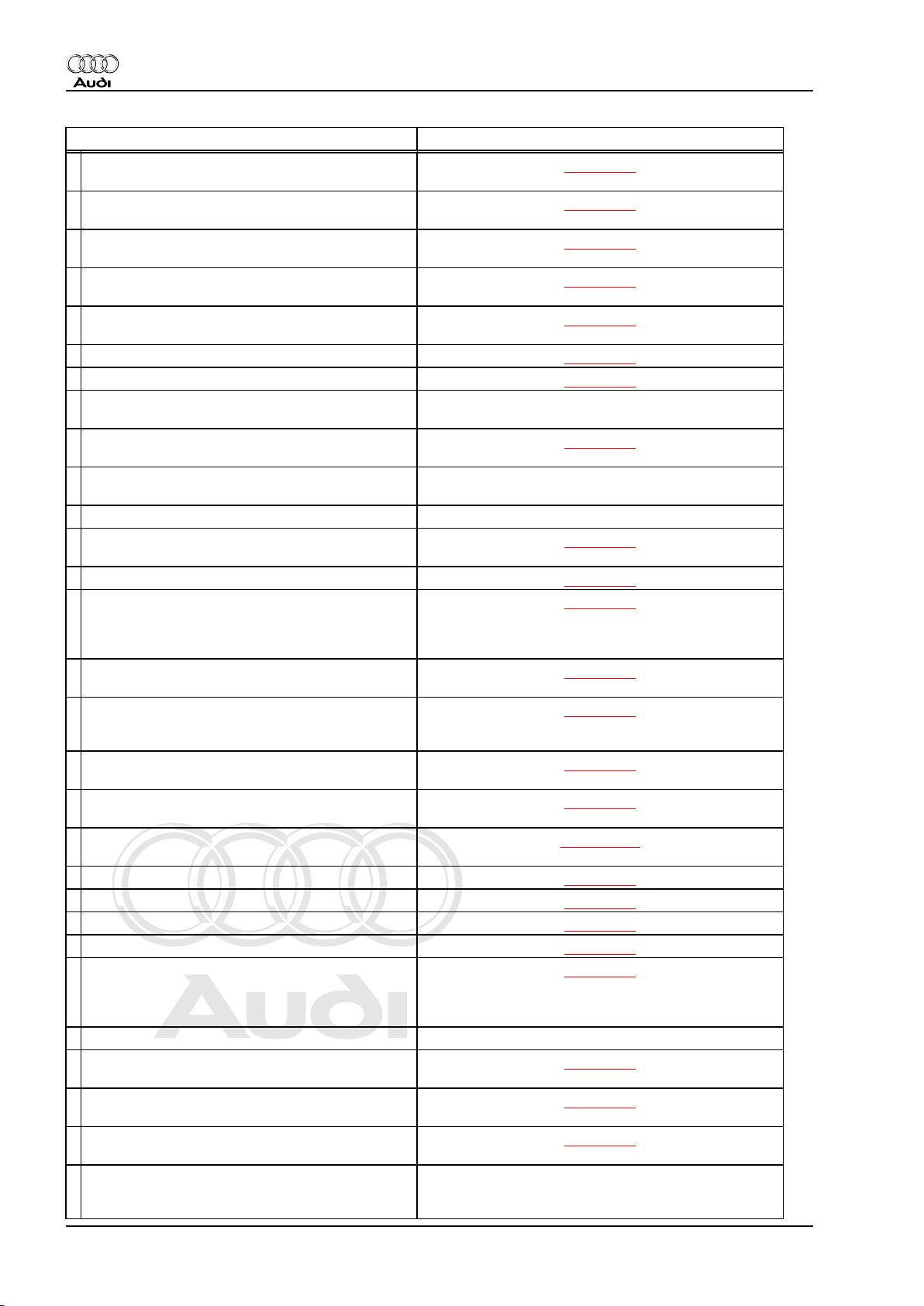

Display on bat‐

tery tester

Battery Very

Delivery Inspection Inspection Service

LongLife Service

Battery OK Battery OK

Good

Battery Good

Battery Not Good

Charge battery

Charge battery

Battery Faulty Renew battery

1)

1)

Battery OK

Charge battery

Renew battery

1)

2)

1) - Perform battery load test again after recharging the battery.

If tester shows “Battery Good” after charging battery, battery is

OK. However, if tester still shows “Battery Not Good”, battery must

be renewed.

14 6. Description of work

Page 19

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

2) - Agree battery replacement with customer.

– Renewing the battery ⇒ Electrical system; Repair group 27;

Removing and installing battery .

Notes on battery load test:

The battery voltage will decrease during the test due to the high

load (high current flow).

If a battery is in working order battery voltage will only drop to

minimum voltage.

If the battery is defective or only insufficiently charged, battery

voltage will very quickly drop below minimum voltage.

After carrying out the load test the voltage will remain at this low

level for quite a while; voltage will only rise again slowly.

6.2 Battery: checking "no load" voltage be‐

fore starting the engine for the first time

(only applies to stock vehicles)

Special tools and workshop equipment required

♦ Digital multimeter -V.A.G 1715-

♦ or

♦ Hand-held multimeter -V.A.G 1526 B-

Audi TT 1999 ➤

Maintenance - Edition 06.2007

Note

♦

The vehicle must not be driven or started with the battery that

is to be tested for at least 2 hours before performing test.

♦

The battery must not be placed under load from connected

electrical equipment for at least 2 hours before the test.

♦

The battery must not be charged for at least 2 hours before

the test.

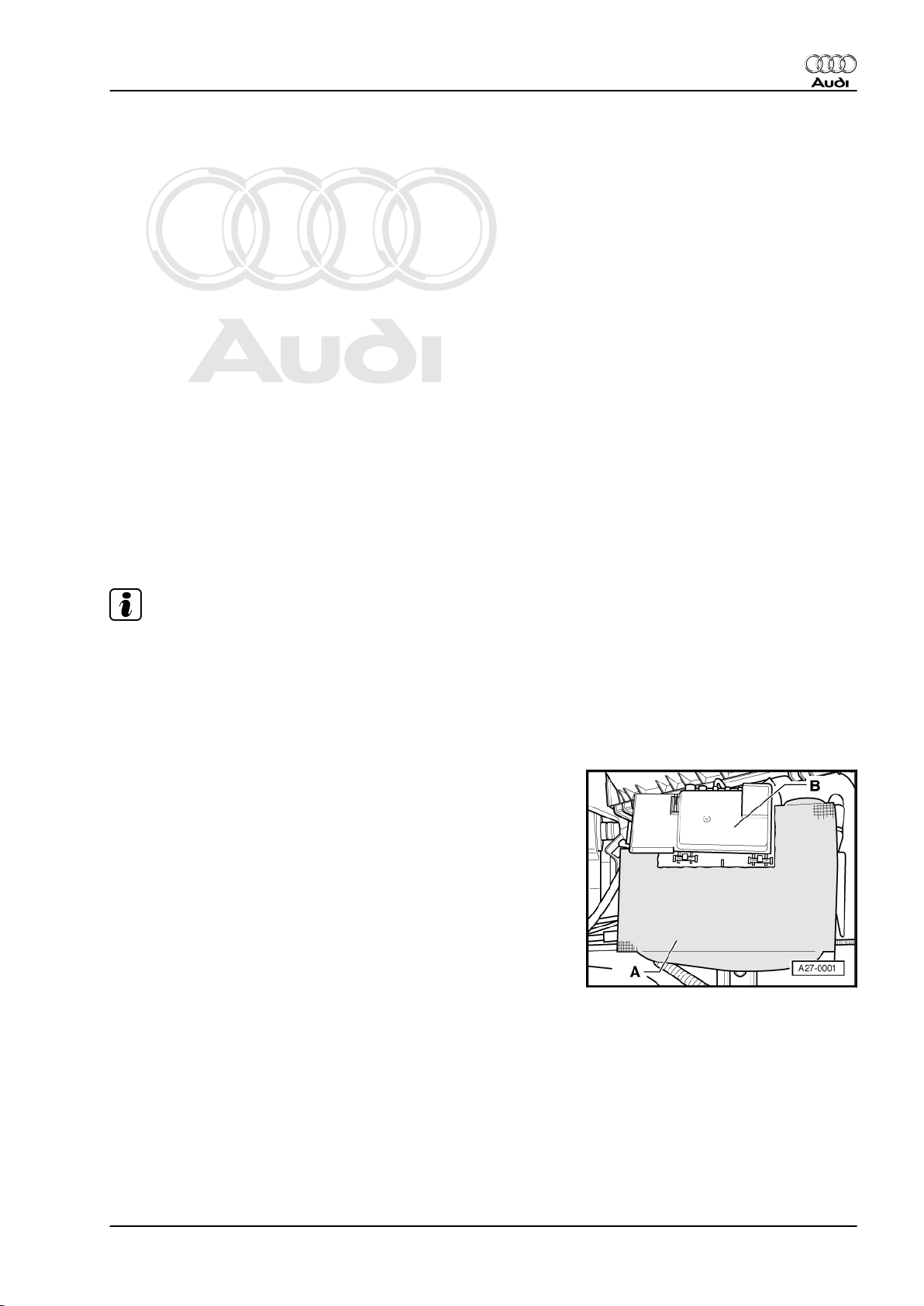

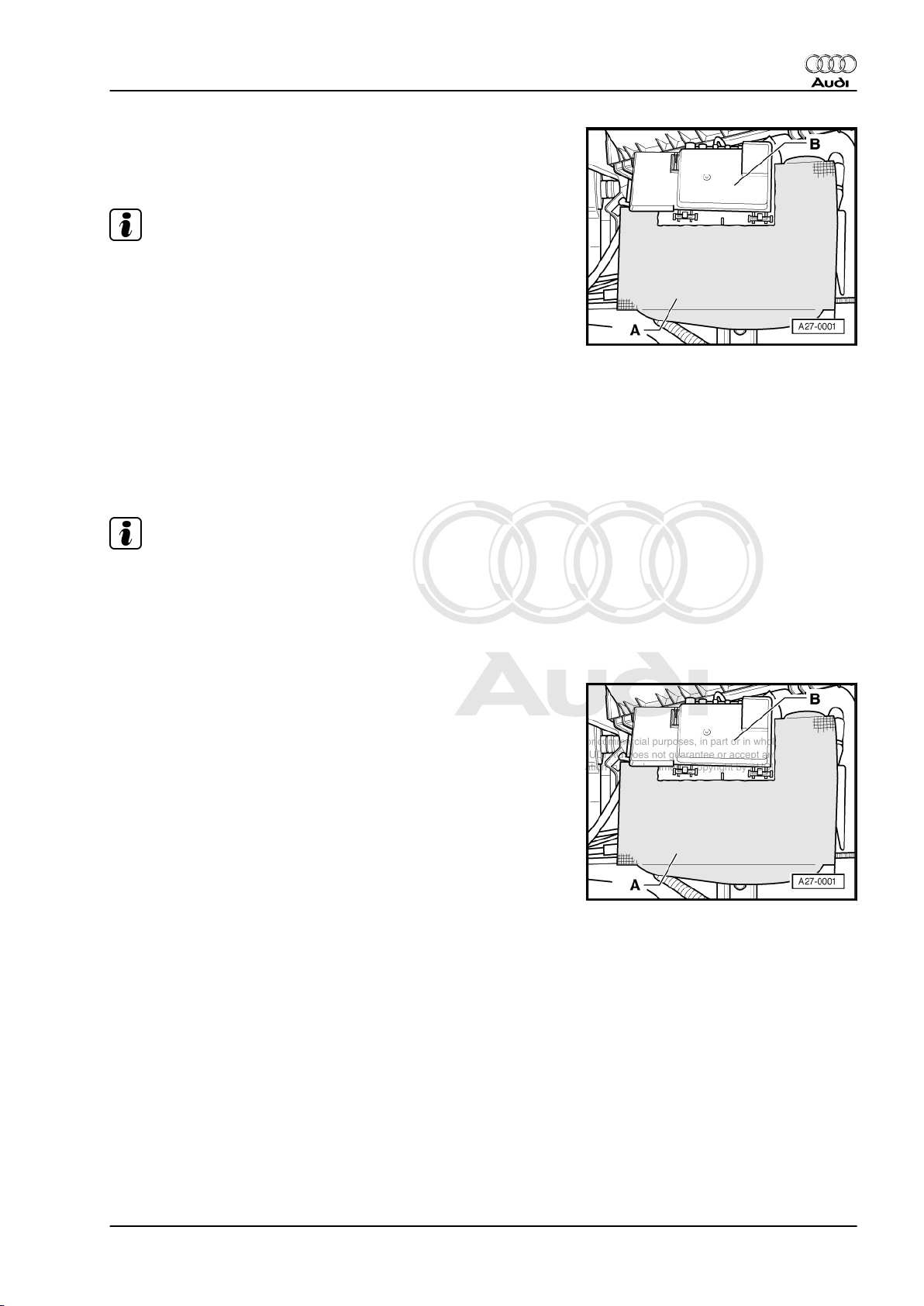

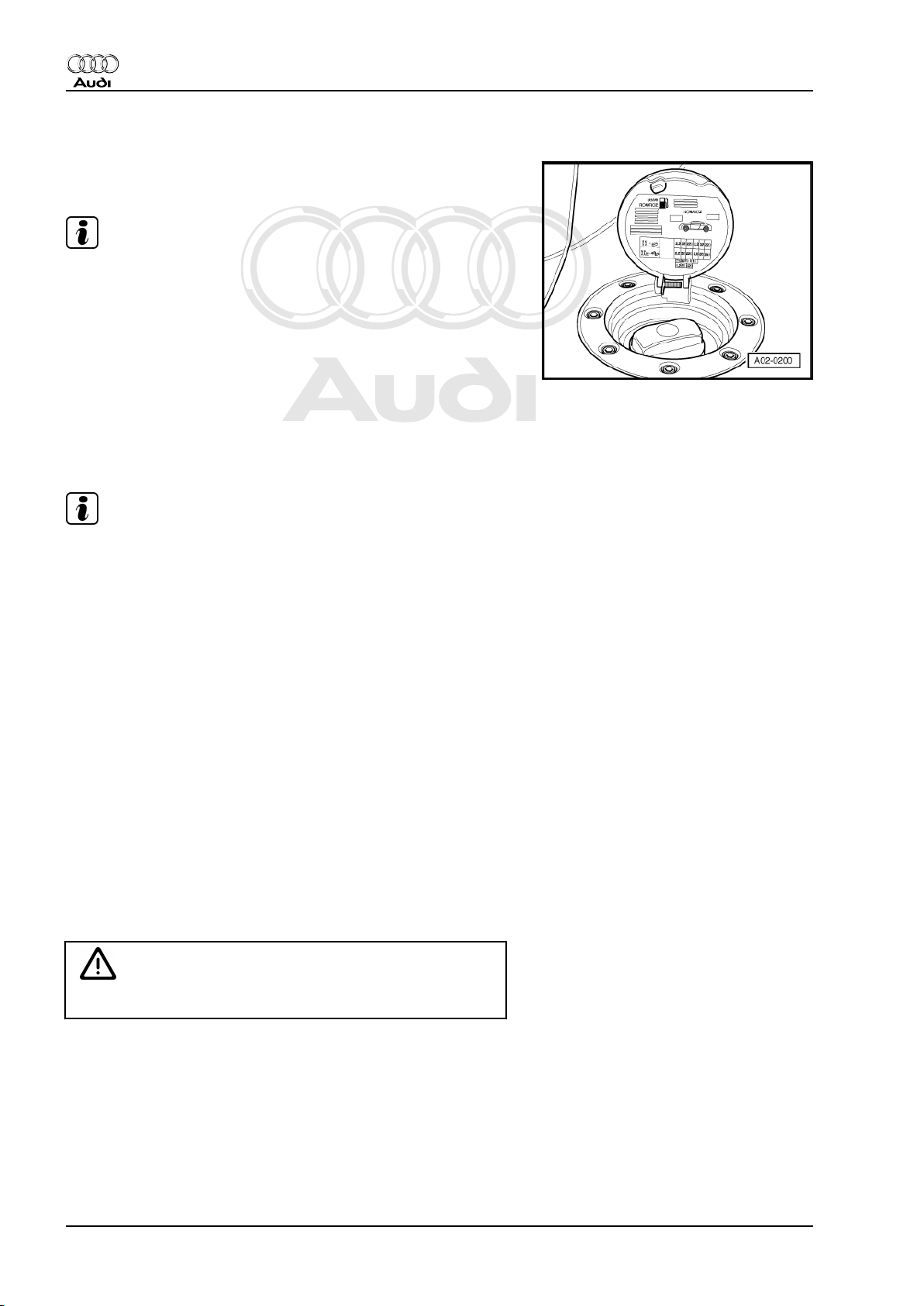

– Open the protective cover on the battery -A- (velcro fastener).

– Open lid -B- of main fuse box towards front of vehicle.

– Check voltage between battery terminals with the ignition

switched off.

♦ If the tester indicates 12.5 V or more, then the battery is OK.

♦ If the voltage is less than 12.5 V, locate the source of the

problem (repair measure).

6. Description of work 15

Page 20

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Maintenance - Edition 06.2007

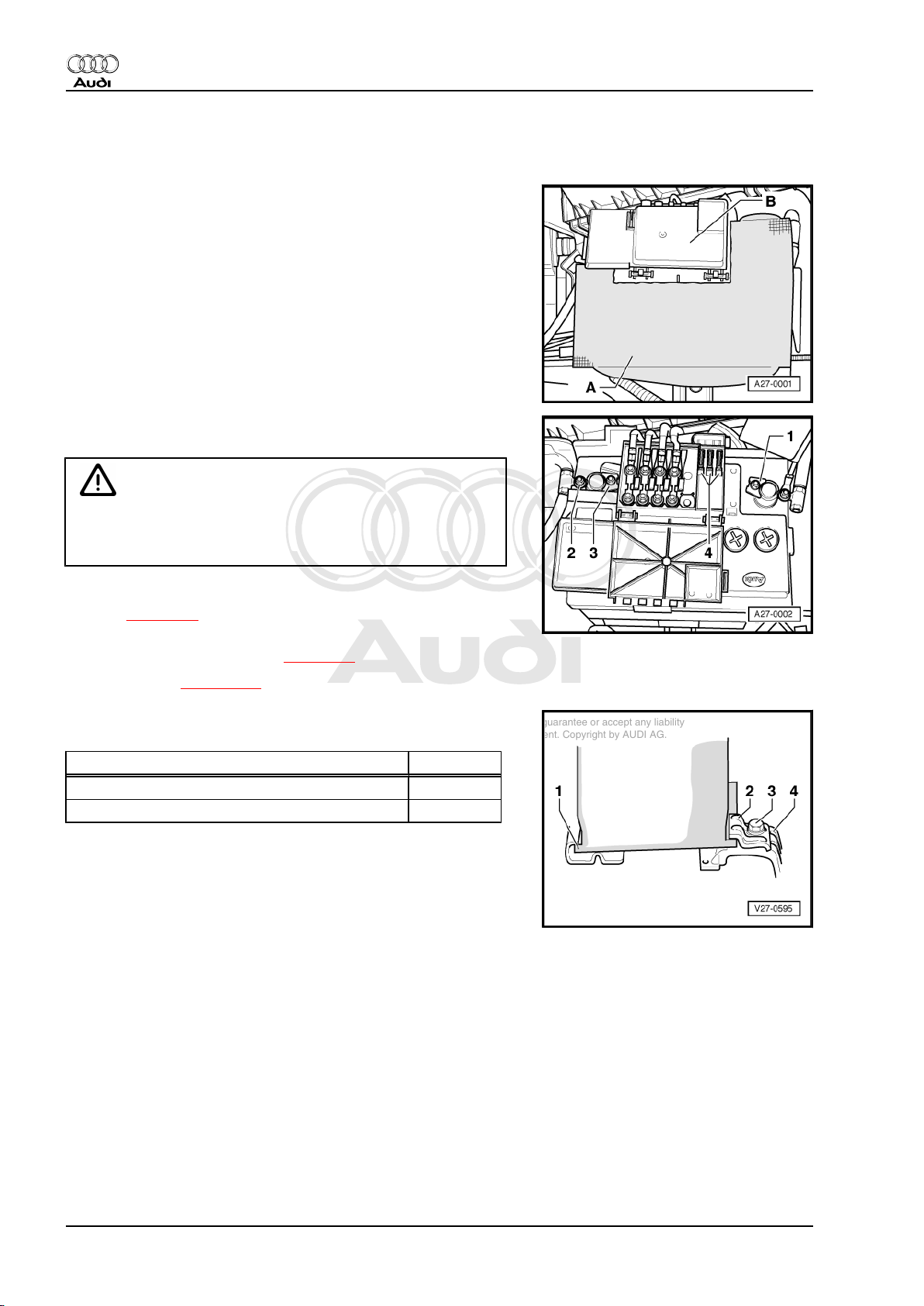

6.3 Battery: checking that battery cables are securely fitted

– Open the protective cover on the battery -A- (velcro fastener).

– Open lid -B- of main fuse box towards front of vehicle.

– Check that the battery terminal clamps are securely fitted. If

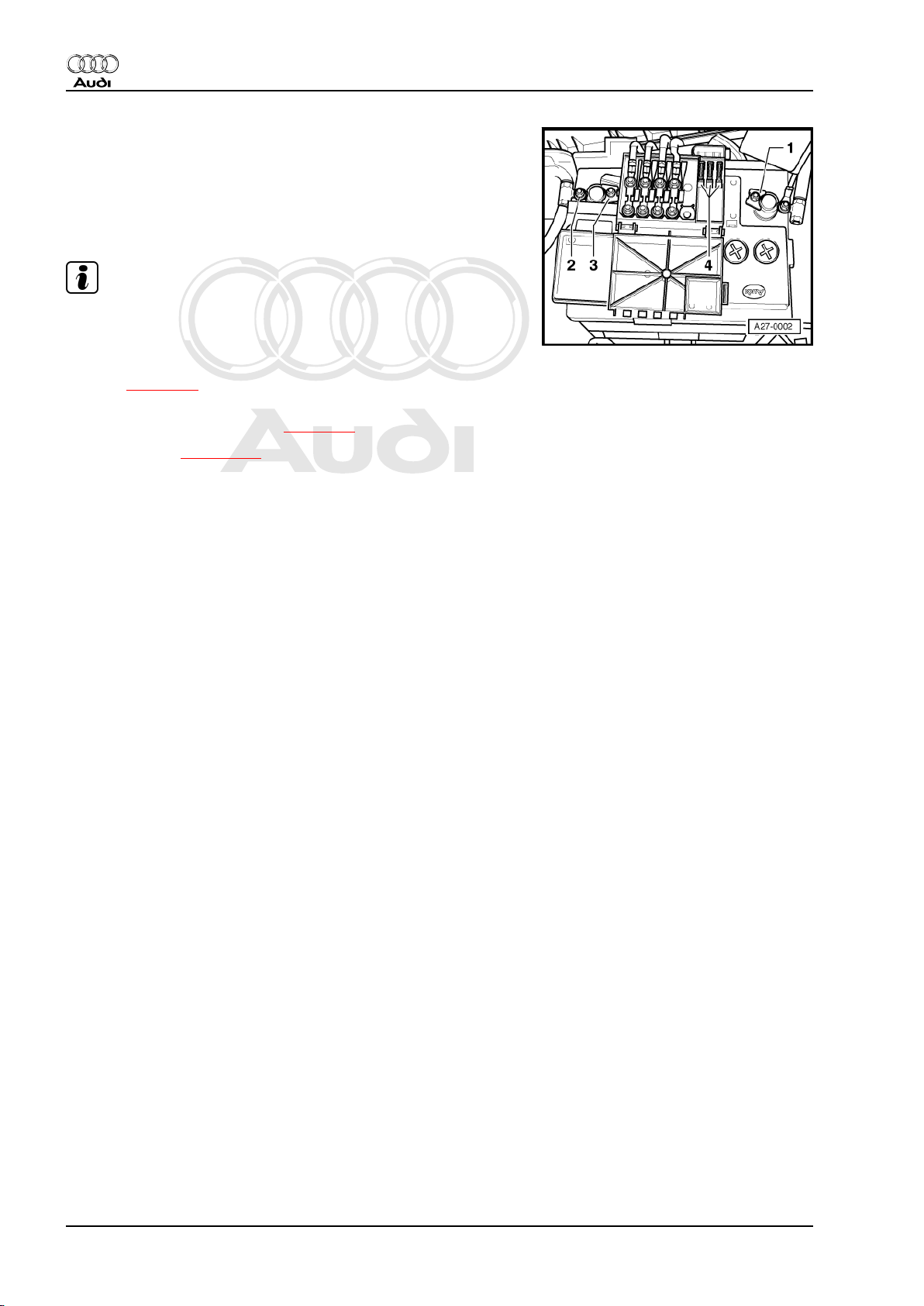

necessary, tighten nuts -1- and -3-.

WARNING

If the battery terminal clamp on the positive terminal is not fitted

securely, disconnect the battery earth strap from the battery

negative terminal first to avoid possible accidents.

– After connecting battery earth strap, enter anti-theft code for

radio ⇒ page 49 .

– Activate the automatic one-touch function for opening and

closing the electric windows ⇒ page 30 .

– Set the clock ⇒ page 100 .

– Check that battery is securely installed. If necessary tighten

securing bolt -3- on retainer plate -2-.

Tightening torque Nm

Battery terminal clamp to battery terminal 5

Bolt on retainer plate 22

6.4 Battery: checking electrolyte level, top‐

ping up with distilled water if necessary

The battery is located in the engine compartment (front left).

16 6. Description of work

Page 21

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

– Open the protective cover on the battery -A- (velcro fastener)

and push slightly downwards.

♦ The electrolyte level must be between min. and max. marks

Note

♦

For batteries with clearly visible min. and max. mark, a visual

check of the battery is sufficient.

♦

If the external min. and max. marks on the battery are not

clearly visible or if the electrolyte level cannot be checked

properly due to an opaque battery housing, the sealing plugs

must be unscrewed ⇒ Topping up with distilled water.

♦

The electrolyte level must align with the marking inside the

battery (plastic moulding). This corresponds to the max mark‐

ing on the outside.

– If necessary, top up battery cells to max. mark with distilled

water.

Topping up with distilled water

Audi TT 1999 ➤

Maintenance - Edition 06.2007

Note

The centre sealing plugs on the battery are concealed by the

bracket for the main fuse box. To unscrew these sealing plugs

you must first remove the main fuse box.

– In the case of vehicles with anti-theft code you will require the

correct code; if necessary obtain the code beforehand.

– Open lid -B- of main fuse box towards front of vehicle.

6. Description of work 17

Page 22

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Maintenance - Edition 06.2007

– Slacken hexagon nut -1- and disconnect battery earth strap.

– Remove the hexagon nut -2- and detach retaining brackets for

main fuse box from battery housing.

– Remove the sealing plugs.

– Only top up the electrolyte level with distilled water.

Note

The use of distilled water prevents contamination of the electro‐

lyte and any associated increase in self discharge.

– After connecting battery earth strap, enter anti-theft code for

radio ⇒ page 49 .

– Activate the automatic one-touch function for opening and

closing the electric windows ⇒ page 30 .

– Set the clock ⇒ page 100 .

Batteries with magic eye

18 6. Description of work

Page 23

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

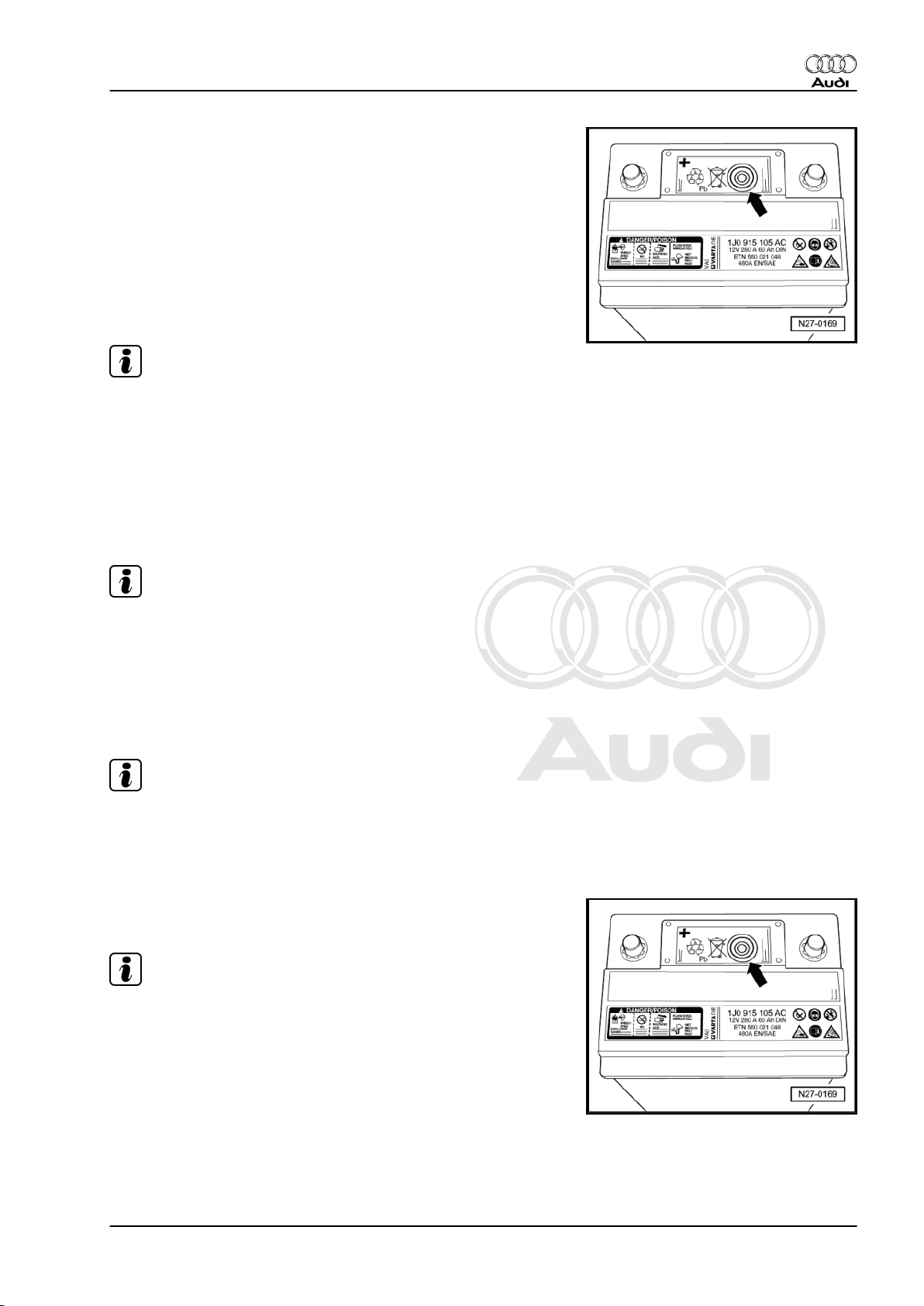

– In the case of batteries (lead-calcium batteries) with magic eye

-arrow- please carry out check as follows:

The magic eye indicates the electrolyte level and the charge level

of the battery. Three different colours are used as indicators:

Green → the battery is sufficiently charged.

Black → no charge or charge too low (repair measure).

Colourless or yellow → critical electrolyte level has been reached.

It is essential to top up with distilled water:

– Remove the foil covering the sealing plug.

Note

♦

Sealed starter batteries have been fitted from week 01, model

year 2001.

♦

On these batteries it is not possible to measure relative density

or top up with distilled water.

– Unscrew sealing plug from battery.

– Use battery filler bottle -VAS 5045- to top up with distilled water

to max. mark.

Audi TT 1999 ➤

Maintenance - Edition 06.2007

Note

The neck of filler bottle -VAS 5045- is designed to prevent over‐

filling of the battery cells and spillage of battery acid. When the

"max." level is reached, the flow of distilled water into the cells is

cut off.

– Screw the sealing plug back onto battery.

Electrolyte level too high

Note

If the electrolyte level is too high (above the max. marking) the

leaking electrolyte (sulphuric acid/water mixture) will cause dam‐

age outside the battery, e. g. to components in engine compart‐

ment.

– The foil covering the sealing plug must be pulled off on bat‐

teries with magic eye -arrow-.

Note

♦

Sealed starter batteries have been fitted from week 01, model

year 2001.

♦

On these batteries it is not possible to measure relative density

or top up with distilled water.

– Unscrew sealing plug from battery.

If the electrolyte level is too high (over-filled), e.g. is above inner

mark for electrolyte level (plastic moulding) or above the exterior

max. marking:

6. Description of work 19

Page 24

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Maintenance - Edition 06.2007

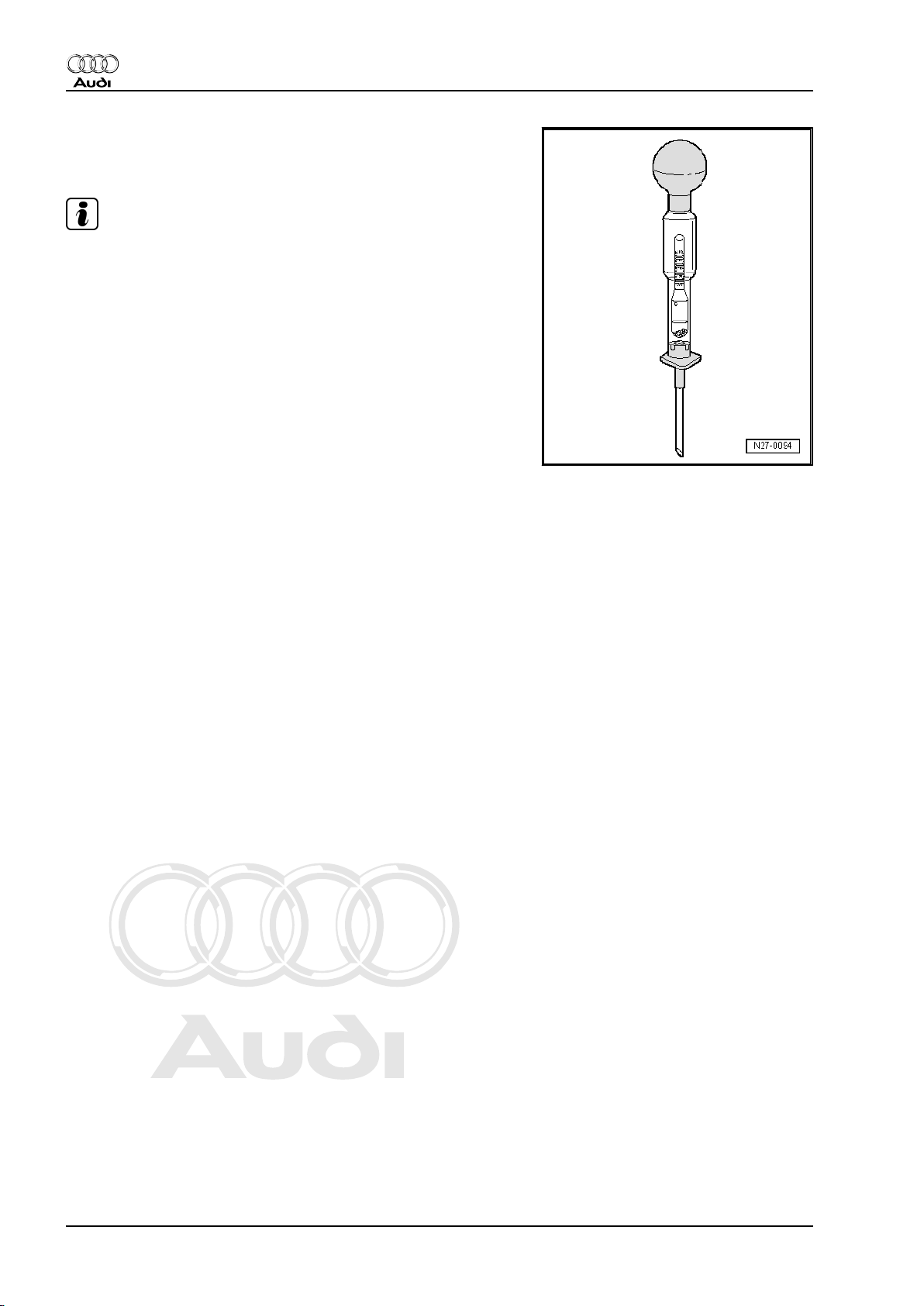

– Draw off electrolyte with a hydrometer (⇒ illustration) until the

electrolyte level reaches the plastic moulding or the max.

marking.

Note

Observe disposal regulations.

– Screw the sealing plug back onto battery.

6.5 Lights, electrical equipment, switches,

displays and other driver-operated con‐

trols: checking operation

– The following components must be checked:

♦ Lighting, headlights, fog lights, turn signals, hazard warning

lights, rear lights, rear fog light, reversing lights, brake lights,

parking light function

♦ Interior lights and reading lights (automatic switch-off function

for front interior light), glove box lighting, ashtray light, luggage

compartment lighting, ignition key light

♦ Warning buzzer indicating that lights and/or radio have been

left on

♦ All switches on console

♦ Driver Information System (DIS)

♦ Instrument cluster including all displays, counters, lights and

illumination

♦ Dual-tone horn

♦ Windscreen wiper/washer system, headlight washer system

♦ Cigarette lighter

♦ Electric exterior mirrors (heated, adjustable)

♦ Electric window lifters

♦ Central locking, remote control (radio-operated), convenience

close function

♦ Seat heating

♦ Radio

20 6. Description of work

Page 25

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

6.6 Tyres: checking condition, wear pattern, tread depth and correcting inflation pressures.

Note

In the interest of driving safety, only tyres of the same type and

tread pattern should be fitted on a vehicle.

6.6.1 Checking tyres

Delivery Inspection

– Check tyre tread surfaces and sidewalls for damage and re‐

move any foreign bodies.

Inspection Service

– Check tyres for scuffing, one-sided wear, porous sidewalls,

cuts and fractures.

Audi TT 1999 ➤

Maintenance - Edition 06.2007

WARNING

Any defects must be reported to the customer.

6.6.2 Checking tyre wear pattern

– The wear pattern of the front tyres indicates, for example,

whether the toe and camber have to be checked.

♦ Feathering on tread indicates incorrect toe setting.

♦ One-sided tread wear is usually due to incorrect camber.

Note

If the above types of wear are found, check wheel alignment to

determine the cause (repair measure).

6.6.3 Checking tyre tread depth

– Checking tyre tread depth

♦ Minimum depth: 1.6 mm

Note

♦

This figure may vary for individual countries due to different

legislation.

♦

The minimum tread depth is reached when the tyres have

worn down level with the 1.6 mm high tread wear indicators

positioned at intervals around the tyre.

♦

If the tread depth is approaching the minimum permissible

tread depth, the customer must be informed.

6. Description of work 21

Page 26

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Maintenance - Edition 06.2007

6.6.4 Inflating to correct pressures

The correct inflation pressures for summer tyres are listed on the

sticker on the inside of the tank flap.

Note

♦

Please note that the inflation pressures listed on the sticker

apply to cold tyres. When the tyres are warm, the actual pres‐

sures will be higher, but must not be reduced.

♦

When using winter tyres, pressures should be increased by

0.2 bar.

6.6.5 Spare wheel

• Temporary (compact) spare wheel

The correct inflation pressure is indicated on the sidewall.

Note

Check the valve extensions for damage and dirt which could

cause leaks. Renew if necessary.

6.7 Brake system: visual check for leaks and damage

– Check following components for leaks and damage:

♦ Brake master cylinder

♦ Brake servo

♦ ABS hydraulic unit

♦ Brake calipers

– Ensure that brake hoses are not twisted.

– Make sure that brake hoses do not touch any components

when steering is on full lock.

– Check brake hoses for porosity, blistering and brittleness.

– Check brake hoses and pipes for chafing.

– Check brake pipe connections and mountings for correct seat‐

ing, leaks and corrosion.

WARNING

Any faults found must be rectified (repair measure).

6.8 Brake fluid level (depends on brake pad wear): checking

Only use new genuine VW/Audi brake fluid in accordance with

US standard FMVSS 116 DOT 4.

22 6. Description of work

Page 27

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

WARNING

♦ Brake fluid is poisonous. It also has caustic properties and

must therefore not be allowed to come into contact with

paintwork.

♦ Brake fluid is hygroscopic, i.e. it absorbs moisture from the

surrounding air. It must therefore always be stored in airtight containers.

– Note the following:

Delivery Inspection

♦ The fluid level must be at the MAX mark.

Note

The fluid level must not exceed the MAX marking, otherwise the

fluid will overflow.

Audi TT 1999 ➤

Maintenance - Edition 06.2007

Inspection Service

When the vehicle is driven, the brake fluid level will drop slightly

with use and as a result of the automatic adjustment of the brake

pads.

– When checking the brake fluid level, always take into account

the amount of wear on the brake pads:

♦ If the brake pads are new or a long way from reaching the wear

limit, the fluid level should be between the MIN and MAX

marks.

♦ If the brake fluid level is at or slightly above the MIN marking

and the brake pads have almost reached the wear limit, top‐

ping up is not required.

WARNING

If the fluid level has fallen below the MIN mark, check the brake

system (repair measure) before adding brake fluid.

6.9 Brake fluid: changing

Note

Only use new genuine VW/Audi brake fluid, refer to ⇒ ETKA .

6. Description of work 23

Page 28

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Maintenance - Edition 06.2007

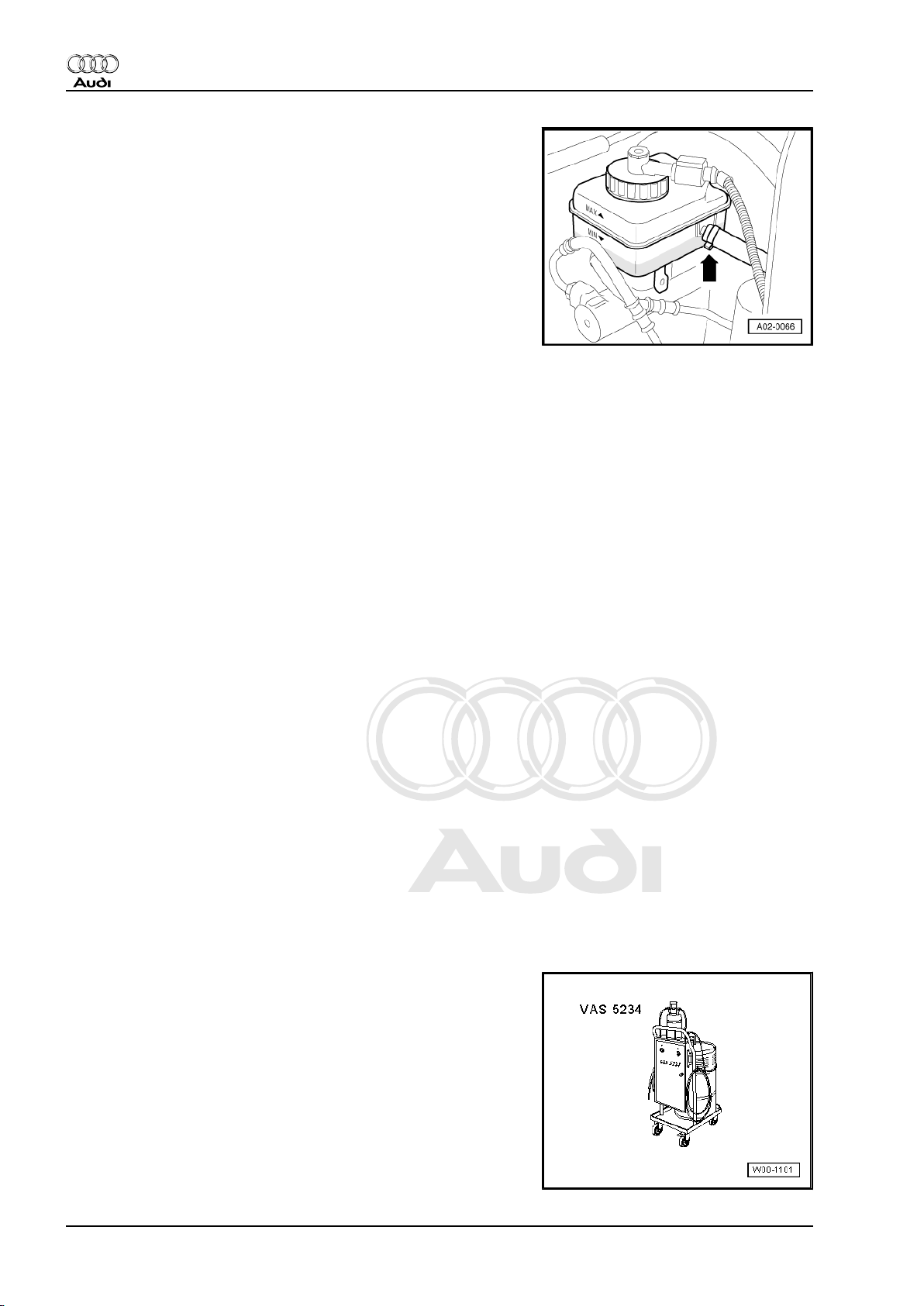

Changing the brake fluid with brake filling and bleeding equipment

-VAS 5234- ⇒ page 26

Changing the brake fluid with brake filling and bleeding equipment

-V.A.G 1869- ⇒ page 24

WARNING

♦ Brake fluid must on no account come into contact with liq‐

uids containing mineral oils (oil, petrol, cleaning agents).

Mineral oils damage the plugs and sleeves in the brake

system.

♦ Brake fluid is poisonous and must under no circumstances

be sucked through a tube using the mouth. Because of its

caustic properties it must also not come into contact with

paintwork.

♦ Brake fluid is hygroscopic, i.e. it absorbs moisture from the

surrounding air. It must therefore always be stored in airtight containers.

♦ Always observe the relevant environmental regulations for

disposal.

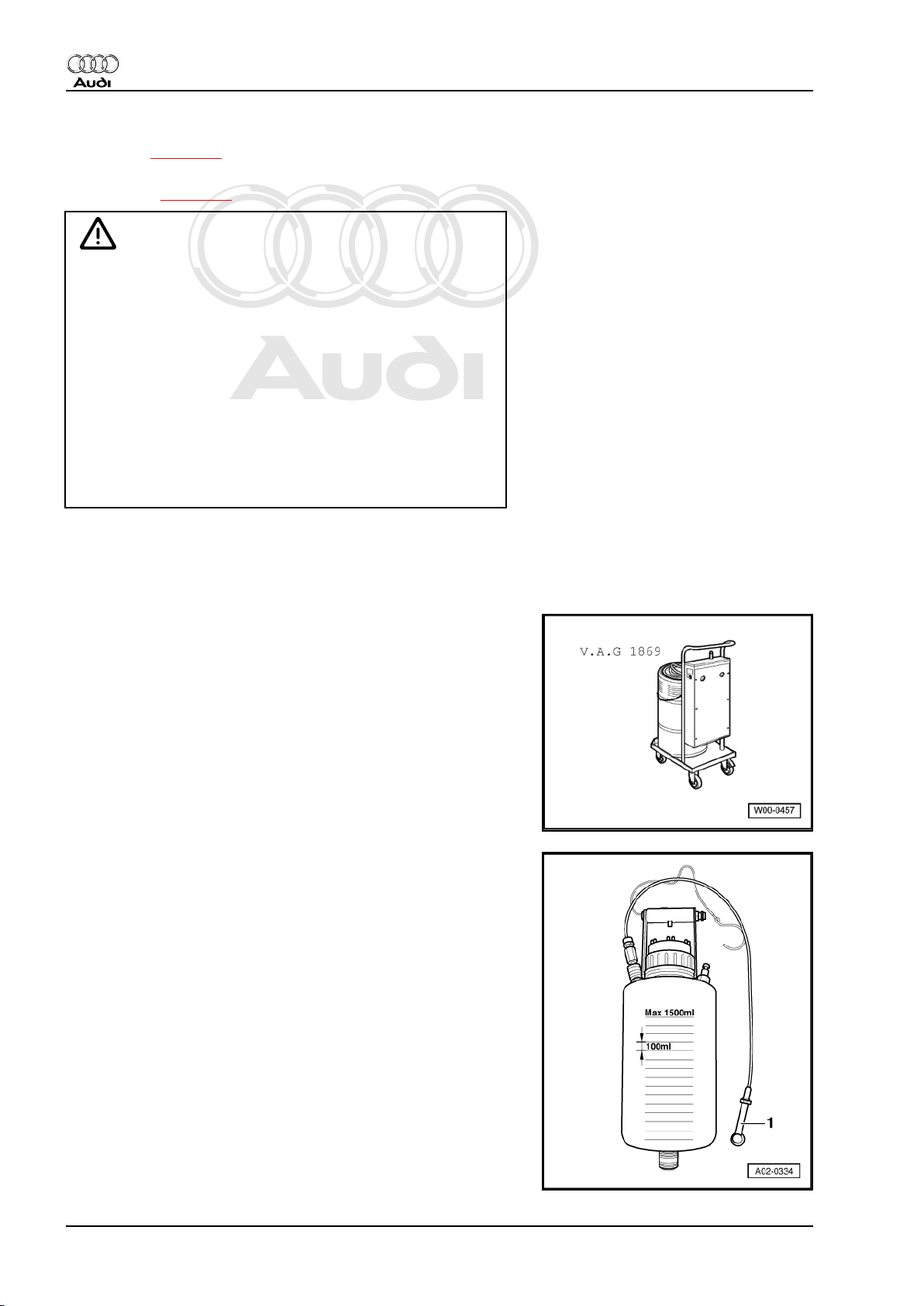

6.9.1 Changing brake fluid with brake filling and bleeding equipment -V.A.G 1869-

Special tools and workshop equipment required

♦ Brake filling and bleeding equipment -V.A.G 1869-

♦ Container for collecting used fluid

24 6. Description of work

Page 29

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Note

♦

The brake fluid reservoir must always be adequately filled to

ensure that no air can enter the brake system from the reser‐

voir.

♦

The strainer in the brake fluid reservoir must not be removed.

♦

Observe the instructions given in the operating manual for the

brake filling and bleeding equipment -V.A.G. 1869- .

WARNING

Do not reuse the old brake fluid that has been extracted.

– Open brake fluid reservoir.

– Open the bleeder screw on brake caliper (rear right).

– Get a suitable container ready to catch the used brake fluid.

Audi TT 1999 ➤

Maintenance - Edition 06.2007

6. Description of work 25

Page 30

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Maintenance - Edition 06.2007

– With engine running, use brake pedal to pump out brake fluid

until fluid level goes down as far as the connection -arrow- on

the reservoir.

– Close bleeder screw.

On vehicles with manual gearbox the clutch slave cylinder must

also be “flushed out” with new brake fluid. When doing so, note

the following:

– Connect brake filling and bleeding equipment -V.A.G 1869- ,

but do not switch on yet.

– Open bleeder screw on clutch slave cylinder.

– Fit bleeder hose leading to brake fluid collector onto bleeder

screw on clutch slave cylinder.

–

Then switch on bleeder appliance and allow about 100 cm3 of

brake fluid to drain out.

– Close bleeder screw.

Sequence for changing brake fluid in brake calipers:

1 - Front left-hand brake caliper

2 - Front right-hand brake caliper

3 - Rear left-hand brake caliper

4 - Rear right-hand brake caliper

– Fit bleeder hose leading to brake fluid collector onto bleeder

screw for relevant brake caliper.

–

Open bleeder screw and allow about 200 cm3 of brake fluid to

drain out.

Used brake fluid is pushed out of the system when new fluid is

pumped in.

– Close bleeder screw.

– Disconnect hose from brake fluid reservoir.

– Check pedal pressure and free play of brake pedal.

♦

Free play: no more than 1/3 of pedal travel

– During the final test drive, make sure that at least one ABS-

controlled brake application is carried out (with noticeable

pulsing of brake pedal).

6.9.2 Changing brake fluid with brake filling and bleeding equipment -VAS 5234-

Special tools and workshop equipment required

♦ Brake filling and bleeding equipment -VAS 5234-

26 6. Description of work

Page 31

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

♦ Container for collecting used fluid

Audi TT 1999 ➤

Maintenance - Edition 06.2007

Note

♦

The brake fluid reservoir must always be adequately filled to

ensure that no air can enter the brake system from the reser‐

voir.

♦

The strainer in the brake fluid reservoir must not be removed.

♦

Observe the instructions given in the operating manual for the

brake filling and bleeding equipment -VAS 5234- .

– Unscrew cap -1- from brake fluid reservoir.

6. Description of work 27

Page 32

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Maintenance - Edition 06.2007

– Use extraction hose included in brake filling and bleeding

equipment -VAS 5234- to extract as much brake fluid as pos‐

sible.

WARNING

Do not reuse the old brake fluid that has been extracted.

– Connect adapter -1- to brake fluid reservoir.

– Connect filling hose -2- included with brake filling and bleeding

equipment -VAS 5234- to adapter.

Vehicles with manual gearbox:

– Remove cap from bleeder screw on clutch slave cylinder.

– Connect bleeder hose -1- attached to collector bottle to bleed‐

er screw on clutch slave cylinder, open bleeder screw and let

approx. 100 ml flow out. Close bleeder screw and fit cap back

on.

– Repeatedly depress the clutch pedal.

Continuation for all vehicles:

– Remove caps from bleeder screws.

– Connect bleeder hose -1- attached to collector bottle to bleed‐

er screw (front left), open bleeder screw and allow approx. 200

ml of brake fluid to flow out. Close bleeder screw.

28 6. Description of work

Page 33

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

– Repeat the procedure on the other front side of the vehicle.

– Connect bleeder hose -1- attached to collector bottle to bleed‐

er screw (rear left), open bleeder screw and allow approx. 200

ml of brake fluid to flow out. Close bleeder screw.

– Repeat the procedure on the other rear side of the vehicle.

– Fit caps back on bleeder screws on brake calipers.

– Move filling lever on brake filling and bleeding equipment -

VAS 5234- to position -B- (see operating instructions).

– Detach filling hose from adapter.

– Unscrew adapter from brake fluid reservoir.

– Screw cap onto brake fluid reservoir.

– Check brake fluid level and correct as necessary.

– Check pedal pressure and free play of brake pedal. Free play:

no more than 1/3 of pedal travel

6.9.3 Table - sequence for changing brake flu‐

id / quantities

Audi TT 1999 ➤

Maintenance - Edition 06.2007

Front left 200 ml

Front right 200 ml

Rear left 200 ml

Rear right 200 ml

Clutch slave cylinder

4)

200 ml

Total quantity 1,000 ml

4) Not on vehicles with automatic gearbox

6.10 Brake pads: checking thickness

WARNING

When brake pad thickness is down to 7 mm (including back‐

plate) the brake pads have reached their wear limit and must

be renewed (repair measure). The customer must be informed.

Front disc brake pads:

a - Pad thickness including backplate

- Wear limit: 7 mm

6. Description of work 29

Page 34

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Maintenance - Edition 06.2007

Rear disc brake pads:

a - Pad thickness including backplate

- Wear limit: 7 mm

Front and rear:

– Determine thickness of outer pads by checking visually (with

electric torch through cut-out in wheel).

– Determine thickness of inner pads by checking visually (with

help of electric torch and mirror).

6.11 Direct shift gearbox (DSG): changing oil and renewing oil filter

⇒ Direct shift gearbox; Rep. Gr. 34 ; Changing gear oil

6.12 Electric windows: checking positions

The electric window lifters “forget” their current positions and the

automatic open/close function when the battery is disconnected.

– Activate the automatic open/close function as follows:

– Switch on ignition.

– Close windows all the way to their top positions using the win‐

dow lifters.

– Then operate all window lifter switches again for at least one

second in the “close” direction to activate the automatic onetouch function.

– Press switch to open window. The side window should move

all the way down automatically.

6.13 Vehicle keys: checking operation

– Open key ring to check each key individually.

– Lock and unlock the driver's door manually with each key.

– Insert each key in the ignition lock and switch on the ignition.

The key symbol for the immobiliser displayed in the instrument

cluster must disappear after two seconds. If the key symbol

flashes, the key has not been matched to the immobiliser. ⇒

Guided Fault Finding; Matching vehicle keys

Note

Make a note in the delivery record of the number of keys which

have been checked and handed over to the customer.

30 6. Description of work

Page 35

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

6.14 Interrogating fault memory for all sys‐

tems:

6.14.1 Fault reader -V.A.G 1551-

– Connect fault reader -V.A.G 1551- with lead -V.A.G 1551/3-

(ignition must be switched off).

– Switch on ignition.

– Switch on printer with PRINT button (indicator lamp in button

lights up).

Indicated on display:

V.A.G - SELF-DIAGNOSIS HELP

1 - Rapid data transfer

V.A.G - SELF-DIAGNOSIS HELP

2 - Flash code output

– Enter “1” for “Rapid data transfer”.

Interrogating fault memory:

– Enter “00” for address word “Automatic test sequence” and

confirm entry with Q key. The -V.A.G 1551- sends all known

address words one after the other.

When a control unit responds stating its identification the display

will show the number of stored faults or “No fault recognised”.

Any system faults that are stored will be displayed one after the

other and printed out. The -V.A.G 1551- will then transmit the next

address word.

The automatic test sequence has ended when the following is

indicated on the display:

Audi TT 1999 ➤

Maintenance - Edition 06.2007

V.A.G - SELF-DIAGNOSIS HELP

1 - Rapid data transfer

V.A.G - SELF-DIAGNOSIS HELP

2 - Flash code output

– Switch off ignition.

If faults have been stored these must be rectified. The fault log is

required for the repair work.

6.14.2 Vehicle diagnostic, testing and informa‐

tion system -VAS 5051-

Special tools and workshop equipment required

6. Description of work 31

Page 36

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Maintenance - Edition 06.2007

♦ Vehicle diagnostic, testing and information system -VAS 5051-

♦ Adapter lead -VAS 5051/5a-

Connecting vehicle diagnostic, testing and information system VAS 5051-

– Storage compartment on driver's side (bottom left)

– Apply handbrake.

– Automatic gearbox: selector lever to position “P” or “N”.

– Manual gearbox: gear lever in neutral.

– Connect fault reader -VAS 5051- with lead -VAS 5051/5a- (ig‐

nition must be switched off).

– Switch on ignition.

Indicated on display:

Selecting operating mode:

– Press button for “vehicle self-diagnosis” on display -arrow-.

Note

If the display does not coincide with the work sequence shown:

⇒ Operating instructions for Vehicle Diagnostic, Testing and In‐

formation System VAS 5051.

Selecting vehicle system:

32 6. Description of work

Page 37

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Indicated on display:

– Press “00 - Interrogate fault memory overall system” on dis‐

play -arrow-.

– The -VAS 5051- sends all known address words one after the

other.

When a control unit responds stating its identification the display

will show the number of stored faults or “No fault recognised”.

Any system faults that are stored will be displayed in a list. The VAS 5051- will then transmit the next address word.

The automatic test sequence has ended when the following is

indicated on the display:

– Press “Print” button -1- on display and then press “Screen” in

the print menu.

The -VAS 5051- prints out all the faults or “No faults detected”. If

faults have been stored these must be rectified. The fault log is

required for the repair work.

– Press “Go to” button -2- on the display.

Audi TT 1999 ➤

Maintenance - Edition 06.2007

Indicated on display:

– Press “Exit” button on display -arrow-.

– Press “Exit” button in the Exit menu.

If faults have been stored these must be rectified. The fault log is

required for the repair work.

6.15 Noise insulation: removing

– Unscrew bolts -arrows- and remove noise insulation.

4-cylinder and 6-cylinder petrol engines:

6.16 Haldex coupling: changing oil

⇒ Rear final drive; Rep. Gr. 39 ; Changing oil in Haldex coupling

6. Description of work 33

Page 38

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Maintenance - Edition 06.2007

6.17 Haldex coupling: renewing oil filter

⇒ Rear final drive; Rep. Gr. 39 ; Changing oil filter in Haldex

coupling

6.18 Haldex coupling: checking oil level

⇒ Rear final drive; Rep. Gr. 39 ; Checking oil level in Haldex

coupling

6.19 Hydraulic system: checking for leaks,

checking hydraulic fluid level and top‐

ping up if necessary

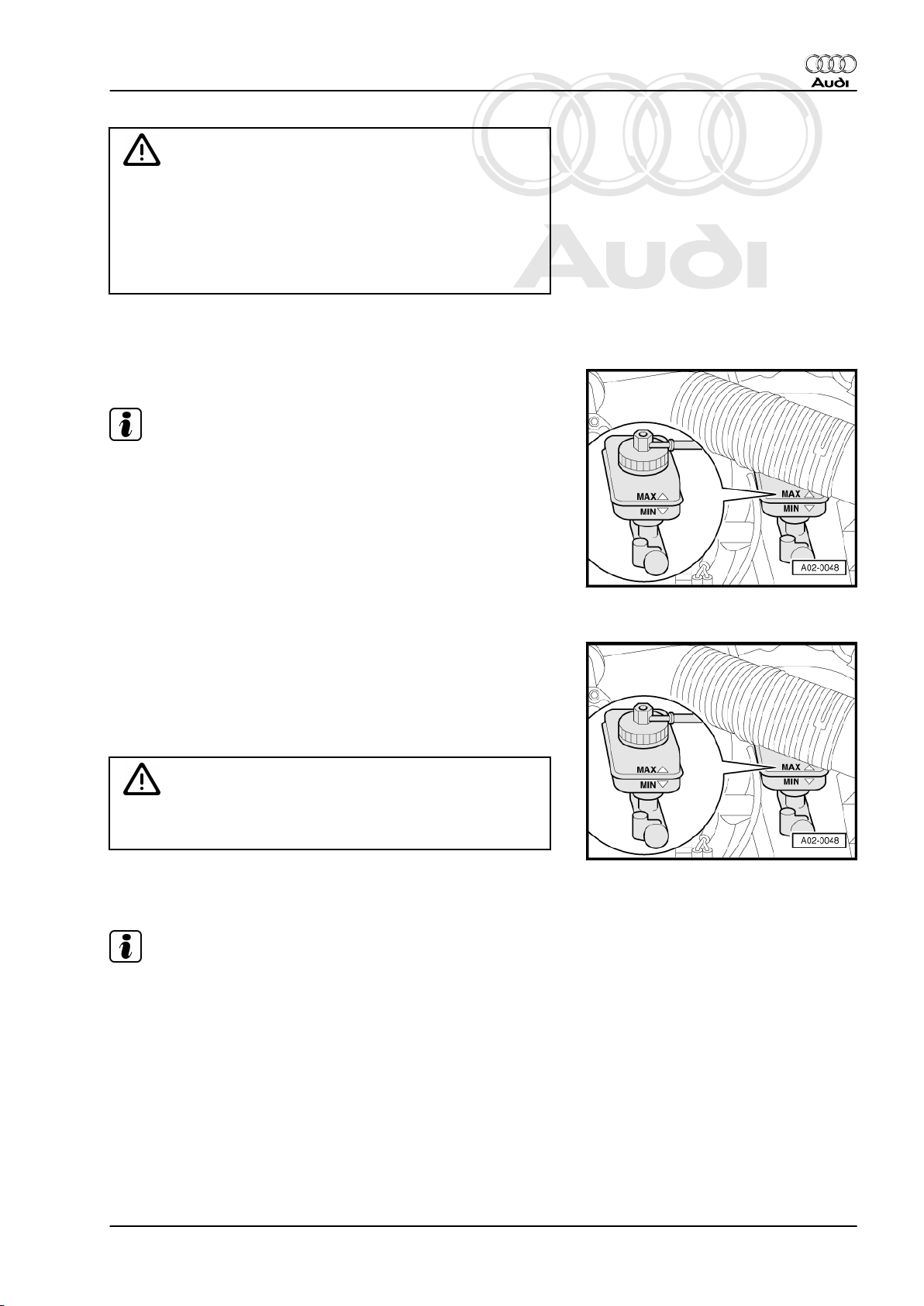

Fluid level in power steering system

• Fluid in cold condition:

– Do not start engine but bring front wheels to straight-ahead

position.

• Fluid at operating temperature (above approx. 50 °C):

– Start engine and bring front wheels to straight-ahead position.

– Use a screwdriver -arrow- to unscrew filler cap with dipstick.

– Clean dipstick with a clean cloth.

– Screw cap on hand tight and unscrew again.

34 6. Description of work

Page 39

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

– Check fluid level:

• Fluid in cold condition:

The fluid level must be in area of MIN. marking (up to 2 mm above

or below marking).

• Fluid at operating temperature (above approx. 50 °C):

Fluid level must be between MIN. and MAX. markings.

Note

♦

The fluid level reading will only be accurate if the cap was

screwed on properly before checking the dipstick.

♦

If the fluid level is above the area specified, the excess fluid

must be extracted.

WARNING

If the fluid level is below the range specified, the hydraulic sys‐

tem must be checked for leaks (repair measure). It is then not

sufficient to merely top up the fluid.

Audi TT 1999 ➤

Maintenance - Edition 06.2007

– If the system is not leaking top up with “G 002 000” fluid.

– Screw cap on hand tight.

6.20 Instrument cluster: setting the language

Vehicles with Driver Information System (DIS)

When a car is delivered to the customer, the multifunction monitor

display can be set to any of the following languages as required:

German, English, French, Italian, Spanish, Portuguese

Cars are delivered by the factory with the multifunction monitor

set to German.

– To change the language proceed as follows:

Connect fault reader -V.A.G 1551- .

– ⇒ page 31

– Switch on ignition.

– Enter “1” for “Rapid data transfer”.

– Enter “17” to select the address word “Dash panel insert” and

confirm entry with Q key.

– Press → key twice to continue.

– Enter “10” to select the function “Adaption” and confirm entry

with Q key.

– Enter “04” to select “Adaption channel 04” and confirm entry

with Q key.

When the following is indicated on the display:

– Press → key to continue.

Indicated on display:

Channel 4 Adaption 2 ->

- ↑ - ↓ -

Channel 4 Adaption 2 Q

Enter adaption value XXXXX

6. Description of work 35

Page 40

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 1999 ➤

Maintenance - Edition 06.2007

– Select desired language according to the following table.

Language version Code

German 00001

English 00002

French 00003

Italian 00004

Spanish 00005

Portuguese 00006

Note

♦

The first four digits must be “0”.

♦

If an incorrect value is entered the function “Adaption” will be

terminated automatically and must be restarted!

Example:

– Enter “00001” (e.g. for German).

When the following is indicated on the display:

Channel 4 Adaption 2 Q

Enter adaption value 00001

– Confirm entry with Q key.

When the following is indicated on the display:

– Confirm entry with Q key.

When the following is indicated on the display: