Page 1

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Service

Body Repairs

Audi TT 2007 ➤

Edition 09.2009

Service Department. Technical Information

Page 2

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Repair Group overview for Body Repairs

Re pa ir G ro up

00 - Technical data

50 - Body - front

51 - Body - centre

53 - Body - rear

Service

Technical information should always be available to the foremen and mechanics, because their

careful and constant adherence to the instructions is essential to ensure vehicle road-worthiness and

safety. In addition, the normal basic safety precautions for working on motor vehicles must, as a

matter of course, be observed.

All rights reserved.

No reproduction without prior agreement from publisher.

Copyright © 2010 Audi AG, Ingolstadt A008JKI0120

Page 3

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

Contents

00 - Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1 General notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 Vehicle identification data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.1 Type plate and vehicle identification number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.2 Vehicle data sticker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3 Expanded foam inserts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

4 General notes on repairs to aluminium parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5 General notes on repairs to steel parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

6 Body construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

6.1 Aluminium panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

7 Corrosion protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

8 Bonded joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

8.1 Bonded joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

8.2 Spot-welded/bonded joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

8.3 Inspecting and repairing bonded joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

8.4 Repair methods for replacing body parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

9 Body panel gaps/shut lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

9.1 Body - front and centre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

10 Body dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

10.1 Floor group, front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

10.2 Floor group, rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

10.3 Body - front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

10.4 Body - centre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

10.5 Body - rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

11 Straightening jig . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

11.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

11.2 Portal gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

50 - Body - front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

1 Longitudinal member, upper part with console (Coupé and Roadster identical) . . . . . . . . 36

1.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

1.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2 Support, left-side - Renewal (Coupé and Roadster identical) . . . . . . . . . . . . . . . . . . . . . . 43

2.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

2.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3 Support, right-side - Renewal (Coupé and Roadster identical) . . . . . . . . . . . . . . . . . . . . . . 46

3.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

3.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4 Upper longitudinal member for wheel housing - Renewal (Coupé and Roadster identical)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5 Suspension strut mounting - Renewal (Coupé and Roadster identical) . . . . . . . . . . . . . . . . 55

5.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

6 Longitudinal member for wheel housing, upper, inner - Renewal (Coupé and Roadster

identical) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

7 Front longitudinal member - Renewal (Coupé and Roadster identical) . . . . . . . . . . . . . . . . 65

Contents i

Page 4

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

7.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

7.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

8 Front longitudinal member - Partial renewal (Coupé and Roadster identical) . . . . . . . . . . 70

8.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

8.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

9 Longitudinal member (front section) - Renewal (Coupé and Roadster identical) . . . . . . . . 73

9.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

9.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

51 - Body - centre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

1 Roof - Renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

1.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

1.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

2 Roof side member - Renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

2.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

2.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

2.3 Foam-filling roof side member . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

3 Outer roof frame - Renewal (Roadster) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

3.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

3.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

4 Front roof cross member - Renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

4.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

4.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

5 Rear roof frame - Renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

5.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

5.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

6 Outer A-pillar - Renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

6.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

6.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

7 Reinforcement tube and inner A-pillar - Renewal (Roadster) . . . . . . . . . . . . . . . . . . . . . . . . 122

7.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

7.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

8 Inner A-pillar - Renewal (Coupé and Roadster) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

8.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

8.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

9 Inner B-pillar - Renewal (Roadster) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

9.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

9.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

10 Outer side member - Renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

10.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

10.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

11 Inner side member - Partial renewal (old part section) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

11.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

11.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

12 Inner side member - Renewal (Roadster) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

12.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

12.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

13 Floor panel - Renewal (Coupé and Roadster identical) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

13.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

53 - Body - rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

1 Rear cross panel (top section) - Renewal (Coupé and Roadster identical) . . . . . . . . . . . . 168

1.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

ii Contents

Page 5

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

1.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

2 Cross panel (inner section) - Renewal (Coupé and Roadster identical) . . . . . . . . . . . . . . 173

2.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

2.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

3 Rain channel - Partial renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

3.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

3.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

4 Rear suspension strut mounting - Renewal (Coupé and Roadster identical) . . . . . . . . . . . . 183

4.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

4.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

5 Rear longitudinal member - Partial renewal (Coupé and Roadster identical) . . . . . . . . . . 186

5.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

5.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

6 Side panel - Renewal (Coupé) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

6.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

6.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

7 Side panel - Renewal (Roadster) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

7.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

7.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

8 Inner side panel - Renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

8.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

8.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

9 Rear wheel housing - Partial renewal (Coupé and Roadster identical) . . . . . . . . . . . . . . . . 217

9.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

9.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

10 Rear wheel housing - Renewal (Coupé and Roadster identical) . . . . . . . . . . . . . . . . . . . . 222

10.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

10.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

11 Spare wheel well - Partial renewal (Coupé and Roadster identical) . . . . . . . . . . . . . . . . . . 226

11.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

11.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

12 Spare wheel well - Renewal (Coupé and Roadster) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

12.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

12.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Contents iii

Page 6

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

iv Contents

Page 7

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

00 – Technical data

1 General notes

This Manual describes only selected repair operations. A de‐

scription is given where the repair method differs from the original

manufacturing process.

Where the repair operation is not described: Separate the original

joint and repair using a replacement part.

If no description is given for any sub-parts supplied, these should

be matched up and butt welded with an SG continuous seam.

Please refer to the information in the Workshop Manual ⇒ General

Information; Body Repairs, General Body Repairs .

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

1. General notes 1

Page 8

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

2 Vehicle identification data

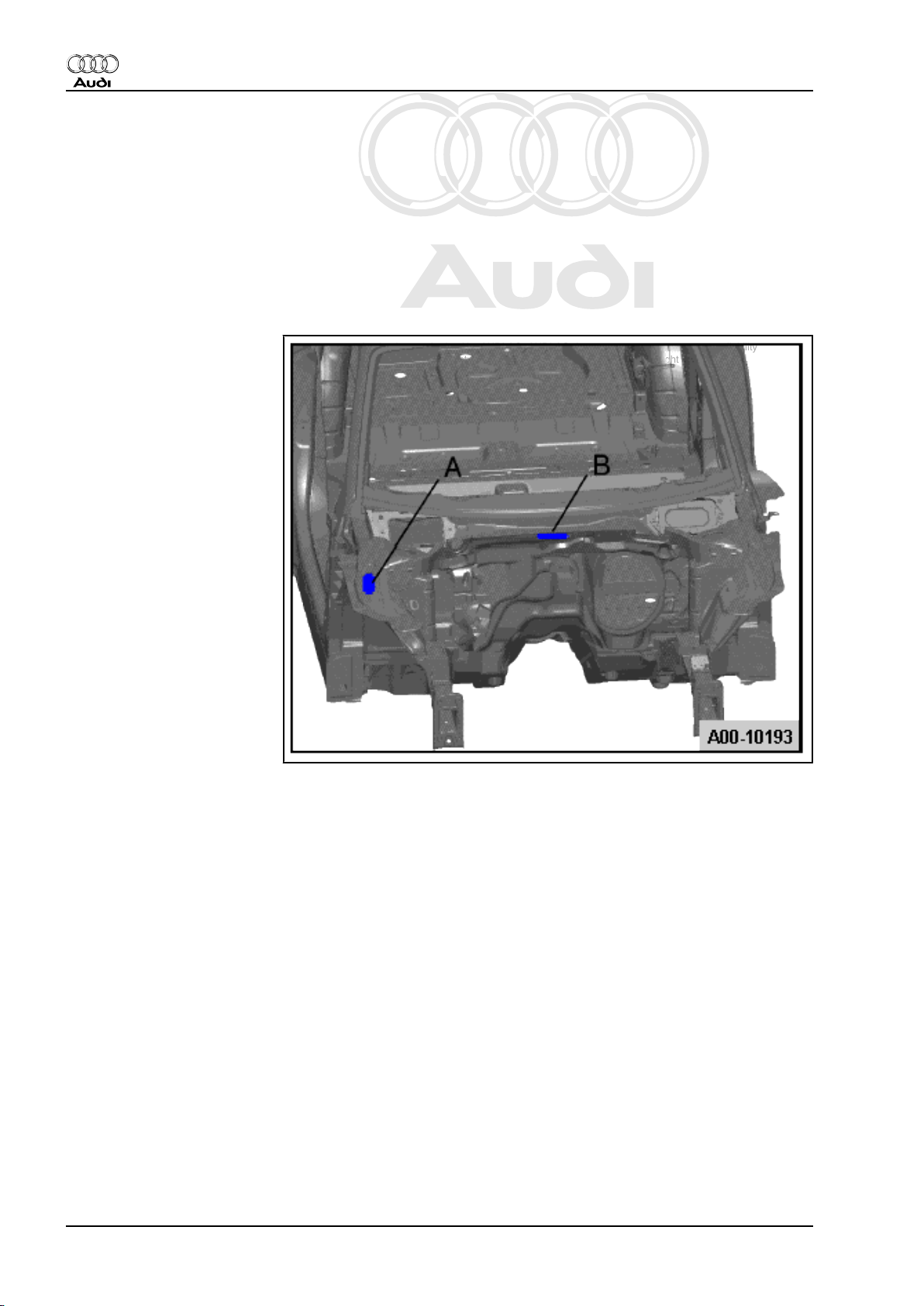

2.1 Type plate and vehicle identification number

The vehicle identification number -B- (chassis number) is stam‐

ped on the flange in the plenum chamber.

The type plate -A- is attached to the wing mounting flange (rightside).

2 Rep. Gr.00 - Technical data

Page 9

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

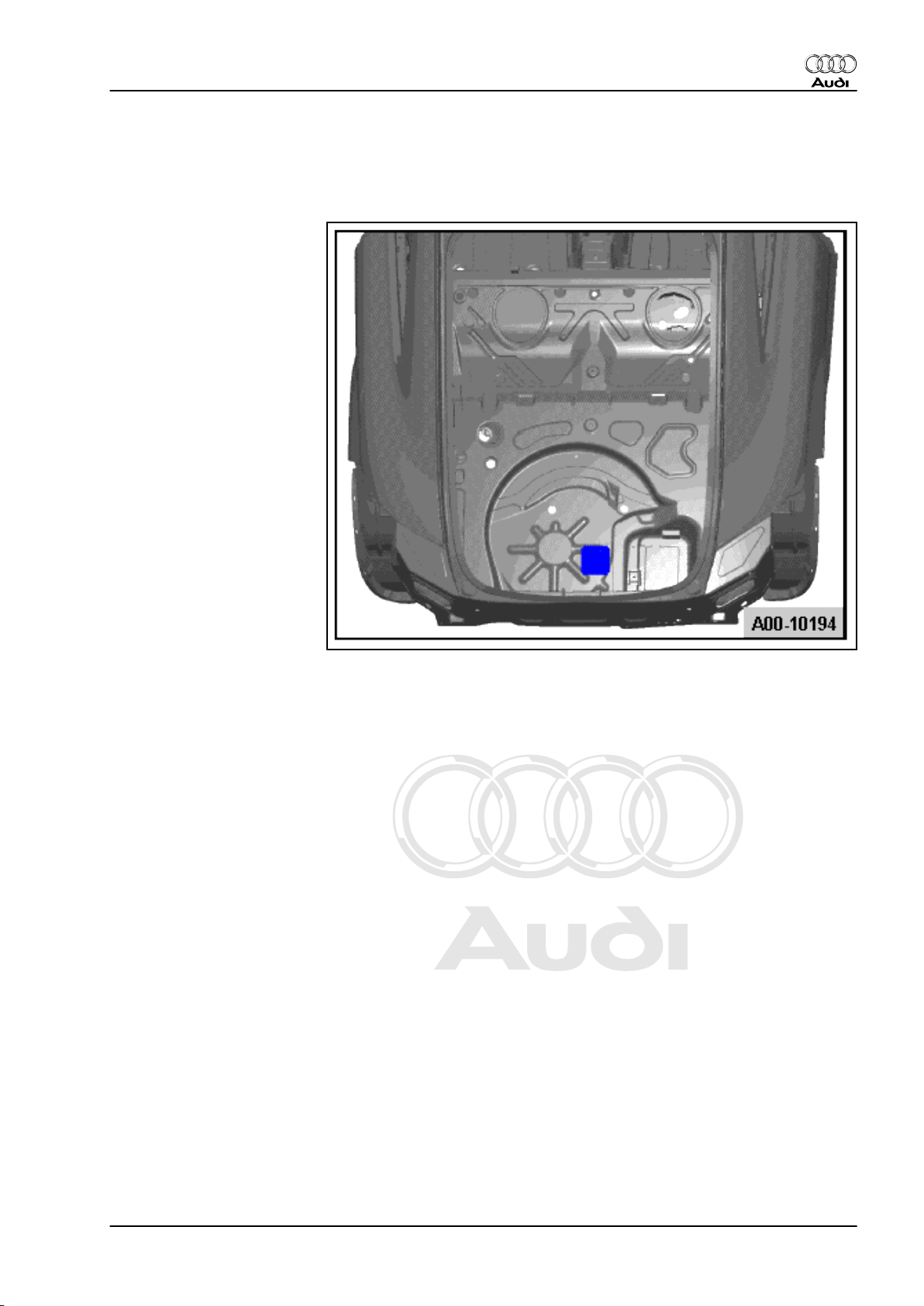

2.2 Vehicle data sticker

The vehicle data sticker is located in the spare wheel well at the

rear of the vehicle.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

2. Vehicle identification data 3

Page 10

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

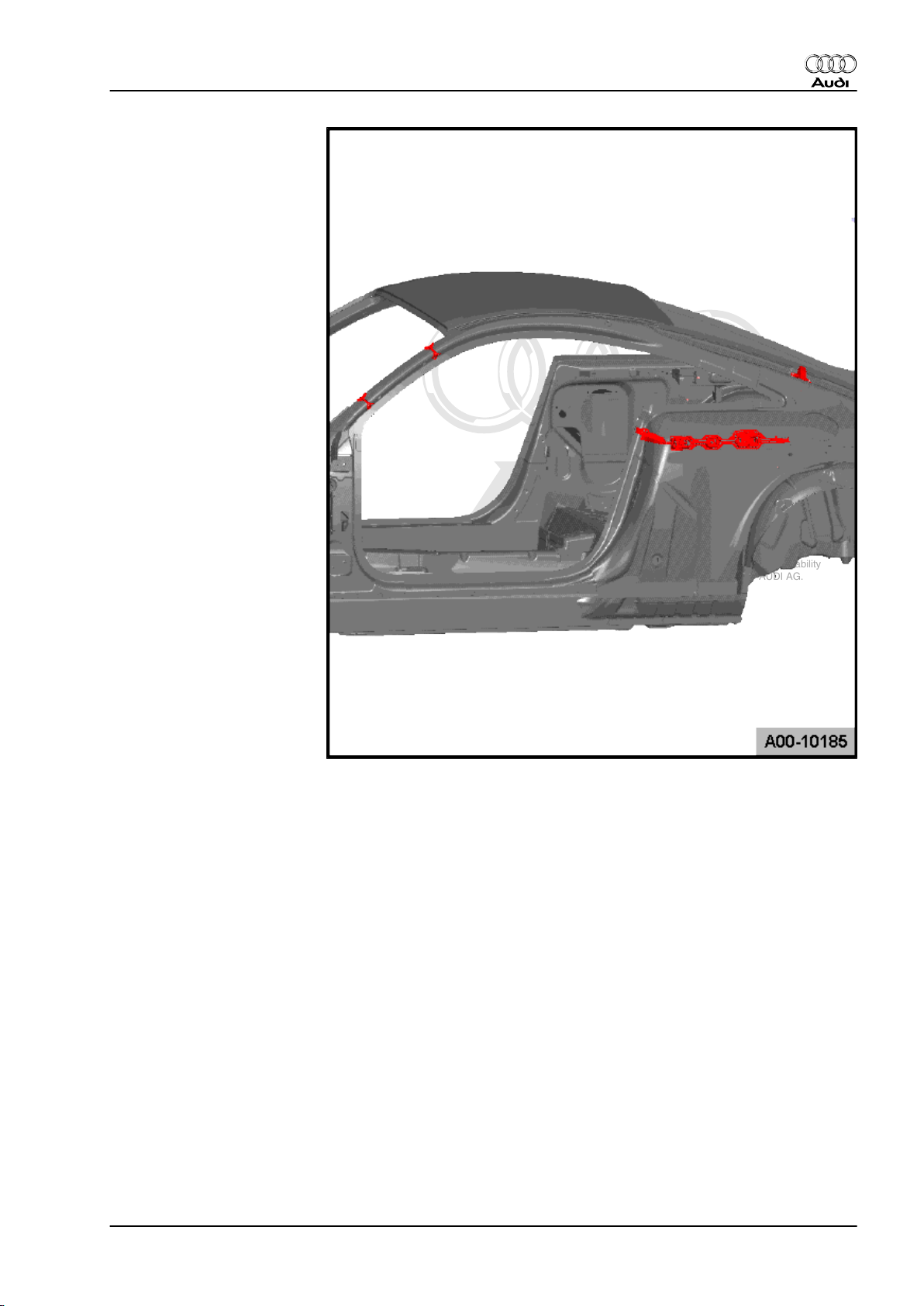

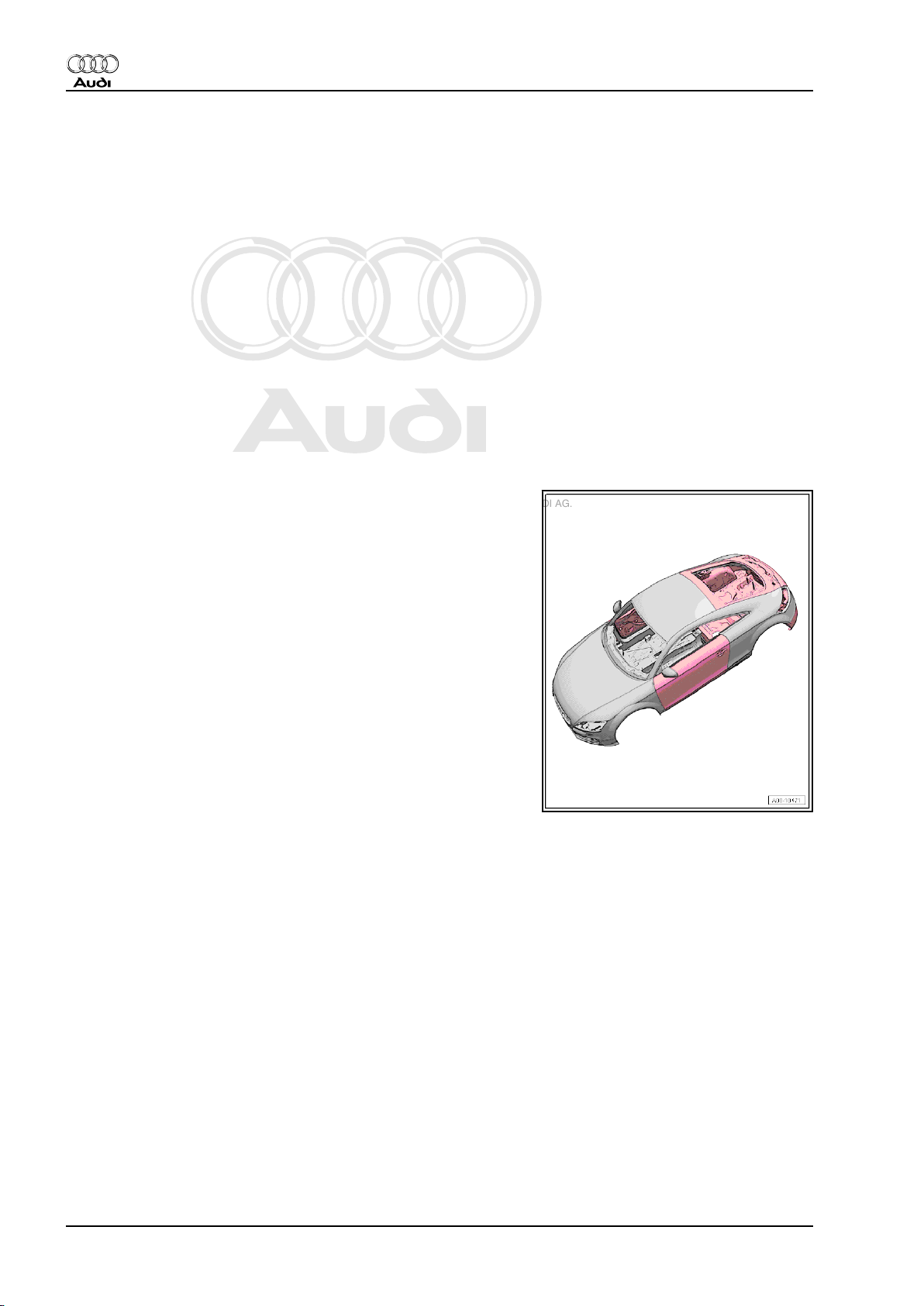

3 Expanded foam inserts

Various body cavities of the Audi TT 2007 are fitted with expanded

foam inserts.

The foam inserts reduce the noise transmitted to the interior when

driving.

These pre-moulded parts are fitted during body manufacture and

subsequently increase their volume in the paint shop drying oven

at approx. 180 °C after priming.

Caution

The replacement foam inserts expand only after reaching

about 180°C. For this reason, an additional filler foam is used

when performing repairs.

Filler foam required for repairs: D 506 KG1 A3.

As the required temperatures cannot be achieved under normal

workshop conditions, proceed as follows:

Remove residue of foam material on vehicle.

Restore paint coating; apply two coats (wet on wet) of glass/paint

primer D 009 200 02 if necessary, flash-off time approx.10 mi‐

nutes.

Requirement

Before continuing with this procedure, ensure that the replace‐

ment panel is ready for installation, i.e. cut to shape, matched up

to the vehicle, corrosion protection applied.

Renewing expanded foam insert

Fix expanded foam insert to vehicle.

Apply filler foam D 506 KG1 A3 to replacement panel.

Secure new part in position. Gently press in new part in vicinity of

expanded foam insert until it makes contact, and then weld into

place.

The foam hardens within 25 minutes.

Do not weld (SG) within 15 mm of the foam insert (on either side).

After painting the vehicle the repaired area must be cavity-sealed.

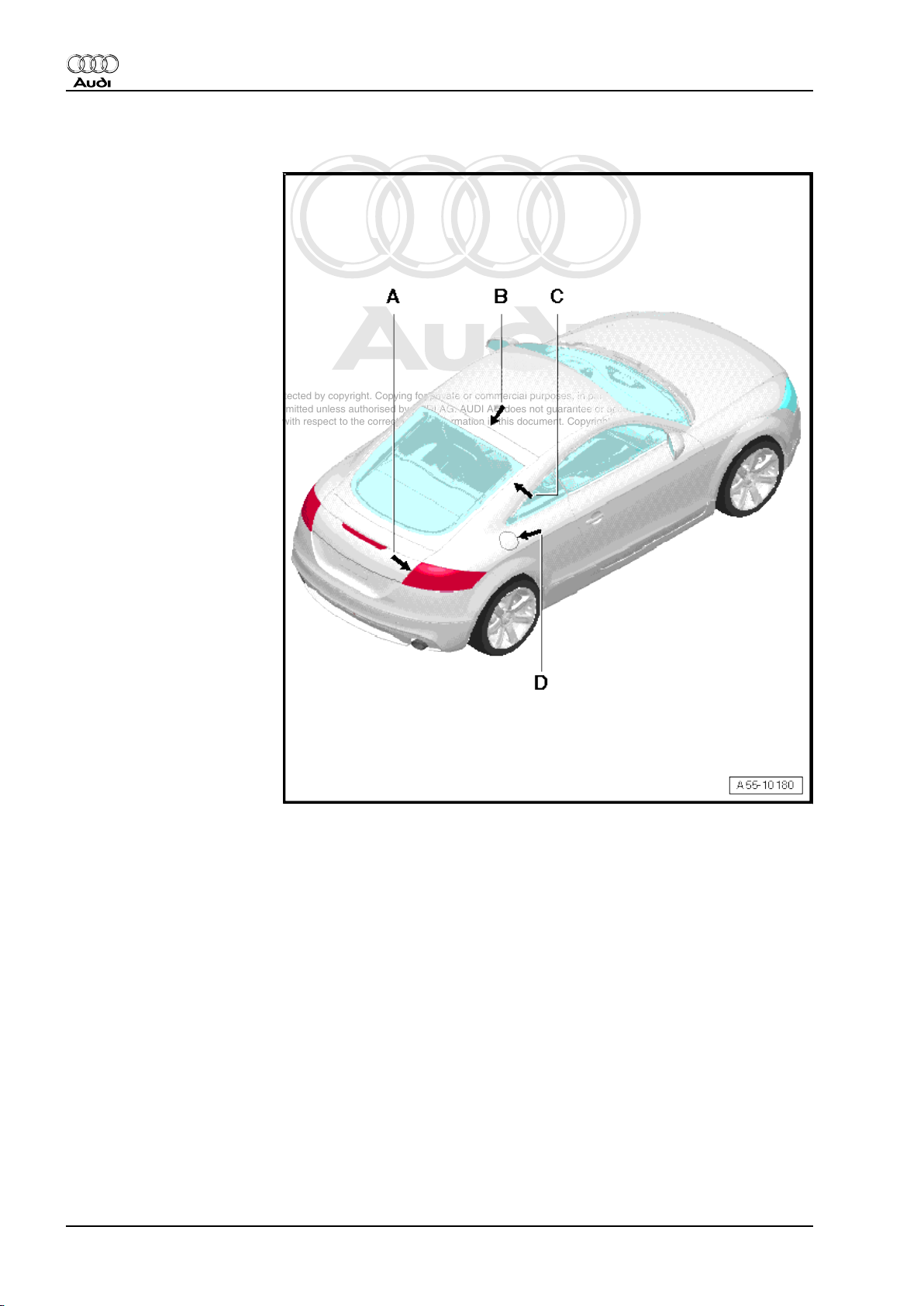

Location of expanded foam parts

4 Rep. Gr.00 - Technical data

Page 11

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

3. Expanded foam inserts 5

Page 12

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

4 General notes on repairs to alumini‐

um parts

The repair methods required for the purely aluminium body parts

are similar to the established procedures for the other Audi mod‐

els with aluminium body.

New joining technique

Flow-drill screws

Flow-drill screws can be easily released in the workshop and re‐

placed with new screws. Oversize screws are available for dam‐

aged threads. New panels have to be pre-drilled to take these

screws.

6 Rep. Gr.00 - Technical data

Page 13

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

5 General notes on repairs to steel

parts

Note

We recommend that repairs should be performed in a specialist

Audi workshop for aluminium.

These repairs are essentially the same as for vehicles with an allsteel body. However, special precautions are required due to the

risk of contact corrosion occurring on the aluminium parts of the

body. The dust produced when sanding or grinding steel parts,

and in particular sparks from cutting and welding operations, must

not be allowed to drop onto aluminium parts. This also applies to

painted aluminium panels. The glowing steel particles can dam‐

age the paint and come into contact with the aluminium, which

can cause contact corrosion on the undamaged aluminium body.

For these reasons, the entire body must be carefully protected

with suitable covers and masking while steel repairs are being

performed. Similarly, cutting operations may only be carried out

with mechanical tools (body saw or nibbler). Where sanding or

grinding is unavoidable, use non-sparking sanding/grinding discs

(or such that produce only a minimum amount of sparking).

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

5. General notes on repairs to steel parts 7

Page 14

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

6 Body construction

The Audi TT 2007 employs the ASF (Audi Space Frame) con‐

struction in an aluminium/steel body.

The repair methods are basically the same as the familiar alumi‐

nium repair methods, except that the combination of aluminium

and steel requires a number of new procedures.

This Workshop Manual describes standard repairs and repairs

carried out using repair methods which deviate from the original

manufacturing process.

Note the following for any repairs which are not described:

Separate at original joint; repair original joint using only genuine

replacement parts: see ⇒ General information; Body repairs,

General body repairs; Safety notes .

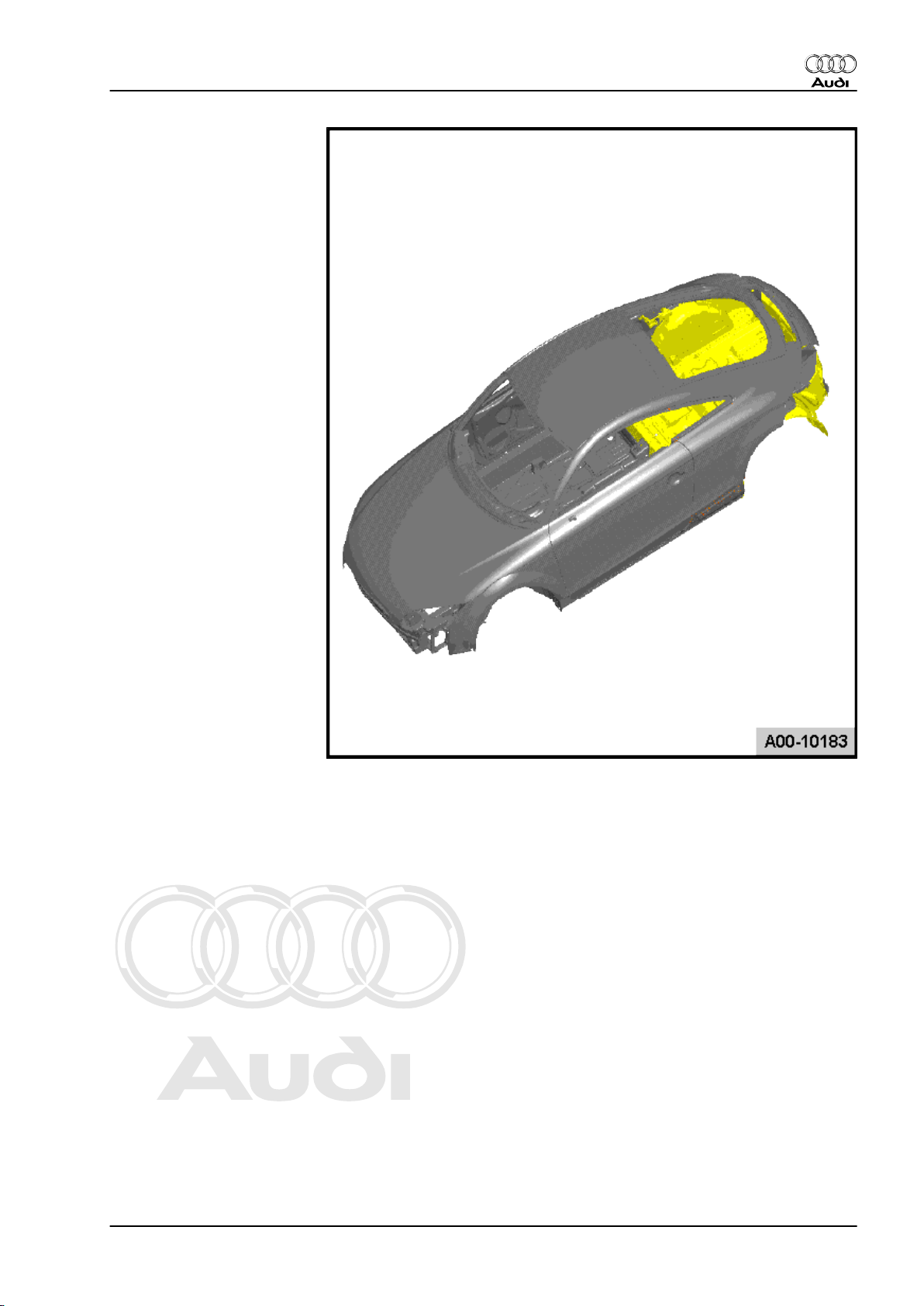

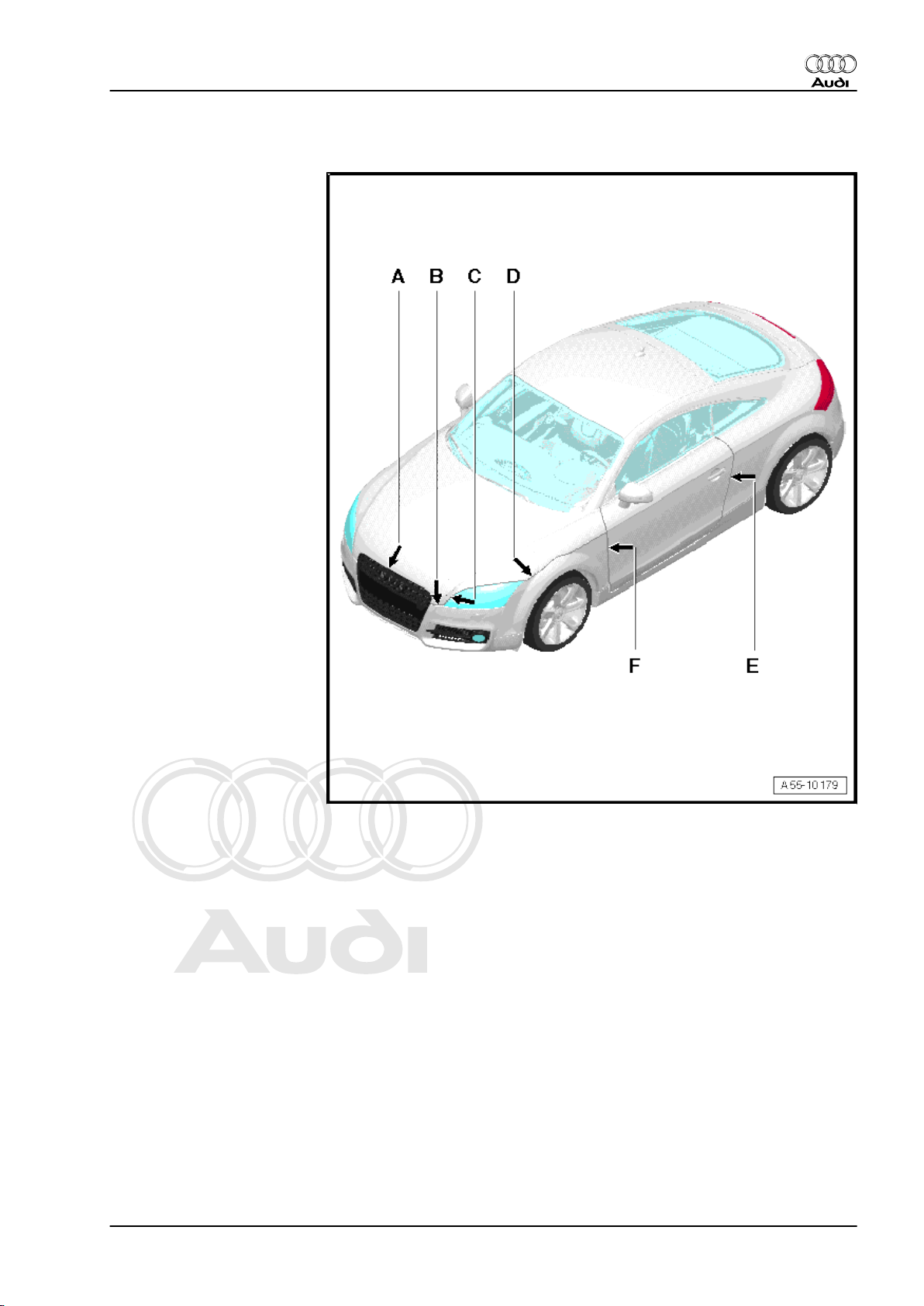

6.1 Aluminium panels

The areas of the body marked in grey - bonnet, plenum chamber,

front end and middle section - are made of aluminium.

⇒ Workshop Manual, General information; chapter on Work pro‐

cedures

Extra-high-strength body panels

Extra-high-strength body panels are used in the following areas:

The steel panels marked in yellow have a tensile strength of 340

– 500 N/mm2.

⇒ Workshop Manual, General information; chapter on Work pro‐

cedures

8 Rep. Gr.00 - Technical data

Page 15

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

6. Body construction 9

Page 16

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

7 Corrosion protection

The rear section of the body is manufactured from panels galvan‐

ised on both sides. Certain areas are cavity-sealed and have to

be re-sealed after completing repair work.

10 Rep. Gr.00 - Technical data

Page 17

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

8 Bonded joints

Bonded and spot-welded bonded joints are employed on the Audi

TT for increased body strength.

8.1 Bonded joints

In the case of adhesive-bonded joints, the joint between the sheet

metal parts is formed only by the adhesive.

8.2 Spot-welded/bonded joints

In spot welded bonded joints an electrically conductive adhesive

is used between the panels, which allows good root penetration

for spot welding.

The welding current must not be increased for spot-weld bonding

operations. The pre-press period must be extended to about 30

– 50 cycles because of the displacement of the adhesive. Always

use a fume extractor.

Spot-weld bonding is not carried out in the service sector.

8.3 Inspecting and repairing bonded joints

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

Particular attention should be given to these joints when diag‐

nosing accident damage and performing body repairs.

Note the following points: Do not use a chisel to test the strength

of a joint or relieve stresses by hammering as this will damage or

destroy the bonded joint.

These joints should be inspected particularly closely when diag‐

nosing accident damage and after performing straightening work

on the body.

If the joint is not accessible with pop rivets, it must be repaired

with an arc-welded seam (SG). In this case the entire area of the

joint must be re-welded, as the heat produced by welding de‐

stroys the adhesive in the bonded joint. The SG seams should be

welded working from the thin to the thick panel. Always use a fume

extractor.

8.4 Repair methods for replacing body parts

When making repairs, welded joints can be used in place of all

spot-welded bonded joints and certain bonded joints if no suitable

body adhesive is available.

Do not make the repair with only the same spot welds or seams

as originally used in production. These alone are not adequate

for a proper joint.

The repair methods are shown in detail on the following pages.

Note

♦

If the instructions call for additional spot welds, these should

be applied in a single operation.

♦

Do not place new spot welds in-between the original spot

welds.

♦

SG plug welding should only be performed after spot welding.

♦

This avoids any increased shunt current when spot welding.

Ensure good root penetration at all joints.

Seal off repaired joint flanges and apply cavity sealing.

8. Bonded joints 11

Page 18

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

9 Body panel gaps/shut lines

Special tools and workshop equipment required

♦ Setting gauge -3371-

9.1 Body - front and centre

♦ Dimension A = 4.5 mm ± 0.5 mm

♦ Dimension B = 4.5 mm ± 0.5 mm

♦ Dimension C = 3.5 mm ± 0.5 mm

♦ Dimension D = 3.5 mm ± 0.5 mm

♦ Dimension E = 3.5 mm ± 0.5 mm

♦ Dimension F = 3.5 mm ± 0.5 mm

12 Rep. Gr.00 - Technical data

Page 19

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

♦ Check that panel gaps are parallel with body lines

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

9.1.1 Body - rear

♦ Dimension A = 4.0 mm ± 0.5 mm

♦ Dimension B = 4.5 mm ± 0.5 mm

♦ Dimension C = 3.5 mm ± 0.5 mm

♦ Dimension D = 2.0 mm ± 0.5 mm

9. Body panel gaps/shut lines 13

Page 20

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

♦ Check that panel gaps are parallel with body lines

14 Rep. Gr.00 - Technical data

Page 21

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

10 Body dimensions

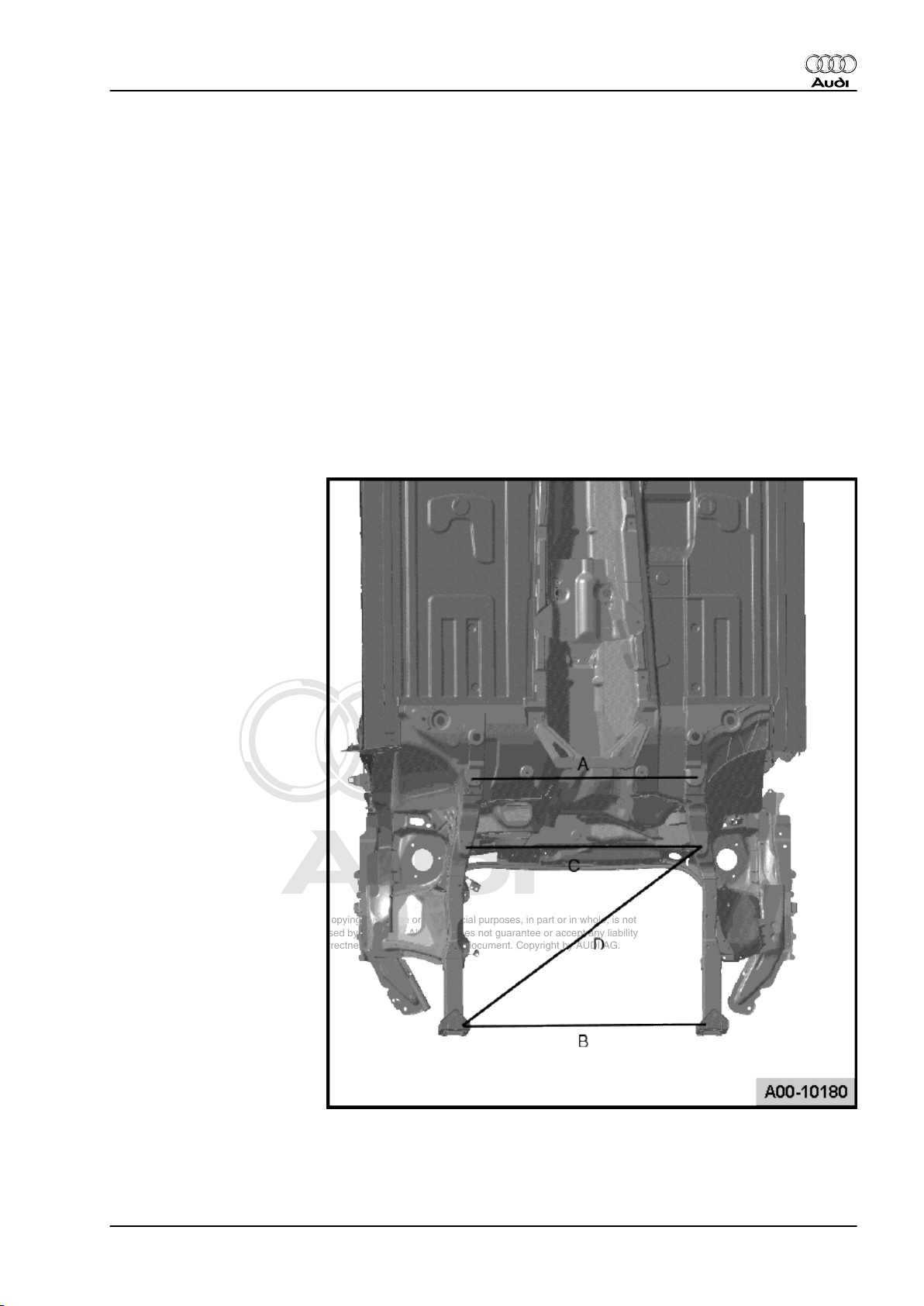

10.1 Floor group, front

Distance between rear attachment points of front suspension

-a- 836 ± 2 mm

Distance between front longitudinal members (front)

-b- 899 ± 2 mm

Distance between front attachment points of front suspension

-c- 873 ± 2 mm

Diagonal distance between front longitudinal member and attach‐

ment points of front suspension

-d- 1084 ± 2 mm

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

10. Body dimensions 15

Page 22

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

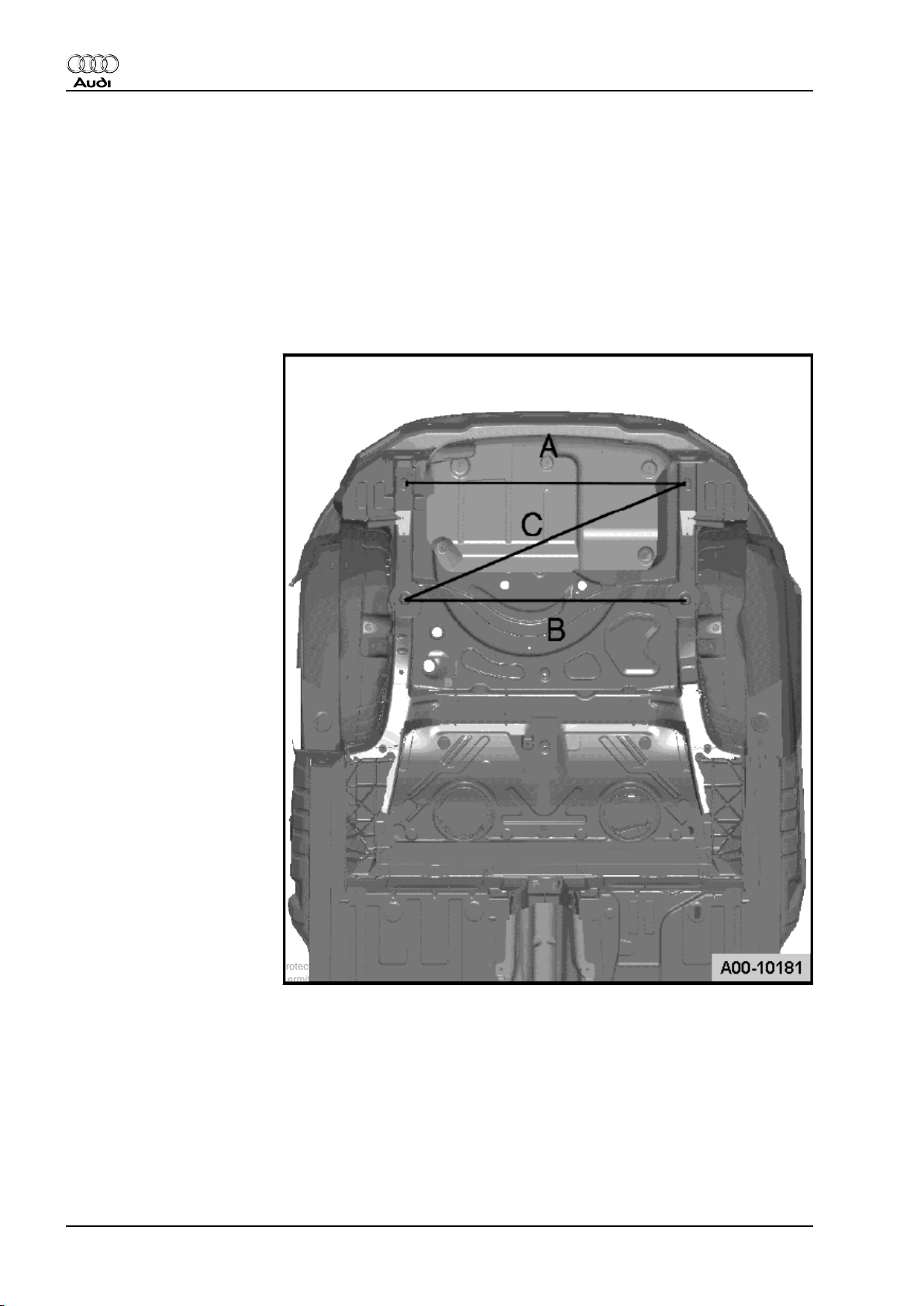

10.2 Floor group, rear

Distance between rear longitudinal members (rear)

-a- 978 ± 2 mm

Distance between rear longitudinal members (front)

-b- 980 ± 2 mm

Diagonal distance between longitudinal member (front) and lon‐

gitudinal member (rear)

-c- 1049 ± 2 mm

16 Rep. Gr.00 - Technical data

Page 23

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

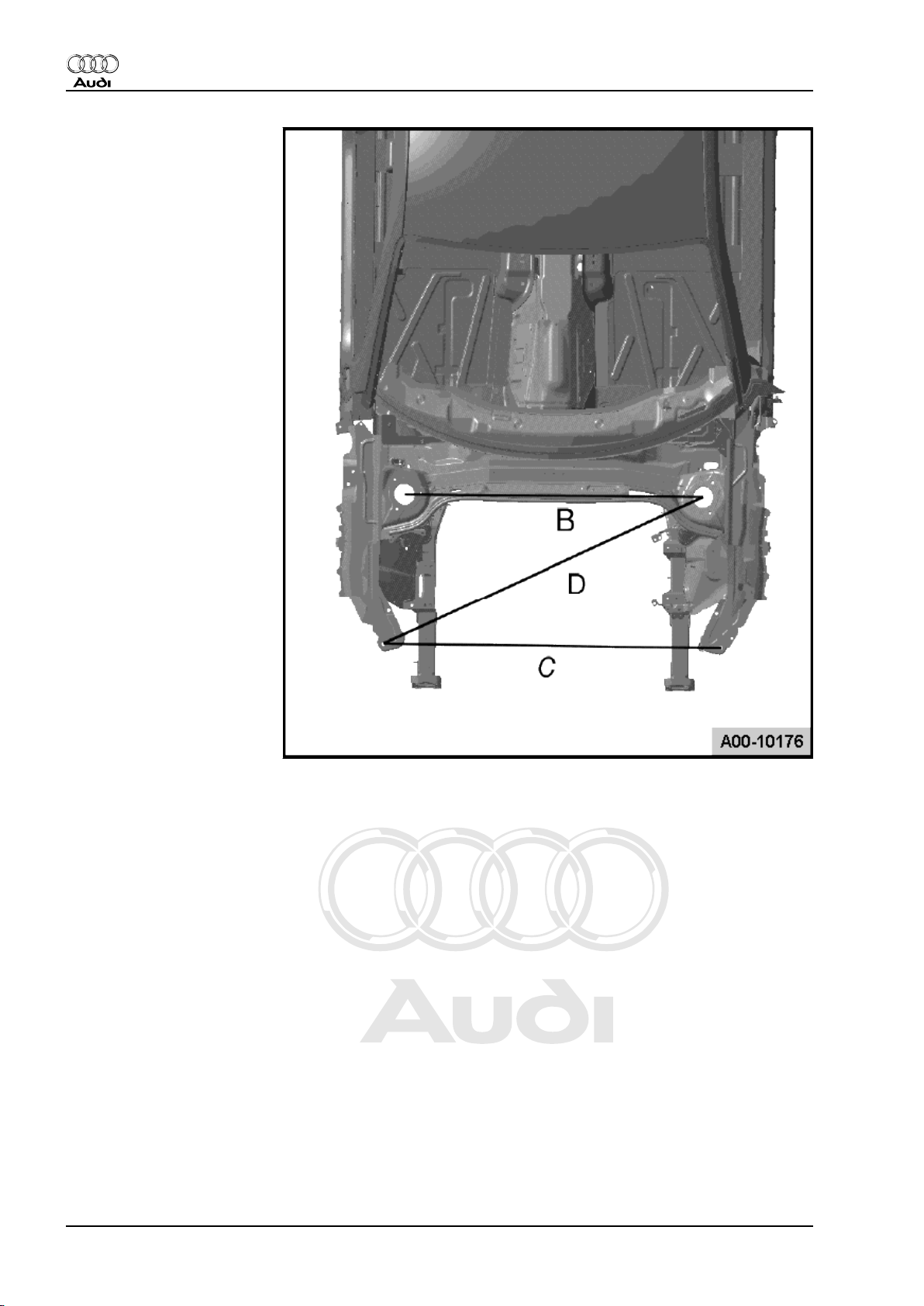

10.3 Body - front

Distance between front longitudinal members

-a- 1018 ± 2 mm

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

Distance between suspension strut mountings

-b- 1129 ± 2 mm

Distance between wing panel mountings

-c- 1271 ± 2 mm

Diagonal distance between suspension strut mounting and wing

panel mounting

-d- 1317 ± 2 mm

10. Body dimensions 17

Page 24

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

18 Rep. Gr.00 - Technical data

Page 25

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

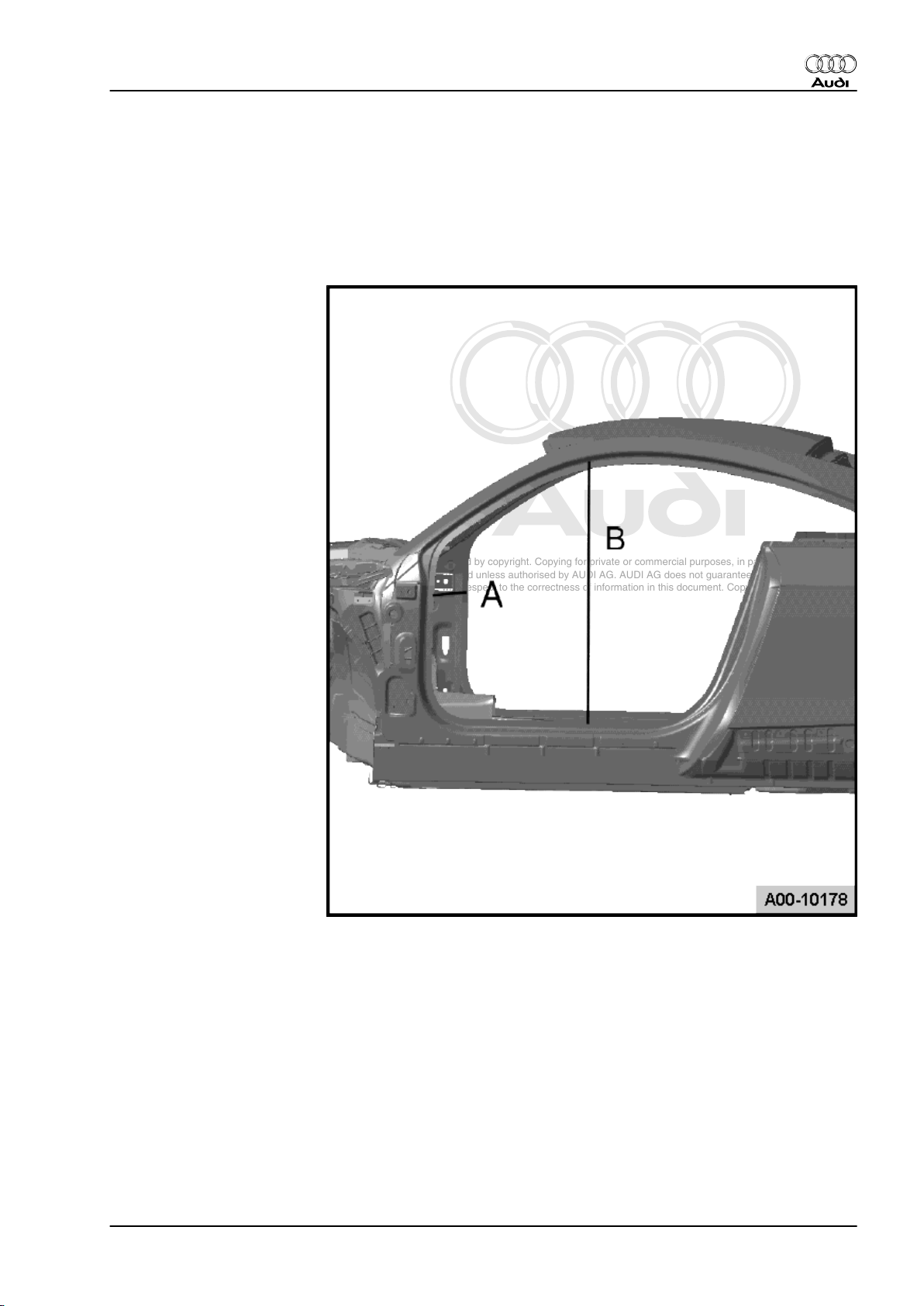

10.4 Body - centre

Distance between A-pillars

-a- 1534 ± 2 mm

Height of door opening

-b- 935 ± 2 mm

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

10. Body dimensions 19

Page 26

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

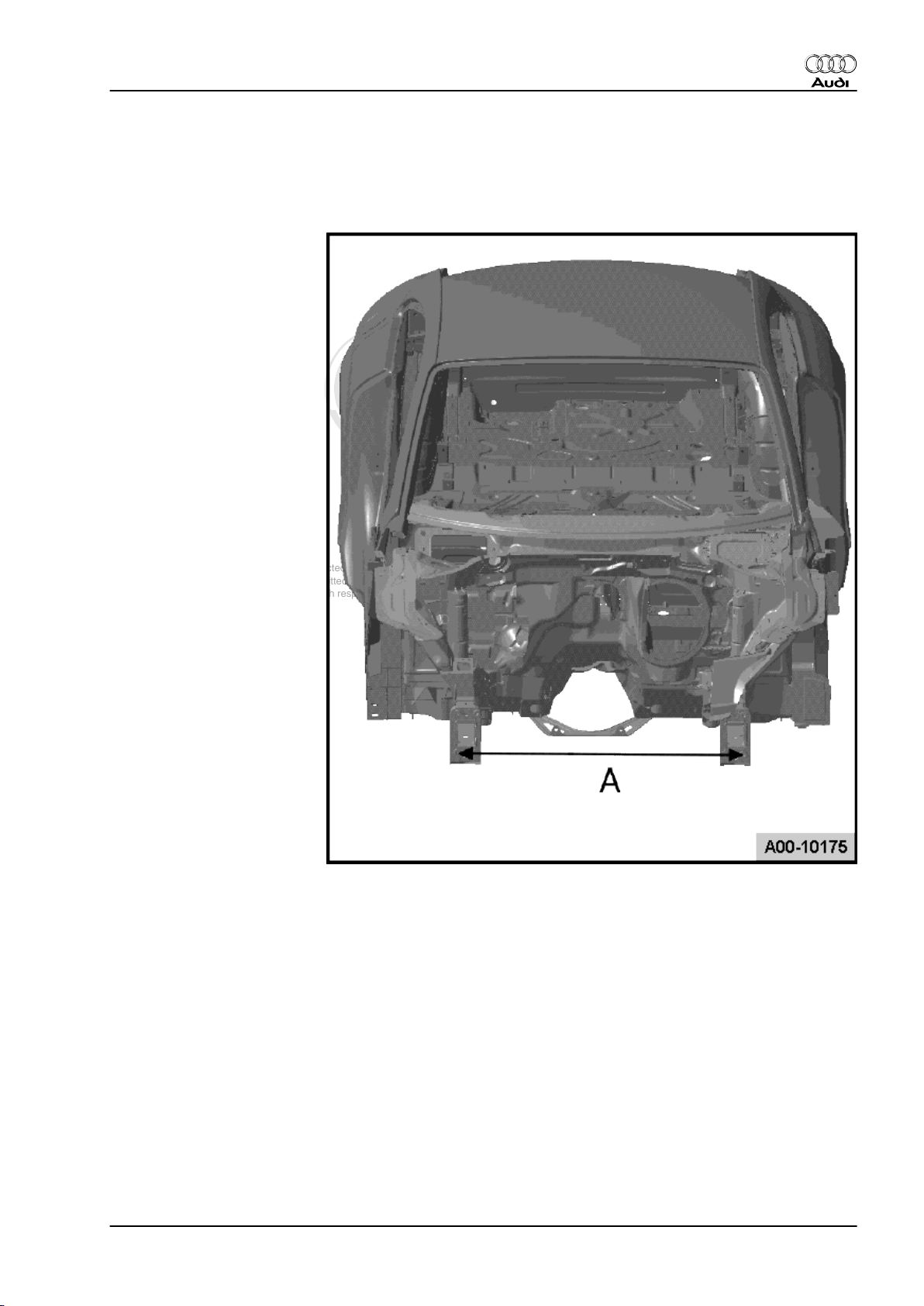

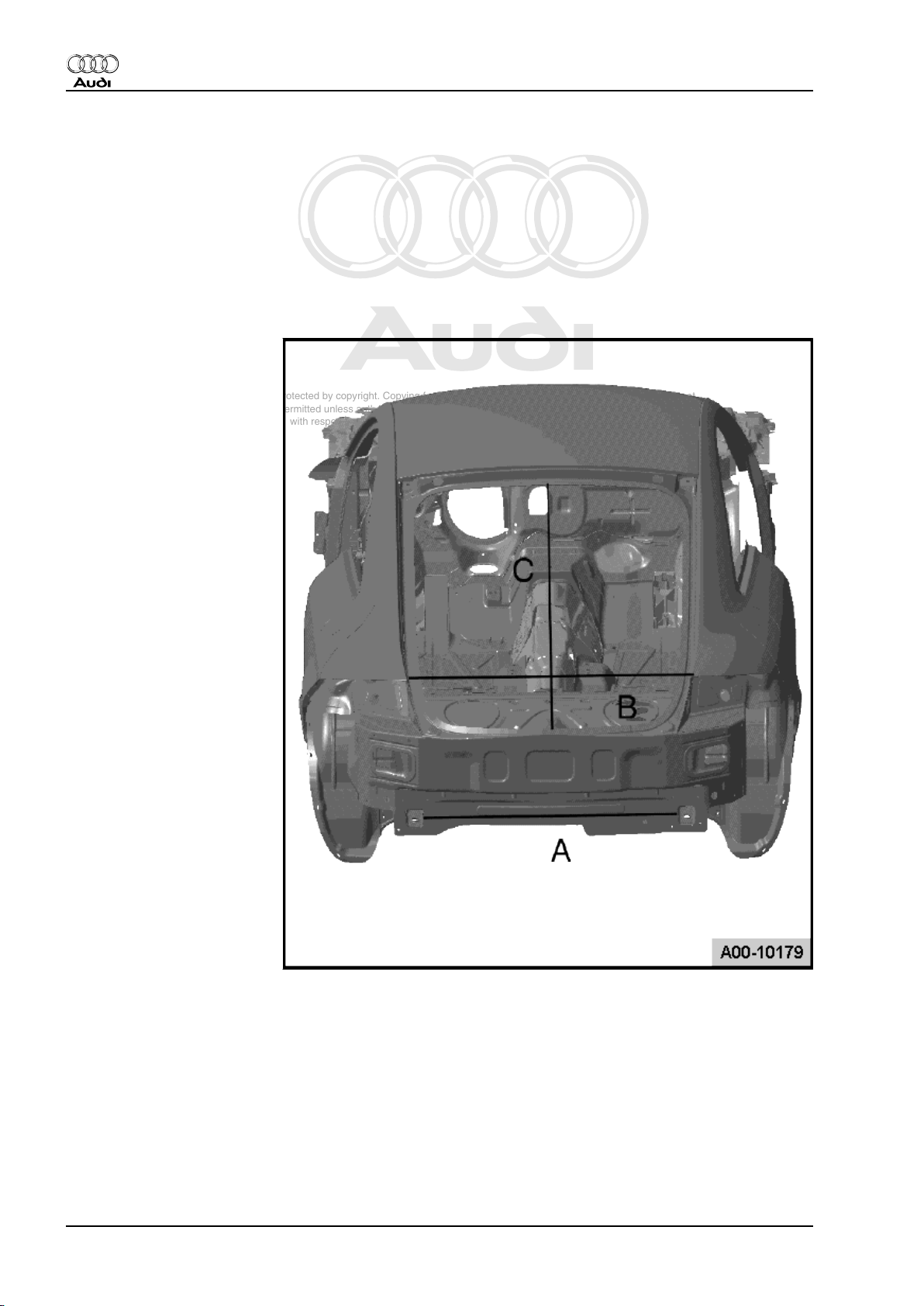

10.5 Body - rear

Distance between rear longitudinal members

-a- 1044 ± 2 mm

Distance between side panels

-b- 913 ± 2 mm

Distance between rear cross panel flange and roof flange

-c- 1269 ± 2 mm

20 Rep. Gr.00 - Technical data

Page 27

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

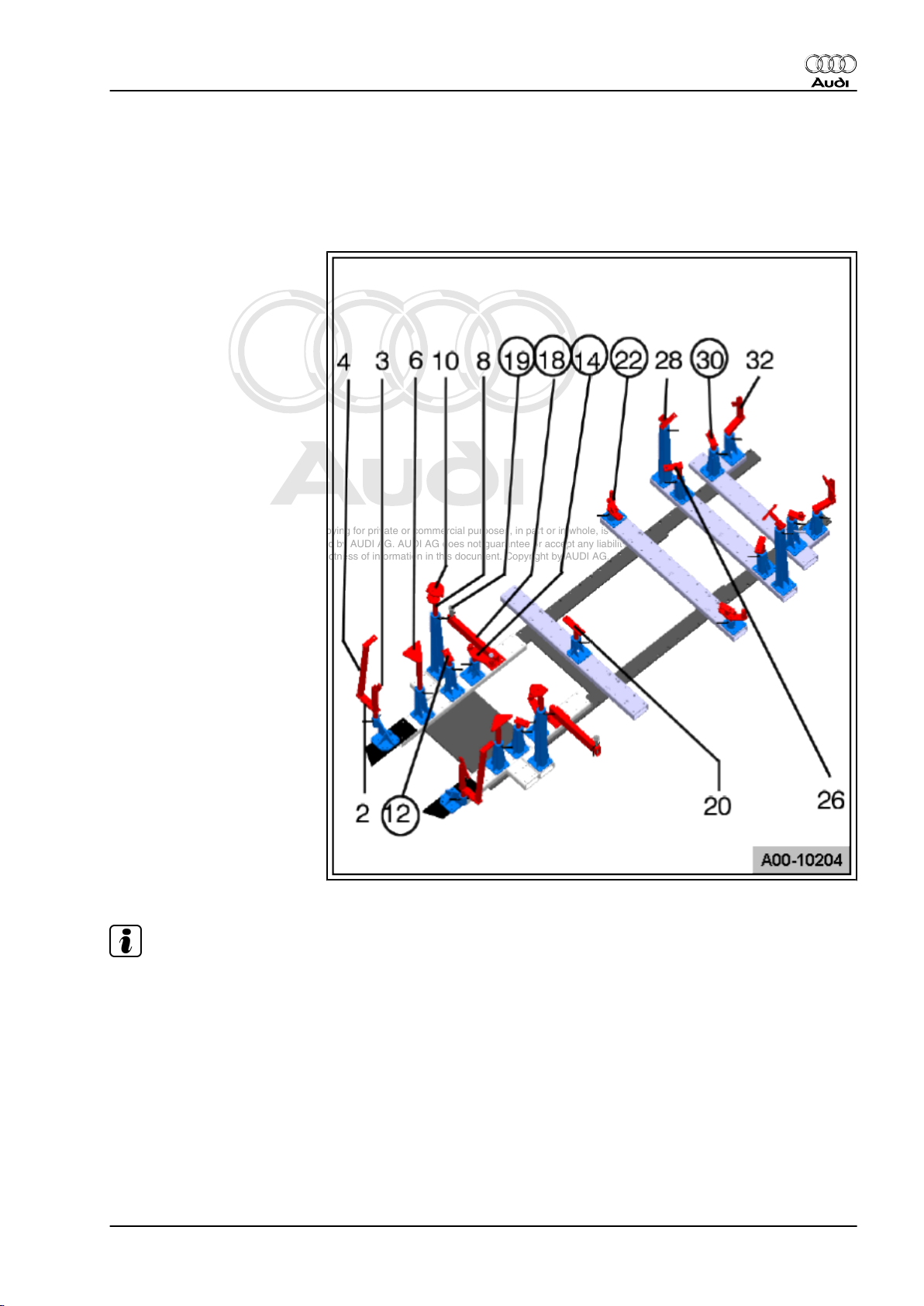

11 Straightening jig

11.1 Overview

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

Note

♦

The item numbers in the illustrations are identical with the end

numbers on the alignment bracket mountings.

♦

The item numbers of the alignment bracket mountings marked

with a circle are for checking the body with mechanical units

installed.

♦

Check the clearance of the alignment brackets before placing

them on the straightening jig. Any obstructing components

should be detached or removed.

♦

The required basic set size is given for the alignment bracket

mountings.

Alignment bracket set Audi TT -VAS 6384-

11. Straightening jig 21

Page 28

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

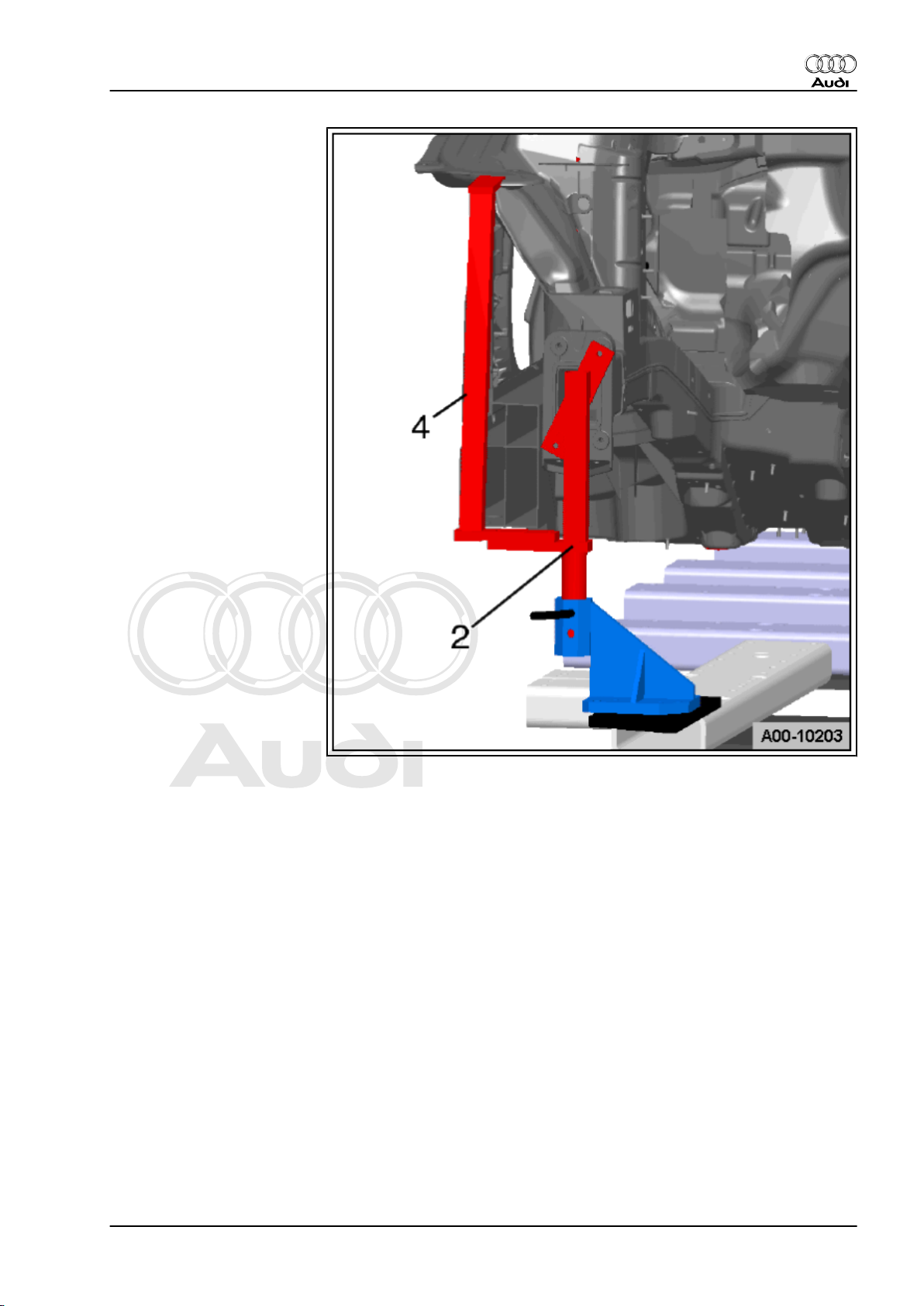

2 - MZ 142 and TV 400

3 - Spacer

4 - MZ 142 and alignment bracket mounting

6 - MZ 260

8 - MZ 602

10 - Spacer

12 - MZ 260

14 - MZ 140

16 - Left and right centring piece identical

18 - Bracket without MZ and alignment bracket

20 - MZ 140

22 - MZ 080

24 - MZ 080 and 22

25 - Spacer

26 - MZ 200

28 - MZ 602

30 - MZ 260

32 - MZ 200

Overview of alignment bracket positions with MZ elements for

vehicles with mechanical units installed

Overview of front alignment brackets

22 Rep. Gr.00 - Technical data

Page 29

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

2 - Front longitudinal member

When checking, bolt on MZ last, as the longitudinal position of the

impact absorber mounting can vary by several mm due to pro‐

duction tolerances - if necessary do not bolt down.

3 - Front longitudinal member / top of wheel housing

Overview of front alignment brackets

6 - Engine carrier mounting

7 - Engine carrier mounting

11. Straightening jig 23

Page 30

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

Overview of front alignment brackets

24 Rep. Gr.00 - Technical data

Page 31

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

6 - Gearbox console

11. Straightening jig 25

Page 32

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

7 - Engine console

Overview of front alignment brackets

26 Rep. Gr.00 - Technical data

Page 33

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

11. Straightening jig 27

Page 34

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

8 - Suspension strut mounting

12 - Mounting for subframe

18 - Mounting for side member

Overview of centre alignment brackets

28 Rep. Gr.00 - Technical data

Page 35

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

11. Straightening jig 29

Page 36

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

18 - Mounting for side member

19 - Spacer, identical on left and right sides

30 Rep. Gr.00 - Technical data

Page 37

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

20 - Mounting for propshaft

11. Straightening jig 31

Page 38

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

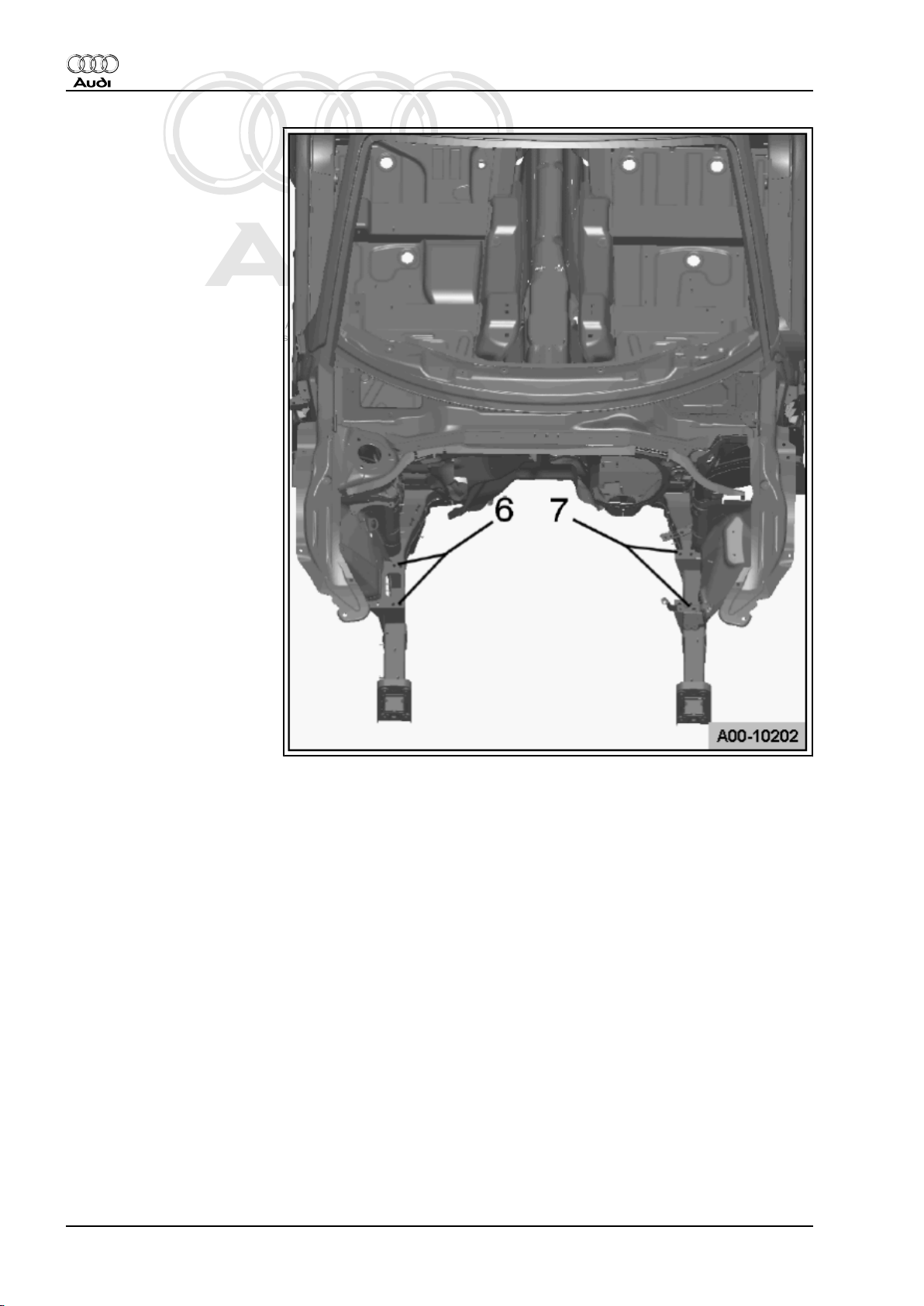

22 -24 - Rear suspension strut mounting

Overview of rear alignment brackets

32 Rep. Gr.00 - Technical data

Page 39

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

11. Straightening jig 33

Page 40

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

22 - Mounting for rear axle

24 - Spacer, identical on left and right sides

– Line up with holes as shown.

26 - Drilling in longitudinal member

28 - Suspension strut mounting

30 - Drilling in longitudinal member

32 - Mounting for rear longitudinal member

11.2 Portal gauge

Portal gauge supplement Audi TT/TT Roadster -VAS 5007/30-

34 Rep. Gr.00 - Technical data

Page 41

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

A - Extension

B - Telescopic column

C - Cross bar 1200 mm

1 - Mounting for A-pillar

5 - Mounting for B-pillar

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

11. Straightening jig 35

Page 42

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

50 – Body - front

RO: 50 40 55 00

1 Longitudinal member, upper part with

console (Coupé and Roadster identi‐

cal)

WARNING

Always observe safety precautions.

Safety notes ⇒ General Information; Body Repairs, General Body

Repairs ; Safety notes .

1.1 Tools

Special tools and workshop equipment required

♦ Compact angle grinder -VAS 5167-

♦ Pneumatic glue gun -V.A.G 2005 B-

♦ Shielded arc welding equipment 250A -VAS 6388-

36 Rep. Gr.50 - Body - front

Page 43

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

♦ Rechargeable riveter -VAS 5279A-

1.2 Procedure

Cutting locations

• Longitudinal member (bottom section) already removed

Engine console

– Separate original joint with rechargeable riveter -VAS 5279B- .

– Remove large punch rivets. Use rechargeable riveter -VAS

5279A- with attachments D13 and D14 from -VAS 5279/2 - or

rechargeable riveter -VAS 5279B- with attachments D13 and

D14 .

– Remove small punch rivets. Use rechargeable riveter -VAS

5279A- with attachments S1 and E2 from -VAS 5279/2 - or

rechargeable riveter -VAS 5279B- with attachments S1 and

E2 .

– Remove remaining material using compact angle grinder -

VAS 5167- .

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

1. Longitudinal member, upper part with console (Coupé and Roadster identical) 37

Page 44

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

Replacement part

♦ Engine console

♦ Body adhesive DA 001 730 A2

Preparing new part

– Prepare flanges on body and new parts for welding.

Welding in

– Fix new part in position with alignment bracket.

– Weld in engine console using shielded arc welding equipment

250A -VAS 6388- : SG continuous seam.

– Rivet in new part using rechargeable riveter -VAS 5279B- .

Countersink holes, working inwards from outside. Use recharge‐

able riveter -VAS 5279A- with attachments D15 and D16 from VAS 5279/2 - or rechargeable riveter -VAS 5279B- with

attachments D15 and D16 .

38 Rep. Gr.50 - Body - front

Page 45

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

– Weld in engine console using shielded arc welding equipment

250A -VAS 6388- : SG continuous seam.

1. Longitudinal member, upper part with console (Coupé and Roadster identical) 39

Page 46

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

Gearbox console

– Separate original joint with rechargeable riveter -VAS 5279B- .

40 Rep. Gr.50 - Body - front

Page 47

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

Replacement part

♦ Gearbox console

♦ Body adhesive DA 001 730 A2

Preparing new part

– Prepare flanges on body and new parts for welding.

Welding in

– Fix new part in position with alignment bracket.

– Weld in gearbox console using shielded arc welding equip‐

ment 250A -VAS 6388- : SG continuous seam.

1. Longitudinal member, upper part with console (Coupé and Roadster identical) 41

Page 48

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

42 Rep. Gr.50 - Body - front

Page 49

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

RO: 50 22 55 50

2 Support, left-side - Renewal (Coupé

and Roadster identical)

WARNING

Always observe safety precautions.

Safety notes ⇒ General Information; Body Repairs, General Body

Repairs ; Safety notes .

2.1 Tools

Special tools and workshop equipment required

♦ Compact angle grinder -VAS 5167-

♦ Pneumatic glue gun -V.A.G 2005 B-

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

♦ Shielded arc welding equipment 250A -VAS 6388-

♦ Rechargeable riveter -VAS 5279A-

2. Support, left-side - Renewal (Coupé and Roadster identical) 43

Page 50

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

2.2 Procedure

Cutting locations

– Separate original joint with rechargeable riveter -VAS 5279A- .

– Remove large punch rivets. Use rechargeable riveter -VAS

5279A- with attachments D13 and D14 from -VAS 5279/2 - or

rechargeable riveter -VAS 5279B- with attachments D13 and

D14 .

– Remove small punch rivets. Use rechargeable riveter -VAS

5279A- with attachments S1 and E2 from -VAS 5279/2 - or

rechargeable riveter -VAS 5279B- with attachments S1 and

E2 .

– Remove remaining material using compact angle grinder -

VAS 5167- .

Replacement parts

♦ Punch rivet

♦ Support

♦ Body adhesive DA 001 730 A2

44 Rep. Gr.50 - Body - front

Page 51

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Preparing new part

– Prepare flanges on body and new parts for welding.

Riveting in

– Rivet in support using rechargeable riveter -VAS 5279A- .

Countersink holes, working inwards from outside. Use recharge‐

able riveter -VAS 5279A- with attachments D15 and D16 from VAS 5279/2 - or rechargeable riveter -VAS 5279B- with

attachments D15 and D16 .

– Weld in support using shielded arc welding equipment 250A -

VAS 6388- : SG continuous seam.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

2. Support, left-side - Renewal (Coupé and Roadster identical) 45

Page 52

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

RO: 50 22 55 50

3 Support, right-side - Renewal (Coupé

and Roadster identical)

WARNING

Always observe safety precautions.

Safety notes ⇒ General Information; Body Repairs, General Body

Repairs ; Safety notes .

3.1 Tools

Special tools and workshop equipment required

♦ Compact angle grinder -VAS 5167-

♦ Pneumatic glue gun -V.A.G 2005 B-

♦ Shielded arc welding equipment 250A -VAS 6388-

♦ Rechargeable riveter -VAS 5279A-

46 Rep. Gr.50 - Body - front

Page 53

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

♦ Pneumatic sabre saw -V.A.G 1523A-

3.2 Procedure

Cutting locations

Note

Partial renewal is possible with the separating cut shown. Place

a backing plate of the same material behind the joint and make

SG continuous seam.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

– Separate original joint with rechargeable riveter -VAS 5279A- .

– Remove large punch rivets. Use rechargeable riveter -VAS

5279A- with attachments D13 and D14 from -VAS 5279/2 - or

rechargeable riveter -VAS 5279B- with attachments D13 and

D14 .

– Remove small punch rivets. Use rechargeable riveter -VAS

5279A- with attachments S1 and E2 from -VAS 5279/2 - or

rechargeable riveter -VAS 5279B- with attachments S1 and

E2 .

– Remove remaining material using compact angle grinder -

VAS 5167- .

3. Support, right-side - Renewal (Coupé and Roadster identical) 47

Page 54

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

Replacement parts

♦ Punch rivet

♦ Support

♦ Body adhesive DA 001 730 A2

Preparing new part

– Prepare flanges on body and new parts for welding.

Riveting in

– Rivet in support using rechargeable riveter -VAS 5279A- .

– Weld in support using shielded arc welding equipment 250A -

VAS 6388- : SG continuous seam.

Countersink holes, working inwards from outside. Use recharge‐

able riveter -VAS 5279A- with attachments D15 and D16 from VAS 5279/2 - or rechargeable riveter -VAS 5279B- with

attachments D15 and D16 .

48 Rep. Gr.50 - Body - front

Page 55

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

3. Support, right-side - Renewal (Coupé and Roadster identical) 49

Page 56

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

RO: 50 72 55 00

4 Upper longitudinal member for wheel

housing - Renewal (Coupé and

Roadster identical)

WARNING

Always observe safety precautions.

Safety notes ⇒ General Information; Body Repairs, General Body

Repairs ; Safety notes .

4.1 Tools

Special tools and workshop equipment required

♦ Compact angle grinder -VAS 5167-

♦ Pneumatic glue gun -V.A.G 2005 B-

♦ Shielded arc welding equipment 250A -VAS 6388-

♦ Rechargeable riveter -VAS 5279A-

50 Rep. Gr.50 - Body - front

Page 57

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

♦ Pneumatic sabre saw -V.A.G 1523A-

4.2 Procedure

Cutting locations

– Roughly cut out part using pneumatic sabre saw -V.A.G

1523A- .

– Separate original joint with rechargeable riveter -VAS 5279A- .

– Remove large punch rivets. Use rechargeable riveter -VAS

5279A- with attachments D13 and D14 from -VAS 5279/2 - or

rechargeable riveter -VAS 5279B- with attachments D13 and

D14 .

– Remove small punch rivets. Use rechargeable riveter -VAS

5279A- with attachments S1 and E2 from -VAS 5279/2 - or

rechargeable riveter -VAS 5279B- with attachments S1 and

E2 .

– Remove remaining material using compact angle grinder -

VAS 5167- .

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

4. Upper longitudinal member for wheel housing - Renewal (Coupé and Roadster identical) 51

Page 58

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

Replacement parts

Note

Use a 4 mm aluminium solid rivet if pressing out the old rivets

created a hole.

Parts

♦ 3.35 x 5 mm punch rivet

♦ Upper wheel housing longitudinal member

♦ Body adhesive DA 001 730 A2

Preparing new part

– Prepare flanges on body and new parts for welding.

Riveting in

– Apply 2-component adhesive DA 001 730 A2 to entire riveting

area using pneumatic glue gun -V.A.G 2005 B- .

Riveting in new part

– Position new part and fix in place.

52 Rep. Gr.50 - Body - front

Page 59

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Body Repairs - Edition 09.2009

Note

Holes must be stamped prior to riveting on.

Secure new part on bracket set.

– Rivet in new part using rechargeable riveter -VAS 5279A- .

Countersink holes, working inwards from outside. Use recharge‐

able riveter -VAS 5279A- with attachments D15 and D16 from VAS 5279/2 - or rechargeable riveter -VAS 5279B- with

attachments D15 and D16 .

Note

Use a 4 mm aluminium solid rivet if pressing out the old rivets created a hole.

Audi TT 2007 ➤

– Secure to A-pillar with an M5 x 18 flange bolt.

4. Upper longitudinal member for wheel housing - Renewal (Coupé and Roadster identical) 53

Page 60

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

Note

♦

The new parts may not be provided with the holes for the bol‐

ted connections.

♦

In this case the new parts have to be drilled out for the bolted

connections.

Note

5.3 x 5 mm punch rivets were previously fitted in the area of the

suspension strut mounting. A stepped seam (stitch seam) must

be made here instead of the punch rivets.

– Make stepped seam (stitch seam) in area of suspension strut

mounting.

54 Rep. Gr.50 - Body - front

Page 61

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

RO: 50 74 55 50

5 Suspension strut mounting - Renew‐

al (Coupé and Roadster identical)

WARNING

Always observe safety precautions.

Safety notes ⇒ General Information; Body Repairs, General Body

Repairs ; Safety notes .

5.1 Tools

Special tools and workshop equipment required

♦ Compact angle grinder -VAS 5167-

♦ Pneumatic glue gun -V.A.G 2005 B-

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

♦ Shielded arc welding equipment 250A -VAS 6388-

♦ Rechargeable riveter -VAS 5279A-

5. Suspension strut mounting - Renewal (Coupé and Roadster identical) 55

Page 62

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

♦ Pneumatic sabre saw -V.A.G 1523A-

5.2 Procedure

Cutting locations

• Longitudinal member (top section) already removed

WARNING

Do not damage adjoining castings.

Note

Refer to General information on aluminium regarding punch rivets

with one-sided access.

– Make separating cut in plenum chamber flange using pneu‐

matic sabre saw -V.A.G 1523A- .

– Separate original joint at support for suspension strut mount‐

ing using rechargeable riveter -VAS 5279A- .

– Remove large punch rivets. Use rechargeable riveter -VAS

5279A- with attachments D13 and D14 from -VAS 5279/2 - or

rechargeable riveter -VAS 5279B- with attachments D13 and

D14 .

– Remove small punch rivets. Use rechargeable riveter -VAS

5279A- with attachments S1 and E2 from -VAS 5279/2 - or

rechargeable riveter -VAS 5279B- with attachments S1 and

E2 .

56 Rep. Gr.50 - Body - front

Page 63

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

Note

Refer to General information on aluminium regarding punch rivets with one-sided access.

– Separate punch rivet with one-sided access at A-pillar (inner).

– Separate original joint with rechargeable riveter -VAS 5279A- .

5. Suspension strut mounting - Renewal (Coupé and Roadster identical) 57

Page 64

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

Replacement parts

♦ Pop rivets

♦ Punch rivets (self-piercing rivets)

♦ Suspension strut mounting

♦ Body adhesive DA 001 730 A2

Note

Refer to General information on bonding.

Preparing new part

– Prepare flanges on body and new parts for welding.

– Prepare flanges on body and new parts for riveting.

Welding in

– Fix new part on alignment bracket.

58 Rep. Gr.50 - Body - front

Page 65

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Note

SG continuous weld seam can also be used in place of riveted

joints.

Riveting in

– Weld windscreen cross member to suspension strut mounting

using shielded arc welding equipment 250A -VAS 6388- : SG

continuous seam.

– Rivet suspension strut mounting to longitudinal member (top

section) using rechargeable riveter -VAS 5279A- .

– Rivet suspension strut mounting to longitudinal member using

rechargeable riveter -VAS 5279A- .

Countersink holes, working inwards from outside. Use recharge‐

able riveter -VAS 5279A- with attachments D15 and D16 from VAS 5279/2 - or rechargeable riveter -VAS 5279B- with

attachments D15 and D16 .

– Weld in new part using shielded arc welding equipment 250A

-VAS 6388- : SG continuous seam.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

5. Suspension strut mounting - Renewal (Coupé and Roadster identical) 59

Page 66

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

– Weld in at separating cut on plenum chamber using shielded

arc welding equipment 250A -VAS 6388- : SG continuous

seam.

– Weld in new part using shielded arc welding equipment 250A

-VAS 6388- : SG continuous seam.

Rivet in remaining joint using rechargeable riveter -VAS 5279A- .

Countersink holes, working inwards from outside. Use recharge‐

able riveter -VAS 5279A- with attachments D15 and D16 from VAS 5279/2 - or rechargeable riveter -VAS 5279B- with

attachments D15 and D16 .

60 Rep. Gr.50 - Body - front

Page 67

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

5. Suspension strut mounting - Renewal (Coupé and Roadster identical) 61

Page 68

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

RO: 50 52 55 50

6 Longitudinal member for wheel hous‐

ing, upper, inner - Renewal (Coupé

and Roadster identical)

WARNING

Always observe safety precautions.

Safety notes ⇒ General Information; Body Repairs, General Body

Repairs ; Safety notes .

6.1 Tools

Special tools and workshop equipment required

♦ Compact angle grinder -VAS 5167-

♦ Pneumatic glue gun -V.A.G 2005 B-

♦ Shielded arc welding equipment 250A -VAS 6388-

♦ Rechargeable riveter -VAS 5279A-

62 Rep. Gr.50 - Body - front

Page 69

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

6.2 Procedure

Cutting locations

– Separate original joint with rechargeable riveter -VAS 5279A- .

– Remove large punch rivets. Use rechargeable riveter -VAS

5279A- with attachments D13 and D14 from -VAS 5279/2 - or

rechargeable riveter -VAS 5279B- with attachments D13 and

D14 .

– Remove small punch rivets. Use rechargeable riveter -VAS

5279A- with attachments S1 and E2 from -VAS 5279/2 - or

rechargeable riveter -VAS 5279B- with attachments S1 and

E2 .

– Remove remaining material using compact angle grinder -

VAS 5167- .

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

Replacement part

♦ Upper wheel housing longitudinal member

6. Longitudinal member for wheel housing, upper, inner - Renewal (Coupé and Roadster identical) 63

Page 70

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

Note

Riveted/bonded joint can also be used in place of weld seam.

Welding in

– Weld in upper wheel housing longitudinal member using shiel‐

ded arc welding equipment 250A -VAS 6388- : SG continuous

seam.

64 Rep. Gr.50 - Body - front

Page 71

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

RO: 50 79 55 00

7 Front longitudinal member - Renewal

(Coupé and Roadster identical)

WARNING

Always observe safety precautions.

Safety notes ⇒ General Information; Body Repairs, General Body

Repairs ; Safety notes .

7.1 Tools

Special tools and workshop equipment required

♦ Compact angle grinder -VAS 5167-

♦ Pneumatic glue gun -V.A.G 2005 B-

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

♦ Shielded arc welding equipment 250A -VAS 6388-

♦ Rechargeable riveter -VAS 5279A-

7. Front longitudinal member - Renewal (Coupé and Roadster identical) 65

Page 72

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

7.2 Procedure

Cutting locations

– Separate original joint using compact angle grinder -VAS

5167- .

– Remove remaining material using compact angle grinder -

VAS 5167- .

– Separate original joint using compact angle grinder -VAS

5167- .

– Remove remaining material using compact angle grinder -

VAS 5167- .

66 Rep. Gr.50 - Body - front

Page 73

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

Replacement part

♦ Longitudinal member

Preparing new parts

– Prepare flanges on body and new parts for welding.

Welding in

– Weld in longitudinal member using shielded arc welding equip‐

ment 250A -VAS 6388- : SG continuous seam.

7. Front longitudinal member - Renewal (Coupé and Roadster identical) 67

Page 74

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

– Weld in new part on bracket set using shielded arc welding

equipment 250A -VAS 6388- : SG continuous seam.

– Weld in connecting bracket using shielded arc welding equip‐

ment 250A -VAS 6388- ; re-establish original joint: SG contin‐

uous seam.

68 Rep. Gr.50 - Body - front

Page 75

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

7. Front longitudinal member - Renewal (Coupé and Roadster identical) 69

Page 76

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi TT 2007 ➤

Body Repairs - Edition 09.2009

RO: 50 79 55 02

8 Front longitudinal member - Partial

renewal (Coupé and Roadster iden‐

tical)

WARNING

Always observe safety precautions.

Safety notes ⇒ General Information; Body Repairs, General Body

Repairs ; Safety notes .

8.1 Tools

Special tools and workshop equipment required

♦ Pneumatic glue gun -V.A.G 2005 B-

♦ Shielded arc welding equipment 250A -VAS 6388-

♦ Rechargeable riveter -VAS 5279A-

70 Rep. Gr.50 - Body - front

Page 77

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

♦ Pneumatic sabre saw -V.A.G 1523A-

8.2 Procedure